Large-area metal bipolar plate for automobile fuel cell

A large-area metal and fuel cell technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as difficult application and large flow resistance of bipolar plates, achieve low manufacturing costs, increase energy density, and reduce mold design The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is implemented under the following conditions of implementation and technical requirements:

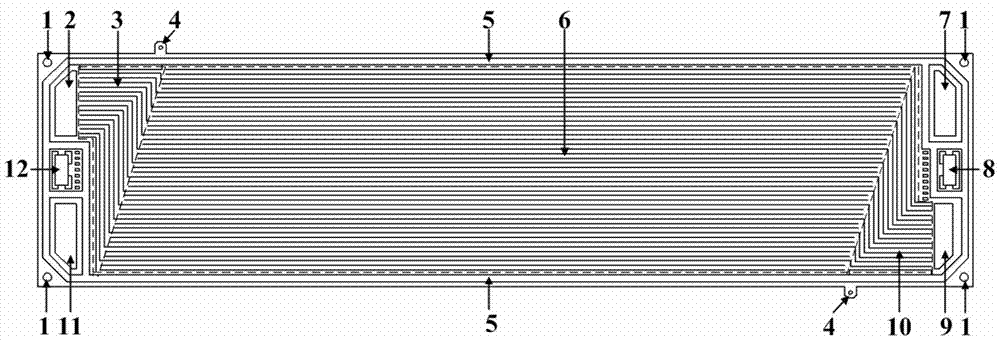

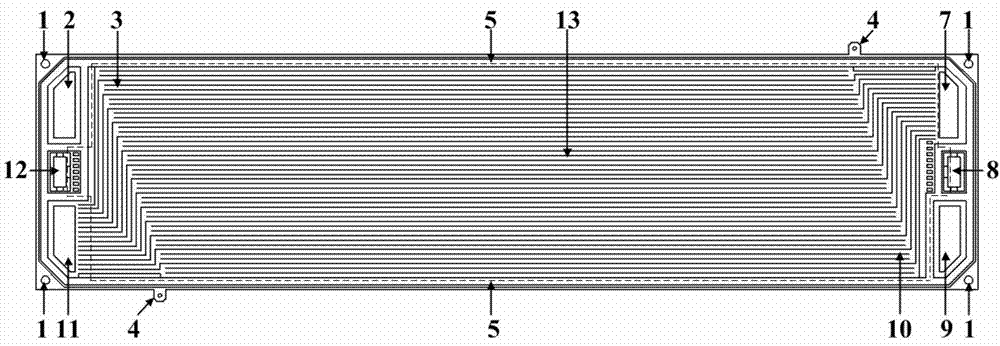

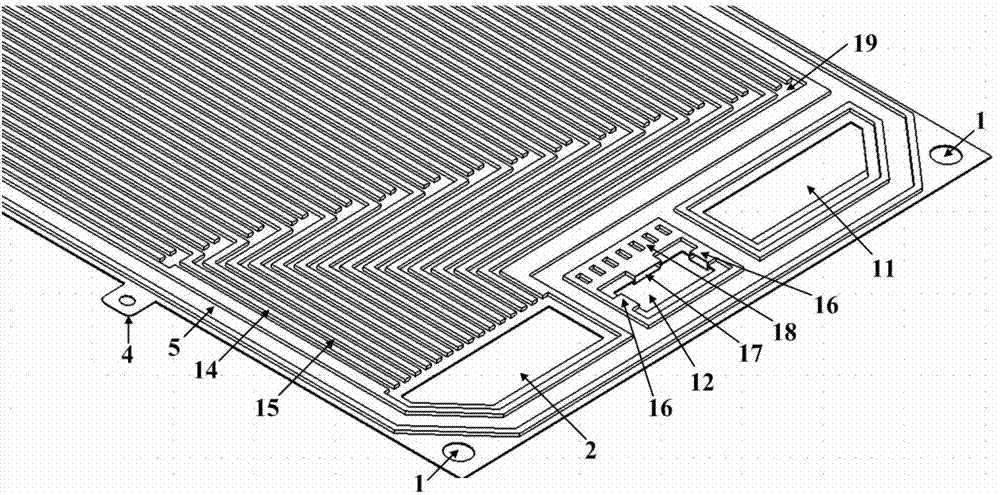

[0028] according to Figure 1~4 The schematic diagram of the structure of the large-area metal bipolar plate of the vehicle fuel cell shown is to design and process the stamping die, including the upper die and the lower die. Prepared by precision stamping forming process with such figure 1 For the unipolar plate with the flow field configuration shown, the punching force is 200 tons, and the punching speed is 30 seconds / sheet. The plate material is stainless steel 316, the material thickness is 0.1mm, and the overall size of the unipolar plate after trimming is 100×400mm. Such as Figure 5 As shown, the depth h of the runner groove 15 is 0.5 mm, the width w of the runner groove 15 is 1.2 mm, and the width of the ridge 14 is n1.0 mm. After two identical unipolar plates are combined, one side forms the fuel flow channel a, and the other side The oxidant flow ...

Embodiment 2

[0033] In this embodiment, the soft film forming process is used to prepare such as Figure 1~4 Large-area metal bipolar plates for automotive fuel cells are shown. The upper mold is processed according to the flow field configuration, and the polyurethane material with a hardness of 55° is used as the soft film, and the 0.2mm thick stainless steel 304 sheet material is placed between the upper mold and the soft film. The forming force is 300 tons, and the forming speed is 60 seconds / piece. The overall size of the monopolar plate after forming and trimming is 100×400mm. Such as Figure 5 As shown, the runner groove 15 is 0.4mm deep, the runner groove 15 is 1.5mm wide, and the ridge 14 is 1.2mm wide. The number of flow channels in the unipolar plate DC field area 6 is 27, and the number of flow channels in the flow field distribution area 3 and the flow field assembly area 10 is 9. The sealing groove 5 is 3.0mm wide and 0.4mm deep. Two identical unipolar plates are connect...

Embodiment 3

[0036] In this embodiment, the hydroforming process is used to prepare such as Figure 1~4 Large-area metal bipolar plates for automotive fuel cells are shown. The unilateral mold is processed according to the flow field configuration, and the hydraulic oil with a viscosity coefficient of 55 is used as the forming medium. One side of the 0.1mm thick stainless steel 304 sheet material is in contact with the unilateral mold and sealed, and the other side is in contact with the hydraulic oil. Through the hydraulic cylinder Adjust the forming force. In this embodiment, the forming hydraulic pressure is 350 MPa, and the forming speed is 120 seconds / piece. The overall size of the monopolar plate after forming and trimming is 100×400mm. Such as Figure 5 As shown, the runner groove 15 is 0.6 mm deep, the runner groove 15 is 0.8 mm wide, and the ridge 14 is 0.5 mm wide. The number of flow channels in the unipolar plate DC field area 6 is 75, and the number of flow channels in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com