Patents

Literature

141results about How to "Evenly distributed holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrorefining catalyst and preparation method thereof

ActiveCN106179380AHigh active site densityEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsNitrogenAluminium oxide

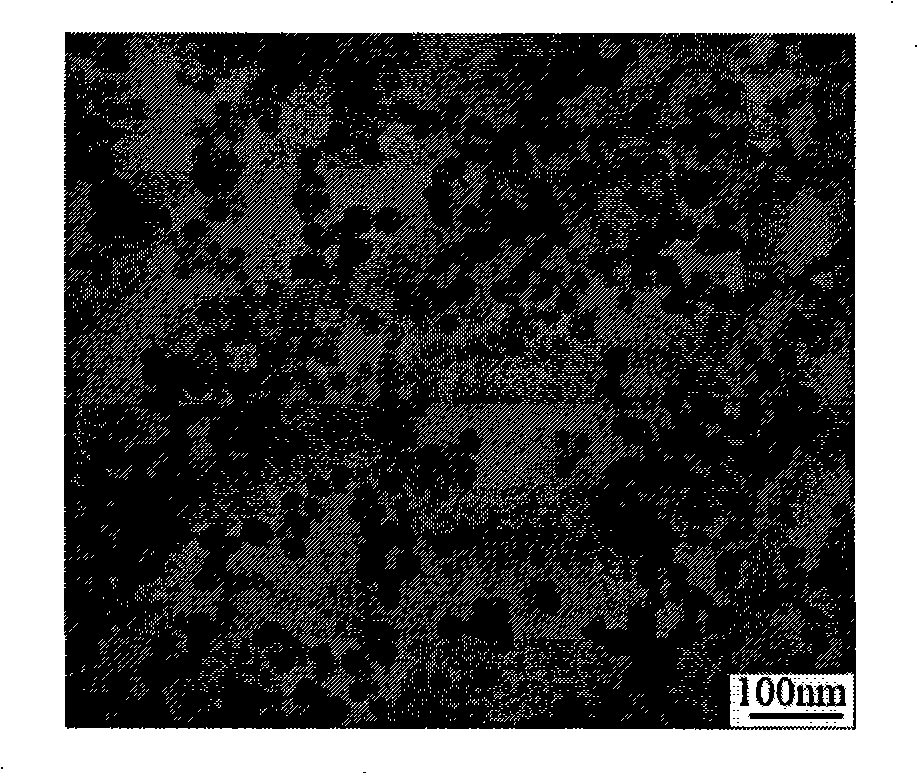

The invention discloses a hydrorefining catalyst and a preparation method thereof. The catalyst is a bulk phase hydrorefining catalyst, and comprises alumina and hydrogenation active metal components W, Ni and Mo. The surface phase of the catalyst has the characteristics of high content of active metals, large density of active sites, uniform dispersion of the active metals, good coordination and cooperation among the active metals, and high utilization rate of the active metals, and the catalyst has the characteristics of reasonable pore structure, high mechanical strength and high hydrodesulfurization and hydrodenitrogenation reaction performances, and is especially suitable for being applied to ultra deep hydrodesulfurization and nitrogen removal reaction of diesel oil fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

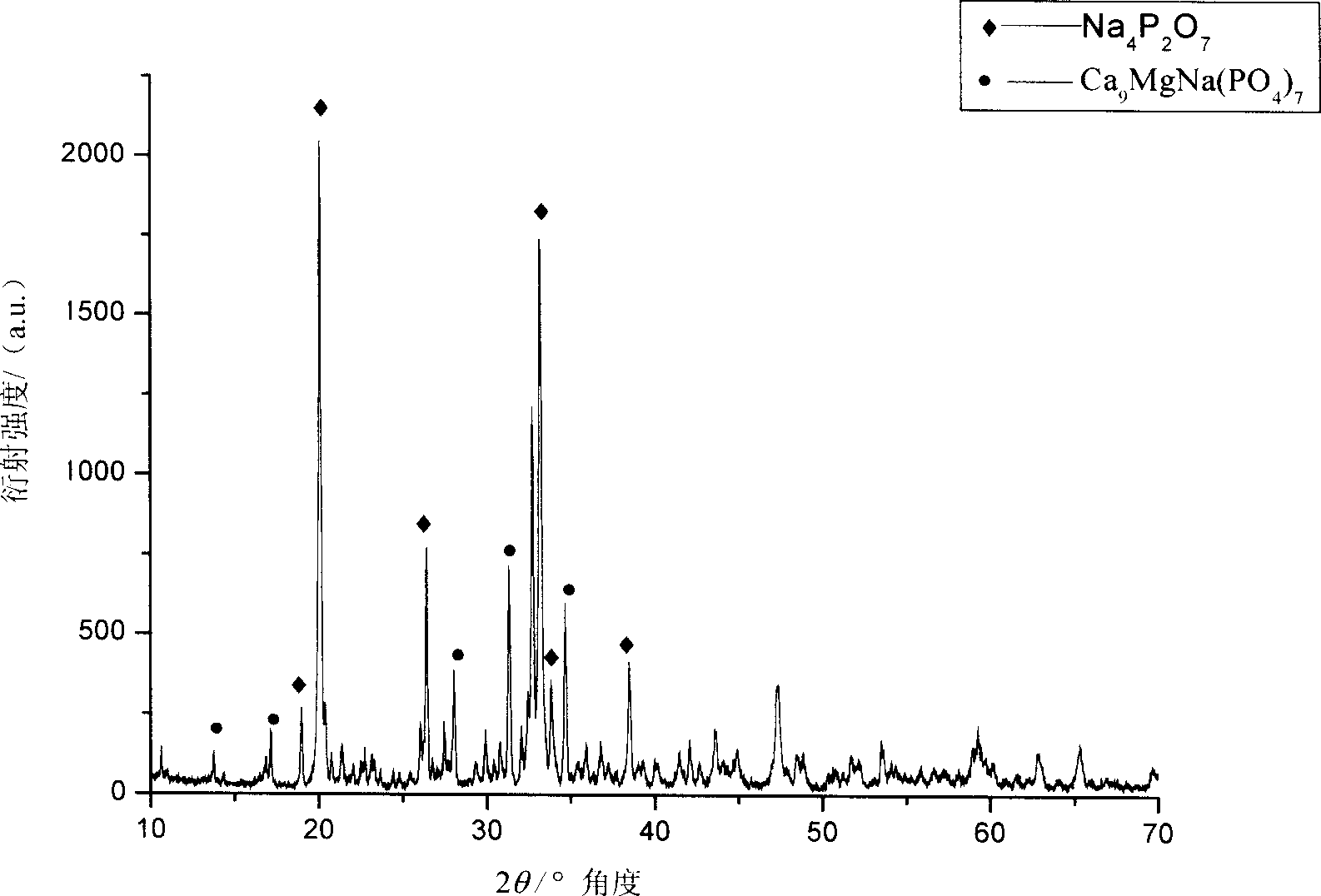

Method for preparing CaO-P2O5-MgO glass reinforced porous beta-tricalcium phosphate bioceramics

InactiveCN1830907AImprove adhesionSuitable for adhesionCeramicwareBioceramicBeta-tricalcium phosphate

A CaO-P2O5-Na2O-MgO glass reinforced porous beta-tricalcium phosphate bioceramic is prepared through proportionally mixing P2O5, CaO, Na2O and MgO, smelting, heat treating for educing crystals to obtain bioglass, proportionally adding it to beta-calcium triphosphate powder, and porous foam immersion.

Owner:TIANJIN UNIV

Preparation method of hydrotreatment catalyst

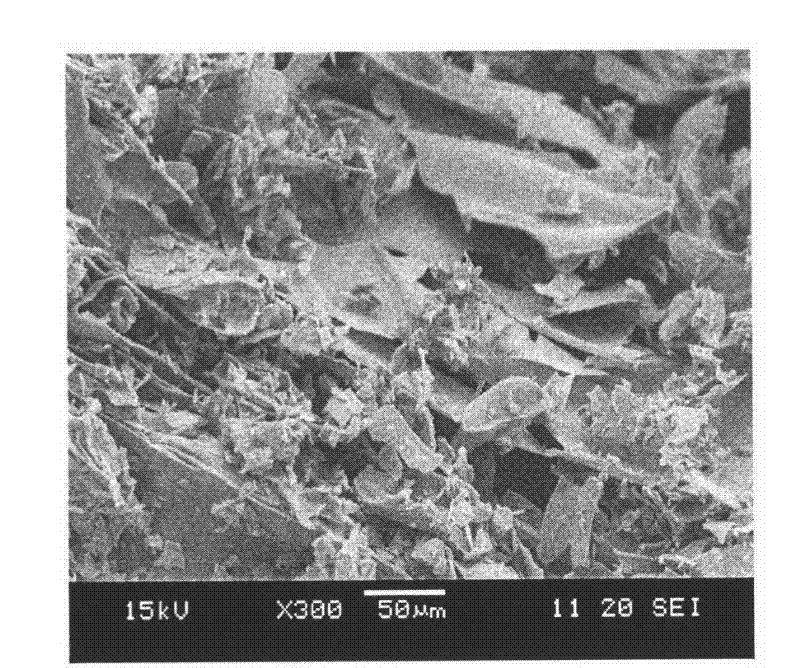

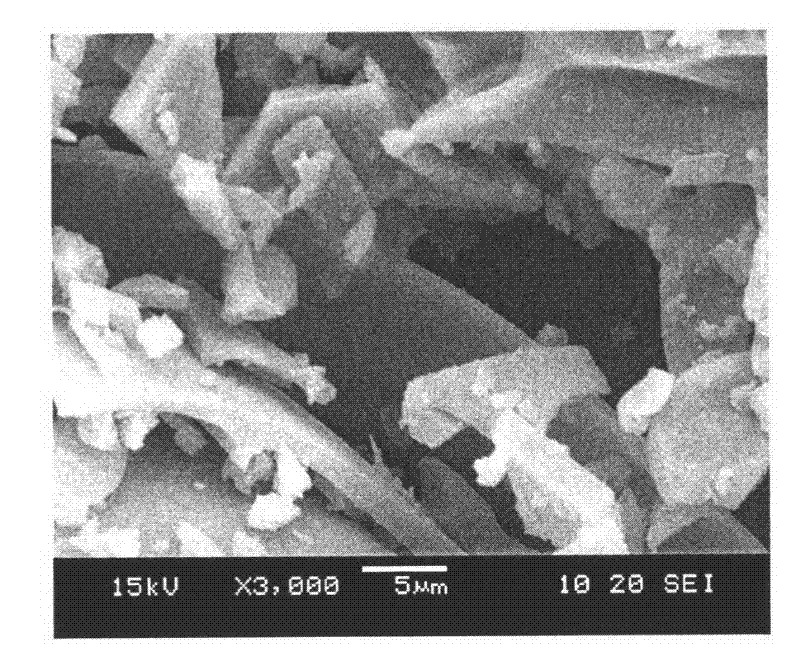

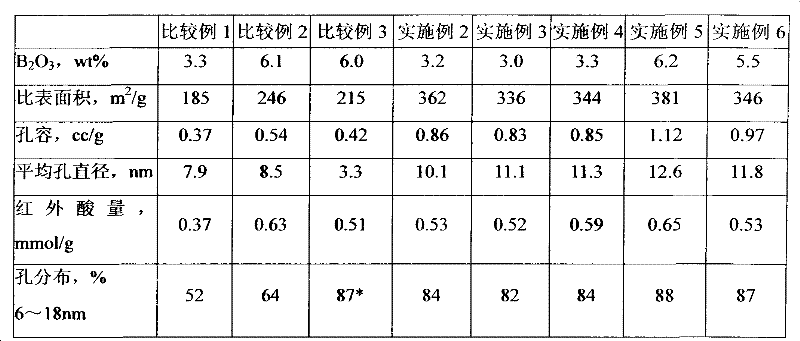

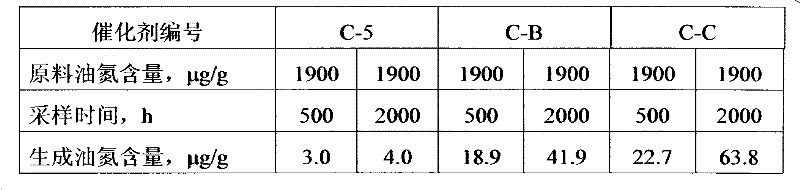

ActiveCN102728374ARegular hole structureEvenly distributed holesMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsLarge poreAluminium hydroxide gel

The invention discloses a preparation method of a hydrotreatment catalyst, comprising the following steps of: introducing silicon and boron additives in the way that an organic silicon source is added after aluminium hydroxide gel forming and then a boron-containing organic compound solution is added, so as to obtain silicon and boron containing aluminium hydroxide, mixing parts of an active metal component with boron-containing aluminium hydroxide by a kneading method, carrying out three-stage roasting to obtain a catalyst intermediate, loading residual part of the active metal onto the catalyst intermediate by dipping, and drying to obtain the hydrotreatment catalyst. By the adoption of the method provided by the invention, the silicon and boron additives and the active metal component are uniformly distributed on the surface of the catalyst. In addition, the active metal component has different existing forms in the catalyst when introduced in the two modes, loss rate of the catalyst activity is reduced by mutual cooperation, and running period of a device is prolonged. The catalyst has large pore volume, large specific surface area, appropriate pore structure and acidity, and is especially suitable for hydrodenitrogenation process of heavy hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

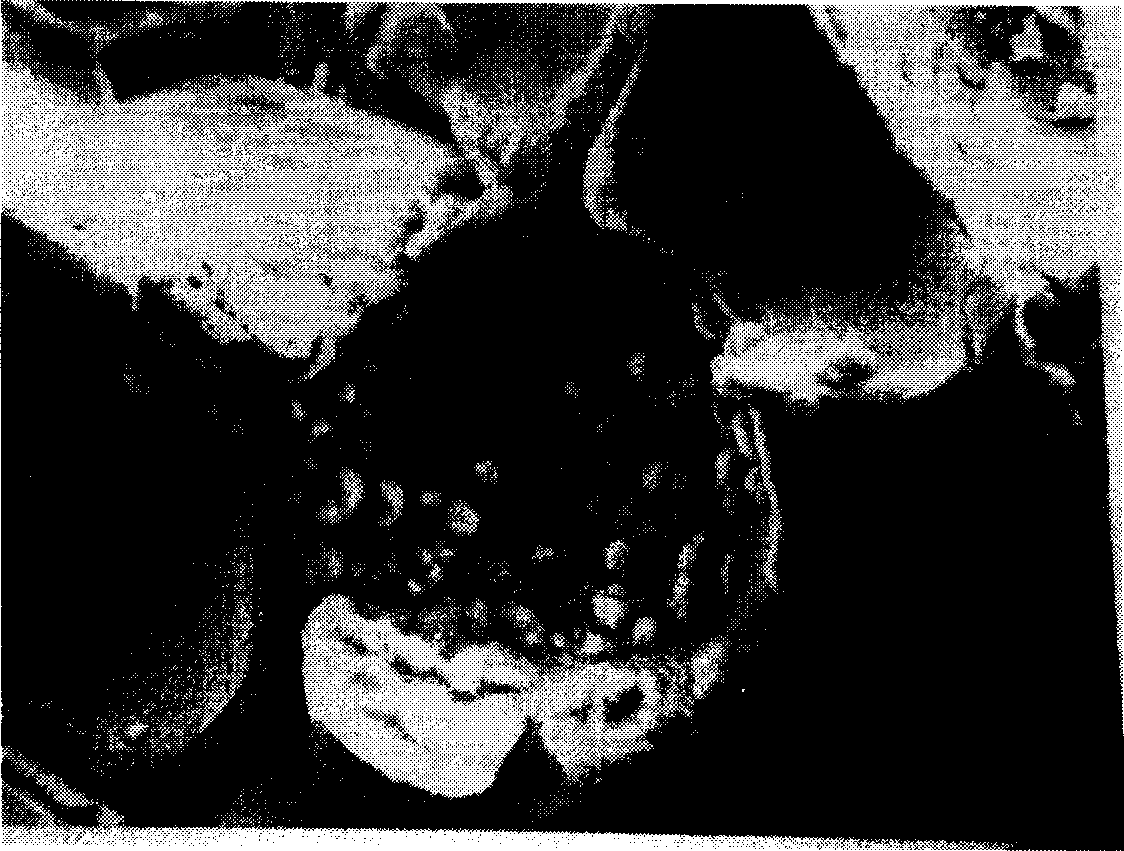

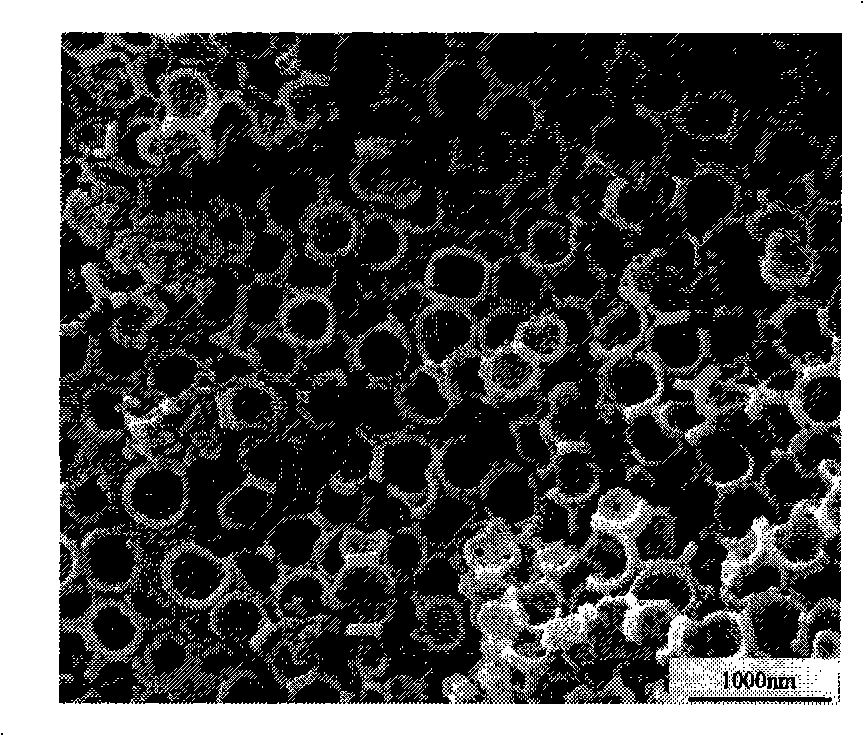

Ordered porous magnetic hydroxylapatite material, preparation method thereof and applications

InactiveCN101337665AMild reaction conditionsEasy to operatePhosphorus compoundsProsthesisApatiteHydroxylapatite

The invention relates to an orderly multi-aperture magnetic hydroxylapatite, the amplitude of the magnetic property of which can be controlled, and the saturation strength of which is between 0.1emu / g and 10emu / g. An orderly multi-aperture hydroxylapatite takes orderly arranged SiO2 as a die plate and is prepared by the steps of adding in drops the precursor of a hydroxylapatite, sintering, removing alkali liquor, etc. The prepared orderly multi-aperture hydroxylapatite is characterized in that apertures are distributed uniformly and the apertures are connected through micro-pores. Magnetic nano-particles are synthesized through the liquid phase method, the surfaces of the magnetic nano-particles are wrapped by SiO2 of different thicknesses, and the magnetic nano-particles have the core-shell structure characteristic. The orderly multi-aperture magnetic hydroxylapatite is formed by the static self-assembly and the wicking action of the magnetic nano-particles and the orderly multi-aperture hydroxylapatite, and the amplitude of the magnetic property can be adjusted by changing the proportion of the aperture size of the orderly multi-aperture hydroxylapatite and the grain size of the magnetic nano-particles. The orderly multi-aperture magnetic hydroxylapatite has the advantages of easily obtained materials, low cost, good magnetic property and biocompatibility of obtained materials, and application to the treatment of orthopedic disorders.

Owner:TONGJI UNIV

Hydrorefining catalyst preparation method

ActiveCN106179386AEvenly dispersedIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHeat treatedMineralogy

The present invention discloses a hydrorefining catalyst preparation method. According to the method, a nickel aluminum precipitate is prepared through a positive adding method, a tungsten, molybdenum and aluminum precipitate is prepared through a parallel flow method, an organic amine is added during any one or two above gelatinization processes, the two precipitates are mixed, aging is performed, a hydrothermal treatment is performed while urea is added, and molding and the like are performed to prepare the catalyst. According to the present invention, the prepared catalyst is particularly suitable for super deep hydrodesulfurization and denitrification reaction of diesel oil distillates, and has high hydrodesulfurization and hydrodenitrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation process of high-performance coating diaphragm having surface coated with organic layer

PendingCN110148699AImprove fitInhibit sheddingCell seperators/membranes/diaphragms/spacersSecondary cells servicing/maintenancePolymer scienceOrganic solvent

The invention discloses a preparation process of a high-performance coating diaphragm having a surface coated with an organic layer, and relates to the technical field of production of lithium ion battery microporous membranes. The process comprises the steps of: dissolving organic viscous high-temperature resin and an additive in an organic solvent to form a polymer solution; then coating the surface of a diaphragm substrate with a polymer solution in a dip-coating or gravure-coating mode; and finally, performing drying in an oven at a temperature of 50-120 DEG C. According to the high-performance coating diaphragm prepared by employing the method, the surface of the substrate is coated with a layer of viscous high-temperature resin so that the problem of bonding of a microporous membraneand a pole piece is solved, and meanwhile, the falling of stepless particles can be well avoided, and therefore, the safety of a lithium battery is solved, and the performance of the lithium batteryis fully played.

Owner:扬州中锂新能源有限公司

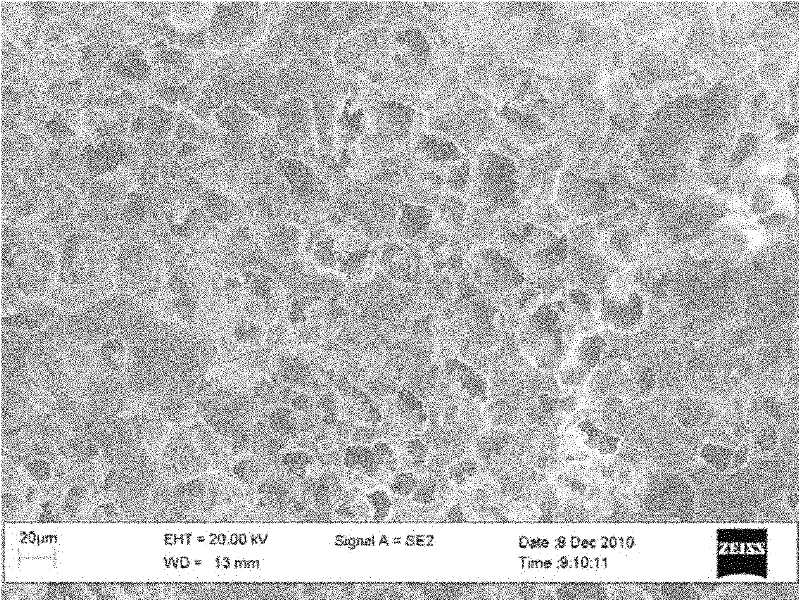

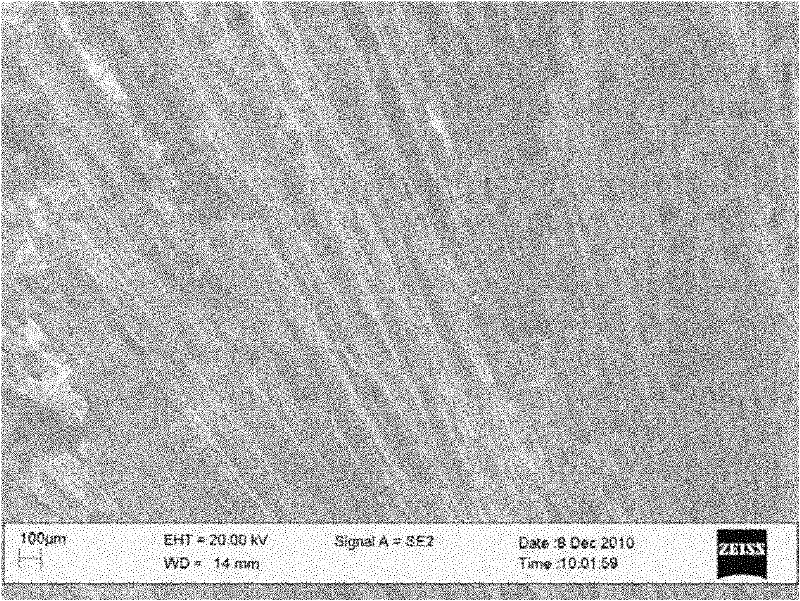

Method for preparing porous ceramic by using tertiary butanol-based freezing sublimation method

InactiveCN102531660ASimple selection of raw materialsSimple processCeramicwareOxide ceramicPolyvinyl butyral

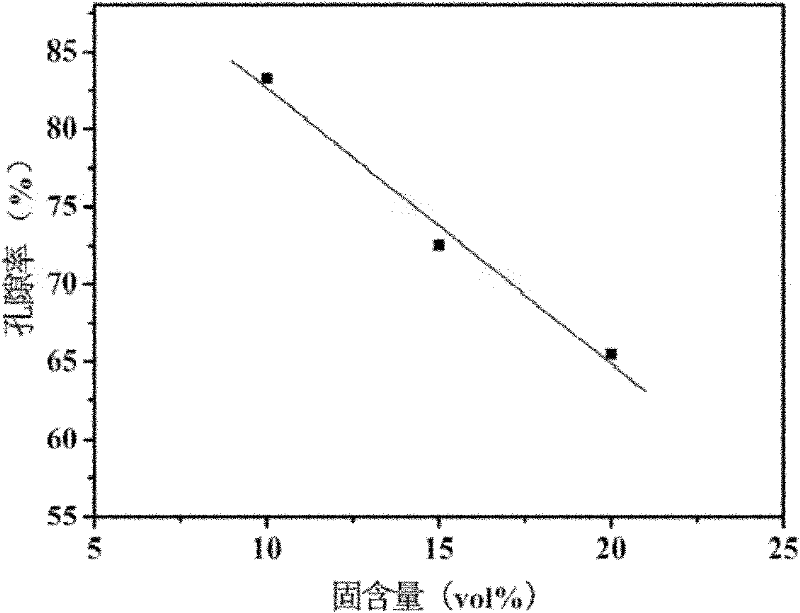

The invention relates to the field of porous ceramics, in particular to a method for preparing a porous ceramic by using a tertiary butanol-based freezing sublimation method. The method disclosed by the invention basically has no restriction to an oxide material system and is generally suitable for engineering ceramics. The method comprises the following steps of: with oxide ceramic powder as a raw material, tertiary butanol as a solvent, citric acid as a dispersing agent and polyvinyl butyral as a binding agent, carrying out ball grinding on the raw material for 5-50h, pouring the uniformly-dispersed raw material into a polyethylene mold of which the bottom temperature is above 0 DEG C and the top temperature is room temperature, and cooling for 5min-2h; and demolding, then sublimating for 24-27h by using a water circulating pump under the condition of suction filtering, and heating to 1200-1600 DEG C in an air furnace and preserving the temperature for 5min-2h. According to the method disclosed by the invention, slurry of an organic system is prepared under the room temperature; and the obtained porous ceramic is distributed with directional holes, wherein the directional holes are polygonal holes and have the size distribution of below 100 microns and the longitudinal lengths of reaching millimeter-scale. According to the method disclosed by the invention, the porosity can be controlled by adjusting the solid content, and the porous ceramic material with ultrahigh porosity (more than 80 percent) can be prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

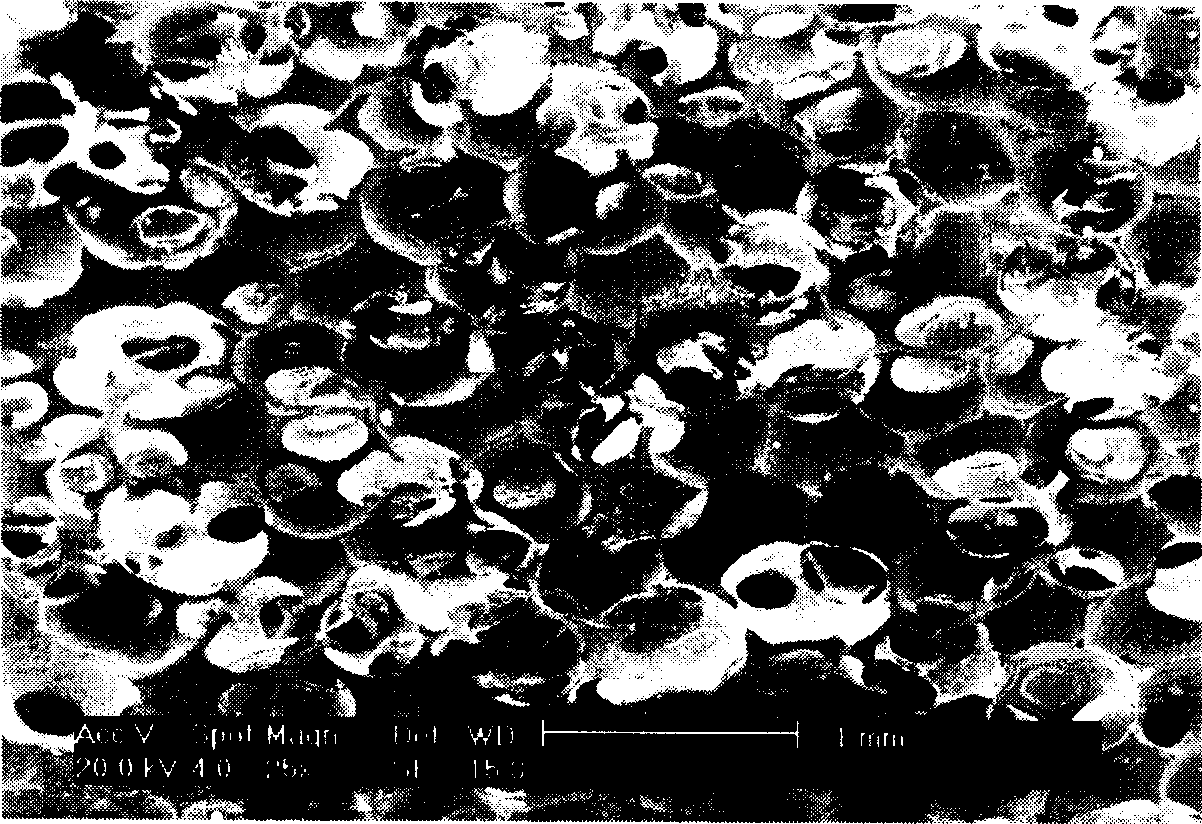

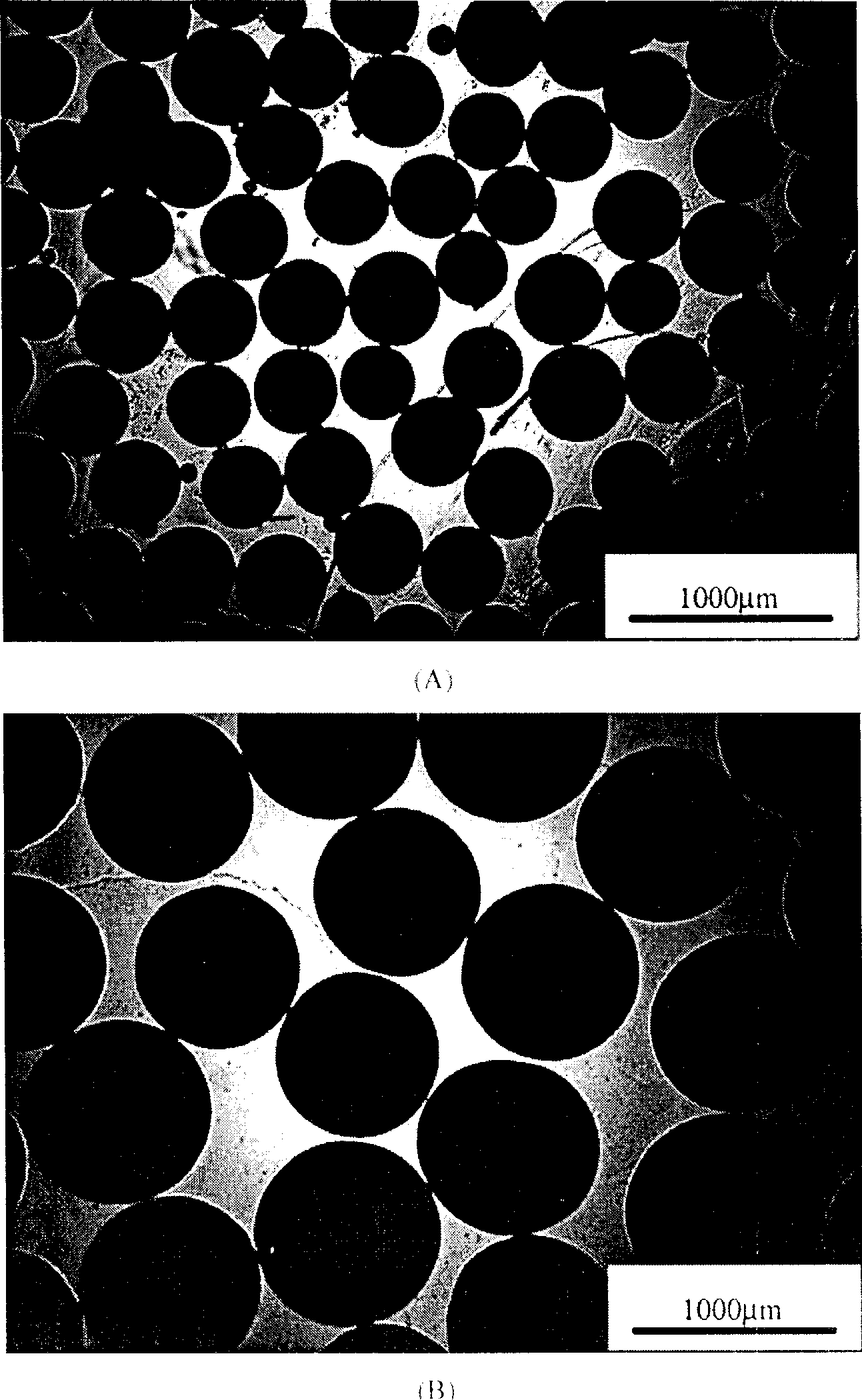

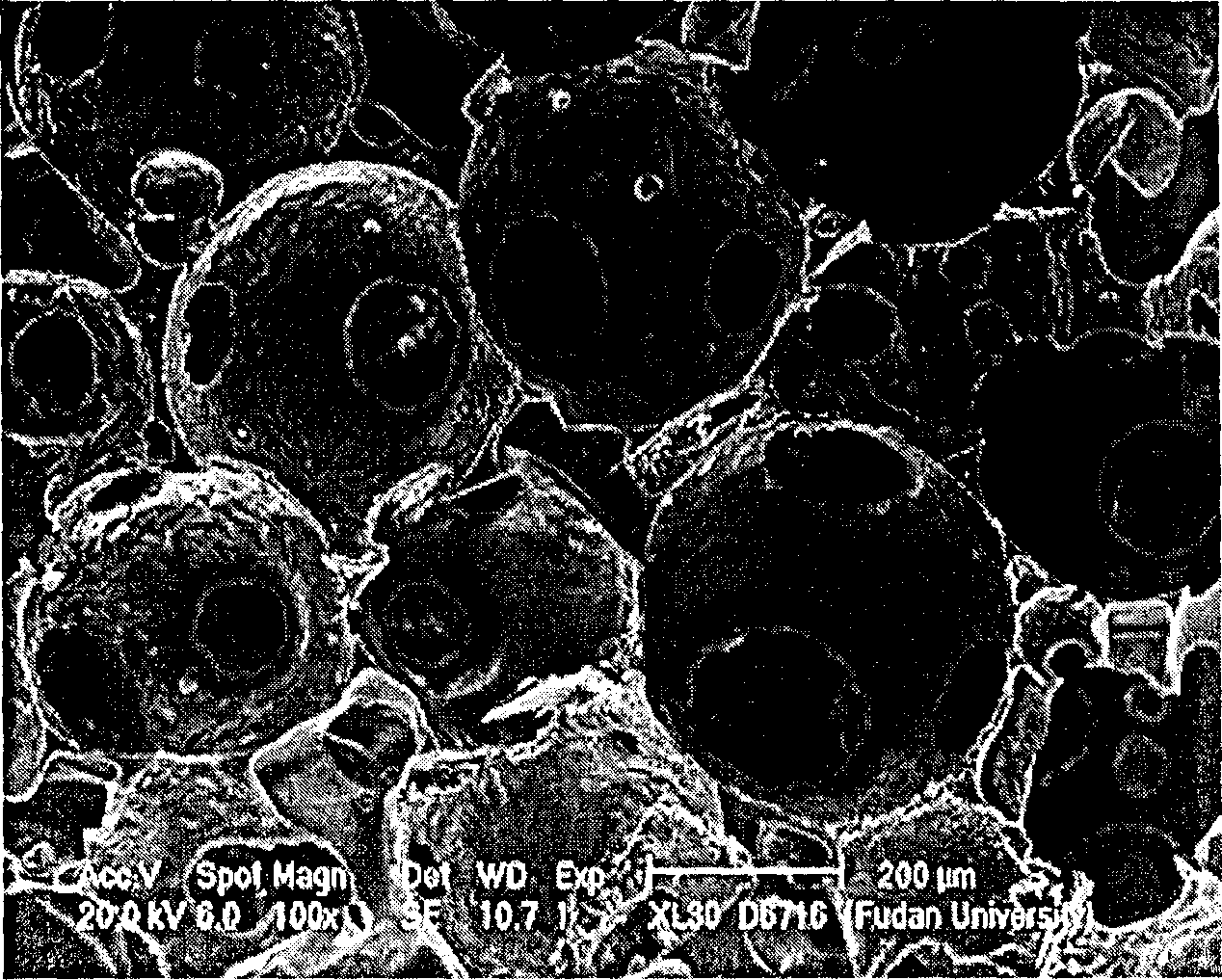

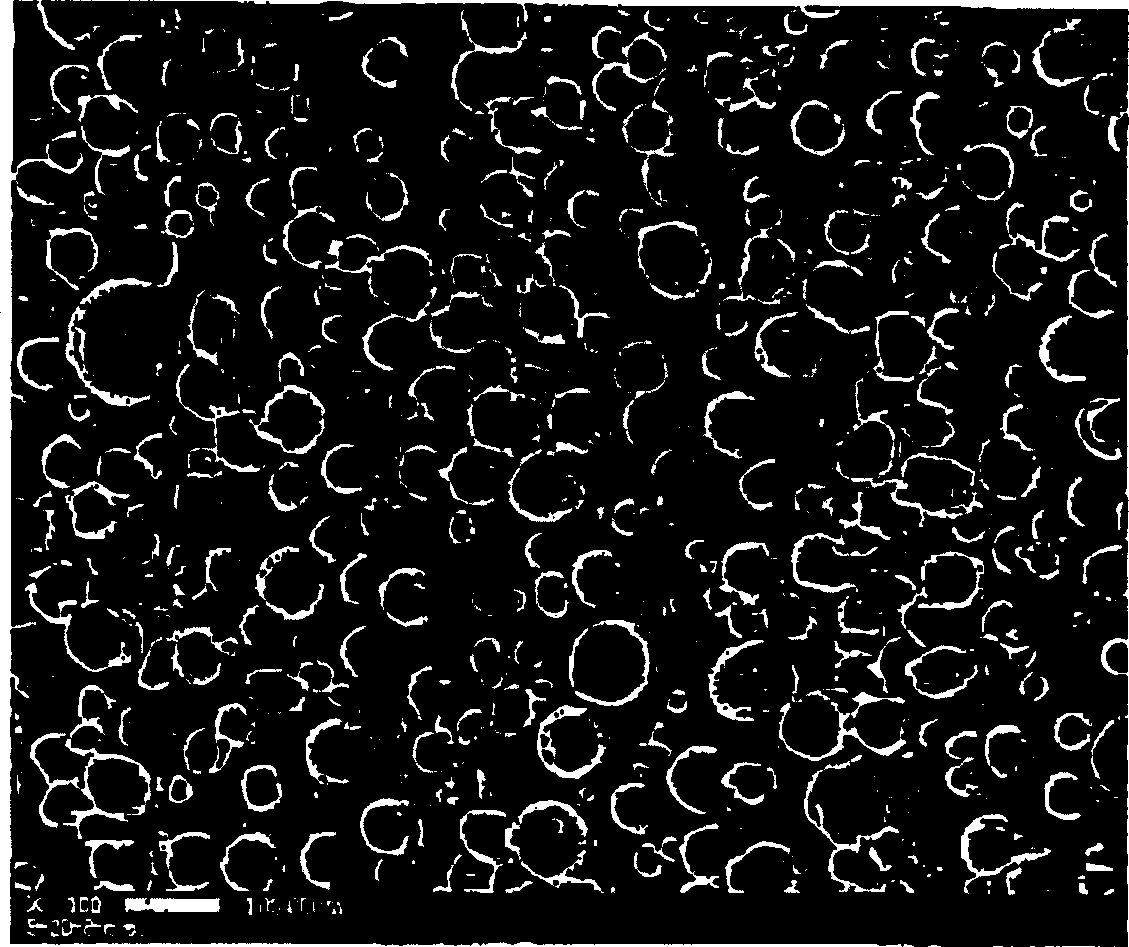

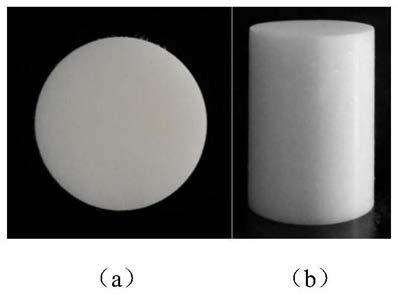

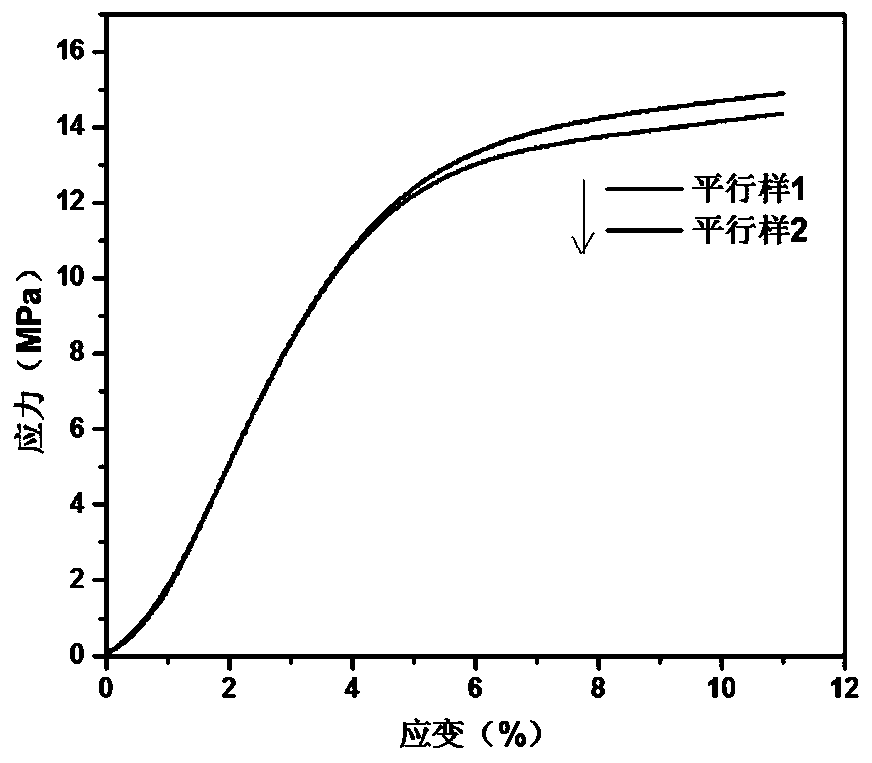

Porous rack with spherical pores and its molding prepn process

InactiveCN1486754ALiquidGood shape retentionPharmaceutical containersMedical packagingSpherical poreBiological materials

The present invention belongs to the field of polymer material and biological material technology, and is especially one porous rack with spherical pores and its molding preparation process. The 3D porous rack is prepared with polymer material as base material and through molding at normal temperature. The simple process may be used in preparing both rack with simple and regular outer appearance and rack with complicated and irregular outer appearance. The prepared porous rack may be relatively thick and has regular spherical pore structure of porosity over 90%, and the pores are communicated mutually and homogeneously distributed. The rack has high mechanical strength, and is suitable as 3D porous cell rack in tissue engineering and in other application fields.

Owner:FUDAN UNIV

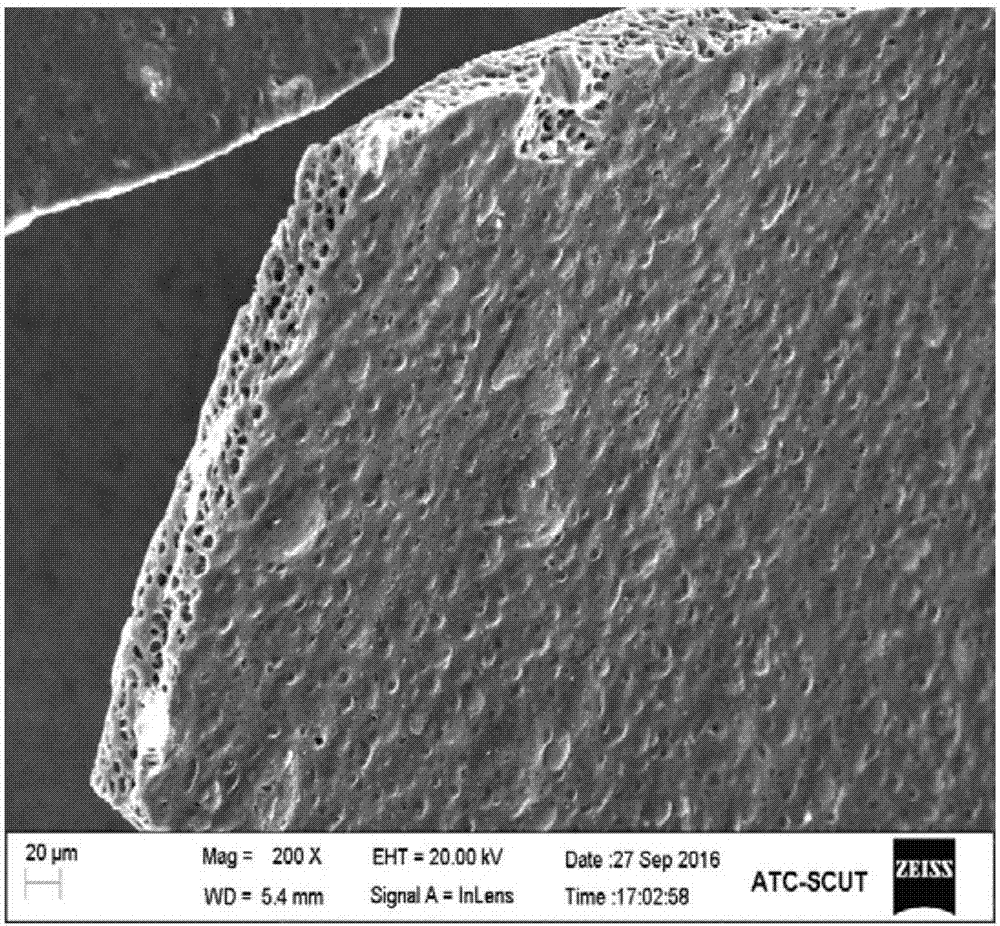

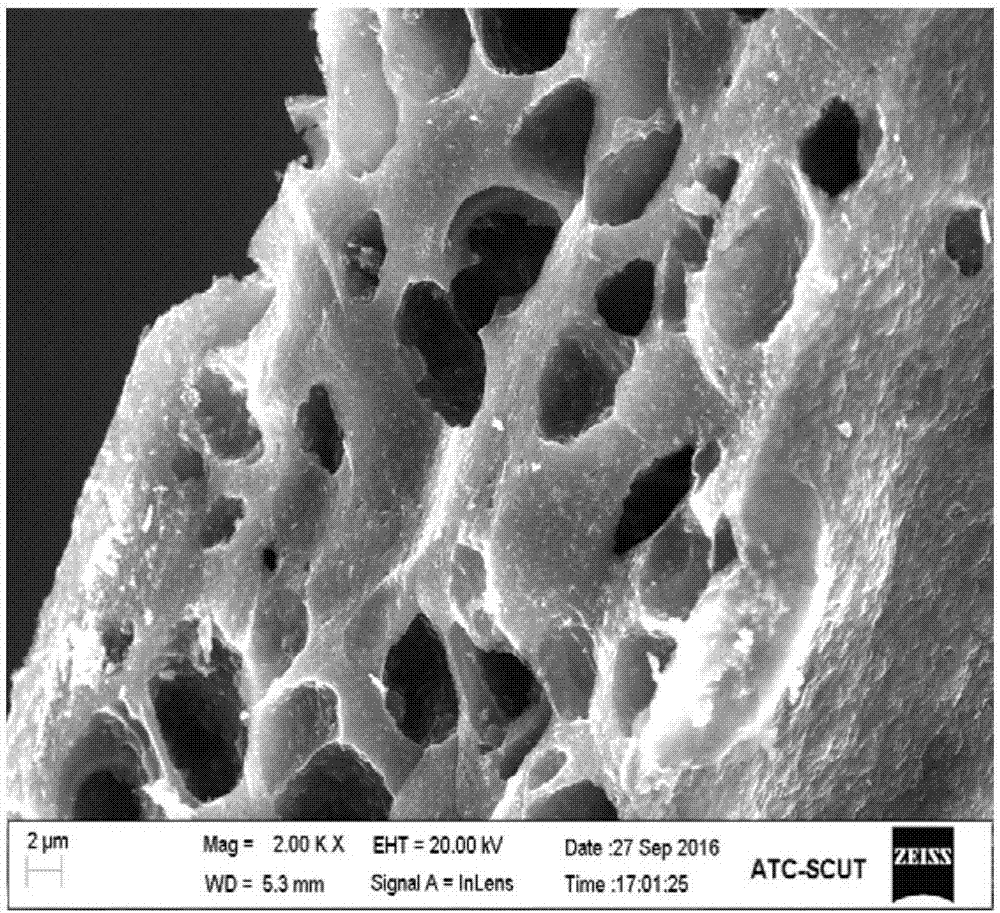

Preparation method of porous polyvinylidene fluoride alloy membrane for treating and recycling waste water

InactiveCN101507902AHigh strengthHigh degree of automationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberPore distribution

The invention relates to a method for preparing a porous polyvinylidene fluoride alloy membrane for wastewater treatment and recycling, and belongs to the technical field of membrane separation technology and wastewater treatment and reutilization. The method comprises the following steps: firstly, weighing polyvinylidene fluoride, polymethyl methacrylate, a diluent or a latent solvent, and an additive according to proportion, placing the raw materials into a mixer in turn for mixing, cooling and granulating the mixture in the air, and obtaining blend raw materials; and secondly, adding the blend raw materials into a double screw extruder to form fused blends, making the fused blends be extruded by double screws and pass through a filter and a spinning pump in turn to form hollow nascent fibers, cooling and washing the hollow nascent fibers, and drying the hollow nascent fibers in the air. The porous polyvinylidene fluoride alloy hollow fiber microporous membrane prepared by the method has good chemical corrosion resistance and hydrophilicity, high strength, large flux, good toughness, uniform pore distribution and superior pollution resistance, and is most suitable to be used in MBR.

Owner:苏州膜华材料科技有限公司

Prepn process of hydroprocessing catalyst

ActiveCN101088610AHigh pore volumeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsPlastic materialsActive component

The present invention relates to preparation process of hydrocarbon hydroprocessing catalyst, which has gamma-Al2O3 as carrier, VIB and VIII metal as the active component, and Ti, etc as the active assistant, with the assistant Ti being introduced in the pH swinging carbonization process for producing aluminum hydroxide. The process of preparing the catalyst is one complete mixing and kneading process including the steps of introducing Ti to aluminum hydroxide powder via adding Ti salt solution, adding Mo and / or W containing alkaline solution, mixing and kneading until the aluminum hydroxide powder is wetted completely by the alkaline solution, adding Co and / or Ni containing acid solution, mixing and kneading to obtain plastic material, extruding, drying, and roasting to obtain the catalyst. The catalyst has homogeneously distributed Ti component and obviously raised performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

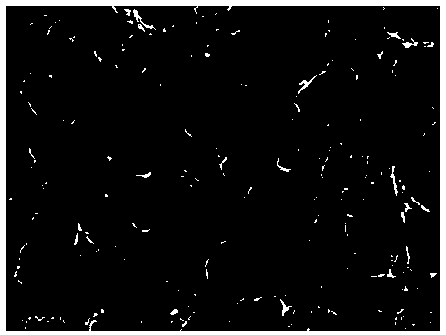

A porous carbon fiber paper for fuel cell with proton exchange membrane and preparation method thereof

InactiveCN1884689AEvenly distributed holesImprove air permeabilitySpecial paperChemical/biochemical paper treatmentHot pressingFiber

The invention discloses an electrode material and preparing material, which consists of chopped carbon fiber and heat cohesion fiber at 20-70:80-30 weight rate. The invention reduces manufacturing cost, which makes porous carbon fiber with even distributing porthole, high permeating degree, good strength and low resistance rate.

Owner:浙江省普瑞科技有限公司

Method for preparing mesoporous activated carbon fibers

InactiveCN104264285APromote gasificationPromote formationFibre treatmentFibre chemical featuresFiberActivated carbon

The invention relates to a method for preparing mesoporous activated carbon fibers, belonging to the technical field of preparation methods of activated carbon fibers, and mainly solving the technical problems of difficulty in continuous spinning, non-uniform pore distribution of the product, complex production process, high requirement on equipment performance, high production cost and large industrial difficulty existing in a conventional method for preparing mesoporous activated carbon fibers. With the adoption of the technical scheme, the method for preparing mesoporous activated carbon fibers comprises the following steps: preparing an impregnant, impregnating, performing extrusion-suction, curing, carbonizing and activating and pickling. The method disclosed by the invention has the advantages of capability of performing continuous spinning, uniform pore distribution of the product, simple production process, low requirement on equipment performance, low production cost and simplicity in industrialization.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

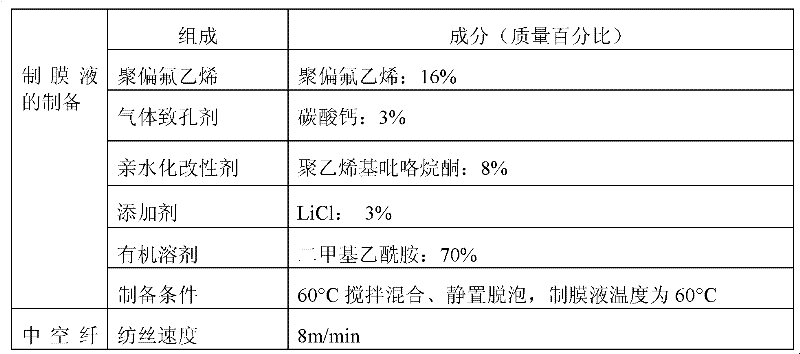

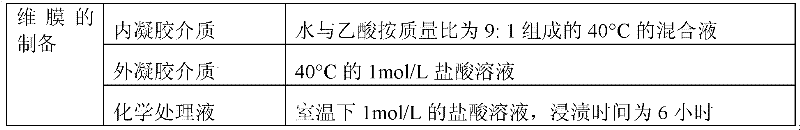

Method for preparing high-flux polyvinylidene fluoride hollow fiber membrane

ActiveCN102512987AImprove throughputFlux does not destroySemi-permeable membranesChemical treatmentChemical reaction

The invention discloses a method for preparing a high-flux polyvinylidene fluoride hollow fiber membrane. The method comprises the following steps of: mixing polyvinylidene fluoride, a gaseous pore-forming agent, a hydrophilic modifier, additives and organic solvents and making a membrane-making solution; allowing an internal gelling medium and the membrane-making solution to pass through spinning nozzles on dry / wet spinning equipment at the same time, injecting into an external gelling medium, and performing phase-splitting treatment to make a primary membrane; and performing special chemical treatment on the primary membrane with a chemical treatment liquid to obtain a high-flux polyvinylidene fluoride hollow fiber membrane. The invention is characterized in that the membrane is reinforced with the pores by chemical reactions between the internal gelling medium, external gelling medium and chemical treatment liquid and the gaseous pore-forming agent; and the polyvinylidene fluoride hollow fiber membrane has a high flux, a high strength, a high entrapment rate and good hydrophilicity.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

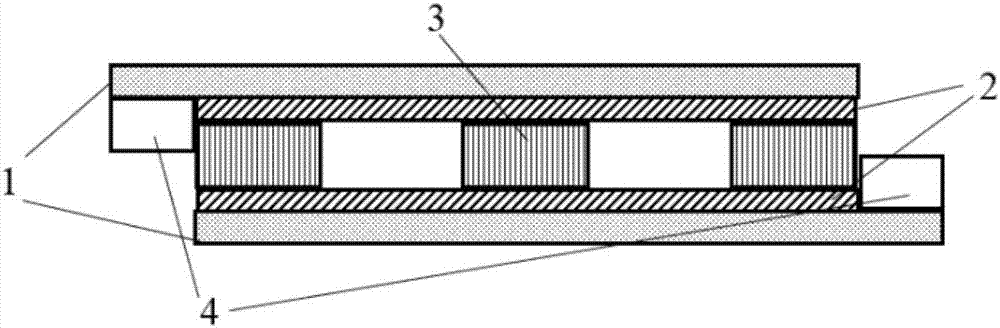

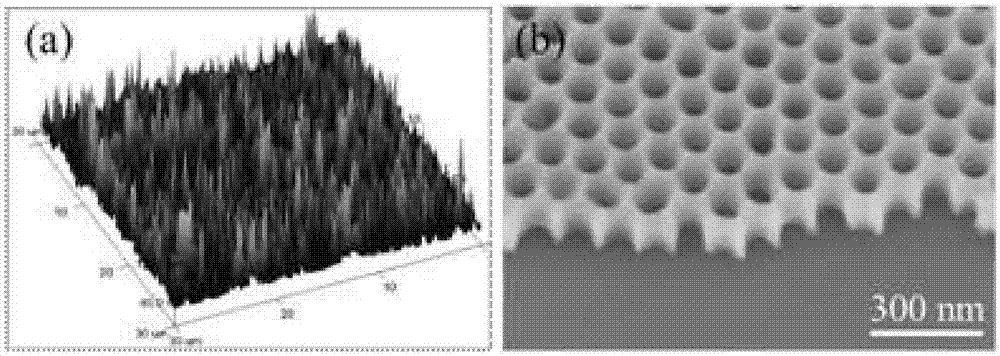

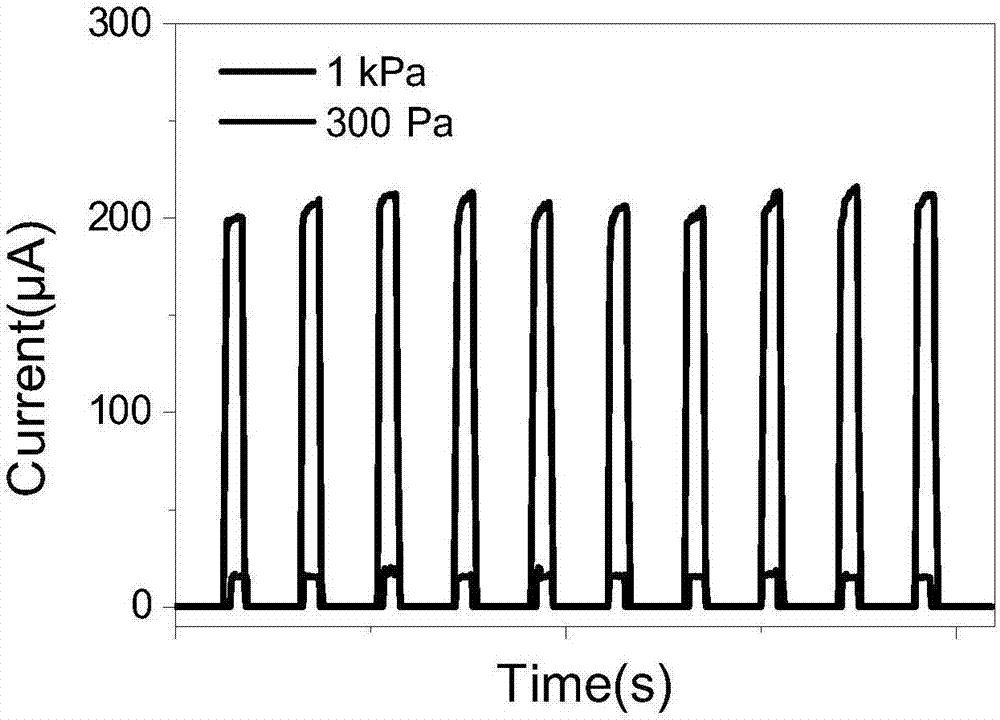

High-sensitivity pressure sensor based on graphene with pointed cone structure and manufacturing method thereof

ActiveCN107101752AUniform heightHighly easy to controlFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesSandwich likeStructure of the Earth

The invention discloses a high-sensitivity pressure sensor based on graphene with a pointed cone structure. The pressure sensor is a composite structure of graphene whose surface is provided with a pointed cone structure and other insulating and porous two-dimensional materials. First, the insulating and porous two-dimensional materials cover the graphene with a pointed cone structure followed by the plating of electrodes; then, the other graphene with a pointed cone structure after the plating of electrodes is placed onto the insulating and porous two-dimensional materials so as to obtain a sandwich-like pressure sensor. The height, the width and the distribution density of the pointed cone of the graphene are uniform and controllable. The pores of the insulating and porous two-dimensional materials are also distributed in a uniform manner with the pore diameters and depths being controllable. According to the invention, a high-sensitivity pressure sensor with pointed cone graphene comes into being, and a method for conveniently and rapidly manufacturing the sensor in large scale is provided. The method can also be used for new flexible electronic devices such as artificial intelligence, etc.

Owner:广州烽鼎医疗科技有限公司

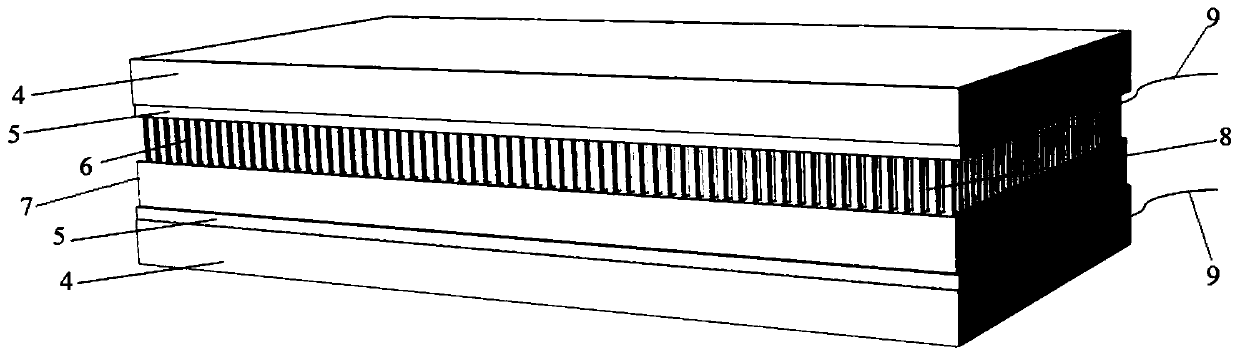

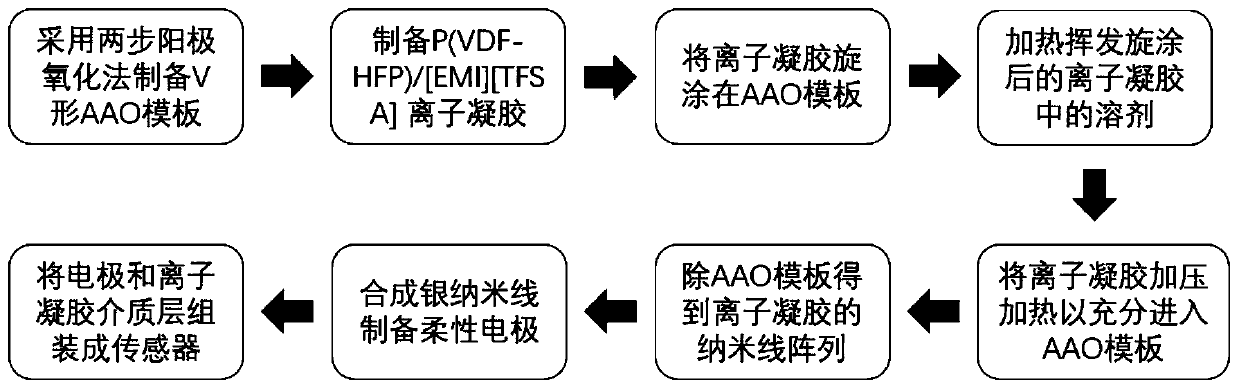

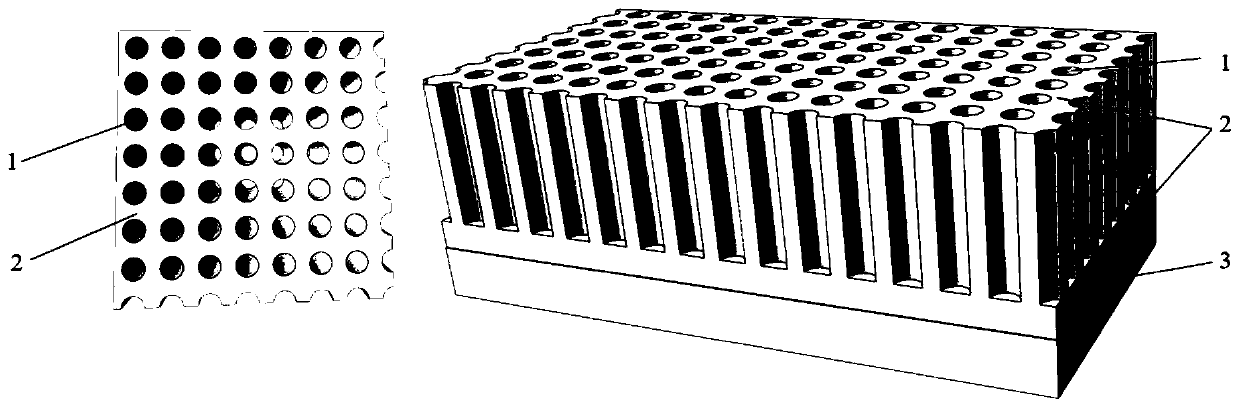

Capacitive pressure sensor and preparation method thereof

ActiveCN109781312AHigh sensitivityHigh dielectric constantForce measurementHysteresisCapacitive pressure sensor

The invention belongs to the technical field of capacitive pressure sensors, and particularly relates to a capacitive pressure sensor and a preparation method thereof. The sensor comprises electrodes,an ionic gel dielectric layer and wires, wherein the electrode is composed of a substrate of which the surface is provided with a silver nanowire layer; a wire extending to the outside of the silvernanowire layer is embedded in the silver nanowire layer; the ionic gel dielectric layer is arranged on the surfaces of the silver nanowire layers on the top electrode and the bottom electrode; the structure of the ionic gel dielectric layer is as follows: columnar ionic gel is distributed on the surface of a substrate layer; wherein the substrate layer in the ionic gel dielectric layer is arrangedon the silver nanowire layer of one electrode, and the silver nanowire layer of the other electrode is arranged on the columnar ionic gel in the ionic gel dielectric layer. The prepared sensor is high in sensitivity, small in hysteresis and good in repeatability, and can be widely applied to electronic skin, wearable products, implantation equipment and multifunctional sensor systems.

Owner:三三智能科技(日照)有限公司

Method for preparing fluorapatite crystal whisker in-situ reinforced porous tricalcium phosphate biological ceramics

The invention relates to a method for preparing fluorapatite crystal whisker in-situ reinforced porous beta-tricalcium phosphate biological ceramics, and belongs to the technical field of the preparation of biological ceramics. The method is characterized by comprising the following steps of: weighing beta-tricalcium phosphate, bioglass and ammonium fluoride (or fluorine salts such as sodium fluoride and the like) serving as raw materials in a mass ratio of (65-85):(10-30):(0.25-1.5), and performing solid-phase reaction at a high temperature to prepare high-strength fluorapatite crystal whisker in-situ reinforced tricalcium phosphate porous biological ceramics. The method has the advantages that toughness is enhanced by introducing fluorapatite crystal whiskers and the strength of a substrate is enhanced, and the biological ceramics are mainly used for the field of the repair of bone tissue engineering at bearing positions or other positions.

Owner:CHINA NAT ACAD NANOTECH & ENG

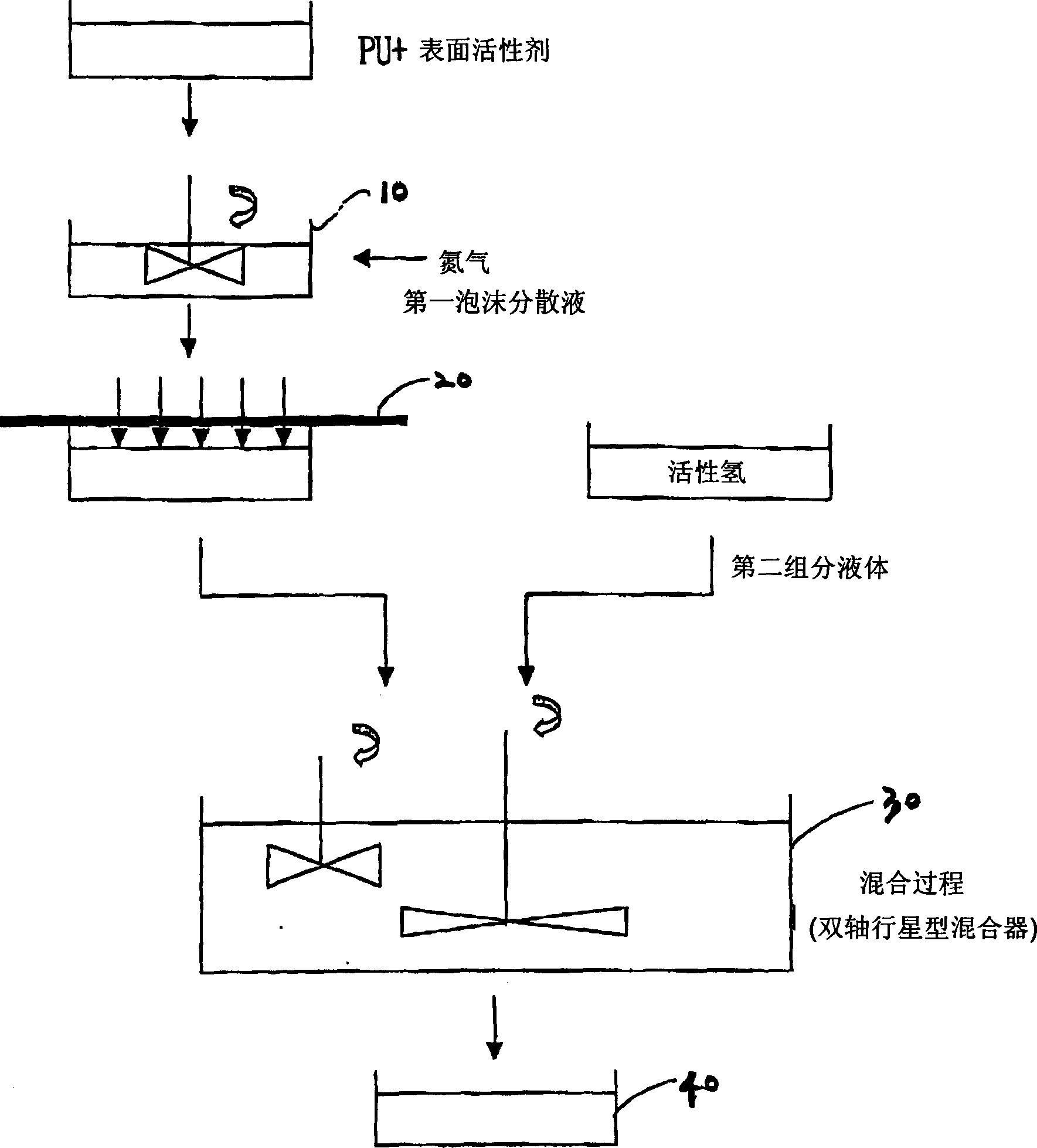

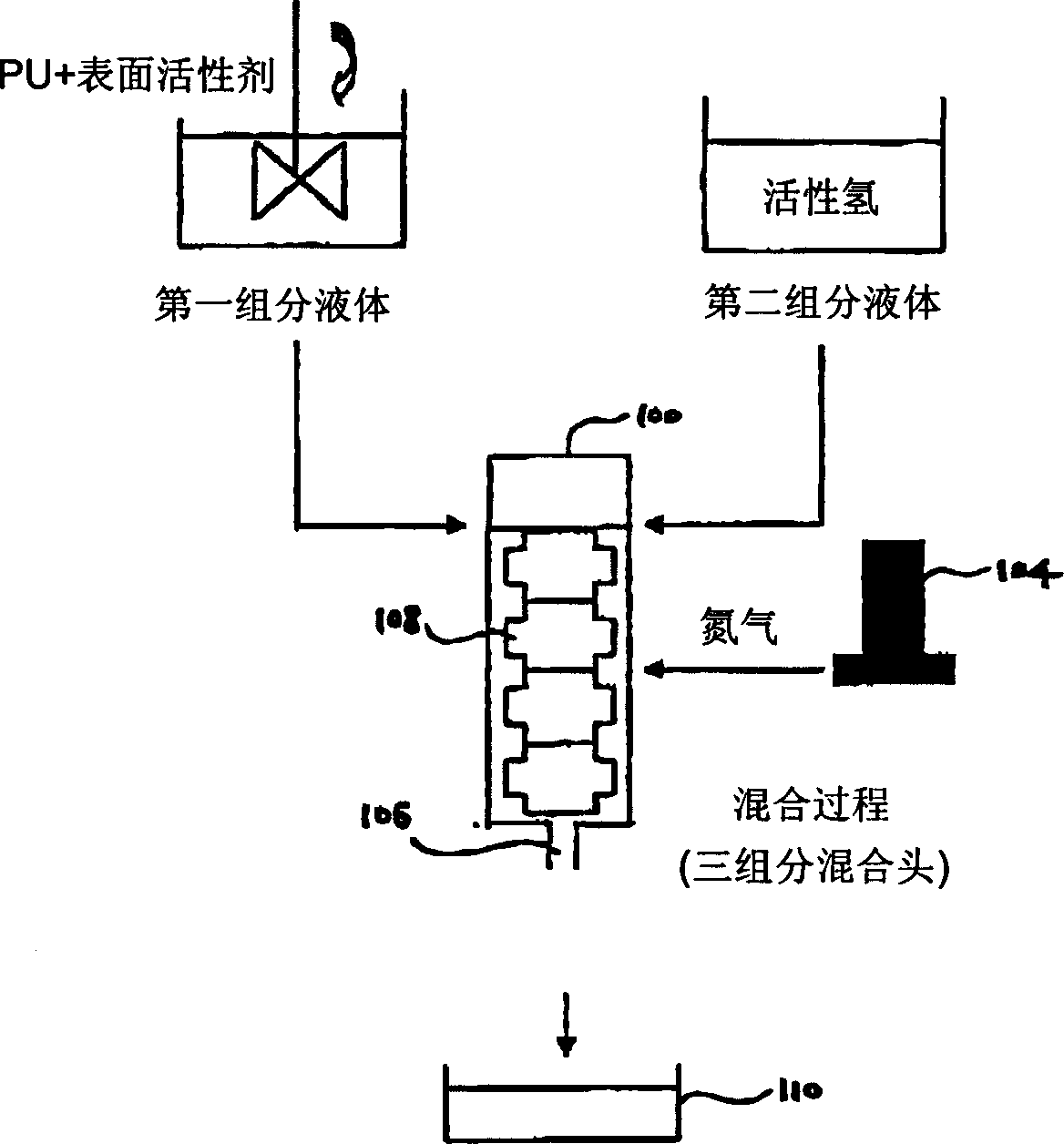

Method of fabricating polyurethane foam with micro pores and polishing pad therefrom

InactiveCN1738845AInhibitionWell mixedSemiconductor/solid-state device manufacturingFlexible-parts wheelsHydrogenReactive gas

To provide a method of fabricating a polyurethane foam with micro pores, and a polishing pad therefrom, the method including steps of (a) adding a nonionic surfactant into at least one of a first ingredient including an isocyanate group-containing compound and a second ingredient including an active hydrogen group-containing compound, (b) agitating and mixing the mixture of the first ingredient and the second ingredient while adding a non-reactive gas thereto, (c) discharging the mixture out of a container at a predetermined rate, and (d) injecting the discharged mixture into a mold so as to form a mold body into a predetermined shape.

Owner:SK恩普士有限公司

Lightweight and high-strength high-molecular material and preparation method thereof

The invention provides a lightweight and high-strength high-molecular material and a preparation method thereof. The preparation system of the material comprises a continuous phase and a dispersion phase; and the continuous phase comprises a gelling agent and an oil phase reactant, and does not include n-octyltriethoxysiloxane, wherein the oil phase reactant is one or more of styrene, methyl methacrylate, an epoxy resin prepolymer and a polyurethane prepolymer. N-octylsiloxane is avoided, so 95% or more of the prepared material is a closed-cell structure, the water absorption rate is small, the heat insulation performance is good, and the mechanical properties and the heat insulation performance of the material are improved.

Owner:SHAANXI NORMAL UNIV

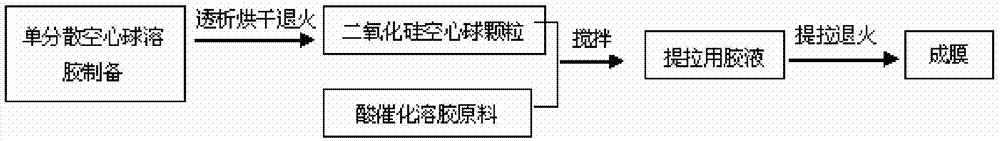

Preparation method of porous silicon dioxide antireflection film

The invention discloses a preparation method of a porous silicon dioxide antireflection film. The preparation method comprises the following steps: (1) preparing a silicon dioxide nano hollow particle sol from ethyl orthosilicate, cetyl trimethylammonium bromide, a phosphate buffer solution and an alkali catalyst used as raw materials; (2) dialyzing the silicon dioxide nano hollow particle sol through a dialysis bag, baking, and annealing to obtain silicon dioxide hollow sphere particles; (3) preparing a colloidal solution from the silicon dioxide hollow sphere particles, ethyl orthosilicate, deionized water, an acid catalyst and anhydrous ethanol used as raw materials; and (4) performing dip coating on a clean glass substrate in the colloidal solution, and annealing to obtain the porous silicon dioxide antireflection film. The antireflection film prepared by the method is a closed-pore porous film, and simultaneously has the characteristics of high transmittance, large hardness and film adhesion and good weather resistance.

Owner:GRIMAT ENG INST CO LTD

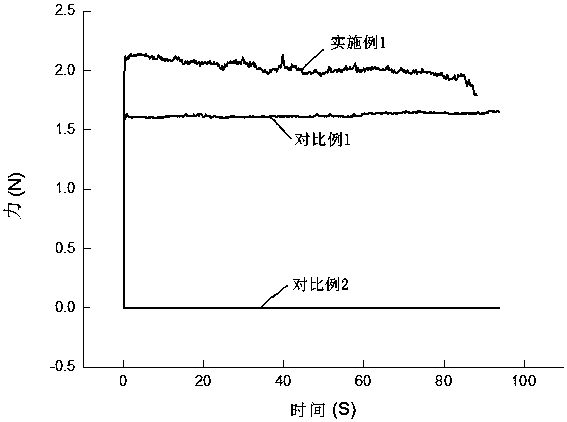

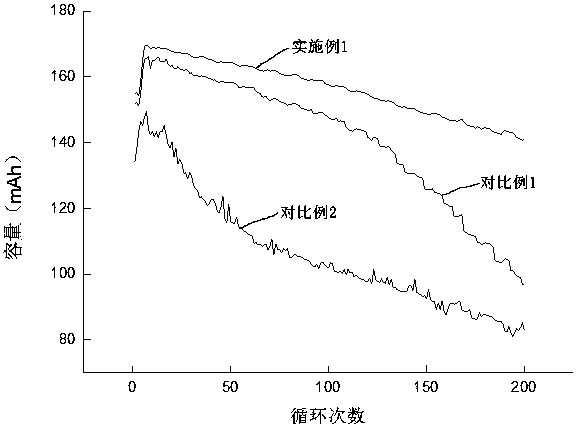

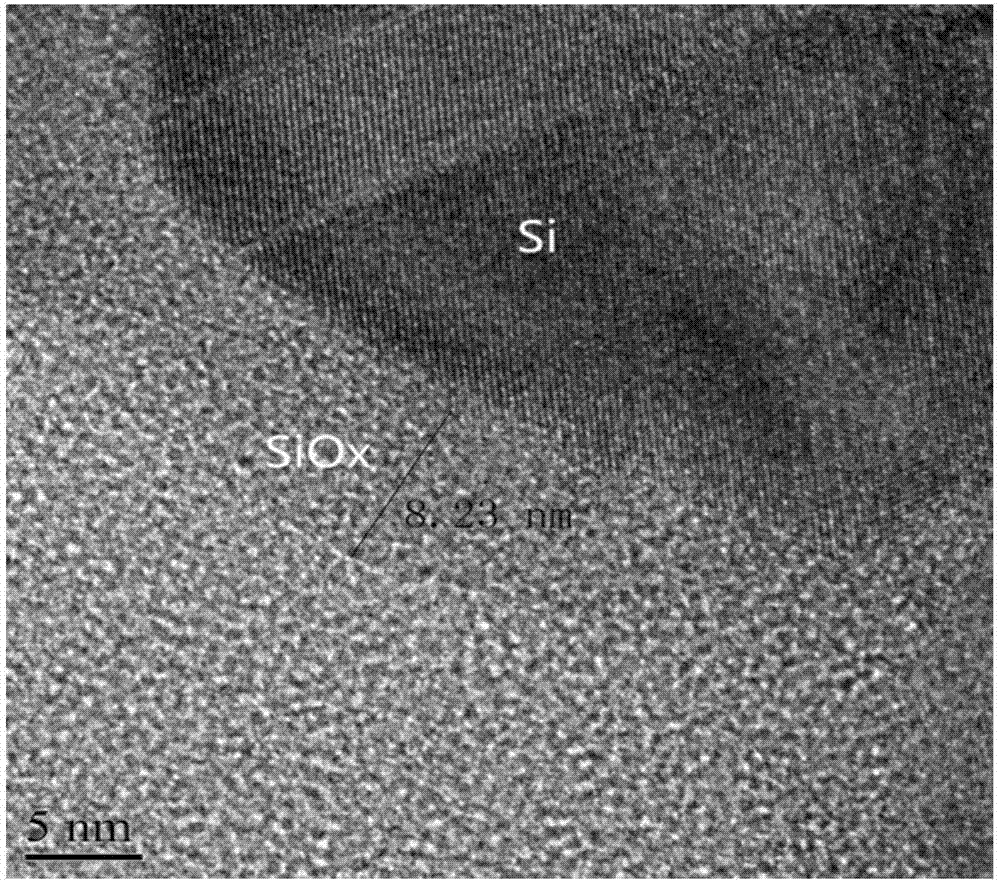

Lithium ion battery silicon doped carbon porous composite film and preparation method thereof

ActiveCN107579203AHigh bonding strengthImprove stabilityMaterial nanotechnologyCell electrodesCarbon compositesComposite film

The invention discloses a lithium ion battery silicon doped carbon porous composite film and a preparation method thereof. The preparation method comprises the following steps: firstly, oxidizing monatomic silicon, modifying the oxidized monatomic silicon through organo-siloxane so as to obtain modified monatomic silicon, preparing a silicon doped carbon composite film through a mixed solution prepared from the organo-siloxane modified monatomic silicon, a carbon-based polymer, a foaming pore forming agent and an organic solvent, and by taking hydrocarbon as a carbon source and an inert gas asa carrier gas, depositing a carbon nano material on the silicon doped carbon composite film by using a chemical vapor deposition method, and performing a method of sublimation pore forming with a foaming agent, thereby obtaining the lithium ion battery silicon doped carbon porous composite film. When the lithium ion battery silicon doped carbon porous composite film is used as a lithium ion battery cathode material, the primary lithium insertion capacity of the material is up to 1027.6mAh / g, the primary lithium removal capacity of the material is 997mAh / g, the coulombic efficiency of the material is 97.02%, the coulombic efficiency of the material is 91.31% after 100 times of circulation, and excellent charge and discharge properties are achieved.

Owner:SOUTH CHINA UNIV OF TECH

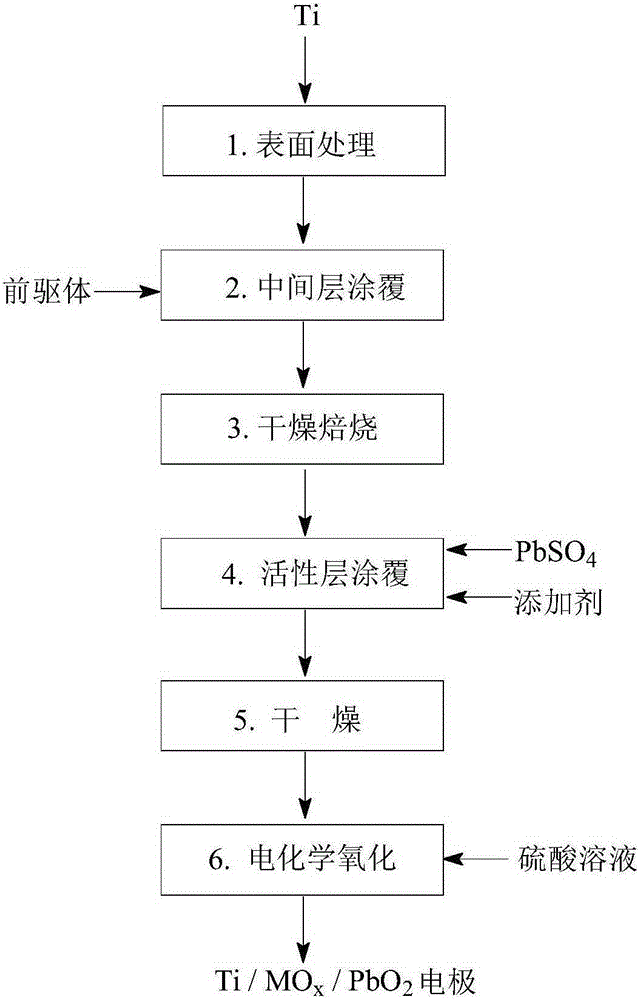

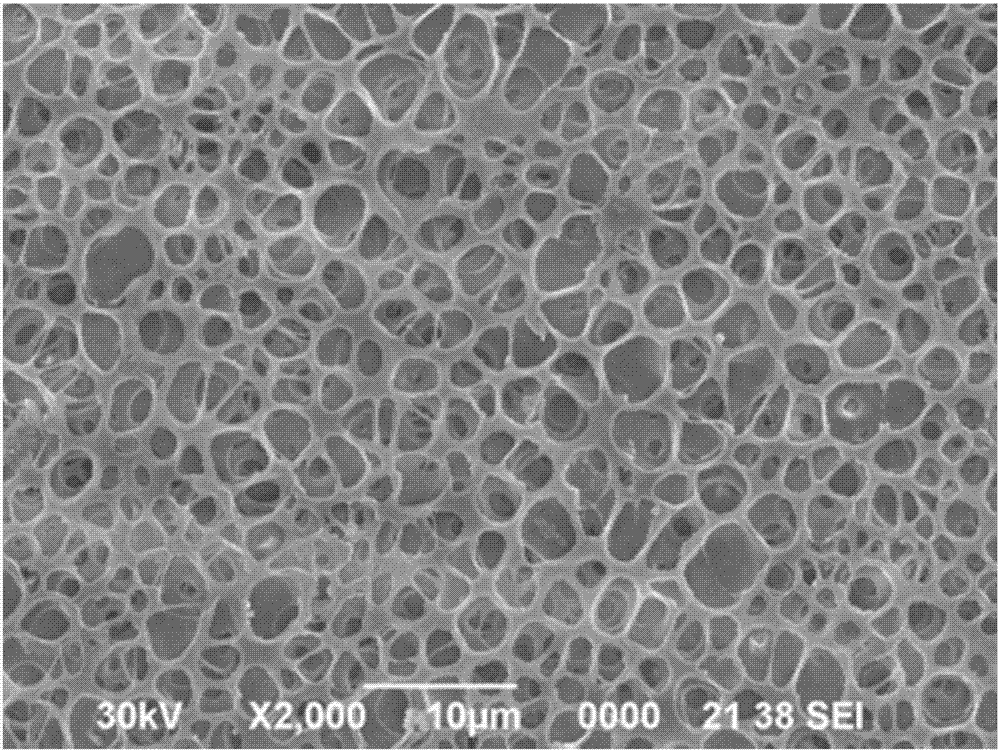

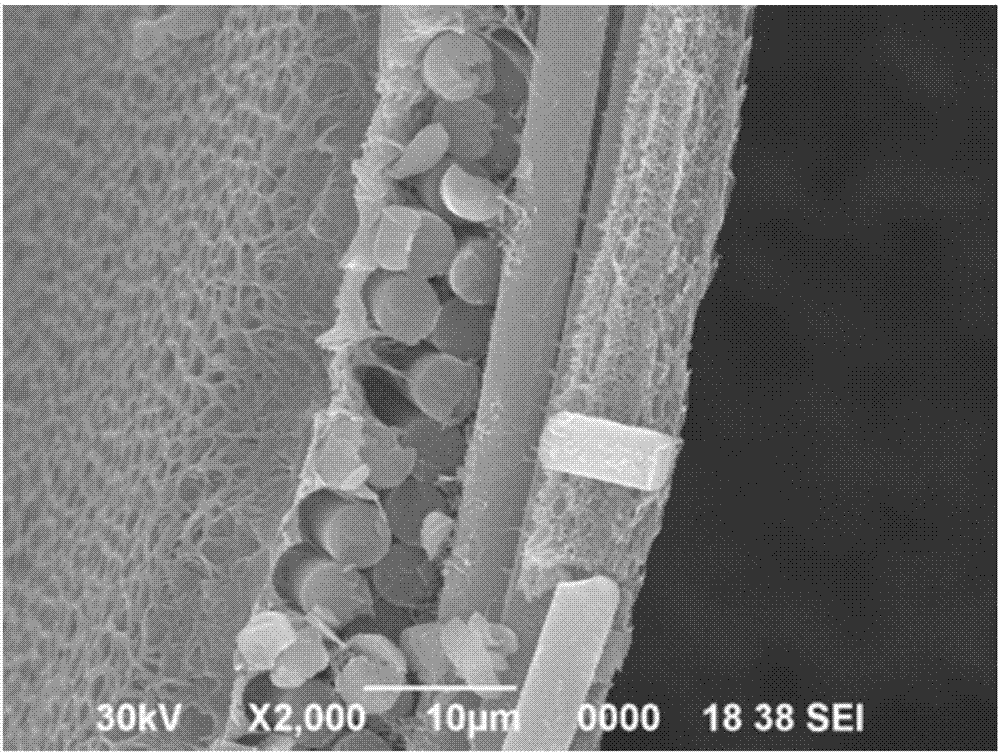

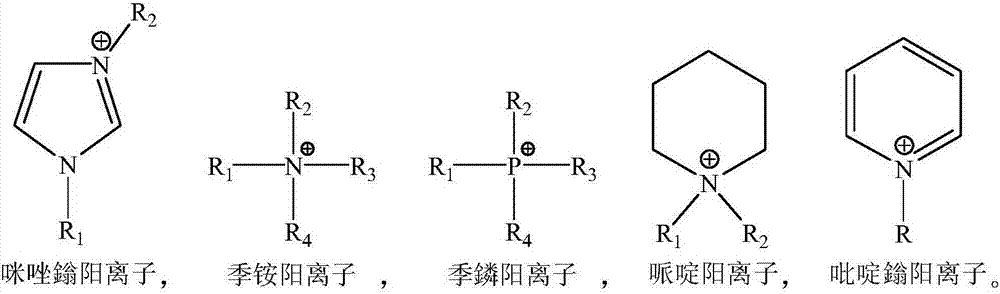

Preparation method of Ti-matrix insoluble anode

ActiveCN105200452AExtended service lifeImprove electrochemical performanceWaste accumulators reclaimingBattery recyclingResource utilizationRare earth

The invention relates to a preparation method of a Ti-matrix insoluble anode and belongs to the field of preparation technologies of electrode materials and resource utilization technologies of waste lead storage batteries. Particularly, metal Ti is used as an electrode matrix, PbSO4 obtained through separation and refinement of lead of the waste lead storage batteries is used as a raw material, a polymeric precursor thermal decomposition-lead sulfate electrochemical oxidation coupling technology is adopted, PbO2 is prepared through PbSO4 anode oxidation, and the obtained PbO2 is directly used as an electro-catalytic electrode material. The preparation method mainly comprises technological processes such as surface treatment of the Ti matrix, interlayer coating, drying and roasting, active layer coating, electrode drying, PbSO4 electrochemical oxidation and the like. The method is simple and can meet different electrode usage requirements by changing electrolyte and operation conditions, meanwhile, a rare earth mixture is added to an electrochemical oxidation solution, the surface of an electrode is treated with a rare earth modification technology, the performance of the electrode can be further improved, and the performance of the electrode is regulated and controlled.

Owner:YANGZHOU UNIV

Aromatic polyamide compound diaphragm, preparation method thereof and secondary battery

ActiveCN107305937AImprove thermal stabilityGood chemical stabilityLi-accumulatorsCell component detailsGlass fiberShrinkage rate

The invention relates to an aromatic polyamide compound diaphragm, a preparation method thereof and a secondary battery. The aromatic polyamide compound diaphragm provided by the invention comprises a glass fiber and aromatic polyamide. The hot-shrinkage rate of the compound diaphragm at 300 DEG C is below 30%. The invention also provides the preparation method for the aromatic polyamide compound diaphragm. The compound diaphragm provided by the invention has excellent mechanical property and heat resistance and is especially suitable for the secondary battery.

Owner:微宏先进膜公司

Method for preparing porous insulation material by microwave heating alkali metal silicate

InactiveCN102381884AEvenly distributed holesShort time periodCeramicwareBuilding insulationMicrowave

The invention relates to a method for preparing a porous foam insulation material by microwave heating alkali metal silicate, which is characterized in that alkali metal silicate is directly heated by microwave for producing an insulation material with low heat conduction coefficient and the usage temperature of -200 DEG C<=T<=1100 DEG C. The method for preparing porous insulation material by microwave heating alkali metal silicate enables uniform heating from the outside to inside of the raw material, which solves the problems of uneven heating of the raw material, environmental pollution and high dissipating energy caused by heating a heating furnace from outside to inside. The produced material can be used for direct usage after microwave foaming, and enables long-term usage when the temperature is lower than 450 DEG C; the usage temperature of the prepared porous foam insulation material can be raised to 1100 DEG C after being treated by acid. The method of the invention has the advantages of simple production technology, short production period; simultaneously the material has the merits of good heat insulation performance and low density. The inorganic insulation material has excellent fireproof function, and can be used for building insulation as well as external layer insulation for kilns and heating furnaces.

Owner:NANJING UNIV OF TECH

Method for preparing catalyst by hydrotreatment

ActiveCN102451699ACentralized distributionRegular hole structureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSimple Organic CompoundsAluminium hydroxide

The invention discloses a method for preparing a catalyst by hydrotreatment. The method comprises the following steps: gelatinizing aluminum hydroxide and adding a stable boron-containing organic compound solution, introducing a boron auxiliary agent to obtain the boron-containing aluminum hydroxide, mixing active metal ingredients with boron-containing aluminum hydroxide by a wet-mixing-kneadingmethod, three-segment roasting to obtain a catalyst intermediate, dipping the residual partial active metal and loading on the catalyst intermediate, drying to obtain the hydrotreatment catalyst. According to the invention, the boron auxiliary agent and the active metal ingredients are uniformly distributed on the surface of the catalyst, active metal ingredients introduced by two modes has different forms in the catalyst, mutual cooperation enables reduction of activity loss rate of the catalyst, and the running period of the apparatus can be prolonged. The catalyst has the characteristics of large pore volume and large specific surface area, and possesses proper pore structure and acidity, is especially suitable for hydrodenitrogenation process of heavy hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydroprocessing catalyst

ActiveCN106179388AImprove distributionEvenly distributedMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSimple Organic CompoundsHydrodesulfurization

The invention discloses a preparation method of a hydroprocessing catalyst. The catalyst is a bulk phase catalyst and comprises Ni<x>W<y>O<z>, MoO3 and aluminum oxide components. The preparation method comprises the following steps of enabling W, Ni and Al components to react with a precipitant to form colloid so as to obtain tungsten, nickel and aluminum precipitate pulp, after performing ageing, performing hydrothermal treatment with steam, adding urea, performing pulping with MoO3, then performing uniform mixing, performing soaking in a solution containing an organic compound, performing shaping and the like so as to prepare the hydroprocessing catalyst. The catalyst is particularly suitable for being used for ultra-deep hydrodesulfurization and denitrification reactions of diesel fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

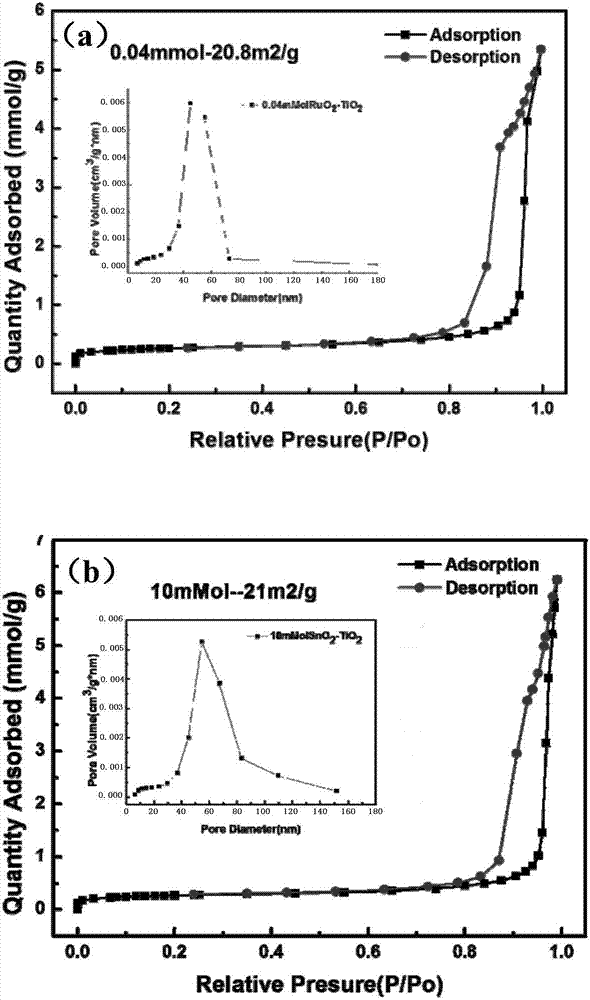

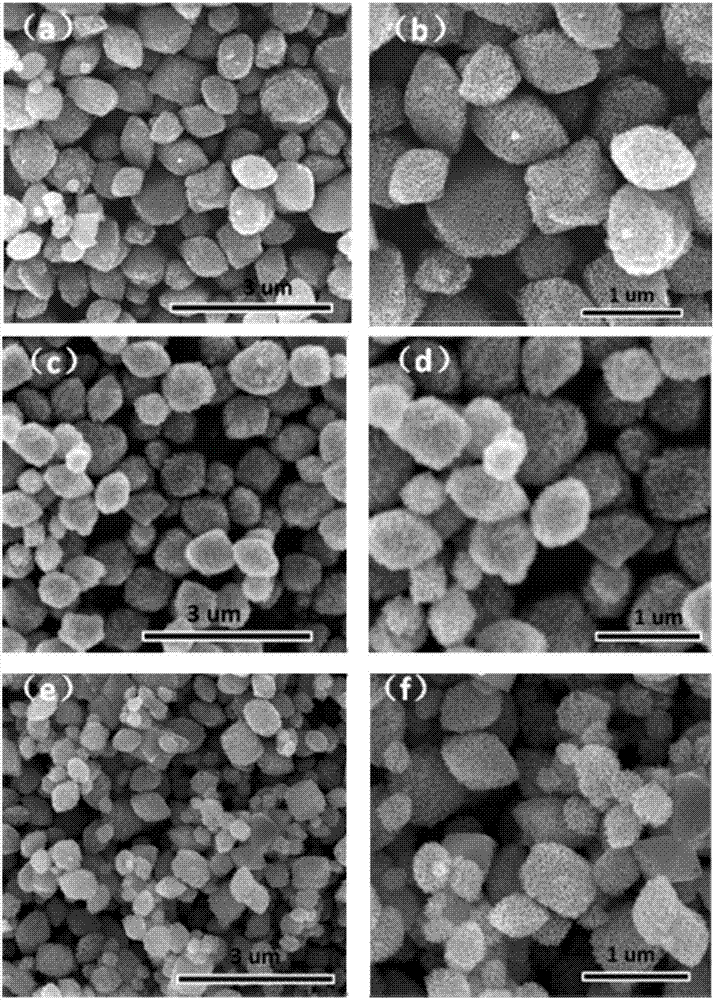

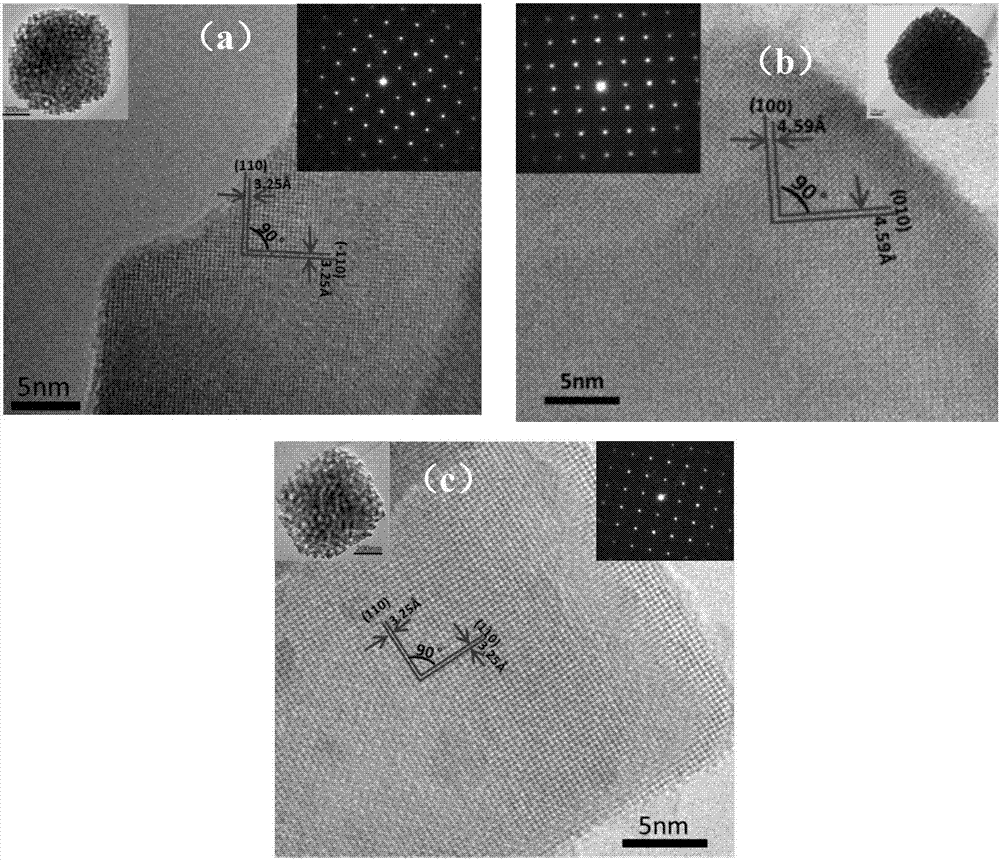

Preparation method for controllable growth of heterogeneous seed meso-porous monocrystalline rutile titanium dioxide

ActiveCN107540014AUniform shapeEvenly distributed holesCatalyst activation/preparationTitanium dioxideSingle crystalCrystal plane

The invention relates to the field of preparation of heterogeneous seed meso-porous metal oxides, and concretely relates to a preparation method for the controllable growth of heterogeneous seed meso-porous monocrystalline rutile titanium dioxide. The method comprises the following steps: carrying out hydrothermal growth by adopting titanium tetrachloride as a precursor and silica spheres containing heterogeneous seeds as a template through a wet chemical process in order to obtain specific crystal plane-exposed rutile titanium dioxide, and etching the template to obtain the meso-porous monocrystalline rutile titanium dioxide containing heterogeneous seeds. The preparation method can realize heterogeneous seed epitaxy growth of a cocatalyst, and solves the problems of poor interface contact quality and low photocatalytic efficiency of a catalyst and the cocatalyst. Compared with traditional seed template methods, the preparation method is characterized in that the titanium tetrachloride precursor and the heterogeneous seed silica template are added into a reaction kettle, and undergo heat treatment and etching to obtain the specific crystal plane-exposed meso-porous moncrystallinerutile titanium dioxide.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Hydrotreating catalyst and preparation method thereof

ActiveCN106179390AIncrease profitReasonable hole structureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemistryOxide

The invention discloses a hydrotreating catalyst and a preparation method thereof. The catalyst is a bulk-phase catalyst; components of the hydrotreating catalyst comprise hydrogenation active metal ingredients W, Ni and Mo, and aluminum oxide, wherein the W and the Ni exist in the form of a compound oxide: NixWyOz; the Mo exists in the form of MoO3. The active-site density of the active metal W and Ni in the epiphase of the catalyst is high; the utilization rate of hydrogenation active metal is high; meanwhile, the pore structures of the catalyst are reasonable; the active metal is more uniformly dispersed; the mechanical strength is high; the hydrotreating catalyst is particularly suitably applied to the ultra-deep hydrodesulfurization and denitrification reactions of a diesel fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bulk phase hydrotreating catalyst preparation method

ActiveCN106179382AEvenly dispersedIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationWater vapor

The invention discloses a preparation method of a bulk phase hydrogenation treatment catalyst. The composition of the catalyst includes hydrogenation active metal components W, Ni and Mo, alumina, and its preparation method is to prepare nickel and aluminum precipitate slurry I by acid precipitation method; adopt co-current precipitation method to prepare tungsten and aluminum precipitate slurry II, mix the two, after aging, hydrothermal treatment with water vapor and add urea, then combine with MoO 3 After beating and mixing evenly, soaking in the solution containing organic compounds, and then forming and other steps to prepare the hydrogenation treatment catalyst. The catalyst is particularly suitable for application in ultra-deep hydrodesulfurization and denitrogenation reactions of diesel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for depositing bionic hydroxyapatite (HA) on zinc phosphate conversion coating surface

ActiveCN104195531AImprove bindingEvenly distributed holesLiquid/solution decomposition chemical coatingDipotassium hydrogen phosphateWater baths

The invention relates to a method for depositing bionic hydroxyapatite (HA) on a zinc phosphate conversion coating surface, which comprises the following steps: preparing a simulated body fluid, in which the solute concentrations are as follows: 8.035-16.07g / L sodium chloride, 0.355-0.71g / L sodium bicarbonate, 0.225-0.45g / L potassium chloride, 0.231-0.462g / L dipotassium hydrogen phosphate dihydrate, 0.311-0.622g / L magnesium chloride hexahydrate, 39-58.5mL / L 1mol / L hydrochloric acid, 0.292-0.584g / L calcium chloride and 0.072-0.144g / L sodium sulfate; and cleaning a stainless steel sample of which the surface is provided with the zinc phosphate chemical conversion coating, putting the cleaned sample into the simulated body fluid, putting in a 36-38 DEG C thermostatic water bath oscillator, immersing for 0.5-30 days, taking out, cleaning with deionized water, and drying to obtain the HA coating. The composite coating is beneficial to enhancing the corrosion resistance of the stainless steel implant, has excellent biological activity, and implements early healing and long-term stability of the stainless steel implant.

Owner:SHANDONG UNIV

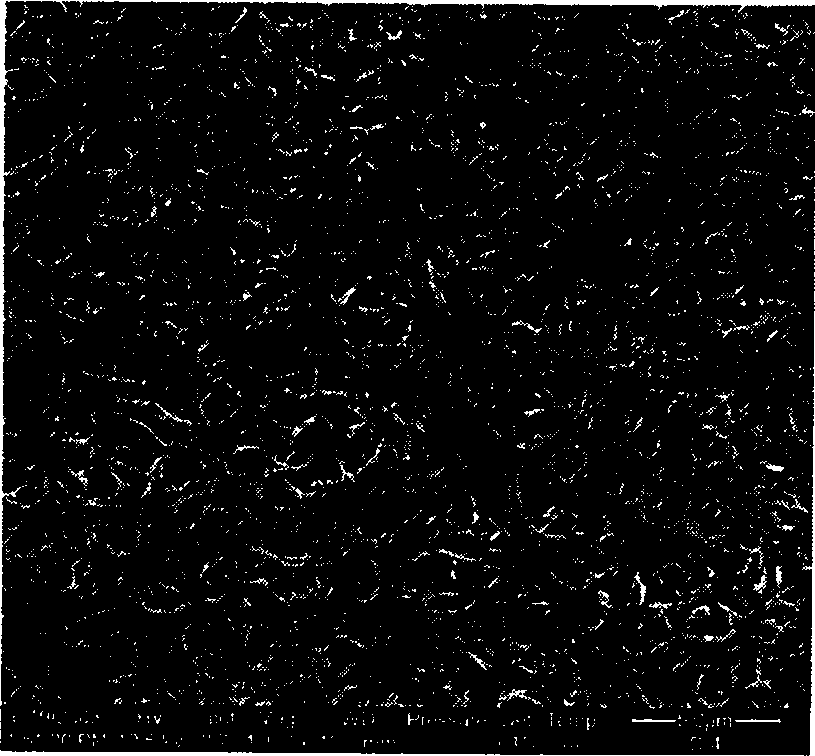

Degradable tubular polymeric multipore foaming material and its preparation method

A degradable tubular high-molecular porous foam material used as the porous cell scaffold of blood vessel tissue or nerve tissue engineering is prepared from a high-molecular material through use of combined mould. Its advantages are high porosity up to 90% and uniform distribution of pores.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com