Three-dimensional ordered macroporous perovskite thermochromatic material and preparation method thereof

A technology of thermochromic materials and three-dimensional order, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems that affect the application of materials and do not consider the influence of surface radiation characteristics, so as to save raw materials, facilitate optical parameters, The effect of uniform hole distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

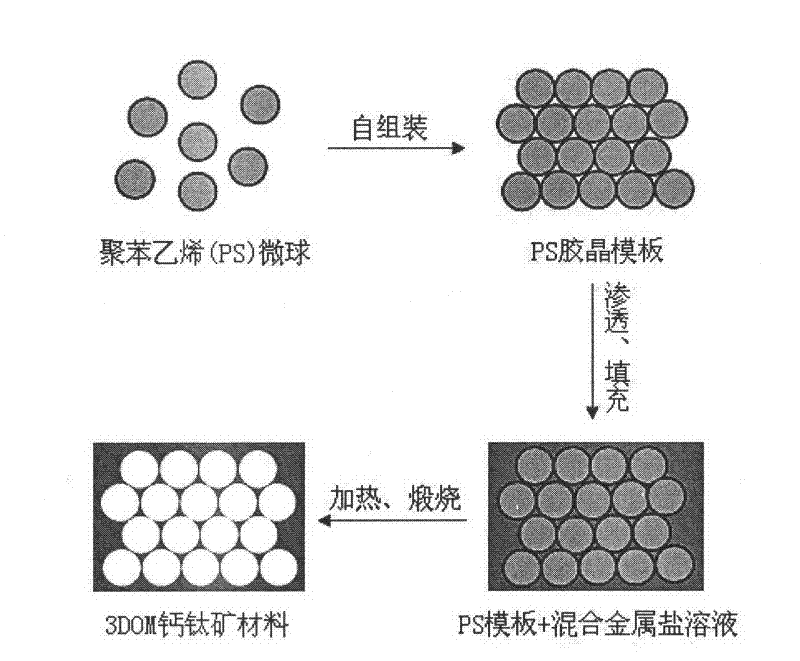

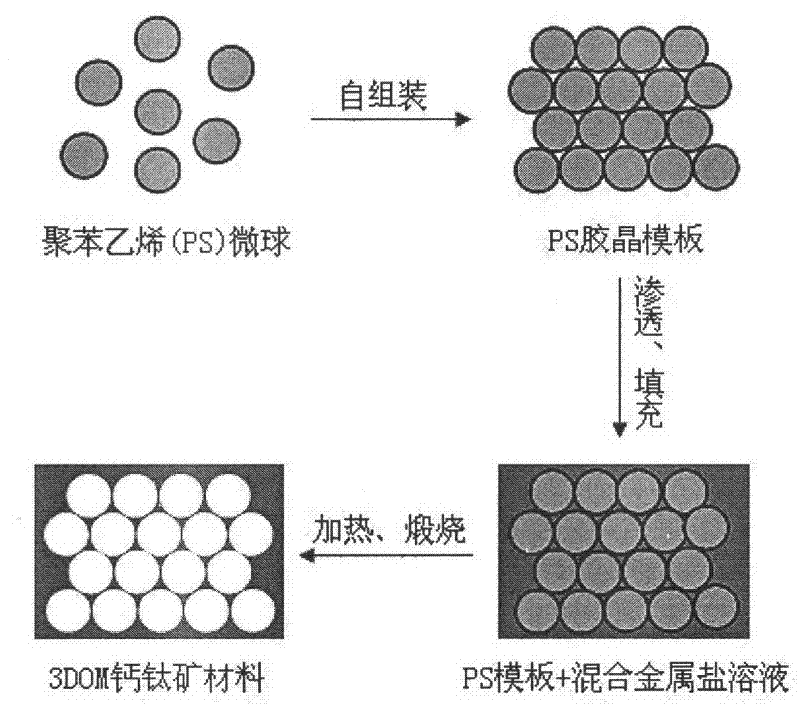

[0015] to combine figure 1 , the preparation method of the three-dimensional ordered macroporous perovskite thermochromic material of the present invention, the steps are as follows:

[0016] The first step, the preparation of polystyrene (PS) colloidal microspheres:

[0017] Styrene (C 8 h 8 ), sodium hydroxide (NaOH), potassium persulfate (K 2 S 2 o 8 ), sodium styrene sulfonate (C 8 h 7 SO 3 Na); potassium bicarbonate (KHCO 3 ), nitrogen (N 2 ), deionized water (H 2 O) as a raw material, using an emulsion polymerization method, by changing the experimental conditions, to prepare monodisperse polystyrene (PS) colloidal microspheres with a particle size of 200-500 nm.

[0018] The second step, the assembly of polystyrene (PS) colloidal crystal template

[0019] The monodisperse polystyrene PS colloidal microspheres are deposited on a clean and dry quartz glass sheet by vertical deposition method, and assembled into a three-dimensional ordered PS colloidal crystal ...

Embodiment 1

[0027] La 0.8 Sr 0.2 MnO 3 Preparation of materials:

[0028] 1. Using the emulsion polymerization method, polystyrene (PS) colloidal microspheres with good monodispersity and an average particle size of about 220nm were prepared by controlling the synthesis conditions;

[0029]2. Immerse the clean and dry quartz glass sheet vertically into the weighing bottle containing the PS colloidal microsphere solution, and use the vertical deposition method to deposit the monodisperse PS colloidal microspheres on the quartz glass sheet to assemble into a three-dimensional ordered PS Colloidal crystal template;

[0030] 3. Choose ethanol as solvent, press La(NO 3 ) 3 ·6H 2 O:Sr(NO 3 ) 2 :Mn(CH 3 COO) 2 4H 2 The ratio of O=0.8:0.2:1 was weighed to prepare a precursor solution by weighing metal nitrate and acetate. After soaking the PS colloidal crystal template in the precursor solution for 5 minutes, pull out the template at a constant speed of 2cm / min, and then immediately p...

Embodiment 2

[0033] La 0.7 Ca 0.2 Sr 0.1 MnO 3 Preparation of materials:

[0034] Adopt the method identical with embodiment 1, press La (NO 3 ) 3 ·6H 2 O:Ca(NO 3 ) 2 4H 2 O:Sr(NO 3 ) 2 :Mn(CH 3 COO) 2 4H 2 The ratio of O=0.7:0.2:0.1:1 was weighed to prepare a precursor solution by weighing metal nitrate and acetate. Preparation of three-dimensional ordered macroporous La 0.7 Ca 0.2 Sr 0.1 MnO 3 perovskite materials.

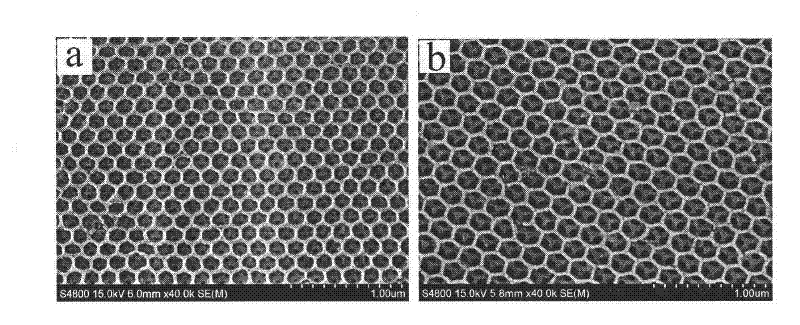

[0035] figure 2 (a) and (b) are the prepared three-dimensional ordered macroporous La 0.8 Sr 0.2 MnO 3 and La 0.7 Ca 0.2 Sr 0.1 MnO 3 Topography of the microstructure of perovskite materials. The structure of the three-dimensional ordered macroporous material is highly ordered, and the pores are evenly distributed, and the large pores are connected with each other by regularly arranged small pores, thus forming a three-dimensional ordered spatial network structure. X-ray diffraction analysis shows that the two materials with different components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com