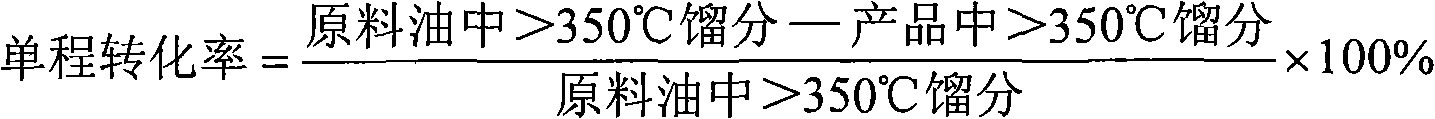

Patents

Literature

94 results about "Smoke point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The smoke point, also referred to as the burning point, is the temperature at which an oil or fat begins to produce a continuous bluish smoke that becomes clearly visible, dependent upon specific and defined conditions. Smoke point values can vary greatly, depending on factors such as the volume of oil utilized, the size of the container, the presence of air currents, the type and source of light as well as the quality of the oil and its acidity content, otherwise known as free fatty acid (FFA) content. The more FFA an oil contains, the quicker it will break down and start smoking. The higher in quality and the lower in FFA, the higher the smoke point. It is important to consider, however, that the FFA only represents typically less than 1% of the total oil and consequently renders smoke point a poor indicator of the capacity of a fat or oil to withstand heat.

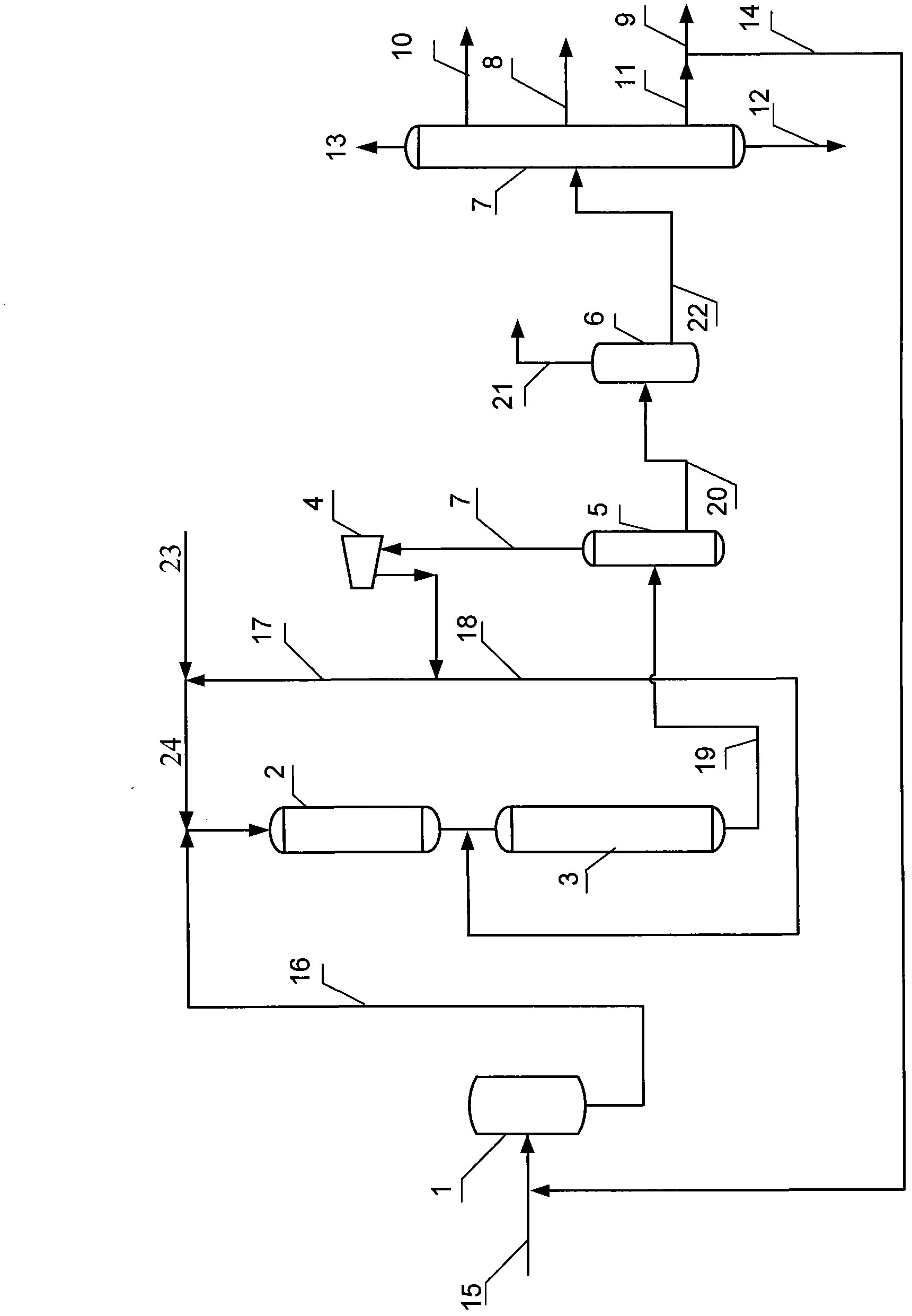

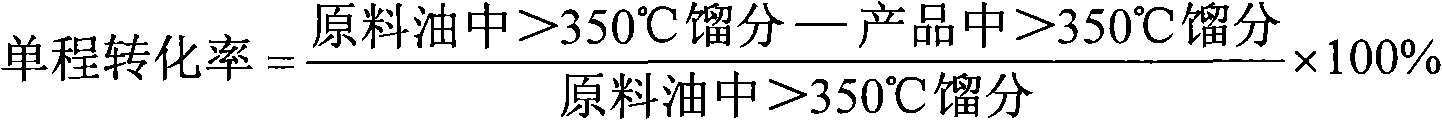

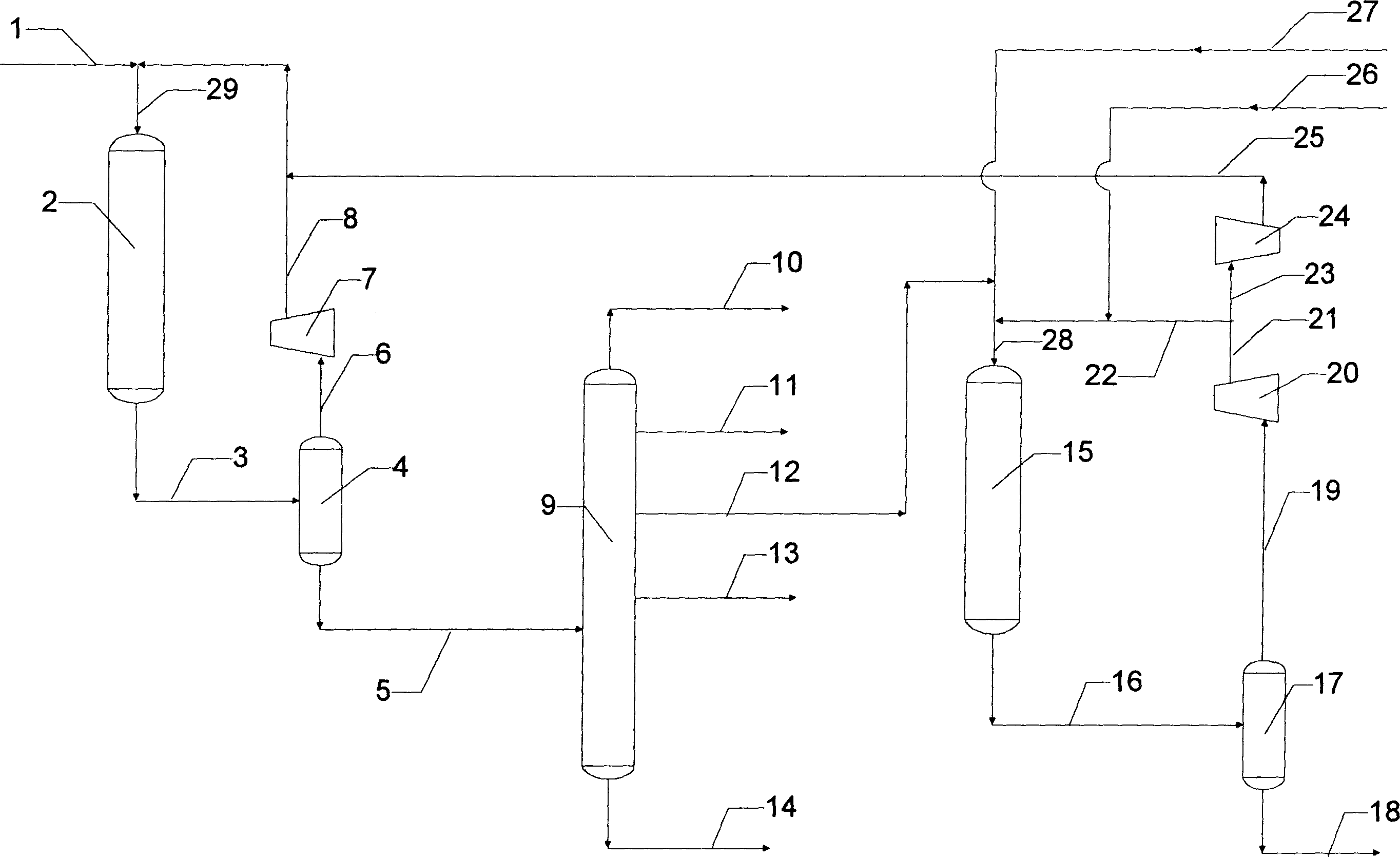

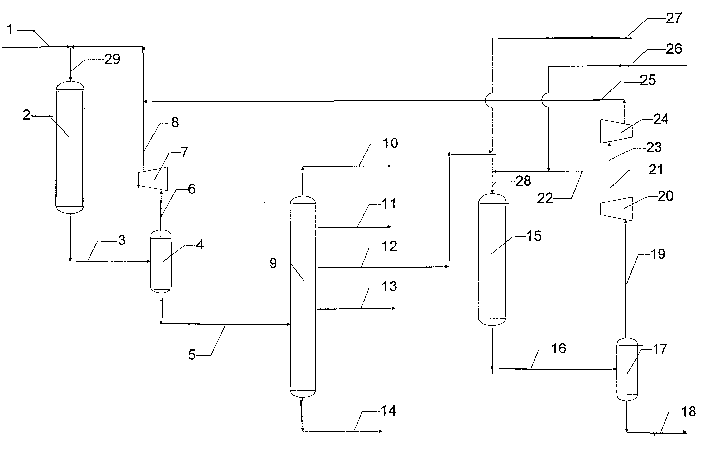

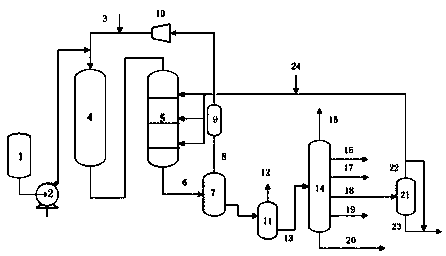

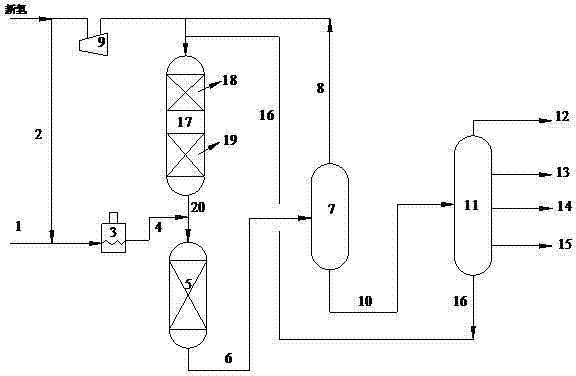

Hydrocracking method for selective increasing of aviation kerosene yield

ActiveCN103013559AGuaranteed selectivityQuality improvementTreatment with hydrotreatment processesHydrogenSmoke point

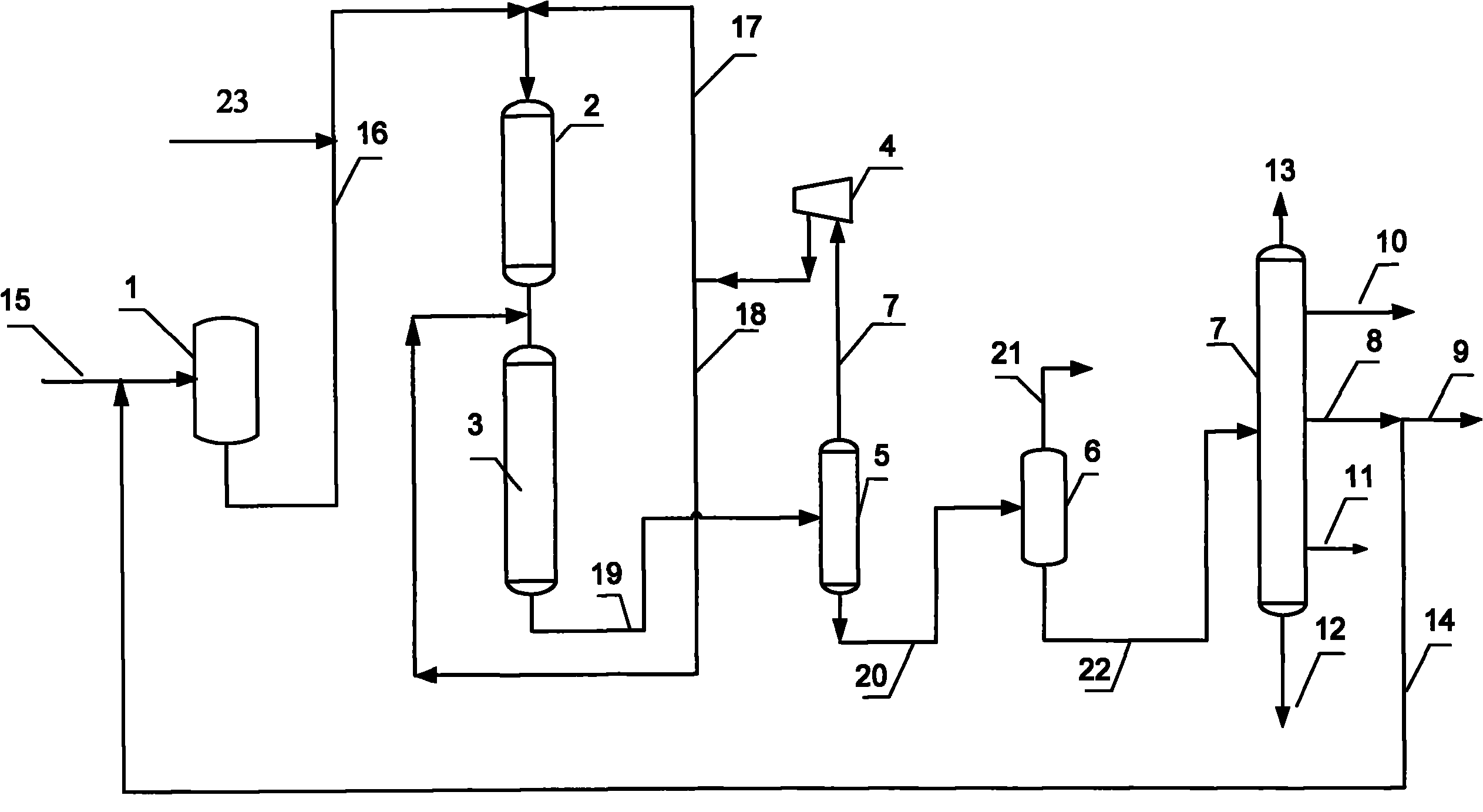

The invention discloses a hydrocracking method for selective increasing of an aviation kerosene yield. The hydrocracking method comprises that raw oil and hydrogen are mixed and then orderly undergo a hydrofinishing reaction and a hydrocracking reaction; a reaction effluent is cooled and is subjected to separation so that a heavy diesel fraction is obtained; and the heavy diesel fraction having the content of 10 to 100% and a temperature of 320 to 370 DEG C is fed back to a raw material tank and then undergoes a reaction sequentially, wherein the heavy diesel fraction has low aromatic hydrocarbon content and naphthenic hydrocarbon content and is an appropriate fraction for selective increasing of aviation kerosene yield. The hydrocracking method realizes high selectivity of an aviation kerosene fraction. The recycle heavy diesel fraction is fed into the raw material tank and undergoes a hydrofinishing reaction in a hydrofinishing reactor and a hydrocracking reaction in a hydrocracking reactor so that an aromatic hydrocarbon further undergoes a hydrogenation saturation reaction. Therefore, the hydrocracking method is conducive to improvement of a smoke point of aviation kerosene and reduction of aromatic hydrocarbon content of aviation kerosene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

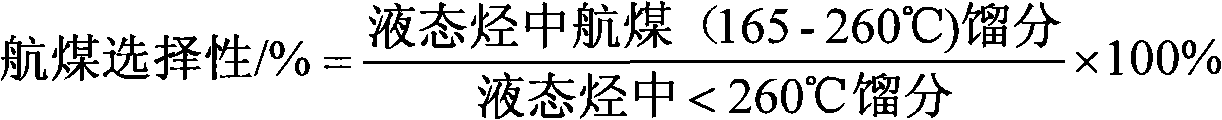

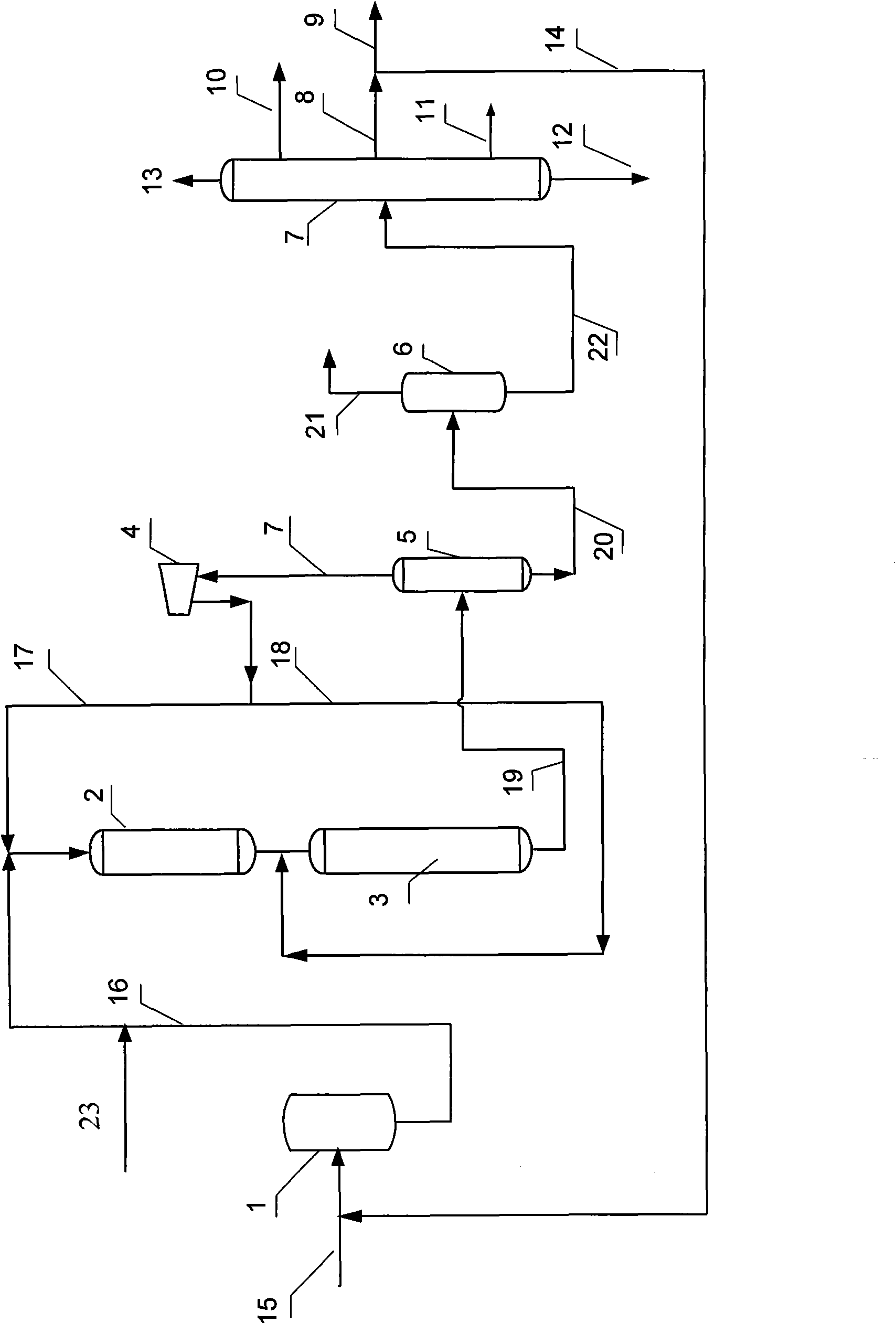

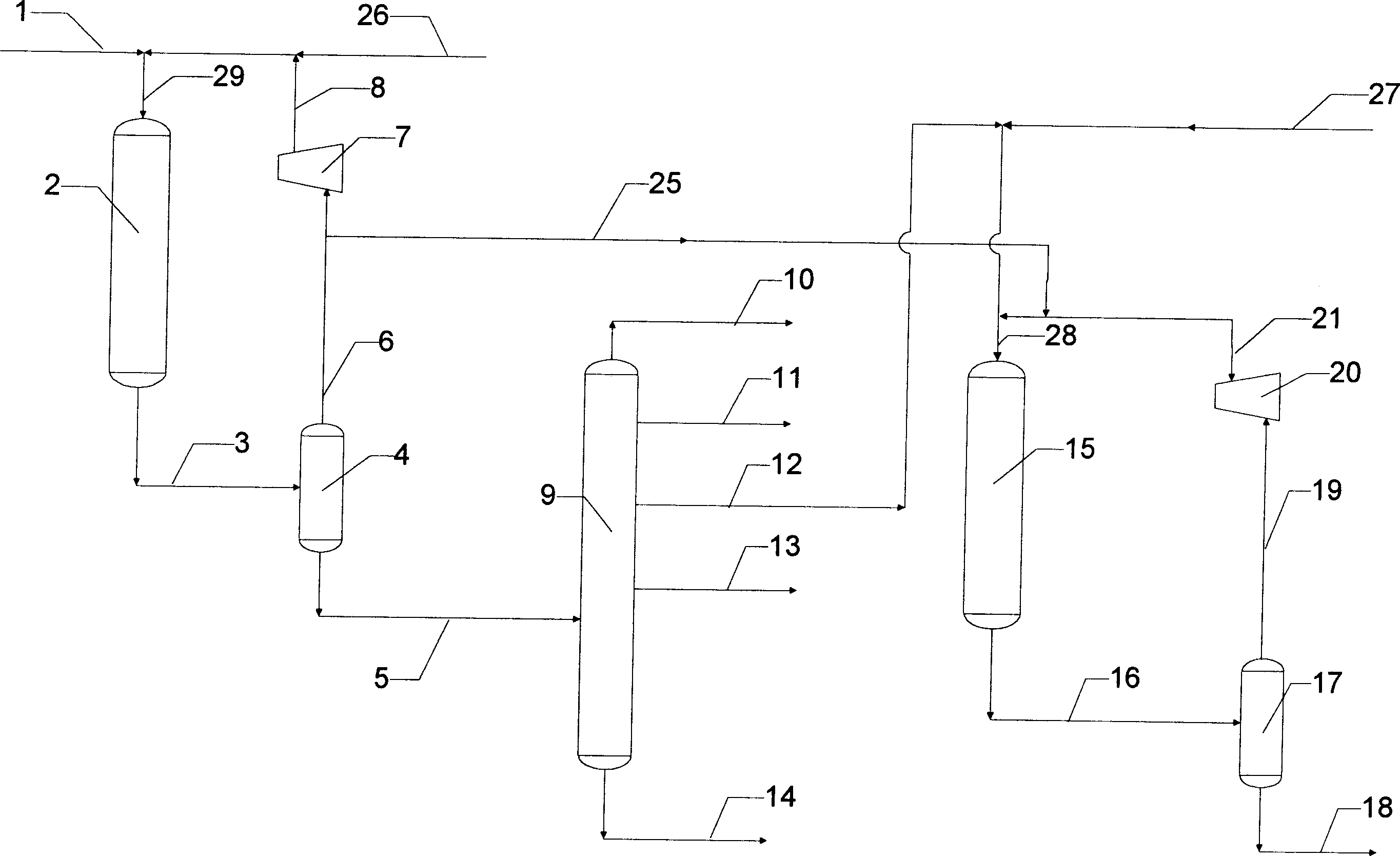

A mid-pressure hydrocracking method for producing jet fuel

ActiveCN102399586AQuality improvementHigh yieldTreatment with hydrotreatment processesKeroseneSmoke point

A mid-pressure hydrocracking method for producing jet fuel is employed under mid-pressure condition; under the control of a certain single- pass conversion, part of kerosene fractions are circulated to a feed tank, and refined, the refined kerosene fractions accounting for 30 percent of the total kerosene fractions. The method of the invention can improve the smoke point of the kerosene fractions and acquire No. 3 jet fuel satisfying GB 6537-2006 standard, and simultaneously acquire maximum high-quality tail oil. The invention has a simple process and low operation cost and equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for blending ethylene tar

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

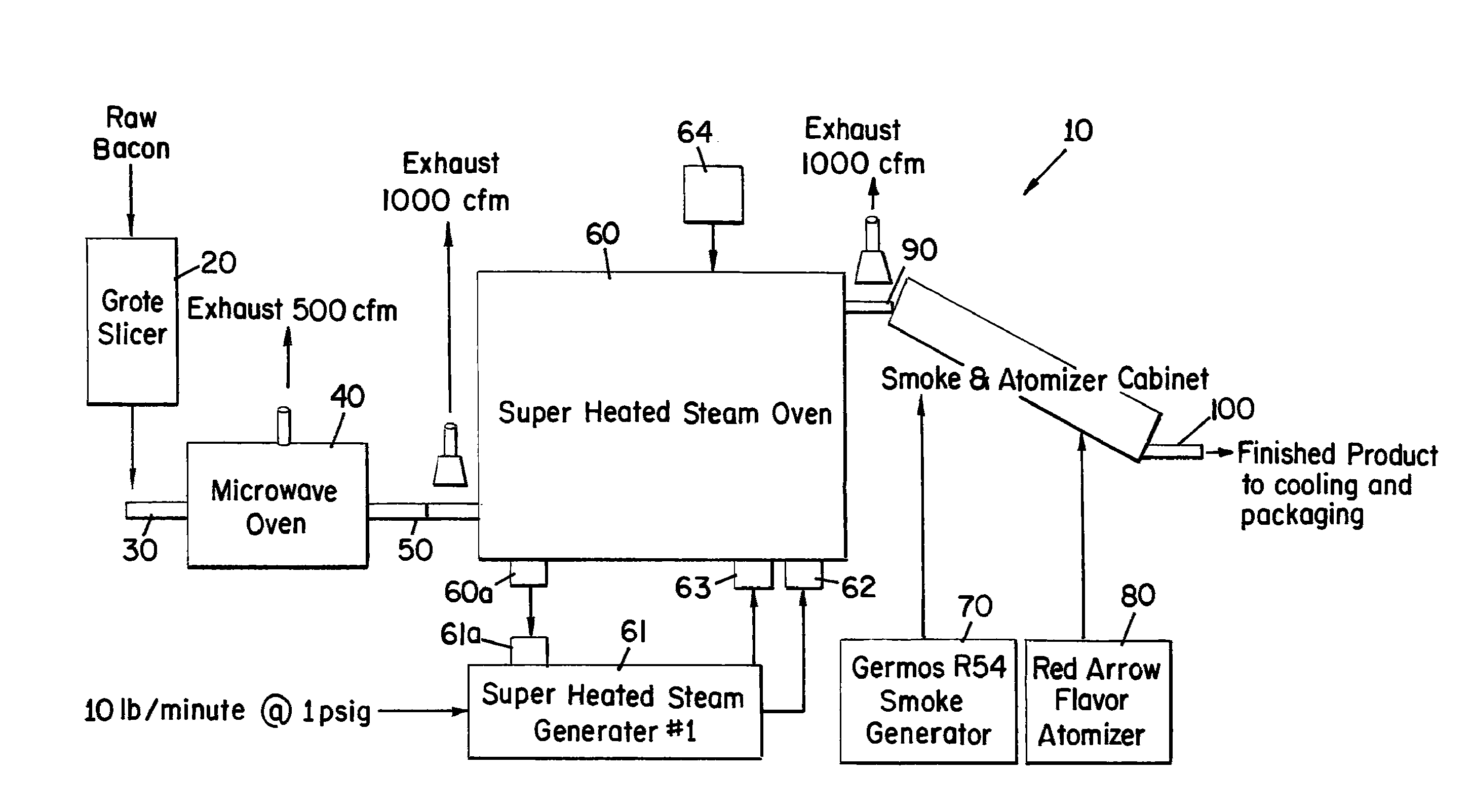

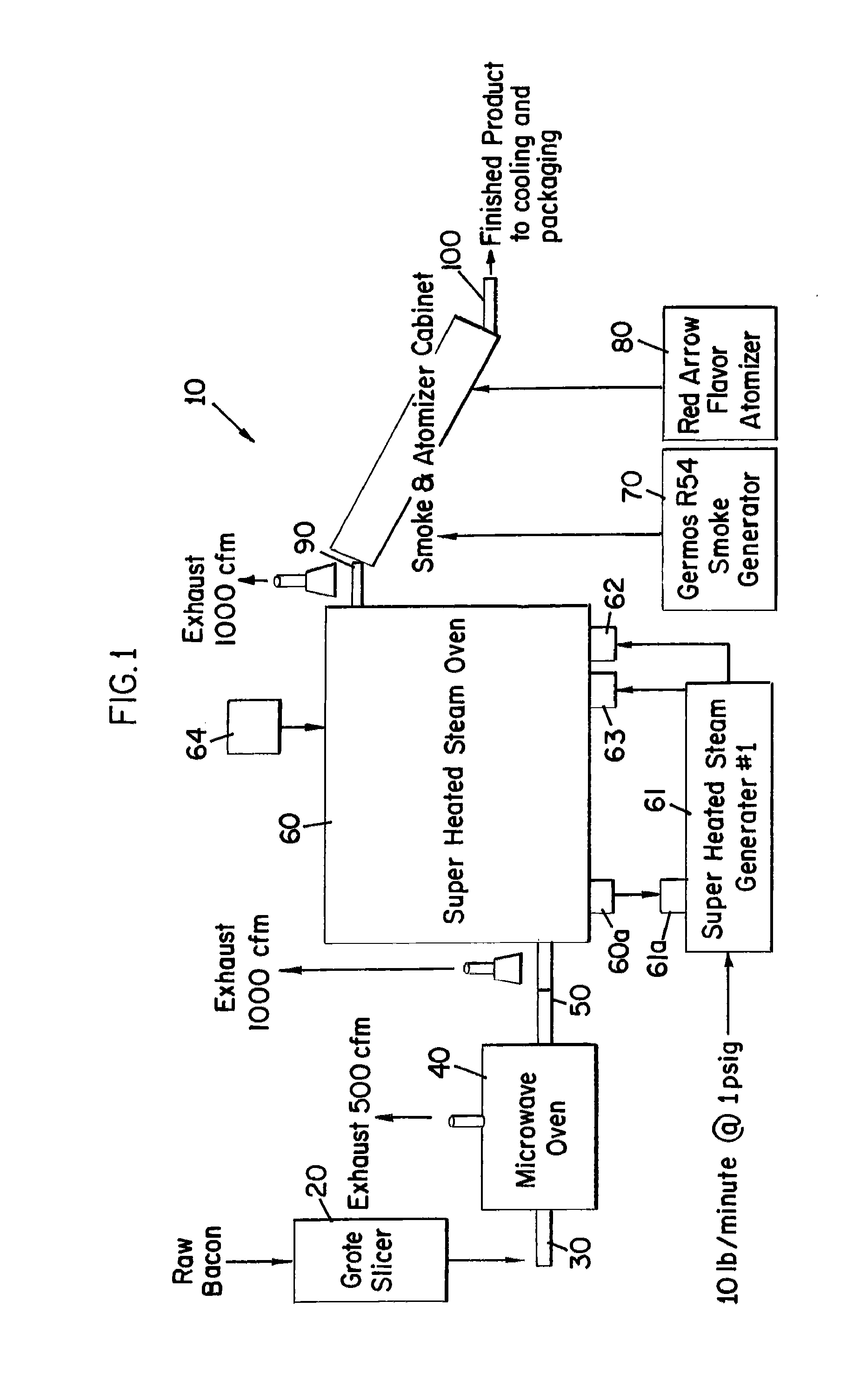

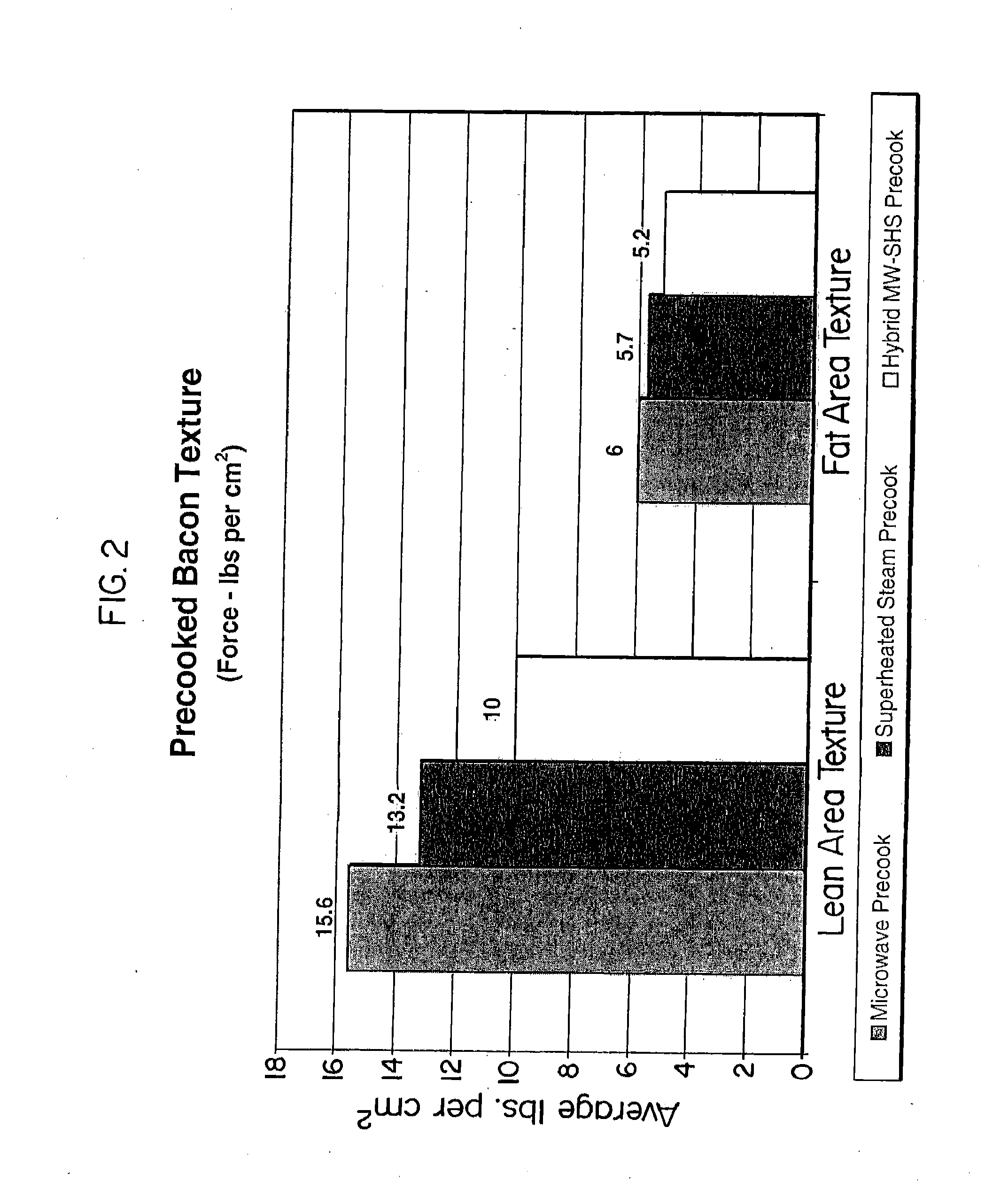

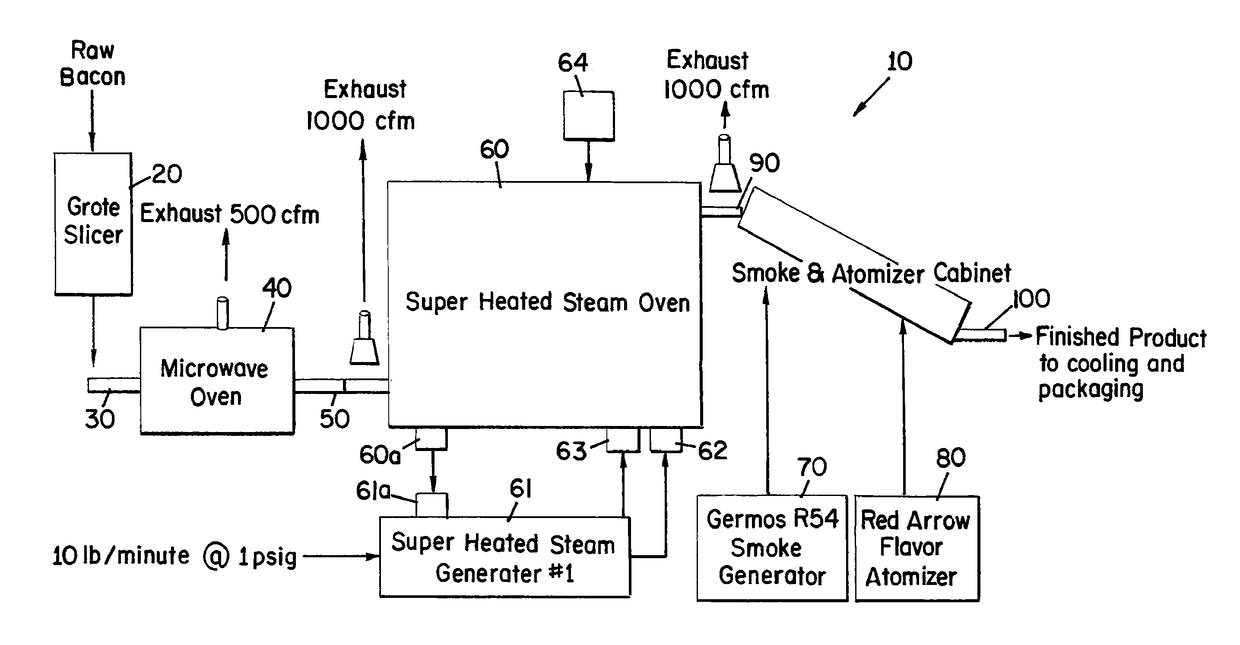

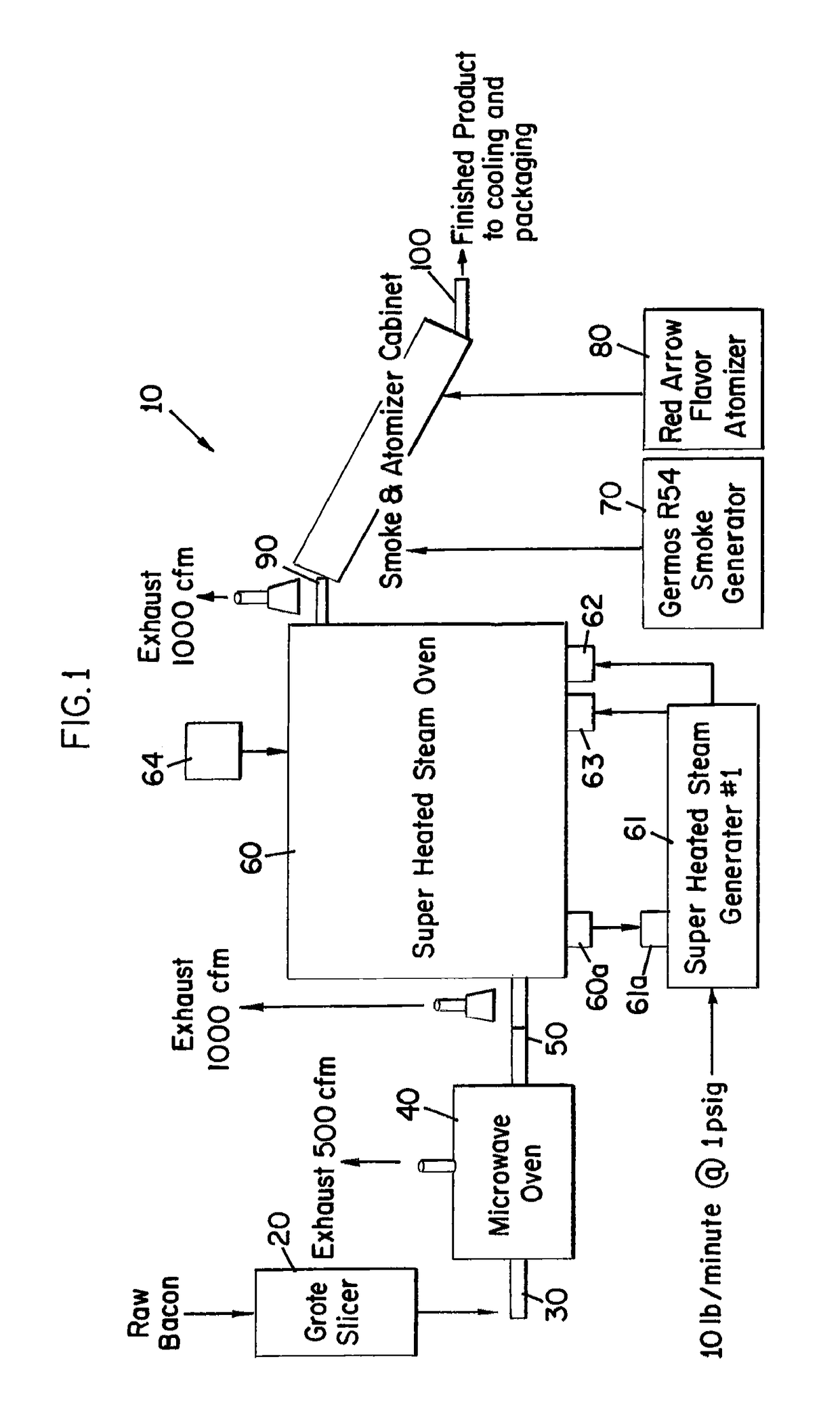

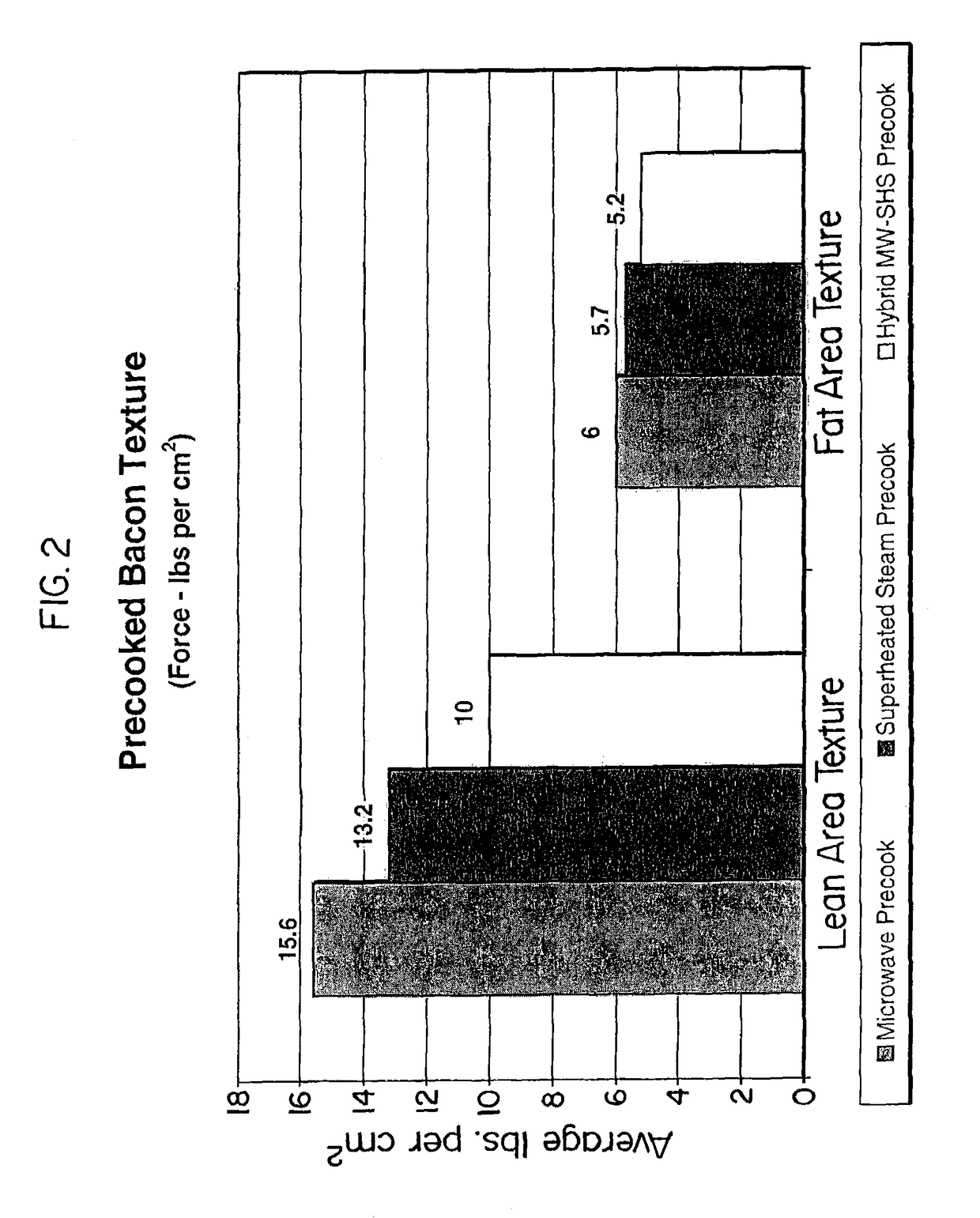

Hybrid bacon cooking system

A method of making precooked meat pieces using a hybrid cooking system comprises preheating meat pieces to a temperature of at least approximately 140° F. to create preheated meat pieces. The preheated meat pieces are transferred to an oven heated with an external heating source. The oven includes internal surfaces, and the external heating source assists in keeping the internal surfaces at a temperature below a smoke point of fat from the meat pieces. The preheated meat pieces are cooked in the oven to a water activity level of 0.92 or less to create precooked meat pieces. Optionally, flavoring could be applied to the precooked meat pieces after the precooked meat pieces have been removed from the oven and before the precooked meat pieces have cooled.

Owner:HORMEL FOODS

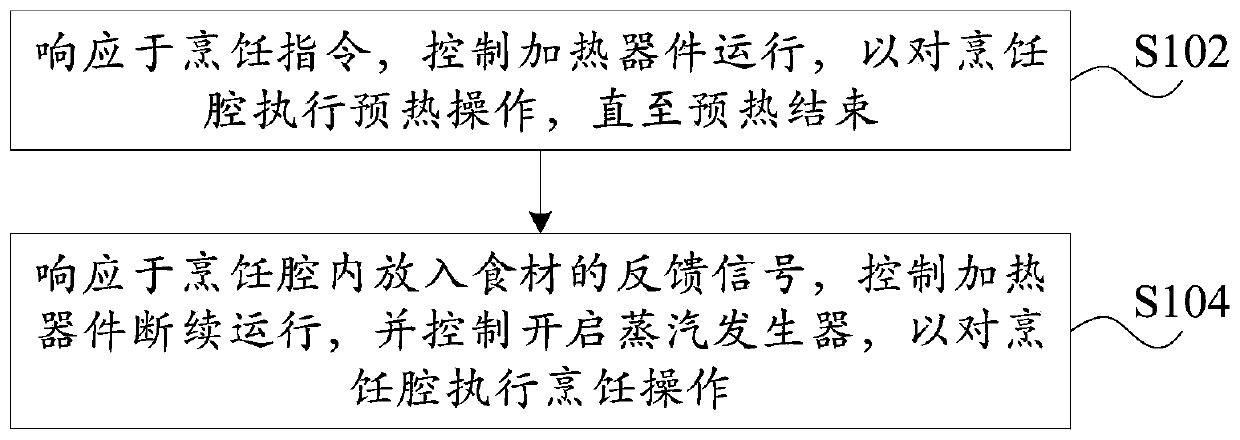

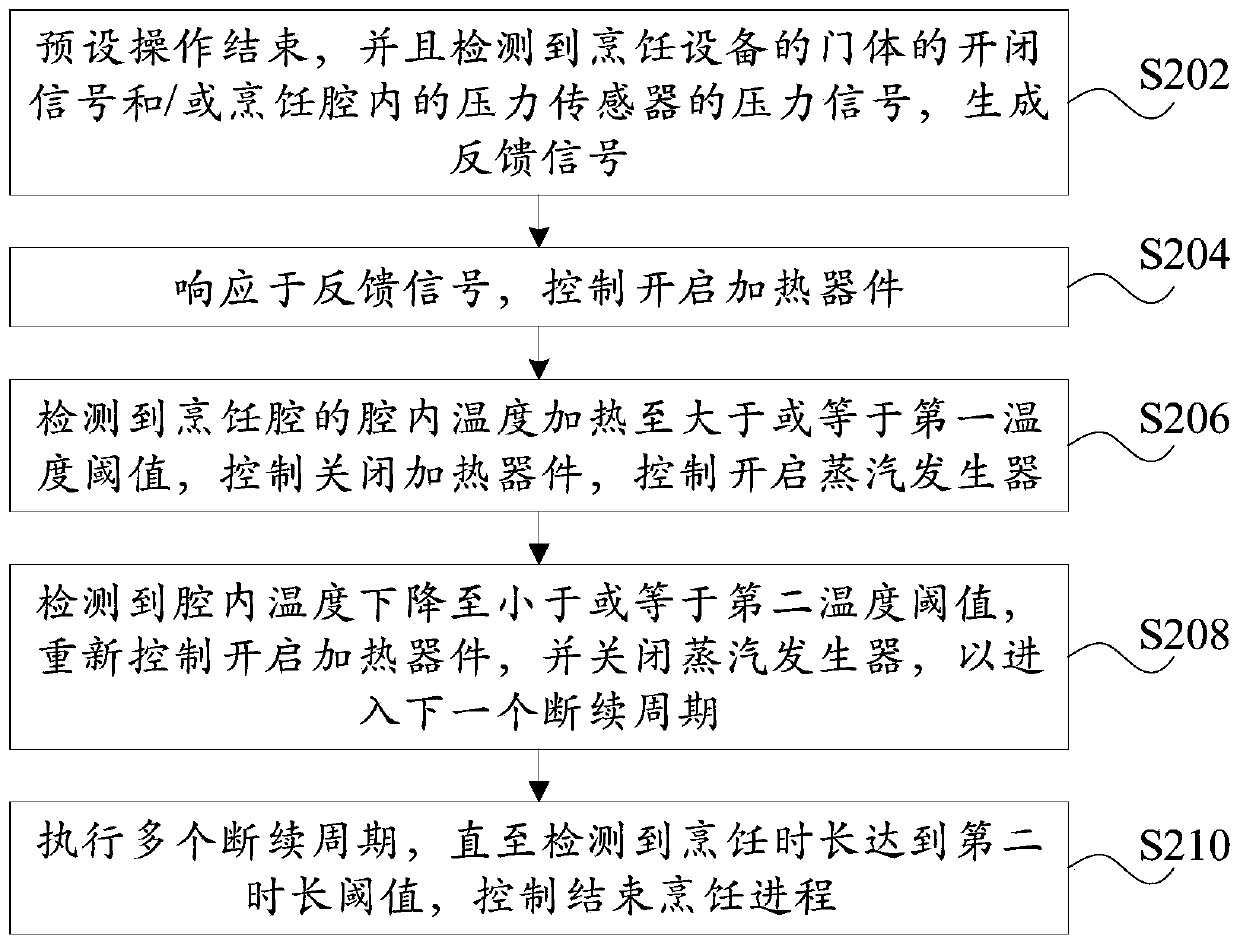

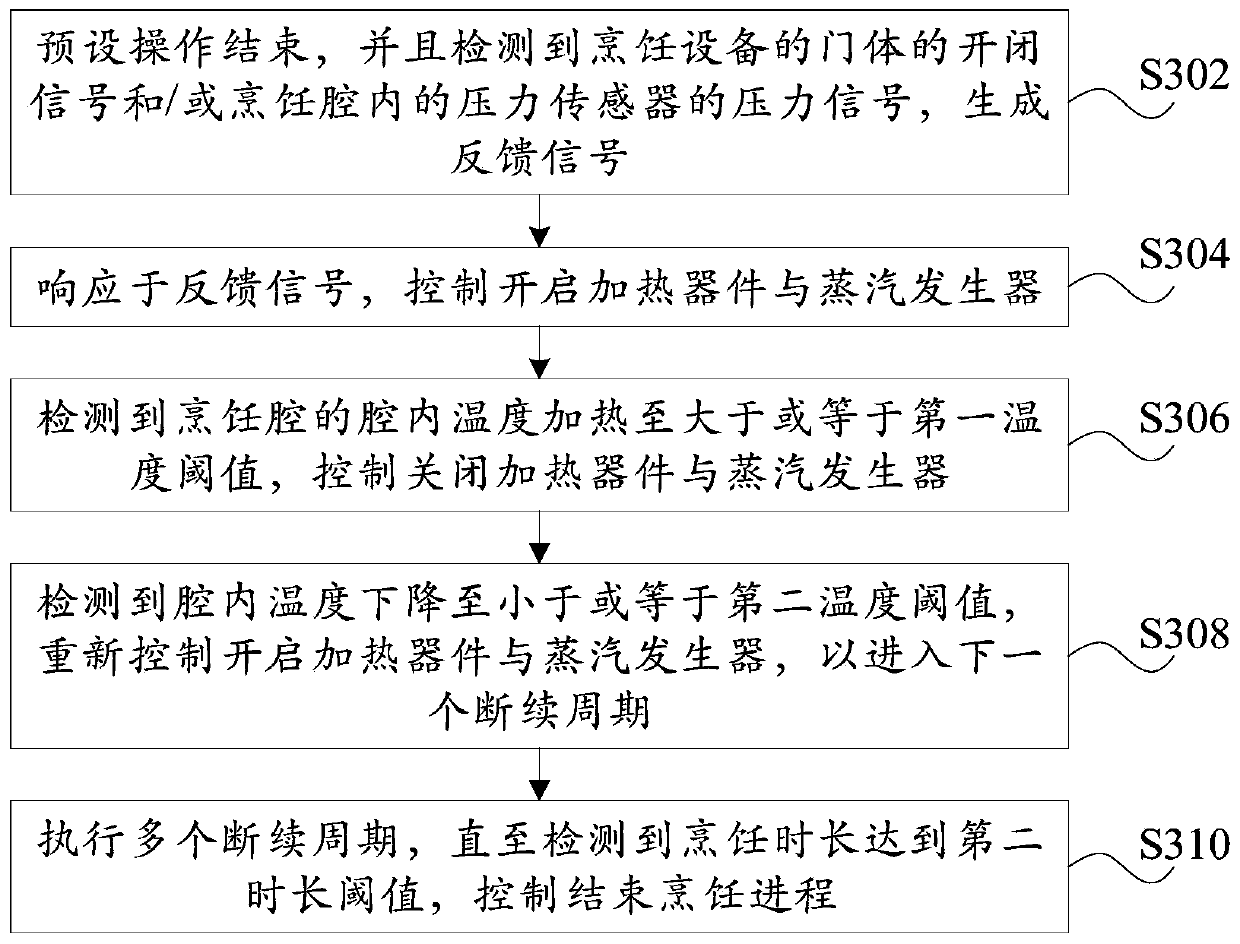

Control method, device, equipment and computer readable storage medium

ActiveCN111035275AEasy to controlImprove cooking resultsSteam cooking vesselsRoasters/grillsOil and greaseSmoke point

The invention provides a control method, device, equipment and a computer readable storage medium, and the method comprises the steps: responding to a cooking instruction, and controlling a heating device to operate so as to carry out the preheating operation on a cooking cavity till the preheating is finished; and responding to a feedback signal of putting food materials into the cooking cavity,controlling the heating device to intermittently operate, and controlling a steam generator to be started so as to execute cooking operation on the cooking cavity. According to the technical scheme, on one hand, the cooking efficiency can be guaranteed, and on the other hand, by reducing the oxygen content in the cooking cavity, the amount of grease for a thermal oxygen reaction can be reduced, sothat the grease smoke point is prevented from being reduced, or the reduction amount of the grease smoke point is reduced, and the generated oil smoke amount is reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

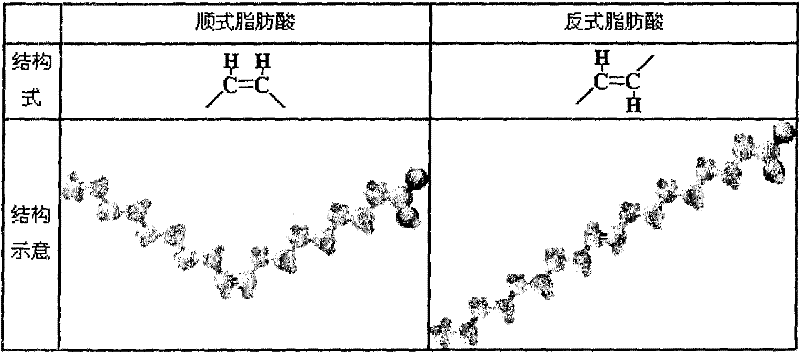

A kind of lower trans fatty acid edible vegetable oil and refining method thereof

InactiveCN102273522ALight colorHigh smoke pointFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The invention relates to fully refined edible vegetable oil with lower trans fatty acid and a refining method thereof. The vegetable oil is rapeseed oil, soybean oil, corn oil or blending oil with any ratio; the trans fatty acid content of the vegetable oil is less than or equal to 1 weight percent; and the oil smoke point is more than or equal to 210 DEG C. The refining method comprises the steps of selecting crude oil, degumming, deacidifying, removing saponin, dehydrating, decoloring, removing impurities, deoxidizing, deodorizing, cooling and obtaining finished products. The refining method is characterized in that: at the decoloring state, the removing grain size of the impurities is reduced from 25 mu m to 10 mu m; and at the deodorizing stage, the deodorizing temperature is controlled to be between 230 and 245 DEG C and the vacuum degree is controlled to be within 2 tau. Oil is refined at lower temperature and a lowest trans fat structure is realized by controlling the grain size of the impurities and the vacuum degree; after being refined, the vegetable oil has good quality, namely the trans fatty acid is reduced to be lower than 60 percent of the normal level; and the refined vegetable oil has light color, high smoke point, high purity and storage resistance and is beneficial to people's long-term health.

Owner:SHENZHEN NANSHUN GREASE

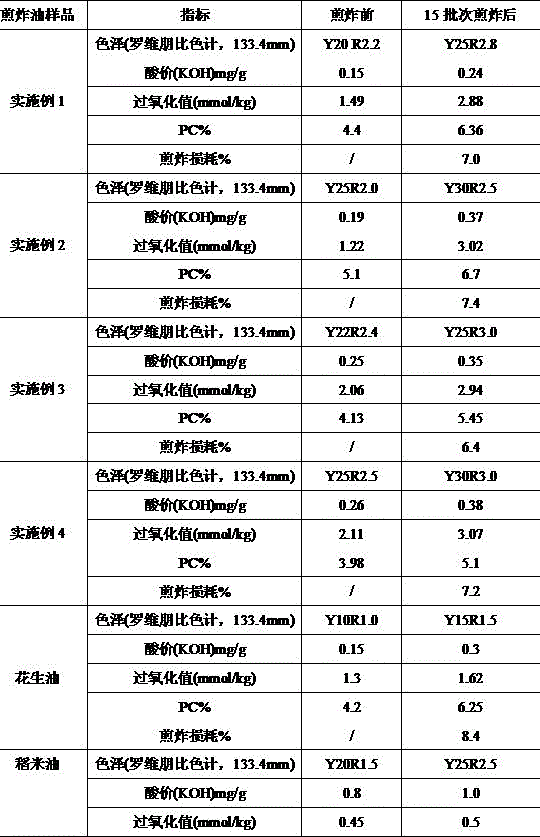

Special blend oil for frying and preparation method thereof

The invention discloses special blend oil for frying. The special blend oil for frying contains 10-50% by weight of high oleic acid peanut oil and 10-50% by weight of rice oil. The blend oil for frying is prepared by compounding any two or more than two of sunflower seed oil, olive oil, soybean oil, corn oil, cottonseed oil, palm oil, rapeseed oil, safflower oil, linseed oil and sesame oil in different proportions. The blend oil for frying is rich in fragrance, bright in color, high in content of oleic acid, rich in oryzanol and vitamin E, reasonable in composition of fatty acids and free of stickiness. Through a high-temperature frying test, the blend oil is high in smoke point, low in content of trans-fatty acids and high in frying stability. The fried food is small in oil content, good in crispy property, excellent in taste and nutritional and healthy. The blend oil disclosed by the invention can be used for frying different food materials, is suitable for being used as special fat for frying food in family and catering industry, is long in expiration date, and is novel nutritional and healthy special blend oil for frying.

Owner:山东金胜粮油食品有限公司

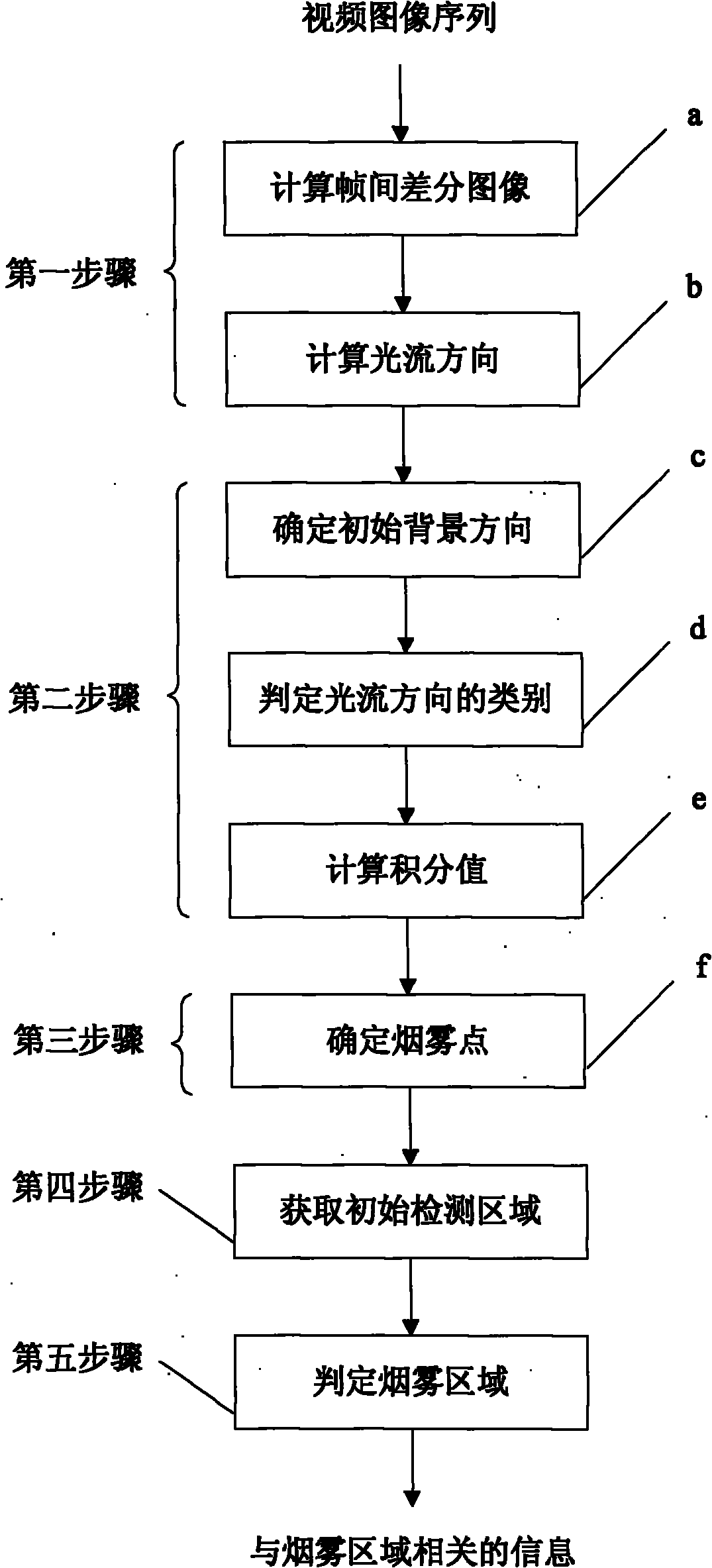

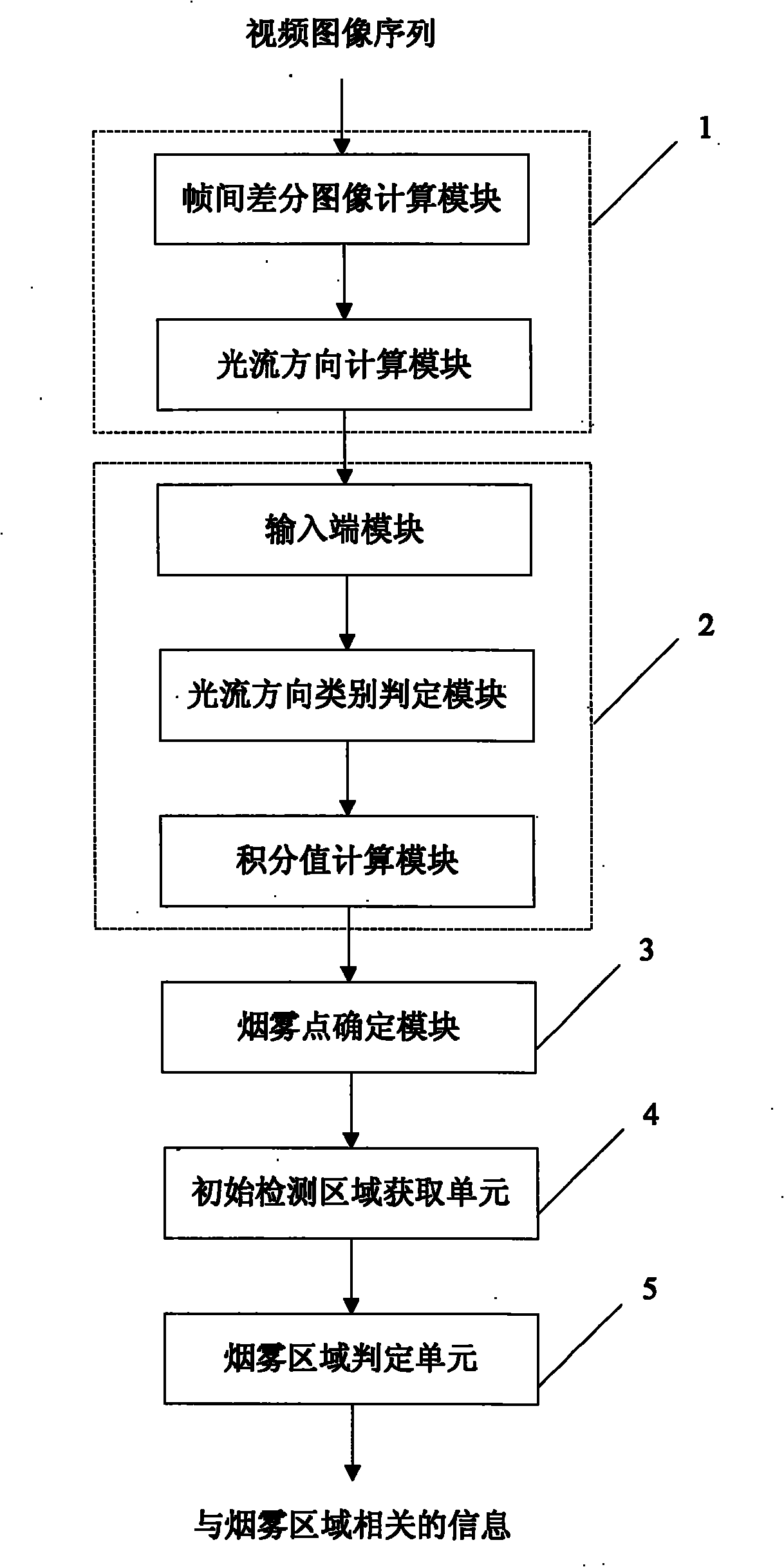

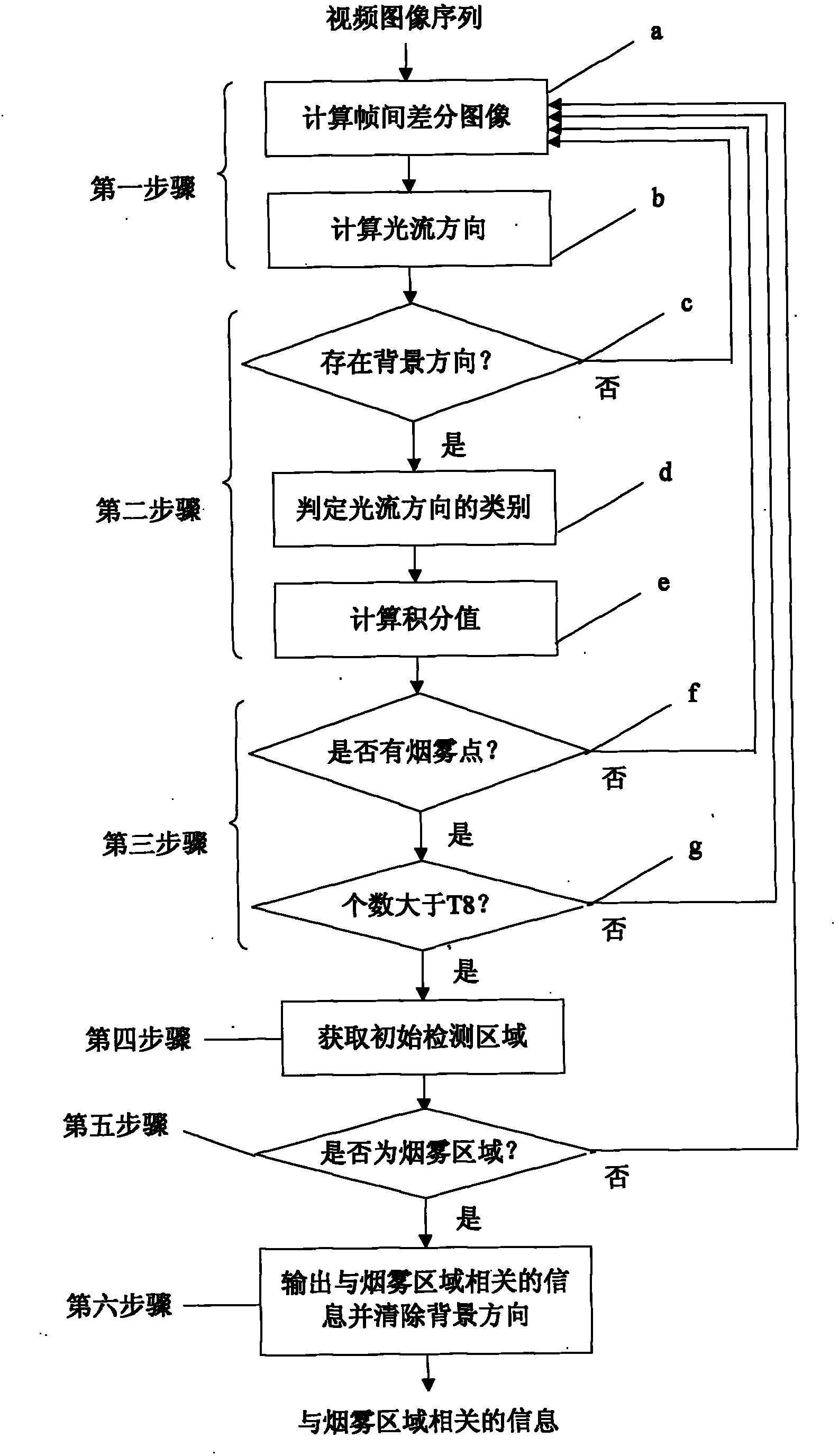

Method and device for detecting smoke in video image sequence

The invention provides a method for detecting smoke in a video image sequence. The method comprises the following steps of: 1, calculating the optical flow direction of each pixel in an interframe difference image of a video image frame; 2, determining the type of the optical flow direction of each pixel according to the deviation between the optical flow direction of each pixel and the background direction at the same pixel position and calculating the integral value corresponding to each pixel based on the type of the optical flow direction of each pixel; 3, determining whether each pixel is a smoke point according to the integral value corresponding to each pixel; 4, obtaining an initial detection area formed by all the smoke points; and 5, judging whether the obtained initial detection area is a smoke area. The method has the advantages of avoiding background establishment, eliminating the influence of illumination, noise and background textures and improving the reliability of smoke detection.

Owner:NETPOSA TECH

Blending of dewaxed biofuels and synthesized paraffinic kerosines with mineral-based kero(JET) distillate cuts to provide on-spec jet fuels

InactiveUS20150112106A1Improve other propertyLowering naphthaleneBiofuelsSolid fuelsParaffin waxKerosene

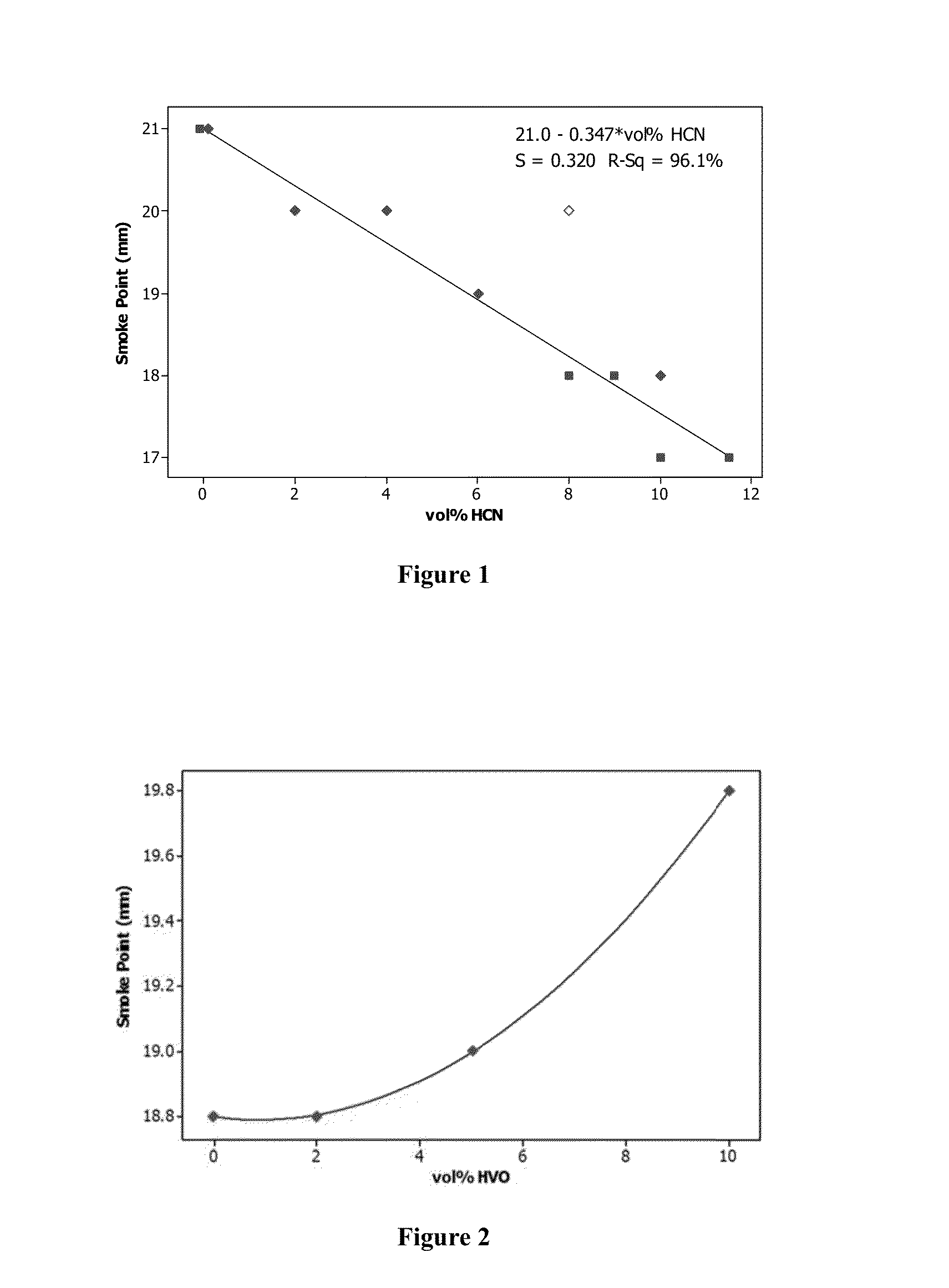

The present invention describes a method of making a jet fuel composition comprising: blending from about 3 vol % to about 30 vol % of a catalytically and / or thermally cracked blendstock into a non-cracked jet-boiling-range distillate to produce a jet-type blend with a smoke point less than 18 mm; and thereafter, blending from about 2 vol % to about 50 vol % of synthesized paraffinic kerosine (SPK) into the jet-type blend to produce a jet fuel with a smoke point of at least 18 mm.

Owner:EXXON RES & ENG CO

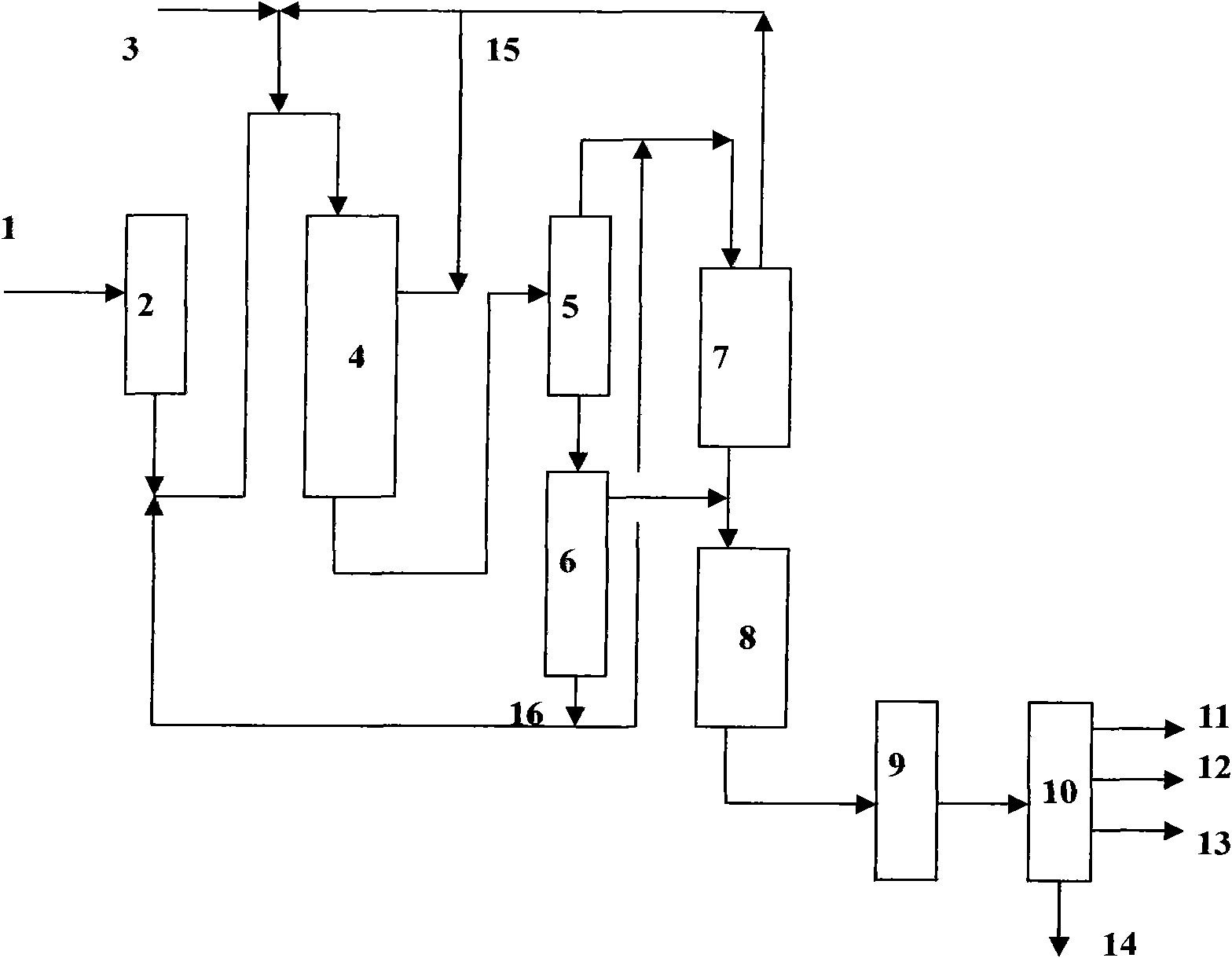

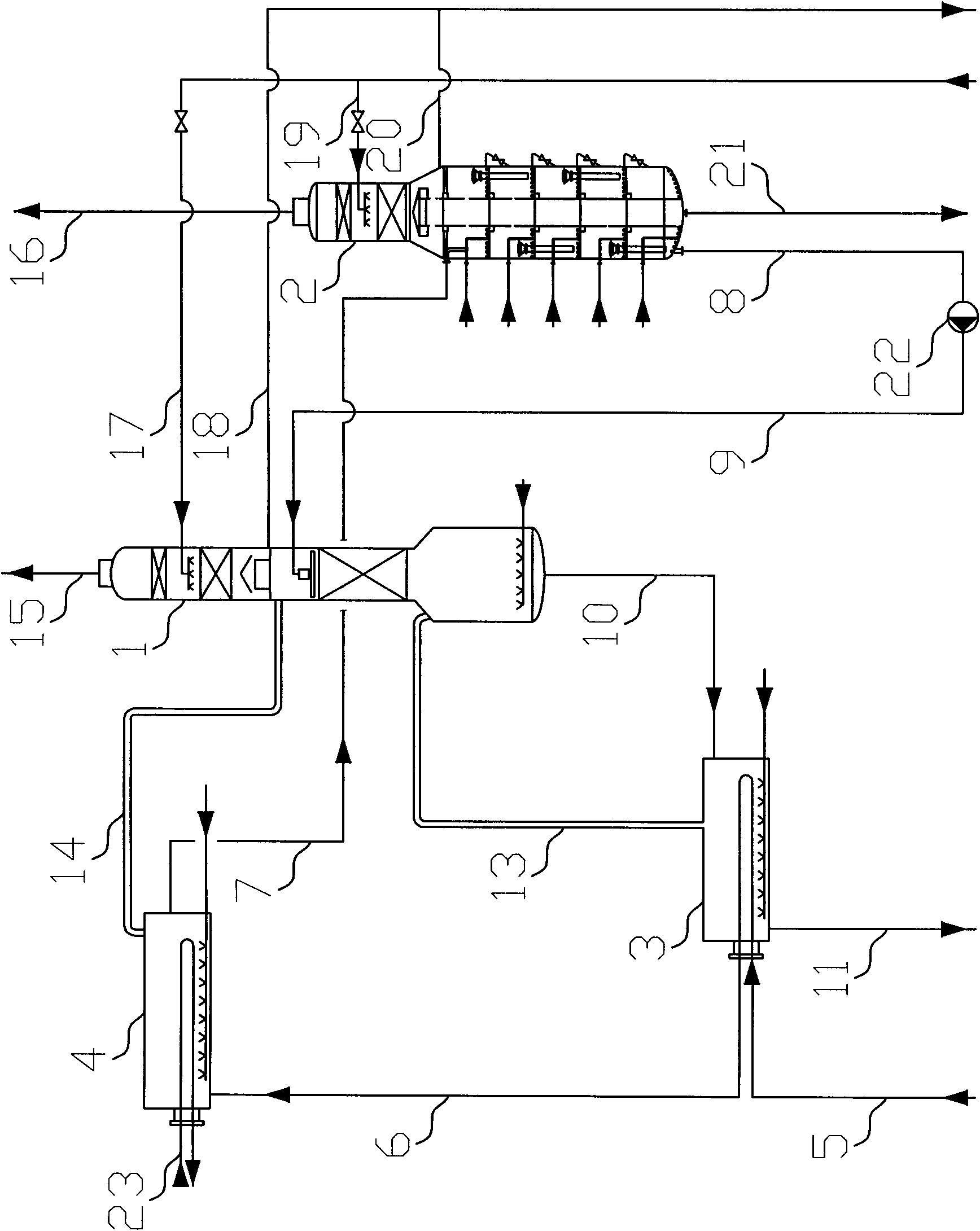

Jet fuel producing process

InactiveCN1453338ABroaden sources of raw materialsTreatment with hydrotreatment processesHydrogenation reactionSmoke point

In the jet fuel producing process, heavy material is first hydrocracked and the resultants of hydrocracking reaction are separated to obtain intermediate fraction oil. The intermediate fraction oil and light material are then hydrogenation processed and the resultants of the hydrogenation reaction are separated to obtain the destination product jet fuel. Fresh hydrogen may be replenished to hydrocracking reaction region and / or hydrogenation processing reaction region. The present invention can produce jet fuel with qualified smoke point, arene content and other indexes at relatively low reaction pressure, and this expands the material source for producing jet fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technology for deodorizing vegetable oil with high content of unsaturated acid

ActiveCN101649250AReduce hydrolysisReduce aggregationFatty-oils/fats refiningVegetable oilAcid value

The invention relates to technology for deodorizing vegetable oil with high content of unsaturated acid, belonging to the technical field of vegetable oil refining. In the technology, two vacuum heatexchangers with the same structure are employed for heat exchanging and heating; a tray deodorization tower and a packing deodorization tower are employed to form double towers for deodorization in sequence. The obvious characteristics of adopting the vacuum heat exchangers for heat exchanging and heating are as follows: the energy is saved and the oil is slowly heated under high vacuum. By adopting the double towers for deodorization in sequence, such indexes as acid value, smoke point, color and the like of the vegetable oil with high content of unsaturated acid can be effectively improved,thus strongly ensuring that the final oil products satisfy the high standard requirements of the clients. The technology is suitable for processing the vegetable oil which has high content of unsaturated acid and is easily decomposed at high temperature, such as corn oil, and features good deodorization effect, simple operation and high comprehensive benefits.

Owner:广西北部湾粮油技术研究有限公司

Method for preparing edible idesia oil

InactiveCN102191128AImprove oil yieldHigh product smoke pointFatty-oils/fats refiningEdible oils/fatsAdditive ingredientSmoke point

The invention discloses a method for preparing idesia oil, which is characterized by comprising the following steps of: filtering crude idesia oil by a filtering cloth to remove mechanical impurities; adding 100 parts of the filtered crude idesia oil into 0.5 to 2.0 parts of degumming agents at 75 to 80 DEG C; stirring for 20 to 35 minutes; cooling and centrifuging to separate the colloid in the lower layer; washing the idesia oil in the upper layer by using deionized water to a neutral state to obtain degummed idesia oil; dehydrating the degummed idesia oil at a vacuum degree of 4000 to 5000 Pa and the temperature of 60 to 80 DEC C for 20 to 30 minutes; continuously deacidifying the dehydrated idesia oil at the temperature of 105 to 130 DEG C, the pressure of 10 to 20 Pa, the feed rate of 80 to 120 mL / h and the film scraper rotation speed of 150 to 200 r / min, wherein the light component is removed free fatty acid, and the heavy component is product oil. The method has the advantages that the colloid and the fatty acid are removed completely, the production period is short, the effective ingredients, such as vitamin E and the like in the grease are effectively remained; the prepared edible idesia oil has the advantages of high yield, high smoke point, stable property in a storage process, no precipitate, and invariant color; and a special deodorization technology is not needed.

Owner:SICHUAN ACAD OF FORESTRY

Process to upgrade kerosenes and a gasoils from naphthenic and aromatic crude petroleum sources

A process to prepare a kerosene and a gasoil product from a crude petroleum source having a Watson characterization factor K value of equal or below 12.0 by (a) isolation of a petroleum derived kerosene fraction and a petroleum derived gasoil fraction from said crude petroleum source, wherein the petroleum derived kerosene fraction has a smoke point of below 25 mm or below 19 mm if naphthalenes content of the kerosene fraction is below 3% vol and the petroleum derived gas oil has a cetane number of below 50 or a density higher than 845 kg / m3, ( ) adding a Fischer-Tropsch derived kerosene fraction to the petroleum derived kerosene fraction in an amount sufficient to obtain a mixture having a smoke point value of above 25 mm or above 19 mm if the naphthalenes content of the mixture is below 3% vol and (c) adding a Fischer-Tropsch derived gas oil fraction to the petroleum derived gasoil fraction such that the resultant mixture has a cetane number value of above 51.

Owner:SHELL OIL CO

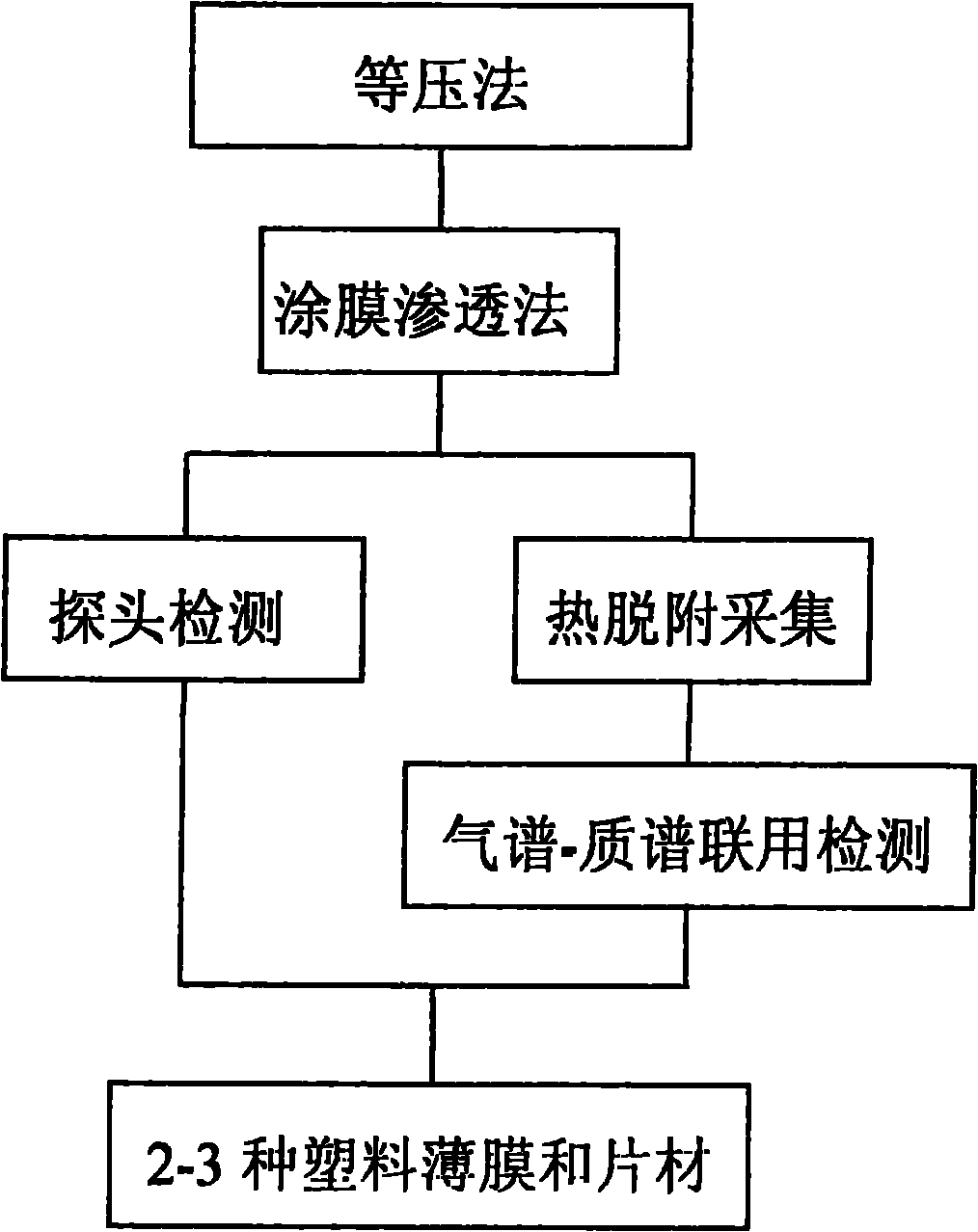

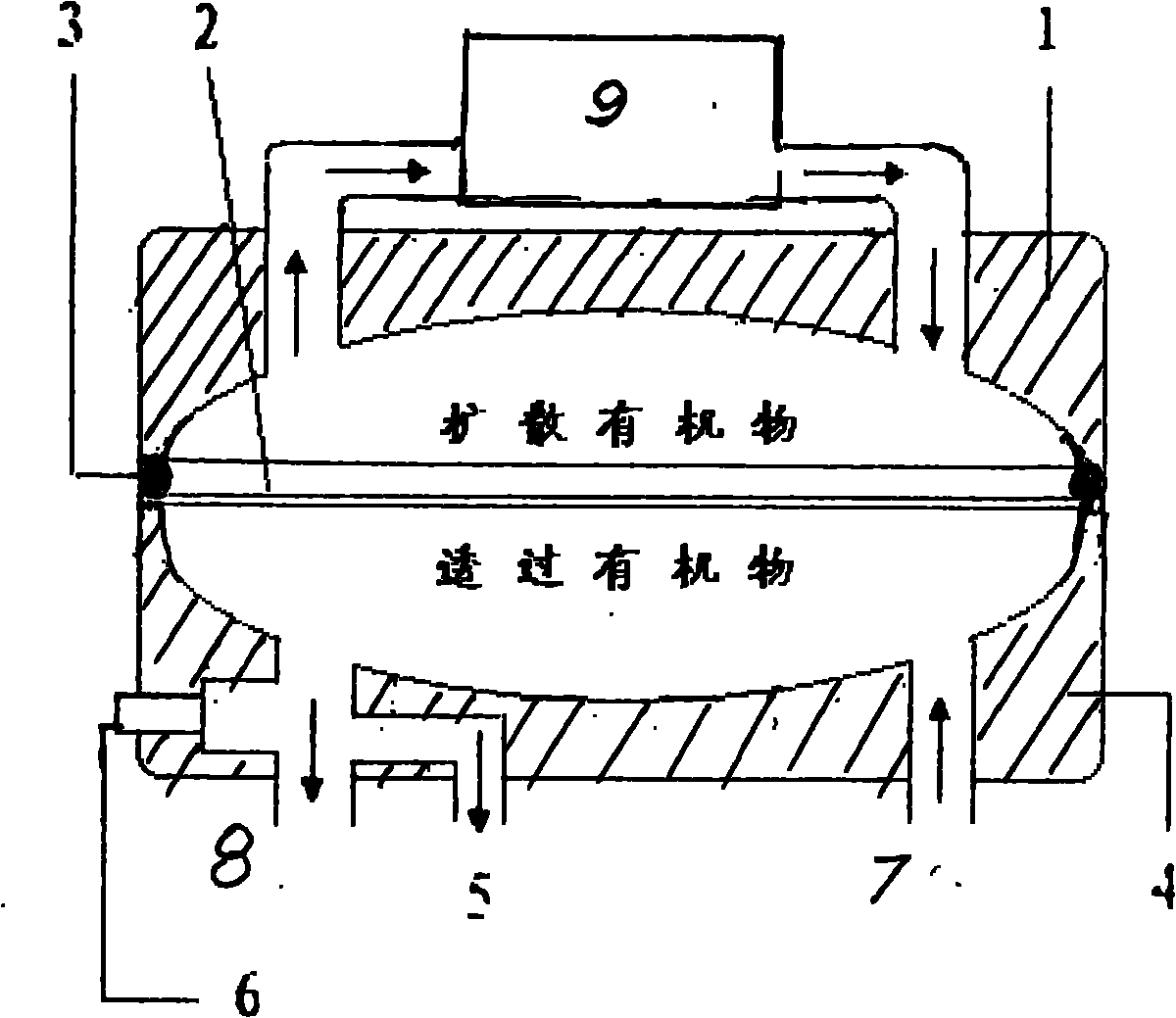

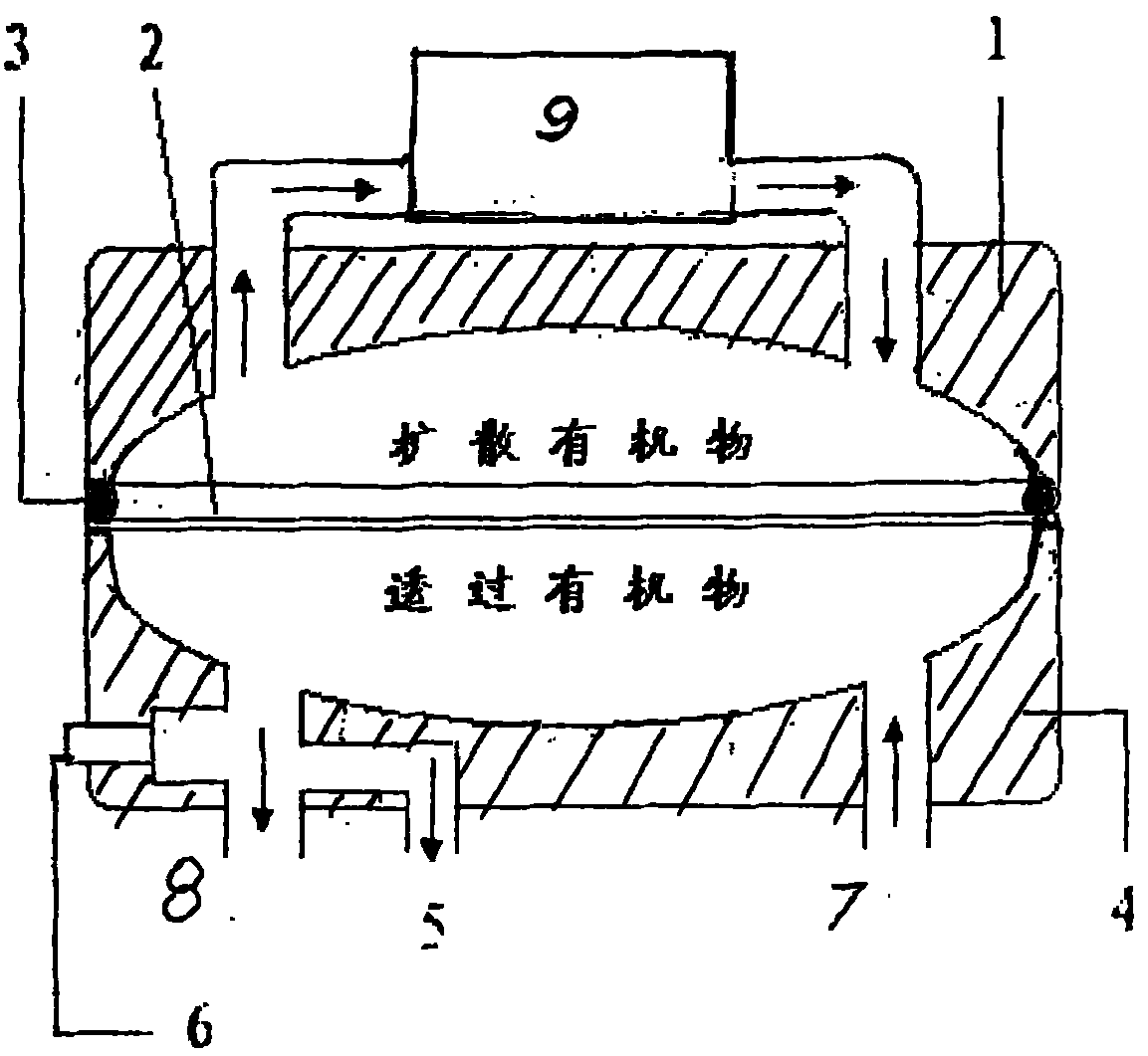

Device for detecting transmissivity of organic matter through plastic film

InactiveCN101769849AAutomate operationImprove detection efficiencyComponent separationPermeability/surface area analysisAutomatic controlEngineering

The invention relates to a device for detecting transmissivity of an organic matter through a plastic film. An openable-closable testing room consists of openable-closable upper and lower testing rooms; an upper accommodating chamber is provided with an upper communicating pipe, a lower accommodating chamber is provided with a lower communicating pipe; and the communicating pipe of the upper accommodating chamber is connected with an air temperature and humidity adjusting circulator, and the lower communicating pipe is connected with a nitrogen source and a tester. An organic matter to be tested is coated on one side of the plastic film and is clamped tightly; a testing outer room is controlled at a certain diffusion temperature and in certain humidity; after a certain period of diffusion time, the organic matter permeates the plastic film to enter a testing inner room; the temperature and the humidity of the testing inner room are kept above the smoke point of the organic matter, and inert gas is introduced into the testing inner room continuously and circularly; after thermal desorption and adsorption enrichment, qualitative and quantitative detection is performed; and the circulation is carried out for many times to reach a certain detection concentration lower limit and then a sensor is used for measurement. The device can implement environmental simulation, automatic control and automatic digital acquisition; the device is convenient, safe and reliable, and highly intelligent to greatly improve the detection efficiency; and the automatic operation saves the manpower.

Owner:王利兵

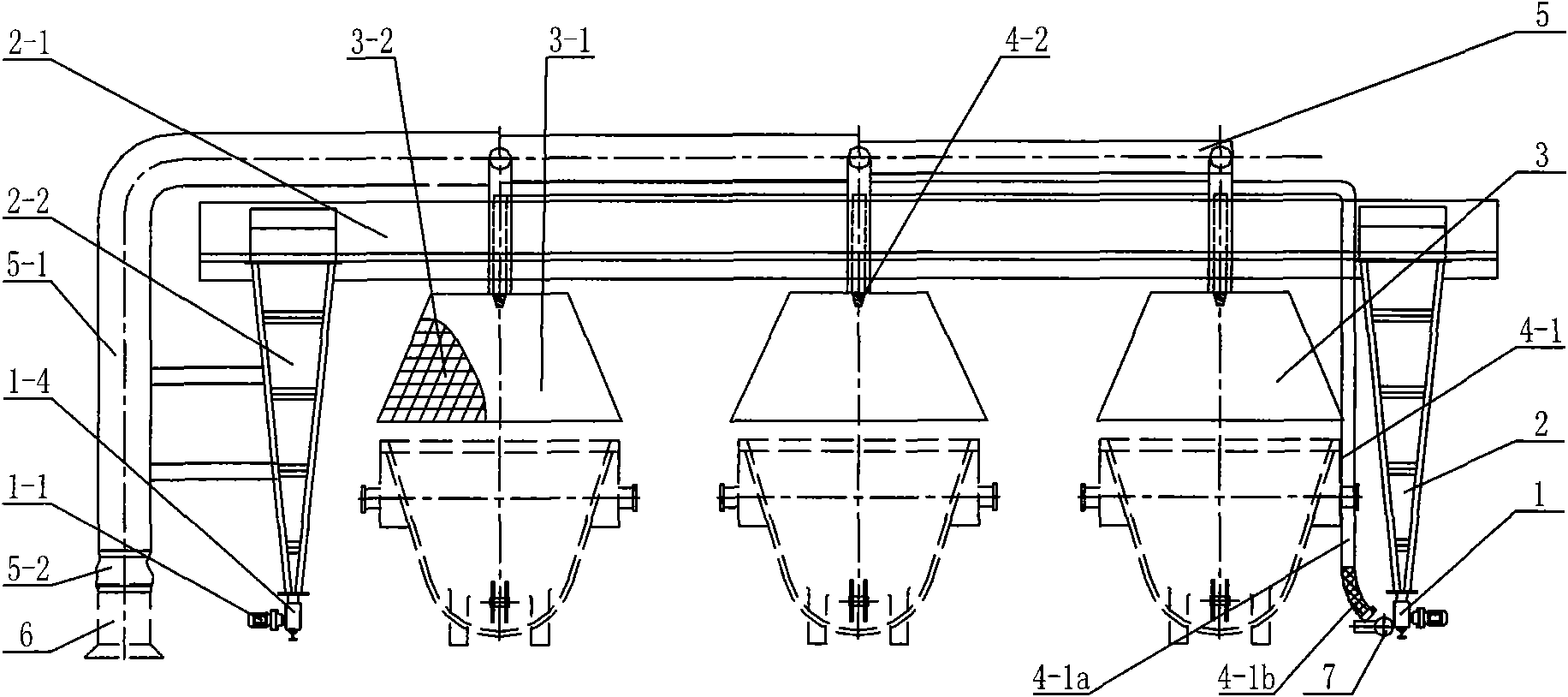

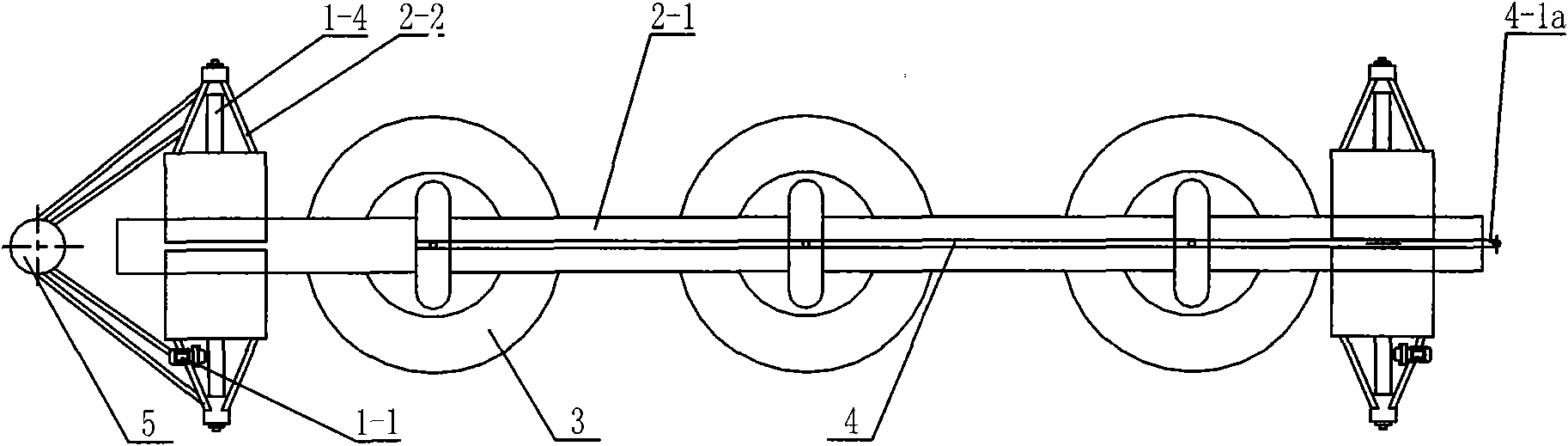

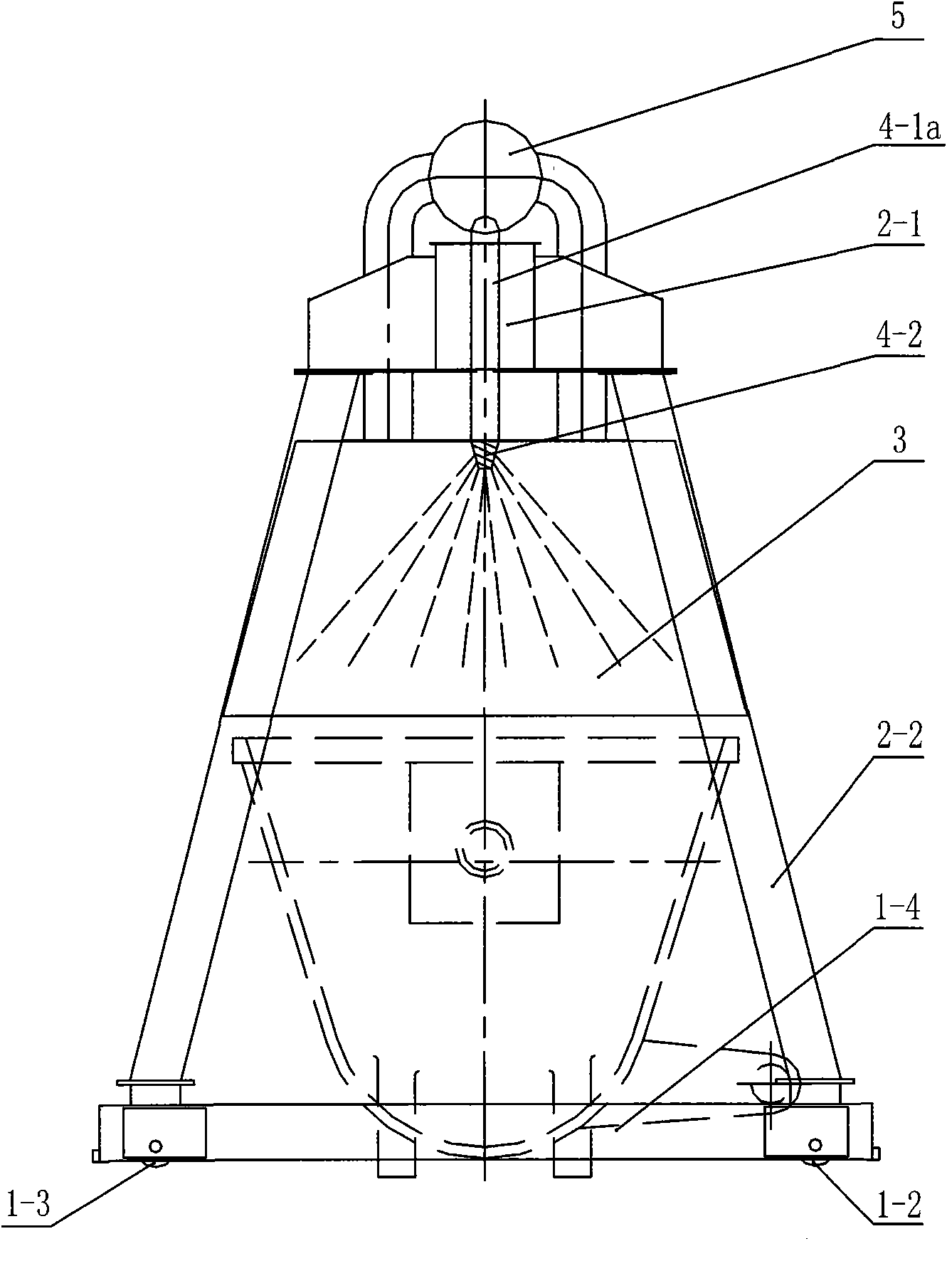

Multi-station mobile steam exhaust and dust removal method and device

ActiveCN102000687ACompact structureHigh degree of automationDispersed particle filtrationDirt cleaningFiberDrive wheel

The invention discloses a multi-station mobile steam exhaust and dust removal method and a multi-station mobile steam exhaust and dust removal device. The device comprises a walking device (1), a portal steel frame supporting device (2), a flue gas collection device (3), a spray cooling device (4) and an exhaust pipeline (5), wherein the walking device (1) comprises a driving device (1-1), a drive wheel device (1-2), a driven wheel device (1-3) and an end beam device (1-4); the portal steel frame supporting device (2) comprises a beam (2-1) and a supporting leg (2-2); the flue gas collection device (3) comprises a dust collection cover (3-1) and a heat insulation device (3-2); the spray cooling device (4) comprises a water pipe (4-1) and an atomizing nozzle (4-2); and the exhaust pipeline (5) comprises an exhaust pipeline body (5-1) and high-temperature-resistant ceramic fiber cloth (5-2). The multi-station mobile steam exhaust and dust removal device can cool high-temperature smoke points or pollution sources by injecting water and recover flue gas in the cooling process; meanwhile, the device can move automatically and has high automation degree and good dust removal effect.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Method for refining linseed oil

InactiveCN104073339AImprove crushing efficiencyImprove continuityFatty-oils/fats refiningFatty-oils/fats productionSmoke pointLinseed oil

The invention relates to a method for refining linseed oil. The method specifically comprises the following steps: screening and blanking; cooking; squeezing; primarily filtering; secondarily filtering; degumming; deacidifying; decoloring; filtering for the third time; deodorizing; finely filtering; and filling. According to the method, a spiral squeezer is adopted in the squeezing section, so that the squeezing efficiency is improved, the continuity is good, the utilization ratio of effective components of the raw material is improved and the smoke point of linseed oil is improved. The oil yield reaches 38.4% and the content of linolenic acid in oil reaches up to 69.76%.

Owner:GANSU LONGYUXIANG GRAIN & OIL IND CO LTD

Special blended olive oil for cooking and preparation method of special blended olive oil

The invention discloses a special blended olive oil for cooking and a preparation method of the special blended olive oil. The blended olive oil is composed of olive oil, sunflower seed oil and rapeseed oil in the mass ratio of (30-40): (10-20): (40-60). The blended olive oil disclosed by the invention has the advantages of good thermal stability and higher smoke point and is more suitable for the Chinese cooking habit; meanwhile, nutrient substances in the product can be remained to the maximum extent in the cooking process; and the smoke point of the blended olive oil is higher than 170 DEG C which is increased by 5-10 DEG C than the smoke point of the olive oil, thus the thermal stability is improved.

Owner:洪申平

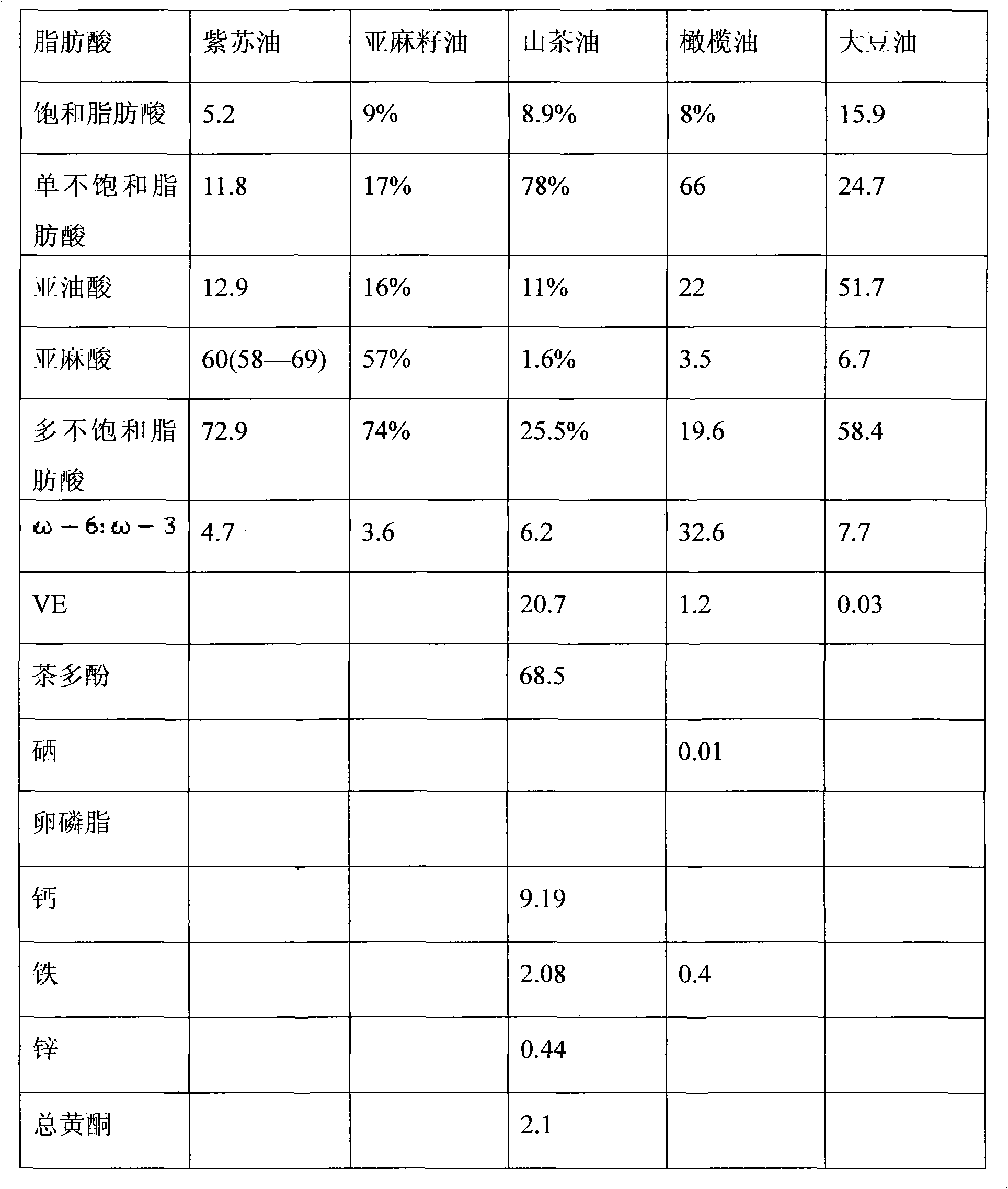

Long chain molecule vegetable blend oil

The invention relates to a long chain molecule vegetable blend oil, which at least comprises the following five components, by volume, 12 parts of perilla oil, 10 parts of linseed oil, 15 parts of camellia oil, 15 parts of olive oil, and 48 parts of soybean oil, wherein the five components are compressed crude oil, are not leaching liquid crude oil, and are subjected to blending combination to obtain the long chain molecule vegetable blend oil. Testing results show that the blend oil product formed according to the volume ratio is rich in alpha-linolenic acid, linoleic acid, oleic acid, selenium, iron, VE, tea polyphenol, lecithin and other nutrients, wherein fatty acid purity is 99.8%, cholesterol content is 0, trans fatty acid content is 0, a ratio of linoleic acid to linseed oil is 4:1, and a smoke point is more than or equal to 220 DEG C.

Owner:上海亿康生物医药科技有限公司

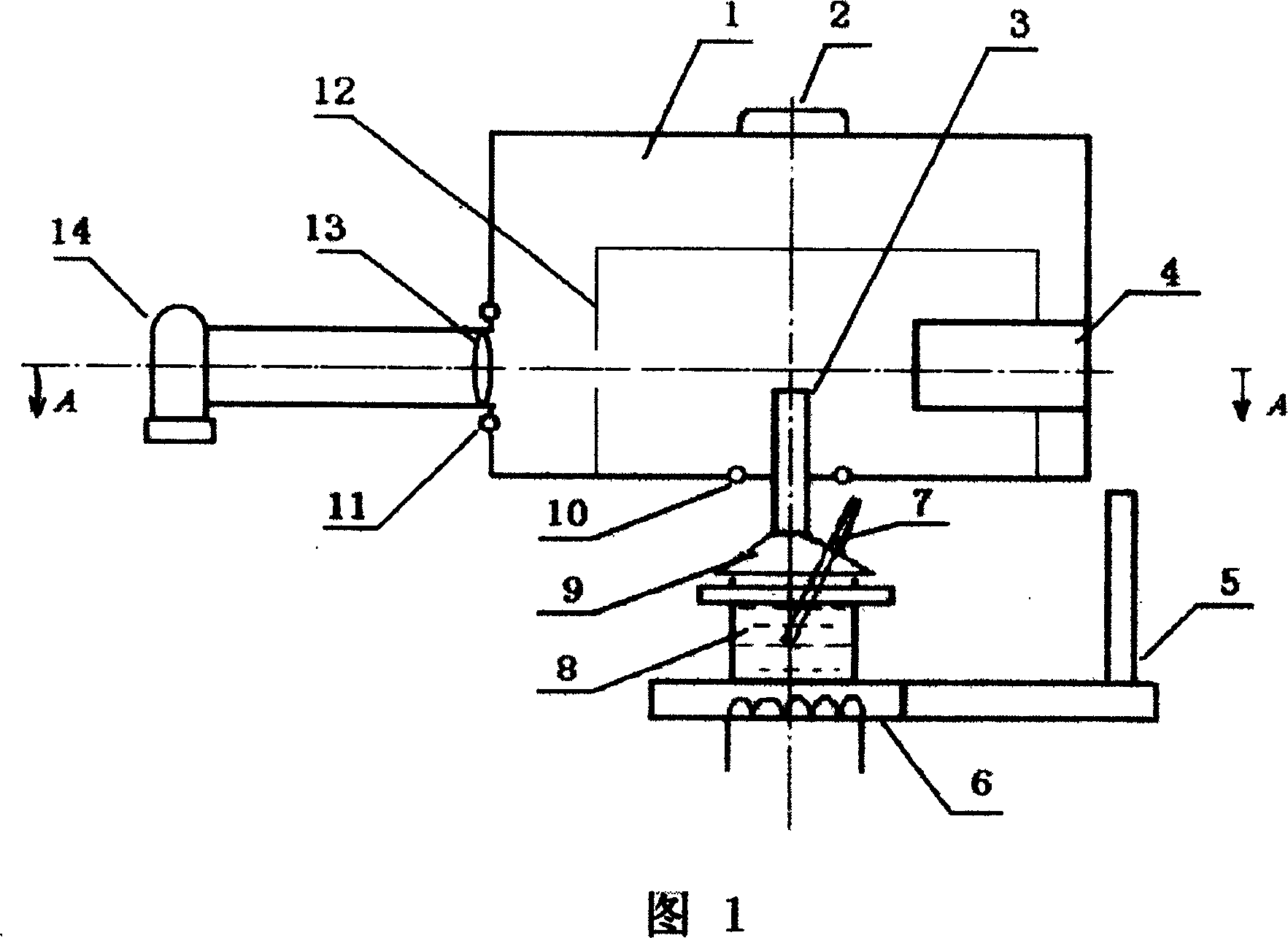

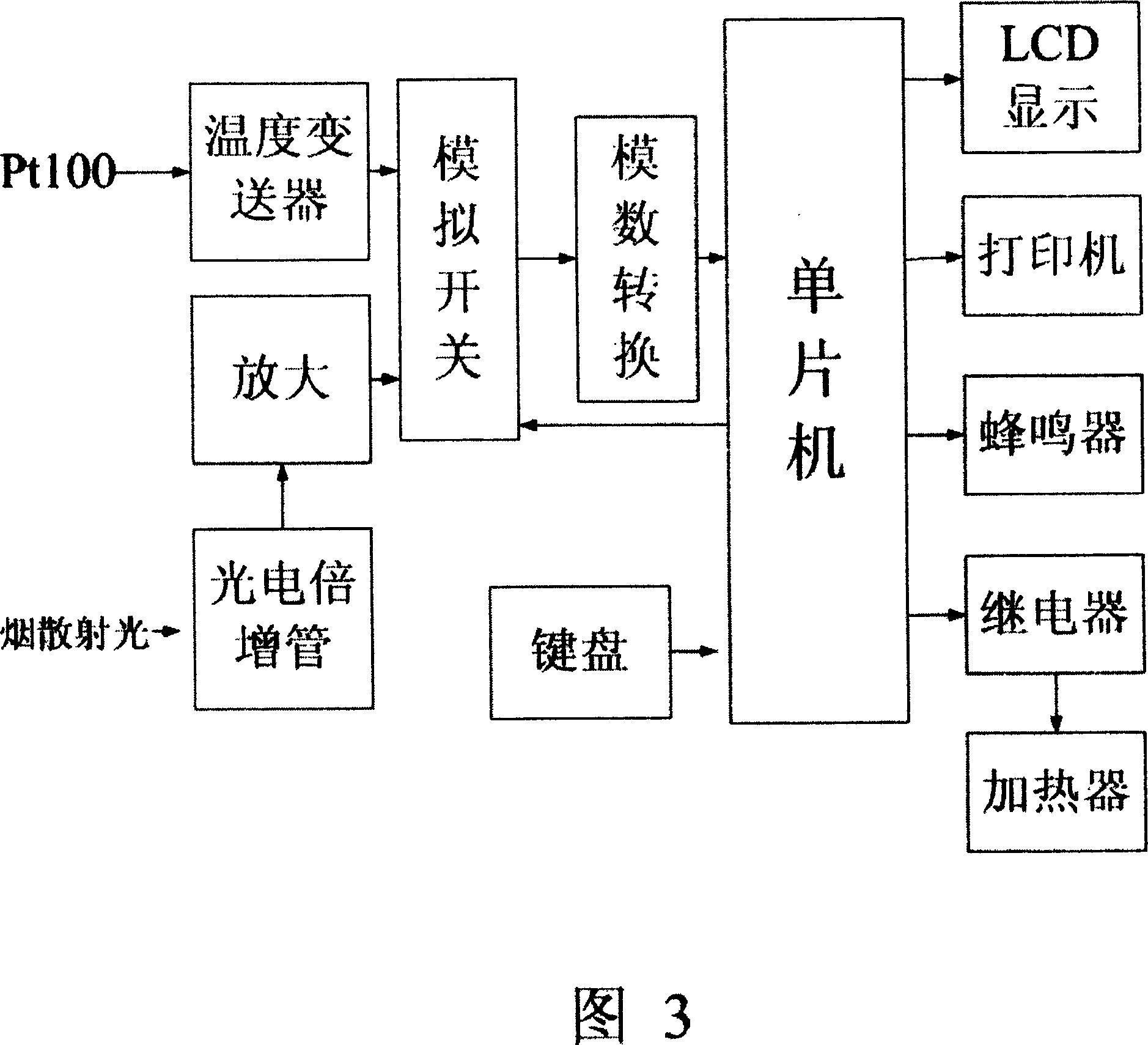

Edible vegetable oil and fat smoke point automatic analyzer

InactiveCN1932495AAvoid pollutionAvoid interferenceMaterial heat developmentScattering properties measurementsOil and greaseVegetable oil

The invention involves a kind of edible plant grease smoke to order an automatic measurement instrument. Measuring the instrument establishes a smoke examination box, examination box from box body, light source, lens, light column, the light detector, cigarette holder, light trap, gasp device to constitute; The ray of light source radiation is through the lens also focuses through a light column in the cigarette holder above, the smoke spreads to shoot output light signal to pass light the column focuses through the lens at light detector up; Be examining light road anti- to extension on-line establish light trap; Cigarette holder just above in order to gasp device, cigarette holder with gather a smoke cover to connect with each other, under one by one in order is sample cup, heating apparatus, the temperature spreads a feeling machine to place in sample cup, is carried out smoke by the single slice machine to order an automatic measurement. Its advantage BE: Light source and light detector aren't on a straight line, adopting light trap in the meantime, raising an examination of intelligent degree and accuracy; The pollution established to shield to lead to flow bore, gasped device and lined up dirty bore, avoided soot to give or get an electric shock a component to the light, let up temperature to the influence which gives or gets an electric shock a component only, raised instrument accuracy and service life.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

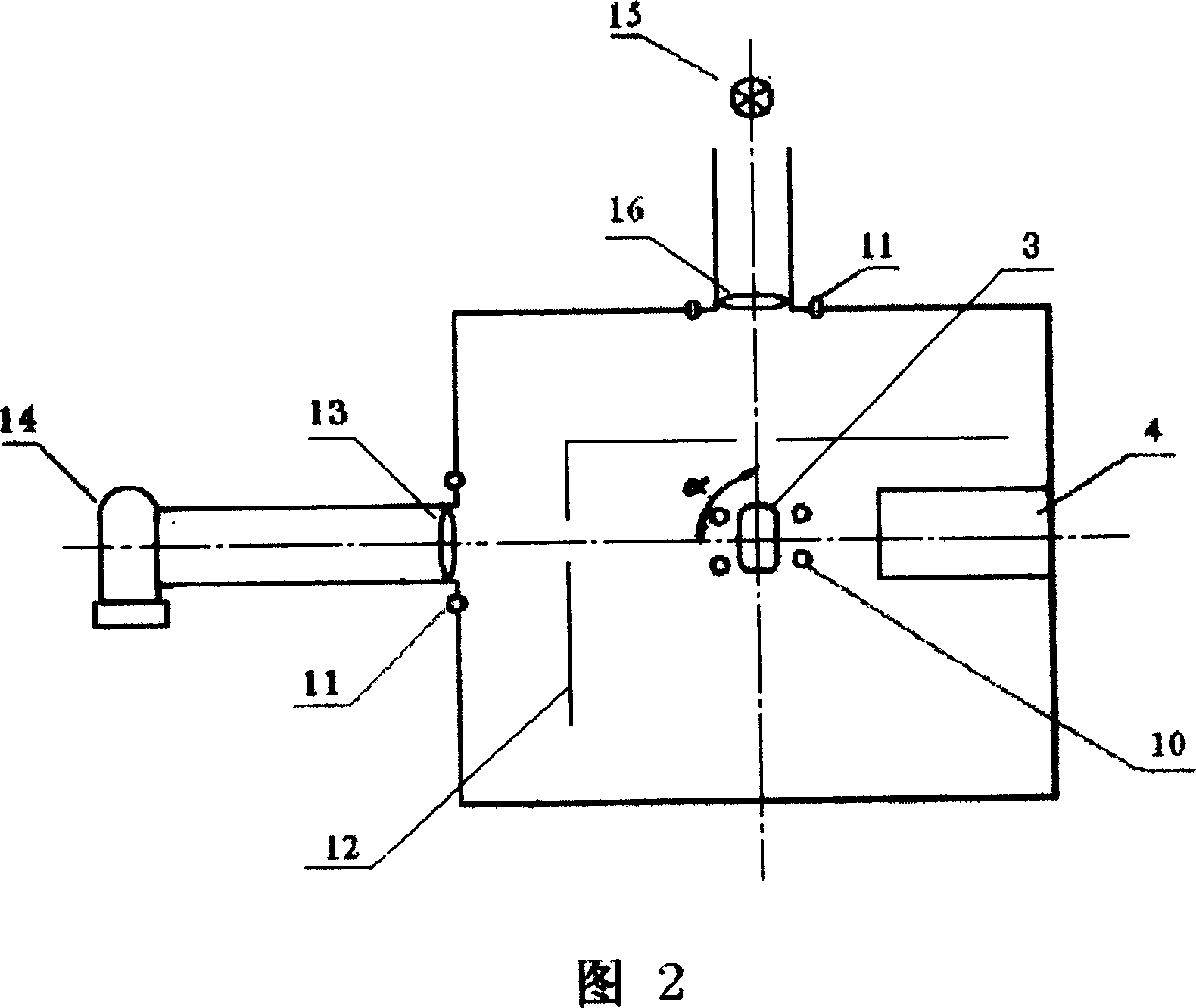

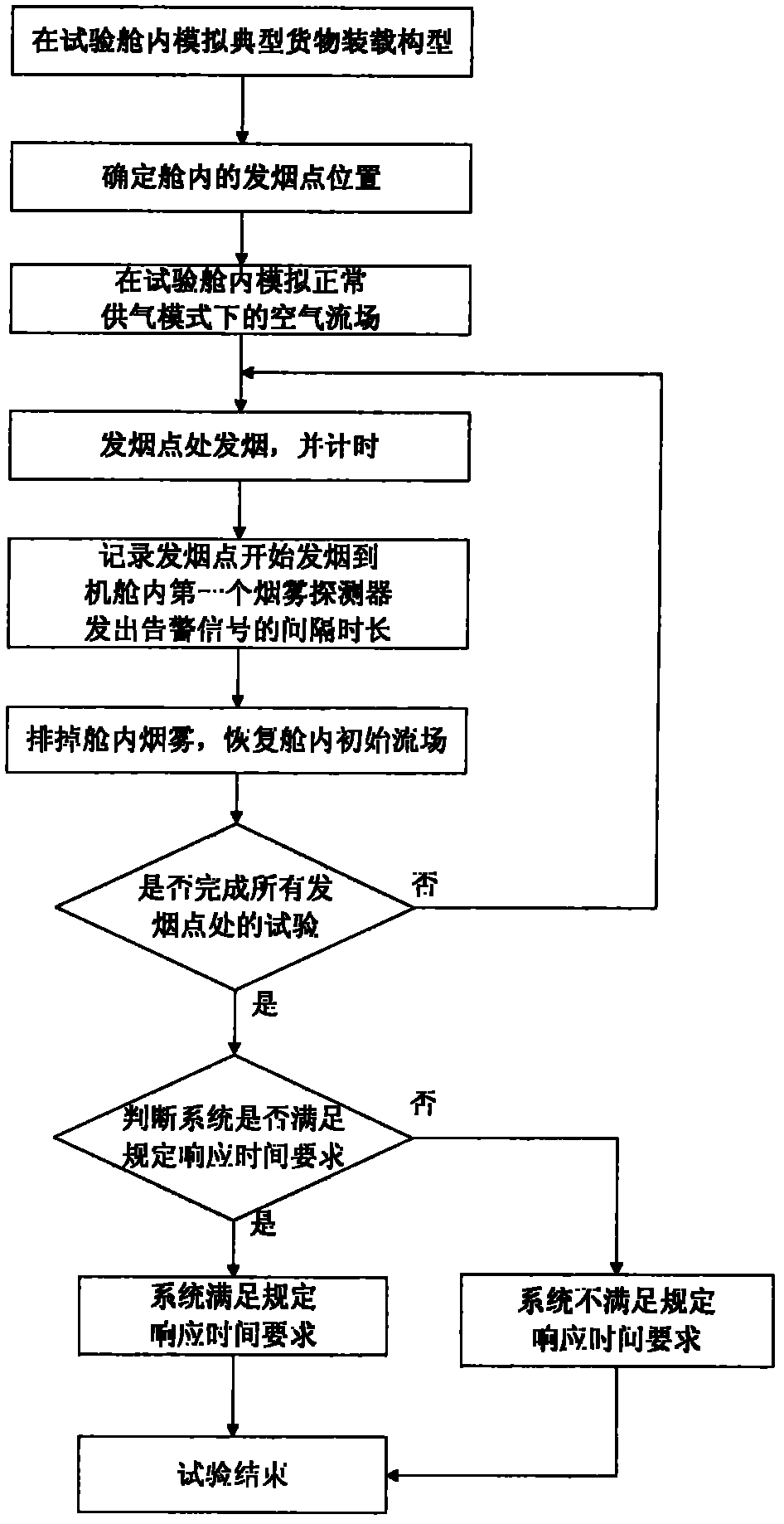

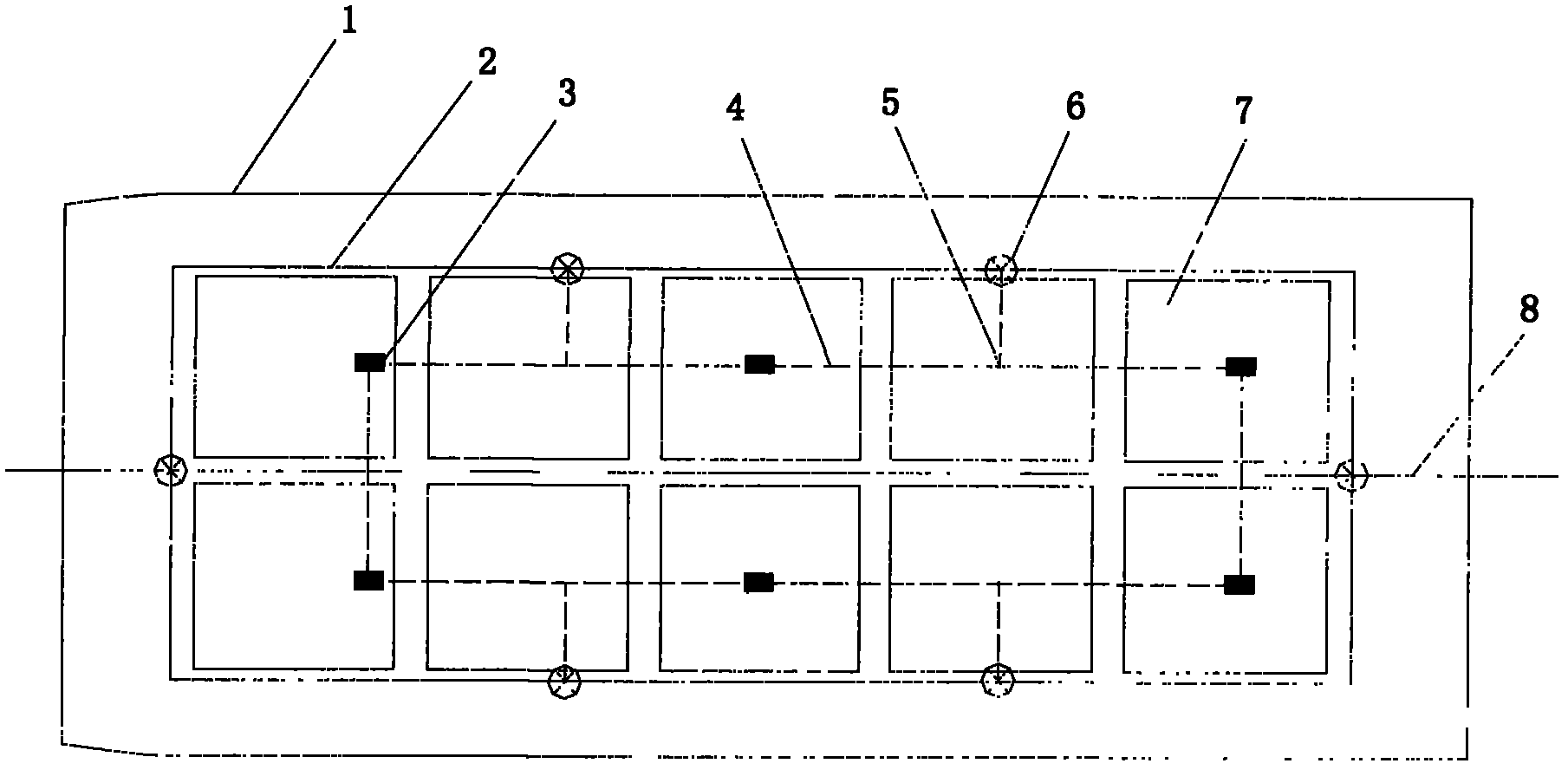

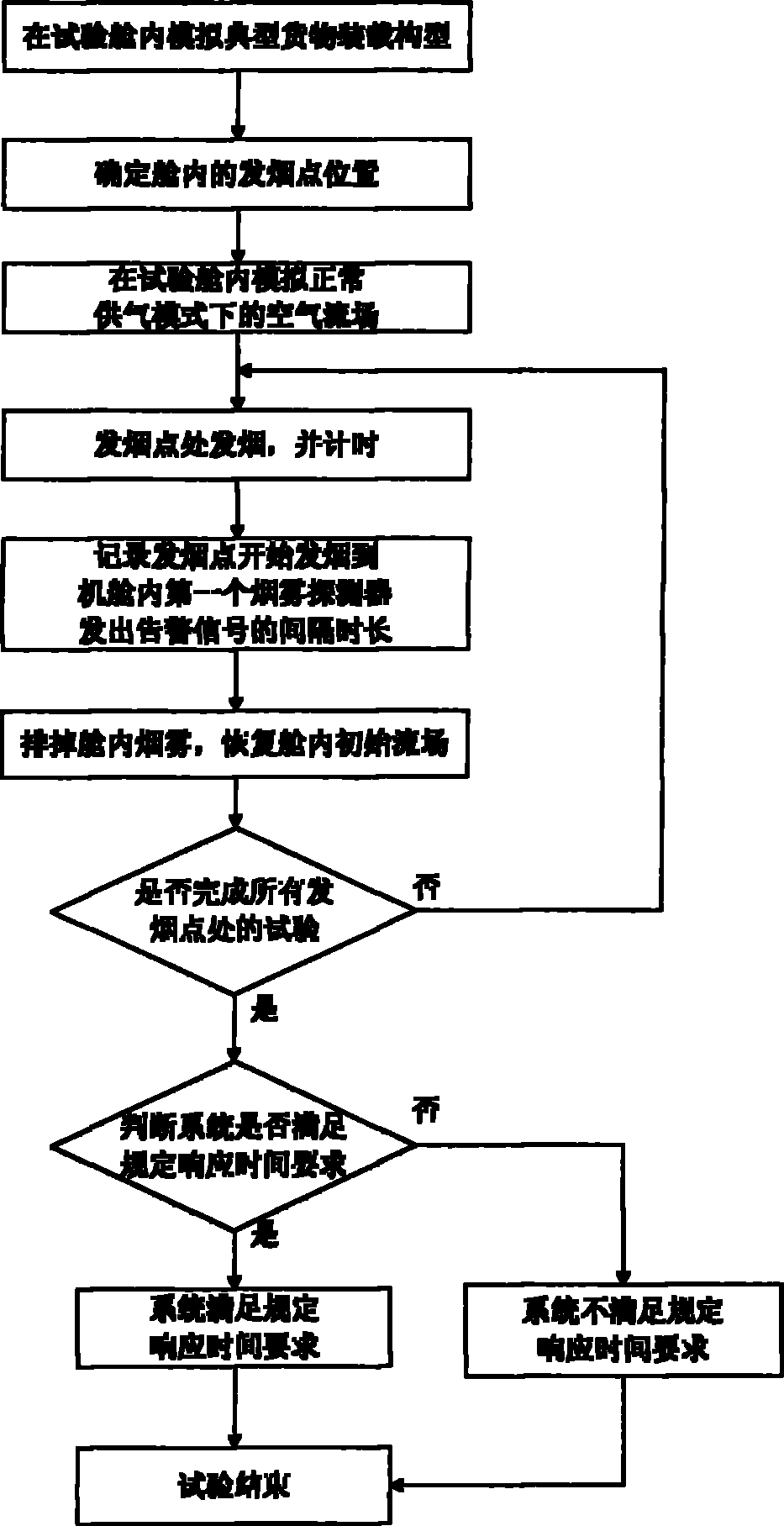

Smoke detection system testing method used in aircraft cabin

The invention relates to a smoke detection system testing method used in an aircraft cabin. The invention mainly provides the smoke detection system testing method which can be applied in the aircraft cabin, is safe and reliable and has strong operability and the steps of the method, especially selection and arrangement of the smoke points. The method has the following advantage: the performancesof the smoke detection systems in the cabins can be efficiently verified through the tests in ground laboratories.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

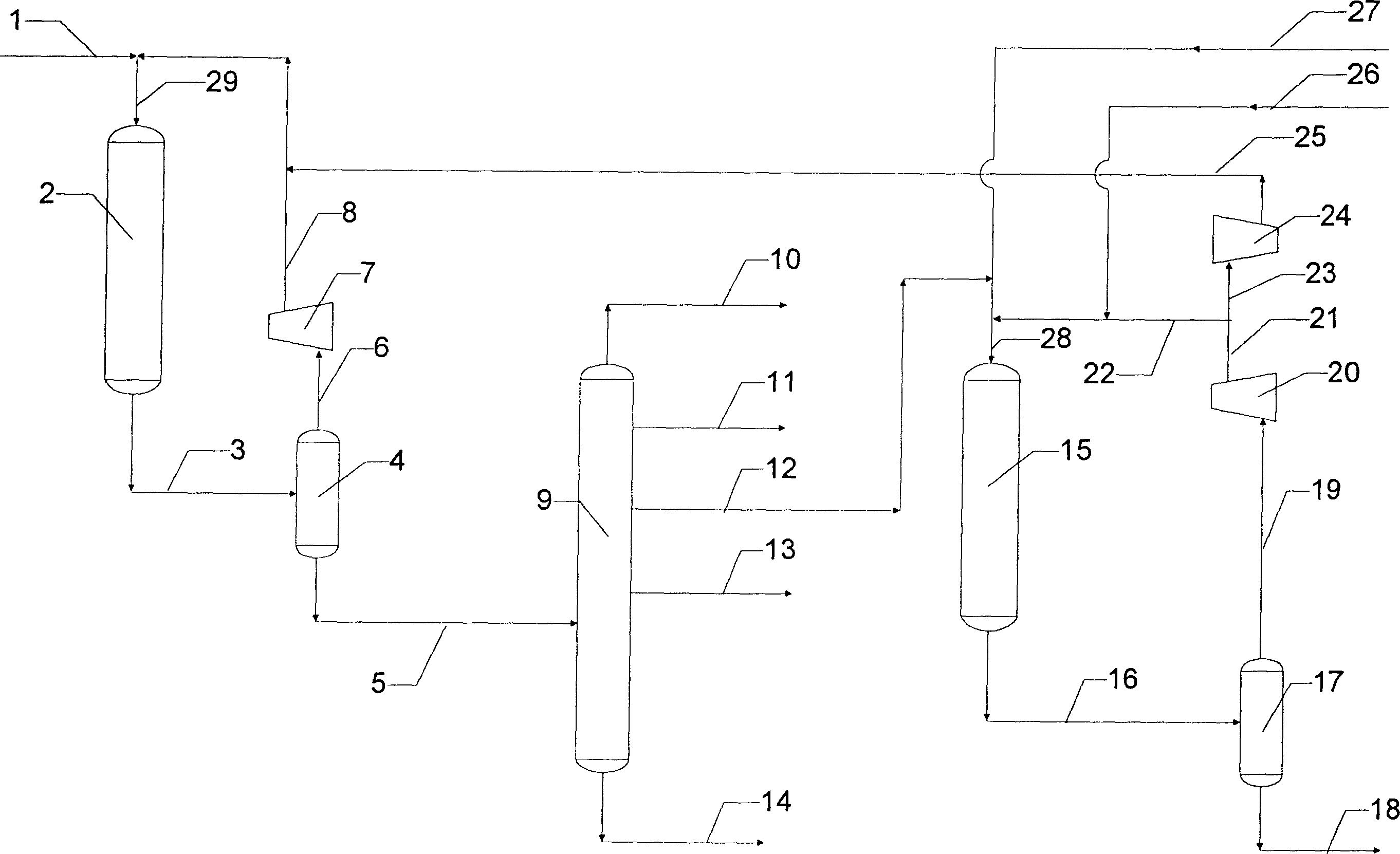

Jet fuel producing process

InactiveCN1224678CBroaden sources of raw materialsTreatment with hydrotreatment processesHydrogenation reactionSmoke point

In the jet fuel producing process, heavy material is first hydrocracked and the resultants of hydrocracking reaction are separated to obtain intermediate fraction oil. The intermediate fraction oil and light material are then hydrogenation processed and the resultants of the hydrogenation reaction are separated to obtain the destination product jet fuel. Fresh hydrogen may be replenished to hydrocracking reaction region and / or hydrogenation processing reaction region. The present invention can produce jet fuel with qualified smoke point, arene content and other indexes at relatively low reaction pressure, and this expands the material source for producing jet fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

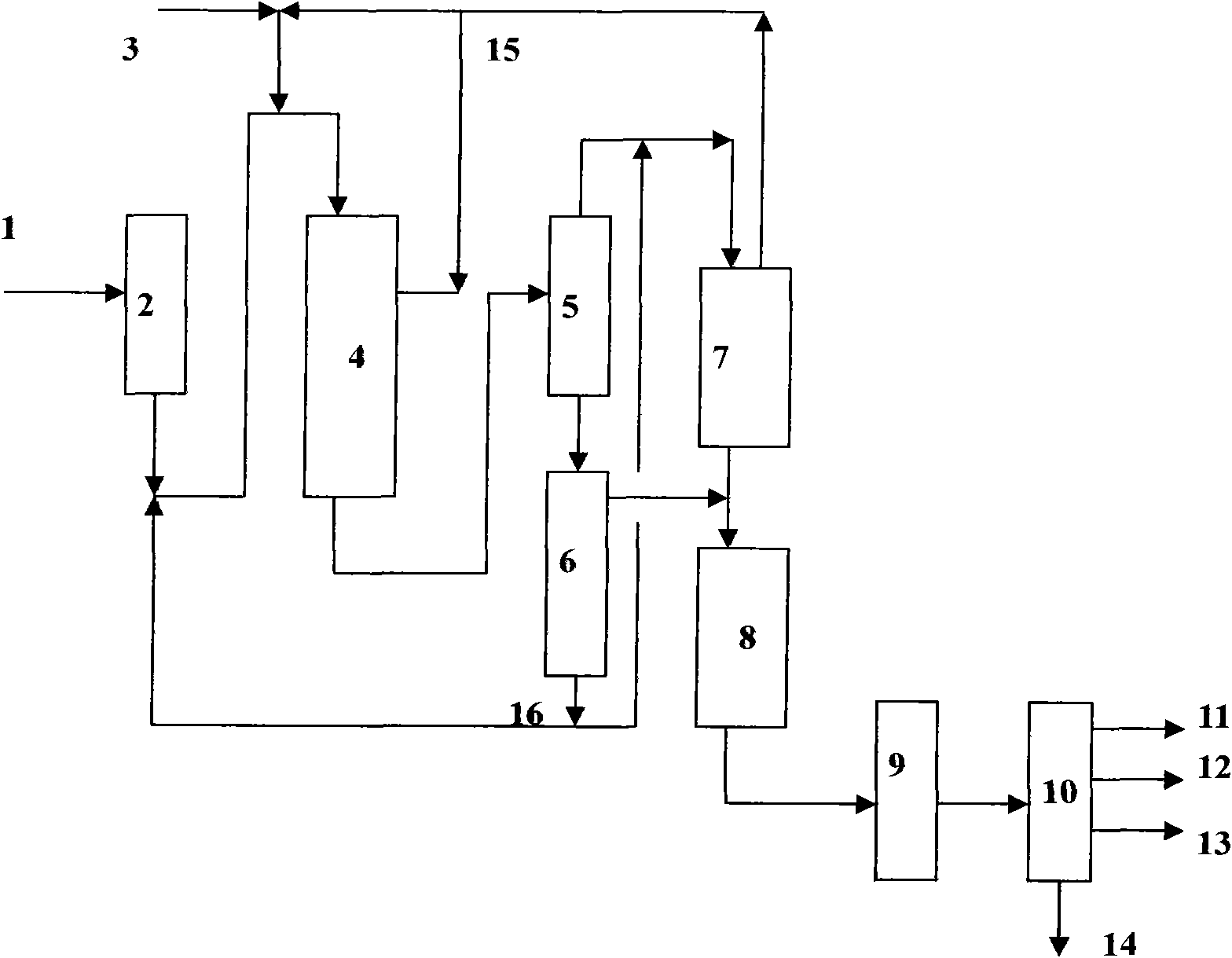

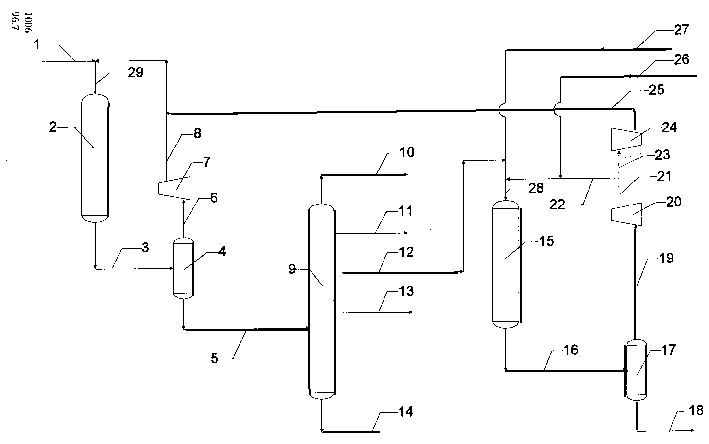

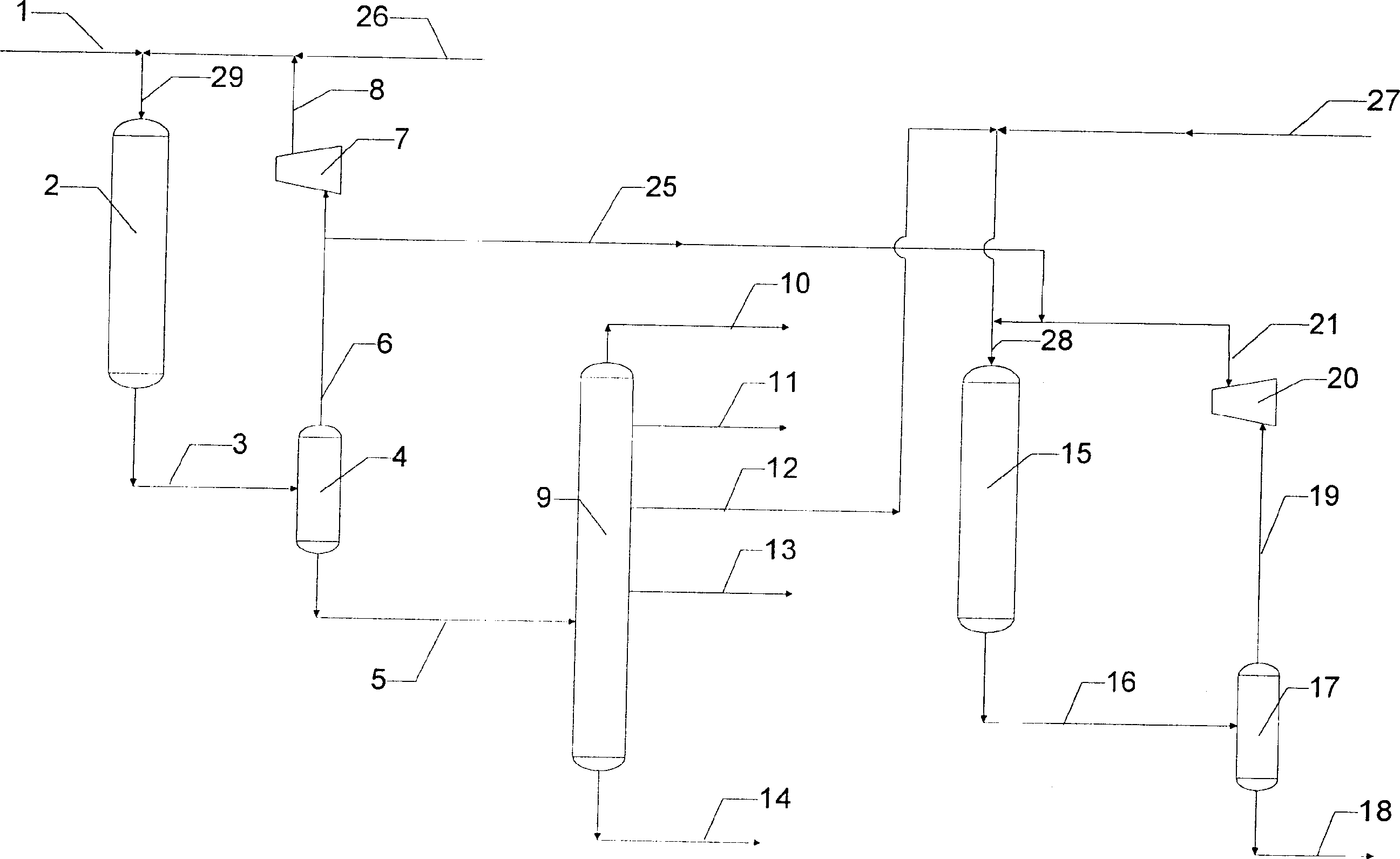

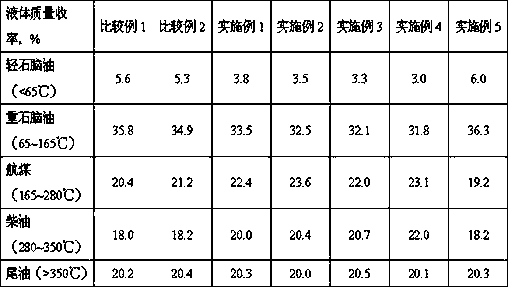

Hydro-cracking method for reducing bromine index of heavy naphtha and increasing smoke point of aviation kerosene

PendingCN111088072AIncrease aromaticsIncreased naphthenic contentTreatment with hydrotreatment processesAlkaneCracking reaction

The invention discloses a hydro-cracking method for reducing bromine index of heavy naphtha. The method comprises the following steps: mixing raw oil and hydrogen, then introducing the mixture into ahydro-refining reactor, carrying out a hydro-refining reaction; introducing the reaction effluent into a hydro-cracking reactor, introducing the oil generated by hydro-cracking into a fractionating tower after going through a high-pressure separator and a low-pressure separator so as to obtain dry gas, liquefied gas, light naphtha, heavy naphtha, light aviation kerosene, heavy aviation kerosene, diesel oil and tail oil, and returning part or all of the light aviation kerosene to the hydro-cracking reactor. According to the method, the content of aromatic hydrocarbons and cyclo-alkane in reactants and ammonia partial pressure can be effectively improved, and secondary cracking reaction of paraffin is inhibited, so that the purposes of reducing the bromine index of heavy naphtha and increasing aviation kerosene smoke point are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

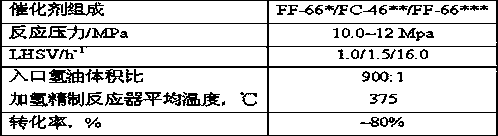

Detection device for smoke point of edible vegetable oil and fat

InactiveCN108226212AAutomatic determinationAccurate measurementInvestigating phase/state changeOil and greaseVegetable oil

The invention discloses a detection device for a smoke point of edible vegetable oil and fat. The detection device comprises a sealed heating unit, an oil cup, a smoke collector, a temperature sensor,a photoelectric smoke sensor, a connecting block and a hoisting arm, wherein the oil cup is arranged above the sealed heating unit; the smoke collector is arranged above the oil cup; a smoke outlet hole is formed in the top part of the smoke collector; the smoke outlet hole is connected to the connecting block through a connecting pipe; an inclined flue which has a high right end and a low left end and is inclined is arranged in the connecting block; the photoelectric smoke sensor is arranged at the left end of the inclined flue; the upper end of the connecting pipe penetrates through the connecting block and is communicated with the inclined flue. The detection device for the smoke point of the edible vegetable oil and fat is reasonable in design and can be used for automatically, accurately and rapidly determining the smoke point of the edible vegetable oil and fat.

Owner:山东盛泰仪器有限公司

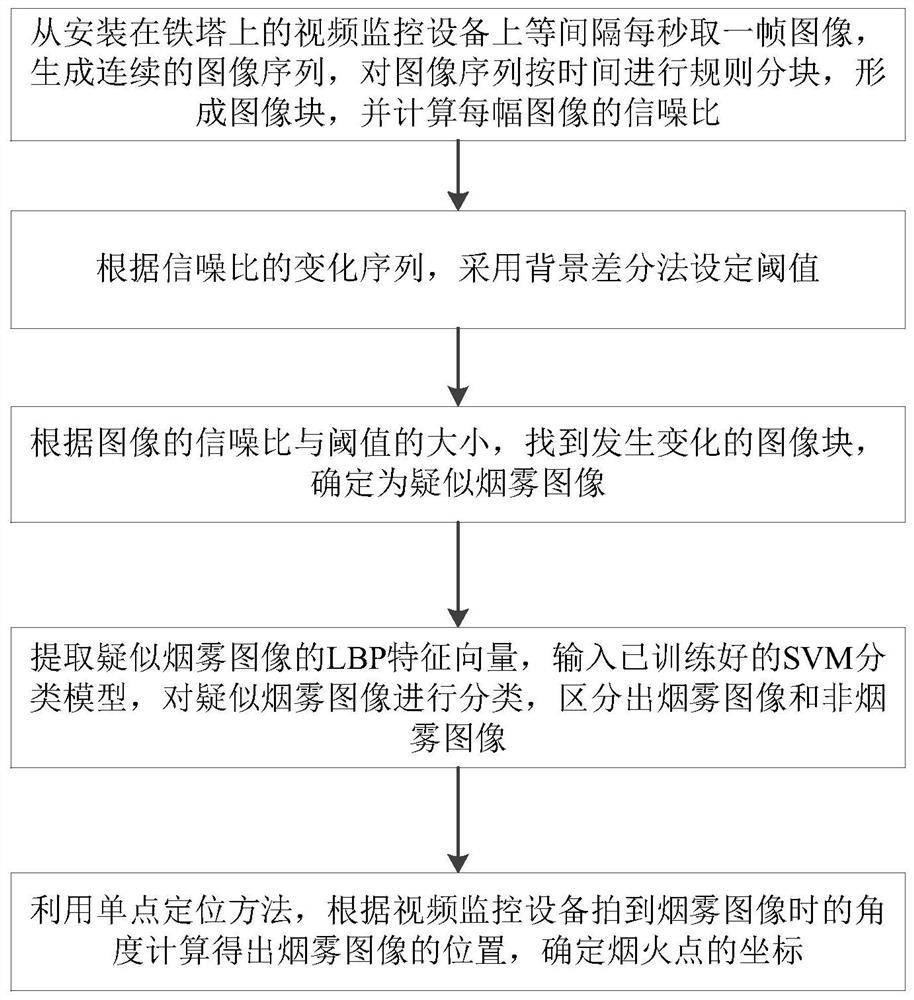

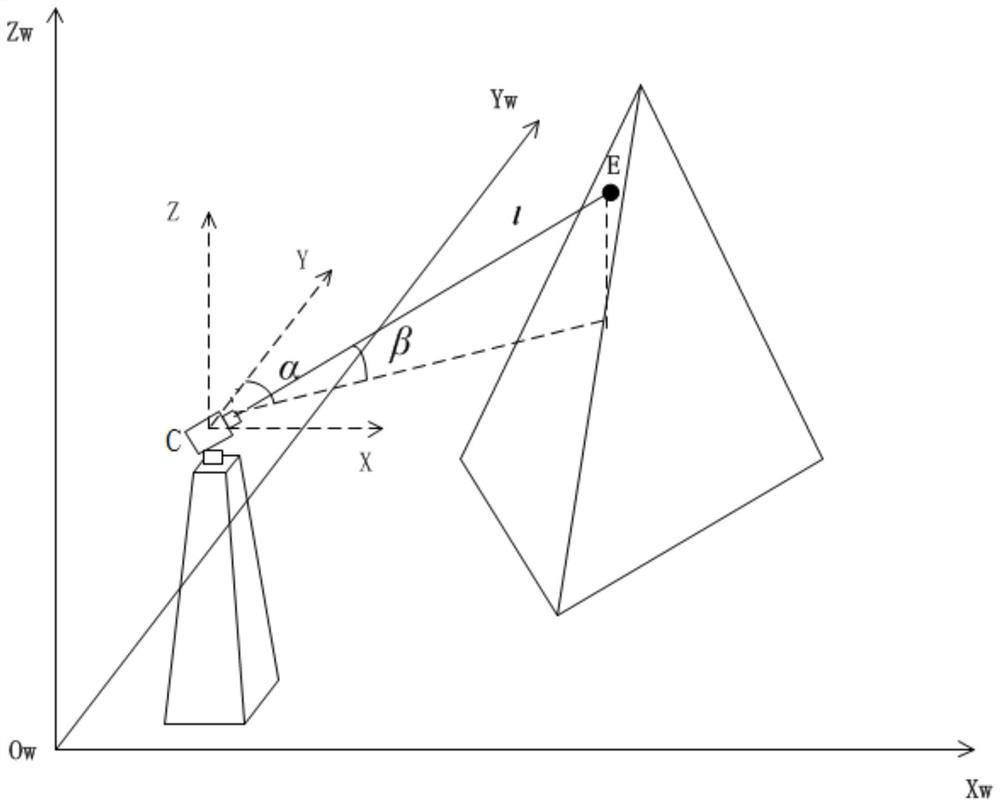

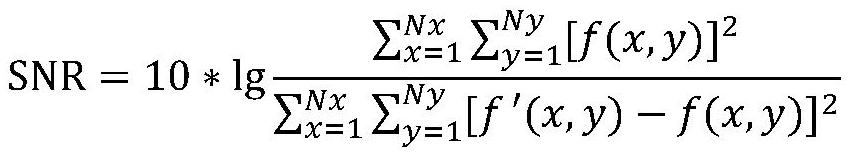

Smoke and fire point positioning method based on video monitoring

PendingCN113989488AReduce labor costsImprove monitoring and identification efficiencyCharacter and pattern recognitionNeural architecturesVideo monitoringFeature vector

The invention discloses a smoke and fire point positioning method based on video monitoring, and the method comprises the following steps: taking a frame of image from video monitoring equipment at equal intervals per second, generating a continuous image sequence, carrying out the regular partitioning of the image sequence according to time, forming image blocks, and calculating the signal-to-noise ratio of each image; setting a threshold value by adopting a background difference method according to the change sequence of the signal-to-noise ratio; according to the signal-to-noise ratio of the image and the threshold value, finding out a changed image block, and determining the changed image block as a suspected smoke image; extracting an LBP feature vector of the suspected smoke image, inputting the LBP feature vector into a trained SVM classification model, classifying the suspected smoke image, and distinguishing a smoke image from a non-smoke image; and calculating the position of the smoke image by using a single-point positioning method, and determining the coordinate of a smoke point by combining forestry compartment data. According to the method disclosed by the invention, video monitoring is utilized to identify the smoke area, the secret-related problem is avoided, and deep learning is utilized to identify smoke, so that the identification accuracy can be improved.

Owner:QINGDAO HAOHAI NETWORK TECH

A hydrocracking method for processing inferior raw materials

ActiveCN103773450BHigh yieldImprove product qualityHydrocarbon oil crackingTreatment with hydrotreatment processesAlkaneMolecular sieve

The invention relates to a hydrocracking method for processing an inferior raw material. The method comprises (1) performing hydrofining reaction of inferior raw oil; (2) performing gas-liquid separation of a hydrofined effluent to obtain a liquid for fractionation; (3) performing hydrocracking reaction on tail oil obtained by the fractionation, two hydrocracking catalyst I and II with different molecular sieve contents existing in a hydrocracking reaction zone; and (4) mixing a hydrocracked effluent and the inferior raw material to get into a hydrotreating reaction zone. According to the method, the upstream catalyst I in the cracking reaction zone has a strong aromatic conversion ability, can convert heavy components in the raw material into smaller molecules to distribute into naphtha and jet fuel fractions, the downstream catalyst II has a strong alkane cracking ability, by synergistic effect of the two catalysts, the quality of hydrocracked products can be significantly improved, and especially, and the smoke point of the jet fuel fractions can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Blend oil suitable for frying food

InactiveCN104782793AReduce erucic acid contentSuitable for fryingEdible oils/fatsCottonseed oilSmoke point

The invention discloses blend oil suitable for frying food. The blend oil is prepared from the following raw materials in percentage by weight: 30%-40% of cottonseed oil, 30%-40% of rapeseed oil and 20%-30% of palm oil, wherein the cottonseed oil and the rapeseed oil are refined salad oil. The blend oil disclosed by the invention is low in erucic acid content, good in shortning performance, high in smoke point and suitable for frying food, and a proportion of the linoleic acid to the linolenic acid meets the edible oil health standards (about 4 to 1).

Owner:广西明华晟粮油科技有限公司

Chinlon DTY oiling agent formula and production method

InactiveCN109267183AEasy to useAvoid separationSynthetic polymer filament chemical after-treatmentSolubilityPolyester

The invention discloses a chinlon DTY oiling agent formula and a production method. The chinlon DTY oiling agent formula comprises the following components by weight percent: 1 to 4 percent of fatty alcohol-polyoxyethylene ether, 1 to 2 percent of polyethylene glycol, 2 to 4 percent of fatty alcohol polyoxyethylene phosphate potassium salt, 1 to 2 percent of sorbitan mo-nooleate, 1 to 2 percent ofanti-splashing agent, 0.1 to 0.4 percent of penetrating agent, and 85.6 to 93.9 percent of cosmetics-level white oil. The chinlon DTY oiling agent formula disclosed b y the invention has the advantage of good application effect; the chinlon DTY oiling agent formula and the production method are suitable for pre-oriented yarn (POY) spinning oiling agents of polyester and chinlon (nylon) and also suitable for producing fully-drawn yarns (FDY) and stretchable yarn (DTY) (a uniform oiling agent in two adjacent steps), have the advantages of high smoke point, high automatic spreadability, high lubricating performance, high strand integrity, excellent washability prior to the staining, and can improve the spinning antistatic performance and the oiling rate of the oiling agent, so that the oiling agent is light in color, the oiling agent is good in solubility with water, has a good emulsification effect, is high in emulsification fast-cut degree, white in color, and capable of preventing theseparation of oil and water for a long term.

Owner:浙江新胜油脂科技有限公司

Hybrid bacon cooking system

Owner:HORMEL FOODS

Low-residue, easy-cleaning and low-viscosity structured lipid pan release compositions and methods

InactiveUS7247334B2Low viscosityHigh smoke pointFatty acid esterificationFatty-oils/fats refiningSmoke pointMedium chain triglycerides oil

Medium chain triglyceride oils are interesterified with long chain edible oils in order to form interesterified structured lipids. These structured lipids find special application in food service pan release cooking compositions and methods. The products have a relatively low viscosity of between about 20 and about 52 centipoise while having a smoke point which is especially suitable for cooking applications. They provide enhanced release properties, reduced darkening effects, less residue build-up, and enhanced cleaning of griddling, cooking and baking pans, containers and utensils.

Owner:BUNGE OILS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com