Patents

Literature

246results about How to "Rapid development of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing blended cements with reduced carbon dioxide emissions

InactiveUS6936098B2Reduce carbon dioxide emissionsImprove carrying capacitySolid waste managementSlagFly ash

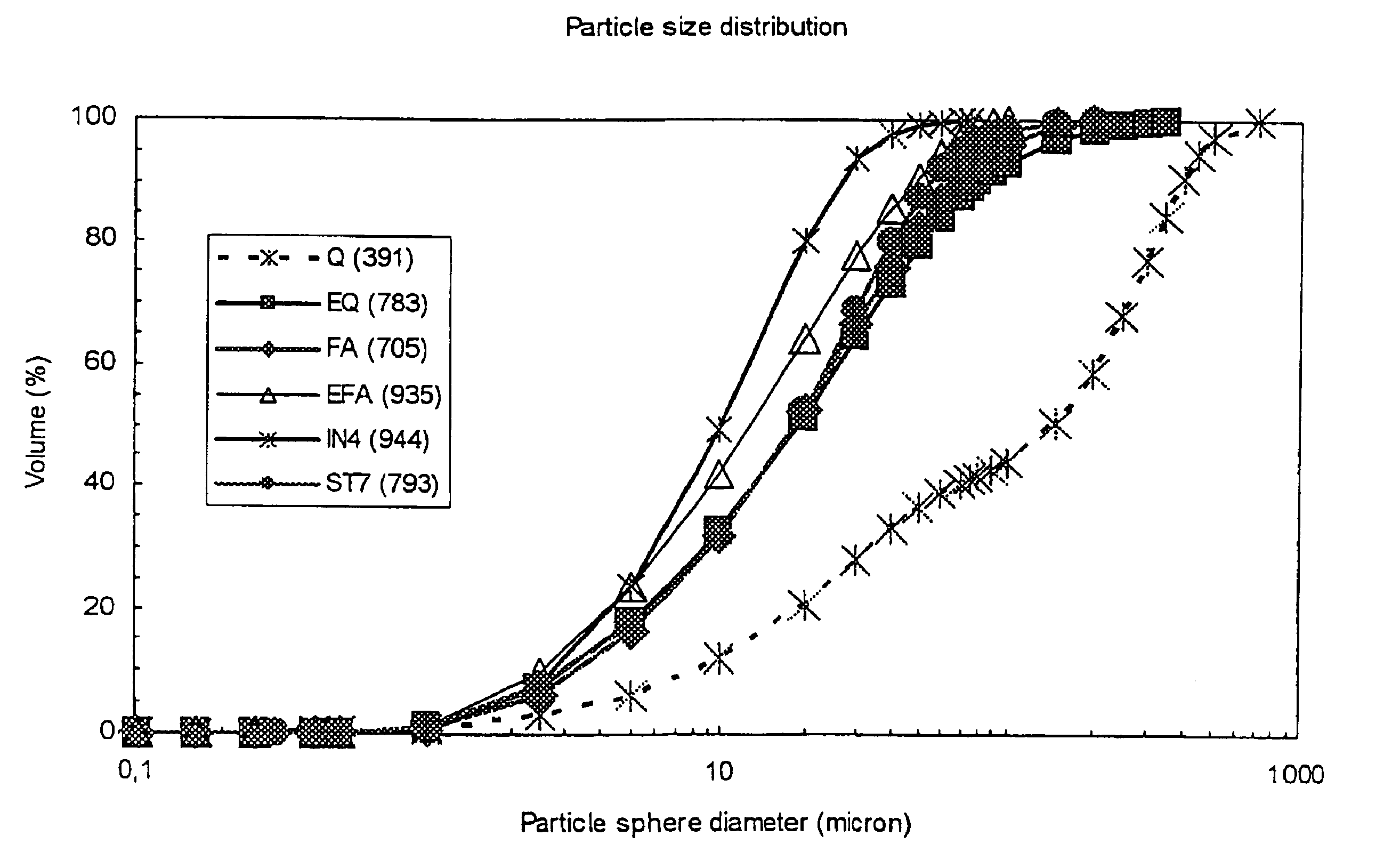

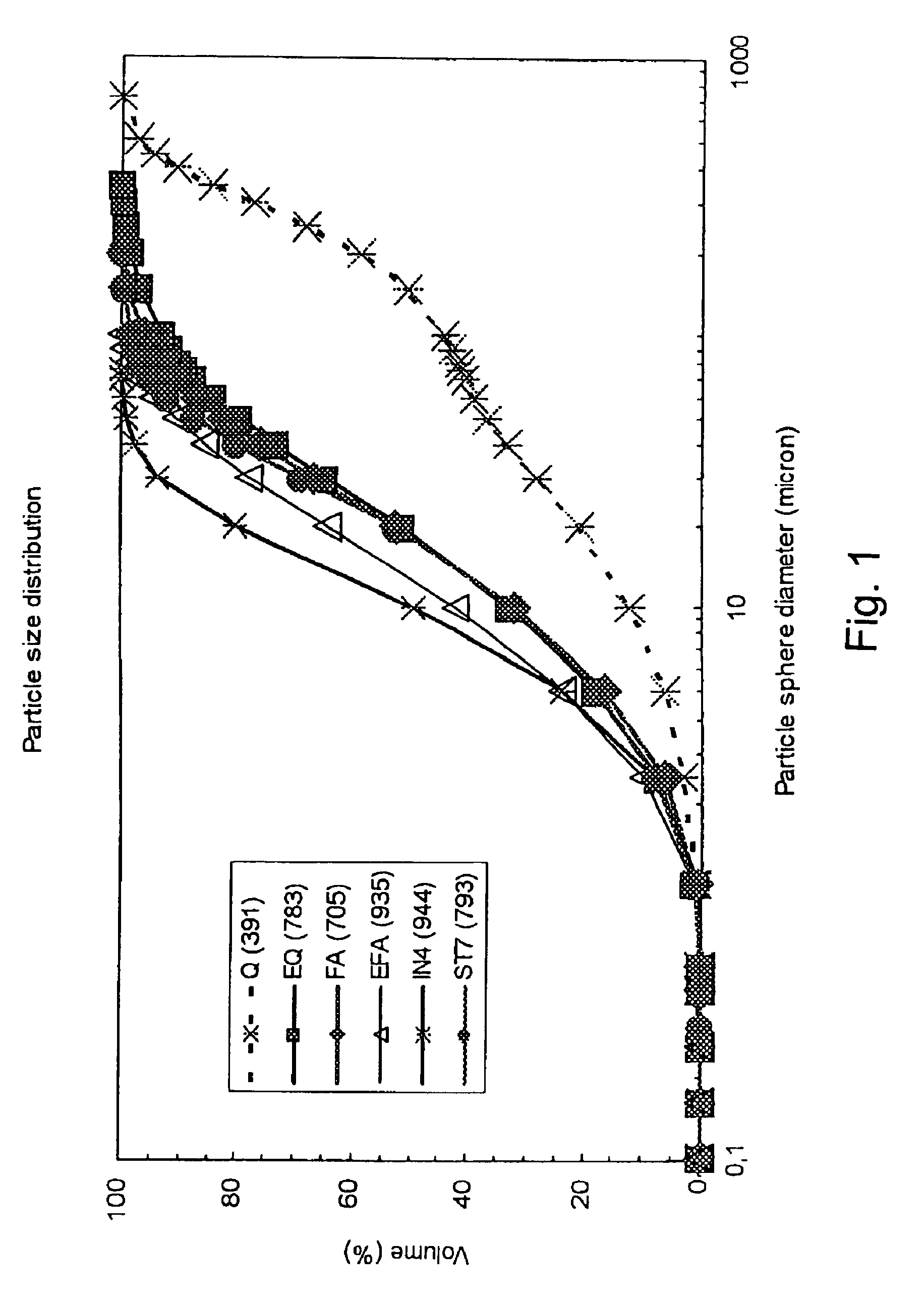

A process for producing blended cement in which the cement contains Portland Cement mixed thoroughly with a microfiller, and possibly a water reducing agent, to provide a dry cement mixture, and fine supplementary cementitious materials selected from the materials blast furnace slag, fly ash, quartz, silica, amorphous silicon dioxide, limestone, and recycled concrete. The supplementary materials are first subjected to a grinding step in a dry state to a specific surface of at least 1000 cm2 / g (Blaine). In a second step the ground supplementary materials are subjected to a grinding step together with at least 20% by weight of the total grinding mass of a highly reactive cement mixture in a dry state, to achieve a specific surface of at least 3000 cm2 / g (Blaine).

Owner:PROCEDO ENTERPRISES ETAB

Concrete healant

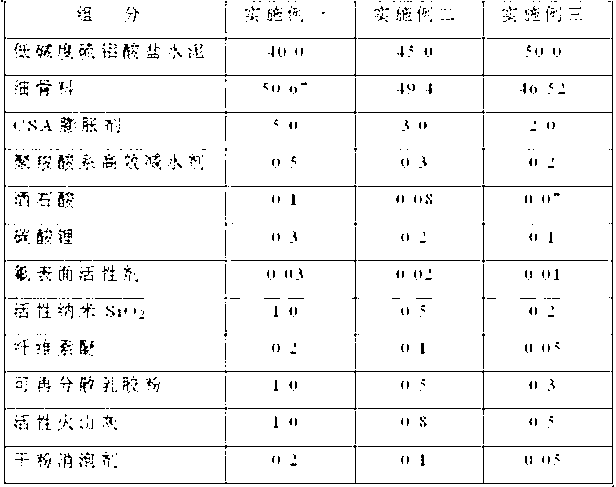

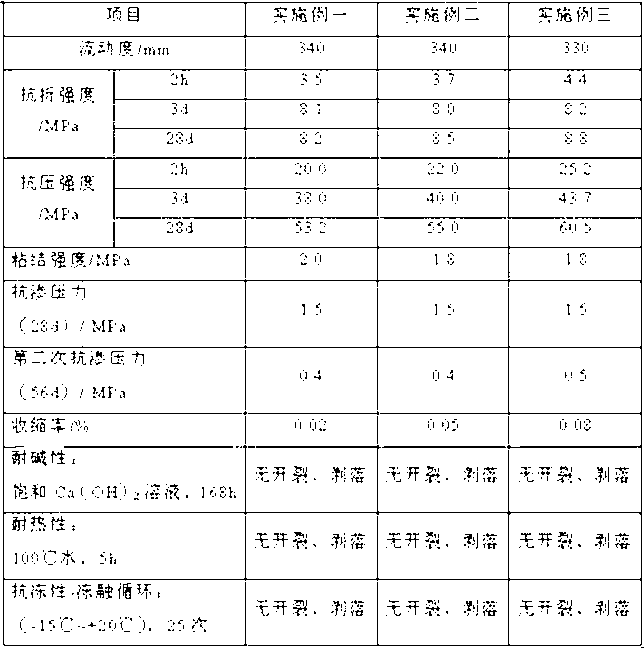

The invention discloses concrete healant, which comprises following components by weight percent: 30 to 55 percent of gelatinization materials, 40 to 65 percent of fine aggregates, 0.1 to 0.5 percent of water reducing component, 0.05 to 0.5 percent of early-strengthening component, 0.05 to 0.2 percent of delayed-coagulation component, 0.2 to 1.0 percent of nano materials, 0.5 to 1.0 percent of high-activity substances, 0.01 to 0.2 percent of water retention thickening component, 0.2 to 2.0 percent of polymer and 0.02 to 0.2 percent of defoaming agent. The concrete healant not only has characteristics of good mobility, fast strength development, high adhesion strength and small retraction, but also can fill active substances into original concrete gaps and can produce compact crystals, so that the cohesion strength of the new and the old concrete interfaces can be remarkably improved, and the concrete healant is applicable to the concrete mending projects of bridges, caves, industrial workshops and civil construction.

Owner:苏州市姑苏新型建材有限公司

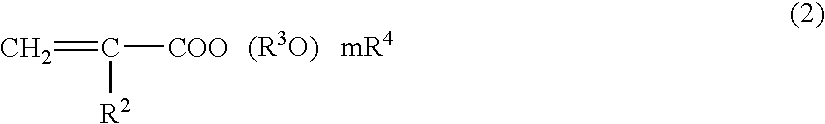

Cement dispersant and concrete composition contain the dispersant

[Object] To provide a cement dispersant and a concrete composition containing the cement dispersant, the cement dispersant having a superior effect of decreasing a high concrete paste viscosity while a water reducing effect, a slump flow retention, and rapid strength development are being satisfied in a region having a low water / binder ratio. [Solving Means] The cement dispersant for ultrahigh performance concrete is provided which is a water-soluble amphoteric copolymer obtained by copolymerizing (A) an alkylene oxide adduct of a polyamide polyamine having an unsaturated group, (B) (meta)acrylic acid or a salt thereof, (C) an ester of a short-chain alkylene glycol and (meth)acrylic acid, and (D) an ester of a long-chain alkylene glycol and (meth)acrylic acid at ratios A:B:C:D of 5 to 25:5 to 30:5 to 40:20 to 80 (percent by weight), in which the total is 100% percent by weight. In addition, the concrete composition containing the above cement dispersant is provided.

Owner:TOHO CHEM IND +1

Curing agent capable of rapidly curing sludge at room temperature and use method thereof

The invention discloses a curing agent capable of rapidly curing sludge at room temperature and a use method thereof. The curing agent is prepared from, by weight, 48%-70% of inorganic micro powder, 28%-50% of emulsion, 0.05%-1.8% of high-performance water-absorbent resin and 0.05%-0.5% of triethanolamine. The emulsion can react with the inorganic micro powder and activated silicon dioxide and aluminum oxide in the sludge to form a zeolite-like crystalline substance of a silicon (aluminum)-oxygen tetrahedron structure. The sludge curing agent is capable of improving the curing strength of the sludge and shortening the curing time, small in air shrinkage and good in water resistance, and dosing of materials can be particularly adjusted according to components of the sludge, so that curing of the sludge is not limited by time, the strength, the stability and the like meet the actual engineering requirements, the cost is low, pollution does not exist, and the curing agent can be widely applied and promoted.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

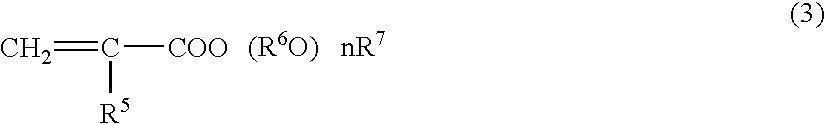

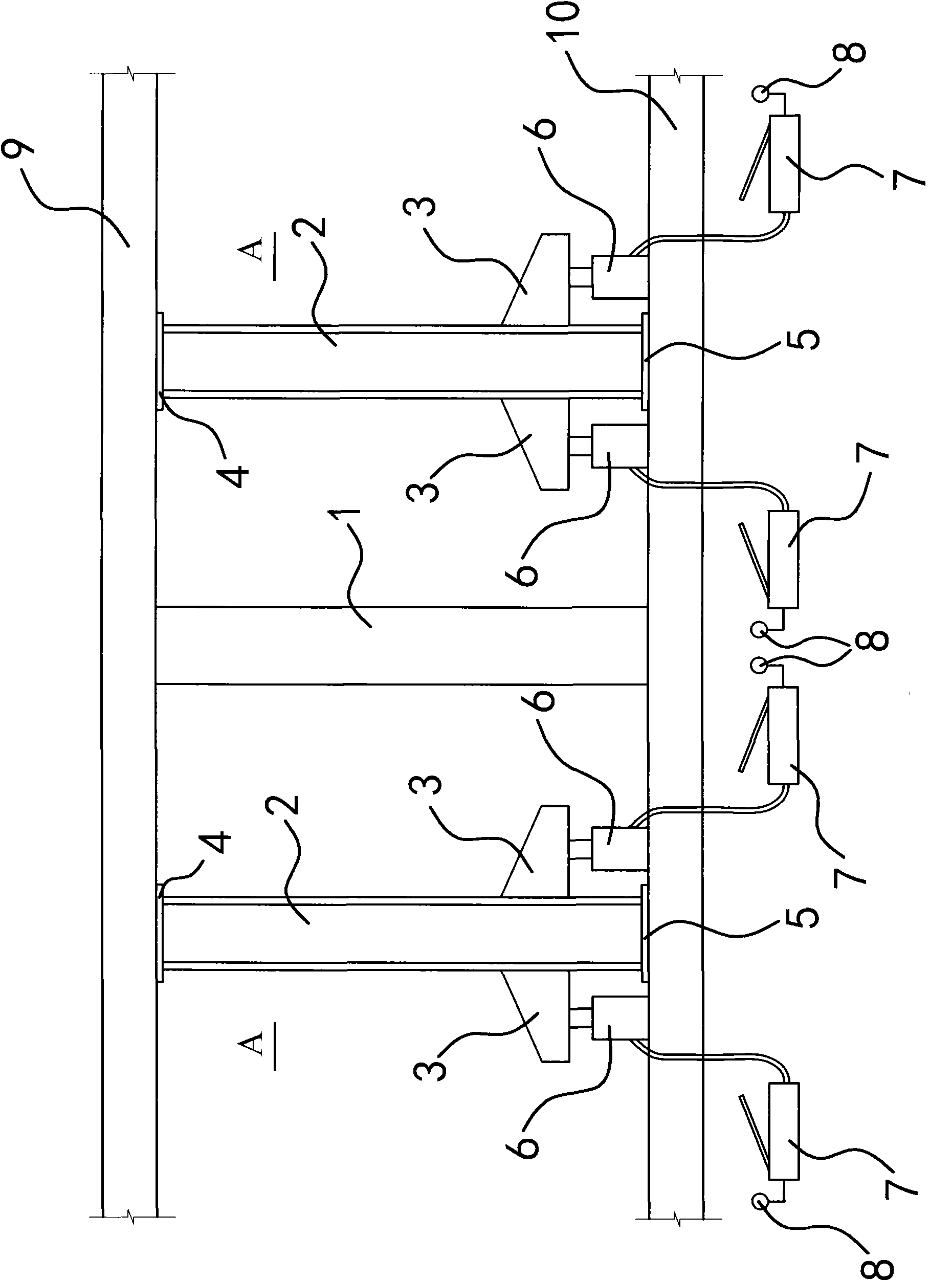

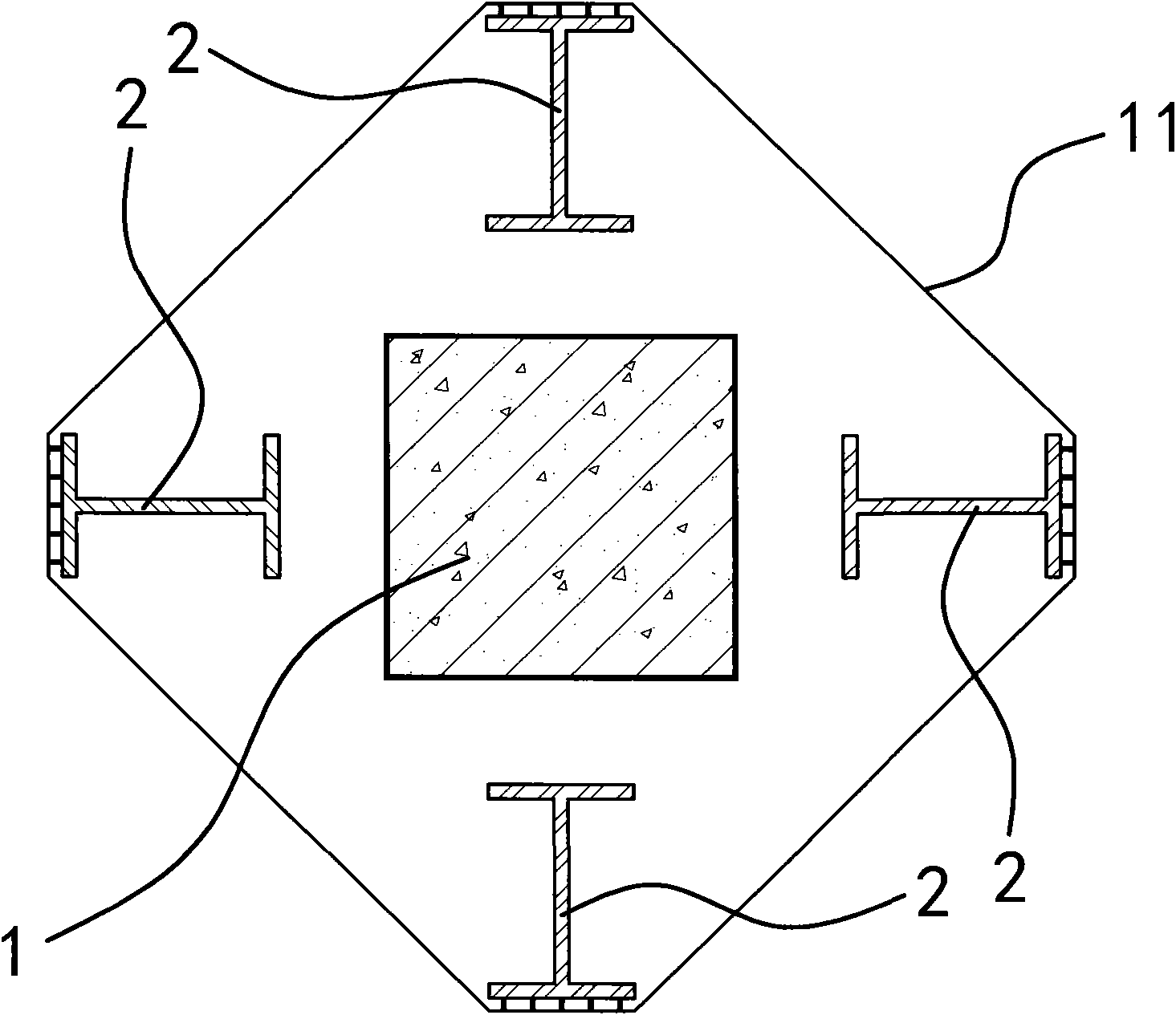

Reinforced concrete column replacing and reinforcing method and device for unloading load of reinforced concrete column

InactiveCN101899907AGood adhesionGuarantee the quality of reinforcementBuilding repairsRebarEngineering

The invention provides a reinforced concrete column replacing and reinforcing method and a device for unloading the load of a reinforced concrete column, belonging to the technical field of buildings. The invention solves the problem that after the existing reinforced concrete column has a quality problem, the reinforcing and repairing works are relatively difficult. The reinforced concrete column replacing and reinforcing method mainly comprises the steps of material preparation, unloading, chiseling, erection of shuttering, replacement and removal of shuttering. The device for unloading the load of the reinforced concrete column comprises a supporting column which can be supported on the beam of the current layer, and hydraulic lifting mechanisms capable of lifting the supporting column are arranged at the two sides of the supporting column. The reinforced concrete column replacing and reinforcing method has the advantages that the original size of the column section can not be changed, and reinforcing traces can not be left. The device for unloading the load of the reinforced concrete column, which adopts hydraulic unloading, has the advantages of large applied force and uniform application of force.

Owner:TAIZHOU BUILDING INSTALLATION ENG

High temperature resistance low-density high-strength cement paste

The invention discloses high temperature resistance low-density high-strength cement paste which consists of the following components in parts by weight: 100 parts of cement, 23 to 35 parts of lightening admixture, 30 to 40 parts of high temperature strength stabilizer, 10 to 23 parts of filler, 1.5 to 2 parts of dispersing agent, 1 to 2 parts of early strength agent and 8 to 15 parts of fluid loss agent, wherein hollow microspheres are used as the lightening admixture; the high temperature strength stabilizer is high-activity silicon powder; the filler is micro silicon; the dispersing agent is an aldehyde ketone condensation product or a naphthalene dispersing agent; the early strength agent is formed by blending two or more of the following components: sulfo-aluminium sulfate, sodium silicate, basic aluminium chloride and the like; and the fluid loss agent is a sulphonated acetone-formaldehyde condensation product. The low-density cement paste can be used for well cementation of a heavy oil thermal recovery well on a low-pressure formation which is easy to leak, the strength recession of cement stones, which is caused by the high temperature, can also be greatly reduced, and the service life of the oil well is prolonged.

Owner:成都欧美克石油科技股份有限公司

Full-solid waste weak concrete material prepared with solid sulphur slag of fluidized bed fire coal

The invention discloses a concrete material which totally adopts industry solids waste to replace cement preparation, comprising a gelled material and a skeletal material. The gelled material is composed of the components with the following weight portions of 36 to 75 portions of fluidized bed burning coal solid sulfur clinker, 9 to 25 portions of acetylene sludge and 6 to 15 portions of phosphogypsum; because the cementing materials such as cement, lime, asphalt, and the like, are not needed at all, material costs are remarkably reduced, great amount of industry solids waste is used to produce building materials, especially the fluidized bed burning coal solid sulfur clinker is used to serve as raw material, environment pollution is avoided, and land resources are saved.

Owner:CHONGQING UNIV

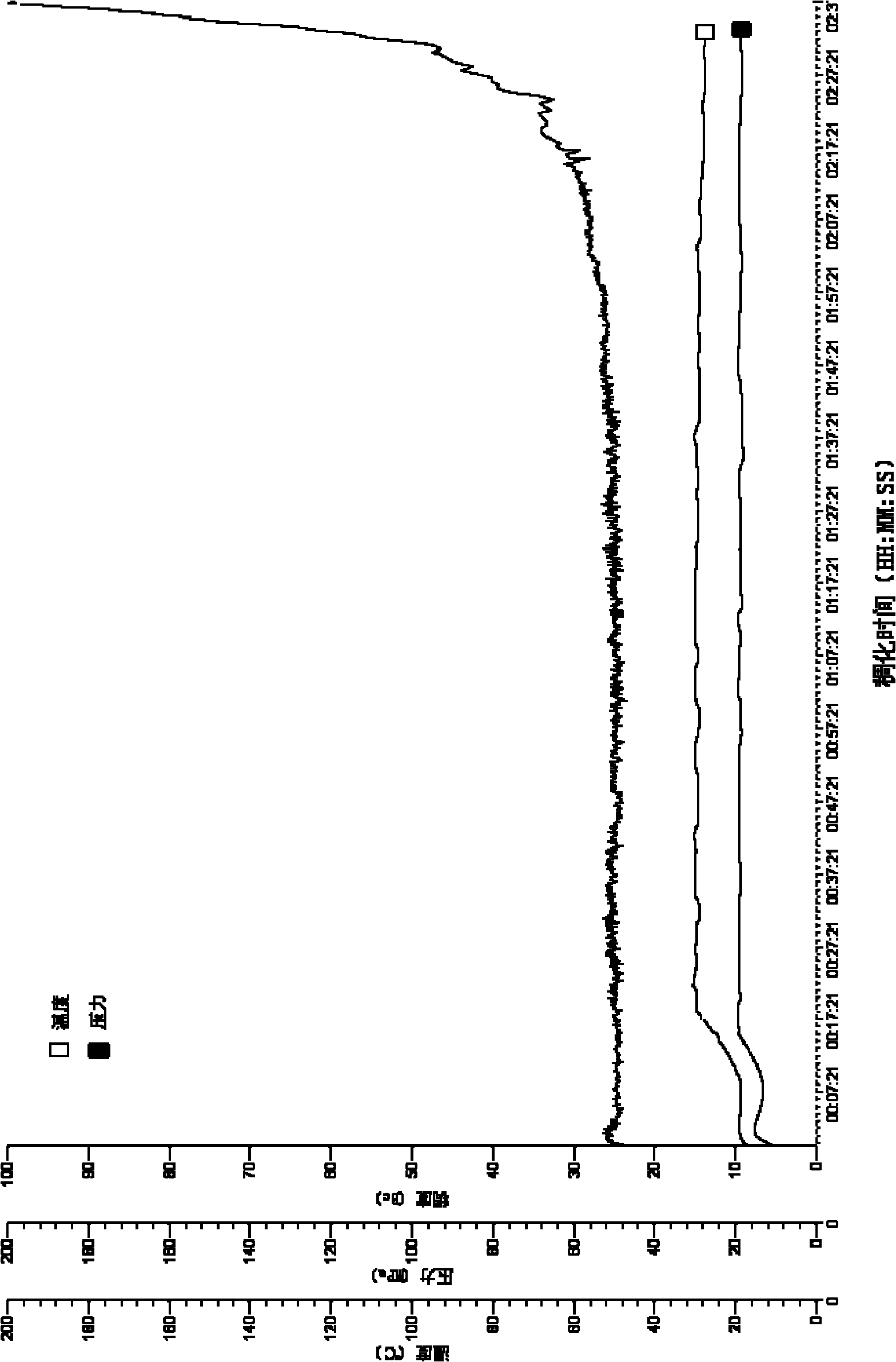

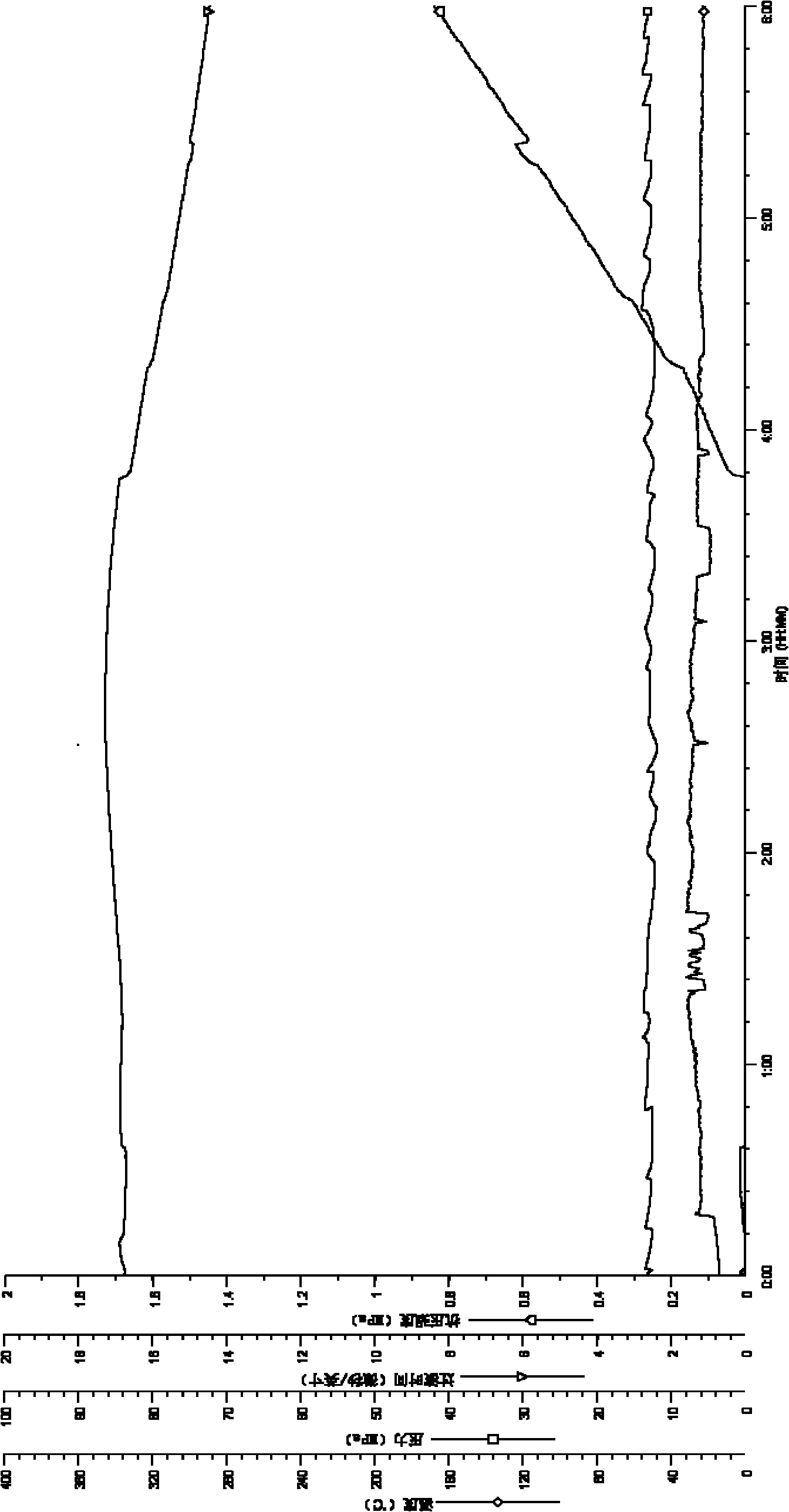

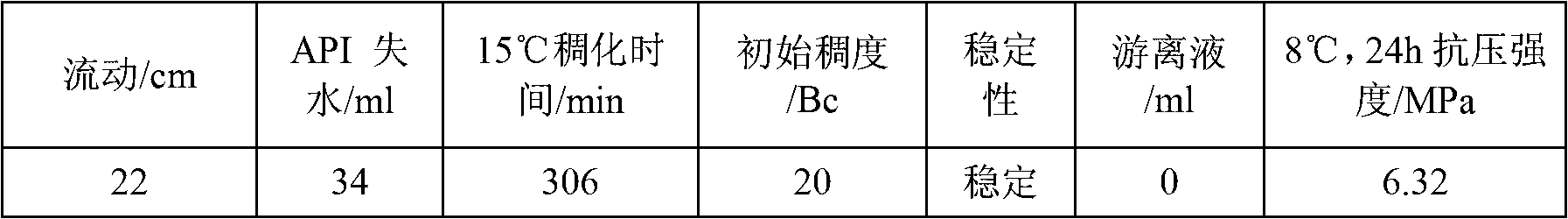

Deep water low temperature cementing cement system

InactiveCN101054513AImprove performanceRapid development of strengthDrilling compositionWell cementingCement slurry

The invention belongs to sea deep water complex well cementing which is suitable for low temperature, tending to superficial water-gassed-out. The mineral components and mass percent composition are: 23-45 wt.% of tricalcium silicate, 12-25 wt.% of calcium sulphoaluminate, 15-23 wt.% of dicalcium silicate, 3-10 wt.% of gypsum, 4-8 wt.% of calcium carbonate, and residual celite, calcium aluminate and other microelement. The using process of the deep water complex well cementing includes: adding 0-3 wt.% of coagulant, 0-1.2 wt.% of retarder, 15-45 wt.% of hollow microglobin and water to prepare a low density cement slurry system of 1.35-1.60g / cm3 which has a controllable gelled time and has a perfect right-angle gelling capacity, a set cement volume microdilatancy and develops fast at low temperature. The inventive deep water low temperature complex well cementing has a high early strength, a short curing time, a powerful channeling-preventing ability, and microdilatancy, which provides a powerful guarantee to improve the deep water complex well quality.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

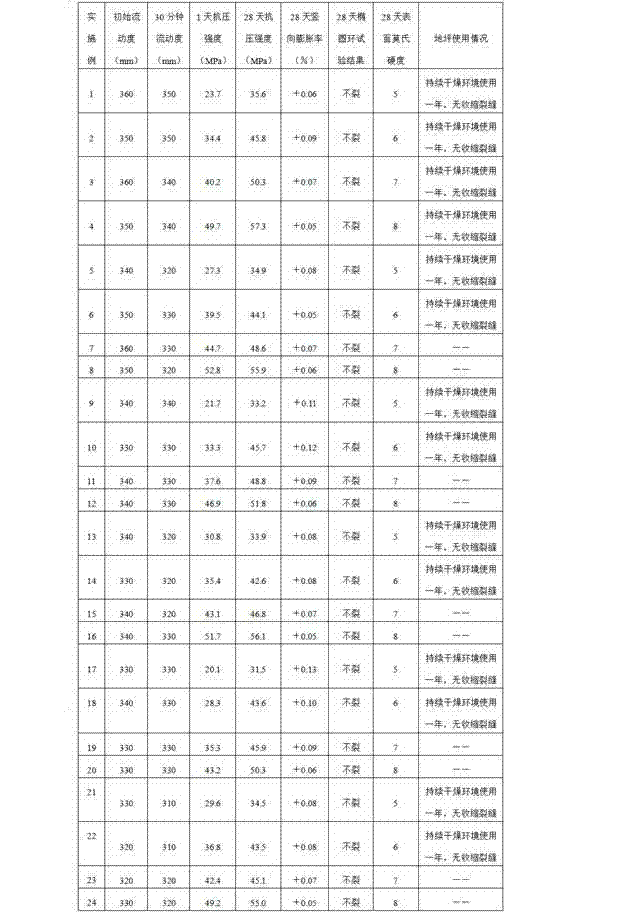

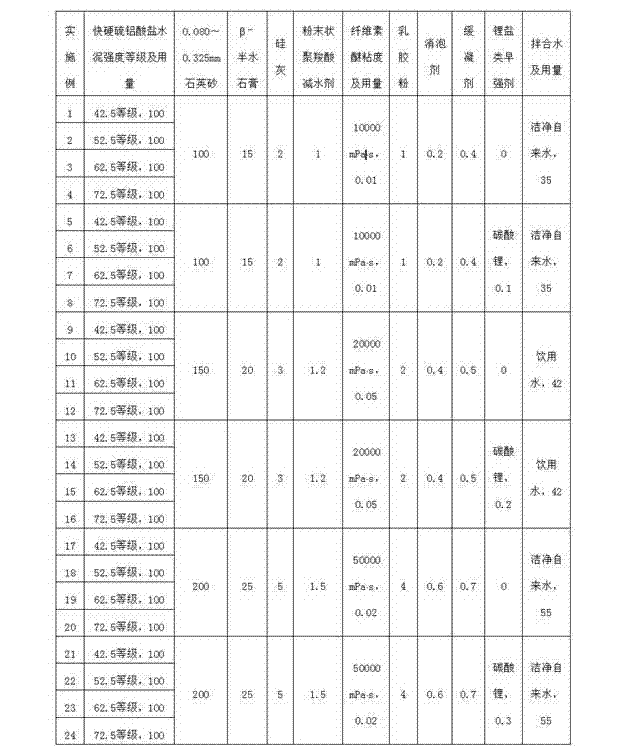

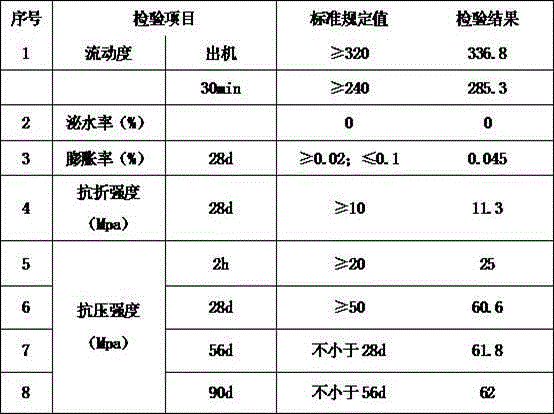

Cement-based self-leveling mortar

ActiveCN102826814AAchieve condensation hardeningAchieve self-leveling performanceCrack resistanceHigh surface

The invention relates to the field of building material, and in particular relates to cement-based self-leveling mortar, which takes sulphoaluminate cement as basic cementing material and quartz sand as aggregate, uses b-semi-hydrated gypsum to control the mortar not to contract and utilizes other additives to enable the prepared mortar to have the comprehensive performances required by the cement-based self-leveling mortar. The newly stirred mortar has the performances of high fluidity, self-leveling property, bleeding resistance and separation resistance; and the hardened mortar has the performances of shrink resistance, crack resistance, high surface hardness and good wear resistance. Compared with the existing self-leveling flooring mortar product with shrink resistance and crack resistance, the cement-based self-leveling mortar is low in production cost and wide in application scope.

Owner:湖南交泰建材有限公司

Method for producing architectural gypsum powder by using phosphogypsum

This invention relates to a method for producing construction gypsum powder from ardealite. The method comprises: (1) prehomogenizing ardealite waste residue, placing in a continuous high-efficiency calcining kiln, and calcining; (2) taking out and aging naturally for 7-15 d; (3) milling into 100-200 mesh powder. This invention uses a unique calcination technique to produce high performance construction gypsum from ardealite waste residue, and has such advantages as no secondary pollution and saved water resource.

Owner:宁夏建筑材料研究院(有限公司)

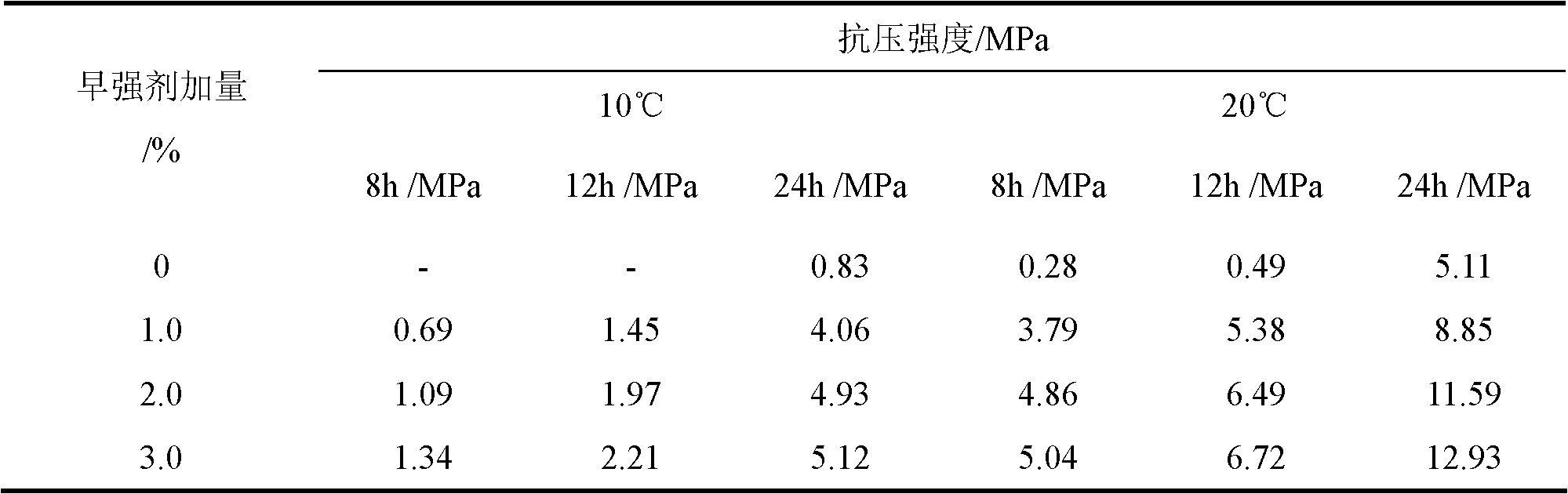

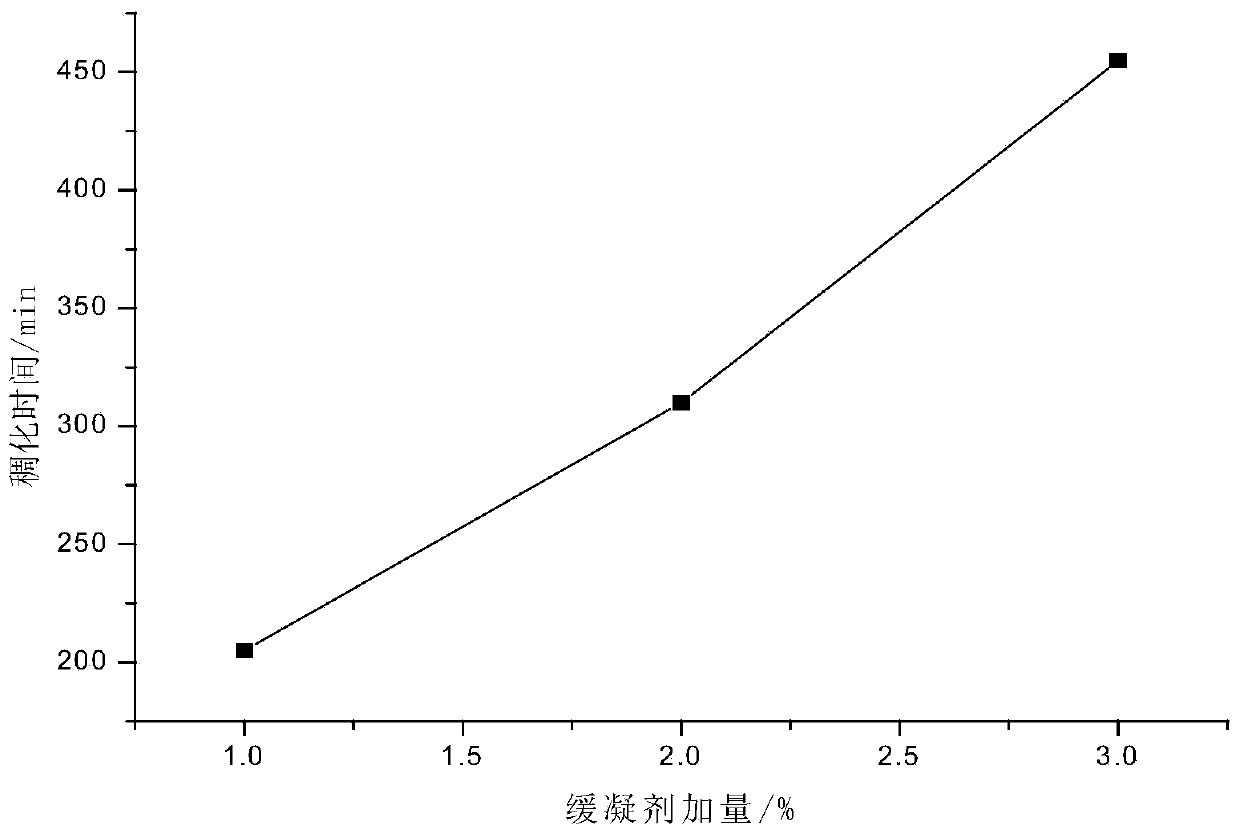

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Bridge bearing mortar and production method thereof

The invention relates to a bridge bearing mortar and a production method thereof. The invention is characterized in that the bridge bearing mortar is prepared from the following raw materials in parts by weight: 45-60 parts of graded quartz sand, 30-40 parts of 42.5 sulfoaluminate cement, 5-15 parts of 42.5 Portland cement, 1-10 parts of U-shaped expanding agent, 0.1-1 part of water reducing agent, 0.1-0.5 part of water retention agent, 0.01-0.1 part of early-strength admixture, 0.2-1 part of retarder and 0.01-0.03 part of defoaming agent. The bridge bearing mortar has the characteristics of low cost, excellent performance, stable quality, high fluidity, short initial and final setting time, quick strength development and favorable micro-expansion, and can be widely used in the bridge bearing mortar for high-speed railways, highways, traffic bridges and other bridges and a production method thereof.

Owner:GUANGXI NANNING BAIRUITONG SYNTHESIS BUILDING MATERIALS TECH

High temperature resistant silicate cement paste and preparation method thereof

ActiveCN108298902AGood settlement stabilityRapid development of strengthDrilling compositionWell cementingFresh water

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

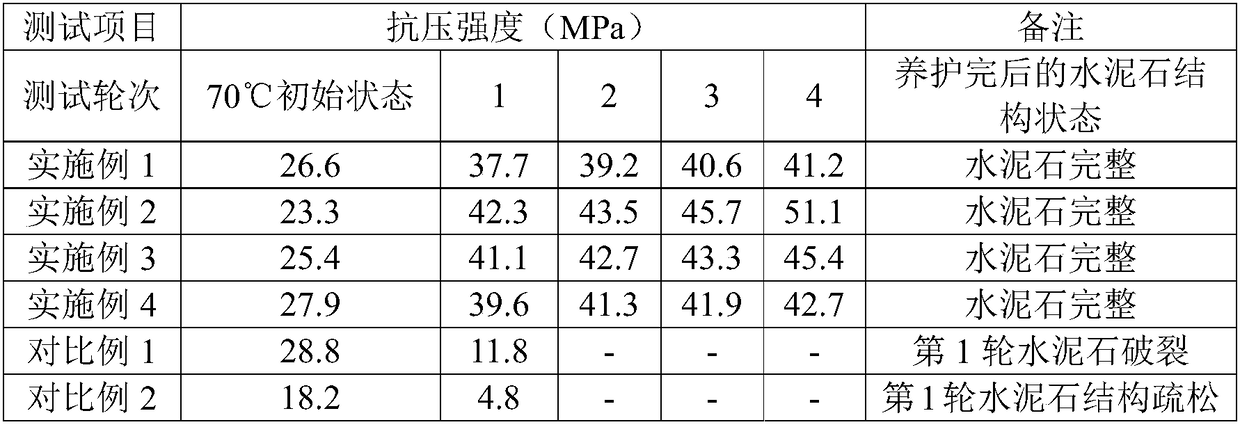

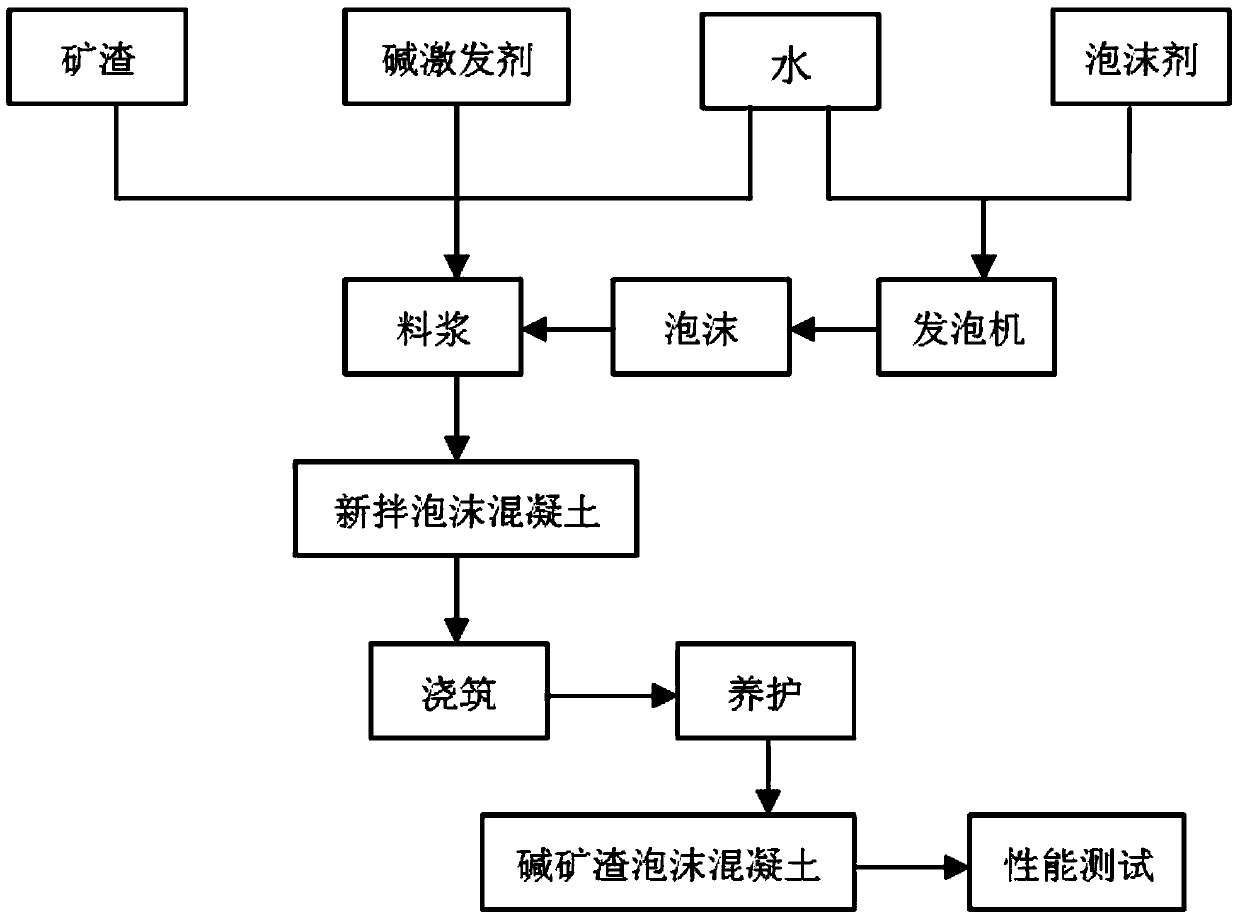

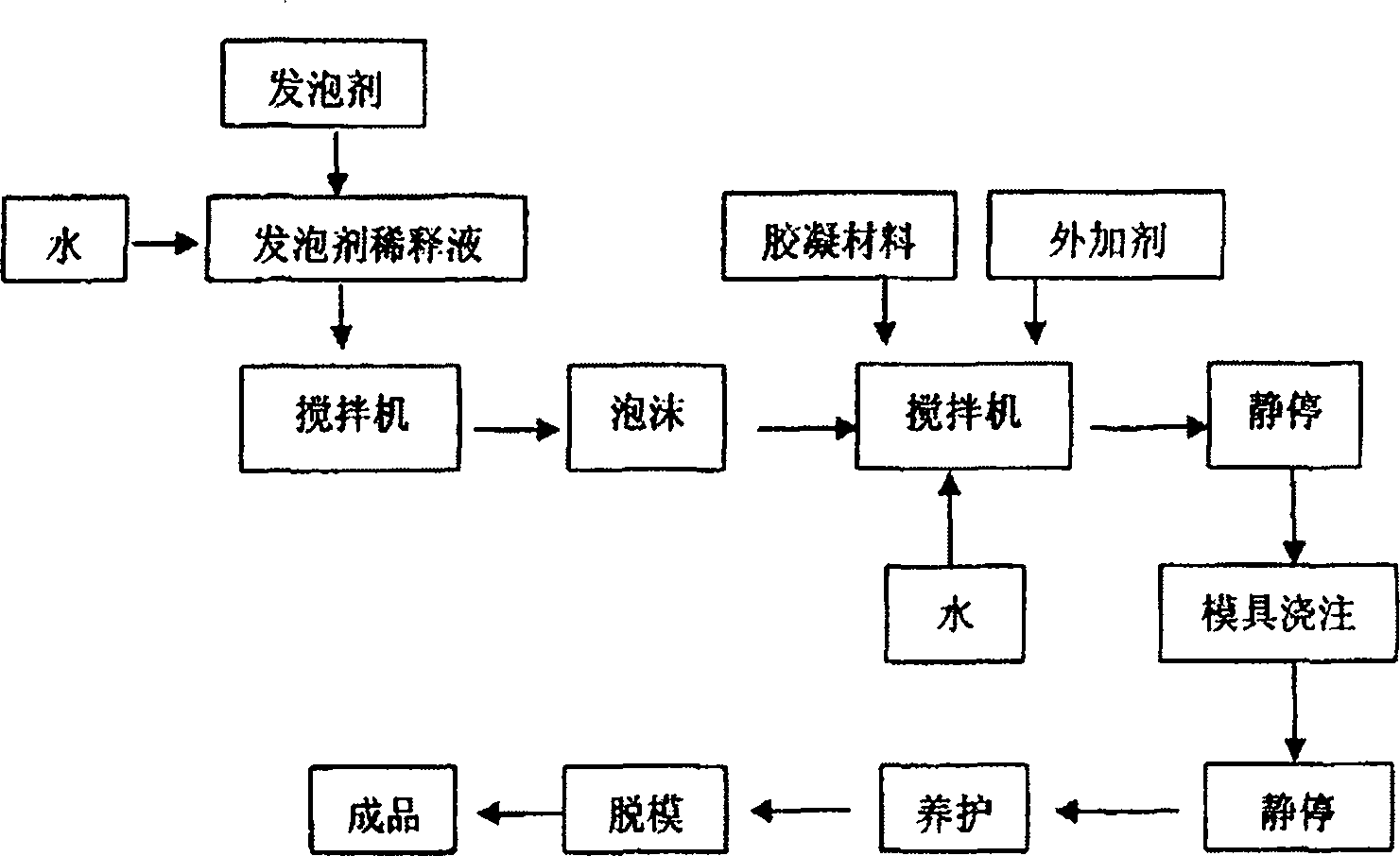

Alkali slag foamed concrete

The invention discloses an alkali slag foamed concrete which comprises slag and an alkali activator, wherein the alkali activator is sodium hydroxide or water glass. When the alkali activator is sodium hydroxide, the alkali slag foamed concrete is composed of the following components in parts by mass: 59-65 parts of slag, 5-6% of NaOH, 23-26 parts of water and 4.8-12.2 parts of foaming agent. When the alkali activator is water glass, the alkali slag foamed concrete is composed of the following components in parts by mass: 56-61 parts of slag, 9-11 parts of water glass, 21-25 parts of water and 5.0-12.2 parts of foaming agent. The volume weight of the foamed concrete is 290-610 kg / m<3>. The alkali slag foamed concrete has the advantages of short setting time, quick strength development, higher later strength, excellent water resistance and excellent weather resistance, and can be used for a long time.

Owner:CHONGQING UNIV

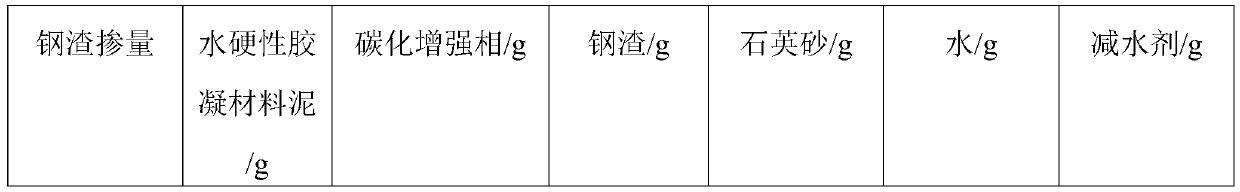

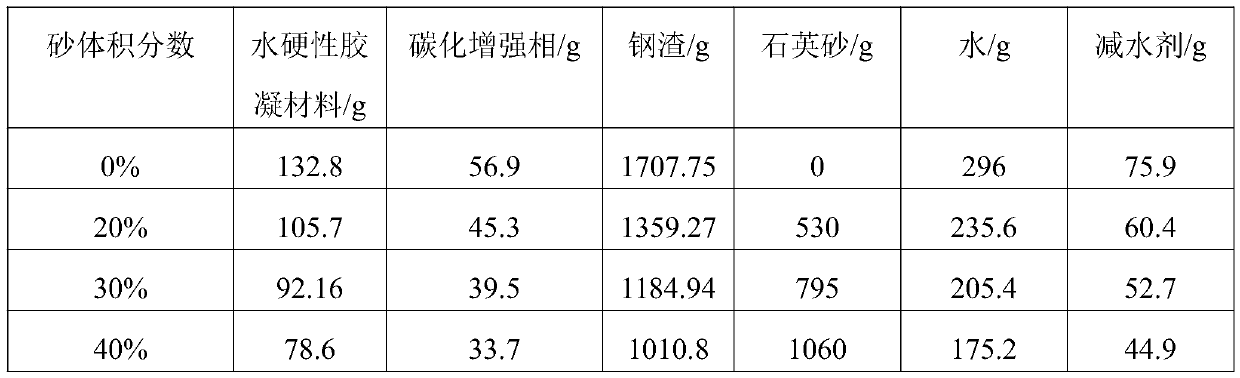

Preparation method of high-performance carbonized reinforced concrete

ActiveCN110818356AHigh strengthGive full play to the carbonization activityCeramic shaping apparatusCompressive resistanceReinforced concrete

The invention discloses a preparation method of high-performance carbonized reinforced concrete, and the method comprises the following steps: mixing steel slag, a hydraulic cementing material, a carbonized reinforced phase and quartz sand, adding water and a water reducing agent, stirring, and carrying out casting molding on the stirred slurry; sealing and maintaining the molded product for 12-24hours, removing a mold, and carrying out drying pretreatment; and putting the dried product into a carbonization kettle with a CO2 atmosphere and an air pressure of 0.1-0.5 MPa, and carrying out carbonization maintenance for 12-24 hours to obtain a steel slag product. The high-performance carbonized reinforced concrete prepared by the invention has excellent working performance; the hydrated andcarbonized synergistic effect of the hydraulic cementing material and the steel slag is fully utilized, the compressive strength can reach 100 MPa within a short time, meanwhile, the utilization rateof the steel slag is remarkably increased, a large amount of CO2 can be solidified and stored, huge environmental benefits are achieved, development of green building materials is facilitated, and a sustainable development road is achieved.

Owner:WUHAN UNIV OF TECH

Composition useful as an adhesive for installing vehicle windows

ActiveUS20080149257A1Rapid development of strengthGood anti-sag performanceAdhesive processesWindowsEndcappingPolyester

In one embodiment, the invention is an composition comprising: a) one or more isocyanate functional polyether polyurethane prepolymers; and b) one or more prepolymers of one or more polyisocyanates and one or more polyesters wherein the terminal groups on the polyester polyol polyurethane prepolymer are the residue of a monofunctional polyalkylene glycol (hereinafter capped polyester polyurethane prepolymer) or one or more polyester polyols which are capped with the residue of one or more monofunctional isocyanates (hereinafter isocyanate capped polyesters); wherein the composition is a low viscous paste at temperature of from about 40 to about 80° C. and is high viscous paste at a temperature of from about 40° C. or less. In a preferred embodiment the composition further comprises c) one or more catalysts for the reaction of isocyanate moieties with hydroxyl groups. In another embodiment the invention is a method of bonding two or more substrates together which comprise contacting the two or more substrates together with a composition according to this invention disposed along at least a portion of the area wherein the substrates are in contact wherein the composition is a low viscous paste. In a preferred embodiment the composition is heated to about 40° C. to about 80° C. and converted to a low viscous paste prior to contacting it with the one or more substrates.

Owner:DOW GLOBAL TECH LLC

Composition useful as an adhesive for installing vehicle windows

ActiveUS7892395B2Rapid development of strengthGood anti-sag performanceWindowsOther chemical processesEndcappingPolyester

Owner:DOW GLOBAL TECH LLC

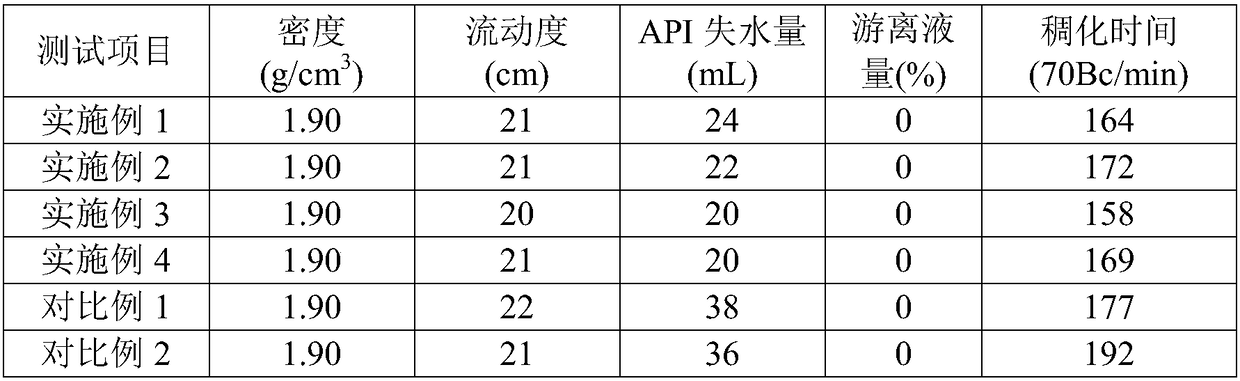

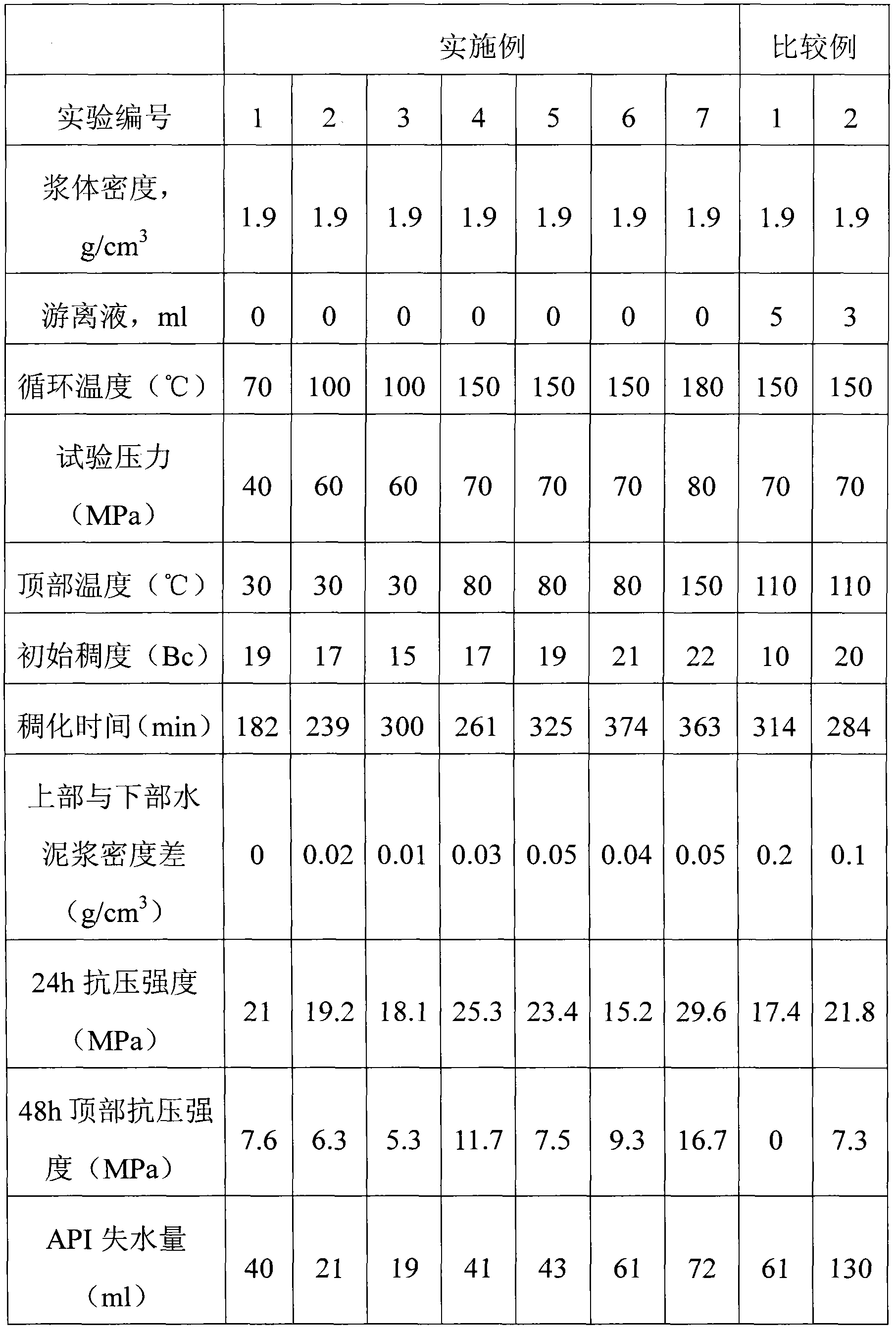

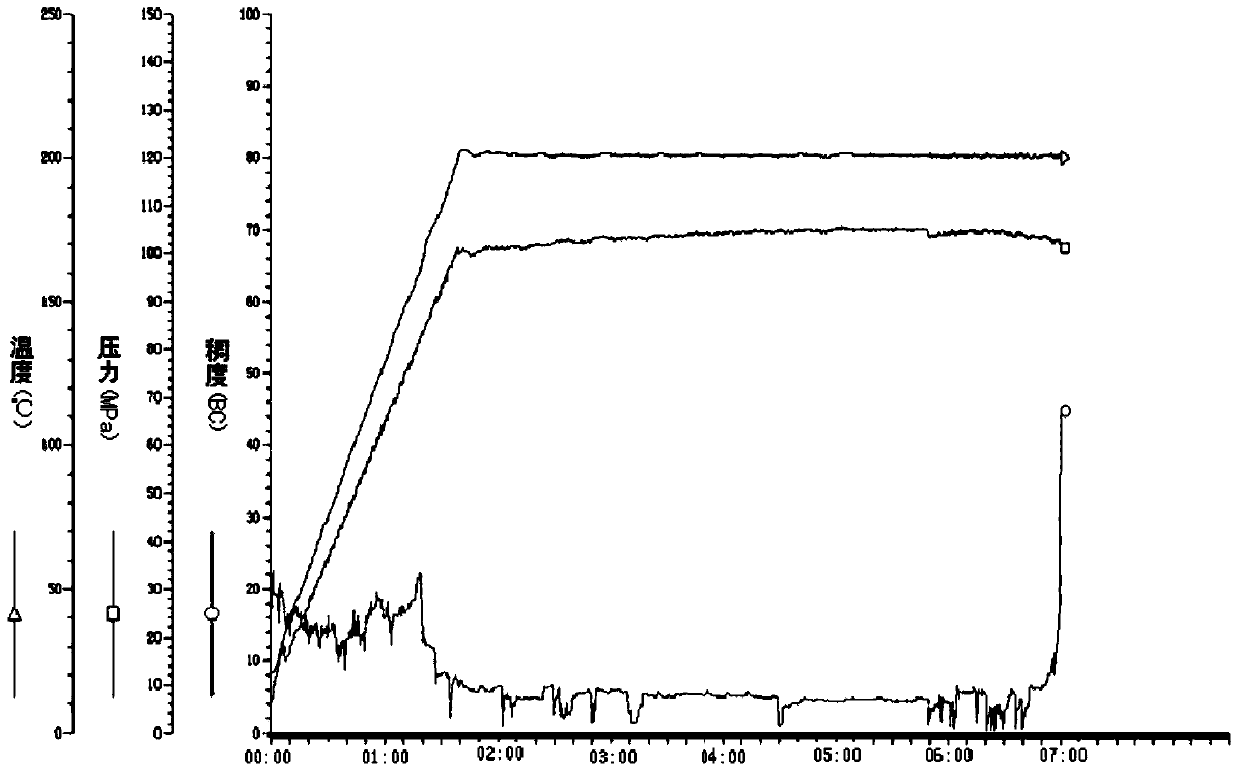

Cementing slurry system suitable for large range of temperature

ActiveCN102127404AImprove performanceRapid development of strengthDrilling compositionPhosphateDiethylenetriamine

The invention relates to a cementing slurry system suitable for large range of temperature. The cementing slurry system comprises the following components in parts by weight: 100 parts of cement, 0-40 parts of high temperature stabilizer, 2-6 parts of filtrate reducer, 0.3-3 parts of retarder and 40-55 parts of water, wherein the cement is G-grade high sulfate-resistant oil well cement; the filtrate reducer is 2-acrylamido-2-methylpropane sulfonic acid (AMPS)-acrylamide polymer, the molar ratio of AMPS to acrylamide polymer monomer is 7:3 and the number average molecular weight is 0.7-1.5 millions; the retarder is a diethylenetriamine derivative with carboxyl groups, phosphate groups and sulfonate groups, the molar ratio of the carboxyl groups to the phosphate groups and sulfo groups is 3:2:1; and the high temperature stabilizer is amorphous silica of which purity is more than 95% and average diameter is 0.1-0.15 micron. The circulating temperature range of the cementing slurry is 70-180 DEG C; under high temperature, the cementing slurry has good slurry stability, low fluid loss water amount and no free liquid; and the cementing slurry system can meet the deep well cementing construction requirement and can be used to increase the cementing quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Method for maintaining porous concrete through carbon dioxide

InactiveCN104290183AImprove the ability to absorb carbon dioxide gasControl moisture contentCeramic shaping apparatusAbsorption capacityMixed materials

The invention discloses a method for maintaining porous concrete through carbon dioxide. The method includes the following steps: (1) concrete is mixed and formed; (2) an obtained initial concrete body is placed into a pre-maintenance device for pre-maintenance, wherein the pre-maintenance temperature ranges from 15 DEG C to 25 DEG C, and the relative humidity ranges from 50% to 70%; air circulates through an air blower or a fan, wherein the pre-maintenance time ranges from 1 h to 18 h; (3) when the residual water-cement ratio of the mixed material body obtained after pre-maintenance reaches a preset residual water-cement ratio, the mixed material body is placed into a CO2 maintenance container, vacuumizing is carried out, then CO2 gas is led into the CO2 maintenance container for CO2 maintenance, the gas is discharged after maintenance is completed, and maintenance is stopped. By means of the method, control over the moisture content of the concrete body can be achieved, the carbon dioxide gas absorption capacity of the concrete can be effectively improved, and the quality of a concrete product can be effectively improved; in addition, the waste greenhouse effect gas, namely the carbon dioxide gas can be effectively used, the emission of the greenhouse gas can be reduced, the environment can be protected, and the greenhouse effect can be suppressed.

Owner:HUNAN UNIV

Inorganic mineral polymer self-leveling mortar and preparation method thereof

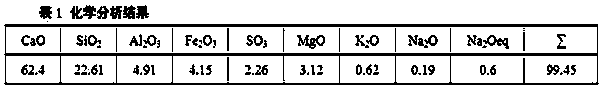

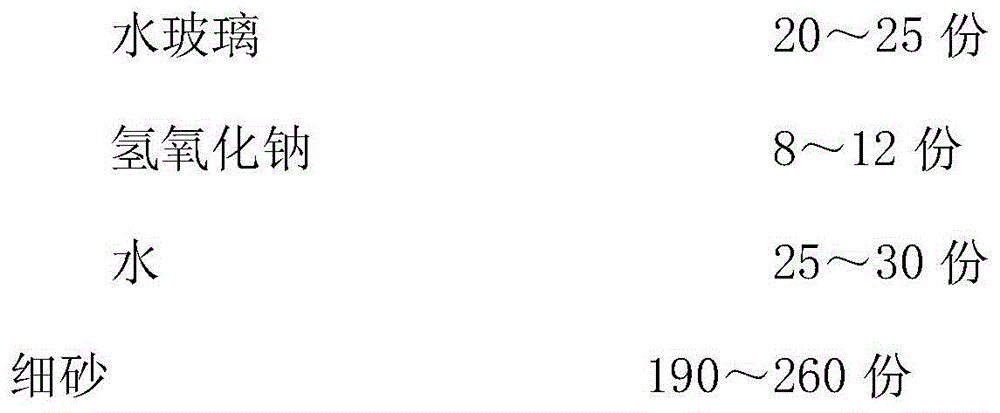

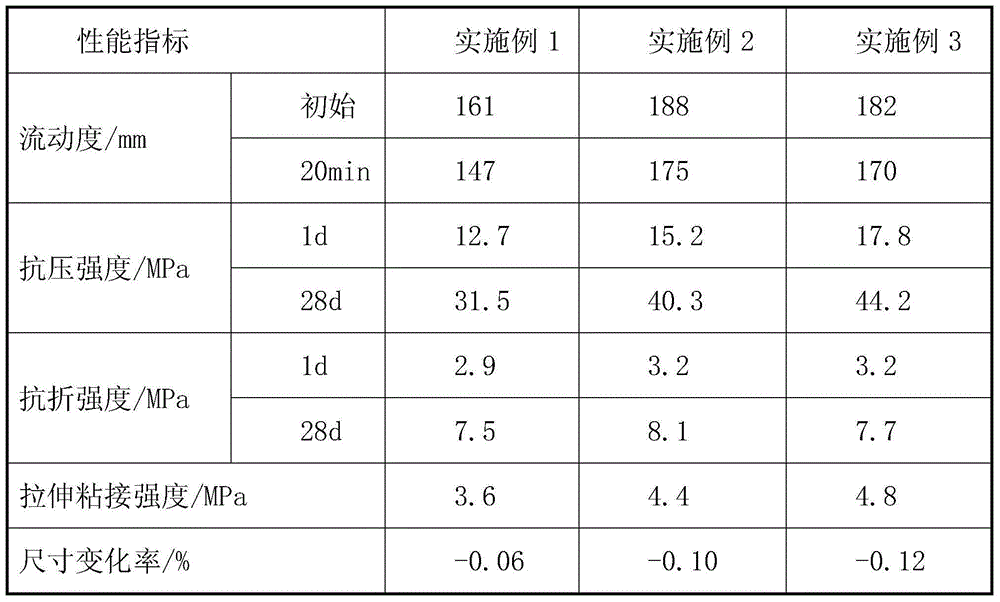

The invention relates to inorganic mineral polymer self-leveling mortar and a preparation method thereof. The mortar mainly comprises the raw materials in parts by weight: 64-72 parts of mine residues, 18-22 parts of kaolin, 10-14 parts of fly ash, 20-25 parts of water glass, 8-12 parts of sodium hydroxide, 25-30 parts of water, and 190-260 parts of fine sand, wherein additives are a water reducing agent, a stabilizing agent and an antifoaming agent; gelating materials adopt inorganic mineral polymers which are made from the mine residues, the kaolin and the fly ash and stimulated by the water glass with a specific modulus of 1.4-1.5; because of a dimensional net structure in the inorganic mineral polymers, the self-leveling mortar disclosed by the invention has higher compressive strength, higher rupture strength and durable and abrasion-proof performance. The 28d compressive strength is 45MPa, the 28d rupture strength is 9MPa, and the cohering strength is 4.5MPa. The mortar disclosed by the invention also solves the problems that the surface is not smooth after the mortar is hardened, the surface is cracked after being retracted, the surface is hollow and peeled; moreover, the utilization rates of industrial by-products are also improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Curable low-density leaking stoppage working fluid and preparation method thereof

InactiveCN106967393AReduce hydrostatic injection pressureExtended stayDrilling compositionFiberWorking fluid

The invention provides a curable low-density leaking stoppage working fluid and a preparation method. The curable low-density leaking stoppage working fluid is prepared from, by weight, 100 parts of G-grade oil well cement, 44-60 parts of slag, 23-67 parts of lightening admixture, 8-12 parts of micro silicon, 0.4-1.2 parts of dispersant, 4-5 parts of fluid loss agent, 0.4 part of retarder, 1 part of fiber, 131-214 parts of water and 0.5 part of foaming agent. The density of the curable low-density leaking stoppage working fluid is 1.20-1.50 g / cm<3>, the curable low-density leaking stoppage working fluid is high in early strength and thixotropy, free of free water and good in system stability, and the technical problem that a curing body cannot be formed due to bridge plug leaking stoppage in a conventional leaking stoppage method and the cement leaking stoppage cutting body difficultly stays at a leaking layer is solved. After leaking stoppage is carried out, the formation pressure bearing capacity at the leaking layer can be improved, and the technical defects of the existing conventional leaking stoppage method are overcome.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Vehicular glass adhesive and method of adhering said glass

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

Vehicular glass adhesive and method of adhering said glass

ActiveUS20110265932A1Molecular weightEasy pumpabilityCovering/liningsNon-macromolecular adhesive additivesAdhesiveGram

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

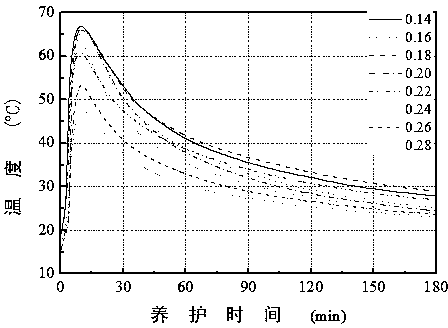

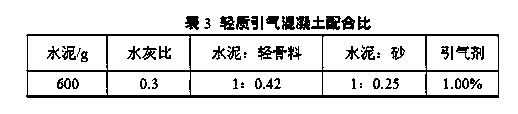

Novel heat-insulation fireproof porous concrete and preparation method thereof

InactiveCN104108949ARapid development of strengthHigh compressive strengthSolid waste managementCeramicwareCompressive resistanceFoaming agent

The invention relates to a novel heat-insulation fireproof porous concrete and a preparation method thereof. The novel heat-insulation fireproof porous concrete has the characteristics of porous property, light weight, low heat conduction coefficient, high strength, good heat insulation effect and high temperature resistance, and belongs to the technical field of fireproof building materials. The novel heat-insulation fireproof porous concrete uses a large amount of industrial waste residue, accords with energy saving and environmental protection requirements, and is deeply and widely concerned in the building industry. Porous concrete with the density of 450-600Kg / m<3> and the anti-compression ability reaching 10MPa is prepared through using Portland cement as a binder, using fly ash and expanded perlite to substitute sand and parts of cement and adding a polypropylene fiber. High-strength porous concrete with the density of 600-800Kg / m<3> and the anti-compression ability reaching 20-30MPa is prepared by adopting an expanded perlite and polypropylene fiber doping technology. Porous concrete prepared by using cement, fly ash, an organic fiber and a self-made composite foaming agent has flow state characteristics, can be conveniently casted in mass, has a heat conduction coefficient of below 0.06J / K.M and a water absorption rate of below 10%, and provides technical support for the preparation of high-performance porous concrete heat insulation wall materials.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Inorganic fiber reinforced composite material and preparation method thereof

InactiveCN102180644AReduce material costsThe preparation process is simpleSolid waste managementBatch productionCorrosion

The invention relates to an inorganic fiber reinforced composite material which is characterized in that the composite material is prepared by magnesium oxide, phosphate, a retarder, short fibers, fillers and water according to a certain weight ratio; the composite material can be used to produce various products by mold pouring or pressure molding, and the operation is simple and convenient; the composite material has the advantages and effects of good mechanical properties, good density, acid and base corrosion resistance, nontoxicity, environmental protection, low cost and wide applications; and the inorganic fiber reinforced composite material has low cost, high strength, and good toughness, is applicable to industrial batch production, is suitable for producing pipes, tanks, decoration materials, handicrafts, fireproof doors and windows and the like with various shape specifications, and can substitute wood, metal, and plastics in many aspects.

Owner:顺平县普惠农丰新能源科技有限公司

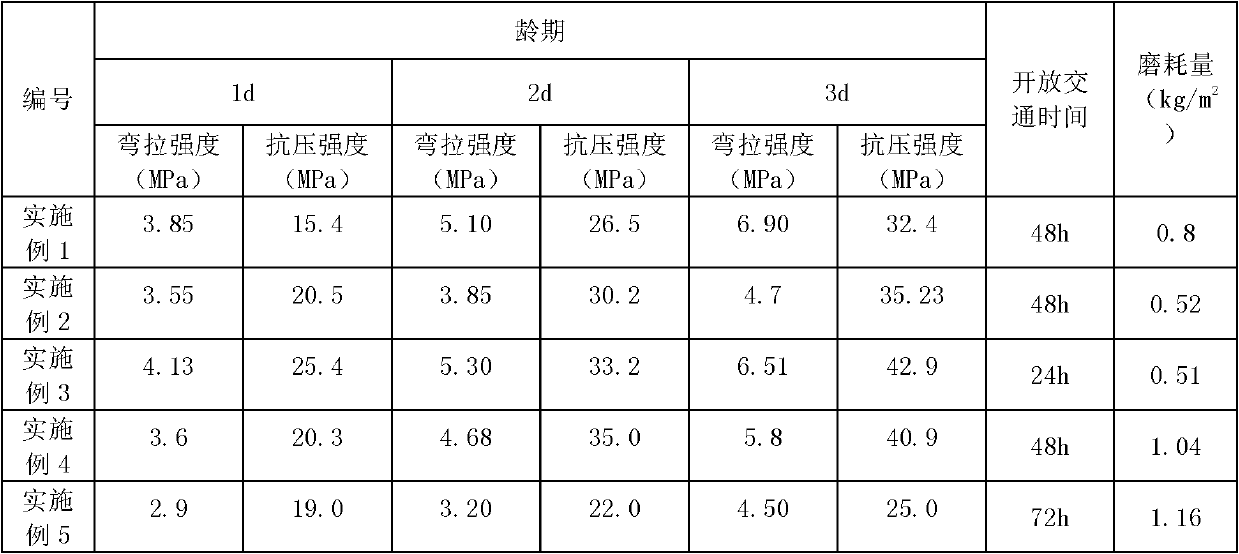

Early-strength fast-track concrete for repairing cement-concrete road surface

InactiveCN102167550AWidely used valueSmall shrinkageSolid waste managementRepair materialRoad surface

The invention relates to early-strength fast-track concrete for repairing a cement-concrete road surface. The early-strength fast-track concrete comprises cement, sand, stone and water, and is characterized by also comprising additives and a mineral admixture, and concretely comprising 10 to 20 percent of cement, 5 to 10 percent of water, 28 to 32 percent of sand, 44 to 48 percent of stone and 0 to 1.0 percent of mineral admixture. The invention overcomes defects of not high early strength, long curing period and traffic impact of the conventional common curing repair material for the cement-concrete road surface and defects of low durability and high construction cost of partial quick curing repair materials, and provides economical and practical early-strength fast-track concrete which meets the requirement of durability of the cement-concrete road surface and quickly cures and repairs the cement-concrete road surface.

Owner:交通运输部公路科学研究院

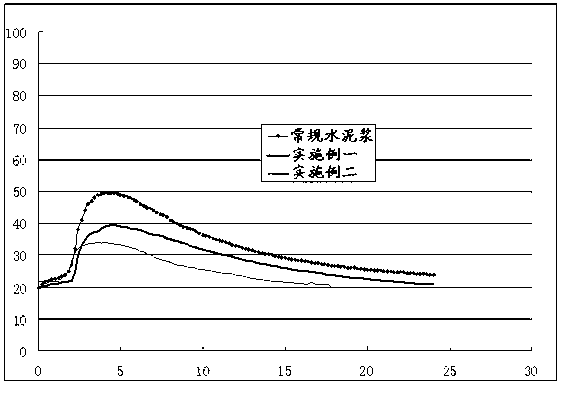

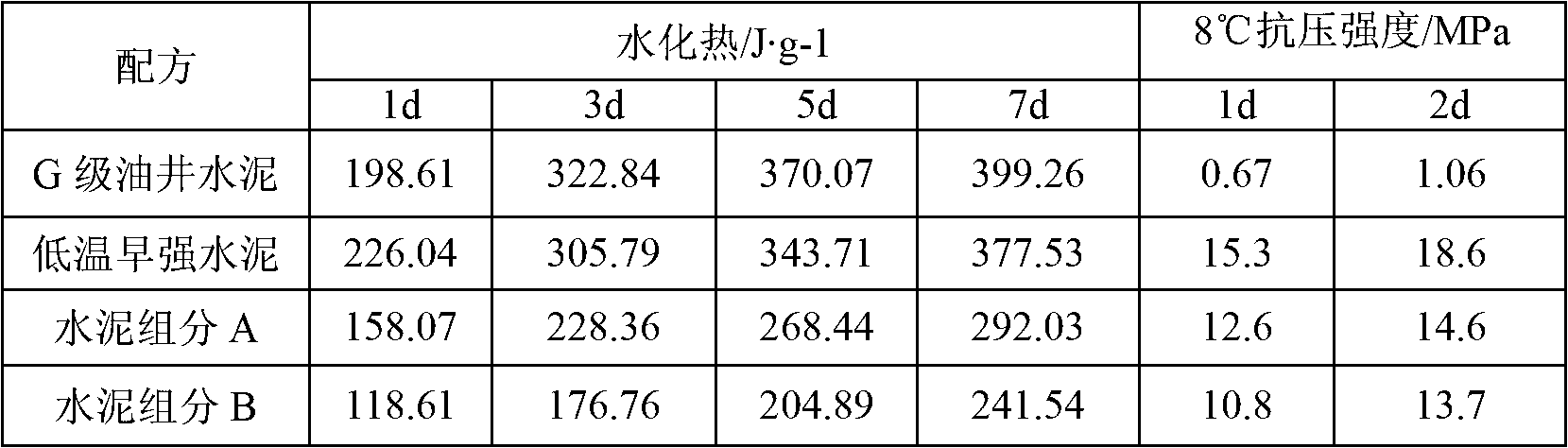

Low-hydration-heat early-strength cement for well cementation

InactiveCN102796500ARapid development of strengthImprove stacking effectDrilling compositionPermafrostHorizon

The invention relates to low-hydration-heat early-strength cement for well cementation, which is used in permafrost horizon or deepwater hydrate-bearing strata in oil drilling engineering. The cement disclosed herein comprises the following ingredients: 30-70wt% of low-temperature early-strength cement, 20-50wt% of pozzolanic material, and 10-40wt% of fine spherical particles. According to the invention, the hydration heat of the cement disclosed herein is 1 / 2 of that of ordinary cement, the low temperature strength develops fast; and the cement disclosed herein can be prepared into low-hydration-heat cement mortar, and has good effect and wide application.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

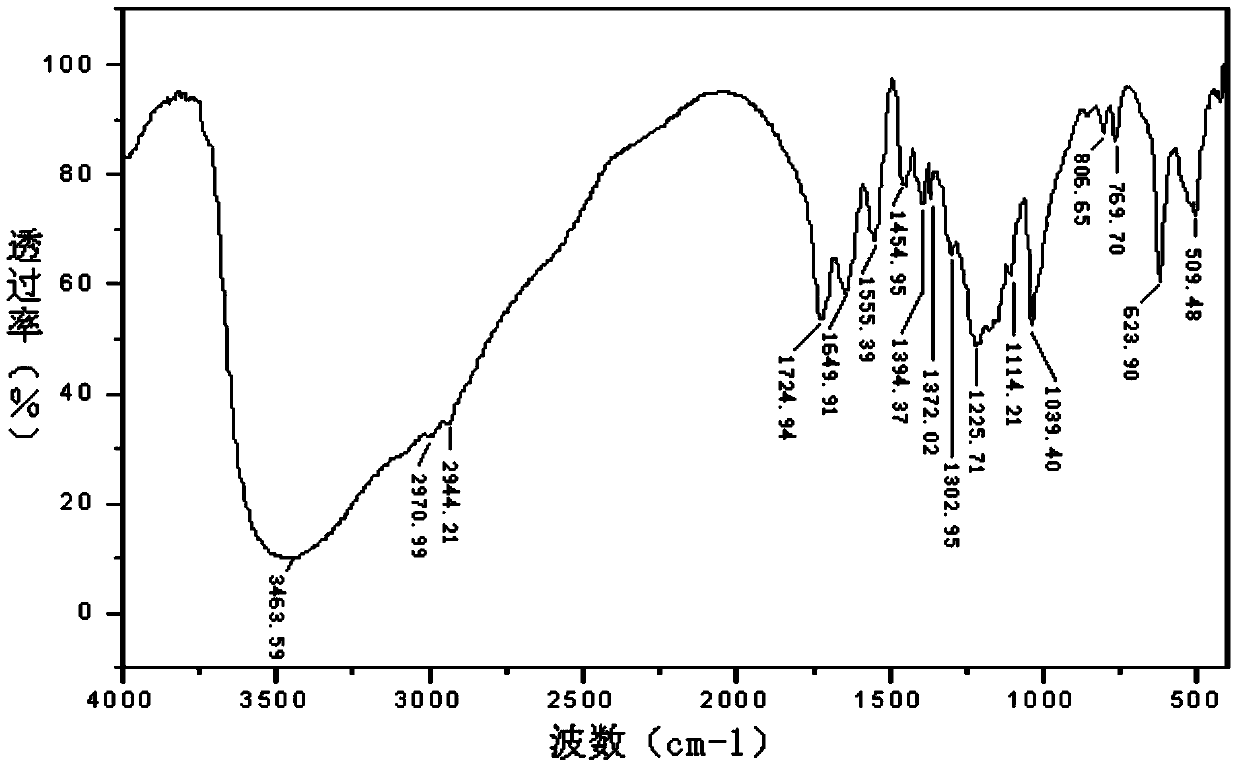

Preparation and application methods of high temperature resistant cement retarder

ActiveCN103739779AWide application temperature rangeRapid development of strengthDrilling compositionPolymer scienceOxygen

The invention discloses preparation and application methods of a high temperature resistant cement retarder. The preparation method comprises the steps of dissolving 2-acrylamido-2-methyl propanesulfonic acid accounting for 40-60% of the total monomer by mass, itaconic acid accounting for 20-40% of the total monomer by mass and maleic acid accounting for 10-20% of the total monomer by mass into water with mass 2-4 times the total mass of the monomer, removing oxygen, adding an initiator ammonium persulfate accounting for 1.5-3% of the total monomer by mass, reacting at 75-100 DEG C for 3-6 hours, and then cooling the reactant to the room temperature, thus obtaining the high temperature resistant cement retarder. The high temperature resistant cement retarder prepared by the method can be used in the temperature range of 100-230 DEG C, is insensitive in additive amount, has short thickening transition time, is well matched with other oil well cement additives, does not have adverse effects on strength development of set cement, and has good salt resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

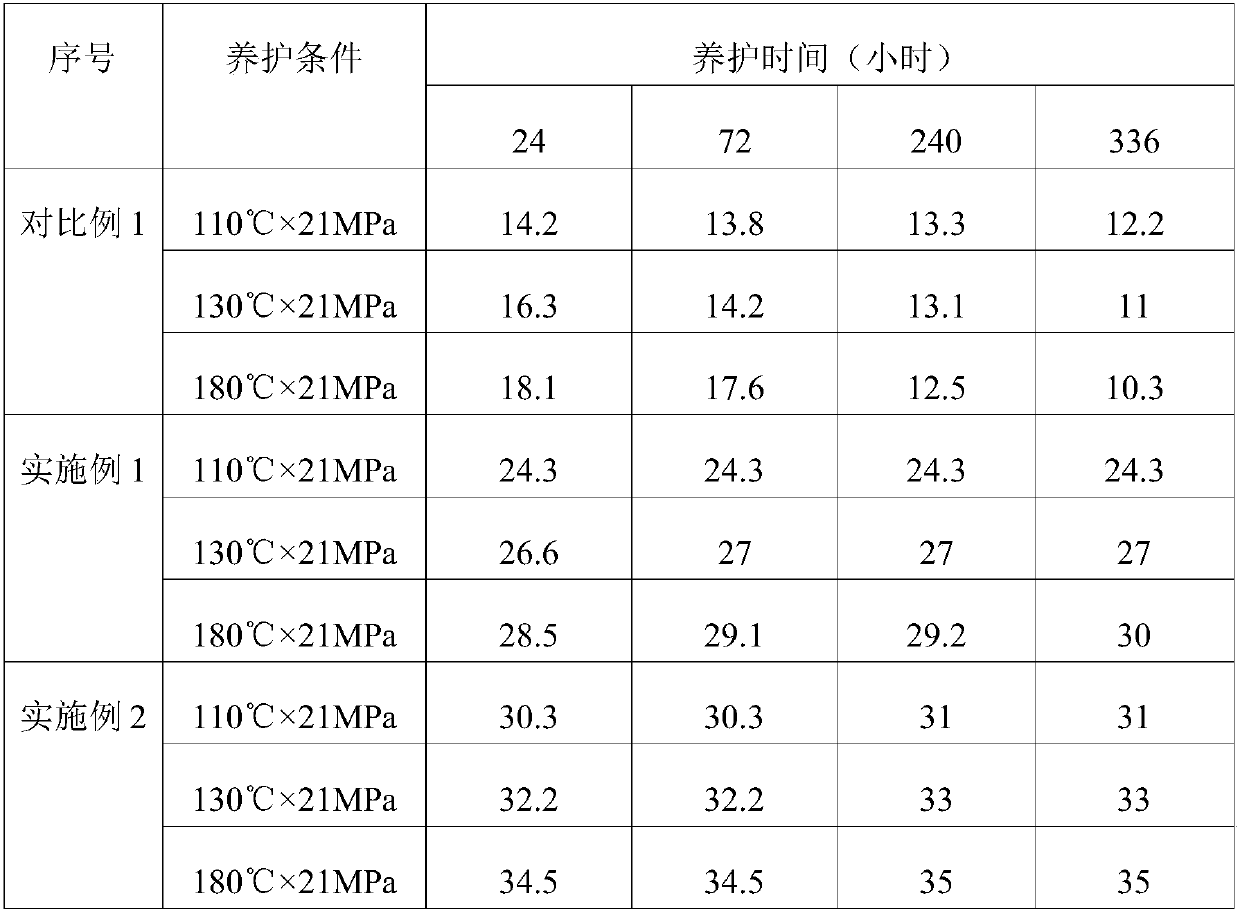

Oil well cement paste system for preventing high-temperature strength retrogression and preparation method thereof

The invention relates to an oil well cement paste system for preventing high-temperature strength retrogression and a preparation method thereof in the field of oil and gas field well drilling and cementing. The system comprises, by weight, 100 parts of cement, 25-45 parts of silica fume, 0-6 parts of a fluid loss agent, 0-5 parts of a retarder, 1-10 parts of a strength enhancer, 0.5-5 parts of asuspension stabilizer and 40-60 parts of water. The strength enhancer in the system is liquid, is low in dosage, can accelerate the strength development of set cement, and greatly improves the strength of the set cement without strength retrogression at high temperature. The system has a wide popularization and application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

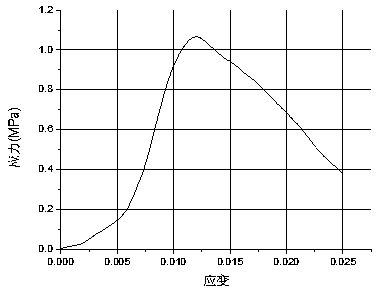

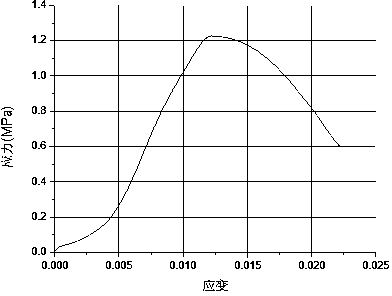

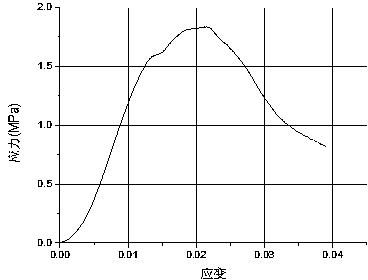

Sodium metasilicate cemented rock similar material and preparation method thereof

The invention discloses a sodium metasilicate cemented rock similar material. The rock similar material with required physical and mechanical parameters is prepared by using coarse aggregates and fine aggregates as aggregates, anhydrous sodium metasilicate as a cementing agent, sodium fluosilicate as a curing agent and water as a blending agent, uniformly mixing and stirring, carrying out rapid mold filling and then curing. The sodium metasilicate cemented rock similar material is wide in raw material source, low in price, nontoxic and harmless; the physical and mechanical parameters of the similar material disclosed by the invention are wide in adjustment range and convenient to adjust, and the deformation damage processes of most project surrounding rocks can be simulated; and a preparation method of the sodium metasilicate cemented rock similar material is simple and convenient for casting moulding and operation; and the operation that a finished product is cured under a special condition is not needed, and the finished product is relatively rapid in strength development and stable in property.

Owner:PLA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com