Sideways-moving tilting brick clamp

A technology of brick clamping and tilting oil cylinders, applied in the direction of lifting devices, etc., can solve problems such as labor shortage and difficulty in recruiting new building materials industry, and achieve the effects of reasonable structure, improved operation efficiency, good stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

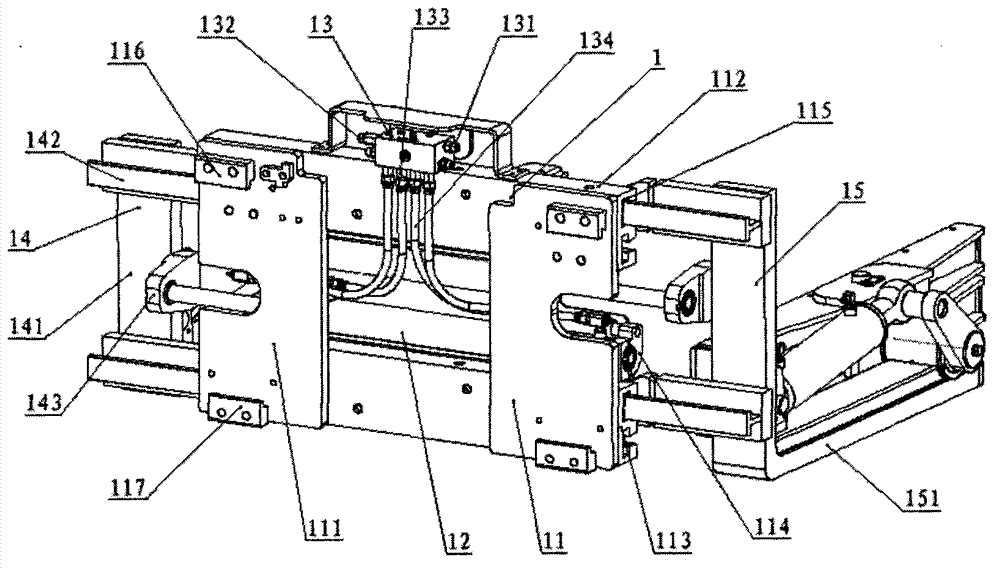

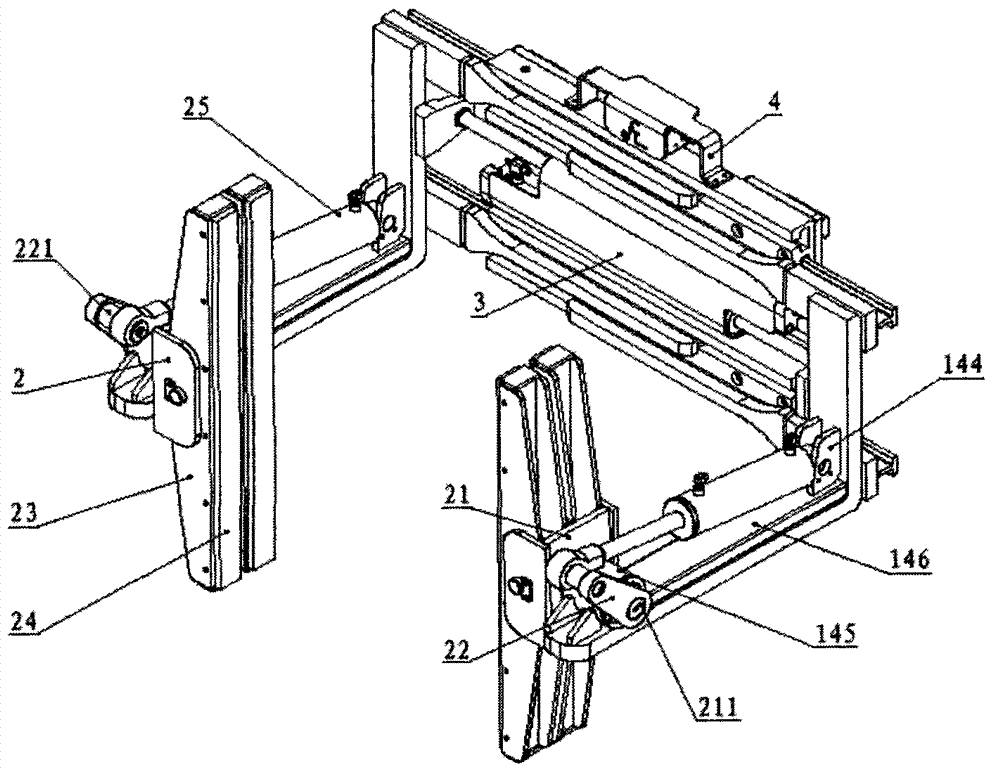

[0014] Such as figure 1 , 2 As shown, a side-moving tilting brick holding clamp includes a side-moving clamping mechanism composed of a bottom plate assembly, a side-moving clamping cylinder, a left clamping arm assembly, a right clamping arm assembly and a lateral clamping cylinder 1. The left and right pivoting arm mechanisms 2 and the hydraulic control valve are composed of the tilting cylinder, the tilting fixture and the clamping arm respectively.

[0015] The bottom plate assembly 11 in the side shifting clamping mechanism is composed of a bottom plate, an upper E-shaped groove guide rail, and a lower E-shaped groove guide rail. The lower part is respectively fixed with upper E-shaped groove guide rail 112 and lower E-shaped groove guide rail 113 by bolts in parallel, and the opposite sides of the left and right two base plates are respectively welded with bases 114 for installing side shifting clamping oil cylinders.

[0016] The left clamping arm assembly 14 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com