Patents

Literature

116results about How to "High smoke point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

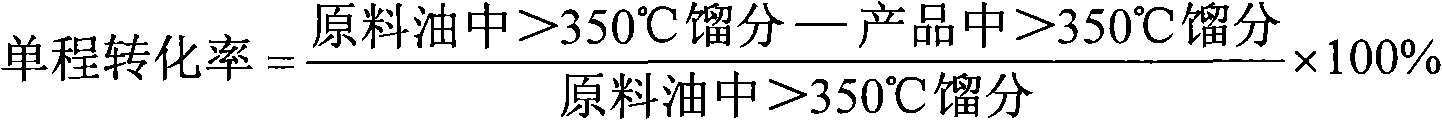

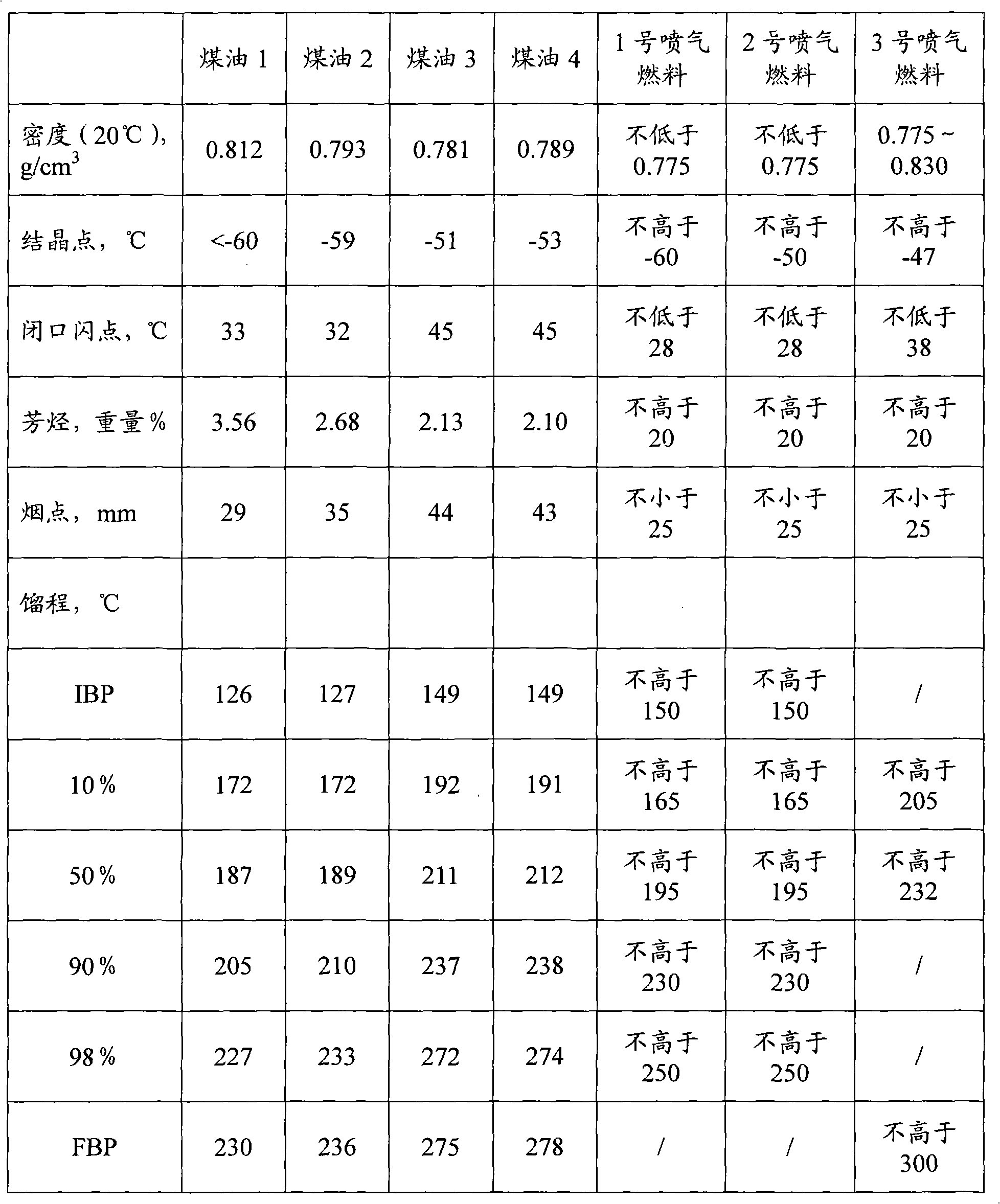

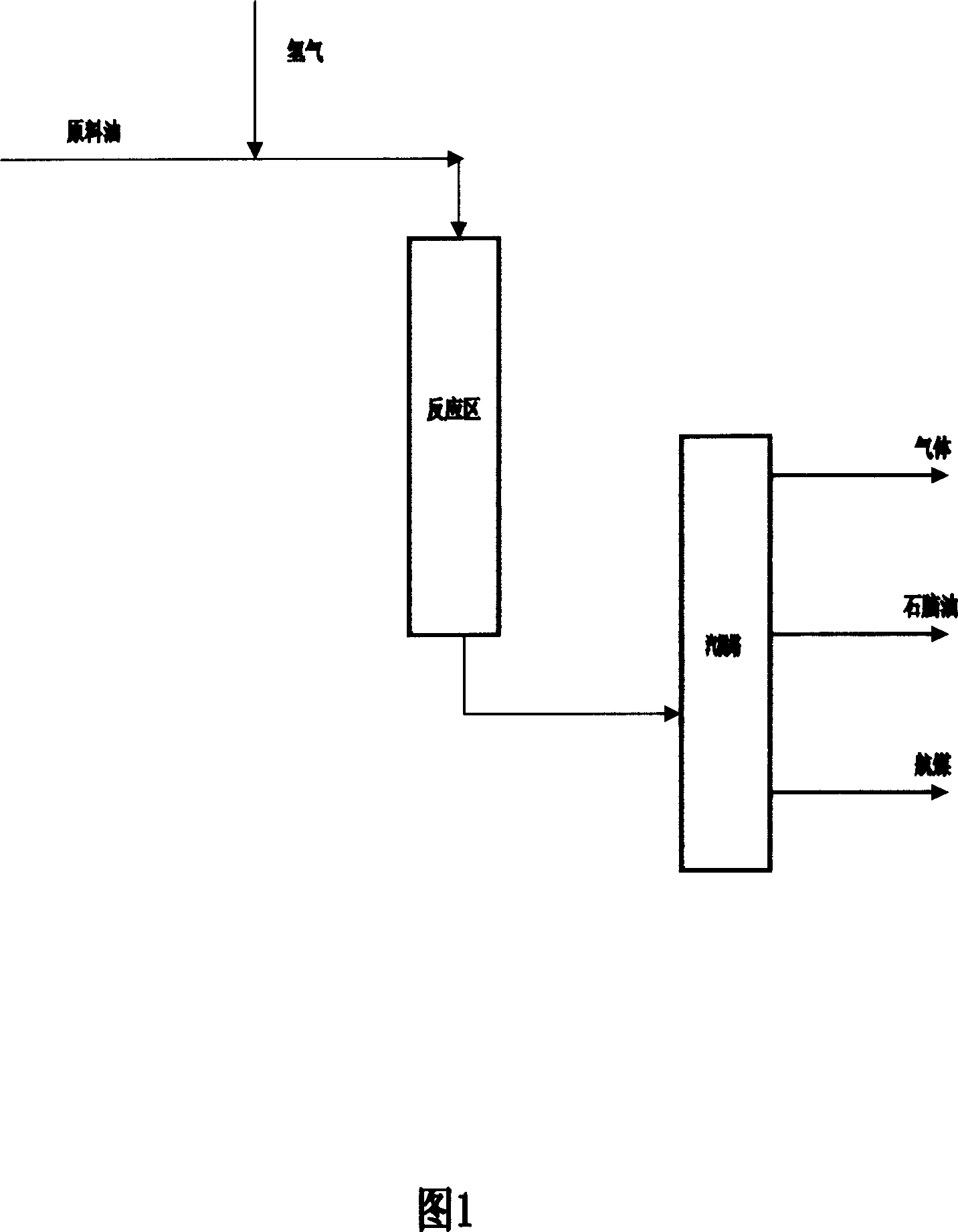

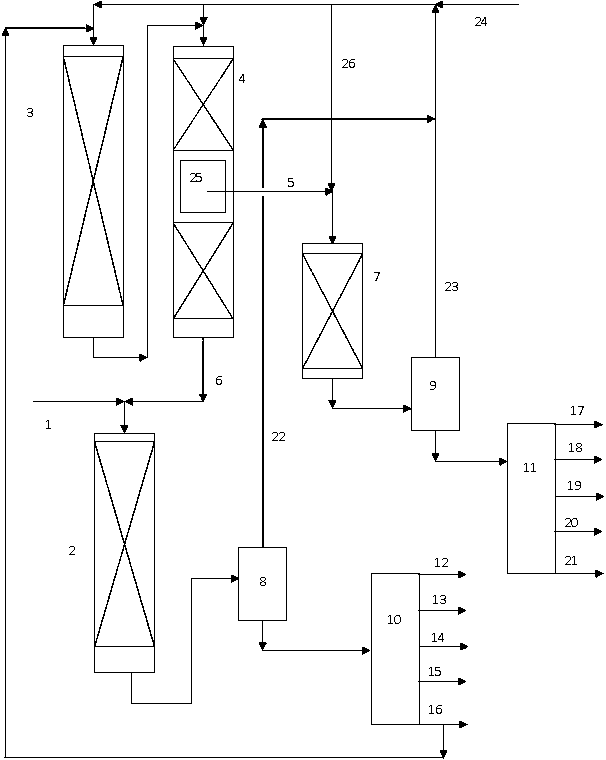

Hydrocracking method for selective increasing of aviation kerosene yield

ActiveCN103013559AGuaranteed selectivityQuality improvementTreatment with hydrotreatment processesHydrogenSmoke point

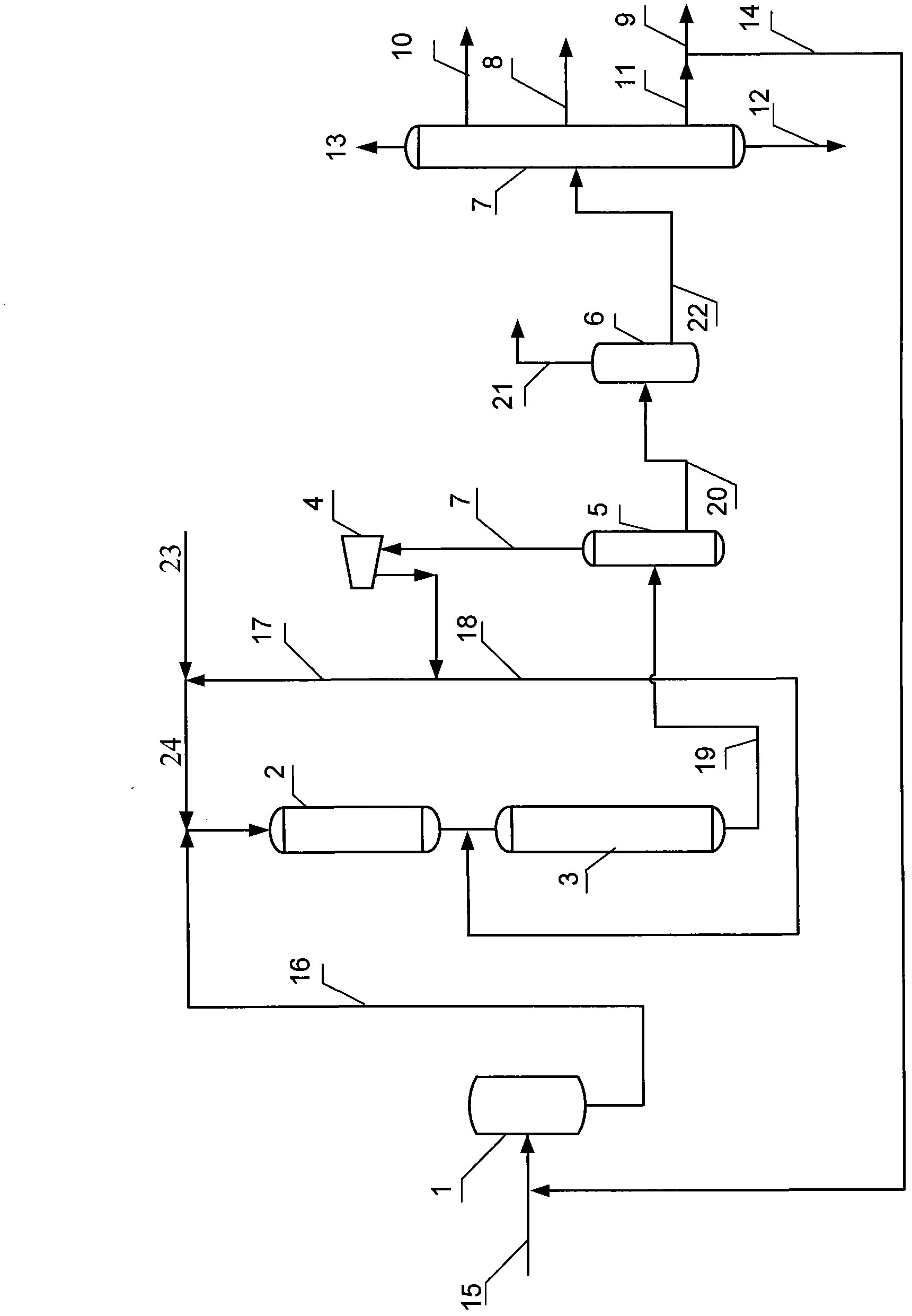

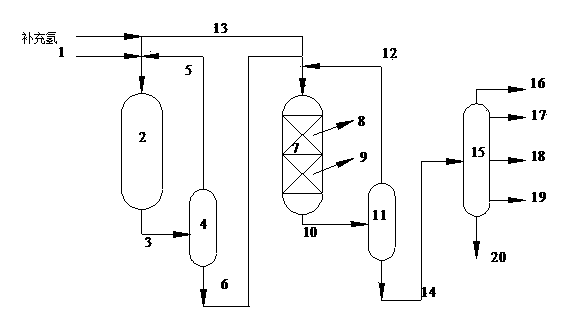

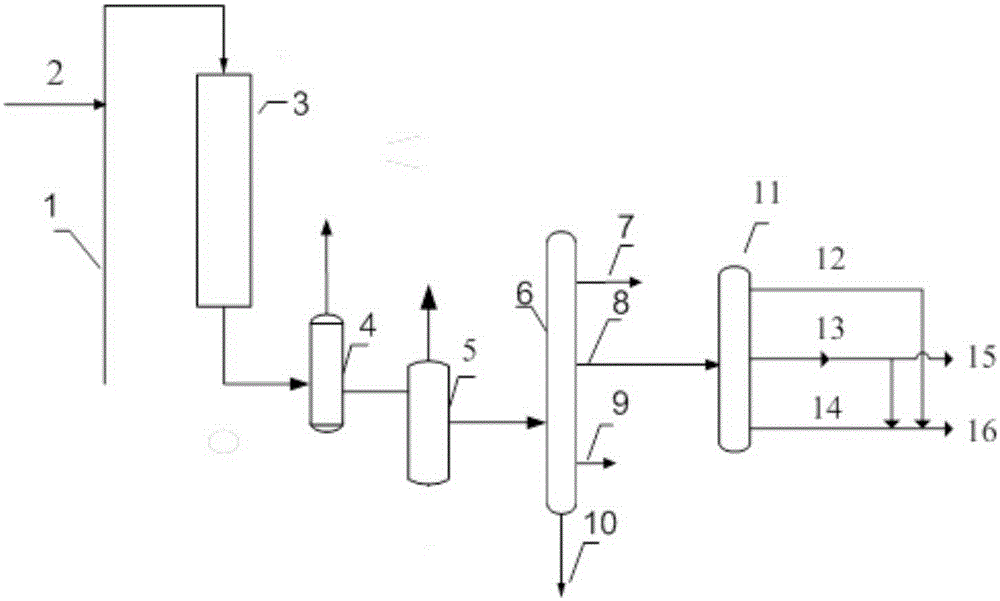

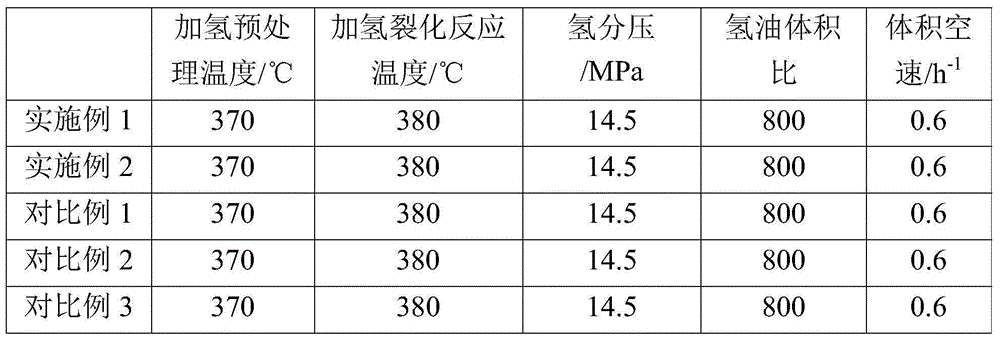

The invention discloses a hydrocracking method for selective increasing of an aviation kerosene yield. The hydrocracking method comprises that raw oil and hydrogen are mixed and then orderly undergo a hydrofinishing reaction and a hydrocracking reaction; a reaction effluent is cooled and is subjected to separation so that a heavy diesel fraction is obtained; and the heavy diesel fraction having the content of 10 to 100% and a temperature of 320 to 370 DEG C is fed back to a raw material tank and then undergoes a reaction sequentially, wherein the heavy diesel fraction has low aromatic hydrocarbon content and naphthenic hydrocarbon content and is an appropriate fraction for selective increasing of aviation kerosene yield. The hydrocracking method realizes high selectivity of an aviation kerosene fraction. The recycle heavy diesel fraction is fed into the raw material tank and undergoes a hydrofinishing reaction in a hydrofinishing reactor and a hydrocracking reaction in a hydrocracking reactor so that an aromatic hydrocarbon further undergoes a hydrogenation saturation reaction. Therefore, the hydrocracking method is conducive to improvement of a smoke point of aviation kerosene and reduction of aromatic hydrocarbon content of aviation kerosene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing jet fuel or jet fuel blending component

ActiveCN101928599ARelaxed reaction conditionsLow operating costTreatment with hydrotreatment processesJet fuelCoal liquefaction

The invention discloses a method for producing a jet fuel or a jet fuel blending component. A mixed oil is obtained by mixing a Fischer-Tropsch synthesis fuel and a direct coal liquefaction oil; and the jet fuel or jet fuel blending component is obtained by hydrorefining, hydrocracking, isocracking and fractionating the mixed oil. According to the method provided by the invention, two prepared coal oils can be converted into the high-quality jet fuel or jet fuel blending component. Compared with hydro-upgrading of the direct coal liquefaction oil, the method has the advantages of mild reaction conditions, low device investment cost and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

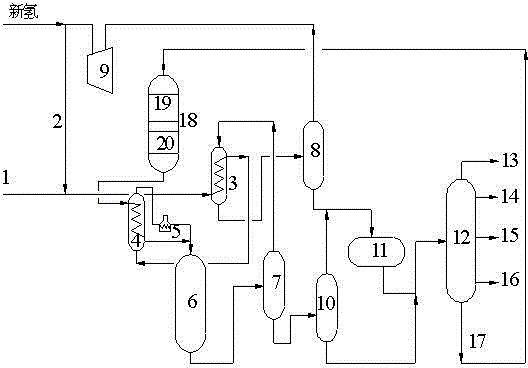

A low-energy hydrocracking method for processing inferior raw materials

ActiveCN104611020BReduce consumptionSave engineering investmentTreatment with hydrotreatment processesHydrocarbon oils treatment productsOperating energyFractionation

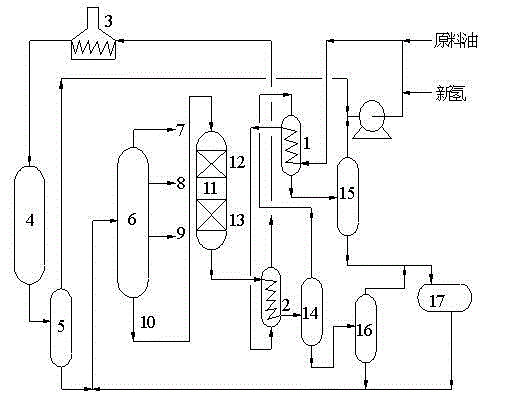

The present invention discloses a low energy consumption hydrocracking method for processing a poor-quality raw material. According to the method, a raw material and hydrogen gas are mixed, are subjected to heat exchange two times, pass through a heating furnace, and then are subjected to a hydrorefining reaction; the refining effluent is subjected to separation and fractionation; the obtained tail oil enters a hydrocracking reaction zone, wherein the cracking reaction zone comprises at least two cracking catalysts, the upstream is a catalyst I, the downstream is a catalyst II, the catalyst I contains 15-50 wt% of a modified Y molecular sieve, the catalyst II contains 3-30 wt% of the modified Y molecular sieve, and the modified Y molecular sieve content in the catalyst I is 10-25% higher than the modified Y molecular sieve content in the catalyst II; and the hydrocracking effluent and poor-quality raw material oil are mixed and then enter a hydrorefining reaction zone. According to the method of the present invention, the high temperature high pressure countercurrent heat transfer technology and the hydrocracking catalyst grading technology are organically combined, and the hydrocracking reaction heat is comprehensively utilized, such that the catalyst selectivity is maintained while the target product quality is improved, and the project investment and the operating energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

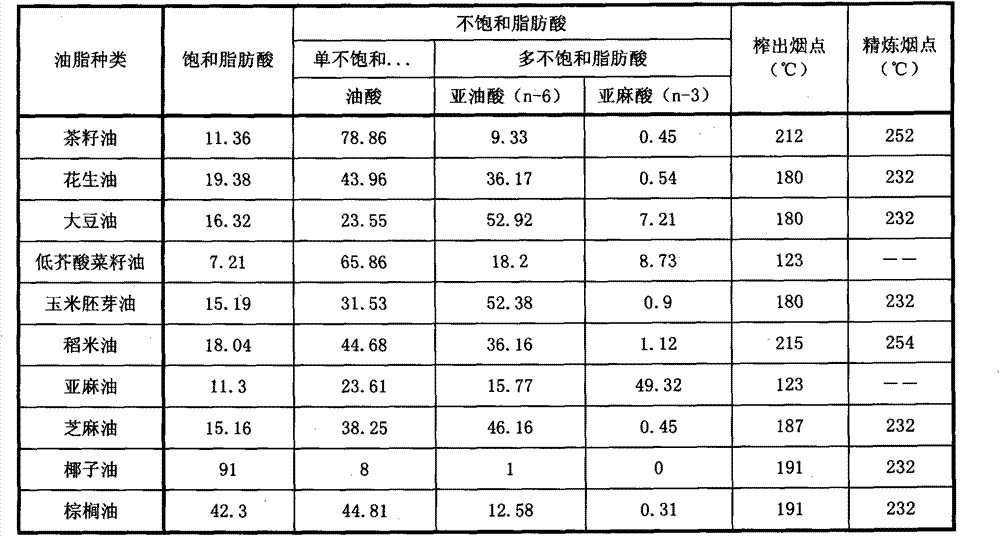

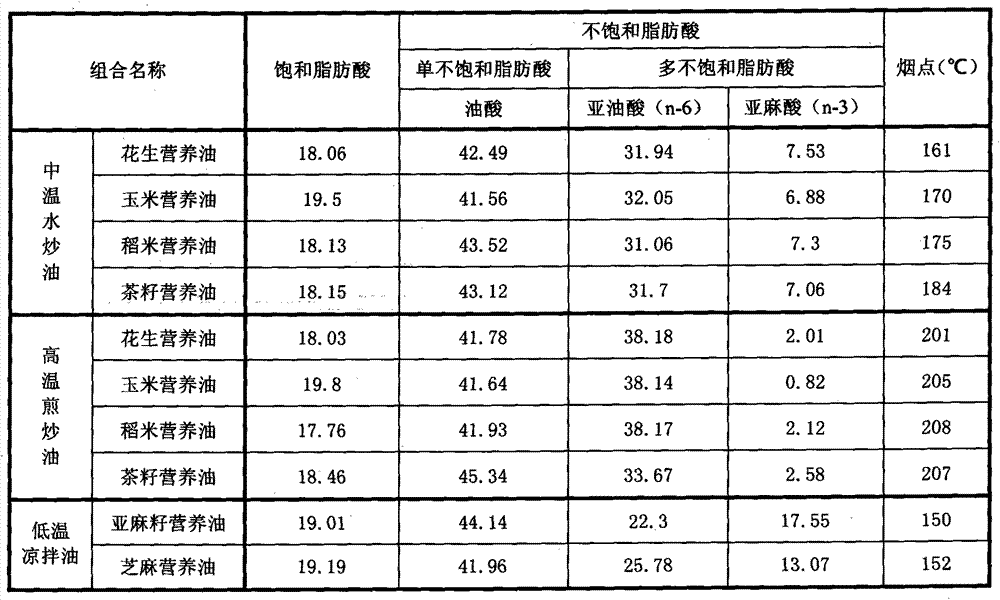

Multivariate plant nutrition oil and preparation method thereof

The invention discloses multivariate plant nutrition oil comprising medium-temperature water-frying oil, high-temperature frying oil and low-temperature salad oil which are respectively prepared from any 2-6 types of 10 types of plant oil such as tea-seed oil, peanut oil and rice oil. Meanwhile, a plurality of plant functional elements such as pollen pini and almond are added to the nutrition oil; the content ratio of saturated fatty acid to monounsaturated fatty acid to polyunsaturated fatty acid in the multivariate plant nutrition oil is 0.45:1:0.9; the content ratio of n-6 polyunsaturated fatty acid to n-3 polyunsaturated fatty acid is (3-6):1. The nutrition oil disclosed by the invention is reasonable in proportioning, the price is considered, and diseases such as hypertension and hyperlipidemia which can be caused by over-high intake of traditional saturated fatty acid and linoleic acid and over-low intake of linolenic acid are solved.

Owner:邓柏福

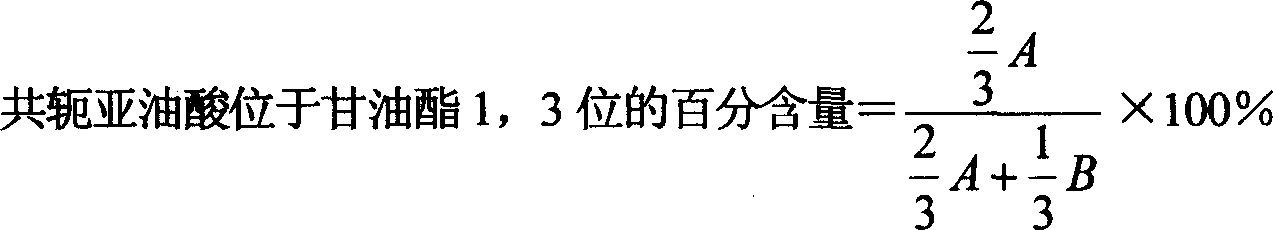

Greasy of containing glycerin ester type conjugate linolic acid and protuction process thereof

ActiveCN100999698AHigh smoke pointAdd flavorFatty acid chemical modificationTriglycerideReaction temperature

The present invention relates to one kind of grease containing glyceride type conjugated linoleic acid and its production process. The grease includes glyceride type conjugated linoleic acid in 1-15 wt%, and over 88 % of the conjugated linoleic acid is located in the 1st and 3rd position. The production process includes the following steps: 1. mixing conjugated linoleic acid donor and triglyceride type grease in the weight ratio of 1-20 to 60; 2. lipase catalyzed reaction of the mixture at 35-90 deg.c; and 3. distilling the reaction product for separating and collecting the glyceride product with combined conjugated linoleic acid. The obtained product may be used to replace common edible oil for replenishing conjugated linoleic acid possessing the health functions of antagonizing atherosclerosiss, resisting cancer, slimming, etc.

Owner:SOUTH CHINA UNIV OF TECH

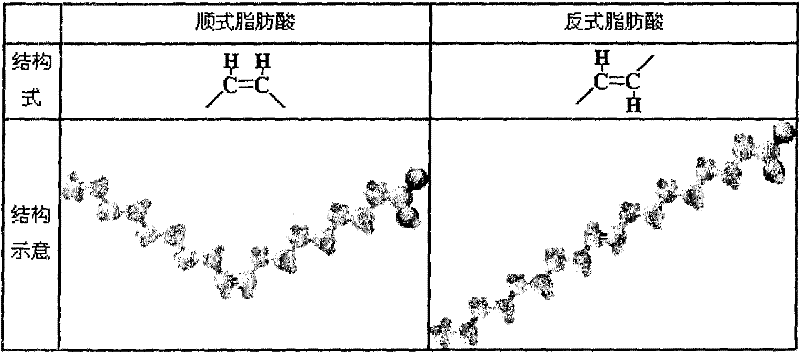

A kind of lower trans fatty acid edible vegetable oil and refining method thereof

InactiveCN102273522ALight colorHigh smoke pointFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The invention relates to fully refined edible vegetable oil with lower trans fatty acid and a refining method thereof. The vegetable oil is rapeseed oil, soybean oil, corn oil or blending oil with any ratio; the trans fatty acid content of the vegetable oil is less than or equal to 1 weight percent; and the oil smoke point is more than or equal to 210 DEG C. The refining method comprises the steps of selecting crude oil, degumming, deacidifying, removing saponin, dehydrating, decoloring, removing impurities, deoxidizing, deodorizing, cooling and obtaining finished products. The refining method is characterized in that: at the decoloring state, the removing grain size of the impurities is reduced from 25 mu m to 10 mu m; and at the deodorizing stage, the deodorizing temperature is controlled to be between 230 and 245 DEG C and the vacuum degree is controlled to be within 2 tau. Oil is refined at lower temperature and a lowest trans fat structure is realized by controlling the grain size of the impurities and the vacuum degree; after being refined, the vegetable oil has good quality, namely the trans fatty acid is reduced to be lower than 60 percent of the normal level; and the refined vegetable oil has light color, high smoke point, high purity and storage resistance and is beneficial to people's long-term health.

Owner:SHENZHEN NANSHUN GREASE

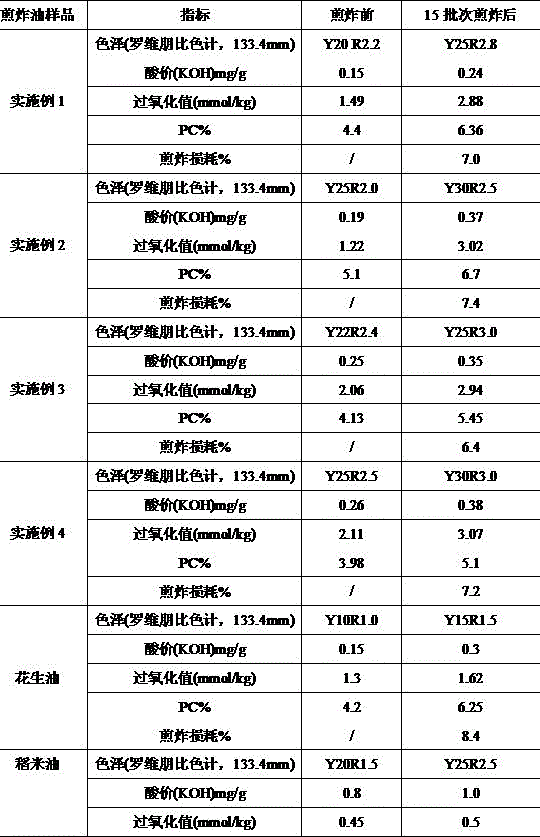

Special blend oil for frying and preparation method thereof

The invention discloses special blend oil for frying. The special blend oil for frying contains 10-50% by weight of high oleic acid peanut oil and 10-50% by weight of rice oil. The blend oil for frying is prepared by compounding any two or more than two of sunflower seed oil, olive oil, soybean oil, corn oil, cottonseed oil, palm oil, rapeseed oil, safflower oil, linseed oil and sesame oil in different proportions. The blend oil for frying is rich in fragrance, bright in color, high in content of oleic acid, rich in oryzanol and vitamin E, reasonable in composition of fatty acids and free of stickiness. Through a high-temperature frying test, the blend oil is high in smoke point, low in content of trans-fatty acids and high in frying stability. The fried food is small in oil content, good in crispy property, excellent in taste and nutritional and healthy. The blend oil disclosed by the invention can be used for frying different food materials, is suitable for being used as special fat for frying food in family and catering industry, is long in expiration date, and is novel nutritional and healthy special blend oil for frying.

Owner:山东金胜粮油食品有限公司

Emulsifiable oil for knitting

InactiveCN1995302AImprove antistatic performanceImprove cooling effectAdditivesDistilled waterAnti oxidant

The invention discloses a lubricating, anti-electrostatic, anti-rust and cooling liquid composition in the weaving manufacturing course, which consists of 85-92% mineral typed basic oil with multiple viscous basic oils and 8-15% additive, wherein the additive is composed of emulsifier, antirust agent, abrasion-proof agent, anti-oxidant, metal deactivator and distill water.

Owner:广东澳力丹润滑油有限公司

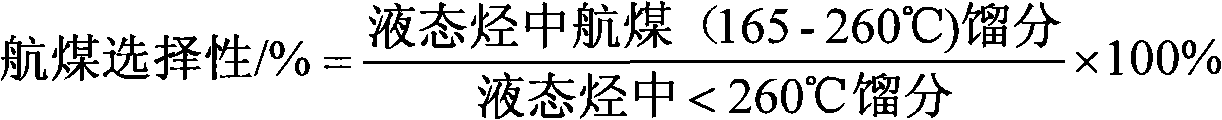

Two-stage hydrocracking method

ActiveCN103773463AIncrease hydrogen partial pressureImprove conversion abilityTreatment with hydrotreatment processesMolecular sieveAlkane

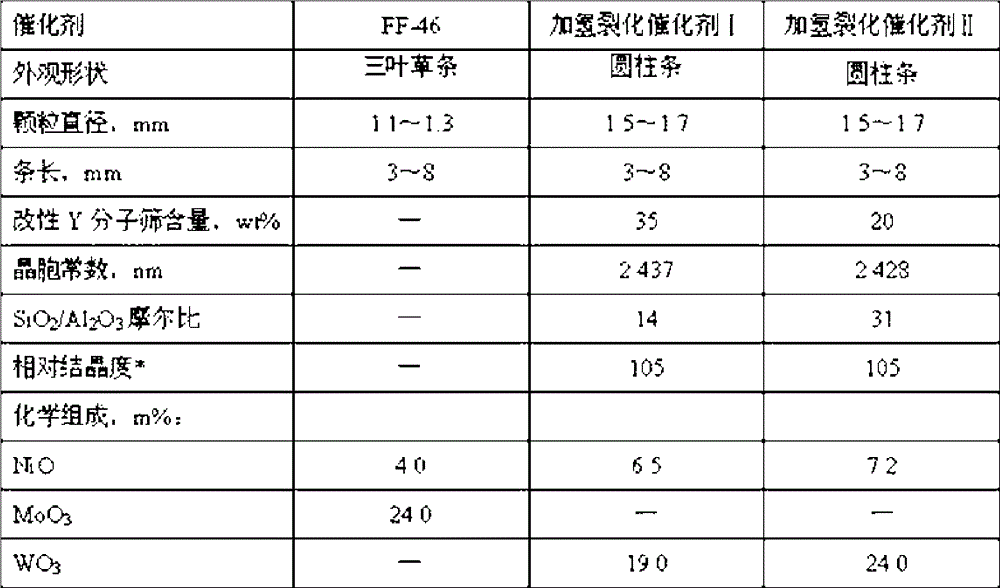

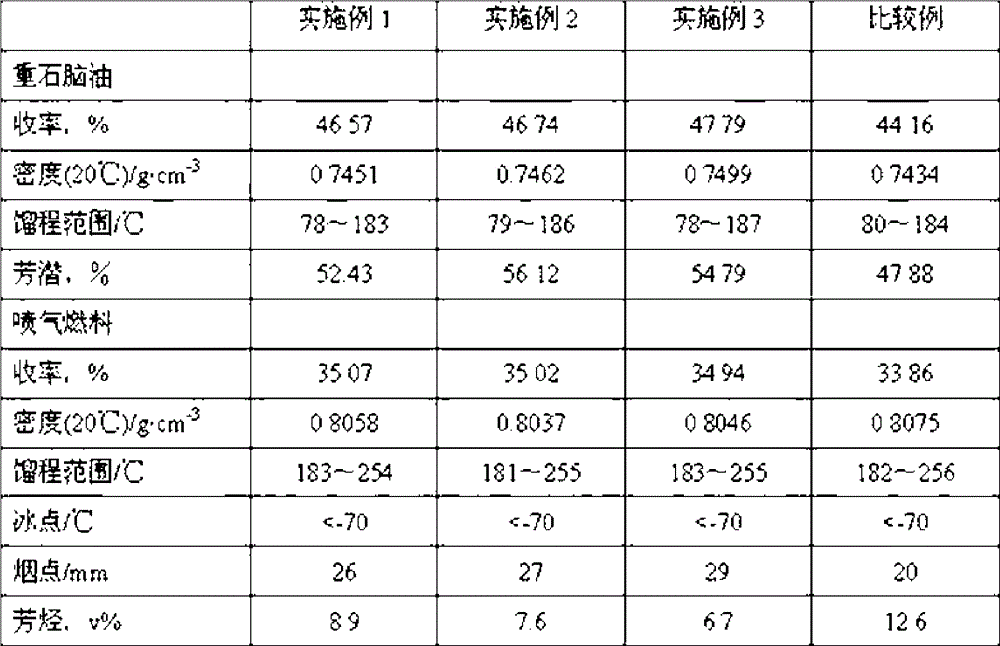

The invention discloses a two-stage hydrocracking method. The two-stage hydrocracking method comprises following steps: (1) inferior raw oil is mixed with hydrogen for hydrofinishing; (2) a hydrofinishing effluent is subjected to gas-liquid separation so as to obtain a gas material and a liquid material; (3) the liquid material is delivered into a hydrocracking reaction zone for hydrocracking, wherein the hydrocracking reaction zone comprises a hydrocracking catalyst I and a hydrocracking catalyst II with different molecular sieve contents; and (4) a hydrocracking effluent is subjected to separation and fractionation so as to obtain needed products. According to the two-stage hydrocracking method, the hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformation ability, and is capable of transforming aromatic hydrocarbons in raw material heavier components into smaller molecules, and distributing the small molecules into naphtha and jet fuel fractions; the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking ability; synergistic effect of the two catalysts is capable of improving quality of hydrocracking products obviously, and especially increasing smoke point of jet fuel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Edible blend oil

InactiveCN106509160AProportional coordinationReasonable proportionEdible oils/fatsNutritive valuesCannabis

The invention discloses an edible blend oil. The edible blend oil is characterized in that a ratio of saturated fatty acids to monounsaturated fatty acids to polyunsaturated fatty acids is less than 1:1:1, and a ratio of omega3 polyunsaturated fatty acid fatty acids to omega6 polyunsaturated fatty acid fatty acids in the polyunsaturated fatty acids is (4-6):1; and the blend oil comprises, by weight, 20-40 parts of olive oil, 30-50 parts of peanut oil, 5-12 parts of cannabis oil, 10-20 parts of walnut kernel oil and 3-5 parts of flaxseed oil. All the unsaturated fatty acids of the blend oil have coordinated proportion, reasonable formula, balanced nutrition and high nutritive values, so the edible blend oil can guarantee the intake of essential fatty acids necessary for the maintenance of life, and also has the efficacy of preventing coronary heart disease, atherosclerosis and senile dementia, lowering the blood pressure and the blood lipid, delaying ageing, and enhancing memory.

Owner:广西放心源生物科技有限公司

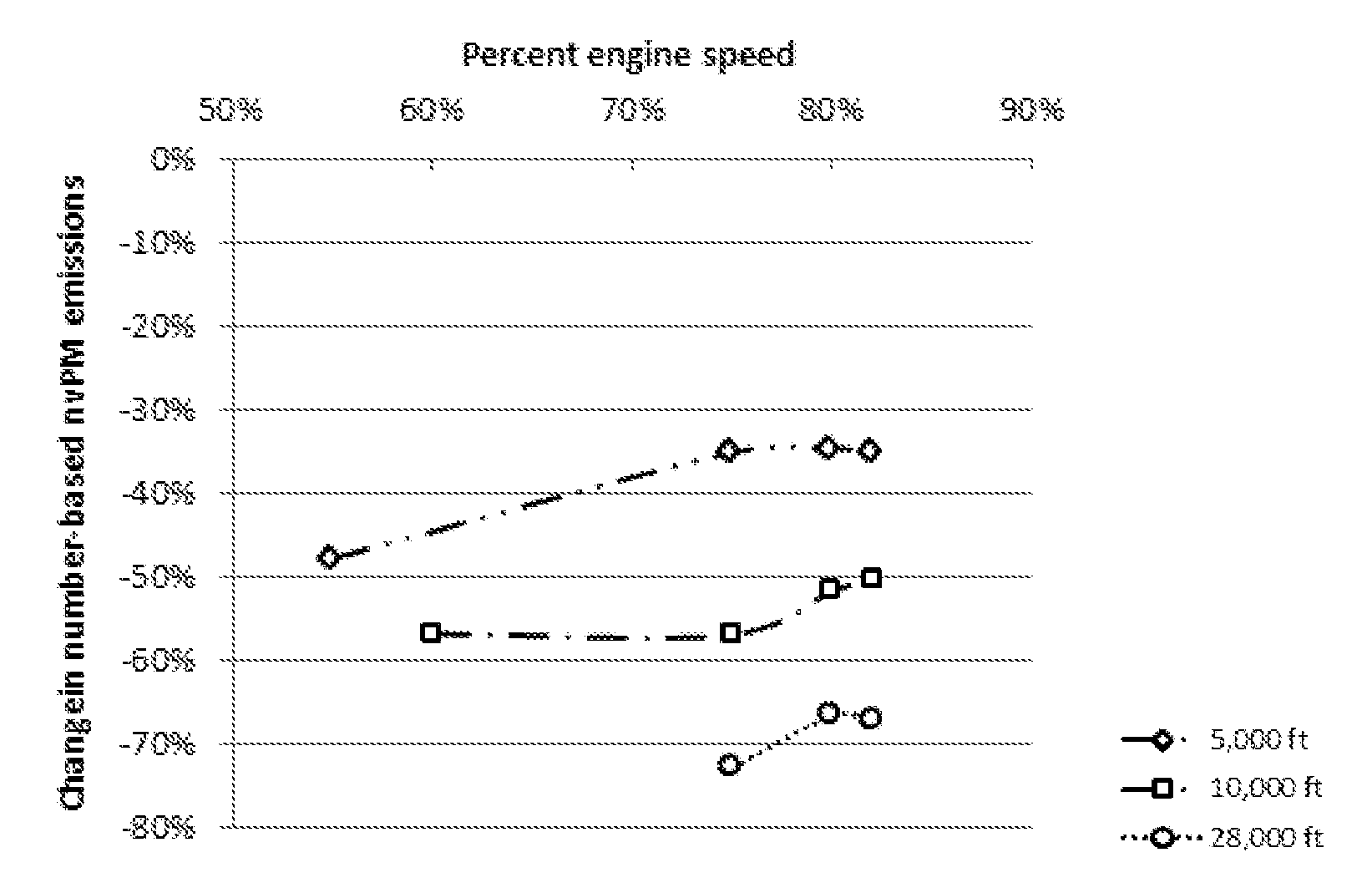

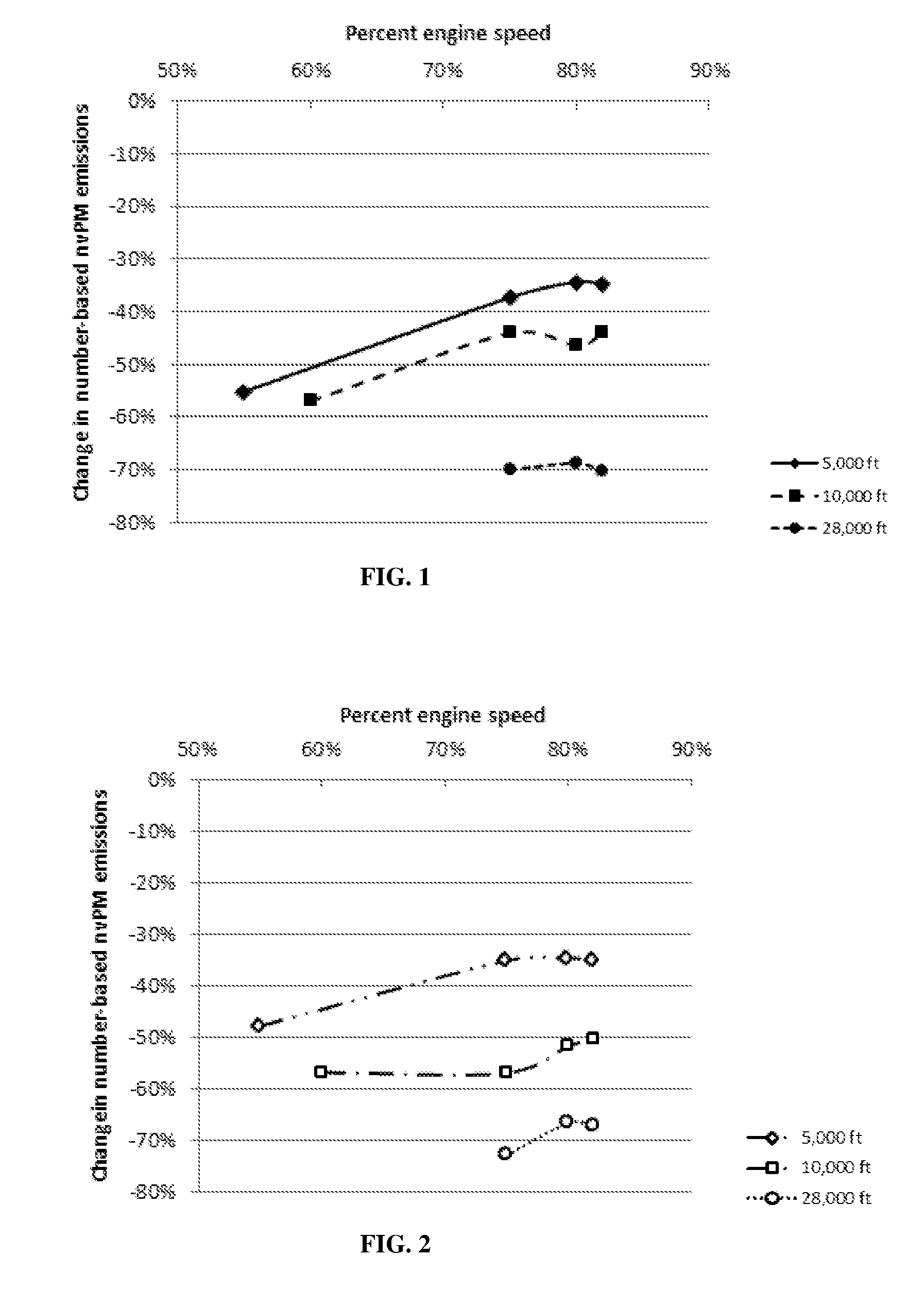

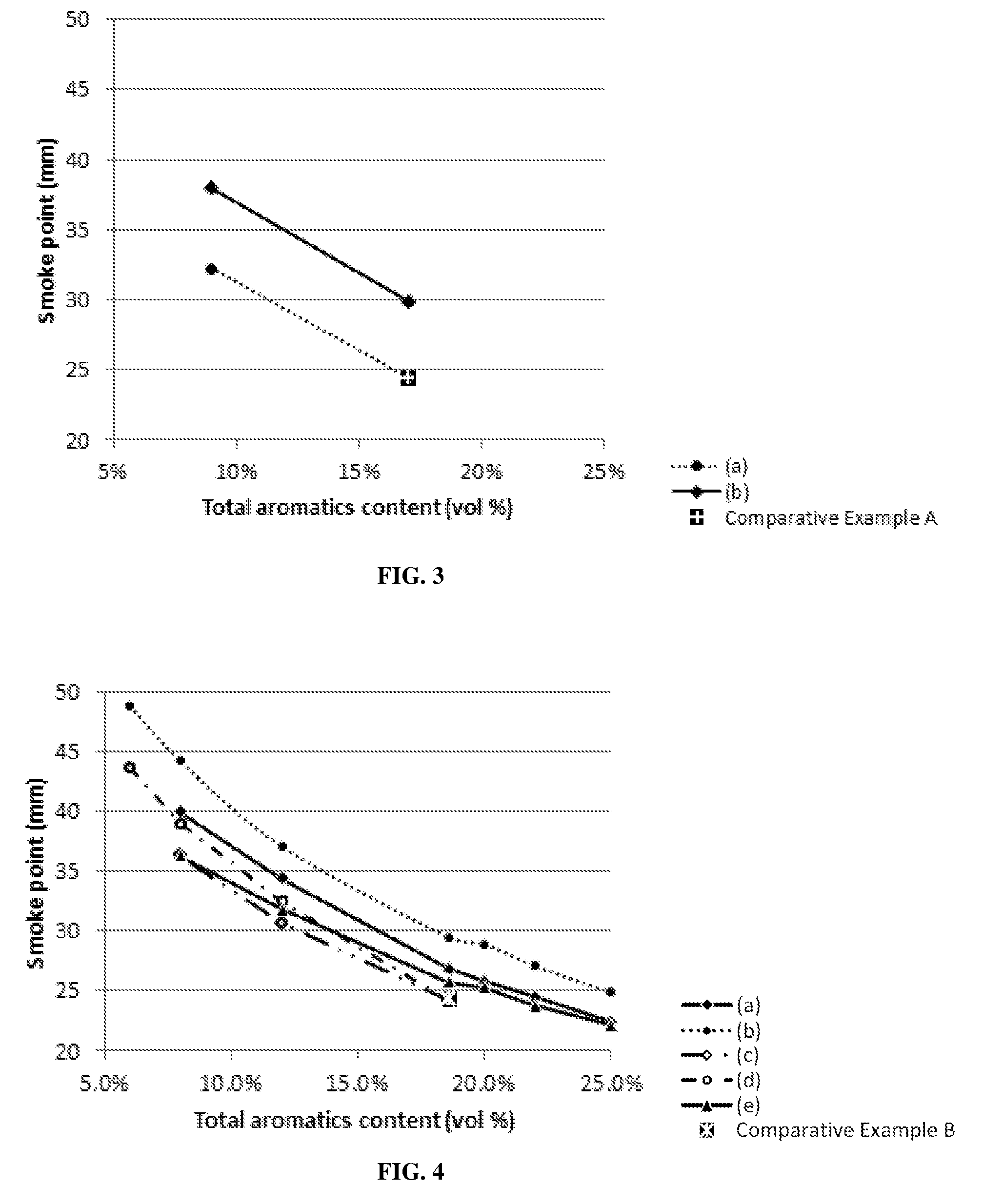

Reduced emissions aromatics-containing jet fuels

InactiveUS20160326448A1Reduce particulate emissionsEnsure compatibilityGas turbine plantsLiquid carbonaceous fuelsTetralinKerosene

Reduced emissions in a jet fuel having aromatics content can be achieved by incorporating a quantity of an aromatic kerosene fuel blending component, preferably a bio-derived synthetic aromatic kerosene, comprising at least 90 wt. % of aromatics, less than 10 wt. % of indanes and tetralins and less than 1 wt. % of naphthalene into a jet fuel in a manner to meet the aromatic content specification for jet fuels. A jet fuel having aromatics content having reduced number-based nvPM emissions compared to equivalent total aromatics content petroleum-derived kerosene jet fuel is obtained.

Owner:SHELL OIL CO

Edible blend oil and its preparation method

InactiveCN107494775AHigh smoke pointExtended shelf lifeEdible oils/fatsNutritive valuesAcute hyperglycaemia

The invention discloses edible blend oil and its preparation method. The edible blend oil is prepared from, by weight, 20-30 parts of corn oil, 20-30g of soybean oil, 10-20 parts of rice oil, 10-20 parts of flaxseed oil, 5-10 parts of peanut oil, 1-2 parts of Vitamin E, 0.5-1 part of hydrolysis plant protein, and 0.5-1 part of green tea extractive. The raw material further comprises lycopene, citric acid and medlar extractive. The edible blend oil is high in nutrition value and good in oxidization stability; after eating for a long time, the edible blend oil has good effect to people with hyperlipidemia, high blood pressure and hyperglycemia, patients with cardia-cerebrovascular disease, fatty liver and obesity.

Owner:宜昌傲海油脂有限公司

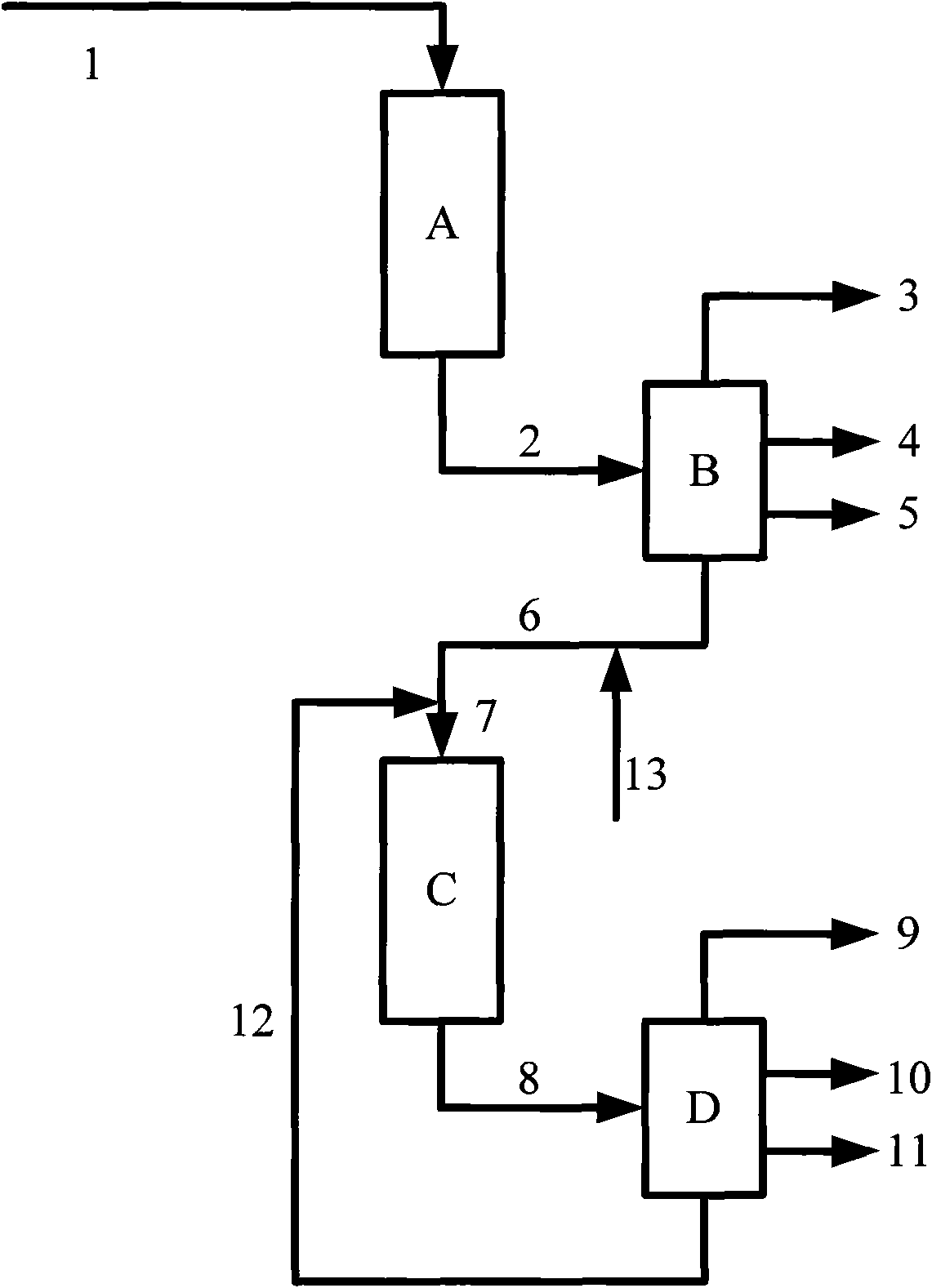

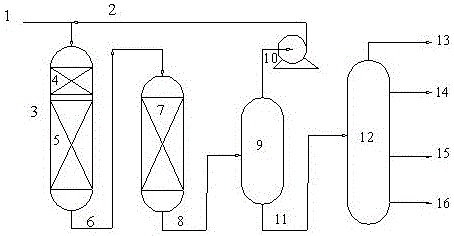

Hydro-cracking method for improving quality of aviation kerosene

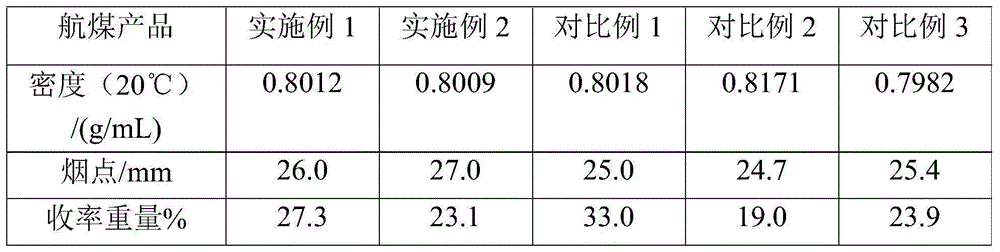

ActiveCN106520195AImprove jet fuel qualityMinor changesTreatment with hydrotreatment processesNaphthaKerosene

The invention relates to the oil refining field, and discloses a hydro-cracking method for improving the quality of aviation kerosene. The method comprises the following steps: subjecting a liquid phase product from a hydro-cracking reaction area to fractionation to obtain a naphtha fraction, a kerosene fraction, a diesel fraction, and a tail oil fraction; and (2) introducing the kerosene fraction obtained in the step (1) into a kerosene fractionating tower to obtain a light aviation kerosene fraction, a medium aviation kerosene fraction, and a heavy aviation kerosene fraction, extracting at least part of the medium aviation kerosene fraction, taking the light aviation kerosene fraction, the heavy aviation kerosene fraction, and residual medium aviation kerosene fraction as the aviation kerosene products, and discharging the aviation kerosene products from the kerosene fractionating tower. The provided method can economically, flexibly, and effectively improve the quality of aviation kerosene from a hydro-cracking device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrocracking method used for producing high-quality jet fuel

ActiveCN103773473AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesAlkaneMolecular sieve

The invention discloses a hydrocracking method used for producing high-quality jet fuel from inferior raw materials. The hydrocracking method comprises following steps: (1) inferior raw material oil is subjected to hydrofinishing reaction; (2) a hydrofinishing effluent is subjected to gas-liquid separation, and an obtained liquid material is subjected to fractionation; (3) tail oil obtained via fractionation is subjected to hydrocracking reaction, wherein a hydrocracking reaction zone comprises a hydrocracking catalyst I and a hydrocracking catalyst II with different molecular sieve contents; and (4) a hydrocracking effluent is subjected to separation, and an obtained liquid product is subjected to fractionation so as to obtain corresponding products. The upper part of the hydrocracking reaction zone is filled with the hydrocracking catalyst I; the hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw materials into smaller molecules, and distributing the smaller molecules into heavy petroleum and jet fuel fractions; the lower part of the hydrocracking reaction zone is filled with the hydrocracking catalyst II; and the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking capacity. The two catalysts are combined, so thathydrocracking product quality is improved obviously, and especially, smoke point of jet fuel fractions is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method used for producing high-quality jet fuel

ActiveCN103773461AImprove qualityHigh smoke pointTreatment with hydrotreatment processesMolecular sieveProcess engineering

The invention discloses a hydrocracking method used for producing high-quality jet fuel. According to the hydrofinishing method, raw material oil is mixed with hydrogen, and an obtained mixture is delivered through a hydrofinishing reaction zone and a hydrocracking reaction zone successively; the hydrocracking reaction zone comprises at least two hydrocracking catalysts, the upper part of the hydrocracking reaction zone is filled with a hydrocracking catalyst I, and the lower part of the hydrocracking reaction zone is filled with a hydrocracking catalyst II; the hydrocracking catalyst I comprises 15 to 50wt% of modified Y molecular sieve; the hydrocracking catalyst II comprises 3 to 25wt% of modified Y molecular sieve; and the content of modified Y molecular sieve of the hydrocracking catalyst I is 10 to 25wt% higher than that of the hydrocracking catalyst II. The hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw material into smaller molecules, and distributing the smaller molecules in heavy petroleum fractions and jet fuel fractions; and the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking capacity. The two catalysts are combined, so that product quality is improved obviously, and especially, smoke point of jet fuel fractions is increased, and tail oil BMCI value is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low energy consumption hydrocracking method for processing poor-quality raw material

ActiveCN104611020AReduce consumptionSave engineering investmentTreatment with hydrotreatment processesHydrocarbon oils treatment productsOperating energyFractionation

The present invention discloses a low energy consumption hydrocracking method for processing a poor-quality raw material. According to the method, a raw material and hydrogen gas are mixed, are subjected to heat exchange two times, pass through a heating furnace, and then are subjected to a hydrorefining reaction; the refining effluent is subjected to separation and fractionation; the obtained tail oil enters a hydrocracking reaction zone, wherein the cracking reaction zone comprises at least two cracking catalysts, the upstream is a catalyst I, the downstream is a catalyst II, the catalyst I contains 15-50 wt% of a modified Y molecular sieve, the catalyst II contains 3-30 wt% of the modified Y molecular sieve, and the modified Y molecular sieve content in the catalyst I is 10-25% higher than the modified Y molecular sieve content in the catalyst II; and the hydrocracking effluent and poor-quality raw material oil are mixed and then enter a hydrorefining reaction zone. According to the method of the present invention, the high temperature high pressure countercurrent heat transfer technology and the hydrocracking catalyst grading technology are organically combined, and the hydrocracking reaction heat is comprehensively utilized, such that the catalyst selectivity is maintained while the target product quality is improved, and the project investment and the operating energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nutrition-balanced edible blend oil

InactiveCN106359657AFit for consumptionProportional coordinationEdible oils/fatsCoronary heart diseaseOmega-6 fatty acid

The invention discloses nutrition-balanced edible blend oil. The blend oil is prepared from the following raw material oil in parts by weight: 4 parts of flaxseed oil, 18 to 28 parts of corn oil, 8 to 15 parts of hemp oil, 8 to 12 parts of rice oil and 10 to 20 parts of tea oil; moreover, the various raw oil is weighed according to a weight ratio 1:(3.5 to 4.5):(4.5 to 5.5) of omega-3 fatty acid to omega-6 fatty acid to omega-9 fatty acid. The blend oil is coordinated in a proportion among the fatty acids, is reasonable in formula, is balanced in nutrition, has the effects of lowering blood pressure, lowering fat, lowering the incidence probability of coronary heart disease, preventing senile dementia and the like, and is very suitable for middle aged and elderly people to eat; by adopting the balanced-nutrition edible blend oil, intake of fatty acids necessary for sustaining life can be ensured.

Owner:广西茶仔龙科技股份有限公司

Aviation kerosene fraction hydroupgrading process

ActiveCN101089134AReduce usageImprove hydrogenation performanceRefining to eliminate hetero atomsCoalComplex oxide

The inferior aviation kerosene fraction hydroupgrading process has the inferior aviation kerosene fraction as the material oil hydroupgraded to result in high quality aviation kerosene product. The catalyst in the hydroupgrading reaction region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst. The present invention facilitates the hydroupgrading operation, increases the treating capacity of the apparatus, increases the service life of the catalyst and raises the quality of the aviation kerosene product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special blended olive oil for cooking and preparation method of special blended olive oil

The invention discloses a special blended olive oil for cooking and a preparation method of the special blended olive oil. The blended olive oil is composed of olive oil, sunflower seed oil and rapeseed oil in the mass ratio of (30-40): (10-20): (40-60). The blended olive oil disclosed by the invention has the advantages of good thermal stability and higher smoke point and is more suitable for the Chinese cooking habit; meanwhile, nutrient substances in the product can be remained to the maximum extent in the cooking process; and the smoke point of the blended olive oil is higher than 170 DEG C which is increased by 5-10 DEG C than the smoke point of the olive oil, thus the thermal stability is improved.

Owner:洪申平

Blend edible oil of peony seed oil and rice germ oil and preparation method of blend edible oil

ActiveCN103815058ALow in linolenic acidNot easily oxidizedEdible oils/fatsOil and greaseHeating time

The invention provides a blend edible oil of peony seed oil and rice germ oil and a preparation method of the blend edible oil. The blend edible oil comprises 42-65% of peony seed oil, 33-52% of rice germ oil, 1-4% of tomato extractive and 1-2% of catechin; the preparation method of the blend edible oil comprises the following steps: the preparation of the peony seed oil; the mixing of main materials; the formation of an emulsification system, and finally, the formation of the finished product of clarified blend edible oil, wherein a subcritical extraction technology and a molecular distillation technology are adopted and combined to extract the peony seed oil, so that the operating temperature is low, the heating time is short, the grease oxidation and rancidification caused by high-temperature can be avoided, the separation degree and the yield coefficient of the product are relatively high, and the acid value of the peony seed oil can also be reduced by the molecular distillation; meanwhile, the blend edible oil is reasonable in matching, healthy, and balanced in nutrition, so that blend oil with high stability and low oil fume generation volume can be formed, and health of long-term cooks is maintained.

Owner:LUOYANG CHUNKUI AGRI DEV

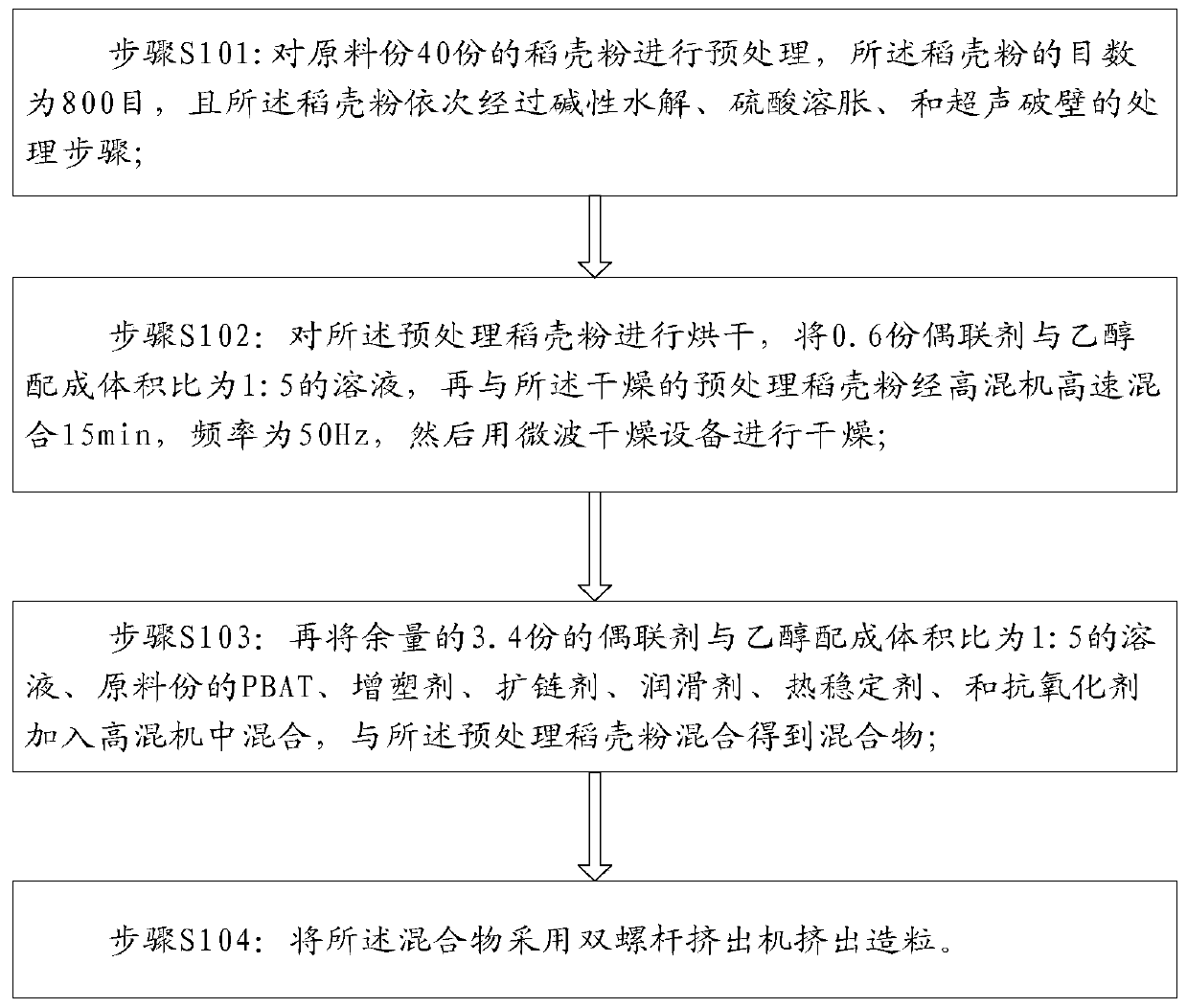

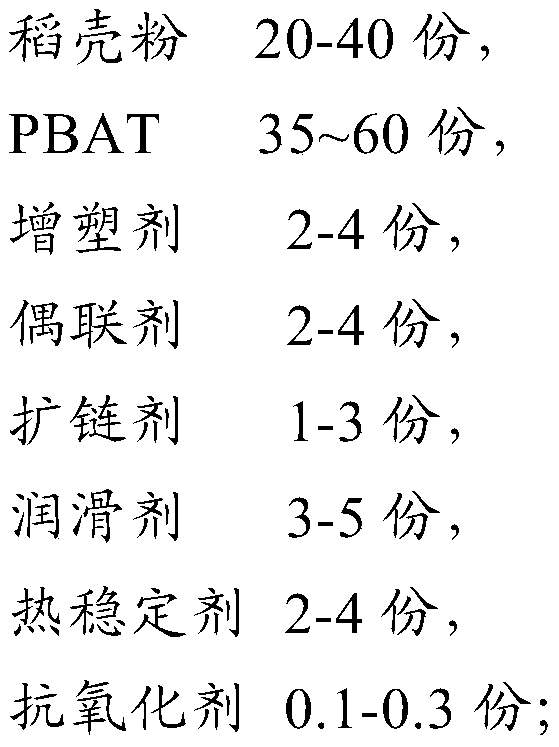

Rice husk powder/PBAT biomass-based fully degradable material and preparation method thereof

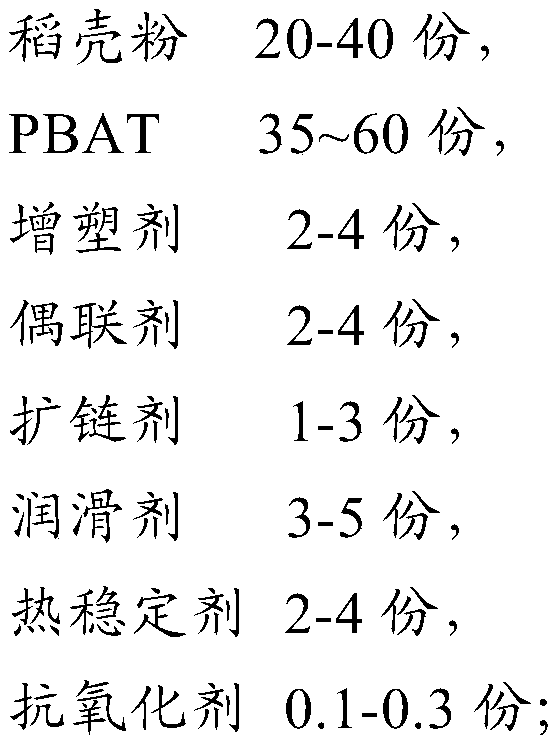

The invention discloses a rice husk powder / PBAT biomass-based fully degradable material and a preparation method thereof. The rice husk powder / PBAT biomass-based fully degradable material comprises, by weight, 20-40 parts of rice husk powder, 35-60 parts of PBAT, 2-4 parts of a plasticizer, 2-4 parts of a coupling agent, 1-3 parts of a chain extender, 3-5 parts of a lubricant, 2-4 parts of a heatstabilizer and 0.1-0.3 part of an antioxidant. The PBAT and rice husk powder are mixed to obtain the material with good comprehensive performances, the addition of the rice husk powder reduces the production cost, and many choices are provided for the application and development of degradable plastics.

Owner:YINGKOU XIAOJIAZU IND

Nutritional and healthcare plant blend oil

InactiveCN106234651AProportional coordinationHigh nutritional valueEdible oils/fatsNutritive valuesOMEGA-3 POLYUNSATURATED FATTY ACIDS

The invention discloses nutritional and healthcare plant blend oil. For the blend oil, the ratio of saturated fatty acid to monounsaturated fatty acid to polyunsaturated fatty acid is 1:1:1, wherein in the polyunsaturated fatty acid, the ratio of omega 3 polyunsaturated fatty acid to omega 6 polyunsaturated fatty acid is 4-6:1. The blend oil is prepared from the following raw material oils in parts by weight: 8-15 parts of tea oil, 8-12 parts of linseed oil, 5-8 parts of avocado oil, 30-45 parts of sunflower seed oil, and 15-25 parts of peanut oil. In the formula of the blend oil disclosed by the invention, all unsaturated fatty acids are coordinated in ratio, reasonable in formula, balanced in nutrition, and high in nutritive value, so that the blend oil not only can ensure intake of fatty acid needed for sustaining life, but also has the efficacies of preventing coronary heart disease, atherosclerosis and senile dementia, decreasing blood pressure and blood lipid, delaying senescence, enhancing memory ability and the like. Meanwhile, the blend oil is relatively low in cost, good in taste and strong in fragrance, and is well received by consumers.

Owner:广西放心源生物科技有限公司

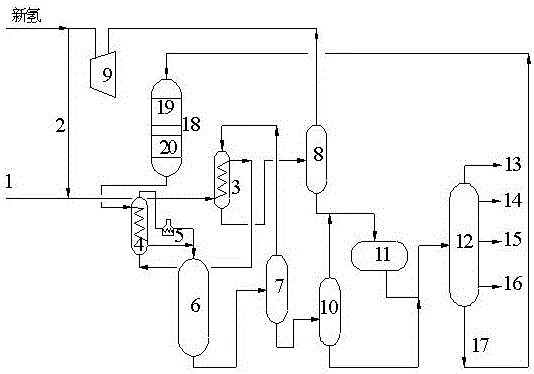

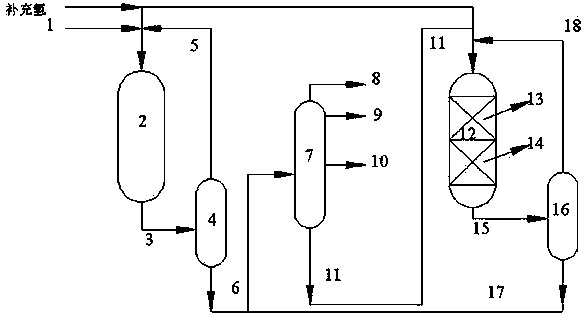

Two-stage hydrocracking method for low energy consumption production of high-quality jet fuels

ActiveCN105001909AReduce consumptionSave engineering investmentHydrocarbon oil crackingTreatment with hydrotreatment processesFractionationHigh pressure

The invention discloses a two-stage hydrocracking method for low energy consumption production of high-quality jet fuels. The method comprises the following steps: mixing a raw material with hydrogen, carrying out two-time heat exchange, allowing the obtained material to go through a heating furnace, and carrying out a hydrofining reaction; carrying out gas-liquid separation and fractionation on a refining effluent; allowing obtained tail oil to enter a hydrocracking reaction zone, wherein the cracking reaction zone comprises at least two cracking catalysts, the upstream is a catalyst I, the downstream is a catalyst II, the catalyst I contains 15-50wt% of modified Y molecular sieve, the catalyst II contains 3-30wt% of the modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-25% higher than the content of the modified Y molecular sieve in the catalyst II; and separating and fractioning a hydrocracking effluent to obtain various products. The method organically combines a high temperature and high pressure countercurrent heat transfer technology with a hydrocracking catalyst grading technology, comprehensively utilizes hydrocracking reaction heat, maintains the catalyst selectivity, improves the quality of target products, and reduces the engineering investment and the operation energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

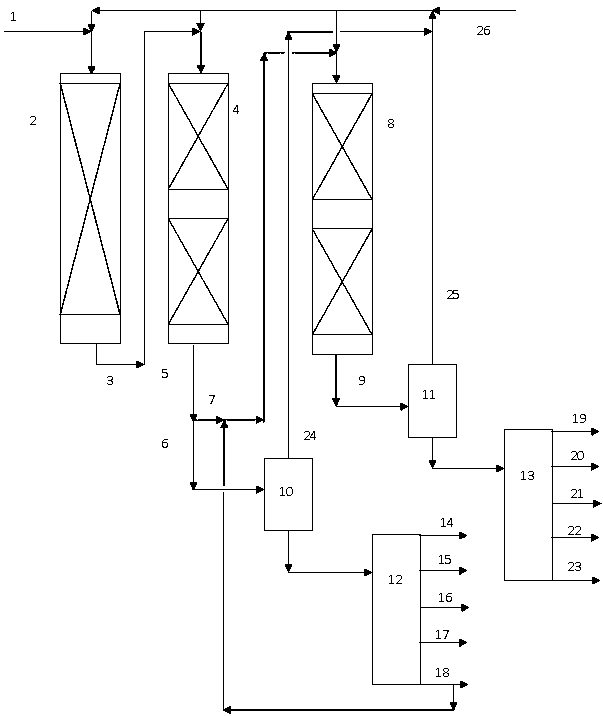

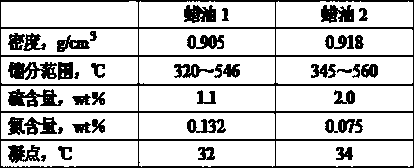

Flexible reverse-sequence hydrocracking process

ActiveCN109988623AEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

The invention discloses a flexible reverse-sequence hydrocracking process. The process comprises the following steps: mixing wax oil raw oil with a hydrocracked material; carrying out hydrogenation pretreatment; carrying out separation fractionation on the hydrogenation pretreated material flow to obtain gas, distillate oil and tail oil; carrying out hydrocracking pretreatment on the obtained tailoil, allowing the tail oil to pass through a first hydrocracking catalyst bed layer in a hydrocracking reactor to obtain a material, and dividing the obtained material into two streams; separating one material stream in a separator, extracting the obtained liquid phase out of the hydrocracking reactor, and subjecting the liquid phase to an isomerization cracking reaction in a hydroisomerization cracking reactor; allowing the other material stream to flow downward to pass through a second hydrocracking catalyst bed layer; and carrying out gas-liquid separation and fractionation on a hydroisomerization cracking reaction product to obtain hydroisomerization cracked naphtha, aviation kerosene, diesel oil and tail oil products. The invention provides the hydrocracking process for simultaneously producing more than two different-specification light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking method for processing inferior raw materials

ActiveCN103773450BHigh yieldImprove product qualityHydrocarbon oil crackingTreatment with hydrotreatment processesAlkaneMolecular sieve

The invention relates to a hydrocracking method for processing an inferior raw material. The method comprises (1) performing hydrofining reaction of inferior raw oil; (2) performing gas-liquid separation of a hydrofined effluent to obtain a liquid for fractionation; (3) performing hydrocracking reaction on tail oil obtained by the fractionation, two hydrocracking catalyst I and II with different molecular sieve contents existing in a hydrocracking reaction zone; and (4) mixing a hydrocracked effluent and the inferior raw material to get into a hydrotreating reaction zone. According to the method, the upstream catalyst I in the cracking reaction zone has a strong aromatic conversion ability, can convert heavy components in the raw material into smaller molecules to distribute into naphtha and jet fuel fractions, the downstream catalyst II has a strong alkane cracking ability, by synergistic effect of the two catalysts, the quality of hydrocracked products can be significantly improved, and especially, and the smoke point of the jet fuel fractions can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

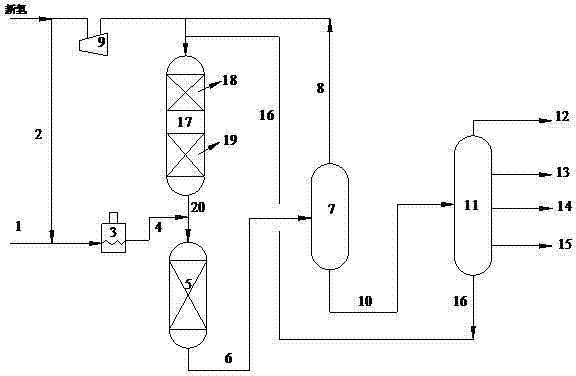

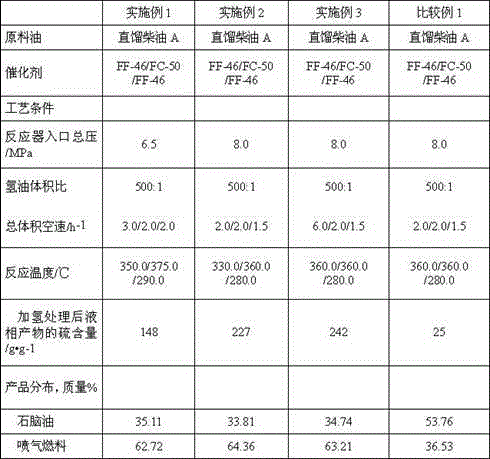

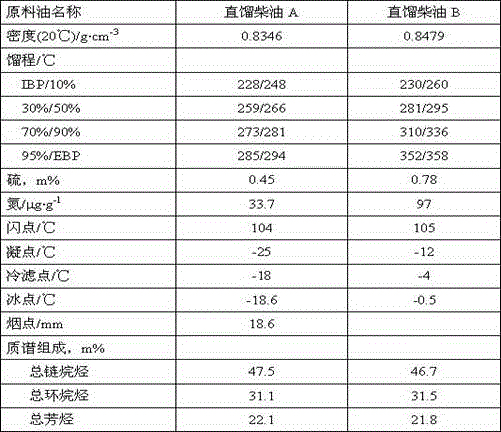

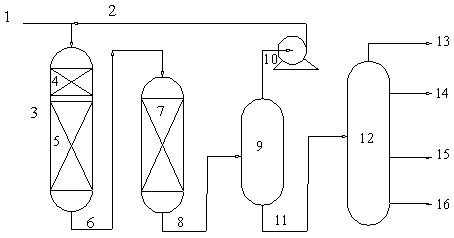

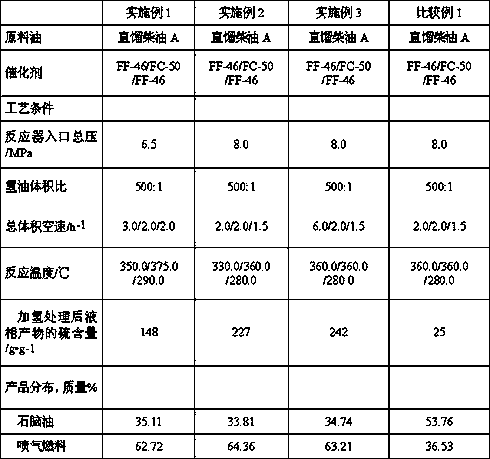

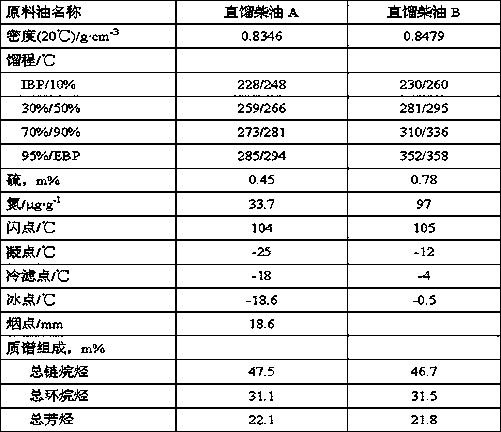

Method for producing jet fuel by straight-run diesel oil

ActiveCN107177374AHigh selectivityReduce secondary cracking reactionsTreatment with hydrotreatment processesChemistryNaphtha

The invention discloses a method for producing jet fuel by straight-run diesel oil. The method comprises the following steps: (1) mixing a straight-run diesel oil raw material with hydrogen gas; enabling a mixture to enter a hydrogenation treatment reaction region; carrying out hydrogenation and desulfurization reaction and hydrogenation and denitrification reaction under a condition of relatively low temperature and / or a large volume space velocity; (2) enabling refined straight-run diesel oil obtained by step (1) to enter a hydrocracking reaction region and be in contact with a hydrocracking catalyst; carrying out hydrocracking reaction; (3) enabling a full-fraction hydrocracking product obtained by step (2) into a hydrogenation refining reaction region and carrying out aromatic hydrogenation saturation reaction; (4) enabling a refined full-fraction product obtained by step (3) to enter a separation and fractionation system, so as to obtain naphtha and jet fuel products and the like. Compared with the prior art, the method disclosed by the invention can be used for producing the straight-run diesel oil into the jet fuel at maximum and the additional value of the product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Blend oil suitable for frying food

InactiveCN104782793AReduce erucic acid contentSuitable for fryingEdible oils/fatsCottonseed oilSmoke point

The invention discloses blend oil suitable for frying food. The blend oil is prepared from the following raw materials in percentage by weight: 30%-40% of cottonseed oil, 30%-40% of rapeseed oil and 20%-30% of palm oil, wherein the cottonseed oil and the rapeseed oil are refined salad oil. The blend oil disclosed by the invention is low in erucic acid content, good in shortning performance, high in smoke point and suitable for frying food, and a proportion of the linoleic acid to the linolenic acid meets the edible oil health standards (about 4 to 1).

Owner:广西明华晟粮油科技有限公司

A hydrocracking process for flexibly producing diesel oil

ActiveCN109988648ALower freezing pointHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

The invention discloses a hydrocracking process for flexibly producing diesel oil. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a hydrocracking reactor, and a hydrocracked material passing through a hydrocracking catalyst bed layer is divided into two streams; one stream of the hydrocracked material is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil; and the other stream of the hydrocracked material is mixed with a part or all of hydrocracking tail oil, and the mixture is fed into a hydrogenation isomerization cracking reactor and subjected to isomerization cracking; and a hydrogenation isomerization cracking product is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil. The invention provides the process for simultaneously producing more than two types of aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially diesel oil products with different condensation points, heat carried by a part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydrogenation isomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for producing jet fuel from straight-run diesel oil

ActiveCN107177374BEfficient conversionHigh smoke pointTreatment with hydrotreatment processesHydrogenNaphtha

The invention discloses a method for producing jet fuel by straight-run diesel oil. The method comprises the following steps: (1) mixing a straight-run diesel oil raw material with hydrogen gas; enabling a mixture to enter a hydrogenation treatment reaction region; carrying out hydrogenation and desulfurization reaction and hydrogenation and denitrification reaction under a condition of relatively low temperature and / or a large volume space velocity; (2) enabling refined straight-run diesel oil obtained by step (1) to enter a hydrocracking reaction region and be in contact with a hydrocracking catalyst; carrying out hydrocracking reaction; (3) enabling a full-fraction hydrocracking product obtained by step (2) into a hydrogenation refining reaction region and carrying out aromatic hydrogenation saturation reaction; (4) enabling a refined full-fraction product obtained by step (3) to enter a separation and fractionation system, so as to obtain naphtha and jet fuel products and the like. Compared with the prior art, the method disclosed by the invention can be used for producing the straight-run diesel oil into the jet fuel at maximum and the additional value of the product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-quality edible oil composition

InactiveCN106417678AProportional coordinationReasonable proportionEdible oils/fatsNutritive valuesCannabis

The invention discloses a high-quality edible oil composition. According to the edible oil composition, a ratio of saturated fatty acids to monounsaturated fatty acids to polyunsaturated fatty acids is 1:1:1, wherein a ratio of omega-3 polyunsaturated fatty acids to omega-6 polyunsaturated fatty acids in the polyunsaturated fatty acids is (4-6):1; the high-quality edible oil composition is composed of the following raw oil in parts by weight: 15-25 parts of olive oil, 10-15 parts of cannabis oil, 8-12 parts of walnut oil, 25-40 parts of corn oil and 5-10 parts of perilla oil. According to the formula in the invention, the ratio of the various unsaturated fatty acids is coordinated, the high-quality edible oil composition is reasonable in formula, balanced in nutrition and high in nutritive value, can achieve the effect of guaranteeing intake of essential fatty acids for sustaining life, has the effects of preventing coronary heart diseases, atherosclerosis and senile dementia, decreasing blood pressure and blood lipid, defying age, enhancing memory ability and the like, can meet the requirements on 'healthy oil', 'rest assured oil', 'long life oil' and 'nutritional oil', and is well received by consumers.

Owner:广西放心源生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com