Patents

Literature

77 results about "Minimum density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Minimum density specifies a minimum size (floor area ratio) for new development. Floor area ratio (FAR) is the amount of floor space developed on a parcel compared to the size of the property. For example, a lot of 10,000 square feet with a minimum FAR of 2 would require a building size of at least 20,000 square feet (i.e.

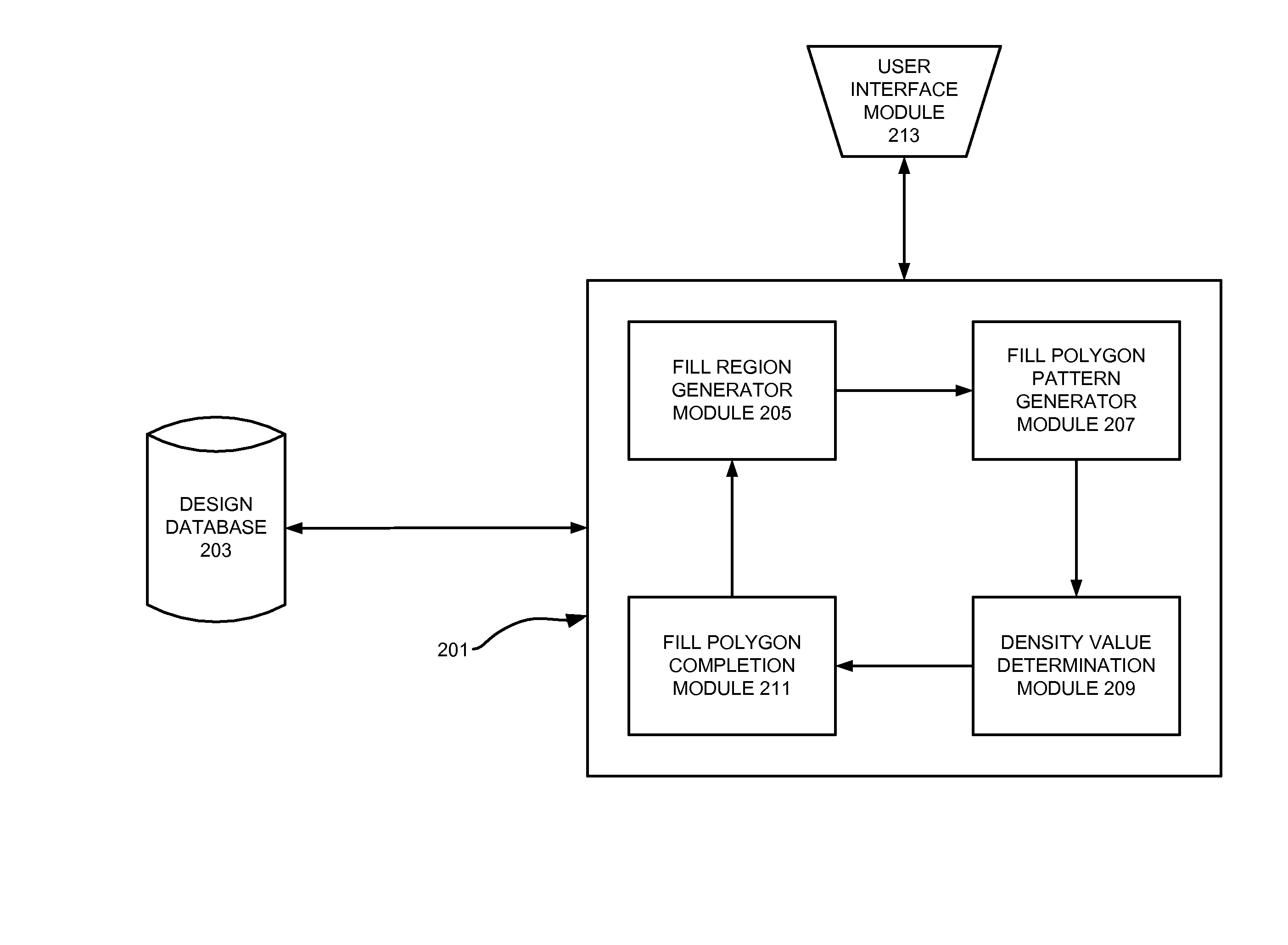

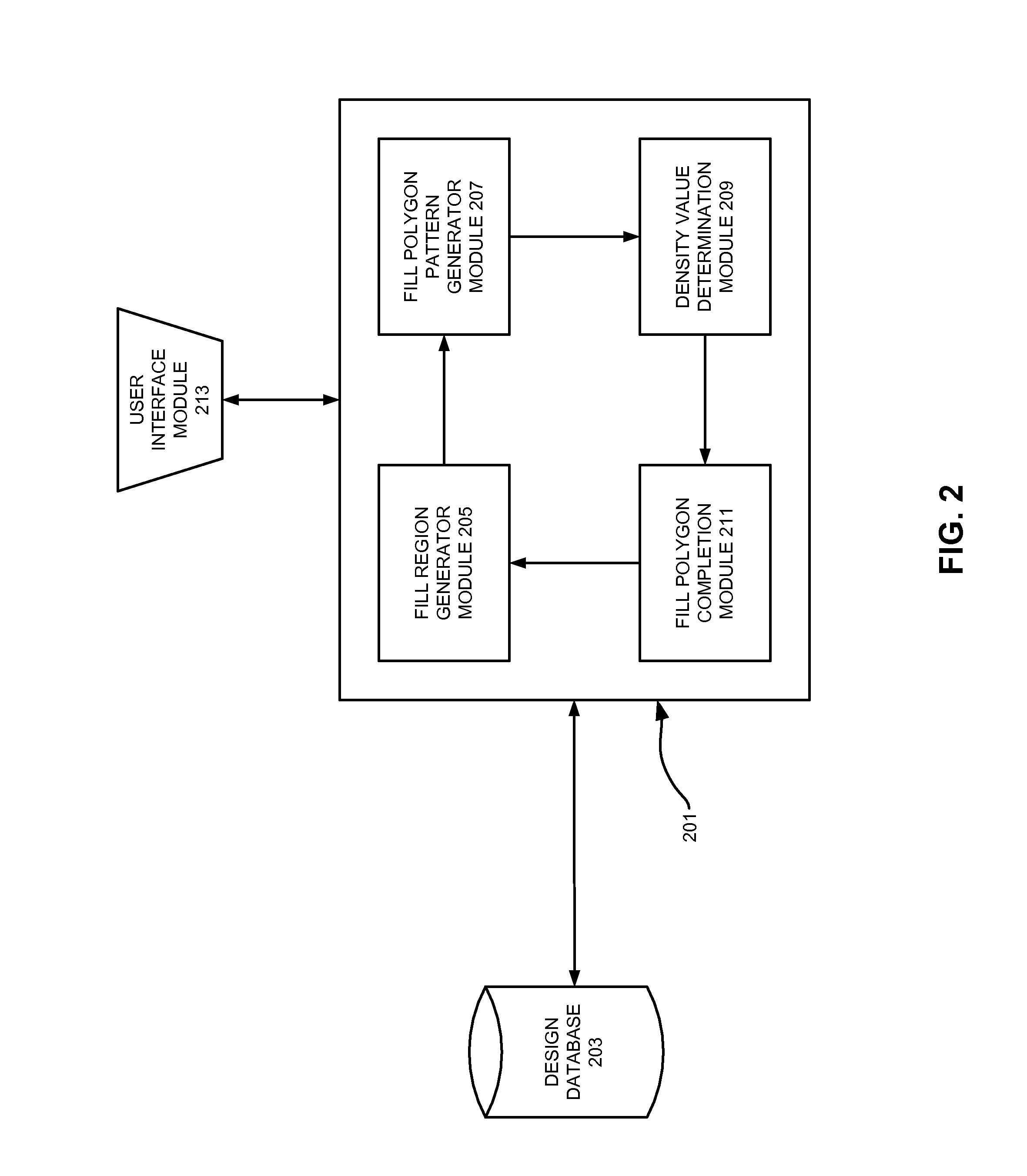

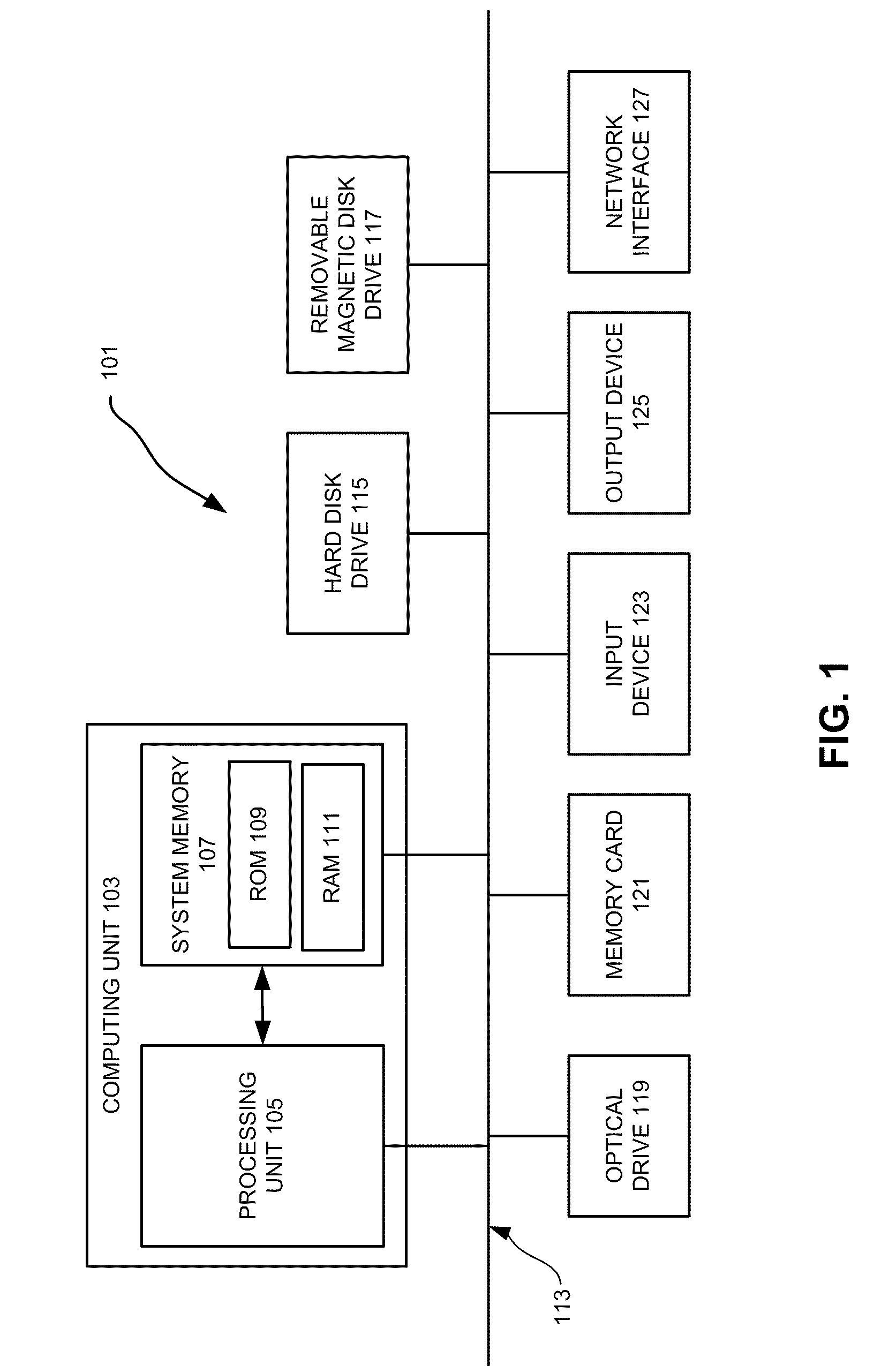

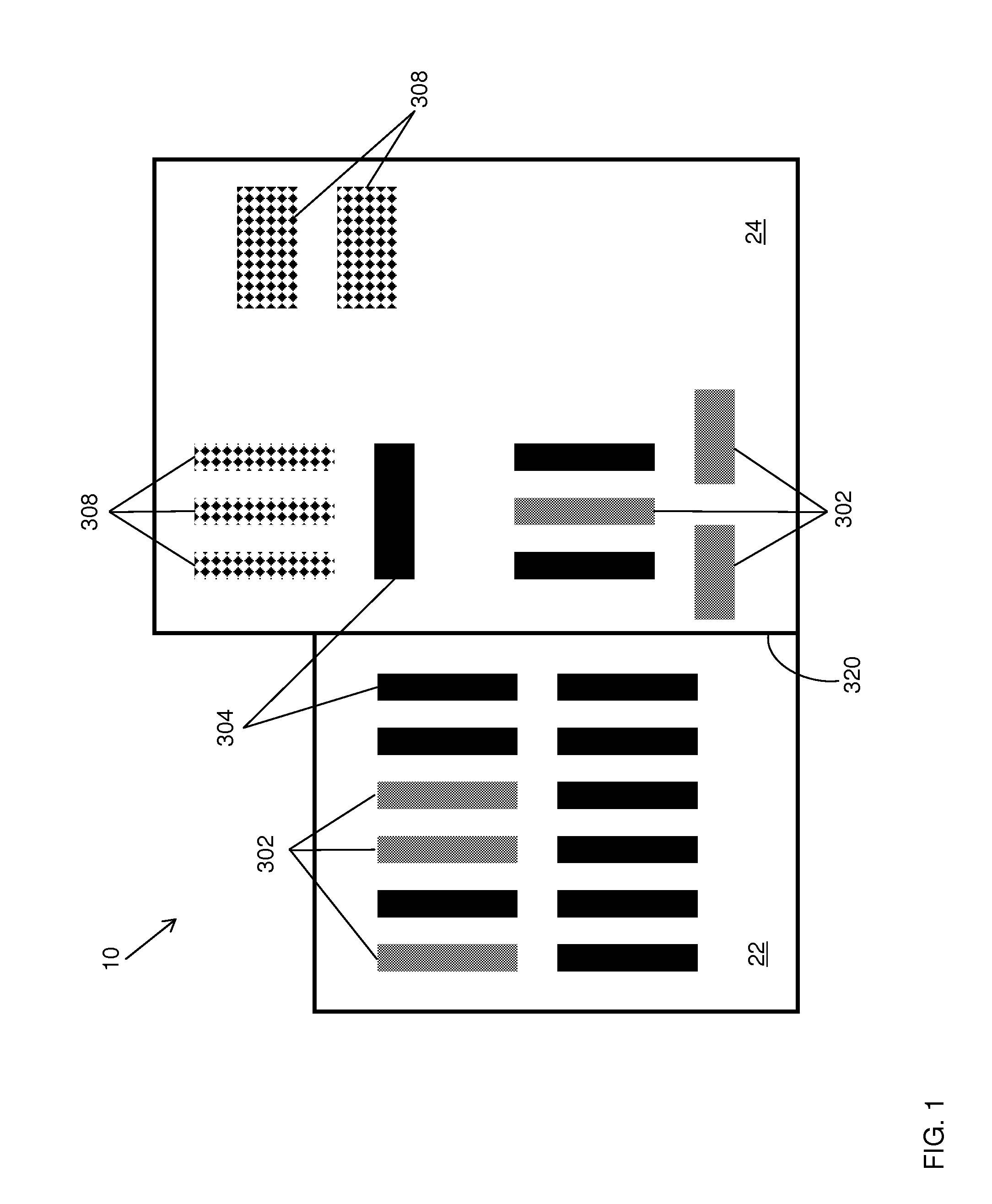

Density-Based Layer Filler for Integrated Circuit Design

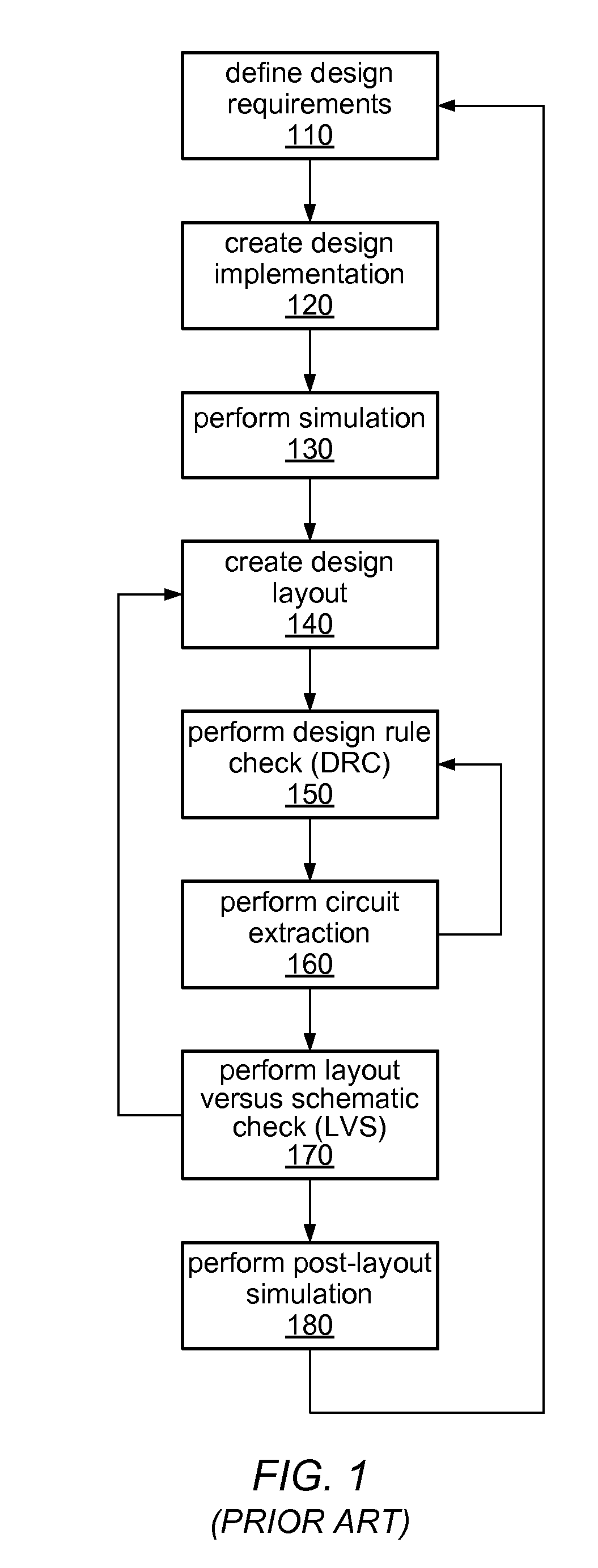

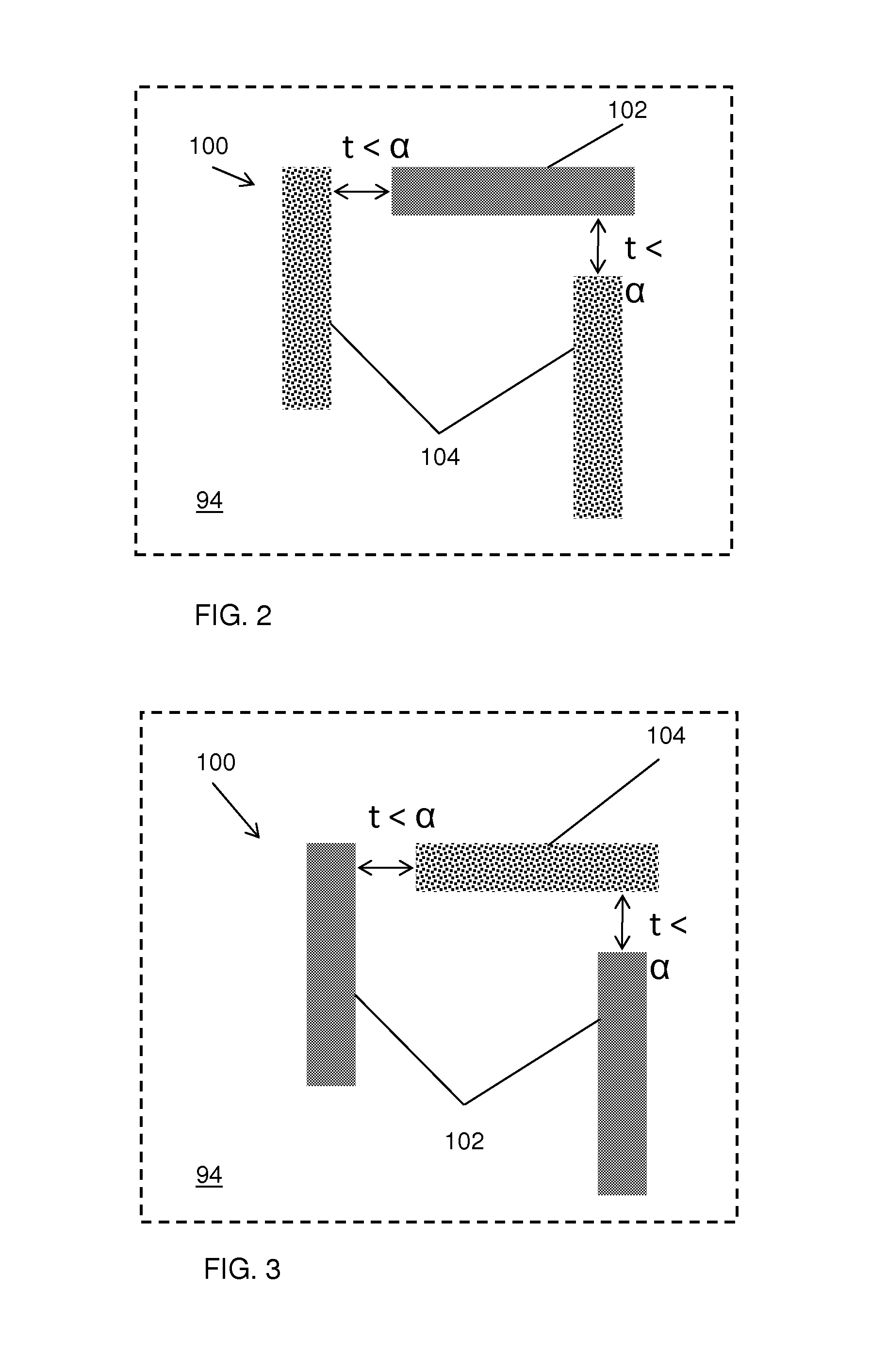

ActiveUS20080120586A1Reduce riskExtended run timeCAD circuit designSoftware simulation/interpretation/emulationElectricityMinimum density

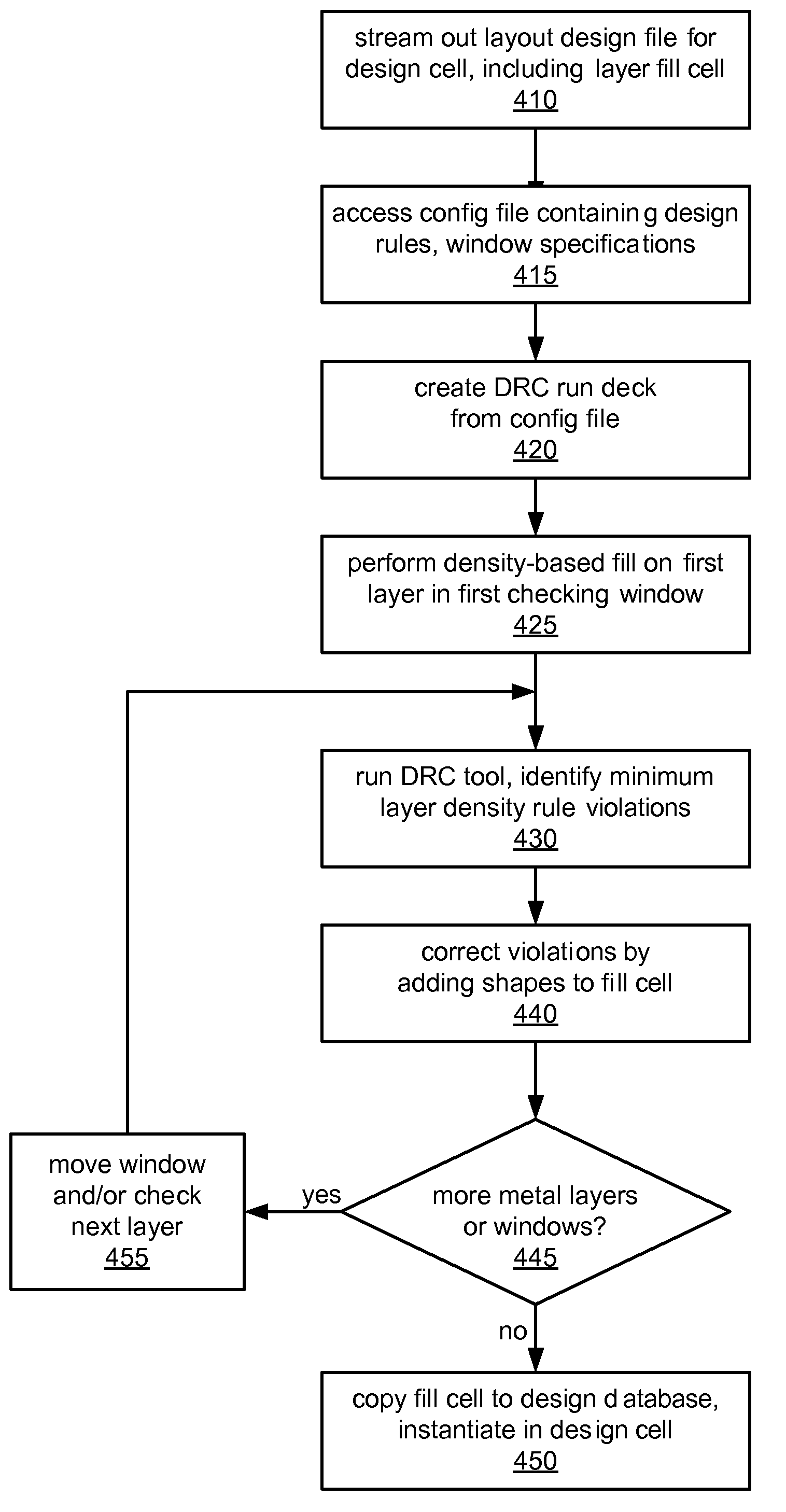

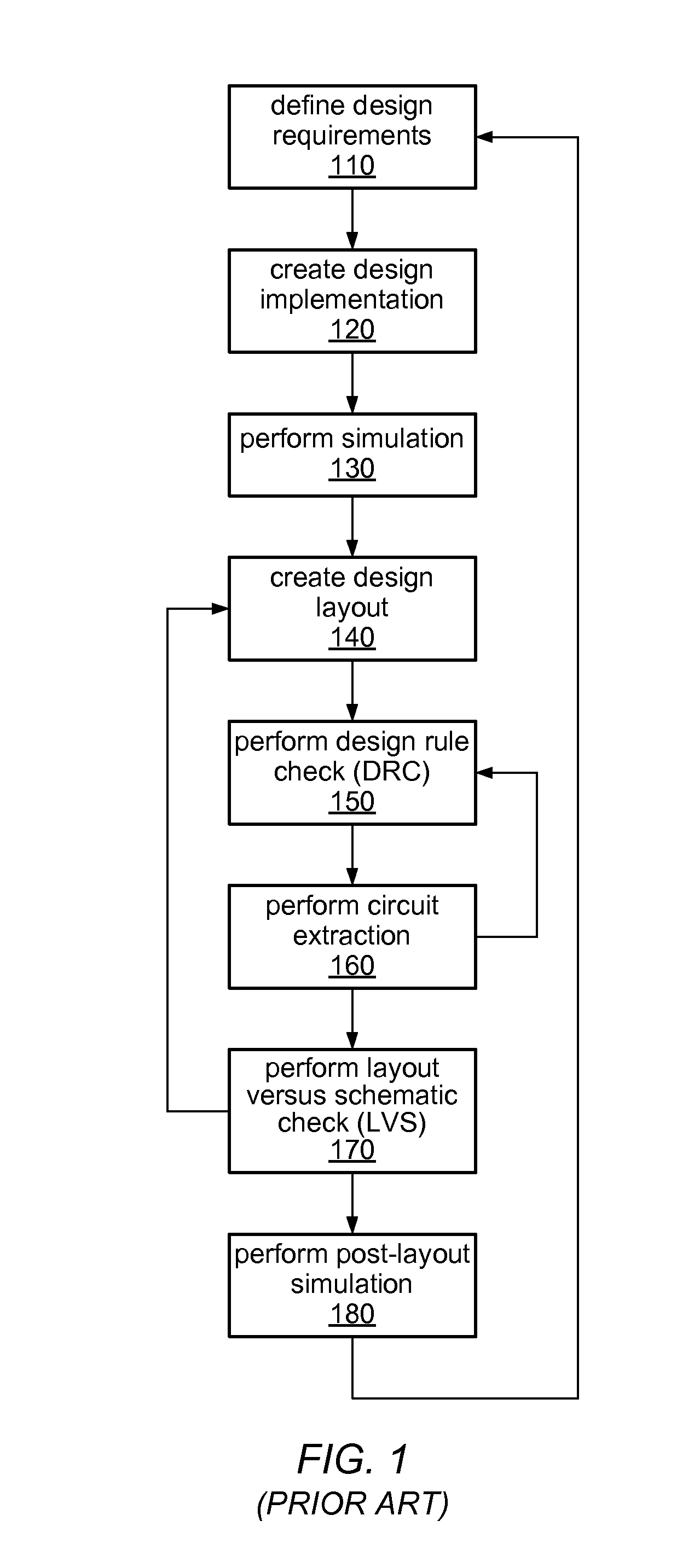

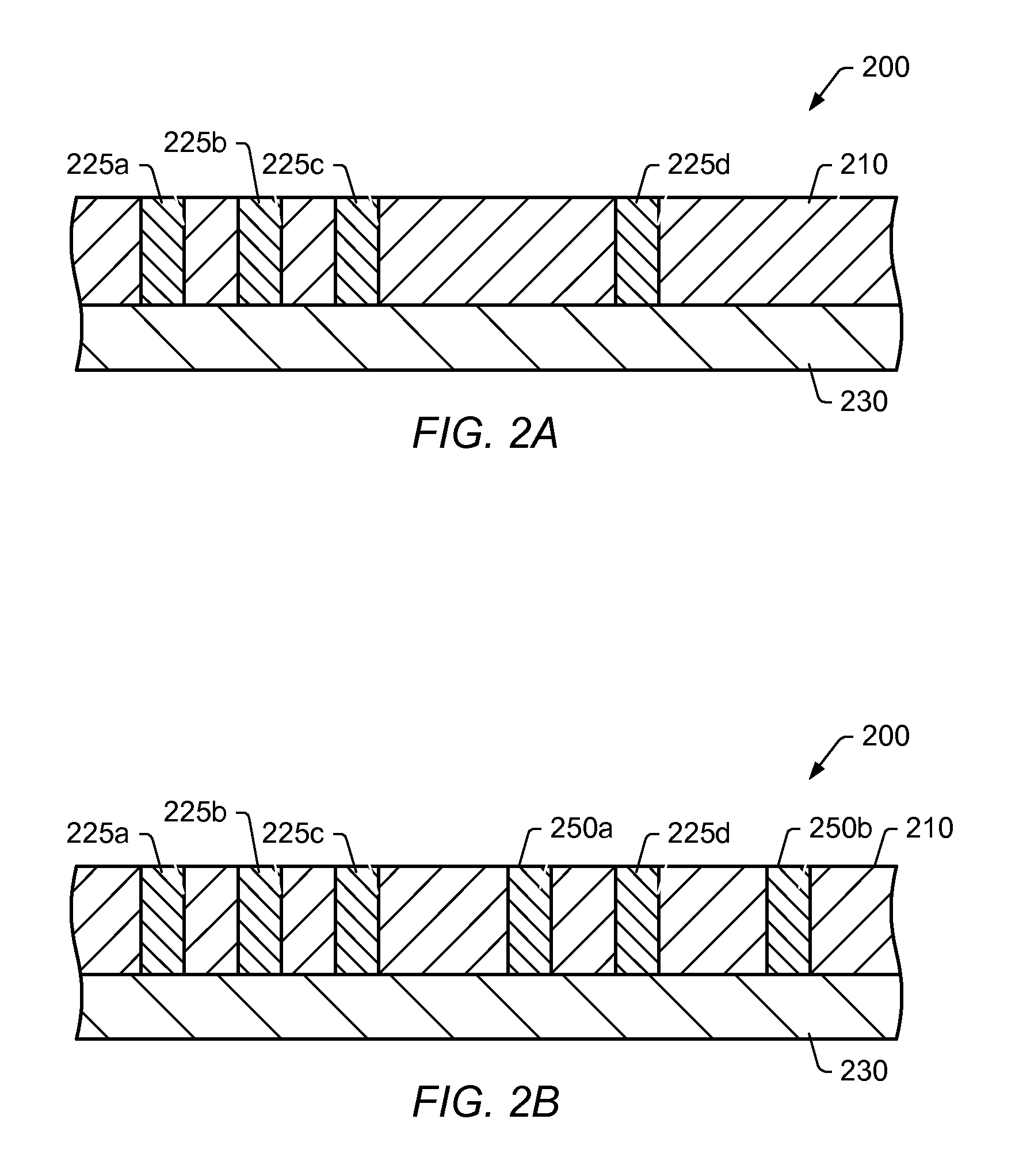

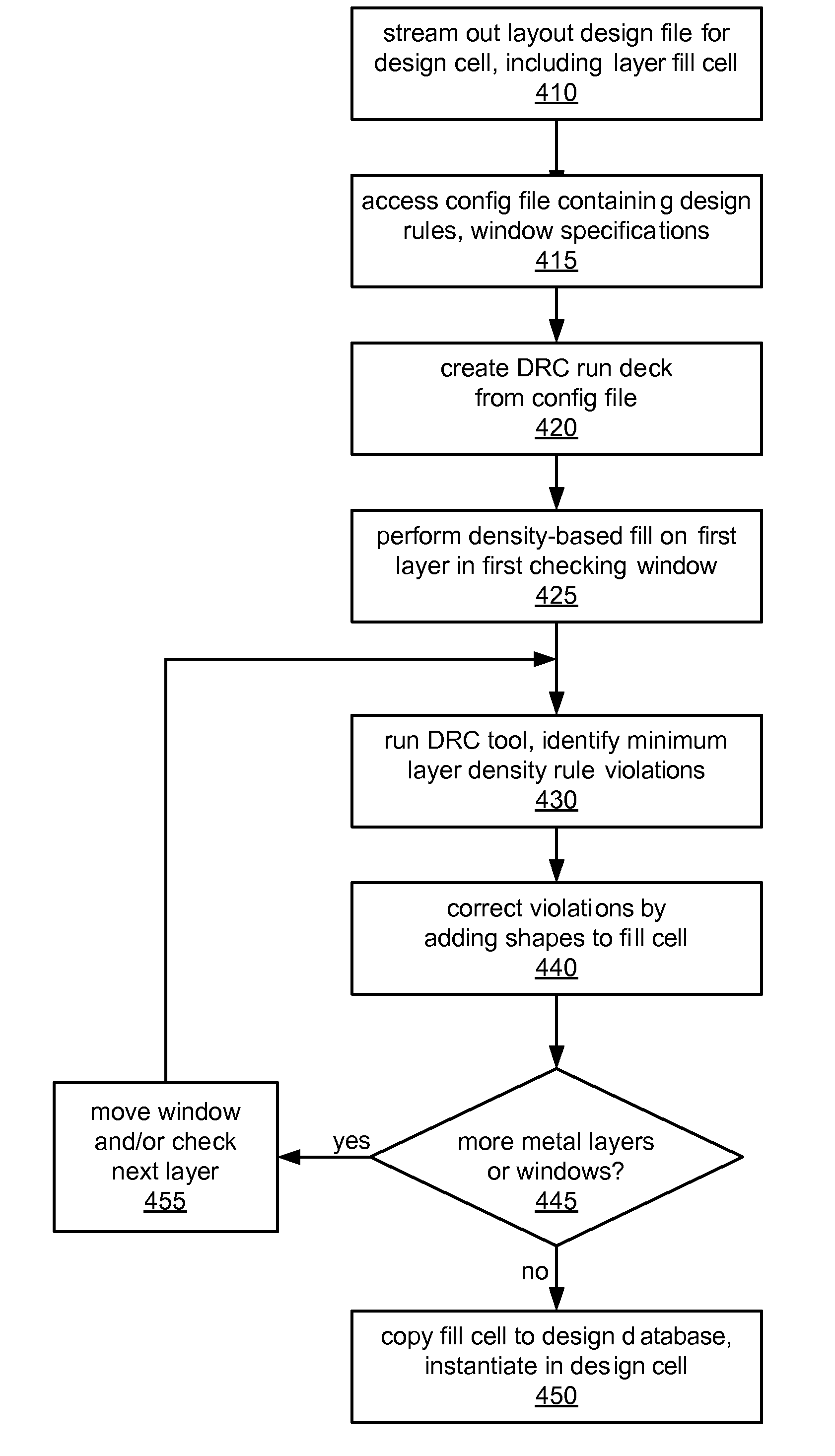

A system and method for performing density-based layer filling on a design layout encoding of an integrated circuit device is disclosed. In some embodiments, the density-based layer filler may identify open areas on a given design layer in which one or more minimum density rules are not met and may insert dummy shapes only in those identified areas. The dummy shapes may be constructed so as not to violate one or more other design rules. The density-based layer filler may access a configuration file comprising layer density rules and other design rules and may generate a run deck dependent on the contents of the configuration file. The density-based layer filler may be applied iteratively to a design in checking windows of various sizes according to multiple window sizes and step values specified in the configuration file. The dummy shapes may be electrically connected to an existing ground wire after insertion.

Owner:ORACLE INT CORP

Density-based layer filler for integrated circuit design

ActiveUS7565638B2Reduce riskExtended run timeCAD circuit designSoftware simulation/interpretation/emulationElectricityMinimum density

A system and method for performing density-based layer filling on a design layout encoding of an integrated circuit device is disclosed. In some embodiments, the density-based layer filler may identify open areas on a given design layer in which one or more minimum density rules are not met and may insert dummy shapes only in those identified areas. The dummy shapes may be constructed so as not to violate one or more other design rules. The density-based layer filler may access a configuration file comprising layer density rules and other design rules and may generate a run deck dependent on the contents of the configuration file. The density-based layer filler may be applied iteratively to a design in checking windows of various sizes according to multiple window sizes and step values specified in the configuration file. The dummy shapes may be electrically connected to an existing ground wire after insertion.

Owner:ORACLE INT CORP

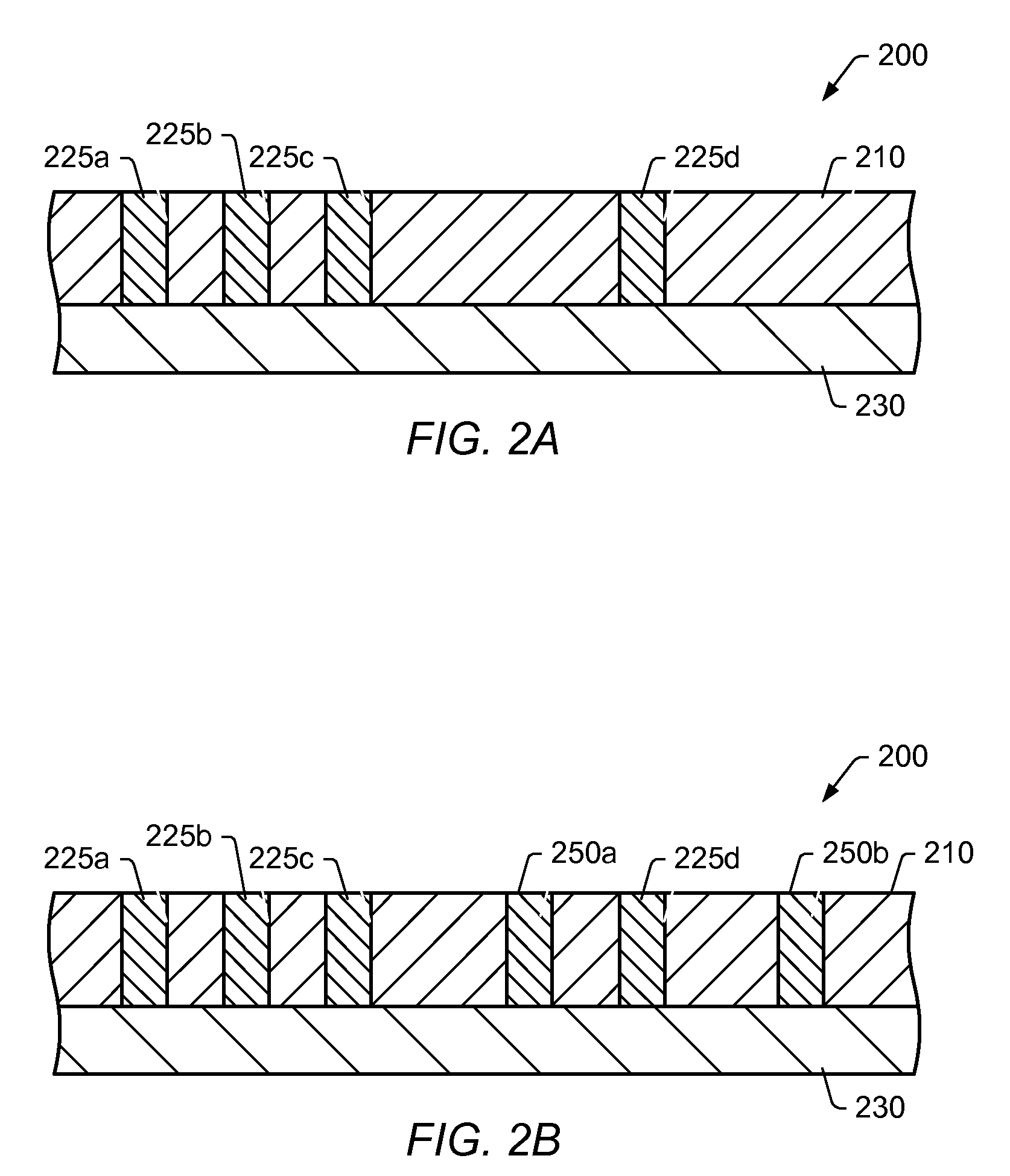

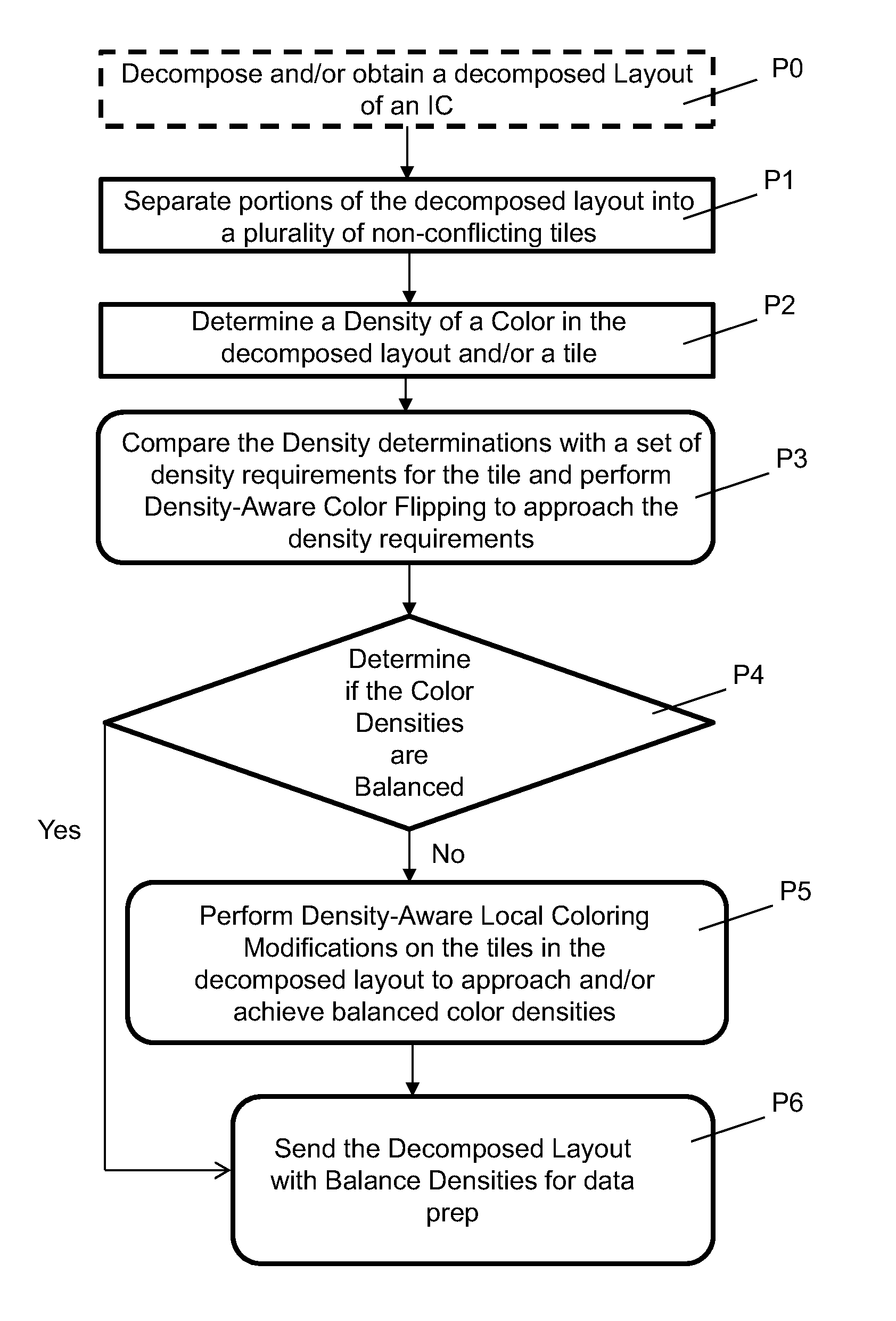

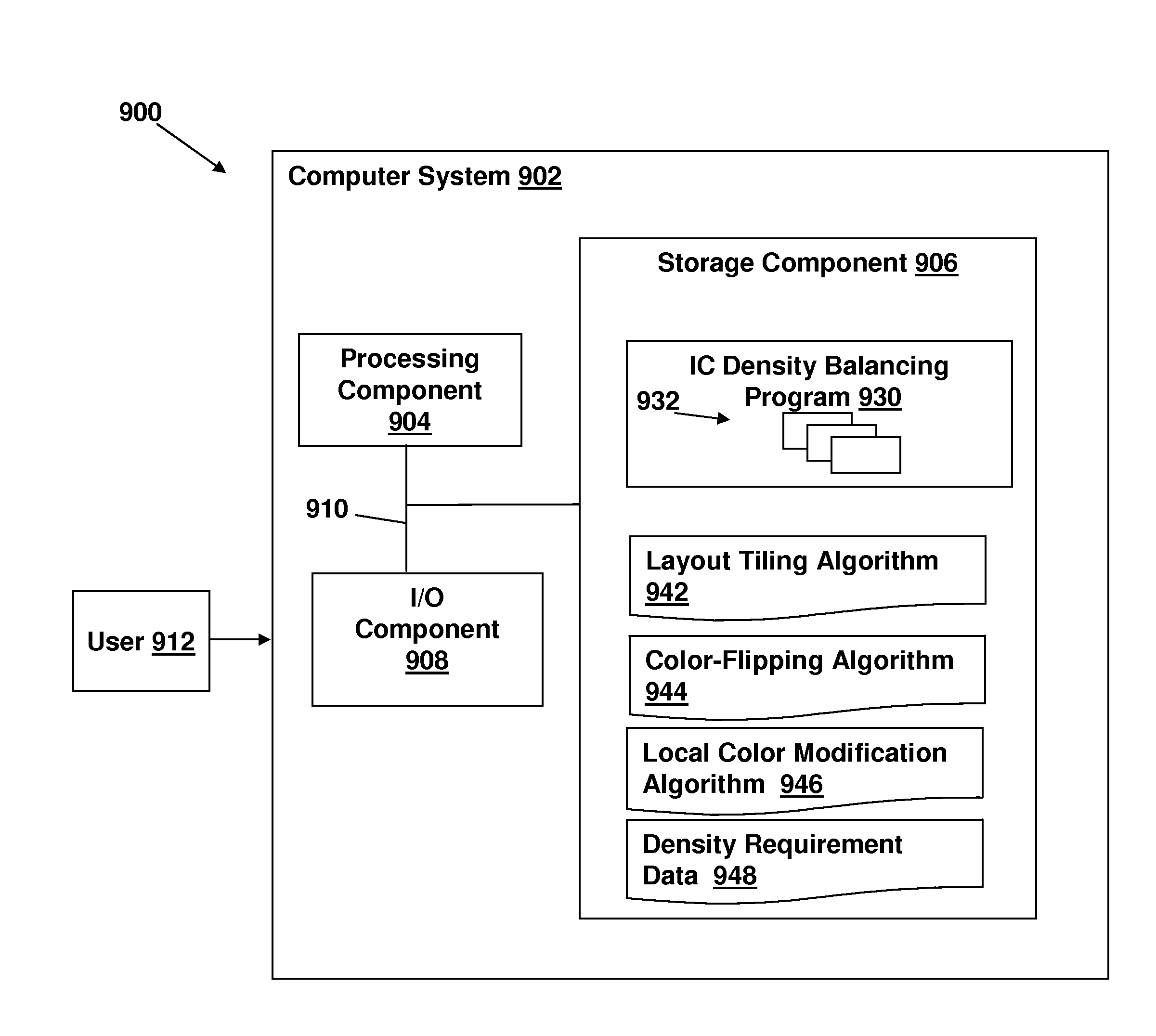

Method for post decomposition density balancing in integrated circuit layouts, related system and program product

ActiveUS8647893B1Programme controlSemiconductor/solid-state device testing/measurementPattern recognitionMinimum density

Embodiments of the invention provide a method of modifying a decomposed integrated circuit (IC) layout. The method includes providing a decomposed IC layout, the decomposed IC layout including a set of colors; determining a density of each color in the decomposed IC layout, wherein each color includes a plurality of features formed by a related exposure; separating the decomposed IC layout into a set of tiles; determining a first color with a minimum density in one tile of the set of tiles and a second color with a maximum density in tile, the first color including a first set of first features and the second color including a first set of second features; and replacing the first set of second features on the tile with a second set of first features, and the first set of first features on the tile with a second set of second features.

Owner:GLOBALFOUNDRIES US INC

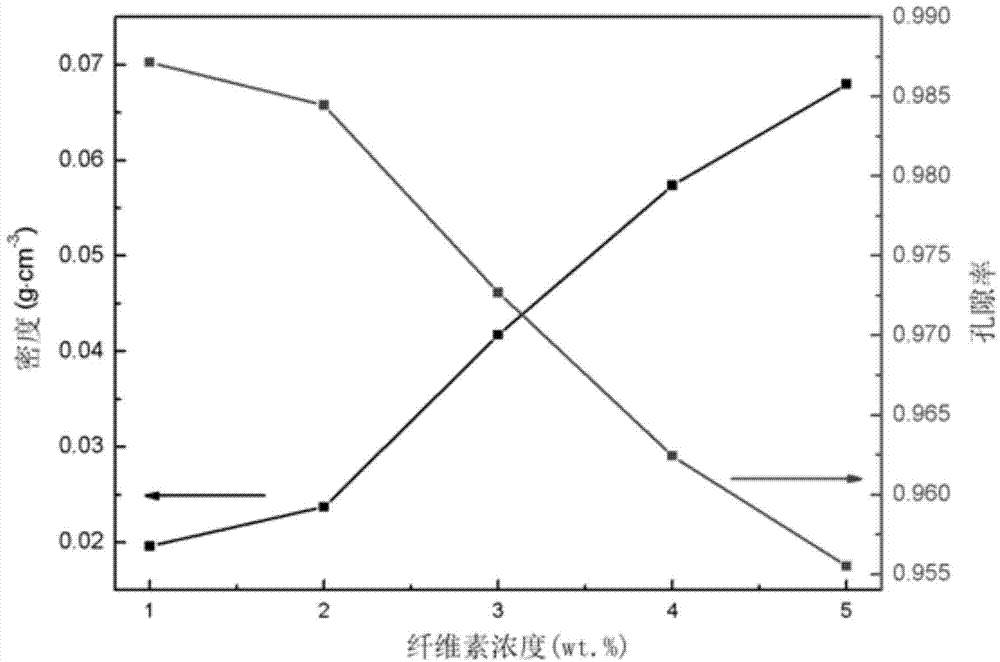

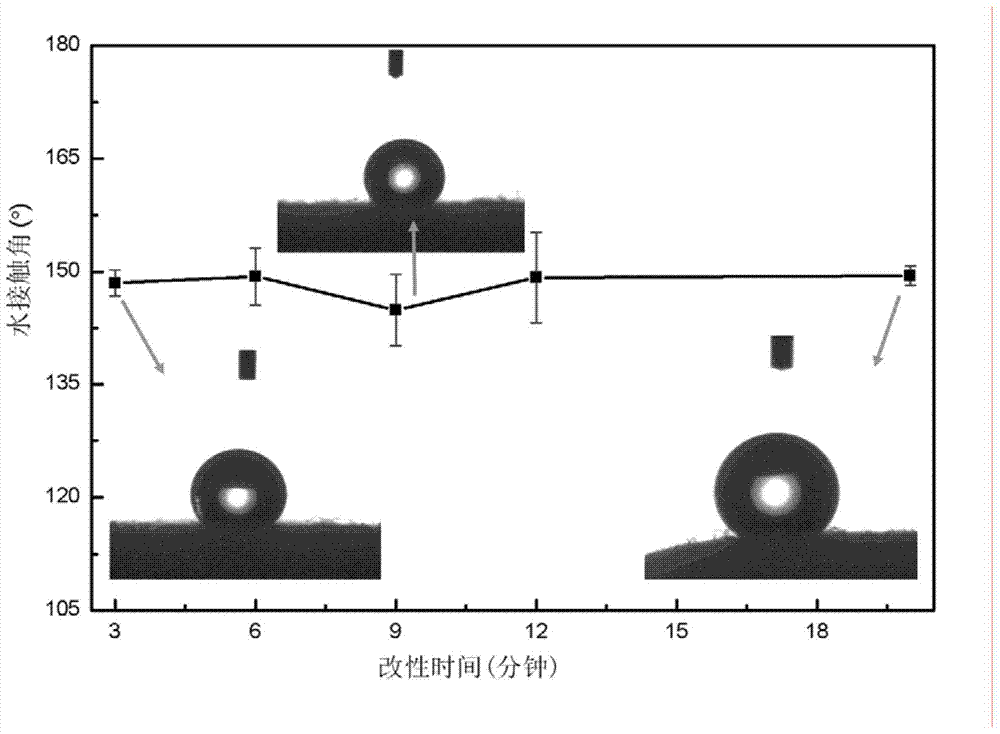

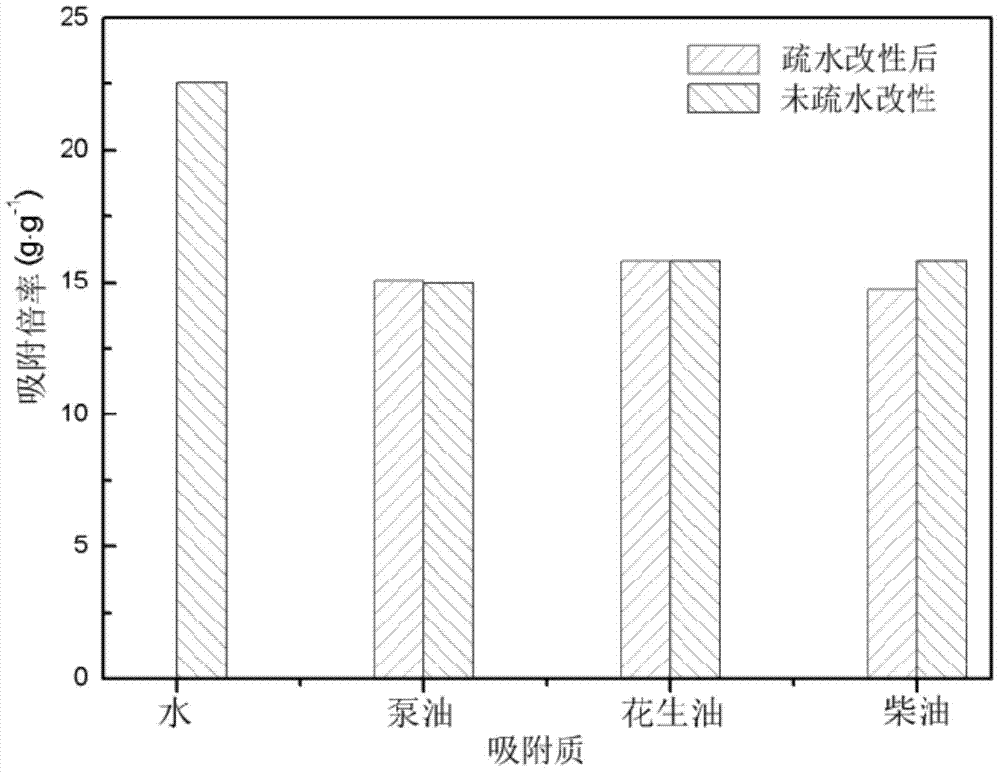

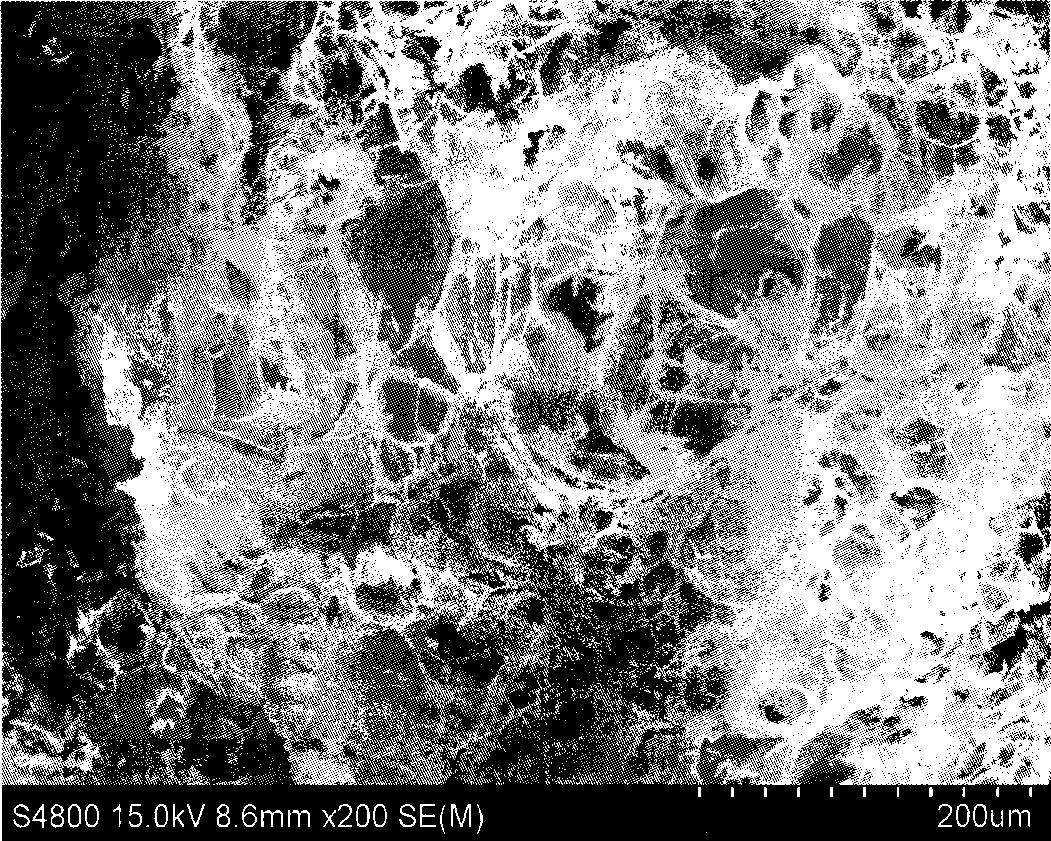

Preparation method of super-hydrophobic cellulose aerogel and application of super-hydrophobic cellulose aerogel in oil stain treatment

The invention discloses a preparation method of a super-hydrophobic cellulose aerogel and application of the super-hydrophobic cellulose aerogel in oil stain treatment. The light-weight porous cellulose aerogel material is prepared from abundant, renewable and degradable cellulose by using an alkali solution (comprising NaOH solution and NaOH / urea solution) as a solvent system. The minimum density can reach 0.0196 g / cm<3>, and the porosity can reach 99%. Compared with the commercial oil-adsorbing felt material, the cellulose aerogel material has higher adsorbing rate and excellent reusability. The hydrophobic modification method can obtain the super-hydrophobic effect in a quick, effective and energy-saving way, and can implement oil stain collection, oil-water separation and the like in a quick and economical way.

Owner:HAINAN UNIVERSITY +1

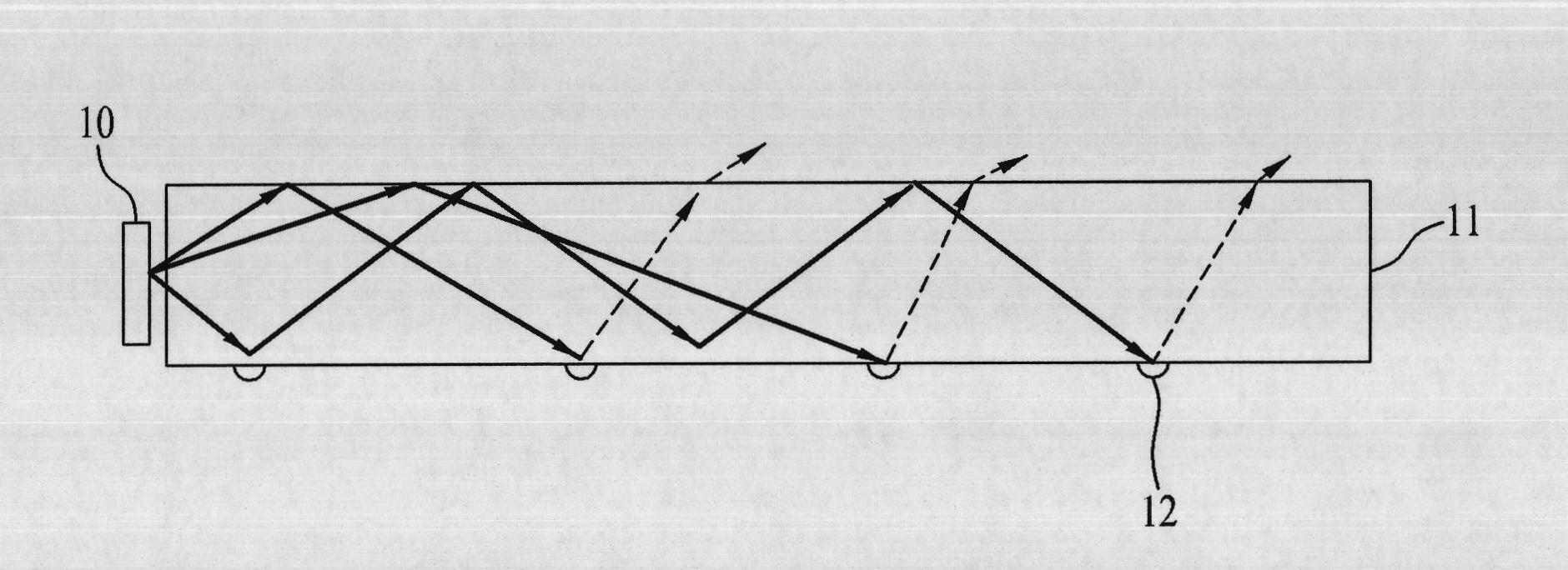

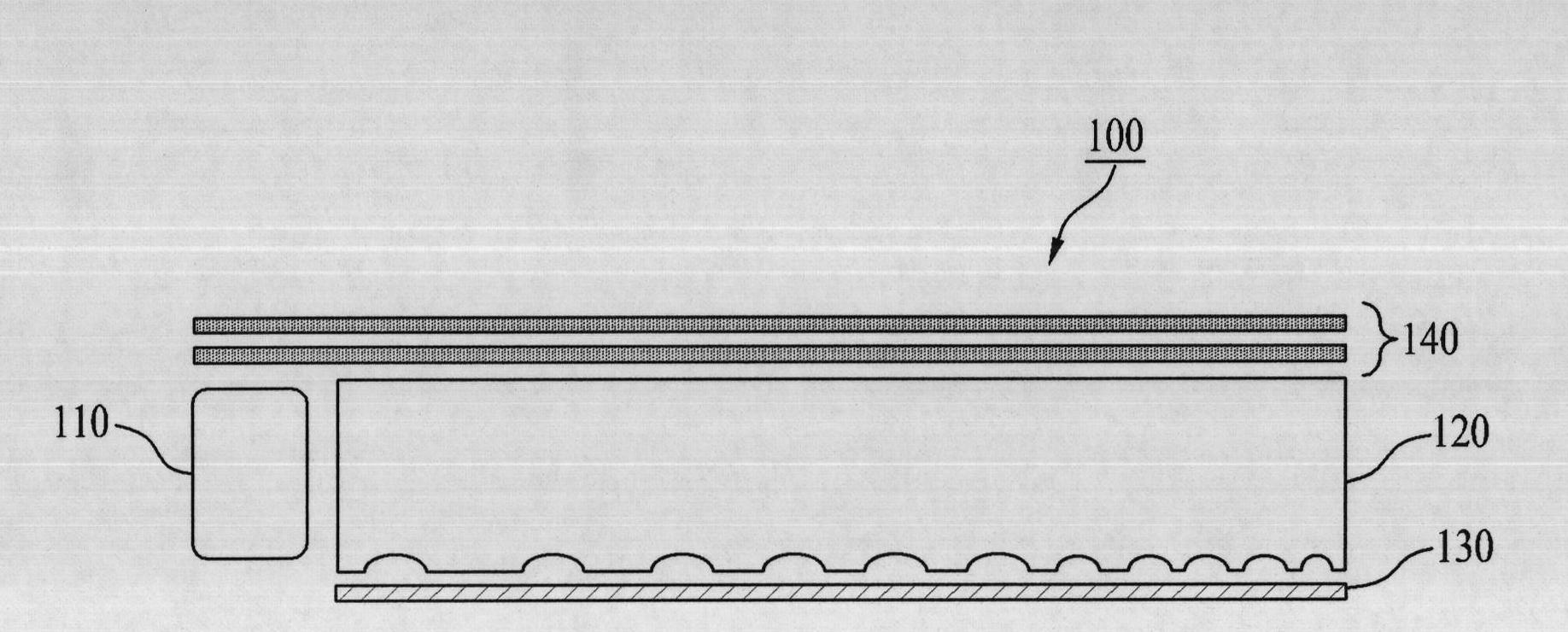

Light guide plate and backlight unit including the same

A light guide plate having a pattern to minimize generation of a dark zone and a backlight unit including the same are disclosed. The light guide plate includes an intaglio pattern consisting of recesses formed in a surface opposite to a light emitting surface thereof to have a cross section having major-axis and minor-axis diameters and depth, the recesses being spaced apart from one another in first and second directions by first and second distances respectively. The density of the intaglio pattern is directly proportional to the major-axis and minor-axis diameters and depth, and is inversely proportional to the first and second distances. The intaglio pattern has the minimum density in a first region adjacent to a light source, and the maximum density in a second region that is the maximum distance from the light source. A density ratio of the maximum density to the minimum density is 900.

Owner:LG DISPLAY CO LTD

Method for preparing fiber base material and silicon dioxide aerogel composite heat insulating sleeve

The invention discloses a method for preparing a fiber base material and silicon dioxide aerogel composite heat insulating sleeve, and belongs to the technical field of materials. The method comprises the following steps: preparing wet gel from polyethoxydisiloxanes, water, a solvent and a catalysts serving as raw materials; and pouring the wet gel into a sleeve die in which a fiber base materialis laid evenly in advance, ageing, putting into an autoclave for drying heat treatment, and reducing temperature and releasing pressure to obtain the fiber base material and silicon dioxide aerogel composite heat insulating sleeve. The method has the advantages of reasonable design and simple operation; the obtained composite heat insulating sleeve has the advantages that: 1, the minimum thickness of the wall of the sleeve is only 0.5mm, the pressive strength can reach over 1MPa, and special dimensions or other special products can be manufactured by a similar process; 2, the minimum density can reach 100kg / m3, and the minimum heat conductivity is only 0.015w / m.k; and 3, the sleeve can resist maximum temperature of 800 DEG C. The sleeve is particularly suitable for the field of aviation with special requirements on heat insulating properties.

Owner:浙江鹏辰造纸研究所有限公司 +1

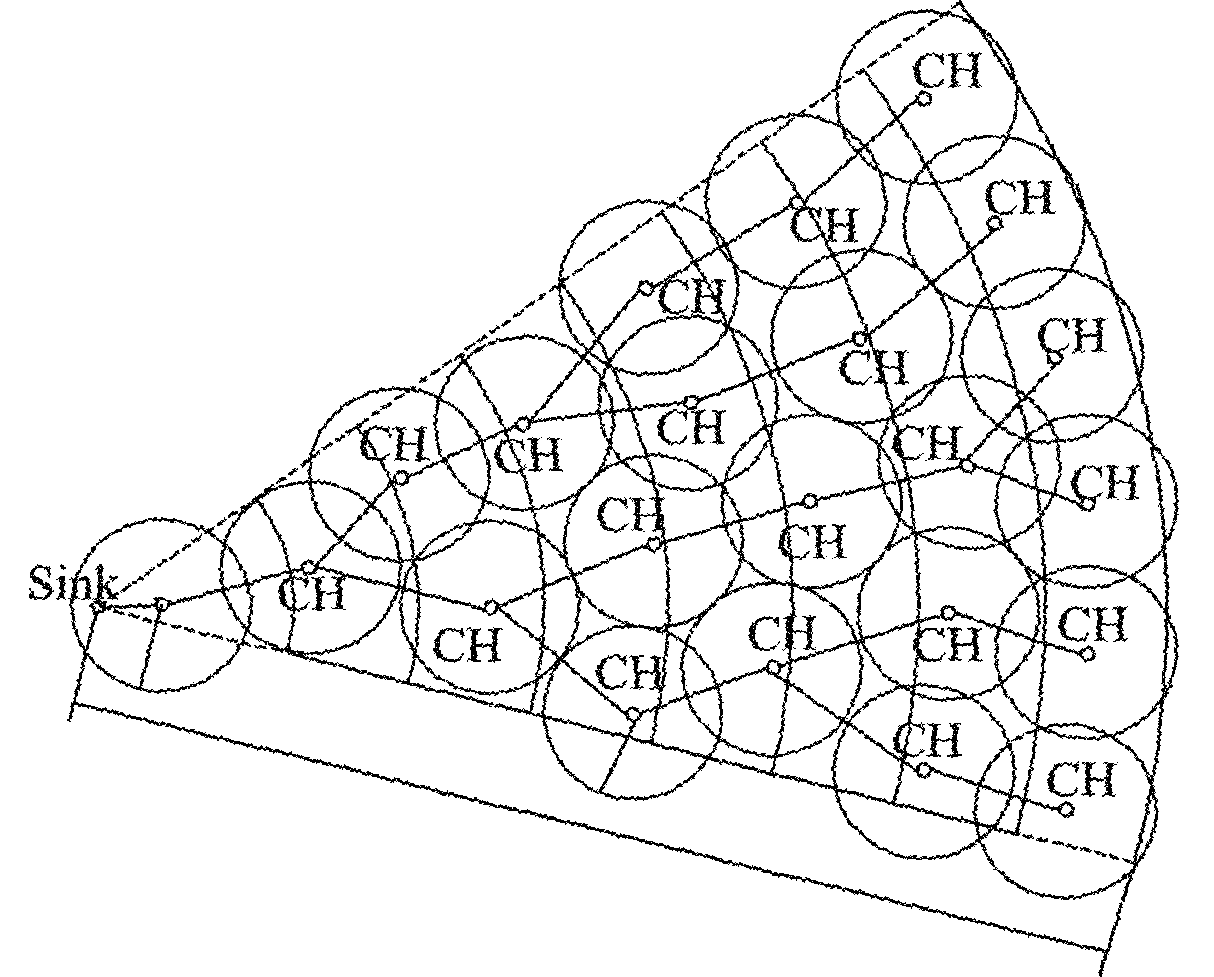

Novel node distribution method for maximizing service lives of clustering wireless sensor networks

InactiveCN103391555ACalculation of energy consumption lawLife maximizationPower managementEnergy efficient ICTNODALMobile wireless sensor network

The invention discloses a novel node distribution method for maximizing the service lives of clustering wireless sensor networks and relates to the technical field of wireless sensor networks. The method has the advantages that 1, data volumes born by nodes of different regions and energy consumption laws in clustering networks which are uniformly deployed and meet the coverage required minimum density are obtained theoretically, and a network service life calculation method is given; 2, a non-uniform node distribution (NUND) algorithm is raised, and the network service lives are optimized under the circumstance of certain distribution nodes; 3, the cluster head alternating frequency of regions with increased distribution nodes is increased according to the node density of different regions based on the NUND distribution scheme, and an improved non-uniform node distribution (I-NUND) scheme is raised, accordingly, the network energy consumption is further reduced, and the network service lives are maximized.

Owner:任炬

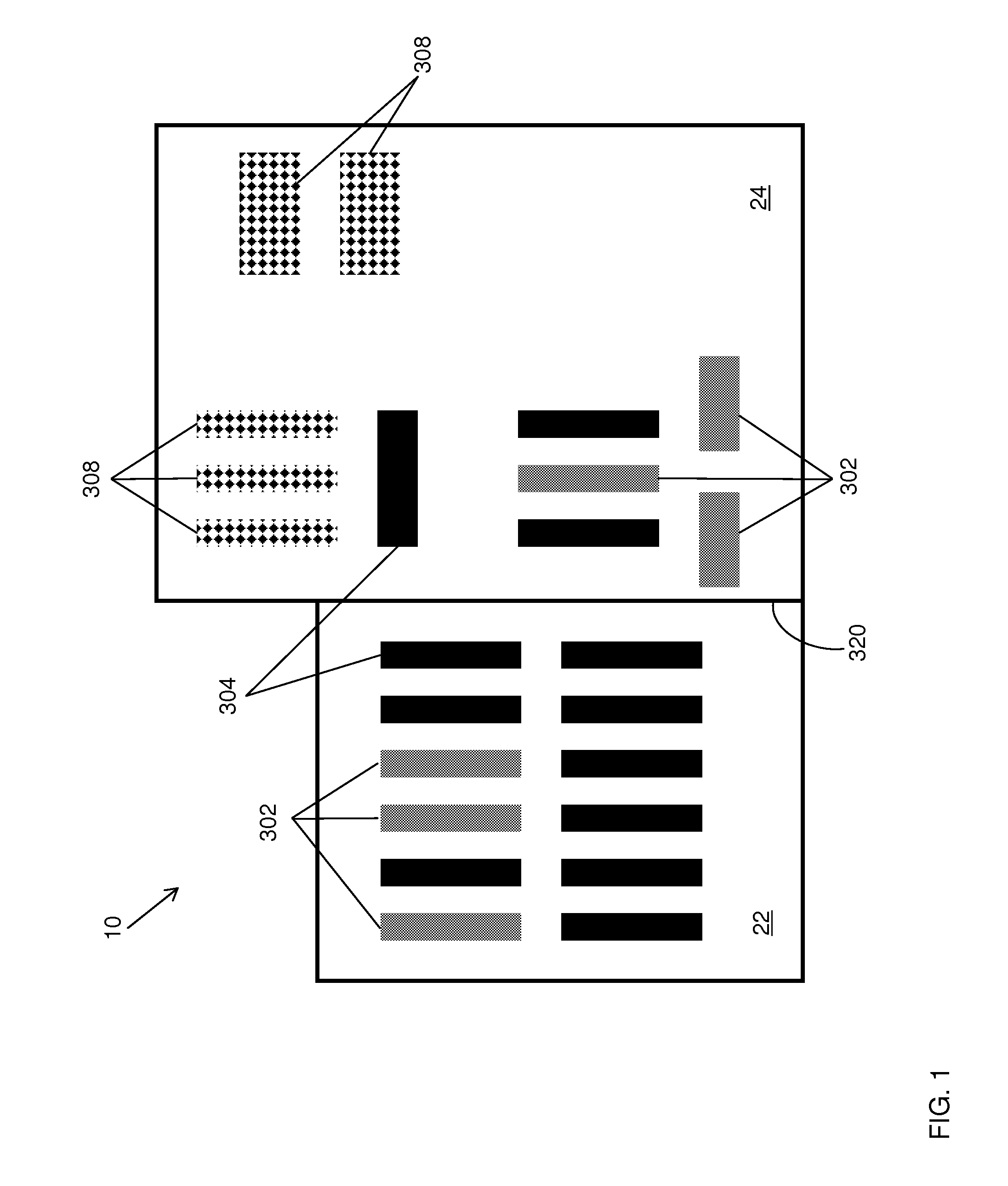

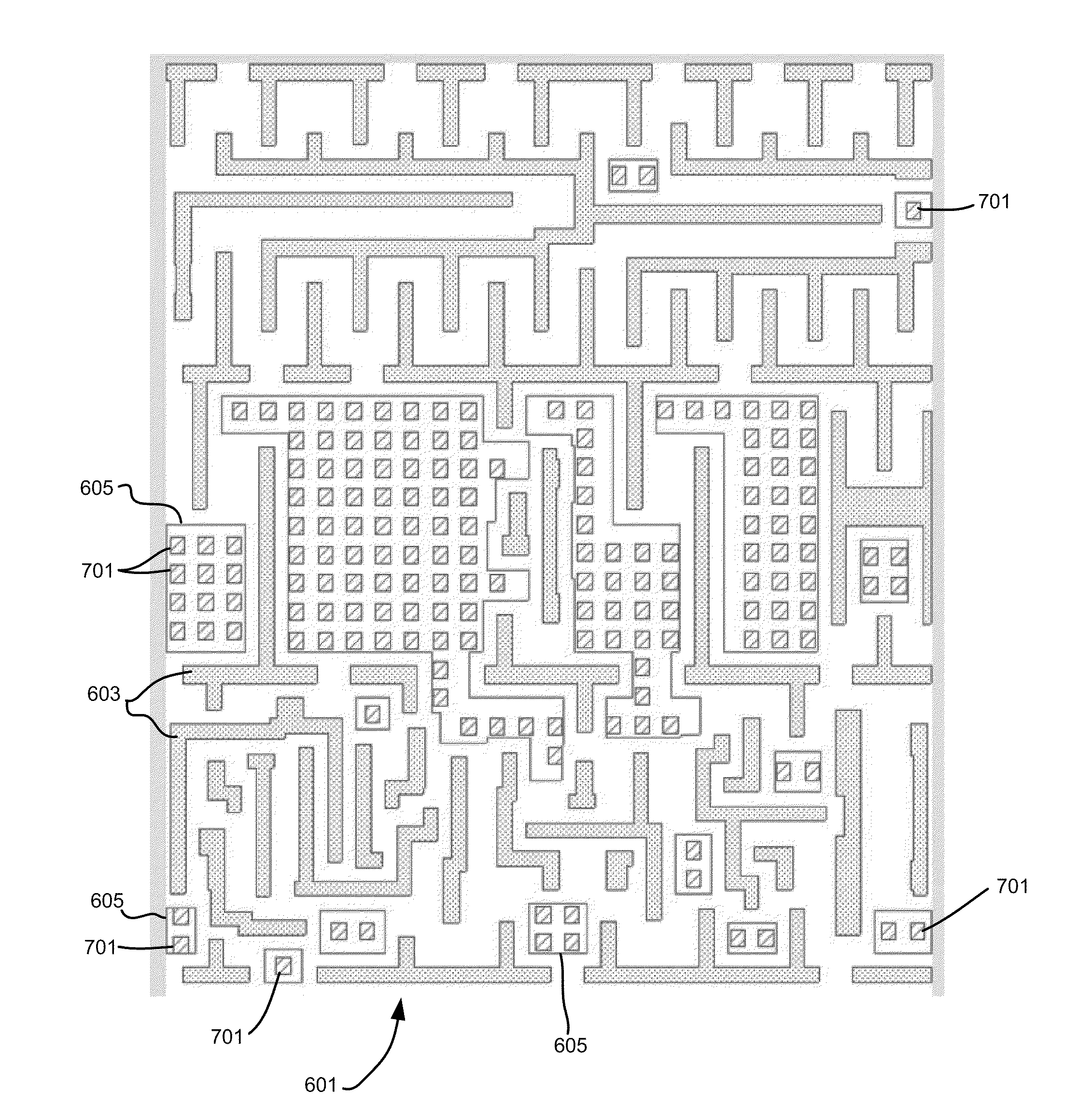

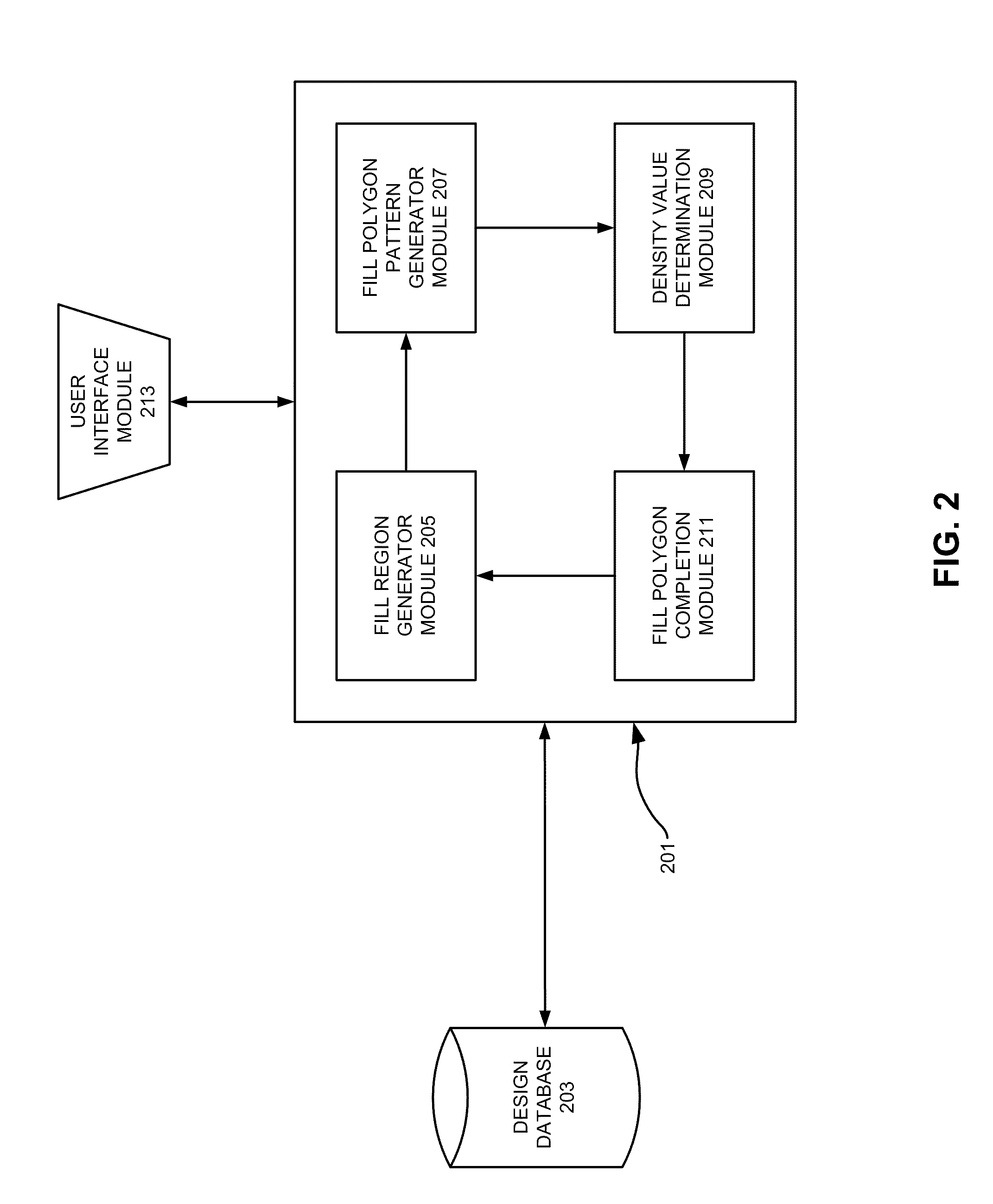

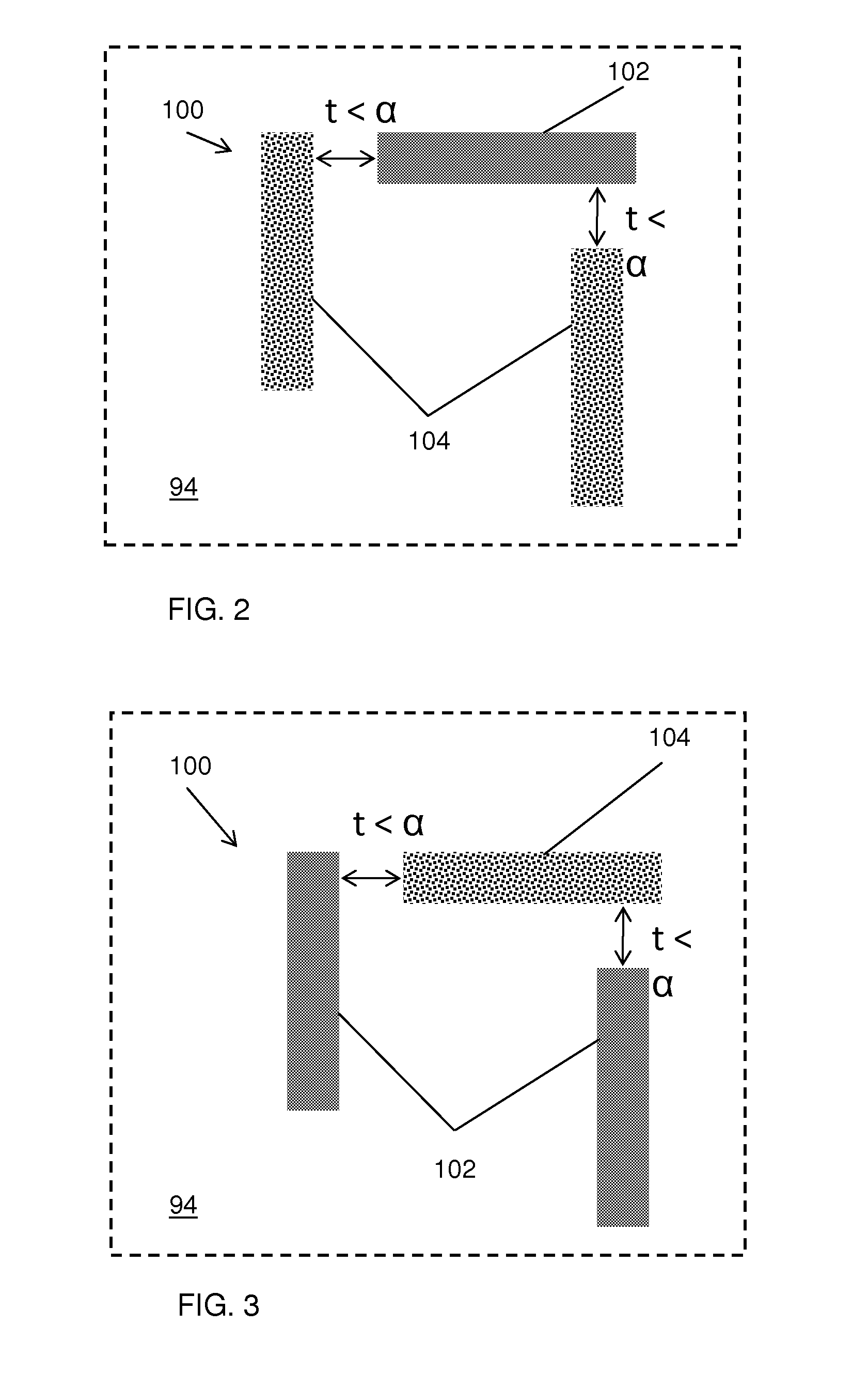

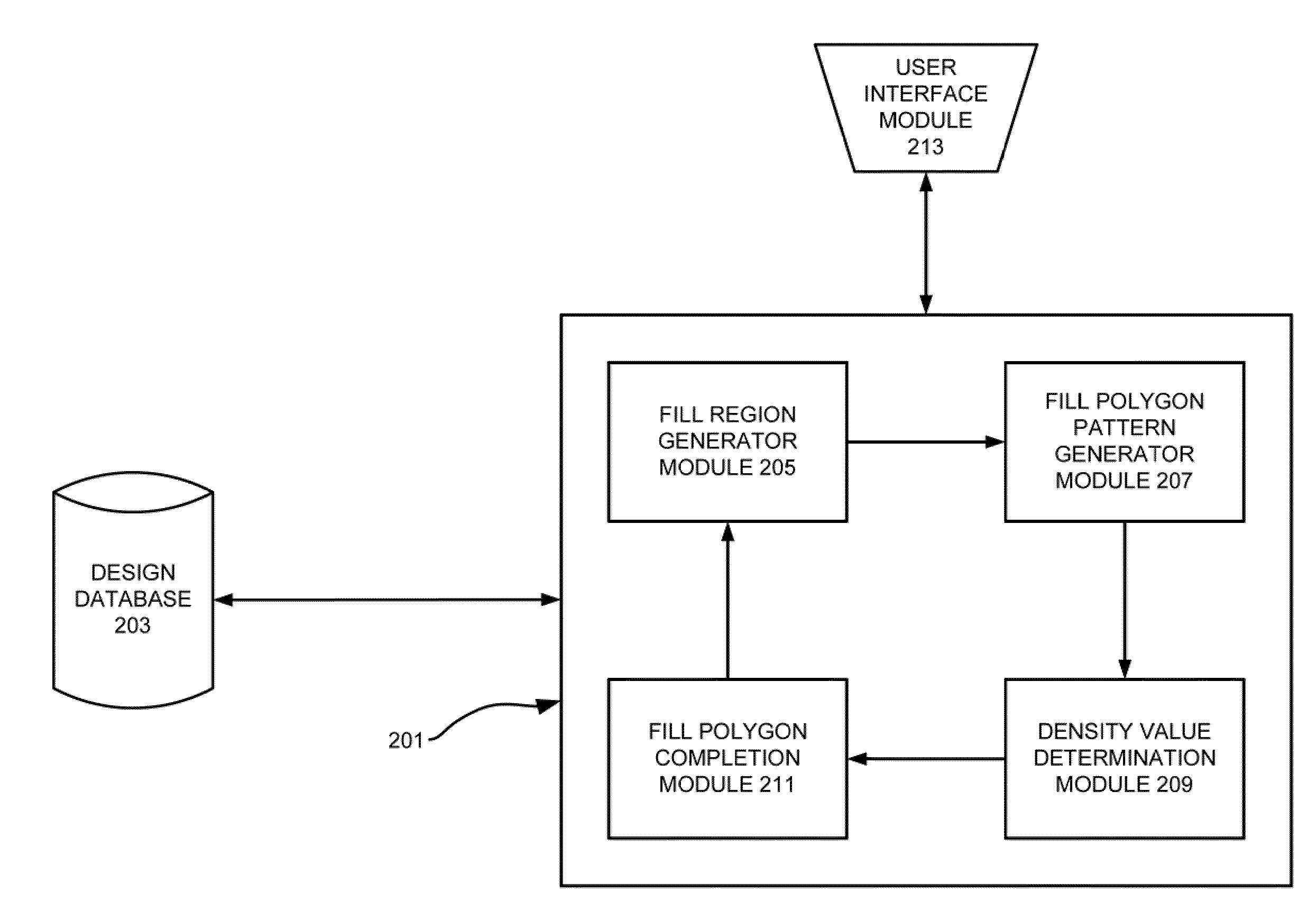

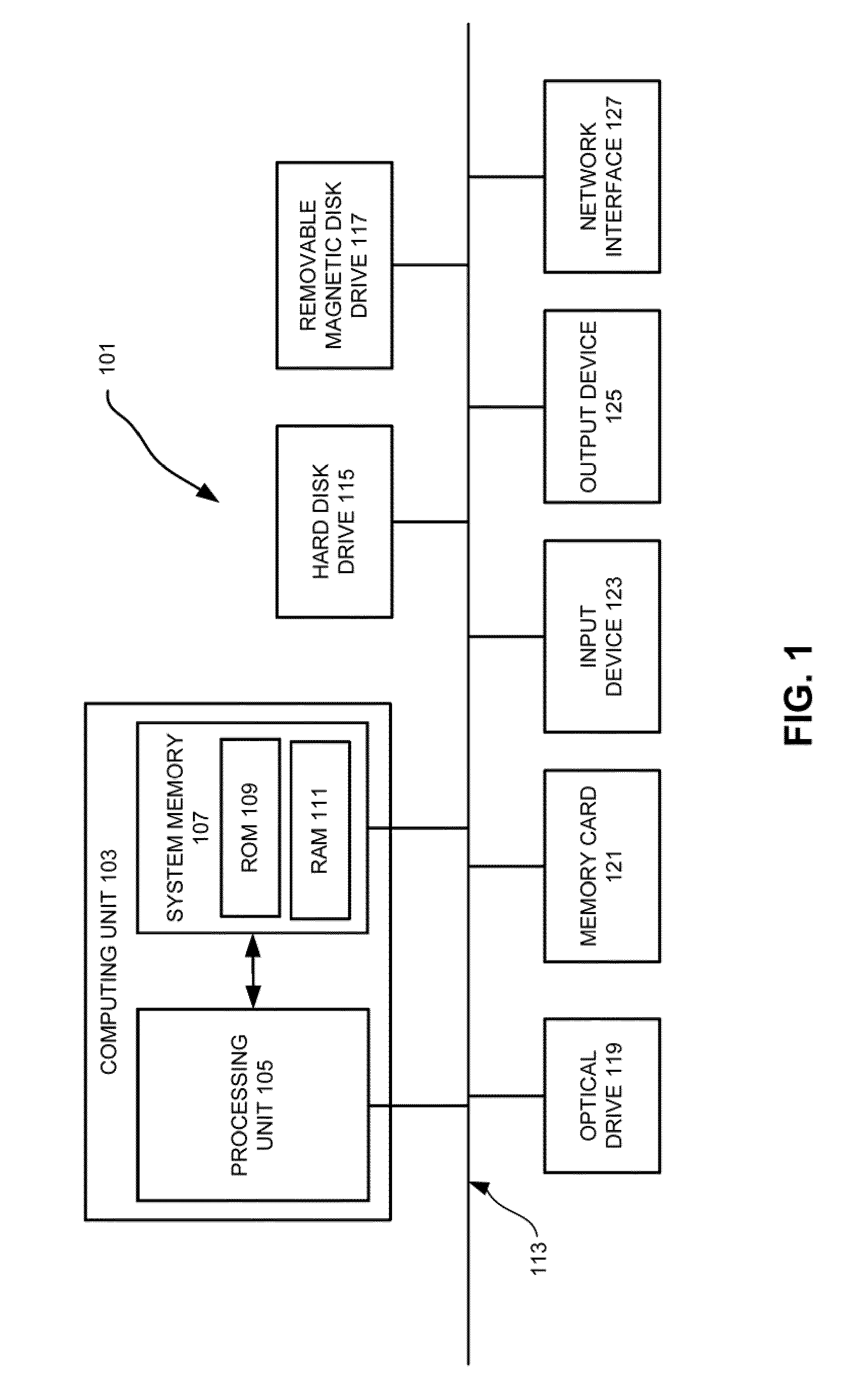

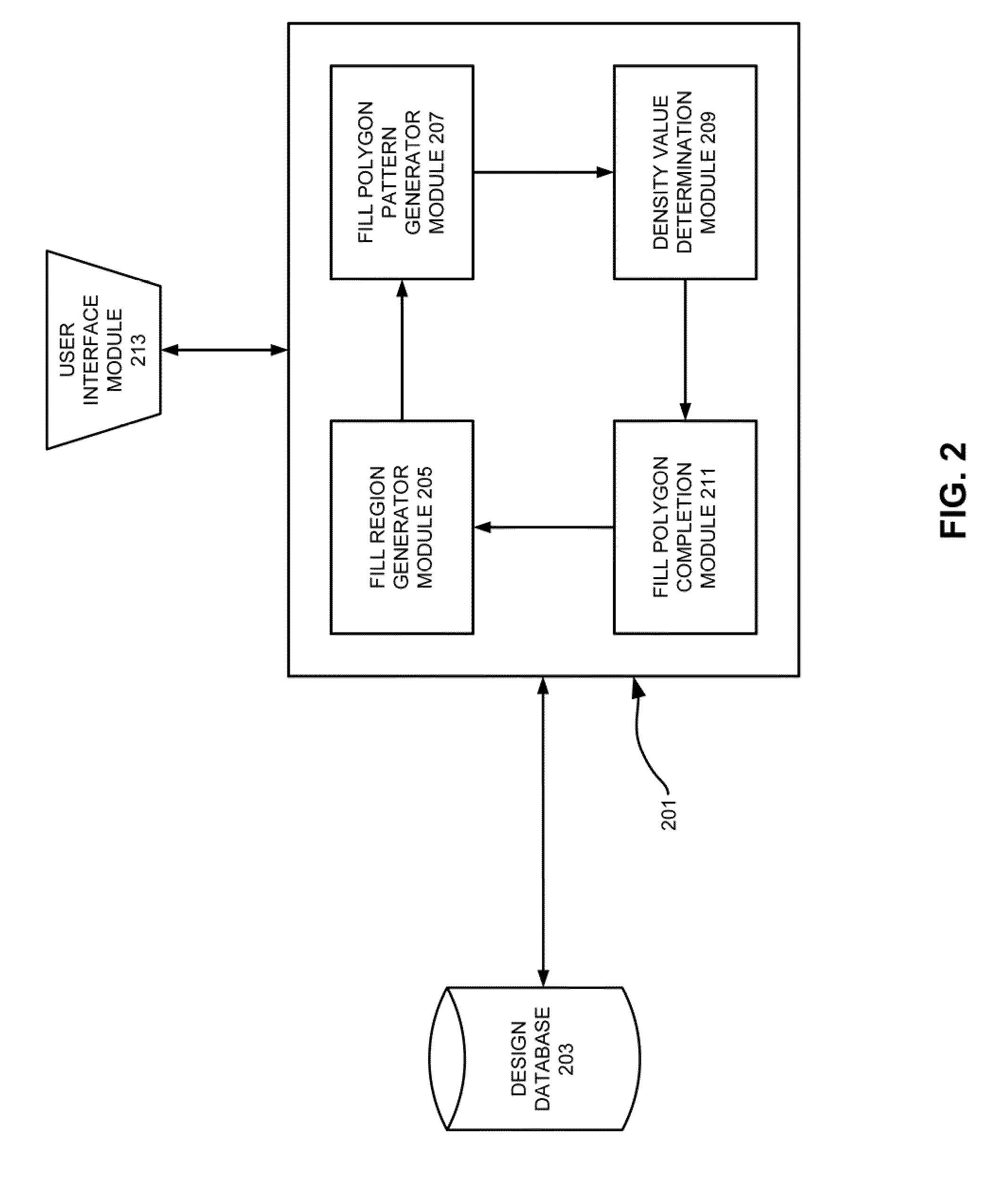

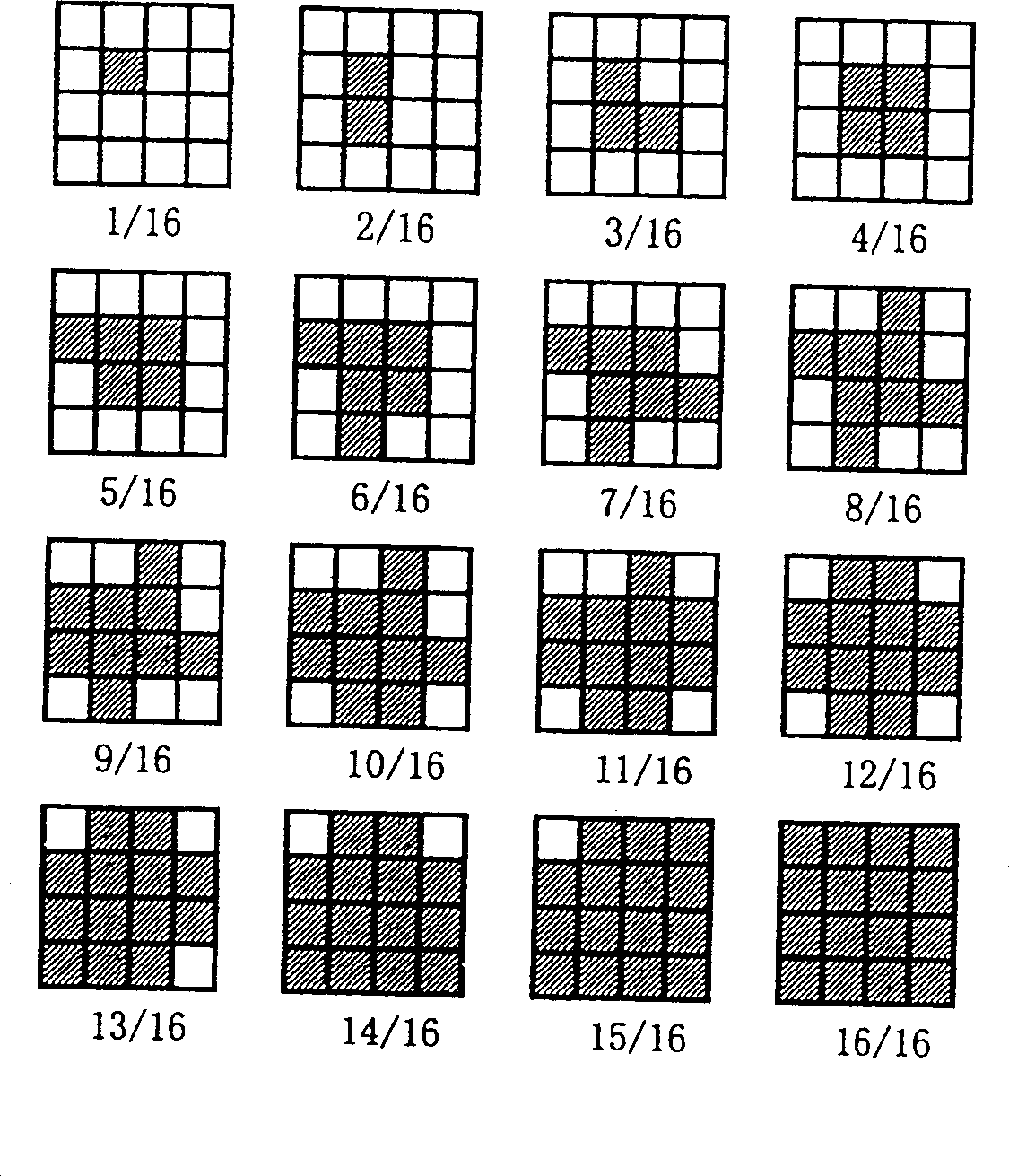

Optimization Of Geometry Pattern Density

InactiveUS20080034332A1Minimize the numberArea maximizationCAD circuit designTotal factory controlGraphicsMinimum density

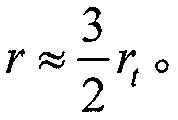

Techniques are provided for optimizing the pattern density in the circuit layout design of a circuit layer. A layer in circuit design is analyzed to define fill regions that can be filled with fill polygons A pattern of fill polygons also is generated, to fill the fill regions. The layout design for the layer then is divided into separate areas or “windows,” and a target density for each window is determined. More particularly, each window is analyzed to determine a target density for the window that will satisfy specified density constraint values, such as a minimum density constraint, a maximum density constraint, or a maximum density gradient constraint. In some implementations, the target density will be the smallest density that will comply with each of the specified density value constraints. Once the target density for the window has been determined, the fill polygons required to most closely approach this target density are selected and added to the circuit layout design. With some implementations, this process may be repeated for fill polygons of different sizes or shapes.

Owner:MENTOR GRAPHICS CORP

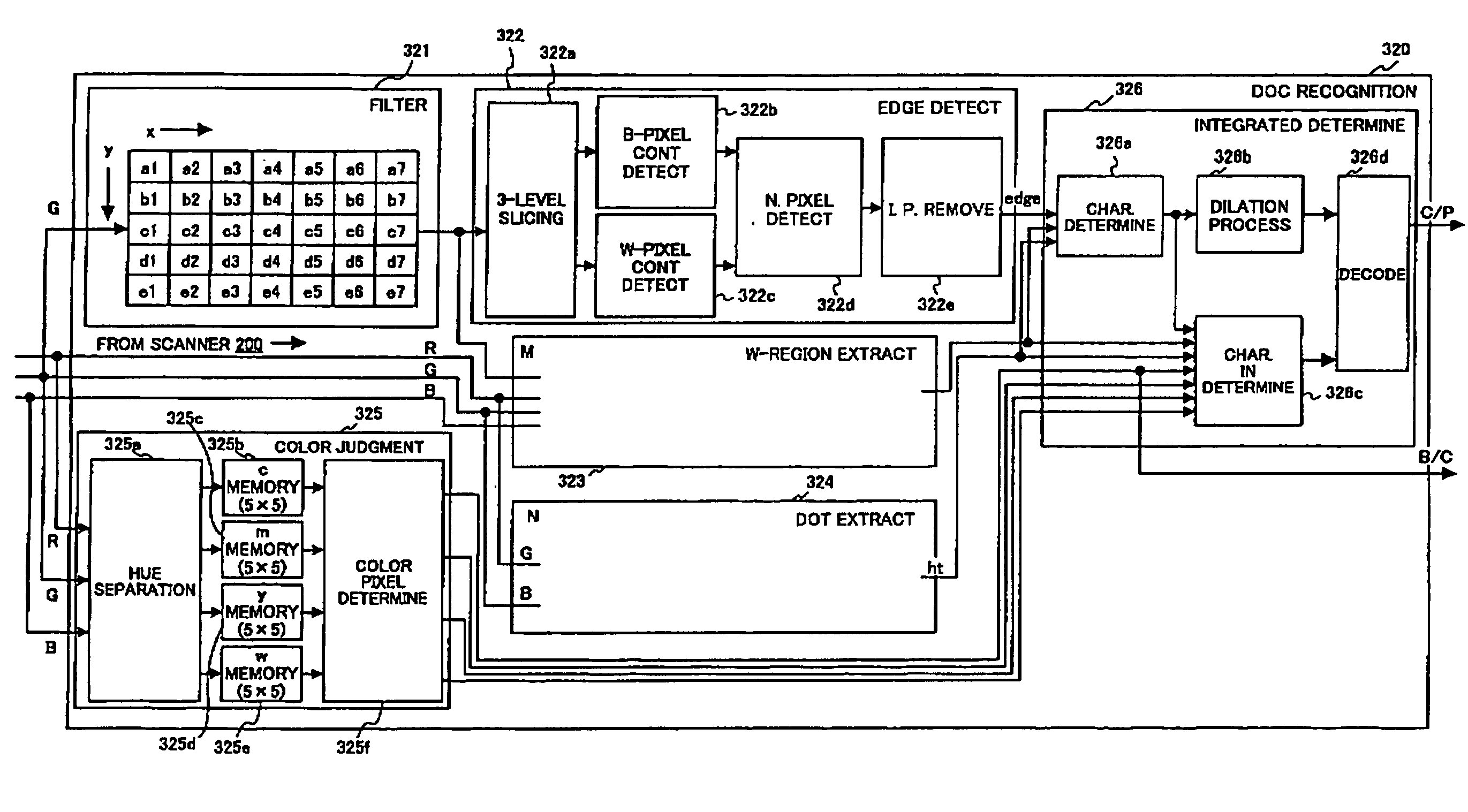

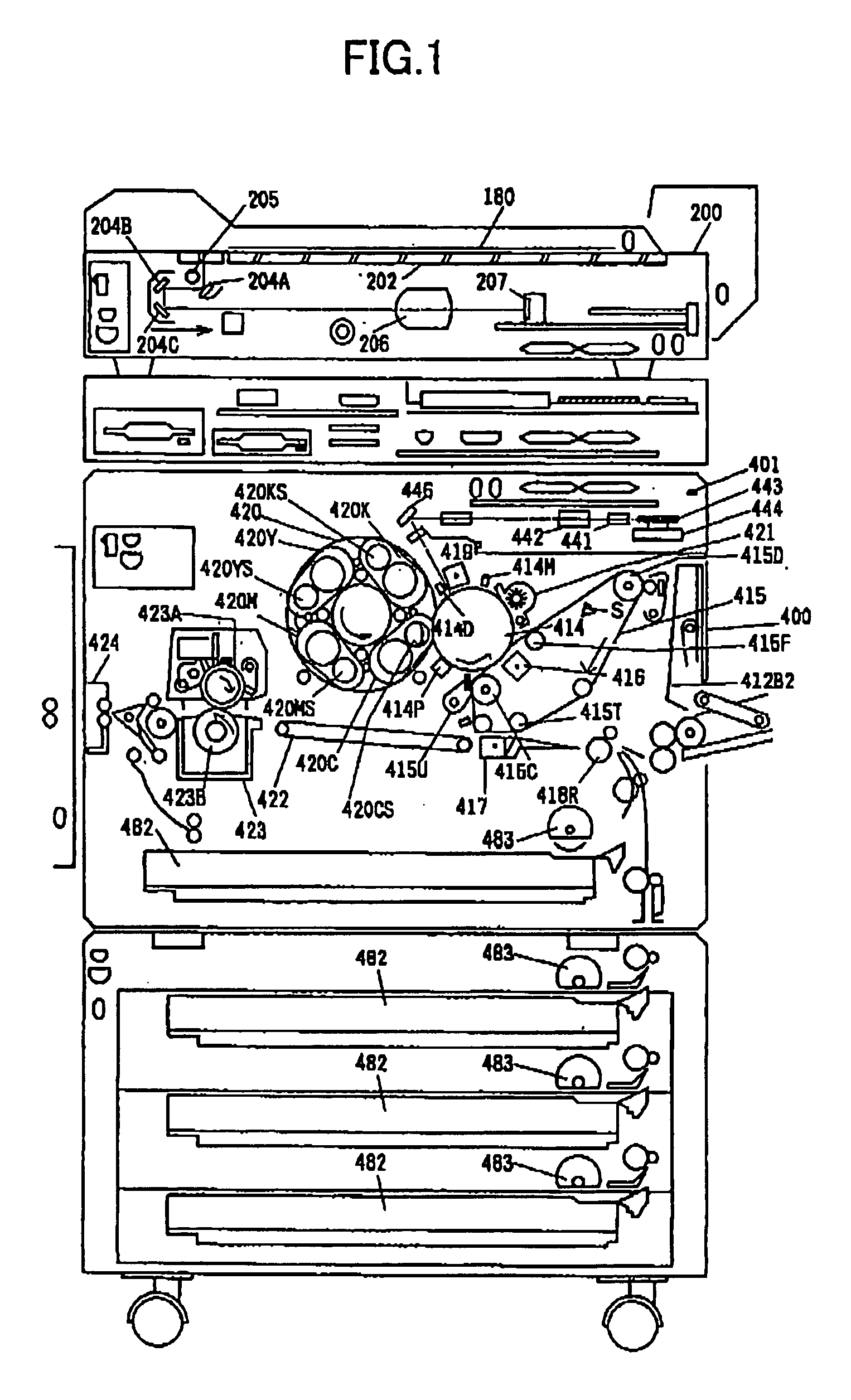

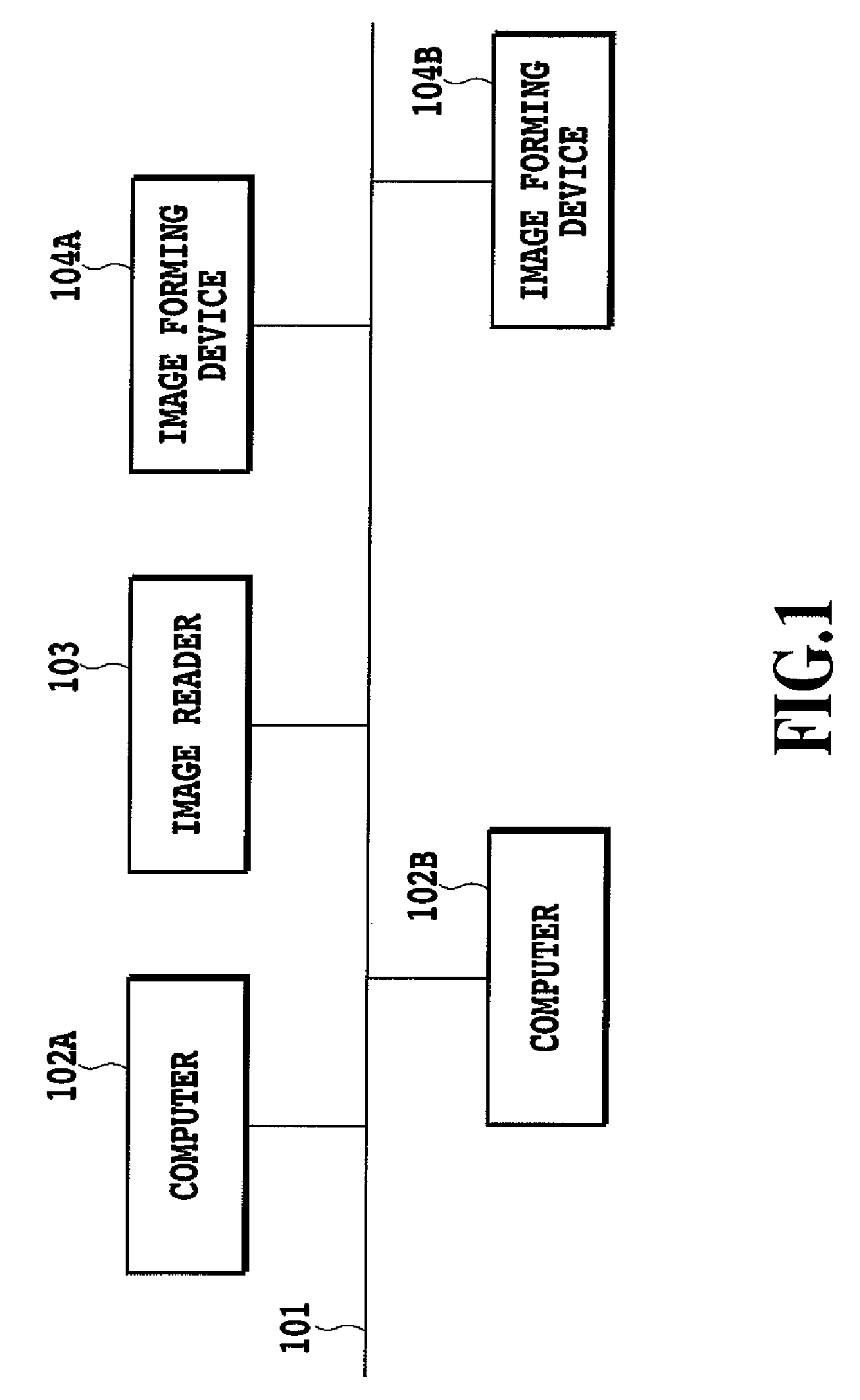

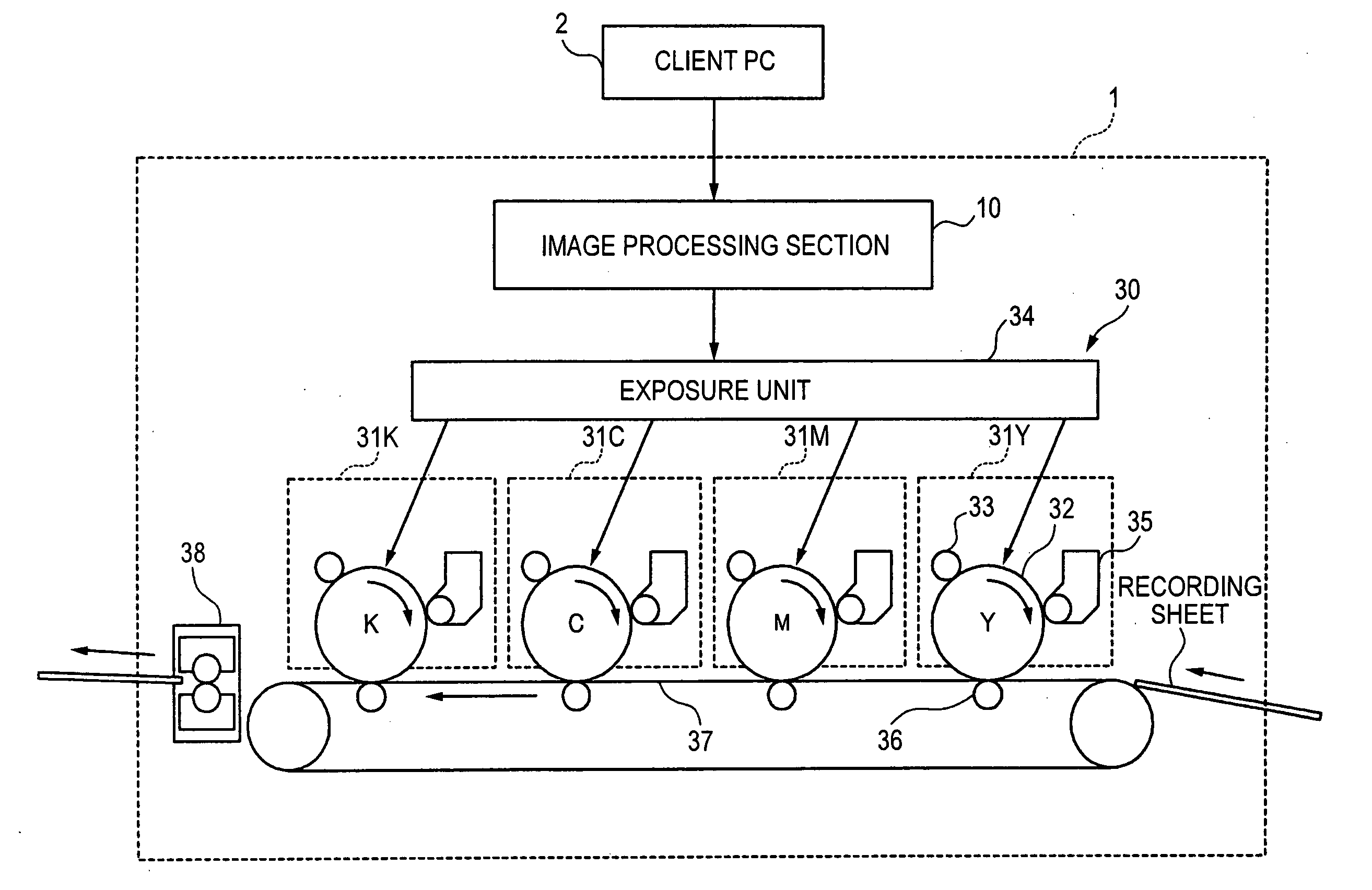

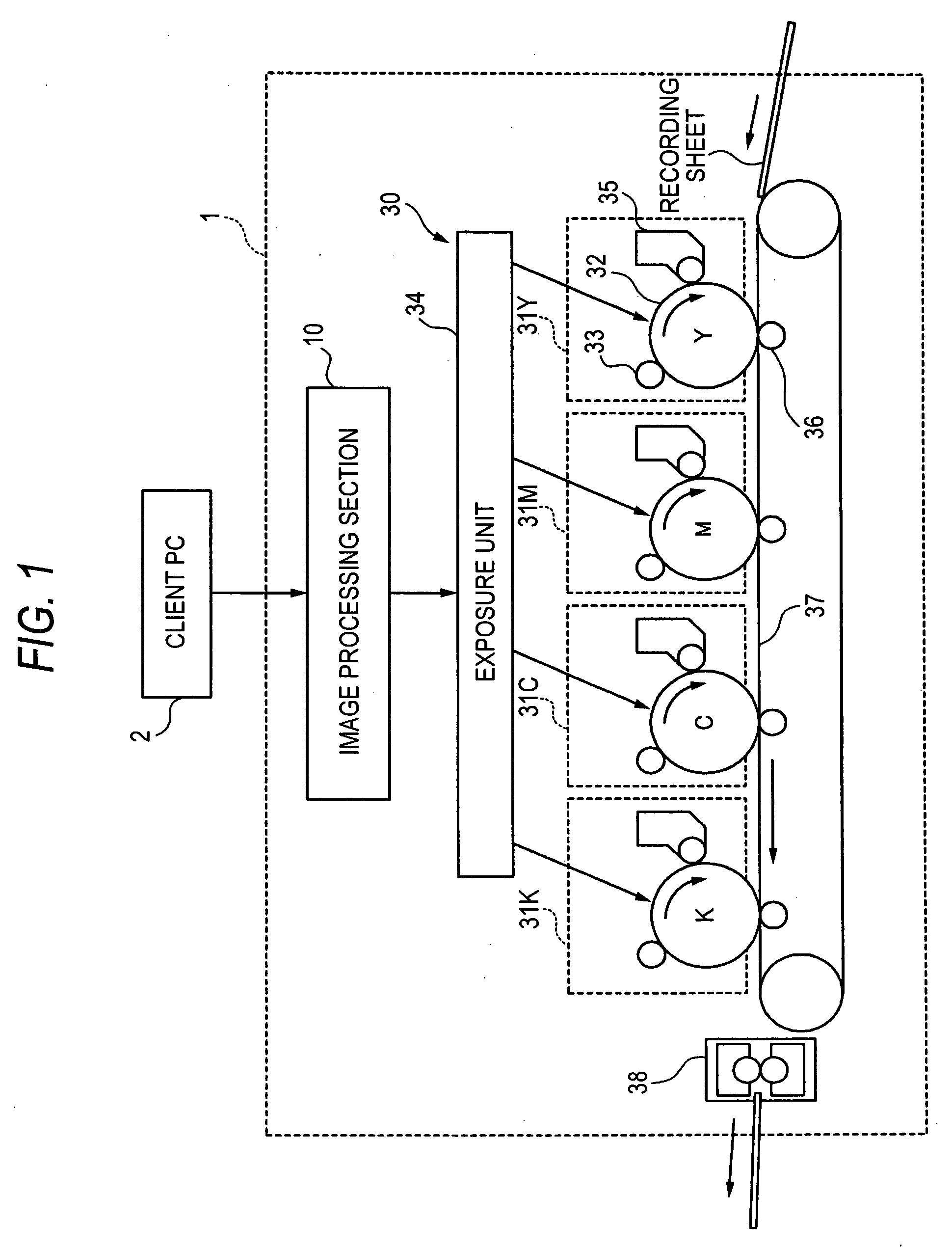

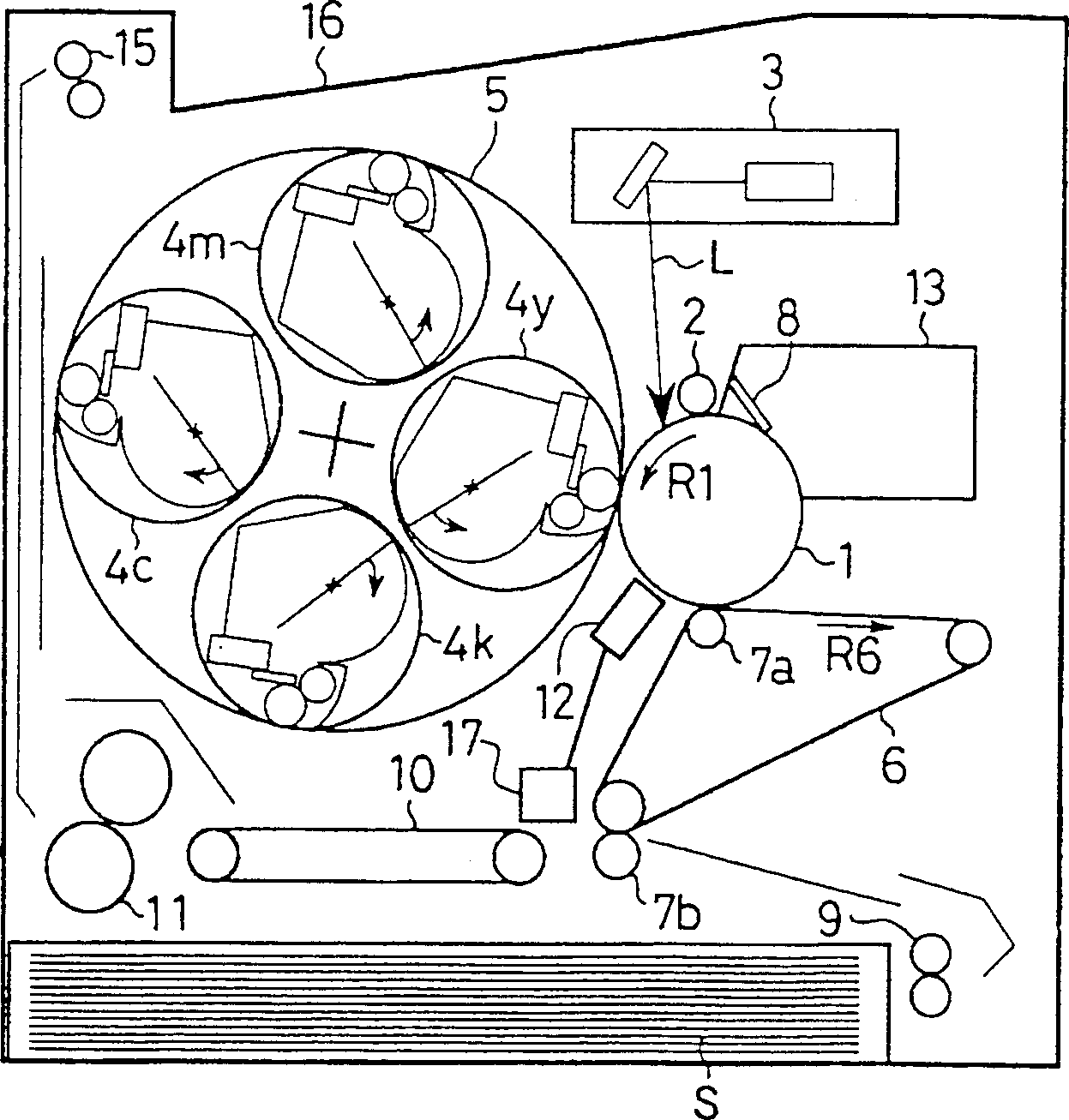

Image processing apparatus including low-linear-density dot region detection unit, and image forming apparatus including the same

InactiveUS7085013B2Easy to implementAvoid misjudgmentImage enhancementDigitally marking record carriersMinimum densityImaging processing

An image processing apparatus includes a maximum / minimum density detecting unit which detects a center pixel of a matrix of N×N pixels in image data that has a maximum or minimum density. A determination unit determines whether the absolute value of a difference between an average of densities of diagonal pixels of the matrix and a density of the center pixel is larger than a threshold value. A peak pixel detecting unit detects peak pixels of the matrix, each peak pixel being the center pixel having a maximum or minimum density, and the absolute value of the difference with respect to the center pixel being larger than the threshold value. A dot region detecting unit detects one of neighboring pixels of the matrix as being a dot region based on the number of the peak pixels in a target region and the number of the peak pixels in each of neighboring regions.

Owner:RICOH KK

Simultaneous Multi-Layer Fill Generation

ActiveUS20110289471A1Minimize the numberArea maximizationSolid-state devicesCAD circuit designMinimum densitySimultaneous equations

Techniques are disclosed for optimizing the pattern density in the circuit layout design of a circuit layer. A layer in circuit design is analyzed to define empty regions that can be filled with fill polygons (referred to hereafter as “fill” regions). Next, a pattern of fill polygons is generated. After the fill polygons have been defined, the layout design for the layer is divided into separate areas or “windows,” and a target density for each window is determined. Once this target density for the window has been determined, the fill polygons required to most closely approach this target density are generated and added to the circuit layout design. This process may be repeated with progressively different (e.g., smaller) fill polygons, until each window meets or exceeds both the specified minimum density and complies with the specified maximum density gradient. Additionally, some implementations may allow a user to simultaneously optimize the density of multiple layers of a circuit by adding fill polygons to multiple layers of a circuit design simultaneously. Representations of sections of a multilayer fill structure will then be added to corresponding layers the circuit design until a specified target density is met.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

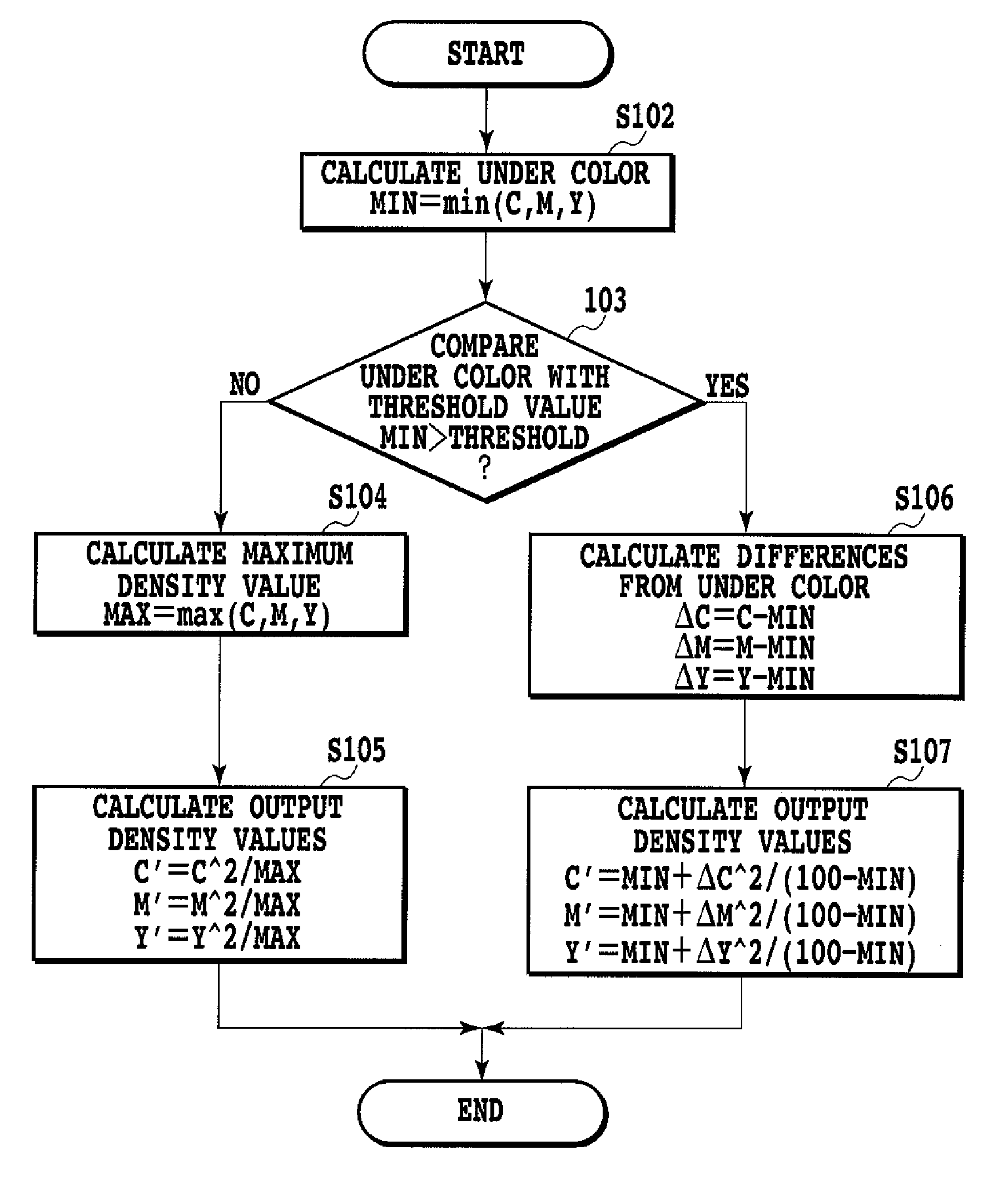

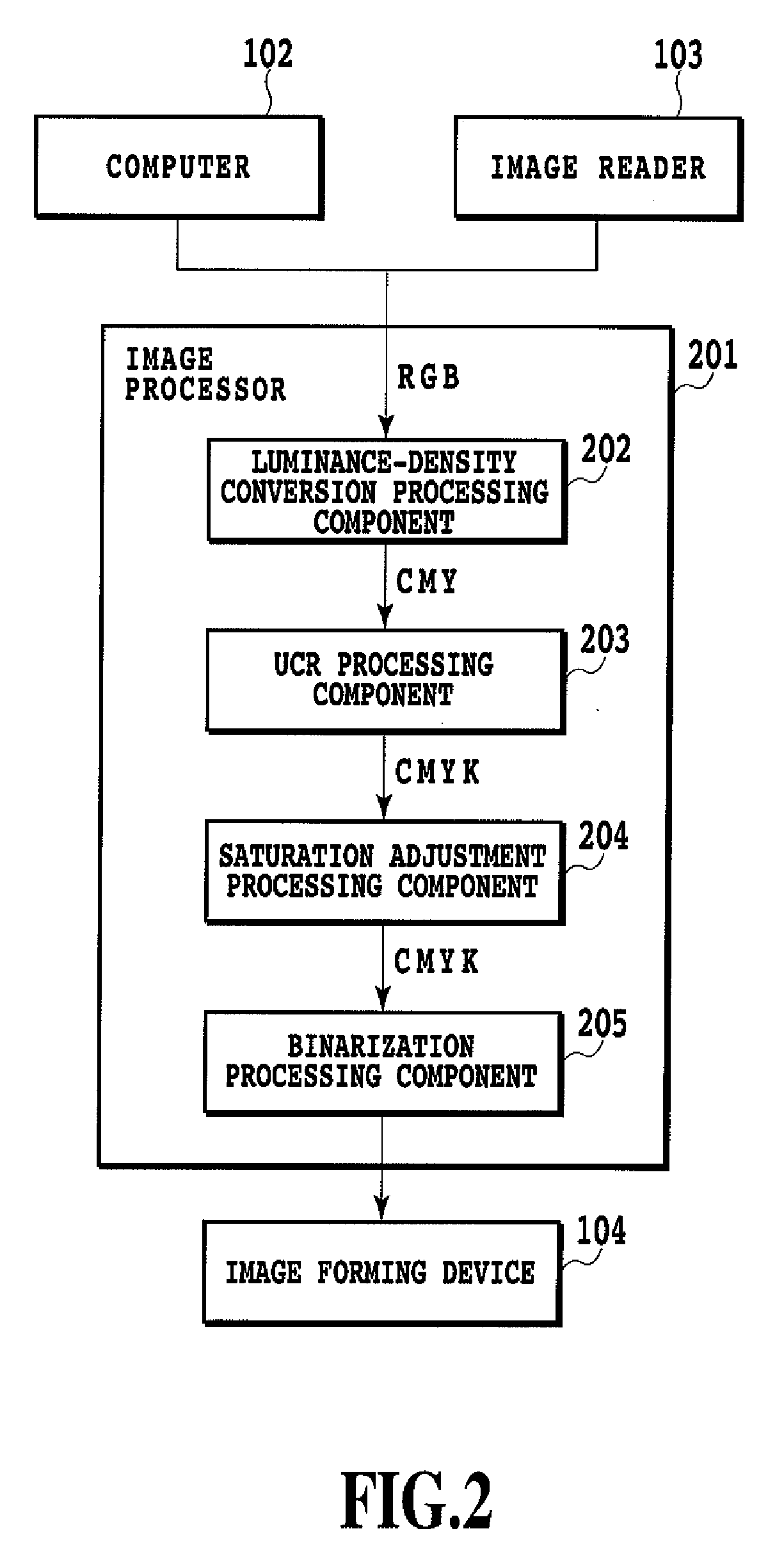

Image processor and image processing method for reducing consumption amount of recording material

InactiveUS8031365B2Reduce consumptionSuppressing unclearness of printed imageDigitally marking record carriersDigital computer detailsMinimum densityDevice form

The present invention provides an image processor for outputting image data to an image forming device forming an image with use of a recording material having a plurality of color components. The processor comprises a component determining a region having higher brightness than predetermined brightness and a region having lower brightness than the predetermined brightness in the image data based on the image data and a component adjusting saturation so as to reduce density values of color components other than a color component having a maximum density value among the plurality of color components of the recording material to increase saturation in a region having brightness determined to be high and reduce density values of color components other than a color component having a minimum density value among the plurality of color components of the recording material to decrease saturation in a region having brightness determined to be low.

Owner:CANON KK

Heat resisting magnesium alloy and compound material containing heat resisting magnesium alloy and preparation method thereof

The invention provides a heat-resistant magnesium alloy, and the compositions in mass percentage of the alloy are: more than or equal to 3 percent and less than or equal to 7 percent of Al, more than or equal to 0.5 percent and less than or equal to 7 percent of Zn more than or equal to 0.5 percent and less than or equal to 2 percent of Ti, more than or equal to 1 percent and less than or equal to 6 percent of Sn, more than or equal to 0.01 percent and less than or equal to 0.1 percent of La, more than or equal to 0.5 percent and less than or equal to 4 percent of Si and more than or equal to 0.05 percent and less than or equal to 0.6 percent of Zr and the balance being manganese. The heat-resistant magnesium alloy uses only such normal non-precious rare elements as Al, Zn, Ti, Sn, La, Si and Zr, has low cost and keeps good heat-resistant property without adding the elements; and the plastic deformation rate of the alloy is 0.2 to 0.35 percent at the temperature of 250 DEG C and under the stress of 30Mpa, and the alloy can be widely applied in the working environment of high temperature. The heat-resistant magnesium-based porous composite material consists of heat-resistant magnesium alloy and a minimum-density heat-resistant inorganic porous material, has heat-resistant function and good damping property below the temperature of 250 DEG C, can be widely applied to the heat-resistant vibration-absorption parts and components of rapid machinery like an automobile, and has the advantages of good vibration-absorption, sound insulation and voice confusion. The composite material is simple in preparation process and low in production cost.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for post decomposition density balancing in integrated circuit layouts, related system and program product

ActiveUS20140065728A1Semiconductor/solid-state device testing/measurementSolid-state devicesPattern recognitionMinimum density

Embodiments of the invention provide a method of modifying a decomposed integrated circuit (IC) layout. The method includes providing a decomposed IC layout, the decomposed IC layout including a set of colors; determining a density of each color in the decomposed IC layout, wherein each color includes a plurality of features formed by a related exposure; separating the decomposed IC layout into a set of tiles; determining a first color with a minimum density in one tile of the set of tiles and a second color with a maximum density in tile, the first color including a first set of first features and the second color including a first set of second features; and replacing the first set of second features on the tile with a second set of first features, and the first set of first features on the tile with a second set of second features.

Owner:GLOBALFOUNDRIES US INC

Light guide plate and back light unit including the same

InactiveCN102338904AMechanical apparatusLight guides for lighting systemsMinimum densityDensity ratio

The invention discloses a light guide plate and a back light unit including the same. A light guide plate having a pattern to minimize generation of a dark zone and a backlight unit including the same are disclosed. The light guide plate includes an intaglio pattern consisting of recesses formed in a surface opposite to a light emitting surface thereof to have a cross section having major-axis and minor-axis diameters and depth, the recesses being spaced apart from one another in first and second directions by first and second distances respectively. The density of the intaglio pattern is directly proportional to the major-axis and minor-axis diameters and depth, and is inversely proportional to the first and second distances. The intaglio pattern has the minimum density in a first region adjacent to a light source, and the maximum density in a second region that is the maximum distance from the light source. A density ratio of the maximum density to the minimum density is 900.

Owner:LG DISPLAY CO LTD

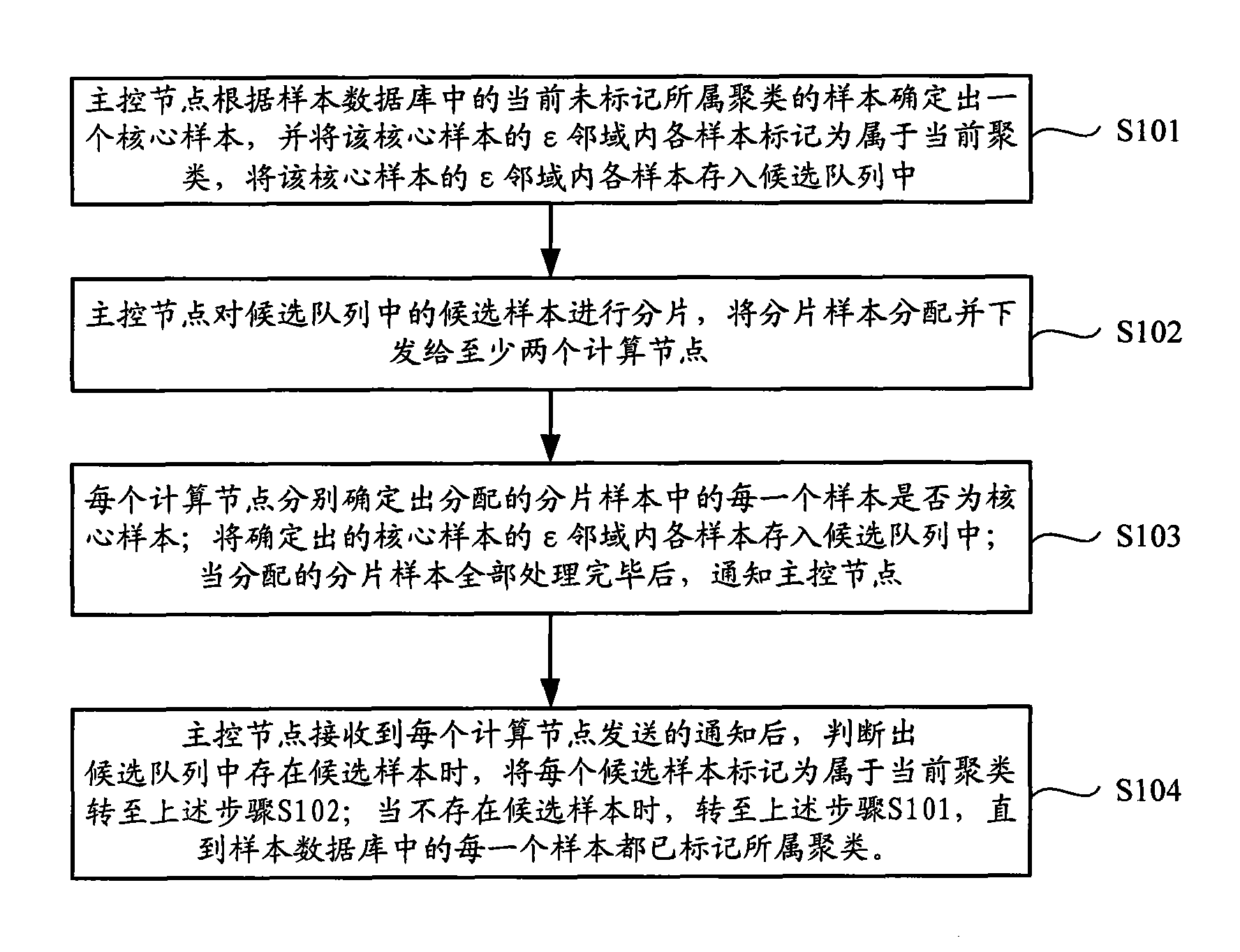

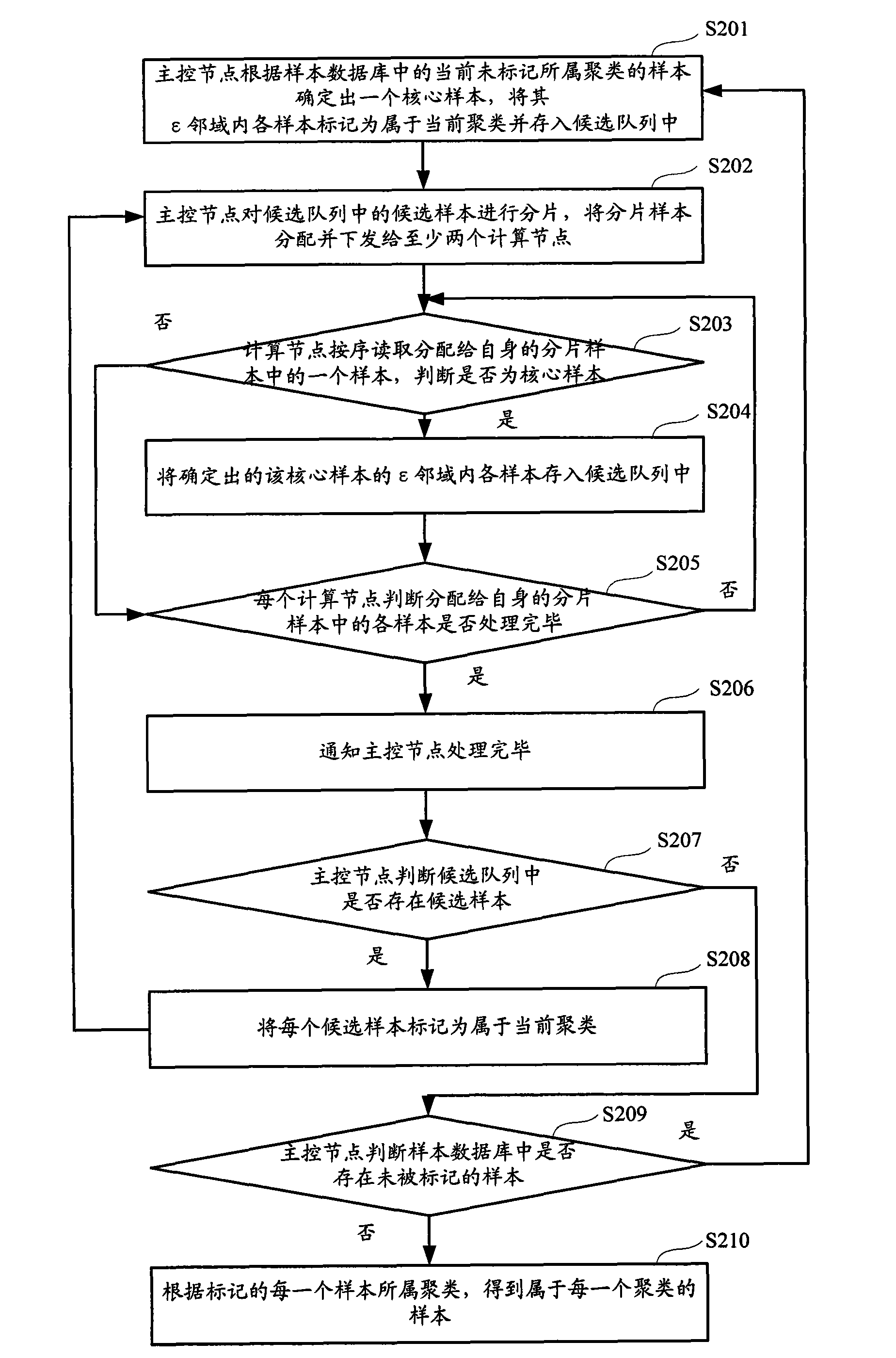

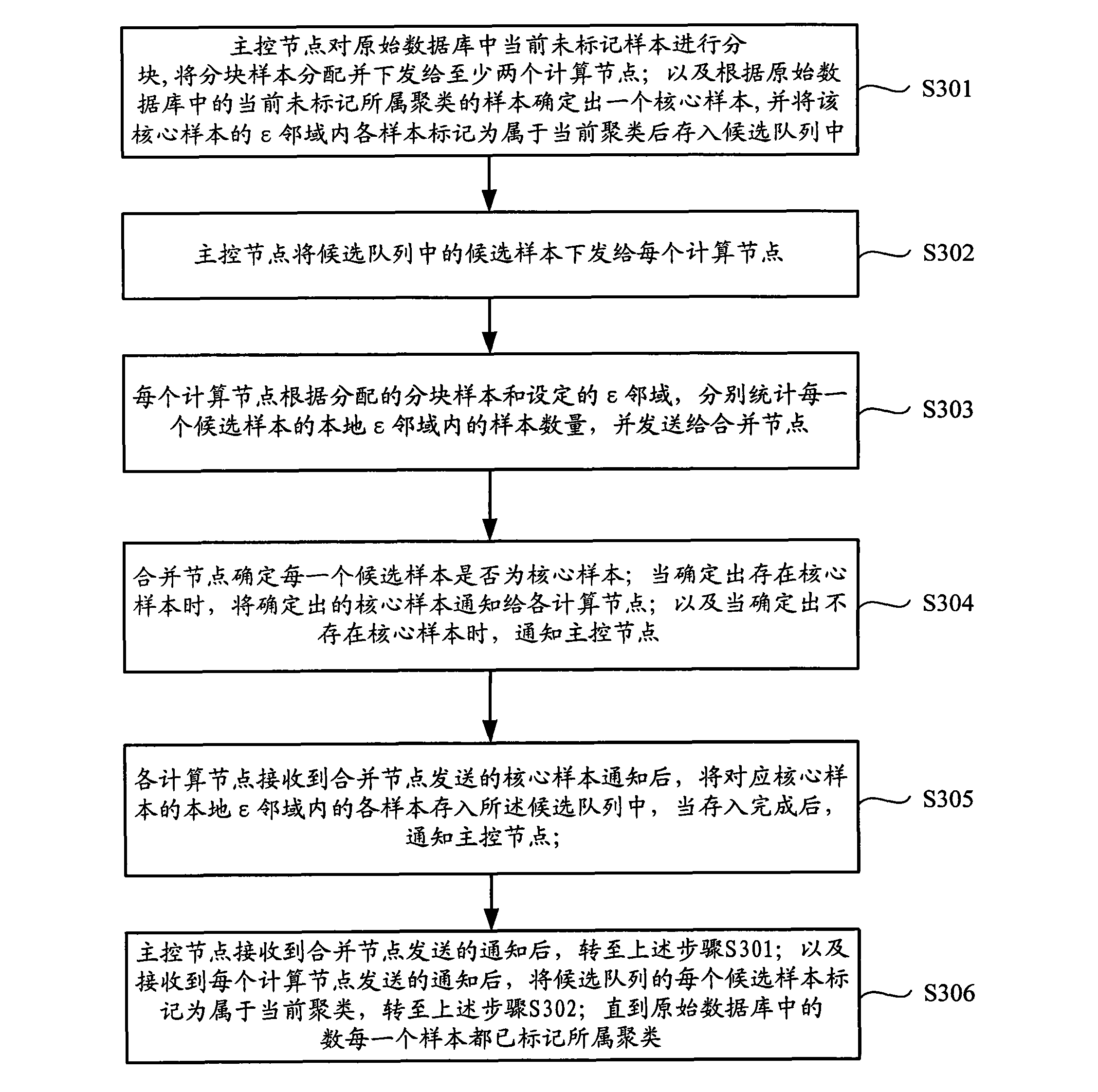

Cluster implementation method and system

ActiveCN101996198AReduce waiting timeImprove computing efficiencySpecial data processing applicationsMinimum densityAlgorithm

The invention discloses a cluster implementation method and system, wherein the method comprises the following steps: carrying out sharding on candidate samples in a candidate queue by a master control node; and respectively determining whether each sample in allocated samples subject to sharding is a core sample parallelly according to a preset epsilon neighborhood and the minimum density by at least two computing nodes, thus due to the parallel processing of the computing nodes, the marking speed of a cluster to which each sample in a sample database belongs is quickened. The invention also discloses another cluster implementation method and system, and the cluster implementation method comprises the following steps: carrying out sharding on samples which are not marked currently in a sample database by a master control node; allocating and issuing the samples subject to sharding to at least two computing nodes; carrying out parallel processing on candidate samples in a candidate queue by the computing nodes; and combining the obtained processing results of the computing nodes by merge nodes. Because each computing node only processes part of samples, the problem that mass data can not be processed by one computer is solved, and because the mass data can be subject to parallel processing by a plurality of the computing nodes and a plurality of the merge nodes, the processing efficiency is greatly improved.

Owner:CHINA MOBILE COMM GRP CO LTD

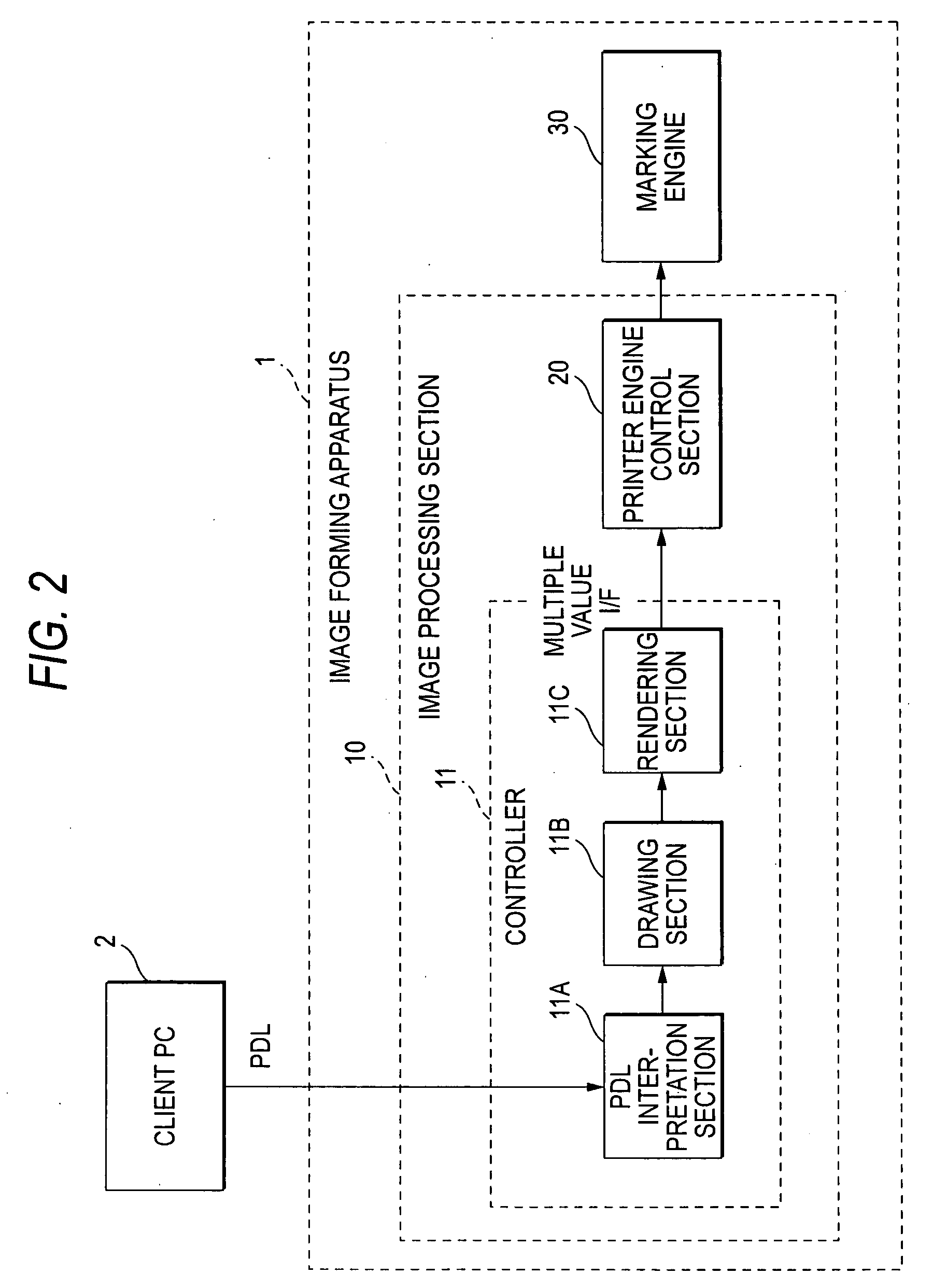

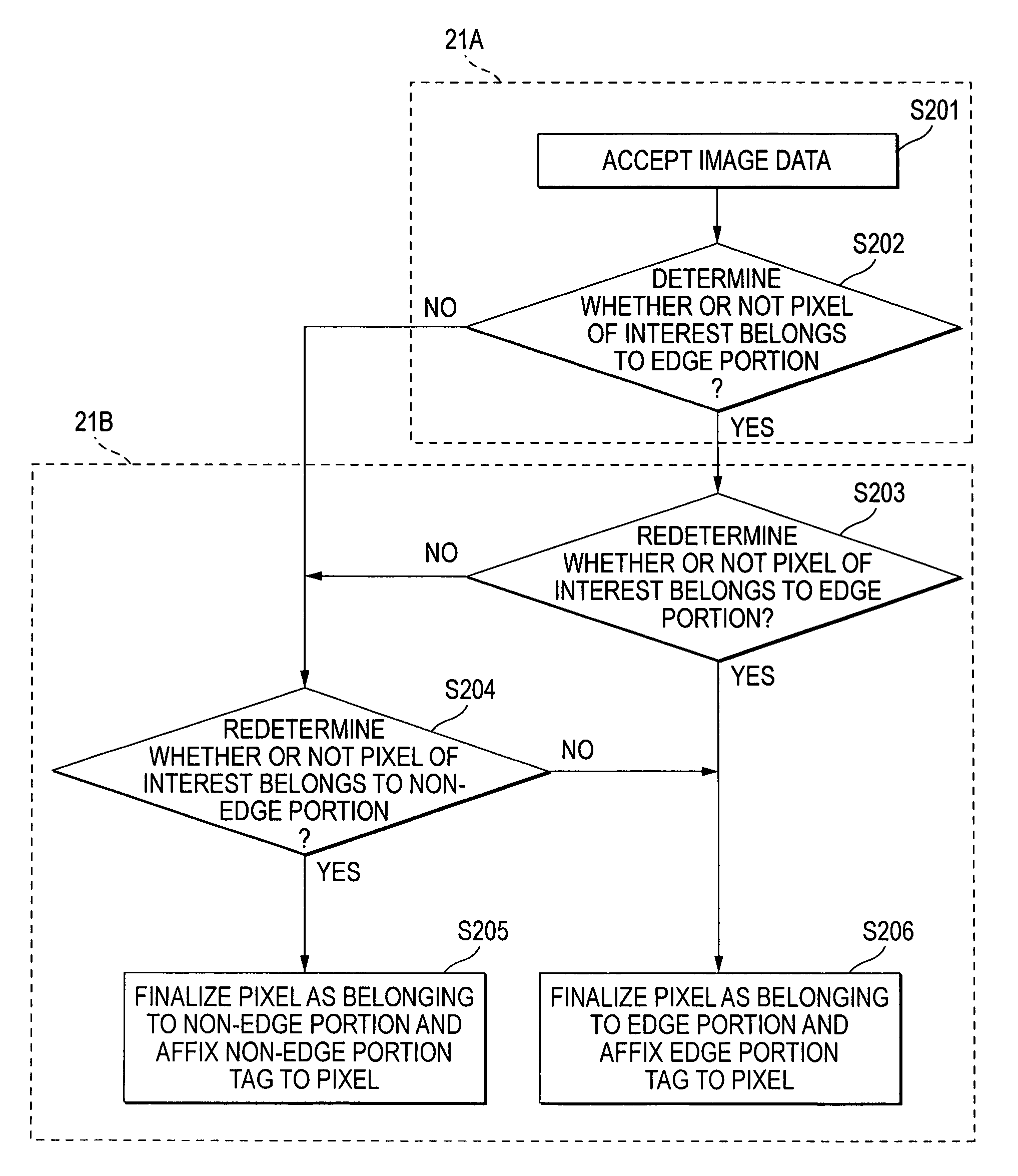

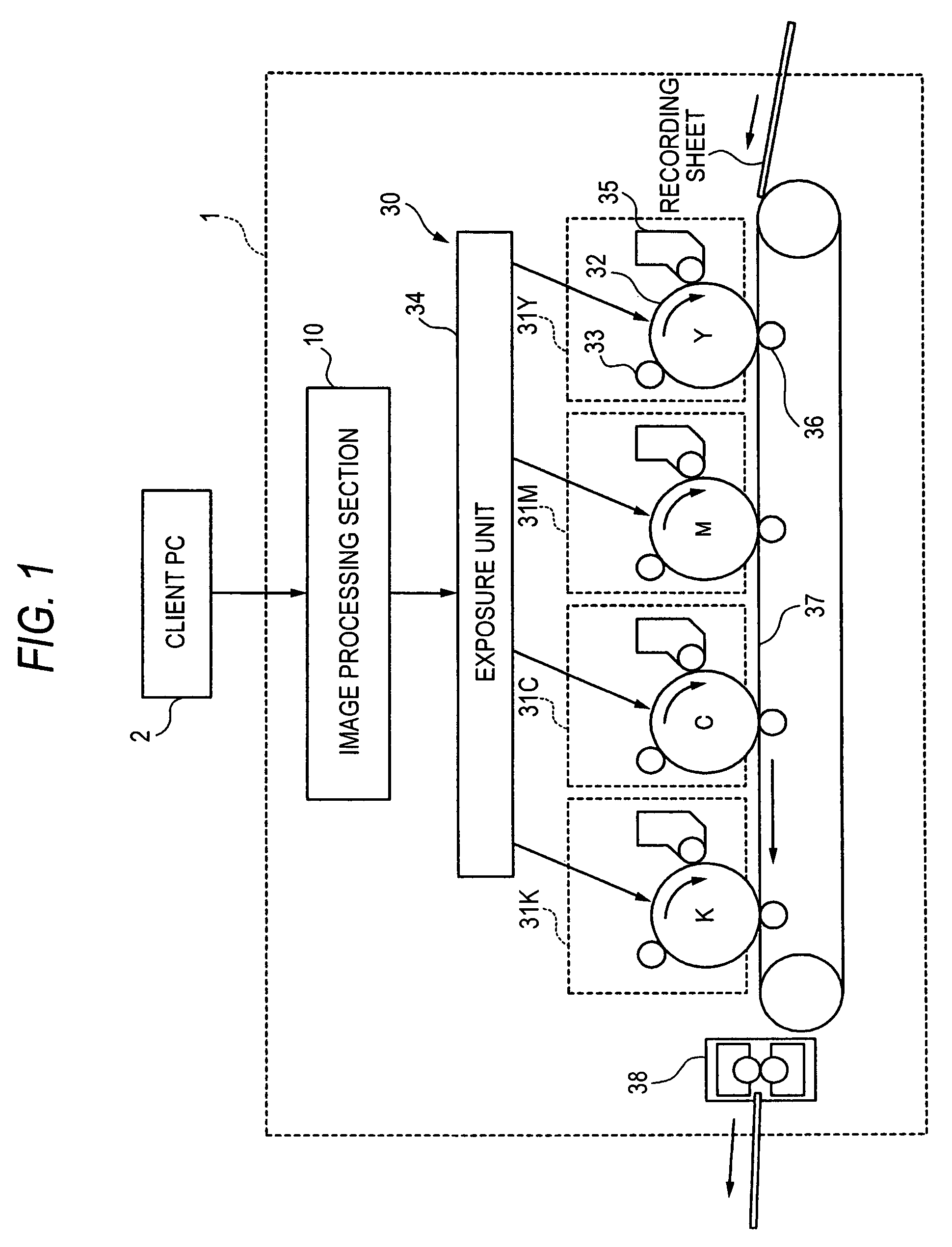

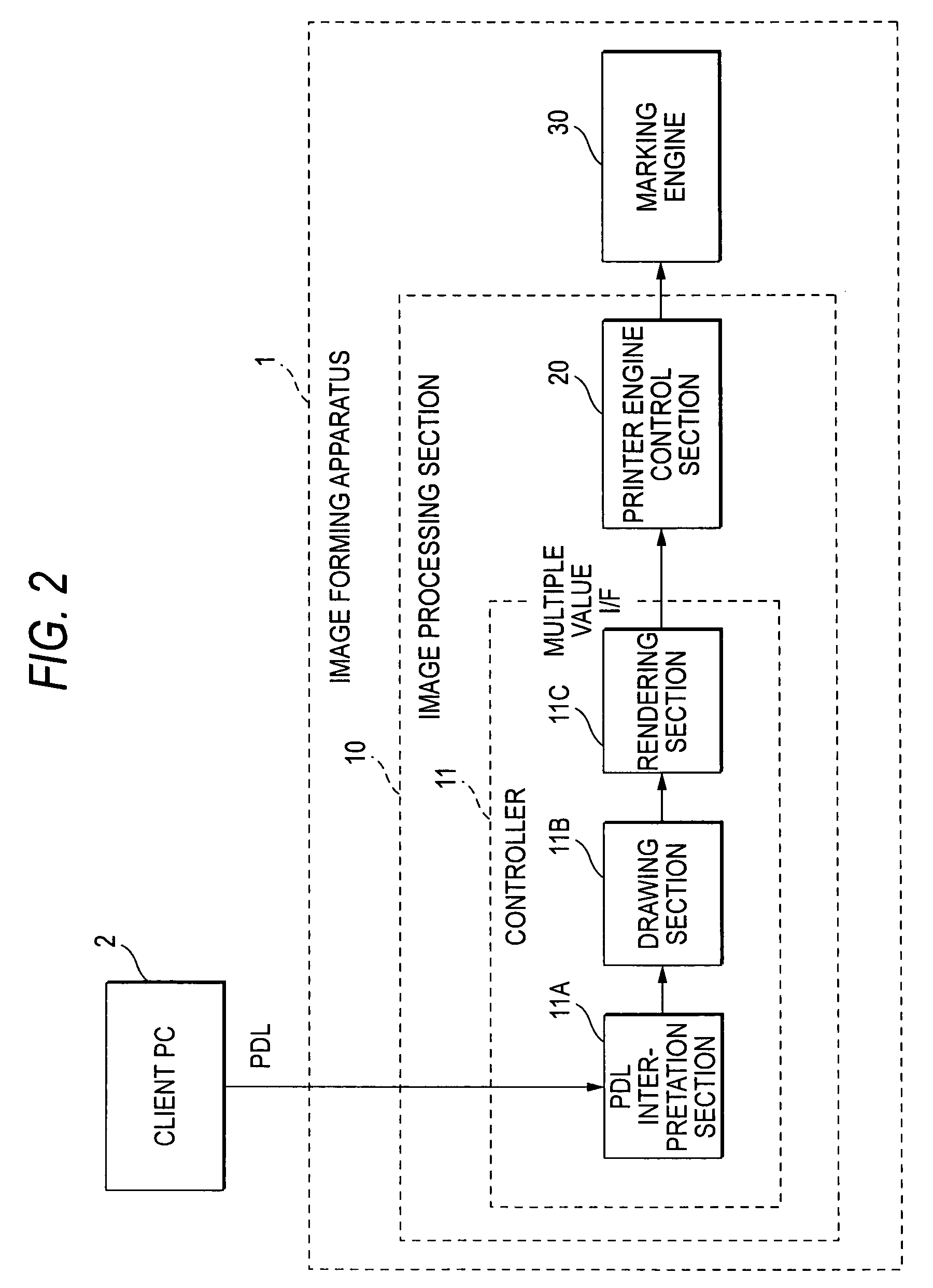

Image processing apparatus, image forming apparatus, and image processing method

InactiveUS20070273927A1Image enhancementDigitally marking record carriersImaging processingMinimum density

An image processing apparatus includes: an acceptance section; an edge detection section; and a screen processing section, wherein the edge detection section includes: a first edge determination section that subjects a pixel of interest to edge determination by reference to information about a density of the pixel of interest and information about densities of pixels around the pixel of interest determined by an edge detection window; and a second edge determination section that compares minimum density information among the information about densities of pixels determined by the edge detection window with a predetermined background threshold value, and that redetermines the pixel of interest, which is determined to belong to an edge portion by the first edge determination section, as belonging to anon-edge portion in cases where the minimum density is equal to or greater than the background threshold value.

Owner:FUJIFILM BUSINESS INNOVATION CORP

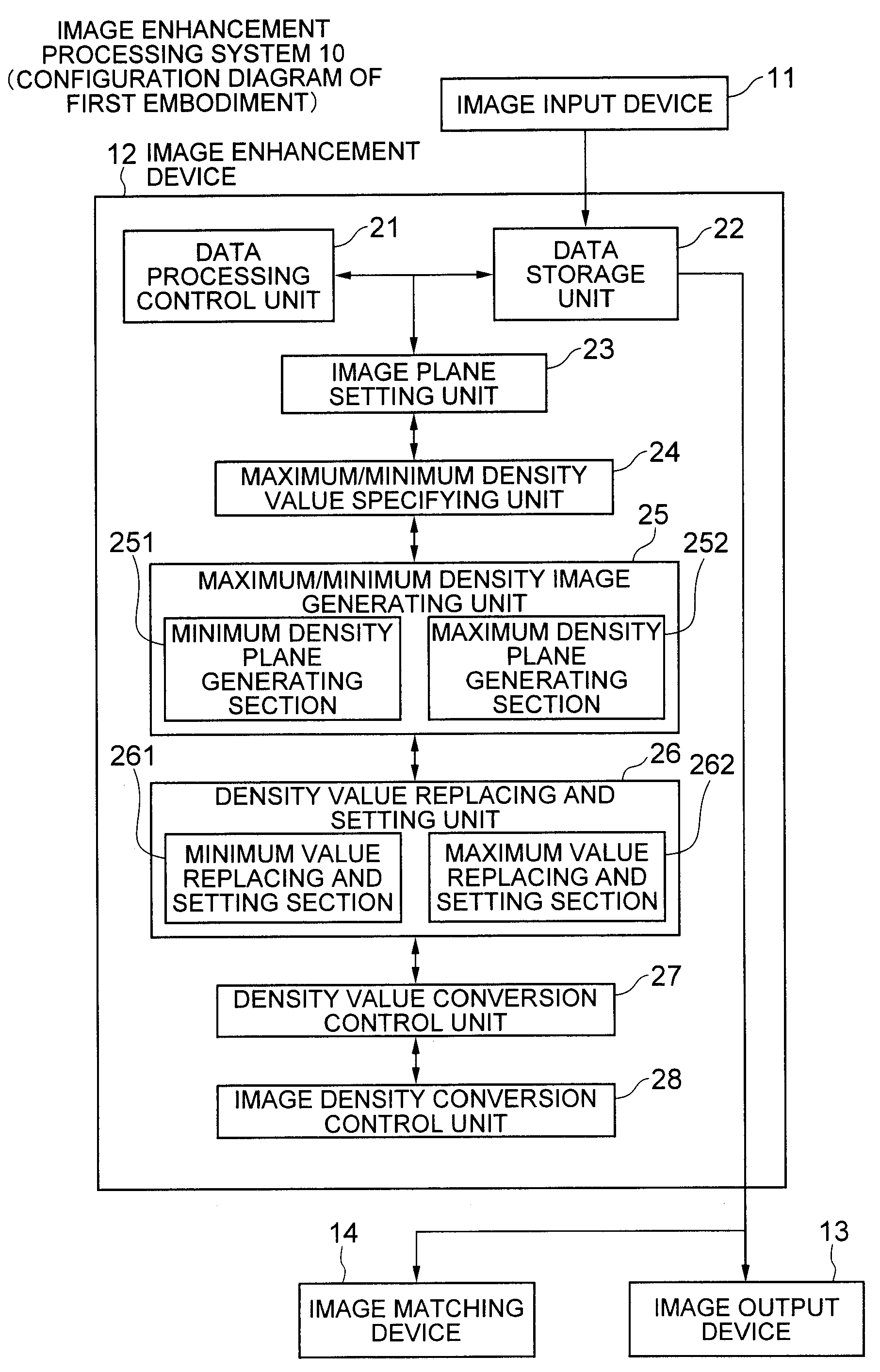

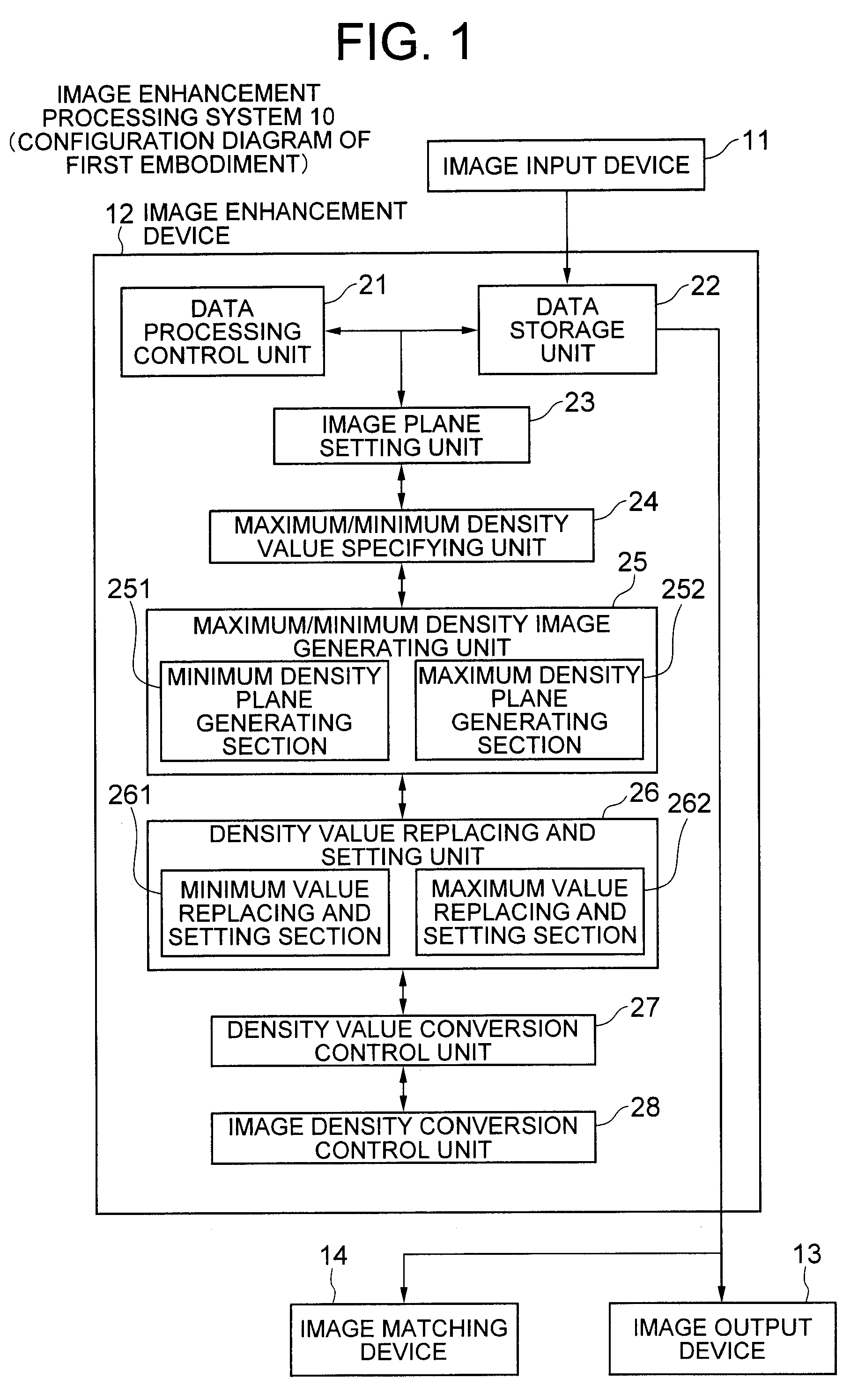

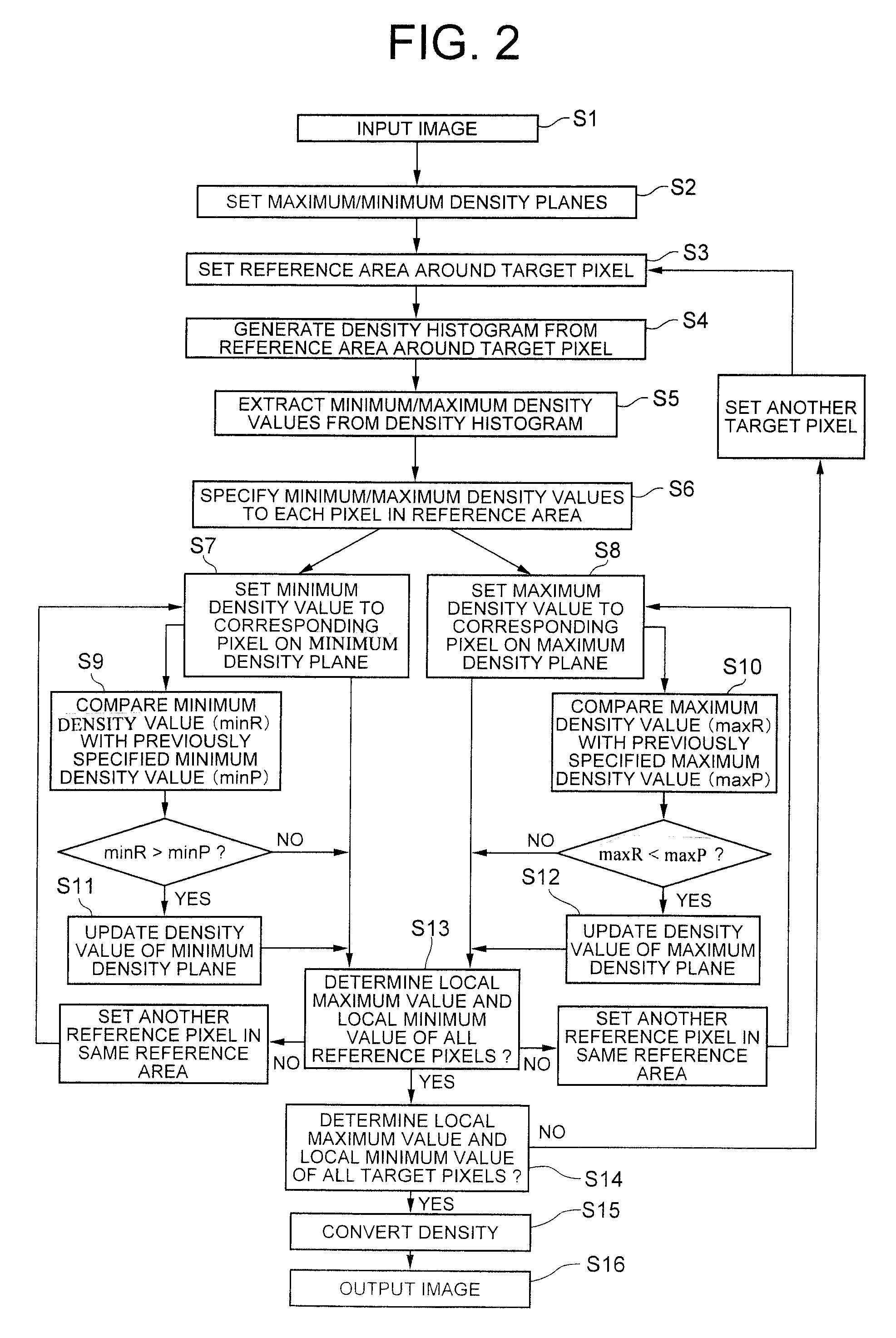

Image density conversion method, image enhancement processor, and program thereof

ActiveUS20080050030A1Remove background noiseImproves fingerprint matching accuracyImage enhancementCharacter recognitionValue setPixel density

Areas, allowed to overlap, are set for respective pixels in an image, and a maximum density value and a minimum density value, among inherent density values of the pixels in each area, are extracted and specified as maximum and minimum density values common to the pixels in the area. Among the density values specified from the overlapping areas, the largest minimum density value is set as a local minimum value and the smallest maximum density value is set as a local maximum value to thereby generate a minimum density plane and a maximum density plane including the pixels having the values. The density values of the pixels at the corresponding positions in the minimum density plane and the maximum density plane are corresponded to the common minimum and maximum values set separately, to thereby linearly convert the whole. Thereby, the pixel density values of the original image are linearly converted simultaneously.

Owner:NEC CORP

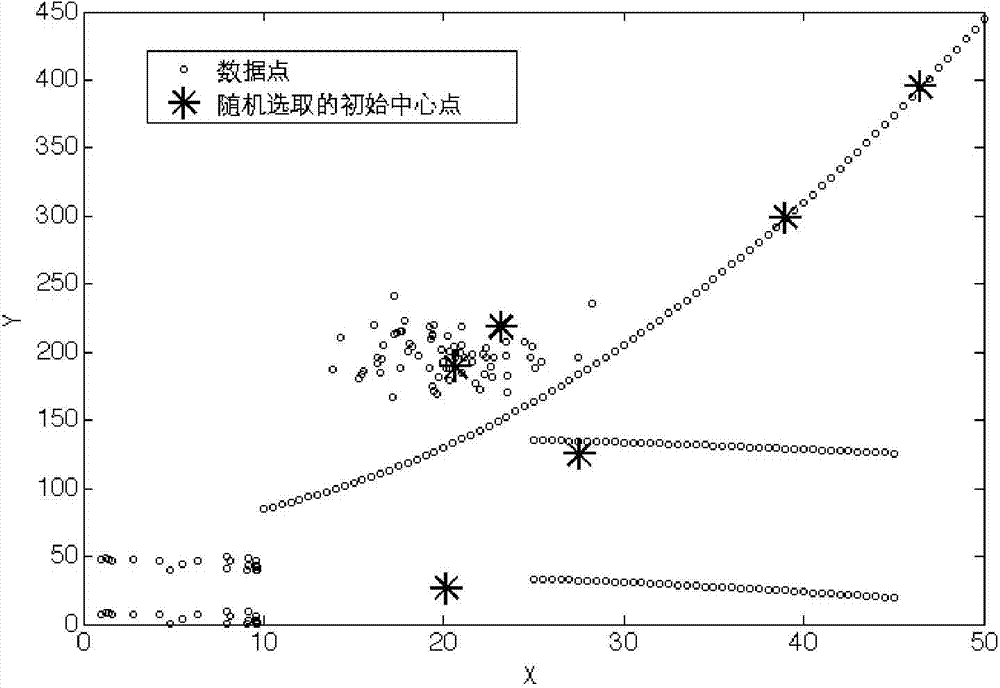

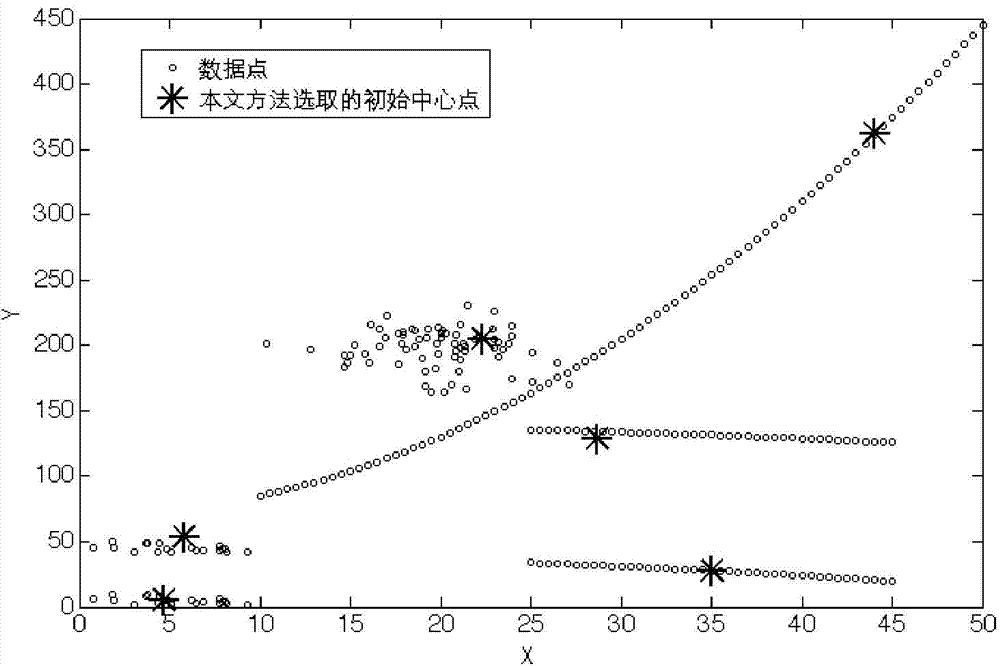

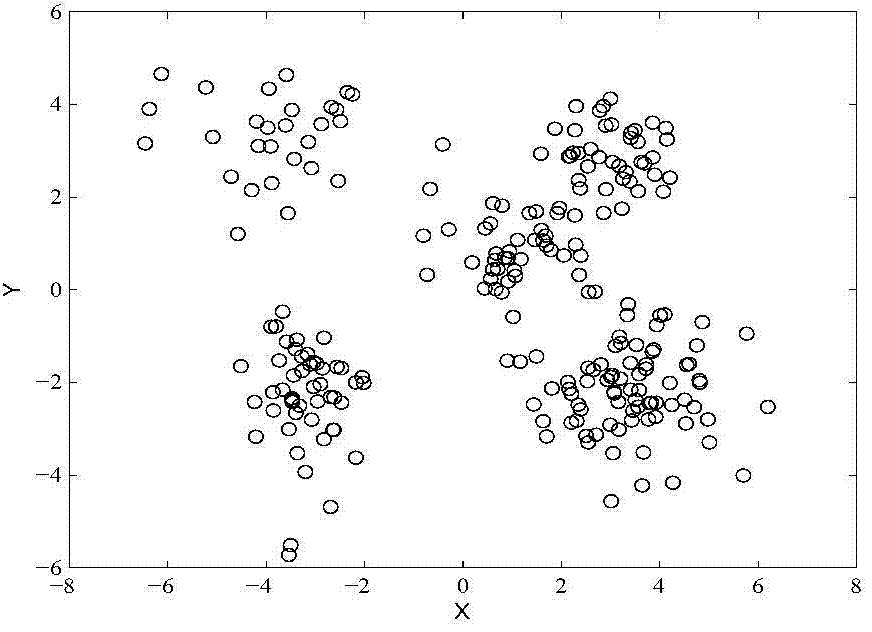

Density-based partitioning and clustering method for K center points in data mining

InactiveCN104765879AImprove accuracySmall distance valueSpecial data processing applicationsComputation complexityMinimum density

The invention relates to a density-based partitioning and clustering method for K center points in data mining. The method comprises the following steps that 1, a needed data set is given, and the clustering number K is determined; 2, the densities and average density of data objects are calculated; 3, the minimum density distance value of each data object in the data set is calculated; 4, the minimum density distance values of the data objects in the data set are descendingly sorted, and K data objects corresponding to the minimum density distance values are selected as a clustering center from large to small according to the determined clustering number K, wherein the densities of the K data objects are larger than the average density; 5, the data objects in the data set are distributed to an initial clustering center closest to the data objects, and a clustering result is obtained. The high-quality center points can be selected, subsequent iteration updating steps in a K-means algorithm are not needed, computation complexity is lowered, classification accuracy is improved, high stability is achieved, and operation efficiency is improved.

Owner:无锡中科泛在信息技术研发中心有限公司

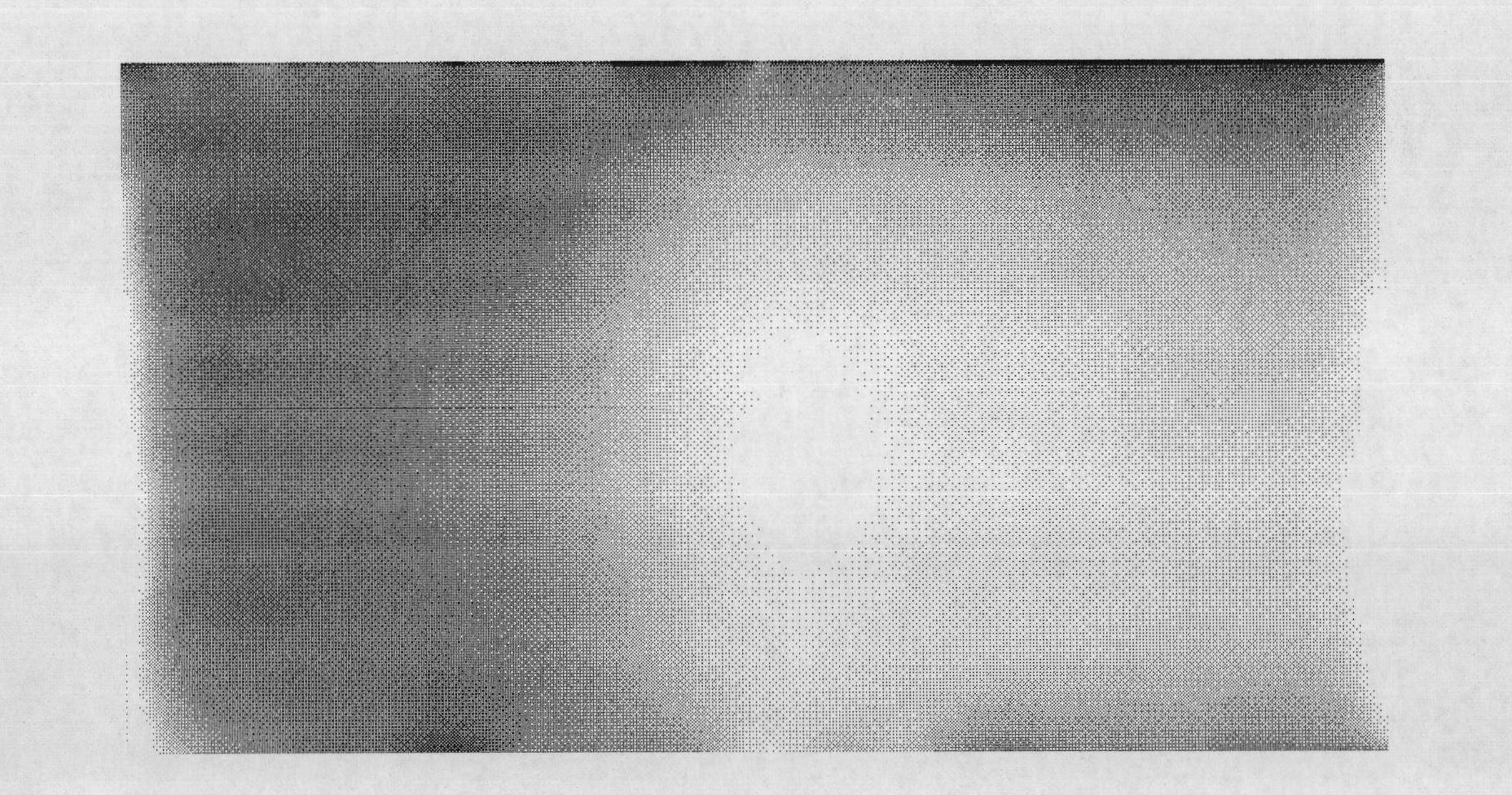

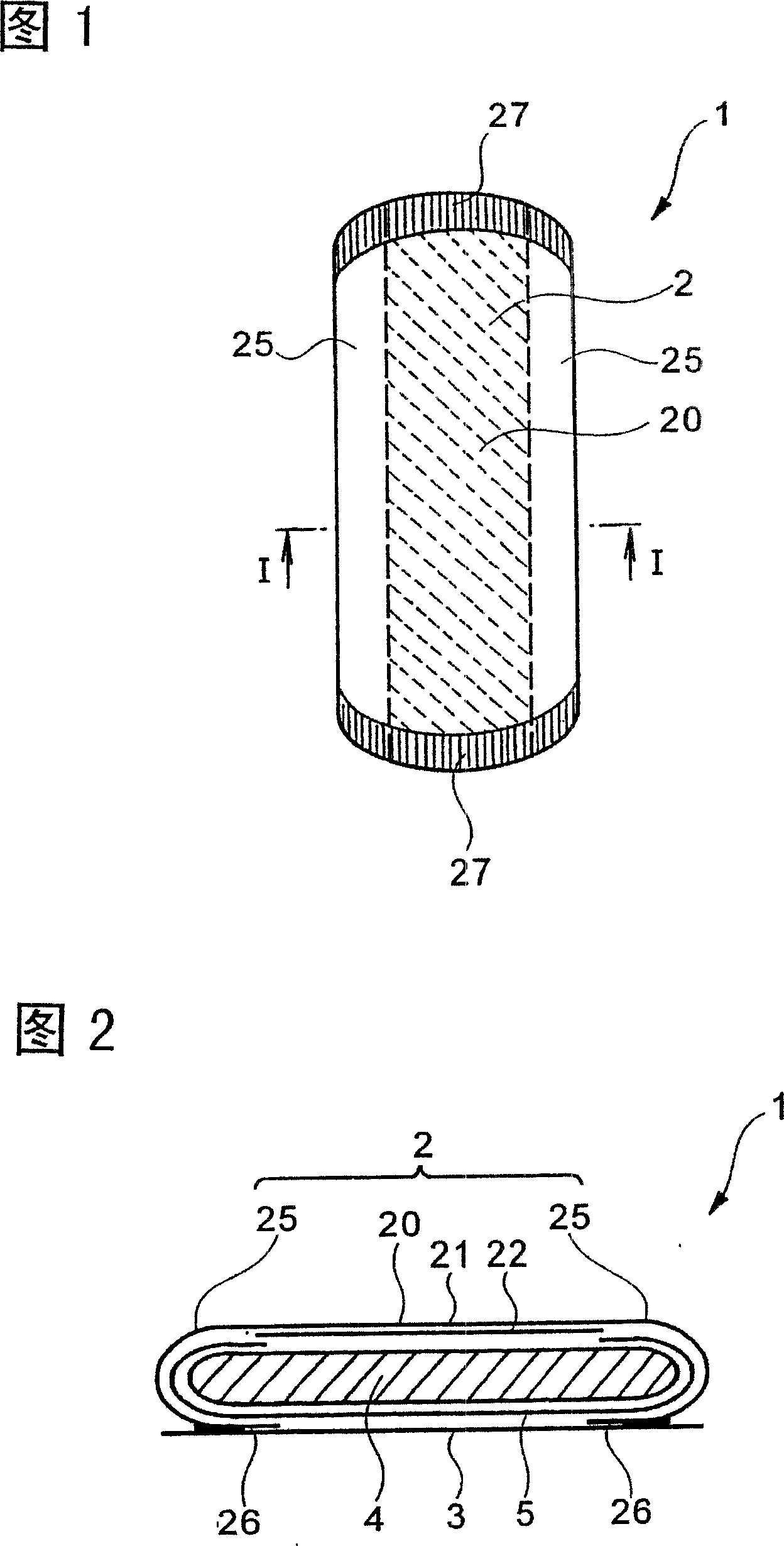

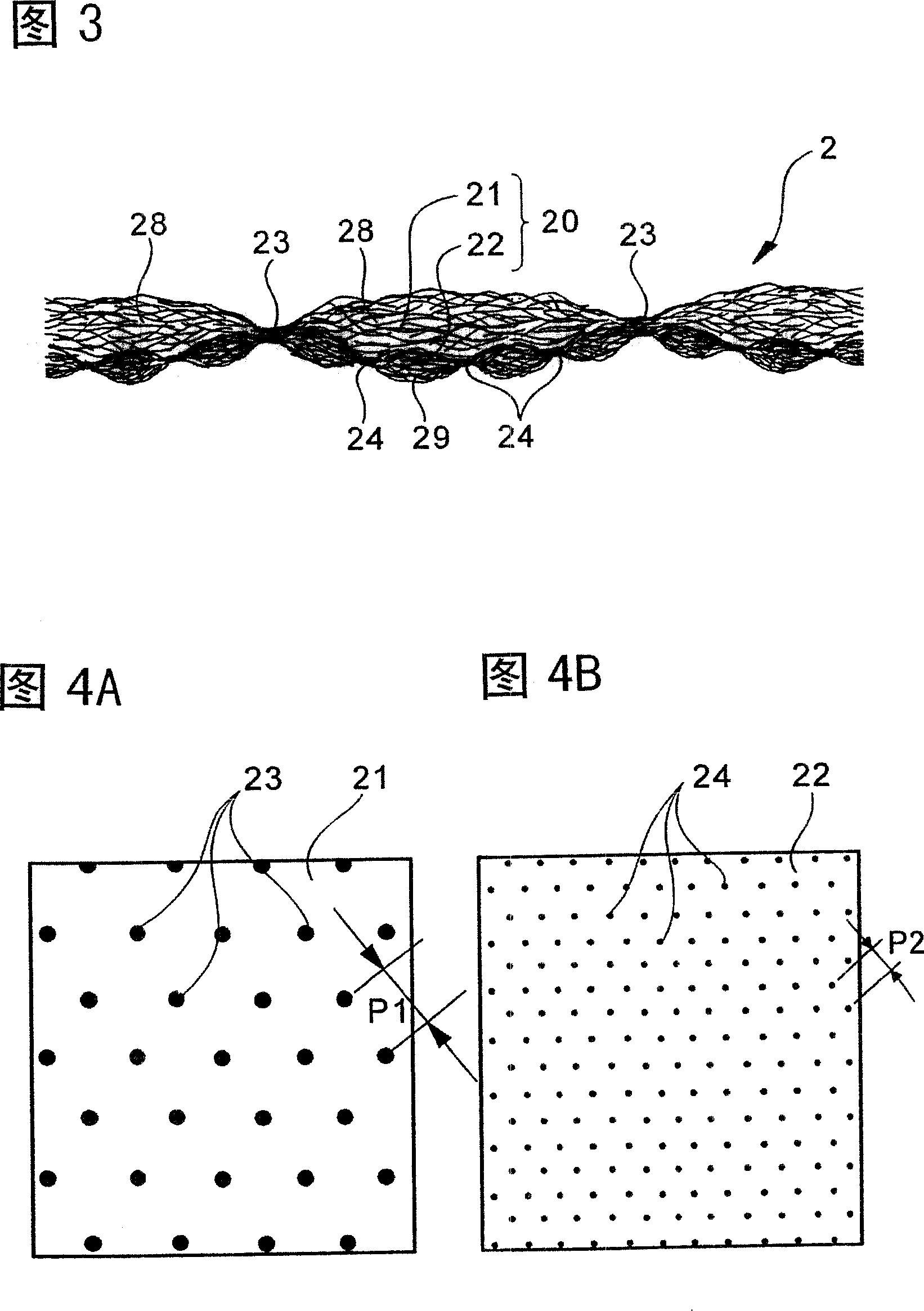

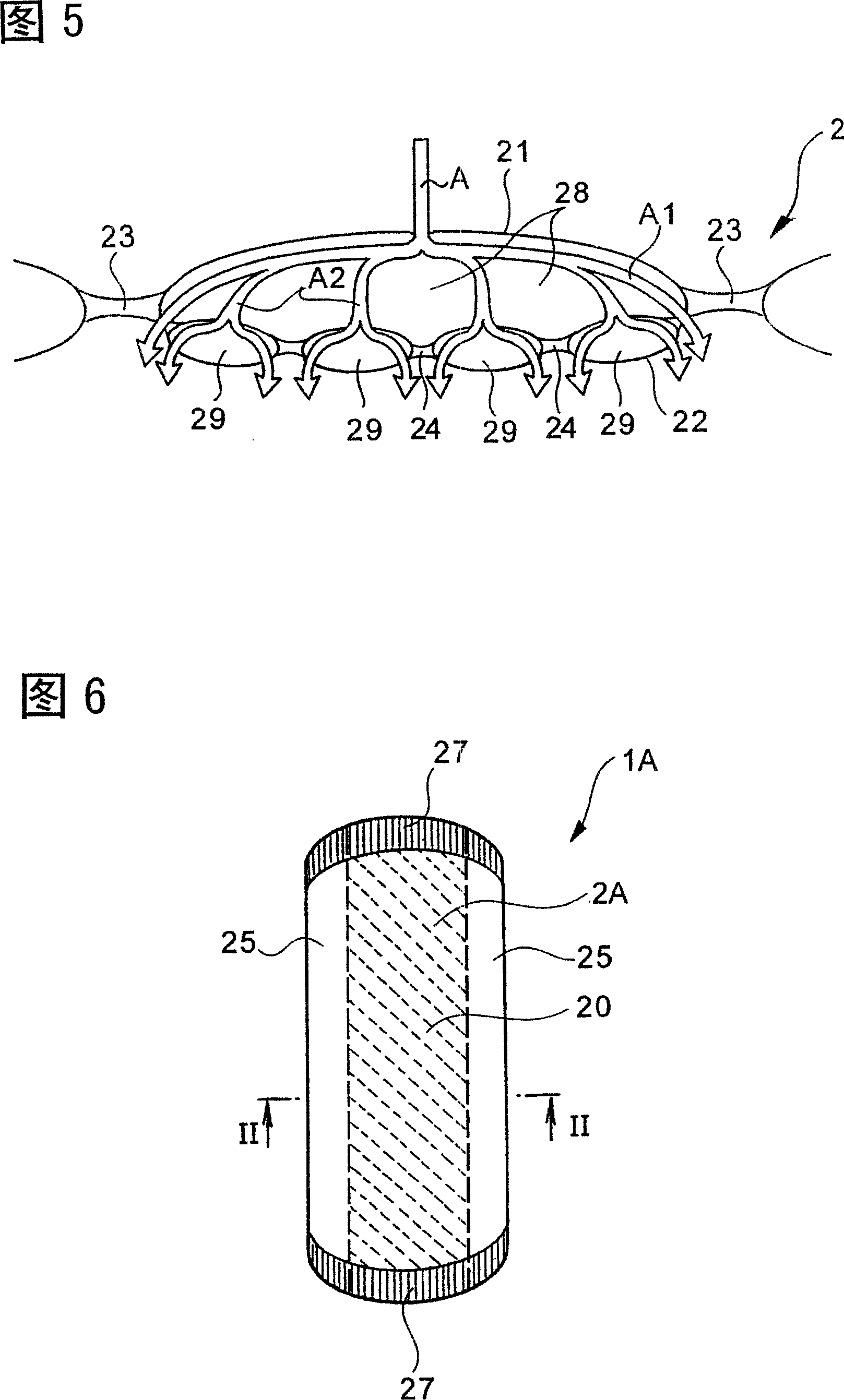

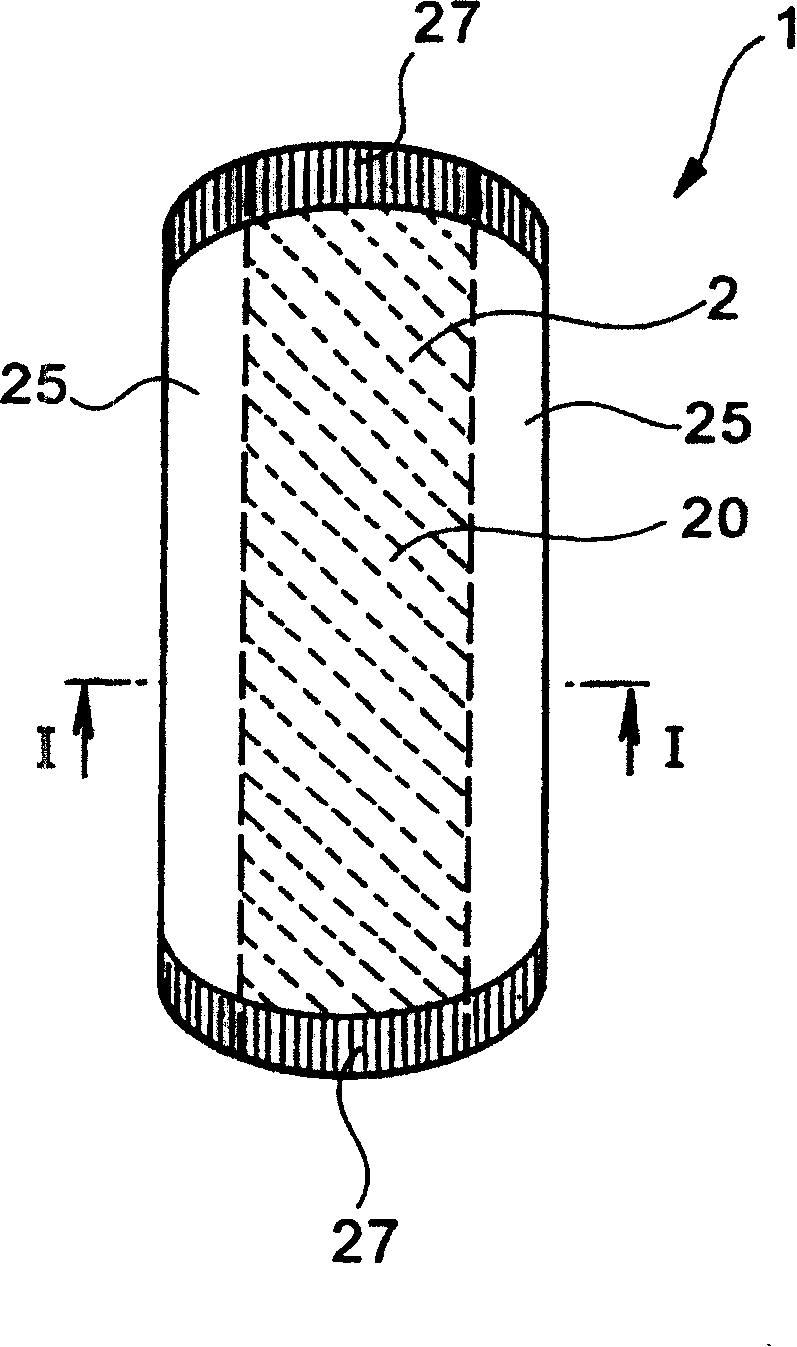

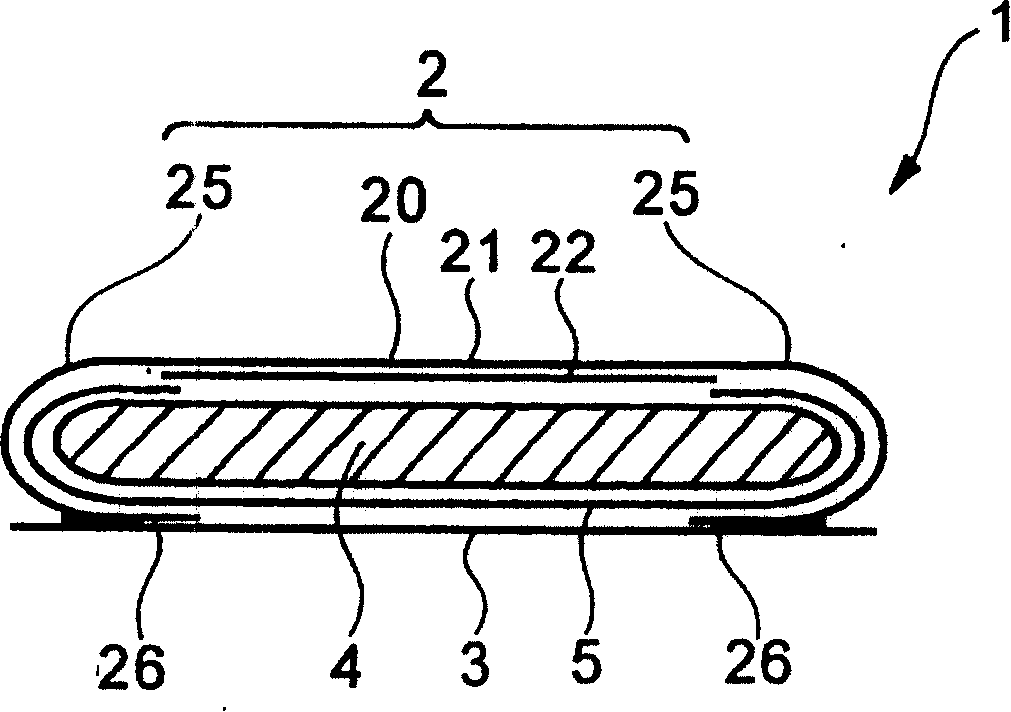

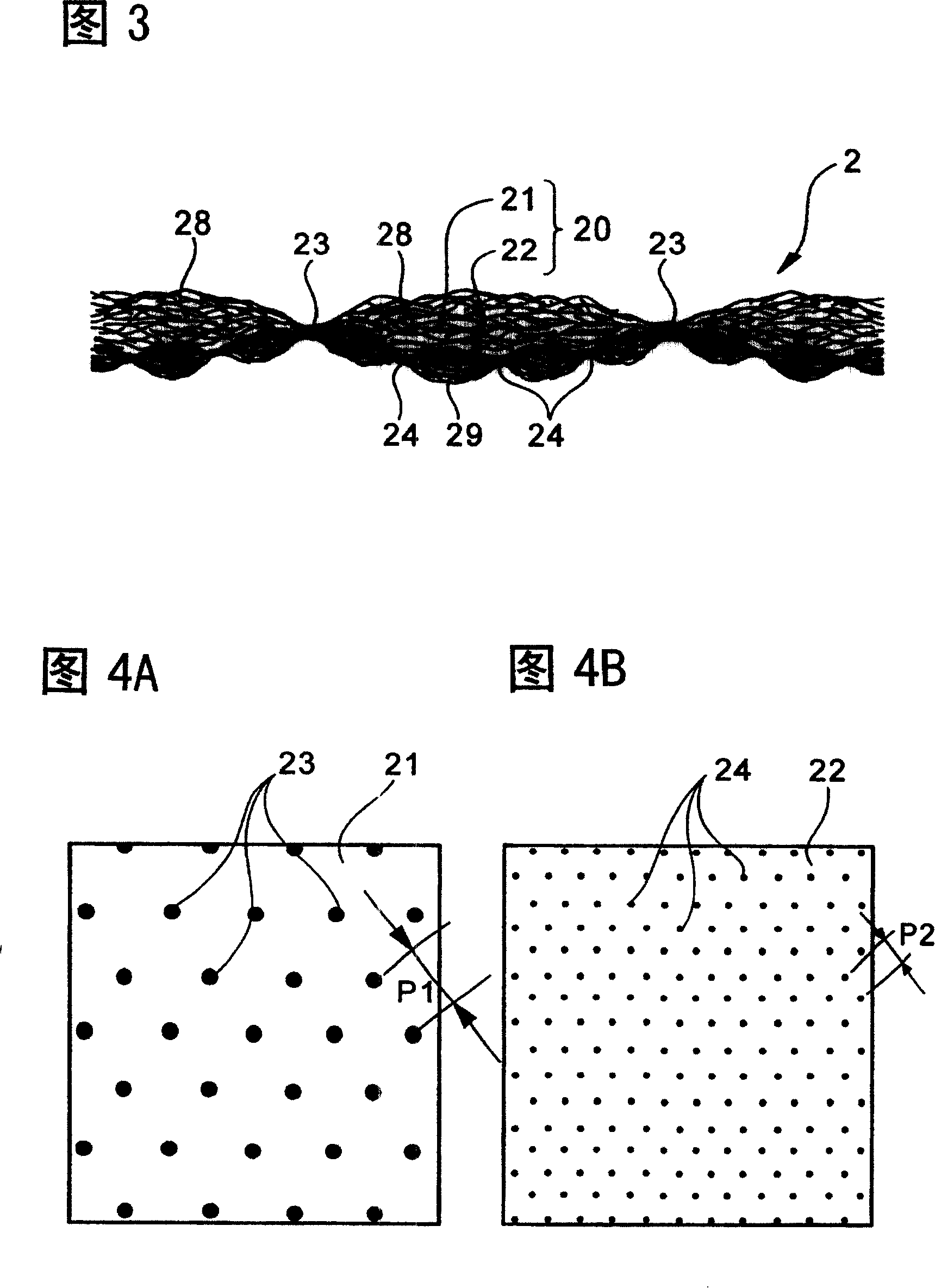

Surface sheet absorbent article and absorbent article

A topsheet of an absorbent article having a laminated nonwoven fabric composed of an upper layer (21) disposed on the skin side and a lower layer (22) disposed on the absorbent member side. The nonwoven fabric has a large number of sheet compressed parts (23) formed by compression joining the upper layer (21) and the lower layer (22) and a large number of lower layer compressed parts (24) positioned between the sheet compressed parts (23) and formed by compressing the lower layer (22). The minimum density of the substantially non-compressed area (29) of the lower layer (22) is equal to or higher than that of the substantially non-compressed area 28 of the upper layer (21).

Owner:KAO CORP

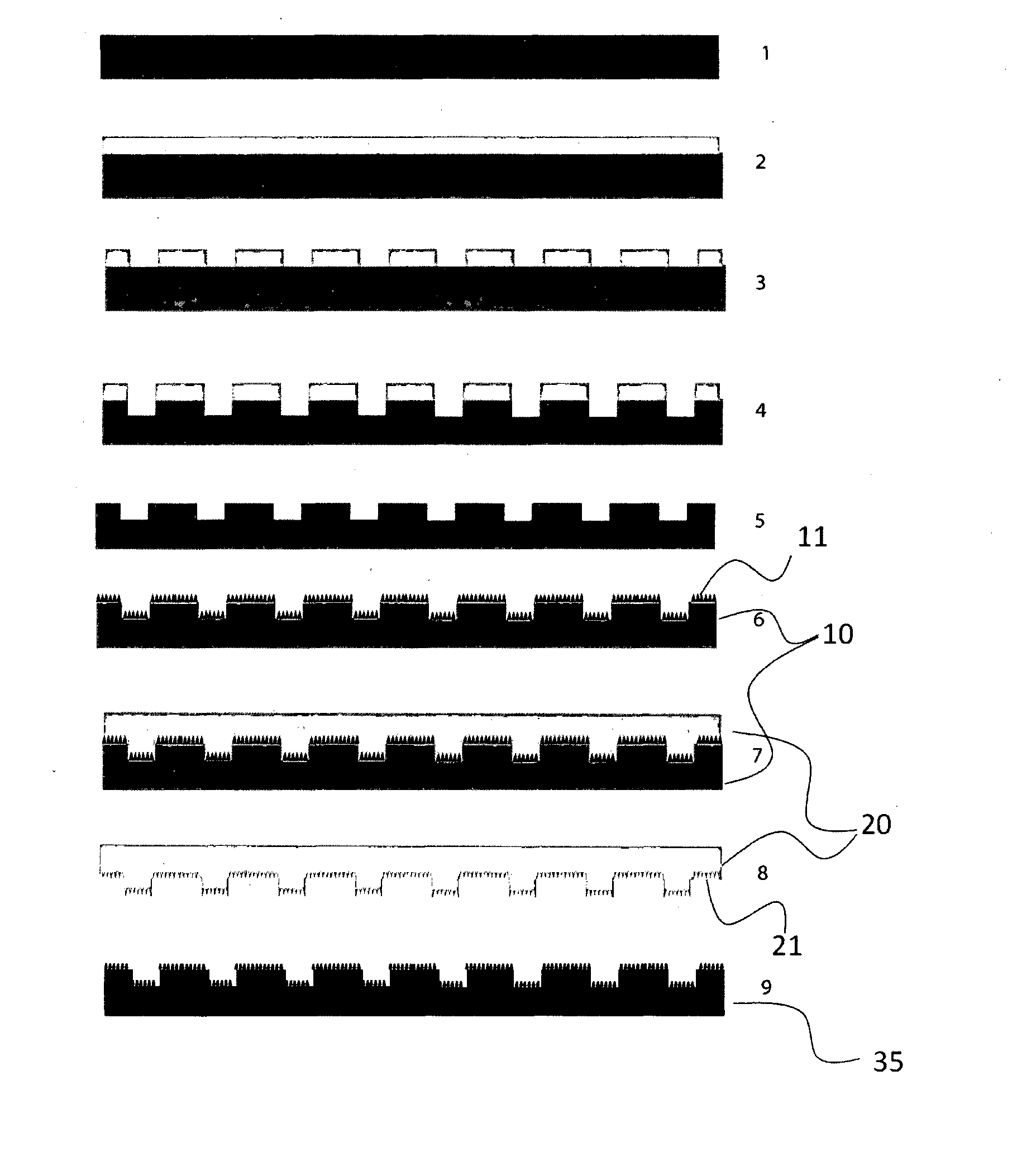

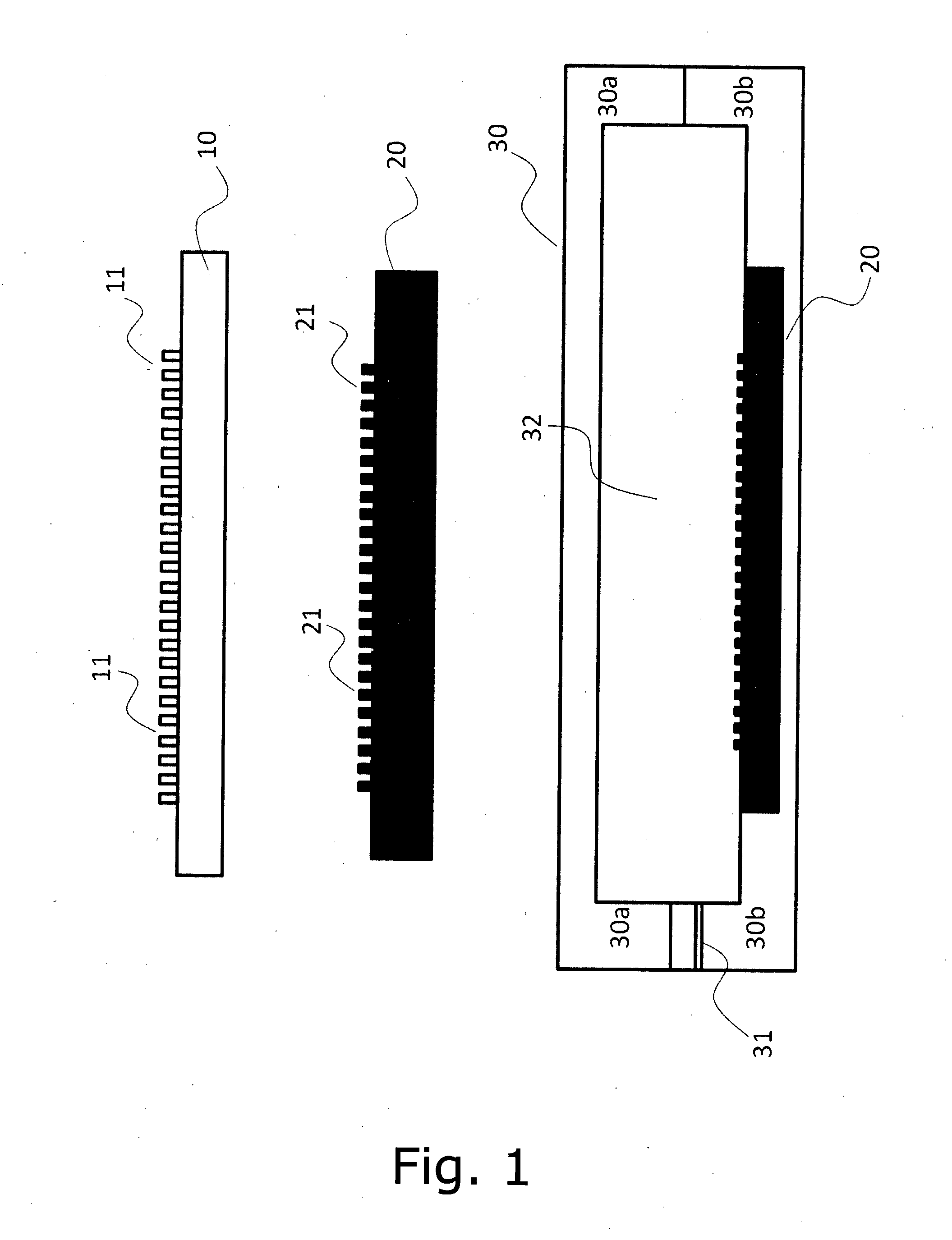

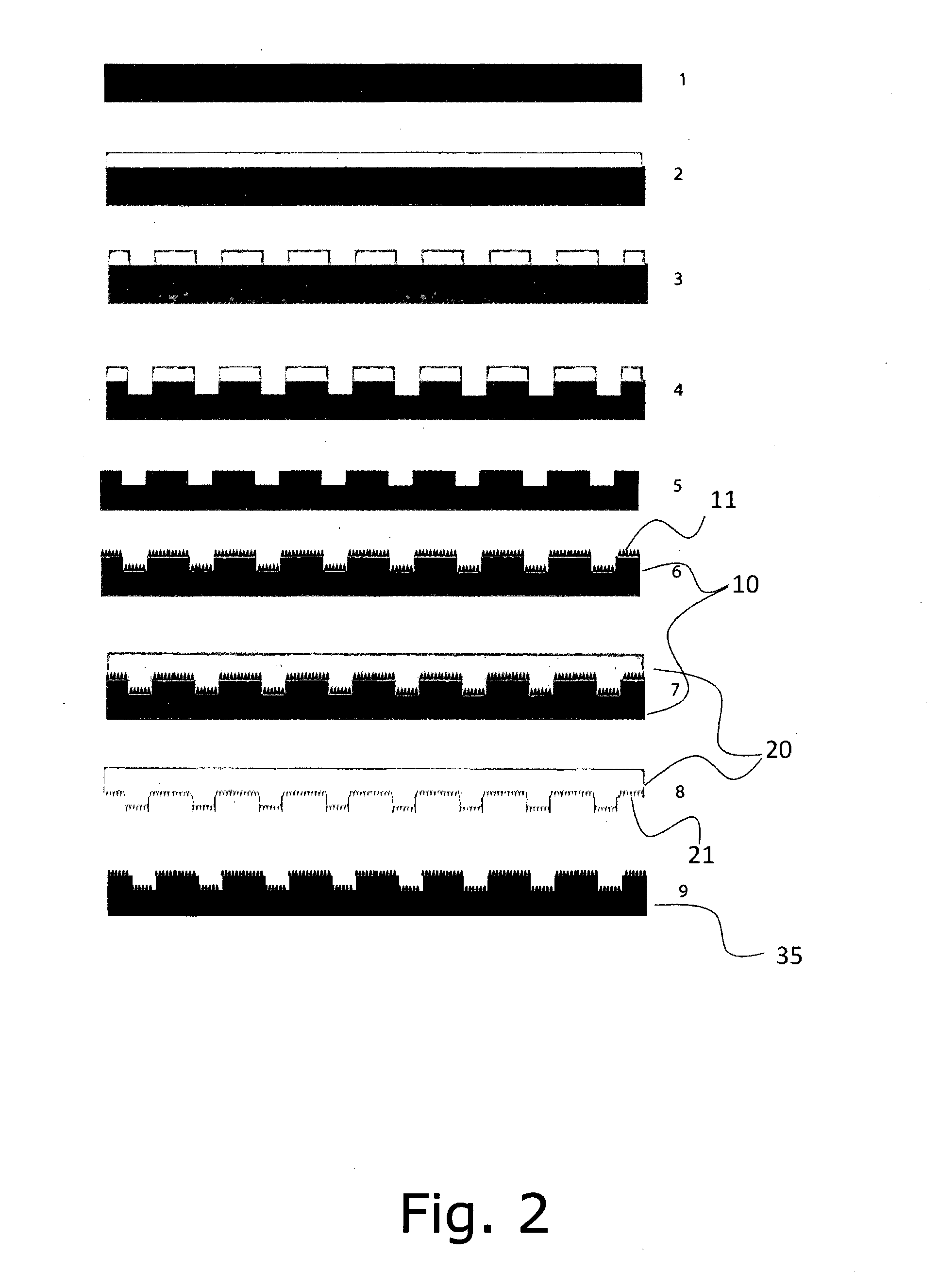

Method for manufacturing a tool part for an injection molding process, a hot embossing process, a nano-imprint process, or an extrusion process

InactiveUS20150026952A1Easy to understandFaster and less complex to implementNanoinformaticsPhotomechanical apparatusVolumetric Mass DensityEngineering

The present invention relates to a method for manufacturing a tool part for an injection molding process, a hot embossing process, nano-imprint process or an extrusion process. First, there is provided a master structure (10) with a surface area comprising nanometre-sized protrusions (11) with a minimum density of approximately 105 protrusions / mm2, the protrusions being positioned in a non-periodic, irregular pattern, said protrusions being created by a process comprising alternating passivation and etching into the master structure. Secondly, there is made a transfer of the master structure into a metal insert (20), the metal insert having a corresponding nanometre-sized pattern (21) from said protrusions, and thirdly, adapting the metal insert into a tool part (30) for enabling nanometre-sized patterns being formed by the tool part. The invention provides an easier and faster way of manufacturing the master structure, e.g. a black silicon wafer. It is a further advantage of the present invention that it provides an advant ageous way of making tools capable of producing self-cleaning surfaces without the need for chemical coating.

Owner:DANMARKS TEKNISKE UNIV +1

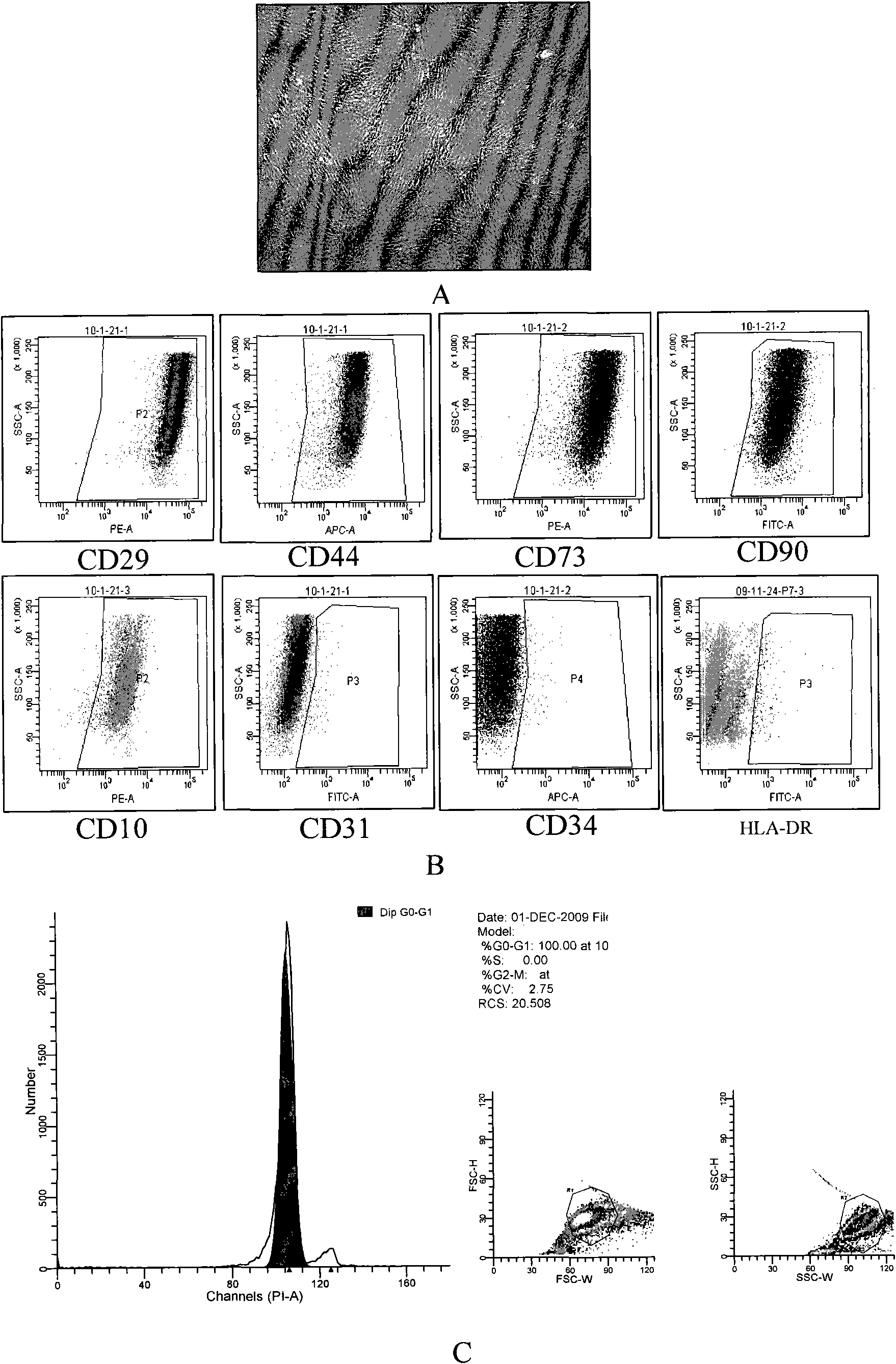

Method for amplifying mesenchymal stem cells of human umbilical cord and placenta in vitro

ActiveCN101831403AActivity without lossHigh puritySkeletal/connective tissue cellsSingle cell suspensionDigestion

The invention discloses a method for amplifying mesenchymal stem cells of a human umbilical cord and a human placenta in vitro. The method comprises the following steps of: using human umbilical cord and placenta as a cell source; digesting tissues by using II type collagenase, centrifuging the product the digestion; removing supernate in the product of the centrifugation; washing the remaining product of the centrifugation by using D-Hank's liquid for three times to obtain single cell suspension; inoculating the single cell suspension in a culture plate or a culture flask; fully replacing the liquid when cell (P0) are adhered after 24 to 72 hours; when 80 to 90 percent of cells are mixed, performing subculture once (P1); inoculating the cells in a roller bottle according to a minimum density of 1,400 cells per cubic centimeter; comparing the growing status, cell amplification time and colony-forming capability of the mesenchymal stem cells between different culture systems to obtain an efficient and stable amplification culture system; and amplifying the mesenchymal stem cells in a large scale in the roller bottle by using the optimal amplification system.

Owner:UNION STEMCELL & GENE ENG +1

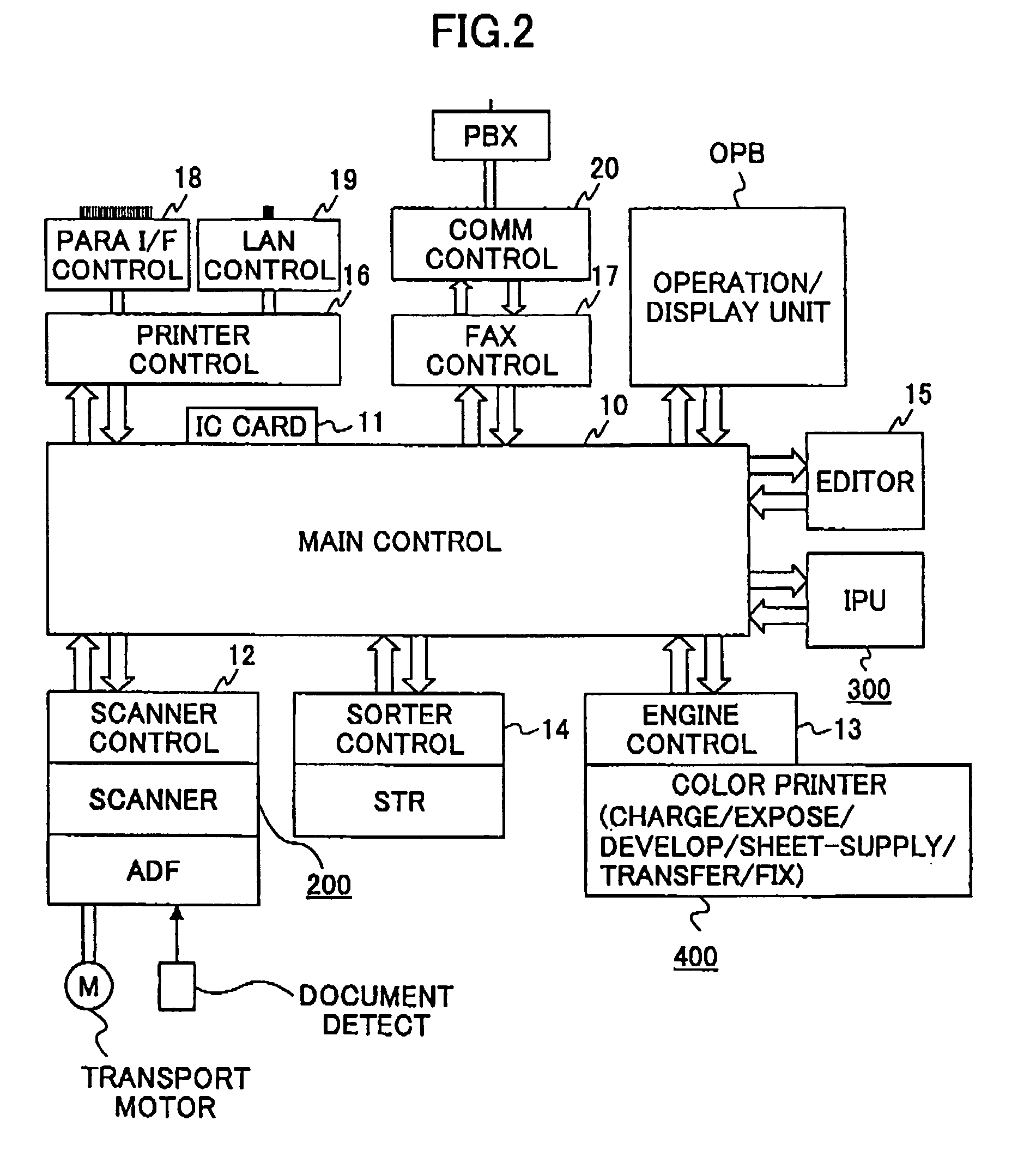

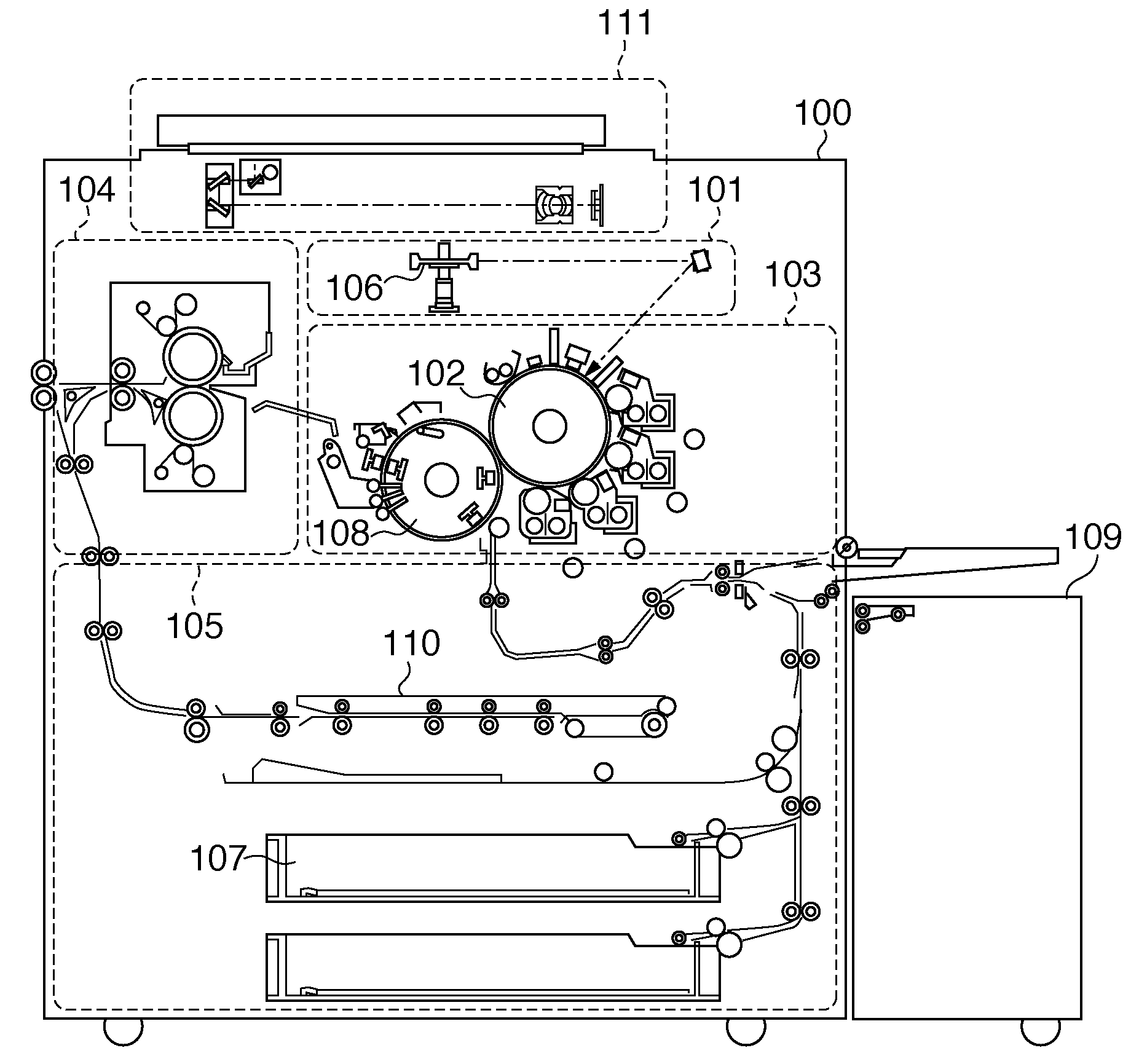

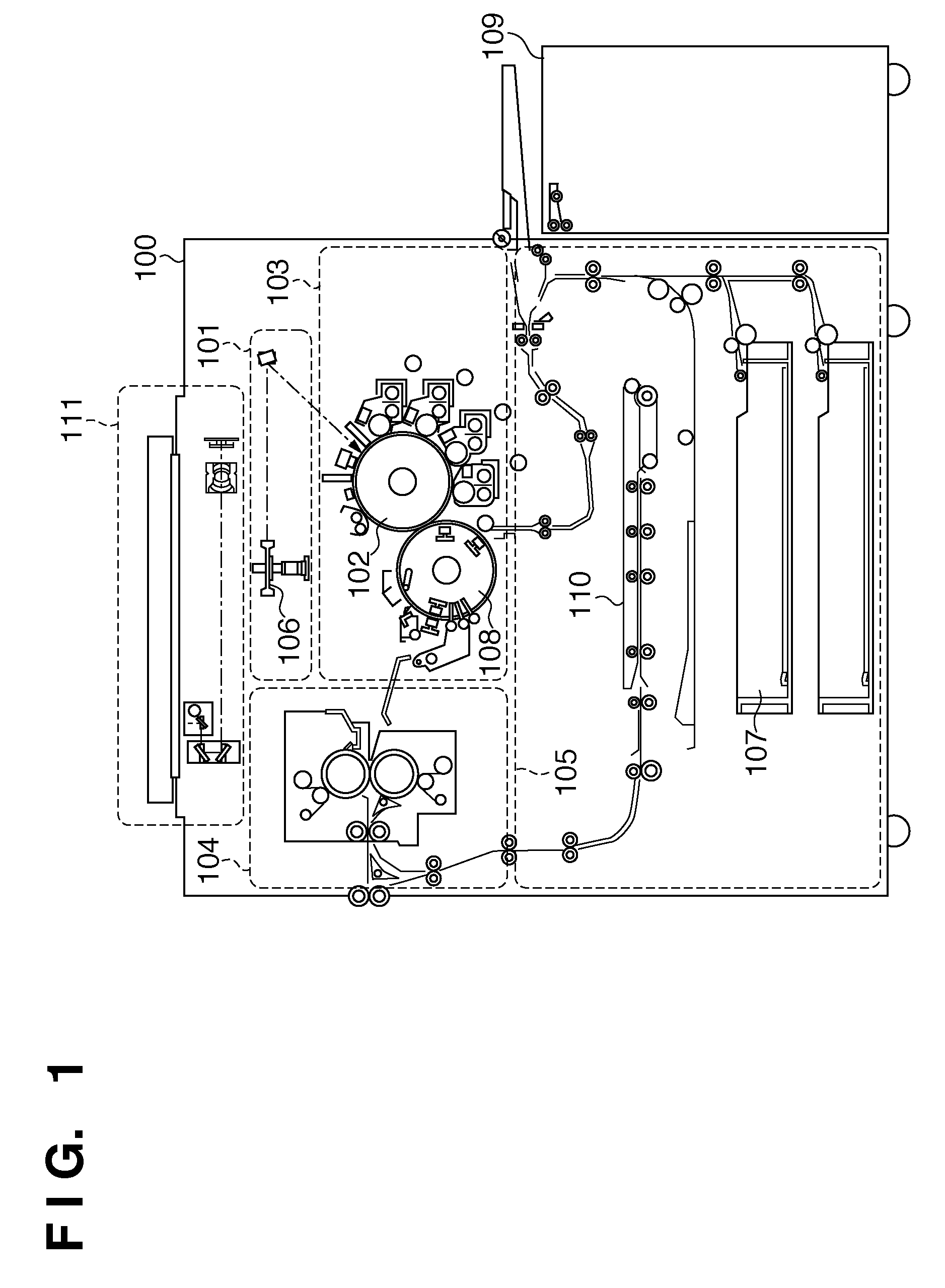

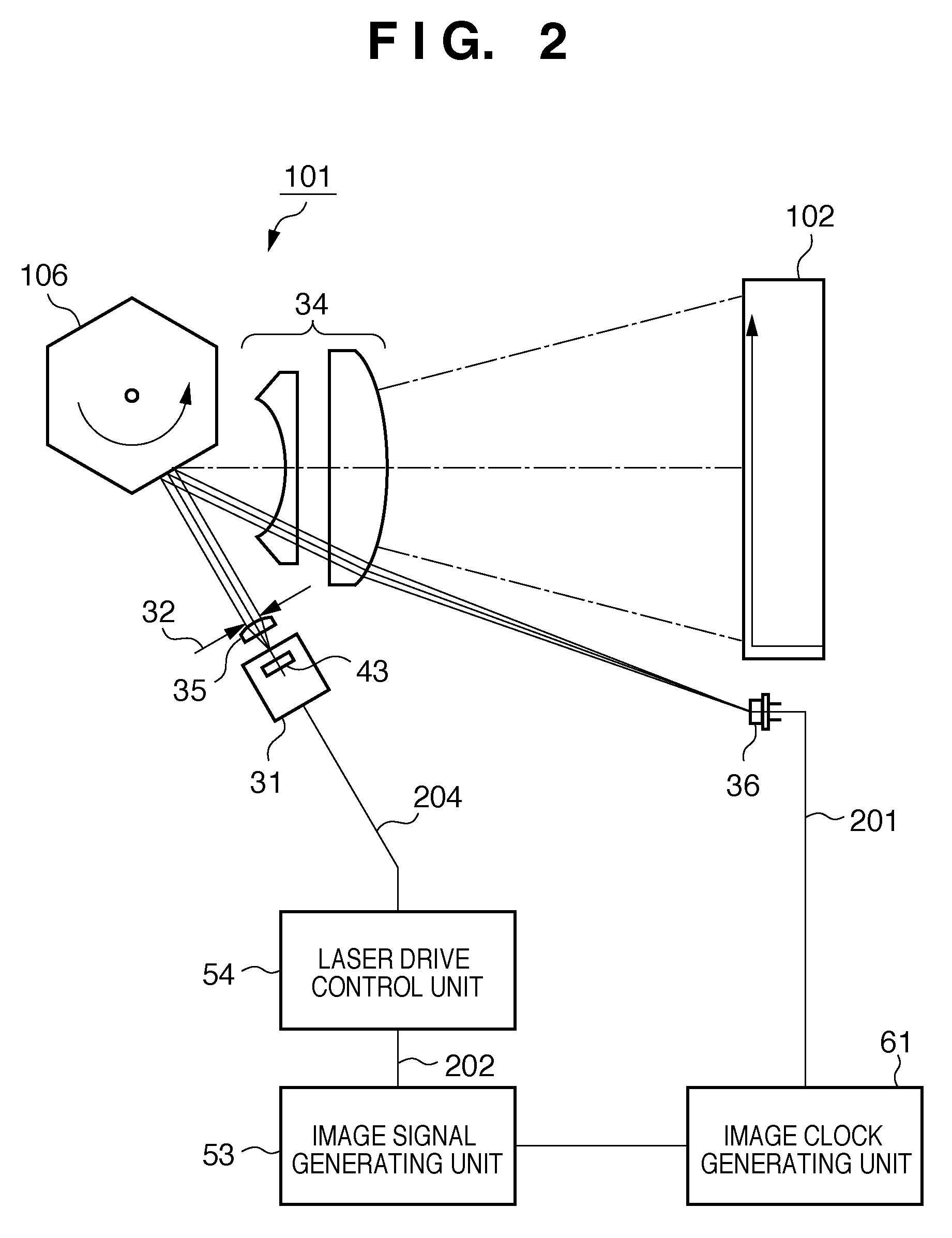

Image forming apparatus, scanning optical apparatus, and control methods thereof

InactiveUS20090016774A1Extended control timeImprove accuracyElectrographic process apparatusMinimum densityImage formation

The present invention provides an image forming apparatus that adjusts the amount of light of a light-emitting unit with high accuracy and suppresses an increase in control time that is required to adjust the amount of light, a scanning optical apparatus, and control methods thereof. To accomplish this, the image forming apparatus of the present invention derives a threshold current and a bias current of the light-emitting unit. Further, the image forming apparatus of the present invention supplies the bias current to the light-emitting unit when causing the light-emitting unit to emit light in an amount of light corresponding to the minimum density level, and supplies a current that is larger than the threshold current to the light-emitting unit when causing the light-emitting unit to emit light in an amount of light corresponding to a density level that is larger than that minimum density level.

Owner:CANON KK

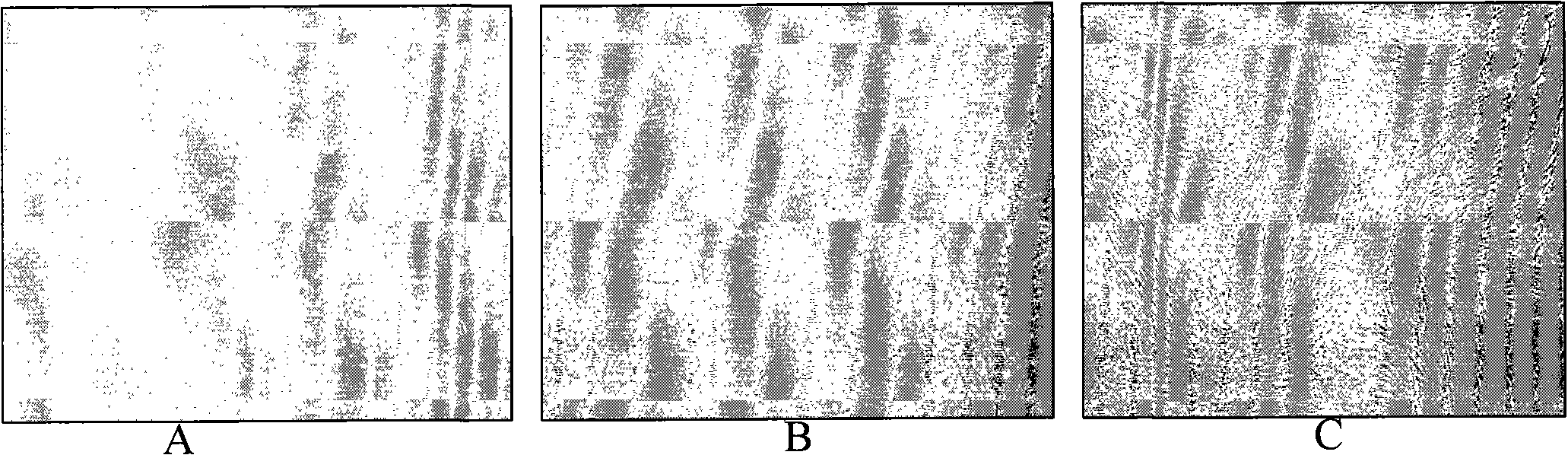

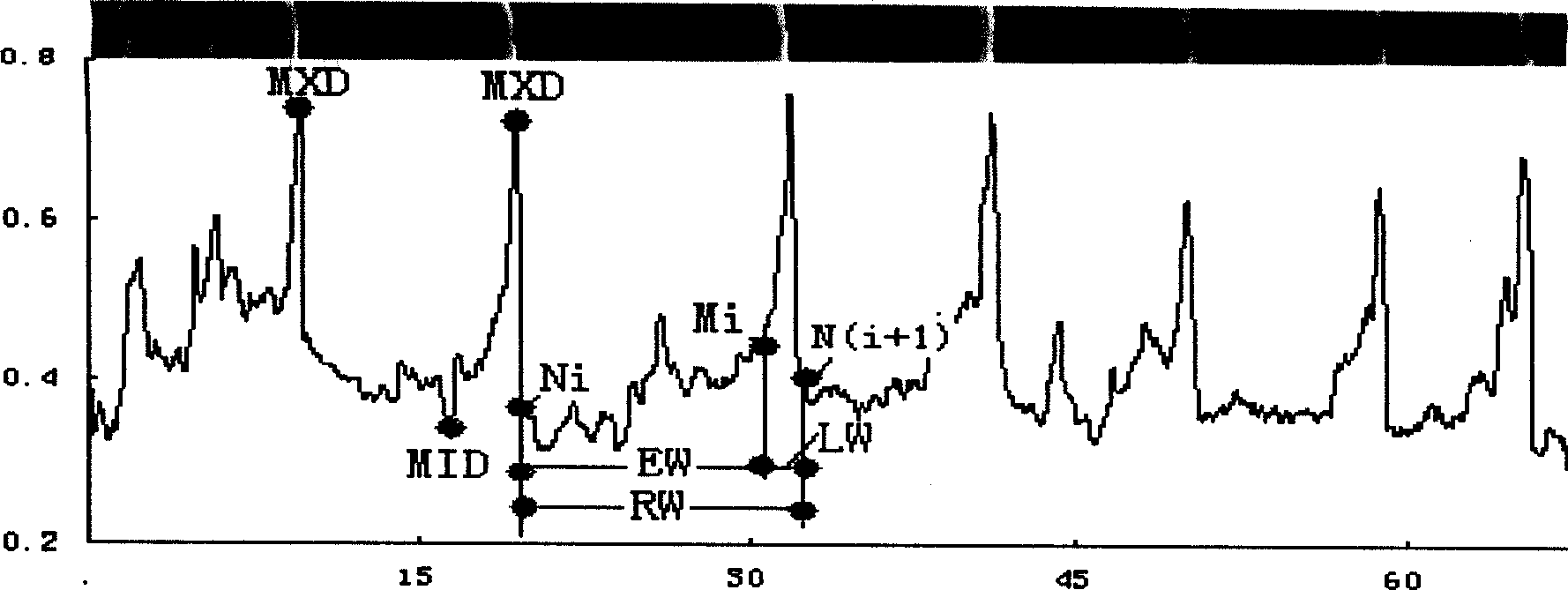

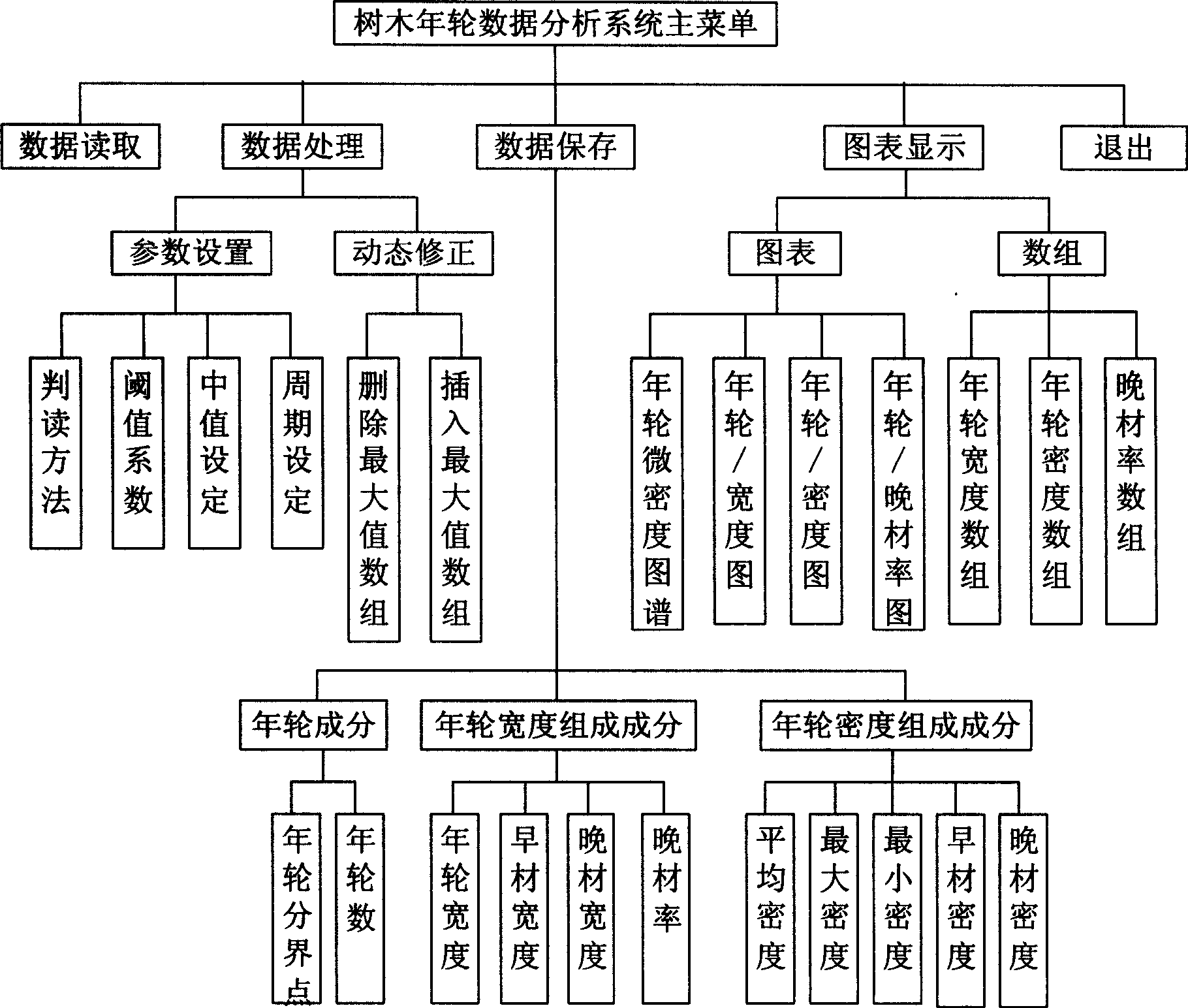

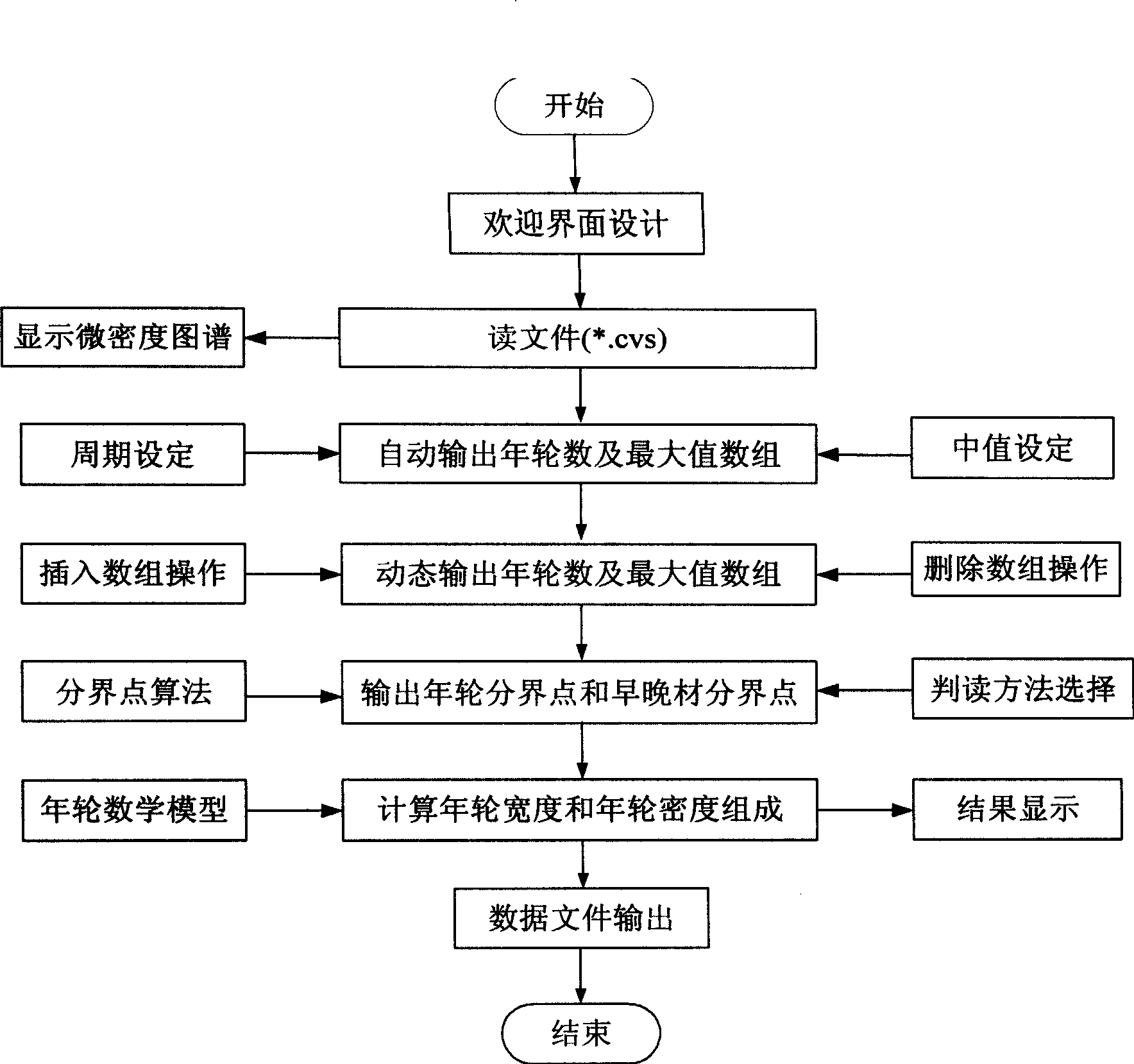

Fast analysis method of tree annual ring composing ingredient

InactiveCN101441180ATime-consuming and laborious to solveSolve the problem of low automatic recognition accuracyMaterial analysis by optical meansUsing optical meansMinimum densityAutomatic judgement

Disclosed is a tree-ring composition rapid analysis method, particularly a rapid measuring method for tree-ring width and tree-ring density, belonging to the measuring field. The tree-ring composition rapid analysis method is to delete the false tree-ring and insert the broken tree-ring in automatic judgement and human-computer interaction mode, and to once read the parameters like tree-ring number, tree-ring width, tree-ring average density, maximum density, minimum density, early wood density, late wood density, early wood width, late wood width, and late wood rate. The method can be used for analyzing the density data measured by the tree-ring density instrument, and can also be used for analyzing the density data measured by the tree-ring digitized map. The tree-ring composition rapid analysis method solves the problem of identifying complex tree-ring, improves the measuring accuracy, in addition, the conventional manual operation that takes both time and effort can be replaced, thereby saving a large amount of time and effort for the tree-ring students.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Simultaneous Multi-Layer Fill Generation

InactiveUS20090077506A1Minimize the numberArea maximizationSolid-state devicesCAD circuit designMinimum densityMaximum density

Techniques are disclosed for optimizing the pattern density in the circuit layout design of a circuit layer. A layer in circuit design is analyzed to define empty regions that can be filled with fill polygons (referred to hereafter as “fill” regions). Next, a pattern of fill polygons is generated. After the fill polygons have been defined, the layout design for the layer is divided into separate areas or “windows,” and a target density for each window is determined. Once this target density for the window has been determined, the fill polygons required to most closely approach this target density are generated and added to the circuit layout design. This process may be repeated with progressively different (e.g., smaller) fill polygons, until each window meets or exceeds both the specified minimum density and complies with the specified maximum density gradient. Additionally, some implementations may allow a user to simultaneously optimize the density of multiple layers of a circuit by adding fill polygons to multiple layers of a circuit design simultaneously. Representations of sections of a multilayer fill structure will then be added to corresponding layers the circuit design until a specified target density is met.

Owner:MENTOR GRAPHICS CORP

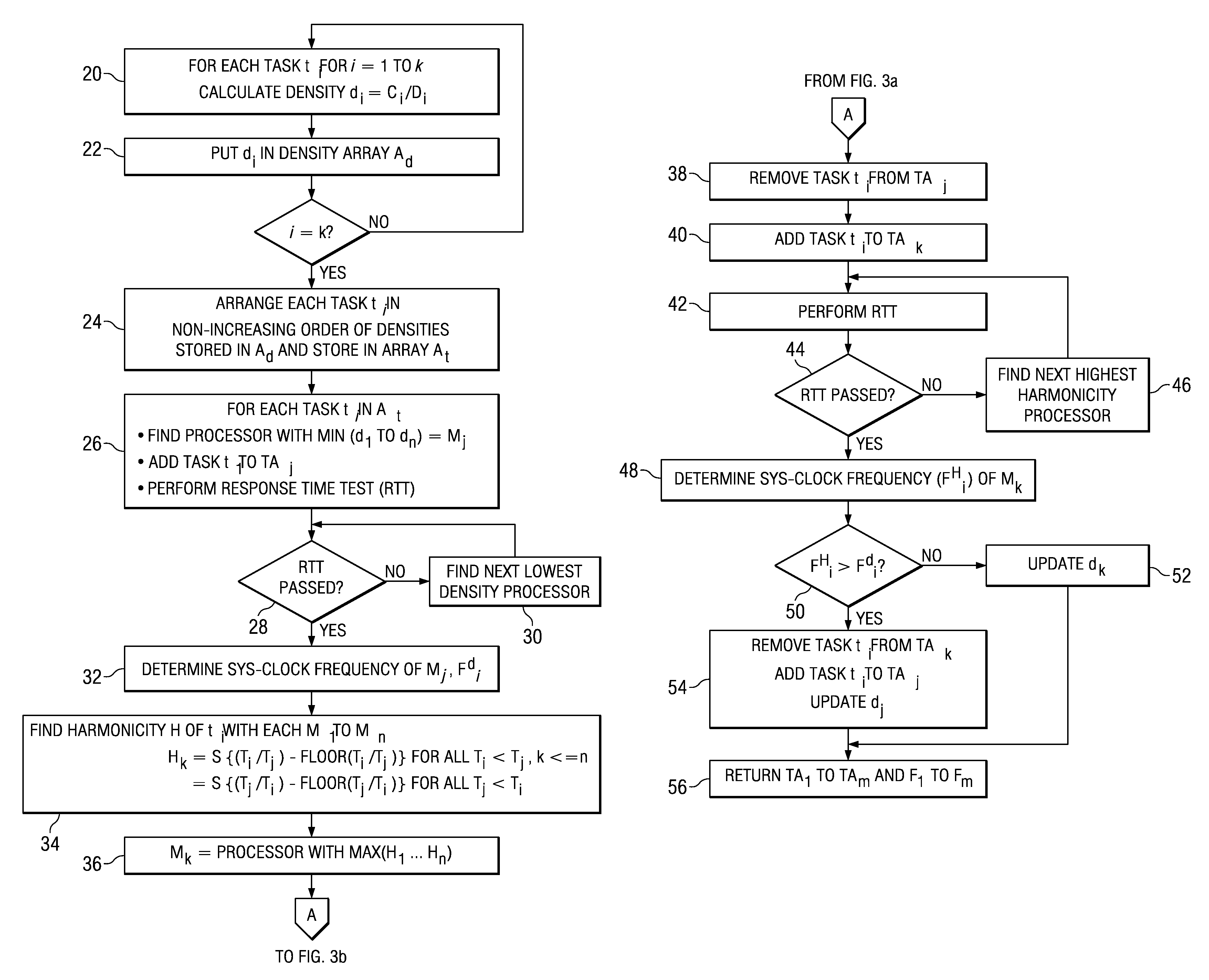

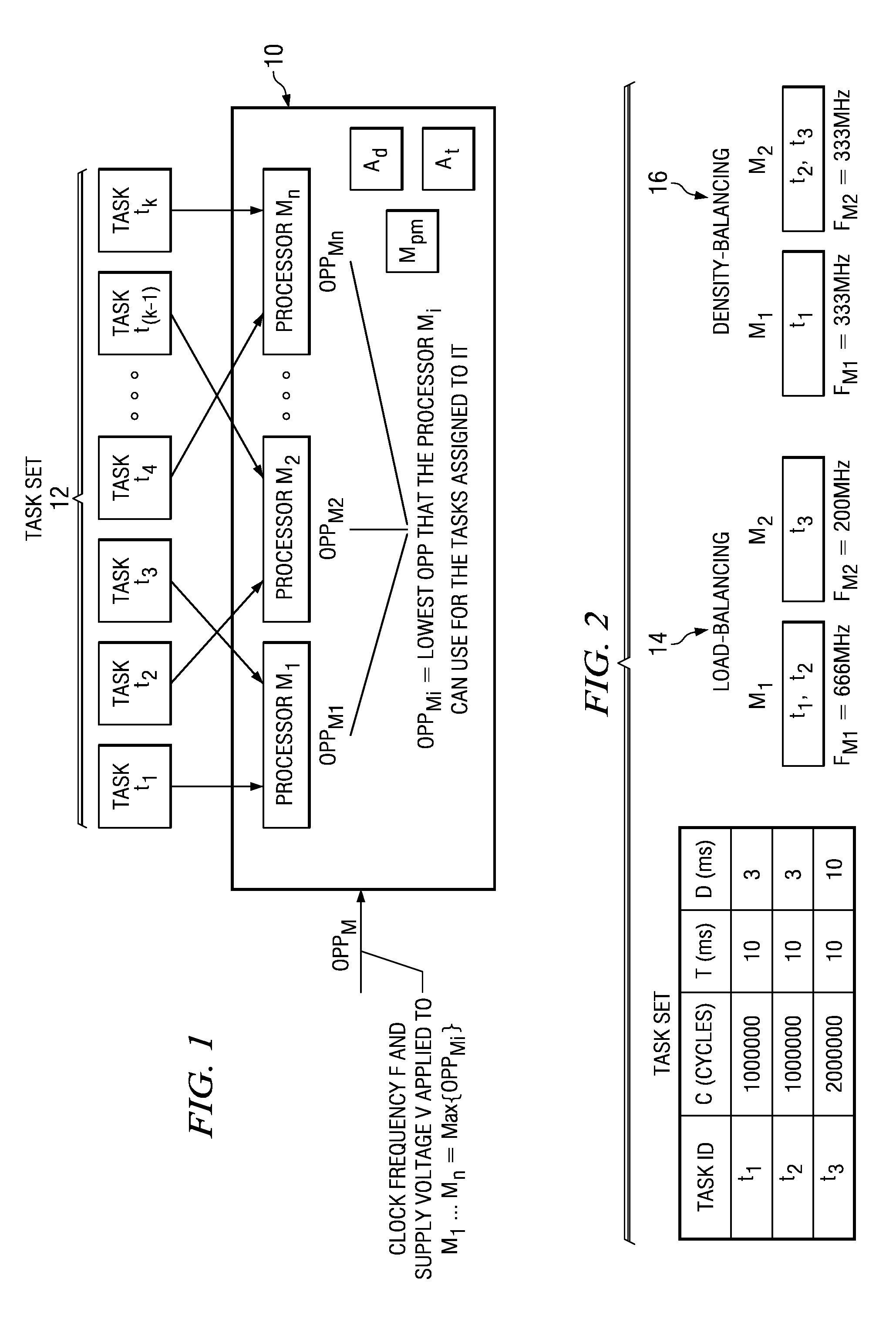

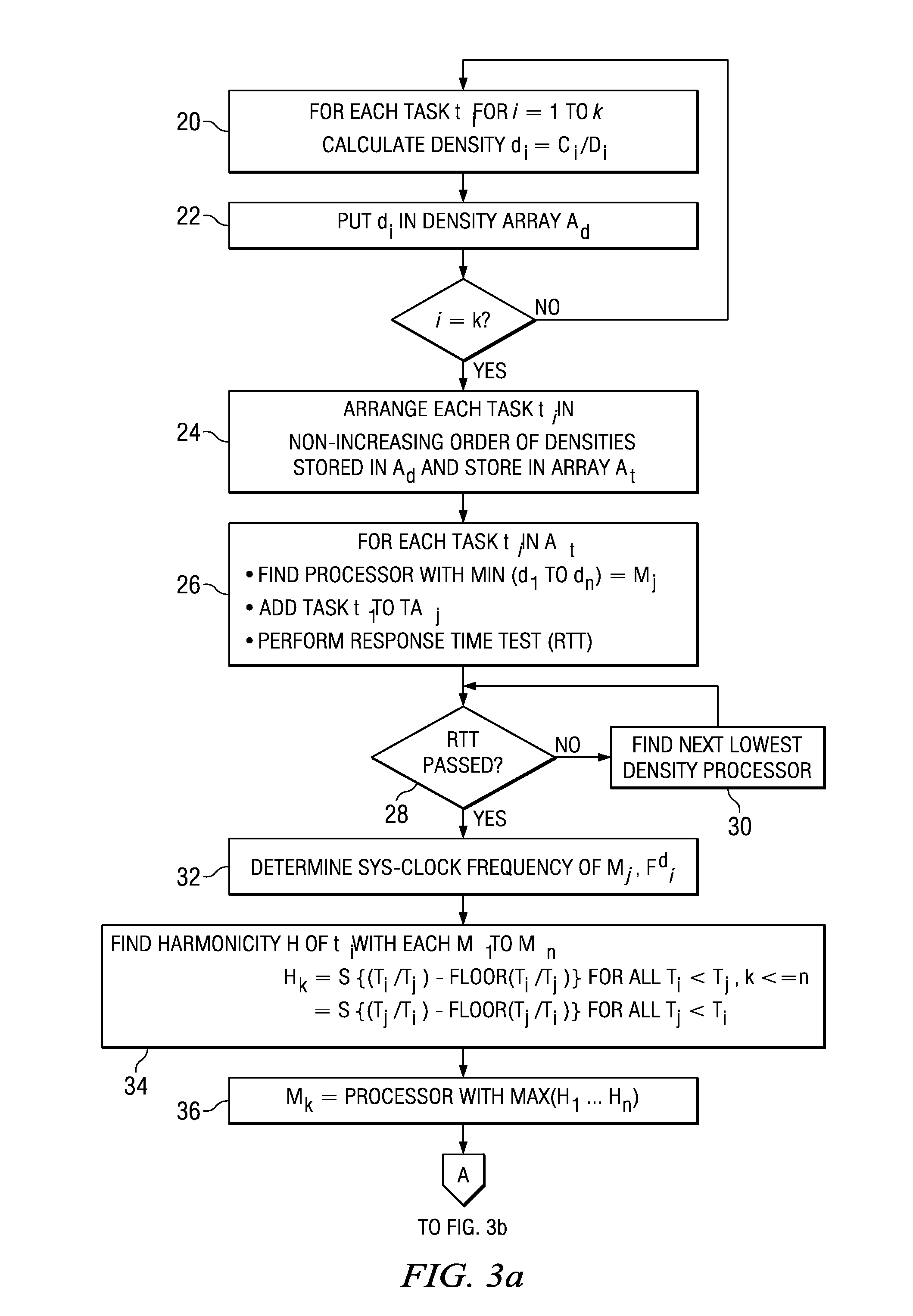

System and method of task allocation in multiprocessing environment based on minimum density or maximum harmonicity that results in lower clock frequency

Systems and Methods for task allocation in a multiprocessor environment employing power management techniques are described wherein tasks are allocated relative to the density given by the ratio of worst-case-execution time and deadline of a task and also the harmonicity of a task's period with respect to a task-set. Tasks are allocated to a given processor based on either minimum density or maximum harmonicity depending on which allocation results in a lower clock frequency. Assigning a task to the processor with lowest density results in balancing the density across processors while assigning task to the processor with maximum harmonicity attempts to maximize the utilization of the processor.

Owner:TEXAS INSTR INC

Image forming unit and displaying unit

Owner:CANON KK

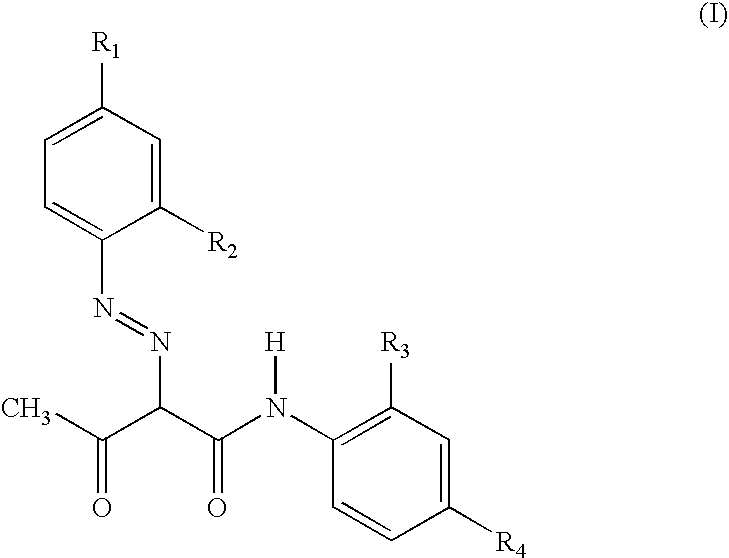

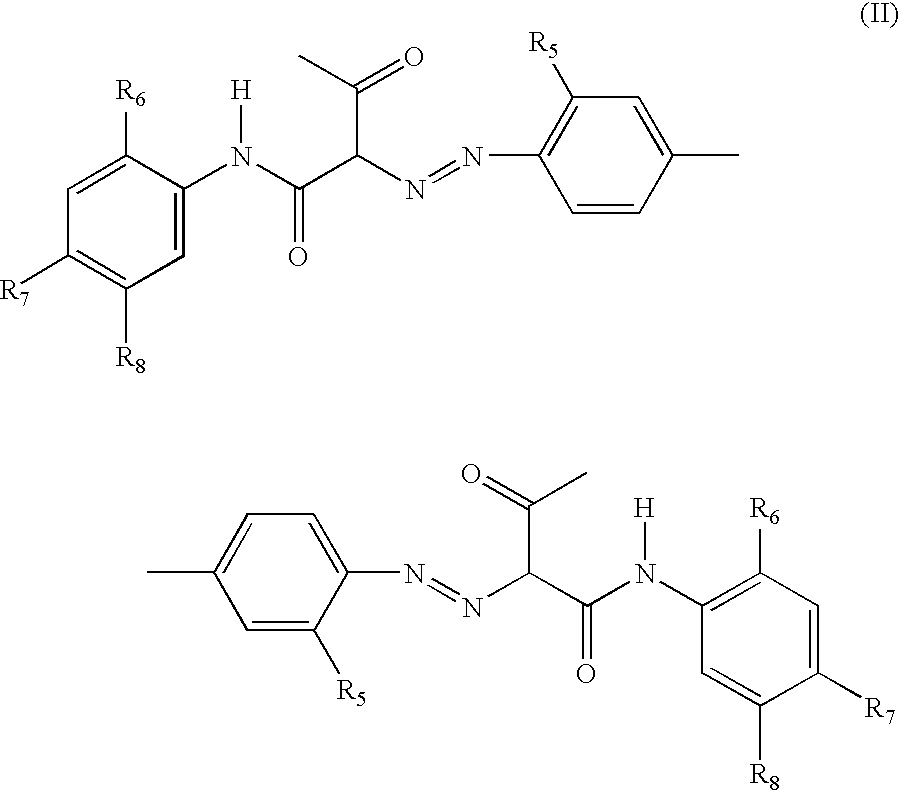

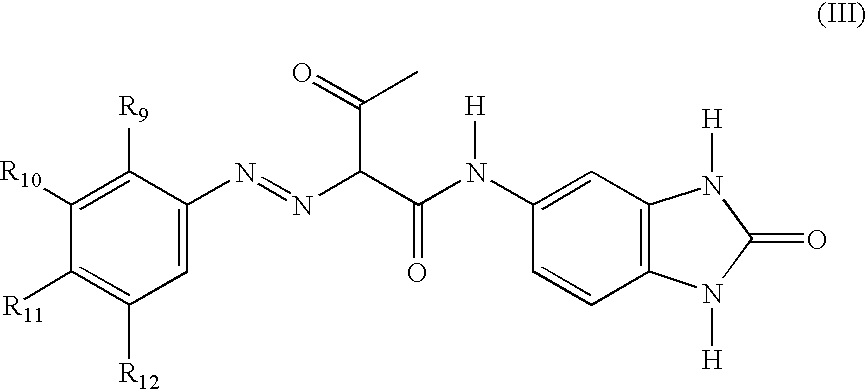

Color photographic materials with yellow minimum density colorants

InactiveUS7629112B1Increased sensitivityAcceptable reproductionPhotoprinting processesSilver halide emulsionsOrganic solventMinimum density

Silver halide color photographic elements having multiple color imaging layers contain a permanent, pre-formed yellow colorant that is present in an amount to provide a status M blue density greater than 0.003 per mg / m2. This colorant provides minimum density at lower cost and can be incorporated with minimal or no organic solvents and thus enable a reduced organic load that may lead to improved film physical properties.

Owner:EASTMAN KODAK CO

Image processing apparatus, image forming apparatus, and image processing method for edge detection processing and determination

InactiveUS7990579B2Image enhancementDigitally marking record carriersImaging processingMinimum density

Owner:FUJIFILM BUSINESS INNOVATION CORP

Top of absorption article and absorption article

A topsheet of an absorbent article having a laminated nonwoven fabric composed of an upper layer 21 disposed on the skin side and a lower layer 22 disposed on the absorbent member side. The nonwoven fabric has a large number of sheet compressed parts 23 formed by compression joining the upper layer 21 and the lower layer 22 and a large number of lower layer compressed parts 24 positioned between the sheet compressed parts 23 and formed by compressing the lower layer 22. The minimum density of a region 29 other than the sheet compressed parts 23 and the lower layer compressed parts 24 on the lower layer 22 is at least the minimum density of a region 28 other than the sheet compressed parts 23 on the upper layer 21.

Owner:KAO CORP

Preparation method for chlorinated polyethylene/polyvinyl chloride composite foaming material

The invention discloses a preparation method of a chlorinated polyethylene / polyvinyl chloride composite foaming material, which belongs to the technical field of foaming material preparation. In the present invention, polyvinyl chloride absorbs dioctyl phthalate and swells to make it soft and elastic, and then blends it with crosslinking agent dicumyl oxide and stearyl acrylate, and adds nucleating agents calcium carbonate, chlorine The chlorinated polyethylene / polyvinyl chloride masterbatch is obtained by cooling and discharging the chlorinated polyethylene / polyvinyl chloride masterbatch. The chlorinated polyethylene / polyvinyl chloride masterbatch is heated and formed in a mold, and then the non-polluting supercritical carbon dioxide is used as a physical foam agent, increase the expansion ratio, and generate uniform and fine cells, thereby obtaining the method of chlorinated polyethylene / polyvinyl chloride composite foam material. Examples prove that the reaction of the preparation process of the present invention is mild, and while maintaining the advantages of low cost and high flame retardancy, the density of the prepared chlorinated polyethylene / polyvinyl chloride composite foam material is the smallest, the cell distribution is uniform, and the strength is also high. has been significantly improved.

Owner:仇颖莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com