Patents

Literature

164 results about "Submicron scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

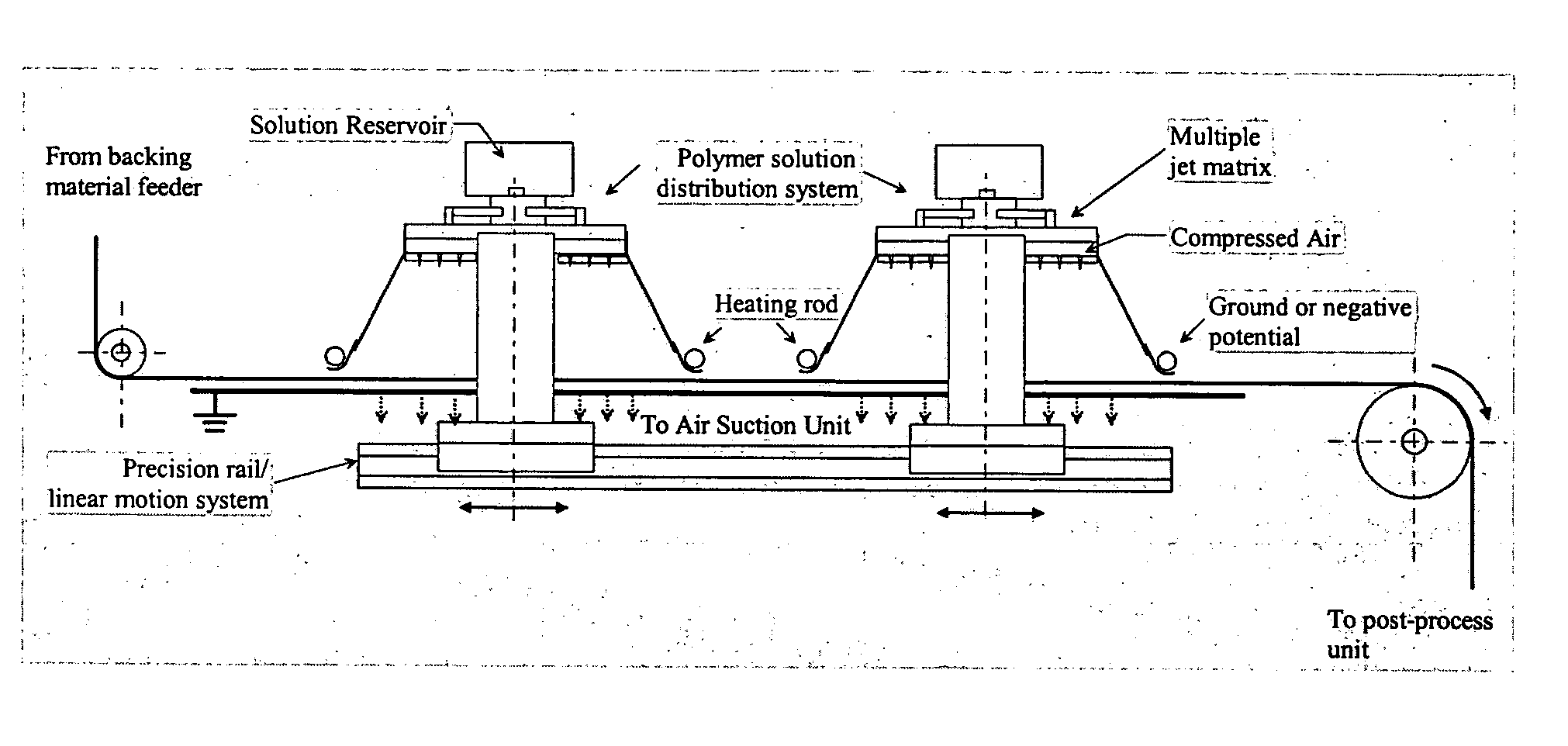

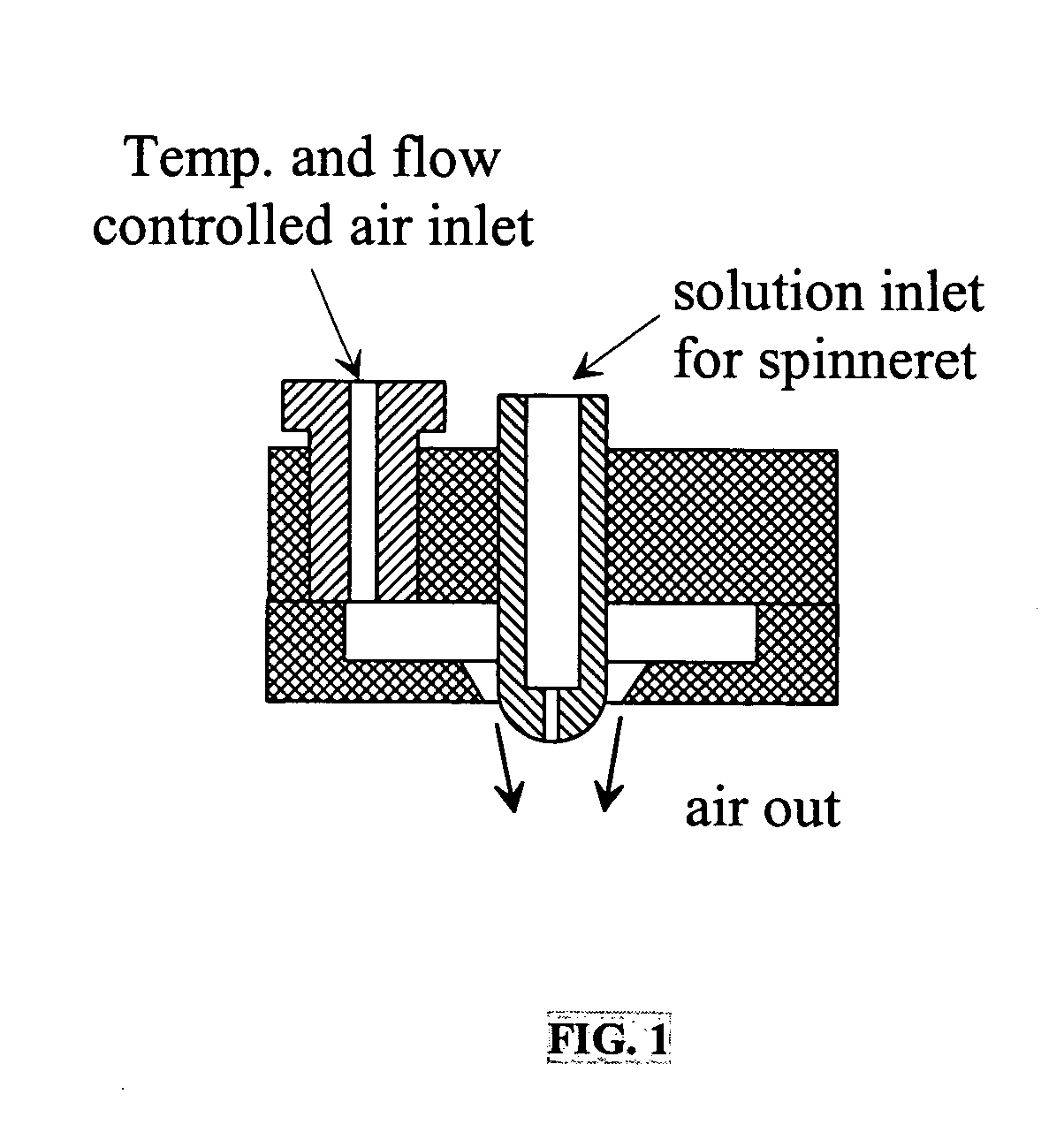

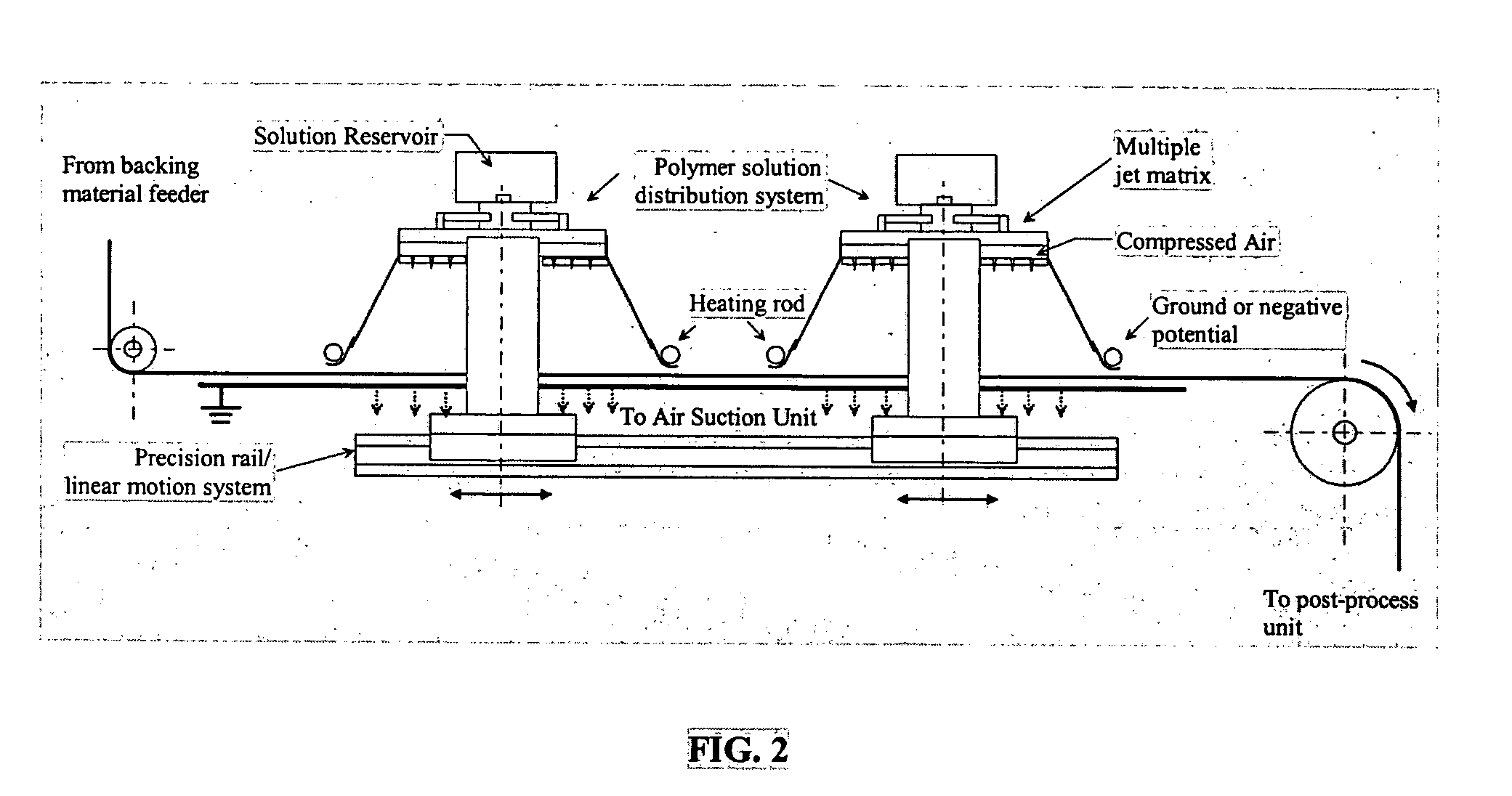

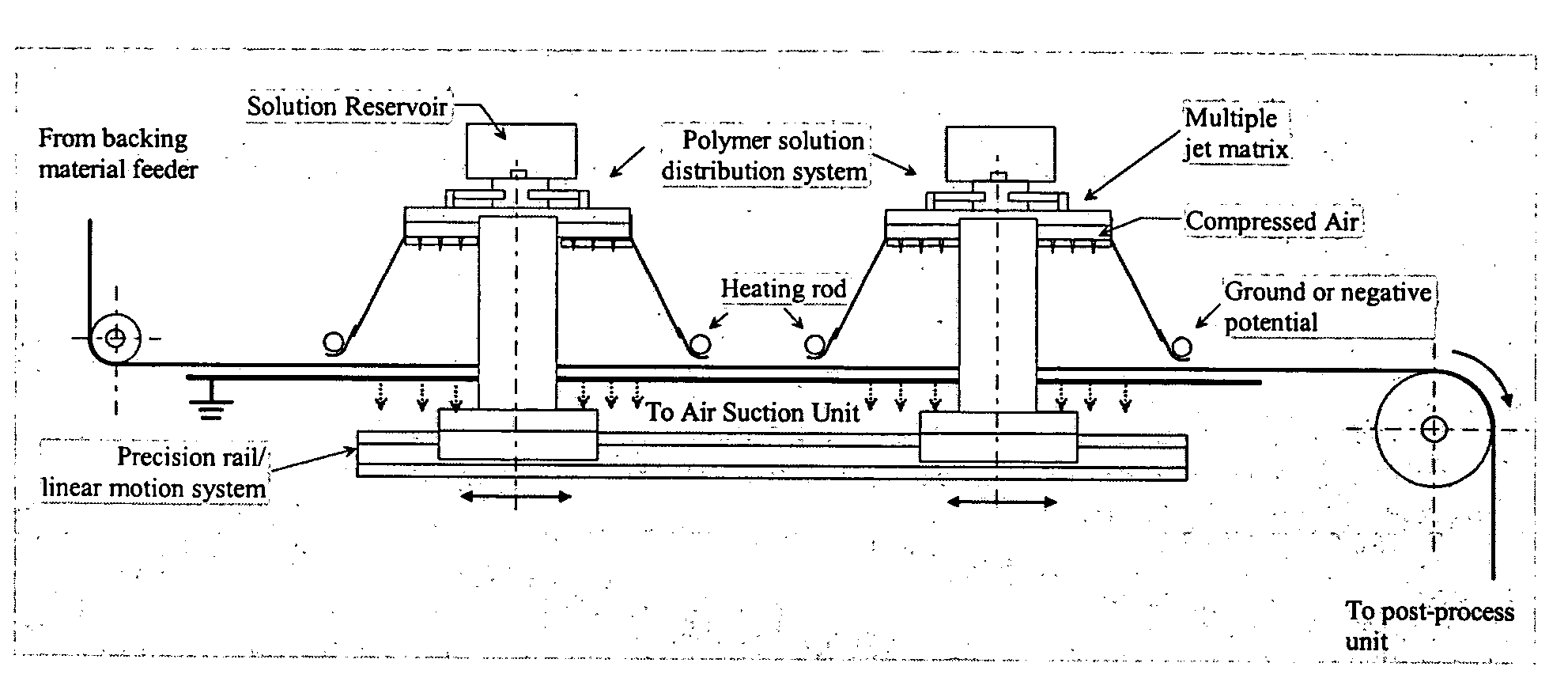

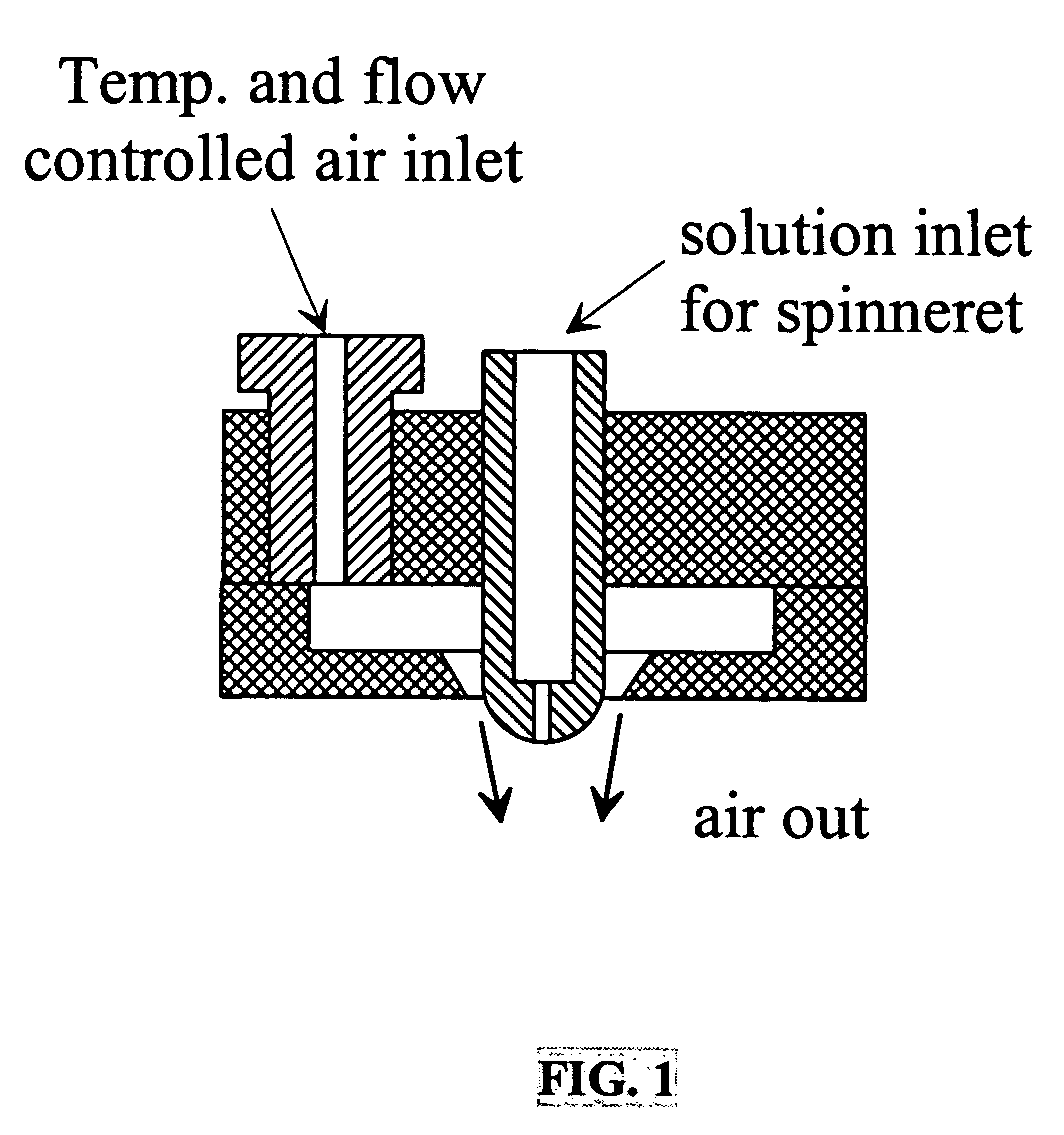

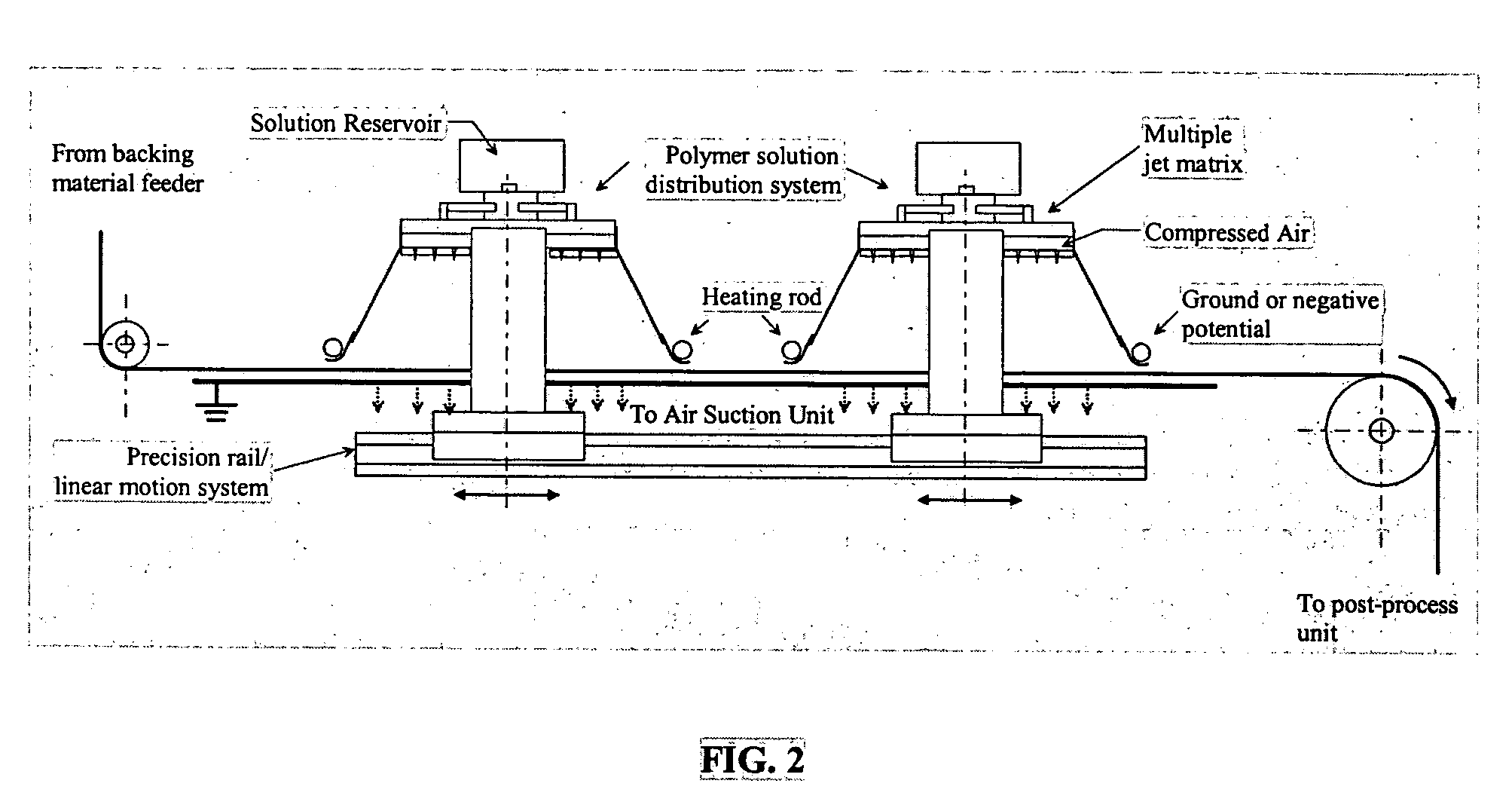

Electro-blowing technology for fabrication of fibrous articles and its applications of hyaluronan

InactiveUS20050073075A1Improve the situationHigh productElectric discharge heatingFibre chemical featuresFiberNanofiber

A method for electroblowing fibers is provided which involves the steps of: forcing a polymer fluid through a spinneret in a first direction towards a collector located a first distance from the spinneret, while simultaneously blowing a gas through an orifice that is substantially concentrically arranged around the spinneret, wherein the gas is blown substantially in the first direction; wherein an electrostatic differential is generated between the spinneret and the collector; and collecting the fibers, and its use in preparing submicron scale fibers of various types, particularly hyaluronan fibers, and the hyaluronan nanofibers thus formed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

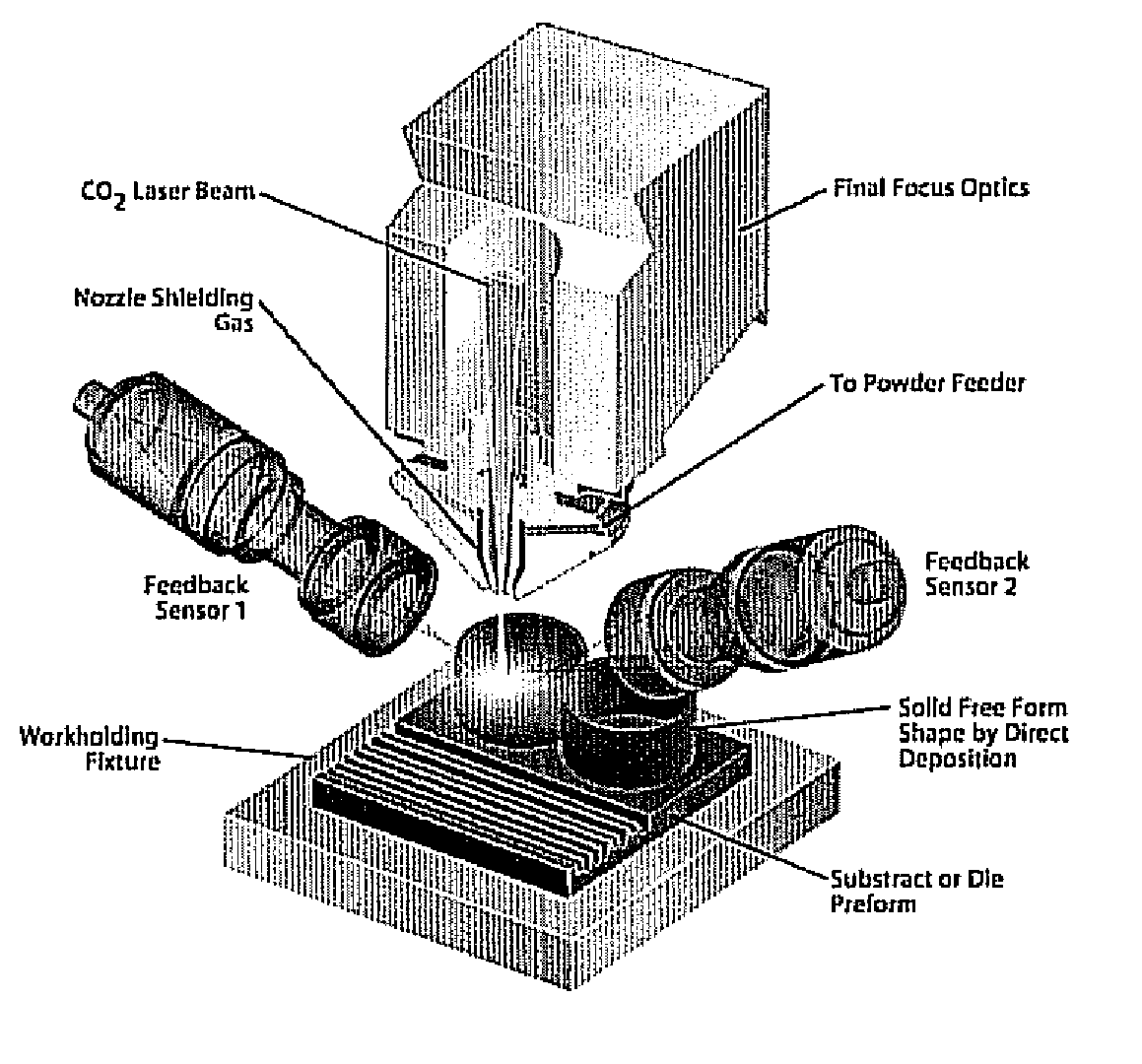

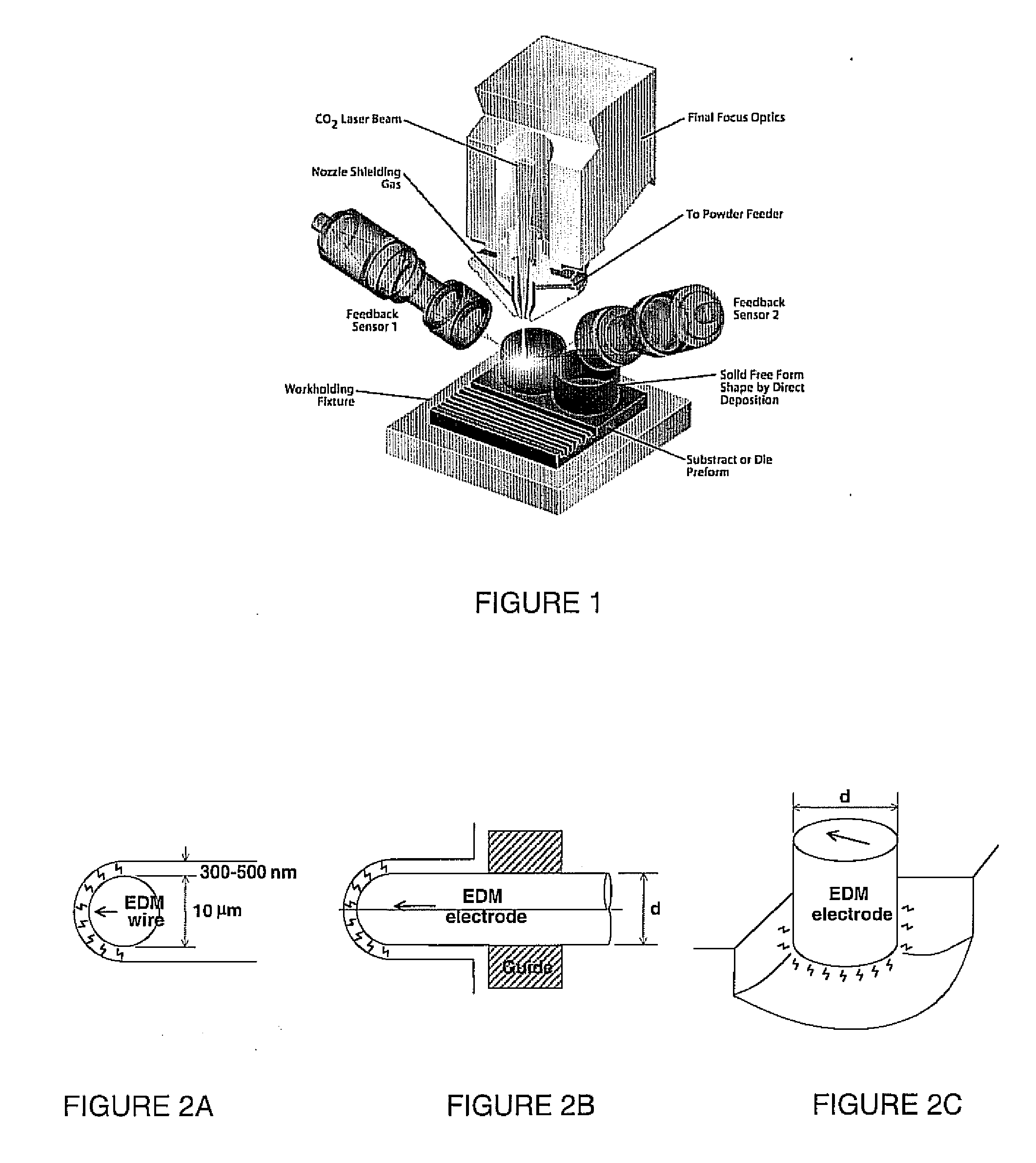

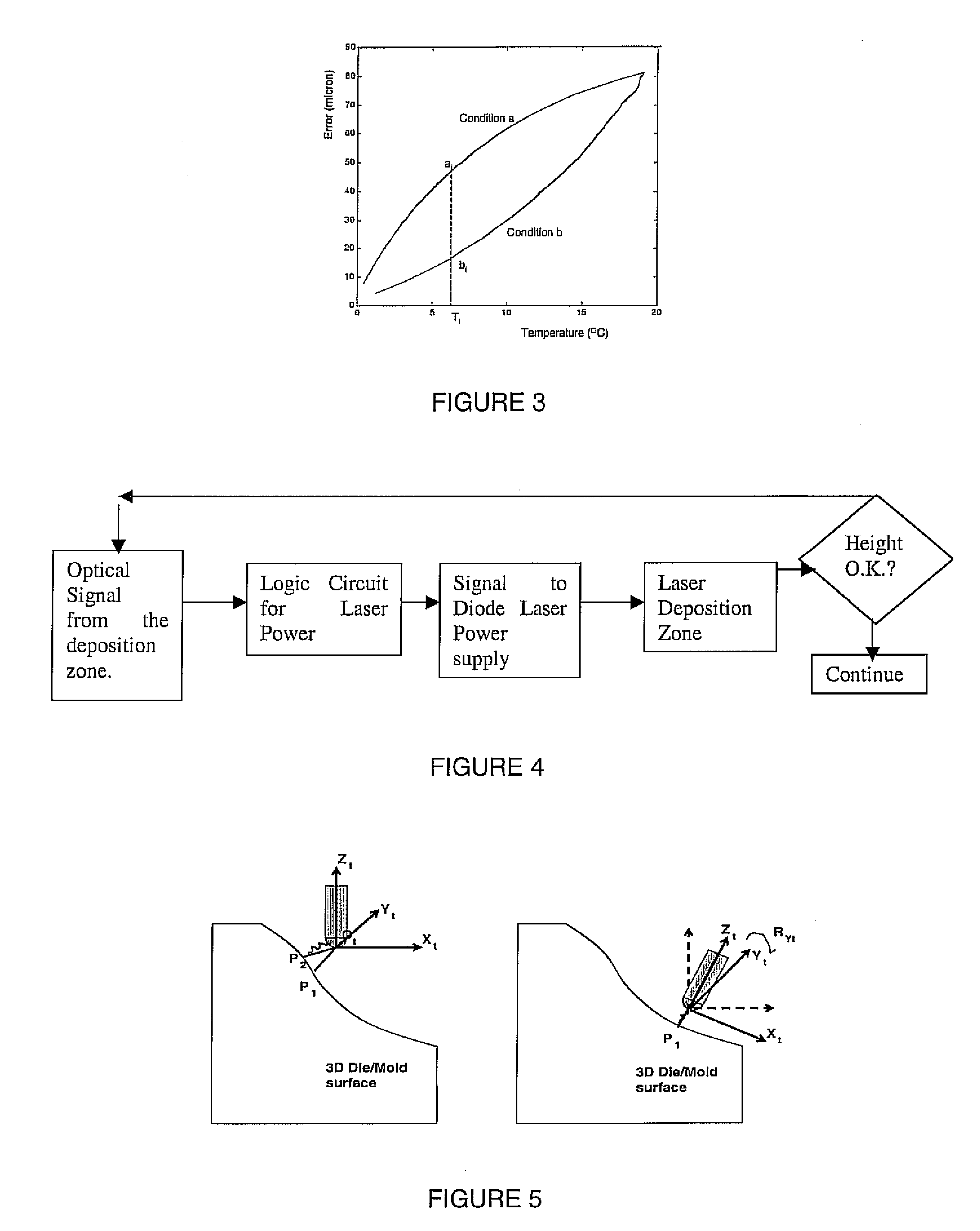

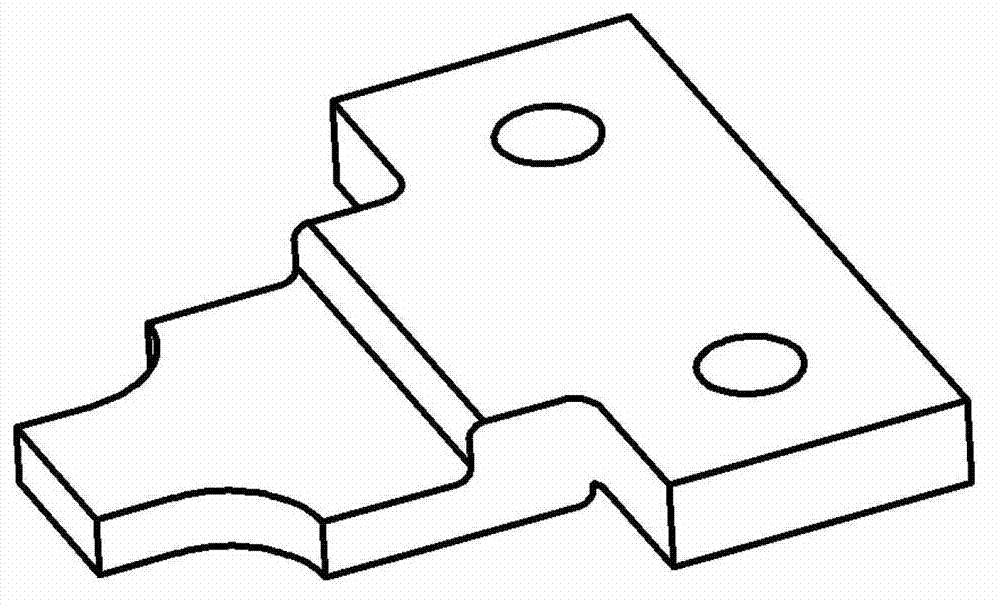

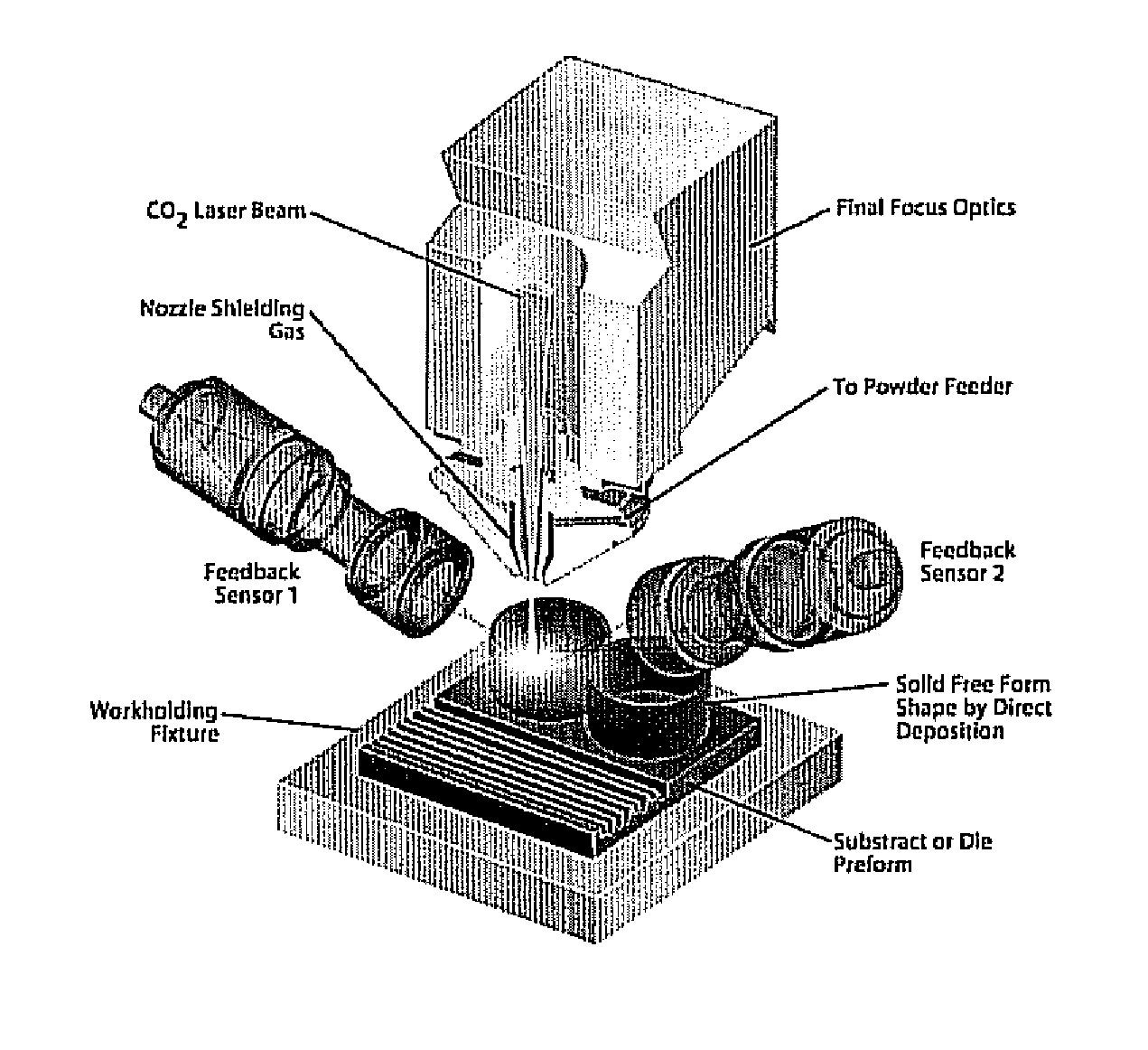

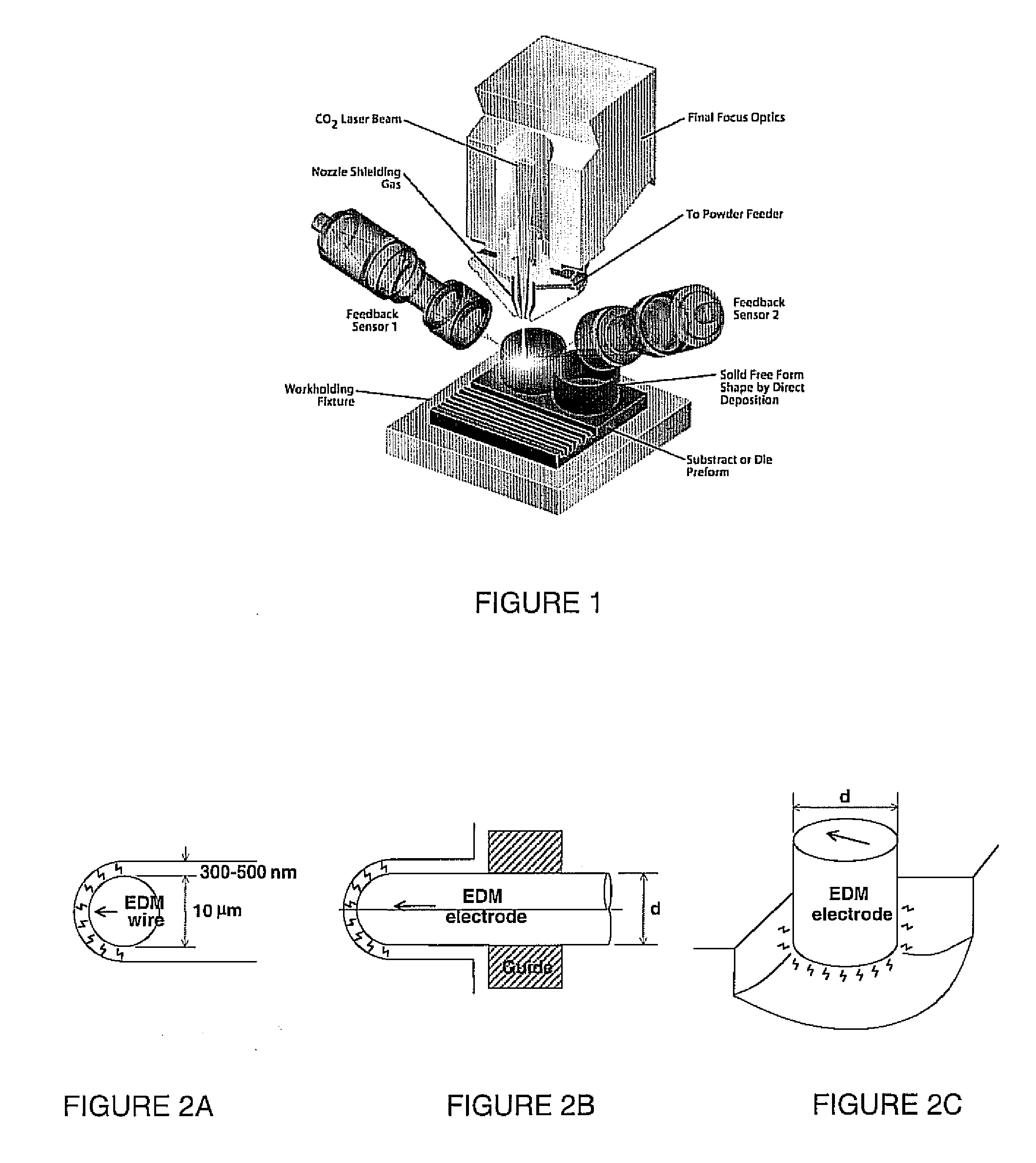

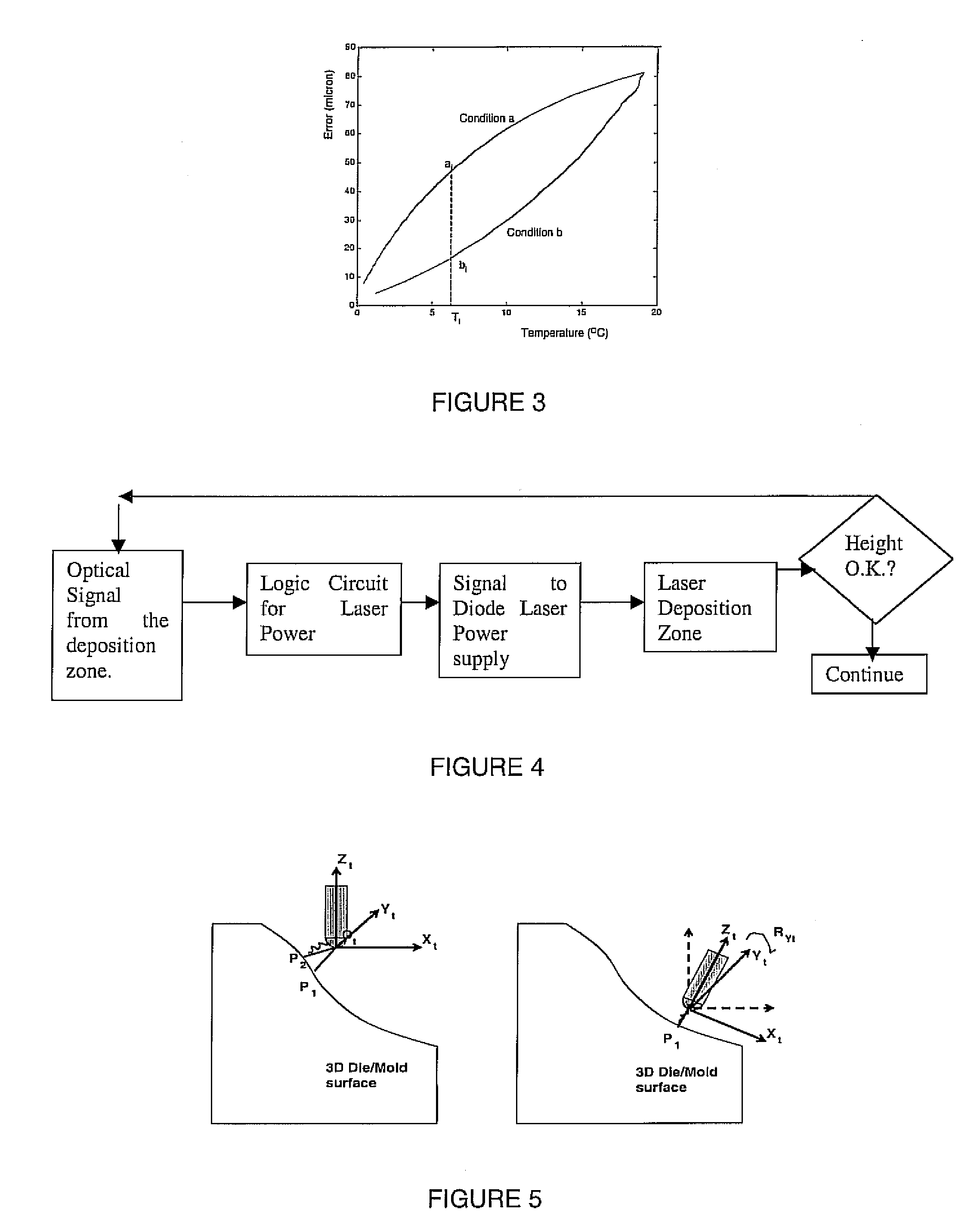

High-speed, ultra precision manufacturing station that combines direct metal deposition and edm

ActiveUS20070205184A1Fast transferImprove efficiencyAdditive manufacturing apparatusElectric discharge heatingEngineeringWorkstation

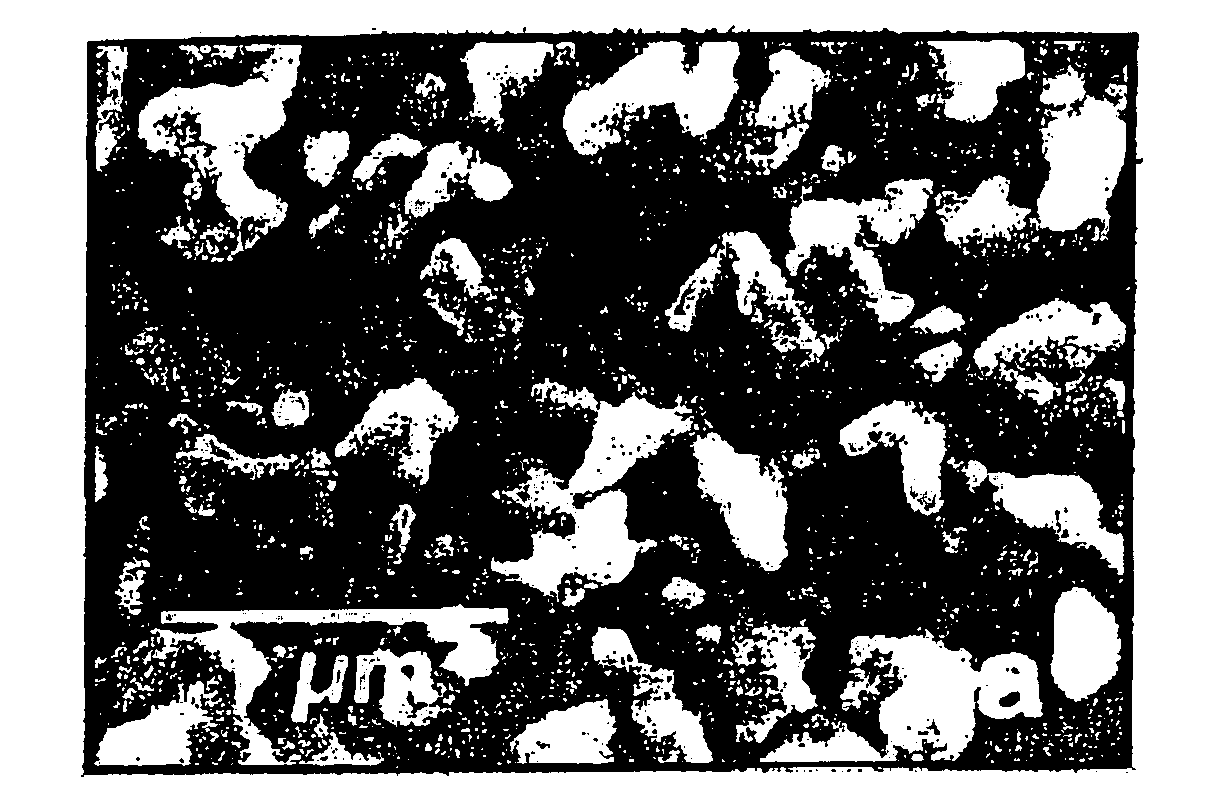

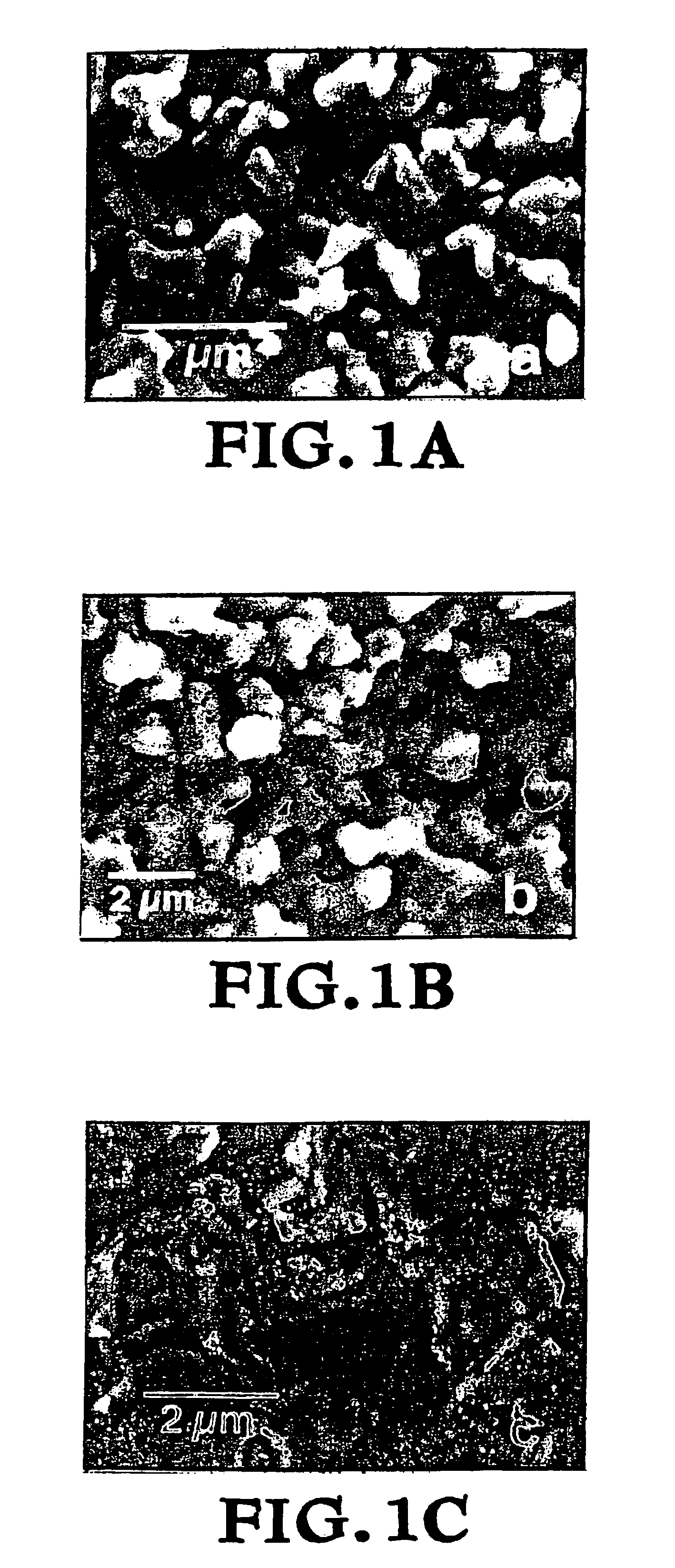

A direct-metal deposition (DMD) processing stage and a 5DOF (degree of freedom) dry micro-EDM (mEDM) stage are integrated to provide the submicron scale resolution necessary for the ultra-precision processing of work pieces. The DMD processing stage includes optical feedback for dimensional control utilizing a high-power, fiber-coupled diode laser with fast response time and small beam parameter product. The electrical discharge machining (EDM) stage is a dry EDM stage using an inert gas with appropriate dielectric properties to perform the surface finishing operations. The system further includes one or more surface treatment operations to obtain a desired level of surface hardness or wear resistance and / or to minimize the distortion induced in treating the surface.

Owner:DM3D TECH

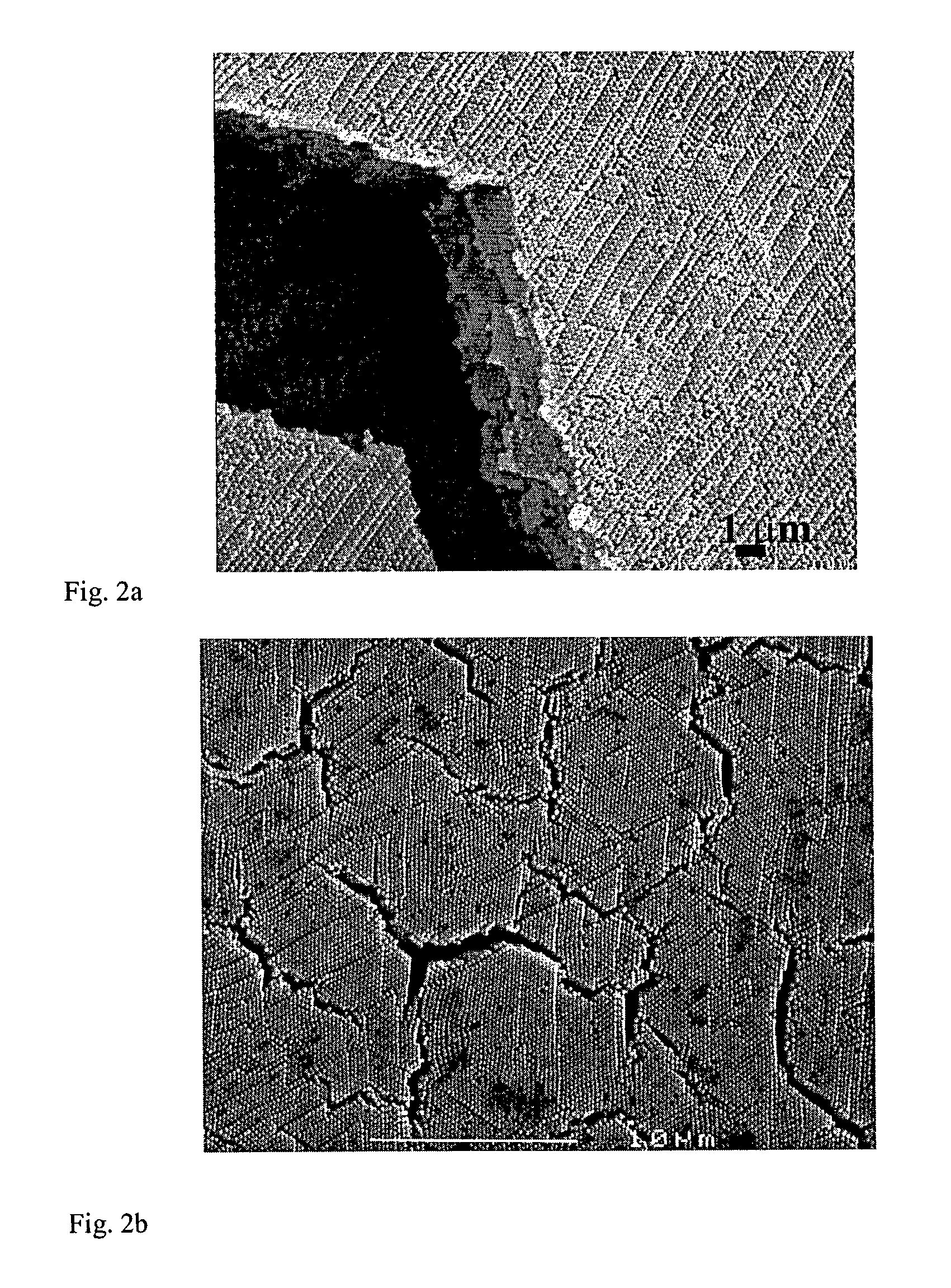

Vapor-deposited porous films for energy conversion

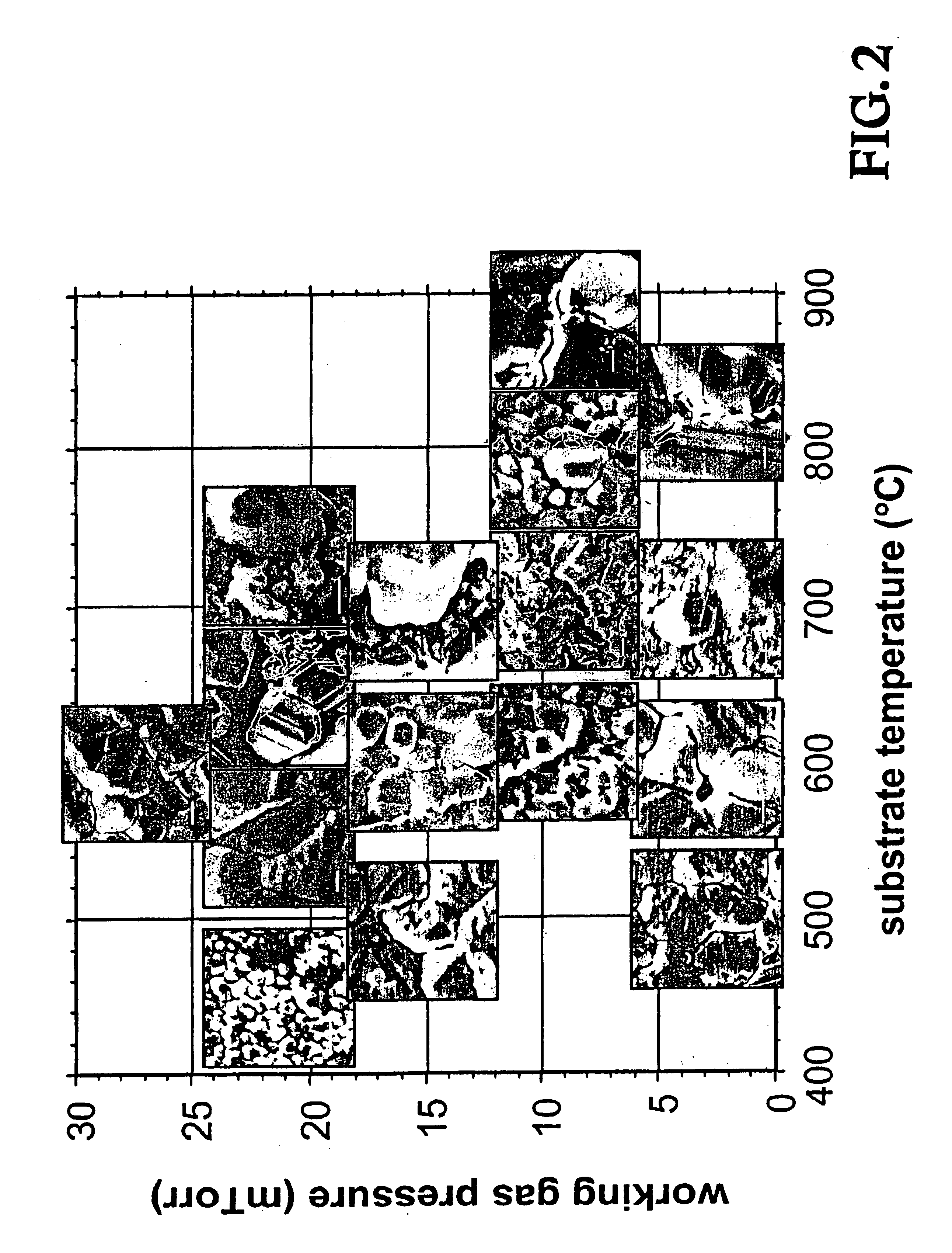

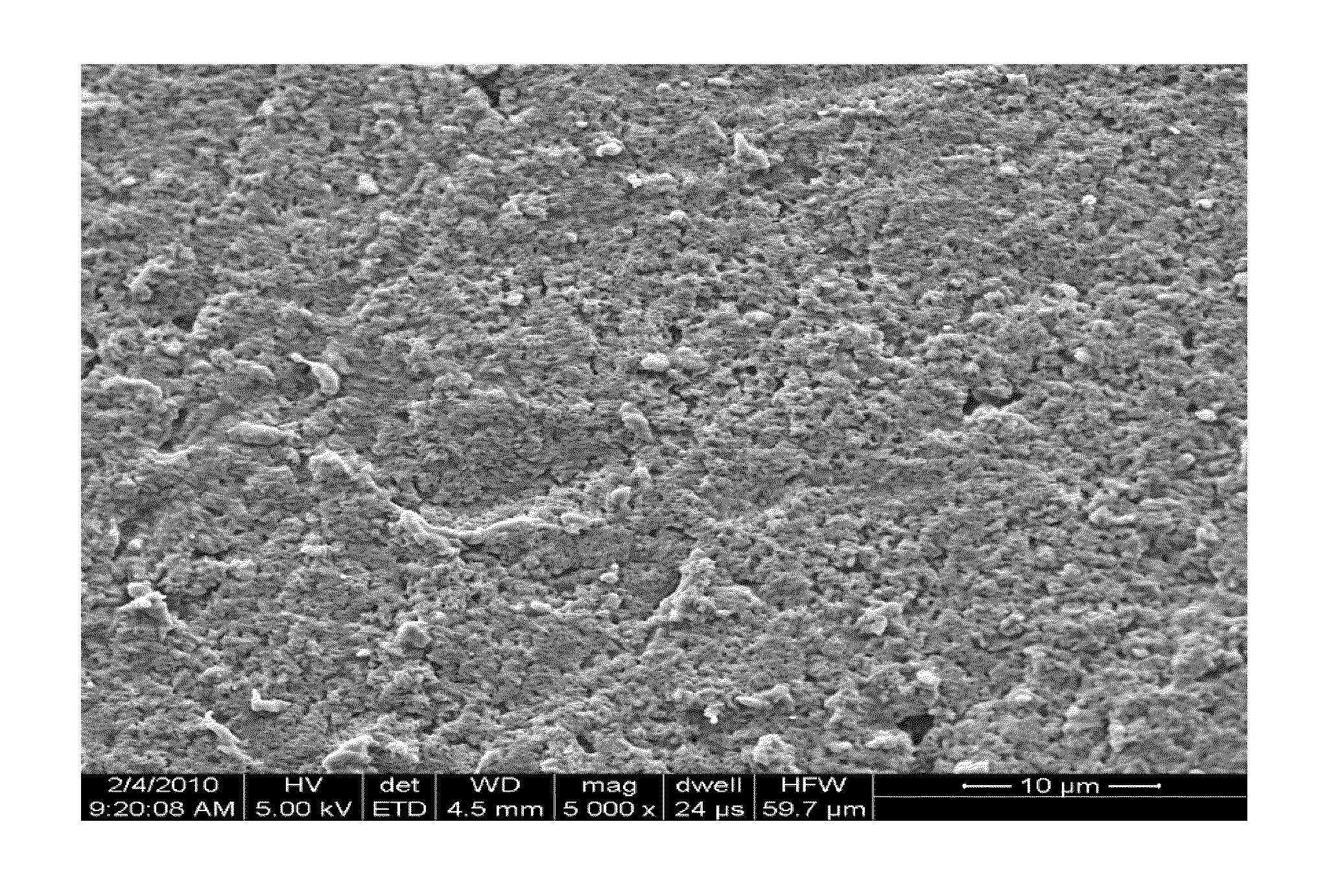

Metallic films are grown with a “spongelike” morphology in the as-deposited condition using planar magnetron sputtering. The morphology of the deposit is characterized by metallic continuity in three dimensions with continuous and open porosity on the submicron scale. The stabilization of the spongelike morphology is found over a limited range of the sputter deposition parameters, that is, of working gas pressure and substrate temperature. This spongelike morphology is an extension of the features as generally represented in the classic zone models of growth for physical vapor deposits. Nickel coatings were deposited with working gas pressures up 4 Pa and for substrate temperatures up to 1000 K. The morphology of the deposits is examined in plan and in cross section views with scanning electron microscopy (SEM). The parametric range of gas pressure and substrate temperature (relative to absolute melt point) under which the spongelike metal deposits are produced appear universal for other metals including gold, silver, and aluminum.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Fatigue damage resistant wire and method of production thereof

ActiveUS20100075168A1Improve resistance to fatigue damageImprove material performanceStentsPig casting plantsFatigue damageWire rod

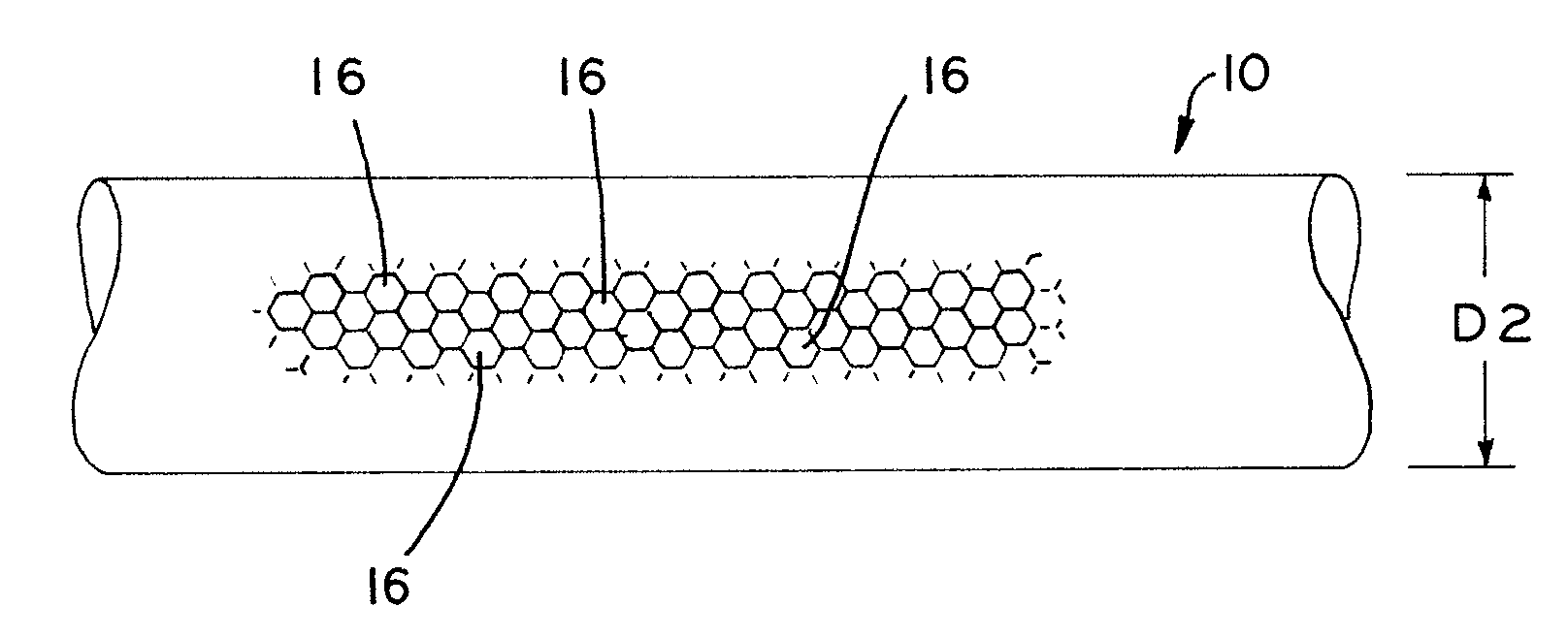

Fatigue damage resistant metal or metal alloy wires have a submicron-scale or nanograin microstructure that demonstrates improved fatigue damage resistance properties, and methods for manufacturing such wires. The present method may be used to form a wire having a nanograin microstructure characterized by a mean grain size that is 500 nm or less, in which the wire demonstrates improved fatigue damage resistance. Wire manufactured in accordance with the present process may show improvement in one or more other material properties, such as ultimate strength, unloading plateau strength, permanent set, ductility, and recoverable strain, for example. Wire manufactured in accordance with the present process is suitable for use in a medical device, or other high end application.

Owner:FORT WAYNE METALS RES PROD LLC

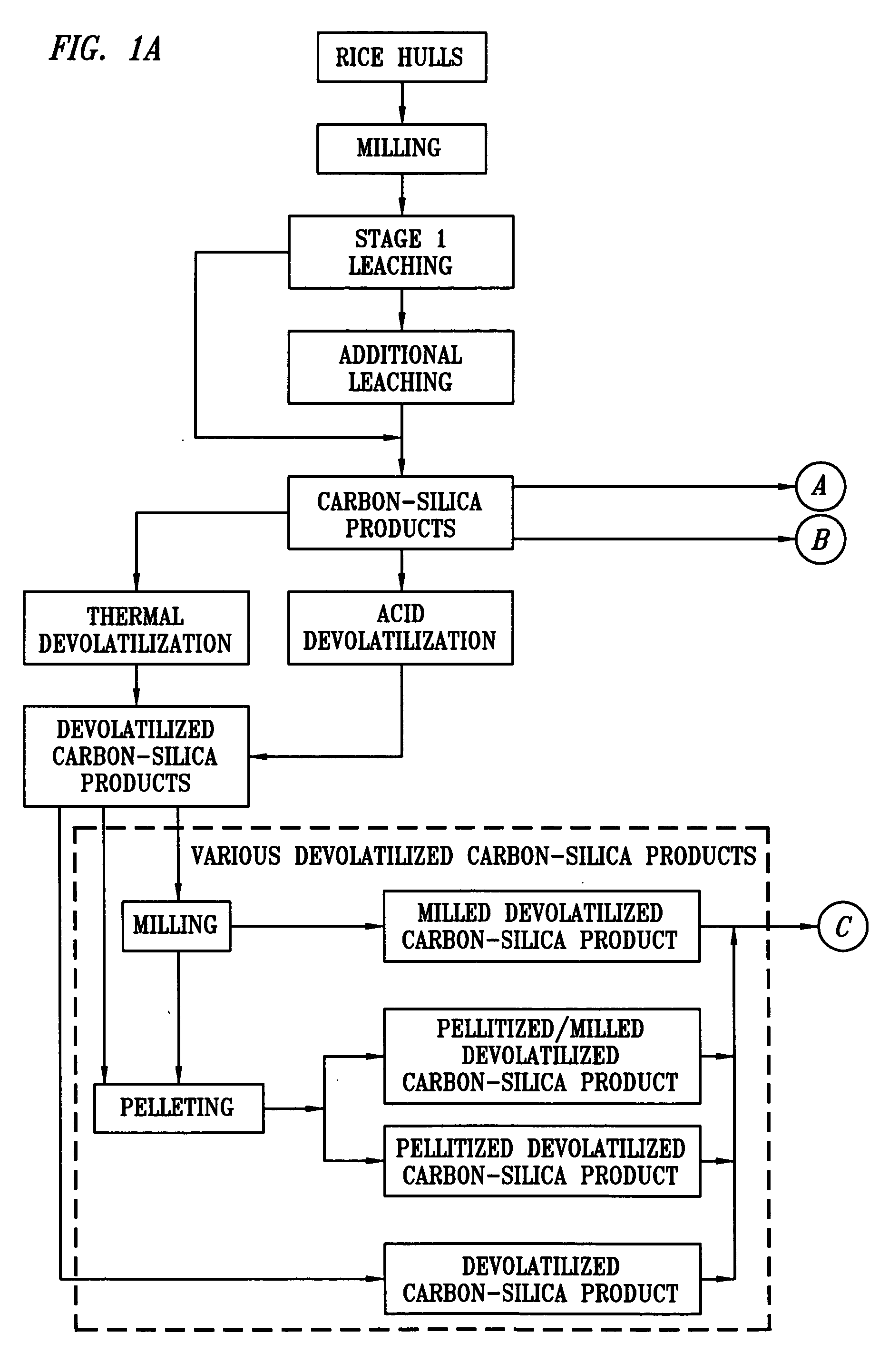

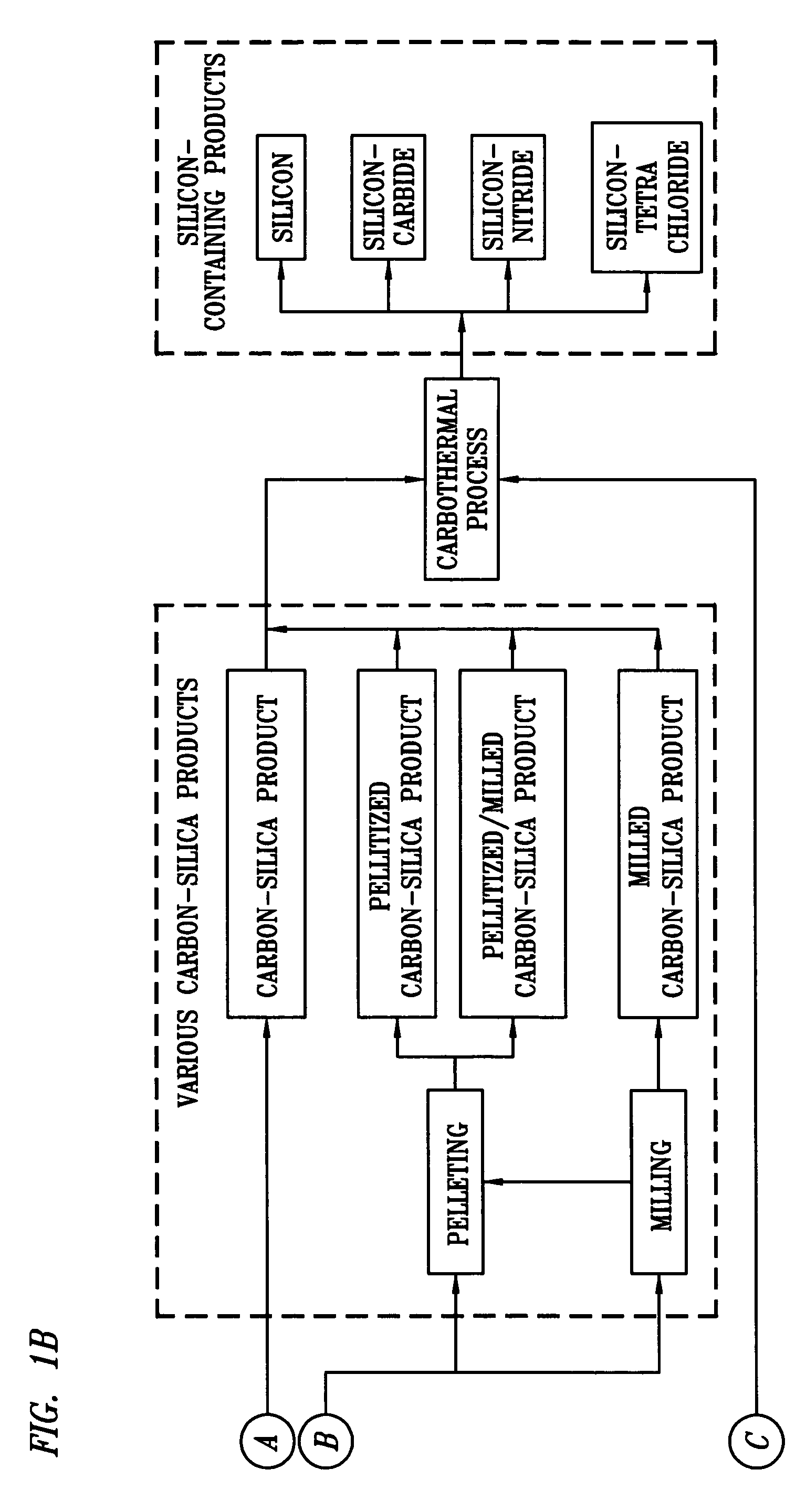

Composition and method for making silicon-containing products

ActiveUS20050227868A1Increase throughputSave energyNitrogen compoundsOther chemical processesPorositySilicon dioxide

A method for producing carbon-silica products from silica-containing plant matter such as rice hulls or straw by leaching with sulfuric acid to remove non-silica minerals and metal while adjusting the mole ratio of fixed carbon to silica in the resultant product. The carbon and silica are intimately mixed on a micron or submicron scale and are characterized by high purity and reactivity, small particle size, high porosity, and contain volatile carbon that can be used as a source of energy for the production of silicon-containing products from the carbon-silica products. High purity silicon-containing products made from the carbon-silica products of the invention are also disclosed.

Owner:SI OPTIONS LLC

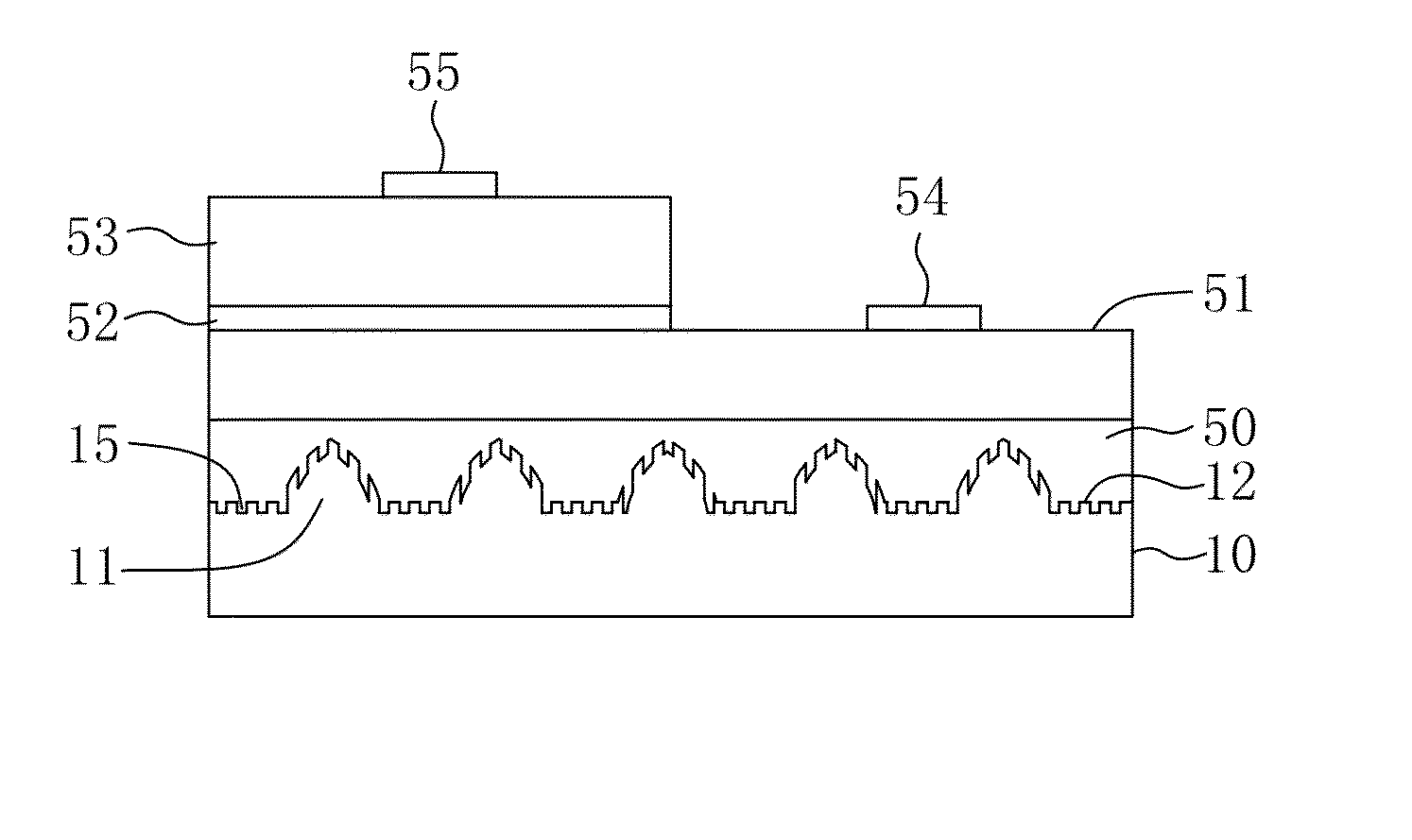

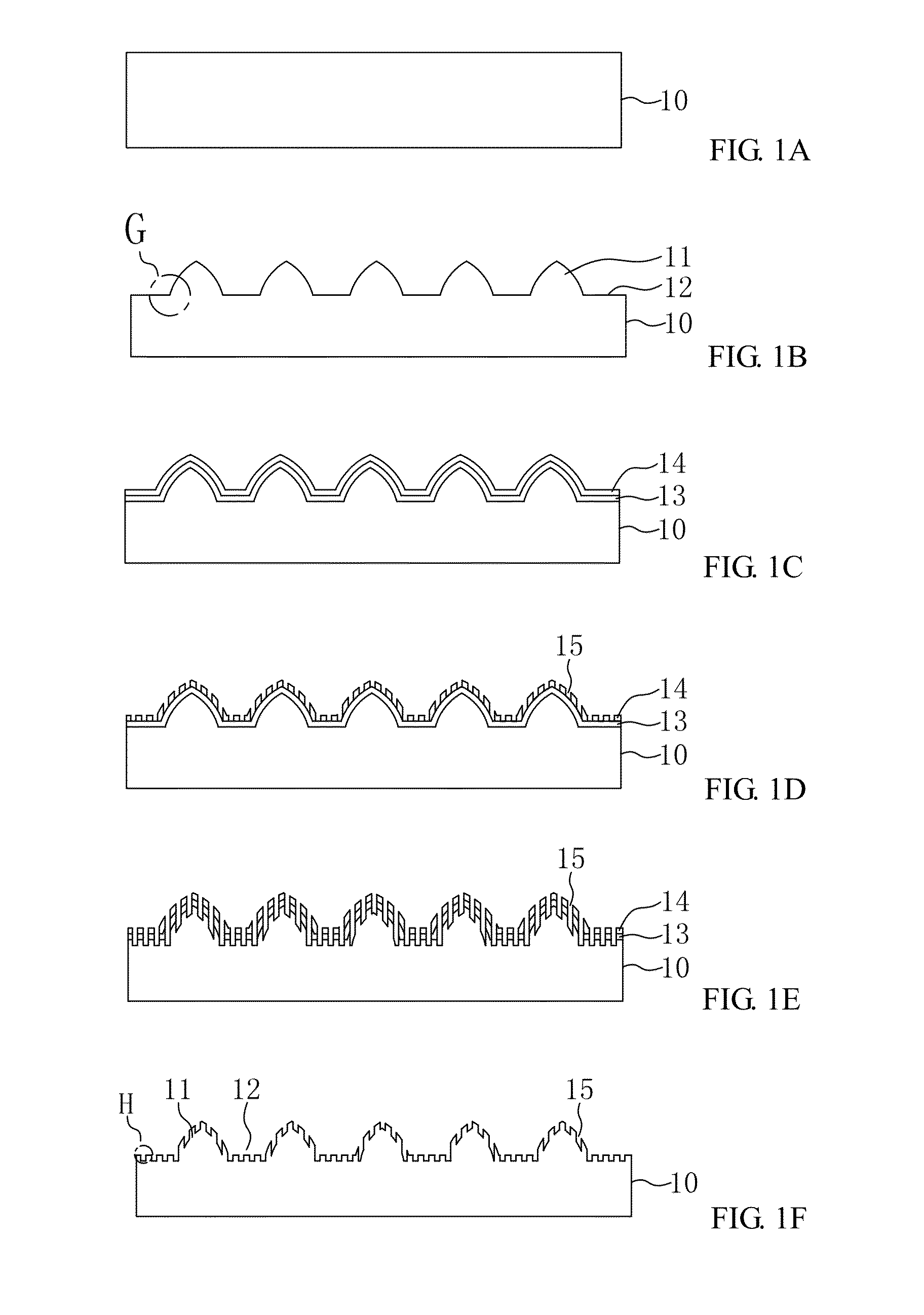

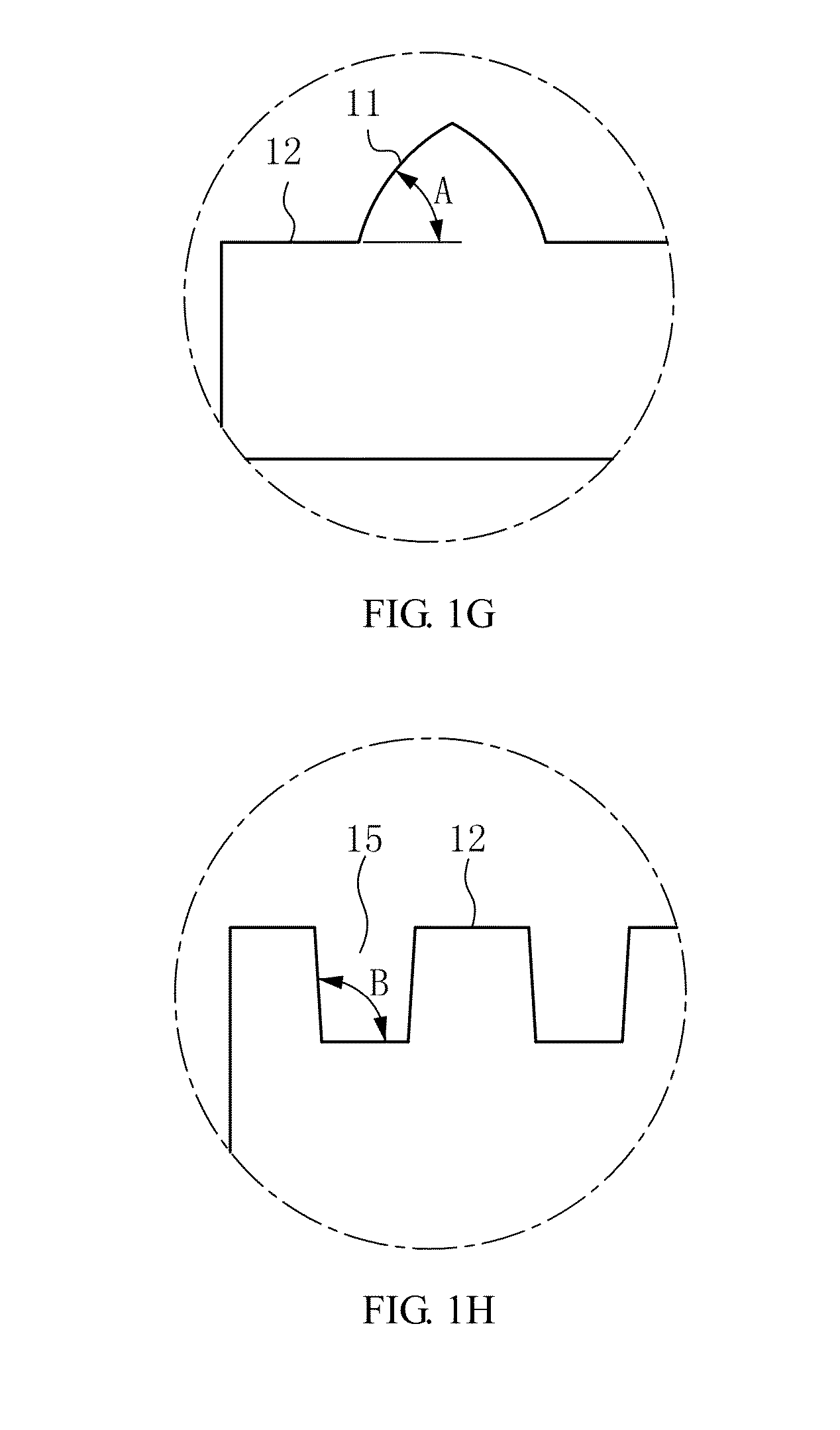

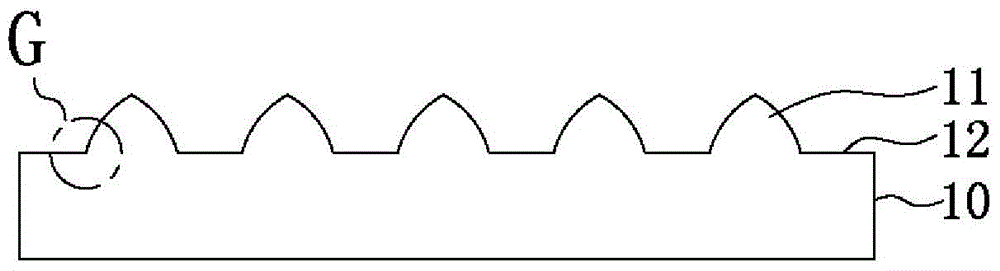

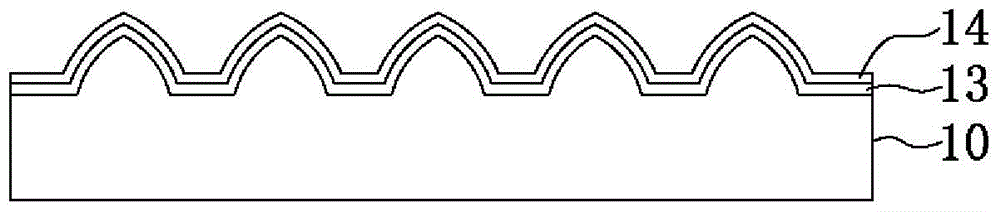

Patterned opto-electrical substrate and method for manufacturing the same

ActiveUS20150076505A1Improve extraction efficiencyImprove reflectance diffuse reflectanceSemiconductor/solid-state device manufacturingSemiconductor devicesMicron scaleEngineering

Owner:KINIK

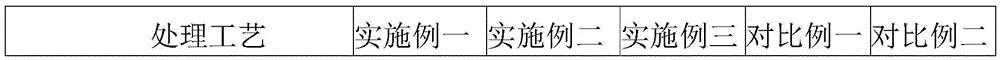

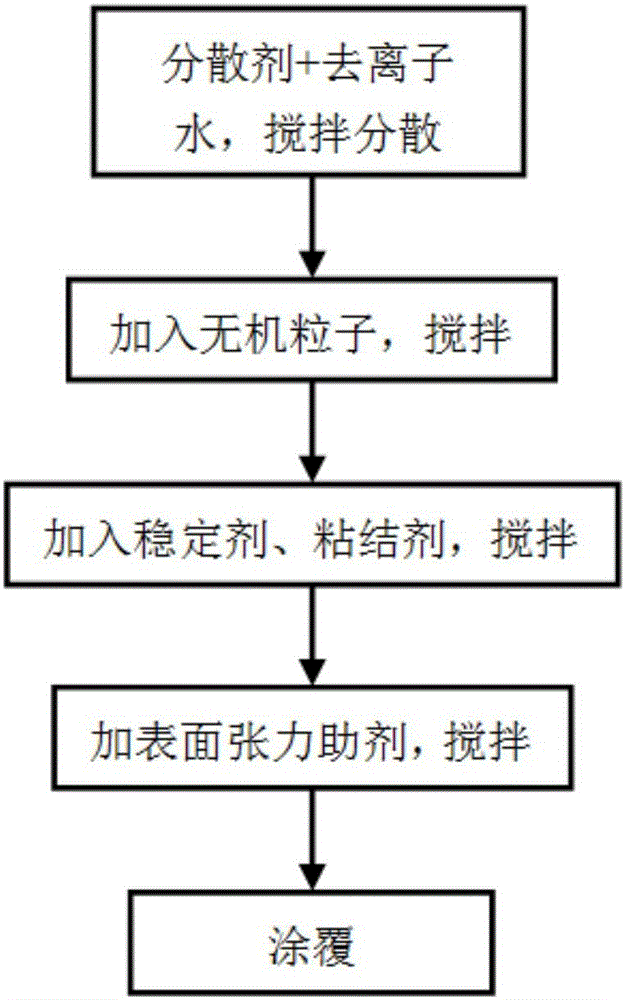

High-heat-conductive composition, preparation method and heat-conductive gasket thereof

InactiveCN105419345AHigh surface energyImprove surface activityHeat-exchange elementsMicron scaleHeat resistance

The invention relates to a high-heat-conductive composition, which includes a polysiloxane substrate and a composite heat-conductive filling material which is prepared through a mechanical fusion method. The composition is prepared through fusion and stirring. The high-heat-conductive composition is prepared from the polysiloxane substrate, and the composite heat-conductive filling material which is prepared through the mechanical fusion method and includes a micron-scale heat-conductive powder, a nano-scale heat-conductive powder and / or a submicron-scale heat-conductive powder, wherein the nano-scale heat-conductive powder and the submicron-scale heat-conductive powder are large in surface area, high in surface energy and high in surface activity. By means of the mechanical fusion method, the nano-scale heat-conductive powder is fused with the micron-scale heat-conductive powder to prepare the composite heat-conductive filling material. The micron-scale heat-conductive powder and the nano-scale heat-conductive powder are fully dispersed and meanwhile interface heat resistance therebetween is greatly reduced. The heat-conductive performance of the nano-scale heat-conductive powder is fully achieved so that the high-heat-conductive composition is better in the heat-conductive performance.

Owner:PINGHU ALLIED IND

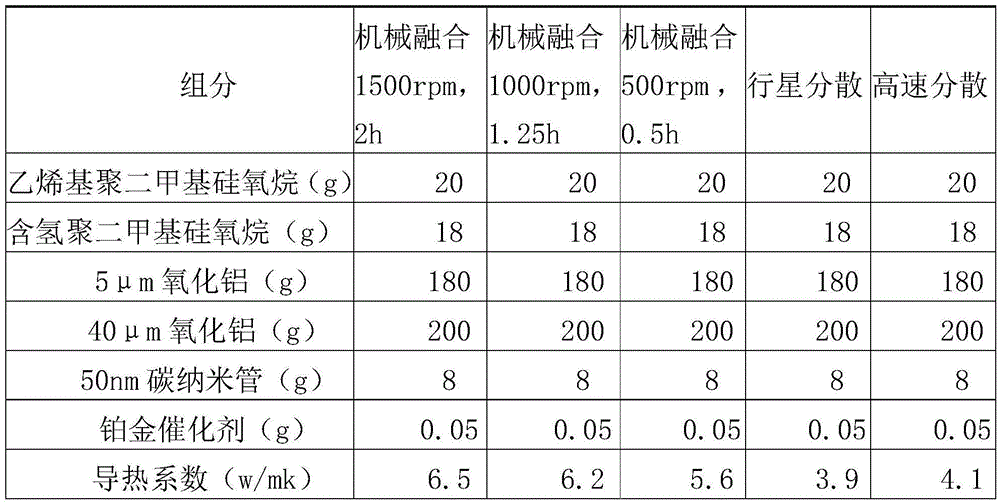

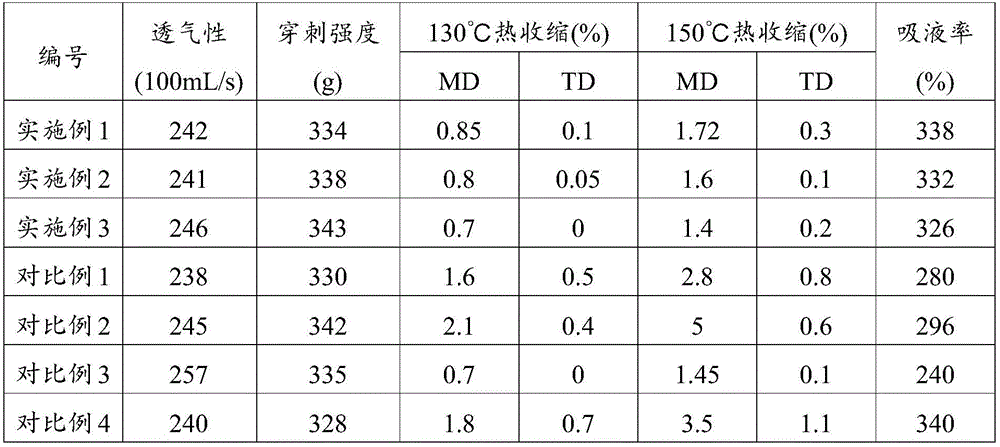

Lithium-ion battery diaphragm and preparation method thereof

InactiveCN106784529AImprove heat shrink resistanceImprove performanceCell seperators/membranes/diaphragms/spacersSecondary cellsMicron scaleInorganic particle

The invention discloses a lithium-ion battery diaphragm and a preparation method thereof. The lithium-ion battery diaphragm disclosed by the invention comprises a base membrane and an inorganic particle coating coated on one side or two sides of the base membrane, wherein the inorganic particle coating is composed of at least two kinds of inorganic particles in different morphologies and different grain sizes; the morphologies of the inorganic particles are not repeatedly selected from sphere, ellipsoid, dumb-bell, sheet or irregular shapes; and the grain sizes of the inorganic particles are not repeatedly selected from micron-scale particles, submicron-scale particles or nanometer-scale particles. In the lithium-ion battery diaphragm disclosed by the invention, the inorganic particles in different morphologies and different grain sizes are formed into the inorganic particle coating; on the one hand, the stability of the inorganic particle coating is enhanced, so that the heat-resistant contractility of the lithium-ion battery is promoted; on the other hand, the adsorptive property of the battery diaphragm to the electrolyte is improved; the overall performance of the battery diaphragm is promoted; and the basis is established for the preparation of a high-quality lithium-ion battery.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

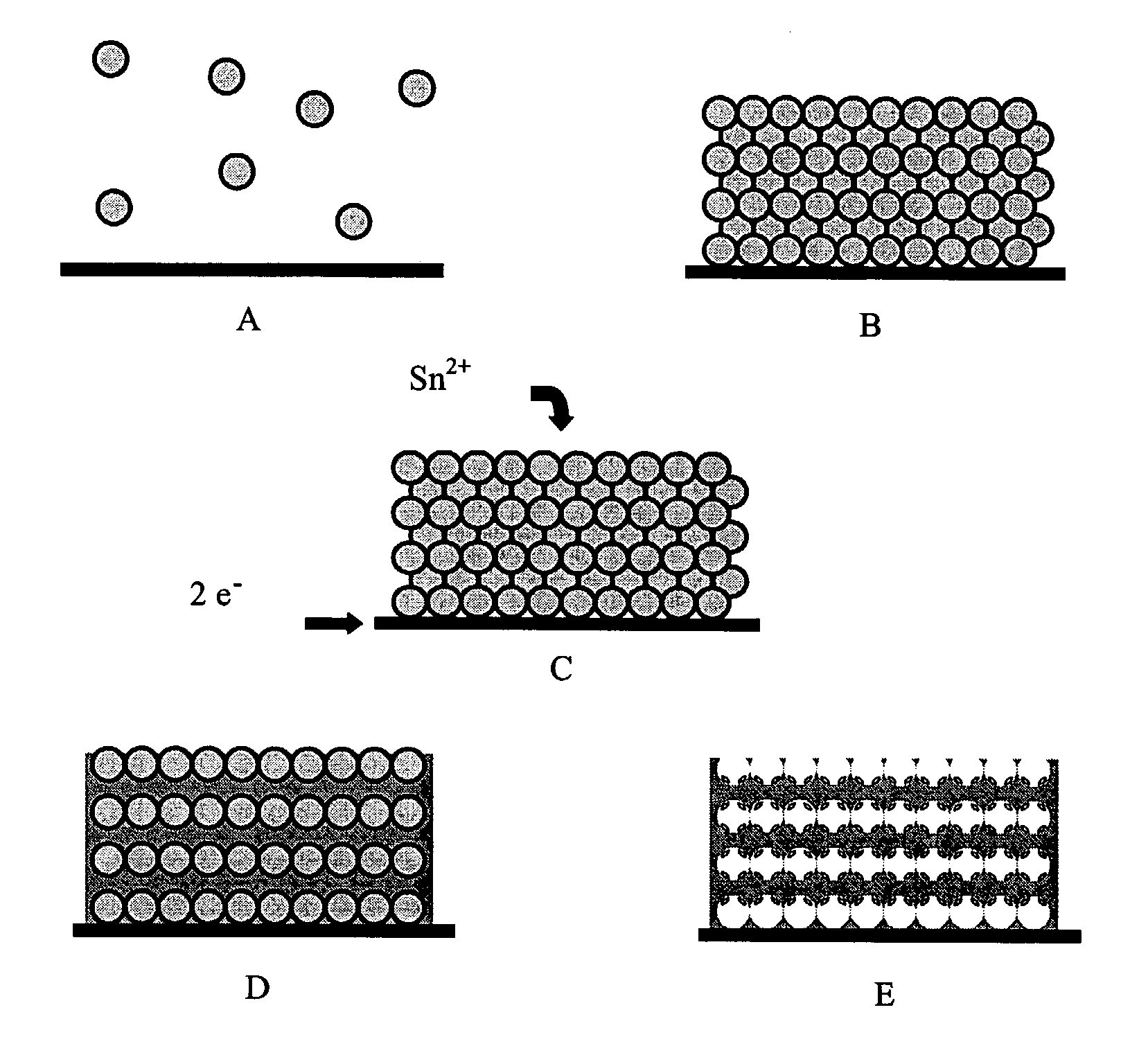

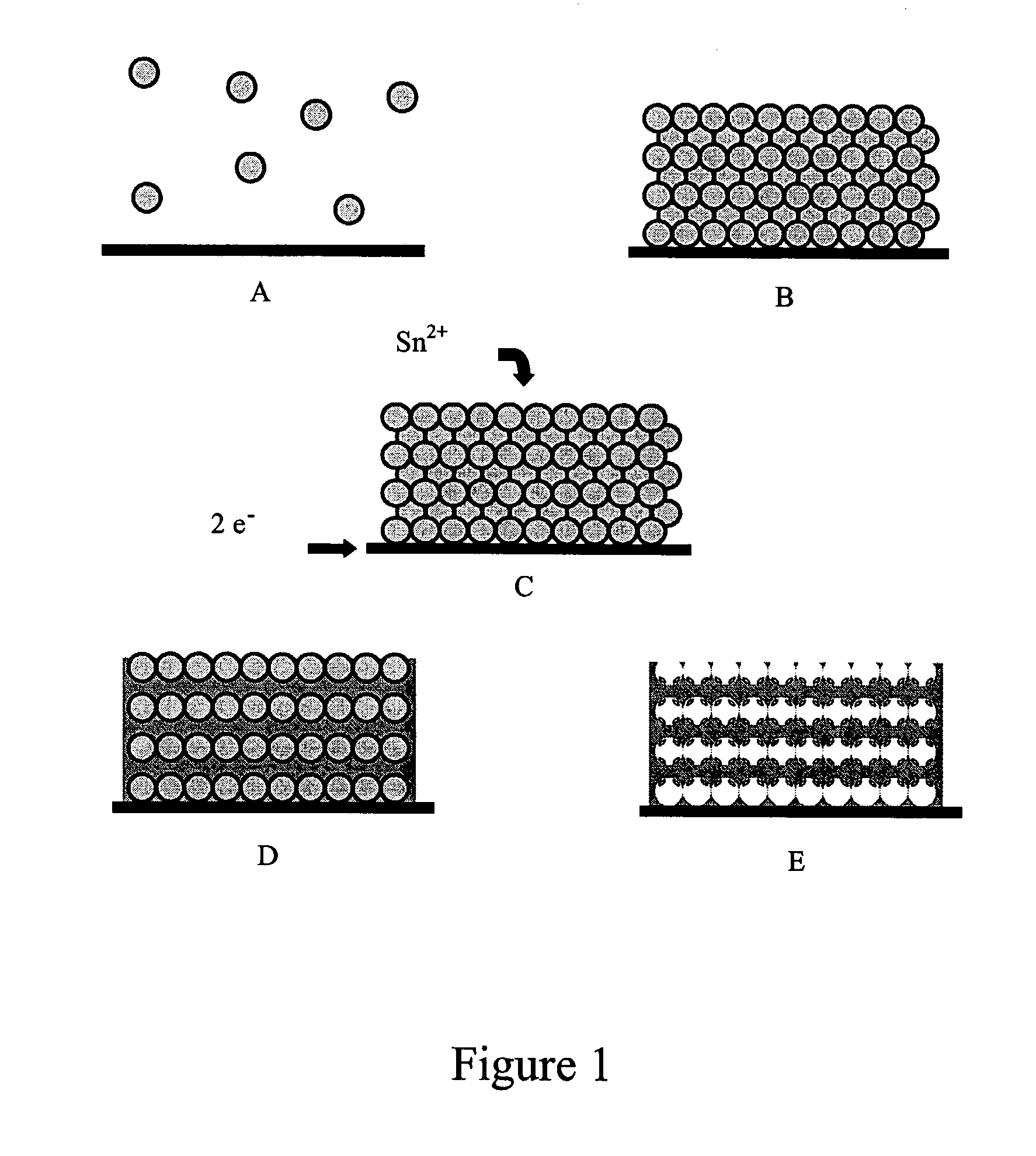

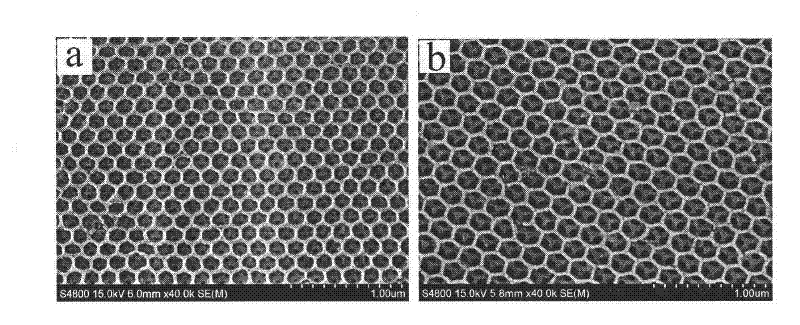

Colloidal sphere templates and sphere-templated porous materials

ActiveUS8137525B1Reduce crackingSpecific charge capacityDuplicating/marking methodsActive material electrodesColloidNanostructured metal

A method of making colloidal sphere templates and the sphere-templated porous materials made from the templates. The templated porous materials or thin films comprise micron and submicron-scaled spheres in ordered, disordered, or partially ordered arrays. The invention is useful in the synthesis of submicron porous, metallic tin-based and other high capacity anode materials with controlled pore structures for application in rechargeable lithium-ion batteries. The expected benefits of the resulting nanostructured metal films include a large increase in lithium storage capacity, rate capability, and improved stability with electrochemical cycling.

Owner:RGT UNIV OF CALIFORNIA

Magnesium hydroxide flame retardant and flame retardant polymer for cables

ActiveCN101712875AEasy to changeEasy to replacePlastic/resin/waxes insulatorsInsulated cablesPolyolefinCrack resistance

The invention relates to improvements of a magnesium hydroxide flame retardant and a flame retardant polymer for cables. Natural magnesium hydroxide with the Mg(OH)2 content being not smaller than 96wt percent is adopted, and micro powder with a mean grain size of 0.5-1 micrometer is obtained through physical ultrafine grinding and grading; then 0.8-3wt percent of coupling agent is added, and an obtained mixture is stirred at a high speed, sufficiently mixed and then subjected to secondary surface processing by high-pressure airflows in a jet mill so as to obtain the magnesium hydroxide flameretardant with good smoothness and basically no aggregates; and the magnesium hydroxide flame retardant can smoothly flow like vegetable seeds under pushing by external forces. A polyolefin flame retardant polymer for cables is prepared from the following components in parts by weight: 100 parts of polyolefin, 100-150 parts of submicron scale magnesium hydroxide, 2-10 parts of oxosilane, 0.2-1 part of antioxygen, 1-10 parts of processing aid and 0-6 parts of functional aid. The flame retardant polymer for cables has the following parameters: the oxygen index (OI) is up to 36-42, the tensile strength is not smaller than 10Mpa, the breaking elongation rate is not smaller than 200 percent, and the volume resistivity is not smaller than 10*1,015. The cracking resistance of the flame retardant polymer for cables is good, and the flame retardant polymer for cables cannot crack within one hour at a temperature of 130 DEG C and exceed the standard of the JB10707-2007 low-smoke non-halogen flame-retardant cable material. The flame retardant polymer for cables has good extrusion manufacturability and wide extrusion temperature range and can be effectively extruded at a temperature of 165-190 DEG C. The extrusion torque is small and reduced by 30 percent, thus the flame retardant polymer for cables can be smoothly extruded out by original equipment without a special screw rod.

Owner:无锡市英普立阻燃材料有限公司

Method for tracking a treatment fluid in a subterranean formation

A method of tracking a treatment fluid in a subterranean formation penetrated by a wellbore provides for injecting the treatment fluid with the plurality of tracer agents into the well and the formation. Each tracer agent is an object of submicron scale. The location and distribution of the treatment fluid is determined by detecting changes in the physical properties of the formation caused by the arrival of the treatment fluid comprising a plurality of tracer agents.

Owner:SCHLUMBERGER TECH CORP

Low-temperature sintered hybrid conductive silver paste for chip package and preparation method thereof

ActiveCN107221373AFully dispersedAchieve low temperature sinteringNon-conductive material with dispersed conductive materialCable/conductor manufactureWater basedMicron scale

The invention discloses low-temperature sintered hybrid conductive silver paste for chip package and a preparation method thereof. The low-temperature sintered hybrid conductive silver paste comprises 50-95wt% of conductive silver powders and 5-50wt% of organic carrier. The conductive silver powders contain 20-60wt% of micrometer-scale flake silver powders, 5-40wt% of submicron-scale spherical silver powders and 20-60 wt% of nano-scale spherical silver powders. The organic carrier contains 3 to 30 wt% of binder, 40 to 97.9 wt% of solvent and 0.01 to 30 wt% of other additives. The surface modification of the micron-scale silver powders and the submicron-scale silver powders can adapt the decomposition temperature of a modified surface dispersant to that of a water-based ionic dispersant of such type, so as to realize the low-temperature sintering of hybrid silver paste.

Owner:SOUTH CHINA UNIV OF TECH

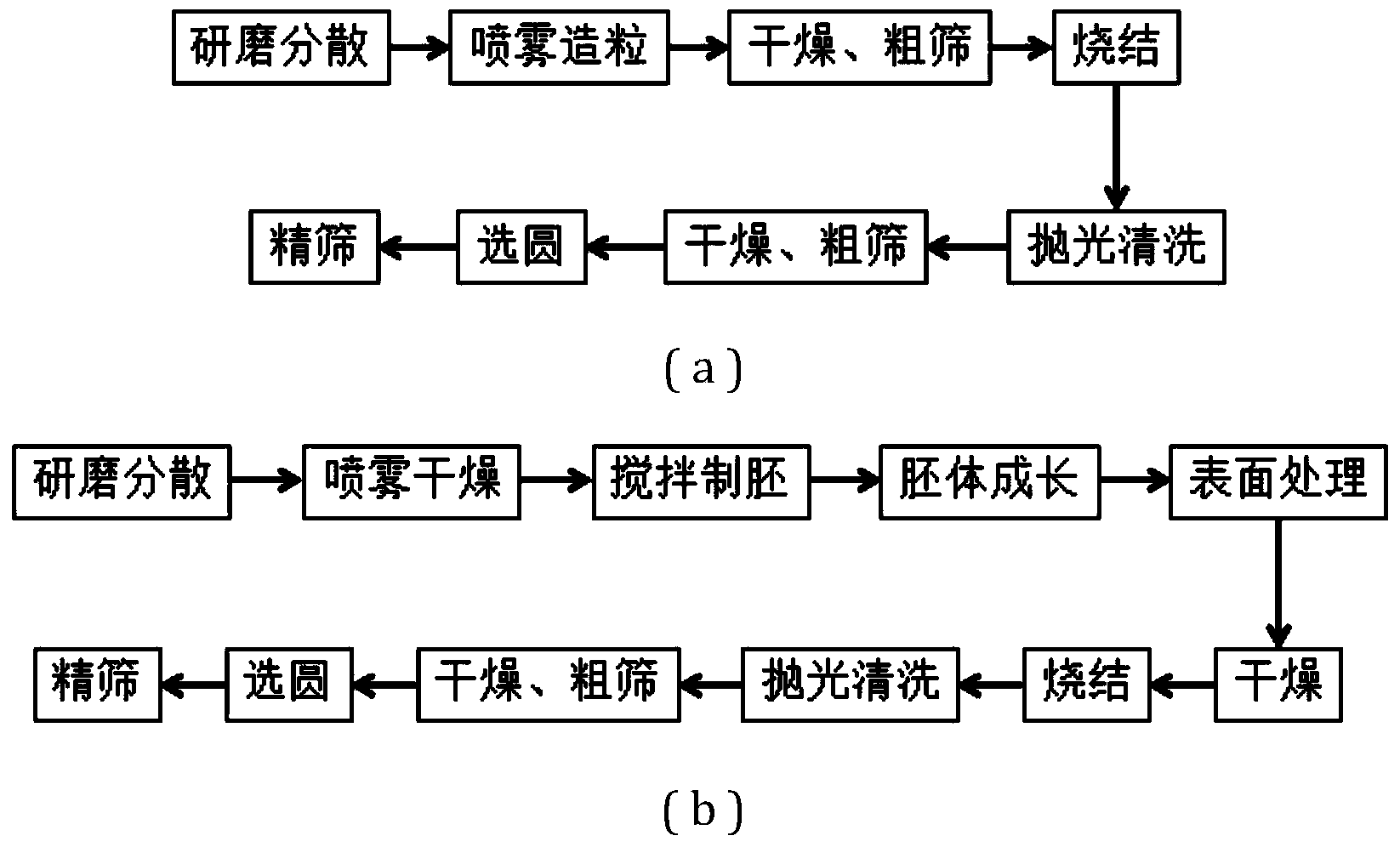

Preparation for high vibration high density lithium iron phosphate

ActiveCN101478045AEasy to processHigh tap densityElectrode thermal treatmentLi-accumulatorsHigh densityLithium iron phosphate

A preparation method of lithium iron phosphate with high tap density relates to the technical field of positive electrode active substance preparation of Li-ion battery. The method comprises the following two steps: firstly, synthesizing submicron-scale lithium iron phosphate powder by soft chemical method; and secondly, spraying a polymer solution into the lithium iron phosphate powder while stirring at high speed to granulate, and sintering. The positive electrode active substance lithium iron phosphate of the Li-ion battery prepared by the two-step method has high tap density of 1.5 g / cm, low specific surface area smaller than 10 m / g, and average particle size of 5 to 15 mum. The method has the advantages of simple implementation, low cost and excellent material processability, and suits industrial production.

Owner:OPTIMUM BATTERY CO LTD +1

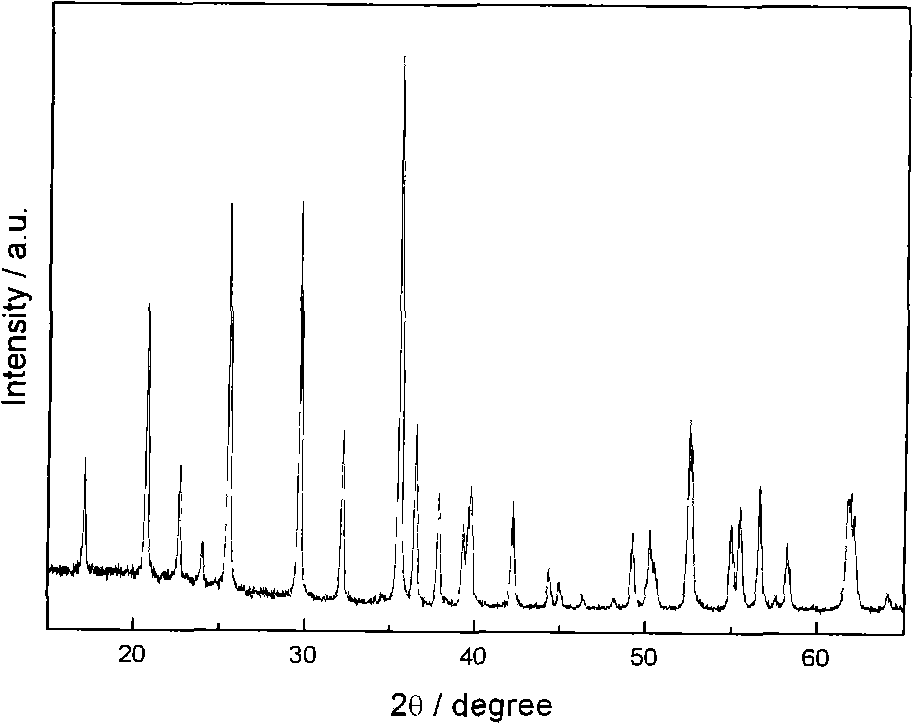

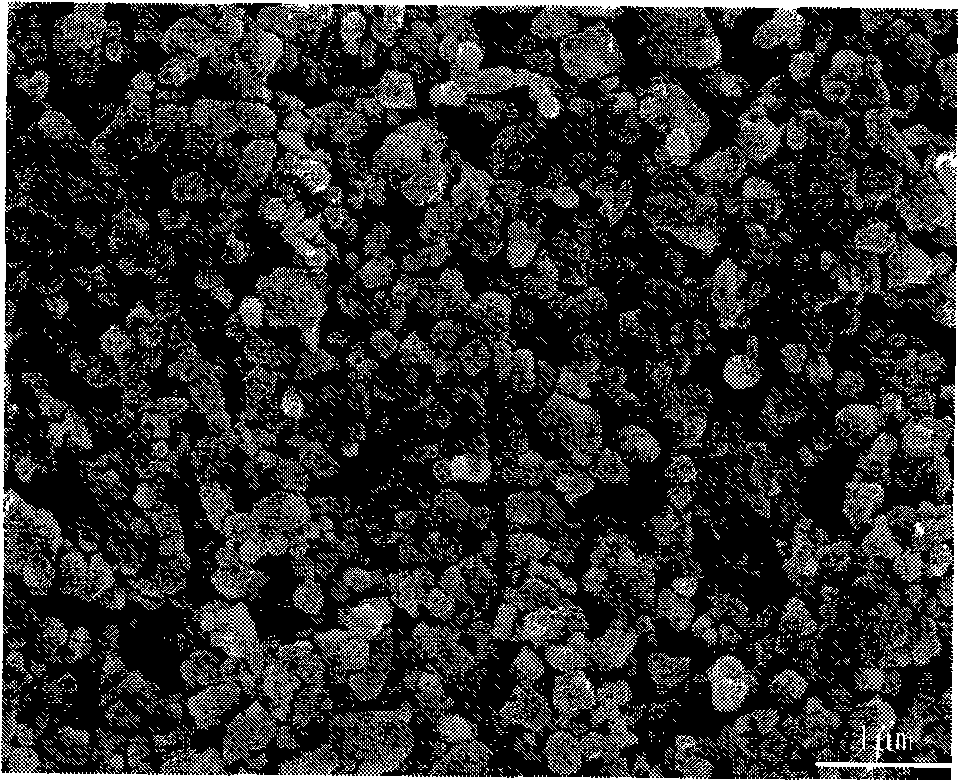

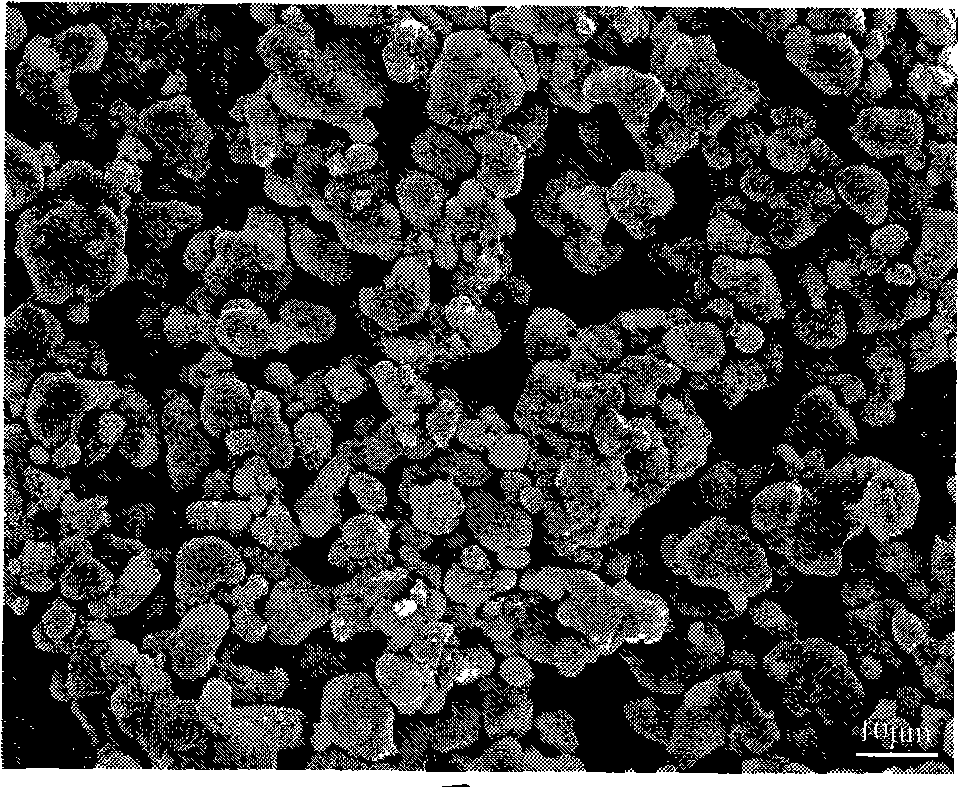

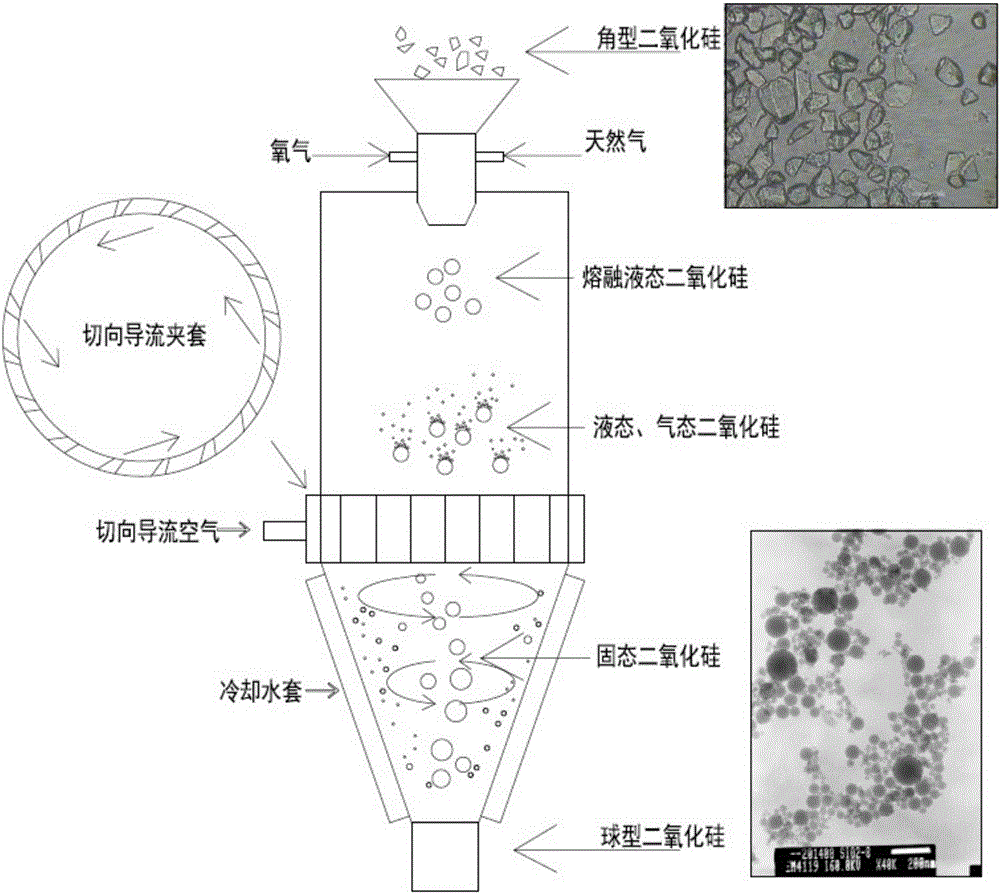

Preparation method for spherical nano-silicon dioxide

The invention relates to a preparation method for spherical nano-silicon dioxide. The method comprises the following steps: supplying silicon dioxide grains with grain size not more than 50mu m; utilizing natural gas and oxygen to generate flame and form flame fields, wherein the silicon dioxide grains are fused in a first flame field at 1700-2000 DEG C to form liquid particles, and the silicon dioxide liquid particles are evaporated in a second flame field at 2300-2600 DEG C higher than the vaporization point of silicon dioxide through liquid particle surface to form nanoscale vaporized matter; quickly cooling and forming, wherein an air cooling system is arranged in an annular tangent air-feeding system in a cooling furnace along a conveying direction of the nanoscale vaporized matter; forming some particles in the vaporized matter into micron-scale and submicron-scale solid spherical particles and forming the rest particles into mono-dispersed nano-spherical particles; grading silicon dioxide grains in different grain sizes. The yield of nano-silicon dioxide prepared according to the method can reach up to 3%-10%.

Owner:ZHEJIANG HUAFEI ELECTRONICS BASE MATERIAL

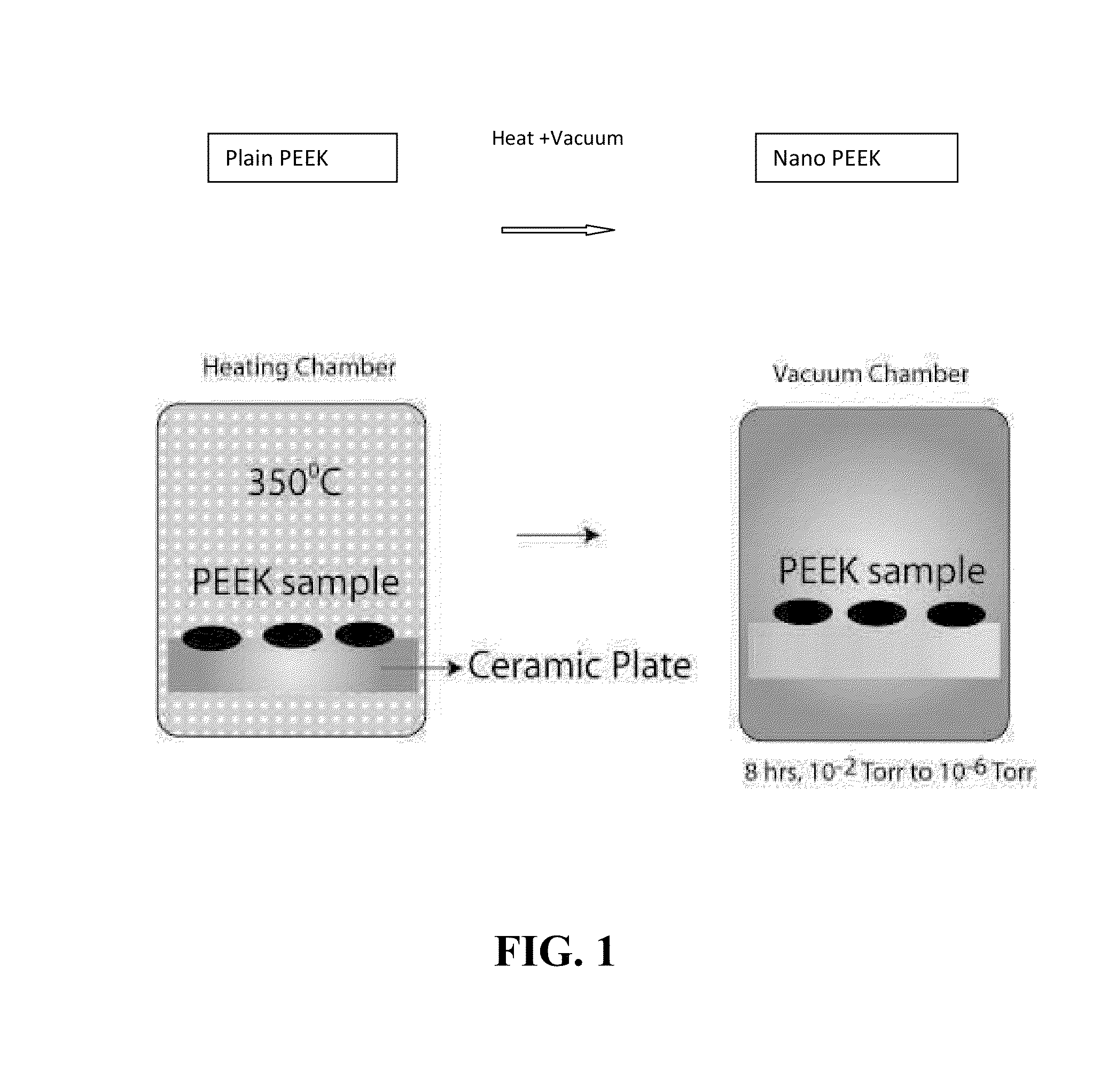

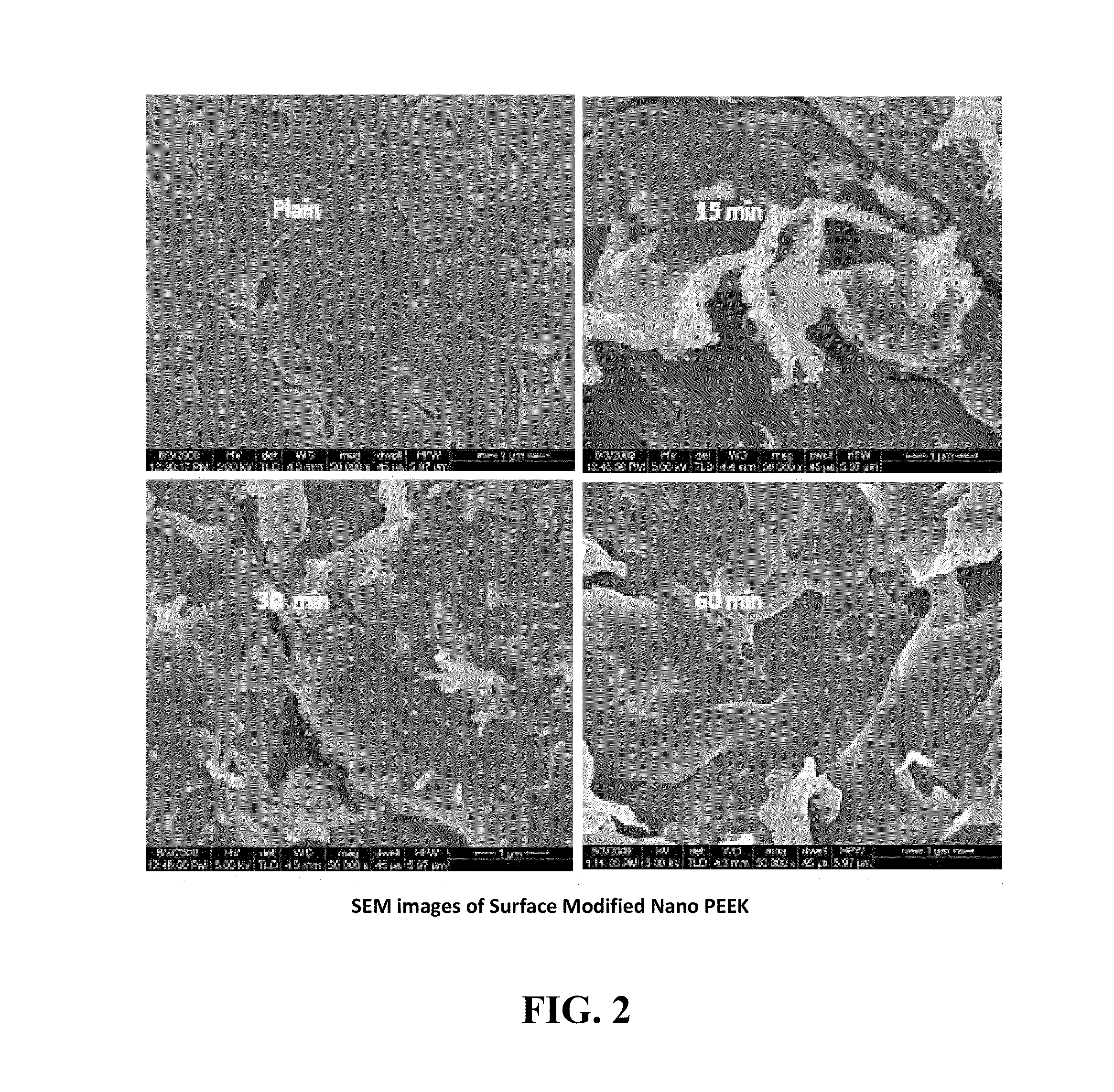

Method for producing nanosurfaces with nano, micron, and/or submicron structures on a polymer

ActiveUS20130330688A1Efficient mass productionReduced particle debrisSuture equipmentsDental implantsNanometrePolymer chemistry

The present invention relates to a modified polymeric material. The modified polymeric material includes a polymer having a modified surface, where the modified surface includes nano, micron, and / or submicron scale features. The present invention also relates to an implant comprising the modified polymeric material. The present invention further relates to processes for making the modified polymeric material and the implant.

Owner:NANOVIS

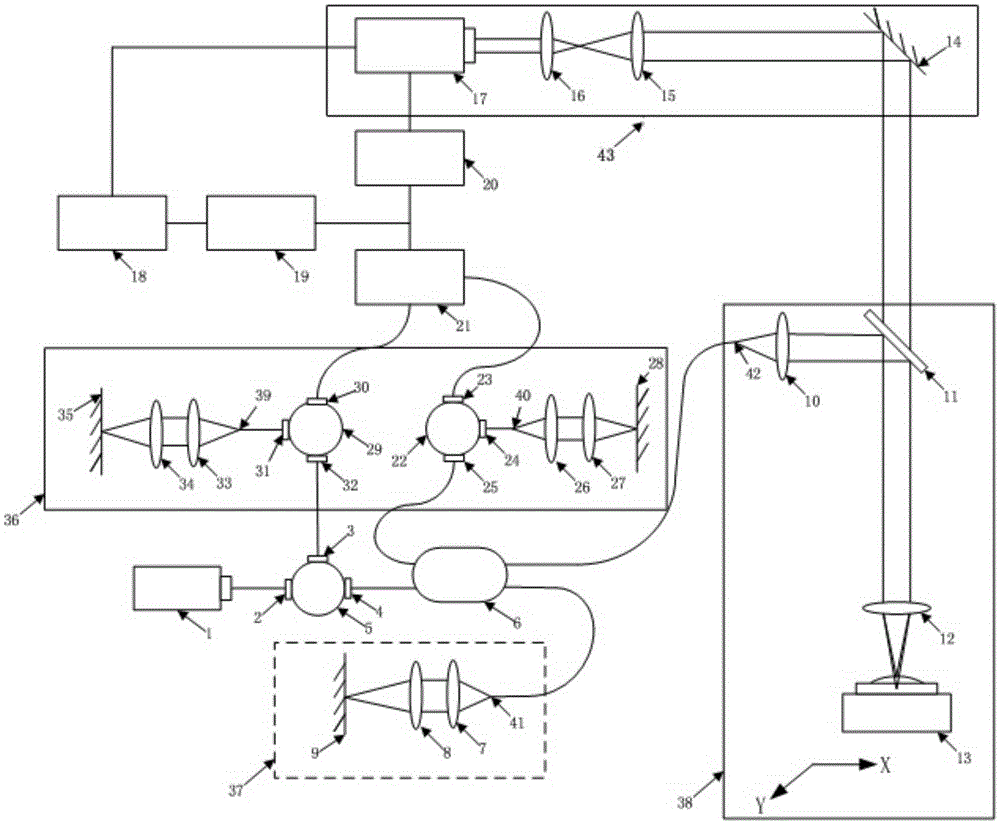

Non-contact photoacoustic detecting method and device based on optical interferometry

InactiveCN105334262AImprove stabilityGood repeatabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationMicrometerOptical probing

The invention discloses a non-contact photoacoustic detecting method based on optical interferometry. The method comprises the following steps of S1, photoacoustic stimulation, S2, optical coherent detection, S3, balance adjustment and S4 detecting window locking. The invention further discloses a non-contact photoacoustic detecting device based on optical interferometry and used for achieving the method. According to the method, the problem that acoustic coupling media must be used in current photoacoustic imaging is solved, and the application range of photoacoustic imaging is widened. High sensitivity is achieved, light spots of probe light can be focused to the micrometer or submicron scale, and high lateral resolution is achieved. Optical detection is adopted, high-speed scanning is easy, and therefore imaging speed can be increased. Real-time detection is carried out to interfere with system sensitivity, balance adjustment is carried out on probe light intensity, and photoacoustic detection is carried out in the state of the highest system sensitivity. The non-contact photoacoustic detecting device based on optical interferometry is further provided, and the stability and repeatability of imaging can be effectively improved.

Owner:NORTHEASTERN UNIV

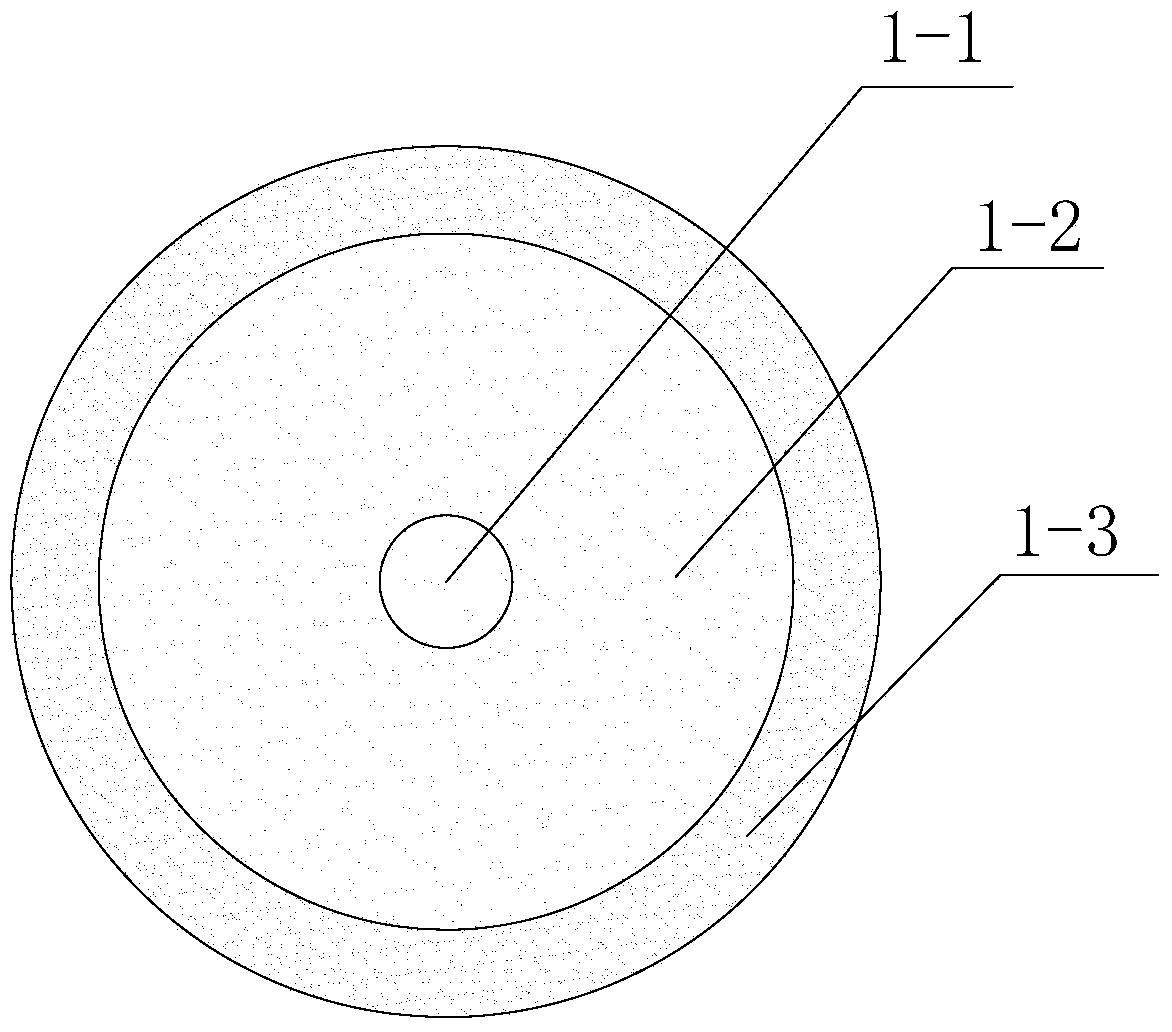

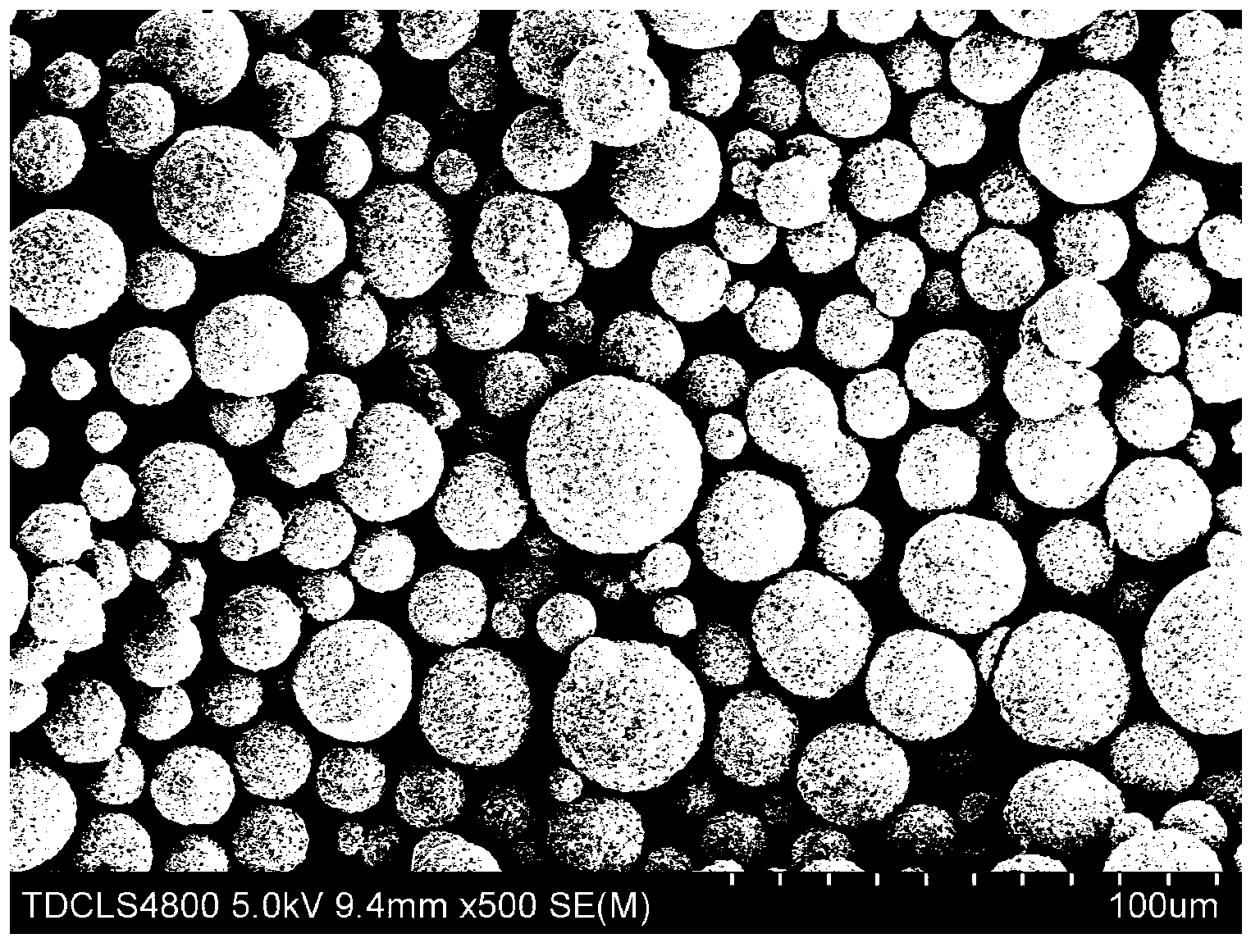

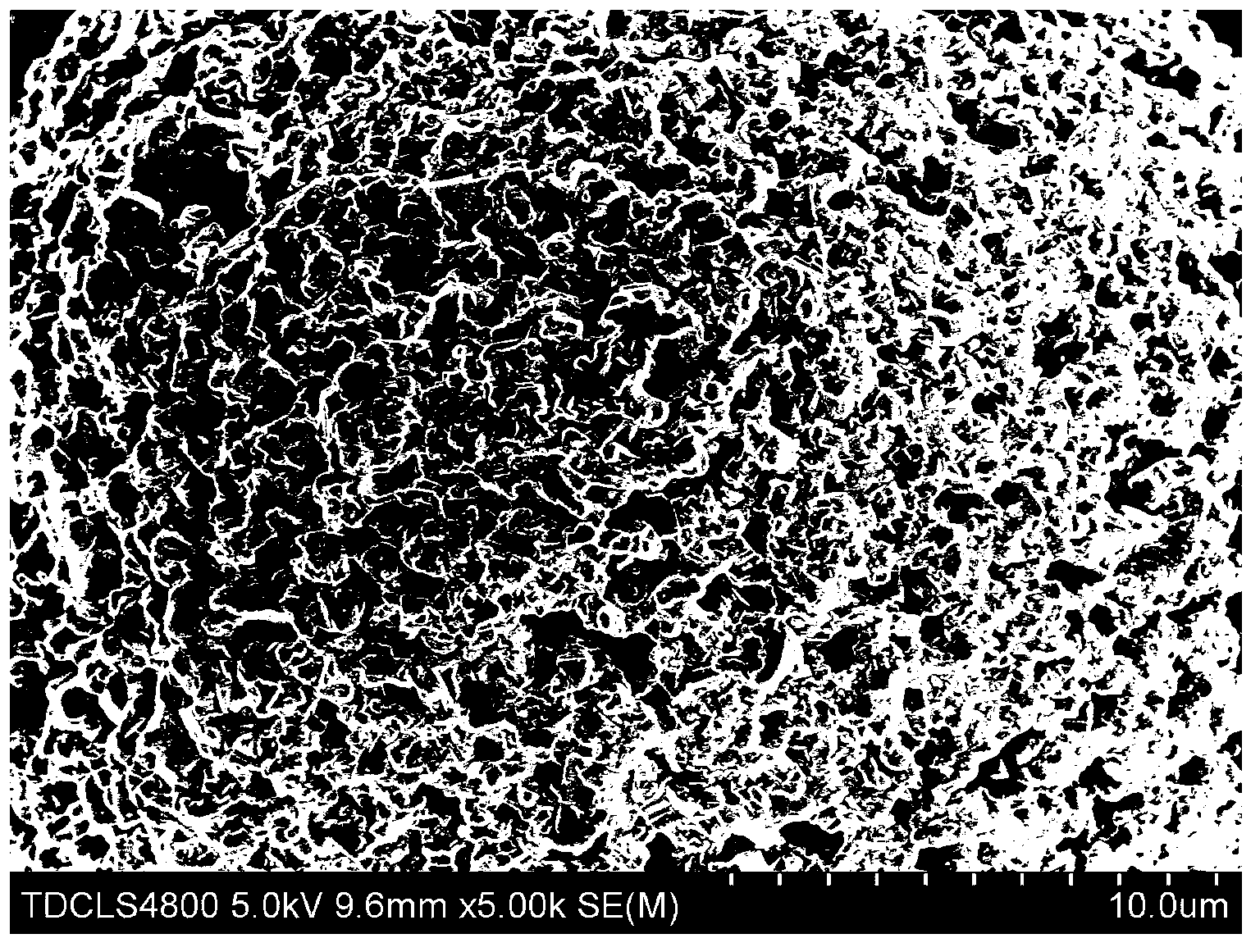

Uniformly-composite spherical ceramic particles and preparation method thereof

The invention relates to the technical field of ceramic-based powder materials and especially relates to uniformly-composite spherical ceramic particles and a preparation method thereof. The uniformly-composite spherical ceramic particles are high-sphericity degree nanoscale and submicron-scale powder aggregates, the aggregate is prepared from at least two different inorganic powder, the inorganic powder particles are bonded by sintering or intermolecular action, local density values of the uniformly-composite spherical ceramic particle from the center to the outer surface are gradually or stepwisely increased and the local density value of the outer surface of the uniformly-composite spherical ceramic particle is maximal The uniformly-composite spherical ceramic particle obtained by the preparation method has the advantages that in a mean volume diameter of 10-500 microns, the difference between the single-particle ingredients and particle total average ingredients is less than 3%, and more than 80% of the particles have a sphericity degree more than 0.92. The preparation method has no pollution and does not discharge toxic gas. The uniformly-composite spherical ceramic particle can be widely used for metal surface frosting treatment, member surface residual stress elimination treatment, strengthening treatment and fatigue-resistance treatment, and can be used for fine processing of nano-powder and preparation of a ceramic coating.

Owner:CHANGZHOU FUNDANT SPECIAL MATERIAL TECH

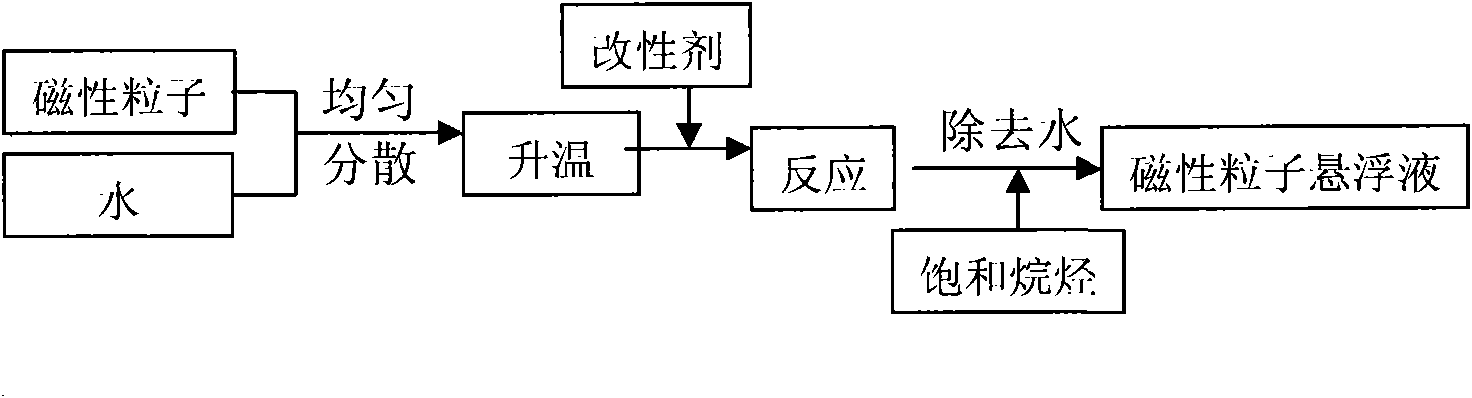

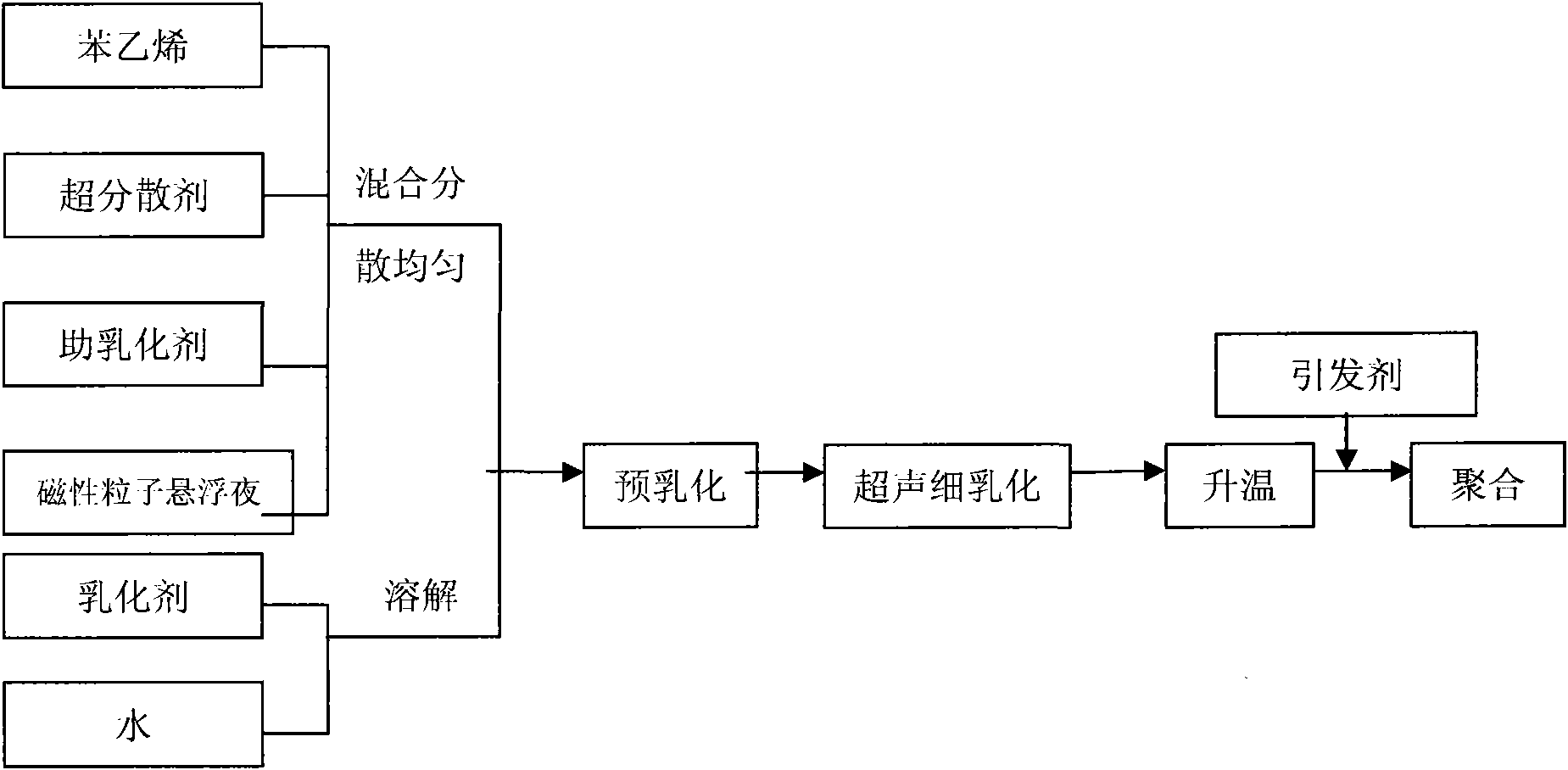

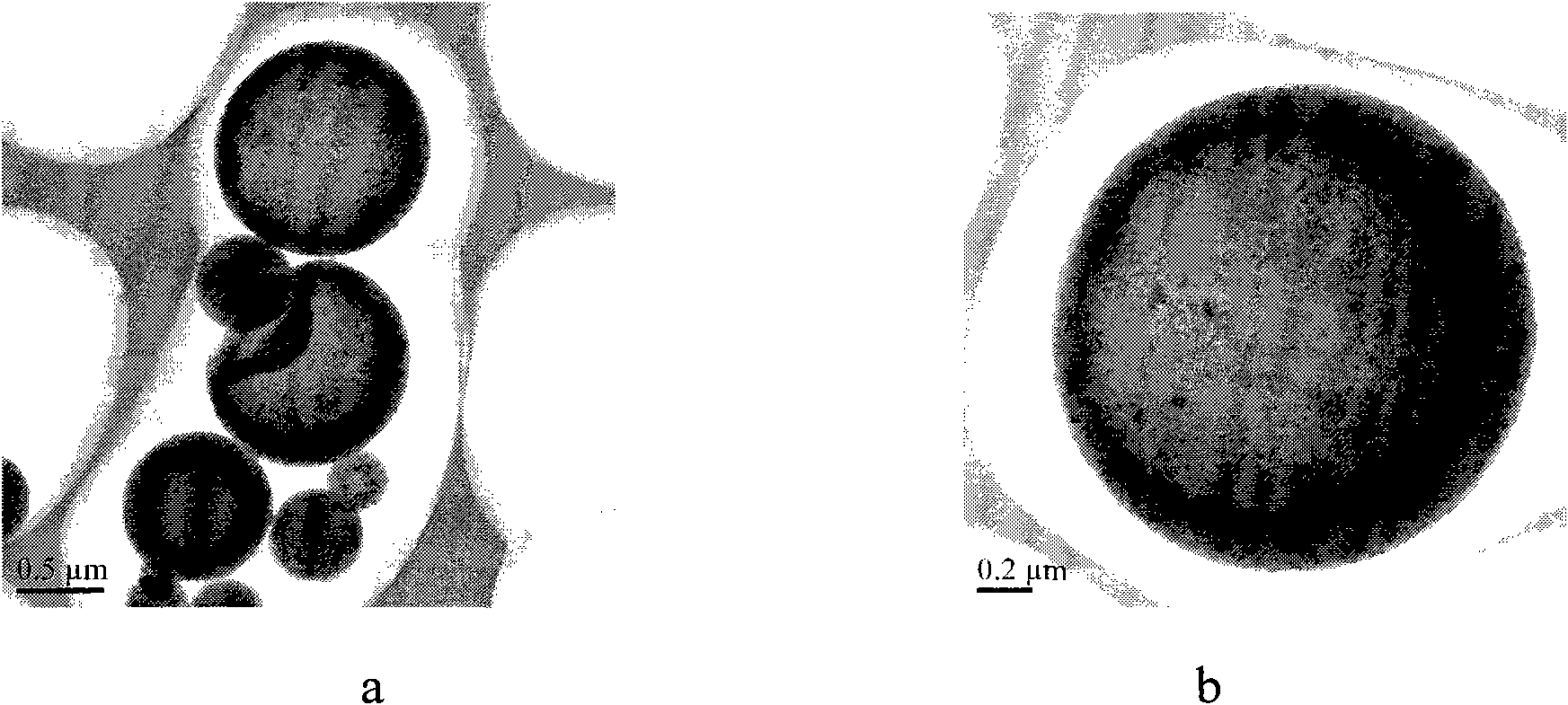

Method for preparing organic/inorganic composite magnetic microcapsules

The invention relates to a method for preparing organic / inorganic composite magnetic microcapsules. The method is characterized by preparing highly magnetic microcapsules by taking styrene as a polymer monomer by a mini-emulsion polymerization method in one step, wherein magnetic particles are dispersed in the capsule wall of polystyrene; and the capsule core is made of unsaturated alkane. The particle diameter of the magnetic particles is within the range from 5 to 15nm; the magnetic particles are modified by a modifier (long-chain unsaturated acid) before use; and the submicron-scale magnetic microcapsules of high magnetic content with particle diameter of between 0.5 and 2mu m and the magnetic content of between 6 and 30 percent are prepared by the mini-emulsion polymerization in one step. The method has the advantages of simple and convenient technological operation, high magnetic content of the prepared microcapsules, high magnetic response, small and uniform particle diameter and capability of meeting the operating requirements in more fields.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

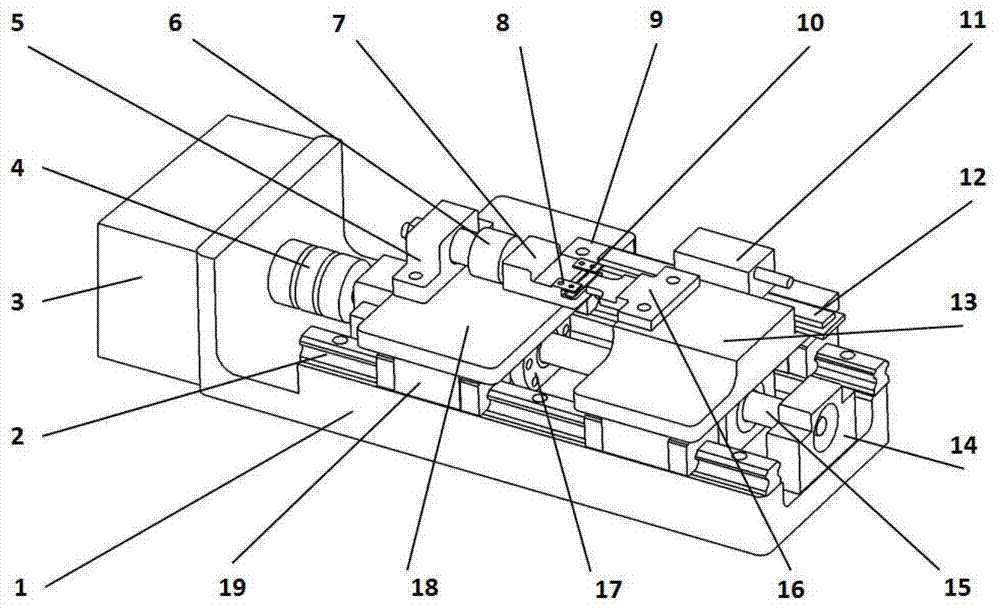

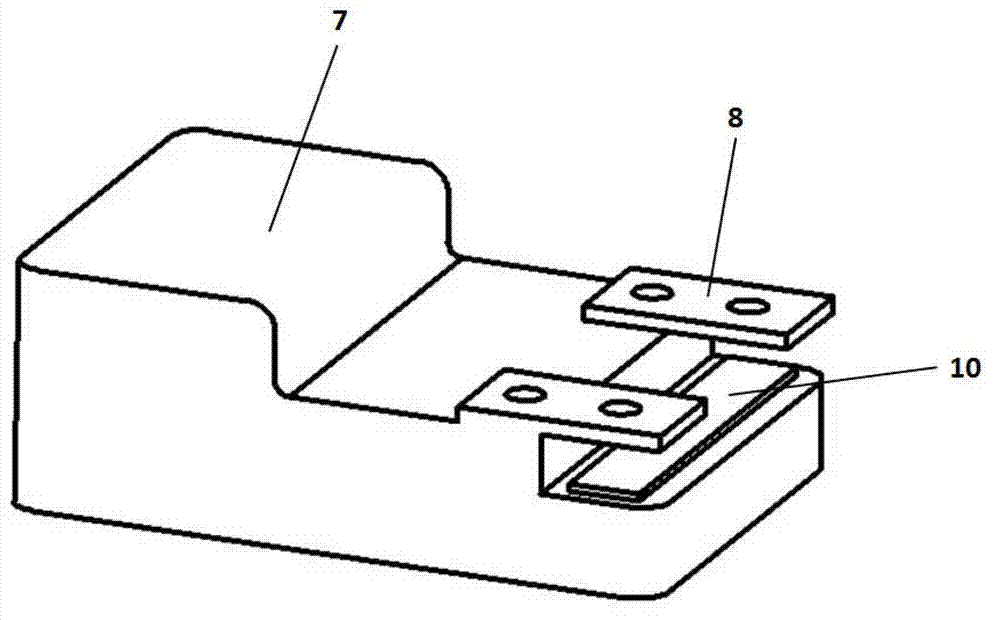

Mechanical-thermal composite in-situ loading system

InactiveCN103091178AAchieve in-situ compressionRealize in situ observationMaterial strength using tensile/compressive forcesBall screwCoupling

The invention discloses a mechanical-thermal composite in-situ loading system which comprises a stepping motor connected with the base, wherein a motor shaft of the stepping motor is connected with a bidirectional ball screw through a coupler; a left lead screw nut and a right lead screw nut are in threaded connection on the bidirectional ball screw; a left objective table and a right objective table are respectively arranged on the left lead screw nut and the right lead screw nut; a left end support and a left clamp are fixedly connected to the left objective table; one end of the base is fixedly connected with the left objective table and the other end of the base is freely suspended; a force sensor is arranged between the left end support and the left clamp; an electric heating film is fixed on the left clamp; a right clamp is fixedly connected to the right objective table; a grating ruler reading head of a grating ruler displacement sensor is fixed on the one side face of the right objective table; a grating ruler main body of the grating ruler displacement sensor is adhered to the base; and the right clamp can press a test piece which is arranged on the electric heating film of the left clamp. The in-situ loading of submicron scale can be realized.

Owner:TIANJIN UNIV

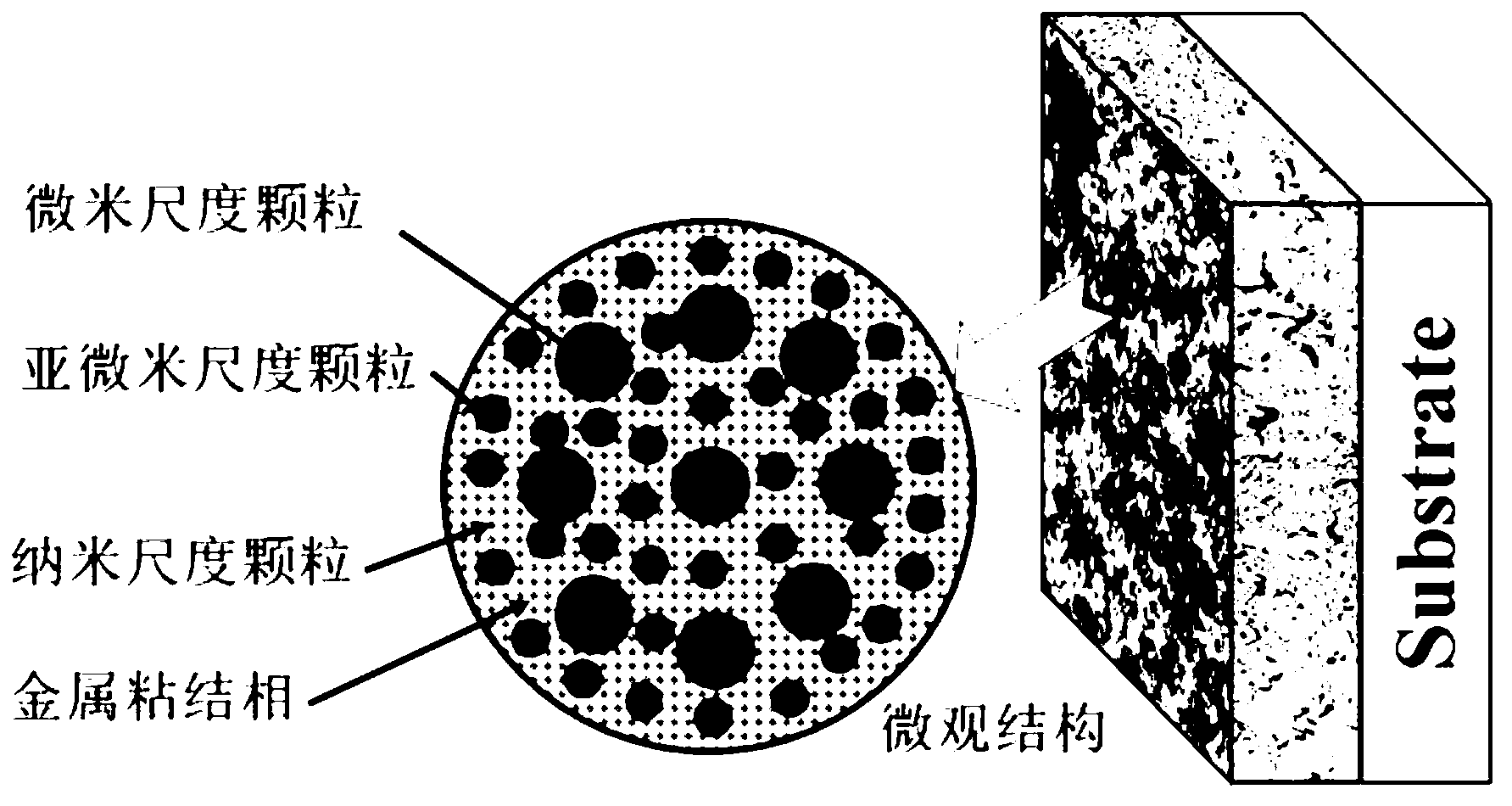

Metal ceramic coating provided with multi-scale WC (wolfram carbide) crystal grains and preparation method

InactiveCN103276340AImprove toughnessEvenly distributedMolten spray coatingMicron scaleCeramic coating

The invention relates to a metal ceramic coating provided with multi-scale WC crystal grains and a preparation method. The grain diameter of each WC crystal grain comprises nanoscale (d is larger than or equal to 10 nm and is smaller than 200 nm), submicron scale (d is larger than or equal to 200 nm and is smaller than or equal to 1 mum) and micron scale (d is larger than 1 mum and is smaller than or equal to 10 mum), and corresponding distribution proportions sequentially are 10%-15%, 20%-25% and 60%-70%. The method comprises the steps as follows: WC-12 Co thermal spray powder is mixed uniformly; a planetary ball mill is adopted to perform uniform powder mixing; sand blasting and cleaning are performed on the surface of a matrix; and a supersonic speed flame thermal spray technology is adopted to prepare a WC-12Co ceramic coating with multi-scale WC grain diameters. Under the condition that the strength and hardness of the WC-12Co ceramic coating are not reduced, the toughness of the coating is improved remarkably, therefore, the metal ceramic coating with high obdurability and abrasion resistance is obtained, and can be widely applied to the field of engineering machinery refabrication.

Owner:TIANJIN UNIV

Patterned opto-electrical substrate and method for manufacturing the same

ActiveCN104465917AImprove light extraction efficiencyImprove luminous brightnessSemiconductor/solid-state device manufacturingSemiconductor devicesMicron scaleEngineering

Owner:KINIK

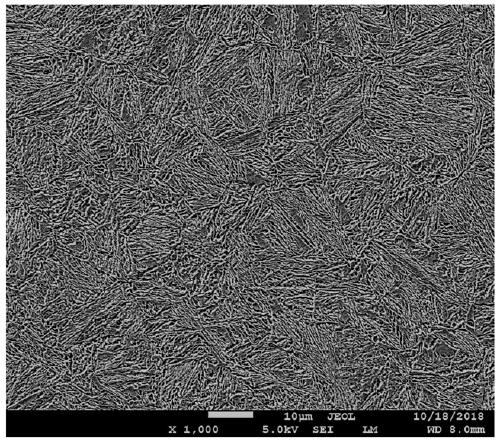

High-toughness bainite wear-resistant steel suitable for liner plate of large semi-autogenous mill and preparation method of high-toughness bainite wear-resistant steel

The invention provides high-toughness bainite wear-resistant steel suitable for a liner plate of a large semi-autogenous mill. The high-toughness bainite wear-resistant steel is prepared from, by masspercent, 0.4% to 0.8% of C, 1.4% to 2.5% of Si, 0.7% to 1.6% of Mn, 1.5% to 2.5% of Cr, 0.2% to 0.7% of Mo, 0.01% to 0.05% of Nb, 0.1% to 0.5% of Cu, 0.1% to 0.5% of Ni, 0 to 0.03% of Al, 0.01% to 0.2% of RE, 0.008% to 0.015% of N, not larger than 0.015% of P, not larger than 0.01% of S, not larger than 0.004% of O and the balance Fe and inevitable impurities. A preparation method is further provided, and comprises the steps that a thick plate formed through smelt forging or rolling is subjected to spheroidizing annealing and heat treatment; and the obtained wear-resistant steel contains nanoscale or submicron-scale carbide-free bainite, thin-film-shaped bainite and a small amount of blocky bainite.

Owner:JIANGXI NAIPU MINING MASCH CO LTD

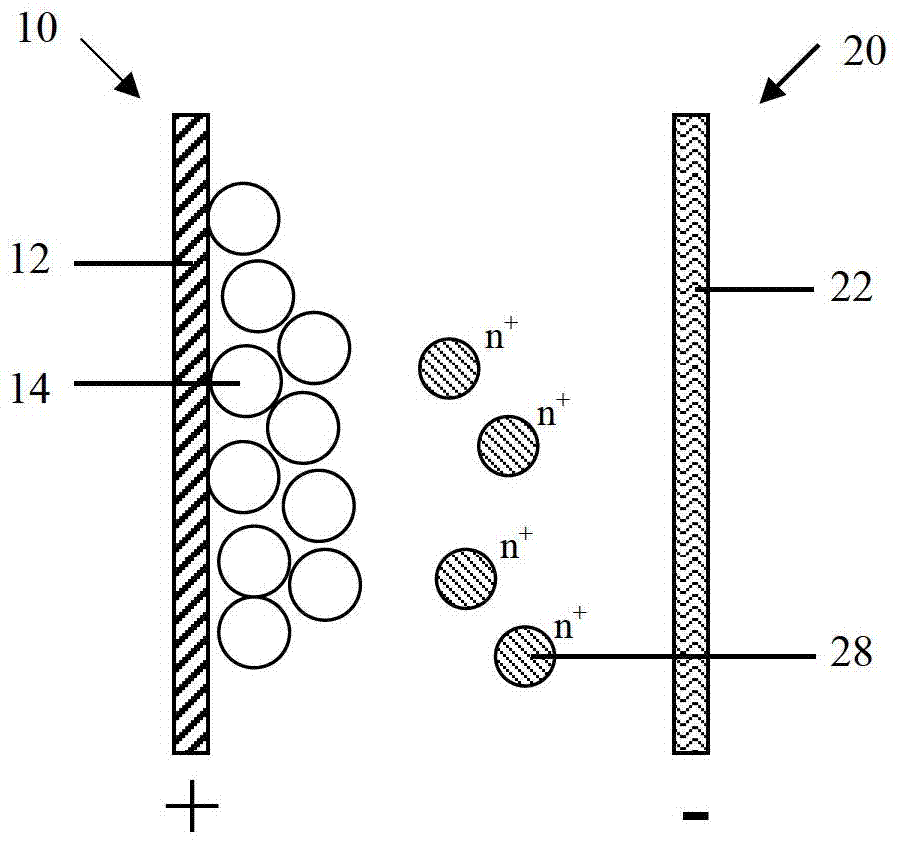

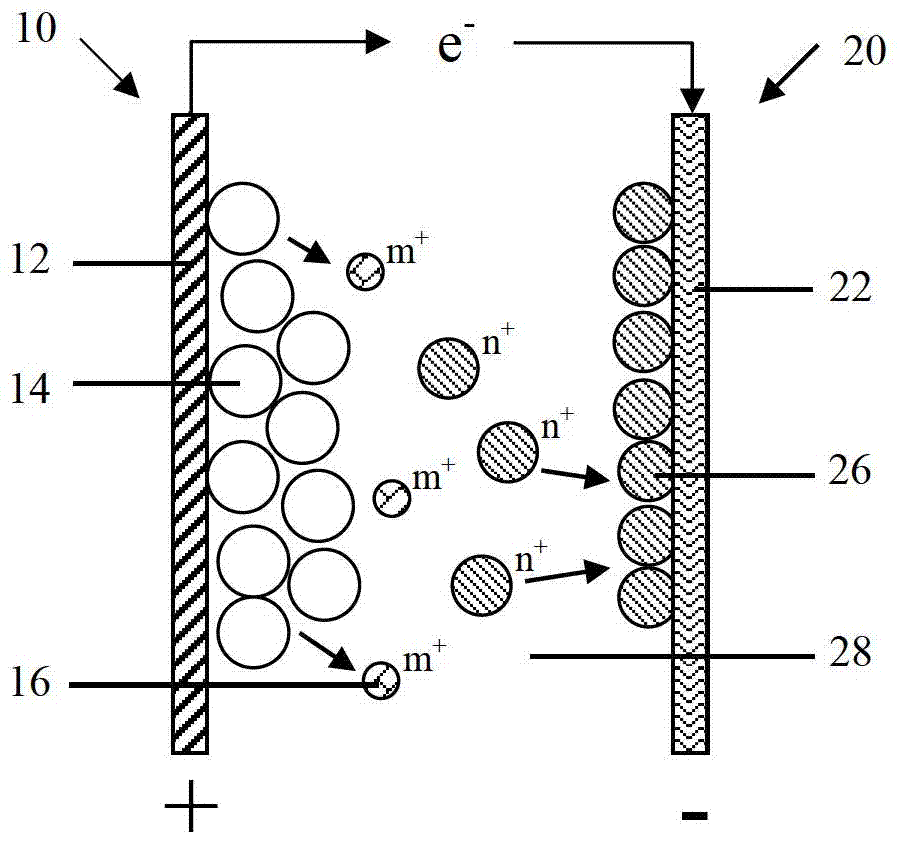

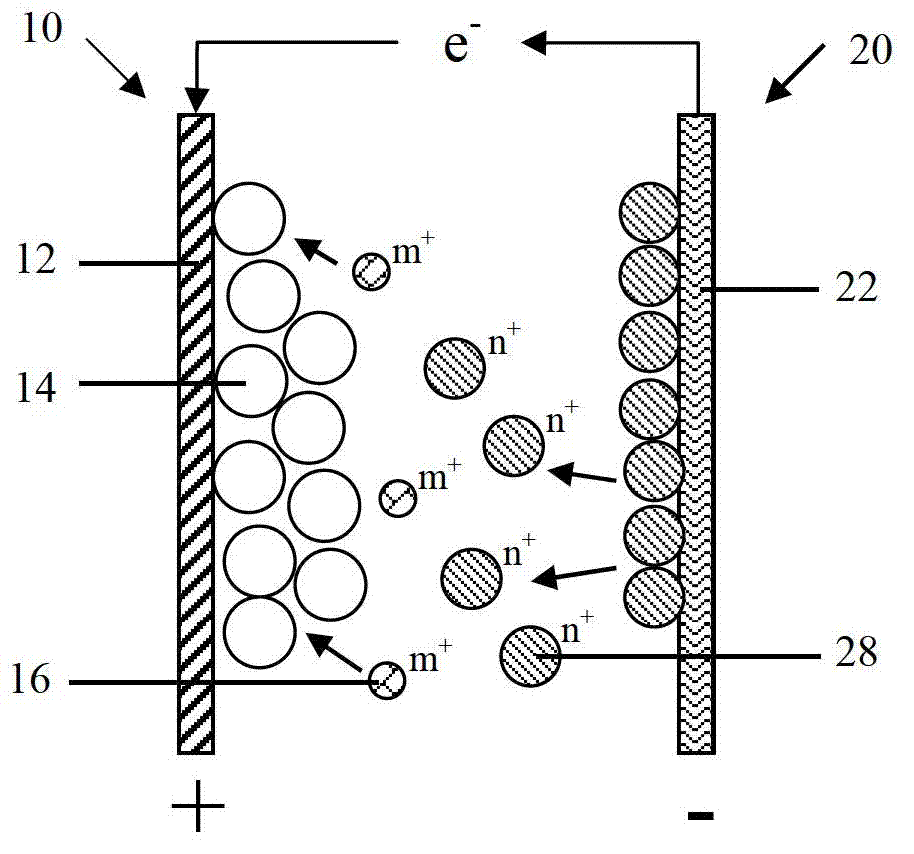

Battery

ActiveCN102903924AOperational securityReduce manufacturing costSecondary cellsActive material electrodesMicron scaleElectrochemical response

The invention discloses a battery. The battery comprises an anode, a cathode and an electrolyte solution. The anode comprises an anode current collector and an anode active material which undergoes an electrochemical reaction and can realize reversible release of an embedded ion. The cathode at least comprises a cathode current collector. The electrolyte solution comprises at least one solvent which can dissolve electrolytes and ionize the electrolytes, and the electrolytes can be ionized into at least one type of active ions which can undergo a reduction-deposition reaction and an oxidation-dissolution reaction at the cathode in a charge-discharge process. A porous layer or a graphene layer is formed on the surface of the cathode and the porous layer has micron scale, submicron scale or nanoscale apertures. The battery can be operated safely, has a low production cost, a long service life and good cycling performances, and can be used as a substitute of an energy storage system and a lead acid battery in the field of large-scale energy storage.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

High-speed, ultra precision manufacturing station that combines direct metal deposition and EDM

ActiveUS8629368B2Fast transferImprove efficiencyAdditive manufacturing apparatusElectric discharge heatingEngineeringBeam parameter product

A direct-metal deposition (DMD) processing stage and a 5DOF (degree of freedom) dry micro-EDM (mEDM) stage are integrated to provide the submicron scale resolution necessary for the ultra-precision processing of work pieces. The DMD processing stage includes optical feedback for dimensional control utilizing a high-power, fiber-coupled diode laser with fast response time and small beam parameter product. The electrical discharge machining (EDM) stage is a dry EDM stage using an inert gas with appropriate dielectric properties to perform the surface finishing operations. The system further includes one or more surface treatment operations to obtain a desired level of surface hardness or wear resistance and / or to minimize the distortion induced in treating the surface.

Owner:DM3D TECH

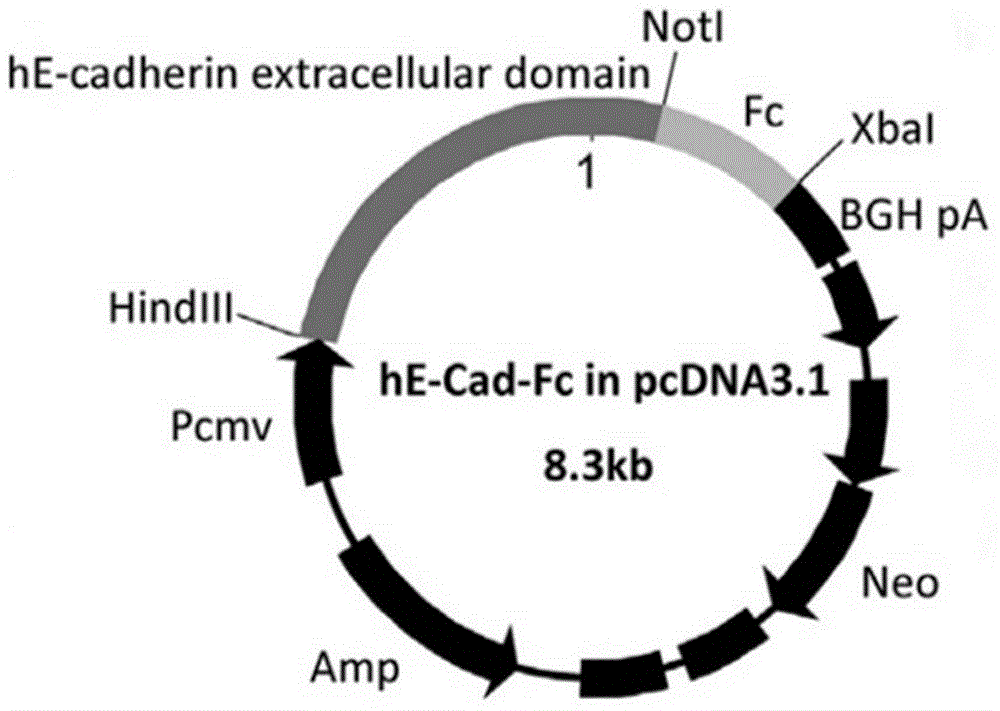

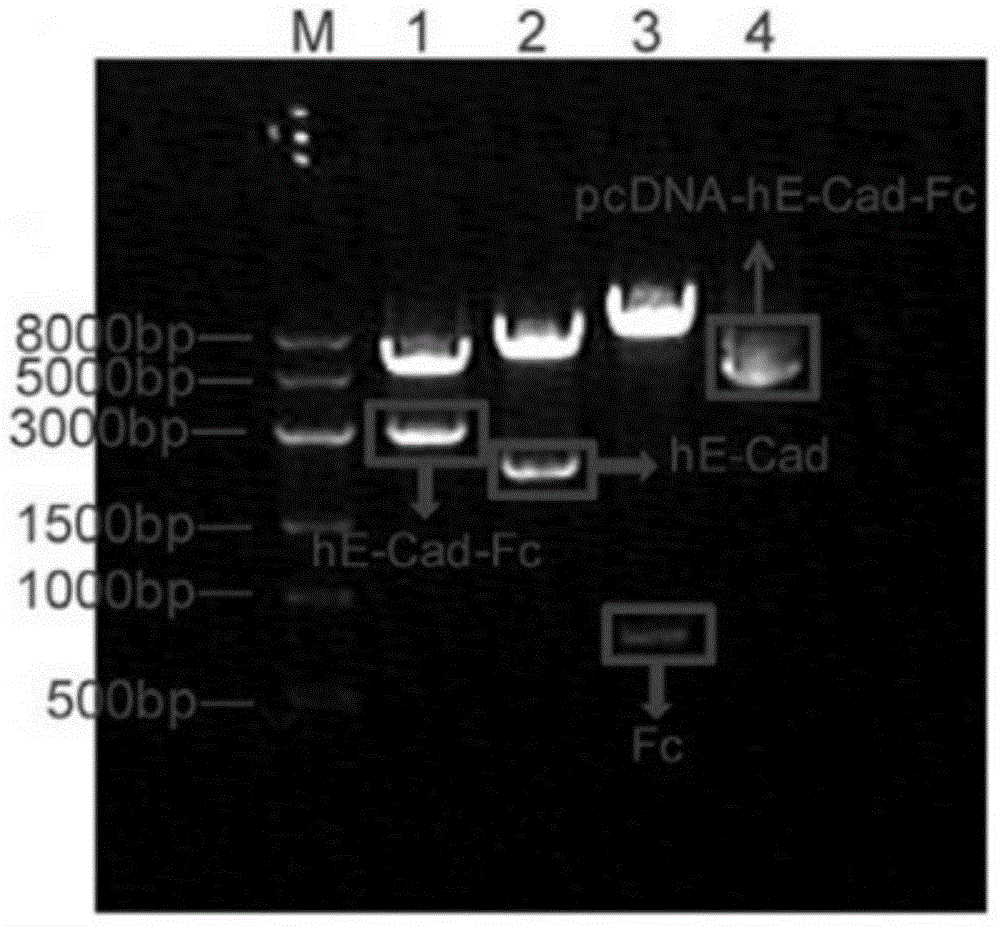

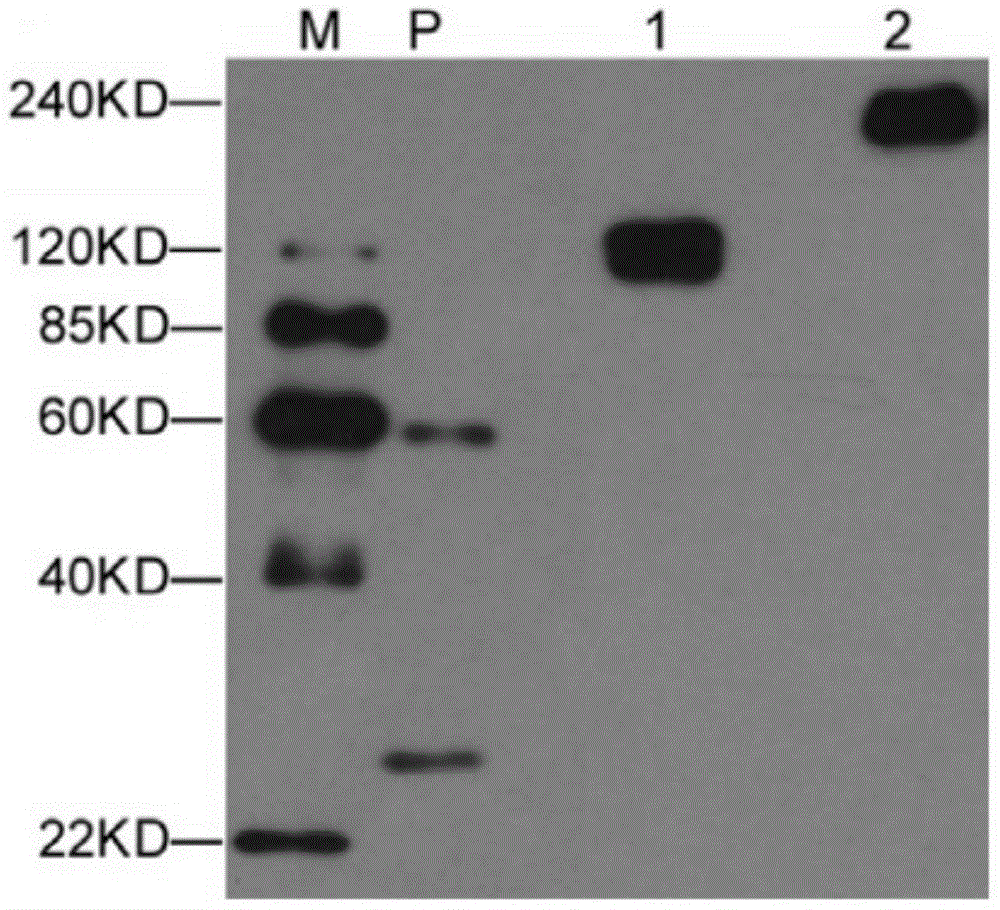

Three-dimensional complex cell aggregate model as well as preparation method and application thereof

ActiveCN104651300AOvercoming heterogeneous growthOvercome inhibitionSkeletal/connective tissue cellsEmbryonic cellsChemical synthesisCell-Extracellular Matrix

The invention provides a three-dimensional complex cell aggregate model as well as a preparation method and application thereof. According to the model, a natural or chemically synthesized polymer is used as a matrix material to prepare submicron-scale microspheres, and cell factors are embedded in or fixed on the surface of the submicron-scale microspheres and are co-cultured with cells to form a complex cell aggregate containing the microspheres, so that the biological activity of the cells in the aggregate can be regulated and controlled from inside to outside. The model can be used for researches of propagation and differentiation of stem cells in a three-dimensional state, overcomes the problems that the cell aggregate is heterogeneous in composition / structure, the cell proliferation efficiency is low and the directional induced differentiation efficiency is low due to non-uniform mass transfer and short acting time of liquid factors in a culture medium during the traditional three-dimensional culture of the stem cells, can be used for stimulating interaction between cells and cells, cells and an extracellular matrix as well as cells and soluble factors, thereby providing a theoretical and technical support for in vitro construction and optimization of a stem cell culture technology, and tissue engineering construction of various tissue and organ analogs or equivalents.

Owner:NANKAI UNIV

Electro-blowing technology for fabrication of fibrous articles and its applications of hyaluronan

InactiveUS7662332B2Improve the situationHigh productElectric discharge heatingFibre chemical featuresFiberNanofiber

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

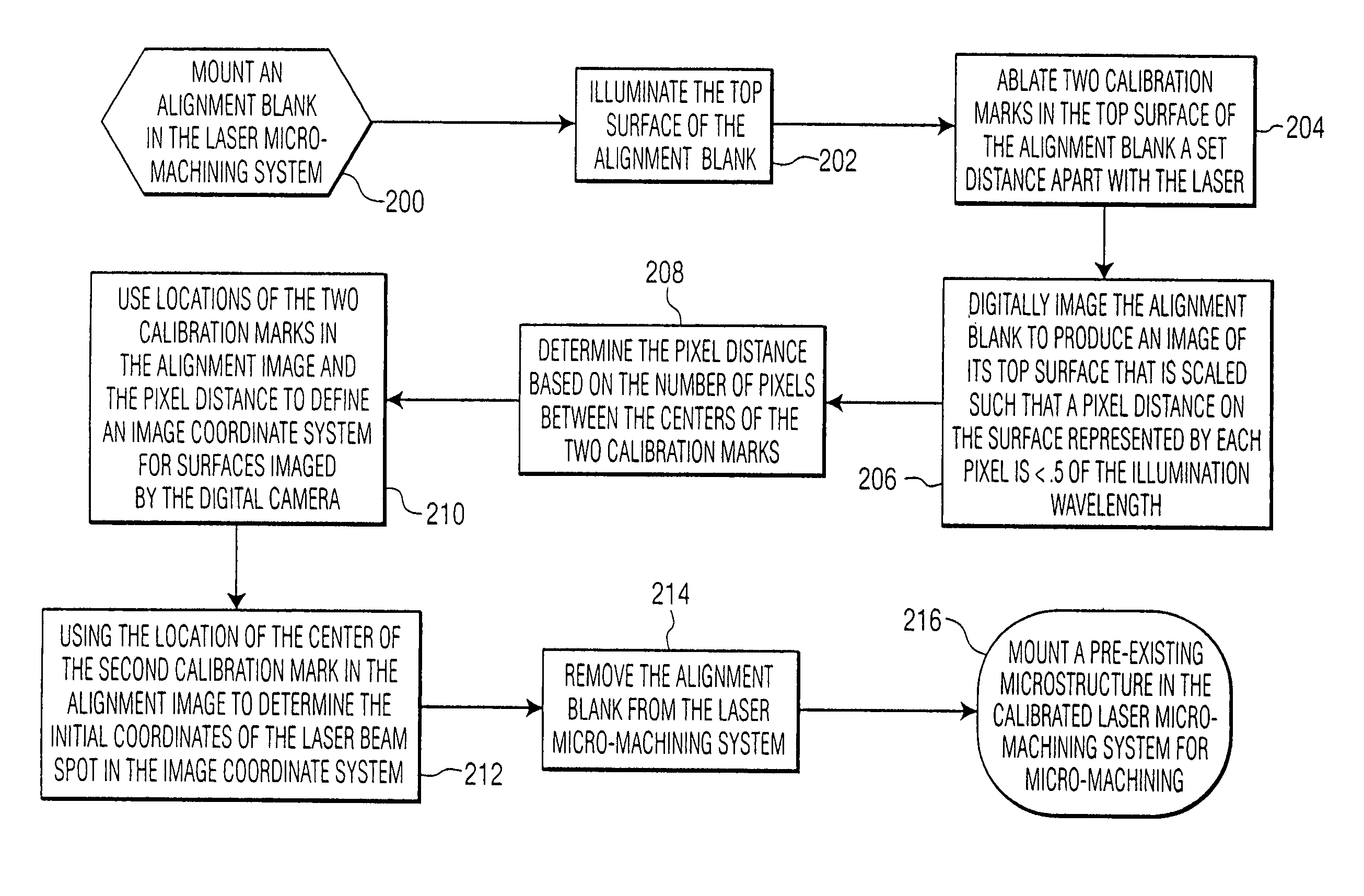

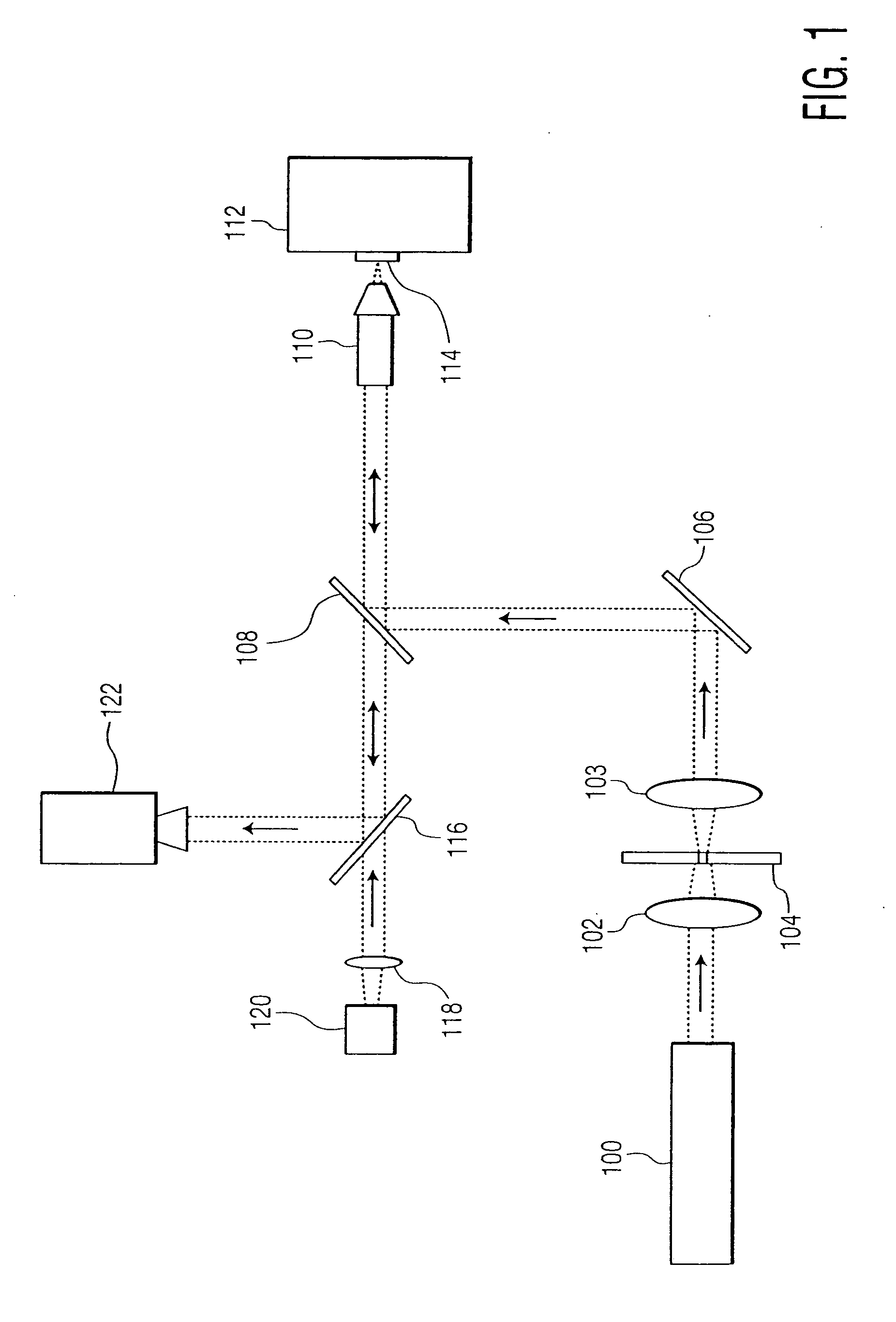

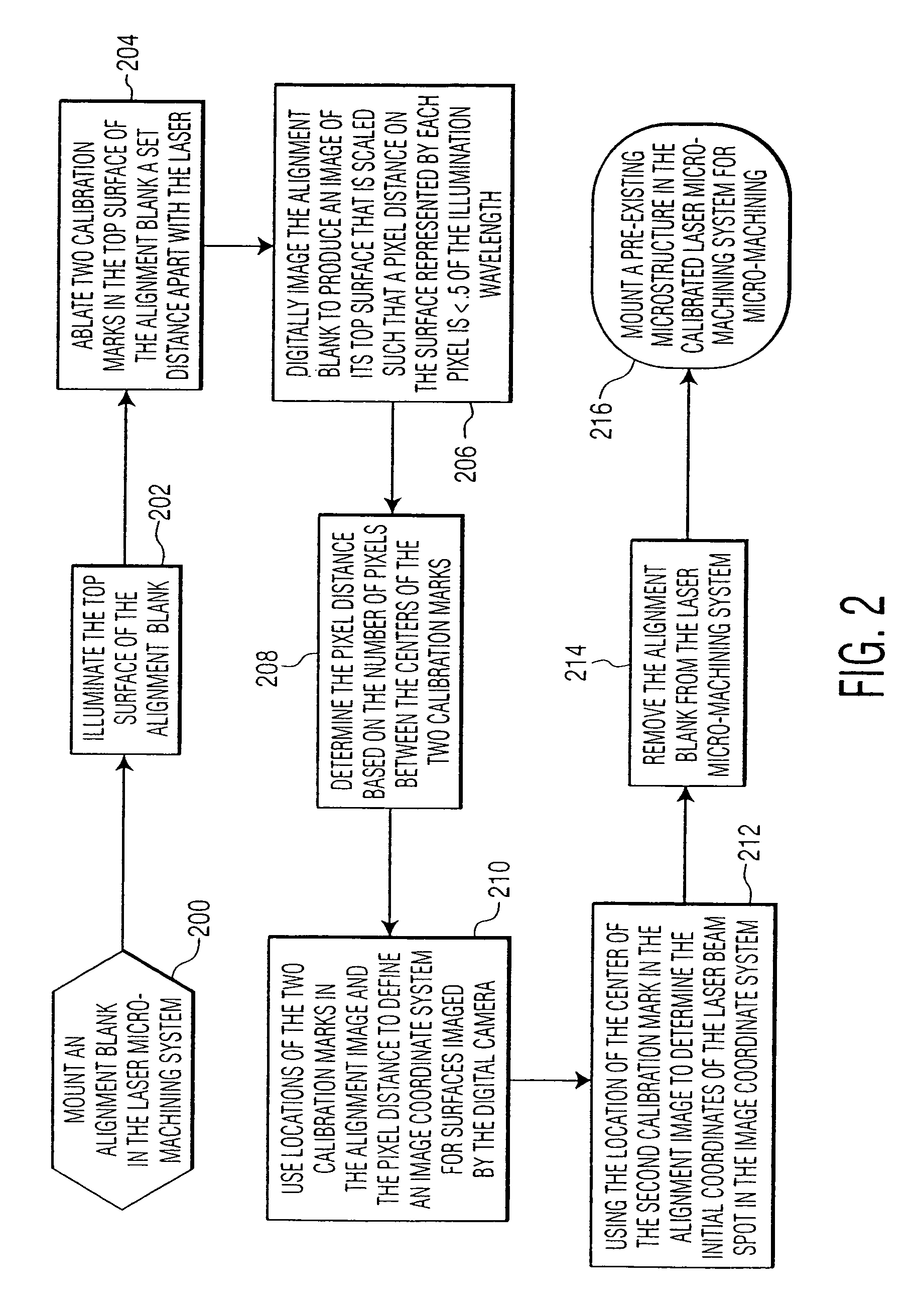

Ultrafast laser direct writing method for modifying existing microstructures on a submicron scale

InactiveUS20070062918A1Semi-permeable membranesFixed microstructural devicesLength waveMachining system

A method for pre-calibration of a laser micro-machining system to achieve alignment tolerances greater than the diffraction limit of an illumination wavelength. A blank is mounted in the system, such that the beam spot is incident on its top surface. Two marks are ablated in the blank. The centers of the marks are a predetermined distance apart. The blank is illuminated with light and imaged with a digital camera. The resulting image is scaled such that each pixel has a width corresponding to a distance on the imaged surface, which is less than half of the illumination wavelength. The number of pixels between the centers of the marks determines this distance. The locations of the marks in the image are determined and a coordinate system is defined for surfaces imaged by the digital camera. Coordinates of the beam spot in this coordinate system are also determined using the second mark.

Owner:LI MING +1

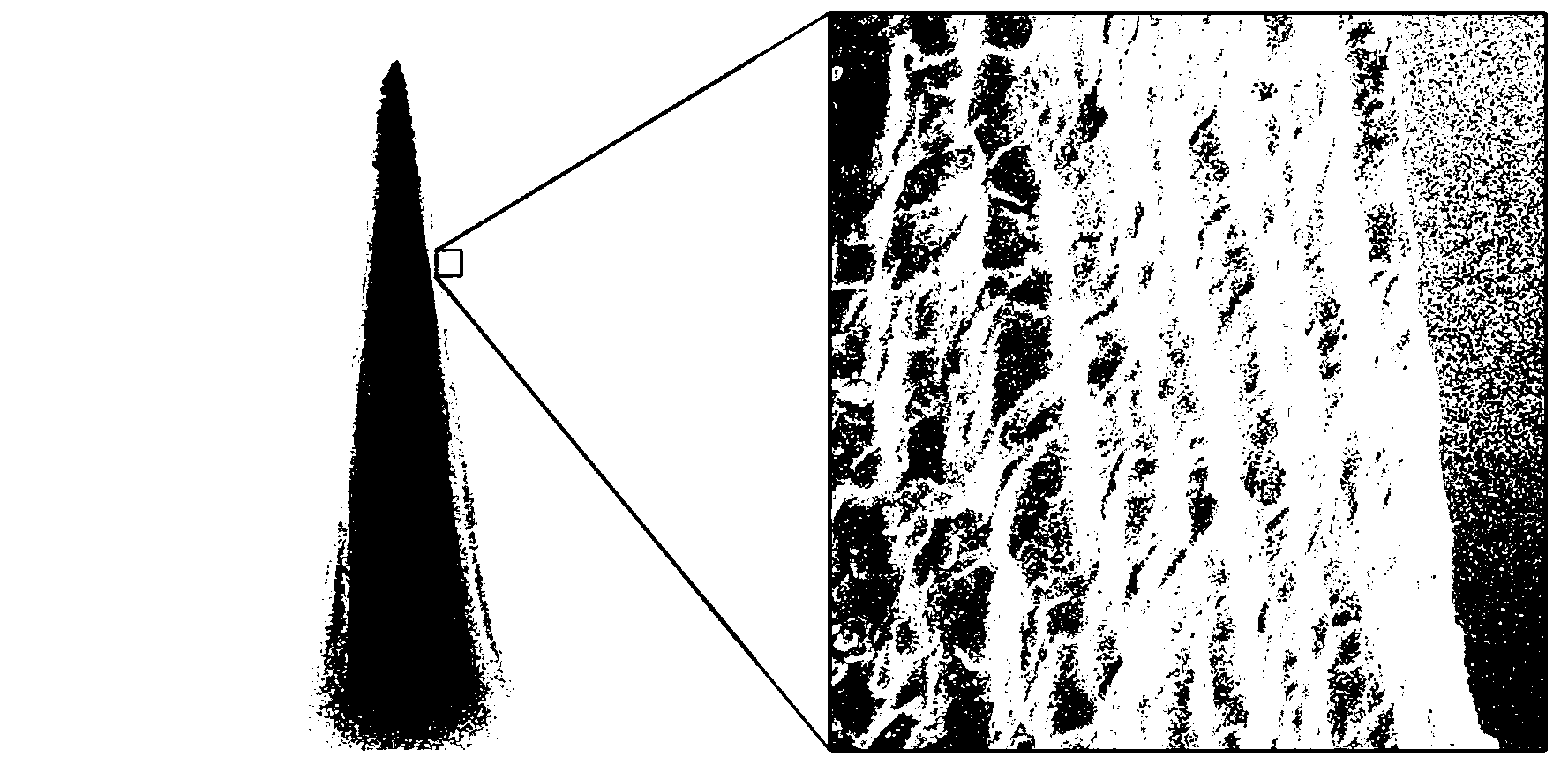

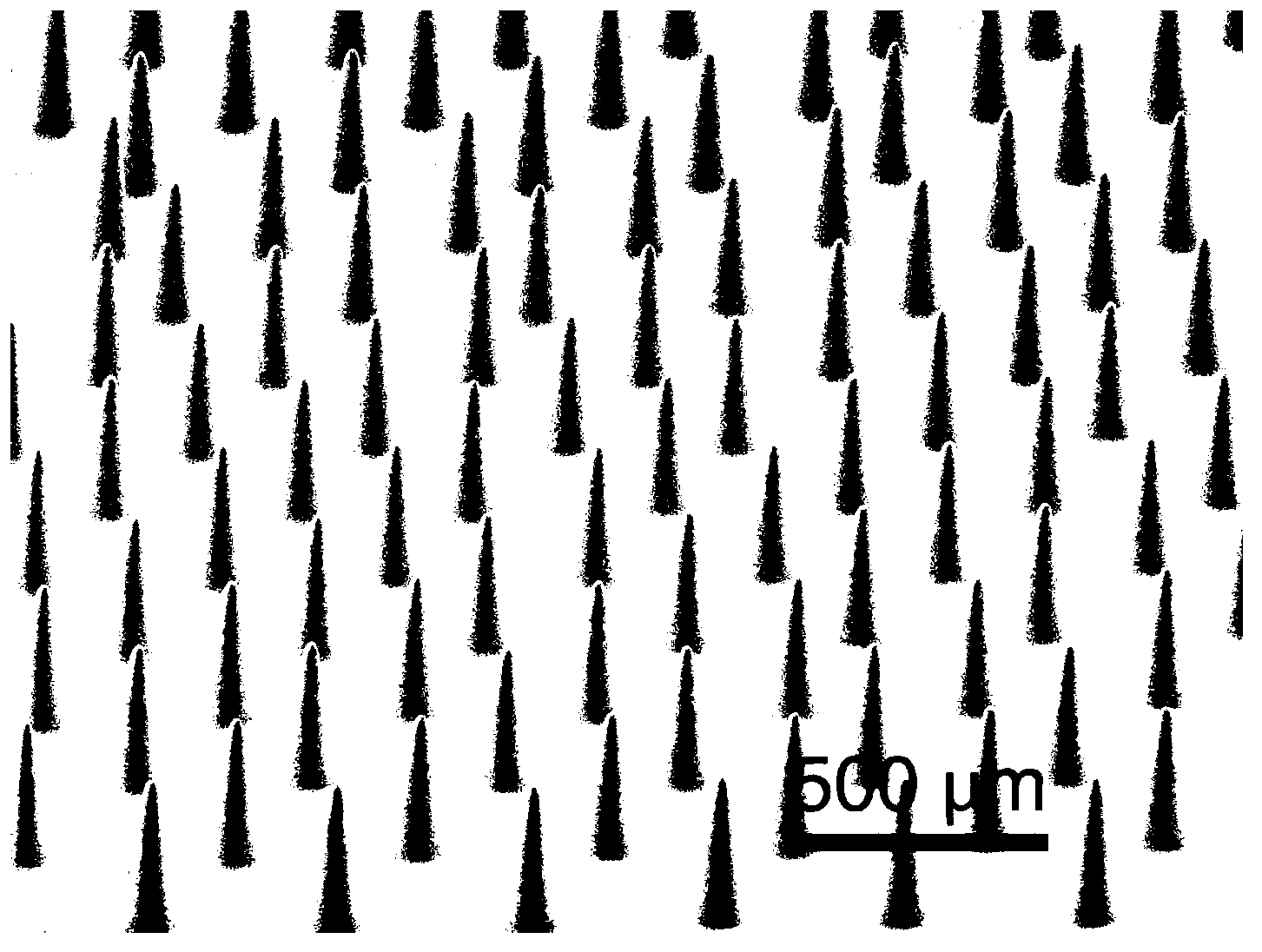

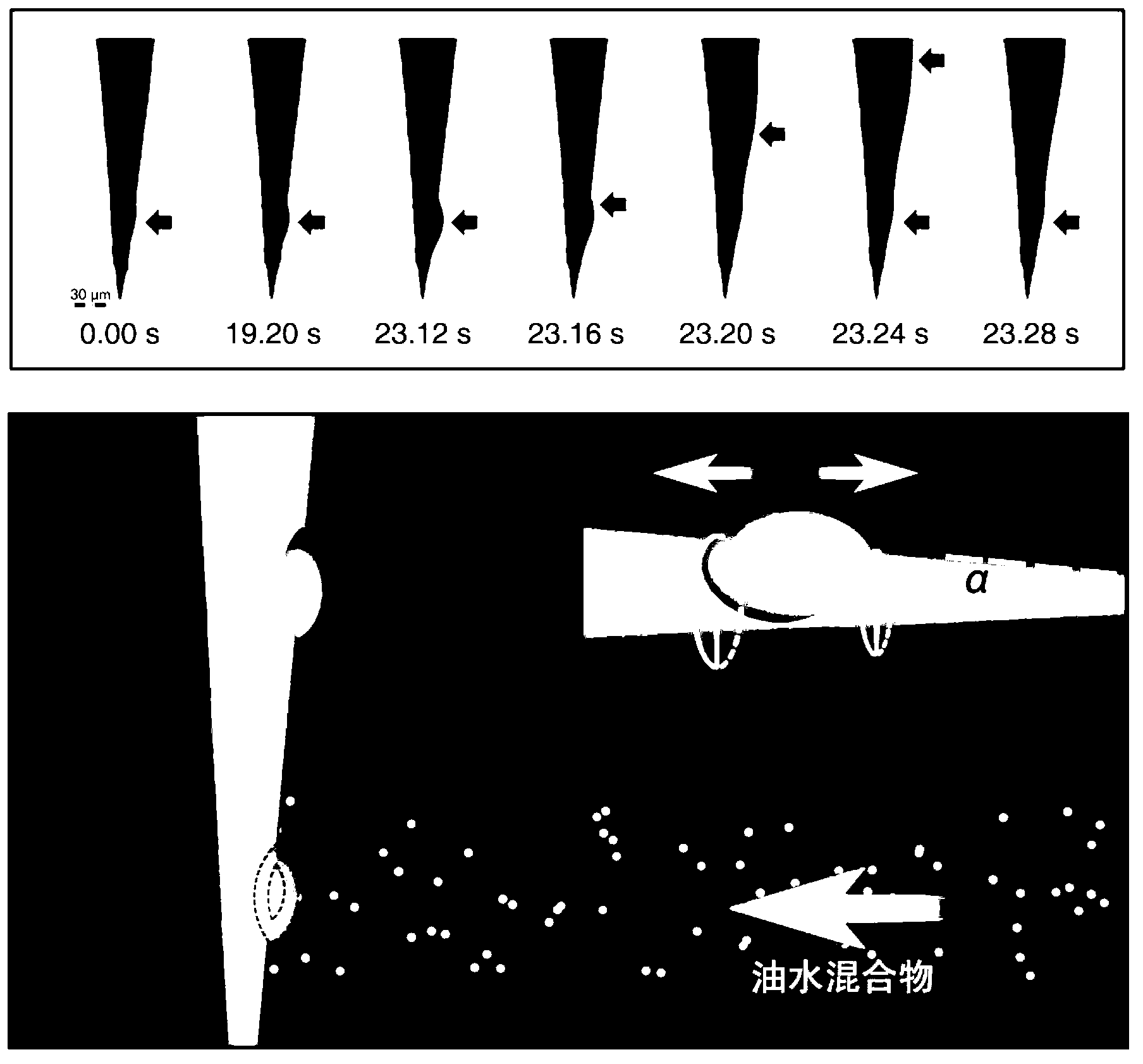

Film with oil-water separation tapered needle array having underwater oleophilic property on surface as well as preparation method and use of film

ActiveCN103263787AContinuous separationReduce manufacturing costLiquid separationPunchingMicrometer scale

The invention belongs to the technical field of function materials, and particularly relates to a film with an oil-water separation tapered needle array having an underwater oleophilic property on a surface as well as a preparation method and the use of the film. The preparation method of the film comprises the following steps of: taking a high-density polyethylene sheet as a substrate, carrying out arraying punching on the surface of the substrate by tapered stainless steel needles having ridge-shaped coarse structures on the surfaces obtained in a sanding way, shaping by polydimethylsiloxane, and building a tapered needle array which is made from the polydimethylsiloxane and has an oil-water separation action on the surface of a polydimethylsiloxane film. The surface of each tapered needle in the tapered needle array has the ridge-shaped coarse structure which has the submicron scale width and the nanoscale width and is along the axial direction of each tapered needle, and the distances among the adjacent tapered needles is micrometer scale, so that the film with the oil-water separation tapered needle array having the underwater oleophilic property on the surface, which can continuously carry out the oil-containing wastewater oil-water separation, is obtained.

Owner:INST OF CHEM CHINESE ACAD OF SCI

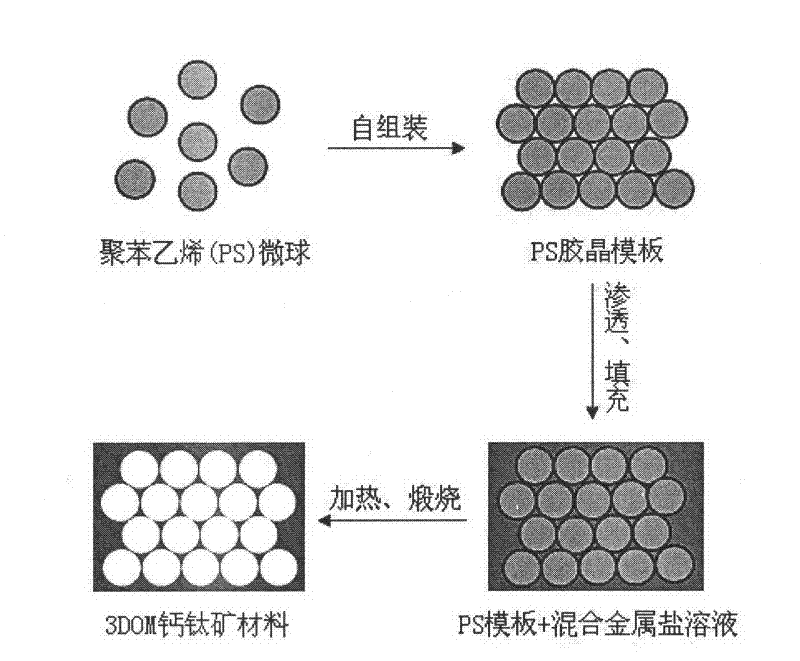

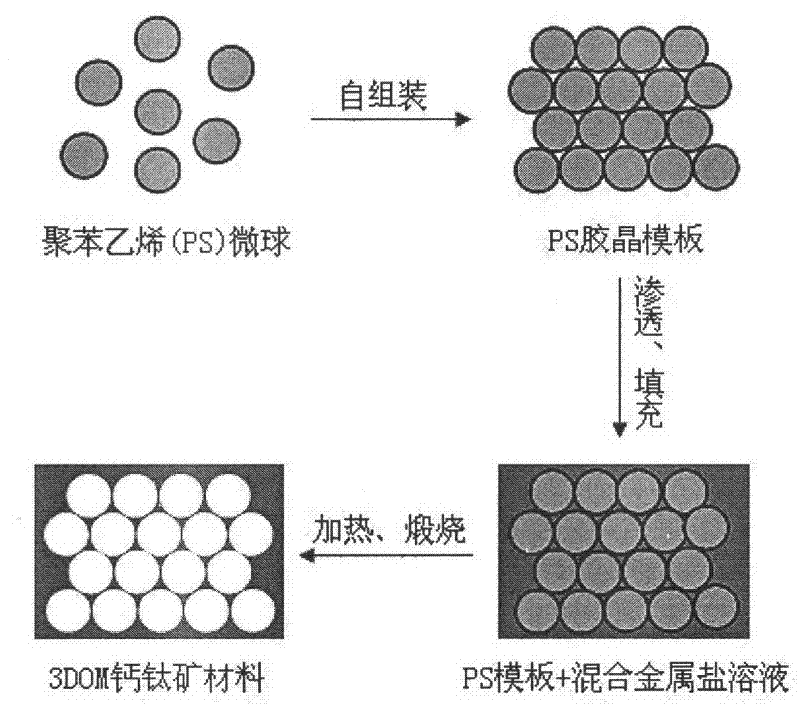

Three-dimensional ordered macroporous perovskite thermochromatic material and preparation method thereof

InactiveCN102241967AMaintain thermochromic propertiesLess materialTenebresent compositionsMaterial consumptionSubmicron scale

The invention discloses a three-dimensional ordered macroporous perovskite thermochromatic material and a preparation method thereof. The preparation method comprises the following steps of: depositing monodisperse polystyrene (PS) colloid microspheres on a clean and dry quartz glass sheet by adopting a vertical deposition method, and assembling into a three-dimensional ordered PS colloid crystal template; filling a precursor solution of La1-xAxMnO3 (A=Ca and / or Sr; and x is more than 0 and less than 3) in clearances of the PS colloid crystal template; and drying and calcining to remove the PS colloid crystal template to obtain the three-dimensional ordered macroporous perovskite thermochromatic material, wherein the surface and interior of the three-dimensional ordered macroporous perovskite thermochromatic material are provided with submicron-scale holes. The three-dimensional ordered macroporous perovskite thermochromatic material keeps the thermochromatic property of the conventional bulk material, and has a periodically arranged three-dimensional space net structure; and in the preparation method for the material, material consumption is low and components are uniformly mixed.

Owner:NANJING UNIV OF SCI & TECH

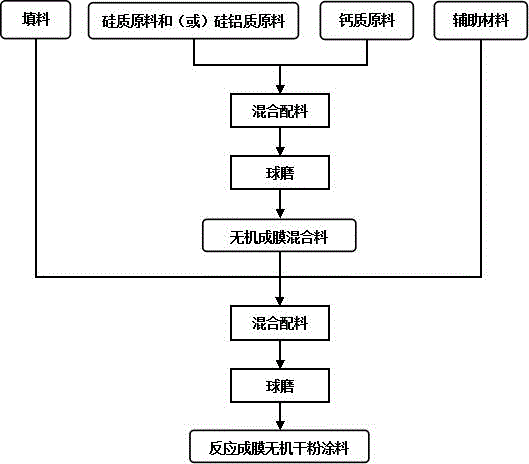

Reaction film formation inorganic dry powder coating material and production method thereof

ActiveCN104927419AShort setting timeImprove early bond strengthCoatingsInvestment materialDrying time

The invention provides a reaction film formation inorganic dry powder coating material and a production method thereof and belongs to the technical field of coating materials. The coating material is composed of, by mass, 20-50% of inorganic film formation material, 20-70% of filler and the balance auxiliary material. The inorganic film formation material is composed of a nano-scale or submicron-scale siliceous material and / or silica-aluminum material with high pozzolanic activity and a calcareous material, wherein the calcareous material has glueyness after being placed in water, the siliceous material and / or silica-aluminum material accounts for 20-50% of the total mass of the inorganic film formation material, and the balance is the calcareous material. Compared with existing coating materials, the coating material has the advantages that painting can be conducted on site after water is added to the coating material and stirred, construction is convenient, water resistance and alkali resistance are excellent, drying time is short, bonding strength is high, and scrub resistance is high.

Owner:WUHAN JIABIYUAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com