Preparation method of porous silicon dioxide antireflection film

A technology of porous silica and anti-reflection film, applied in the direction of coating, etc., can solve the problems of particle deformation, different pore size, unsuitable for anti-reflection film formation, etc., and achieve strong adhesion, high hardness, and solar energy utilization efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

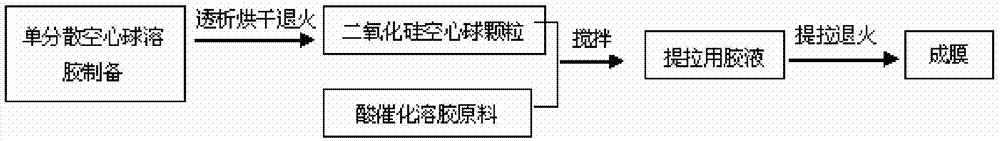

Method used

Image

Examples

Embodiment 1

[0031] First, use deionized water and electronics industry cleaning agent to clean and remove the dirt on the surface of the flake or tubular glass. After washing, put it in absolute ethanol and acetone for ultrasonic treatment for 30 minutes each, and dry the cleaned glass sample;

[0032] At room temperature, add 0.0005mol cetyltrimethylammonium bromide to 50mL phosphate buffer solution, stir for 2 hours to dissolve; after heating the solution to 80°C, add 0.003mol ethyl orthosilicate and 0.003 mol of ammonia water, then continue to stir and react for 2 hours; after the reaction, the reaction solution is transferred to a dialysis bag with a molecular weight cut-off of 14000, and dialyzed in water for 48 hours to obtain solution A;

[0033] Transfer the dialyzed solution into a clean glass bottle, dry at 100°C, and then bake at 700°C in air for 2 hours to obtain silica hollow sphere powder B;

[0034] Mix the dried silica hollow spheres, 0.4mol deionized water, 0.005mol hydro...

Embodiment 2

[0038] First, use deionized water and electronics industry cleaning agent to clean and remove the dirt on the surface of the flake or tubular glass. After washing, put it in absolute ethanol and acetone for ultrasonic treatment for 30 minutes each, and dry the cleaned glass sample;

[0039] At room temperature, add 0.0006mol of cetyltrimethylammonium bromide to 50mL of phosphate buffer solution, stir for 2 hours to dissolve; after heating the solution to 80°C, add 0.012mol of ethyl orthosilicate and 0.012 mol of ammonia water, then continue to stir and react for 2 hours; after the reaction, the reaction solution is transferred to a dialysis bag with a molecular weight cut-off of 14000, and dialyzed in water for 48 hours to obtain solution A;

[0040] Transfer the dialyzed solution into a clean glass bottle, dry at 100°C, and then bake at 700°C in air for 2 hours to obtain silica hollow sphere powder B;

[0041]Mix the dried silica hollow spheres, 0.2mol deionized water, 0.005m...

Embodiment 3

[0045] First, use deionized water and electronics industry cleaning agent to clean and remove the dirt on the surface of the flake or tubular glass. After washing, put it in absolute ethanol and acetone for ultrasonic treatment for 30 minutes each, and dry the cleaned glass sample;

[0046] At room temperature, add 0.0007mol of cetyltrimethylammonium bromide to 50mL of phosphate buffer solution, stir for 2 hours to dissolve; after heating the solution to 80°C, add 0.008mol of ethyl orthosilicate and 0.008 mol of ammonia water, then continue to stir and react for 2 hours; after the reaction, the reaction solution is transferred to a dialysis bag with a molecular weight cut-off of 14000, and dialyzed in water for 48 hours to obtain solution A;

[0047] Transfer the dialyzed solution into a clean glass bottle, dry at 100°C, and then bake at 700°C in air for 2 hours to obtain silica hollow sphere powder B;

[0048] Mix the dried silica hollow spheres, 0.2mol deionized water, 0.005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com