Patents

Literature

49results about How to "Reasonable hole structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking co-catalyst for producing diesel oil and its preparing method

InactiveCN1683474AReasonable hole structureReasonable strengthCatalytic crackingIn situ crystallizationSodium oxide

The catalytic cracking co-catalyst for increasing diesel oil yield is prepared through roasting kaolin at over 900 deg.c for in-situ crystallization. The co-catalyst contains type-Y zeolite in 5-20 wt%, as well as magnesia 0.5-3 wt%, RE oxide 0.5-5 wt%, and sodium oxide less than 0.6 wt%, and the zeolite has Si / Al ratio of 4.0-6.0. Adding certain amount of the catalytic cracking co-catalyst without altering the main catalyst in the oil refining apparatus can raise diesel oil yield of FCC catalyzed apparatus, improve product distribution, raise available catalyst utilization, and improve the activity stability of the catalyst system and heavy metal resistance.

Owner:PETROCHINA CO LTD

Preparation method of hydrotreatment catalyst composition

ActiveCN102451705AImprove adhesionEasy to shapeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminateOrganic solvent

The invention discloses a preparation method of a hydrotreatment catalyst composition. According to the method, during preparation of a mixture of NixWyOz composite oxide precursor and Al2O3 precursor, sodium meta aluminate is employed as an aluminium source, and sodium meta aluminate and CO2 gas are added with swing addition during a gelatinizing process; after gelatinization, the mixture, molybdena and organic solvent are beaten, mixed, moulded and dried to obtain the catalyst. Particles prepared by the method are large and uniform to improve physical and chemical properties of the catalyst; the catalyst has characteristics of large pore volume, large specific surface area, reasonable aperture distribution and high effective utilization rate of active metal, etc.; and the method solves a problem of difficulty in forming of bulk phase catalyst. The catalyst prepared by the method of the invention is especially suitable for super-deep desulphurization reaction in production of super-cleaning diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

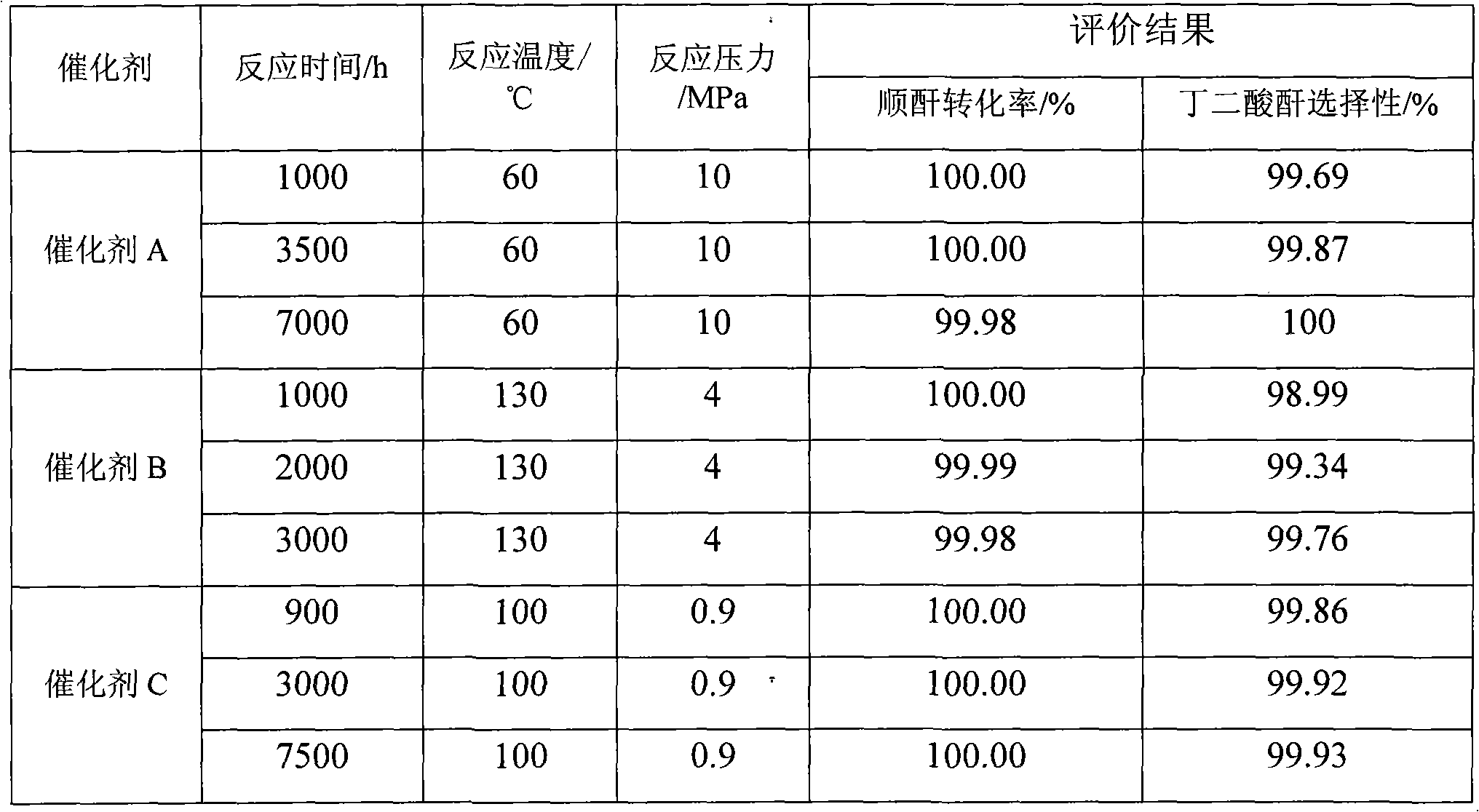

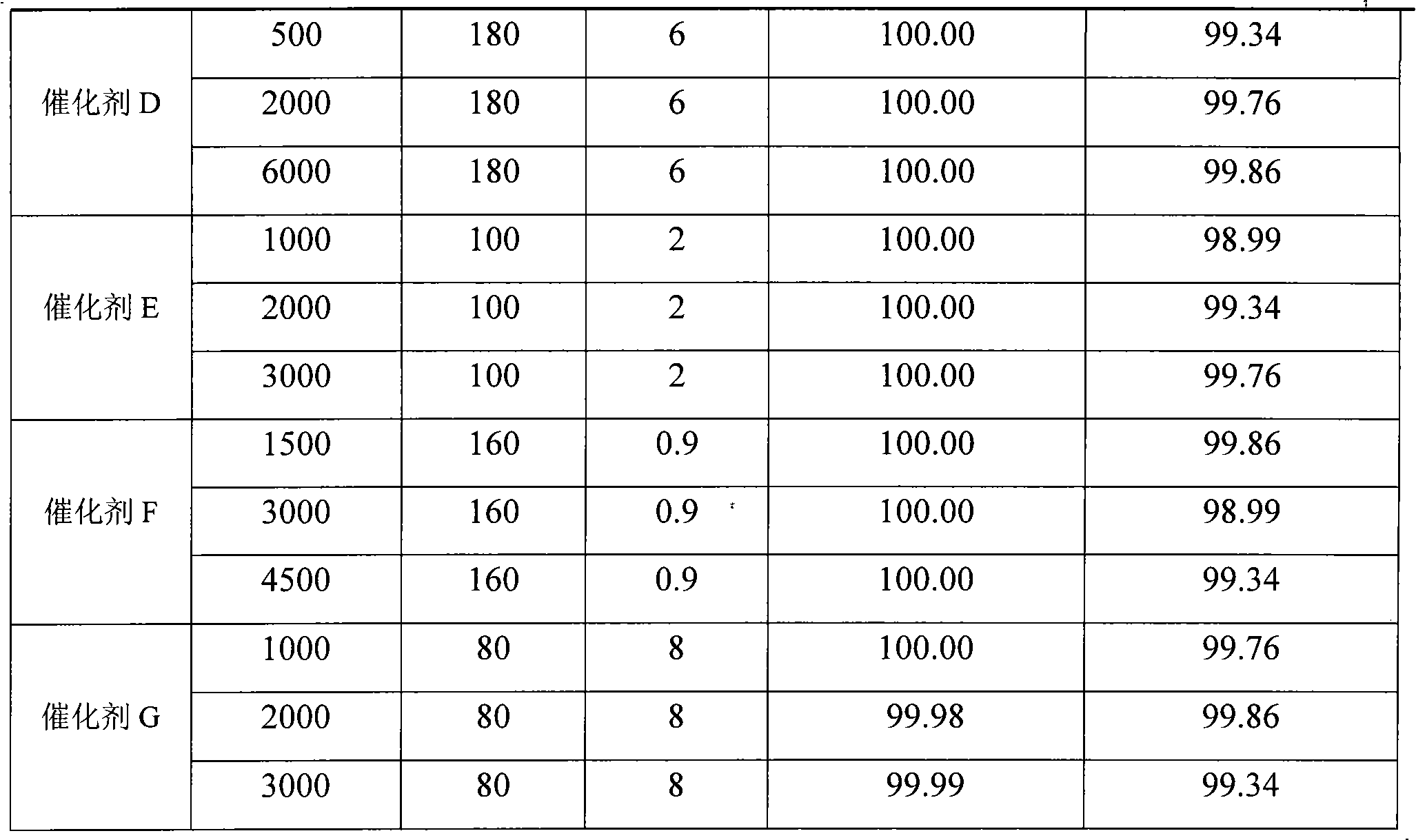

Preparation method of catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride

ActiveCN101502802BHigh yieldHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedHigh activity

Owner:SHANXI UNIV

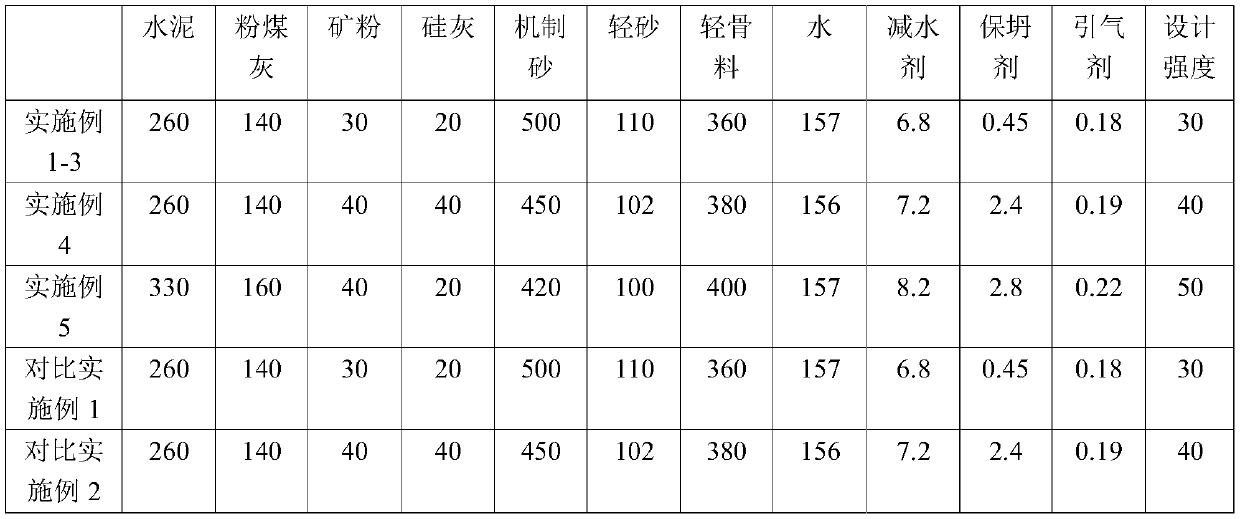

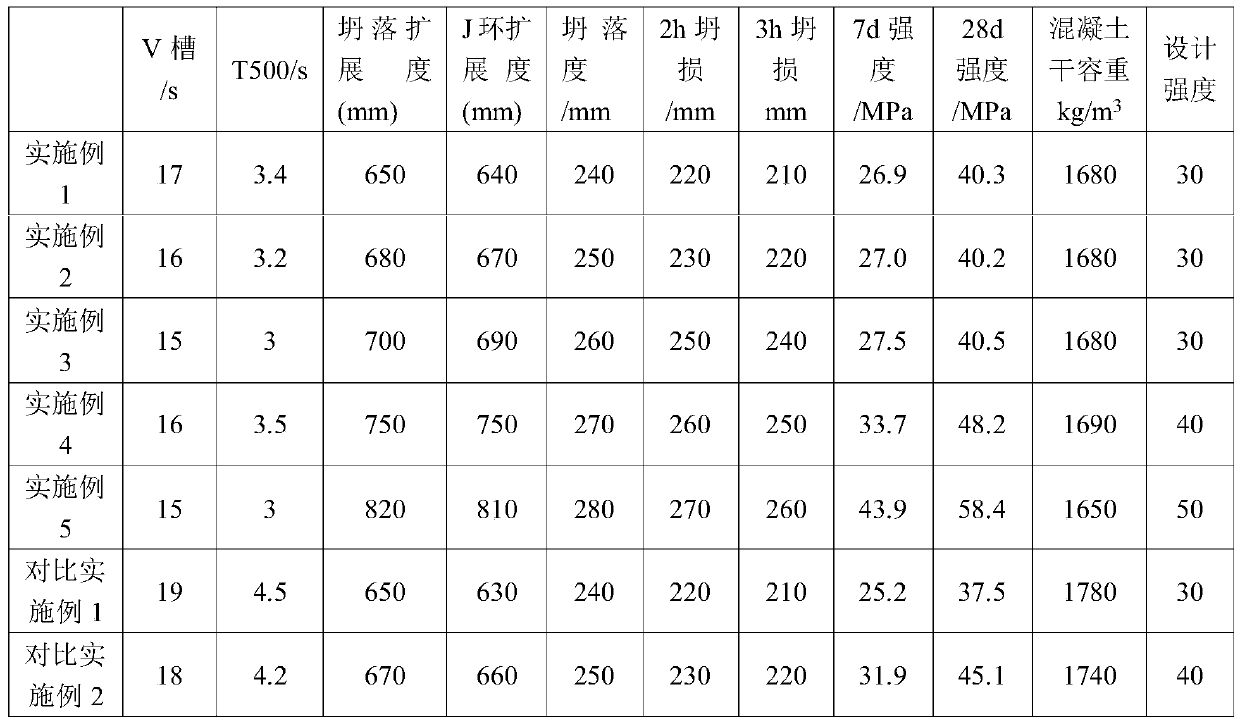

Self-compacting lightweight aggregate machine-made sand concrete and preparation method thereof

InactiveCN110240446ASolve the problem of insufficient resources and tight supplyImprove cohesionCeramicwareRosinWater reducer

The invention discloses self-compacting lightweight aggregate machine-made sand concrete. The sand concrete comprises the following raw materials in parts by weight: 260-330 parts of concrete, 140-160 parts of fly ash, 30-40 parts of mineral powder, 20-40 parts of silica fume, 420-500 parts of machine-made sand, 100-110 parts of light sand, 360-400 parts of lightweight aggregate, 150-160 parts of water, 6.8-8.3 parts of a water reducer, 0.45-2.8 parts of a slump preserving agent and 0.18-0.22 part of an air entraining agent, wherein the slump preserving agent is obtained by compounding isopentenol polyoxyethylene ether (TPEG), acrylic acid and a compound molecular weight regulator, the air entraining agent is a rosin soap type air entraining agent obtained by compounding rosin, caustic soda, triethanolamine and sodium lauryl sulfate. The machine-made sand is used to replace natural sand, and the concrete prepared by a secondary mixing method solves the problems of easy flotation of lightweight aggregate concrete aggregate, shortage of natural sand supply, and high water demand rate, easy separation and poor pumpability of lightweight aggregate machine-made sand concrete.

Owner:中建西部建设贵州有限公司

Preparation method of hydrotreating catalyst composition

ActiveCN103055887AImprove adhesionUniform grain sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionSlurry

The invention discloses a preparation method of a hydrotreating catalyst composition. The method comprises the steps of subjecting a salt mixed solution A in which CO2 is dissolved to react with an alkaline solution B containing aluminium to prepare gel, when reaction is completed, controlling the pH value of pulp in a reaction tank to be 7.0-9.0, preparing a mixture of an NixWyOz composite oxide precursor and an Al2O3 precursor, pulping the mixture and MoO3 to prepare a dry body, and then forming, drying and roasting the dry body to obtain a final catalyst, wherein the salt mixed solution A contains components Ni and W. The method has the beneficial effects that the problem that bulk phase catalysts are difficult to form is solved; the physical and chemical properties of the catalyst are adjusted, and the catalyst has the advantages of larger specific surface area, uniform pore distribution and high effective utilization rate of reactive metals; and the catalyst is especially suitable for the ultra-deep desulfurization reaction for producing ultra-clean diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron nickel Fischer-Tropsch synthetic catalyst and preparation thereof

ActiveCN101279260AMild conditionsSimple preparation processHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionPtru catalystPhysical chemistry

The invention discloses a Fischer-Tropsch synthesis iron-based catalyst containing nickel, wherein Fe:Ni:K:Cu:SiO2 equals to 100:0.01-40:0.1-15:0.1-15:2-50. Solution containing metals of iron, nickel and copper and soda solution are carried out coprecipitation, which is adopted by the invention, after precipitation paste and solution containing silicon are carried out size mixing, serum acquired is transferred into a spray dryer for drying and molding, and then baking is carried out to obtain the catalyst. The catalyst of the invention is suitable for low temperature Fischer-Tropsch synthesis reaction and has the advantages of good activity and selectivity, high product conversion rate, mild reaction conditions, etc.; in addition, the preparation process of the invention is simple and the catalyst prepared has better granularity and intensity, which is suitable for a process of slurry-bed Fischer-Tropsch reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Ultra-fine titanium aluminum composite oxide and preparation method thereof

The invention discloses ultrafine titanium-aluminum composite oxide and a preparation method thereof. The method comprises the following steps: aluminum salt and titanium salt are dropped into the mixture of hydrocarbon component and surfactant with the VB value less than 1 to form an ultra solubilization micellar system, so as to react under the existence of precipitant and or catalyst; and the obtained reaction product is baked and / or roasted to obtain the ultrafine titanium-aluminum composite oxide. The titanium-aluminum composite oxide hole has a more rational structure, the pore volume with the hole diameter of 4 nm to 20 nm occupies 75 percent to 95 percent of the whole pore volume, thereby being favorable for improving the selectivity and the activity of the catalyst. The amount of the surfactant and the hydrocarbon component used for the method is little, the cost is low, the ultrafine particles are in a single dispersed state, the process is simple, and the invention can be used for the mass industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-abrasion resistance lithium-containing iron series Fischer-Tropsch synthetic catalyst, catalyst bonding agent containing blending silica sol and preparation method and application thereof

ActiveCN102872877AHigh mechanical strengthGood hydrothermal stabilityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsLithiumSlurry reactor

The invention provides a high-abrasion resistance lithium-containing iron series Fischer-Tropsch synthetic catalyst and a preparation method thereof. The catalyst comprises the following elements of: Fe, Cu, K, Li and SiO2 in a weight ratio of 100:(1.5-15):(1.5-15):(0.1-8):(10-60). The invention also provides a catalyst bonding agent for preparing the Fischer-Tropsch synthetic catalyst and a preparation method thereof and application of the catalyst bonding agent containing blending silica sol of lithium silicate and potassium silicate to the preparation of the high-abrasion resistance lithium-containing iron series Fischer-Tropsch synthetic catalyst. The catalyst bonding agent contains the blending silica sol of the lithium silicate and the potassium silicate, and lithium-ion and potassium-ion interactive arrangement chain sections are positioned on a polysilicate molecular chain. The lithium-containing iron series Fischer-Tropsch synthetic catalyst has high mechanical strength and hydrothermal stability and high Fischer-Tropsch synthetic activity, and is suitable to be used in a slurry reactor; and a preparation process is simple and is suitable for large-scale production.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

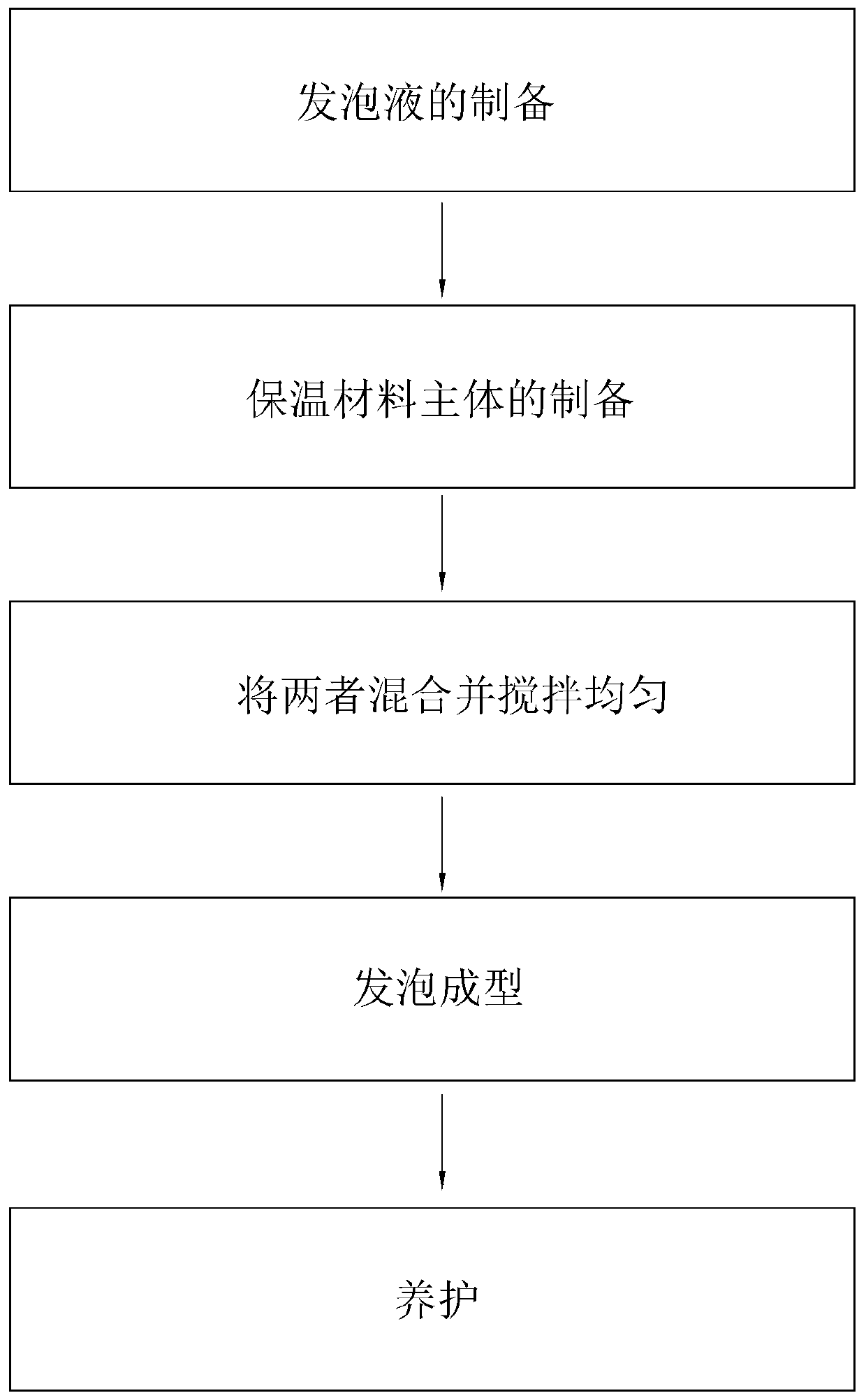

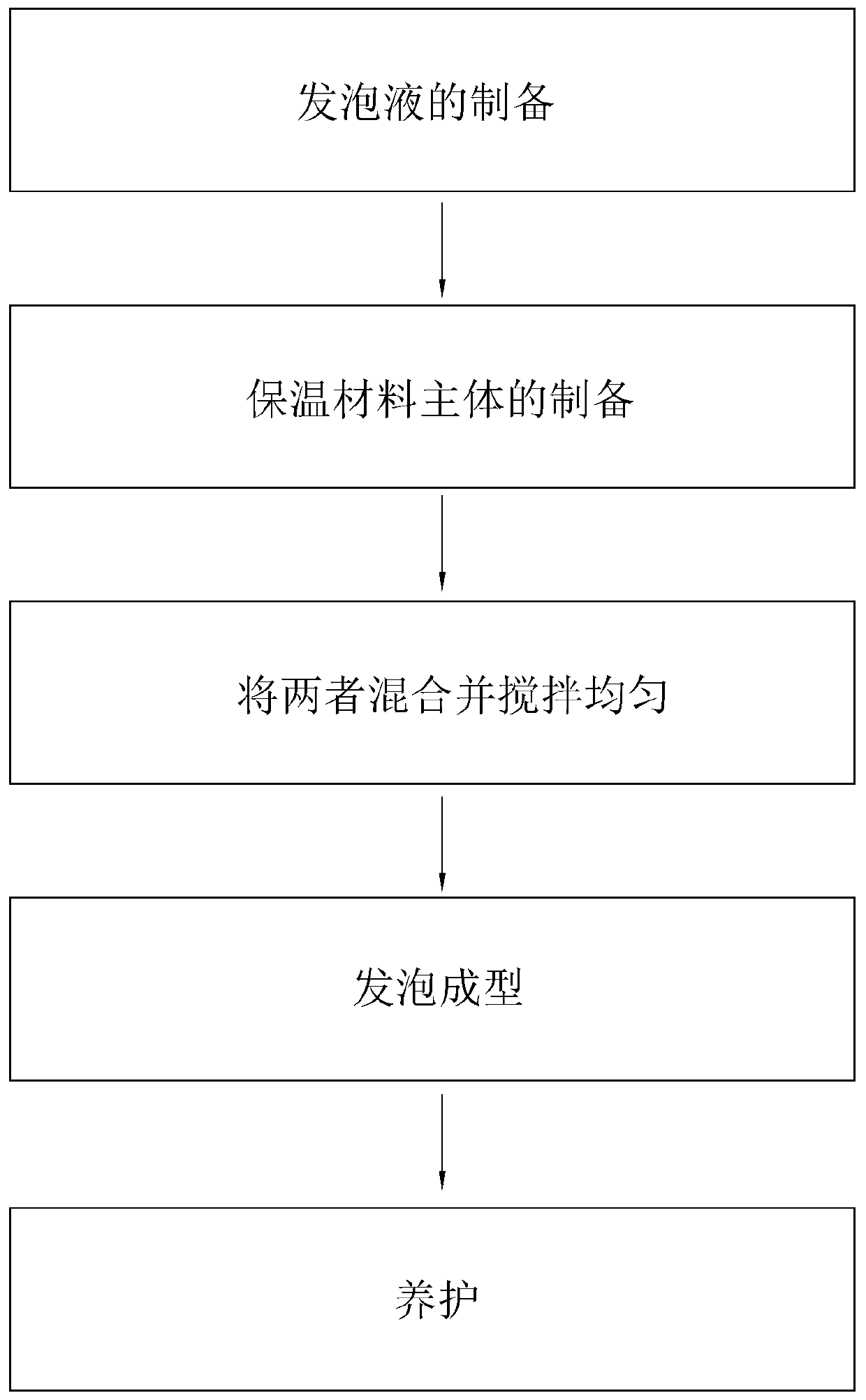

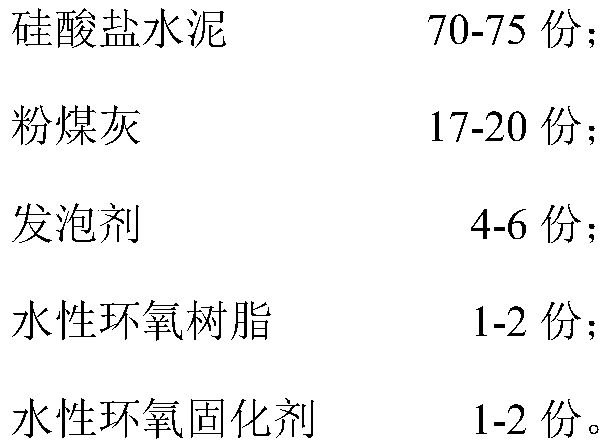

Exterior wall environmental-friendly thermal insulation material

ActiveCN109704673AImprove structural stabilityReduce sizeCeramicwareFoam concreteEnvironmental resistance

The invention discloses an exterior wall environmental-friendly thermal insulation material. The exterior wall environmental-friendly thermal insulation material comprises, by weight, 70 to 75 parts of Portland cement, 17 to 20 parts of fly ash, 4 to 6 parts of a foaming agent, 1 to 2 parts of an aqueous epoxy resin, and 1 to 2 parts of an aqueous epoxy hardener. The advantages are that: the aqueous epoxy resin is high in bonding force, is capable of increasing bonding force of concrete among bubbles in foamed concrete layers so as to form a whole body, realize co-force loading, increase foamed concrete layer strength, and the binding firmness of foamed concrete layers with compact concrete layers; and in addition, after adding of the aqueous epoxy resin, thermal insulation layer surface is more smooth, after moulding, the morphology is more complete. The aqueous epoxy resin is also capable of achieving fixing and anti-cracking effects, and increasing structure strength and prolongingservice life obviously.

Owner:温州市艺都装潢有限公司

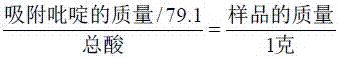

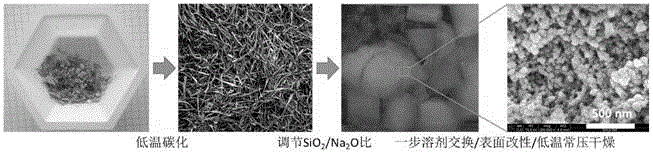

Preparation method of biomass-based nano-silica aerogel

The invention relates to a preparation method of biomass-based nano-silica aerogel. The method comprises the following steps: acidifying straws used as a raw material by hydrochloric acid to remove impurities, pyrolyzing the acidified straws at a high temperature, and combing a high-speed vibration ball mill with an ultrasonic dispersion process to extract biomass-based nano-silica from the raw material straws; carrying out a heating reaction on the biomass-based nano-silica and a NaOH solution, and cooling and filtering the obtained solution to obtain a biomass-based water glass solution; adding sulfuric acid to adjust the pH value to 1-2, and dropwise slowly adding the NaOH solution to make the pH value reach 7-8, carrying out continuous stirring standing, and cleaning the obtained material with deionized water to remove impurities in order to synthesize biomass-based hydrogel; exchanging the hydrogel with an anhydrous ethanol solvent; and freeze-drying the exchanged biomass-based hydrogel by using a vacuum freeze drying machine to obtain the biomass-based nano-silica aerogel. The obtained nano-silica aerogel has the advantages of high specific surface area, reasonable pore structure, low apparent density and excellent thermal performance, can be used in the fields of buildings, medicines and chemical engineering catalysis materials, and realizes waste recycling.

Owner:林扬东方(北京)科技有限公司

Continuous casting nozzle inner wall coating

The invention belongs to the technical field of continuous-casting functional refractory materials, and provides a continuous casting nozzle inner wall coating. The continuous casting nozzle inner wall coating is prepared from, by mass, 20%-40% of Bonite of which the particle size is larger than 0 mm and smaller than or equal to 1 mm, 40%-60% of a light porous material of which the particle size is larger than 0 mm and smaller than or equal to 1 mm, 5%-20% of alpha-Al2O3 of which the particle size is 325 meshes, 5%-20% of silica of which the particle size is 80 meshes, 5%-15% of a binding agent, 1%-5% of a thickening agent of which the particle size is 325 meshes and water, wherein the adding amount of the water accounts for 50%-100% of the total weight of the raw materials. A lining prepared from the coating has the lower size density and the reasonable pore structure, therefore, the heat conductivity of the lining is lower, the heat-insulating property is more excellent, the problem of matrix damage caused by mismatch of the thermal and mechanical properties does not exist, and the better social benefit and economic benefit are achieved.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

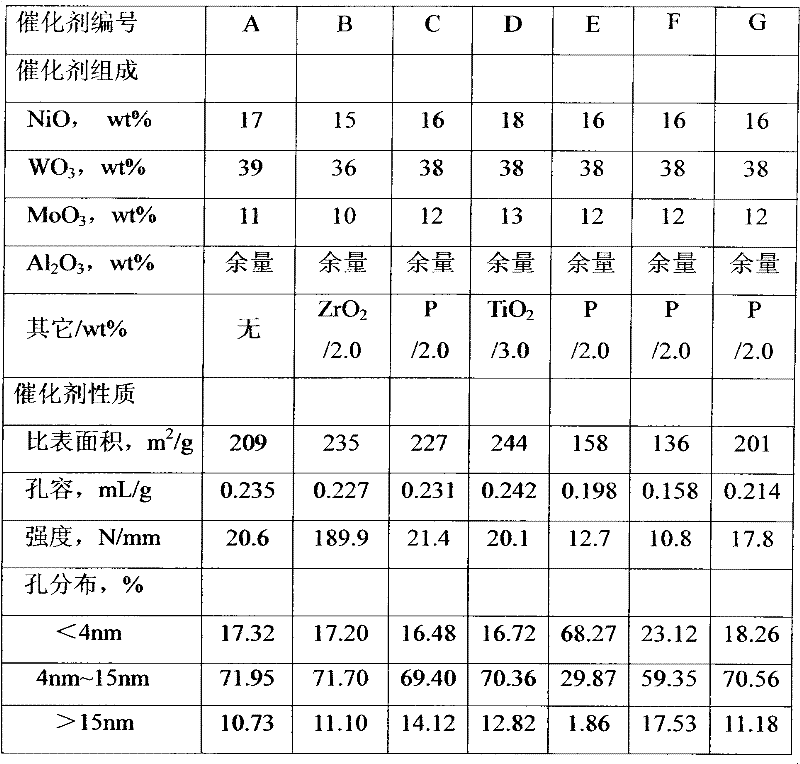

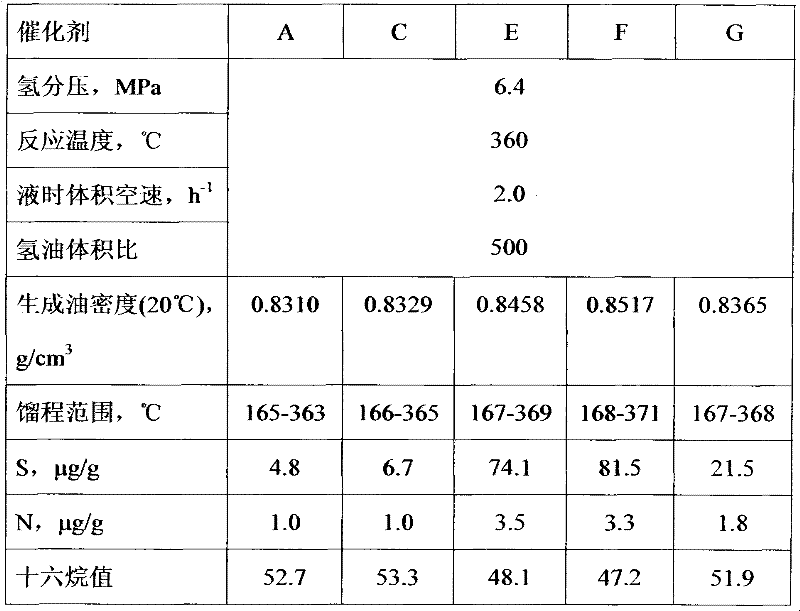

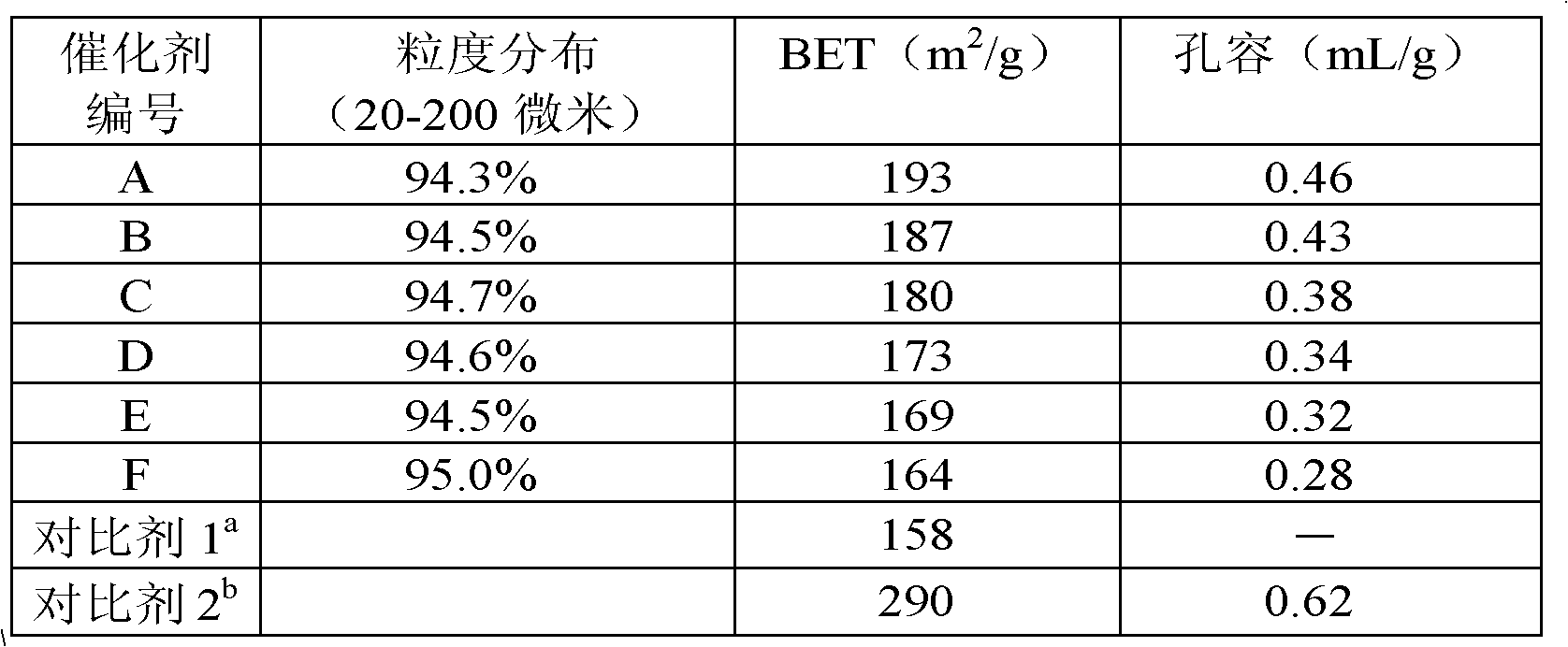

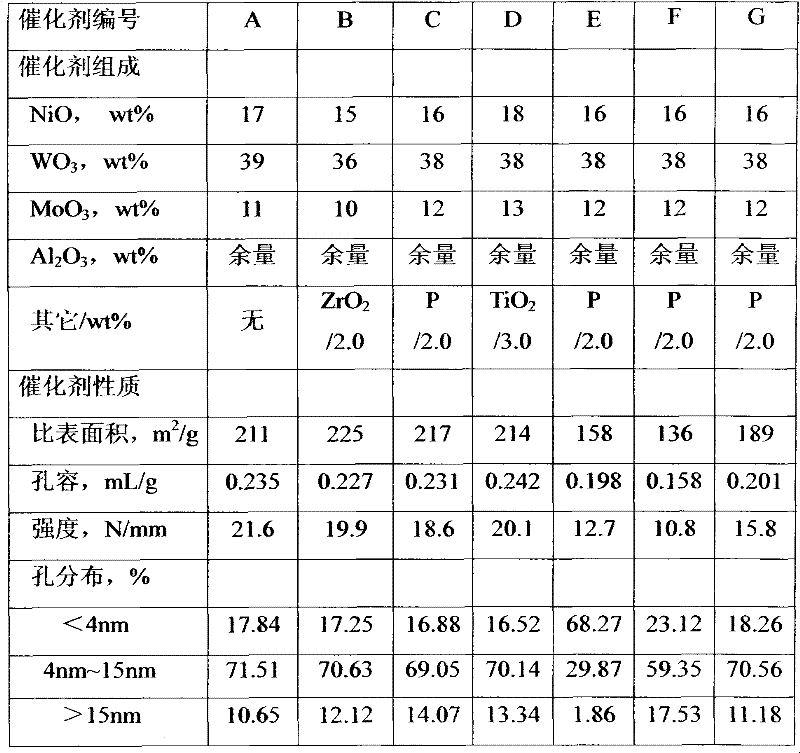

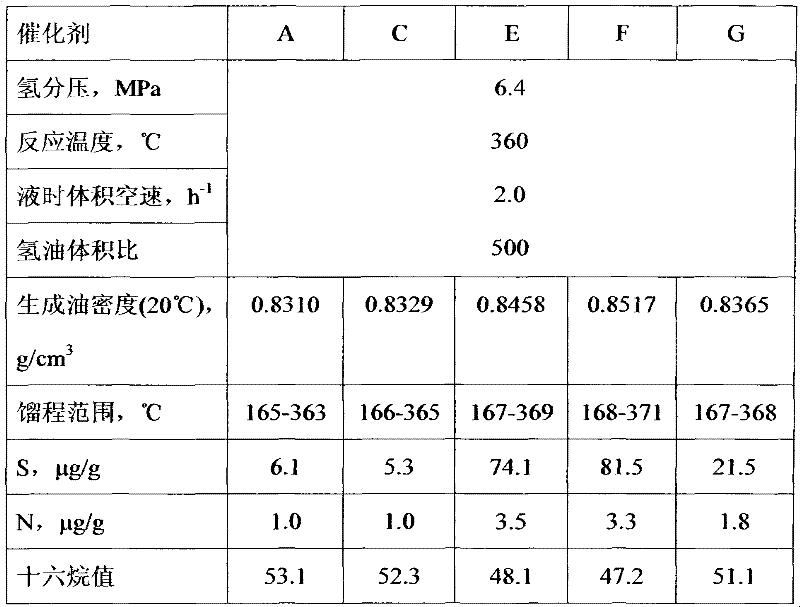

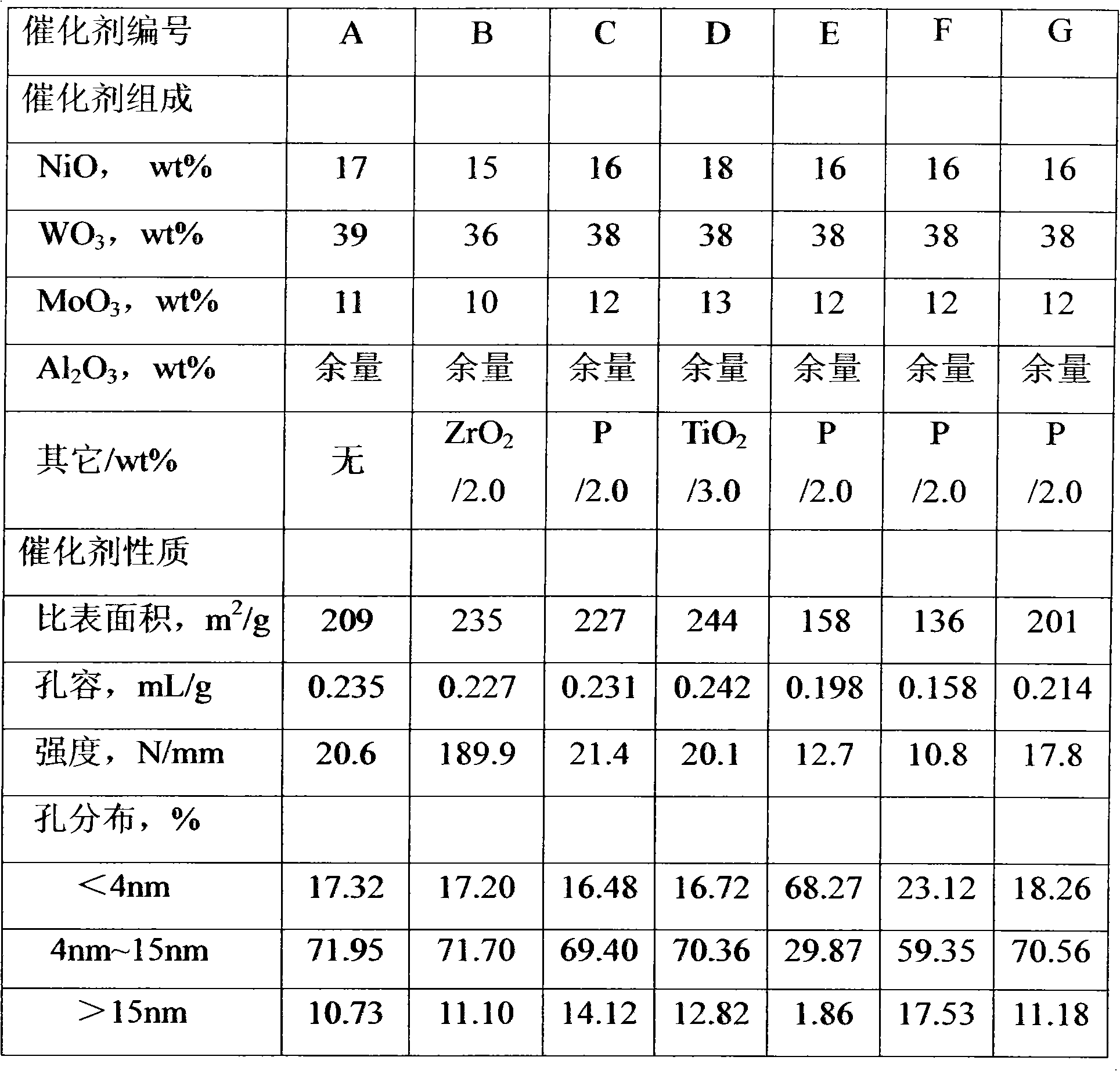

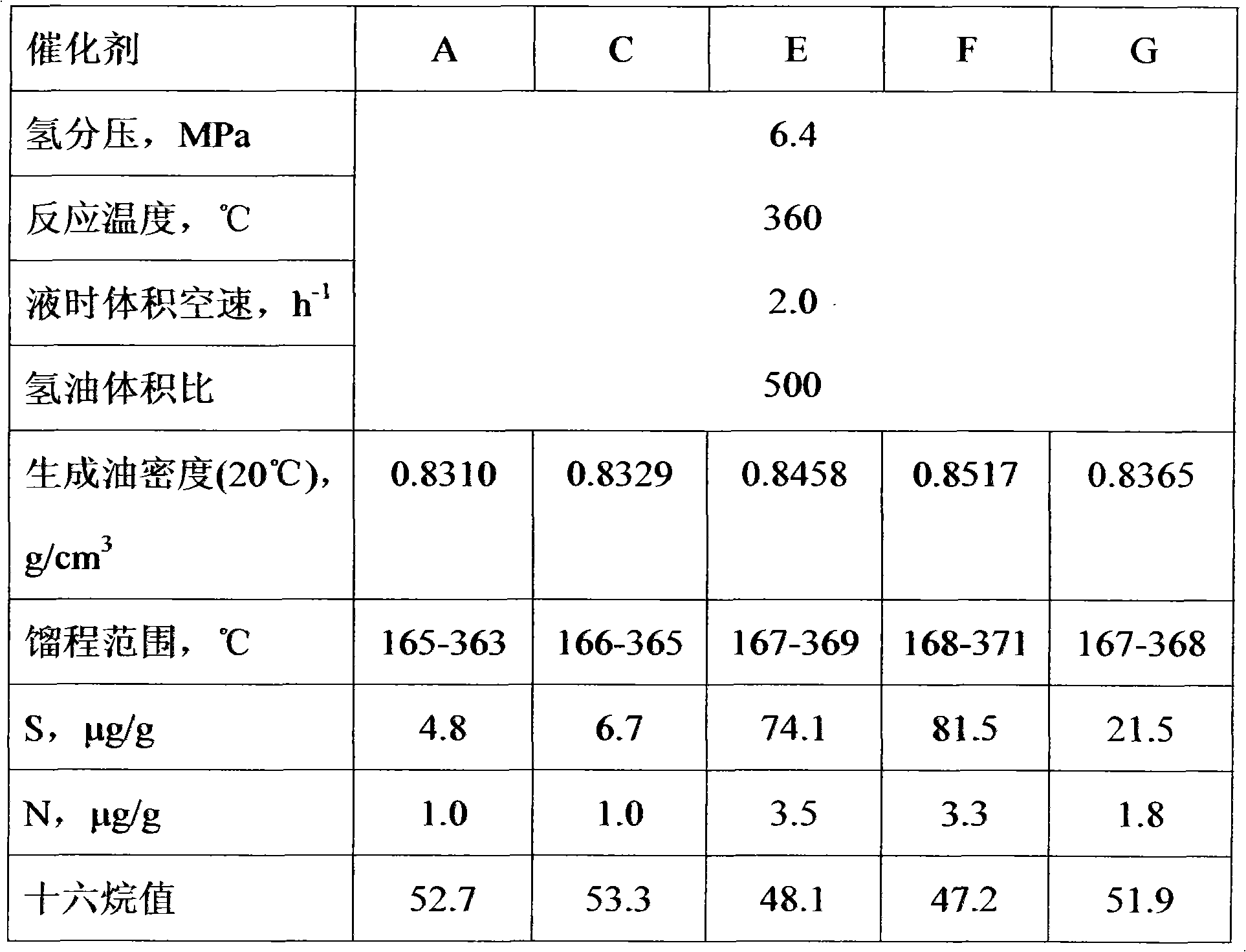

Hydrotreating catalyst and preparation method thereof

ActiveCN106179390AIncrease profitReasonable hole structureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemistryOxide

The invention discloses a hydrotreating catalyst and a preparation method thereof. The catalyst is a bulk-phase catalyst; components of the hydrotreating catalyst comprise hydrogenation active metal ingredients W, Ni and Mo, and aluminum oxide, wherein the W and the Ni exist in the form of a compound oxide: NixWyOz; the Mo exists in the form of MoO3. The active-site density of the active metal W and Ni in the epiphase of the catalyst is high; the utilization rate of hydrogenation active metal is high; meanwhile, the pore structures of the catalyst are reasonable; the active metal is more uniformly dispersed; the mechanical strength is high; the hydrotreating catalyst is particularly suitably applied to the ultra-deep hydrodesulfurization and denitrification reactions of a diesel fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrogenation catalyst composition

ActiveCN102451706AImprove adhesionEasy to shapeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAluminateOrganic solvent

The invention discloses a method for preparing a hydrogenation catalyst composition. The method comprises the following steps: preparing a mixture of a NixWyOz composite oxide precursor and an Al2O3 precursor by a coprecipitation method, using sodium meta-aluminate as an aluminum source, introducing a proper amount of CO2 gas during gelling process, beating and mixing with molybdenum oxide and anorganic solvent after gelling, molding and drying to obtain the catalyst. The method of the invention is capable of solving the problem of difficult shaping of a bulk phase catalyst and adjusting thephysicochemical property of the catalyst, possesses the advantages of large specific surface area, uniform aperture distribution, high effective utilization rate. The catalyst is especially suitable for producing super clean diesel oil in a super deep desulphurization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrofining catalyst composition

ActiveCN106179377AEvenly dispersedImprove coordinationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsDistillationPrecipitation

The invention discloses a preparation method of a hydrofining catalyst composition. The catalyst composition is a bulk phase hydrofining catalyst composition, and comprises hydrogenation active metal components W, Ni and MO, and alumina. The preparation method of the catalyst composition comprises the following steps: preparing a nickel and aluminum mixed precipitate through an ammonia distillation and precipitation technology in the presence of an organic compound, preparing a tungsten, molybdenum and aluminum mixed precipitate through a parallel flow precipitation technology, mixing the nickel and aluminum mixed precipitate with the tungsten, molybdenum and aluminum mixed precipitate, ageing the obtained mixture, carrying out hydrothermal treatment and adding urea, and molding the finally obtained mixture to prepare the catalyst composition. The catalyst composition prepared through the method is especially suitable for being applied to ultra deep hydrodesulfurization and nitrogen removal reactions of diesel oil fractions, and has high hydrodesulfurization and hydrodenitrogenation reaction performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of copper-silicon catalyst

InactiveCN108722420AReasonable hole structureLower acid centerCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsCyclohexanoneCyclohexene

The invention belongs to the technical field of catalyst production and provides a preparation method and application of a copper-silicon catalyst. The catalyst has the characteristics of high conversion rate of cyclohexanol and high selectivity of cyclohexanone. The catalyst provided by the invention mainly comprises Cu2O / SiO2; in addition, an active additive is added to improve an acid site on the surface of the catalyst, so that side reaction such as cyclohexane is effectively inhibited.

Owner:CHINA PETROLEUM & CHEM CORP +1

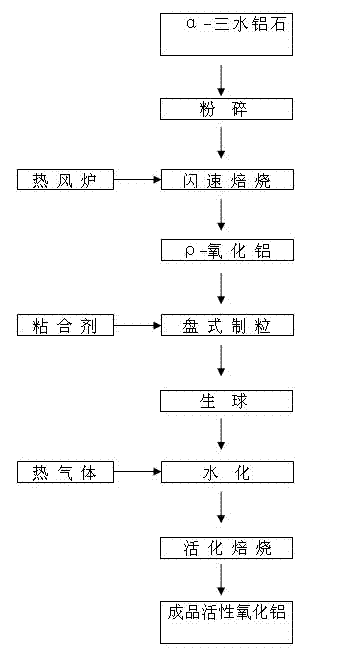

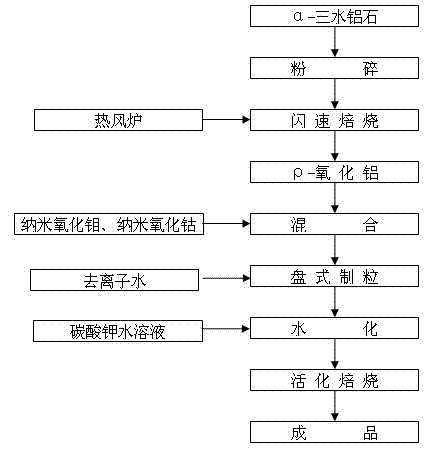

Preparation method capable of improving low-temperature activity of low-pressure cobalt-molybdenum sulfur-tolerant shift catalyst

ActiveCN103611544ALow costOmit the dipping processMetal/metal-oxides/metal-hydroxide catalystsChemical industryPtru catalyst

The invention relates to a preparation method capable of improving the low-temperature activity of a low-pressure cobalt-molybdenum sulfur-tolerant shift catalyst. The sulfur-tolerant shift catalyst which contains nano-molybdenum oxide and nano-cobalt oxide is produced directly by utilizing a conventional process capable of producing a spherical activated alumina carrier by adopting a quick release method. An impregnation process is omitted; the preparation is simple; the cost is low; catalytic active components are uniform; a porous structure is reasonable; the specific surface area is increased remarkably; the low-temperature activity is high; through the detection at 160 DEG C according to a national chemical industry standard HG / T2779-2009, the CO conversion rate is greater than or equal to 90 percent, the activation temperature is 40 DEG C lower than that of an SB303Q-type cobalt-molybdenum sulfur-tolerant shift catalyst; the low-pressure cobalt-molybdenum sulfur-tolerant shift catalyst is particularly suitable for a depth conversion workshop section of an ammonia synthesis plant, namely the conversion process in which the CO at an outlet of a conversion system is less than equal to 0.3 percent; steam is saved by 300kg per ton of ammonia; the energy-saving effect is remarkable.

Owner:湖北双雄催化剂有限公司

Preparation method of hydrotreating catalyst composition

ActiveCN103055887BImprove adhesionUniform grain sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionSlurry

The invention discloses a preparation method of a hydrotreating catalyst composition. The method comprises the steps of subjecting a salt mixed solution A in which CO2 is dissolved to react with an alkaline solution B containing aluminium to prepare gel, when reaction is completed, controlling the pH value of pulp in a reaction tank to be 7.0-9.0, preparing a mixture of an NixWyOz composite oxide precursor and an Al2O3 precursor, pulping the mixture and MoO3 to prepare a dry body, and then forming, drying and roasting the dry body to obtain a final catalyst, wherein the salt mixed solution A contains components Ni and W. The method has the beneficial effects that the problem that bulk phase catalysts are difficult to form is solved; the physical and chemical properties of the catalyst are adjusted, and the catalyst has the advantages of larger specific surface area, uniform pore distribution and high effective utilization rate of reactive metals; and the catalyst is especially suitable for the ultra-deep desulfurization reaction for producing ultra-clean diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

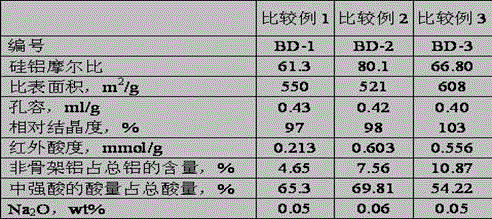

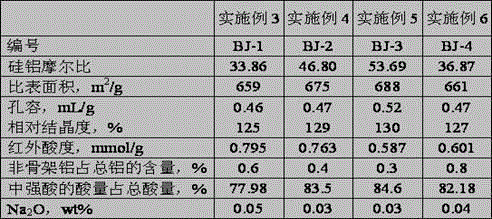

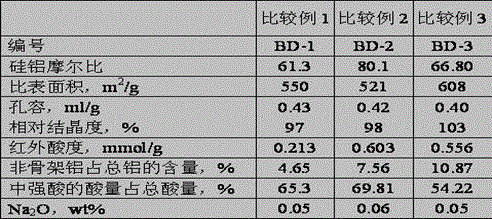

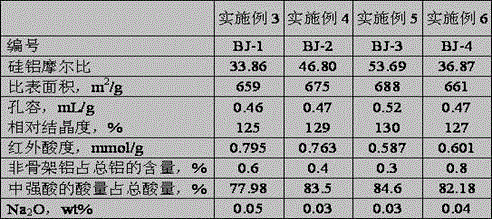

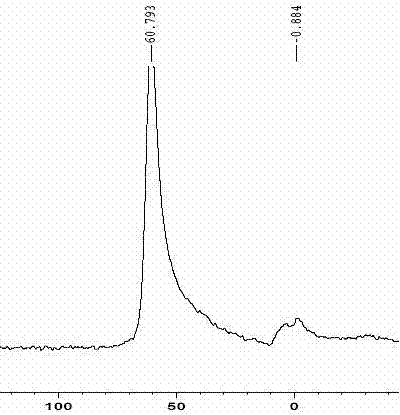

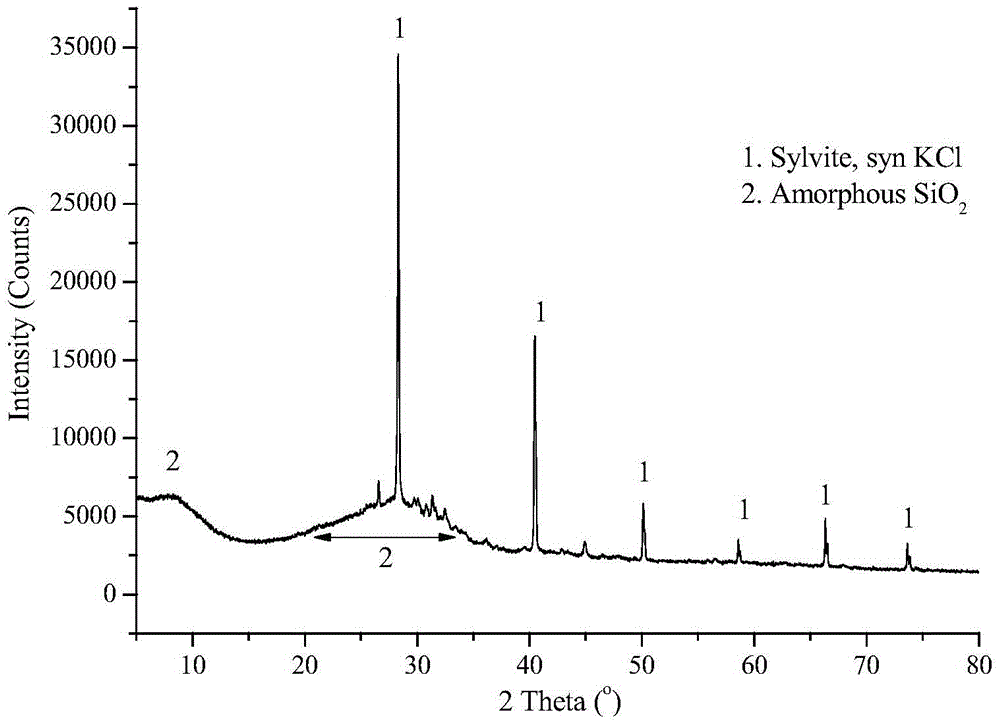

A hydrocracking catalyst and a preparing method thereof

ActiveCN104667958ALarge specific surface areaHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

A hydrocracking catalyst and a preparing method thereof are disclosed. The catalyst comprises metal components with hydrogenation activity and a carrier comprising a beta molecular sieve, amorphous silicon aluminum and aluminum oxide, wherein properties of the beta molecular sieve are as follows: the specific surface area is 400-800 m2 / g, the total pore volume is 0.4-0.55 mL / g, the SiO2 / Al2O3 mole ratio is 30-60, the relative crystallinity is 120-140%, the infrared acid content is 0.55-1.0 mmol / g, the non-framework aluminum accounts for less than 1% of the total aluminum, the amount of medium-strong acids which is measured by a NH3-TPD method accounts for 70-85% of the total acid amount, and the percent of Na2O is not more than 0.15 wt%. The preparing method includes mixing the beta molecular sieve, the amorphous silicon aluminum and the aluminum oxide, kneading and forming to prepare the carrier; and loading the metal components with hydrogenation activity by a conventional method. The beta molecular sieve which is proper in silicon aluminum ratio, large in specific surface area, proper in acidity, reasonable in pore structure and low in content of non-framework aluminum, and the amorphous silicon aluminum are adopted as cracking components of the catalyst. The prepared catalyst is characterized by producing a clean diesel oil product with a low condensation point with the highest yield, improving properties of hydrogenation tail oil, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Middle-oil type hydrocracking catalyst carrier and preparation method thereof

ActiveCN107233927AImprove pore structureUniform structureCatalyst carriersMolecular sieve catalystsMolecular sieveSmoke point

The invention discloses a high-activity middle-oil type hydrogenation catalyst carrier and a preparation method thereof. A beta molecular sieve obtained through modification has a balanced cracking performance. The catalyst carrier comprises the following components in percent by mass in terms of a catalyst dry basis: 5%-20% of the modified beta molecular sieve, 20%-50% of amorphous silica-alumina, 20%-50% of macroporous alumina and 10%-25% of small-pore alumina. A catalyst prepared by using the catalyst carrier has the characteristics that the catalytic activity and middle-oil selectivity are high, the low-temperature performance of middle-distillate products is good, the smoke point of aviation kerosene is high, and the cetane number of diesel is high.

Owner:PETROCHINA CO LTD

Hydrocracking catalyst and its preparation method

ActiveCN104667958BLarge specific surface areaHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sieveStrong acids

A hydrocracking catalyst and a preparing method thereof are disclosed. The catalyst comprises metal components with hydrogenation activity and a carrier comprising a beta molecular sieve, amorphous silicon aluminum and aluminum oxide, wherein properties of the beta molecular sieve are as follows: the specific surface area is 400-800 m2 / g, the total pore volume is 0.4-0.55 mL / g, the SiO2 / Al2O3 mole ratio is 30-60, the relative crystallinity is 120-140%, the infrared acid content is 0.55-1.0 mmol / g, the non-framework aluminum accounts for less than 1% of the total aluminum, the amount of medium-strong acids which is measured by a NH3-TPD method accounts for 70-85% of the total acid amount, and the percent of Na2O is not more than 0.15 wt%. The preparing method includes mixing the beta molecular sieve, the amorphous silicon aluminum and the aluminum oxide, kneading and forming to prepare the carrier; and loading the metal components with hydrogenation activity by a conventional method. The beta molecular sieve which is proper in silicon aluminum ratio, large in specific surface area, proper in acidity, reasonable in pore structure and low in content of non-framework aluminum, and the amorphous silicon aluminum are adopted as cracking components of the catalyst. The prepared catalyst is characterized by producing a clean diesel oil product with a low condensation point with the highest yield, improving properties of hydrogenation tail oil, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Trifluorotrichloroethane hydrodechlorination catalyst and preparation method thereof

ActiveCN112547036AUniform pore size distributionReasonable hole structurePreparation by dehalogenationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention relates to a trifluorotrichloroethane hydrodechlorination catalyst and a preparation method thereof. The active component of the catalyst is Pd-Ir-Ni alloy, the carrier is activated carbon, the catalyst comprises the following components in percentage by mass: 0.05 to 2% of Pd, 0.1 to 0.5% of Ir, 0.1 to 5% of Ni and the balance of activated carbon, the average particle size of the catalyst is 5 to 10nm, the average pore size of the catalyst is 0.8 to 2.2 nm, and the BET specific surface area of the catalyst is 800 to 1500m<2> / g. The catalyst is suitable for the hydrodechlorination reaction of trichlorotrifluoroethane, the noble metal content of the catalyst is low, the catalytic activity of the Pd-Ir-Ni solid solution alloy is high, and the catalyst is tightly combined with the carrier, and is high in stability and long in service life.

Owner:SINOCHEM LANTIAN +2

Lithium-sulfur battery positive electrode material prepared by polyaniline modified sodium polyacrylate

PendingCN110600721AHigh retention rateImprove performanceSecondary cellsPositive electrodesPorous carbonSlurry

The invention provides a lithium-sulfur battery positive electrode material prepared by polyaniline modified sodium polyacrylate. A certain concentration of aniline hydrochloric acid solution and ammonium persulfate hydrochloric acid solution are prepared and mixed. A certain mass of sodium polyacrylate is taken and a certain amount of mixed solution is absorbed to react for a period of time underthe condition of ice bath and frozen and dried and then carbonized in a tubular furnace at a certain temperature under N2 atmosphere and then washed and dried so as to obtain a nitrogen doped porouscarbon composite material. The porous carbon composite material is ground and mixed with sulfur in a certain proportion in a specific way to prepare a slurry which is coated, dried and cut into a suitable size so as to obtain the electrode material. The electrode material prepared by the nitrogen-sulfur doped sodium polyacrylate has good performance, simple preparation and low cost.

Owner:YANCHENG ZENGCAI SCI & TECH

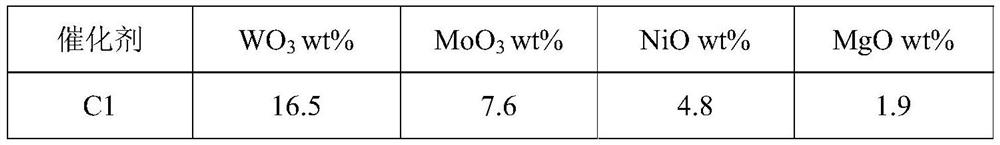

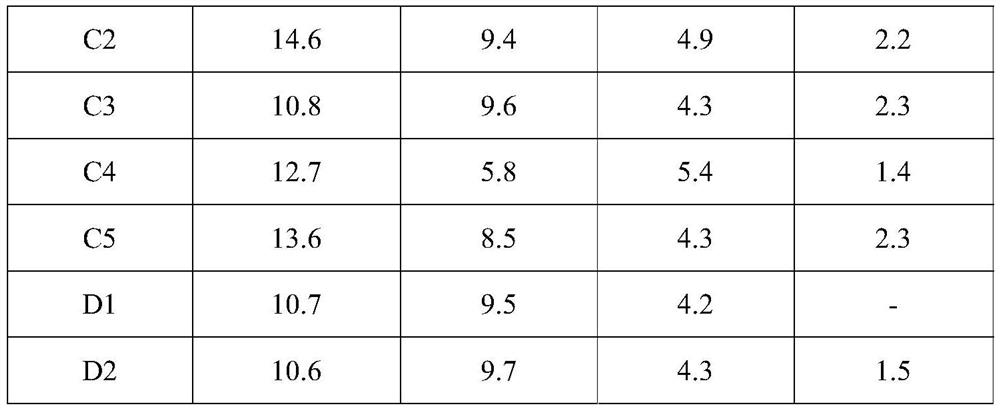

Hydrotreating catalyst, preparation method and application thereof

PendingCN111957318AImprove performanceHigh low temperature activityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOxide matrix

The invention discloses a hydrotreating catalyst, which comprises a metal active component and a carrier for loading the metal active component, wherein the metal active component comprises WO3, NiO and MoO3, the structure of the carrier comprises MgO and a metal oxide matrix containing pore channels, MgO is uniformly dispersed in the metal oxide matrix containing pore channels, and at least mostMgO is uniformly dispersed on the surfaces of the pore channels of the metal oxide matrix containing pore channels. The hydrotreating catalyst has high desulfurization, denitrification and hydrogenation saturation properties at the same time, is suitable for various distillate hydrotreating processes, and is especially suitable for a hydrofining process aiming at desulfurization, hydrogenation denitrification and hydrogenation saturation. The invention also discloses a preparation method and application of the hydrotreating catalyst.

Owner:CNOOC OIL & PETROCHEMICALS CO LTD +3

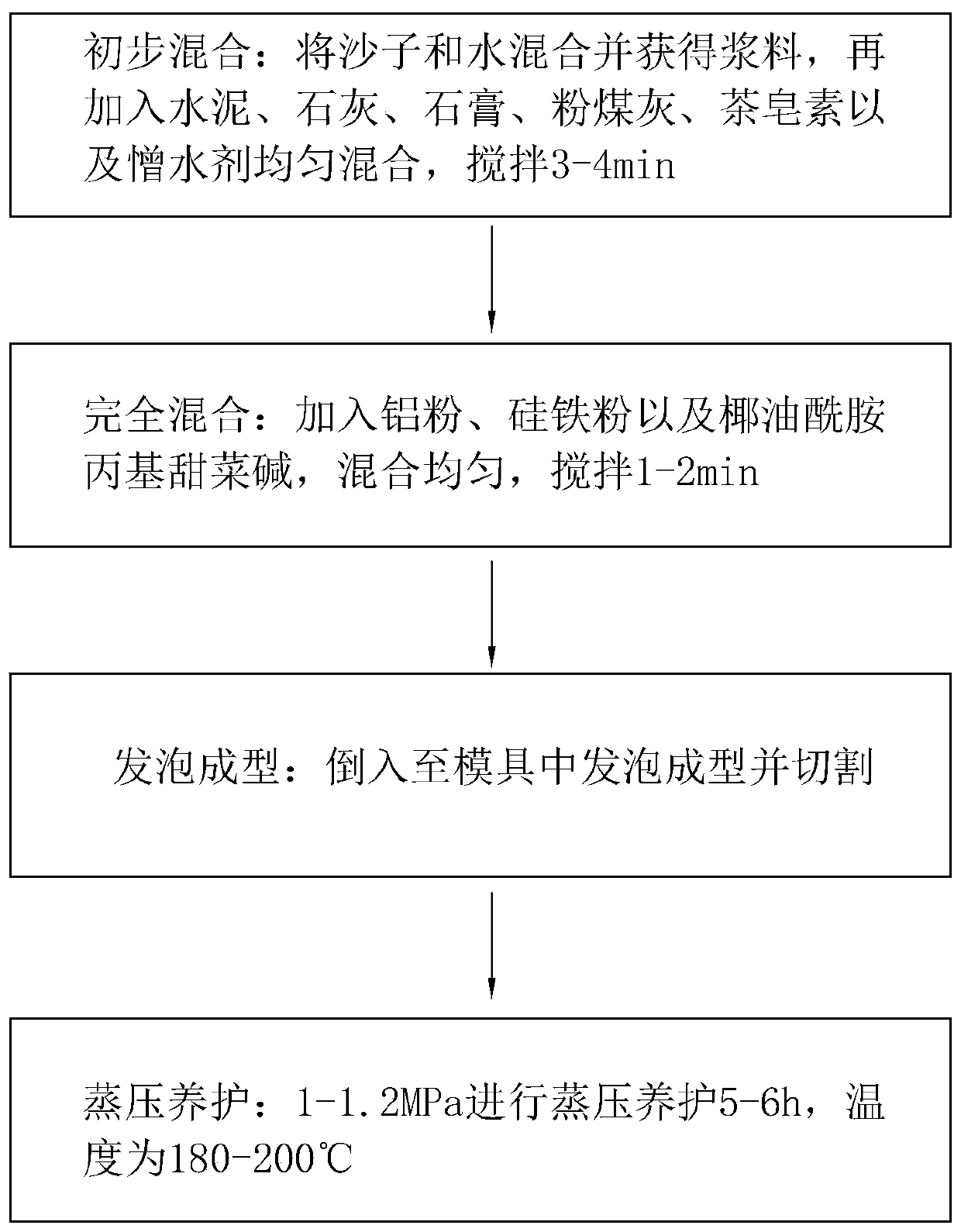

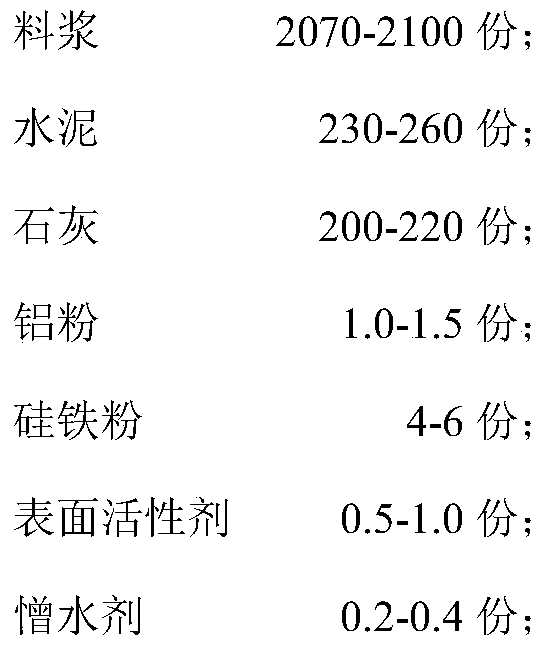

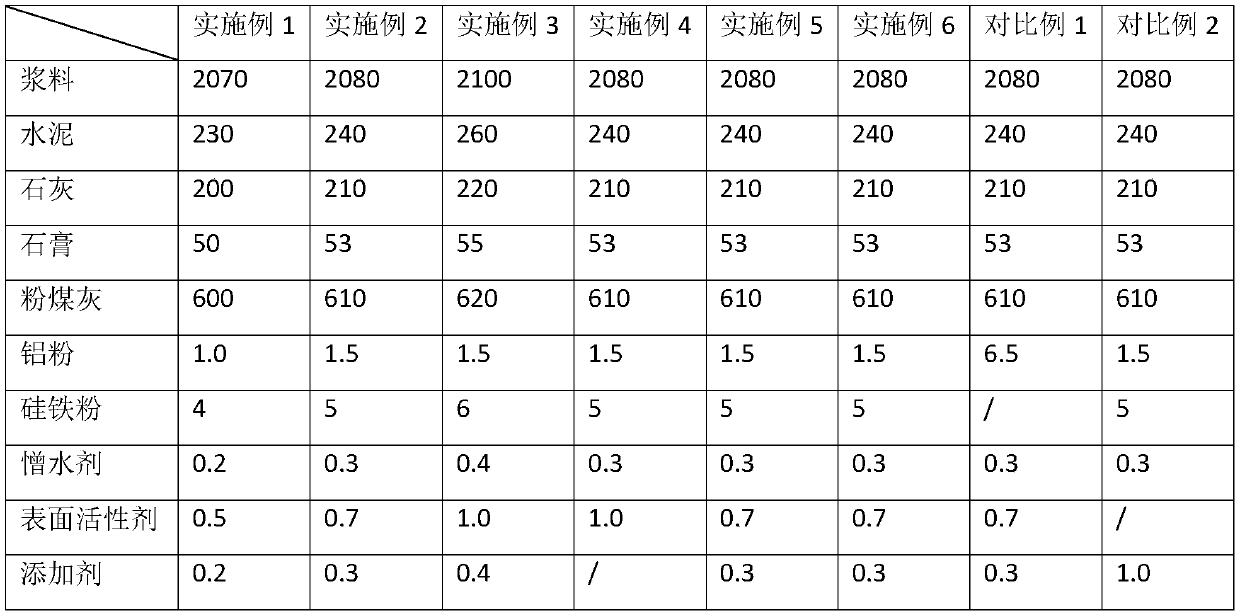

Aerated concrete block and production method thereof

InactiveCN110922146APromotes rapid hydrationFast hardeningCeramic shaping apparatusCement mixing apparatusThermal insulationFerrosilicon

The invention discloses an aerated concrete block and a production method thereof, and relates to the technical field of building materials. The aerated concrete block is produced from, by weight, 2070-2100 parts of a slurry, 230-260 parts of cement, 200-220 parts of lime, 1.0-1.5 parts of aluminum powder, 4-6 parts of ferrosilicon powder, 0.5-1.0 part of a surfactant and 0.2-0.4 part of a water repellent; the slurry is a mixture of sands and water, and the proportion of the sands in the slurry is 55-60%; and the surfactant is tea saponin. The aerated concrete block adopting the above settingand proportioning of the system has a good strength, can effectively reduce the production cost, can be used as a building exterior wall, can meet the requirement of saving 65% of energy of a buildingwithout depending on other thermal insulation materials, and can reduce the construction procedures and reduce the load of the building due to the low volume weight.

Owner:温州明远新型建材有限公司

Preparation method of hydrogenation catalyst composition

ActiveCN103055886BImprove adhesionEasy to shapeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionSlurry

The invention discloses a preparation method of a hydrogenation catalyst composition. The method comprises the steps of filling clear water into a reaction tank and filling CO2 into the clear water; and adding a salt mixed solution A containing components Ni and W and an alkaline solution B containing aluminium to the reaction tank in parallel to prepare gel, controlling the pH value of pulp in the reaction tank to be 7.0-9.0, preparing a mixture of an NixWyOz composite oxide precursor and an Al2O3 precursor, then beating the mixture and MoO3 to prepare a dry body, and then forming, drying and roasting the dry body to obtain a final catalyst. The method has the beneficial effects that the problem that bulk phase catalysts are difficult to form is solved; the physical and chemical properties of the catalyst are adjusted, and the catalyst has the advantages of larger specific surface area, uniform pore distribution and high effective utilization rate of reactive metals; and the catalyst is especially suitable for the ultra-deep desulfurization reaction for producing ultra-clean diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrotreatment catalyst composition

ActiveCN102451705BImprove adhesionEasy to shapeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminateOrganic solvent

The invention discloses a preparation method of a hydrotreatment catalyst composition. According to the method, during preparation of a mixture of NixWyOz composite oxide precursor and Al2O3 precursor, sodium meta aluminate is employed as an aluminium source, and sodium meta aluminate and CO2 gas are added with swing addition during a gelatinizing process; after gelatinization, the mixture, molybdena and organic solvent are beaten, mixed, moulded and dried to obtain the catalyst. Particles prepared by the method are large and uniform to improve physical and chemical properties of the catalyst; the catalyst has characteristics of large pore volume, large specific surface area, reasonable aperture distribution and high effective utilization rate of active metal, etc.; and the method solves a problem of difficulty in forming of bulk phase catalyst. The catalyst prepared by the method of the invention is especially suitable for super-deep desulphurization reaction in production of super-cleaning diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

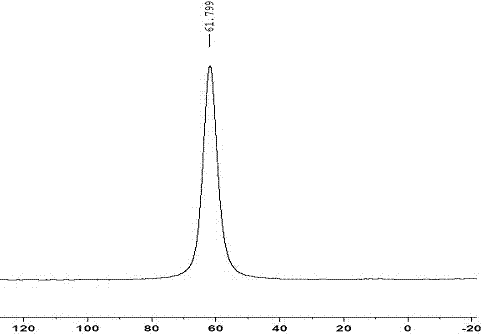

A kind of beta molecular sieve and preparation method thereof

ActiveCN104671251BUniform structureSuitable for acidityCatalyst carriersMolecular sieve catalystsMolecular sieveWater vapor

The invention discloses a beta molecular sieve, a preparation method thereof and a hydrogenation catalyst containing the beta molecular sieve. The properties of the β molecular sieve are as follows: SiO 2 / Al 2 o 3 The molar ratio is 30~150, the non-framework aluminum accounts for less than 2% of the total aluminum, and the silicon atoms coordinated by the Si(0Al) structure account for more than 95% of the silicon atoms in the skeleton structure. The preparation method comprises: contacting the original powder of beta molecular sieve with normal pressure and dynamic steam, and then contacting with ammonium fluorosilicate. The β molecular sieve of the present invention is suitable as an acidic component of a diesel oil hydrogenation upgrading catalyst and a hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for preparing silica airgel by drying at low temperature and normal pressure with straw as raw material

The invention relates to a method for preparing silica aerogel from straws as raw materials by virtue of low-temperature atmospheric-pressure drying. The method comprises the following steps: firstly carrying out low-temperature ashing treatment on agricultural waste straws as the raw materials, cleaning with a low-concentration hydrochloric acid solution, leaching a hydrosol by controlling the content of an alkali to prepare the hydrosol through ion-exchange treatment, directly carrying out one-step silanization treatment on the obtained hydrosol with an alkane solvent having low surface tension and high saturated vapor pressure and finally carrying out atmospheric-pressure drying to obtain the silica aerogel. The obtained silica aerogel material has excellent performance and can be used as materials in building, medicine, water treatment, industrial heat insulation, chemical engineering catalysis. The method, compared with other preparation methods of the aerogel, has the advantages of simple overall process, low cost, high specific surface area, reasonable pore structure, low apparent density, high hydrophobicity and high utilization rate of wastes and is suitable for large-scale production and applications.

Owner:CHANGZHOU UNIV

Iron nickel Fischer-Tropsch synthetic catalyst and preparation thereof

ActiveCN101279260BMild conditionsSimple preparation processHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSlurryPrecipitation

The invention discloses a Fischer-Tropsch synthesis iron-based catalyst containing nickel, wherein Fe:Ni:K:Cu:SiO2 equals to 100:0.01-40:0.1-15:0.1-15:2-50. Solution containing metals of iron, nickel and copper and soda solution are carried out coprecipitation, which is adopted by the invention, after precipitation paste and solution containing silicon are carried out size mixing, serum acquired is transferred into a spray dryer for drying and molding, and then baking is carried out to obtain the catalyst. The catalyst of the invention is suitable for low temperature Fischer-Tropsch synthesisreaction and has the advantages of good activity and selectivity, high product conversion rate, mild reaction conditions, etc.; in addition, the preparation process of the invention is simple and thecatalyst prepared has better granularity and intensity, which is suitable for a process of slurry-bed Fischer-Tropsch reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com