Oil well cement paste system for preventing high-temperature strength retrogression and preparation method thereof

A technology of oil well cement slurry and high temperature strength, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems that are difficult to meet the requirements of oil well cement slurry engineering applications, poor compatibility of cement slurry admixtures, complex formulas, etc. problems, to achieve the effect of improving long-term sealing integrity, reducing the cost of popularization and application, and simple promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

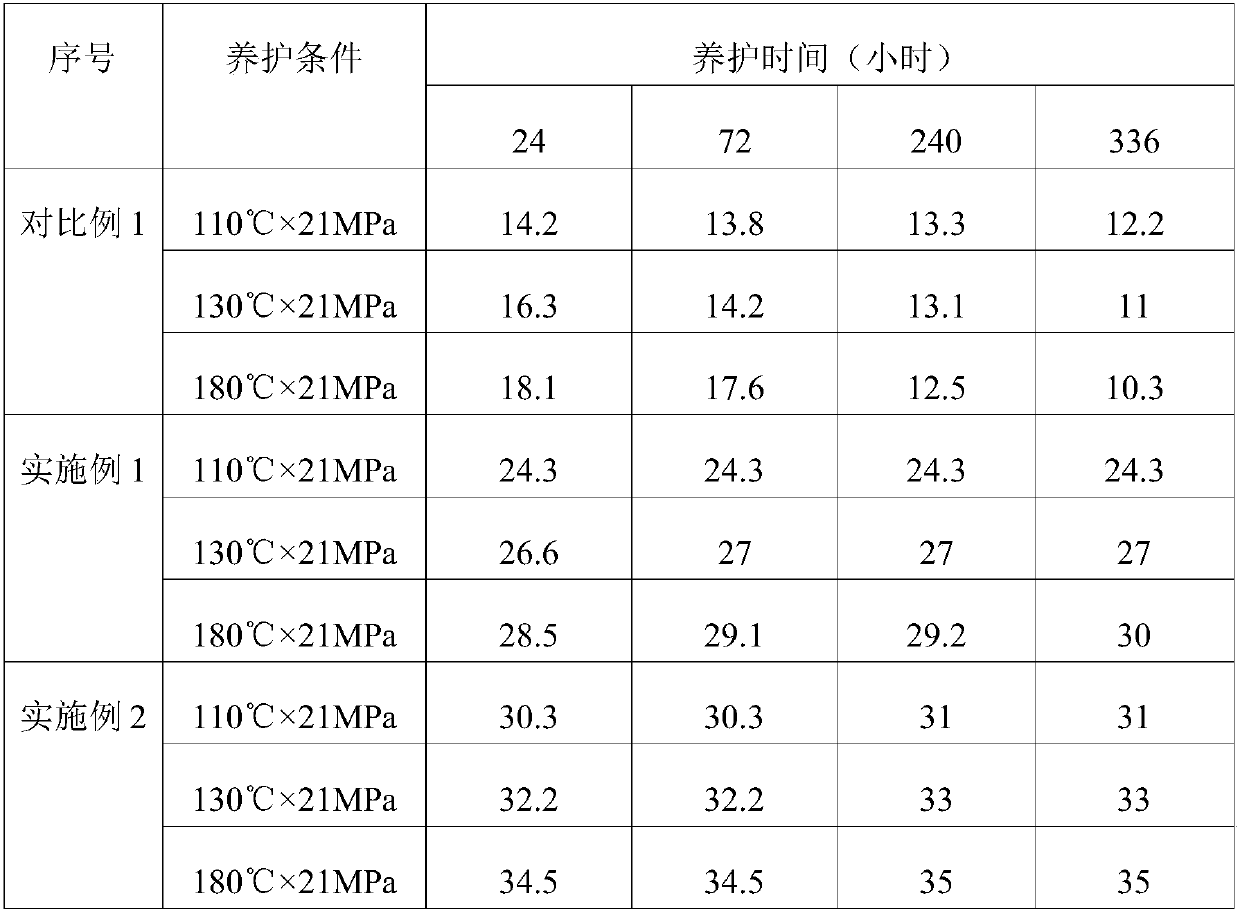

[0042] Weigh 500 parts by weight of cement, 175 parts by weight of silica fume, 20 parts by weight of fluid loss reducer, 5 parts by weight of retarder, 5 parts by weight of strength enhancer, 2.5 parts by weight of suspension stabilizer and 235 parts by weight of tap water. According to the test method for the compressive strength of oil well cement in the API specification, dry mix cement, silica fume and suspension stabilizer together, add other components into water and stir evenly, and finally mix the two together with a high-speed mixer, pour into the corresponding The mold is cured under the corresponding temperature conditions, and the corresponding compressive strength is tested with a pressure testing machine after demoulding. The test results are shown in Table 1.

Embodiment 2

[0044]Weigh 500 parts by weight of cement, 175 parts by weight of silica fume, 20 parts by weight of fluid loss reducer, 5 parts by weight of retarder, 10 parts by weight of strength enhancer, 5 parts by weight of suspension stabilizer and 230 parts by weight of tap water. According to the test method for the compressive strength of oil well cement in the API specification, dry mix cement, silica fume and suspension stabilizer together, add other components into water and stir evenly, and finally mix the two together with a high-speed mixer, pour into the corresponding The mold is cured under the corresponding temperature conditions, and the corresponding compressive strength is tested with a pressure testing machine after demoulding. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com