A flexible ordered mesoporous tio 2 Nanofiber membrane and preparation method thereof

A nanofiber membrane and mesoporous technology, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, artificial filaments made of inorganic materials, etc., can solve the problems of disordered fiber mesopore structure, wide pore size distribution, complex process, etc., to achieve Effects of reducing micro-defects on the fiber surface, inhibiting grain size growth, and promoting diffusion migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

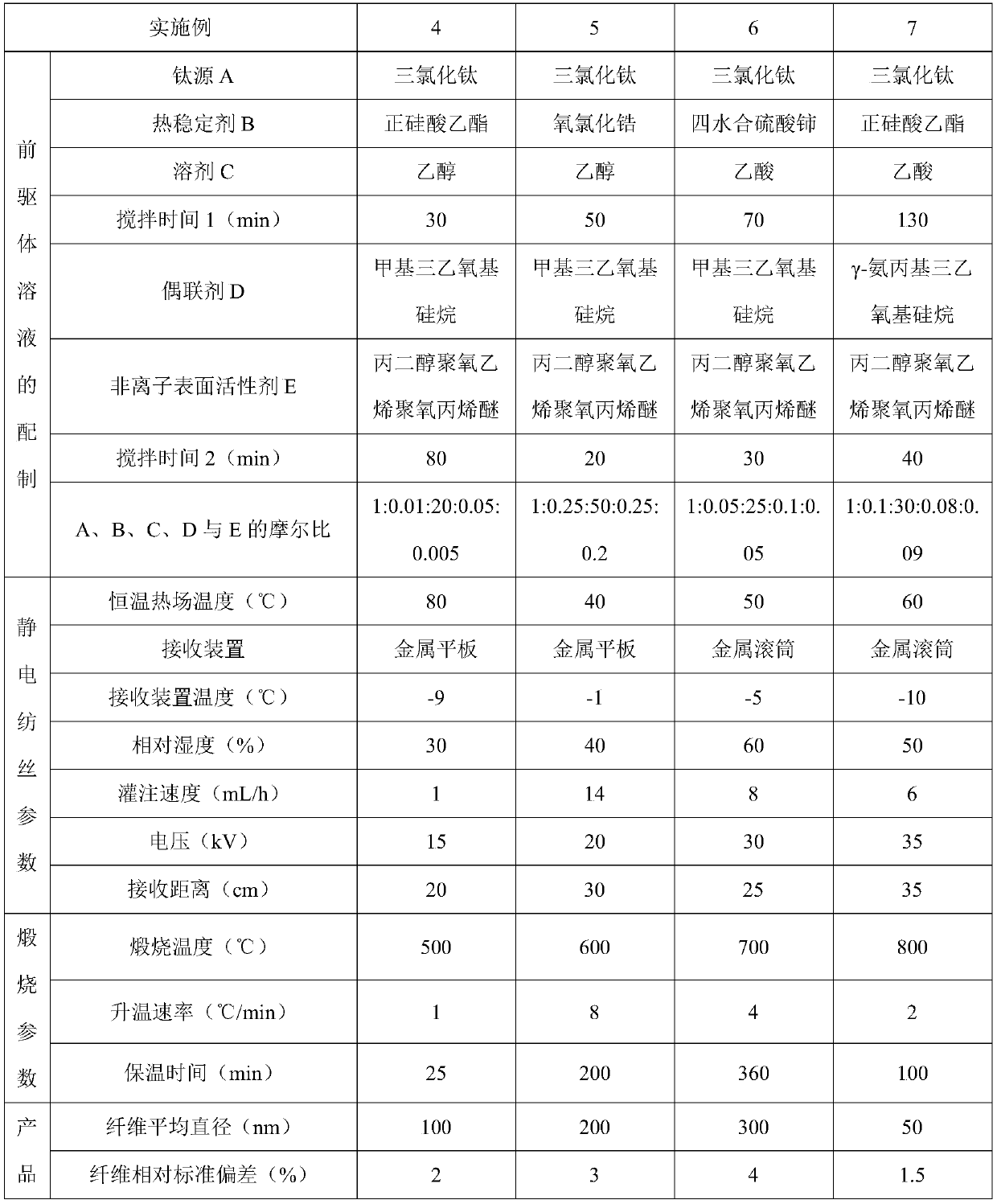

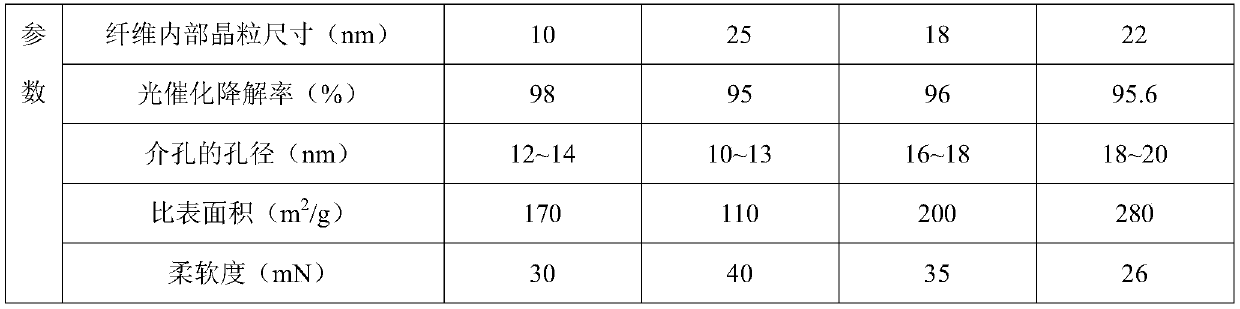

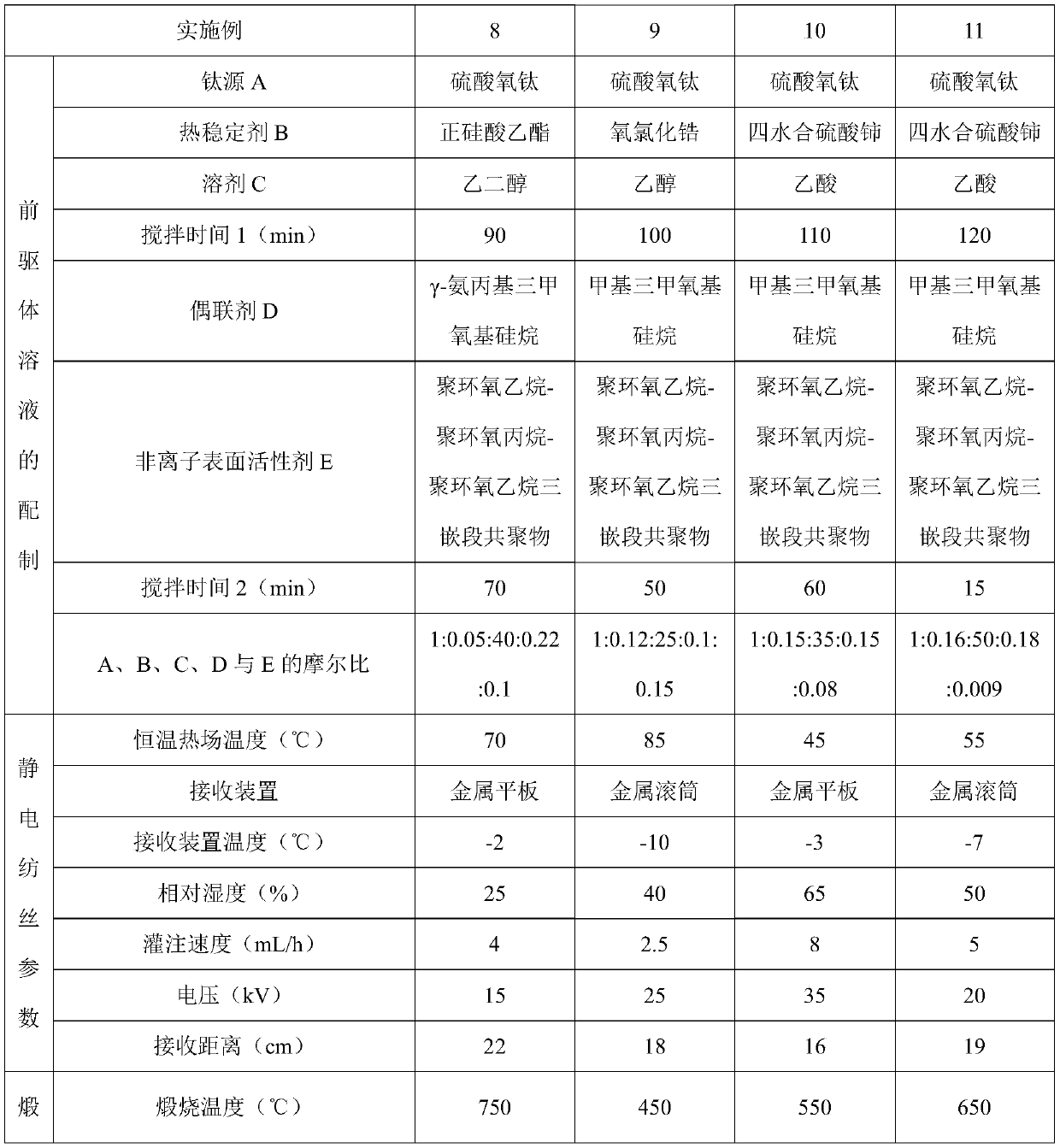

Examples

Embodiment 1

[0035] A flexible ordered mesoporous TiO 2 The preparation method of nanofibrous film, the steps are as follows:

[0036] (1) Dissolve the titanium source titanium isopropoxide and heat stabilizer ethyl orthosilicate in the solvent ethanol and stir for 30 minutes, then add the coupling agent N-(β-aminoethyl)-γ-aminopropylmethyl in sequence Dimethoxysilane and non-ionic surfactant polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer were stirred for 10 min and mixed uniformly to obtain a precursor solution, wherein in the solution, titanium source, heat stable The molar ratio of agent, solvent, coupling agent and nonionic surfactant is 1:0.25:50:0.25:0.2;

[0037] (2) Prepare the precursor fiber film by electrospinning the above precursor solution, apply a constant temperature thermal field of 40°C in the spinning interval during electrospinning and control the temperature of the metal drum receiving device to 0°C; The parameters are: relative humidity...

Embodiment 2

[0044] A flexible ordered mesoporous TiO 2 The preparation method of nanofibrous film, the steps are as follows:

[0045] (1) Dissolve titanium source tetrabutyl titanate and heat stabilizer zirconium oxychloride in solvent ethanol and stir for 150 minutes, then add coupling agent γ-aminopropyltrimethoxysilane and nonionic surfactant polyoxygen Ethylene polyoxypropylene was stirred for 90 minutes and mixed evenly to prepare a precursor solution, wherein the molar ratio of titanium source, heat stabilizer, solvent, coupling agent and nonionic surfactant in the solution was 1:0.01:20:0.05:0.005;

[0046] (2) Prepare the precursor fiber film by electrospinning the above precursor solution, apply a constant temperature thermal field of 90°C in the spinning interval during electrospinning and control the temperature of the metal plate receiving device to -10°C; The parameters of silk are: relative humidity 70%, perfusion speed 0.1mL / h, voltage 40kV, distance between receiving devi...

Embodiment 3

[0050] A flexible ordered mesoporous TiO 2 The preparation method of nanofibrous film, the steps are as follows:

[0051] (1) Dissolve the titanium source titanium trichloride and the heat stabilizer cerium sulfate tetrahydrate in the solvent acetic acid and stir for 90 minutes, then add the coupling agent methyltrimethoxysilane and the nonionic surfactant glycerol polyoxyethylene in sequence The polyoxypropylene block copolymer was stirred for 50 minutes and mixed evenly to prepare a precursor solution, wherein the molar ratio of titanium source, heat stabilizer, solvent, coupling agent and nonionic surfactant in the solution was 1:0.13:35:0.15 :0.1;

[0052] (2) Prepare the precursor fiber film by electrospinning the above precursor solution, apply a constant temperature thermal field of 65°C in the spinning interval during electrospinning and control the temperature of the metal drum receiving device to -5°C; The parameters of silk are: relative humidity 45%, perfusion sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com