Steam-curing-free low-cost ultra-high performance concrete and preparation method thereof

An ultra-high performance, low-cost technology, applied in the field of building materials, can solve the problems of high cost and complicated maintenance of ultra-high performance concrete, and achieve the effect of increasing physical and mechanical properties and working performance, improving physical and mechanical properties, and improving early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

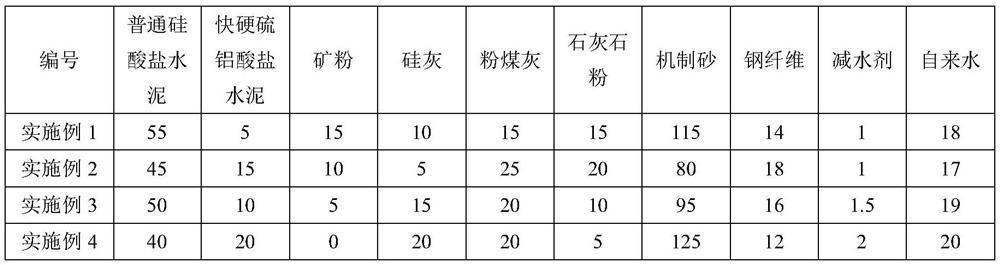

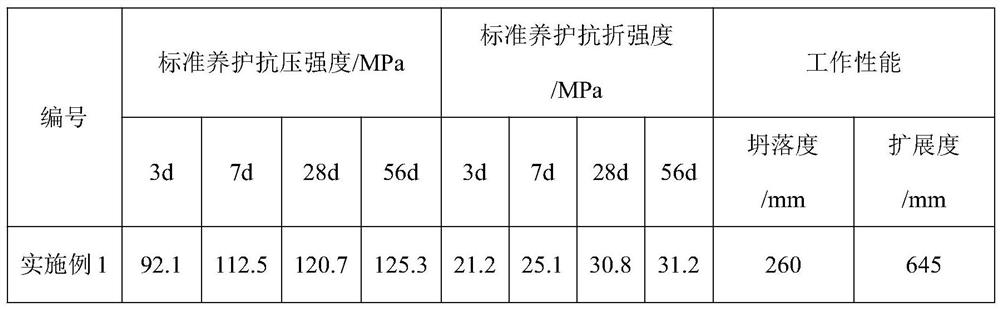

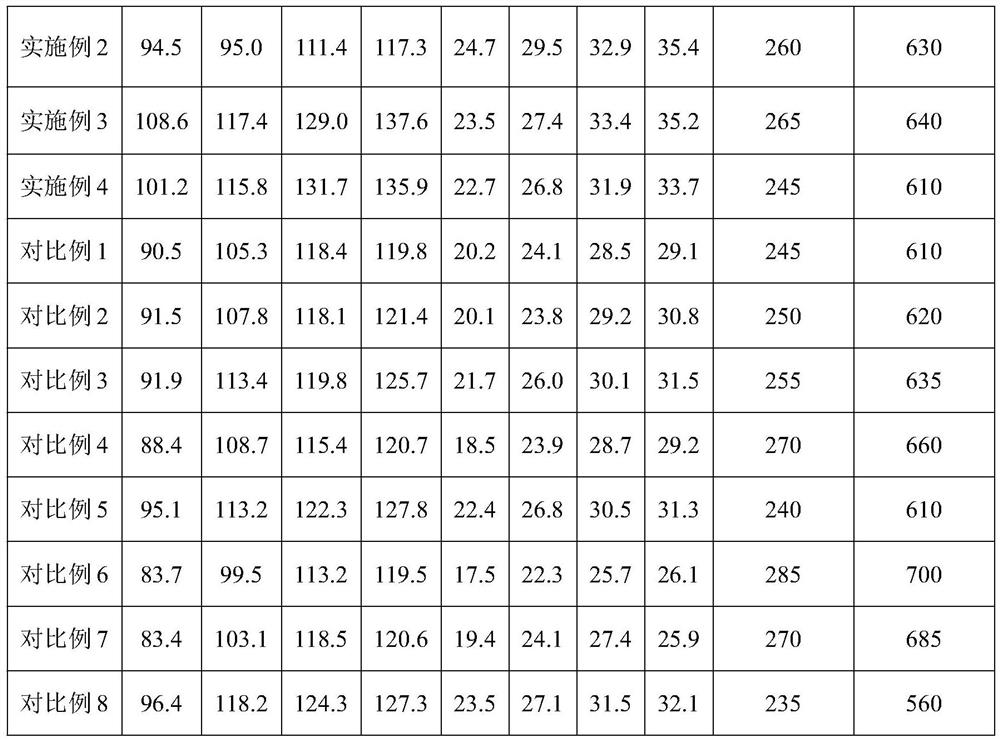

Embodiment 1

[0048] This embodiment discloses the preparation method of the steam-free low-cost ultra-high performance concrete of the present invention, specifically:

[0049] Step 1. Weigh 5500g of ordinary Portland cement, 500g of fast-hardening sulfoaluminate cement, 1500g of mineral powder, 1000g of silica fume, 1500g of fly ash, 1500g of limestone powder, 11500g of machine-made sand, 1400g of waste steel fiber, and water reducing agent 100g, water 1800g;

[0050] Step 2. First add ordinary Portland cement, rapid hardening sulfoaluminate cement, silica fume, fly ash, mineral powder, limestone powder and machine-made sand into the forced mixer for dry mixing for 3 minutes, and mix the water reducing agent and 900g of water evenly Finally, add the mixer and stir evenly, then add the remaining water into the mixer and stir, and at the same time, sprinkle steel fibers evenly and stir evenly, that is, steam-free low-cost ultra-high performance concrete.

Embodiment 2

[0052] This embodiment discloses the preparation method of the steam-free low-cost ultra-high performance concrete of the present invention, specifically:

[0053] Step 1. Weigh 4500g of ordinary Portland cement, 1500g of fast-hardening sulfoaluminate cement, 1000g of mineral powder, 500g of silica fume, 2500g of fly ash, 2000g of limestone powder, 8000g of machine-made sand, 1800g of waste steel fiber, and water reducing agent 100g, water 1700g;

[0054] Step 2. First add ordinary Portland cement, rapid hardening sulfoaluminate cement, silica fume, fly ash, mineral powder, limestone powder and machine-made sand into the forced mixer for dry mixing for 3 minutes, and mix the water reducing agent and 850g of water evenly Finally, add the mixer and stir evenly, then add the remaining water into the mixer and stir, and at the same time, sprinkle steel fibers evenly and stir evenly, that is, steam-free low-cost ultra-high performance concrete.

Embodiment 3

[0056] This embodiment discloses the preparation method of the steam-free low-cost ultra-high performance concrete of the present invention, specifically:

[0057] Step 1. Weigh 5000g of ordinary Portland cement, 1000g of fast-hardening sulfoaluminate cement, 500g of mineral powder, 1500g of silica fume, 2000g of fly ash, 1000g of limestone powder, 9500g of machine-made sand, 1600g of waste steel fiber, and water reducing agent 150g, water 1900g;

[0058] Step 2. First add ordinary Portland cement, rapid hardening sulfoaluminate cement, silica fume, fly ash, mineral powder, limestone powder and machine-made sand into the forced mixer for dry mixing for 3 minutes, and mix the water reducing agent and 950g of water evenly Finally, add the mixer and stir evenly, then add the remaining water into the mixer and stir, and at the same time, sprinkle steel fibers evenly and stir evenly, that is, steam-free low-cost ultra-high performance concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com