Platform for disassembling and assembling disc hob

A technology for assembling platforms and disc-shaped hobs, which is applied to hand-held tools and manufacturing tools, can solve the problems of consuming manpower and time resources, heavy workload, and high labor intensity, and achieve shortened construction period, simple installation, and reduced downtime the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

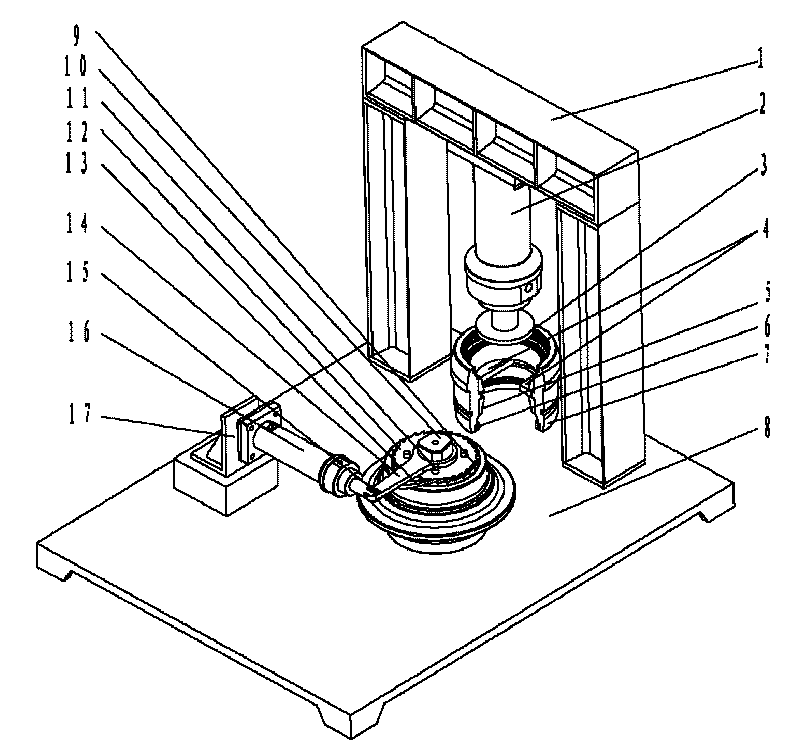

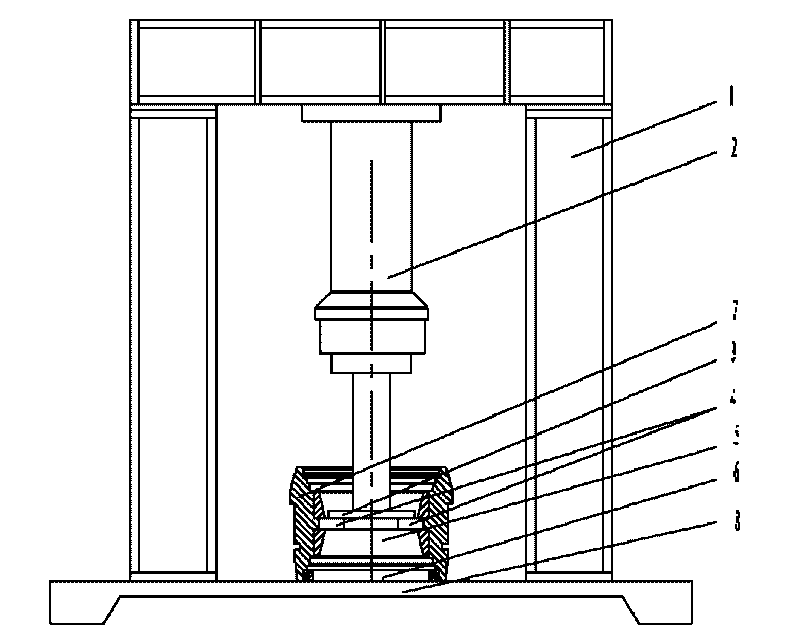

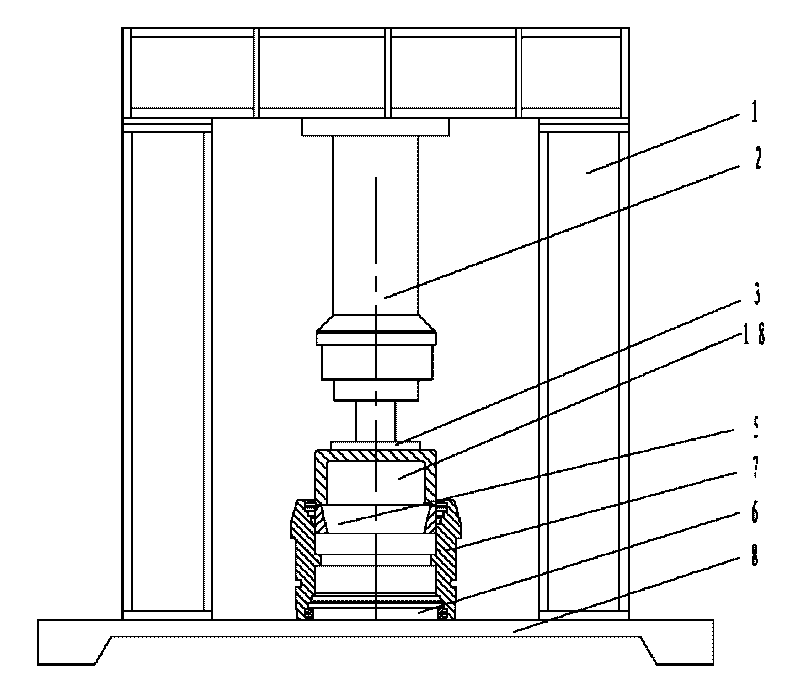

[0020] see figure 1 , figure 2 with image 3 , the present invention mainly includes a hob end cover dismounting device and a hob bearing outer ring dismounting device. The hob end cover dismounting device is composed of a first hydraulic cylinder 16 placed horizontally, a hydraulic cylinder mounting seat 17, a ratchet lever 14, a pawl 13, a positioning hole 20 and a ratchet disc 12. The bottom of the first hydraulic cylinder 16 is welded to The hydraulic mount 17 on the platform base 8 is hinged by the first pin 19, the piston rod of the first hydraulic cylinder 16 and one end of the ratchet rod 14 are hinged by the second pin 15, and the second pin 15 can be easily disassembled. The first hydraulic cylinder 16 is equipped with a pressure gauge, which can detect the working pressure of the first hydraulic cylinder 16 in real time. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com