High temperature resistant silicate cement paste and preparation method thereof

A technology of portland cement and portland, which is applied in the field of oil well cement, can solve the problems that the cement sheath loses its interlayer isolation ability, easily causes cementing accidents, and the compressive strength is easy to decline, so as to reduce the cementing construction work cost, improve the safety of cementing construction, and the effect of no decline in compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

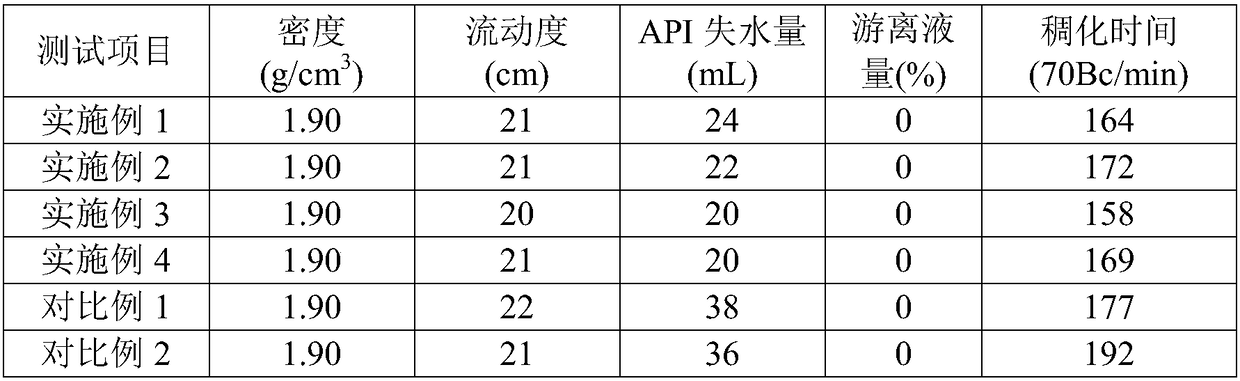

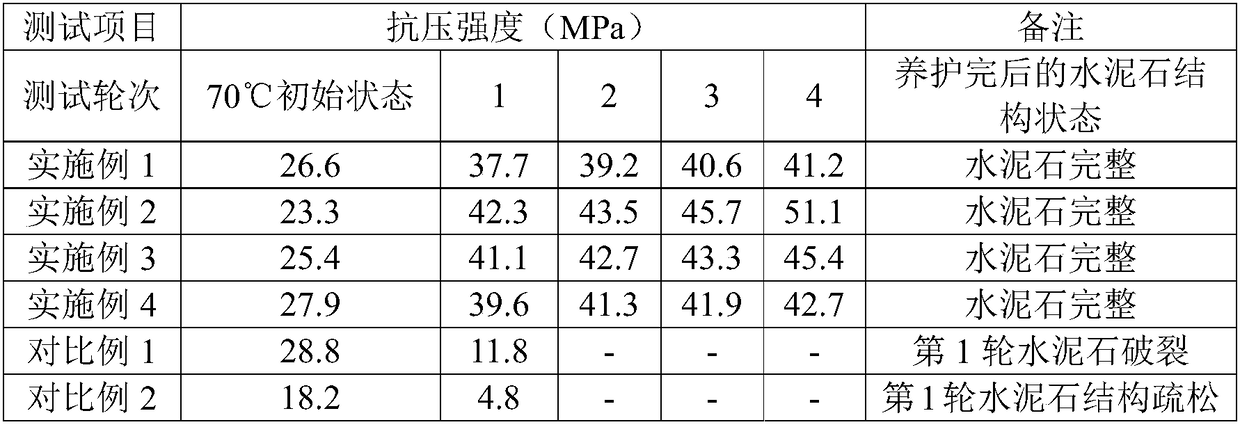

Examples

Embodiment 1

[0051]This example provides a high-temperature resistant portland cement slurry, which is composed of the following components in proportion by weight: 100 parts of grade A portland cement, 69 parts of high-temperature reinforcing materials, 73 parts of fresh water, and 1 part of sulfonated Acetone formaldehyde polymer dispersant, 3 parts of 2-acrylamido-2-methylpropanesulfonic acid polymer fluid loss reducer, 0.6 part of 2-acrylamido-2-methylpropanesulfonic acid polymer retarder, 0.3 parts of tributyl phosphate, 0.1 parts of attapulgite and 2 parts of iron ore powder.

[0052] Among them, the high-temperature reinforcing material is composed of silica minerals, plagioclase, whiskers and sulfate in a mass ratio of 50:10:4:5; the particle size of the high-temperature reinforcing material formed by mixing is 0.01mm-0.15mm.

[0053] The high temperature resistant Portland cement slurry of the present embodiment is prepared through the following steps:

[0054] Dry mix the high-t...

Embodiment 2

[0058] This embodiment provides a high temperature resistant Portland cement slurry, which is composed of the following components in proportion by weight: 100 parts of Portland cement, 70 parts of high temperature reinforcing materials, 75 parts of fresh water, and 1.2 parts of sulfonated acetone formaldehyde Polymer dispersant, 3 parts of 2-acrylamido-2-methylpropanesulfonic acid polymer fluid loss reducer, 1.2 parts of 2-acrylamido-2-methylpropanesulfonic acid polymer retarder, 0.3 parts Tributyl phosphate, 0.2 parts of attapulgite and 4 parts of iron ore powder.

[0059] Among them, the high-temperature reinforcing material is composed of silica minerals, aluminates, mineral fibers, calcium hydroxide, phosphate minerals and magnesium silicate minerals in a mass ratio of 60:2:3:2:2:1; The particle size of the high-temperature reinforcing material formed by mixing is 0.01mm-0.15mm, and then the density regulator is used to adjust the density of the prepared high-temperature ...

Embodiment 3

[0061] This embodiment provides a high temperature resistant Portland cement slurry, which is composed of the following components in proportion by weight: 100 parts of Portland cement, 78 parts of high temperature reinforcing materials, 77 parts of fresh water, and 1.2 parts of sulfonated acetone formaldehyde Polymer dispersant, 3 parts of 2-acrylamido-2-methylpropanesulfonic acid polymer fluid loss reducer, 1.2 parts of 2-acrylamido-2-methylpropanesulfonic acid polymer retarder, 0.3 parts Tributyl phosphate, 0.1 parts of attapulgite and 2 parts of iron ore powder.

[0062] Among them, the high-temperature reinforcing material is composed of silica minerals, metakaolin, mineral fibers, phosphate minerals and magnesium silicate minerals in a mass ratio of 60:10:4:3:1; the high-temperature reinforcing materials formed by mixing The particle size is 0.01mm-0.15mm, and then the density regulator is used to adjust the density of the prepared high temperature Portland cement slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com