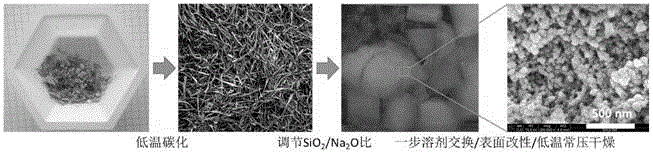

A method for preparing silica airgel by drying at low temperature and normal pressure with straw as raw material

A technology of low temperature and atmospheric pressure, silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of low efficiency of multi-step replacement, high risk of equipment, difficulty in large-scale production, etc., and achieve high waste utilization rate, The preparation method is simple and the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Straw pretreatment

[0025] Put the wheat straw into the muffle furnace, calcine at 400°C for 20 minutes in an air atmosphere, and take it out for rapid air cooling.

[0026] (2) Take 3g of powdered straw ash, stir and wash it with 100mL of 0.44mol / L dilute hydrochloric acid solution at 50°C for 60 minutes, and separate it with suction filtration equipment.

[0027] (3) Wash the washed wet filter residue directly into a beaker with 50 mL of deionized water, and prepare a 0.8 mol / L sodium hydroxide solution with 50 mL of deionized water, and put it into a boiling state to react for 3 hours. After the reaction, use suction filtration equipment to separate, and continue to wash the filter residue into the filtrate with 50 mL of deionized water.

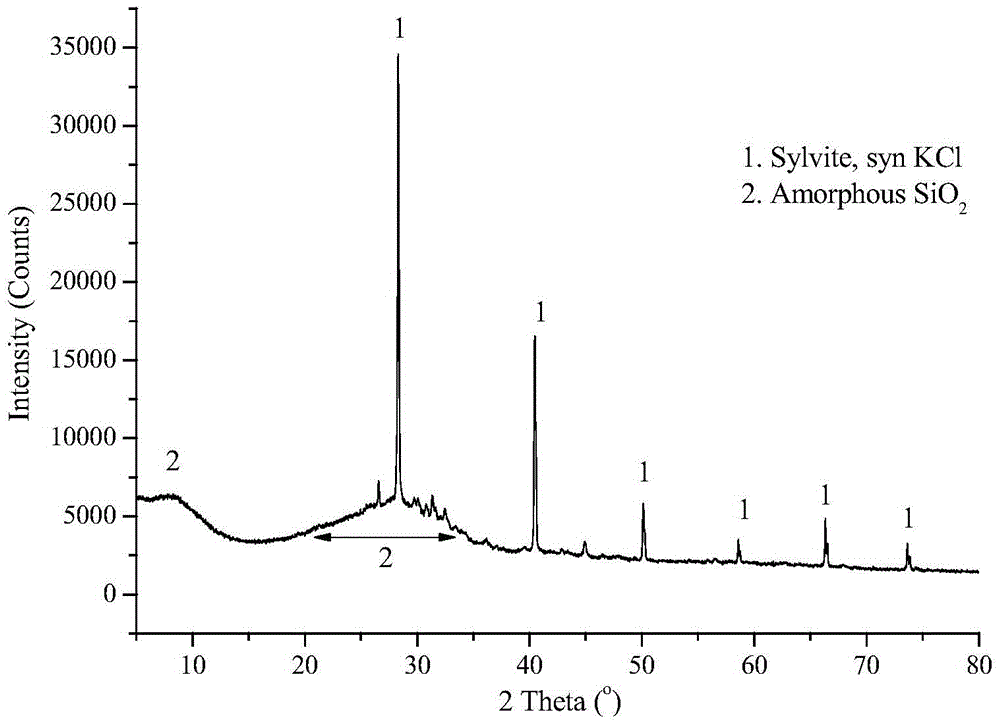

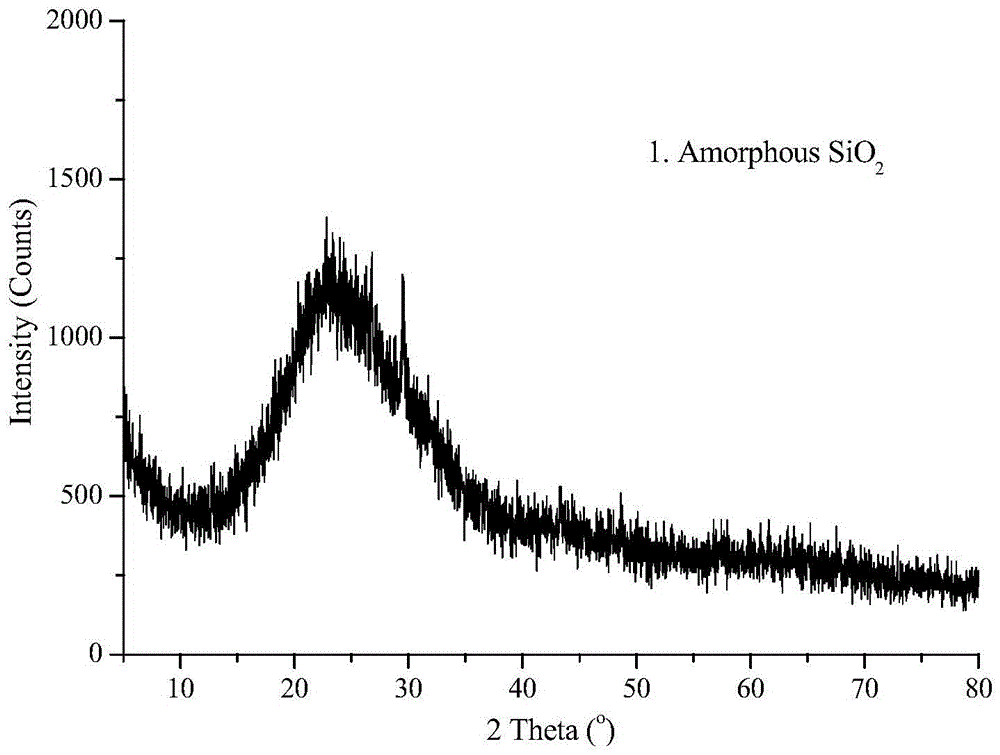

[0028] (4) The obtained filtrate was concentrated under distillation to 20 mL, and 20 mL of tetraethoxysilane was added for silicon replenishment treatment.

[0029] (5) Pass the concentrated solution through IR-120H cationi...

Embodiment 2

[0037] (1) Straw pretreatment

[0038] Put the corn stalks into the muffle furnace, calcine at 500°C for 60 minutes in an air atmosphere, and take them out for rapid air cooling.

[0039] (2) Take 3 g of powdered straw ash, stir and wash it with 100 mL of 0.25 mol / L dilute hydrochloric acid solution at 50° C. for 60 minutes, and separate it with suction filtration equipment.

[0040] (3) Wash the washed wet filter residue directly into a beaker with 50 mL of deionized water, and prepare a 0.4 mol / L sodium hydroxide solution with 50 mL of deionized water, and put it into a boiling state to react for 5 hours. After the reaction, use suction filtration equipment to separate, and continue to wash the filter residue into the filtrate with 50 mL of deionized water.

[0041] (4) Concentrate the obtained filtrate to 20 mL under distillation. Add 4ml of tetraethoxysilane for silicon replenishment treatment.

[0042] (5) Pass the concentrated solution through the IR-120H cationic res...

Embodiment 3

[0048] (1) Put the rice straw into the muffle furnace and calcinate at 200°C for 500 minutes in an air atmosphere, take it out and cool it quickly after calcining;

[0049] (2) The straw ash obtained by calcining in step (1) is stirred and cleaned with 0.01mol / L dilute hydrochloric acid solution, and then the solid-liquid separation is carried out through suction filtration equipment, wherein the solid-liquid ratio of straw ash to dilute hydrochloric acid is 100g: 2-20L ;

[0050] (3) The wet filter residue cleaned in step (2) is directly added to 0.2mol / L sodium hydroxide solution, wherein the solid-to-liquid ratio of the wet filter residue and sodium hydroxide solution is 100g: 2-20L, and the above solution is boiled Down reaction 20 minutes, after reaction, separate with suction filtration equipment;

[0051] (4) The filtrate obtained by step (3) separation is concentrated under distillation, according to SiO 2 : Na 2 0 molar ratio adds 20mL trimethoxy silicon to carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com