Patents

Literature

43 results about "Commercial Oils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol-based biological fuel oil for boiler and preparation method thereof

InactiveCN101948702ALow costRaw materials are cheap and easy to getBiofuelsLiquid carbonaceous fuelsBiodieselAlcohol

The invention provides a biodiesel-based alcoholic fuel oil, which consists of the following substances in percentage by mass: 20 to 50 percent of refined biodiesel, 40 to 80 percent of industrial methanol and 5 to 30 percent of additive, wherein the additive comprises 5 to 20 percent of solvent aid, 1 to 15 percent of cosurfactant, 0.2 to 2 percent of stabilizer and 0.1 to 1 percent of corrosion inhibitor. A preparation method comprises the following steps of: mixing the substances in percentage by mass, and stirring the mixture uniformly at normal temperature to obtain the fuel oil. The fuel oil has the advantages of low cost, high heat value and stable performance; the preparation method has the advantages of simple process, convenience and safety of use and good adaptability to the boiler; and compared with diesel oil, the fuel oil is economic and energy-saving, has low environmental pollution, is regenerative energy, and can be used as commercial oil for great popularization and use.

Owner:KUNMING UNIV OF SCI & TECH

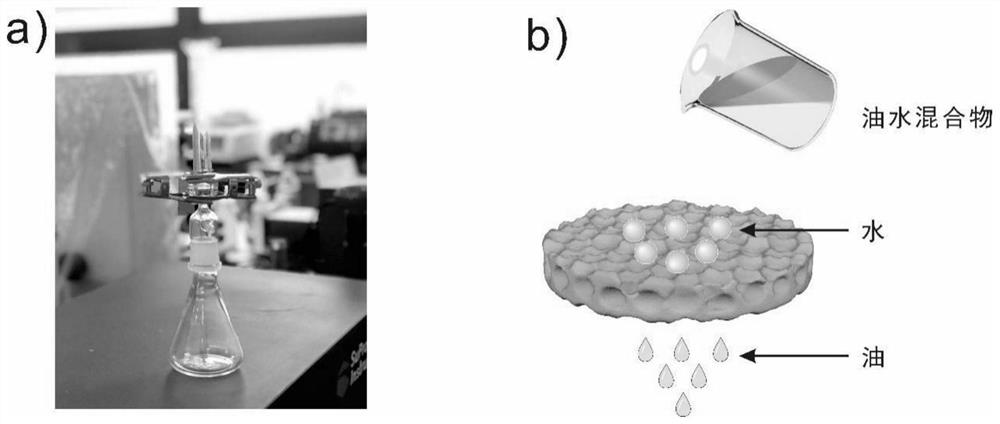

Preparation method of super-hydrophobic cellulose aerogel and application of super-hydrophobic cellulose aerogel in oil stain treatment

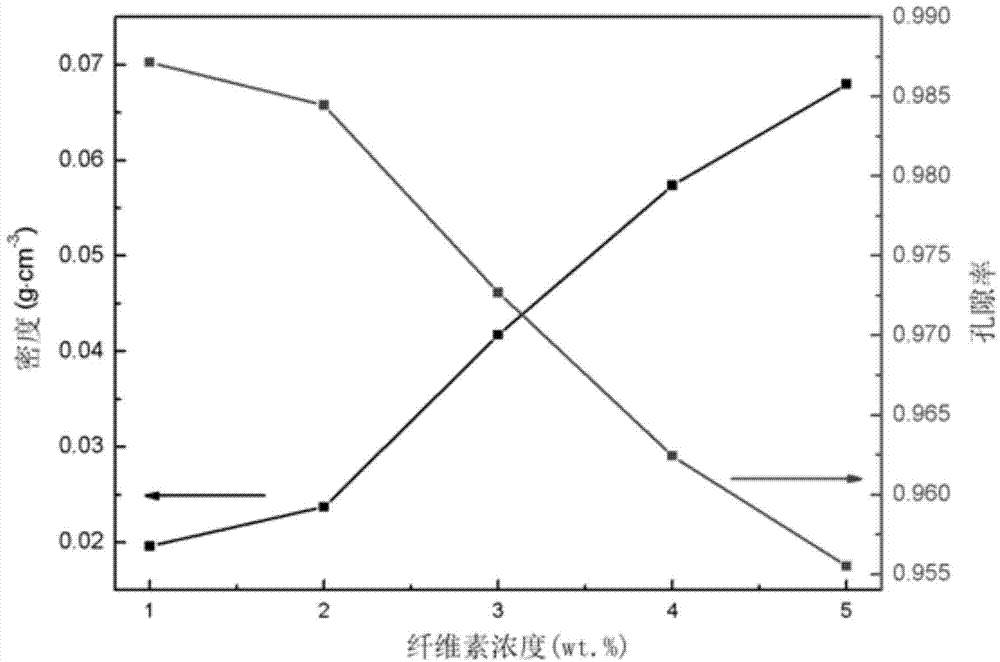

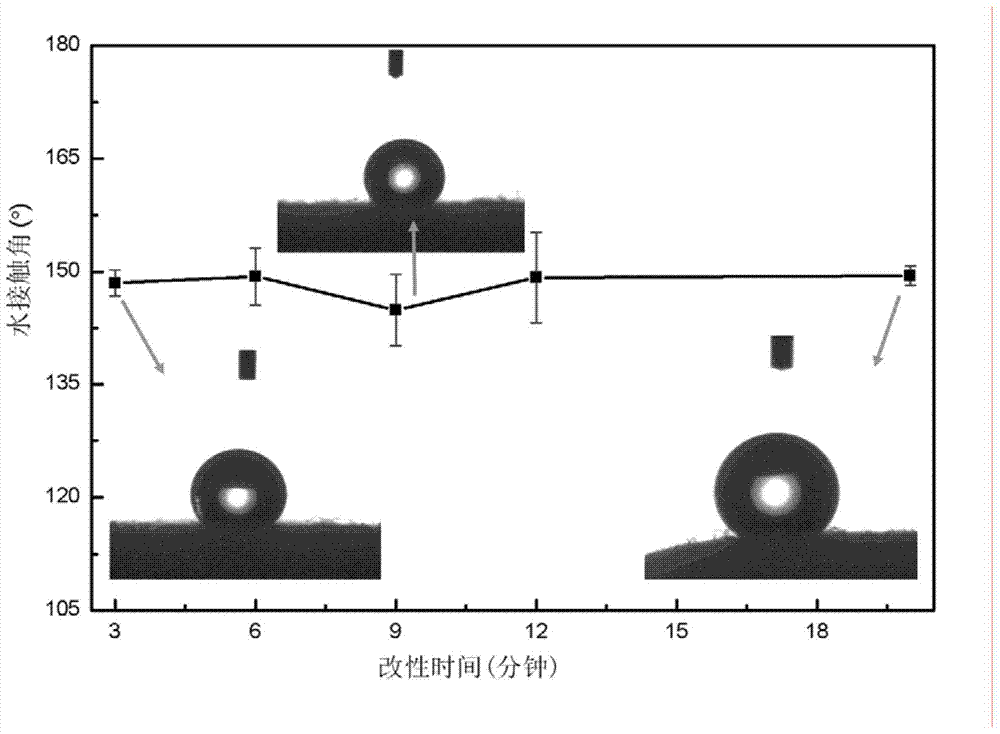

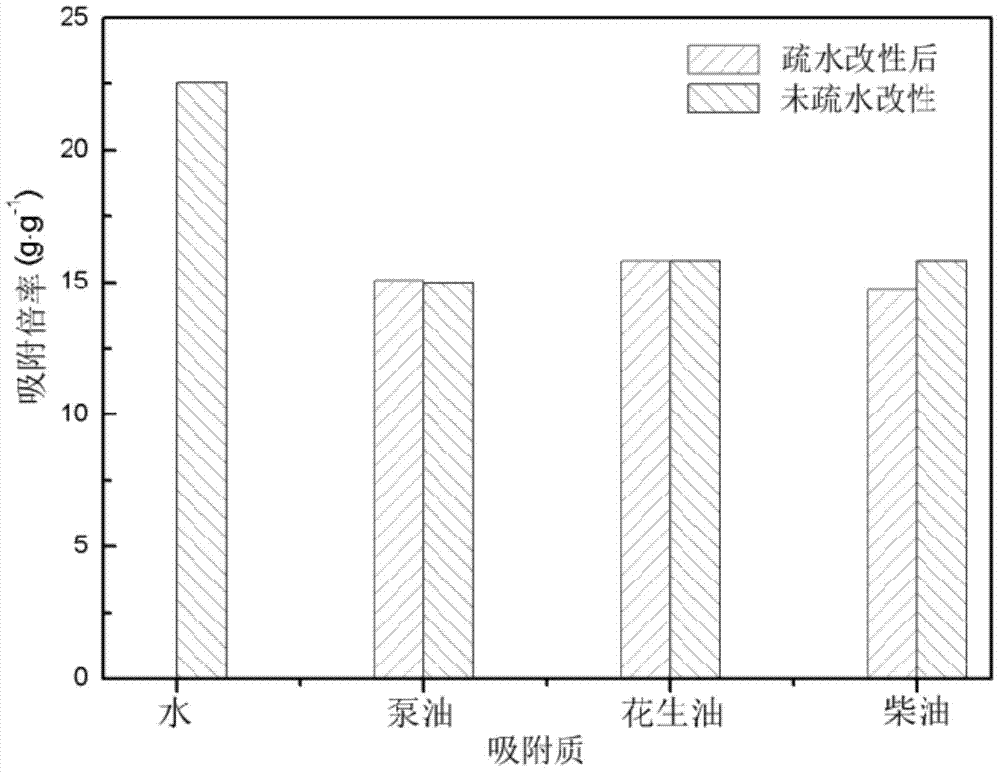

The invention discloses a preparation method of a super-hydrophobic cellulose aerogel and application of the super-hydrophobic cellulose aerogel in oil stain treatment. The light-weight porous cellulose aerogel material is prepared from abundant, renewable and degradable cellulose by using an alkali solution (comprising NaOH solution and NaOH / urea solution) as a solvent system. The minimum density can reach 0.0196 g / cm<3>, and the porosity can reach 99%. Compared with the commercial oil-adsorbing felt material, the cellulose aerogel material has higher adsorbing rate and excellent reusability. The hydrophobic modification method can obtain the super-hydrophobic effect in a quick, effective and energy-saving way, and can implement oil stain collection, oil-water separation and the like in a quick and economical way.

Owner:HAINAN UNIVERSITY +1

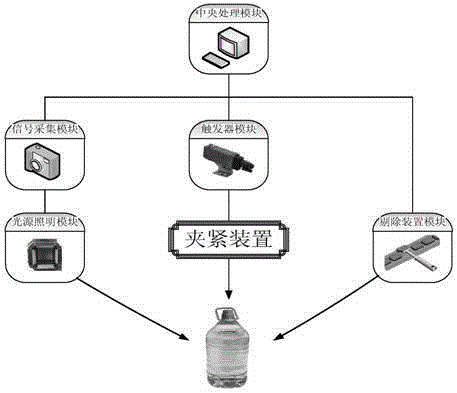

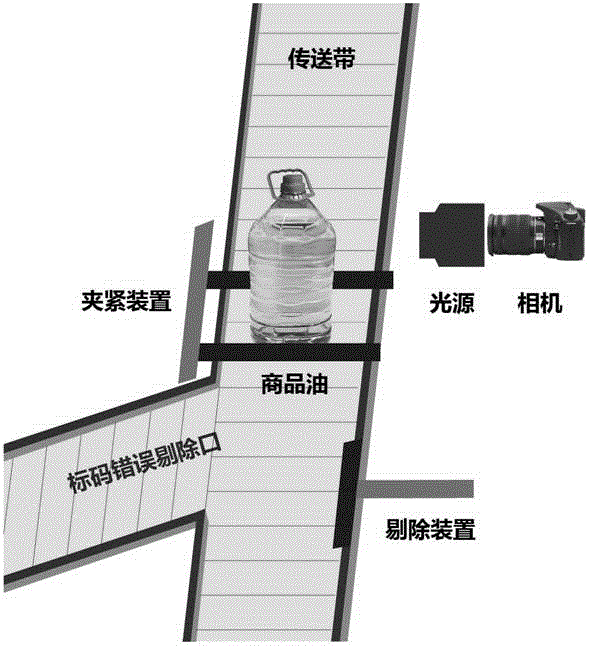

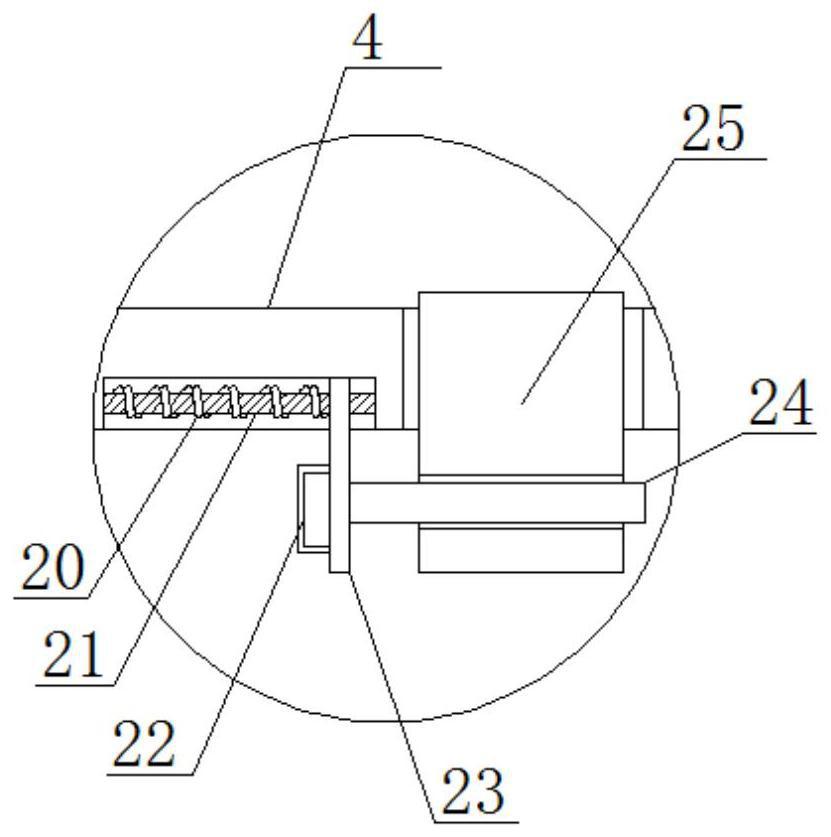

Commercial oil surface laser code recognition method with self modeling function

InactiveCN105260734AStable alignmentImprove detection accuracyNeural learning methodsCharacter recognitionImaging processingCranial nerves

The invention discloses a commercial oil surface laser code recognition method with a self-modeling function. The content of the method comprises the steps that model statistics is carried out on a commercial oil laser code based on a neural network recognition algorithm, and a self modeling technology is realized; a character template image of the designated commercial oil laser code to be detected is acquired, a brain cranial nerve function of the human is simply simulated through the neural network recognition algorithm so as to realize an input-output mapping model, classification, recognition and acquisition for characters are completed, and the characters act as a template; a commercial oil laser code image is acquired, and an image processing phase of character recognition and character reading is carried out; if a matching result is that the character is qualified, the commercial oil is qualified and continuous to be transported, and if the matching result is that the character is not qualified, the unqualified commercial oil is removed by a removing device; and finally, a function of character recognition is realized, character detection for a laser barcode on the commercial oil is completed, and thus accurate detection for the commercial oil laser barcode can be achieved.

Owner:YANSHAN UNIV

Microemulsified biodiesel and preparation thereof

The invention relates to micro-emulsified biological diesel oil and a method for preparing the same. The micro-emulsified biological diesel oil is characterized by comprising the following substances in percentage by weight: wherein 50 to 60 percent of mineral diesel oil, 25 to 30 percent of animal grease, 10 to 15 percent of methanol, 0.5 to 3.0 percent of naphthenic acid, 0.5 to 3.0 percent of OP emulsifier, 0.5 to 2.0 percent of sodium dodecyl sulfonate and 0.5 to 2.0 percent of trolamine. The method for preparing the micro-emulsified biological diesel oil comprises the following steps: the animal grease, the methanol, the OP emulsifier, the sodium dodecyl sulfonate and the trolamine are evenly mixed according to weight percentage; the mixed solution is slowly poured into the mineral diesel oil under the stirring condition; simultaneously, according to the requirement of the weight percentage, the naphthenic acid is added and fully stirred and mixed, thereby preparing the micro-emulsified biological diesel oil. The micro-emulsified biological diesel oil has the advantages of high combustion efficiency, small environmental pollution, simple preparation process, convenient use and good stability and can be used as commercial oil for mass popularization and use.

Owner:郑州侨联生物能源有限公司

Alcohol ether diesel oil for vehicles

InactiveCN102533363AAbundant resourcesStable and renewable supplyLiquid carbonaceous fuelsAlcoholEther

Alcohol ether diesel oil for vehicles is energy-saving environment-friendly composite diesel oil. The alcohol ether diesel oil is prepared by diesel oil 52-76%, carbinol 6-12%, dimethyl ether 2-5%, water 8-15%, emulsifier 7-15% and an addition agent 1-3% by weight. Compared with other composite diesel oils, the alcohol ether diesel oil has the advantages of being good in stability, long in retention period, small in corrosion to the vehicles, low in cost, energy-saving, environment-friendly and the like, and can serve as commercial oil to be popularized and applied extensively.

Owner:张永辉

Practical micro-emulsified environment-friendly and energy-saving diesel oil and preparation method thereof

The invention discloses practical micro-emulsified environment-friendly and energy-saving diesel oil and a preparation method thereof. The yellowish and crystal practical micro-emulsified environment-friendly and energy-saving diesel oil is prepared by stirring 60-80% of diesel oil, 5-20% of aviation kerosene, 6-12% of micro-emulsifying agent, 6-13% of water and 0.5-2% of modifier for 10-20 minutes under normal temperature and normal pressure. The practical micro-emulsified environment-friendly and energy-saving diesel oil has the advantages of good fluidity, high impetus, low oil consumption, practicability, environment friendliness, energy saving, simplicity in production equipment, wide source of raw materials, low investment and high economic benefit, and can be widely popularized and utilized as commercial oil.

Owner:陈卫

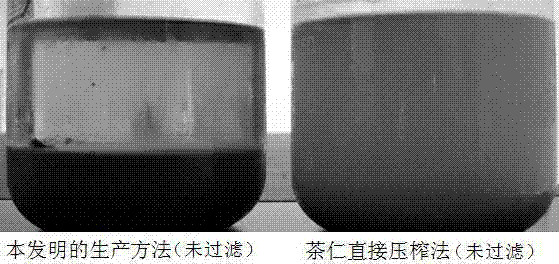

Production method of squeezed green tea seed oil

ActiveCN103666751AHigh nutritional valueEasy to squeeze outFatty-oils/fats productionResidual oilCommercial Oils

The invention discloses a production method of squeezed green tea seed oil. The production method comprises the main steps of green tea seed collecting and drying, green tea seed hulling, low-temperature drying of tea seed kernels, tea seed kernel and rice hull premixing, low-temperature mechanical squeezing, filtering and purifying and the like. The oil yield of the squeezed tea seeds accounts for over 90% of the total oil content of the tea seeds, and the residual oil ratio is within 10%, so that the problem of low oil yield of the traditional green tea seed oil squeezing method is solved, and the oil yield is increased by over 10% as comparison with the oil yield obtained by using the traditional squeezing technology. By using the direct squeezing method, the production capacity is improved, the production cost is reduced, the processing time is shortened, and no waste water and waste gas are generated. The produced squeezed commercial oil prepared from the green tea seeds is moderate in color and luster, few in impurity, free of bitterness and capable of ensuring that the quality of a finished product of green tea seed oil is up to the national edible oil standard while retaining original fatty acid components, tea polyphenol and natural active beneficial components to the maximum extent.

Owner:ZHEJIANG BAIFAN AGRI DEV CO LTD +1

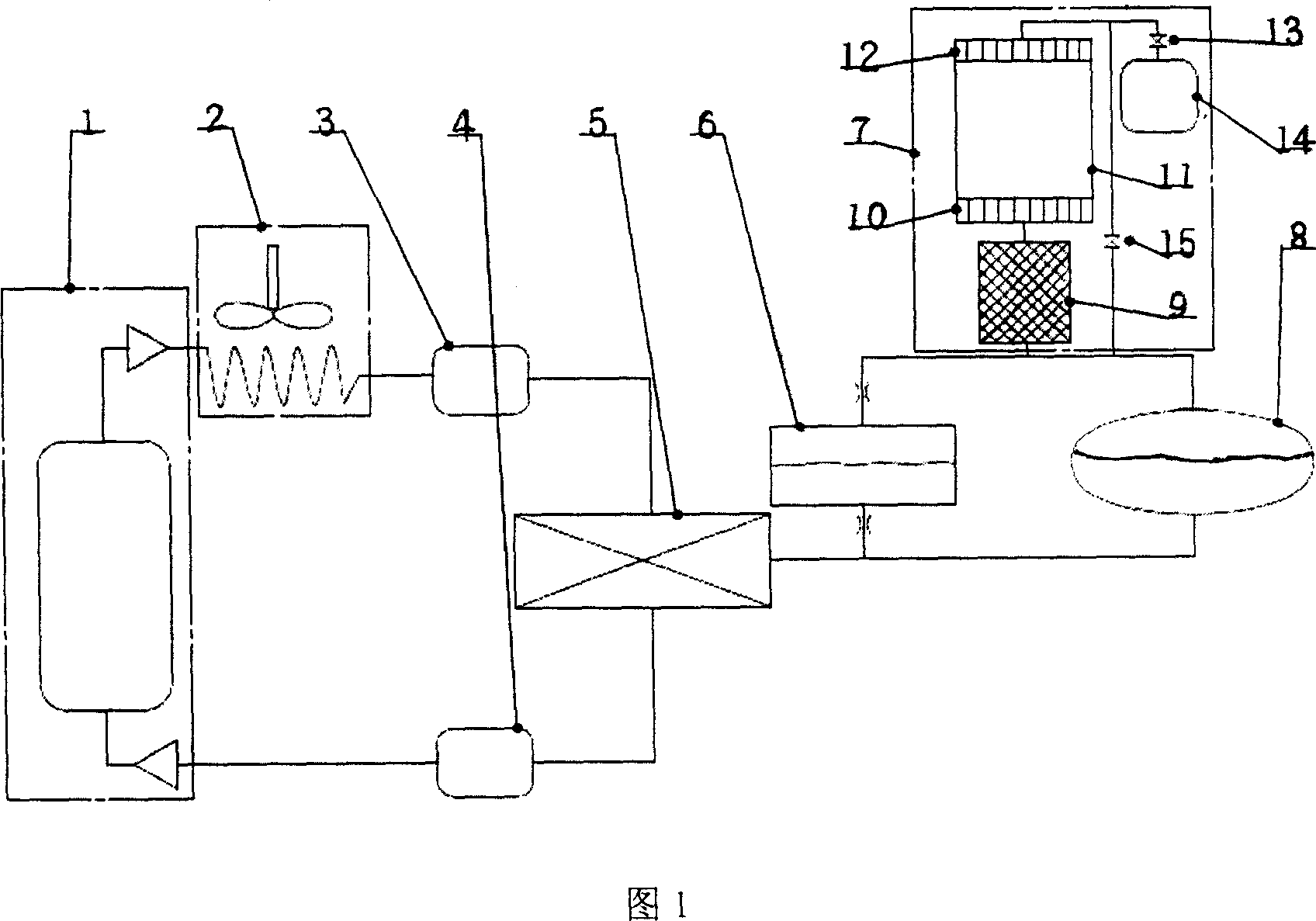

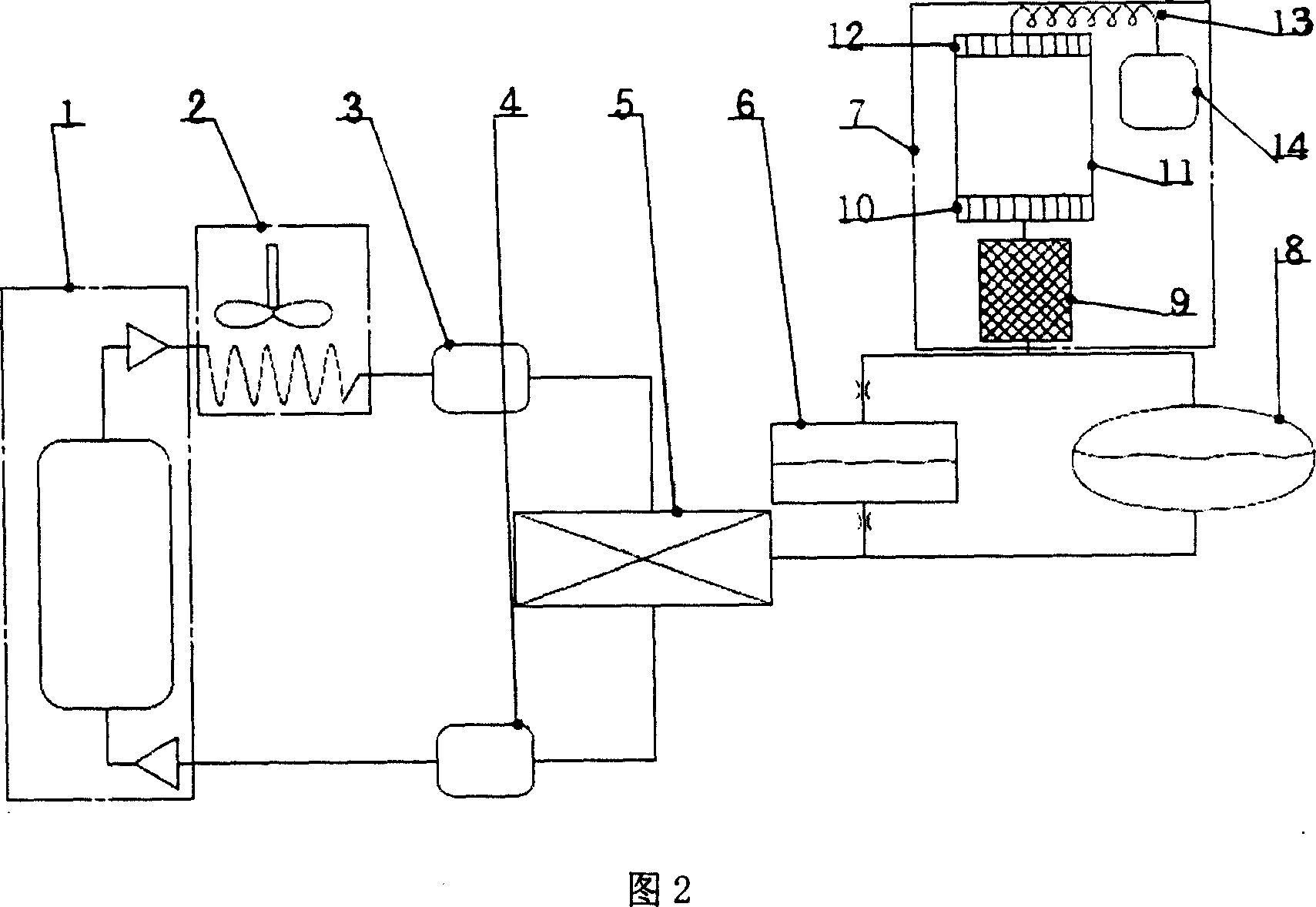

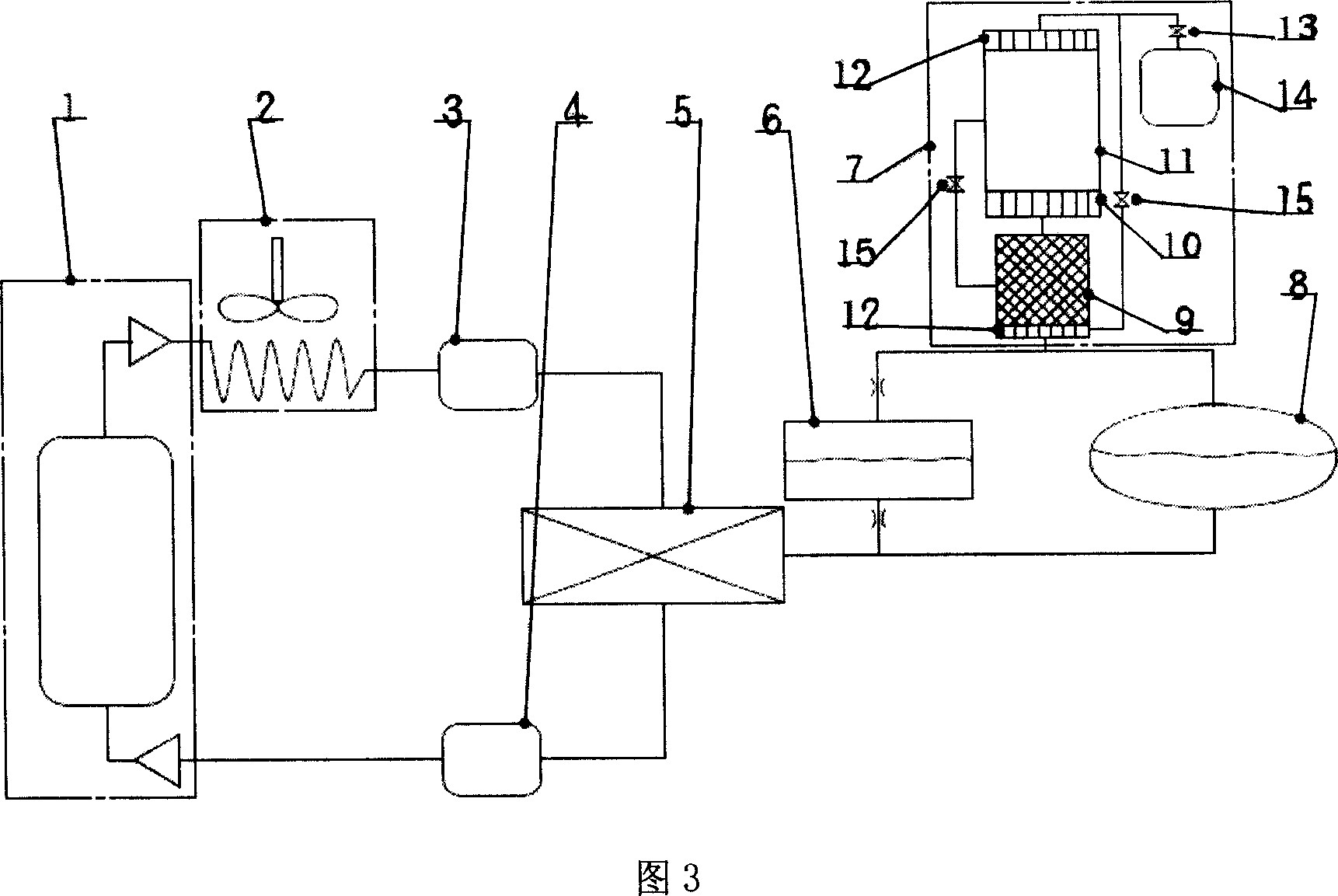

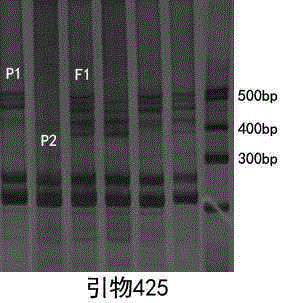

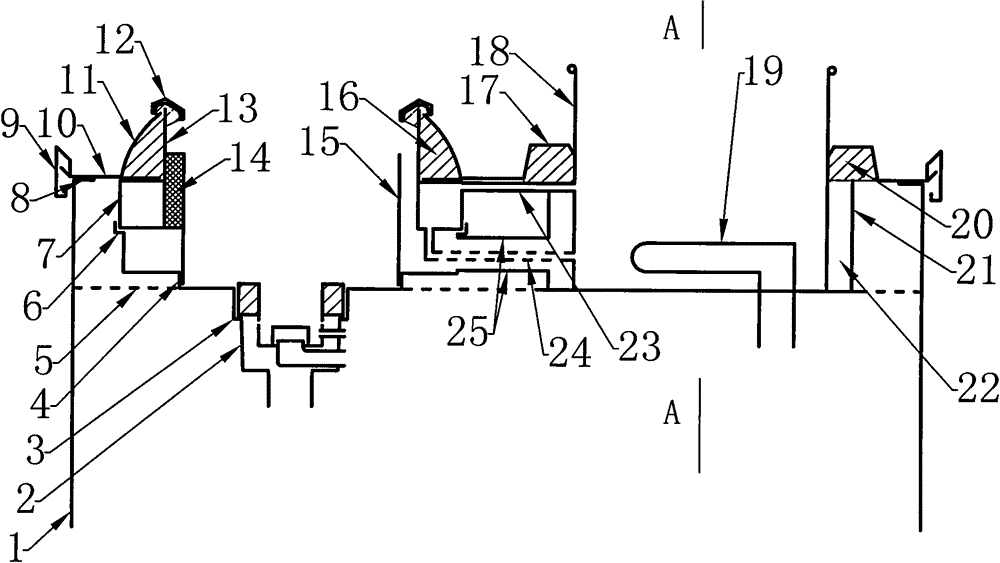

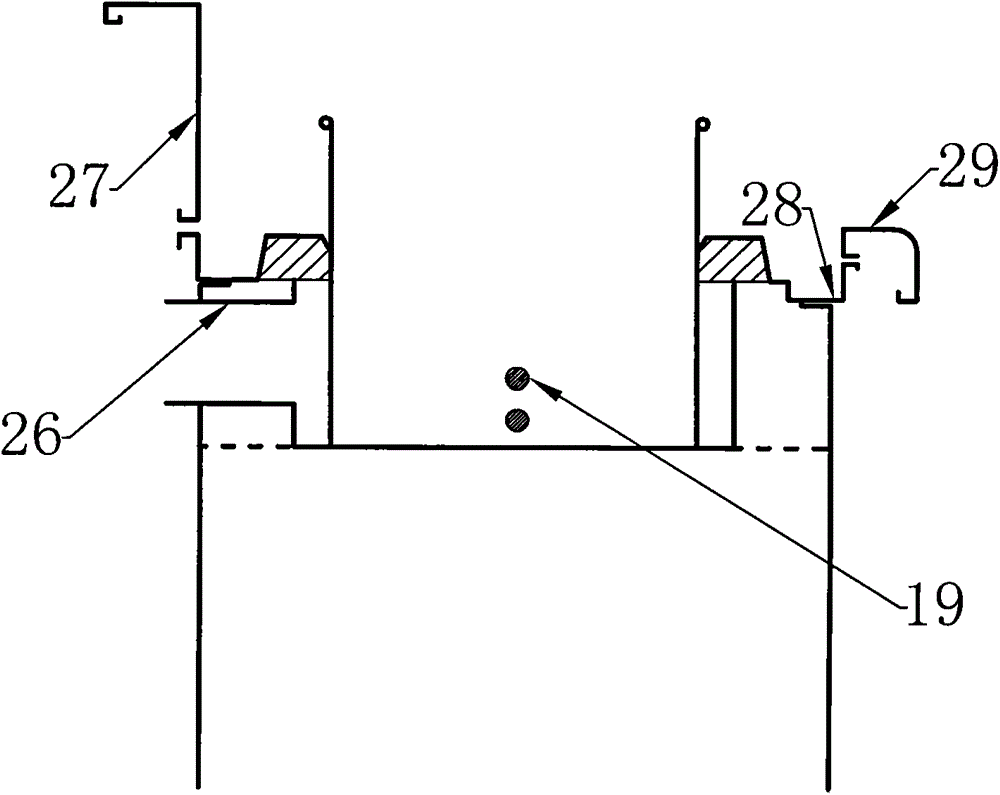

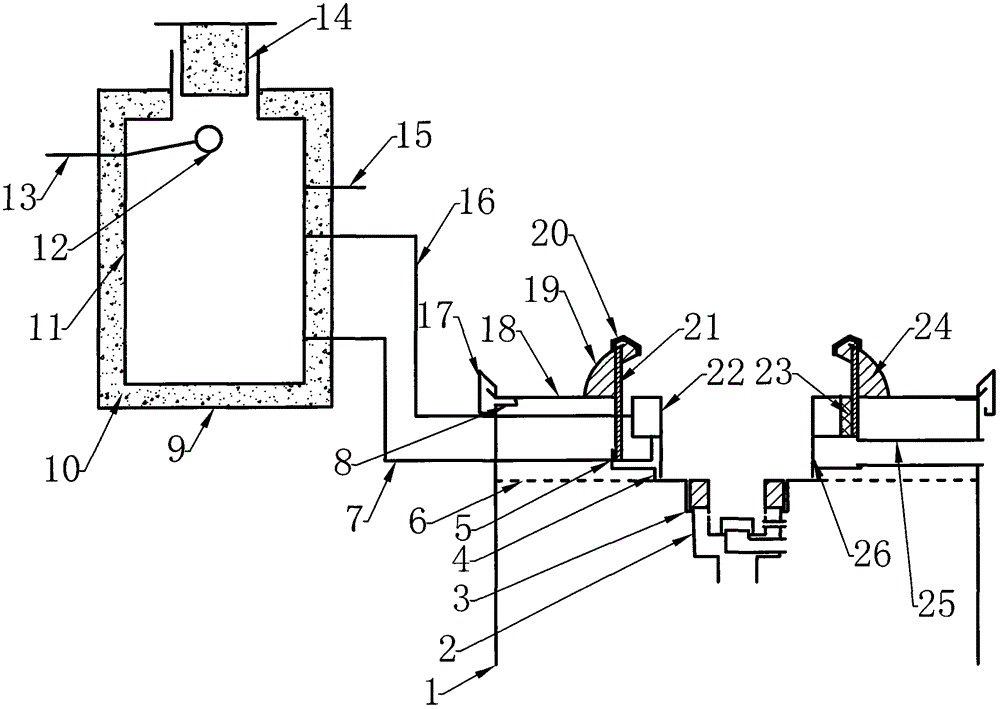

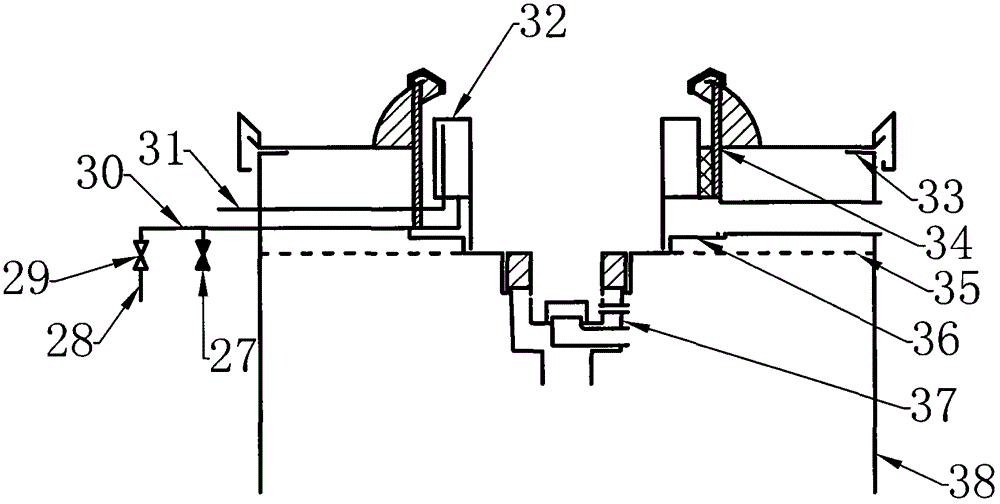

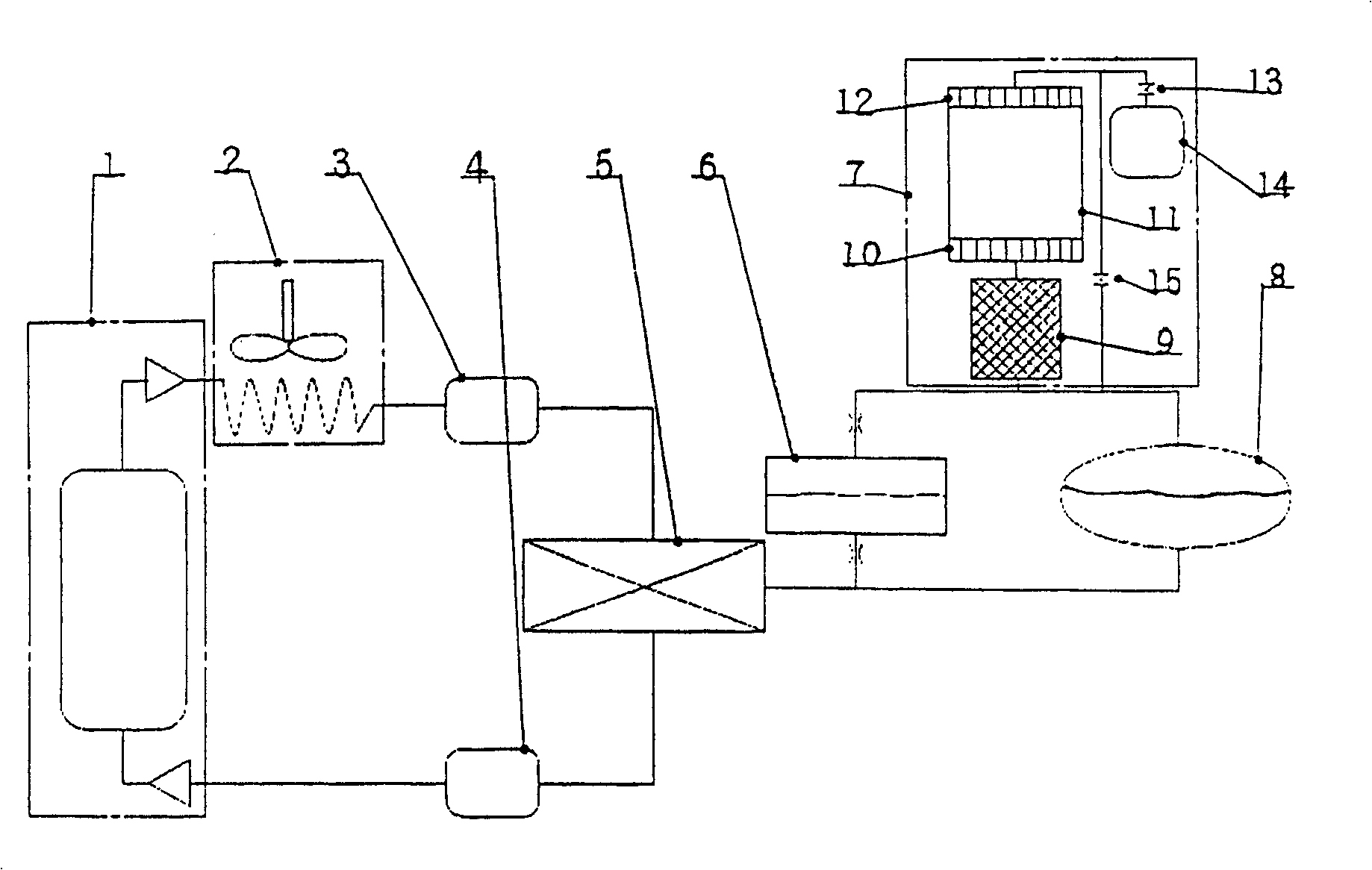

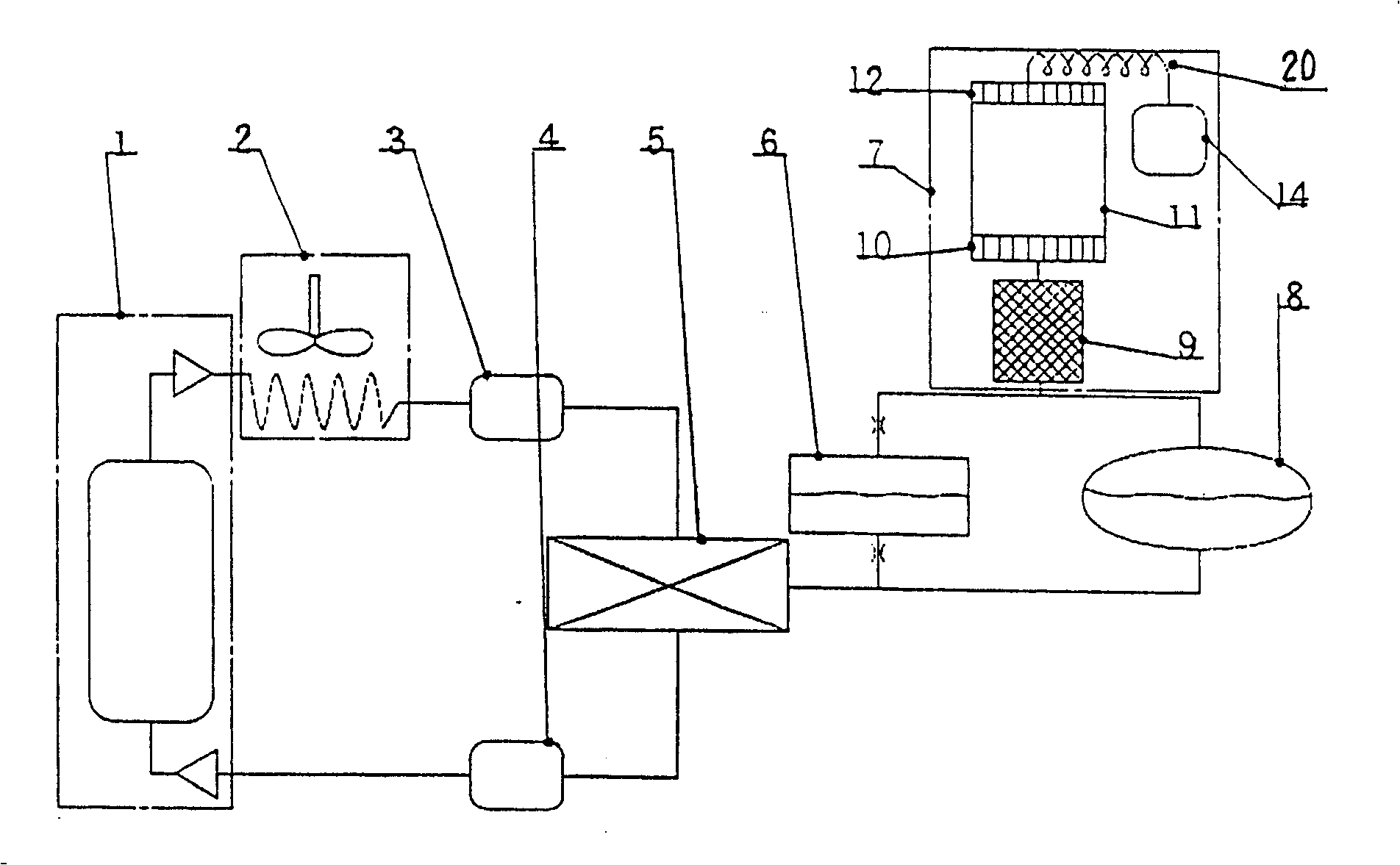

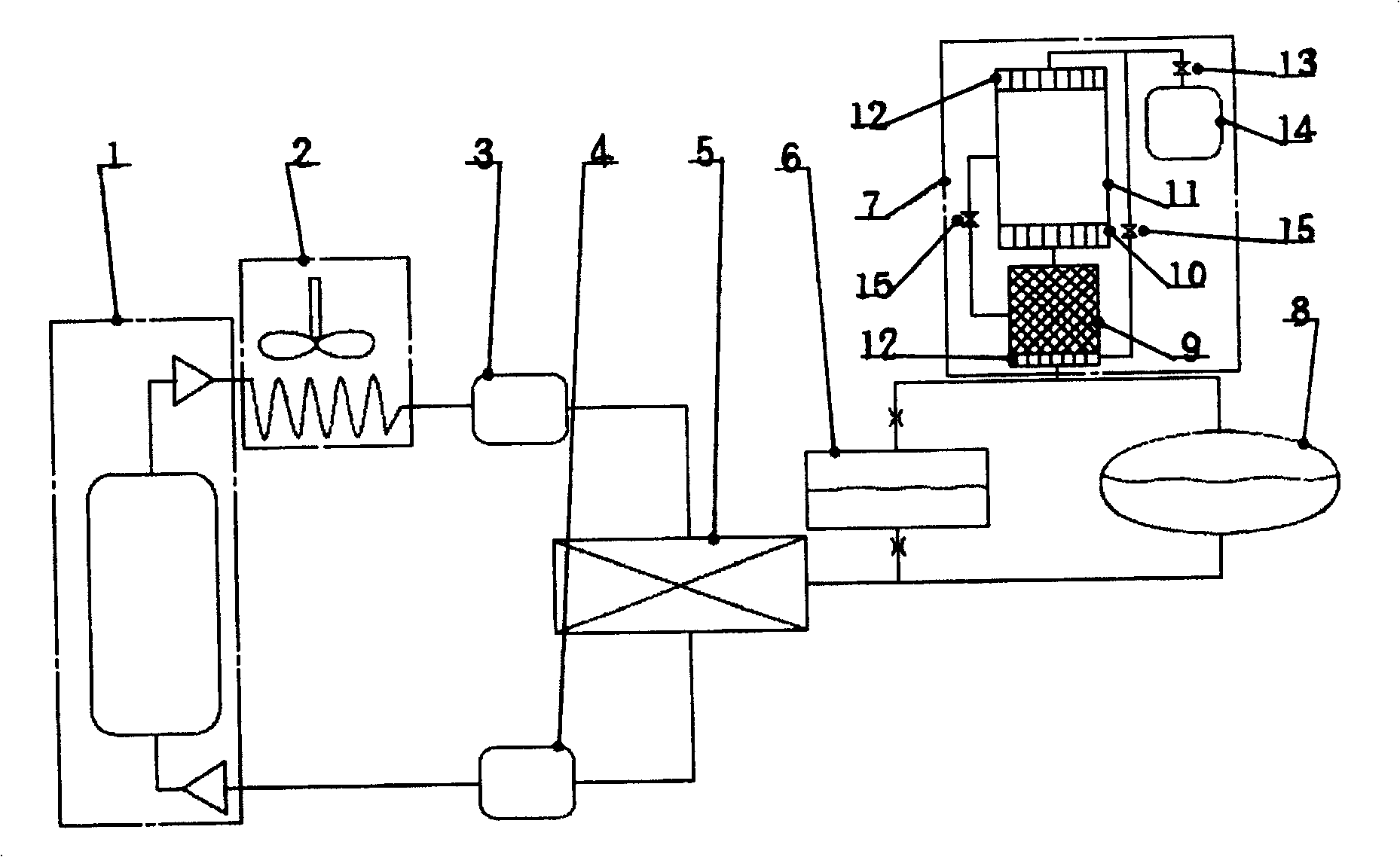

Oil lubrication compressor gas supplied circulating refrigerating device

InactiveCN101063564AEasy to processReduce manufacturing costCompressorCompression machinesHigh pressureCommercial Oils

The invention relates to an oil lubrication valve compressor air feed recirculation refrigerator, comprising a high pressure end of a oil lubrication compressor, a water condenser, a high pressure air collector, an oil lubrication rotatable valve, a low pressure air collector and a low pressure end of the oil lubrication compressor sequentially connected, and a return circuit is formed, further comprising a balance air room and an elastic film box paralleled arranged between the condenser and the oil lubrication rotatable valve, the balance air room and the elastic film box are composed by a box provided with a small hole at the box wall and an elastic film arranged inside the box body, the inner cave of the elastic film box body is divided to two parts respectively communicated with the condenser and the oil lubrication rotatable valve. The damage of the elastic film caused by the abrupt decrease of the pressure on one side of elastic film in the process of starting the hypothermia process could be prevented, the high stability commercial oil lubrication compressor could be used to drive the condenser, simultaneously the pressure vibration frequency could be controlled according to the request of the condenser, The invention is a high reliability and low cost recirculation refrigerator.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Environment-friendly automotive alcohol ether diesel for Fischer-Tropsch synthesis liquid wax

The invention discloses environment-friendly automotive alcohol ether diesel for Fischer-Tropsch synthesis liquid wax. The alcohol ether diesel is characterized by being prepared from the following raw materials in percentage by weight: 52-76% of a mixture of industrial white oil and aviation fuel, 6-12% of methanol, 2-5% of dimethyl ether, 8-15% of Fischer-Tropsch synthesis liquid wax, 7-15% of DMMN 3-8 (polyoxymethylene dimethyl ethers) and 1-3% of an additive. The alcohol ether diesel is excellent in stability, excellent in dynamic performance, capable of avoiding layering during long-stemstorage, low in vehicle corrosion, low in cost, energy-saving and environment-friendly, and can serve as commercial oil to popularize and use.

Owner:桂林千升元环保能源有限公司

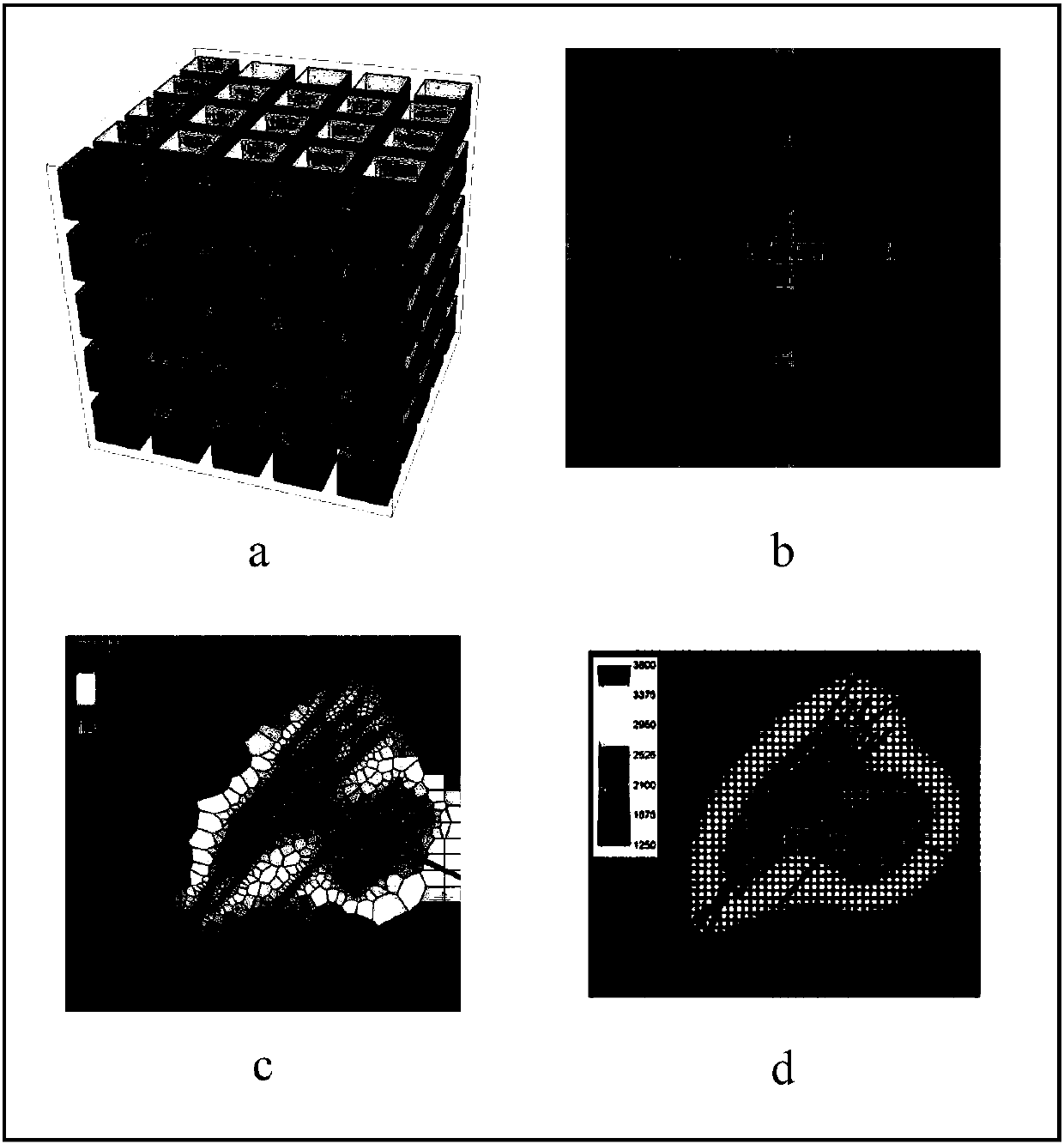

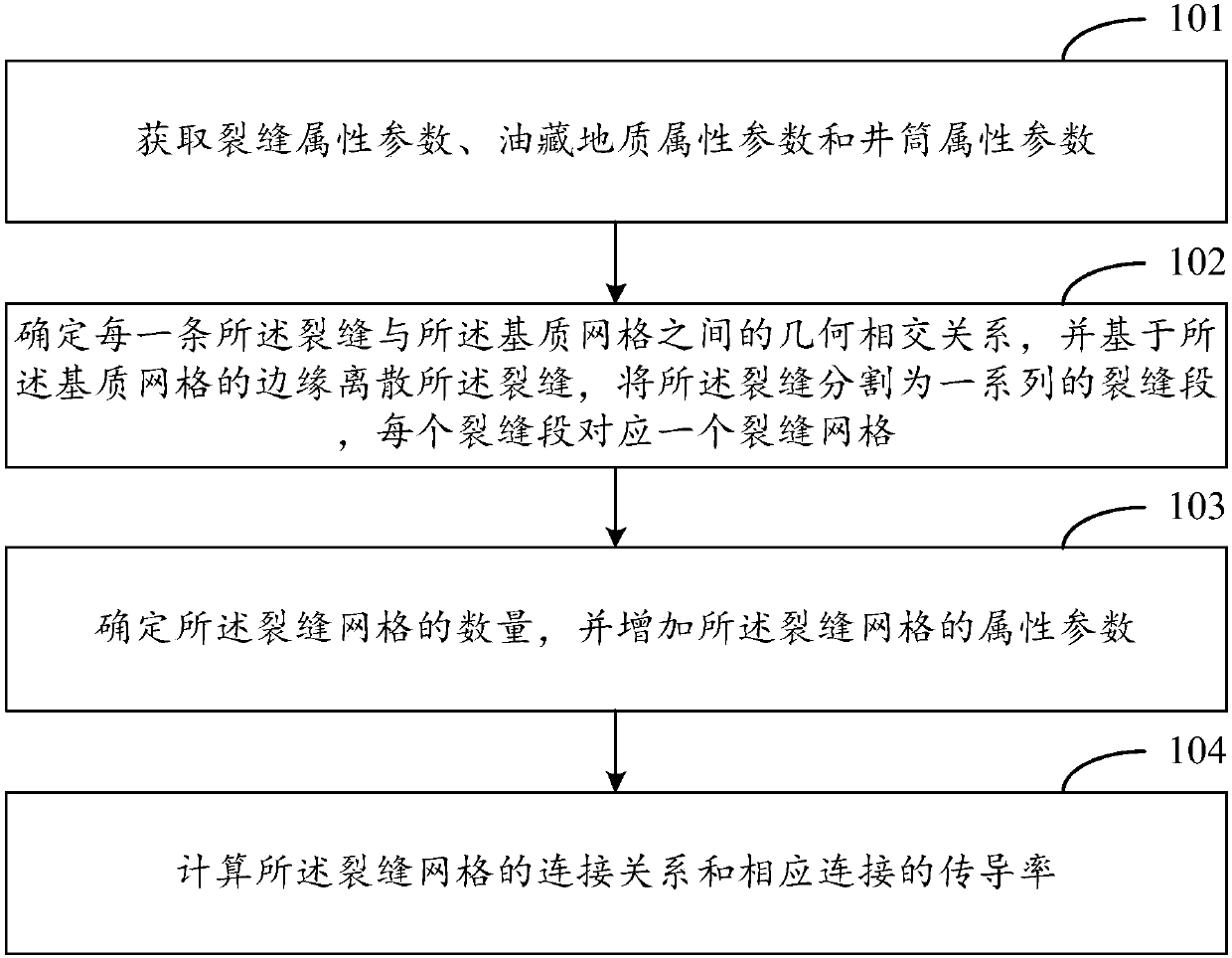

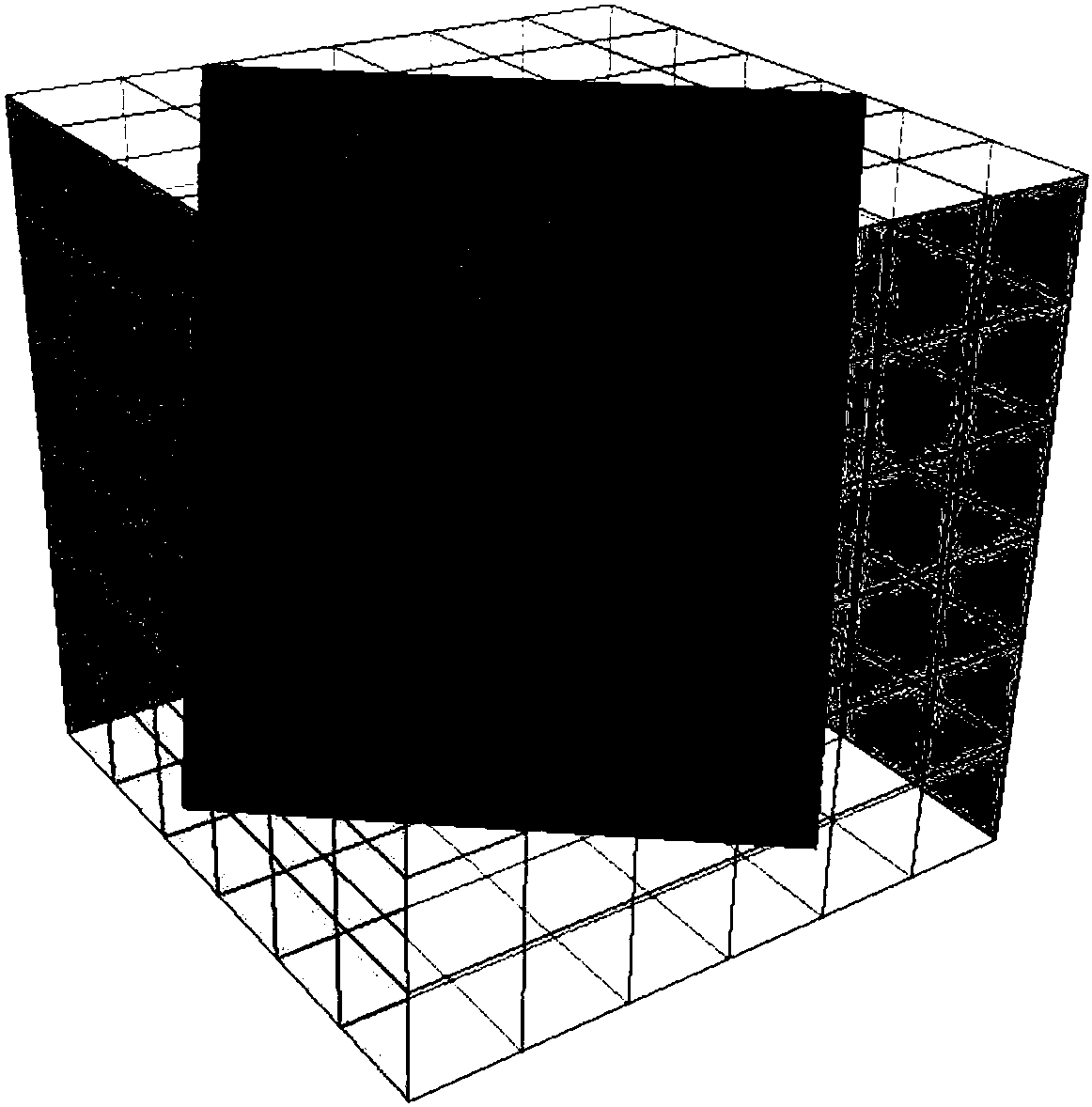

Non-invasive EDFM method for simulating complex crack and non-invasive EDFM device for simulating complex crack

The invention provides a non-invasive EDFM method for simulating a complex crack and a non-invasive EDFM device for simulating the complex crack. The method comprises the steps that the crack attribute parameters, the oil deposit geological attribute parameters and the wellbore attribute parameters are acquired; the geometric intersecting relation between each crack and the matrix grid is determined, and each crack segment is corresponding to one crack grid; the number of the crack grids is determined, and the attribute parameters of the crack grids are added; and the connection relation of the crack grids and the conductivity of the corresponding connection are calculated, wherein the connection relation and the conductivity are used for determining flowing and mass transferring of the fluid in the crack and the oil deposit geology. According to the method, crack simulation is completed by using the non-invasive mode through the third-party software, and only the keywords provided bythe commercial oil deposit numerical simulation software require to be given and modified without modifying the source code of the third-party commercial oil deposit numerical simulation software; meanwhile, local grid encryption does not need to be performed around the crack so that the total number of the grids can be greatly reduced and the complex crack can be rapidly simulated.

Owner:美国德州模拟技术公司

Material for efficiently removing basic nitrogen compounds in oils

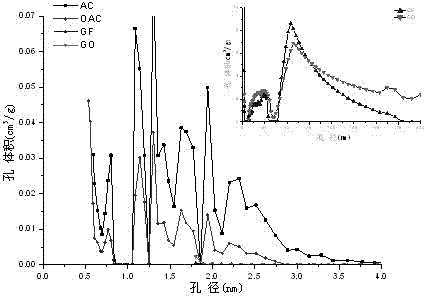

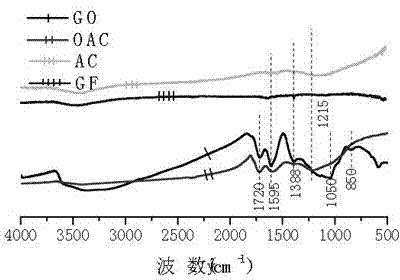

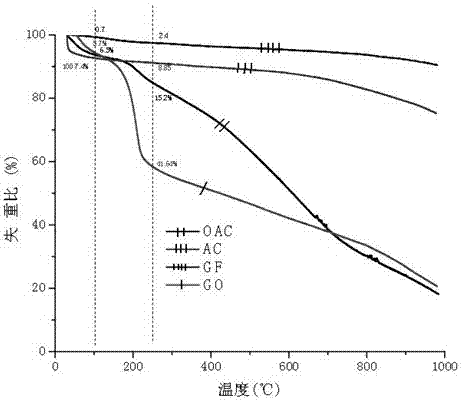

InactiveCN104232149AWide variety of sourcesLow priceSolid sorbent liquid separationHydrocarbon oils refiningAbsorption capacitySorbent

The invention discloses an adsorbing material for efficiently adsorbing and removing nitrogen. Firstly, modified graphite oxide is prepared by using an oxidizing and drying method, and the physical and chemical properties of the modified graphite oxide are qualitatively and quantificationally analyzed precisely by adopting different expression means, and then, the adsorbent is used for testing adsorption behaviors for quinoline and methyl substituted quinoline in different solvents. The adsorption capacity of the adsorbent adopted by the invention on quinoline mainly depends on high oxygen content of the adsorbent and a carboxyl functional group produced in an oxidizing process of the adsorbent, so that the adsorption capacity of the adsorbent on quinoline and methyl substituted quinoline in oils is ultrahigh; besides, according to the experimental results of influences of different solvents on the absorption capacity of the adsorbent, the adsorbent does not like the conventional oxide activated carbon adsorbent the high adsorption capacity of which is easily affected by other components in the oil, so that the prospect that the adsorbent can be used for adsorption, denitrification and refining of commercial oils on a large scale is further expanded.

Owner:SUZHOU UNIV

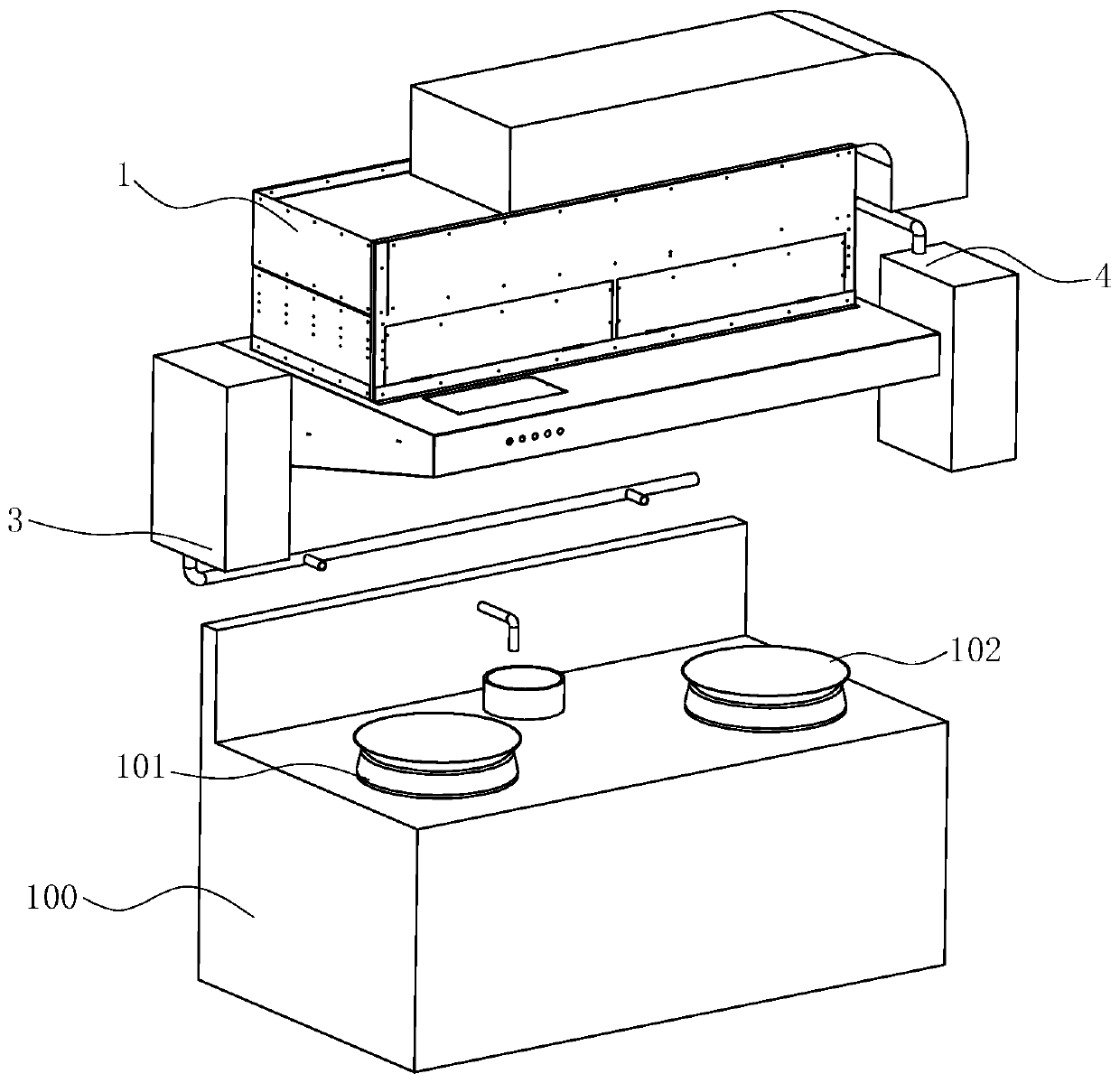

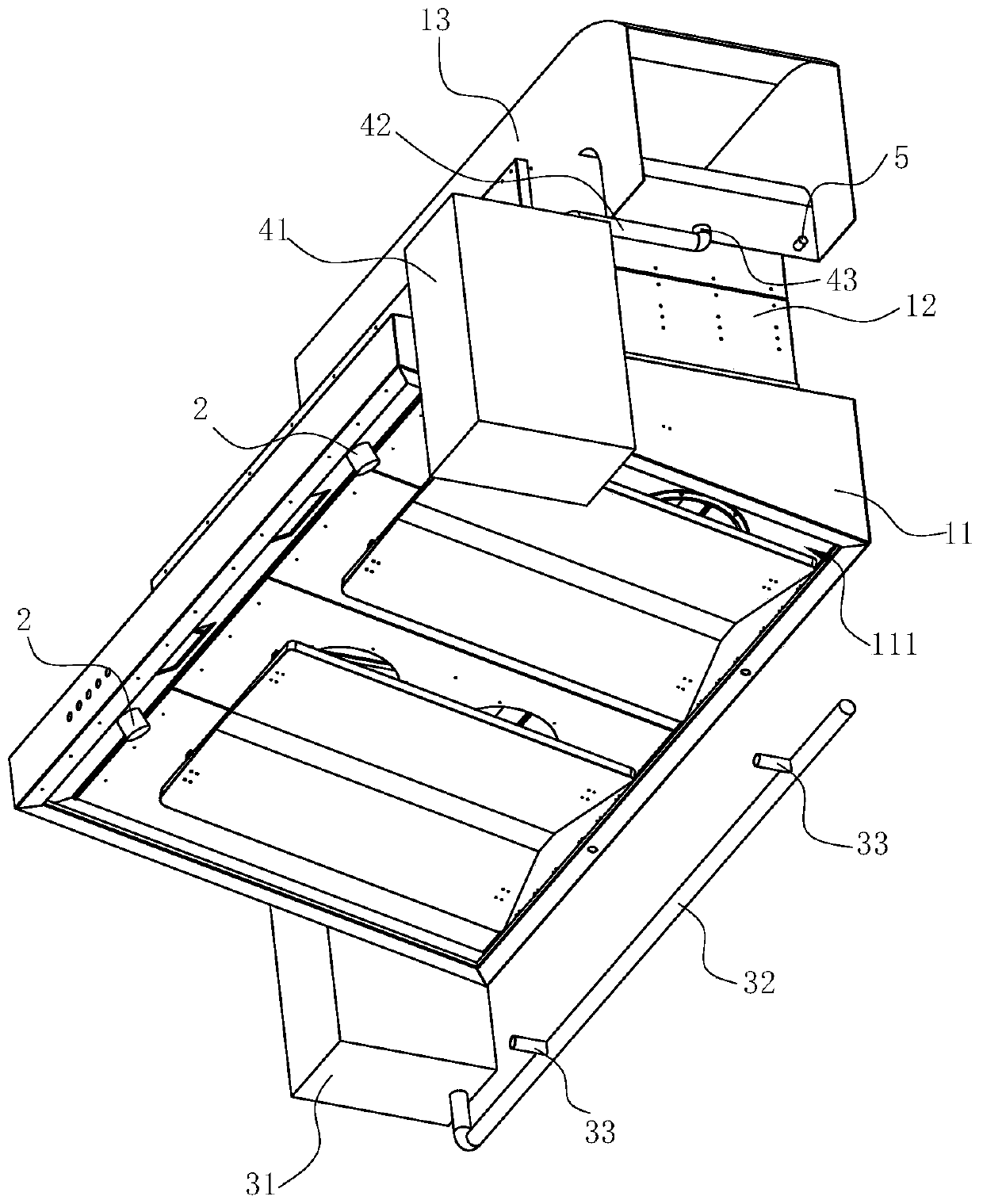

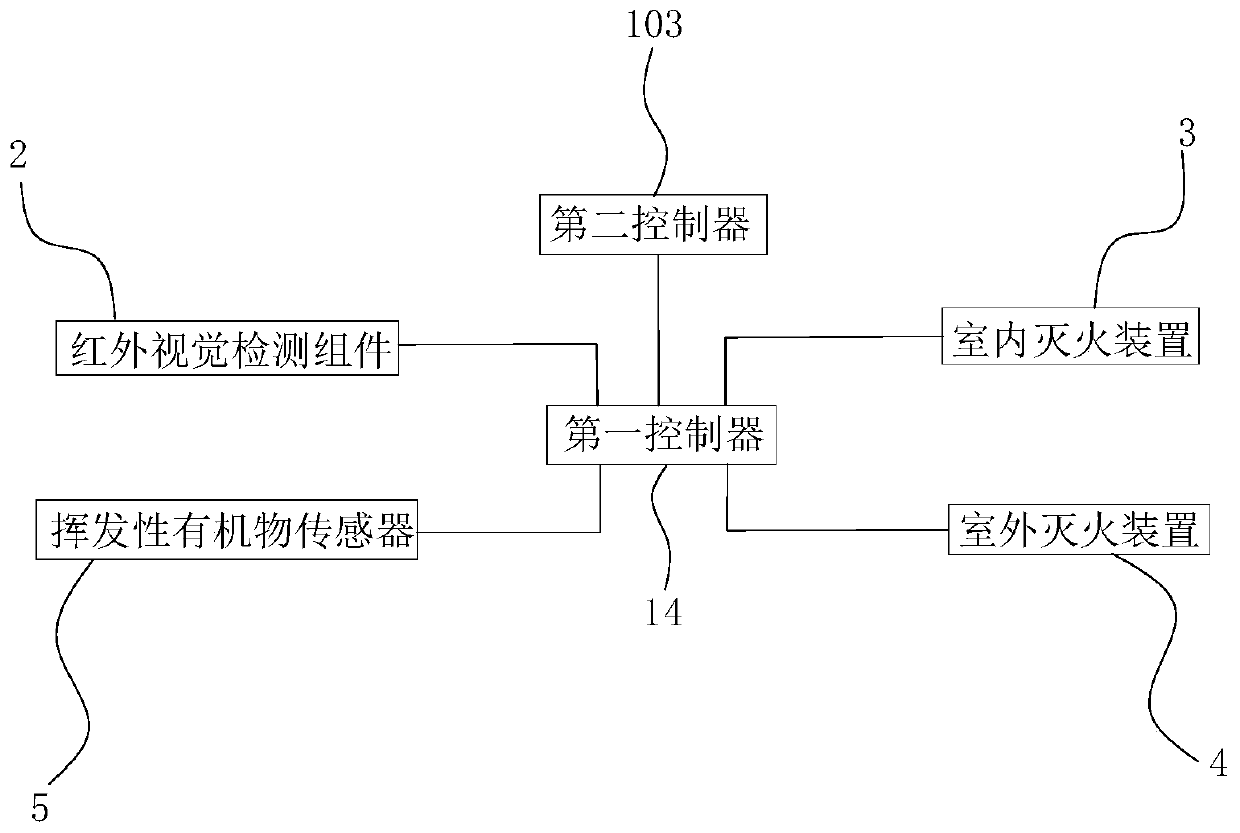

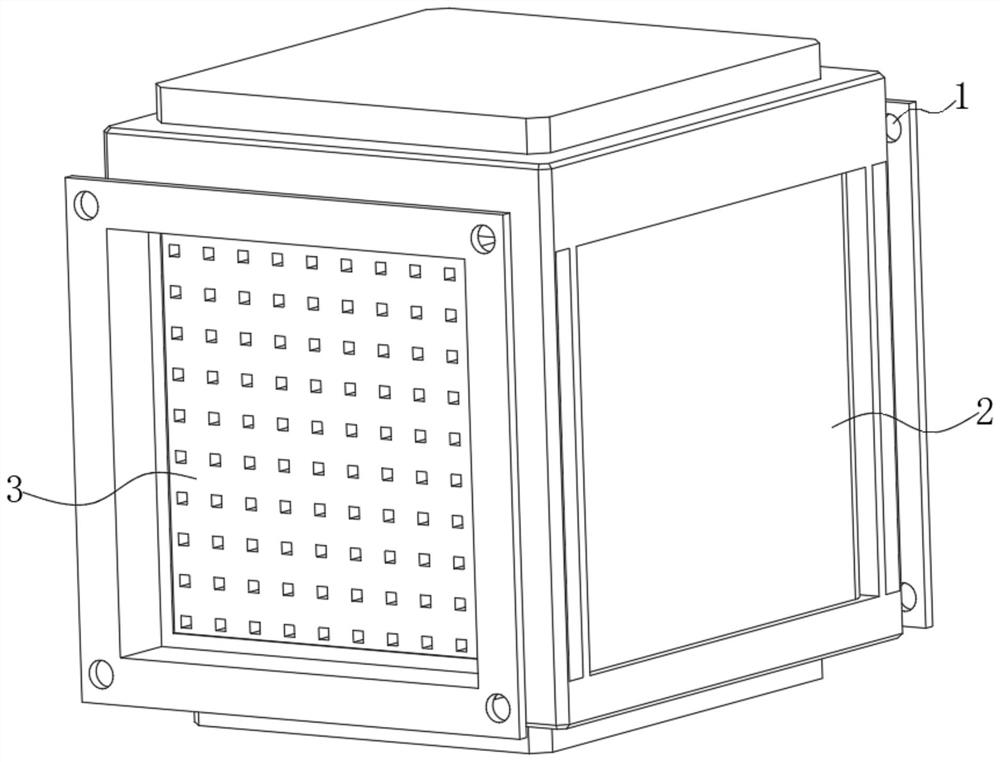

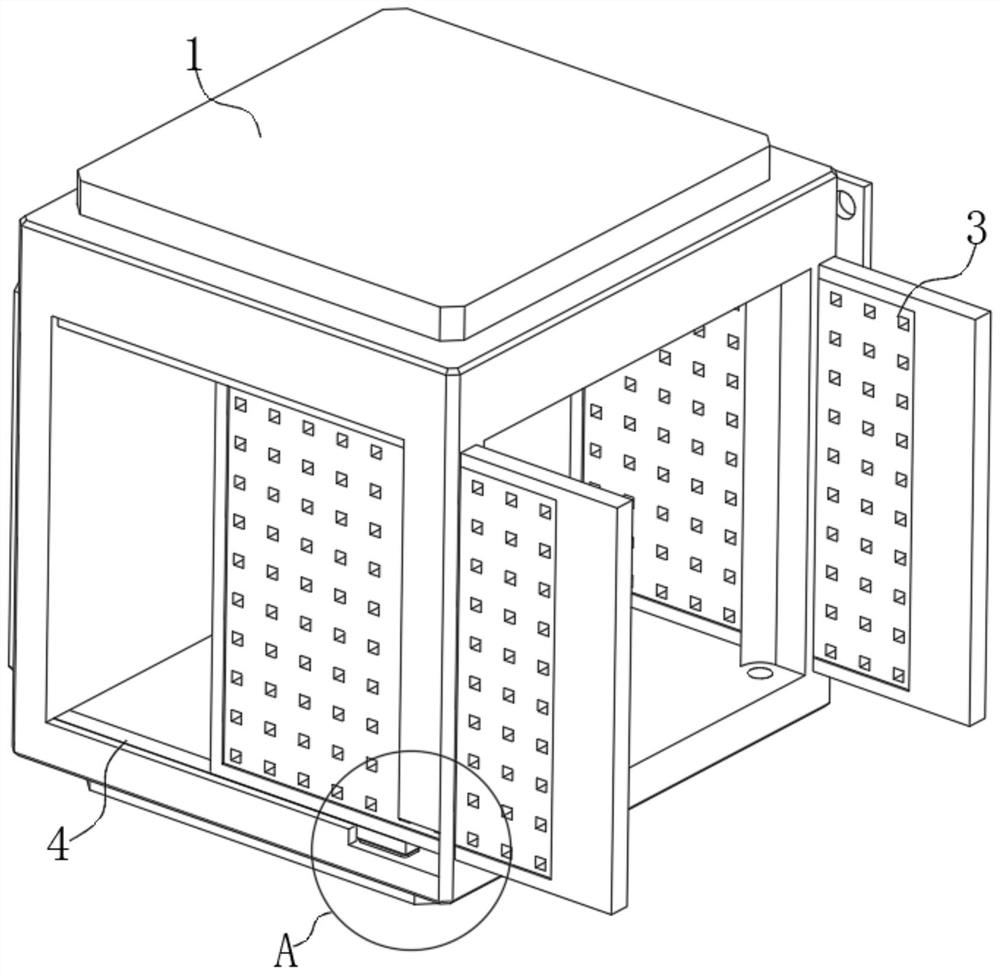

Commercial oil fume purification device and control method of commercial oil fume purification device for fire extinguishment

PendingCN110107941AAvoid spreadingAvoid misuseDomestic stoves or rangesLighting and heating apparatusElectricityVisual inspection

The invention discloses a commercial oil fume purification device. The commercial oil fume purification device comprises a range hood main body, an infrared visual inspection component for monitoringthe temperature of the upstream region of the range hood main body, and an indoor fire extinguishing device for extinguishing the fire in the upstream region of the range hood main body, wherein the infrared visual inspection component is electrically connected to a first controller of the range hood main body; and the range hood main body comprises a smoke exhausting pipeline. The commercial oilfume purification device is characterized by further comprising an outdoor fire extinguishing device for extinguishing the fire in the smoke exhausting pipeline. The invention also discloses a controlmethod of the commercial oil fume purification device for fire extinguishment. Compared with the prior art, the commercial oil fume purification device has the advantages that the simultaneous fire extinguishment at the front end and the rear end can prevent the fire from spreading backwards; the effect of protecting components and facilities at the rear end is better than the effect of purely protecting the front end, and thus, the safety damage is reduced; the need for replacing the components of the whole device is eliminated; and the fire extinguishment speed is relatively fast, and thus,the loss is reduced at the greatest extent.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

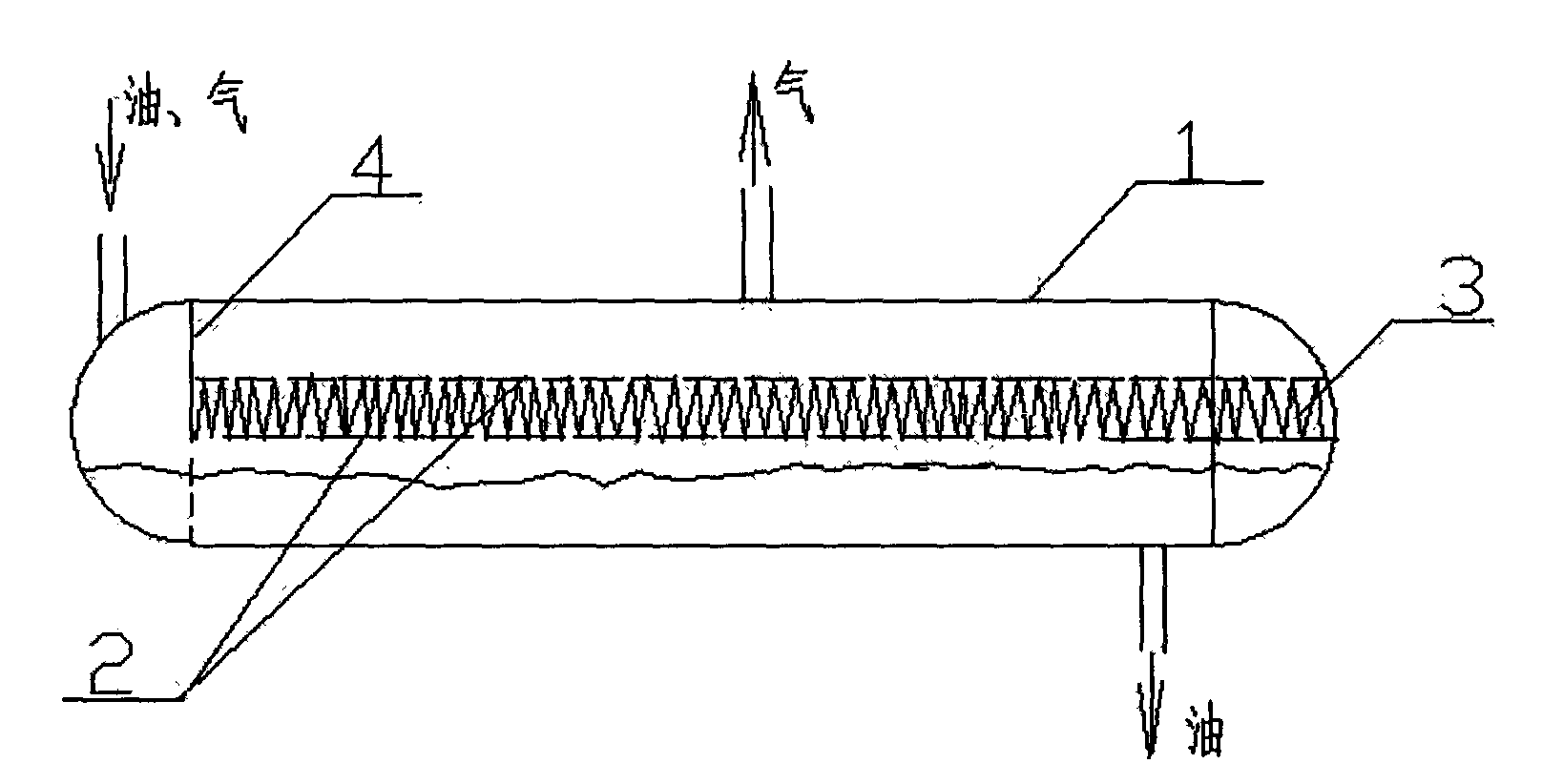

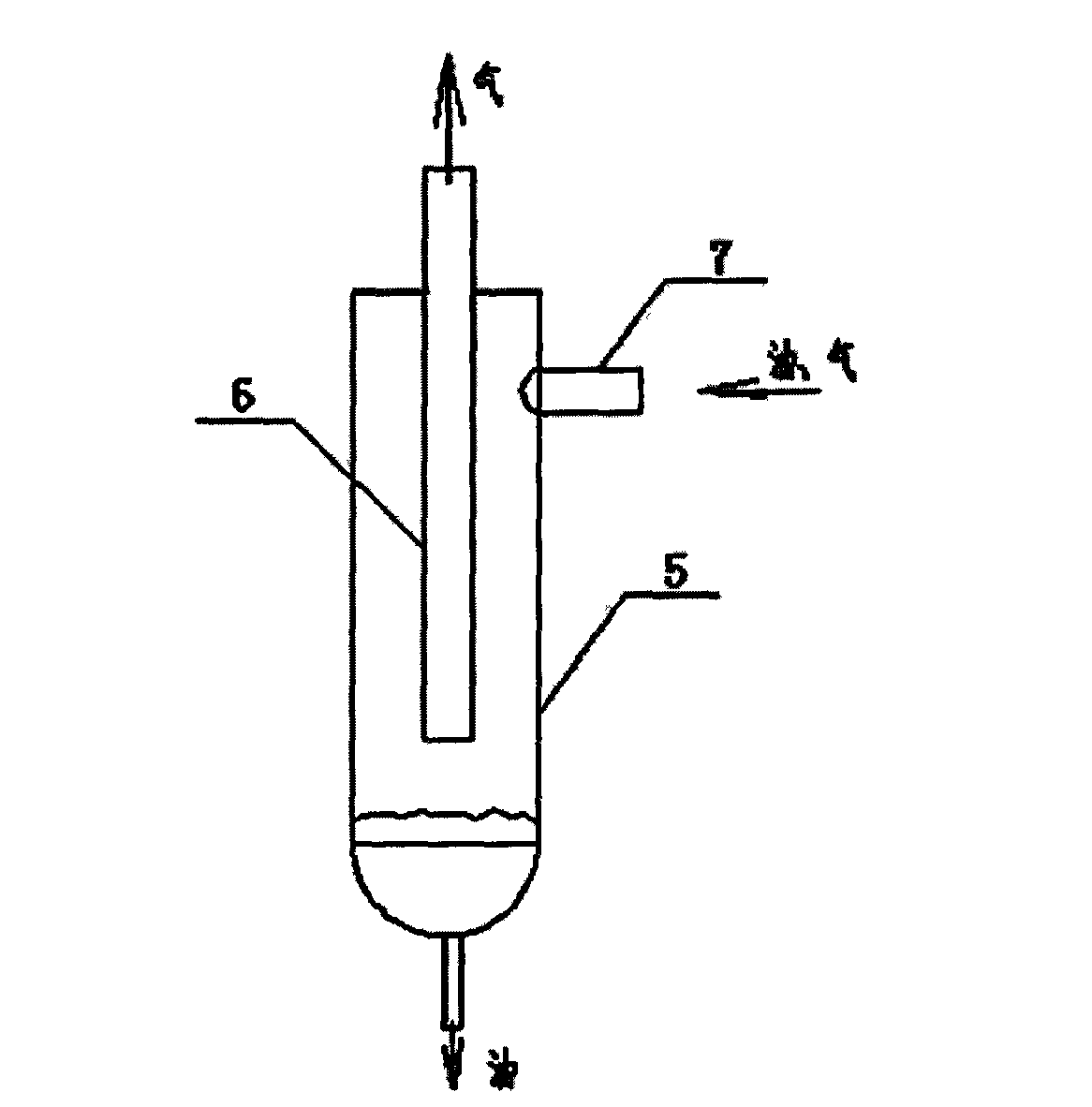

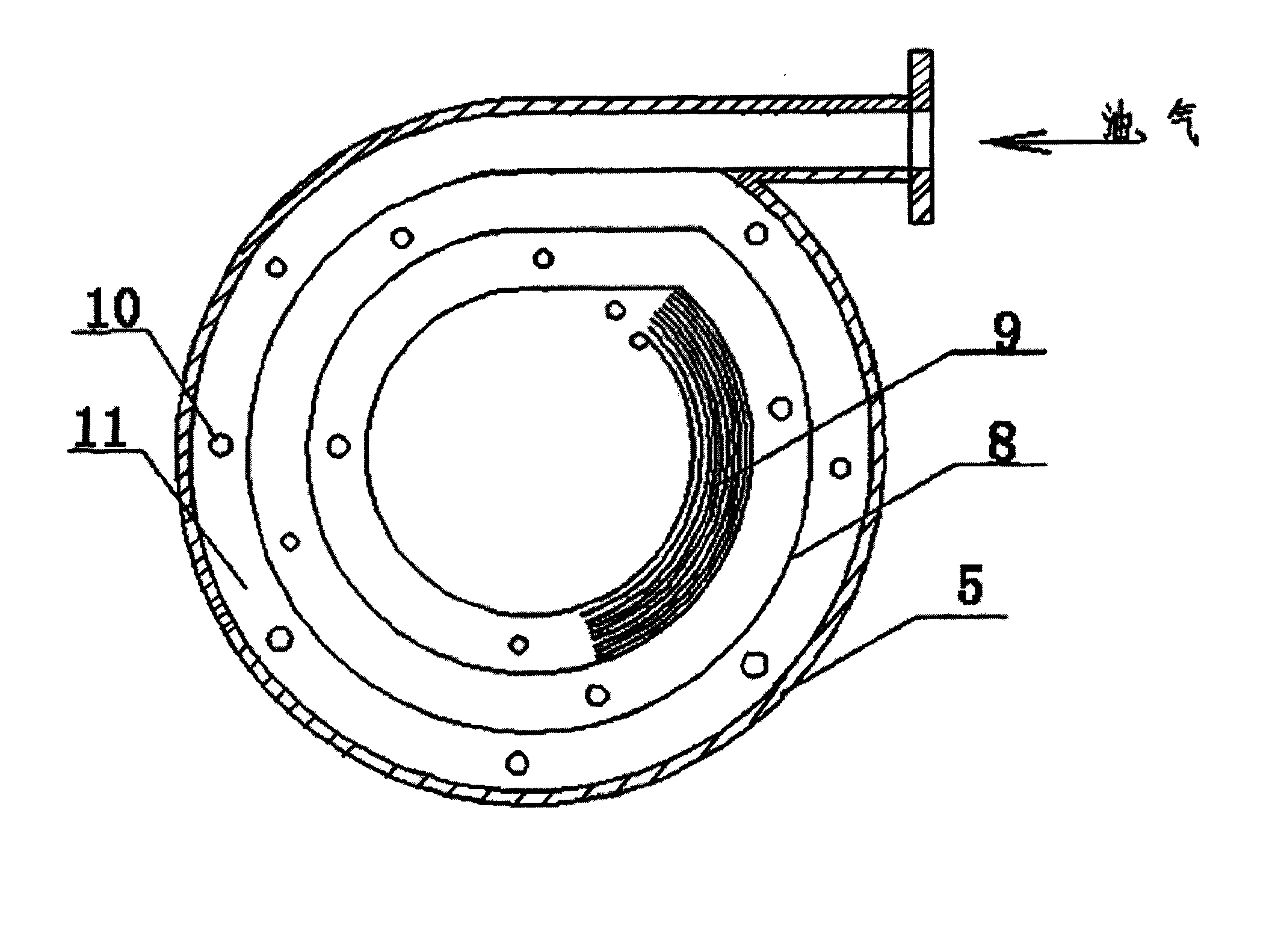

Oil-gas separator having fully-closed helical channel and tail portion micro-channels

InactiveCN103912499AReduce volumeSmall weightRotary/oscillating piston pump componentsLiquid fuel engine componentsHelical scanEngineering

The invention relates to an oil-gas separator having a fully-closed helical channel and tail portion micro-channels. The oil-gas separator comprises a cylindrical housing and an upper end plate, and is characterized by further comprising a helical channel plate and a lower end plate, wherein the helical channel plate is arranged inside the cylindrical housing, and the upper end and the lower end of the helical channel plate are sealed through the upper end plate and the lower end plate. According to the present invention, the submicron-scale fine oil droplets can be separated with the micro-channel separation device, such that the separation recovery on oil under the all operating condition can achieve 99.9%; the volume, the weight and the aerodynamic resistance of the oil-gas separator of the present invention are much smaller than the volume, the weight and the aerodynamic resistance of any one of the current commercial oil-gas separators; and the oil-gas separator belongs to the air compressor and refrigerator fitting technology.

Owner:吴昊

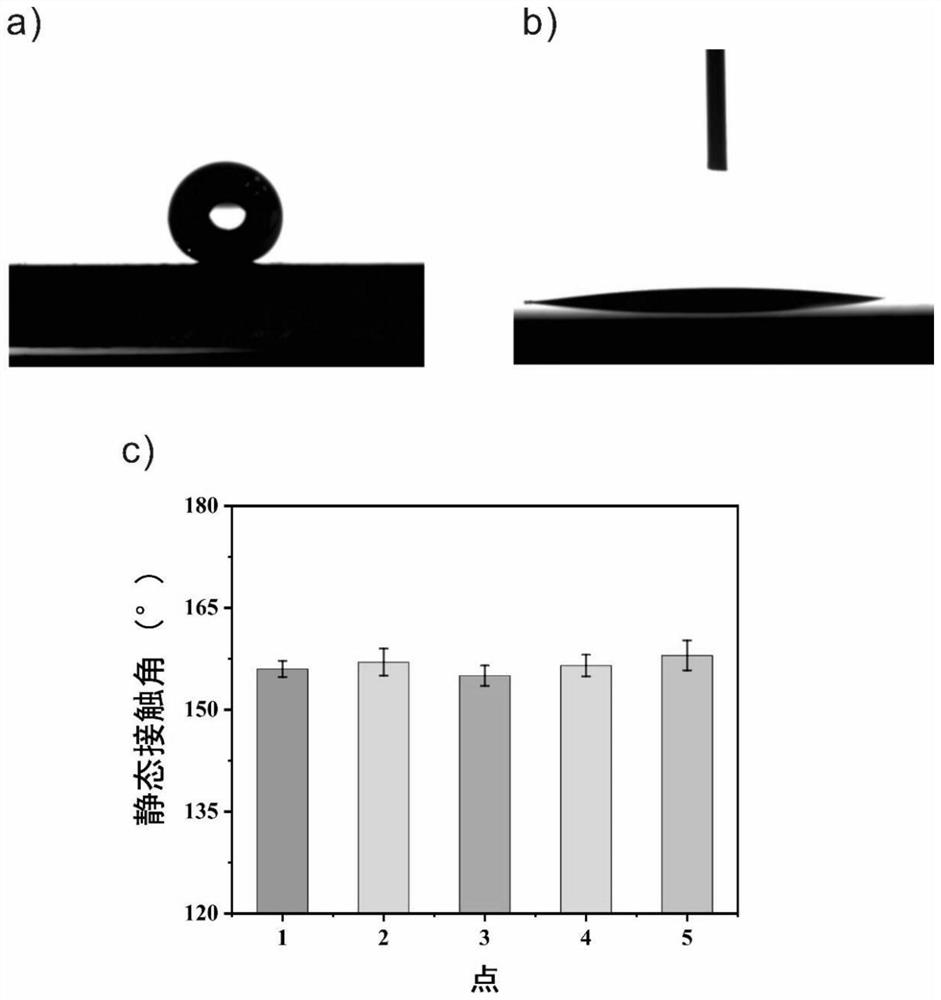

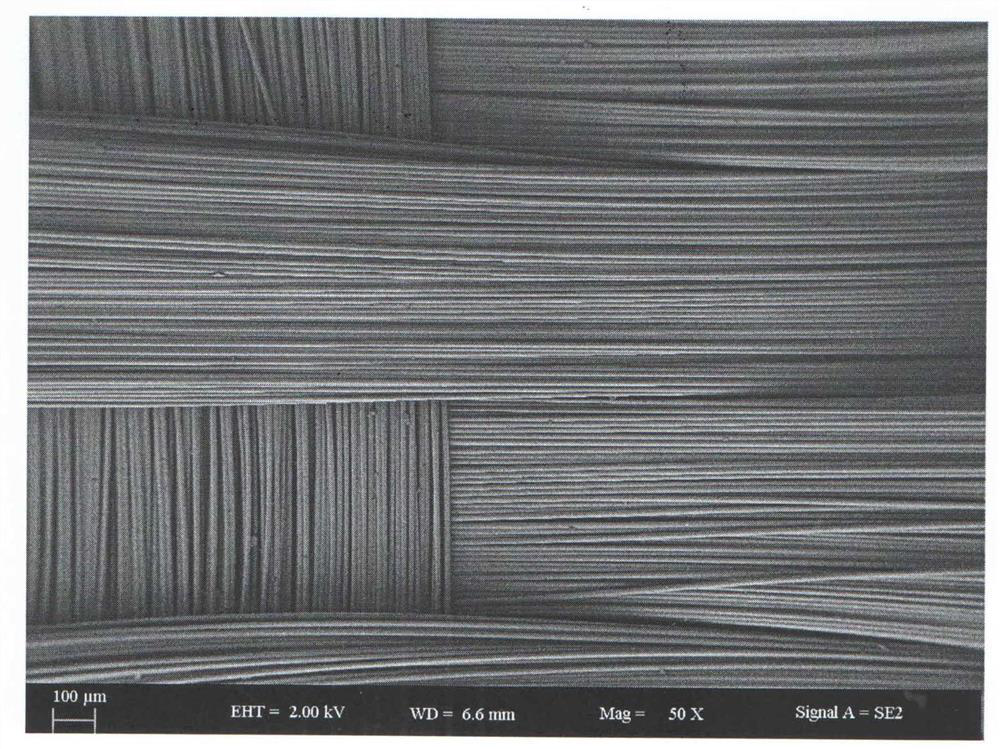

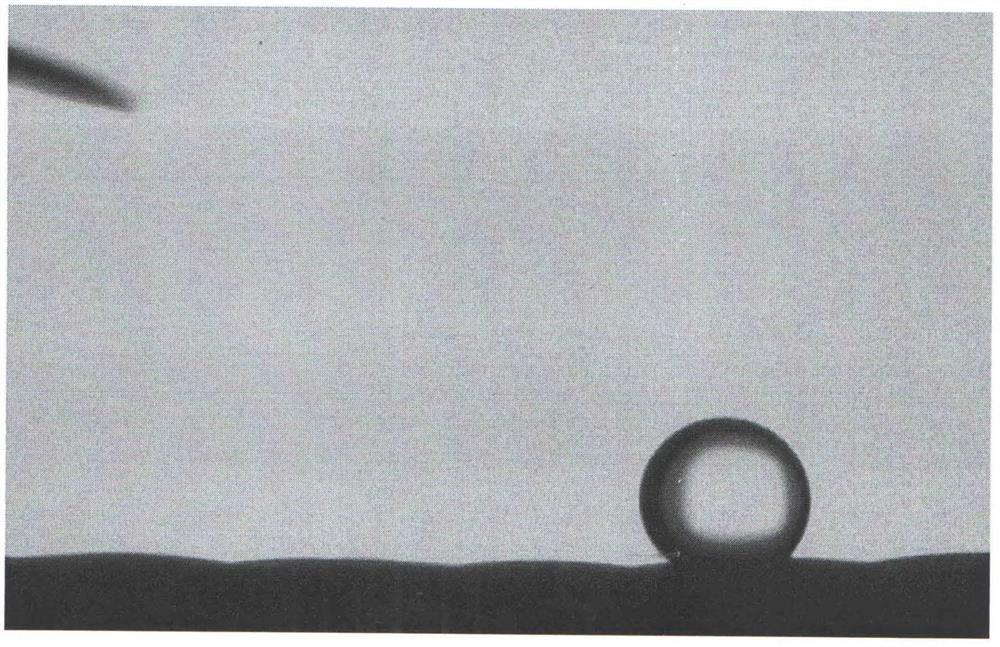

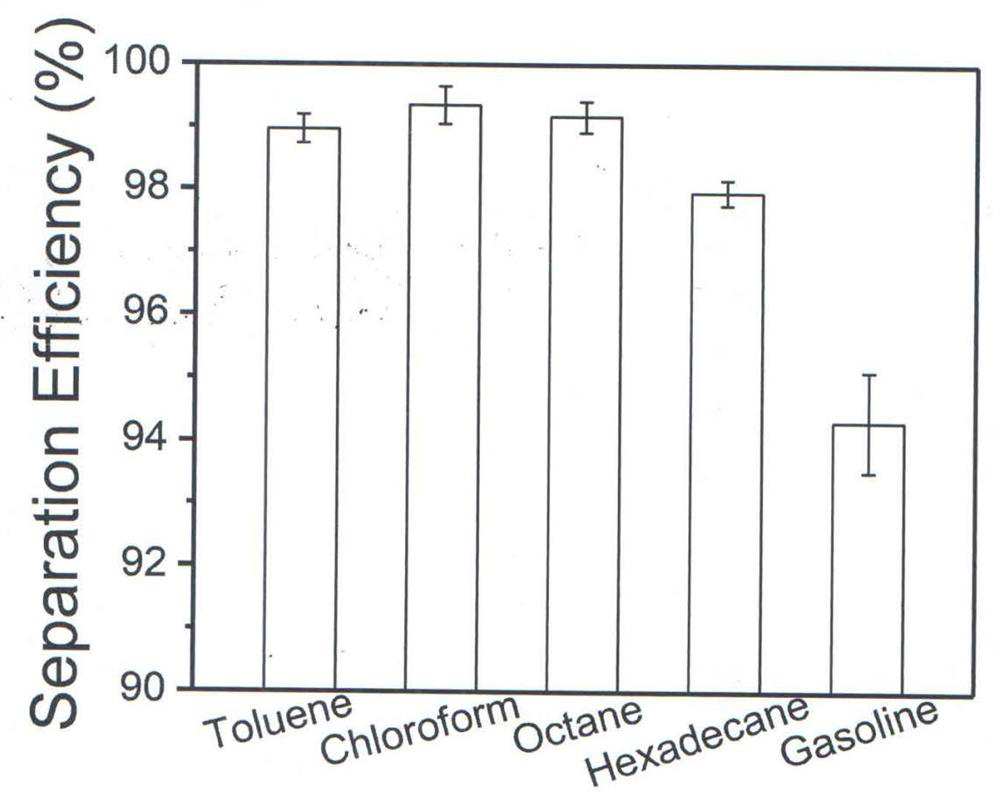

Super-hydrophilic and super-oleophobic oil-water separation ceramic membrane as well as preparation method and application thereof

PendingCN112121647ASuperhydrophilic and superoleophobicImprove cycle performanceSemi-permeable membranesMembranesCommercial OilsCeramic membrane

The invention belongs to the technical field of oil-water separation, and discloses a super-hydrophilic and super-oleophobic oil-water separation ceramic membrane as well as a preparation method and application thereof. The oil-water separation ceramic membrane is prepared by the following steps of: mixing ceramic powder and a pore forming agent, carrying out dry pressing molding under 1-20MPa, and carrying out isostatic cool pressing under 200-250MPa to obtain a ceramic blank; and sintering the ceramic blank at 1000-2000 DEG C, then immersing the ceramic blank into a mixed liquid of TEOS andPDMS, transferring the ceramic blank into a reaction chamber filled with acid steam, balancing at 30-60 DEG C, and drying at 40-60 DEG C to obtain the product. The oil-water separation ceramic membrane disclosed by the invention has super-hydrophilicity and super-oleophobicity, can still keep relatively high hydrophobicity after being repeatedly used for tens of times during super-hydrophobic treatment, can be repeatedly subjected to super-hydrophobic treatment even if the hydrophobicity becomes poor, and can be recycled, so that the problem of poor circularity of a commercial oil-water separation membrane is solved.

Owner:GUANGDONG UNIV OF TECH

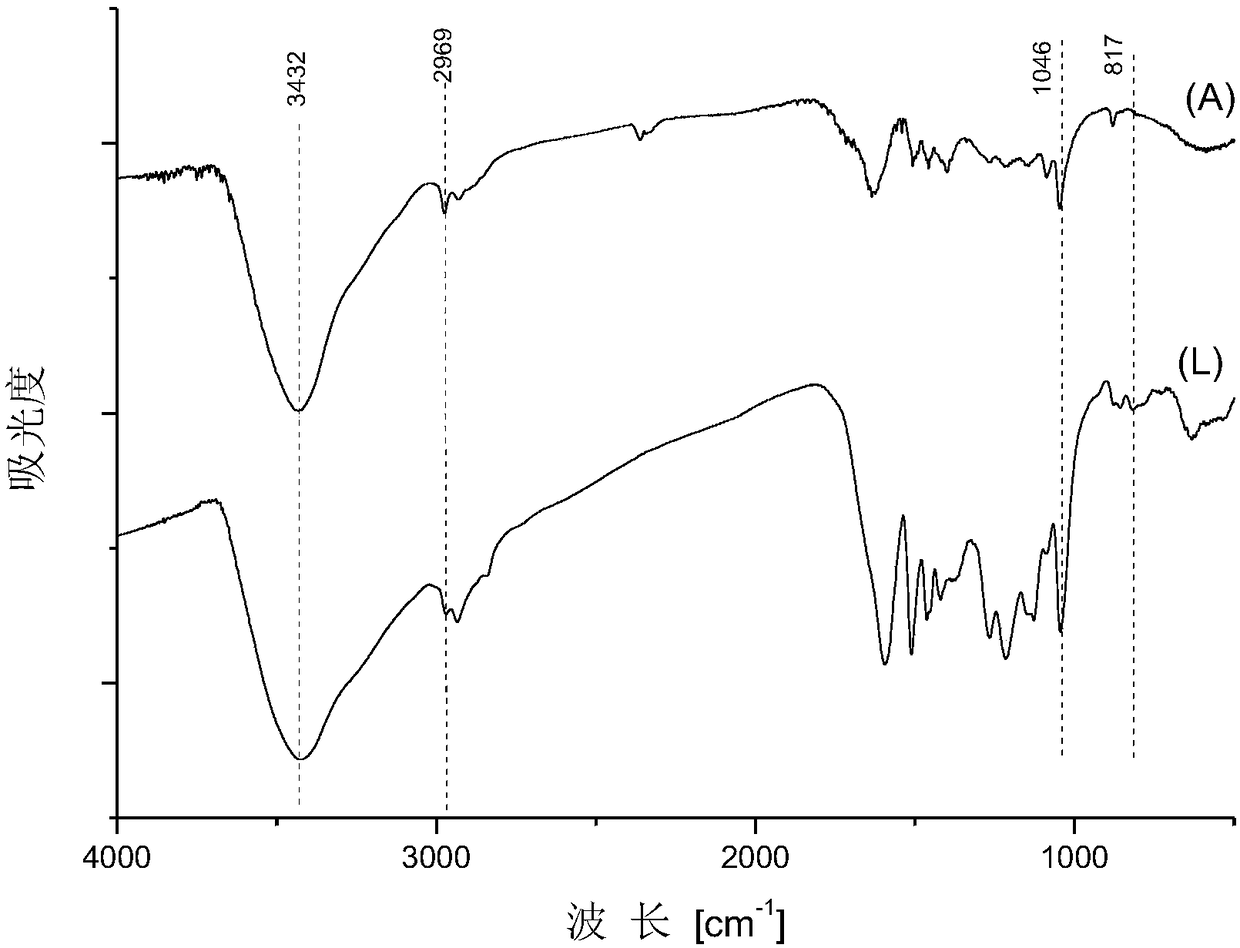

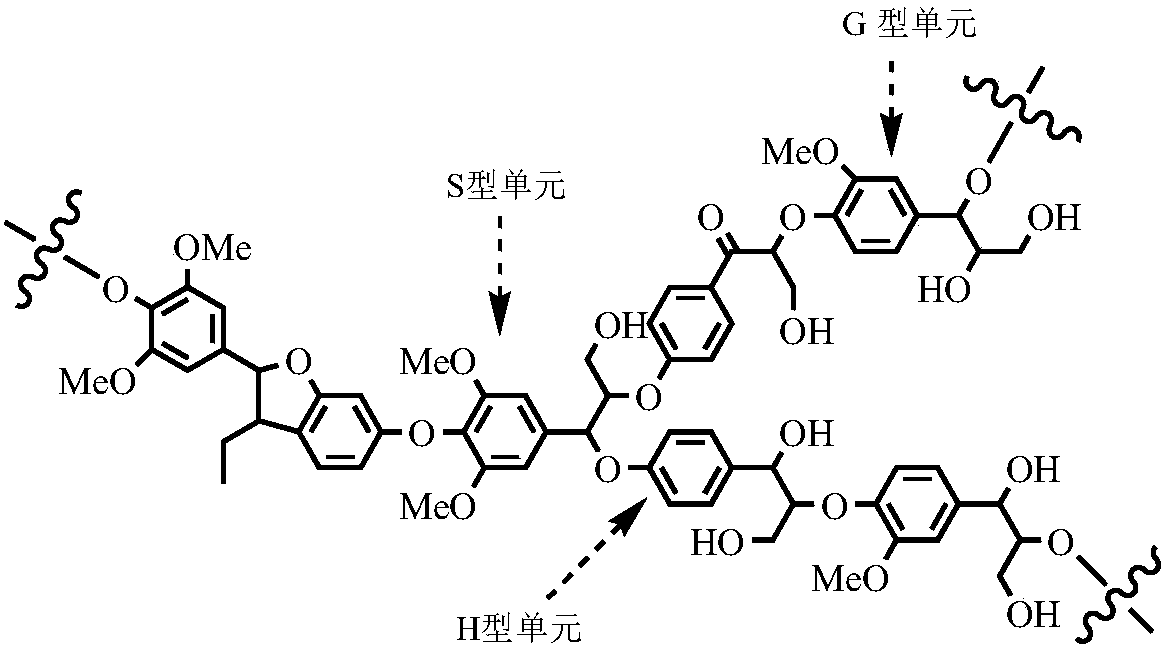

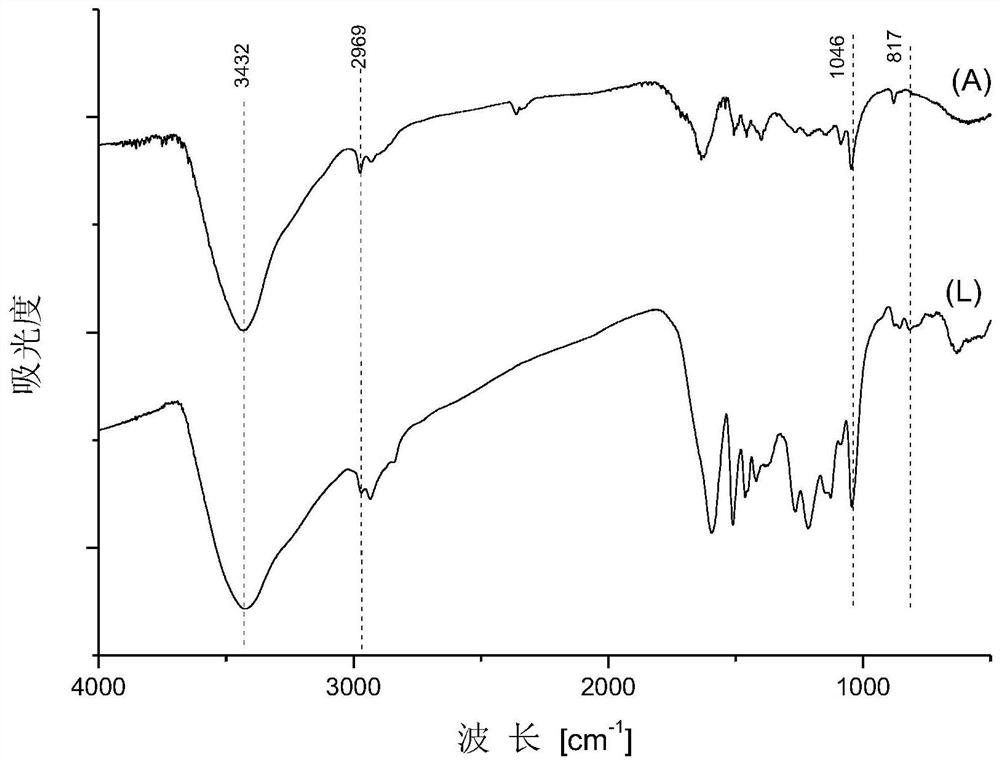

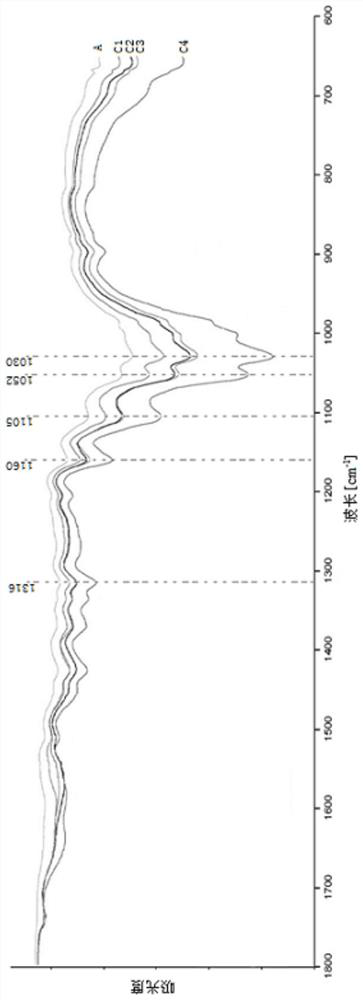

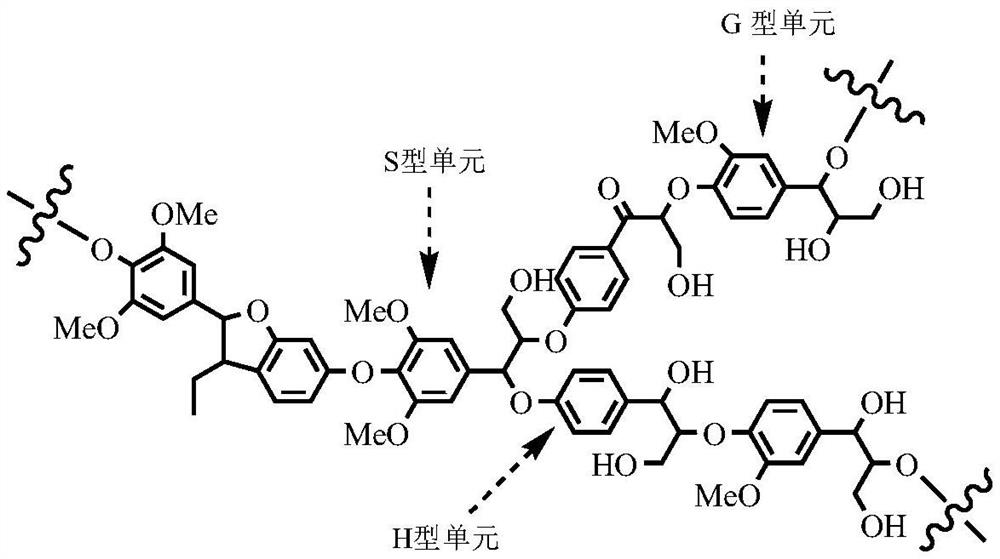

Preparation method of organosilicone-modified lignin-based strong-oil absorption material

ActiveCN109364896ASimple preparation processSimple processOther chemical processesWater contaminantsHydrolysatePhysical chemistry

The invention discloses a preparation method of an organosilicone-modified lignin-based strong-oil absorption material, and belongs to the technical field of oil absorption materials. The method comprises the following steps: performing hydroxymethylation on lignin to prepare hydroxymethylated lignin, and enabling the hydroxymethylated lignin and the organo-siloxane hydrolysate to produce polymerization reaction so as to prepare the organosilicone-modified lignin-based strong-oil absorption material. The method disclosed by the invention is simple in process, mild in reaction conditions, highin product yield, simple in processing method and low in energy consumption; the prepared organosilicone-modified lignin-based strong-oil absorption material has good oil absorption rate and biodegradability, is environmentally-friendly, and can solve the problem that the conventional commercial oil absorption material cannot be biodegraded, and effectively treat a sea surface oil pollution problem and an oil recycling problem in the waste liquid.

Owner:南京悦优生物科技有限公司

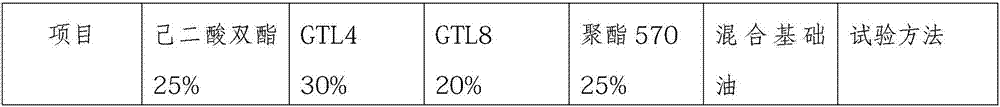

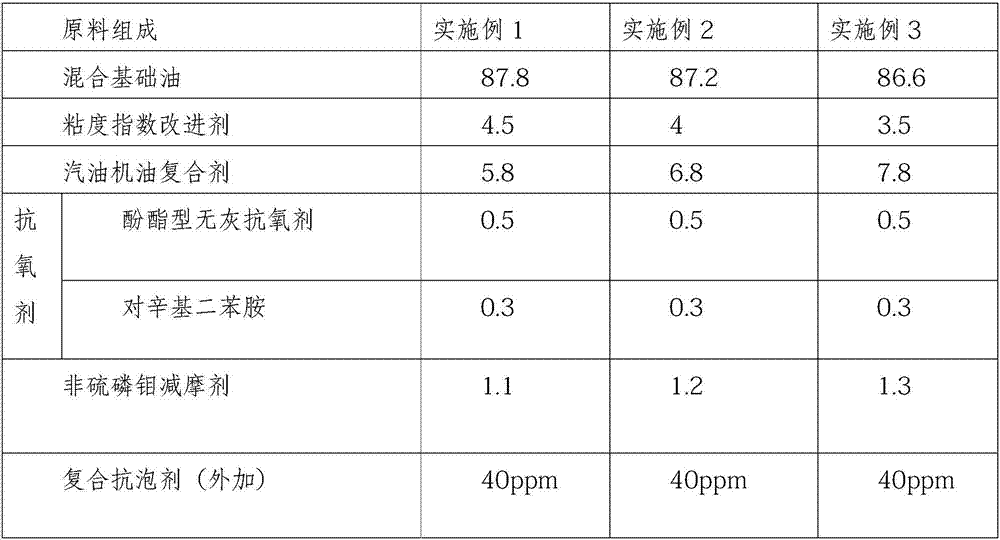

Pedal motorcycle special-purpose long-life low-noise lubricating oil

The invention relates to pedal motorcycle special-purpose long-life low-noise lubricating oil. The pedal motorcycle special-purpose long-life low-noise lubricating oil at least comprises 5.8%-7.8% of a gasoline-engine oil compound, 0.8% of an antioxidant, 1.1%-1.3% of an anti-wear friction reducer, 3.5%-4.5% of a viscosity index improver and 86.6%-87.8% of mixed base oil. The lubricating oil also comprises a compound anti-foaming agent. The gasoline-engine oil compound comprises an ashless dispersant and a total calcium-based detergent. The anti-wear friction-reducing agent is one or more of molybdenum dialkyldithiocarbamate, a molybdate and a molybdenum-amine complex. The viscosity index improver is ethylene-propylene copolymer liquid sol. Compared with the commercial oil, the lubricating oil needs longer time in consumption of the same amount of oxygen and has good oxidation resistance and abrasion resistance and a long service life. The pedal motorcycle using the lubricating oil has low noise and friction.

Owner:北京雅士科莱恩石油化工有限公司

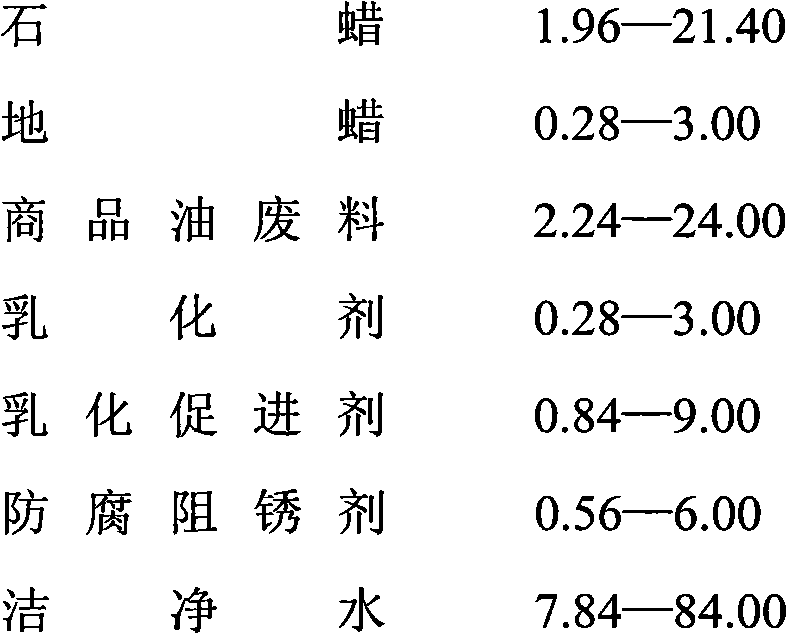

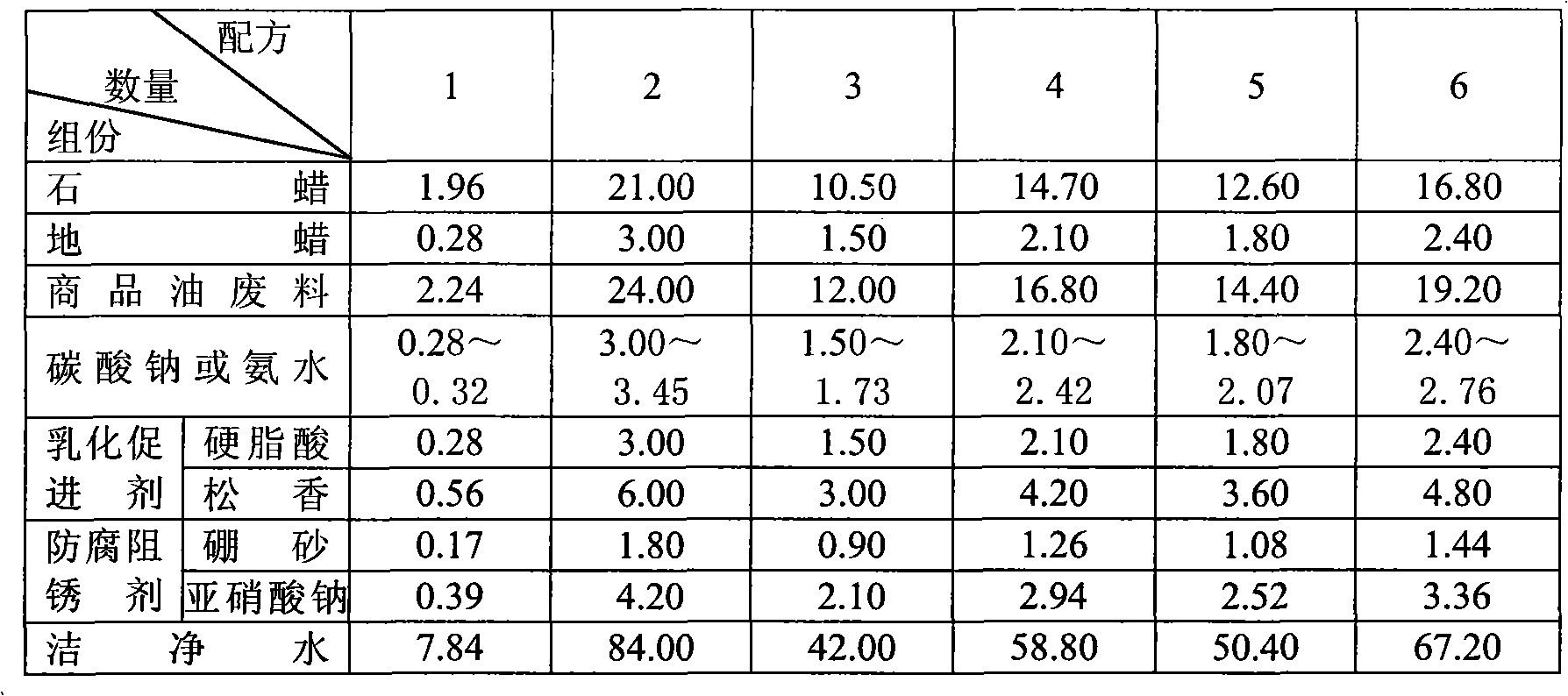

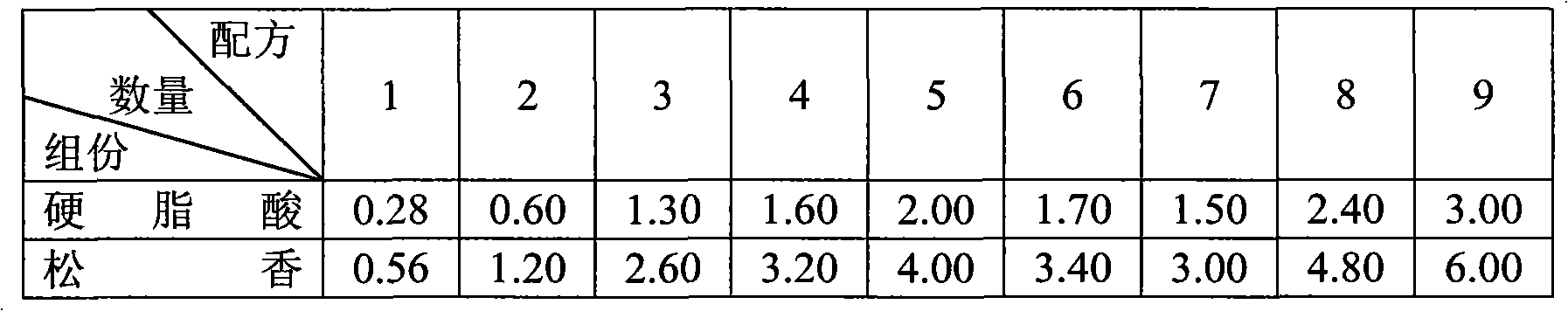

Emulsion ferrous metal (steel) antirust solution

The invention discloses emulsion ferrous metal (steel) antirust solution. The antirust solution is characterized by being 44 weight percent oil-in-water (o / w) saponified emulsion prepared from the following merchant raw materials in part by weight: 1.96 to 21.00 parts of paraffin, 0.28 to 3.00 parts of earth wax, 2.24 to 24.00 parts of commercial oil waste, 0.28 to 3.00 parts of emulsifying agent, 0.84 to 9.00 parts of emulsifying accelerant, 0.56 to 6.00 parts of anticorrosive rust inhibitor and 7.81 to 84.00 parts of clean water.

Owner:蒋欣

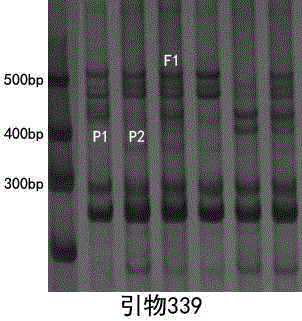

A kit for rapid identification of the purity of No. 19 oil sunflower variety

InactiveCN104164513BSpeed up identification timeAmplification effect is stableMicrobiological testing/measurementBiotechnologyHybrid seed

The invention discloses a kit for quickly identifying the purity of No. 19 oil sunflower variety. By establishing the optimal program including the oil sunflower SSR technology, the optimized combination of each component of the PCR amplification reaction and the amplification kit, and the color development program of the amplified band; the commercial oil sunflower variety Xinkui 19 and its parents Using DNA as a template, a large number of SSR primer molecular markers were screened and repeated, and primer markers 399 and 425, which can simultaneously distinguish the male parent, female parent and hybrid species, were obtained. These two primer markers can be effectively used to identify the above-mentioned new sunflower The purity of No. 19 hybrid seeds and the identification of the authenticity of the seeds are beneficial to the efficient and accurate quality control of oil sunflower hybrid seeds and speed up the quality inspection process of Xinkui No. 19 commercial seeds. It can be effectively used to identify the purity of sunflower hybrid seeds, distinguish the authenticity of the seeds, shorten the time from DNA extraction to molecular marker purity verification to within one working day, and has important application value.

Owner:新疆康地种业科技股份有限公司

Low-noise maintenance-free commercial oil gas hot water oven

InactiveCN105202600AHigh thermal efficiencyLarge heat exchange areaLighting and heating apparatusWater heating stoves/rangesLow noiseCombustion noise

The invention provides a low-noise maintenance-free commercial oil gas hot water oven which is mainly composed of a support, a waste heat recovering device, a combustor and a water tank. High-temperature waste flames and high-temperature waste smoke make contact with the waste heat recovering device in first time and in first space, and heat efficiency can be greatly improved. A waste heat recovering device body is connected with a pipe-like wing plate and a waste heat recovering device fort, the heat exchange area of the waste heat recovering device is large enough, and therefore the waste heat recovering effect is good. An oven body and the water tank are integrally installed, and kitchen space can be saved greatly. While cooking and dish frying are normally carried out, waste heat is utilized for generating a large amount of hot water or boiled water. A water-cooled flue and the water-cooled chamber are adopted in the oven, and therefore the big and difficult problem that the combustor is burned out easily is solved; the closed combustor is arranged, a silencer is installed on a smoke discharge pipe, and therefore combustion noise is low; the system is low in manufacturing cost, the service life is long, reliability is high, the combustor is free of maintenance, the production technology is simple, large-scale industrialized production can be achieved, and the oven has a wide market prospect.

Owner:侯国山

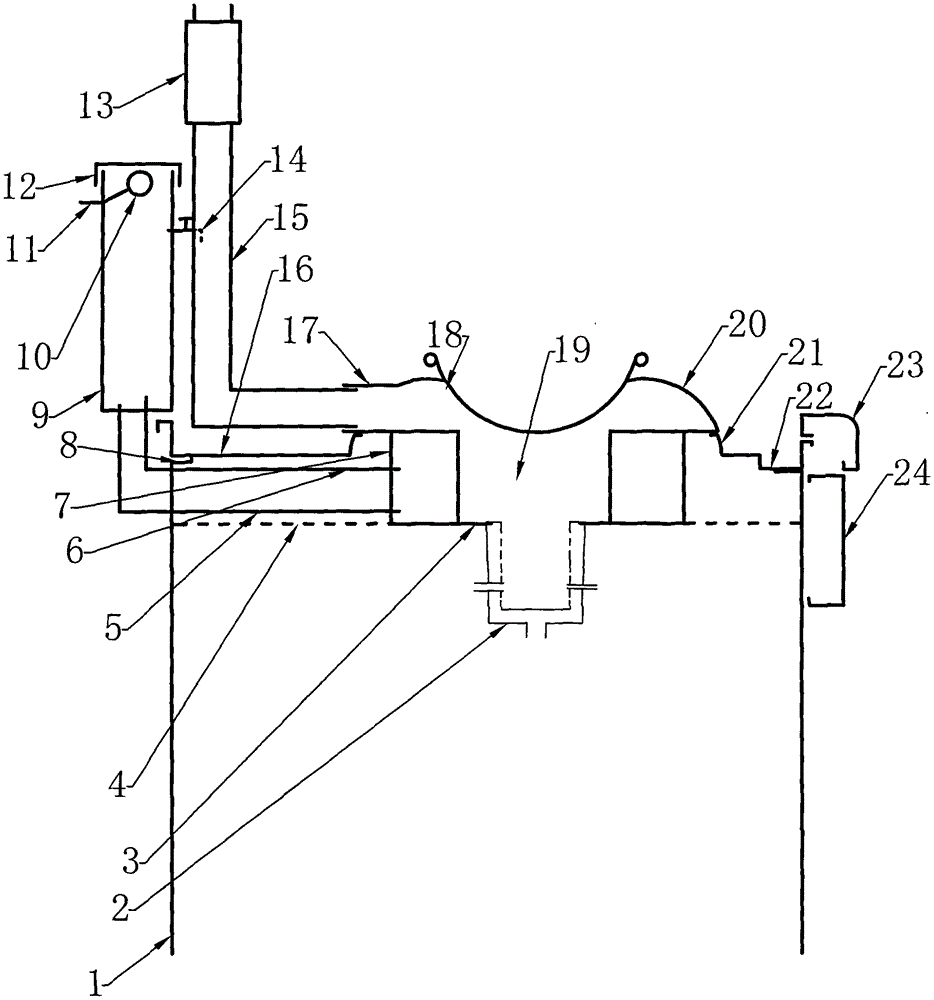

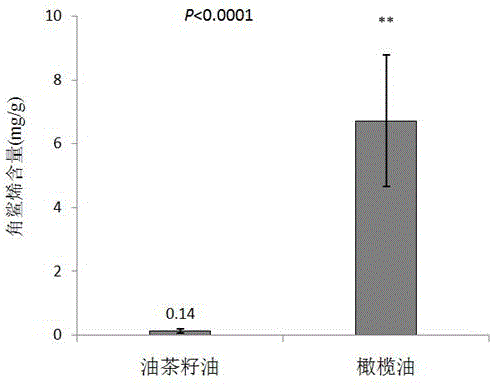

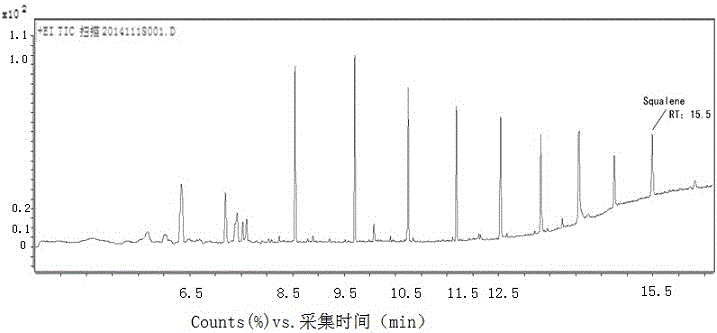

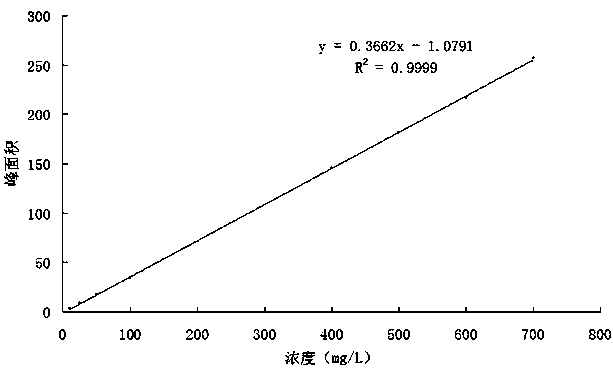

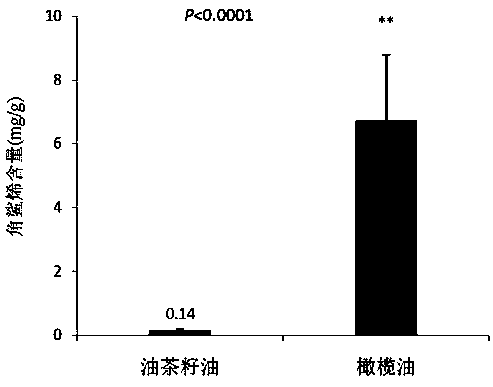

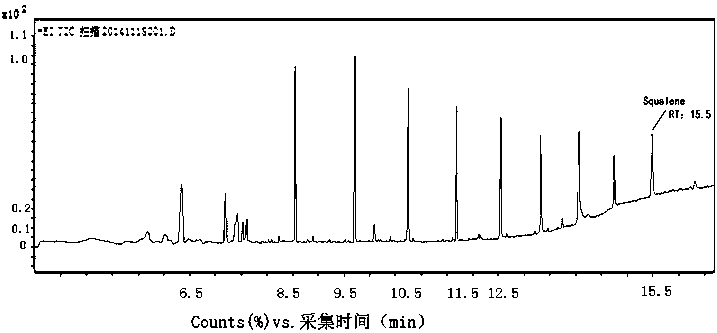

Establishing method of squalene as identification marker of olive oil and camellia seed oil

ActiveCN105784906ASimple methodGood repeatabilityComponent separationStatistical analysisCommercial Oils

The invention discloses an establishing method of squalene as an identification marker of olive oil and camellia seed oil. The method includes the steps of firstly, preparing a squalene standard product into different concentrations, detecting peak areas of different concentrations through a gas chromatograph, and calculating the standard curve and the calculation formula of the relation of the peak areas and the concentrations; secondly, conducting high-temperature saponification on camellia seed oil and olive oil extracted from camellia seeds and olive fruit respectively, or a trace sample of commercial oil, extracting squalene with petroleum ether, and detecting the peak areas of squalene in samples through the gas chromatograph to obtain the squalene contents of various samples; finally, conducting differential statistics and analysis on the squalene contents of all camellia seed oil and olive oil to obtain the squalene contents of camellia seed oil and olive oil. The sample preprocessing is simple, data is visual and reliable, and repeatability is high.

Owner:ZHEJIANG UNIV +1

Microemulsified biodiesel and preparation thereof

The invention relates to micro-emulsified biological diesel oil and a method for preparing the same. The micro-emulsified biological diesel oil is characterized by comprising the following substances in percentage by weight: wherein 50 to 60 percent of mineral diesel oil, 25 to 30 percent of animal grease, 10 to 15 percent of methanol, 0.5 to 3.0 percent of naphthenic acid, 0.5 to 3.0 percent of OP emulsifier, 0.5 to 2.0 percent of sodium dodecyl sulfonate and 0.5 to 2.0 percent of trolamine. The method for preparing the micro-emulsified biological diesel oil comprises the following steps: the animal grease, the methanol, the OP emulsifier, the sodium dodecyl sulfonate and the trolamine are evenly mixed according to weight percentage; the mixed solution is slowly poured into the mineral diesel oil under the stirring condition; simultaneously, according to the requirement of the weight percentage, the naphthenic acid is added and fully stirred and mixed, thereby preparing the micro-emulsified biological diesel oil. The micro-emulsified biological diesel oil has the advantages of high combustion efficiency, small environmental pollution, simple preparation process, convenient use and good stability and can be used as commercial oil for mass popularization and use.

Owner:郑州侨联生物能源有限公司

Noiseless waste-heat-recoverable commercial oil-gas range

InactiveCN105276641AImprove Noise CancellationExcellent waste heat recovery functionLighting and heating apparatusWater heating stoves/rangesElectricityEngineering

A noiseless waste-heat-recoverable commercial oil-gas range is mainly composed of a support, a waste-heat recoverer, a pedestal, a fire-stopping ring, an annular barrel, an electric heater and a bucket. A flue, an annular flue, a pipe, an enclosed space and a smoke pipe together form a muffler, and the muffler possesses good noise-reduction function. Also, the flue, the annular flue, the pipe, the enclosed space and the smoke pipe together form a waste-heat recovering system, and the waste-heat recovering system possesses excellent waste-heat recovering function. The range body and a water box are integrally installed, and thus a large amount of kitchen space is saved. When normal cooking and dish frying are performed, waste heat is utilized for generating a large amount of hot water, boiling water or steam. The oil-gas range can be used as an electric steamer through cooperation of the electric heater and the bucket even the range is not used to cook or fry dish. The system is low in manufacture cost, long in service life, high in reliability and simple in production technology, is suitable for large-scale industrialized production, and possesses wide market prospect.

Owner:侯国山

A preparation method of organosilicon-modified lignin-based strong oil-absorbing material

ActiveCN109364896BSimple preparation processSimple processOther chemical processesWater contaminantsCommercial OilsHydrolysis

The invention discloses a method for preparing an organosilicon-modified lignin-based strong oil-absorbing material, which belongs to the technical field of oil-absorbing materials. The method is to carry out hydroxymethylation of lignin to prepare hydroxymethylated lignin, and then polymerize the hydroxymethylated lignin with organosiloxane hydrolyzate to prepare organosilicon-modified lignin-based strong oil-absorbing oil Material. The method has the advantages of simple process, mild reaction conditions, high product yield, simple treatment method, low energy consumption, and the prepared organosilicon-modified lignin-based strong oil-absorbing material not only has good oil absorption rate, but also has biodegradability and is environmentally friendly. Friendly, it can solve the problem that conventional commercial oil-absorbing materials cannot be biodegraded, and can effectively deal with the problems of oil pollution on the sea surface and oil recovery in waste liquid.

Owner:南京悦优生物科技有限公司

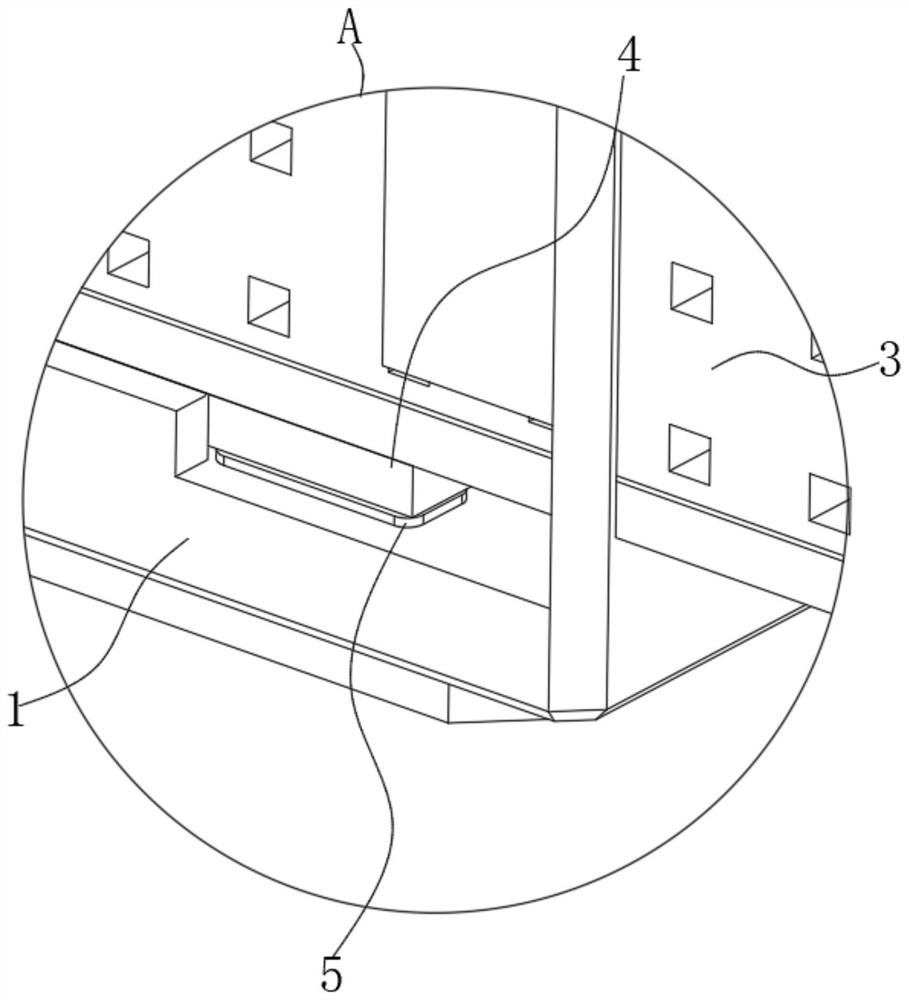

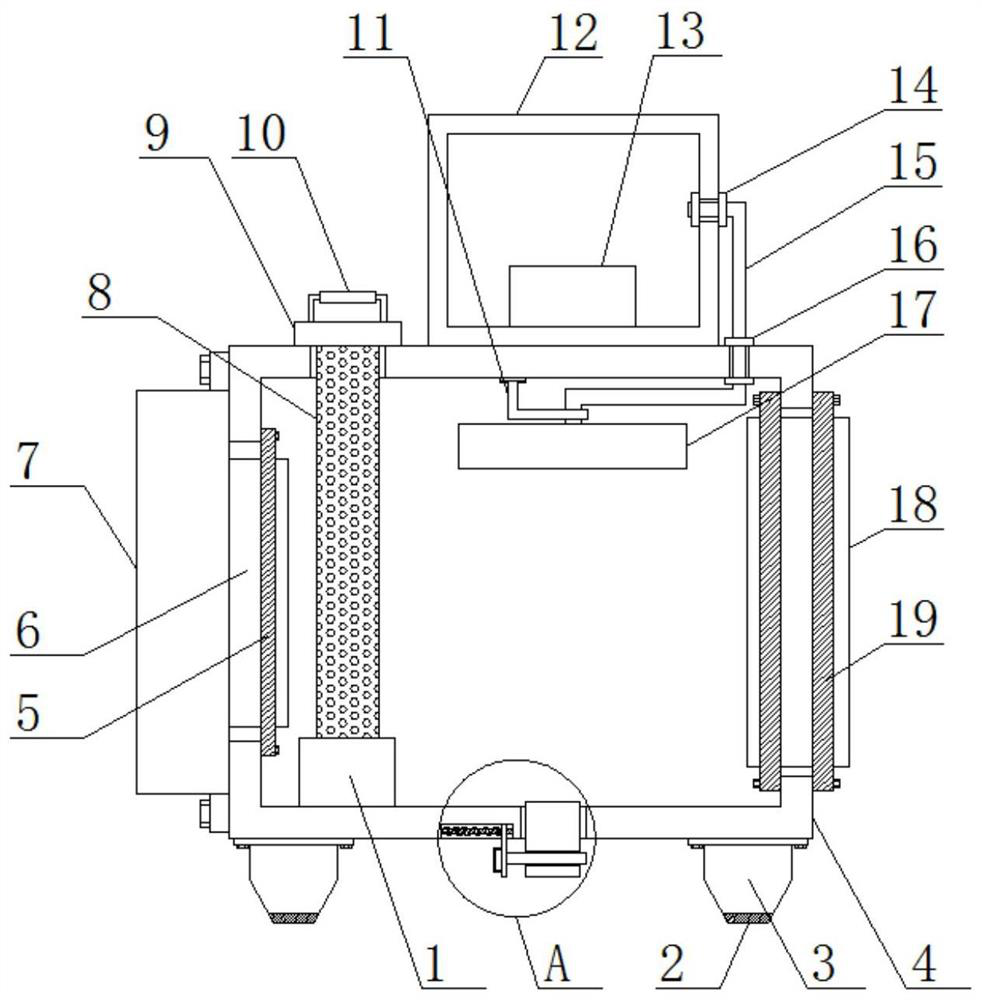

Commercial cooking fume treatment device of Internet of Things based on X86 master control

ActiveCN114515479AEasy to cleanEasy to remove for cleaningHuman health protectionGas treatmentThe InternetProcess engineering

The invention discloses an Internet of Things commercial oil fume treatment device based on X86 master control, relates to the technical field of oil fume treatment, and solves the problem that in the prior art, a user does not know when to clean a filter screen, the oil fume treatment device comprises an oil fume purifier body, one side of the oil fume purifier body is provided with an opening and closing door, and the other side of the oil fume purifier body is provided with an opening and closing door. Filter screens located in the oil fume purifier body are arranged on the other two sides, perpendicular to the opening and closing door, of the oil fume purifier body, the filter screens are slidably connected with the oil fume purifier body, mounting strips fixedly connected with the oil fume purifier body are mounted at the bottom ends of the filter screens, and pressure sensors are fixedly connected to the bottom ends of the mounting strips; according to the commercial cooking fume treatment system and device based on the internet of things and based on the X86 master control, by arranging the pressure sensor, the problem that a user does not know when to clean the filter screen in the prior art is solved.

Owner:浙江机电职业技术学院

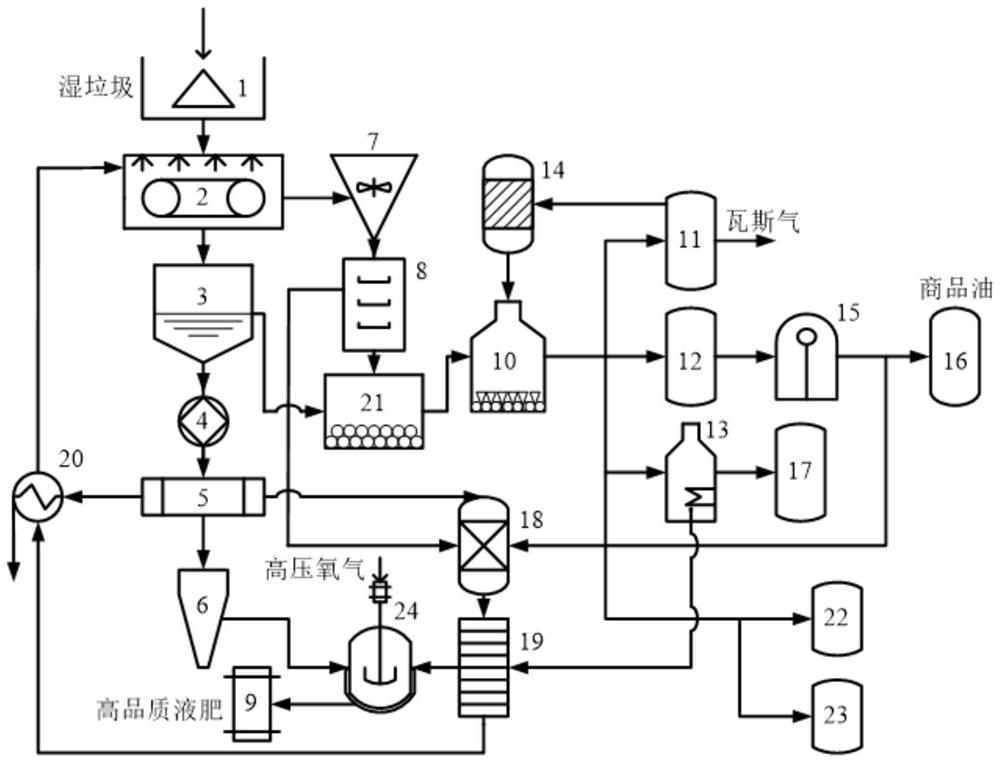

Supercritical water treatment wet garbage poly-generation comprehensive utilization system and treatment process

ActiveCN114308981ARealize resource utilizationReduce pollutionTransportation and packagingSolid waste disposalEngineeringCommercial Oils

The invention relates to a supercritical water treatment wet garbage poly-generation comprehensive utilization system and a treatment process, and the system comprises a liquid fertilizer output unit which is used for converting liquid in wet garbage into high-quality liquid fertilizer and comprises a wet garbage wet liquid supply branch and a supercritical water supply branch; the commercial oil output unit is used for converting solids in the wet garbage into commercial oil and comprises an oil phase supply branch and a solid phase supply branch; the wet garbage wet liquid supply branch and the supercritical water supply branch are overlapped on the high-temperature steam shower device (2) and the oxidation reactor (24); and the liquid fertilizer output unit further comprises a leachate collector (6). Compared with the prior art, the supercritical water, the wet garbage solid-phase dry distillation furnace, the gas combustion furnace, the semi-coke combustion furnace and the first-stage high-pressure spiral heat exchanger are organically combined, and scientific, efficient and comprehensive utilization of wet garbage waste is achieved.

Owner:SHANGHAI UNIV OF ENG SCI +1

Noise-free waste-heat-regeneration commercial oil gas stove

InactiveCN105222174AHigh thermal efficiencyIncrease the heat exchange areaLighting and heating apparatusWater heating stoves/rangesLow noiseCombustion noise

A noise-free waste-heat-regeneration commercial oil gas stove is mainly composed of a bracket, waste heat recovery devices, bases, fire-resistant rings, combustion heads and a heat preservation water tank. High-temperature waste flame and high-temperature waste smoke are in contact with the waste heat recovery devices in the first time and the first space, so that thermal efficiency is improved greatly. A plurality of heat exchange wing plates are arranged on the outer surfaces of the waste heat recovery devices, and the waste heat recovery devices have enough heat exchange areas, so that an excellent heat exchange effect is realized. Plenty of hot water, boiled water or seam can be generated by using waste heat while the oil gas stove is used for cooking. A combustion mode of the oil gas stove is a sealed combustion mode, and combustion noise is directly discharged out of a room or eliminated through a silencer, so that no combustion noise in a kitchen is realized. A stove chamber, flues, an annular flue and a smoke pipe of the oil gas stove form a simple silencer, so that the requirement of low noise in the kitchen is realized. The oil gas stove provided by the invention is low in system manufacture cost, long in service life, high in reliability and simple in production process, can be industrially produced on a large scale and has a wide market prospect.

Owner:侯国山

Establishment of squalene as a marker for identification of olive oil and camellia oleifera oil

ActiveCN105784906BSimple methodGood repeatabilityComponent separationStatistical analysisCommercial Oils

The invention discloses an establishing method of squalene as an identification marker of olive oil and camellia seed oil. The method includes the steps of firstly, preparing a squalene standard product into different concentrations, detecting peak areas of different concentrations through a gas chromatograph, and calculating the standard curve and the calculation formula of the relation of the peak areas and the concentrations; secondly, conducting high-temperature saponification on camellia seed oil and olive oil extracted from camellia seeds and olive fruit respectively, or a trace sample of commercial oil, extracting squalene with petroleum ether, and detecting the peak areas of squalene in samples through the gas chromatograph to obtain the squalene contents of various samples; finally, conducting differential statistics and analysis on the squalene contents of all camellia seed oil and olive oil to obtain the squalene contents of camellia seed oil and olive oil. The sample preprocessing is simple, data is visual and reliable, and repeatability is high.

Owner:ZHEJIANG UNIV +1

Preparation method of polyethyleneimine oil-water separation composite membrane material

ActiveCN112642304AThe preparation method is simple and easyEasy to masterMembranesSemi-permeable membranesOrganosolvOil phase

The invention discloses a preparation method of a polyethyleneimine oil-water separation composite membrane material. The method comprises the following steps: taking basalt fiber fabric as a substrate material, taking polyethyleneimine as a functional material, and taking a mechanism that elemental sulfur can react with polyethyleneimine and amino on a silane coupling agent KH-550 as a mechanism so as to obtain the oil-water separation material with a function of selectively separating an oil-in-water emulsion. According to the method, the silane coupling agent KH-550 is used for endowing amino groups to the basalt fiber fabric, then a soaking method is adopted for coating the surface of the basalt fiber fabric with the polyethyleneimine, and finally the elemental sulfur is used for fixing the polyethyleneimine to the surface of the basalt fiber fabric, so that the composite membrane material is obtained. Polyethyleneimine modification fully changes the wettability of the fiber fabric under water, and provides a favorable premise for the material to separate the oil-water emulsion under the action of gravity. The composite membrane material is mainly used for treating an emulsified oil-water mixture, and can be used for effectively separating various oil-in-water emulsions prepared by taking an organic solvent and a commercial oil product as oil phases.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

High-efficiency commercial oil fume purification device

InactiveCN112254189AAchieve purificationImprove adsorption efficiencyDomestic stoves or rangesLighting and heating apparatusAlkaline waterActivated carbon

The invention belongs to the technical field of oil fume treatment, and particularly relates to a high-efficiency commercial oil fume purification device. The high-efficiency commercial oil fume purification device comprises a box body. A cavity is formed in the box body. A fixed block is fixed at the bottom end in the cavity. An activated carbon rod is inserted into the fixed block. The upper endof the activated carbon rod penetrates through the box body and is connected with a sealing block. The lower end of the sealing block abuts against the side wall of the upper end of the box body, anda lifting handle is fixed to the upper end of the sealing block. An alkaline water storage box is fixed to the upper end of the box body. A booster pump is fixed in the alkaline water storage box. The interior of the alkaline water storage box communicates with a liquid conveying pipe. One end of the liquid conveying pipe sequentially penetrates through the alkaline water storage box and the boxbody and communicates with a spray head. A fixing frame is fixed to the top end in the cavity. The liquid conveying pipe is sleeved with the fixing frame. The high-efficiency commercial oil fume purification device combines a chemical oil fume treatment mode and a physical oil fume treatment mode, and the oil fume treatment efficiency is improved.

Owner:陈波

Oil lubrication compressor gas supplied circulating refrigerating device

InactiveCN100441980CEasy to processReduce manufacturing costCompressorCompression machinesHigh pressureCommercial Oils

The invention relates to an oil lubrication valve compressor air feed recirculation refrigerator, comprising a high pressure end of a oil lubrication compressor, a water condenser, a high pressure air collector, an oil lubrication rotatable valve, a low pressure air collector and a low pressure end of the oil lubrication compressor sequentially connected, and a return circuit is formed, further comprising a balance air room and an elastic film box paralleled arranged between the condenser and the oil lubrication rotatable valve, the balance air room and the elastic film box are composed by a box provided with a small hole at the box wall and an elastic film arranged inside the box body, the inner cave of the elastic film box body is divided to two parts respectively communicated with the condenser and the oil lubrication rotatable valve. The damage of the elastic film caused by the abrupt decrease of the pressure on one side of elastic film in the process of starting the hypothermia process could be prevented, the high stability commercial oil lubrication compressor could be used to drive the condenser, simultaneously the pressure vibration frequency could be controlled according to the request of the condenser, The invention is a high reliability and low cost recirculation refrigerator.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com