Oil-gas separator having fully-closed helical channel and tail portion micro-channels

A technology of oil-gas separator and micro-channel separation, which is applied in the direction of rotary piston type/oscillating piston type pump components, machines/engines, components of pumping devices for elastic fluid, etc., to achieve the effect of cost reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

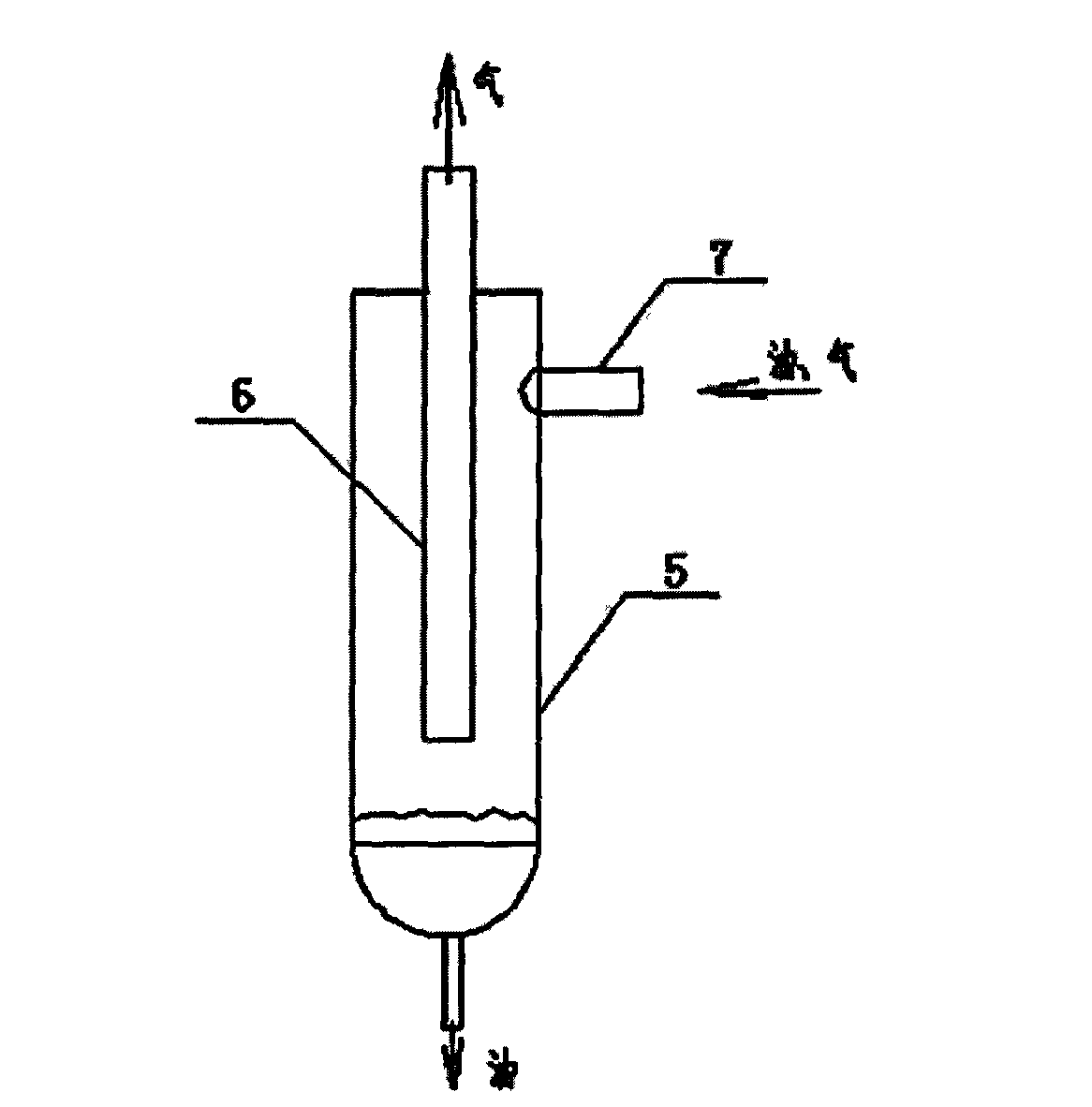

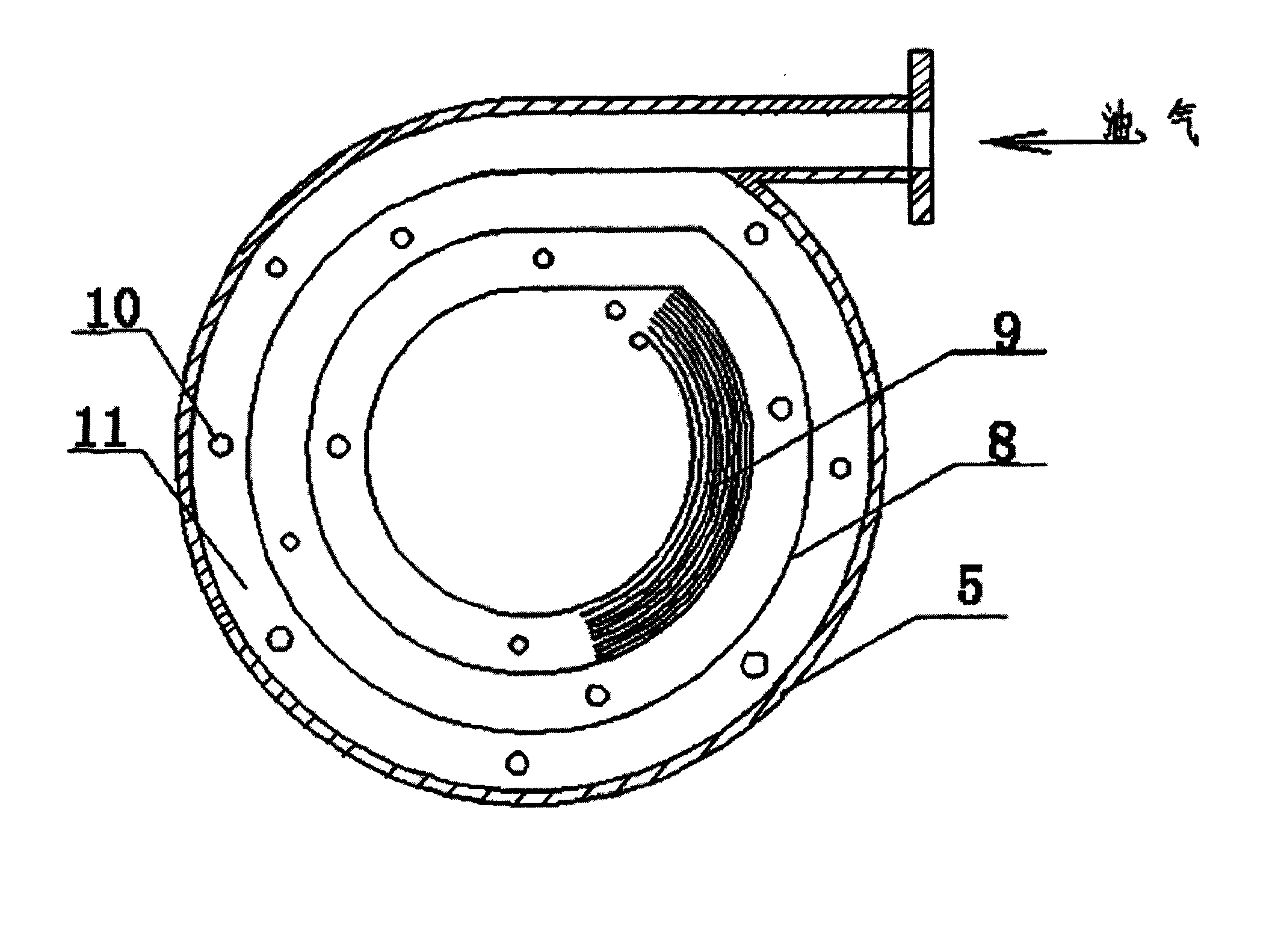

[0038] See attached Figure 4 , the fully enclosed spiral channel and tail microchannel oil-gas separator of the present invention comprises a vertical cylindrical shell 5, a spiral channel plate 8, a microchannel separation device 9, an oil outlet 10 on the lower end plate, and several oil outlets The lower end plate 11 of the center of circle has the upper end plate 12 of large air outlet orifice.

[0039] attached Figure 4In order to cooperate with the concrete embodiment of Freon 22 refrigerating power 100kw fully enclosed spiral channel and tail microchannel oil-gas separator, the shell diameter of its vertical cylindrical shell 5 is 160mm, the cylinder height is 400mm, and the rectangular airflow channel is 13mm wide and 180mm high , the gas flow rate in the channel is 4m / s, the microchannel separation device 9 is made of parallel bundled plastic tubes with an inner diameter of 1.5mm and an outer diameter of 1.8mm, and the peripheric angle of the microchannel separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com