Preparation method of catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride

A technology of succinic anhydride and catalyst, which is applied in the field of supported nickel catalyst and its preparation, can solve the problems of high catalyst cost and high reaction pressure, and achieve the effects of simple preparation method, high hydrogenation selectivity, and good use stability

Active Publication Date: 2010-11-10

SHANXI UNIV

View PDF5 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this process provides a continuous production method for succinic anhydride, its reaction pressure is relatively high, which requires special requirements for the design and material of the reactor, and the active metal content in the catalyst is 60wt%-65wt%, so Catalyst costs are high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Login to View More

Abstract

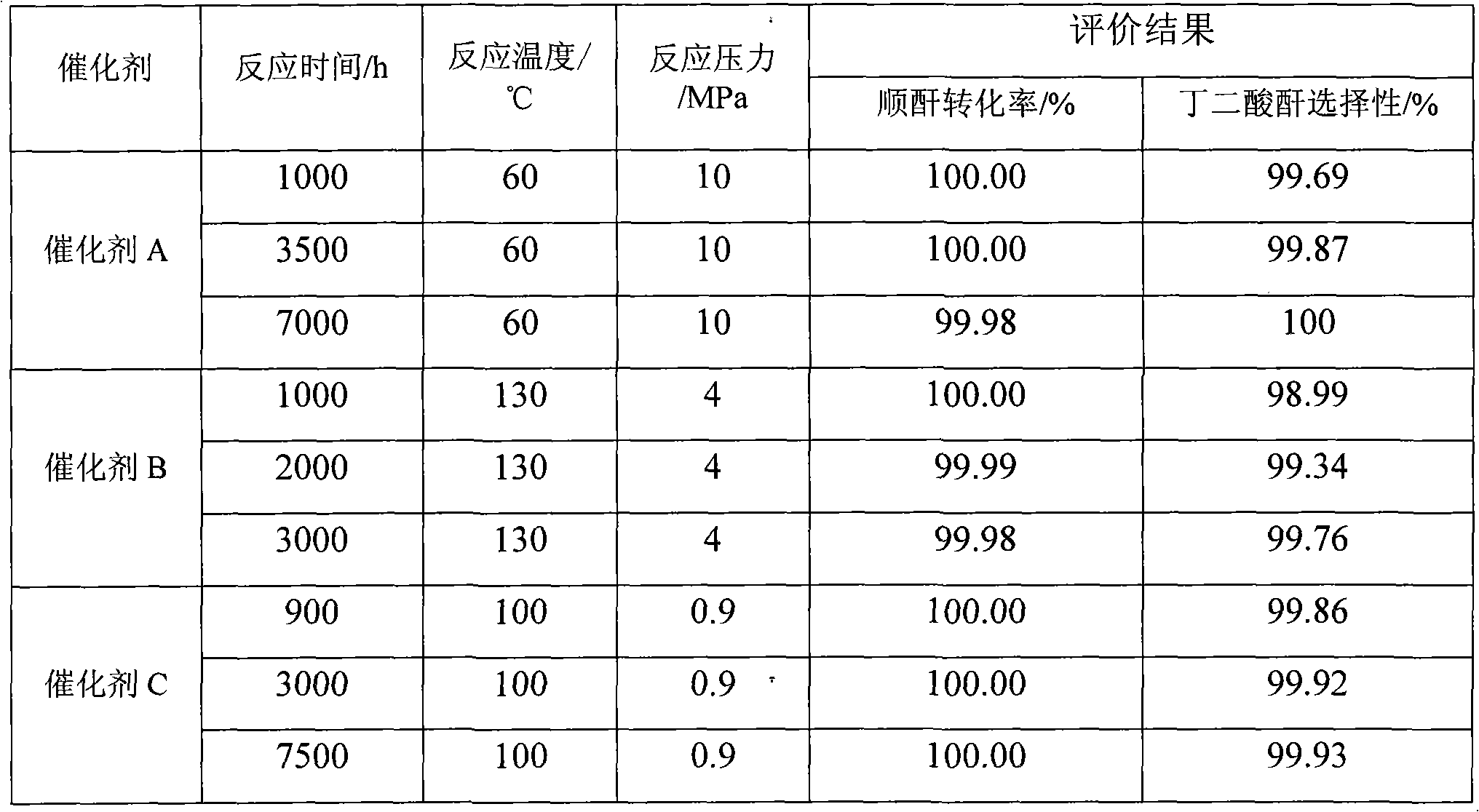

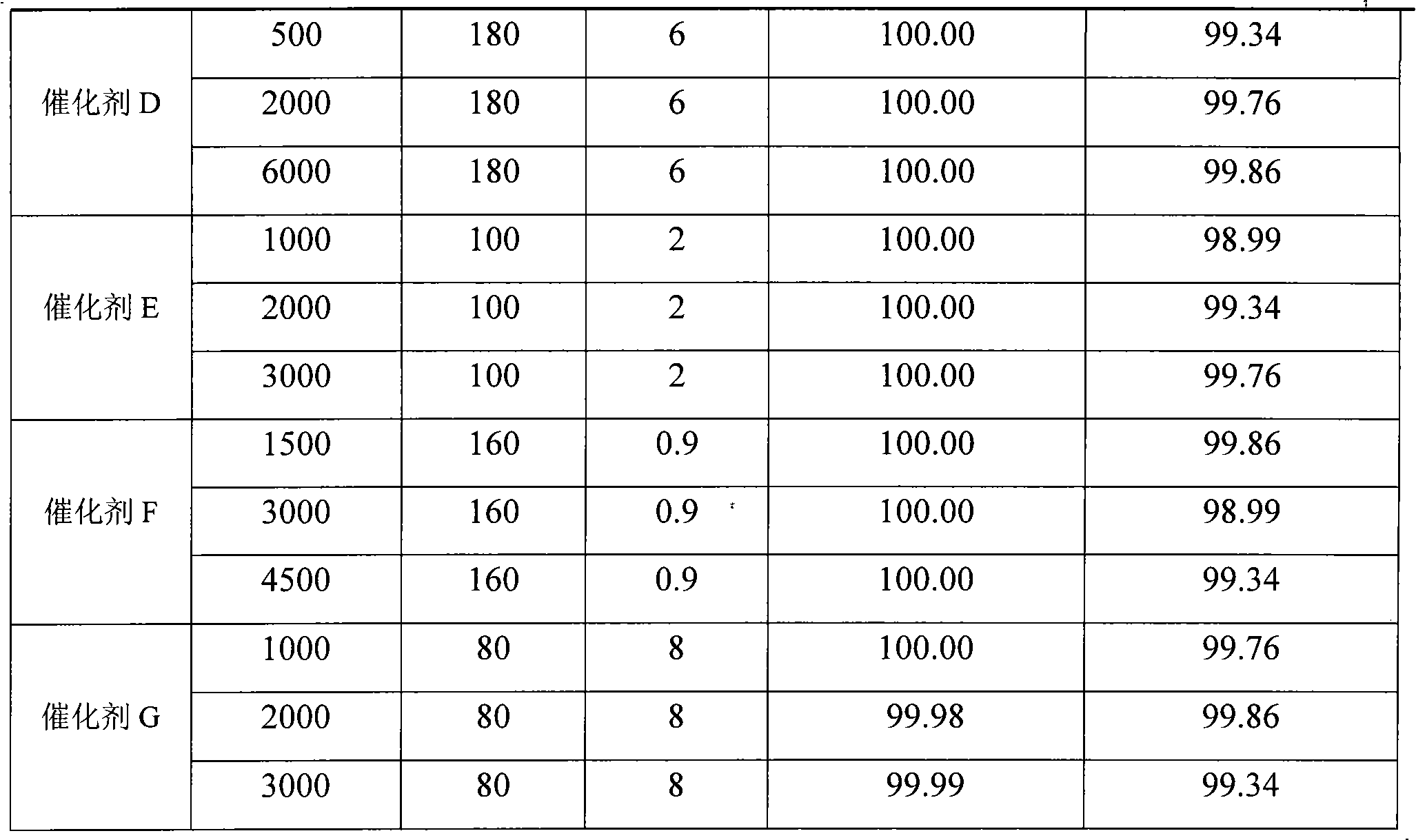

The invention provides a catalyst for continuously producing butanedioic anhydride by maleic anhydride hydrogenation. The catalyst is a nickel loaded catalyst prepared by an equivalent-volume impregnation method, wherein in the catalyst, the content of nickel is 13 to 20 weight percent, the content of accelerating agent is 1 to 7 weight percent, and a carrier is a composite oxide of SiO2 and Al2O3 or SiO2-Al2O3. A preparation method for the catalyst comprises the following steps: impregnating impregnation solution blended by ammonia water and active metal salt solution on a carrier subjected to baking pretreatment at a temperature between 400 and 800 DEG C by the equivalent-volume impregnation method to form the catalyst through drying, baking and reducing treatment. The catalyst is applied to continuously preparing the butanedioic anhydride by maleic anhydride hydrogenation on a fixed bed reactor, the conversion rate of maleic anhydride is more than or equal to 99.98 percent, and theselectivity of the butanedioic anhydride is more than or equal to 98.85 percent. The catalyst achieves the technical-scale continuous production of the butanedioic anhydride, and has the advantages of high activity, good selectivity, high yield (more than or equal to 98.83 percent) and long service life.

Description

Catalyst preparation method for continuous production of succinic anhydride by hydrogenation of maleic anhydride technical field The invention relates to a nickel-loaded catalyst, in particular to a nickel-loaded catalyst used for hydrogenation of maleic anhydride on a fixed-bed reactor to continuously produce succinic anhydride and a preparation method thereof. Background technique Succinic anhydride (Succinic acid), also known as succinic anhydride, has a molecular formula of C4H4O3. It is an important raw material for organic synthesis and is widely used in medicine, food flavorings, pesticides, fine chemicals, alkyd resins and other fields. In recent years, succinic anhydride Anhydrides Due to the application of succinic acid in the fields of fully biodegradable plastic polybutylene succinate (PBS) and organic coatings, the demand has increased greatly. The current production methods of succinic anhydride can be divided into three methods: succinic acid dehydration me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J23/755B01J23/72B01J23/83C07D307/60

Inventor 赵永祥张因张鸿喜潘丽杨燕萍

Owner SHANXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com