Preparation method of coated halogen-free flame-retardant foamable polystyrene

A foamed polystyrene, expandable polystyrene technology, applied in the direction of adhesive types, aldehyde/ketone condensation polymer adhesives, polymer adhesive additives, etc., can solve the problem of adding composite flame retardants. It can avoid fire, improve flame retardant and smoke suppression function, and highlight flame retardant and smoke suppression performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

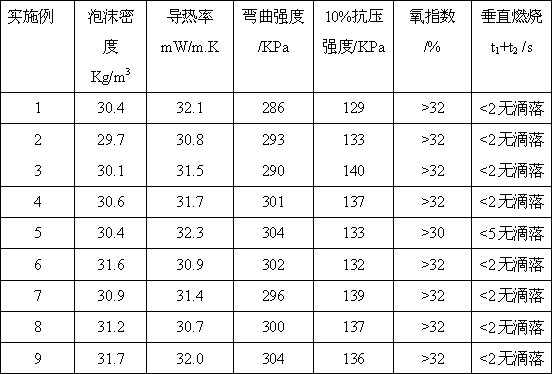

Examples

Embodiment 1

[0028] (1) Synthesis of halogen-free flame retardant expandable polystyrene particles:

[0029] First add 150g of deionized water to the reactor, then add 0.3g of polyvinyl alcohol, raise the temperature to 75°C to completely dissolve the polyvinyl alcohol, then add 1.5g of tricalcium phosphate, and mix well to obtain a mixed solution A;

[0030] Then 15g of ammonium polyphosphate is added to the reaction kettle containing 100g of styrene, stirred evenly and 0.08g of benzoyl peroxide is added to obtain a mixed solution B containing monomers;

[0031] Then add the above mixed solution B to the mixed solution A, adjust the stirring speed to 500 rpm, heat the reaction vessel, control the temperature at 75°C for 1 hour, then raise the temperature to 85°C, continue the reaction for 2 hours, use a straw Take the reaction material and observe it in a surface device. When the particles of the reaction material become hard and brittle, add 12g of pentane foaming agent to the reaction k...

Embodiment 2

[0038] (1) Synthesis of halogen-free flame retardant expandable polystyrene particles:

[0039] First add 140g of deionized water to the reaction kettle, then add 0.2g of polyvinyl alcohol, raise the temperature to 75°C to completely dissolve the polyvinyl alcohol, then add 1.8g of tricalcium phosphate, and mix well to obtain a mixed solution A;

[0040] Then 16g of ammonium polyphosphate was added to the reaction kettle containing 100g of styrene, stirred evenly and 0.07g of benzoyl peroxide was added to obtain a mixed solution B containing monomers;

[0041] Then add the above mixed solution B into the mixed solution A, adjust the stirring speed to 600 rpm, heat the reaction kettle, control the temperature at 75°C for 1 hour, then raise the temperature to 84°C, continue the reaction for 2 hours, use a straw Take the reaction material and observe it in a surface device. When the particles of the reaction material become hard and brittle, add 14g of pentane foaming agent to th...

Embodiment 3

[0048] (1) Synthesis of halogen-free flame retardant expandable polystyrene particles:

[0049] First add 130g of deionized water into the reactor, then add 0.15g of polyvinyl alcohol, raise the temperature to 75°C to completely dissolve the polyvinyl alcohol, then add 1.1g of tricalcium phosphate, and mix well to obtain a mixed solution A;

[0050] Then 15g of PNP expansion flame retardant was added to the reaction kettle containing 100g of styrene, stirred evenly and 0.09g of benzoyl peroxide was added to obtain the mixed liquid B containing the monomer;

[0051] Then add the above mixed solution B to the mixed solution A, adjust the stirring speed to 600 rpm, heat the reactor, control the temperature at 75°C for 1 hour, then raise the temperature to 85°C, continue the reaction for 2 hours, use a straw Take the reaction material and observe it in a surface device. When the particles of the reaction material become hard and brittle, add 14g of pentane foaming agent to the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com