Early-strength low-hydration heat evolution cement paste system applicable to deepwater shallow cementation

A hot water and mud technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of polluting the marine environment, easily generating channeling flow, and easily pressurized and leaking formations, so as to overcome the problems of large hydration heat release, The effect of improving early strength and good early strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

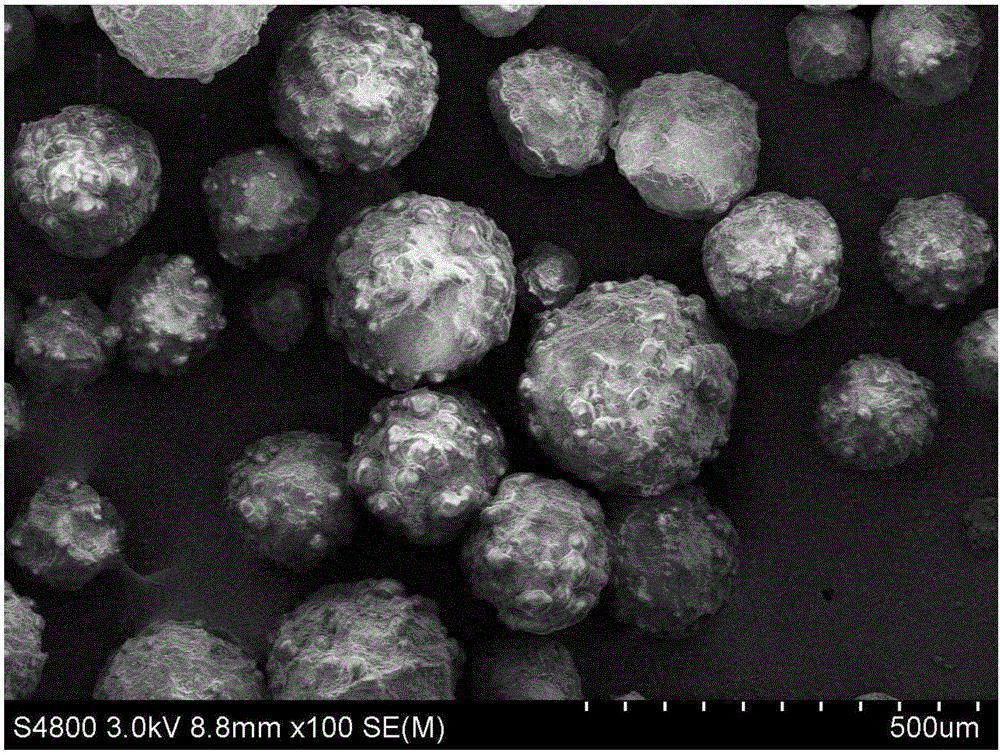

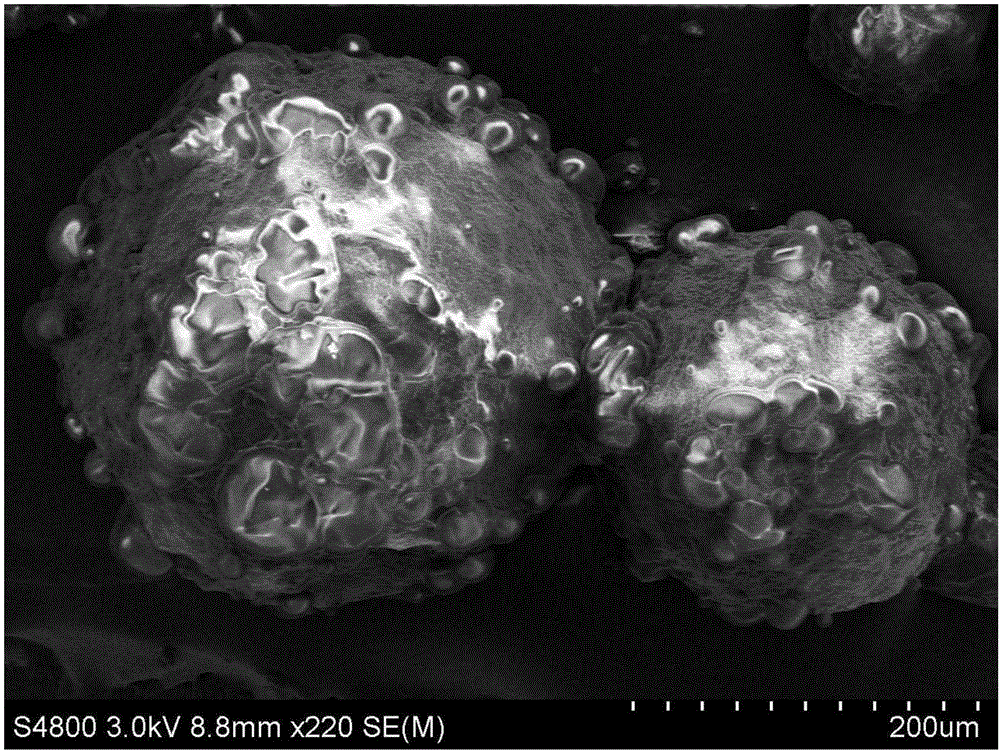

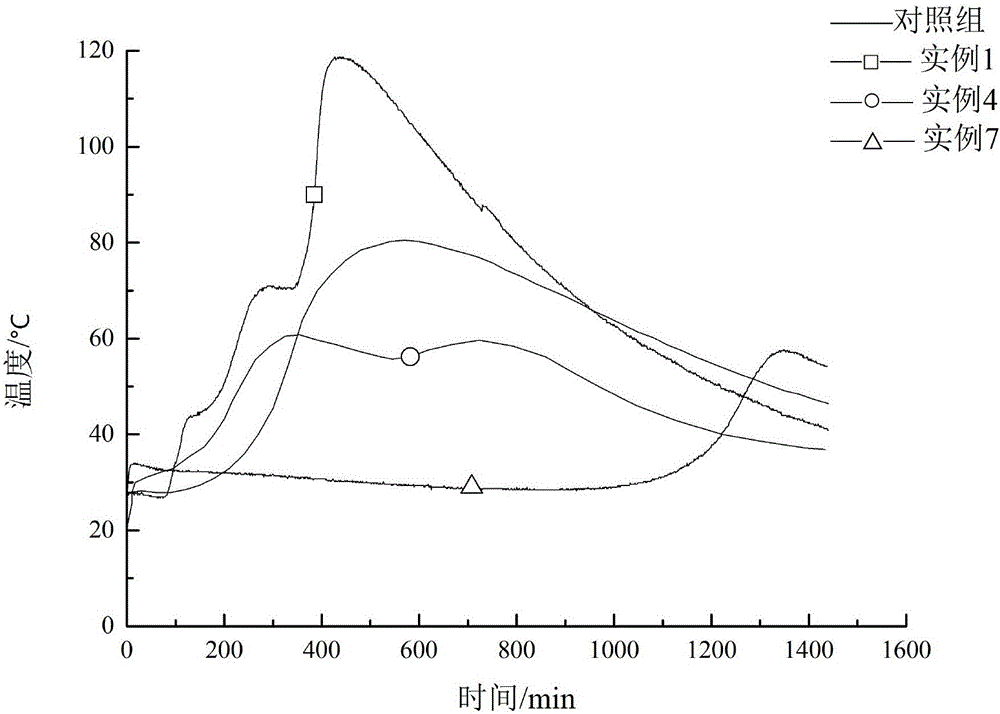

Image

Examples

Embodiment 1

[0043] Cement slurry formula: 100 parts of cement (30 parts of Shengwei G grade cement and 70 parts of Jinghua CA-50 aluminate cement), 0.06 part of early strength agent triethanolamine, retarder (0.4 part of citric acid + 1 part of boric acid + 0.3 part of aluminum sulfate), 0.3 part of sulfonated aldehyde and ketone drag reducer, and 44 parts of water.

[0044] Among them: 30 parts of Shengwei G grade cement + 70 parts of Jinghua CA-50 aluminate cement. Titanium 2%, sulfur trioxide 1.3%, magnesium oxide 1.1%, and the balance is trace elements.

[0045] Preparation method: dissolve early strength agent and retarder in water, and then prepare cement slurry with the obtained aqueous solution and cement according to API10B-3-2004 oil well cement test method.

Embodiment 2

[0047] Cement slurry formula: 100 parts of cement (50 parts of Shengwei G grade cement and 50 parts of Jinghua CA-50 aluminate cement), 5 parts of hydrophilic paraffin microcapsules prepared in Example 8, 0.10 part of early strength agent triethanolamine, 0.35 parts of boric acid as retarder, 10 parts of microsilicon as suspension material, 0.5 parts of sulfonated aldehyde and ketone drag reducer, 0.5 part of AMPS water loss reducer, 0.5 part of tributyl phosphate defoamer, and 58.2 parts of water.

[0048] Preparation method: dry mix cement, phase change material and floating beads, dissolve early strength agent and retarder in water, then dry mix cement with the obtained aqueous solution to prepare cement slurry according to API10B-3-2004 oil well cement test method.

Embodiment 3

[0050] 100 parts of cement (50 parts of Shengwei G grade cement and 50 parts of Jinghua CA-50 aluminate cement), 10 parts of hydrophilic paraffin microcapsules prepared in Example 8, 10 parts of Y-6000 hollow glass floating beads, early strength 0.06 parts triethanolamine, 0.35 parts boric acid retarder, 10 parts microsilicon suspension material, 0.5 parts sulfonated aldehyde and ketone drag reducer, 0.7 parts AMPS fluid loss reducer, 0.7 part tributyl phosphate defoamer, 68.6 parts of water. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com