Bipolar thin film transistor and preparation method thereof

A thin film transistor and bipolar technology, which is applied in the field of bipolar thin film transistors and their preparation, can solve the problems of different preparation processes, increased process complexity of CMOS circuits and AM-OLED pixel circuits, and difficulty in obtaining p-type conductance. , to achieve the effect of increasing the complexity of the preparation process and having a great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

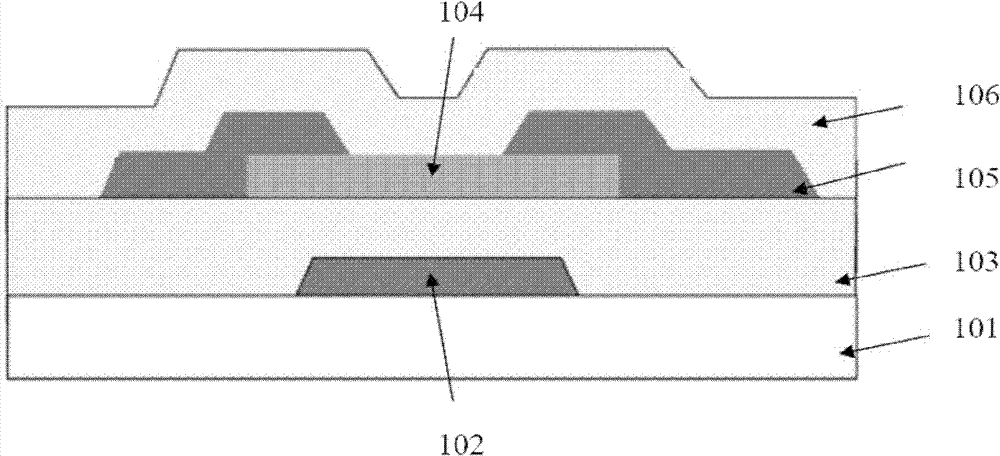

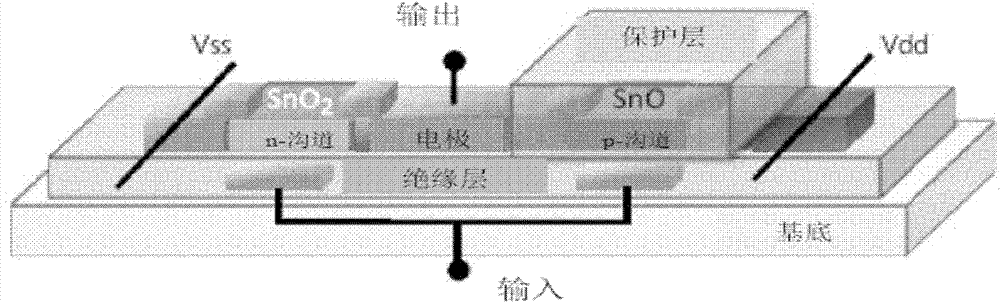

[0016] The present invention proposes a bipolar thin film transistor, such as figure 1 Shown is a schematic structural diagram of the transistor, including: 101 is a substrate; 102 is a gate; 103 is an insulating layer; 104 is an active layer; 105 is a source and drain electrode; 106 is a protective layer. The active layer 104 of the transistor may be:

[0017] Use SnO 2 The thin film is used as the active layer of n-TFT;

[0018] Use SnO or ATO film as the active layer of p-TFT.

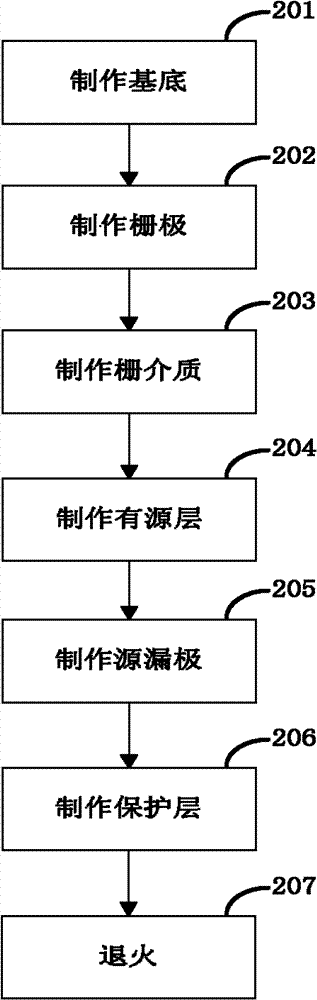

[0019] Such as figure 2 As shown, the preparation method of the above-mentioned bipolar thin film transistor comprises:

[0020] 201. Alkali-free glass as the substrate;

[0021] 202. First prepare a 100nm ITO film by DC magnetron sputtering with an ITO target, and wet etch with dilute hydrochloric acid to form a gate;

[0022] 203. Use SiO agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com