Sodium metasilicate cemented rock similar material and preparation method thereof

A technology of rock similarity and sodium metasilicate, which is applied in the field of geomechanical model tests, can solve the problems that cannot fully meet the needs of model tests, and achieve the effects of stable properties, large adjustment range, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of sodium metasilicate cemented rock similar material, this method comprises the steps:

[0032] (1) Weigh coarse aggregate, barite powder, anhydrous sodium metasilicate, sodium fluorosilicate and water according to the proportion of each component;

[0033] (2) Put the anhydrous sodium metasilicate into the container, pour in water, fully dissolve to form a sodium metasilicate solution;

[0034] (3) Pour the coarse aggregate, barite powder and sodium fluorosilicate into the mixer, and mix well to form a solid mixture;

[0035] (4) Stir the solid mixture again, and at the same time slowly and evenly pour the sodium metasilicate solution in step (2) into the solid mixture, and mix well;

[0036] (5) Put the mixed material into the mold, vibrate it, and pour it into shape;

[0037] (6) Put the test piece in a ventilated and dry place for 5-7 days, and demould, and then you can get a test piece of sodium metasilicate cemented rock similar mat...

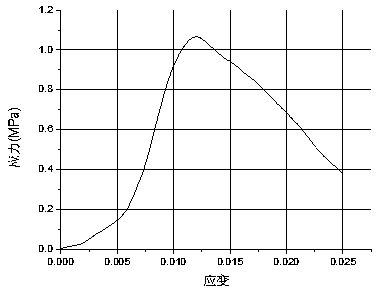

Embodiment 1

[0040] Embodiment 1: material proportioning

[0041] Quartz sand 30% of the total weight of the aggregate

[0042] Barite powder 70% of the total weight of aggregate

[0043] Anhydrous sodium metasilicate 3% of the total weight of aggregate

[0044] Sodium fluorosilicate 60% of the total weight of anhydrous sodium metasilicate

[0045] Water 15% of the total weight of the aggregate

[0046] First pour the quartz sand, barite powder and sodium fluorosilicate weighed according to the proportion into the mixer, and mix well; then mix the anhydrous sodium metasilicate weighed according to the proportion with water, and fully dissolve; then Pour the anhydrous sodium metasilicate solution into the mixture, and mix well; then put the mixed mixture into the mold, and vibrate to make it densely formed; after 5 to 7 days of natural curing, it can be demolded.

[0047] Cylindrical molds are used for sample preparation, which can be used to make standard uniaxial compression samples, ...

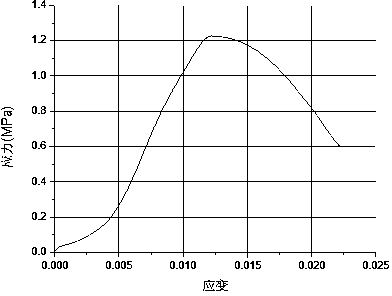

Embodiment 2

[0049] Embodiment 2: material proportioning

[0050] Quartz sand 40% of the total weight of the aggregate

[0051] Barite powder 60% of the total weight of aggregate

[0052] Anhydrous sodium silicate 4% of the total weight of aggregate

[0053] Sodium fluorosilicate 60% of the total weight of anhydrous sodium metasilicate

[0054] Water 12% of the total weight of the aggregate

[0055] First pour the quartz sand, barite powder and sodium fluorosilicate weighed according to the proportion into the mixer, and mix well; then mix the anhydrous sodium metasilicate weighed according to the proportion with water, and fully dissolve; then Pour the anhydrous sodium metasilicate solution into the mixture, and mix well; then put the mixed mixture into the mold, and vibrate to make it compact; after 5 to 7 days of natural curing, it can be demolded.

[0056]Cylindrical molds are used for sample preparation, which can be used to make standard uniaxial compression samples, Brazilian sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com