High-temperature-resistant suspending agent for flexible cement mortar and preparation method thereof, and cement mortar

A high-temperature flexible, cement slurry technology, applied in the field of petroleum exploration, can solve the problems that the fluidity of the slurry cannot be guaranteed, the preparation method of the suspension stabilizer DRY-S2 is not given, and the pumpability is good. The effect of excellent settlement stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of suspending agent for high-temperature-resistant flexible cement slurry: put 100 parts by weight of water into the slurry cup, add 30 parts by weight of spherical silica with a particle size of 100-200 μm, and add 6 parts by weight of glass fiber with a size of 2.5mm-3.5mm , add 6 parts by weight of sodium silicate, add 6 parts by weight of styrene-acrylic latex, stir at 50°C for 3 hours, and after stirring evenly, suspending agent A is obtained.

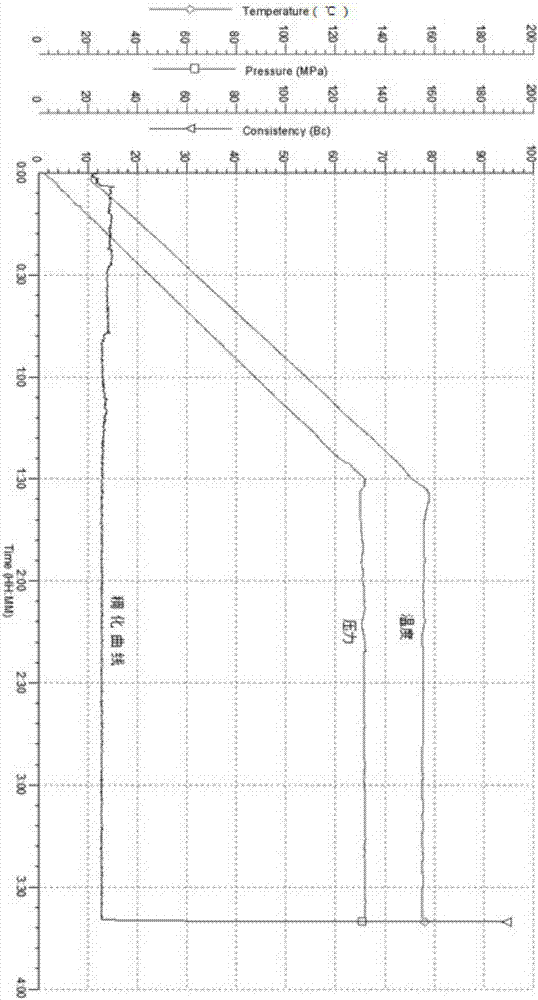

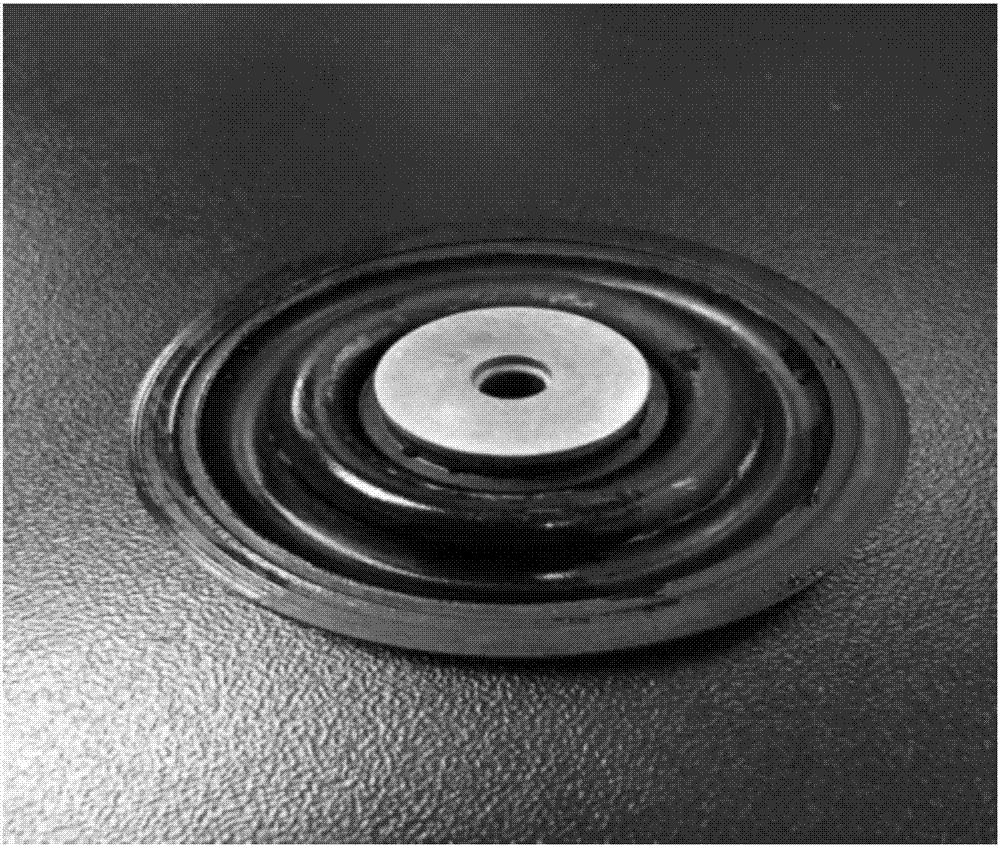

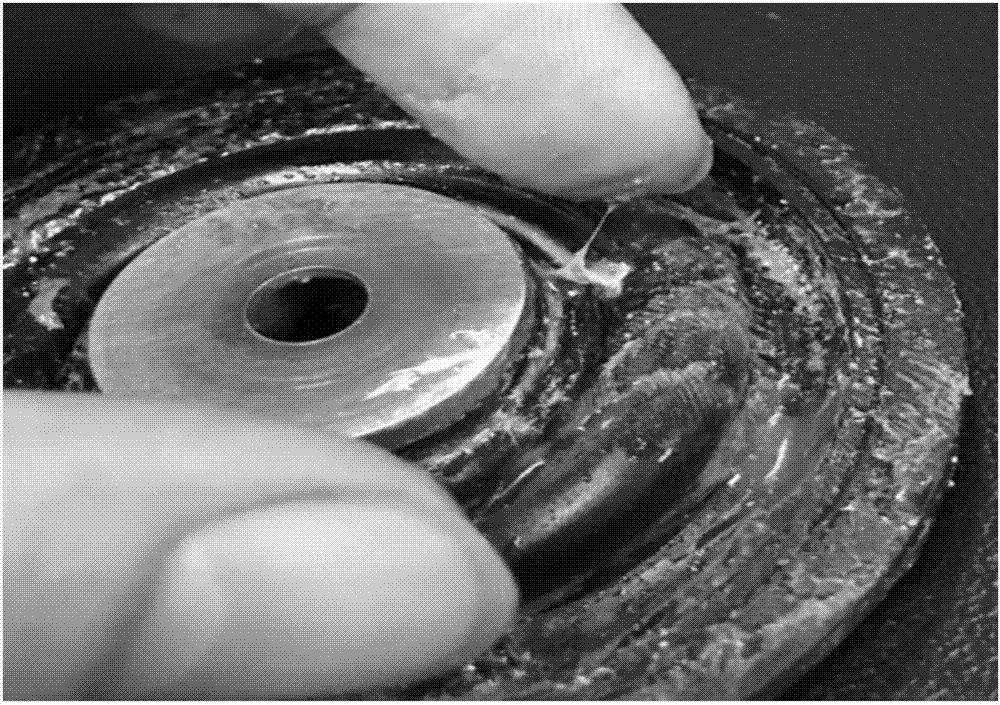

[0033] Prepare cementing cement slurry: prepare cement slurry according to GB / T19139 standard, weigh 100 parts by weight of Jiahua G grade oil well cement, 8 parts of elastic particles (styrene-butadiene rubber), 5 parts of fluid loss reducer DZJ-Y (market (commercially available), 2.0 parts of dispersant DZS (commercially available) and 3.5 parts of retarder DZH (commercially available), mix homogeneously, add 1.0 part of suspending agent A of the present invention in the cement slurry, and the liquid-solid rati...

Embodiment 2

[0035] Preparation of suspending agent for high-temperature-resistant flexible cement slurry: put 100 parts by weight of water into the slurry cup, add 40 parts by weight of spherical silica (100-200 μm), and add 7 parts by weight of glass fiber (size is 2.5mm-3.5mm) , add 7 parts by weight of sodium silicate, add 7 parts by weight of styrene-acrylic rubber, stir at 30°C for 5 hours, and after stirring evenly, suspending agent B is obtained.

[0036] Preparation of cementing cement slurry: prepare cement slurry according to GB / T19139 standard, weigh 100 parts by weight of Jiahua G grade oil well cement, 20 parts of elastic particles (styrene-butadiene rubber), 5 parts of fluid loss reducer DZJ-Y (city (commercially available), 2.0 parts of dispersant DZS (commercially available) and 3.5 parts of retarder DZH (commercially available), mix homogeneously, add 3.0 parts of suspending agent B of the present invention in the cement slurry, and the liquid-solid ratio is 0.44, get fle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com