Rice husk powder/PBAT biomass-based fully degradable material and preparation method thereof

A rice husk powder, fully degradable technology, applied in the field of rice husk powder/PBAT biomass-based fully degradable materials and preparation, can solve incompatibility and other problems, achieve good thermal stability, reduce production costs, and increase tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

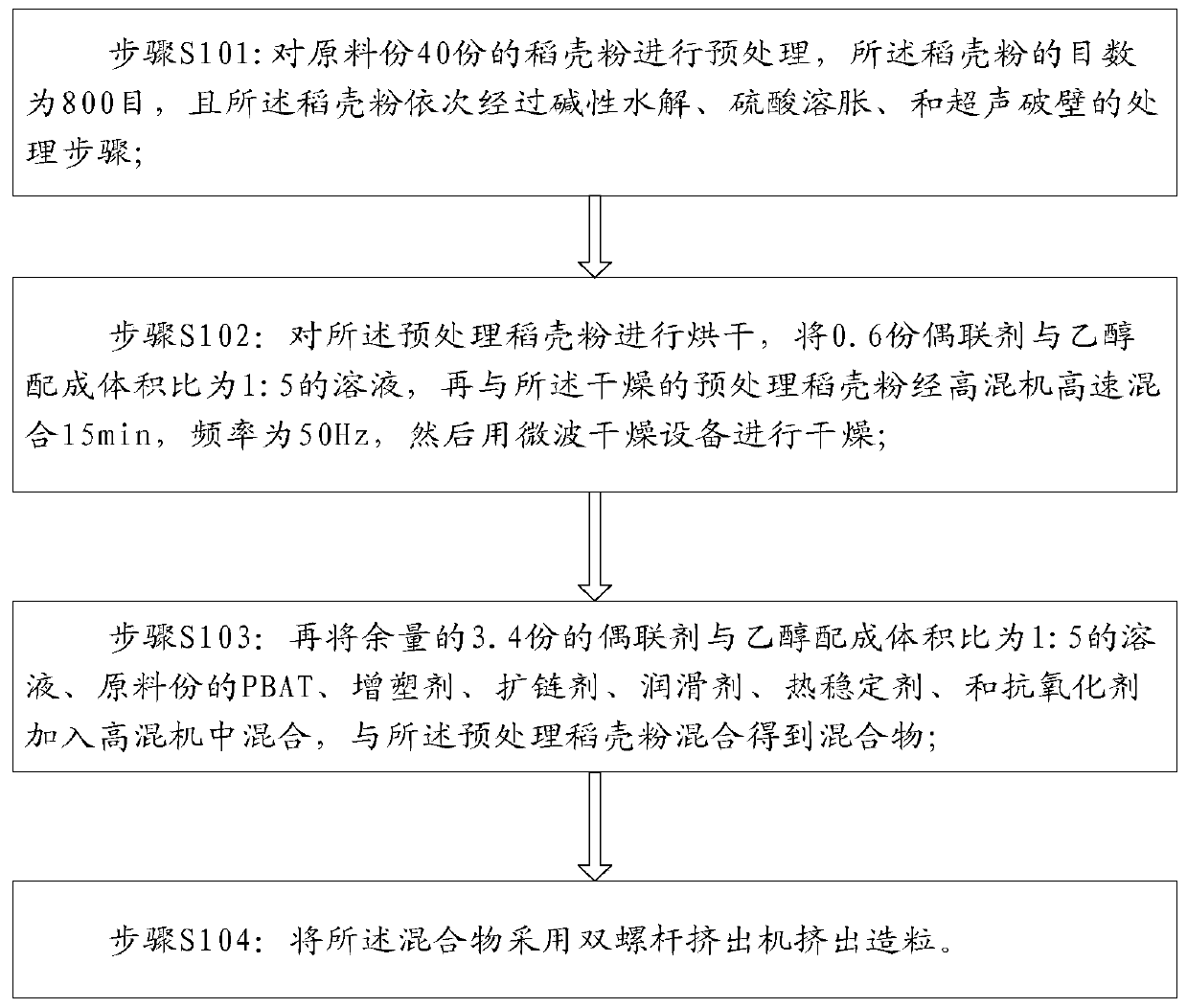

Method used

Image

Examples

Embodiment 1

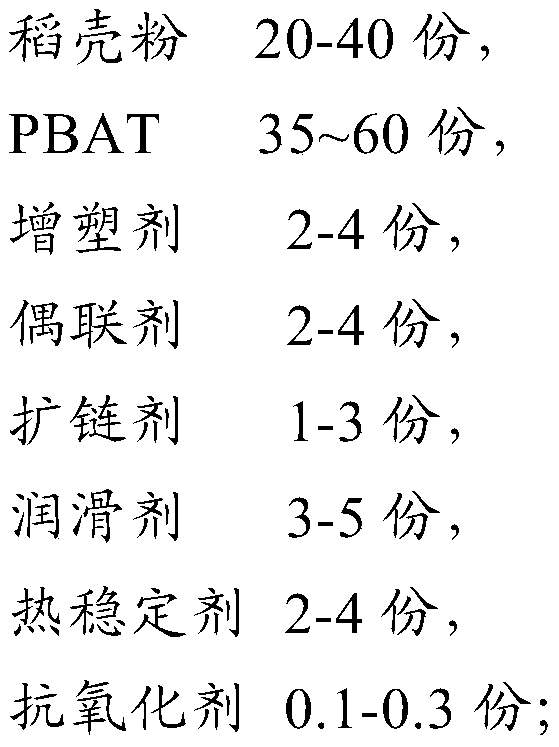

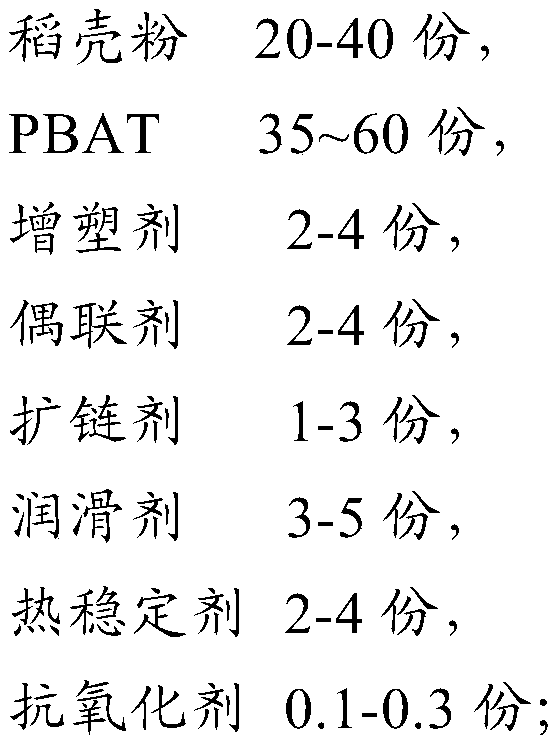

[0041] This embodiment provides a kind of rice husk powder / PBAT biomass-based fully degradable material, including the following components by weight:

[0042]

[0043]

[0044]Described coupling agent is silane coupling agent KH560, and described chain extender is BASF chain extender ADR, and described lubricant is stearic acid; Described plasticizer is acetyl tri-n-butyl citrate ATBC; Described The antioxidant was BASF Antioxidant 1010.

[0045] Adopt rice husk powder and polybutylene terephthalate-butylene adipate copolyester PBAT among the present invention as main material, plasticizer, coupling agent, chain extender, lubricant, thermal stabilizer, Biomass-based fully degradable materials prepared with antioxidants as auxiliary materials have high tensile strength, high elongation at break, and good thermal stability.

[0046] The rice husk powder has a mesh number of 800 mesh, and the rice husk powder undergoes the steps of alkaline hydrolysis, sulfuric acid swell...

Embodiment 2

[0068] This embodiment provides a kind of rice husk powder / PBAT biomass-based fully degradable material, including the following components by weight:

[0069]

[0070]

[0071] Wherein, the coupling agent is silane coupling agent KH560, the chain extender is BASF chain extender ADR, and the lubricant is stearic acid; the plasticizer is acetyl tri-n-butyl citrate ATBC; The antioxidant is BASF antioxidant 1010.

[0072] The rice husk powder has a mesh number of 700 mesh, and the rice husk powder undergoes the steps of alkaline hydrolysis, sulfuric acid swelling, and ultrasonic wall breaking in sequence, including:

[0073] The 700-mesh rice husk powder was hydrolyzed by adding a 6% sodium hydroxide solution at a mass fraction of 175° C. for 20 minutes, washed with distilled water until neutral after hydrolysis, and dried to obtain hydrolyzed rice husk powder;

[0074] Then, the hydrolyzed rice husk powder was stirred while adding concentrated sulfuric acid with a mass fr...

Embodiment 3

[0090] This embodiment provides a kind of rice husk powder / PBAT biomass-based fully degradable material, including the following components by weight:

[0091]

[0092] Wherein, the coupling agent is silane coupling agent KH560, the chain extender is BASF chain extender ADR, and the lubricant is stearic acid; the plasticizer is acetyl tri-n-butyl citrate ATBC; The antioxidant is BASF antioxidant 1010.

[0093] The rice husk powder has a mesh number of 600 mesh, and the rice husk powder undergoes the steps of alkaline hydrolysis, sulfuric acid swelling, and ultrasonic wall breaking in sequence, including:

[0094] The 600-mesh rice husk powder was hydrolyzed by adding a sodium hydroxide solution with a mass fraction of 6% at a hydrolysis temperature of 170° C. for 15 minutes, washed with distilled water until neutral after hydrolysis, and dried to obtain hydrolyzed rice husk powder;

[0095] Then, the hydrolyzed rice husk powder was stirred under the condition of 38°C while...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com