Novel heat-insulation fireproof porous concrete and preparation method thereof

A technology of porous concrete and thermal insulation, applied in the field of building fireproof materials, can solve the problems of cracking, low strength, water absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

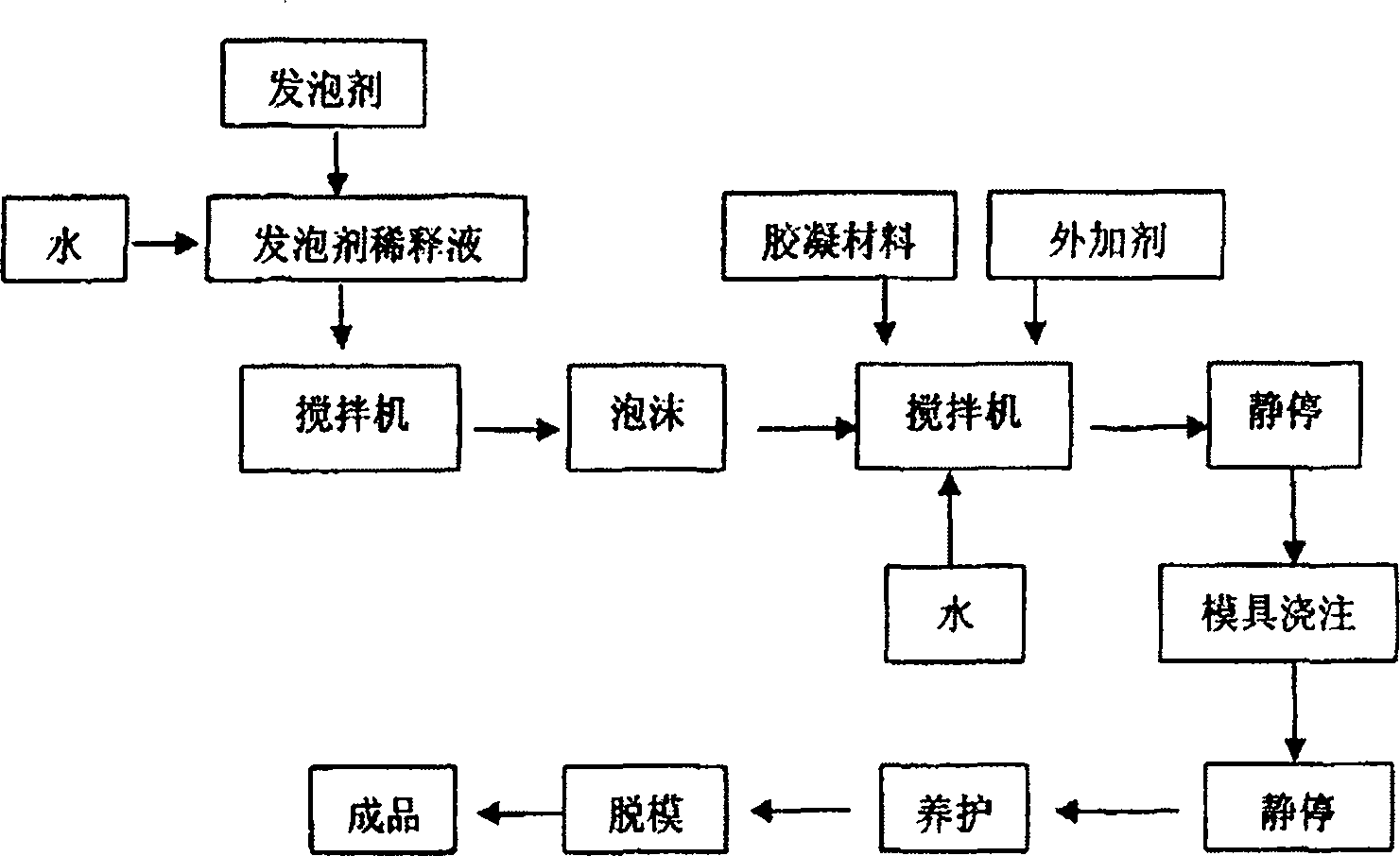

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the influence of fly ash content on foamed concrete performance

[0031] By adding different amounts of fly ash to the porous concrete, the compressive strength of the porous concrete mixed with fly ash is greatly lower than that of pure cement porous concrete, while the strength of the fly ash porous concrete is significantly improved after adding chemical activators. Increase. By testing the strength of concrete after 28 days, the effect of fly ash on its strength is determined. The specific process is as follows:

[0032]Add water to 42.5MPa ordinary Portland cement (the water-cement ratio is 1:0.5), add different proportions of 0, 10%, 20%, 30%, 40% fly ash and corresponding chemical activators, add 0.6 % organic fiber and 5% expanded perlite are stirred evenly to obtain cement-based slurry, 2% foaming agent solution is added, and the foaming agent solution is made into foam by a foaming machine. Mix the foam and cement-based slurry evenly to obtain...

Embodiment 2

[0034] Example 2: Effect of expanded perlite particles on porous concrete

[0035] Add water to 42.5MPa ordinary Portland cement (the water-cement ratio is 1:0.5), add 20% fly ash and the corresponding chemical activator, add 0.6% organic fiber, add different proportions of 0, 5%, 10 %, 15% of the expanded perlite is stirred evenly to obtain a cement-based slurry, and two foaming agent solutions of 2% and 5% are added, and the foaming agent solution is made into foam by a foaming machine. Mix the foam and cement-based slurry evenly to obtain a porous concrete slurry. The foam slurry is poured into a standard test mold of 100mm×100mm×100mm, and the curing room temperature is 26°C±2°C. After standing for 8 hours, the formwork is removed. Spray water to the test block once a day. After 28 days, put the test block into an 85°C drying oven to dry to constant weight, and measure its density and strength. A total of 2 groups of 6 pieces were made for each batch of test pieces. After...

Embodiment 3

[0037] Embodiment 3: the impact of different content organic fibers on porous concrete

[0038] Add water to 42.5MPa ordinary Portland cement (the water-cement ratio is 1:0.5), add 20% of fly ash and corresponding chemical activators, add 15% of expanded perlite, and add 0.4% of different proportions , 0.6%, 0.8%, 1.0% of the organic fibers are stirred evenly to obtain cement-based slurry, add 2% foaming agent solution, and use a foaming machine to make the foaming agent solution into foam. Mix the foam and cement-based slurry evenly to obtain a porous concrete slurry. The foam slurry is poured into a standard test mold of 100mm×100mm×100mm, and the curing room temperature is 26°C±2°C. After standing for 8 hours, the formwork is removed. Spray water to the test block once a day. After 28 days, put the test block into an 85°C drying oven to dry to constant weight, and measure its density and strength. A total of 2 groups of 6 pieces were made for each batch of test pieces. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com