Patents

Literature

820 results about "Chemical decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical decomposition is the breakdown of a single entity (normal molecule, reaction intermediate, etc.) into two or more fragments. Chemical decomposition is usually regarded and defined as the exact opposite of chemical synthesis. In short, the chemical reaction in which two or more products are formed from a single reactant is called a decomposition reaction.

Process for producing single wall nanotubes using unsupported metal catalysts

InactiveUS6221330B1Continuous and efficient productionMaterial nanotechnologyFibre chemical featuresHydrogenGas phase

A process for producing hollow, single-walled carbon nanotubes by catalytic decomposition of one or more gaseous carbon compounds by first forming a gas phase mixture carbon feed stock gas comprising one or more gaseous carbon compounds, each having one to six carbon atoms and only H, O, N, S or Cl as hetero atoms, optionally admixed with hydrogen, and a gas phase metal containing compound which is unstable under reaction conditions for said decomposition, and which forms a metal containing catalyst which acts as a decomposition catalyst under reaction conditions; and then conducting said decomposition reaction under decomposition reaction conditions, thereby producing said nanotubes.

Owner:HYPERION CATALYSIS INT

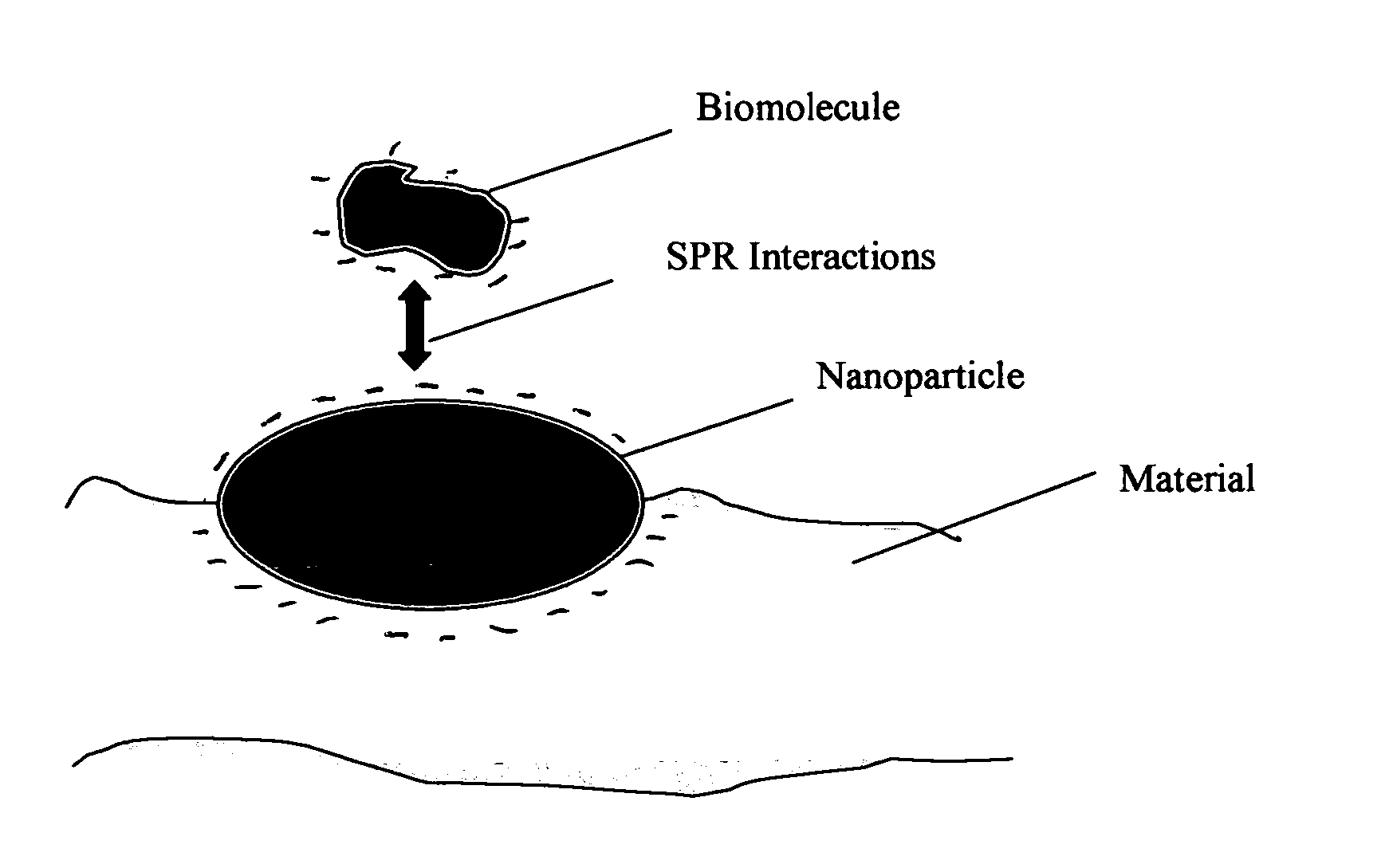

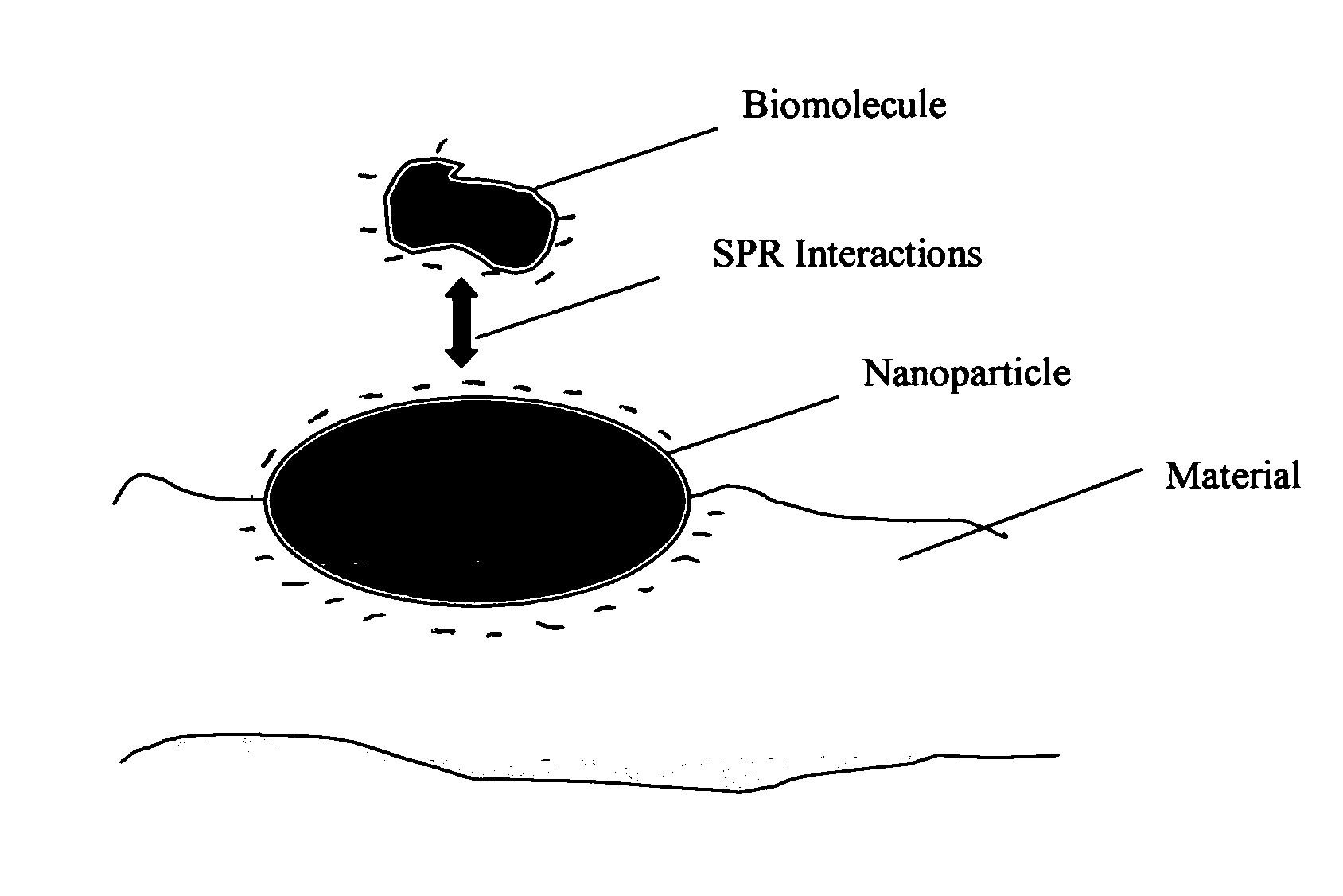

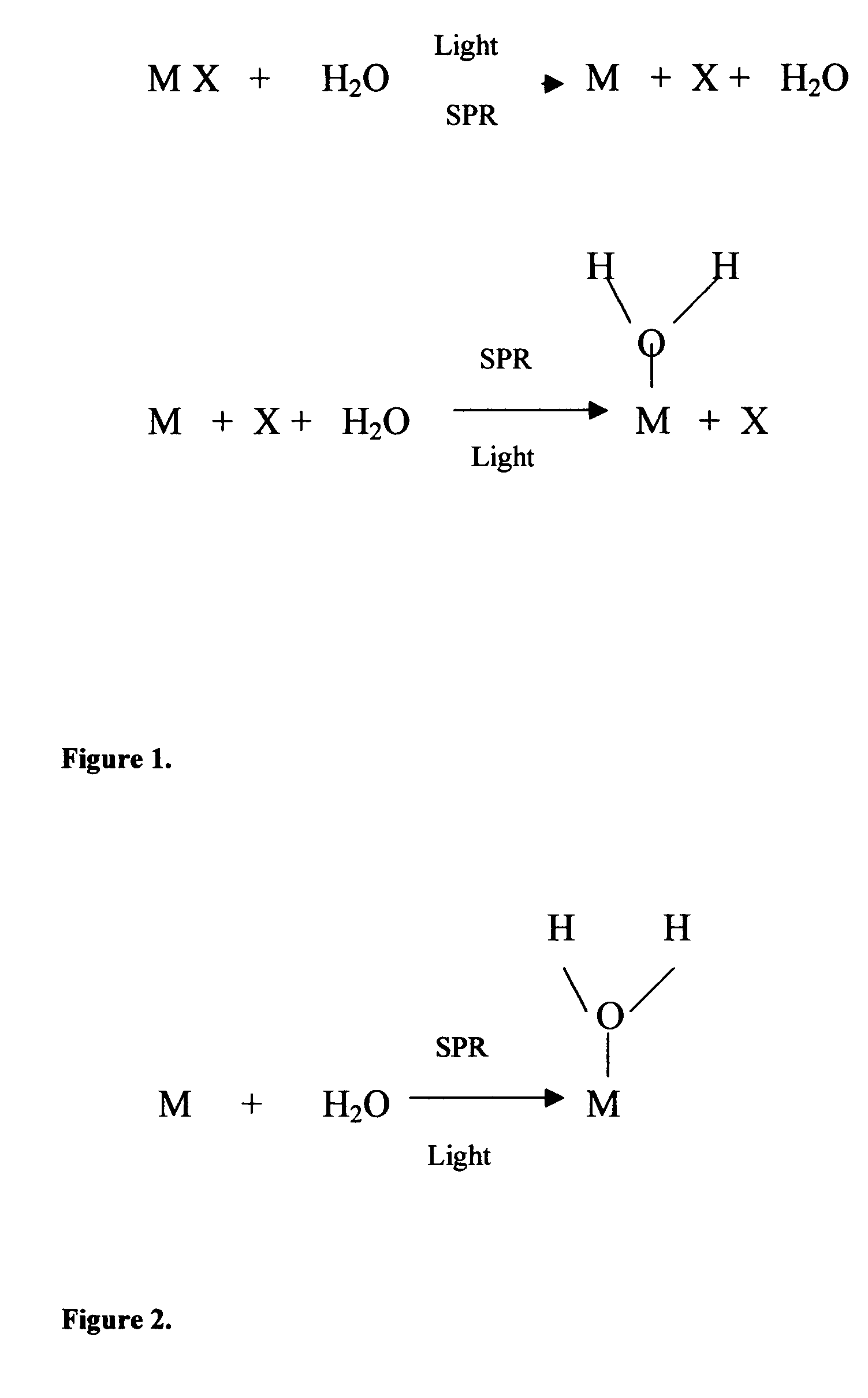

Method of plasmon-enhanced properties of materials and applications thereof

InactiveUS20050164169A1Bioreactor/fermenter combinationsMaterial nanotechnologyInfraredThermochromism

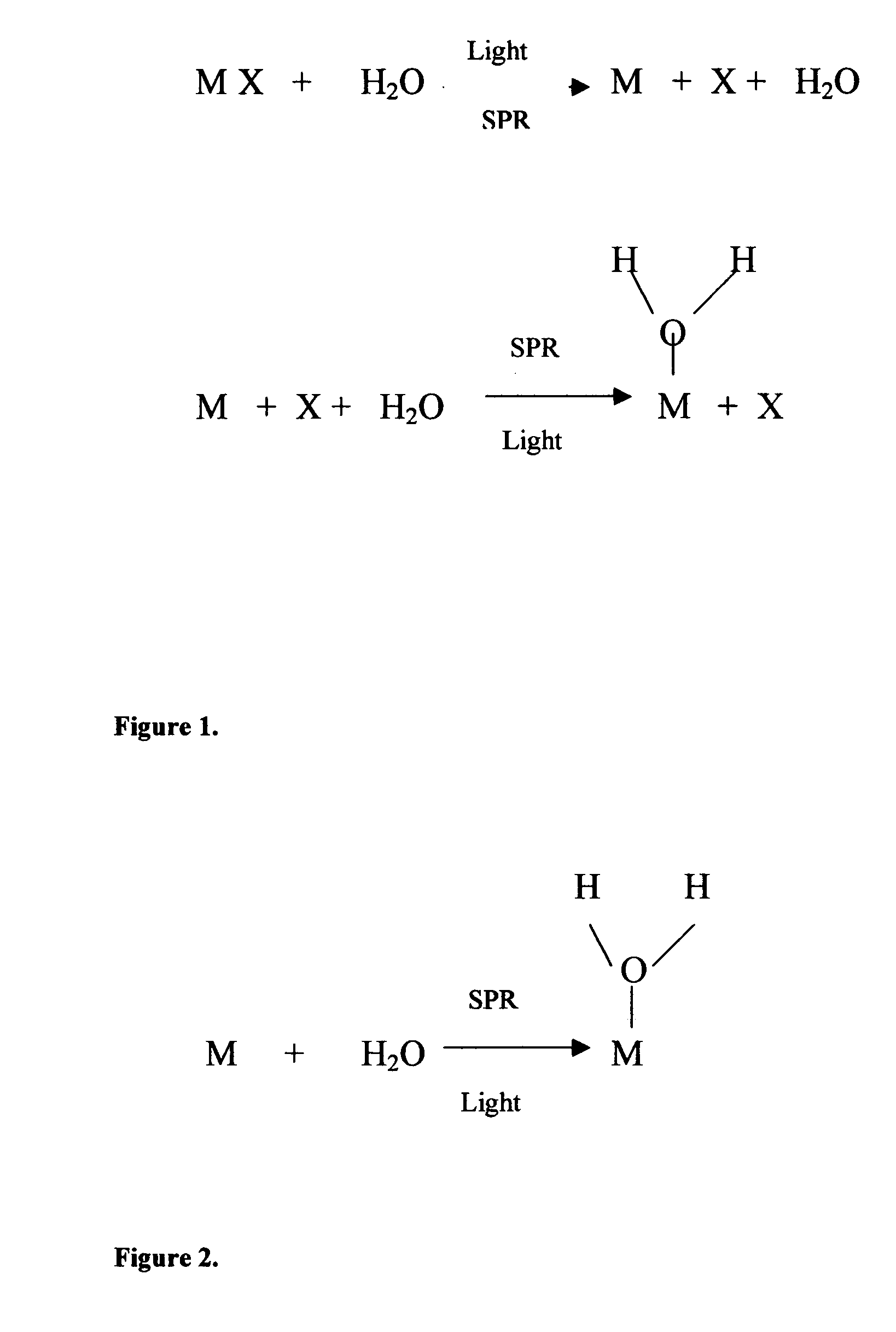

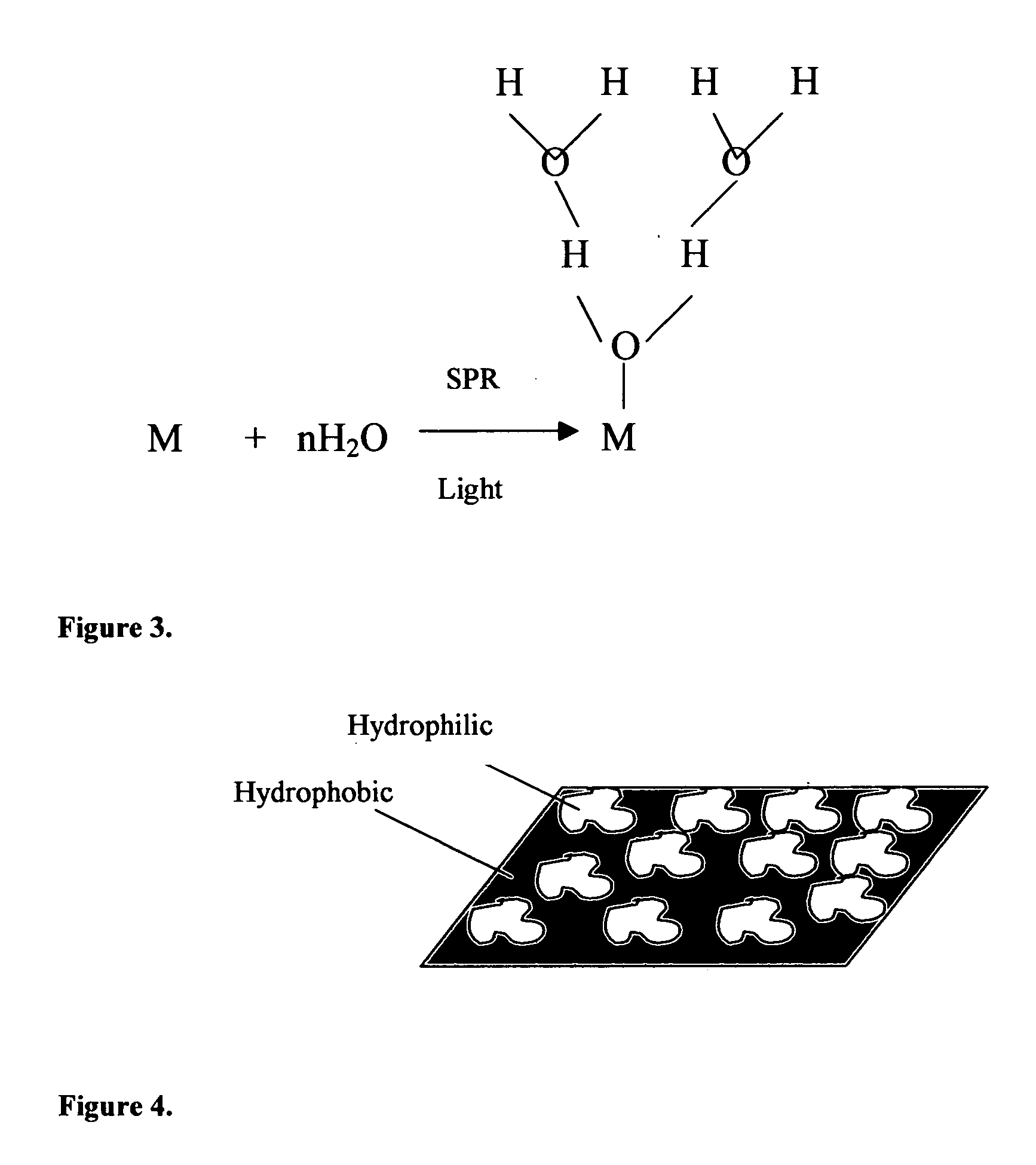

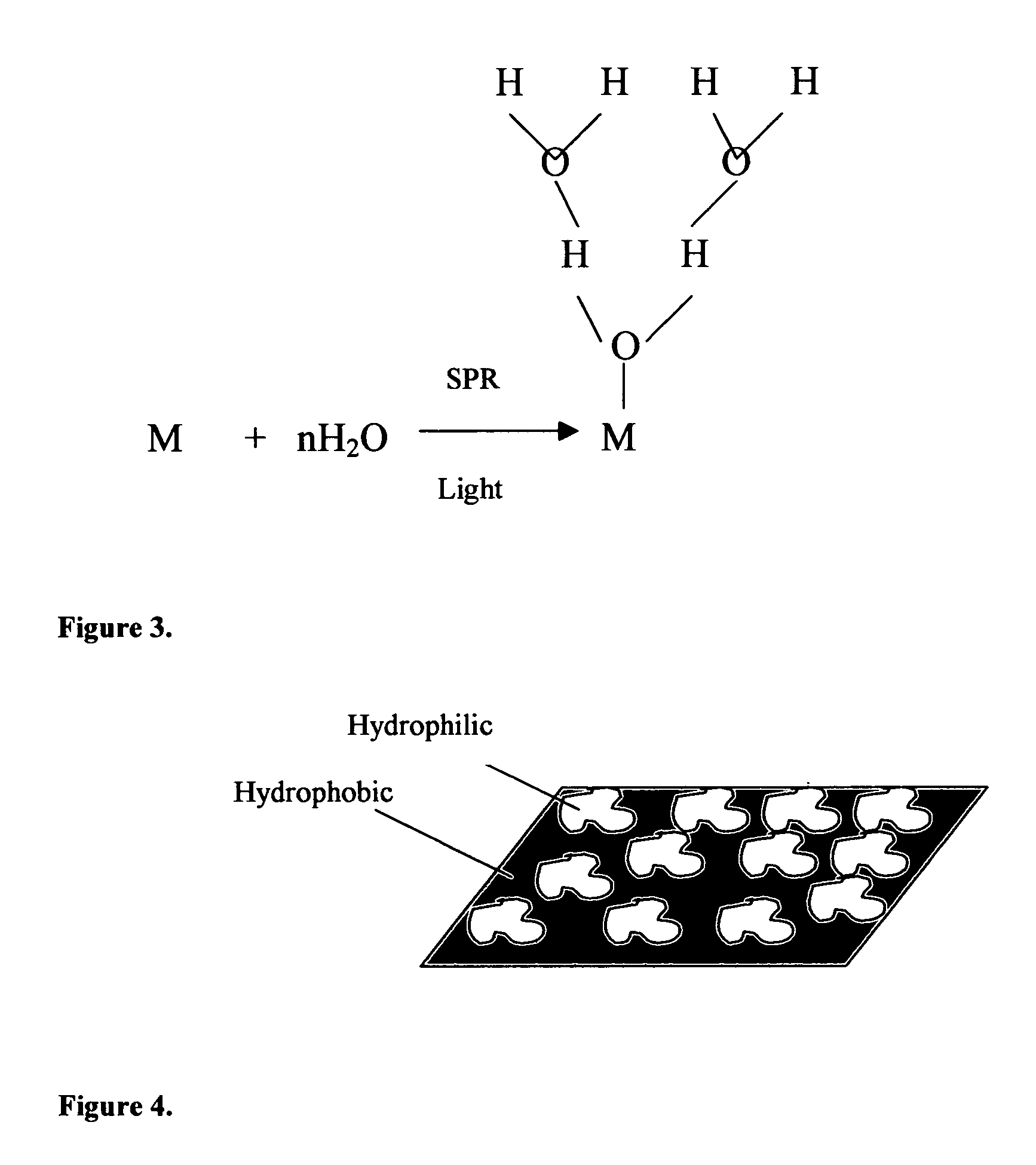

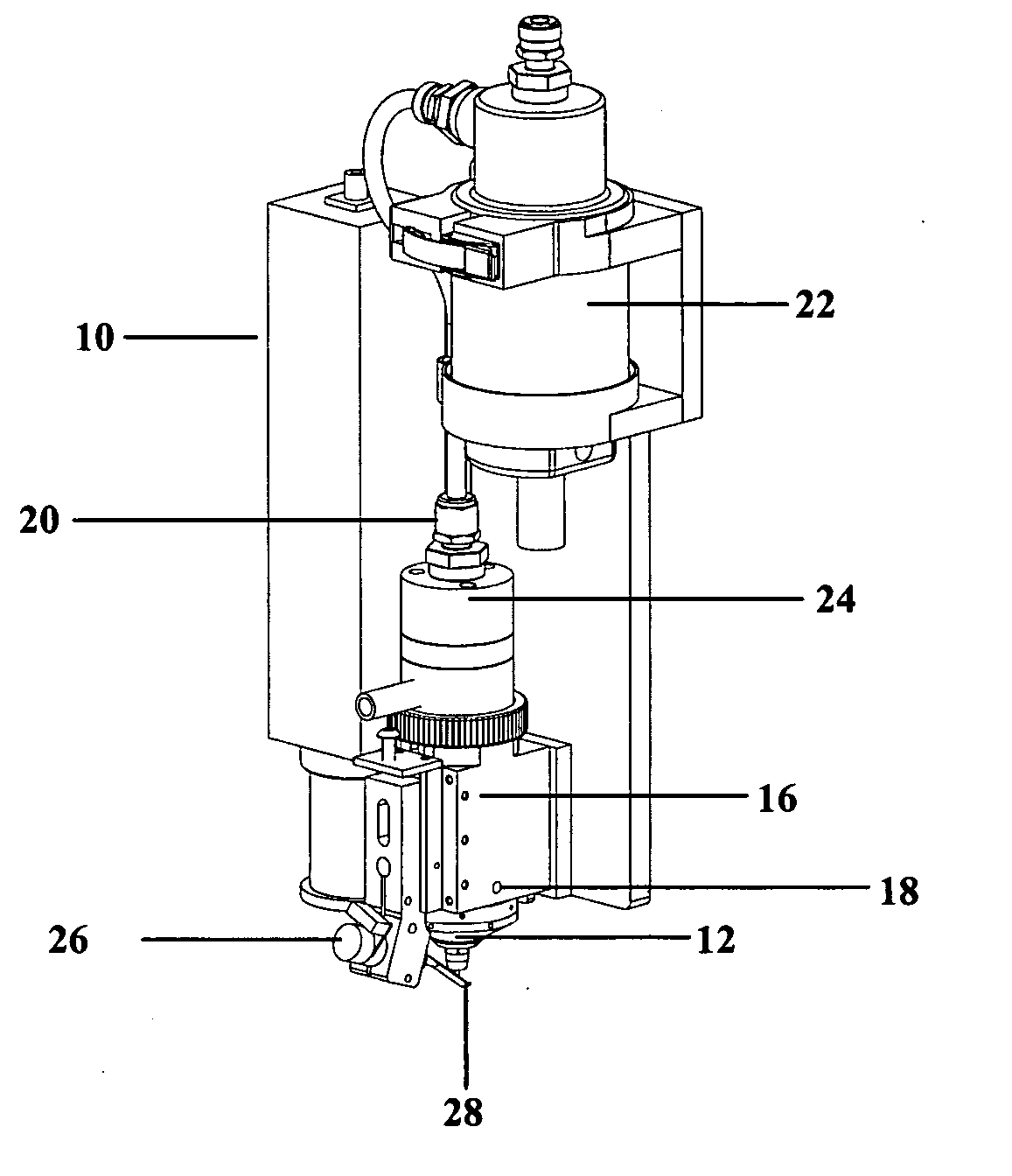

Methods and applications of surface plasmon resonance-enhanced antibacterial, anti-adhere, adhere, catalytic, hydrophilic, hydrophobic, spectral change, biological and chemical decomposition properties of materials with embedded nanoparticles are disclosed. A method of the nonlinear generation of surface plasmon resonance enables the use of light with wavelengths from X-Ray to IR to enhance properties of materials by several orders of magnitude. The nanoparticle size is crucial for the enhancement and their size is considered to be in the proposed methods and applications within a range of 0.1 nm to 200,000 nm. The nanoparticles preferably are made of noble metals and / or semiconductor oxides. The invention describes a very broad spectrum of applications of surface plasmon resonance-enhanced properties of materials with embedded nanoparticles, from environmental cleanup by road pavement and construction materials, self-cleaning processes of surface materials, thermochromic effects on heat blocking materials, corrosion preventing paint, to sanitization by antibacterial textile fabrics, filters, personal clothing, contact lenses and medical devices.

Owner:SPR ADVANCED TECH INC

Semiconductor processing methods of chemical vapor depositing SiO2 on a substrate

InactiveUS6974780B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction intermediateChemical vapor deposition

Owner:MICRON TECH INC

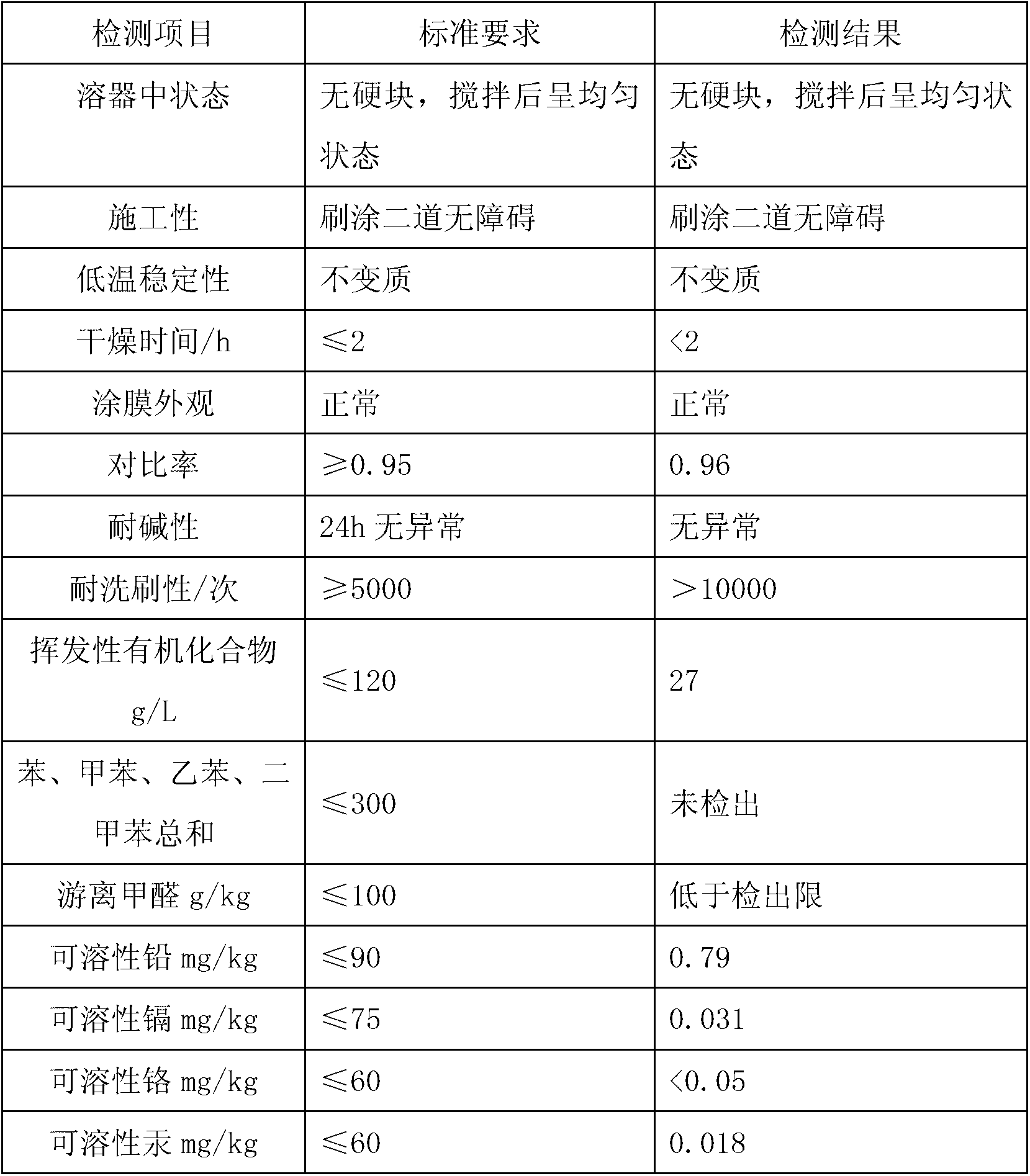

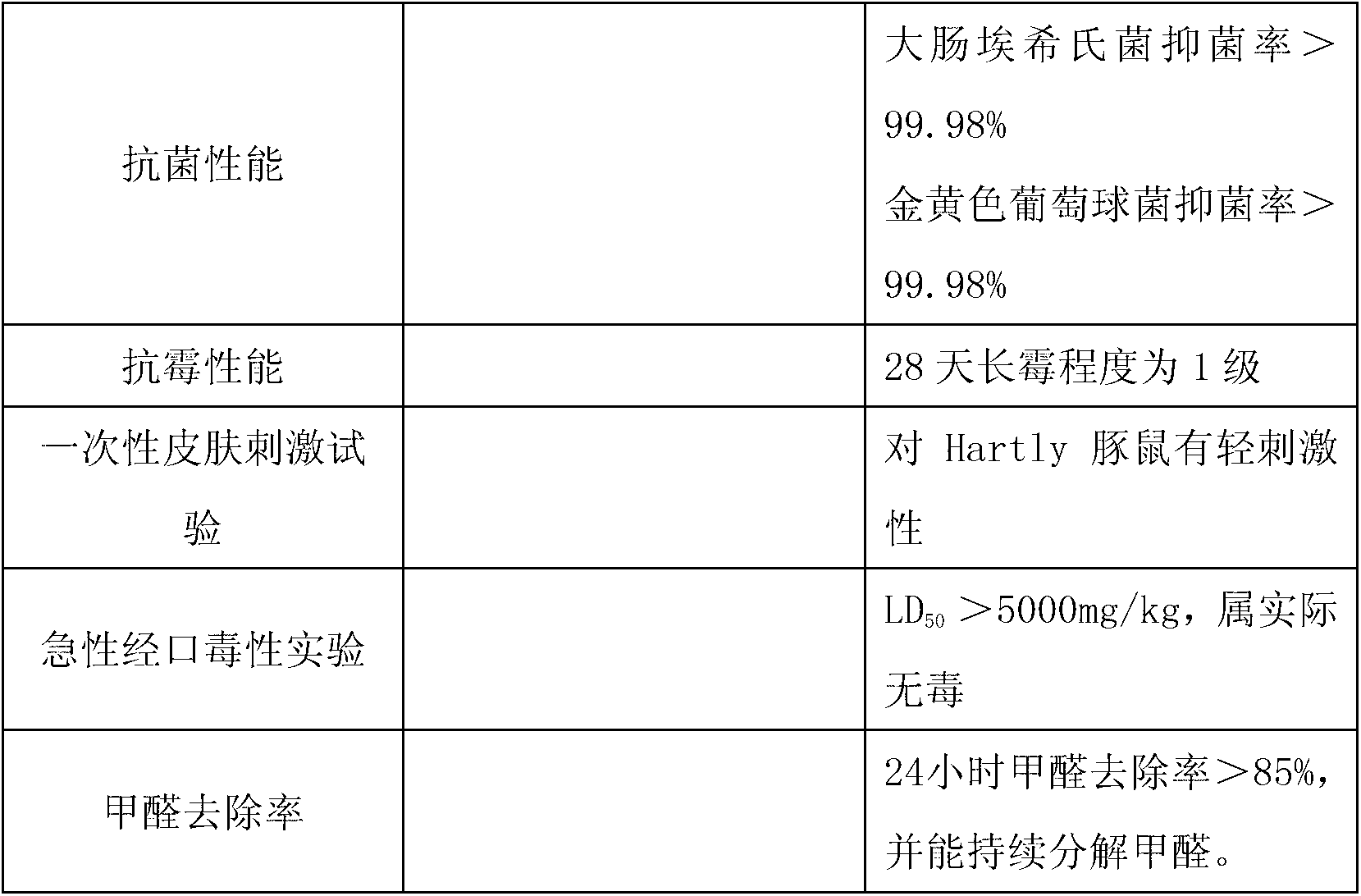

Odorless anti-formaldehyde environment-friendly internal wall latex paint and preparation method thereof

ActiveCN103059679AStrong absorption capacityStrong sustainable degradation abilityEmulsion paintsEmulsionSlurry

The invention discloses an odorless anti-formaldehyde environment-friendly internal wall latex paint and a preparation method thereof. The odorless anti-formaldehyde environment-friendly internal wall latex paint is prepared from the following components in percentage by weight: 1-15% of visible light induced nano titanium dioxide photocatalyst slurry, 15-35% of odorless emulsion, 1-15% of formaldehyde absorbent, 0.5-2% of dispersing agent, 0.2-3% of thickening agent, 0.2-1% of wetting agent, 0.1-1% of defoaming agent, 0.5-5% of film-forming assistant, 0.2-3% of anti-freeze agent, 20-40% of pigment and filler, 0.1-1% of pH regulator, 0.01-0.1% of anticorrosive bactericide and 15-40% of deionized water. The invention adopts an IPS+odorless technique, and the visible light induced nano titanium dioxide photocatalyst and the formaldehyde absorbent are added, thereby achieving the optimal effect of removing formaldehyde and other harmful substances through physical adsorption and chemical decomposition. The invention can be widely used for decorative spraying of various internal walls and other constructions.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

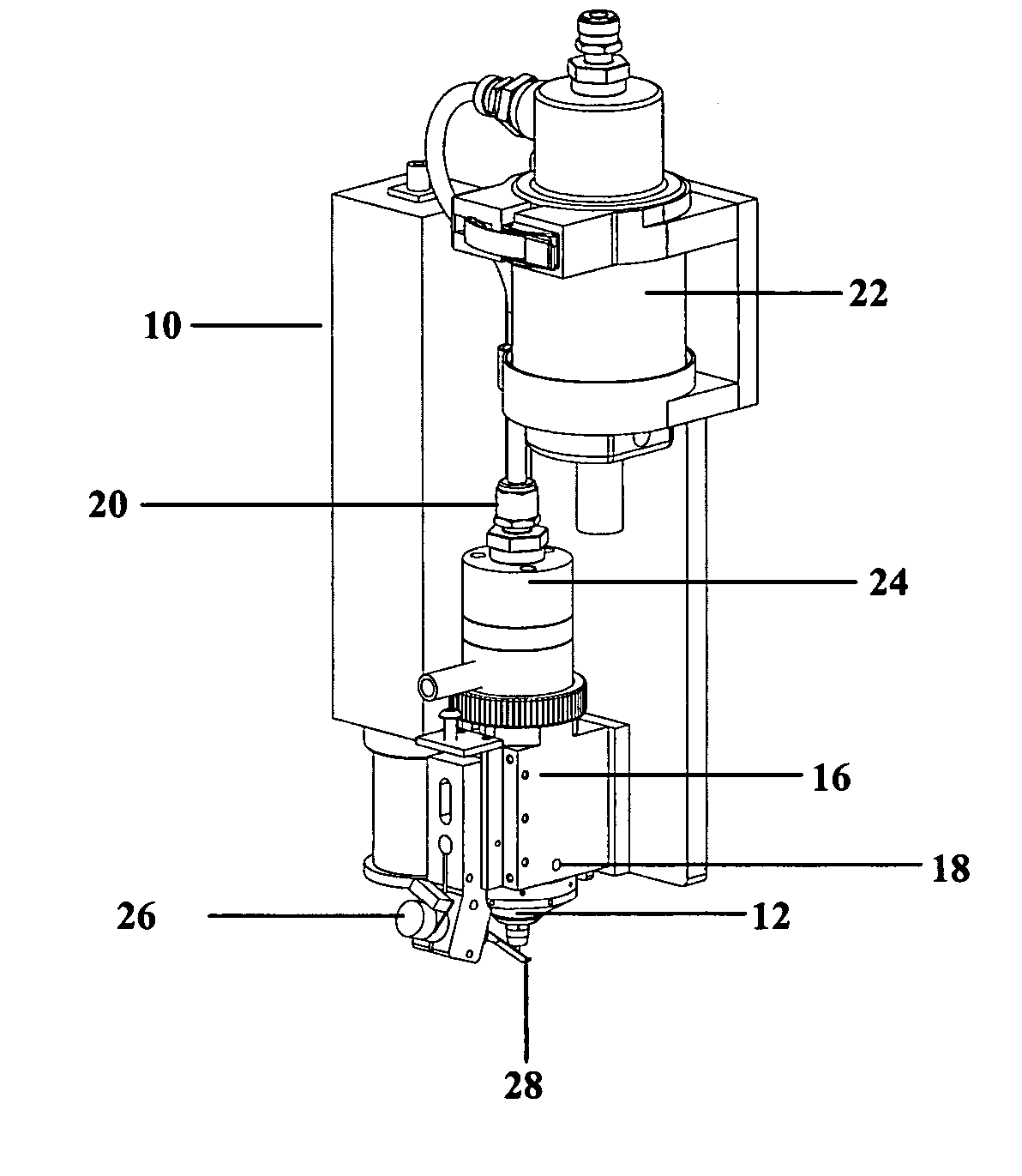

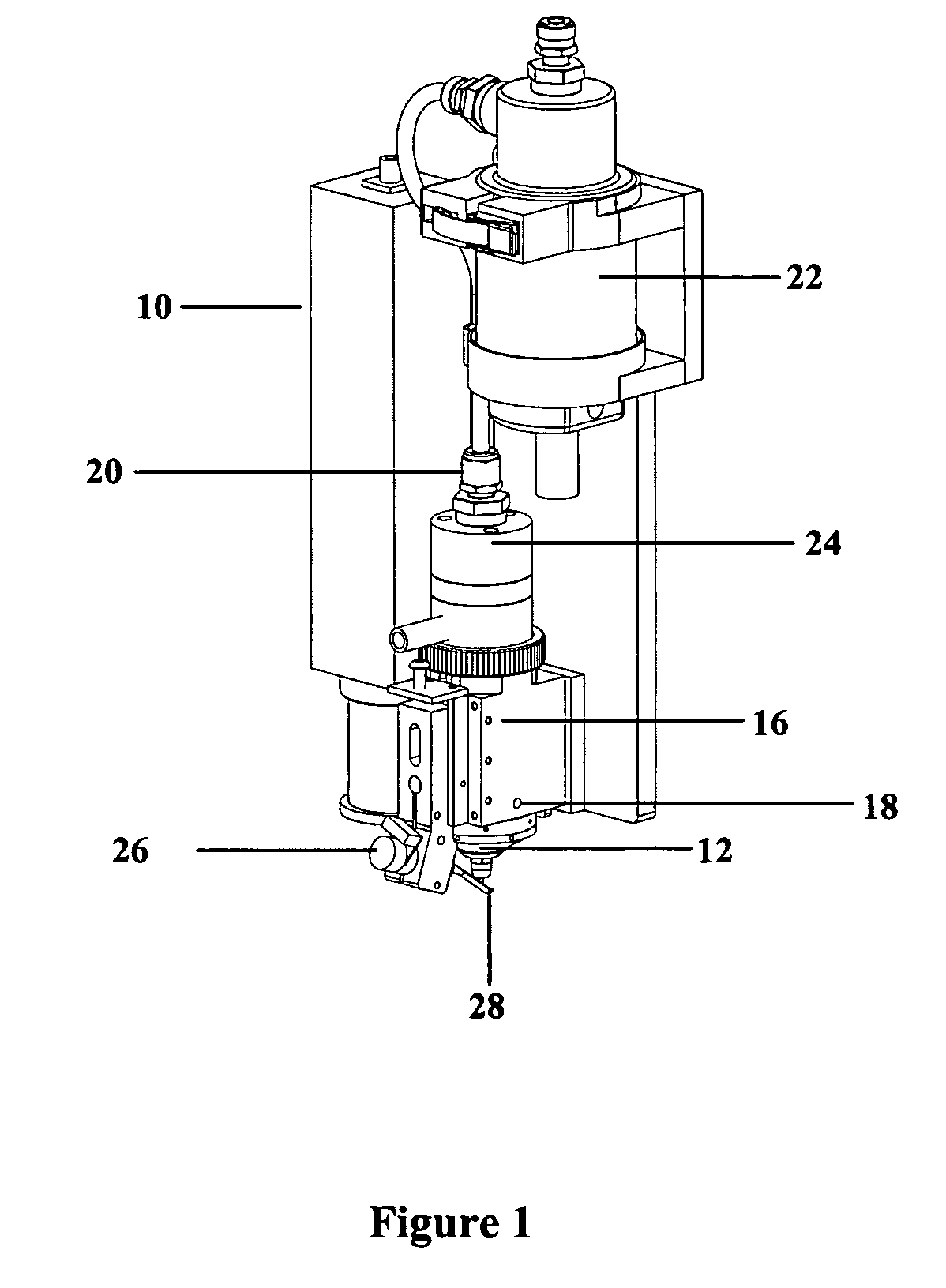

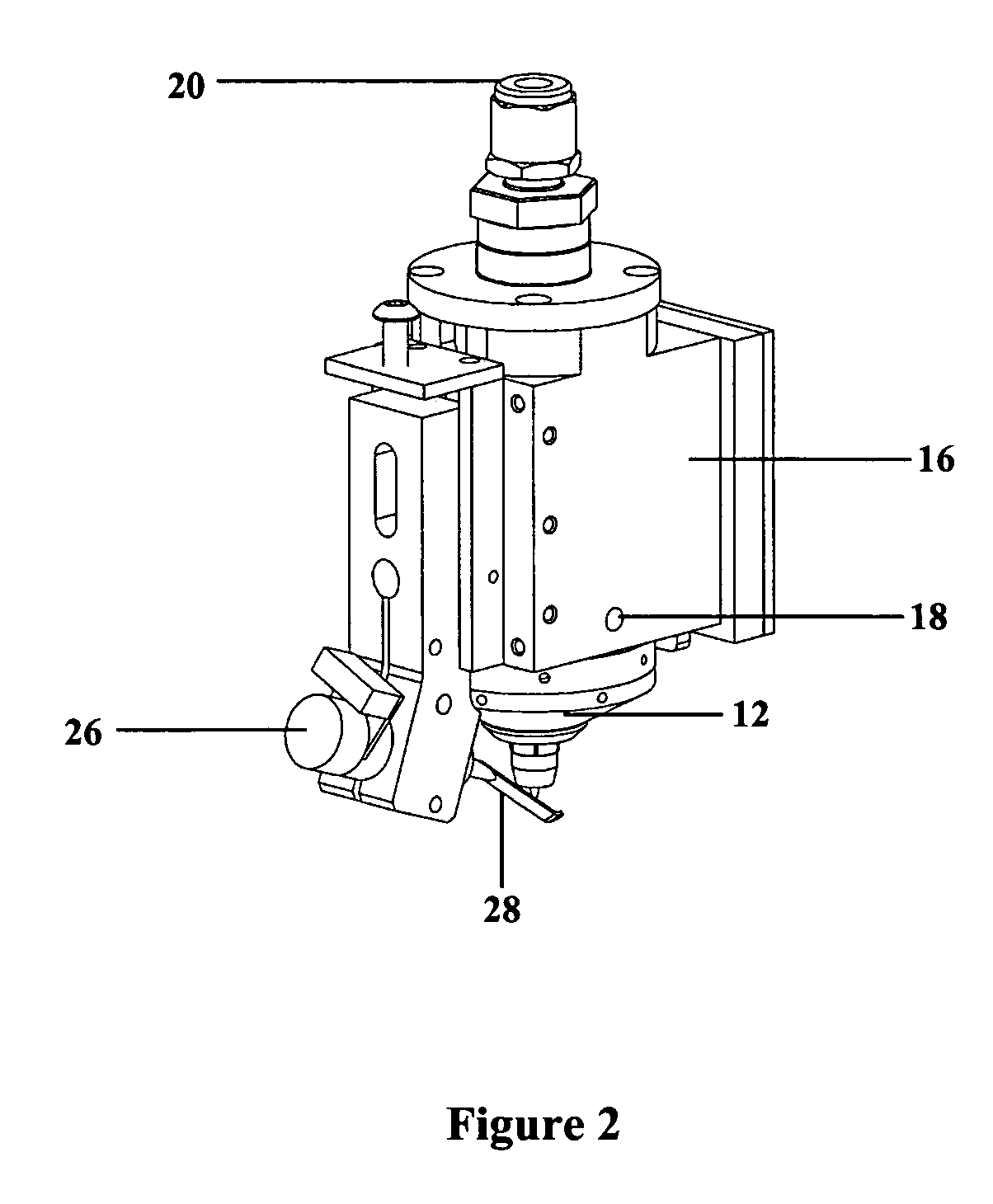

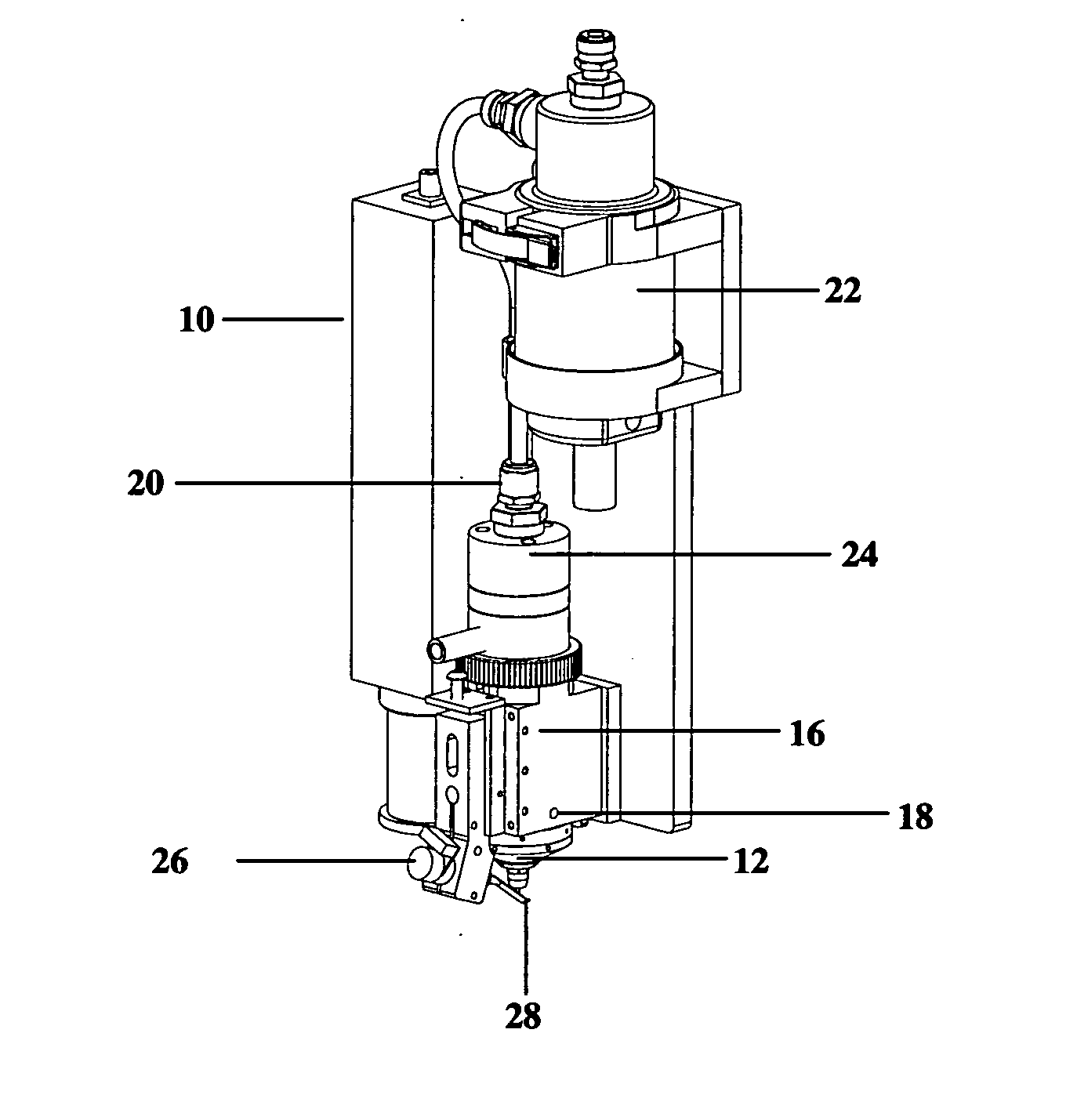

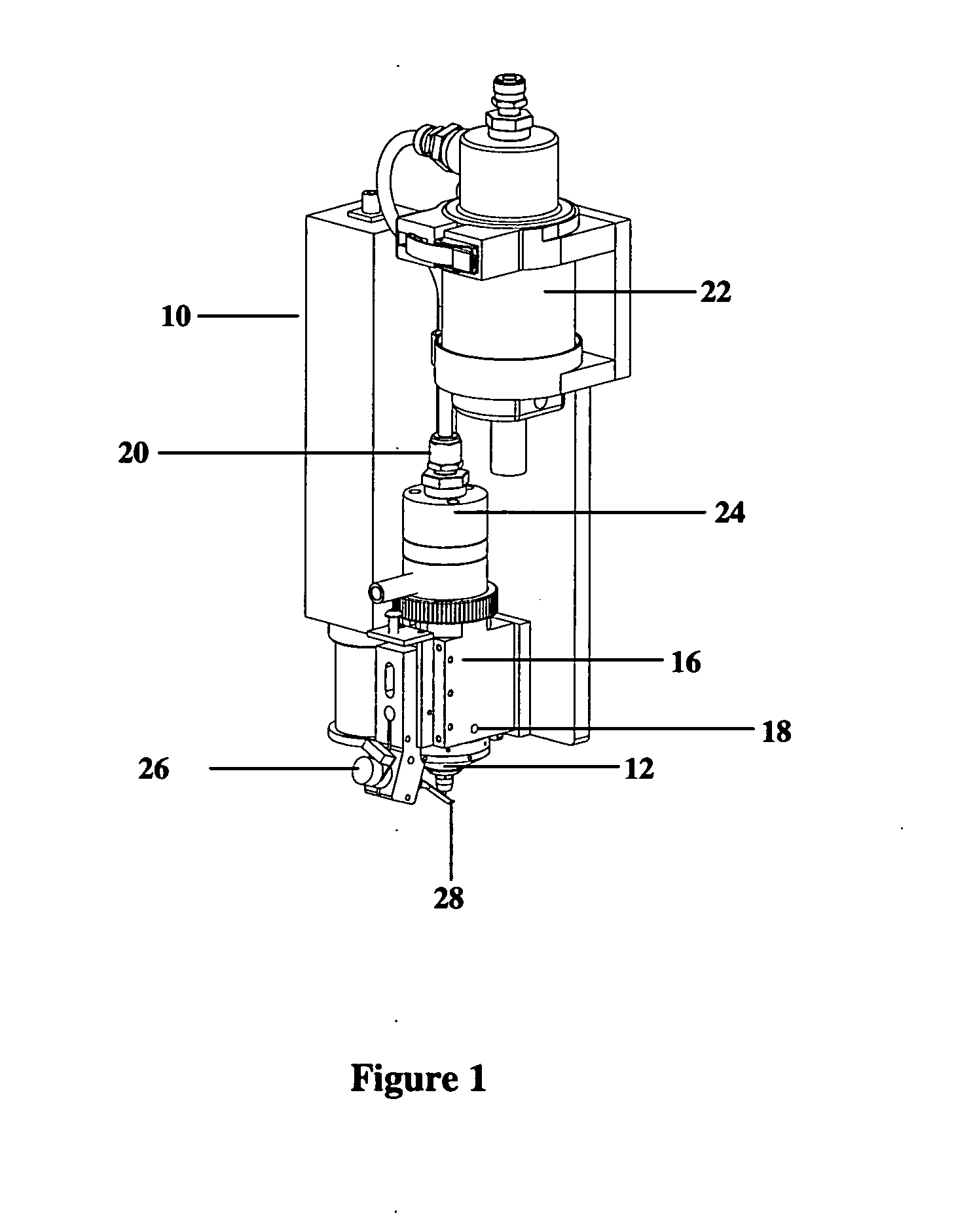

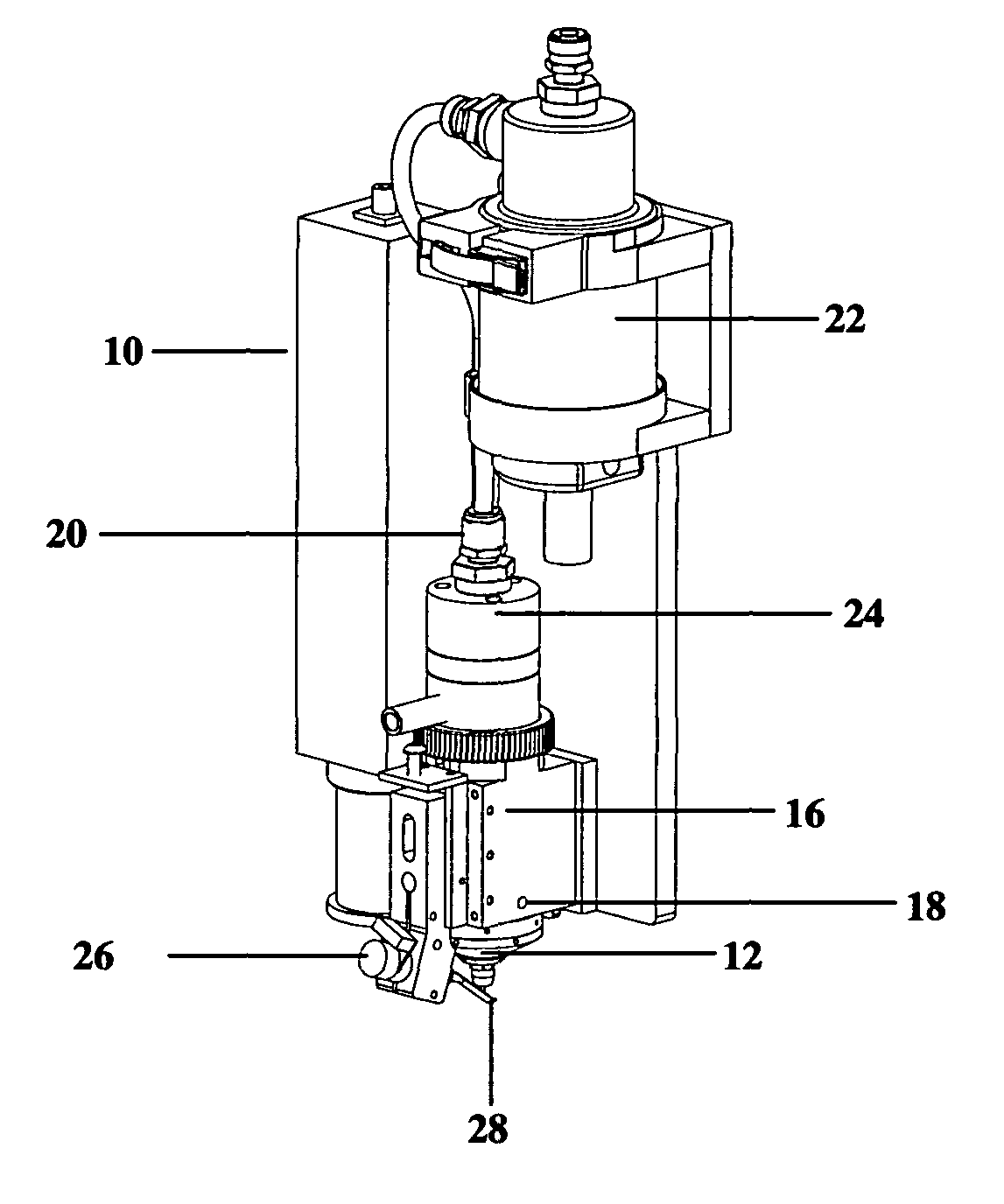

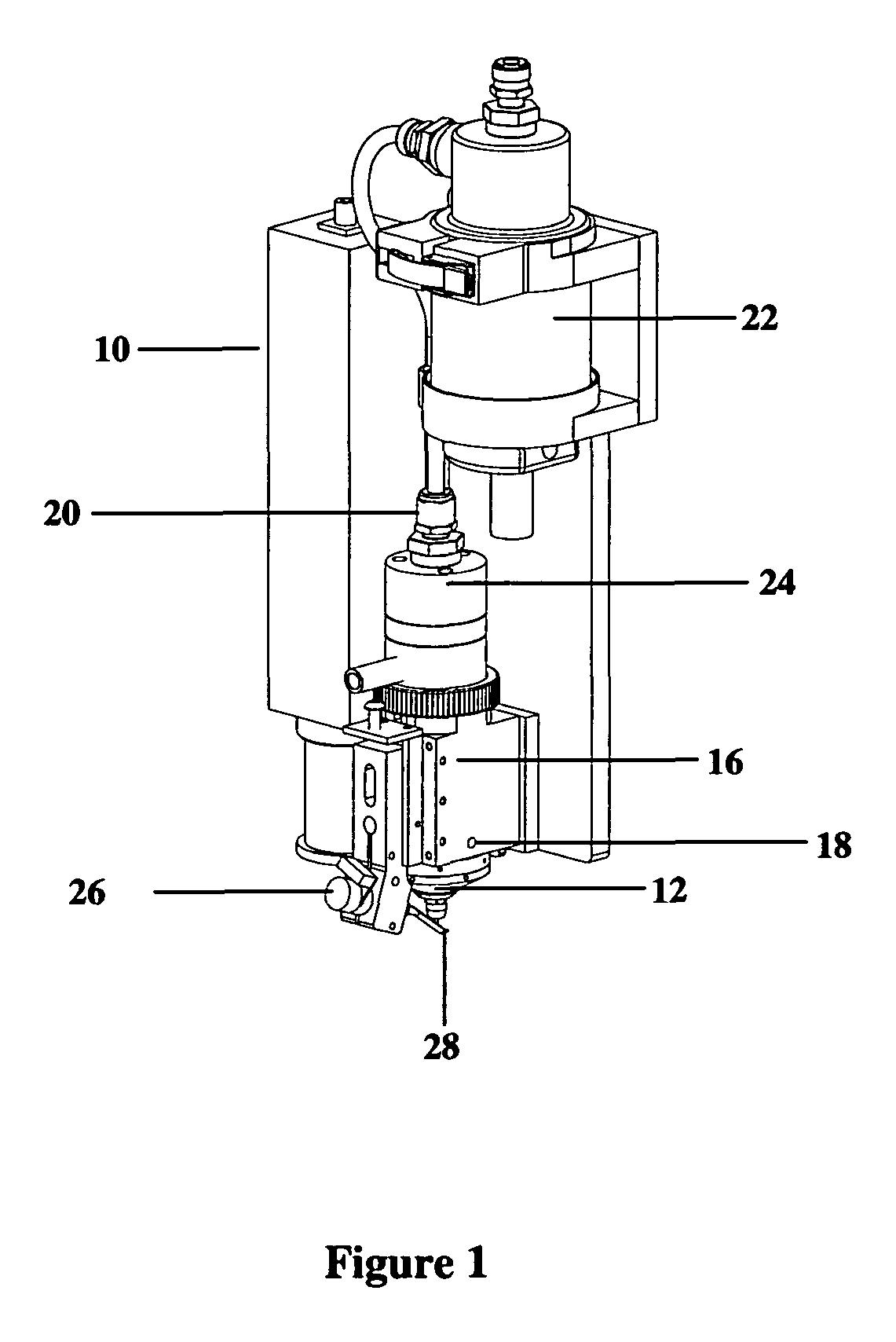

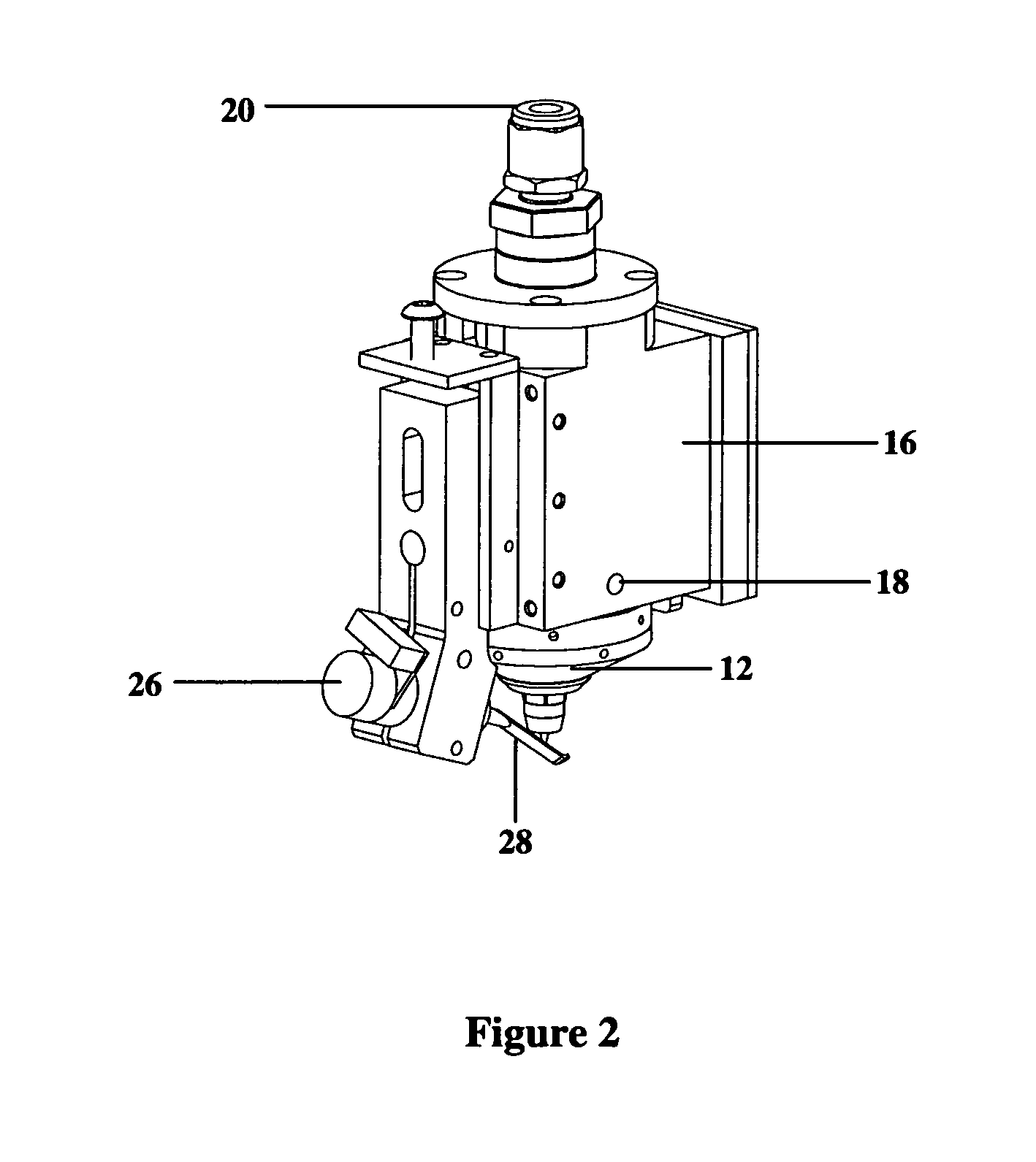

Laser processing for heat-sensitive mesoscale deposition

InactiveUS7294366B2Low damage thresholdElectric discharge heatingRadiation applicationsLaser processingHeat sensitive

A method of depositing various materials onto heat-sensitive targets. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts.

Owner:OPTOMEC DESIGN CO

Laser processing for heat-sensitive mesoscale deposition of oxygen-sensitive materials

InactiveUS20070019028A1Damage to materialRadiation applicationsPretreated surfacesForming gasHeat sensitive

A method of depositing various materials onto heat-sensitive targets, particularly oxygen-sensitive materials. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts. Cover gases and / or forming gases may be used during thermal processing to change the material properties, for example by preventing oxidation.

Owner:OPTOMEC DESIGN CO

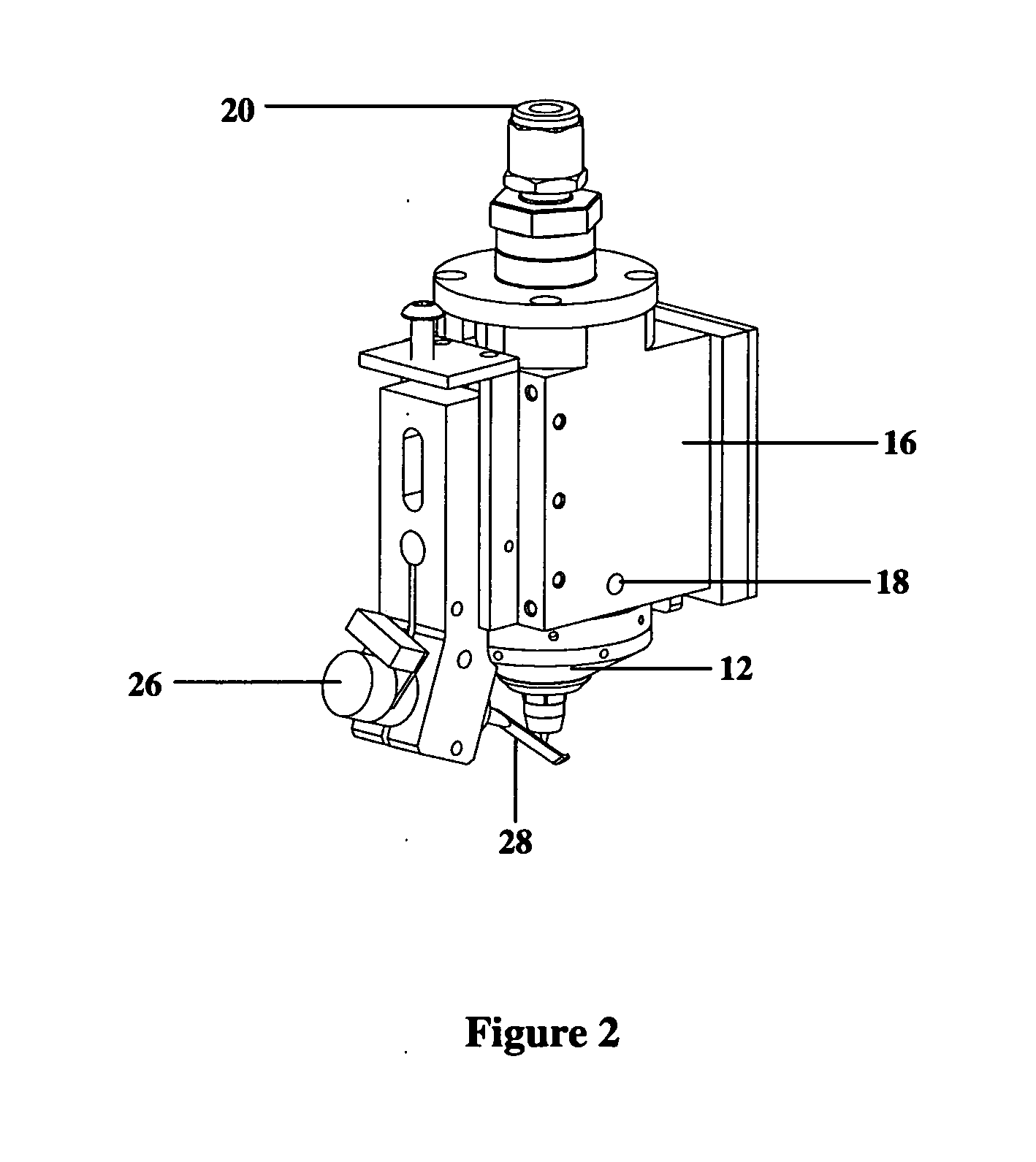

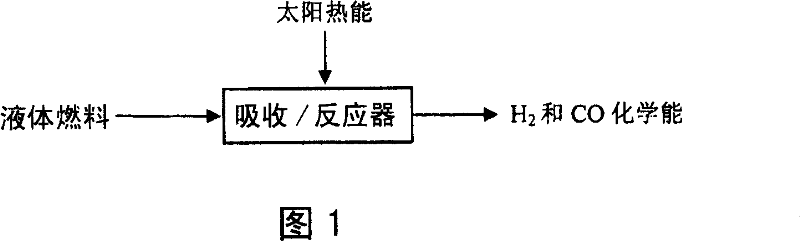

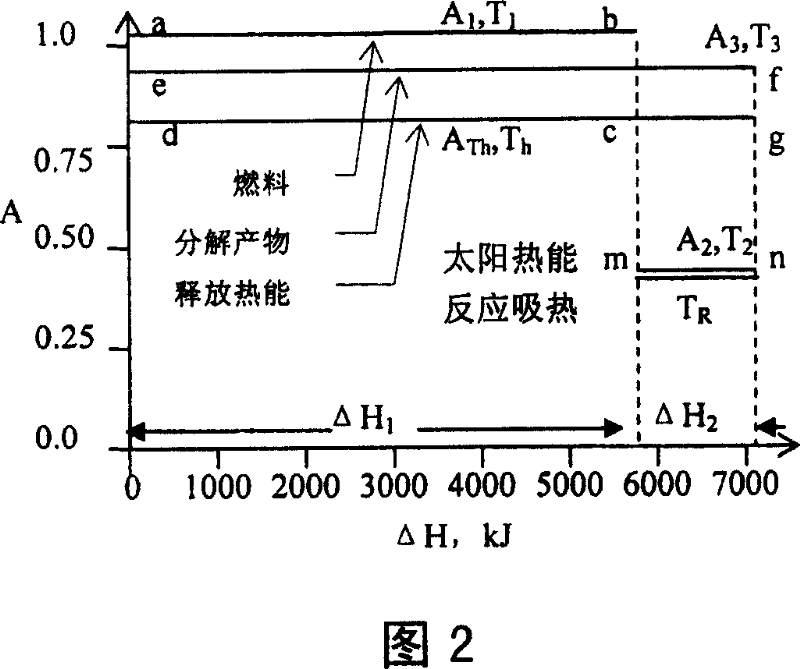

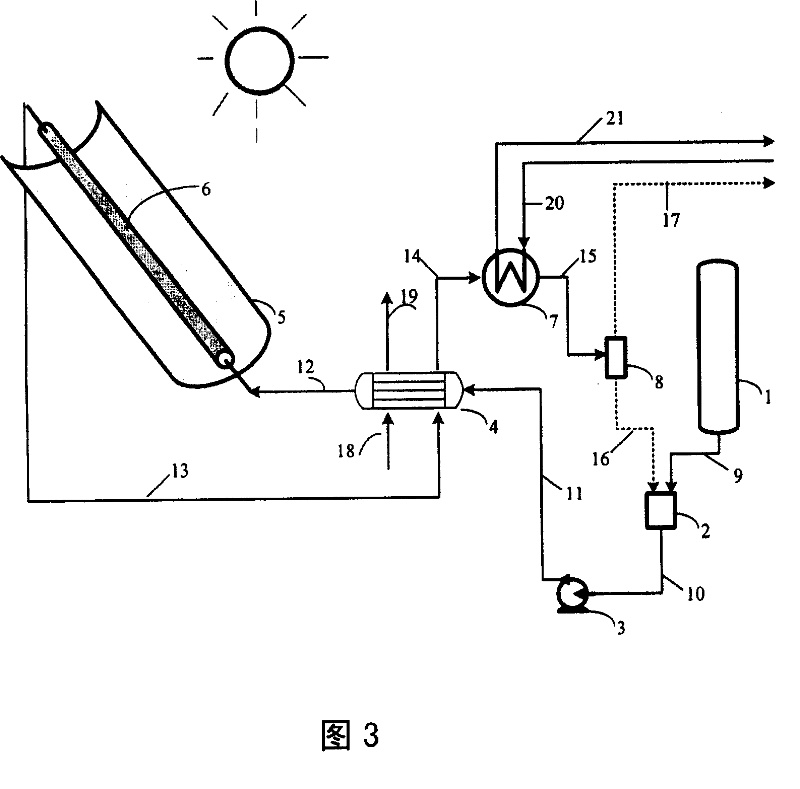

Method and apparatus for converting solar energy into fuel chemical energy

It relates to a method and device of changing solar energy to chemical energy. It accumulates the solar energy and changing it to heat energy ranging from 150deg.C-300deg.C, providing reaction heat for the liquid fuels, allowing the middle and low level solar energy changing and stored into high level chemical energy, with the liquid being carbinol or dimethyl ether synthetic fuel, with the catabolite being hydrogen and monoxide formed gas. It can be used for multi purposes, providing fine synthetic fuel and material for customers.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Oral formulation for delivery of poorly absorbed drugs

InactiveUS20060088592A1Promote absorptionReduce inactivationHeavy metal active ingredientsMultiple-port networksSucrosePolyvinyl alcohol

A composition for oral delivery of a poorly absorbed drug is disclosed. The composition includes the drug, an enhancer for increasing absorption of the drug through the intestinal mucosa, a promoter, which alone does not increase absorption of the drug through the intestinal mucosa, but which further increases the absorption of the drug in the presence of the enhancer, and optionally a protector for protecting the drug from physical or chemical decomposition or inactivation in the gastrointestinal tract. Illustrative enhancers include sucrose fatty acid esters, and illustrative promoters include aminosugars and amino acid derivatives, such as poly(amino acids). Illustrative protectors include methylcellulose, poly(vinyl alcohol), and poly(vinyl pyrrolidone).

Owner:PROCARRIER

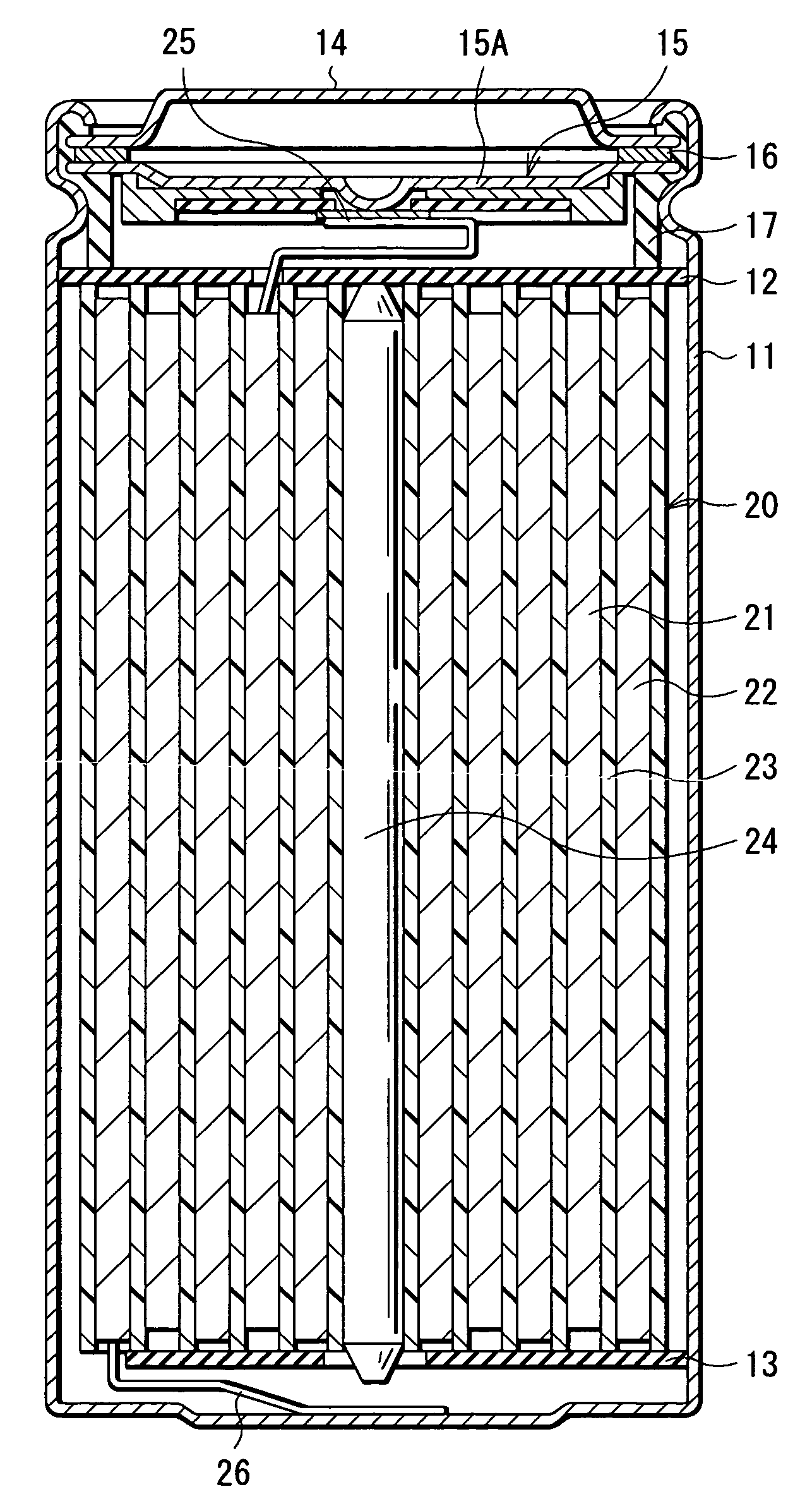

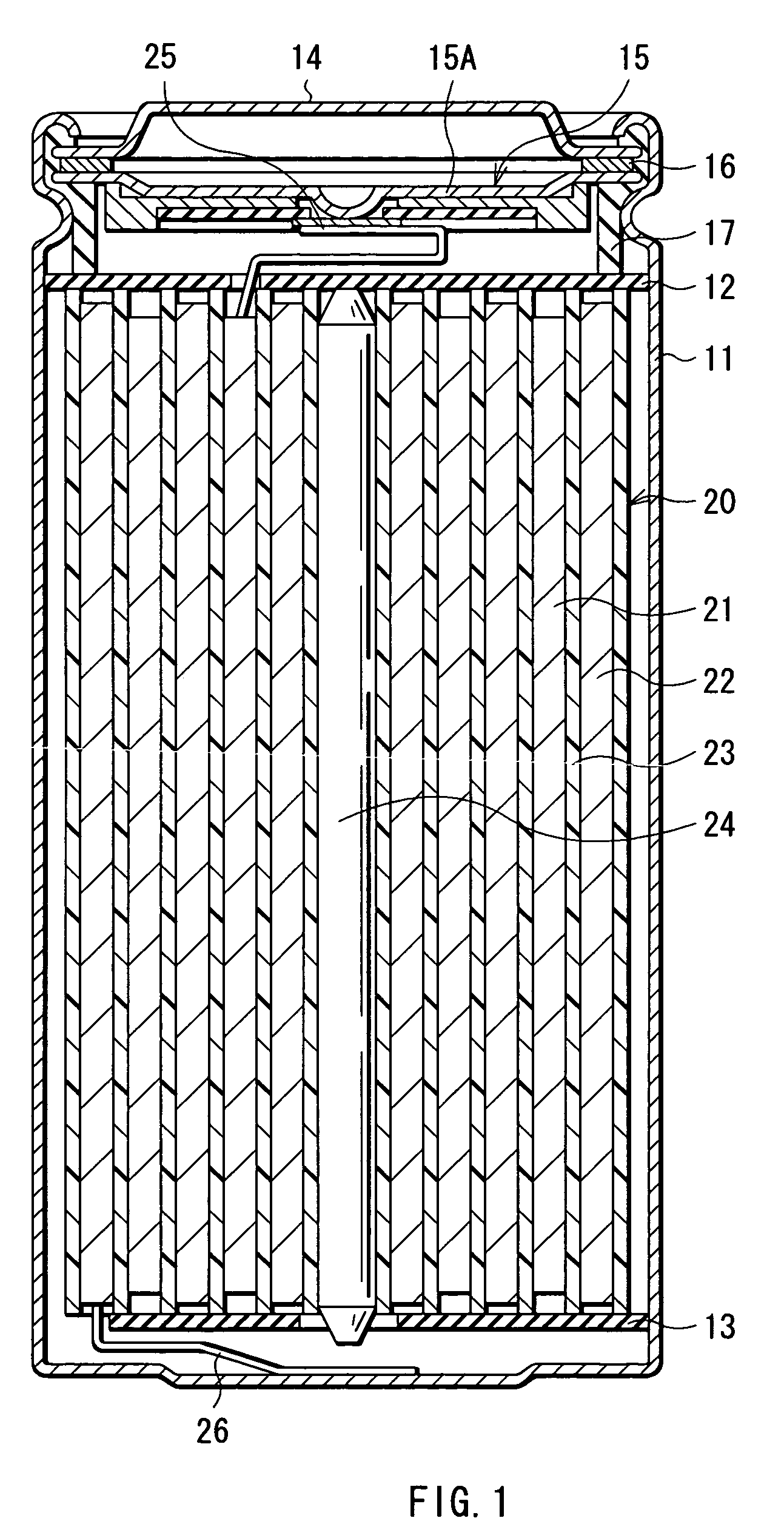

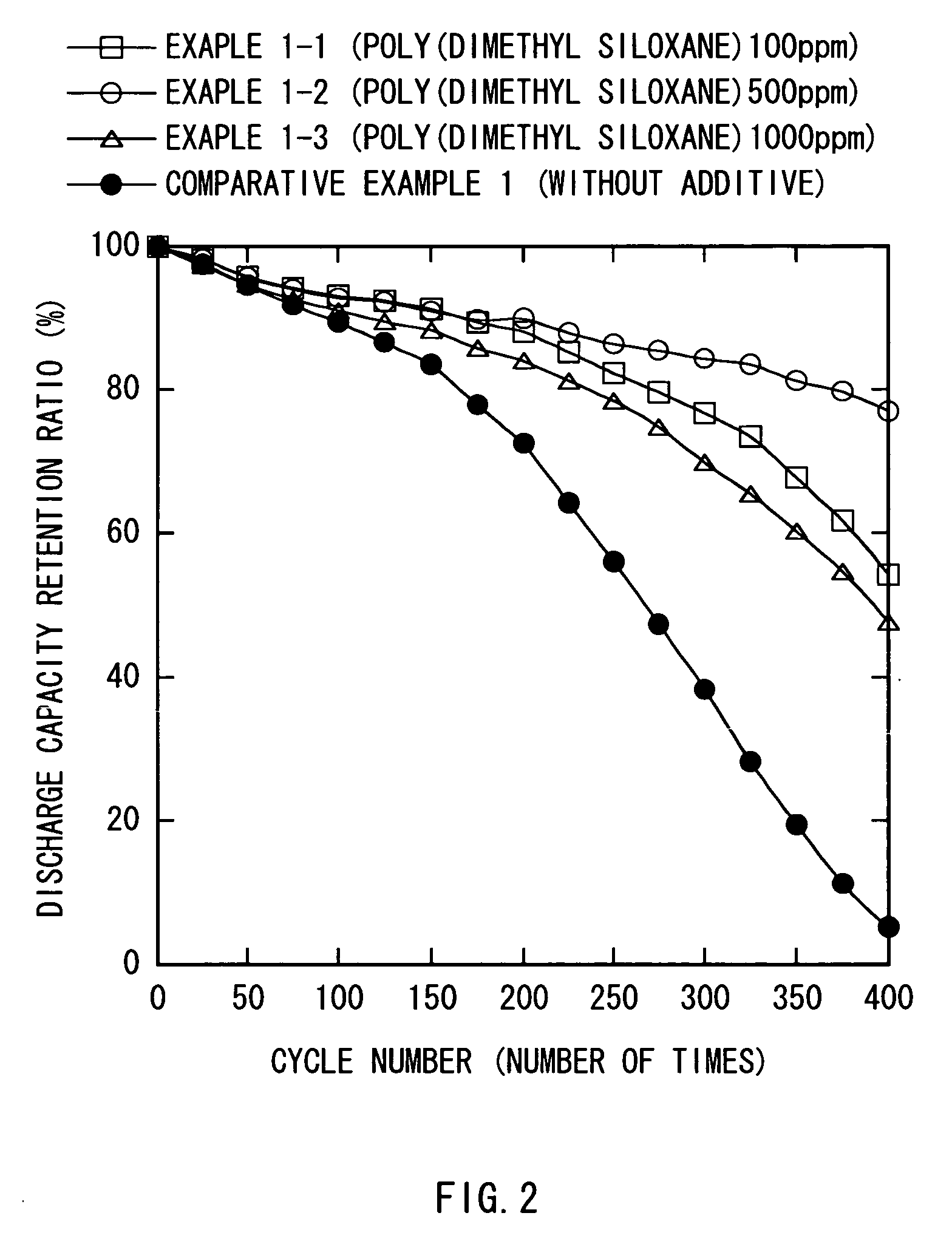

Electrode and battery

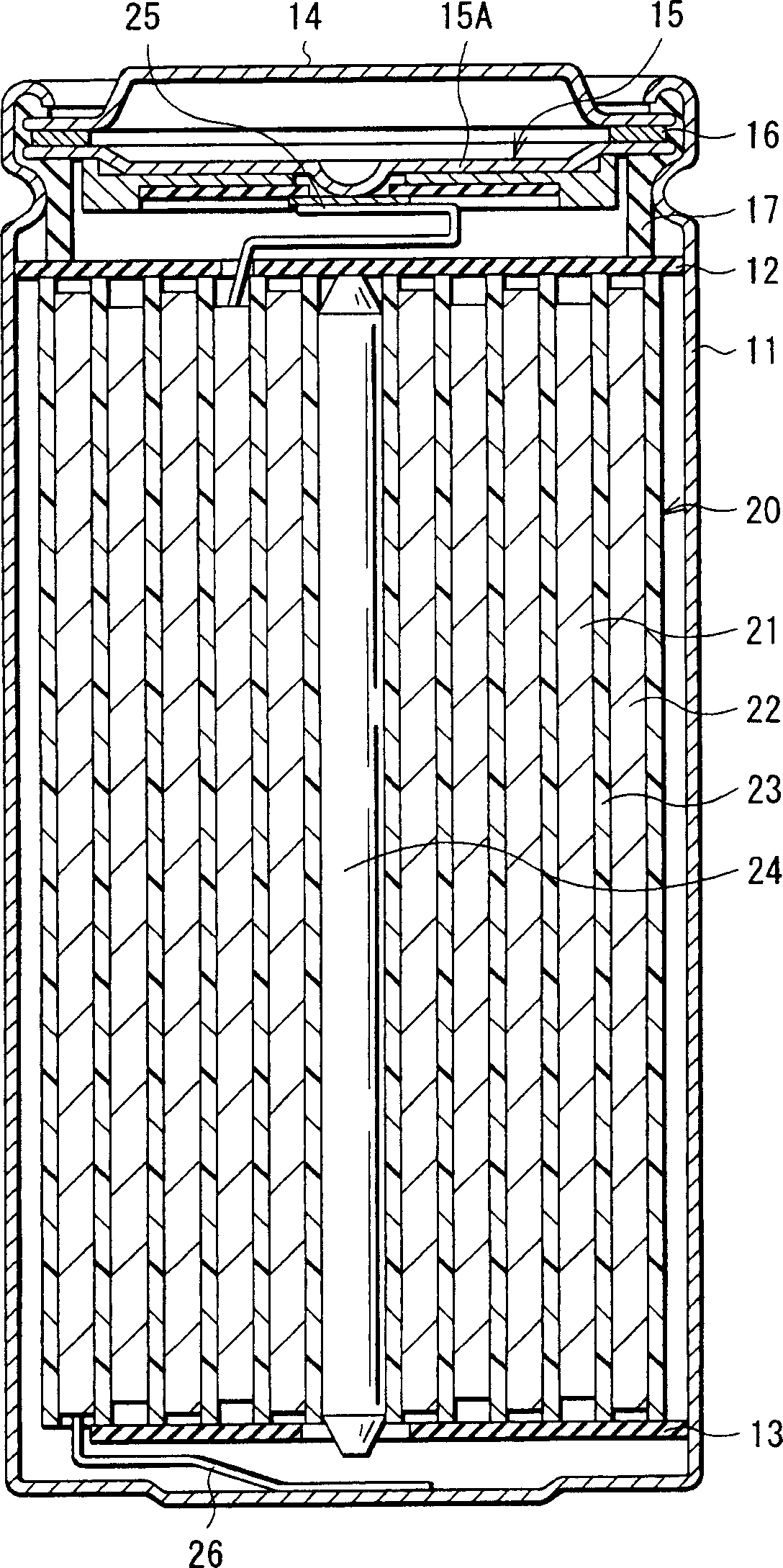

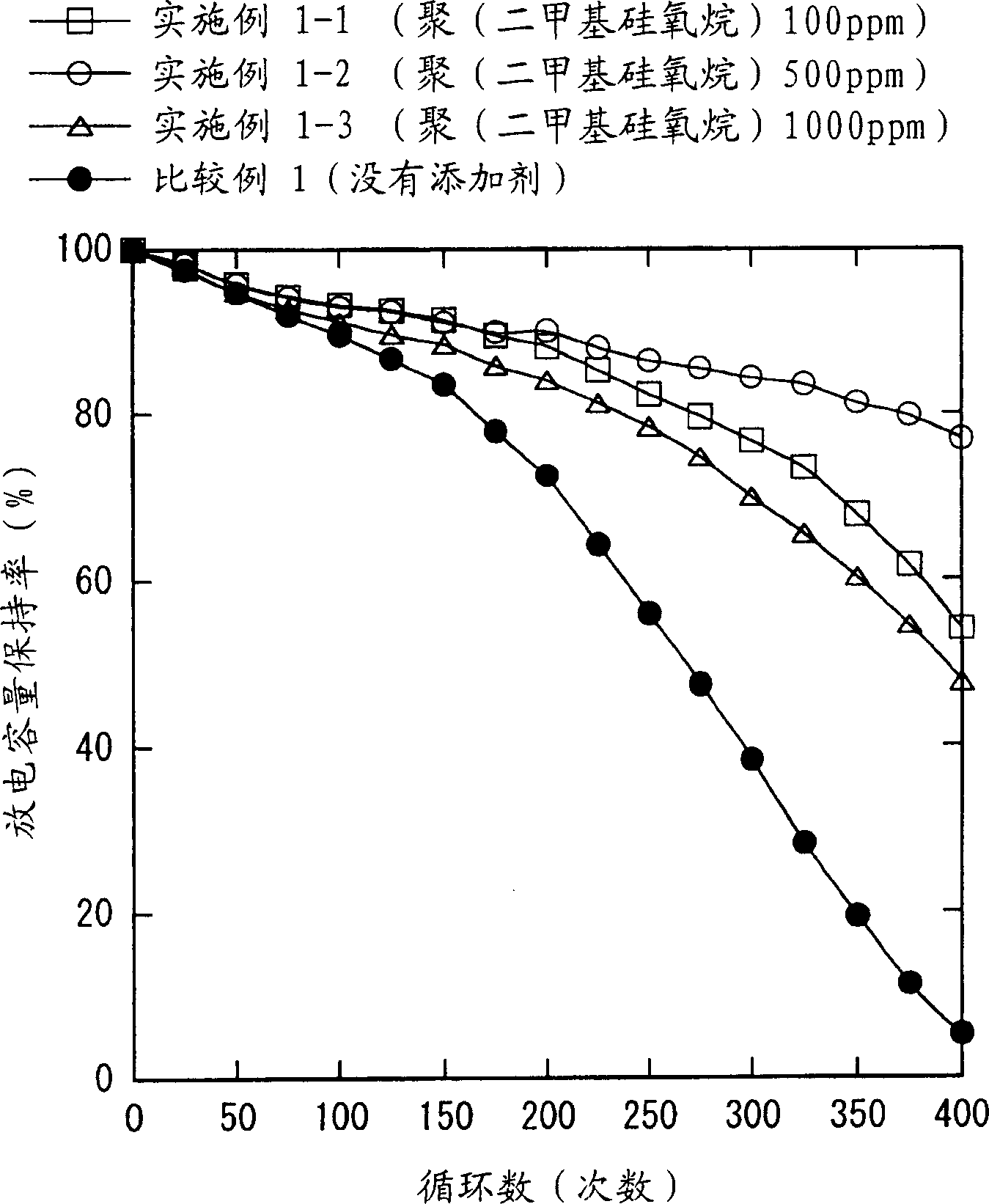

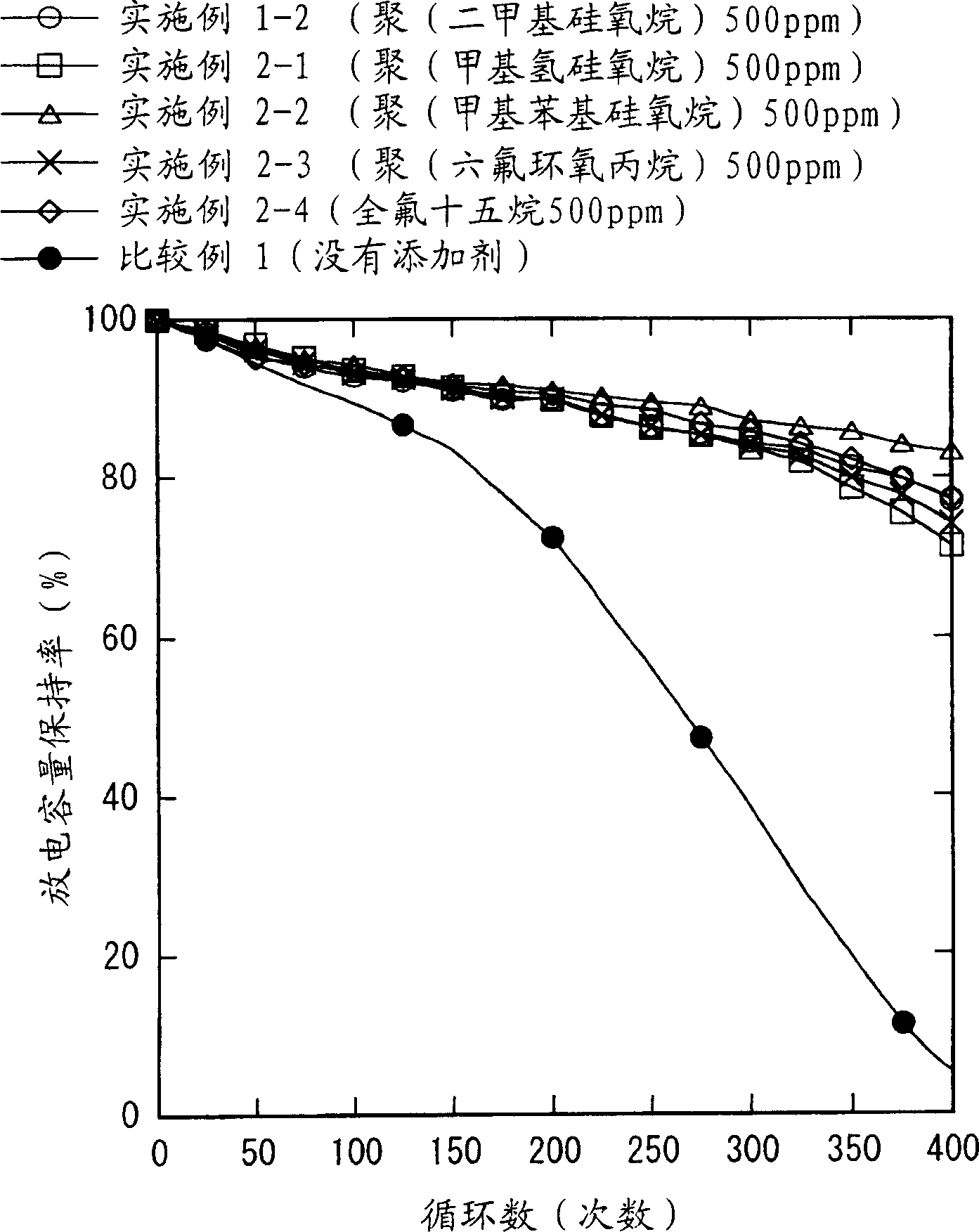

InactiveUS20060063073A1Excellent battery characteristicsEfficient coatingFinal product manufactureOrganic electrolyte cellsAlkanePerfluoropolyether

An electrode and a battery coverable of improving cycle characteristics by forming an effective coat are provided. A cathode (21) and an anode (22) are wound with a separator (23) impregnated with an electrolytic solution inbetween. On the surface of the cathode (21) or the anode (22), a coat containing a compound, which has a smaller surface tension than of the electrolytic solution and is insoluble into the electrolytic solution, specifically, a coat containing siloxane such as poly (dimethyl siloxane), poly (methyl hydro siloxane), and poly (methyl phenyl siloxane), or perfluoro polyether such as poly (hexafluoro propylene oxide), or perfluoro alkane such as perfluoro pentadecane is provided. Thereby, without using a great deal of the compound for forming the coat, the coat effective to inhibit decomposition reaction of the electrolytic solution is formed.

Owner:SONY CORP

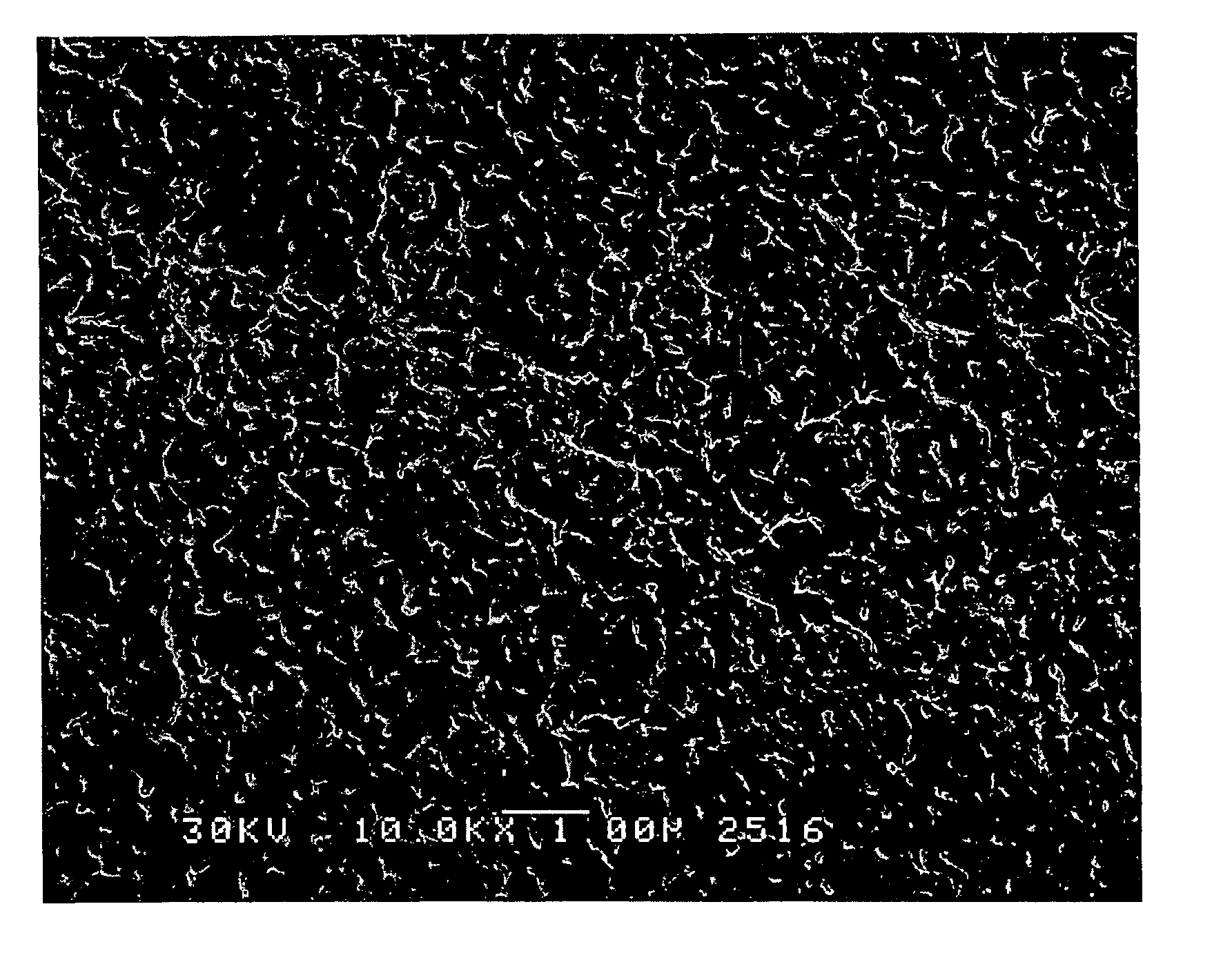

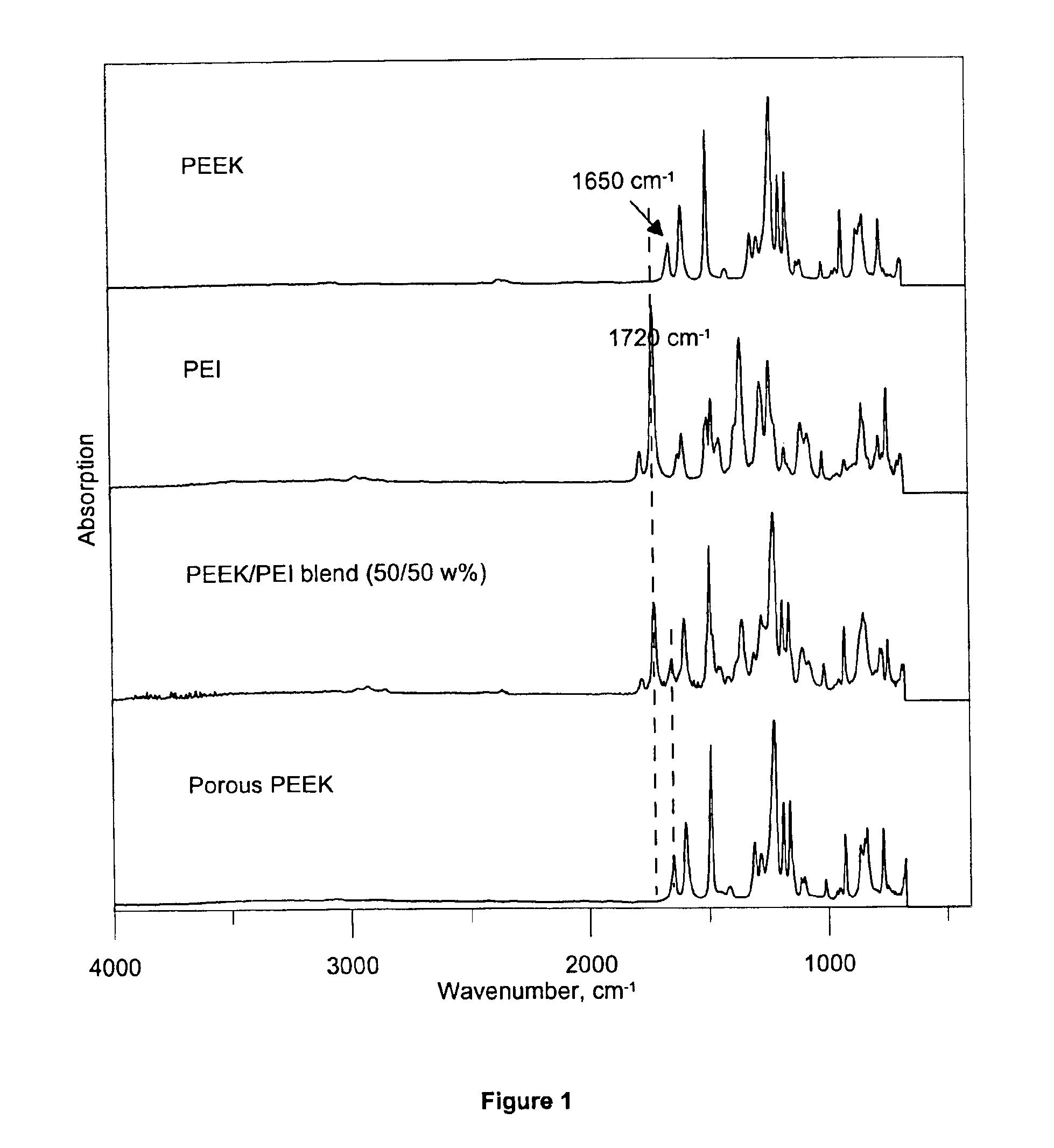

Porous poly(aryl ether ketone) membranes, processes for their preparation and use thereof

ActiveUS6887408B2Simple and cost-effective and industrially feasibleIncreased porous structureMembranesSemi-permeable membranesArylPorous medium

Porous poly(aryl ether ketone) (PAEK) articles are prepared from PAEK / polyimide blends by selective chemical decomposition and subsequent removal of the polyimide phase. Porous PAEK articles exhibit highly interconnected pore structure and a narrow pore size distribution. The porous PAEK articles of the present invention can be utilized as a porous media for a broad range of applications, including membranes for fluid separations, such as microfiltration, ultrafiltration, nanofiltration, and as a sorption media.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

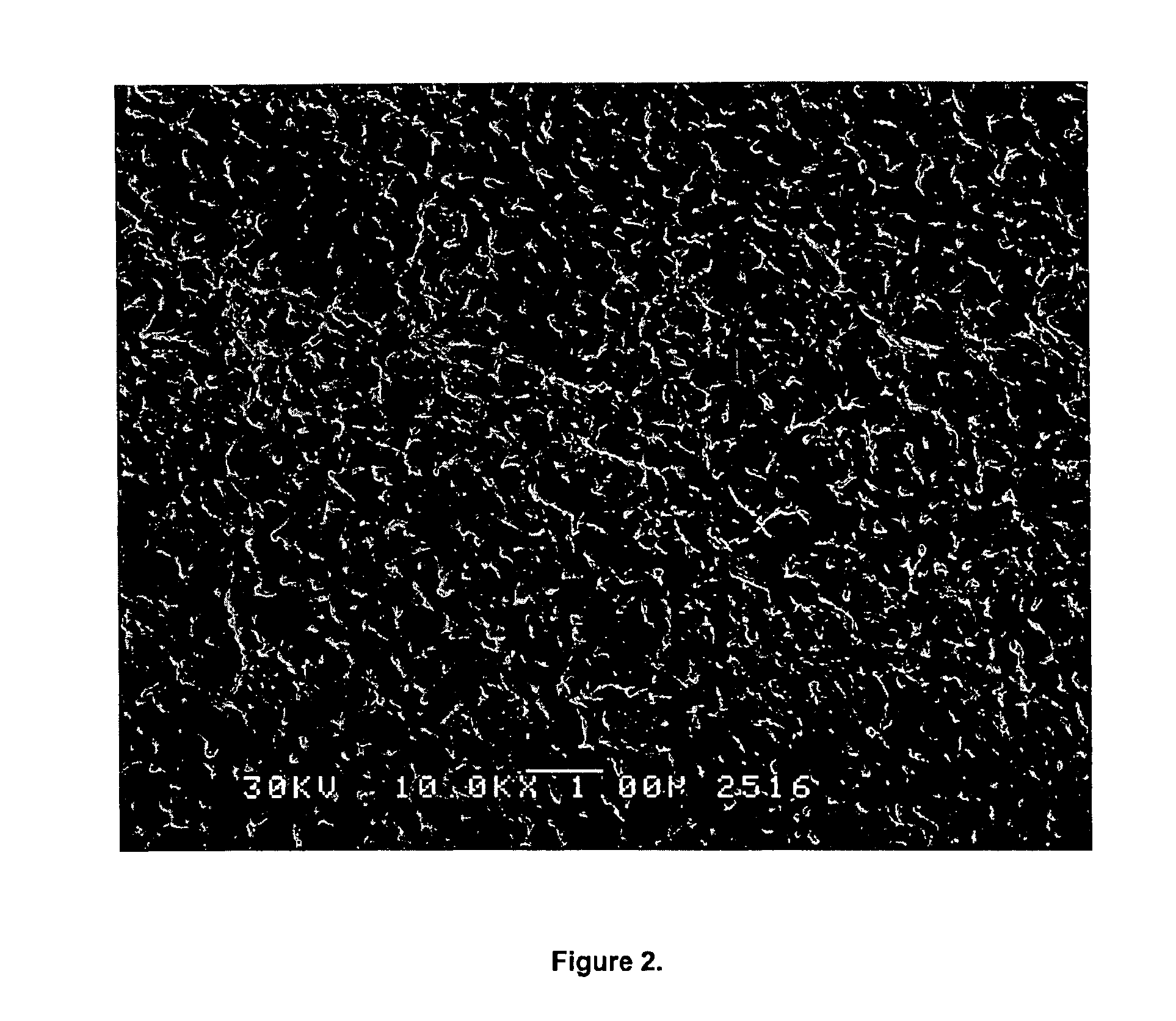

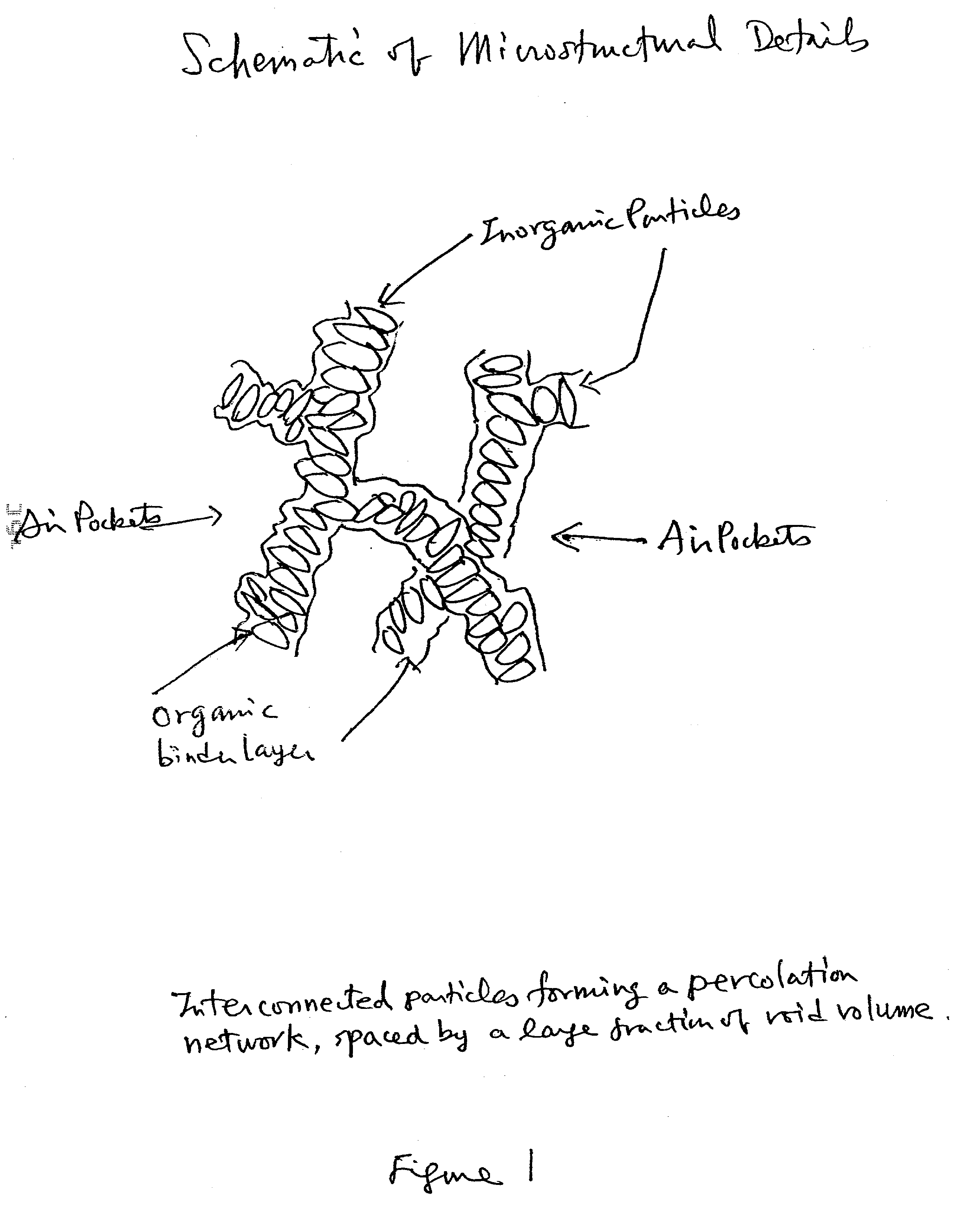

Construction board materials with engineered microstructures

InactiveUS20020128352A1Superior sound isolationGood thermal insulation propertiesInorganic particleThin layer

The present invention discloses a composition of matter for use in wallboard in the construction that has a morphology of pores and a network of interconnected inorganic particles that are coated with a thin layer of organic binder. The process used to produce the wallboard can use either hydrophobic or hydrophilic prepolymers or preferably both to create the desired network of coated inorganic particles. A preferred embodiment uses at least one hydrophobic constituent and a decomposition reaction that produces a gas to form one or more layers or a gradient of the morphology in one or more layers to create wallboard products with superior properties to those wallboard products now known.

Owner:SAINT GOBAIN PLACO SAS

Method of plasmon-enhanced properties of materials and applications thereof

Methods and applications of surface plasmon resonance-enhanced antibacterial, anti-adhere, adhere, catalytic, hydrophilic, hydrophobic, spectral change, biological and chemical decomposition properties of materials with embedded nanoparticles are disclosed. A method of the nonlinear generation of surface plasmon resonance enables the use of light with wavelengths from X-Ray to IR to enhance properties of materials by several orders of magnitude. The nanoparticle size is crucial for the enhancement and their size is considered to be in the proposed methods and applications within a range of 0.1 nm to 200,000 nm. The nanoparticles preferably are made of noble metals and / or semiconductor oxides. The invention describes a very broad spectrum of applications of surface plasmon resonance-enhanced properties of materials with embedded nanoparticles, from environmental cleanup by road pavement and construction materials, self-cleaning processes of surface materials, thermochromic effects on heat blocking materials, corrosion preventing paint, to sanitization by antibacterial textile fabrics, filters, personal clothing, contact lenses and medical devices.

Owner:SPR ADVANCED TECH INC

Laser processing for heat-sensitive mesoscale deposition

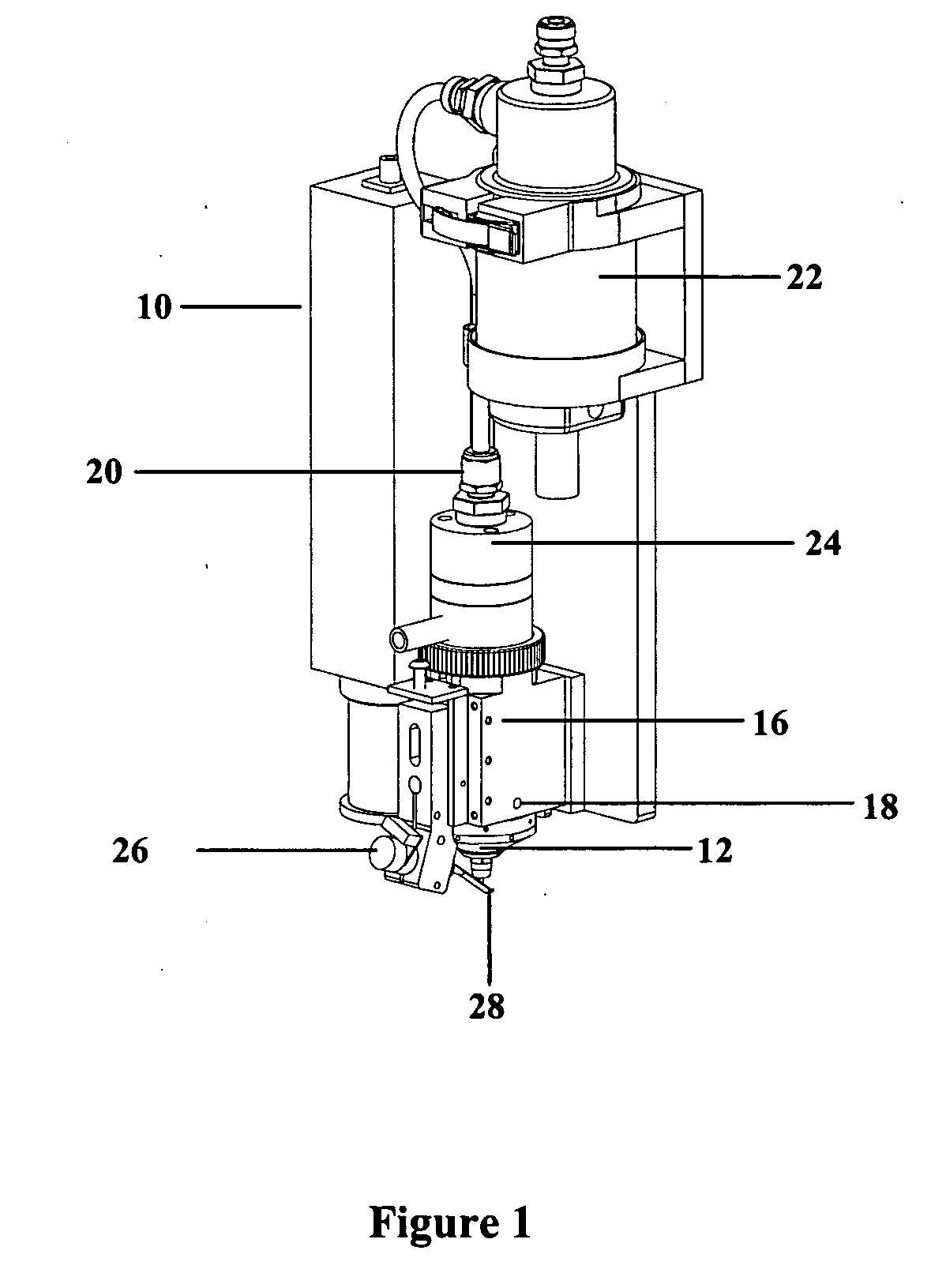

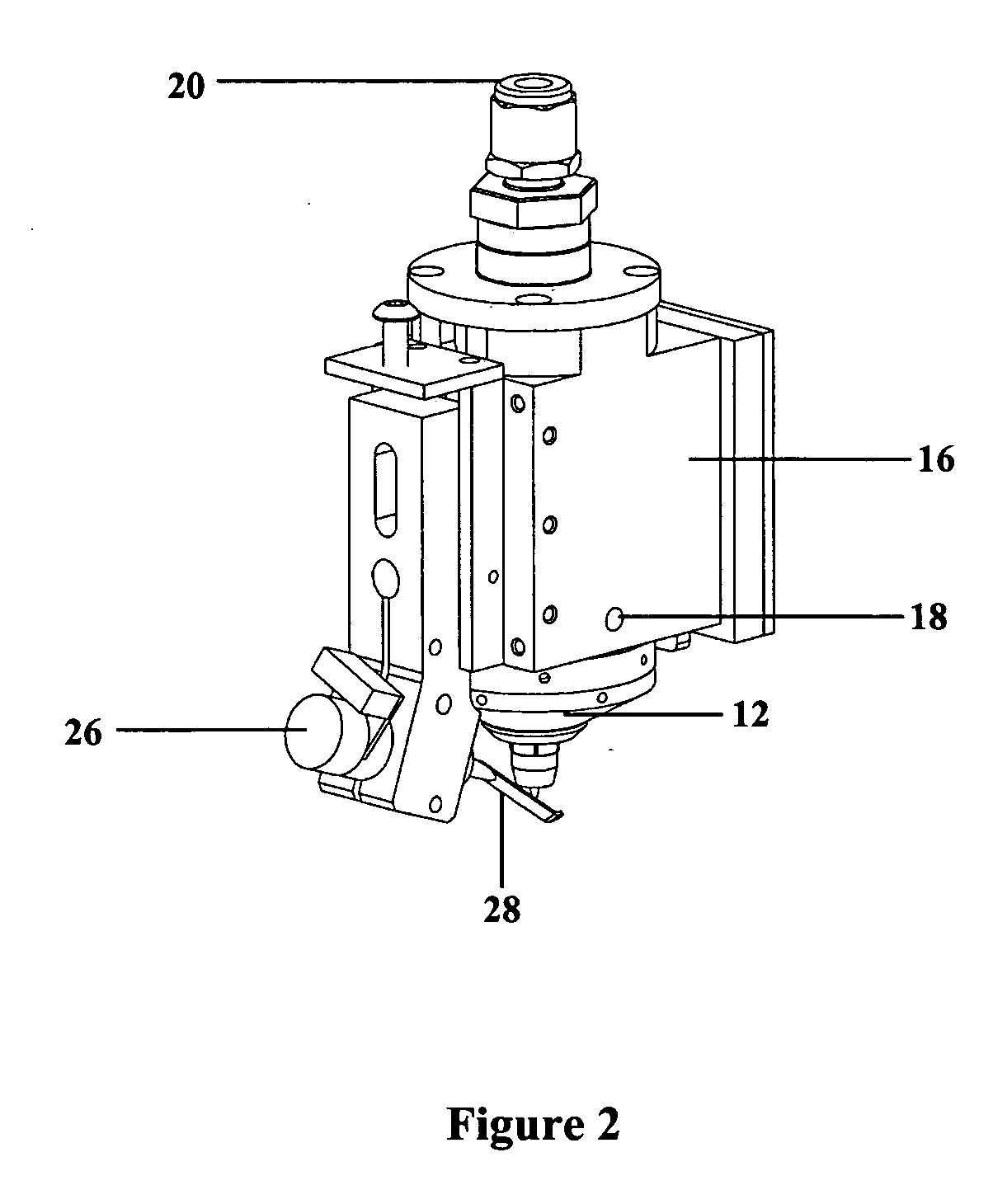

InactiveUS20050129383A1Low damage thresholdDamage to materialSolid-state devicesMetal-working apparatusLaser processingHeat sensitive

A method of depositing various materials onto heat-sensitive targets. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts.

Owner:OPTOMEC DESIGN CO

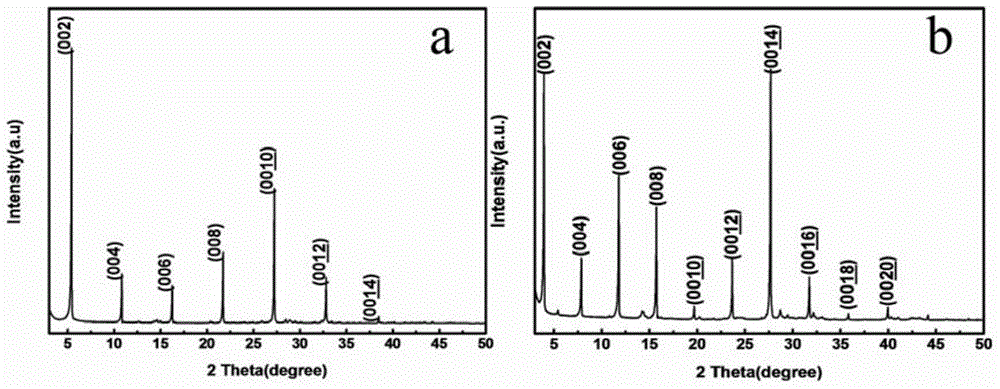

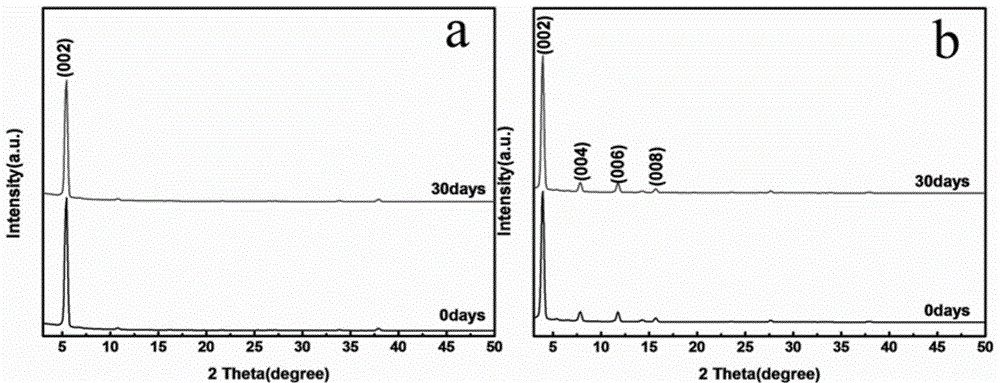

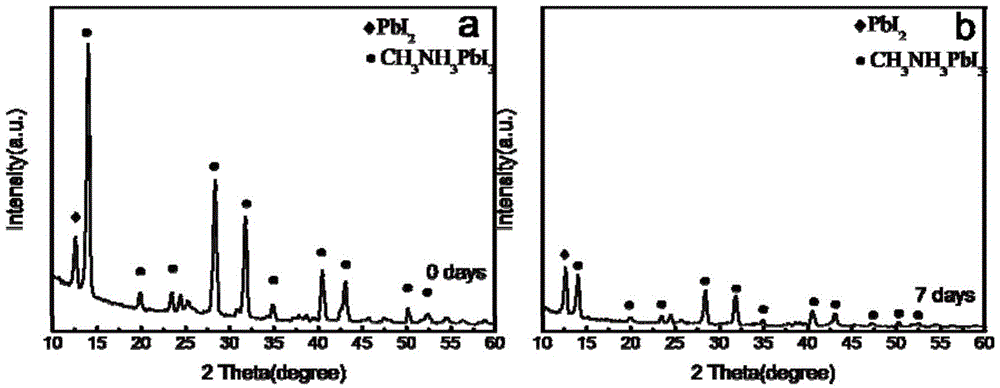

Perovskite solar cell and method for manufacturing same

InactiveCN104795501ASimple and fast operationLow costFinal product manufactureSolid-state devicesHole transport layerMetal electrodes

The invention relates to a perovskite solar cell and a method for manufacturing the same. The perovskite solar cell comprises an FTO (fluorine-doped tin oxide) transparent conducting glass substrate, an electron transport layer, a light absorption layer, a hole transport layer and a metal electrode. The light absorption layer is made of (C<6>H<5>CH<2>CH<2>NH<3>)<2>(CH<3>NH<3>)<n-1>Pb<n>I<3*n+1> (the n is equal to 1 or 2) materials which are of two-dimensional layered structures. The perovskite solar cell and the method have the advantages that the layered perovskite light absorption layer is manufactured by the aid of a spin coating process, the method is simple and is excellent in film-forming property, the materials of the light absorption layer can be changed along with the layer number n, gaps of the materials can be adjusted, and the materials are excellent in chemical stability and still can keep the excellent layered structures without chemical decomposition after being exposed at high air humidity (50-80%) for 30 days, solar cell prototype devices with excellent and stable performance can be obtained, and the perovskite solar cell and the method are favorable for promoting perovskite solar cell commercialization progress.

Owner:WUHAN UNIV OF TECH

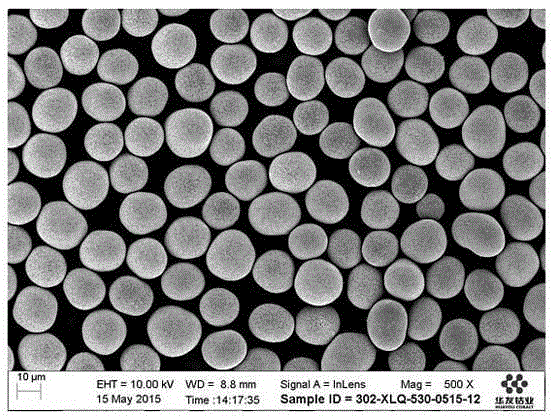

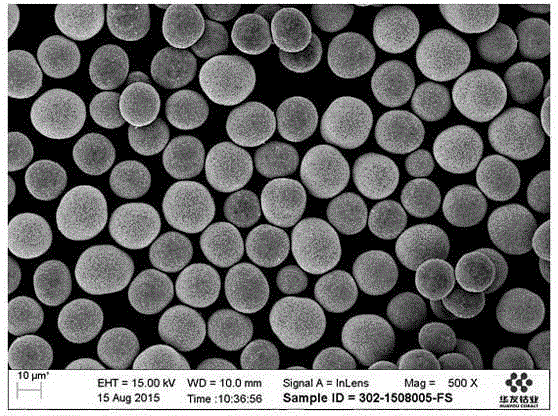

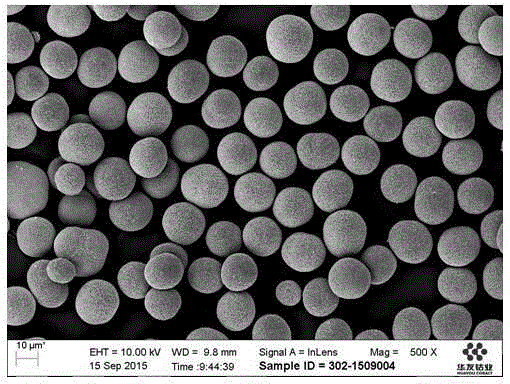

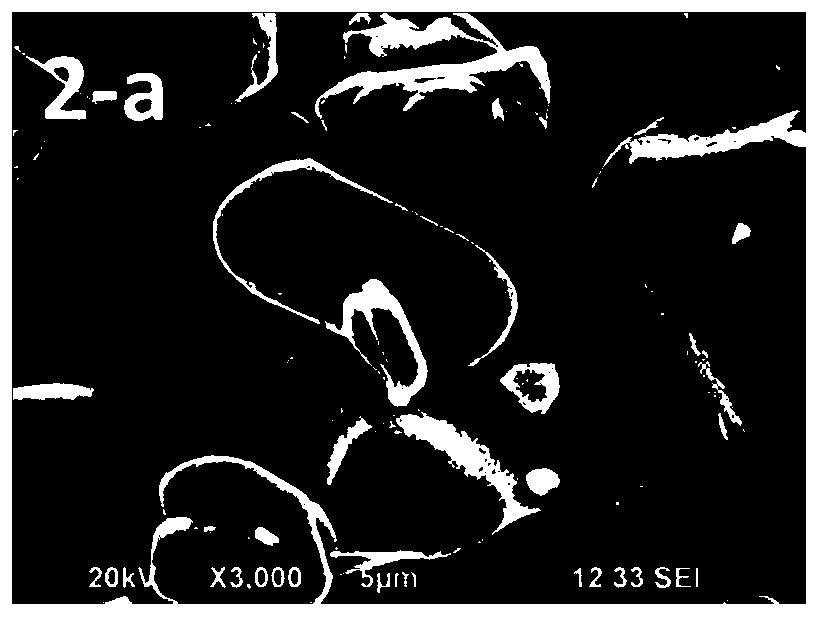

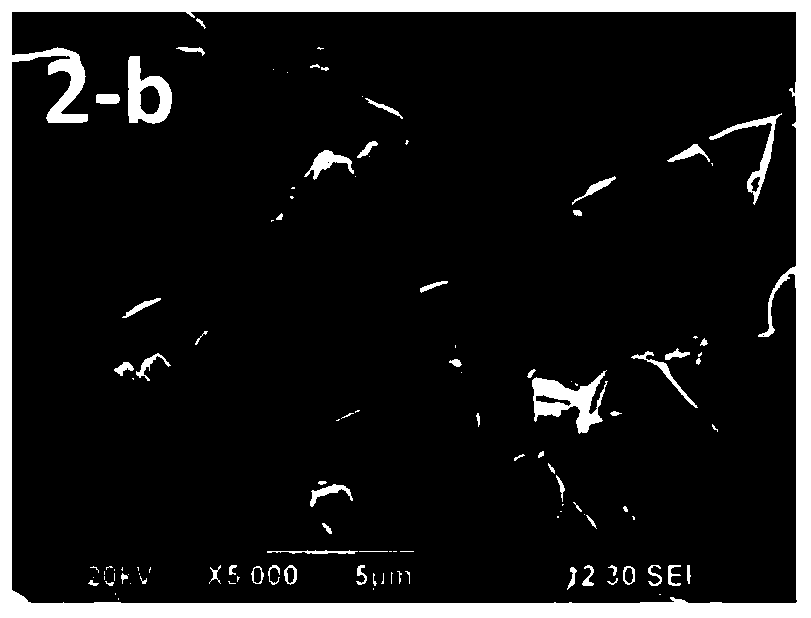

Preparation method of large-particle-size and high-density spherical cobalt oxide

The invention discloses a preparation method of large-particle-size and high-density spherical cobalt oxide. The preparation method aims at achieving the purposes that the median particle size D50 of the cobalt oxide is larger than or equal to 15 microns, particle size distribution is uniform, compacting density (TD) is larger than or equal to 2.2 g / cm<3>, and the large-particle-size and high-density spherical cobalt oxide can meet the development requirement of high-voltage lithium cobaltate. The preparation method of the cobalt oxide includes the cobalt carbonate synthesis stage and the spherical cobalt carbonate thermal decomposition stage. In the cobalt carbonate synthesis stage, a cobalt carbonate precursor prepared through many times of cyclic crystallization is compact and uniform in particle size distribution; due to the segmented thermal decomposition, cobalt carbonate is locally decomposed in the low-temperature pre-decomposing stage, a micro hole channel is formed, release of CO2 gas during subsequent decomposition is facilitated, and particles are prevented from crazing or being broken; in the high-temperature thermal decomposition stage, the particle surface is compact, and therefore the large-particle-size and high-density spherical cobalt oxide is prepared.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

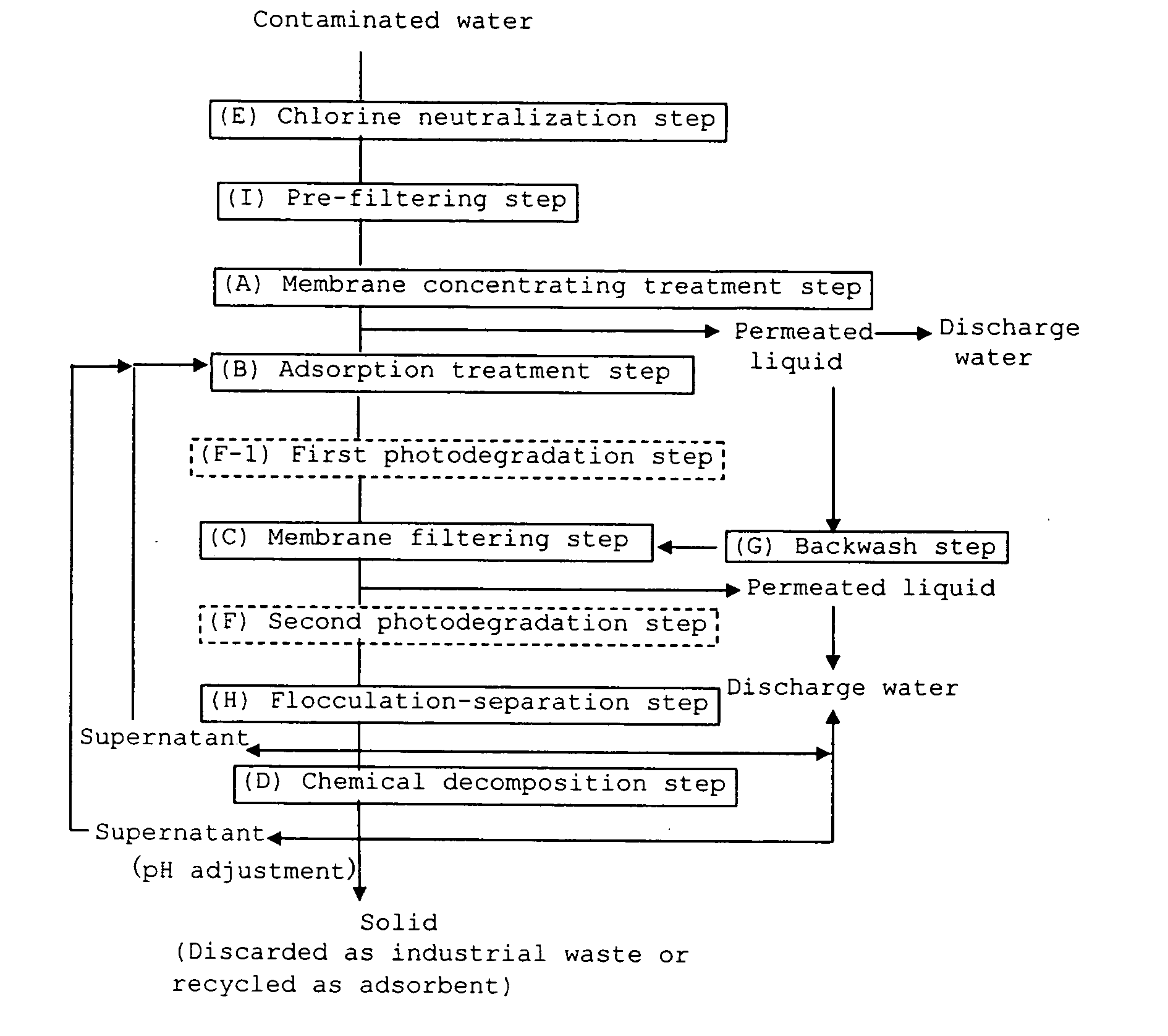

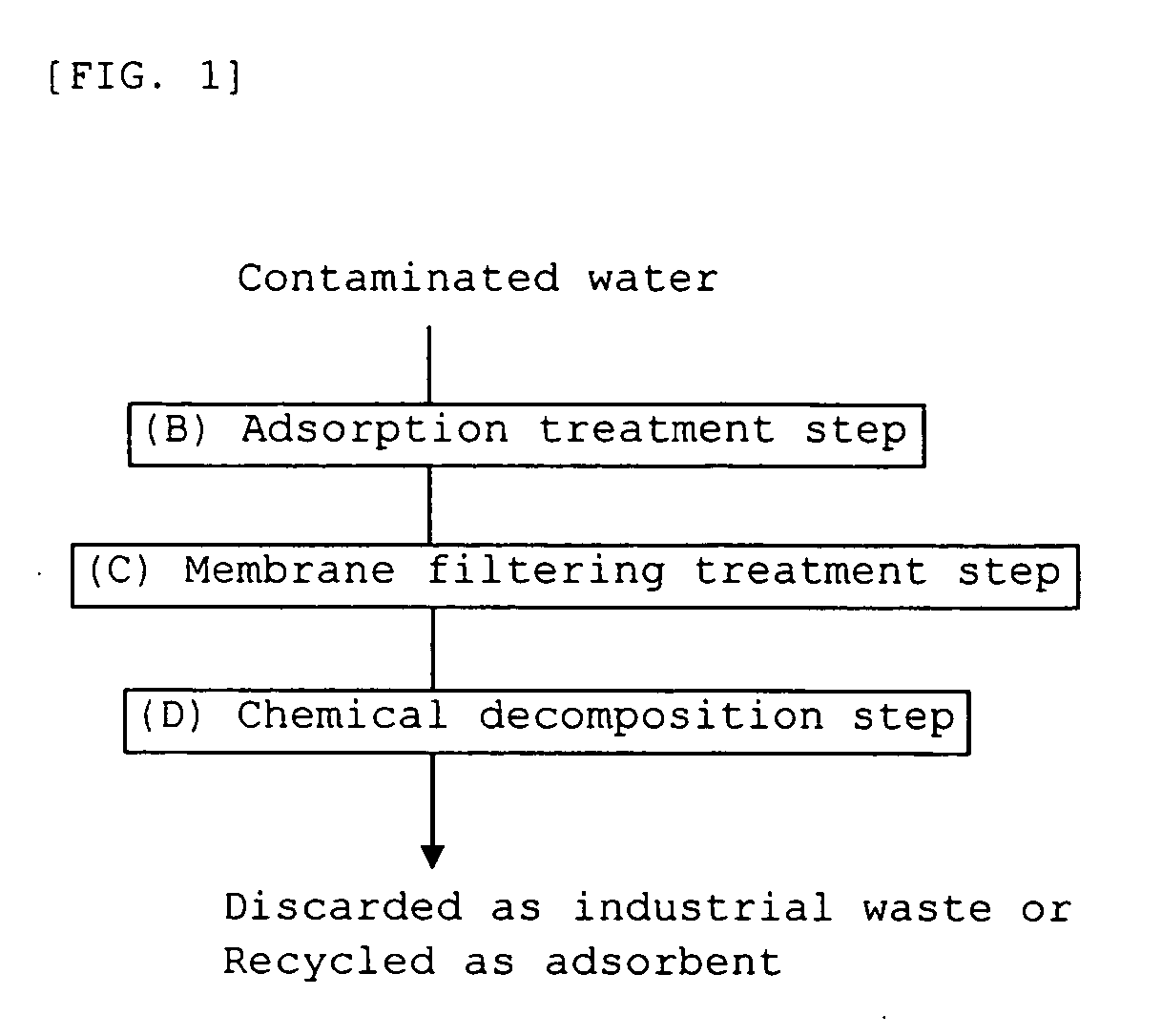

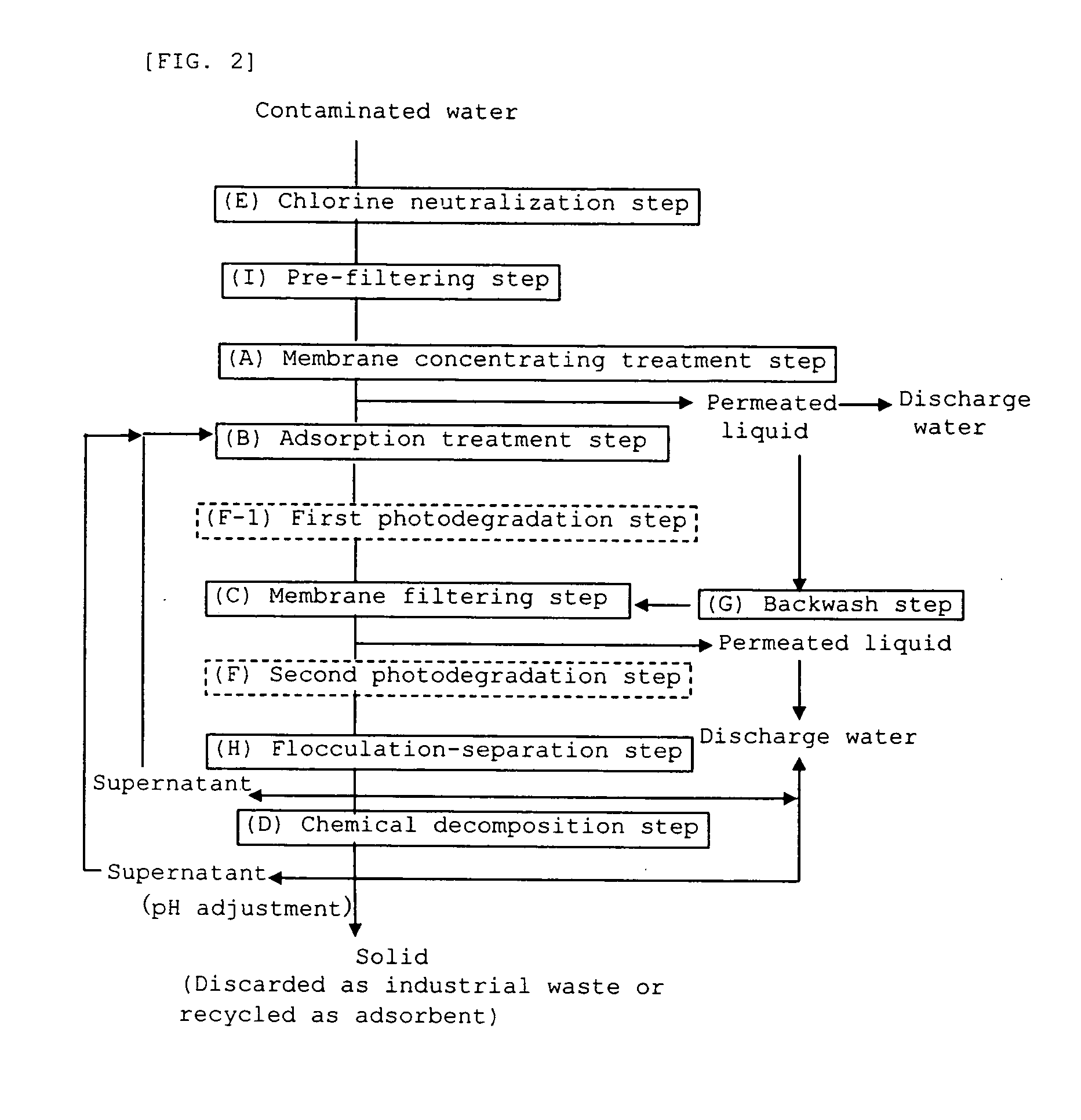

Method for treating raw water containing hardly decomposable substance

InactiveUS20070119779A1Efficient decompositionReduce concentrationUltrafiltrationSolid sorbent liquid separationDesorptionSorbent

Provided a method for treating hardly-decomposable-substance-containing water, in which hardly decomposable substances such as dioxins, contained in contaminated water (treatment raw water) are concentrated and rendered harmless by providing the steps of (B) adding an adsorbent to water containing a hardly decomposable substance (treatment raw water) to cause the hardly decomposable substance to be adsorbed on the adsorbent (adsorption treatment step), (C) separating a permeated liquid through a filter membrane to concentrate the adsorbent adsorbing the hardly decomposable substance (membrane filtering treatment step), and (D) chemically decomposing the hardly decomposable substance adsorbed on the concentrated adsorbent with a peroxide without any operation of desorption from the adsorbent (chemical decomposition step), and the method can be applied to water containing a reducing substance such as bisulfate that neutralize free chlorine and can render the hardly decomposable substances harmless efficiently at a low cost without being limited by properties of the hardly decomposable substances contained.

Owner:IDEMITSU KOSAN CO LTD

Laser processing for heat-sensitive mesoscale deposition of oxygen-sensitive materials

InactiveUS8110247B2Low damage thresholdRadiation applicationsPretreated surfacesForming gasLaser processing

Owner:OPTOMEC DESIGN CO

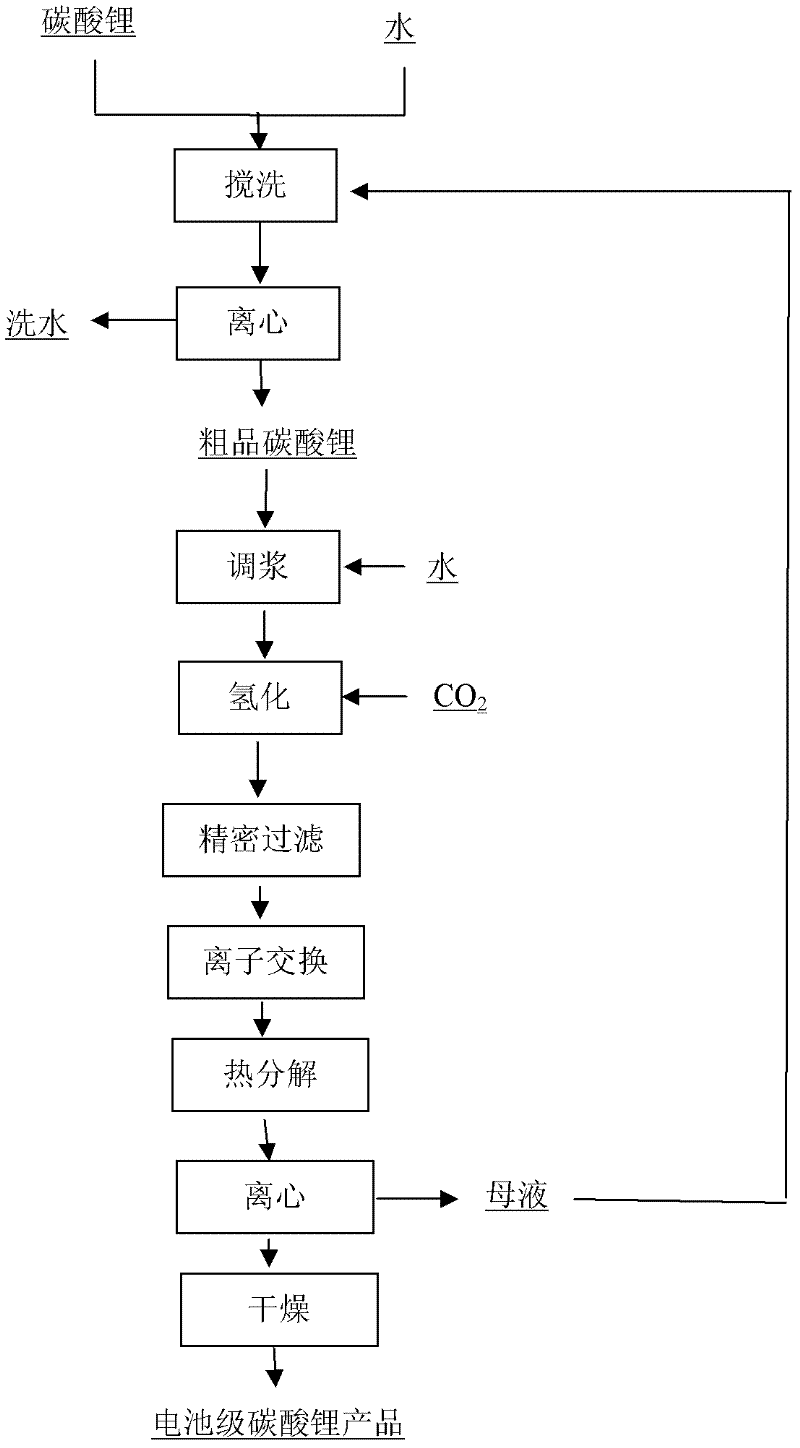

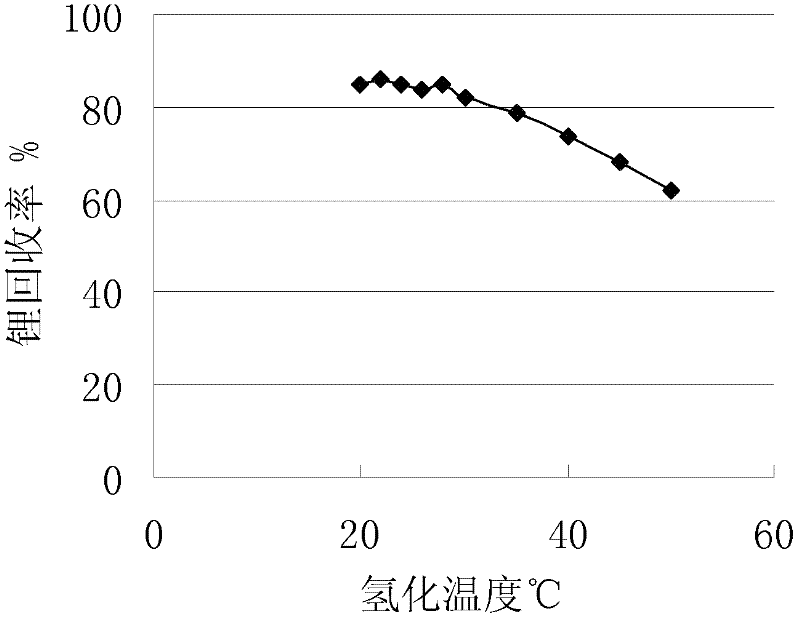

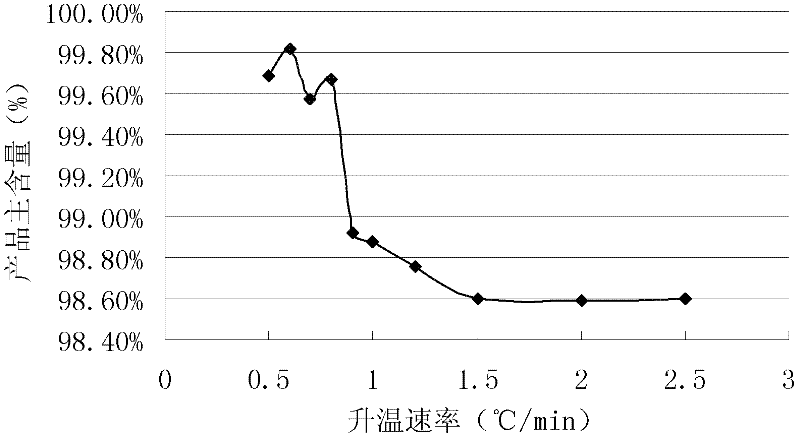

Method for purifying lithium carbonate

ActiveCN102531002ALow impurity contentImprove qualityLithium carbonates/bicarbonatesLithium oxideHydrogenation reaction

The invention relates to a method for purifying lithium carbonate, belonging to the technical field of the preparation of high-purity lithium carbonate. The method is characterized by safe production process and high lithium yield. The method comprises the following specific steps: (1) washing lithium carbonate to be purified to remove impurities, and adding water to prepare lithium carbonate slurry; (2) introducing CO2 into the lithium carbonate slurry prepared in the step (1) to carry out hydrogenation reaction, stopping introducing CO2 when the concentration of lithium oxide concentration in a solution is 10-30g / L, and filtering the solution to obtain a hydrogenated solution, wherein the hydrogenation reaction is carried out at the pressure of 0.2-0.6Mpa and the temperature of 20-30 DEG C; (3) subjecting the hydrogenated solution obtained in the step (2) to an ion exchange resin to remove impurity ions in the hydrogenated solution; and (4) heating the hydrogenated solution in which the impurity ions are removed in the step (3) to 70-90 DEG C to carry out decomposition reaction, separating solid from liquid to obtain the wet lithium carbonate, and drying the wet lithium carbonate. The produced battery-level lithium carbonate has high main content, excellent quality and stable performance.

Owner:天齐锂业(射洪)有限公司

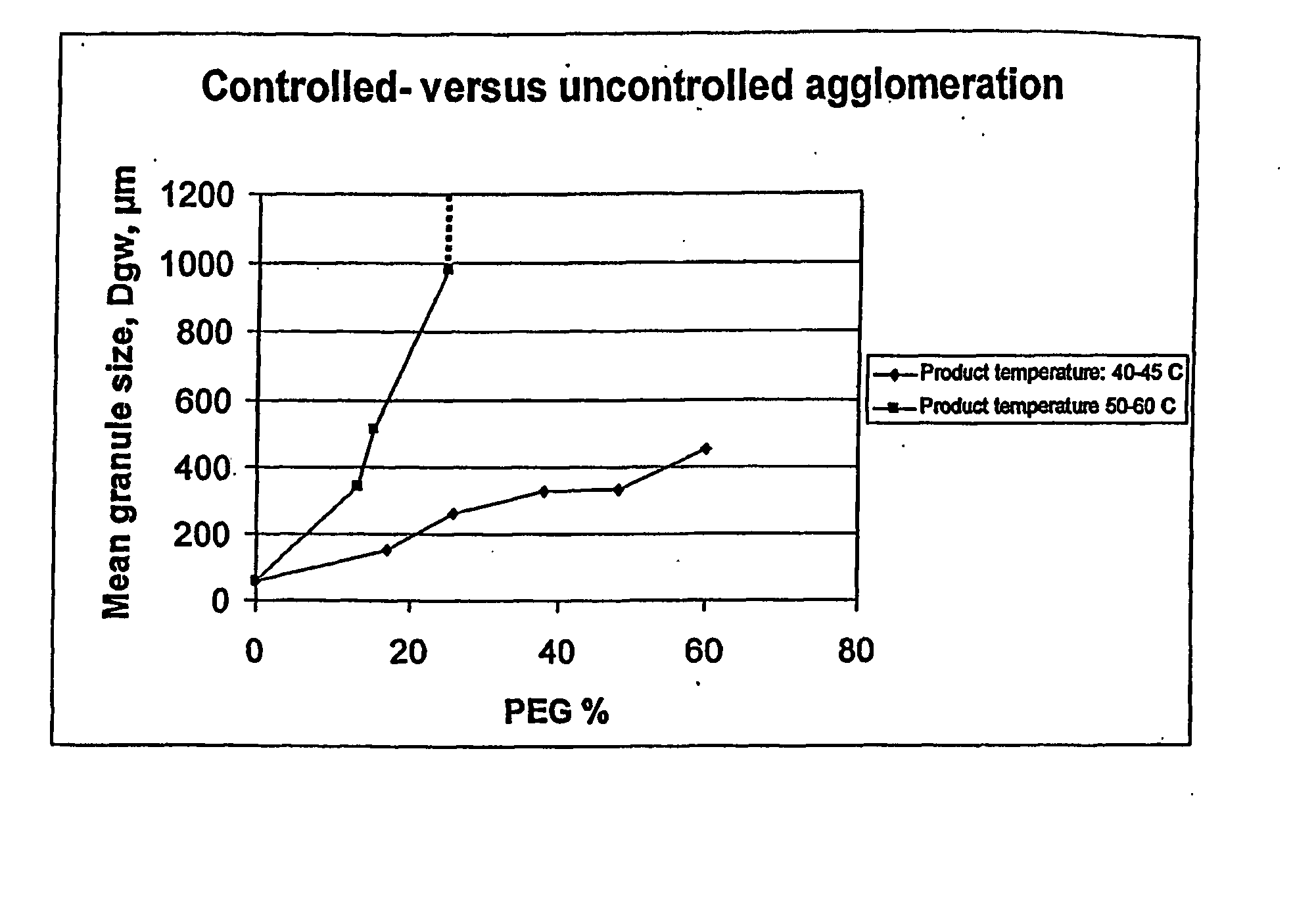

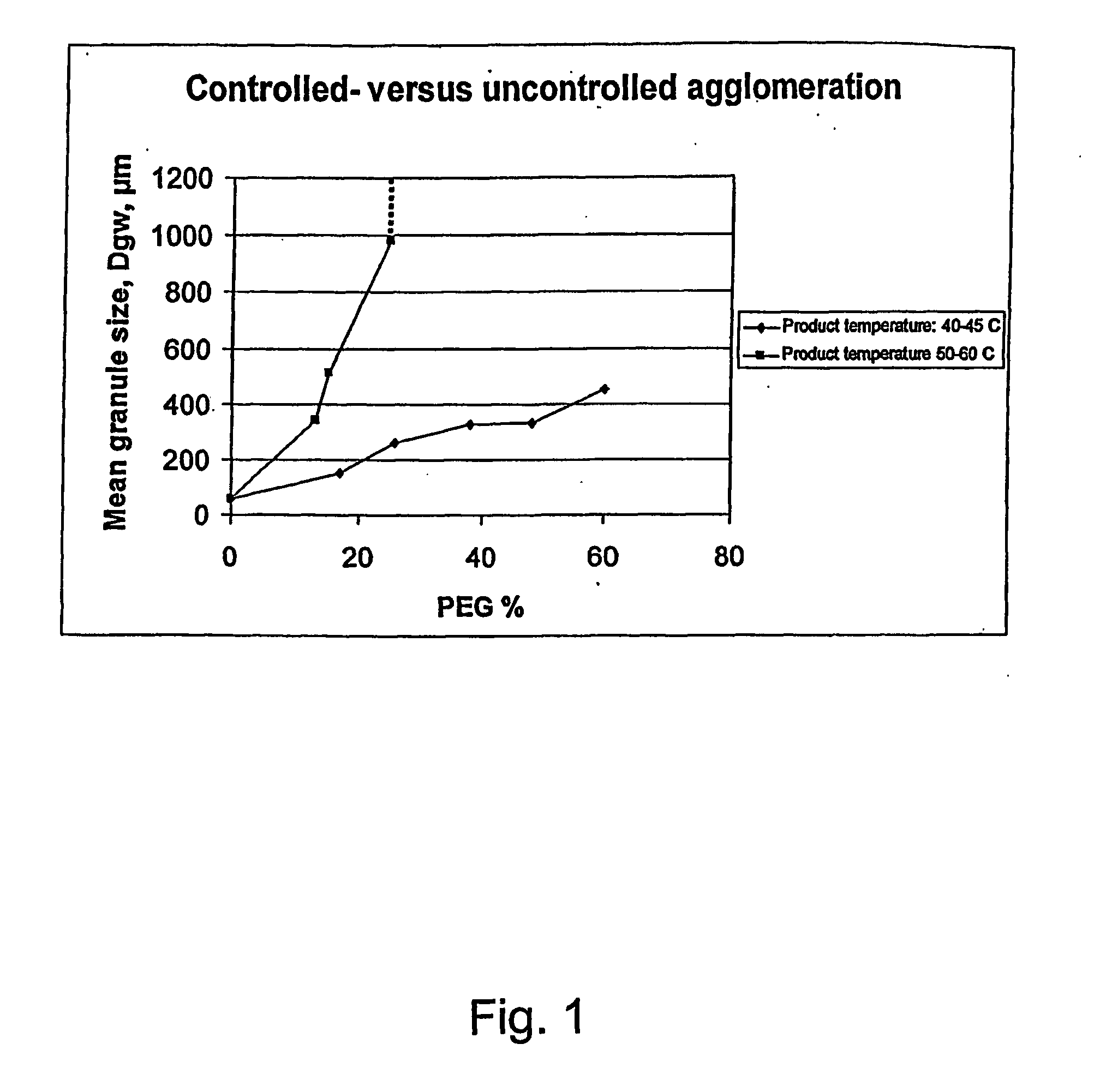

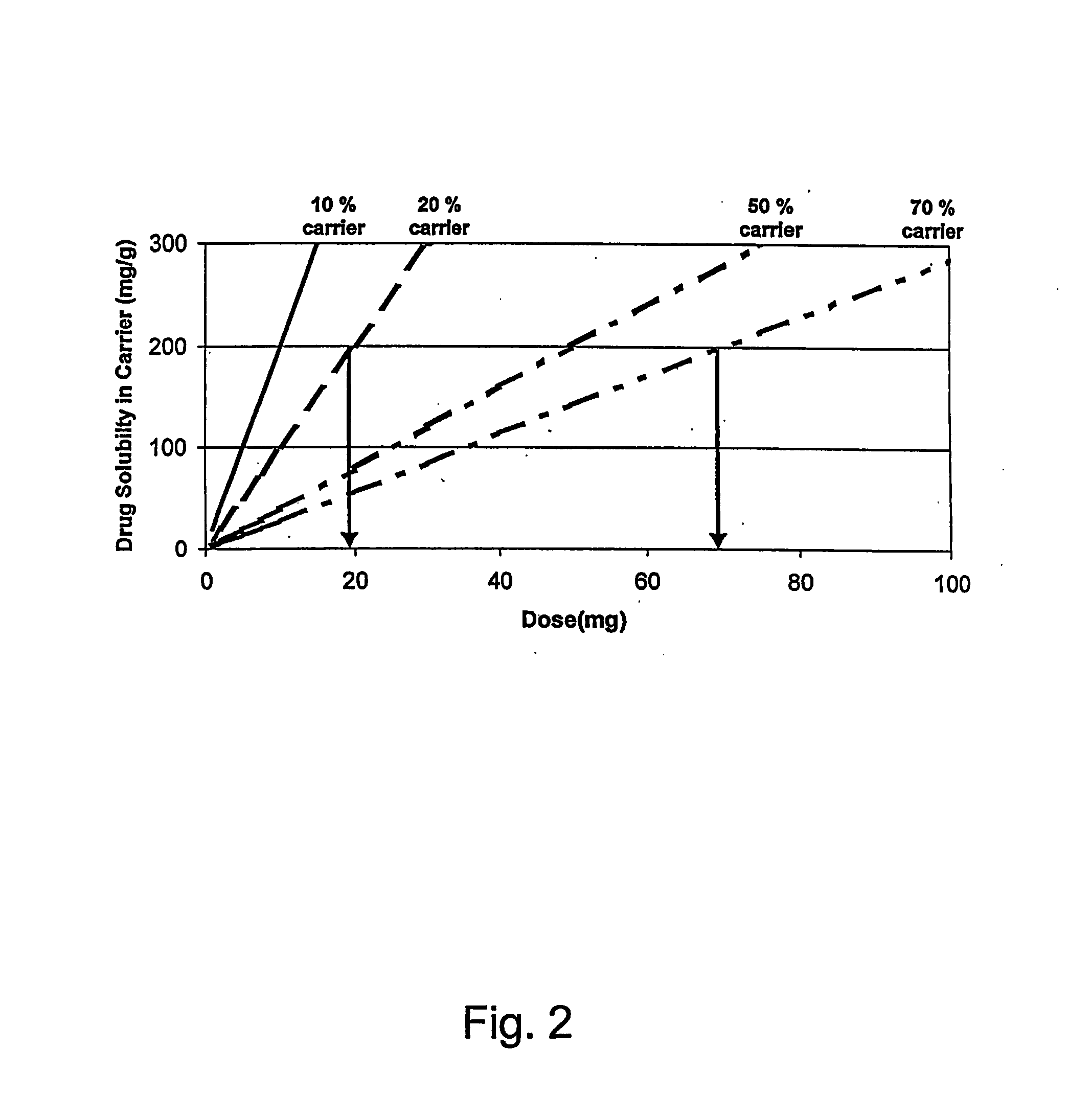

Controlled agglomeration

InactiveUS20070275074A1Improve solubilityLow water solubilityPowder deliveryBiocideSolid massAqueous solubility

A process for the preparation of a particulate material by a controlled agglomeration method, i.e. a method that enables a controlled growth in particle size. The method is especially suitable for use in the preparation of pharmaceutical compositions containing a therapeutically and / or prophylactically active substance which has a relatively low aqueous solubility and / or which is subject to chemical decomposition. The process comprising i) spraying a first composition comprising a carrier, which has a melting point of about 5° C. or more which is present in the first composition in liquid form, on a second composition comprising a material in solid form, the second composition having a temperature of at the most a temperature corresponding to the melting point of the carrier and / or the carrier composition and ii) mixing or others means of mechanical working the second composition onto which the first composition is sprayed to obtain the particulate material.

Owner:VELOXIS PHARM INC

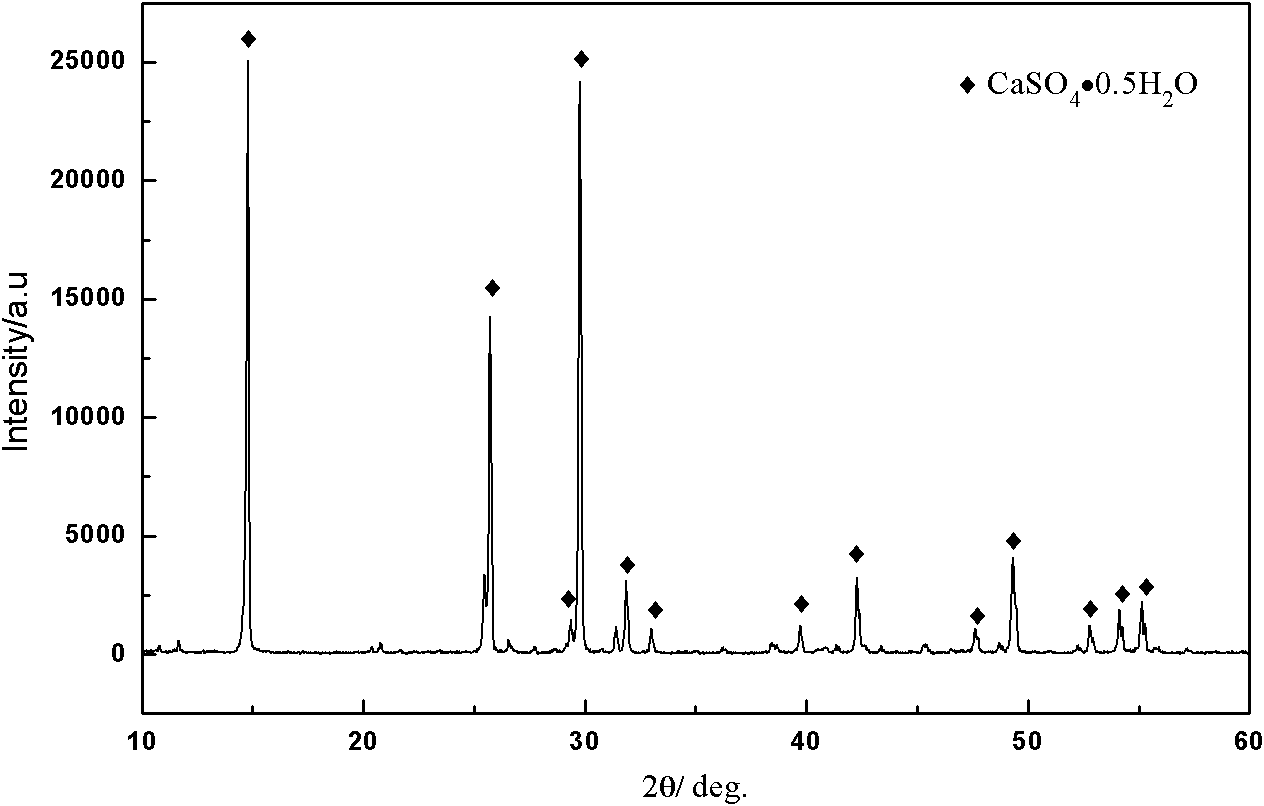

Method for extracting tungsten from scheelite and producing high-quality calcined gypsum

ActiveCN102021329AReduce lossesLow costCalcium/strontium/barium sulfatesProcess efficiency improvementPhosphoric acidSeed crystal

The invention provides a method for extracting tungsten from scheelite and producing high-quality calcined gypsum, comprising the following steps: adding a mixed acid of phosphoric acid and sulphuric acid to decompose scheelite; and after decomposition, adding hydrated gypsum seed crystals to finish the dewatering conversion process of dihydrate gypsum to obtain hydrated gypsum with good properties. The invention has the following advantages: the efficient atmospheric pressure leaching of scheelite is realized, the resource and energy consumption is saved, and the decomposition rate of scheelite can reach over 98%; the serious problems of Cl<-> corrosion and HCl volatilization in the traditional acid decomposition process can be overcome; the recycling of phosphoric acid is basically realized, and the leaching cost and the wastewater discharge are greatly reduced; the leaching device is simple, the operation is convenient and industrialization is easy to realize; the obtained byproduct gypsum has pure quality and can be used to produce gypsum boards, and can be used in retarder, plaster and the like produced by using cement; and due to the recrystallization process, the P2O5 content in gypsum is further reduced to below 0.5%.

Owner:CENT SOUTH UNIV

Method of producing tungstic acid by closed type hydrochloric acid decompose tunstite

A process for preparing tungstic acid from scheelite by decomposing it by hydrochloric acid in sealed condition includes such steps as adding hydrochloric acid and powered scheelite to reactor, sealing, thermal decomposing reaction while stirring, filter and washing to obtain H2WO4. Its advantages are high productivity, less consumption of hydrochloric acid and energy, and less environmental pollution.

Owner:ZIGONG CEMENTED CARBIDE CORP

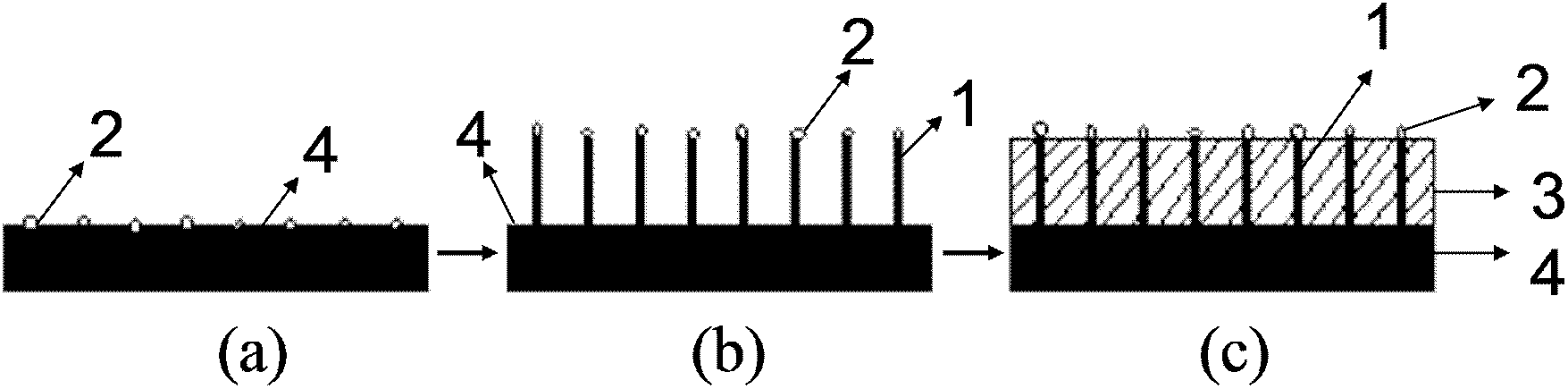

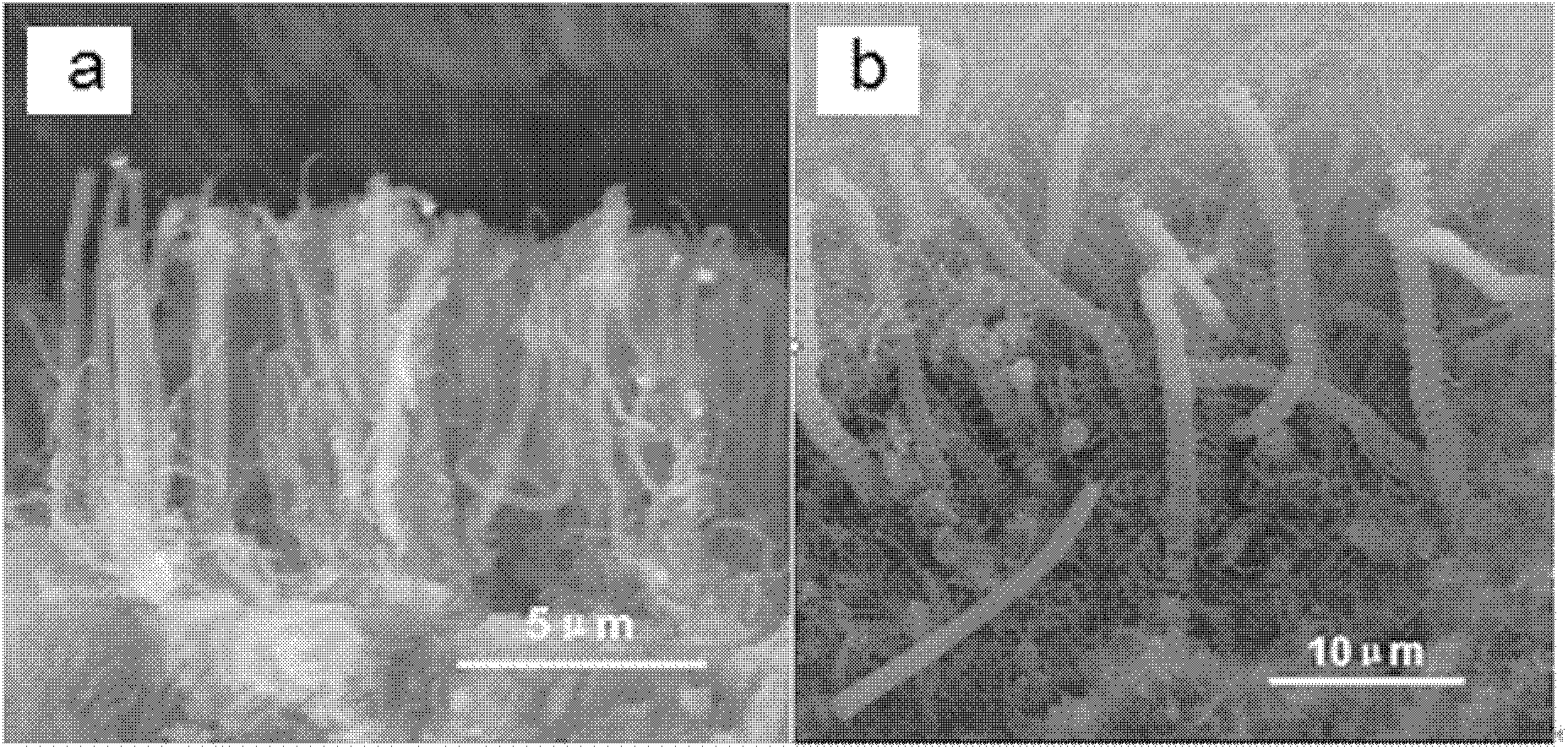

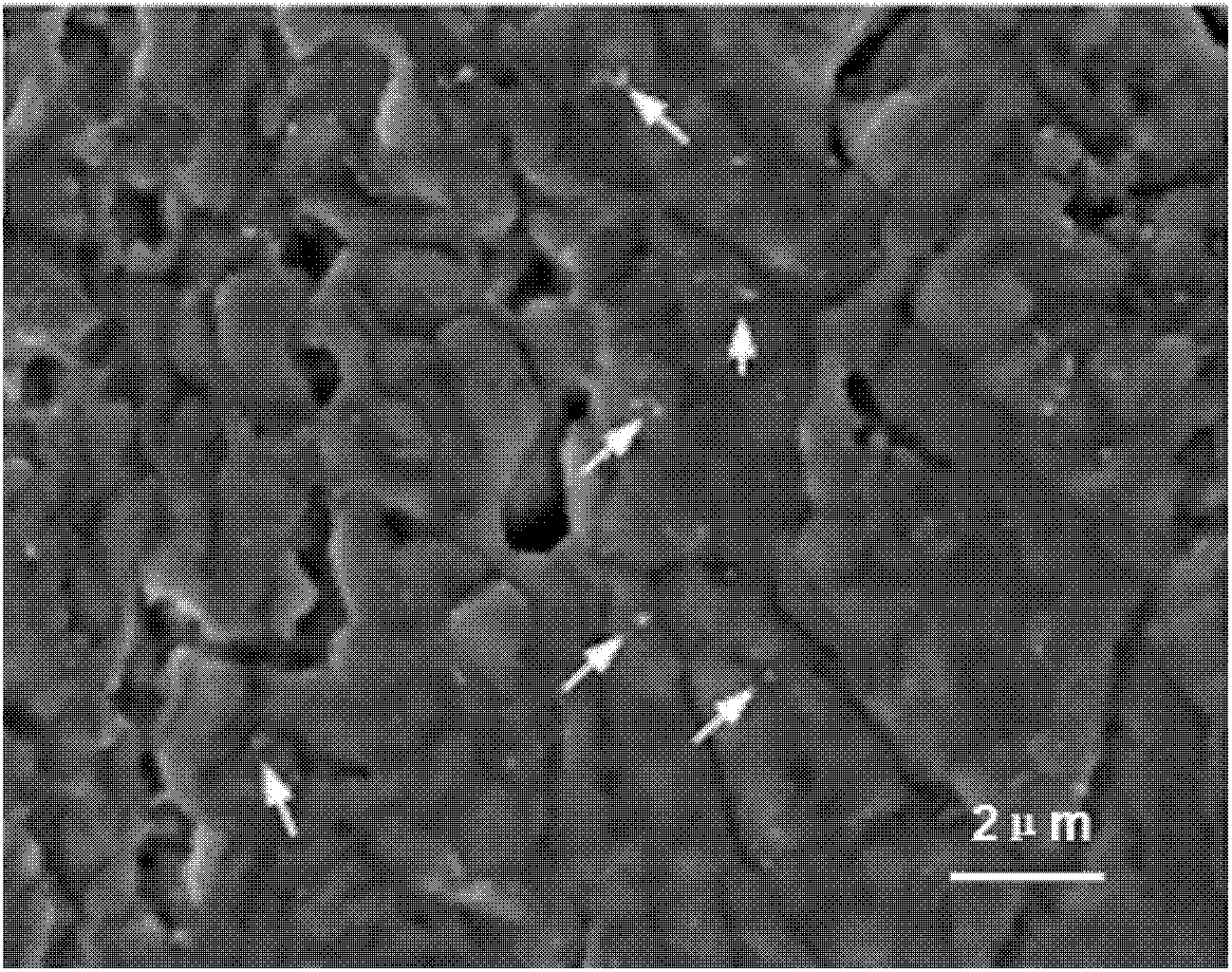

Method for preparing compound electrical contact material

InactiveCN102324335AConducive to play ballistic conduction characteristicsCost-effectiveContact materialsCatalytic pyrolysisCarbon nanotube

The invention discloses a method for preparing a compound electrical contact material. The technical process comprises the following steps of: (1) preparing a catalyst precursor, preparing a Ni-based catalyst from a mixed aqueous solution of hexahydrated nickel nitrate and hexahydrated yttrium nitrate, and depositing on a sample copper sheet which is subjected to plasma treatment and washed to obtain a catalyst precursor, wherein the mass ratio of nickel to yttrium is 1-10; (2) preparing a CNTs (Carbon Nanotube) array, putting the catalyst precursor into a quartz boat, undergoing a decomposition reaction under the protection of argon gas, and undergoing a catalytic pyrolysis reaction to obtain a sample copper sheet on which a CNTs array grows; and (3) preparing a CNTs-Ag-Cu compound electrical contact material, adding a silver nitrate aqueous solution into the sample copper sheet on which the CNTs array grows, soaking the silver nitrate aqueous solution into the CNTs array of the sampler copper sheet under the low ultrasonic action, evaporating and decomposing repeatedly for 3-20 times for 0.2-3 hours every time till the CNTs array is fully filled.

Owner:TIANJIN POLYTECHNIC UNIV

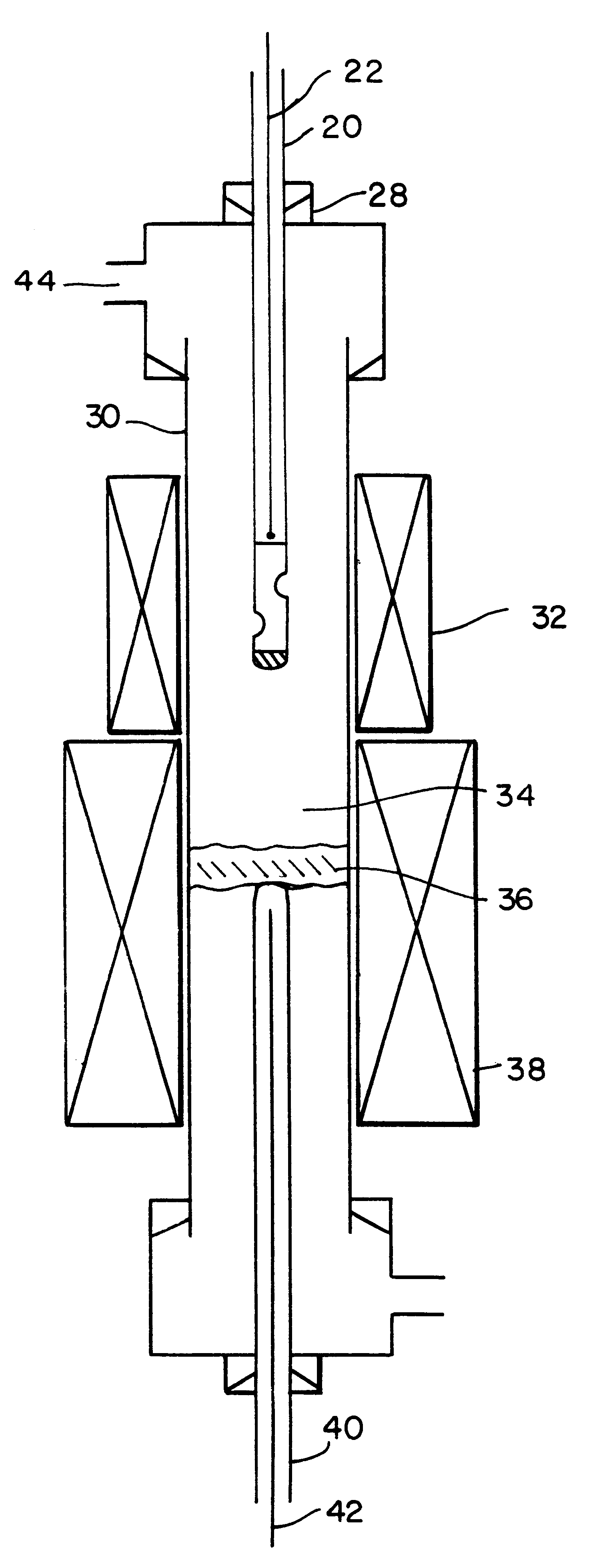

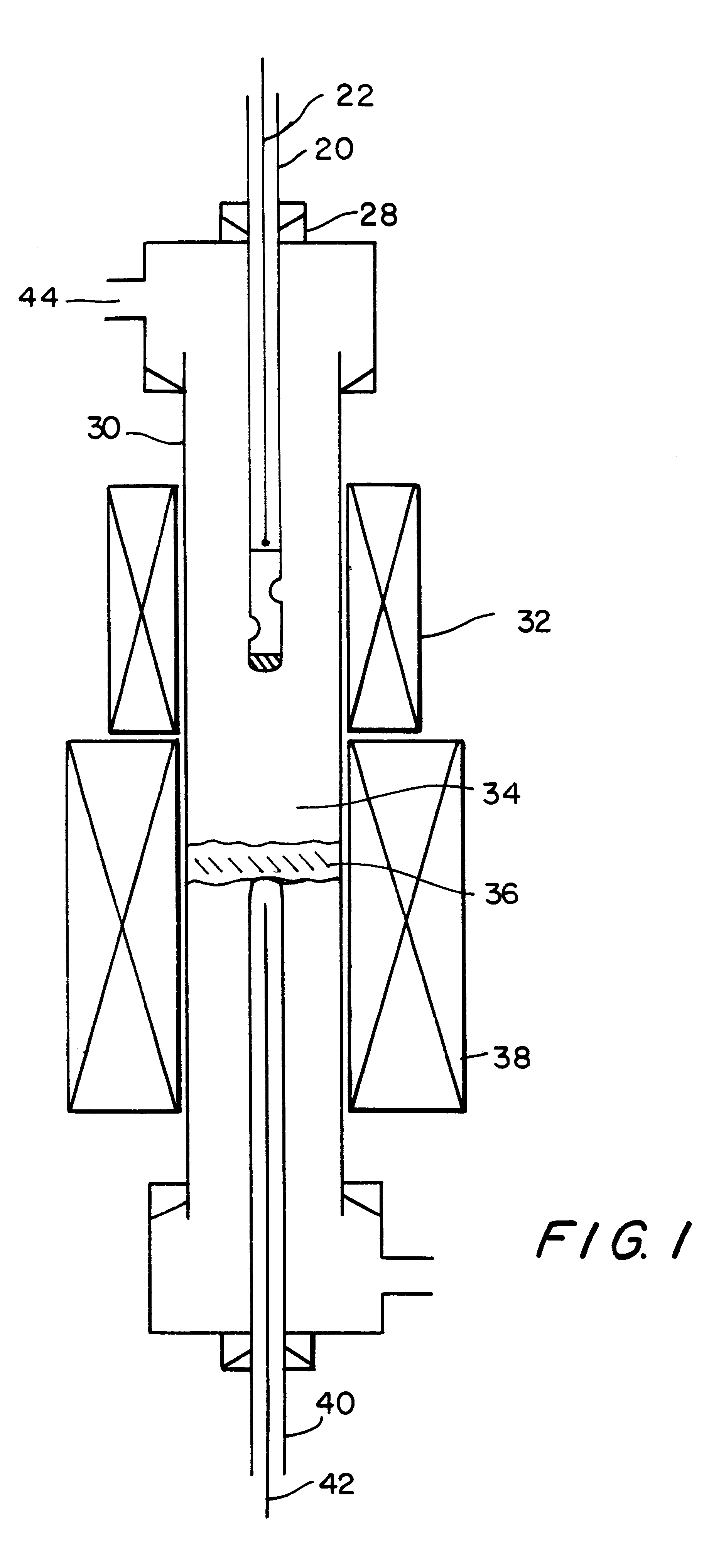

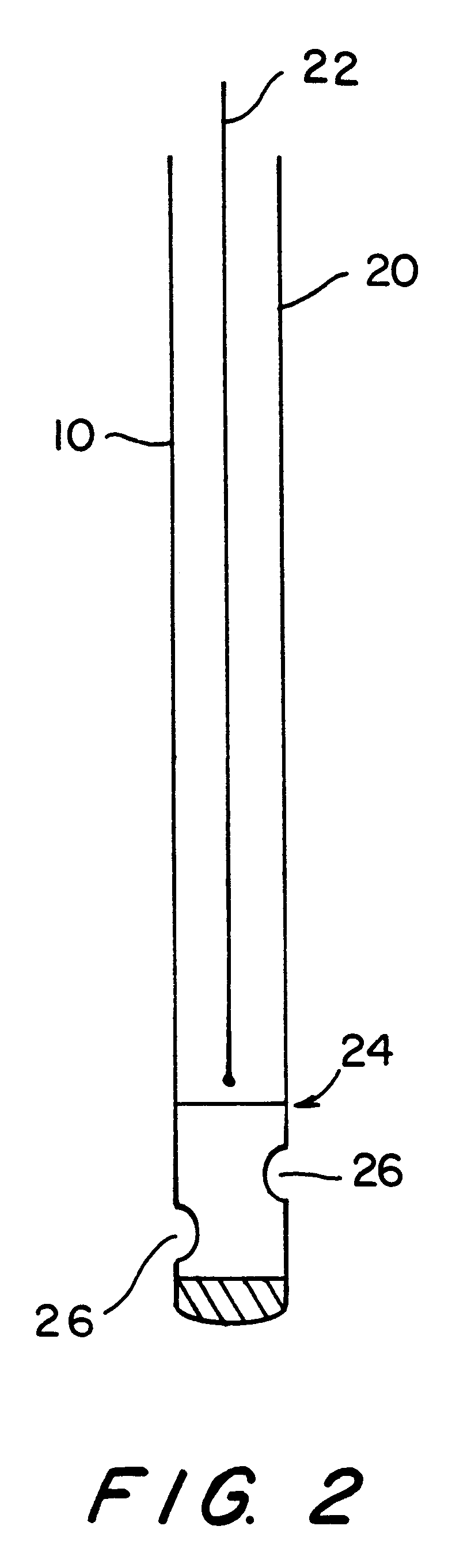

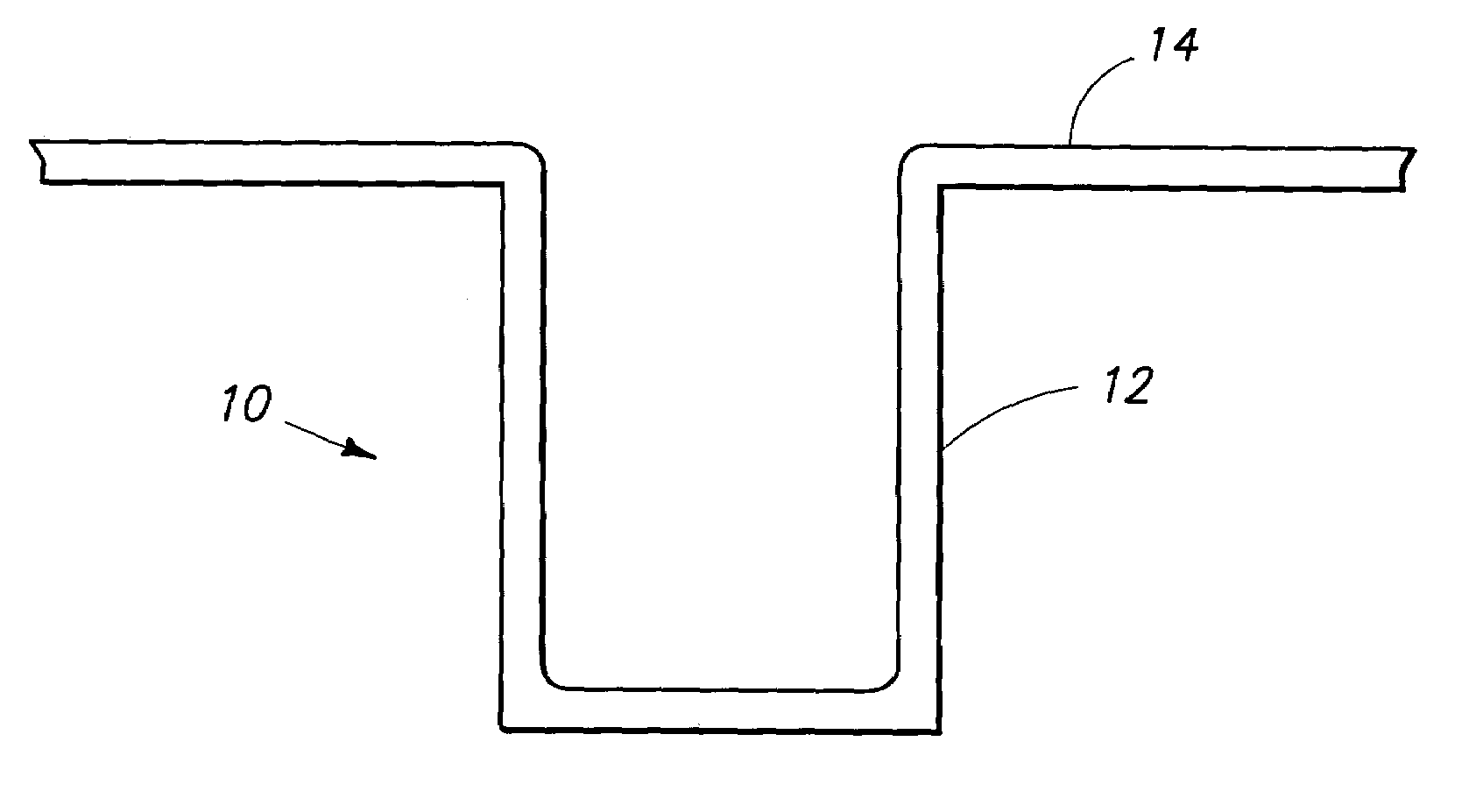

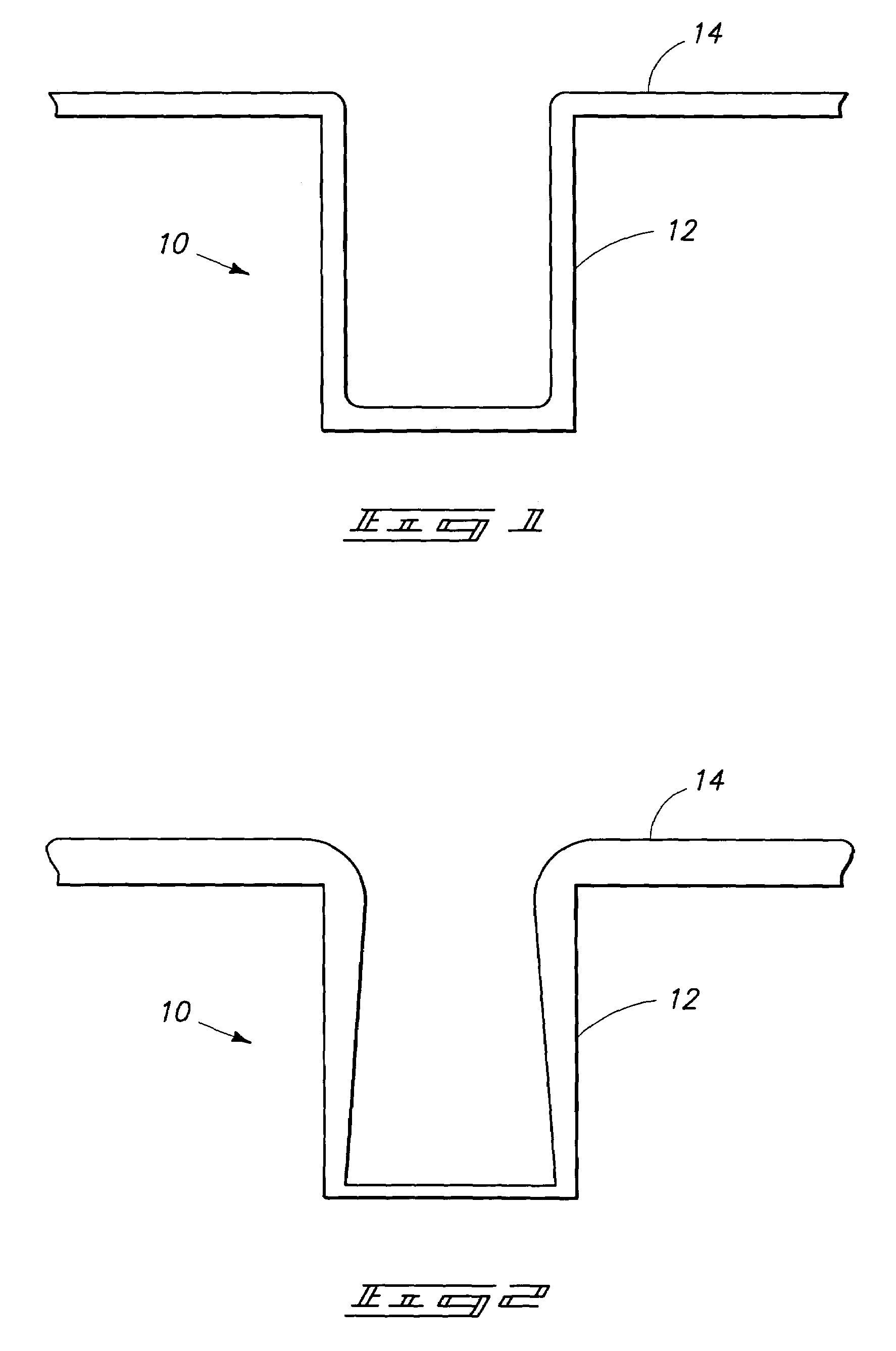

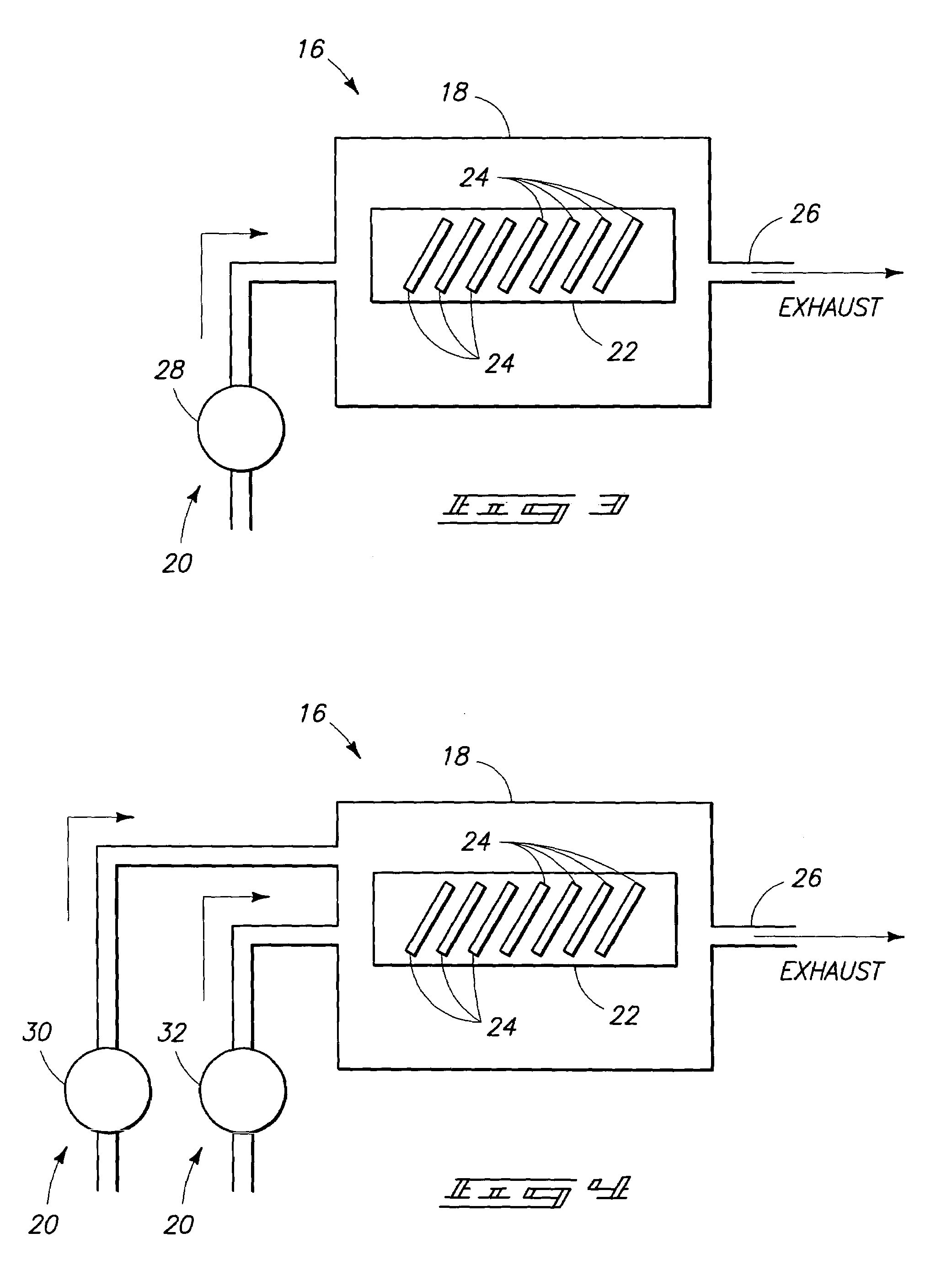

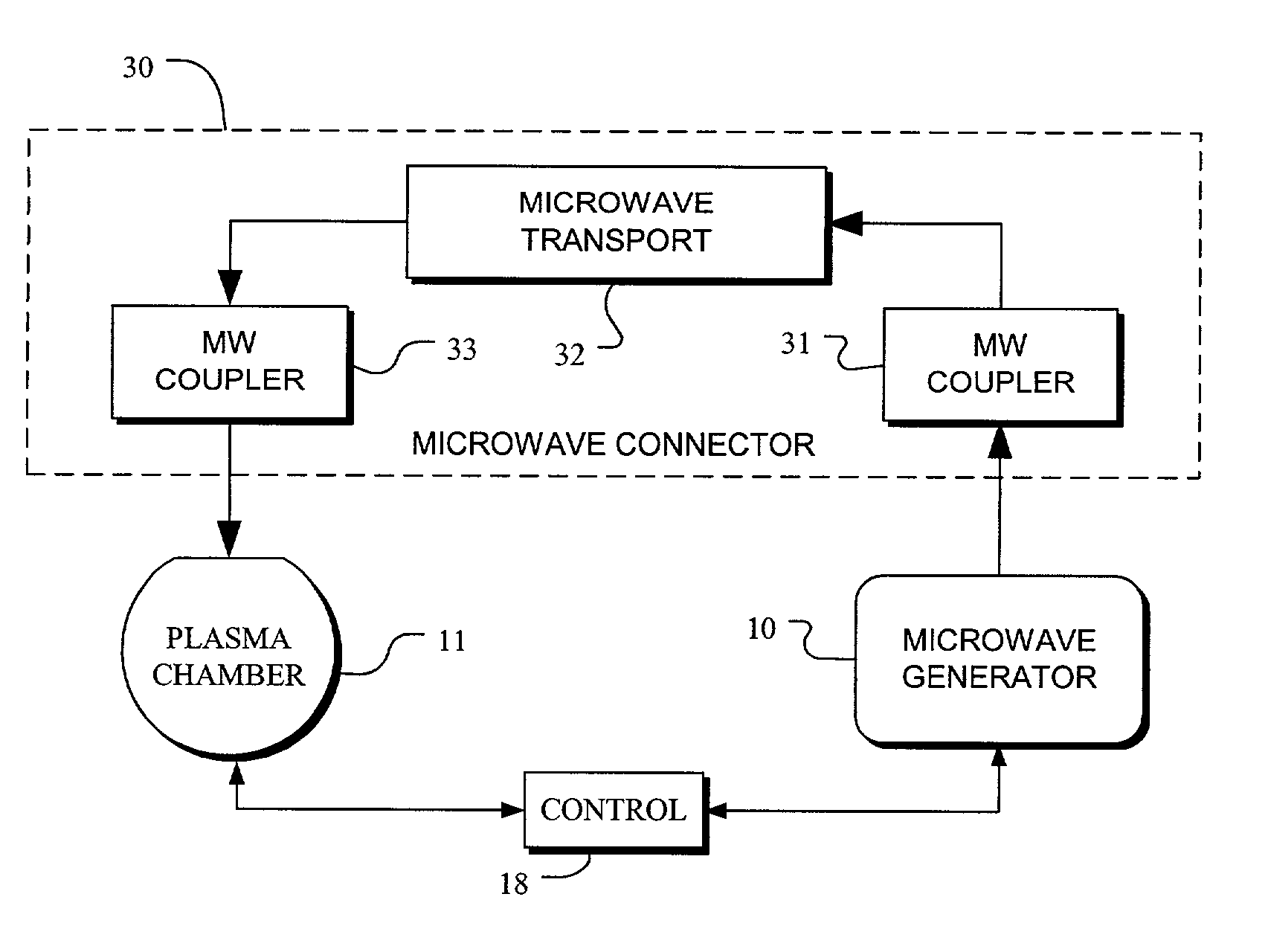

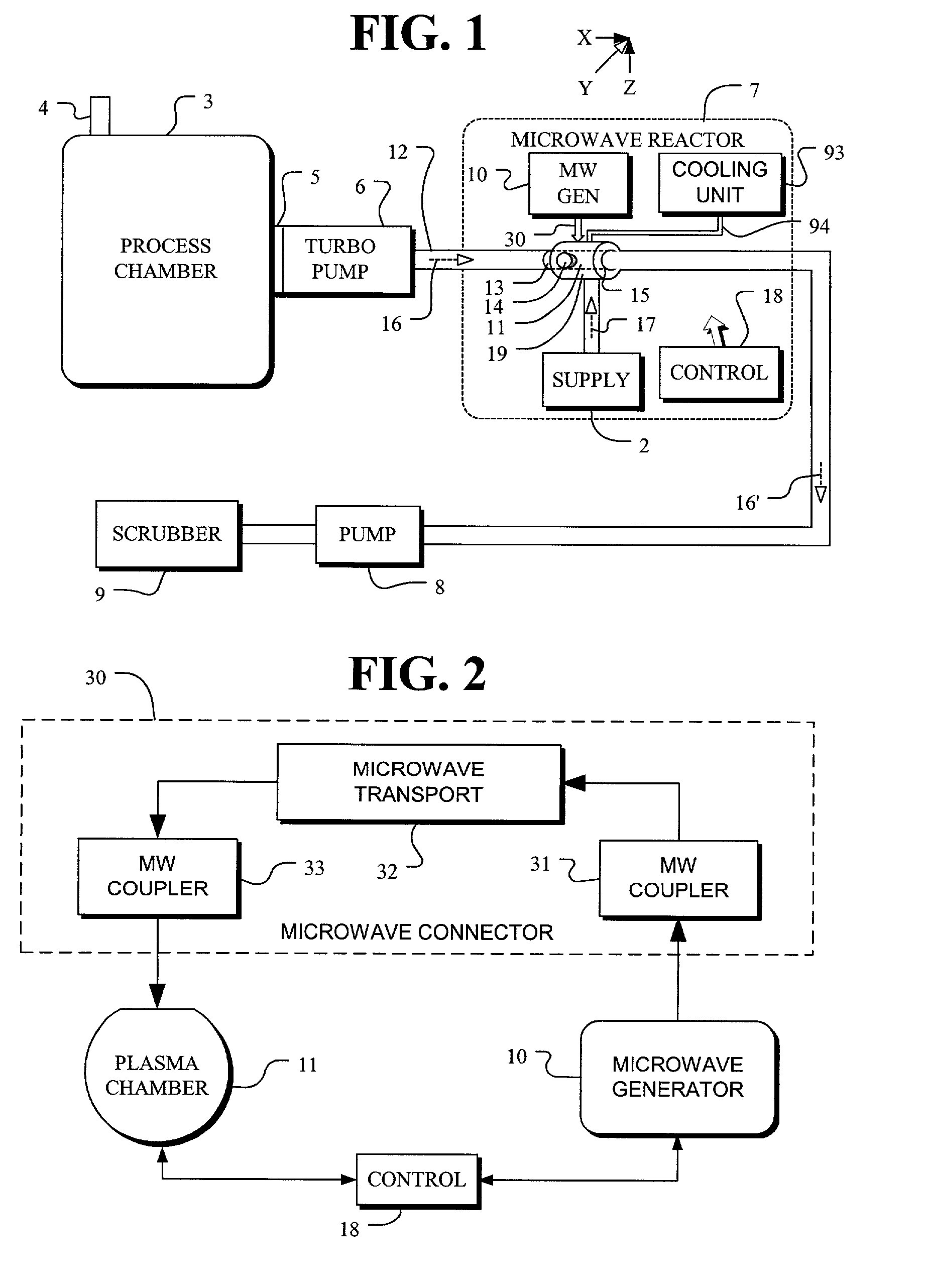

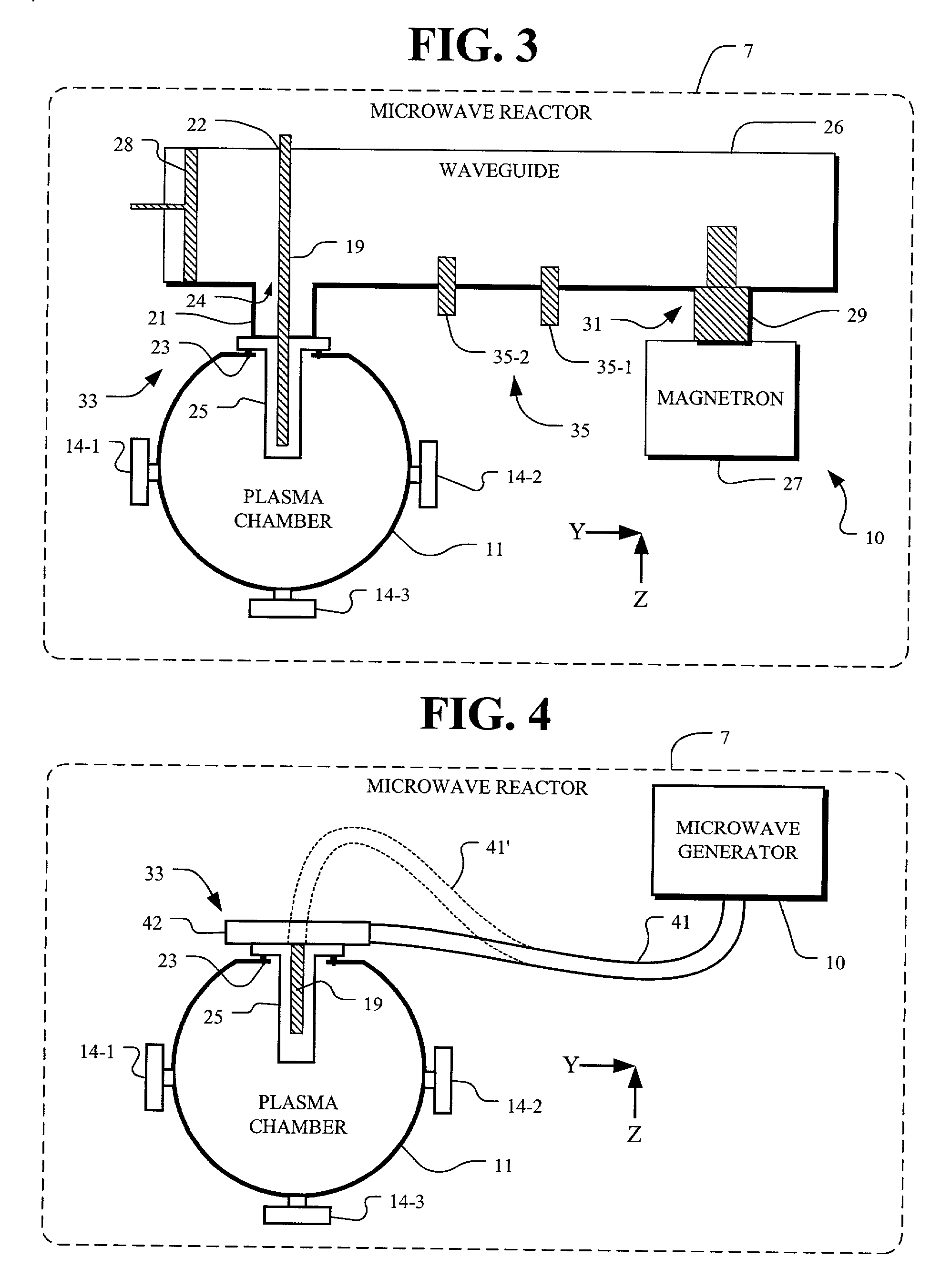

Microwave gas decomposition reactor

InactiveUS20020127155A1Facilitate gas decompositionDispersed particle separationMicrowave heatingMicrowaveGreenhouse

A microwave reactor for decomposing waste green house gases resulting from the manufacture of semiconductors and from other industrial processes. The microwave reactor includes a plasma chamber having a gas inflow port spaced apart from a gas outflow port for transporting gases through the plasma chamber. A gas plasma is generated in the plasma chamber to facilitate the gas decomposition. The structure of the microwave reactor includes an insulating cover protruding into the plasma chamber and forming an internal cavity that is isolated from gases in the plasma chamber. A microwave antenna extends into the internal cavity of the plasma chamber to couple the microwave energy into plasma chamber for causing a plasma to form in the gases.

Owner:MINAEE BRUCE +2

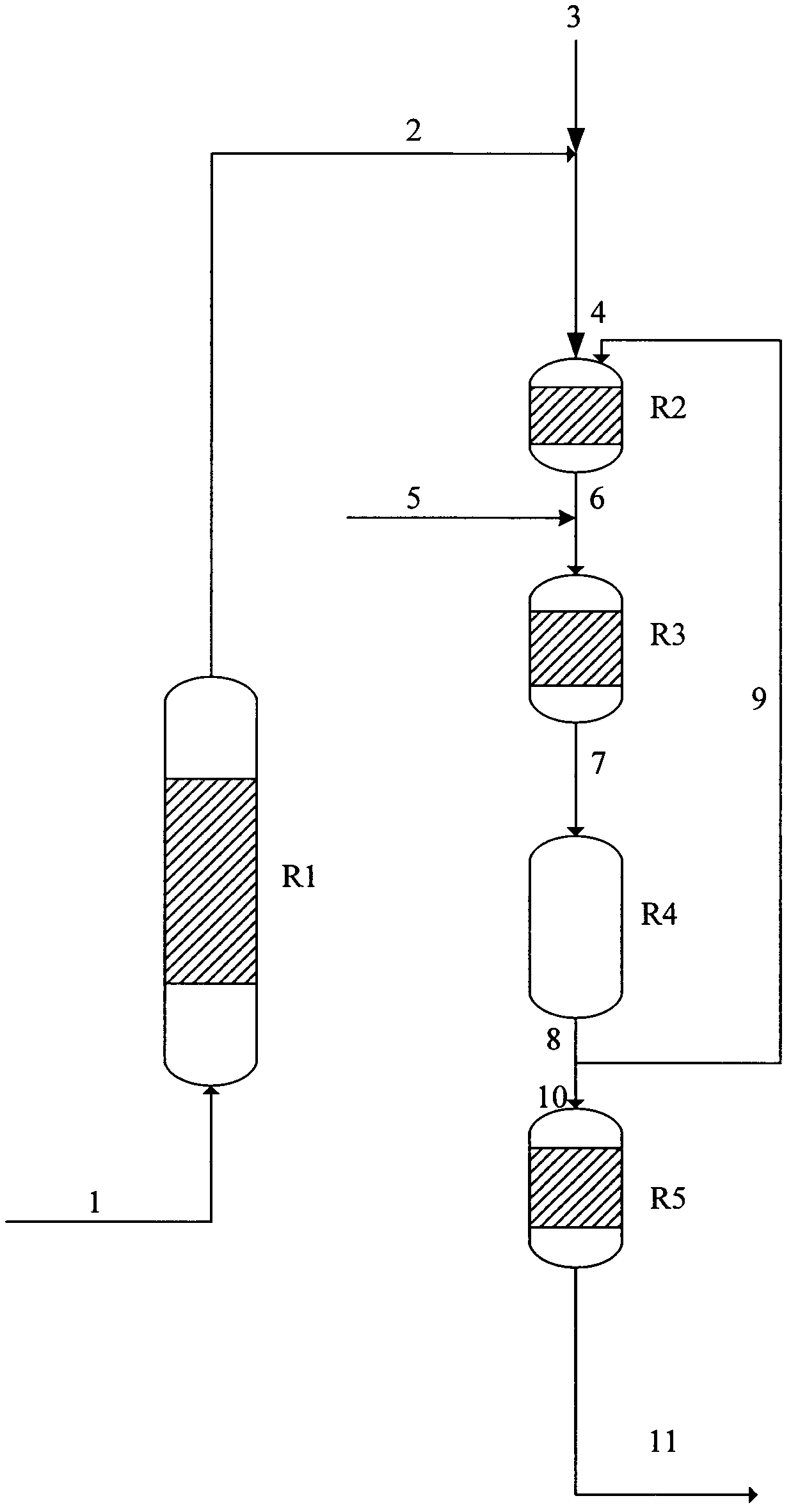

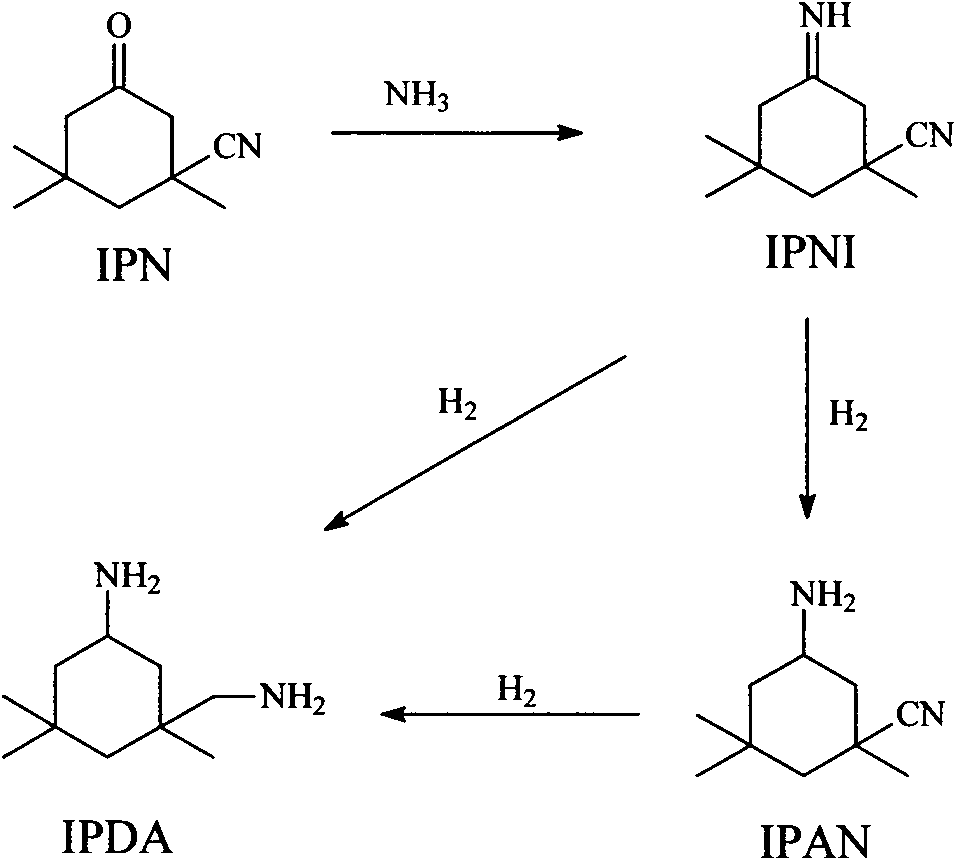

Preparation method for 3-aminomethyl-3,5,5-trimethylcyclohexyl amine

ActiveCN104230721AAvoid decompositionNo damage to service lifeOrganic compound preparationAmino compound preparationHydrogenation reactionOrganic chemistry

The invention provides a preparation method for 3-aminomethyl-3,5,5-trimethylcyclohexyl amine. According to the preparation method, imidization reaction materials containing 3-cyano-3,5,5-trimethylcyclohexyl imine is subjected to first-stage hydrogenation reaction under the help of a cycled material of a subsequent step, so that a first hydrogenation reaction material is obtained, and also generation of HCN-removed products is effectively inhibited, then a second-stage hydrogenation reaction is performed under the effect of a heating-degradable alkali auxiliary agent, then heating is performed to decompose the alkali auxiliary agent, a part of degraded materials is taken as the cycled material and is returned to the first-stage hydrogenation reaction as an auxiliary agent, and the residual part is subjected to third-stage hydrogenation reaction, so that 3-aminomethyl-3,5,5-trimethylcyclohexyl amine is obtained, and the content of 3-cyano-3,5,5-trimethylcyclohexyl amine and secondary amine products is effectively reduced.

Owner:WANHUA CHEM GRP CO LTD +1

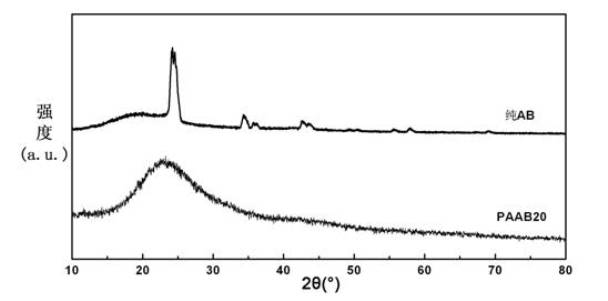

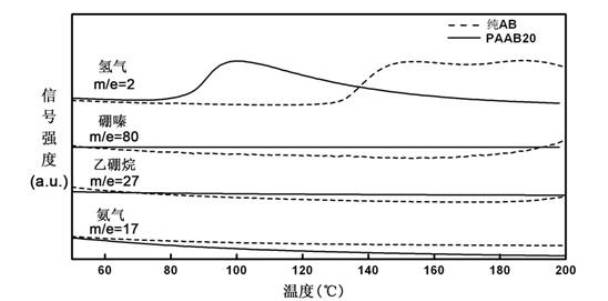

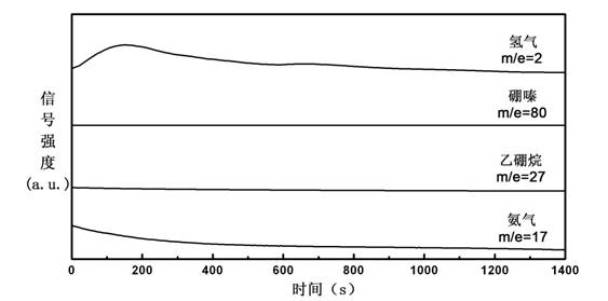

Organic matter and ammonia borane compounded hydrogen storage material and preparation method thereof

ActiveCN102030313ALowering the temperature of thermally liberated hydrogenInhibitionMonoborane/diborane hydridesPolyethylene oxideSolvent

The invention relates to an organic matter and ammonia borane compounded hydrogen storage material. The hydrogen storage material is prepared by compounding the organic matter and the ammonia borane, wherein the organic matter is phthalic anhydride, polyethylene oxide, dextrose, mannitol or mannitol hexaacetic ester. The preparation method comprises the following steps: 1) adding the organic matter to the purified acetonitrile solvent, and stirring for dissolving; 2) dissolving the ammonia borane into the mixing solvent comprising acetonitrile and methanol, and stirring at the temperature of 20 to 70 DEG C to obtain a uniform solution; and 3) carrying out vacuum drying, and removing the solvent, thus obtaining the hydrogen storage material. The invention has the advantages that the ammonia borane and the organic matter are taken as raw materials to prepare the hydrogen storage material at the lower hydrogen discharge temperature; the thermal decomposition and hydrogen discharge temperature of the ammonia borane can be effectively reduced; the generation of harmful gas impurities of borazole, diborane, ammonia and the like is effectively inhibited; the hydrogen storage material has quicker hydrogen discharge kinetics; in addition, the heat discharge amount is less in the hydrogen discharge course; and the enthalpy change of a decomposition reaction approaches to thermal neutrality; and the hydrogen storage material is beneficial to realizing the regeneration of reaction products through a solid-gas reaction or a chemical process under the relatively mild condition.

Owner:NANKAI UNIV

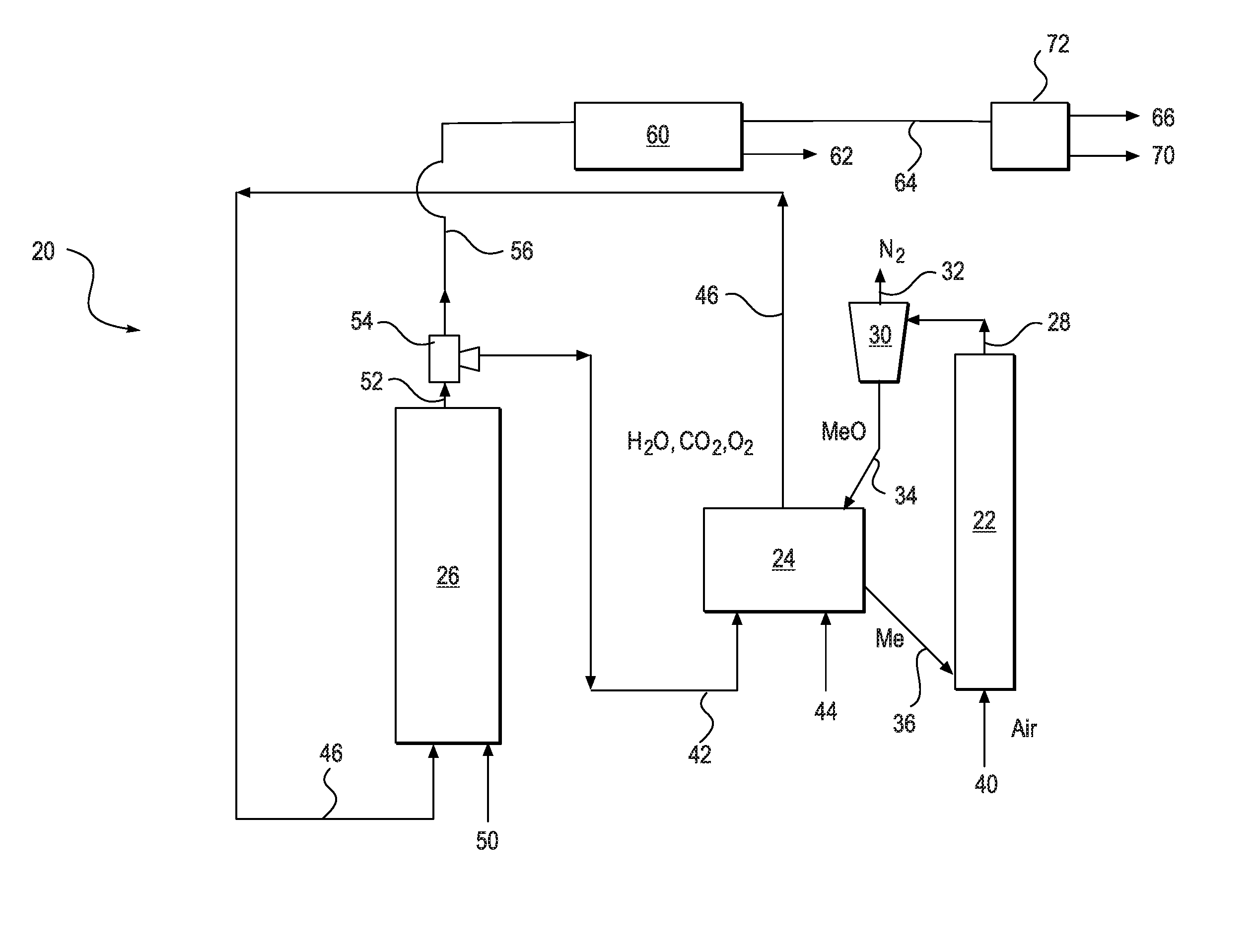

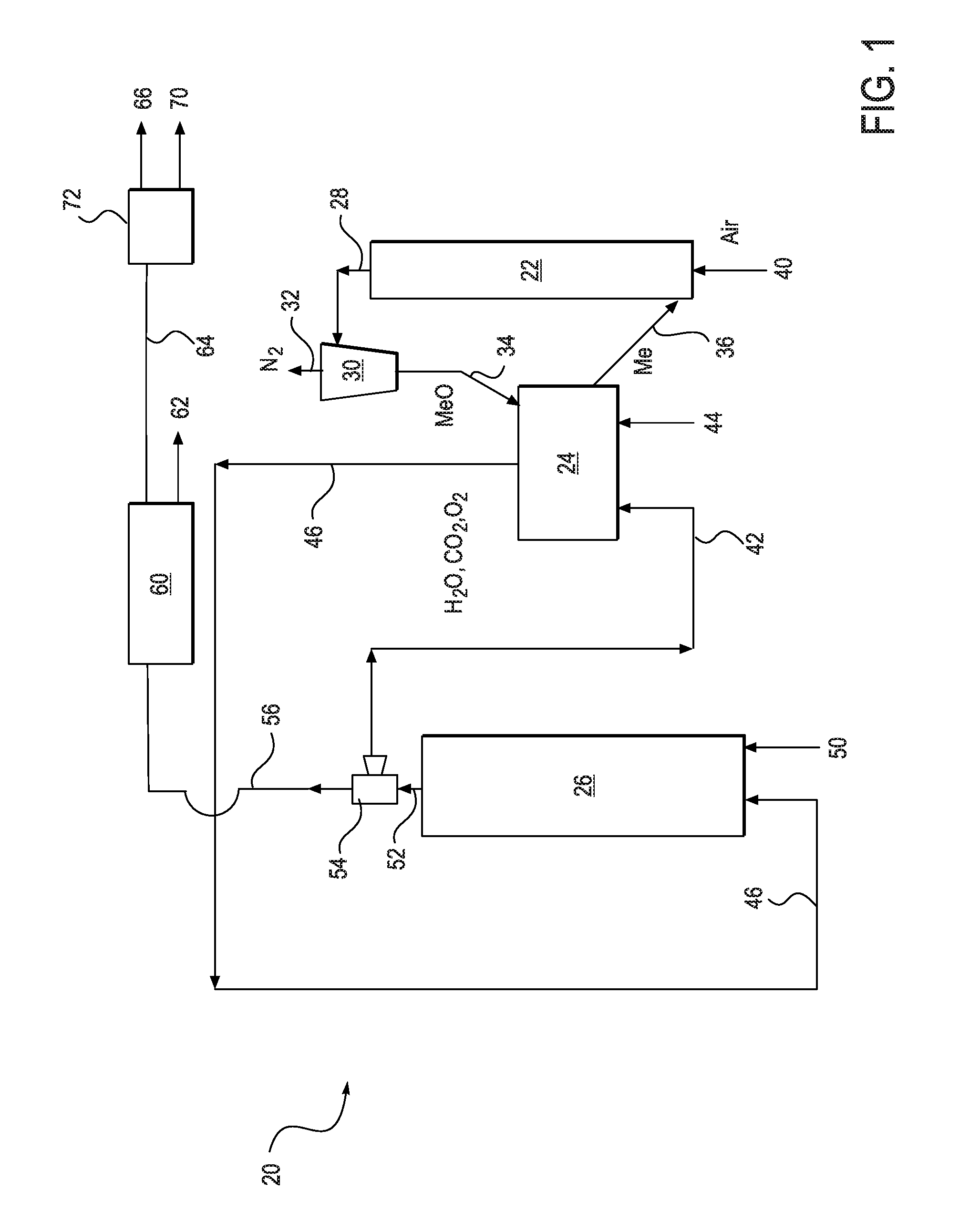

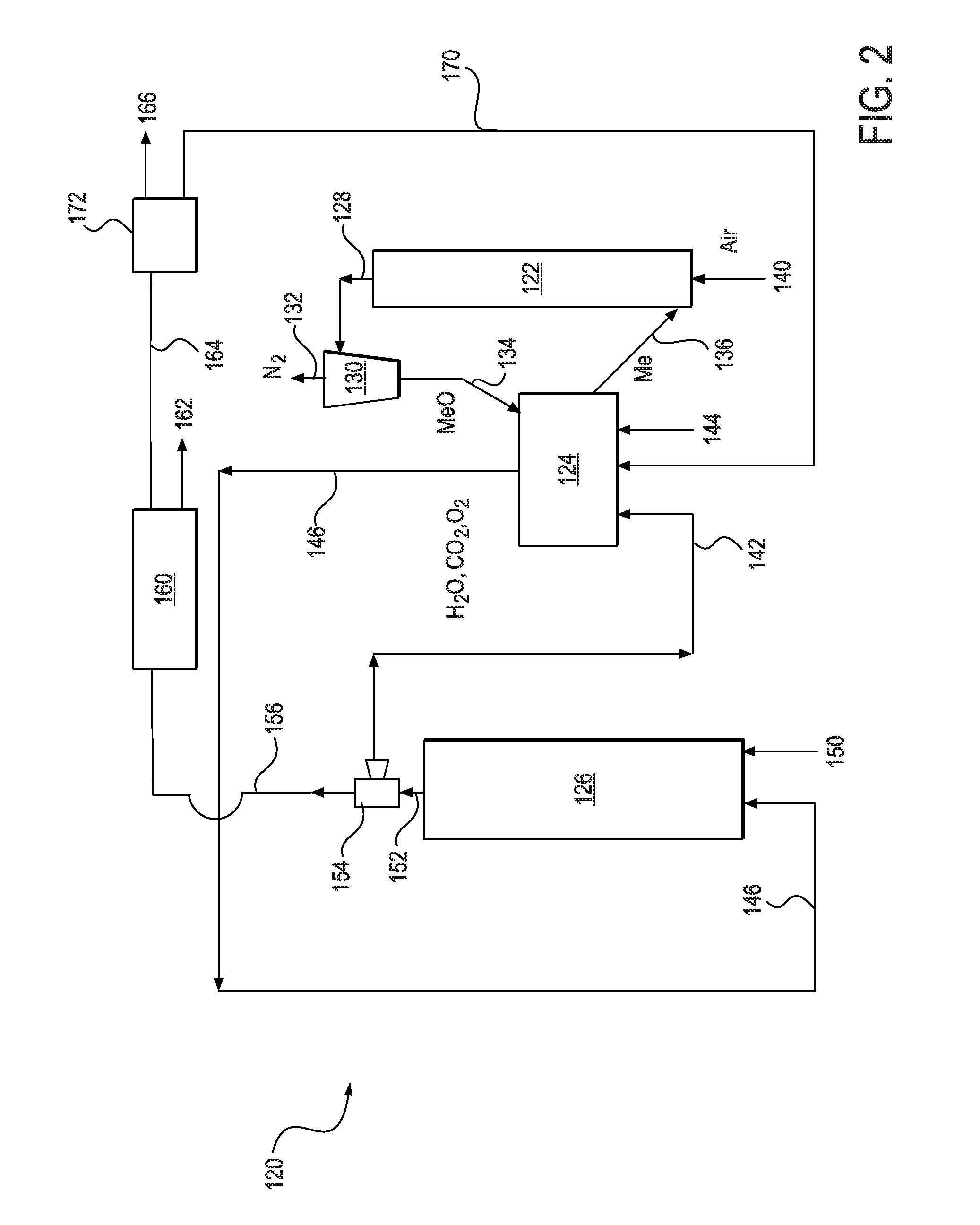

Method and system for capturing carbon dioxide in an oxyfiring process where oxygen is supplied by regenerable metal oxide sorbents

An oxyfiring system and method for capturing carbon dioxide in a combustion process is disclosed. The oxyfiring system comprises (a) an oxidation reactor for oxidizing a reduced metal oxide; (b) a decomposition reactor wherein a decomposition fuel is combusted and oxidized metal oxide sorbents are reduced with oxygen being released and a flue gas with an oxygen enriched carbon dioxide stream is produced; (c) a fuel combustion reactor for combusting a primary fuel and the oxygen enriched carbon dioxide stream into a primary flue gas; and (d) separation apparatus for separating a portion of the primary flue gas so that a carbon dioxide enriched stream can be prepared. The method comprises providing a primary fuel and an oxygen enriched carbon dioxide stream to a fuel combustion reactor. The primary fuel and oxygen enriched carbon dioxide stream are combusted into a primary flue gas stream which is split into a first flue gas portion and a second flue gas portion. The first flue gas portion is processed to produce a high purity carbon dioxide stream suitable for sequestration. The second flue gas portion is sent to the decomposition reactor to provide heat and serve as a fluid stream. The primary flue gas may include oxygen or else synthesis gas depending on whether the oxygen enriched carbon dioxide stream contains a stoichiometric excess or deficit of oxygen needed for complete combustion.

Owner:CHEVROU USA INC

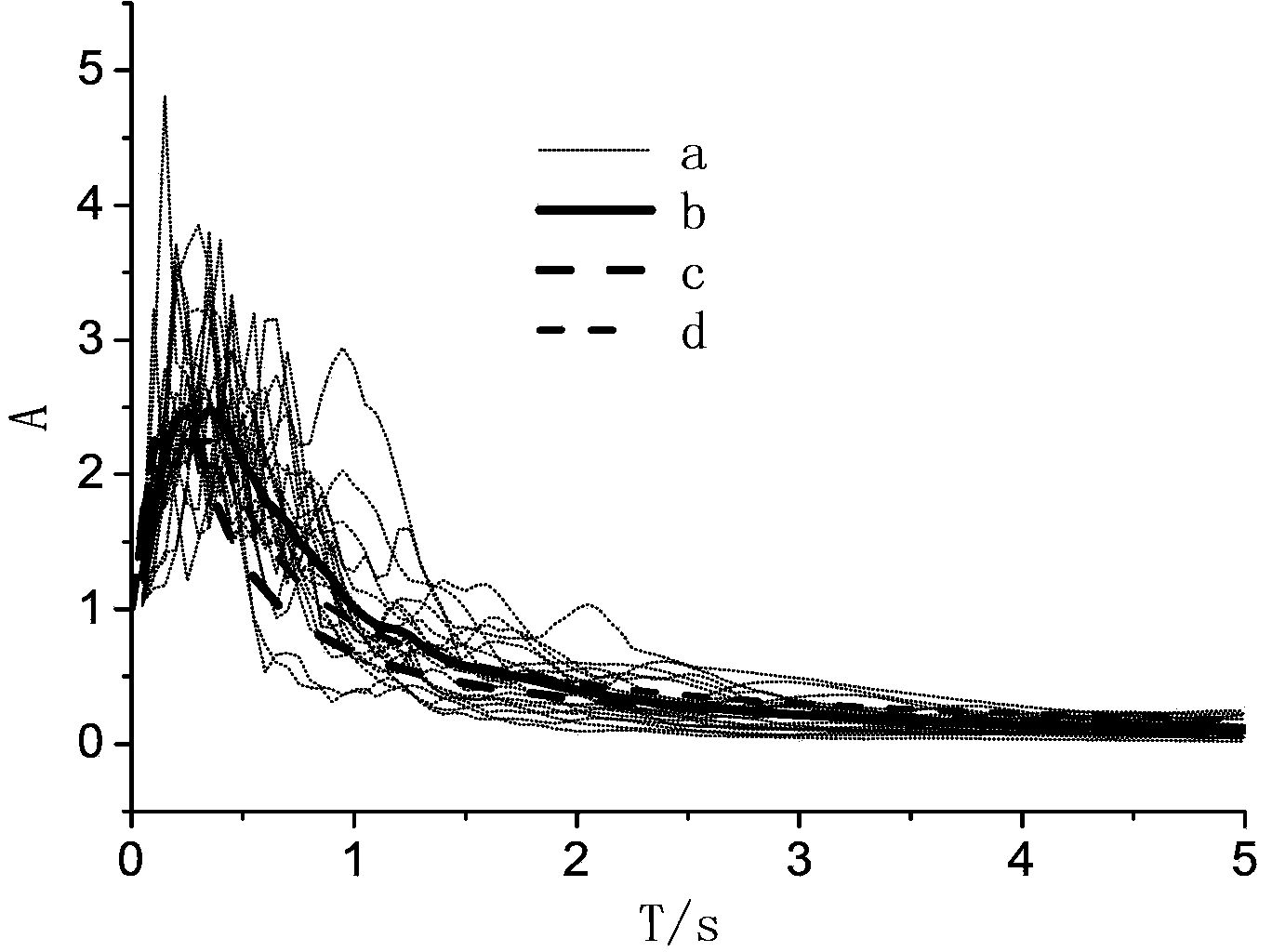

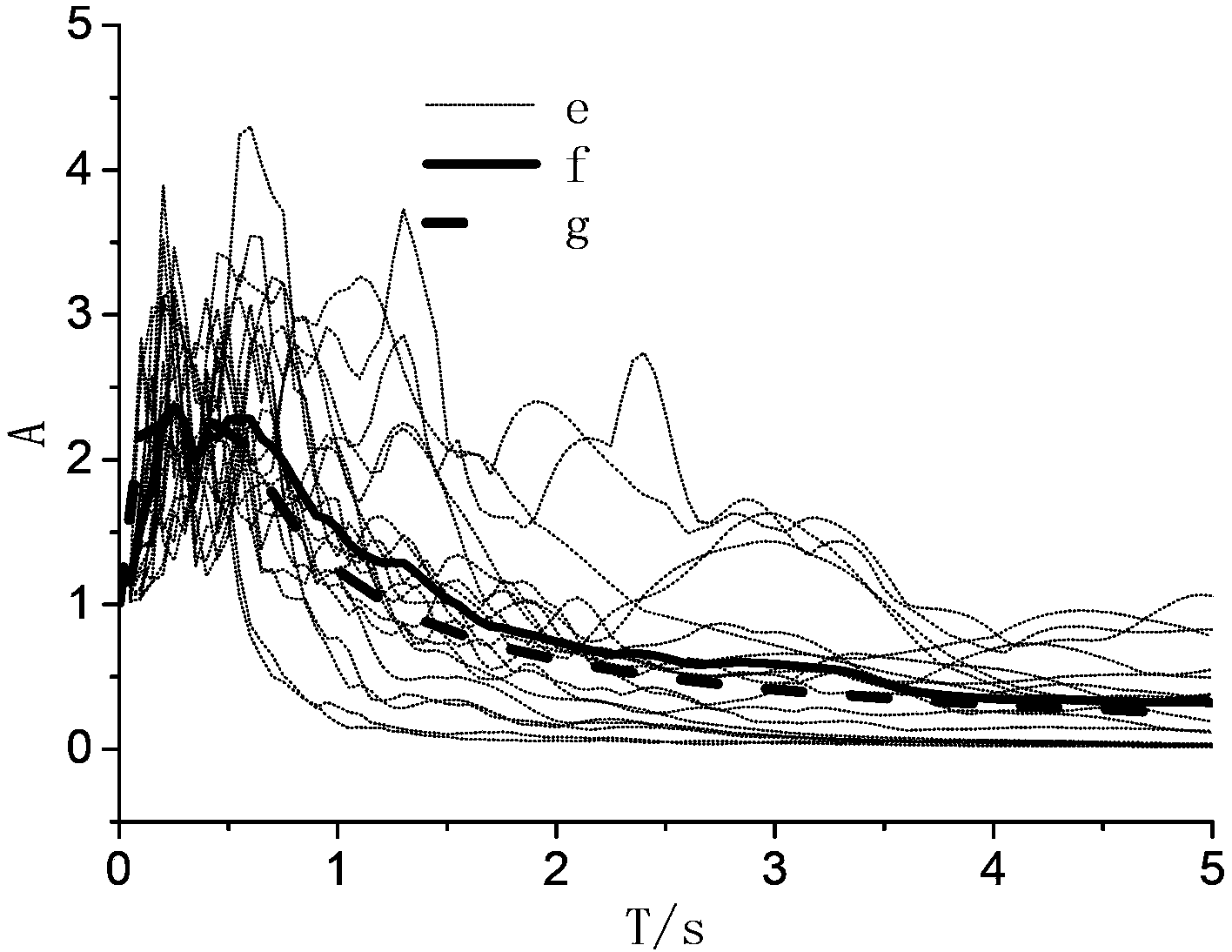

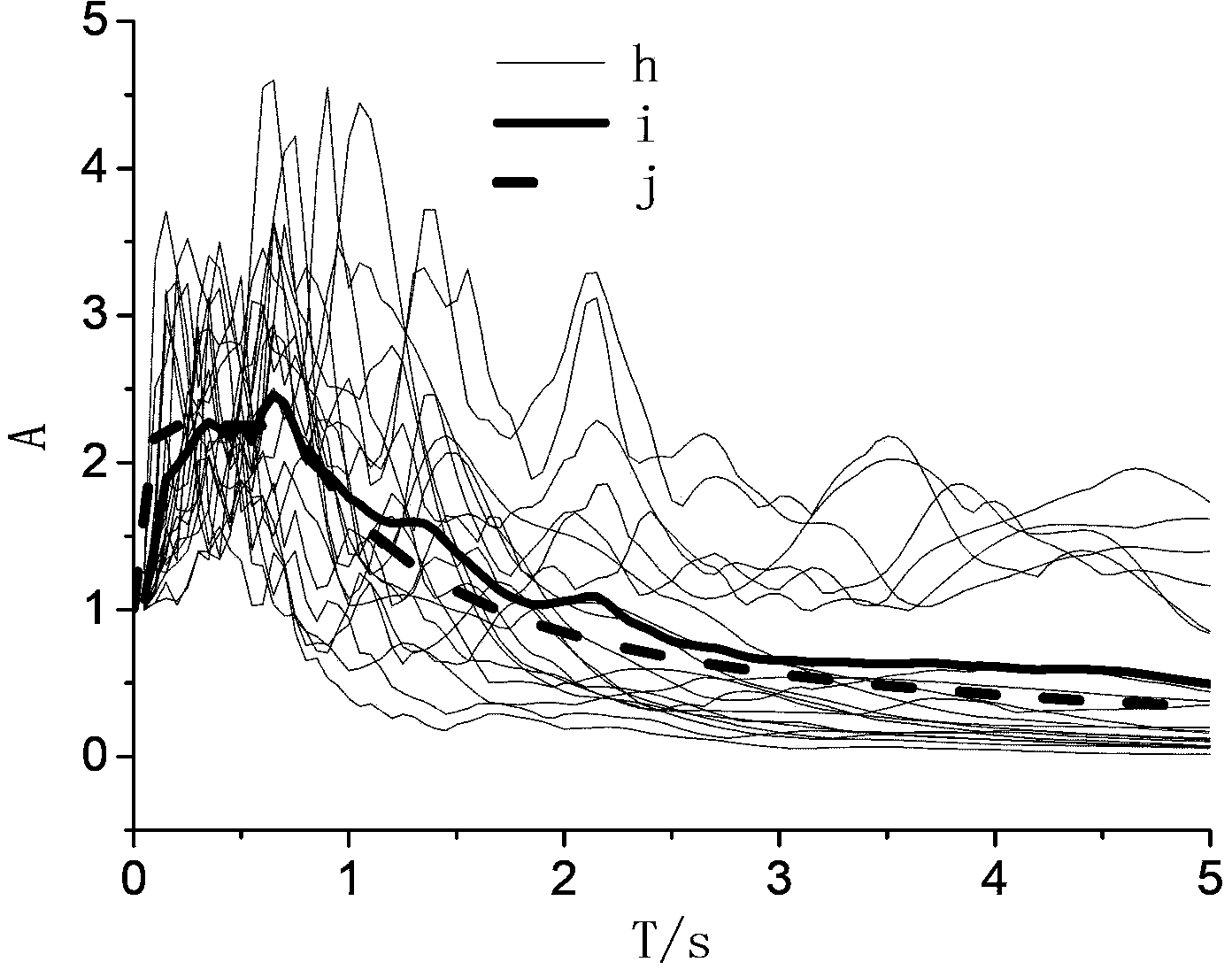

Selection method for inputting earthquake waves in time-procedure analysis for earthquake resistance of complex structures

The invention discloses a selection method for inputting earthquake waves in time-procedure analysis for earthquake resistance of complex structures to meet the earthquake-resistant requirements of the complex structures such as a high-pier long-span girder bridge, a cable-stayed bridge, a suspension bridge and a super high-rise building. The method comprises the steps that firstly, alternative earthquake waves which meet different site conditions such as earthquake magnitude, distance, an acceleration peak value and long cycle characteristics are selected in an American PEER strong earthquake record database, and a primary-selection database is formed; secondly, the minimum relative weighted average error of spectrum values of alternative earthquake wave response spectrums and design response spectrums in the primary-selection database near previous orders of periodic points of platforms stages and the complex structures is used as a double-control index according to site conditions, and the specific input earthquake waves are determined to meet the requirement that a time-procedure analysis result is in accordance with response spectrum analysis analytic statistics. According to the selection method, engineering realization is easy to achieve, and the method is compared with multiple mode decomposition reaction spectrum methods. In addition, due to the fact that the earthquake waves are selected in the appointed primary-selection database, similar classification of the site conditions is ensured, and the quality of input earthquake waves is ensured.

Owner:DALIAN MARITIME UNIVERSITY

Method for decomposing thermosetting epoxy resin or composite material thereof by high-temperature water phase

InactiveCN101519505AHigh catalytic activityNo pollution in the processPlastic recyclingEpoxySingle substance

The invention relates to a method for decomposing a thermosetting epoxy resin or a composite material thereof by high-temperature water phases, which belongs to the technical field of regenerative utilization of waste resin materials or treatment of industrial wastes. The method is characterized by comprising the following steps: putting certain amount of thermosetting epoxy resin sheets or granules, and deionization and catalyst heteropolyacid into a high-temperature high-pressure stainless steel reaction kettle; heating the reaction kettle to raise the temperature to a temperature of 250 and 370 DEG C for 30 to 120 hours; and decomposing the water diversion phase so that the decomposed product becomes an oligomer or a single substance which cannot be dissolved in liquid phase and is easy to separate. The method mainly adopts heteropoly acid, phosphotungstic acid, tungstosilicic acid, or molybdenum phosphoric acid as a catalyst, the addition of the catalyst is 0.1 to 3.0 percent of that of deionized water, and a higher decomposition rate of the epoxy resin can be obtained finally. The method does not need to use an organic solvent as a decomposing liquid, but uses water as the decomposing liquid, thus the method has low cost and is pollution-free to the environment; and the method can achieve the aims of waste regeneration and utilization as well as environmental protection.

Owner:SHANGHAI UNIV

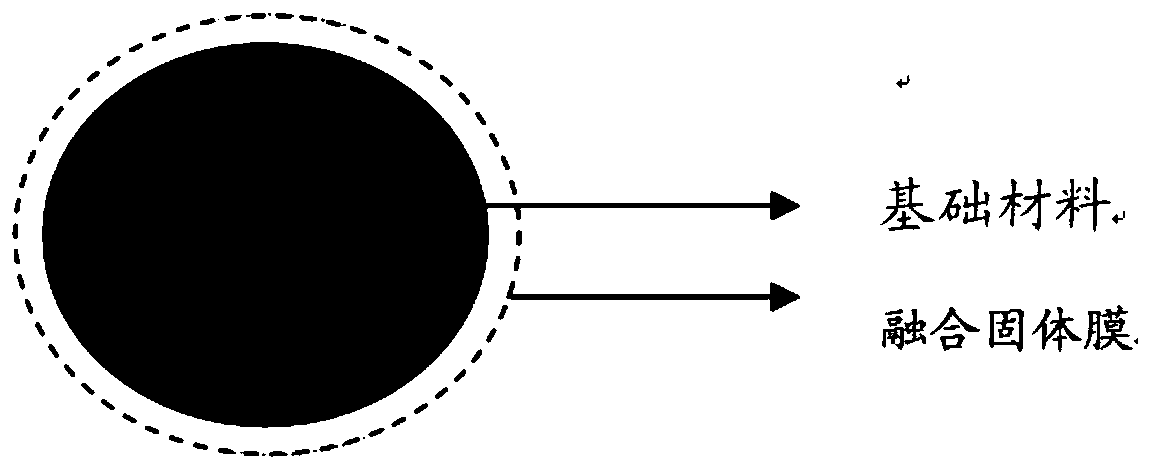

Positive electrode material of lithium ion battery as well as preparation method and application of positive electrode material

PendingCN109888208AImprove interfacial ionic conductivityReduce exposureCell electrodesSecondary cellsElectrical conductorComposite oxide

The invention relates to a positive electrode material of a lithium ion battery. The positive electrode material comprises a basic material and a fast ion conductor coating layer, wherein the coatinglayer is selected from a lithium-titanium composite oxide, a lithium-zirconium composite oxide or a lithium-phosphorus composite compound, wherein the basic material is selected from one or more thantwo of lithium cobalt oxide, lithium nickel cobalt aluminate, lithium nickel cobalt manganate, lithium manganate, lithium iron phosphate, lithium nickel manganate or lithium nickel cobalt oxide; the preparation method comprises the following stepsof preparing the raw materials containing elements in the fast-ion conductor into a precursor, and then carrying out surface fusion with the basic material, and the solid coating film is formed by sintering, so that the ion migration capacity is improved, and the decomposition reaction of the transition element to the electrolyte is reduced, the cyclelife of the prepared lithium ion battery is prolonged, the safety is improved, and the positive electrode material has a wide application prospect.

Owner:高点(深圳)科技有限公司 +1

Electrode and battery

An electrode and battery enabling to improve cycle characteristics owing to formation of an effective coating are disclosed. A positive electrode (21) and a negative electrode (22) are wound while having a separator (23) interposed therebetween. The separator (23) is impregnated with an electrolyte. The surface of the positive electrode (21) or the negative electrode (22) is provided with a coating which contains a compound having a surface tension smaller than that of the electrolyte and insoluble to the electrolyte, specifically a siloxane such as poly(dimethylsiloxane), poly(methylhydrosiloxane) or poly(methylphenylsiloxane), a perfluoropolyether such as poly(hexafluoropropylene oxide), or a perfluoroalkane such as perfluoropentadecane. Consequently, a coating effective for suppressing decomposition reaction of the electrolyte can be formed without using a large amount of the compound which forms the coating.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com