Preparation method of super-hydrophobic cellulose aerogel and application of super-hydrophobic cellulose aerogel in oil stain treatment

A technology of cellulose airgel and cellulose hydrogel, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of destroying the modified substrate structure, low modification efficiency, waste of modifiers, etc., and achieves Broad application prospects, high adsorption ratio, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Rinse the cotton linter cellulose with distilled water and absolute ethanol repeatedly, and fully dry it, then take 3% by mass of cellulose and add it to NaOH / urea / water solution precooled at -18°C for 20 minutes (NaOH mass fraction 7 %, mass fraction of urea 12%, water mass percentage 78%). Stir at 750r / min for 10min to obtain a cellulose solution. Then transfer the cellulose solution to the desired mold.

[0037] 2. The configured 17wt.%H 2 SO 4 The solution was dropped into the cellulose solution along the inner wall of the mold, and stood still for 6 hours after the dropping was completed, and the cellulose hydrogel was obtained after complete gelation. Then use distilled water to wash repeatedly to remove residual salt, and a pure cellulose hydrogel can be obtained.

[0038] 3. Freeze the obtained cellulose hydrogel at -18° C. for 24 hours to obtain cellulose jelly, and then freeze-dry to obtain cellulose aerogel. The freeze-drying temperature is -65° C., a...

Embodiment 2

[0042] 1. Rinse the resinous cellulose with distilled water and absolute ethanol repeatedly, and fully dry it, then take 2% by mass of cellulose and add it to -18°C pre-cooled NaOH / urea / water solution (NaOH mass fraction 7%, urea The mass fraction of 12%, water mass percentage 79%). Stir at 750r / min for 10min to obtain a cellulose solution. Then transfer the cellulose solution to the desired mold.

[0043] 2. Drop absolute ethanol into the cellulose solution along the inner wall of the mould, stand still for 6 hours after the addition, and wait for complete gelation to obtain cellulose hydrogel. Then use distilled water to wash repeatedly to remove residual salt, and a pure cellulose hydrogel can be obtained.

[0044] 3. Freeze the obtained cellulose hydrogel at -18° C. for 24 hours to obtain cellulose jelly, and then freeze-dry to obtain cellulose aerogel. The freeze-drying temperature is -80° C., and the pressure is 1 Pa.

[0045] 4. Place the prepared cellulose aerogel ...

Embodiment 3

[0048] 1. Repeatedly rinse waste paper cellulose with distilled water and absolute ethanol, and fully dry it, then take 3% by mass of cellulose and add it to -18°C pre-cooled NaOH / water solution (NaOH mass fraction 8%, water mass fraction percent 89%). Stir at 750r / min for 10min to obtain a cellulose solution. Then transfer the cellulose solution to the desired mold.

[0049] 2. The configured 17wt.%H 2 SO 4 The solution was dropped into the cellulose solution along the inner wall of the mold, and stood still for 6 hours after the dropping was completed, and the cellulose hydrogel was obtained after complete gelation. Then use distilled water to wash repeatedly to remove residual salt, and a pure cellulose hydrogel can be obtained.

[0050] 3. Freeze the obtained cellulose hydrogel at -18° C. for 24 hours to obtain cellulose jelly, and then freeze-dry to obtain cellulose aerogel. The freeze-drying temperature is -65° C., and the pressure is 10 Pa.

[0051] 4. Place the p...

PUM

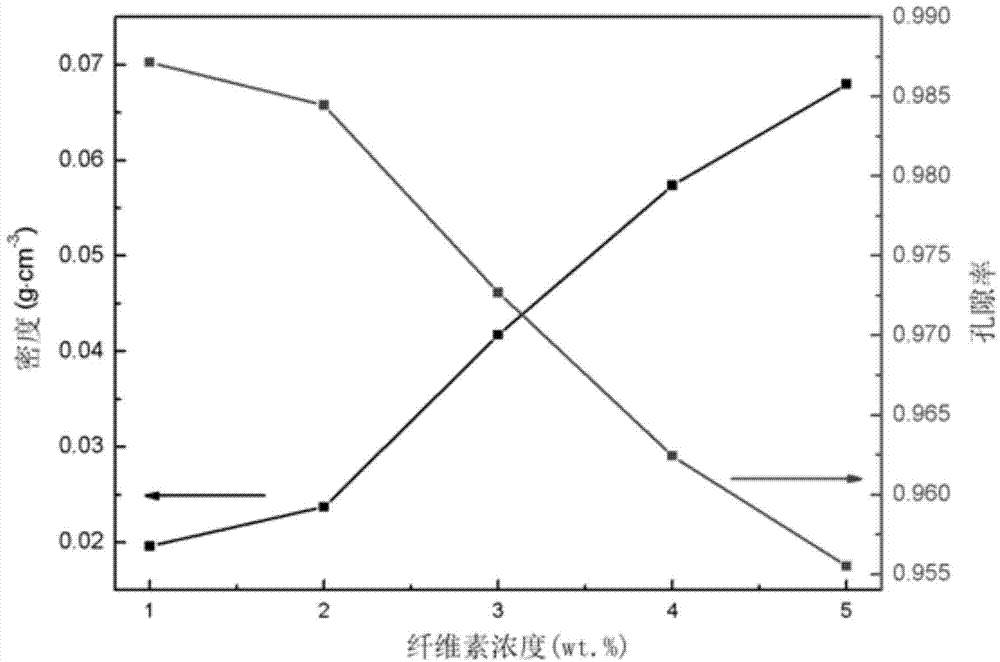

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com