Preparation method capable of improving low-temperature activity of low-pressure cobalt-molybdenum sulfur-tolerant shift catalyst

A sulfur-resistant shift and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. problems, to achieve the effect of omitting the impregnation process, reasonable pore structure, and uniform active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

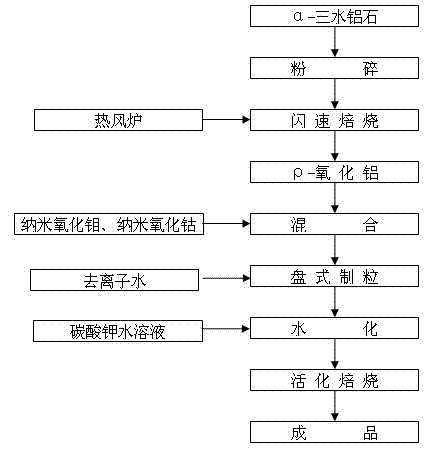

[0055] according to figure 2 After drying the raw material α-gibbsite, it is crushed to 325 mesh in the crushing process, and the fine α-gibbsite stays in the high-temperature rapid dehydration device with the hot gas at 600-900 °C in the highly turbulent hot air flow. 0.1 ~ 1 second for flash roasting to generate transitional alumina, and then pass through a cyclone to separate fine powder (ρ-alumina), nano-molybdenum oxide and nano-cobalt oxide (origin: Hubei Zhongao Nanomaterials Co., Ltd. ) Mix evenly, the mixing ratio is 93.5% ρ-alumina, 6.0% nano-molybdenum oxide, 0.5% nano-cobalt oxide (all are mass percentages), and then add deionized water as a binder, in the disk granulation molding The green balls of the required size are made in the machine, and then immersed in an aqueous solution with a concentration of 40% potassium carbonate in mass fraction for hydration. The final activation process is roasted at 450-550 °C to prepare a high-activity cobalt-molybdenum sul...

Embodiment 2

[0057] according to figure 2 After drying the raw material α-gibbsite, it is crushed to 325 mesh in the crushing process, and the fine α-gibbsite stays in the high-temperature rapid dehydration device with the hot gas at 600-900 °C in the highly turbulent hot air flow. 0.1 ~ 1 second for flash roasting to generate transitional alumina, and then pass through a cyclone to separate fine powder (ρ-alumina), nano-molybdenum oxide and nano-cobalt oxide (origin: Hubei Zhongao Nanomaterials Co., Ltd. ) Mix evenly, the mixing ratio is 93.5% ρ-alumina, 6.0% nano-molybdenum oxide, 0.5% nano-cobalt oxide (all are mass percentages), and then add deionized water as a binder, in the disk granulation molding The green balls of the required size are made in the machine, and then immersed in an aqueous solution with a concentration of 50% potassium carbonate in mass fraction for hydration, and the final activation process is roasted at 450-550 ° C to prepare a high-activity cobalt-molybdenum s...

Embodiment 3

[0059] according to figure 2 After drying the raw material α-gibbsite, it is crushed to 325 mesh in the crushing process, and the fine α-gibbsite stays in the high-temperature rapid dehydration device with the hot gas at 600-900 °C in the highly turbulent hot air flow. 0.1 ~ 1 second for flash roasting to generate transitional alumina, and then pass through a cyclone to separate fine powder (ρ-alumina), nano-molybdenum oxide and nano-cobalt oxide (origin: Hubei Zhongao Nanomaterials Co., Ltd. ) Mix evenly, the mixing ratio is 93.5% ρ-alumina, 6.0% nano-molybdenum oxide, 0.5% nano-cobalt oxide (all are mass percentages), and then add deionized water as a binder, in the disk granulation molding The green balls of the required size are made in the machine, and then immersed in an aqueous solution with a concentration of 60% potassium carbonate by mass fraction for hydration, and the final activation process is roasted at 450-550 ° C to prepare a high-activity cobalt-molybdenum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com