Direct quench heat treatment for aluminum alloy castings

一种铝合金铸件、直接的技术,应用在热处理设备、热处理过程控制、制造工具等方向,能够解决晶格应变能量增大、延展率降低等问题,达到降低残余应力、提高生产率、减少工序和设备的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] A set of 12V8 cylinder blocks made of 319 aluminum alloy (the composition of the alloy is shown in Table 1) is divided into five sections along the section through the center of the hole, each section is about 5 inches thick. The two end sections of each cylinder block were discarded, as the geometry and heating history of these sections were quite different from the remaining three sections.

[0048] Table 1: Chemical Properties of Alloy 319

[0049] Si

Fe

Cu

mn

Mg

7

0.4

3.0

0.2

0.35

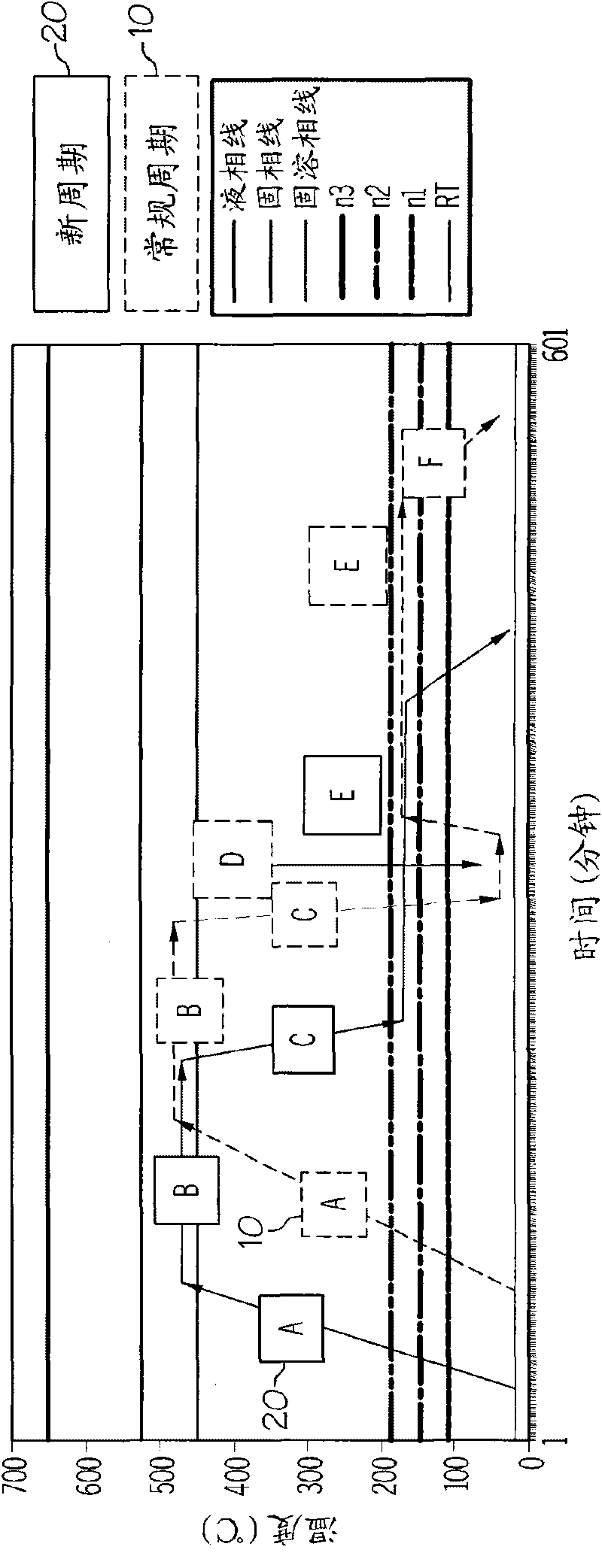

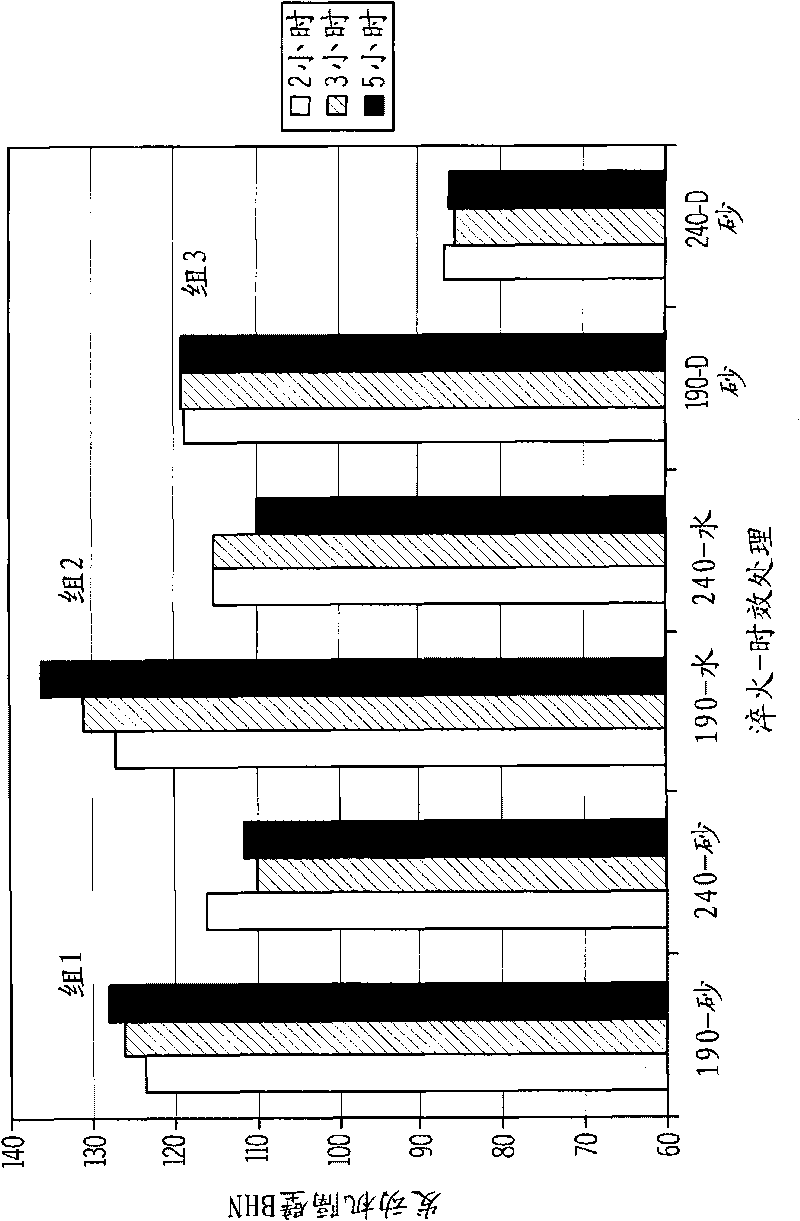

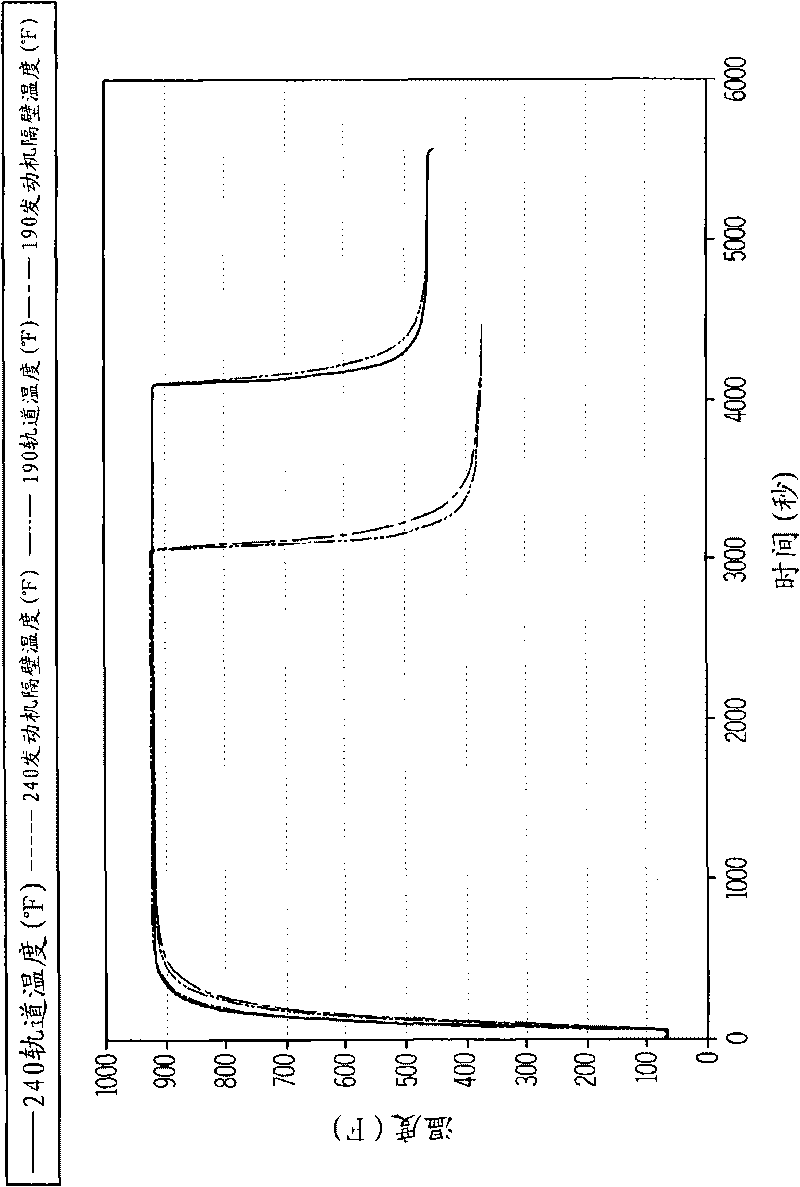

[0050] Randomly group these thirty-six segments and follow figure 2 Heat treatment was carried out in two stages for each condition.

[0051] Table 2

[0052]

[0053] After heat treatment, samples were cut from each section; two from the bulkhead, two from the inner bolt hub and two from the outer bolt hub. figure 2 with 3 The Brinell hardness as well as the tensile strength and elongation for each heat treatment grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com