Patents

Literature

74results about How to "Good thermal insulation properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

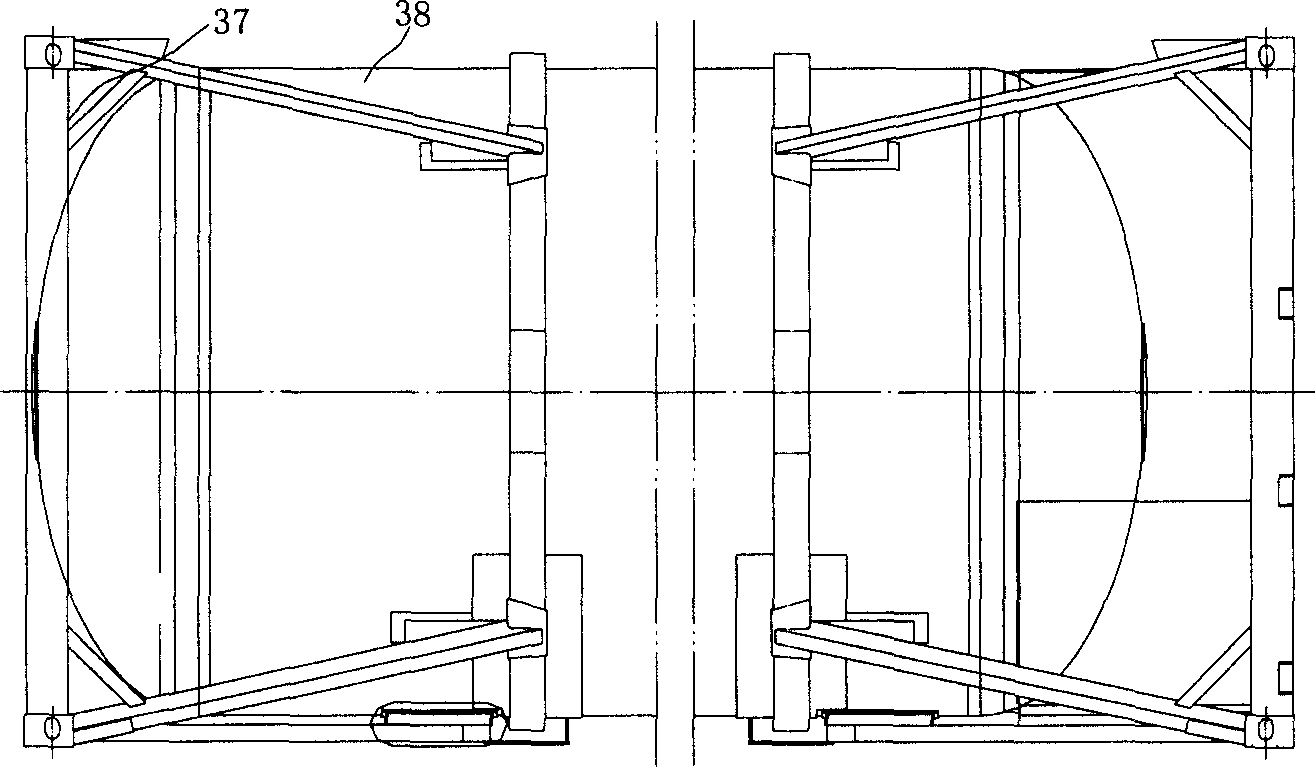

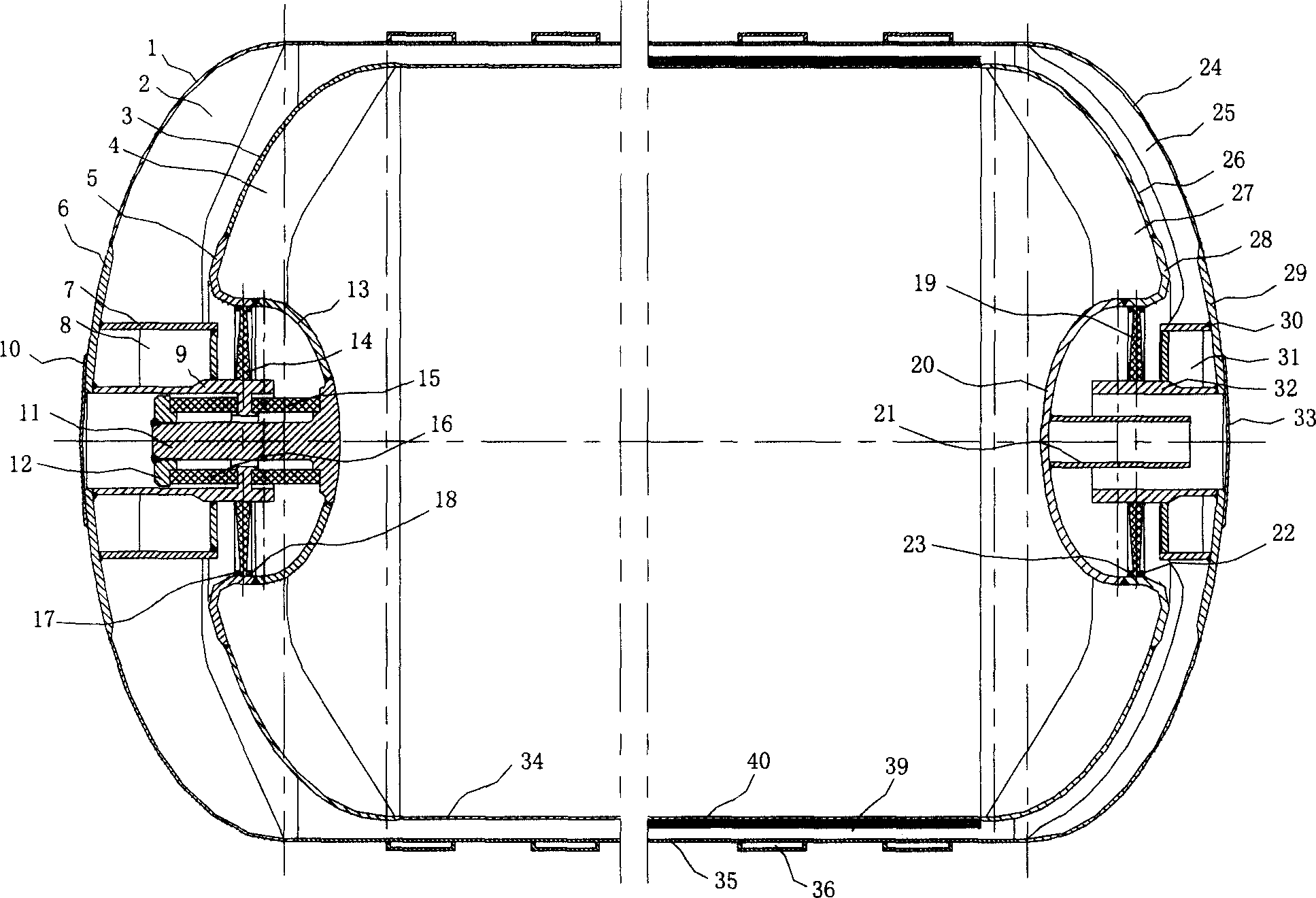

High vacuum heat insulation low temperature liquefied gas storage tank

ActiveCN1683816AIncrease effective volumeReduce heat transfer areaVessel mounting detailsVessel manufacturingEngineeringHeat conducting

The high vacuum heat insulating low temperature liquefied gas storing tank includes frame and tank body. The tank body consists of outer casing, inner container and combined support structures connecting the outer casing and the inner container. The combined support structures are set between the inner sealing head and outer sealing head on two ends of the tank to bear the radial load and the axial load with great bearing force. The heat conducting area between the inner container and the outer casing is small, and the inner container has great effective loading volume.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

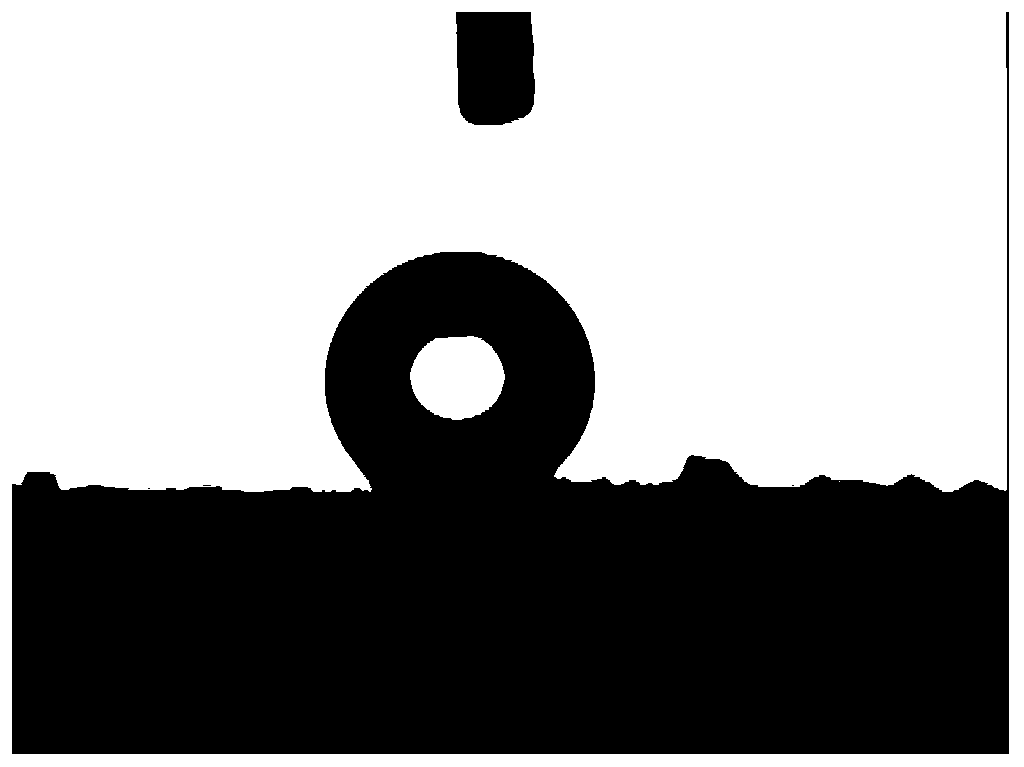

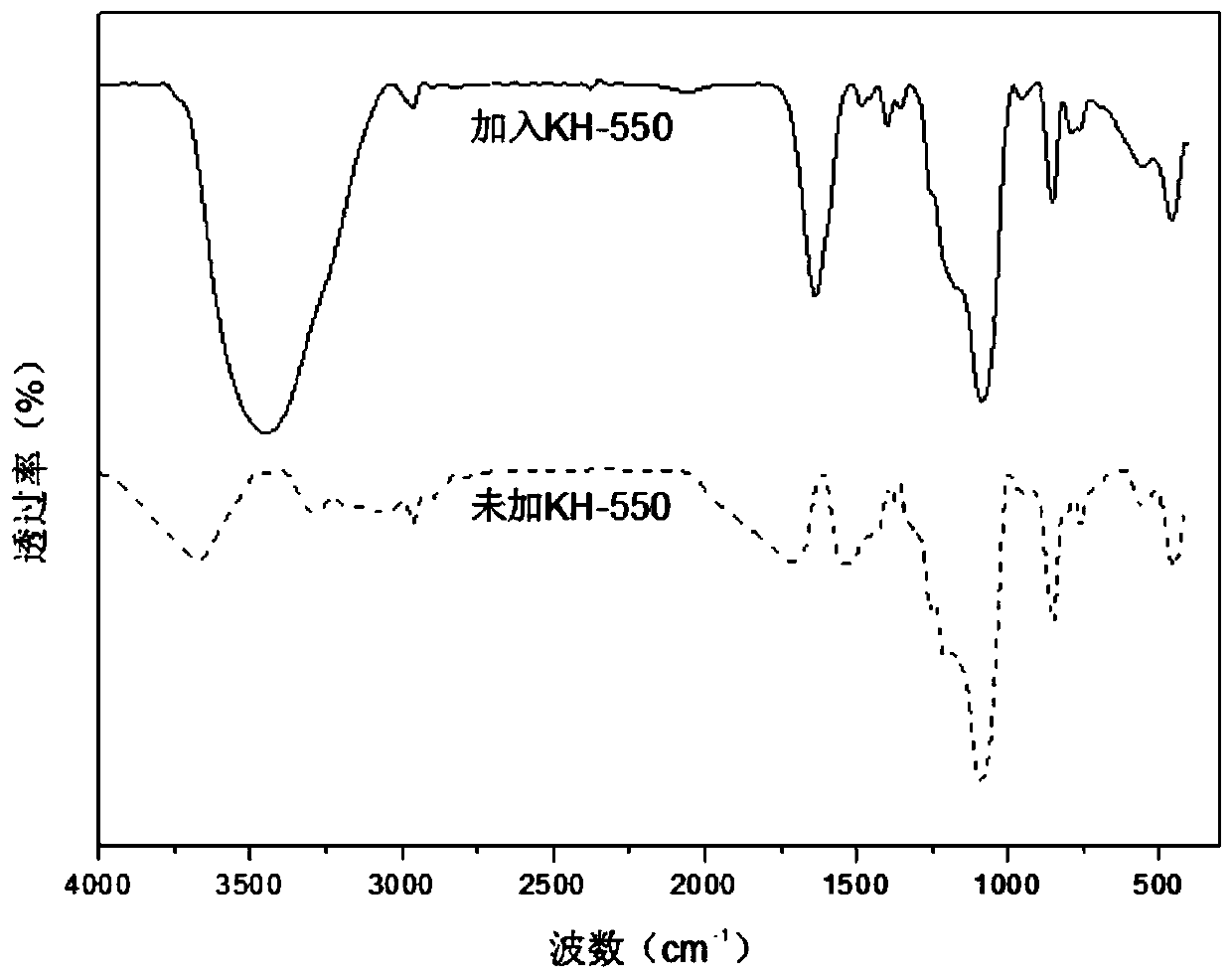

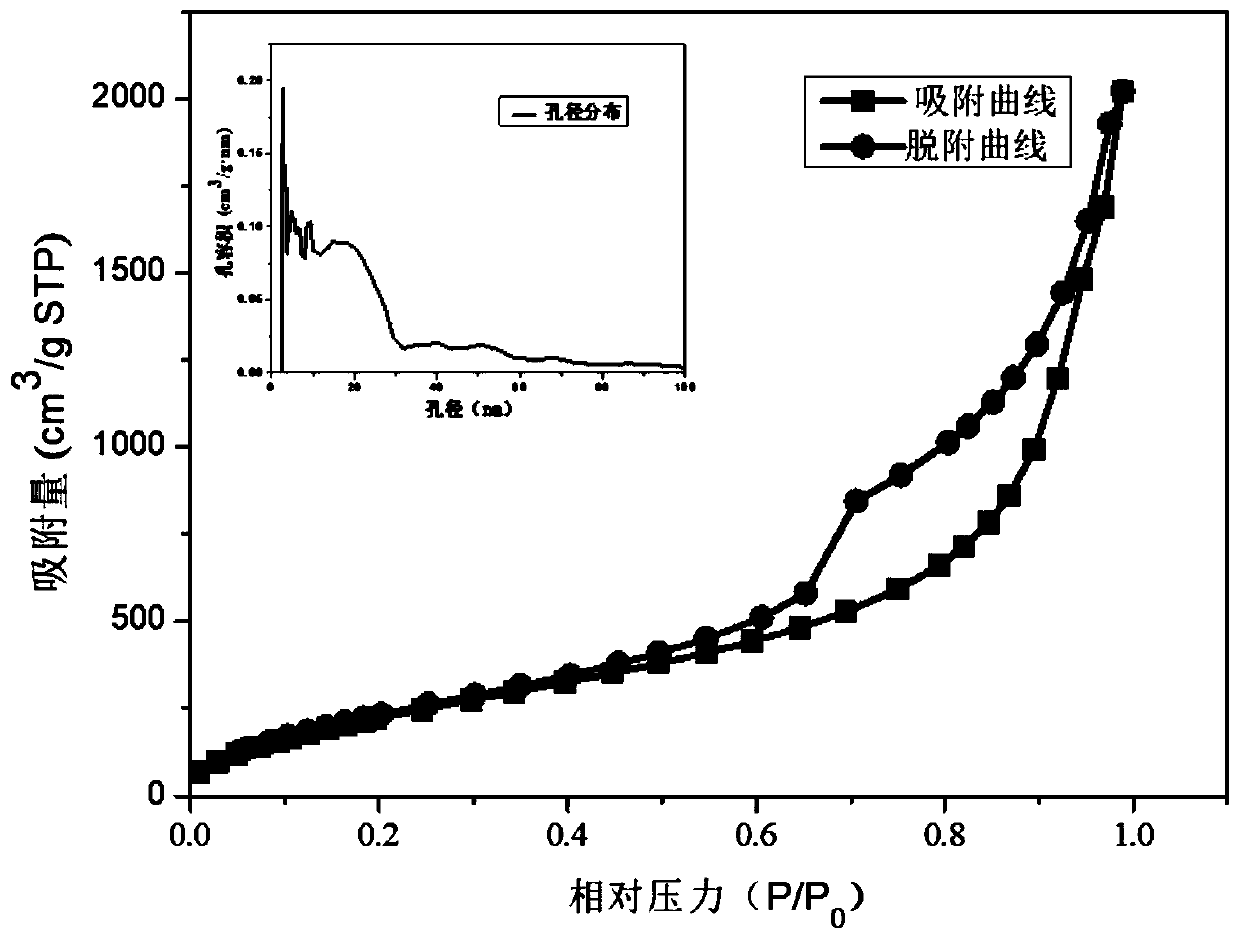

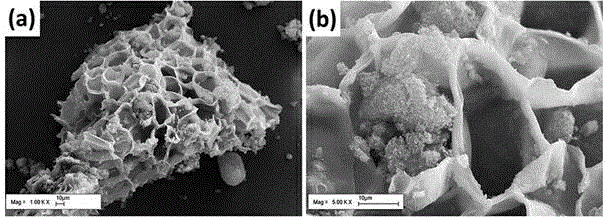

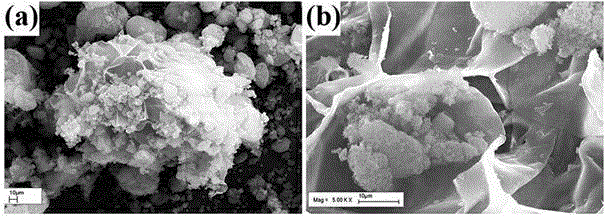

Normal-pressure preparation method of high specific surface area intensive-hydrophobicity graphene oxide/silica composite aerogel

InactiveCN110422850AImprove bindingShorten the formation timeCarbon compoundsSilicon compoundsSolventChemical bond

The invention discloses a normal-pressure preparation method of a high specific surface area intensive-hydrophobicity graphene oxide / silica composite aerogel. The method comprises the following steps:by taking tetraethoxysilane as a precursor, adding a graphene oxide turbid liquid under an acidic condition, adding an ethanol liquid of aminopropyl triethoxy silane and graphene oxide hydrosol, continuously dropping the ethanol liquid of aminopropyl triethoxy silane, forming a graphene oxide / silica composite alcogel under an ultrasonic condition, and performing aging, maturing, solvent replacement, surface modification, and normal-pressure drying, so as to obtain the composite aerogel. By adopting the method, a silane coupling agent, namely the aminopropyl triethoxy silane, is adopted to replace a conventional alkali catalyst, and the aminopropyl triethoxy silane is used as a silicon source and is easy in chemical bond combination with an acidic group carboxyl in the graphene oxide because of an alkali group amino in the aminopropyl triethoxy silane, so that the combination force can be improved, in addition, the formation time of the gel is greatly shortened, and the graphene oxide / silica composite aerogel which is high in specific surface area, intensive in hydrophobicity and low in heat conduction coefficient can be prepared.

Owner:SOUTH CHINA UNIV OF TECH

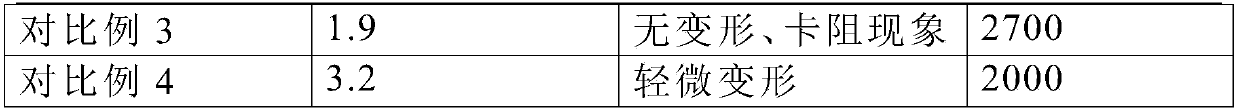

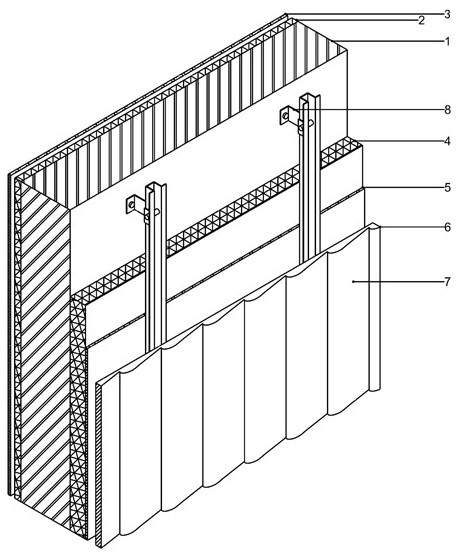

Installation method for thermal insulation and decoration integrated facade panels

The invention relates to an installation method for thermal insulation and decoration integrated facade panels in the field of construction methods of the construction industry. The method includes the following steps: (Step 1) main wall surface treatment; (Step 2) datum line making; (Step 3) framing installation; (Step 4) thermal insulation and decoration integrated facade panel installation; (Step 5) gap filling; (Step 6) sealant filling; (Step 7) panel surface cleaning. When the method disclosed by the invention is adopted, integral installation is convenient, cost is reduced, the construction period is short, the load of facade panels is reduced greatly, the utilizability of space and land is enhanced, the application range is wide, temperature is kept, heat is insulated, energy consumption is reduced, structural destruction caused by the circulation of rain, snow, freezing, thawing, dryness and wetness is prevented, the worry about the water seepage of wall surfaces is eased after installation, the phenomenon that indoor wall surfaces go moldy is effectively prevented, and the thermal insulation and decoration integrated facade panels are environment-friendly and durable.

Owner:杭锦旗亿利朗新材料科技有限公司

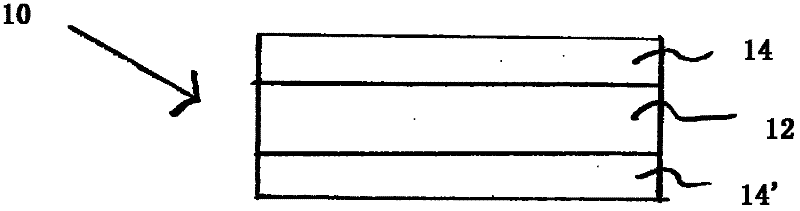

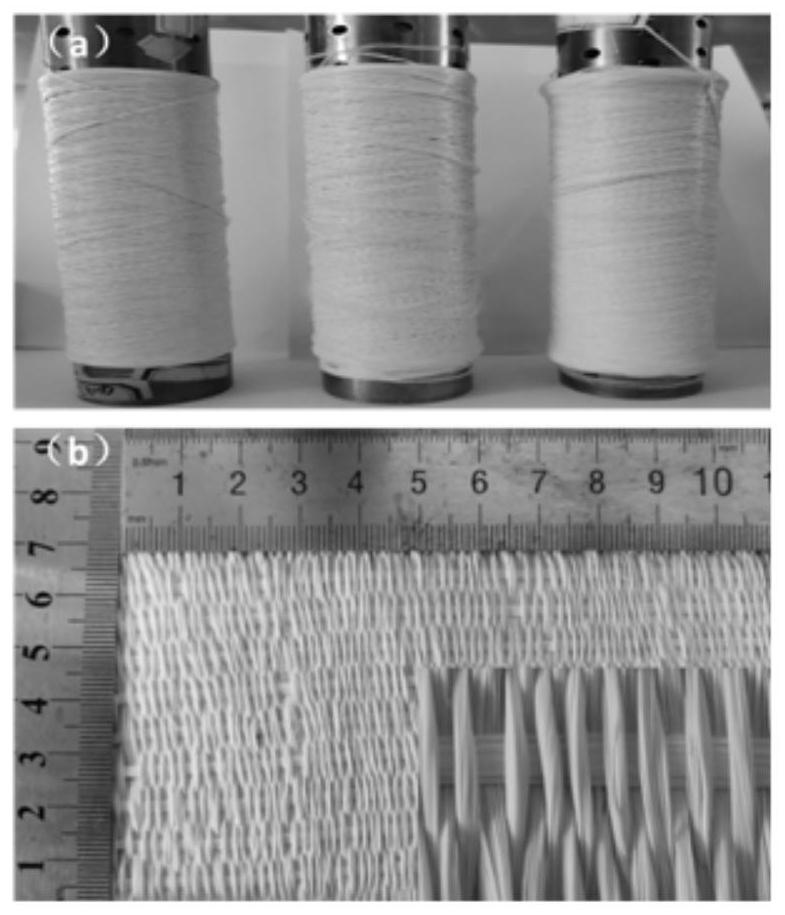

Composite material comprising soft carbon fiber felt and hard carbon fiber felt

InactiveCN102575400AKeep positiveGood thermal insulation propertiesHeating/cooling textile fabricsCeramic layered productsFiberCarbon fibers

The invention relates to a composite material comprising at least one layer of soft carbon fiber felt and at least one layer of hard carbon fiber felt, wherein the at least one layer of soft carbon fiber felt is connected to the at least one layer of hard carbon fiber felt via a binder.

Owner:SGL CARBON SE

Nano-porous aerogel/fiber composite super thermal insulation material and preparation method thereof

The invention discloses a nano-porous aerogel / fiber composite super thermal insulation material and a preparation method thereof. The aerogel / fiber composite super thermal insulation material comprises silicon dioxide aerogel, alumina micro powder, zirconium oxide fibers and opacifying agent of titanium dioxide. The preparation method comprises that organic solvent, cross-linking agents and organic monomers make up pre-mixed solution according to a certain proportion, the silicon dioxide aerogel, the alumina micro powder, the zirconium oxide fibers, pore-forming agents, suspending agents and the titanium dioxide make up slurry through a ball milling process according to a certain proportion, then a certain amount of initiating agents and a certain amount of catalytic agents are dropwise added into the slurry through vacuum bubble removal, composite material in-situ solidification is achieved through a gel injection moulding process, and then demoulding, vacuum drying and degreasing glue discharging are conducted. The nano-porous aerogel / fiber composite super thermal insulation material has a nano-porous / reinforced fiber composite microstructure, the heat conductivity is 0.040-0.046W*m<-1>*K<-1> (298K), and the flexure strength is as high as 12-14MPa. Preparation processes are simple, industrialized application is easily achieved on a large scale, and the nano-porous aerogel / fiber composite super thermal insulation material is suitable for thermal protection of aerospace, military affairs and severe rugged environments.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

Preparation method of composite silicon dioxide aerogel felt

ActiveCN110922095APrevent powder dropGood thermal insulation propertiesCeramicwareFiberThermal insulation

The invention belongs to the field of thermal insulation materials, and discloses a preparation method of a composite silicon dioxide aerogel felt. The preparation method comprises the following steps: mixing water, silicon dioxide aerogel powder, resin, a curing agent and low-density microspheres to a uniform state to obtain aerogel slurry; dipping a plurality of single-layer fiber felts into theaerogel slurry to obtain a plurality of single-layer aerogel fiber felts; superposing the single-layer aerogel fiber felts together to obtain a multilayer aerogel fiber felt; and curing the multilayer aerogel fiber felt according to a curing process of preserving heat at 80-90 DEG C for 1-3h, preserving heat at 100-120 DEG C for 1-4h and finally preserving heat at 140-160 DEG C for 1-3h to obtainthe composite silicon dioxide aerogel felt. On the premise that the heat insulation effect of the aerogel felt is not affected, the mechanical property of the aerogel felt is enhanced, the situationthat powder falls off from a traditional silicon dioxide aerogel felt is overcome, and the dust pollution problem of aerogel in the storage, transportation, installation and use processes is reduced.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Aerogel

ActiveUS20180327548A1Good thermal insulation propertiesIncrease productivityAerogel preparationSilicon compoundsHydrolysateCompound (substance)

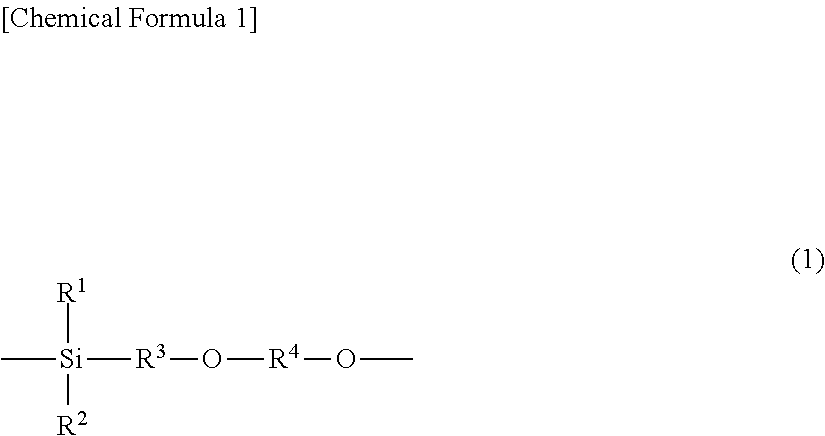

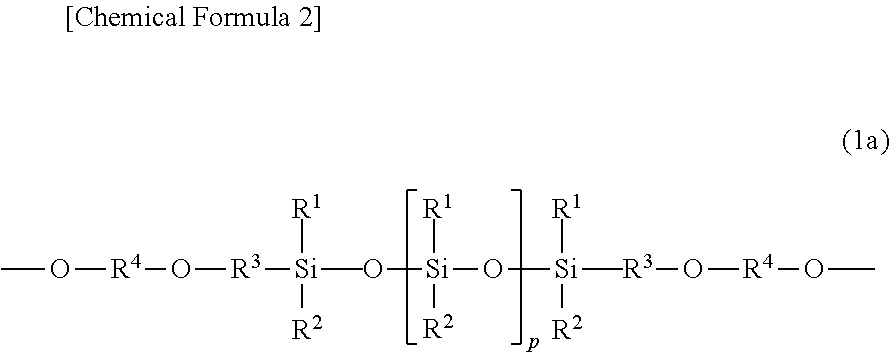

Aerogel is a dried product of wet gel being a condensate of sol containing at least one selected from the group consisting of a polysiloxane compound having a hydrolyzable functional group or a condensable functional group and having an average molecular weight of 300 to 1500 g / mol, and a hydrolysis product of the polysiloxane compound having a hydrolyzable functional group.

Owner:RESONAC CORP

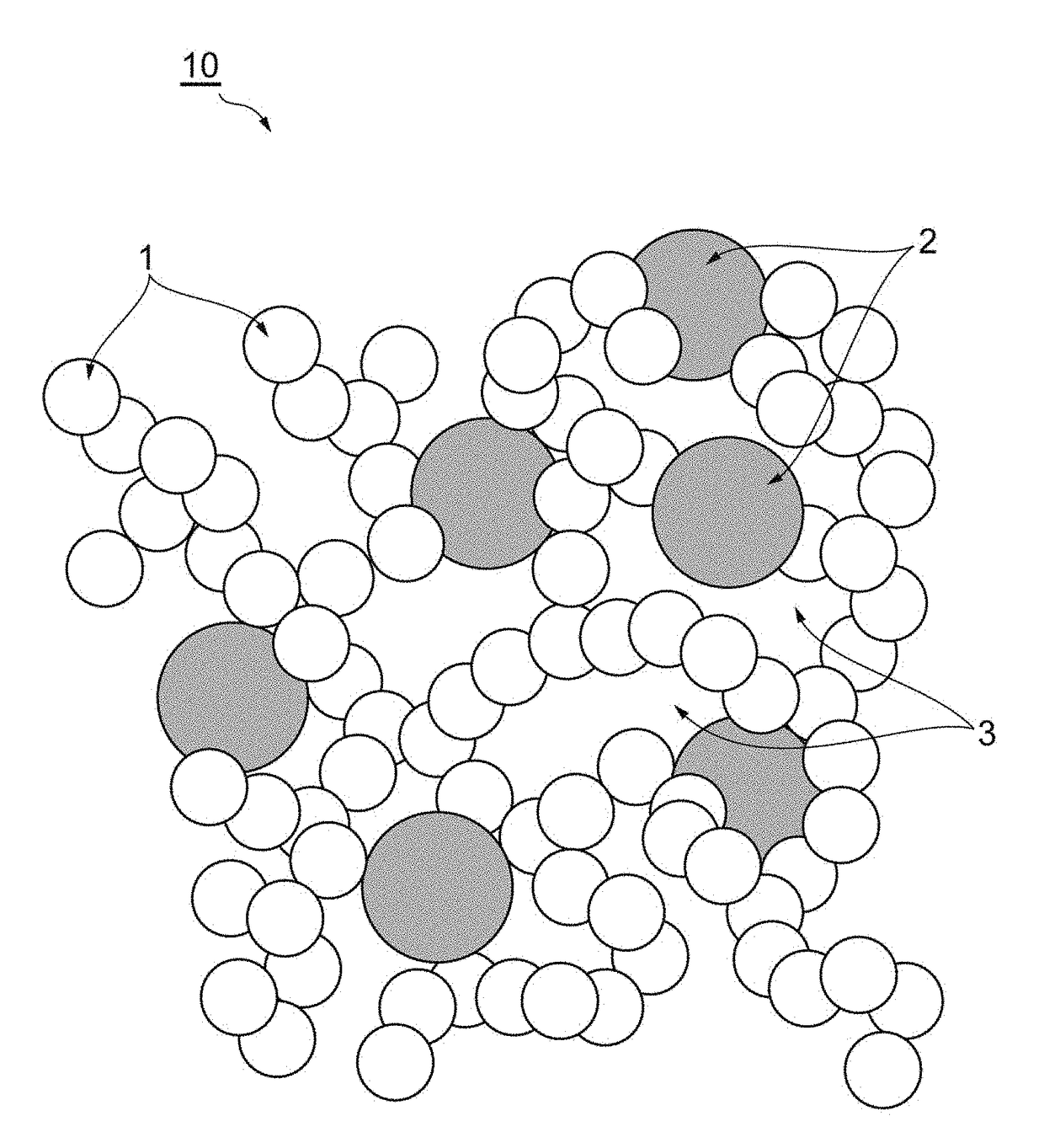

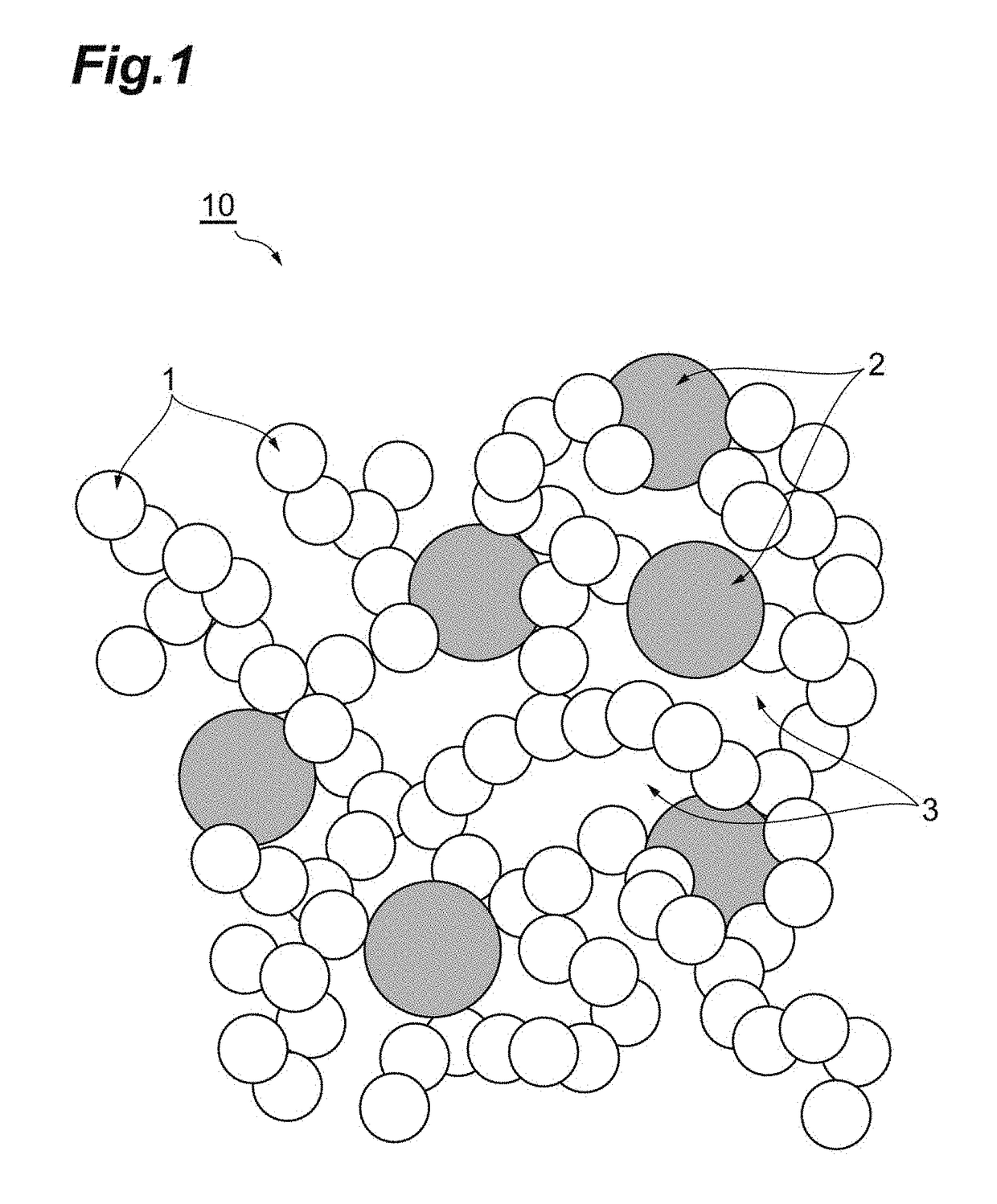

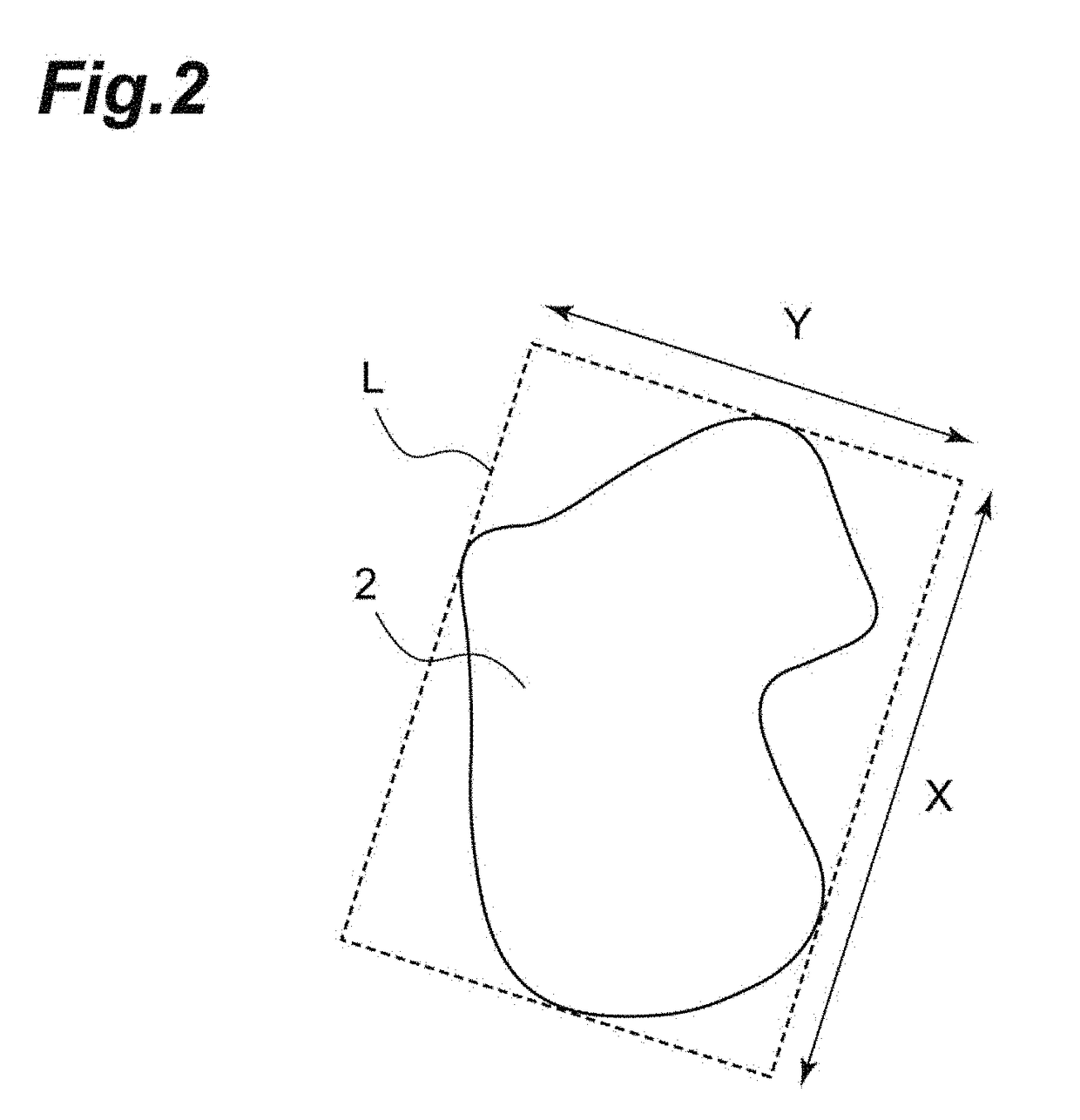

Aerogel composite, and supporting member and heat insulation material provided with aerogel composite

ActiveUS20170283269A1Good thermal insulation propertiesIncrease flexibilitySilicaLayered productsSilica particleThermal insulation

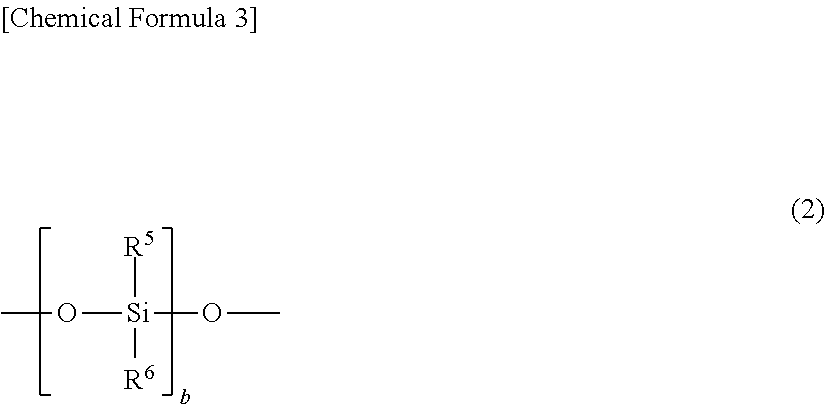

The invention relates to an aerogel composite comprising an aerogel component and a silica particle, and being superior in thermal insulation properties and flexibility.

Owner:RESONAC CORP

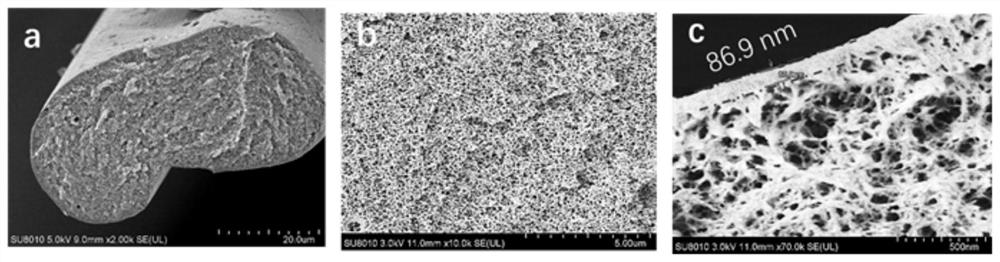

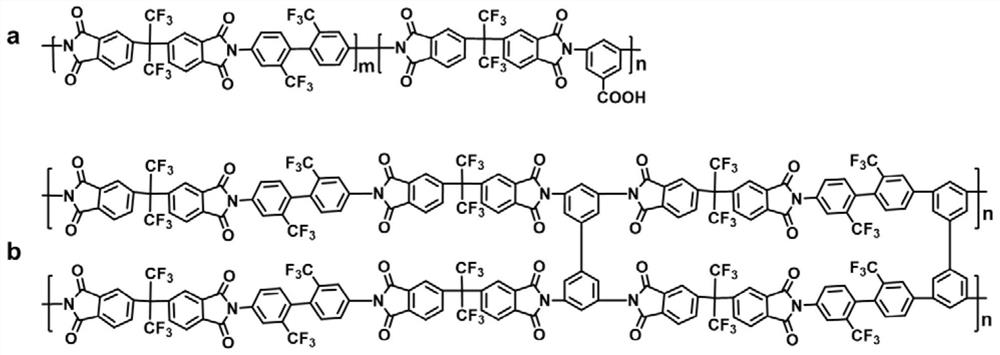

Polyimide aerogel fiber as well as preparation and application thereof

ActiveCN111808283ASimple processThe spinning process is green and environmentally friendlyArtificial filament washing/dryingArtificial filament heat treatmentDiaminePolyimide

The invention relates to a polyimide aerogel fiber as well as preparation and application thereof, and the polyimide aerogel fiber is obtained by taking a binary anhydride and a diamine as raw materials through wet spinning and freeze drying. The method is simple to operate, environment-friendly in process and beneficial to large-scale production. The polyimide aerogel fiber material prepared by the method is high in strength and good in heat resistance, has excellent heat insulation and preservation characteristics, and can be widely applied to the field of preparation of various heat insulation and preservation.

Owner:DONGHUA UNIV

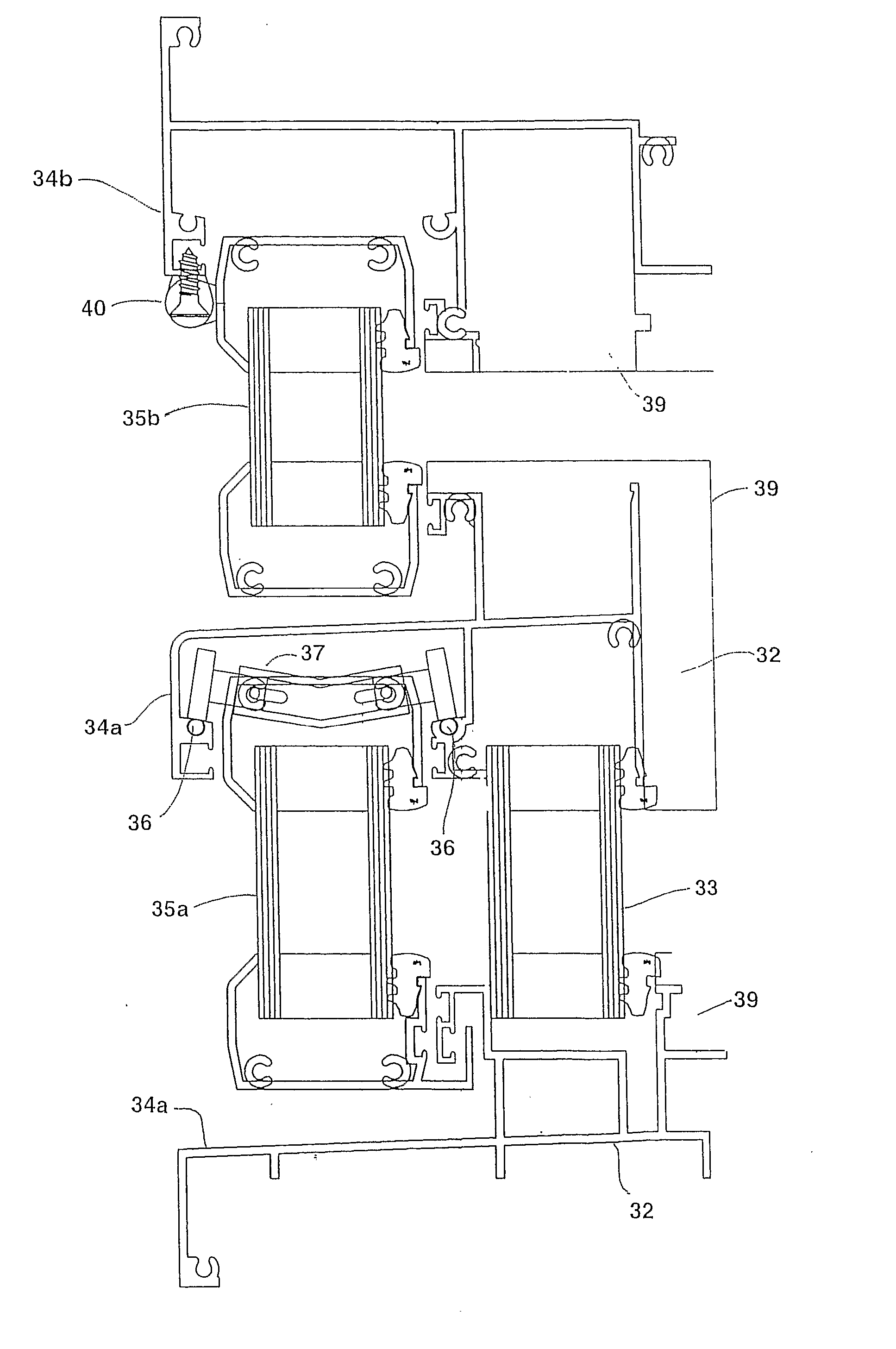

Joinery system

InactiveUS20070186494A1Good thermal insulation propertiesImproved aesthetic appeal to consumersWing arrangementsWing framesElectrical and Electronics engineeringSurface plate

A joinery assembly which includes a fixed panel form (32) is adapted to receive and locate a fixed panel (33), where at least a portion of the exposed surfaces of the fixed panel form are covered by a cladding material (39). The joinery system also includes a movable panel forms (34a, 34b), each adapted to receive a movable panel such as a sliding panel (35a) and / or a hinged panel (35b) respectively, where each of the movable panels has an interior surface and an exterior surface. At least a portion of the interior surface of a movable panel received by a movable panel form is covered by the cladding material applied to the exposed surfaces of the fixed panel form.

Owner:HPJ HLDG

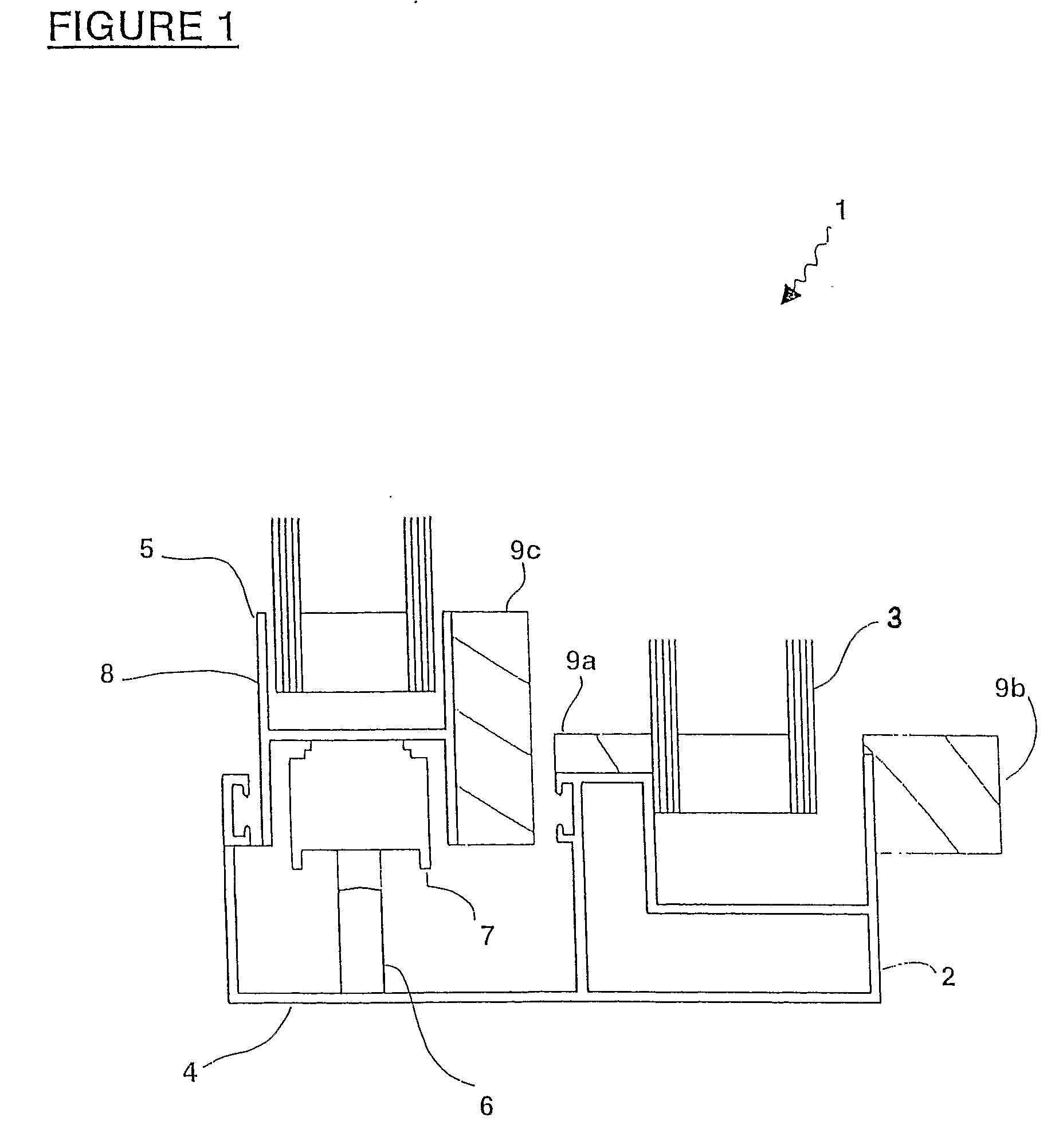

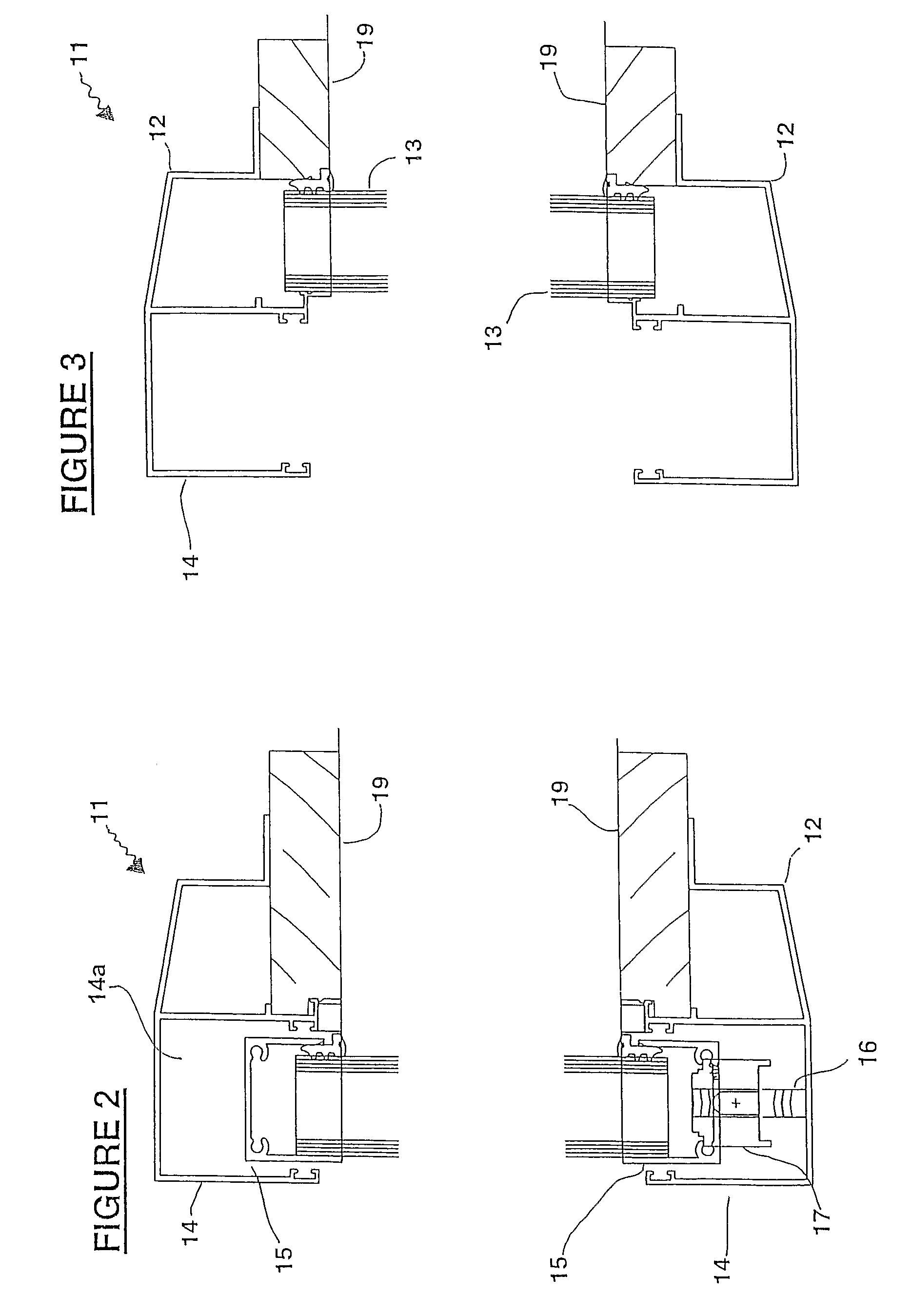

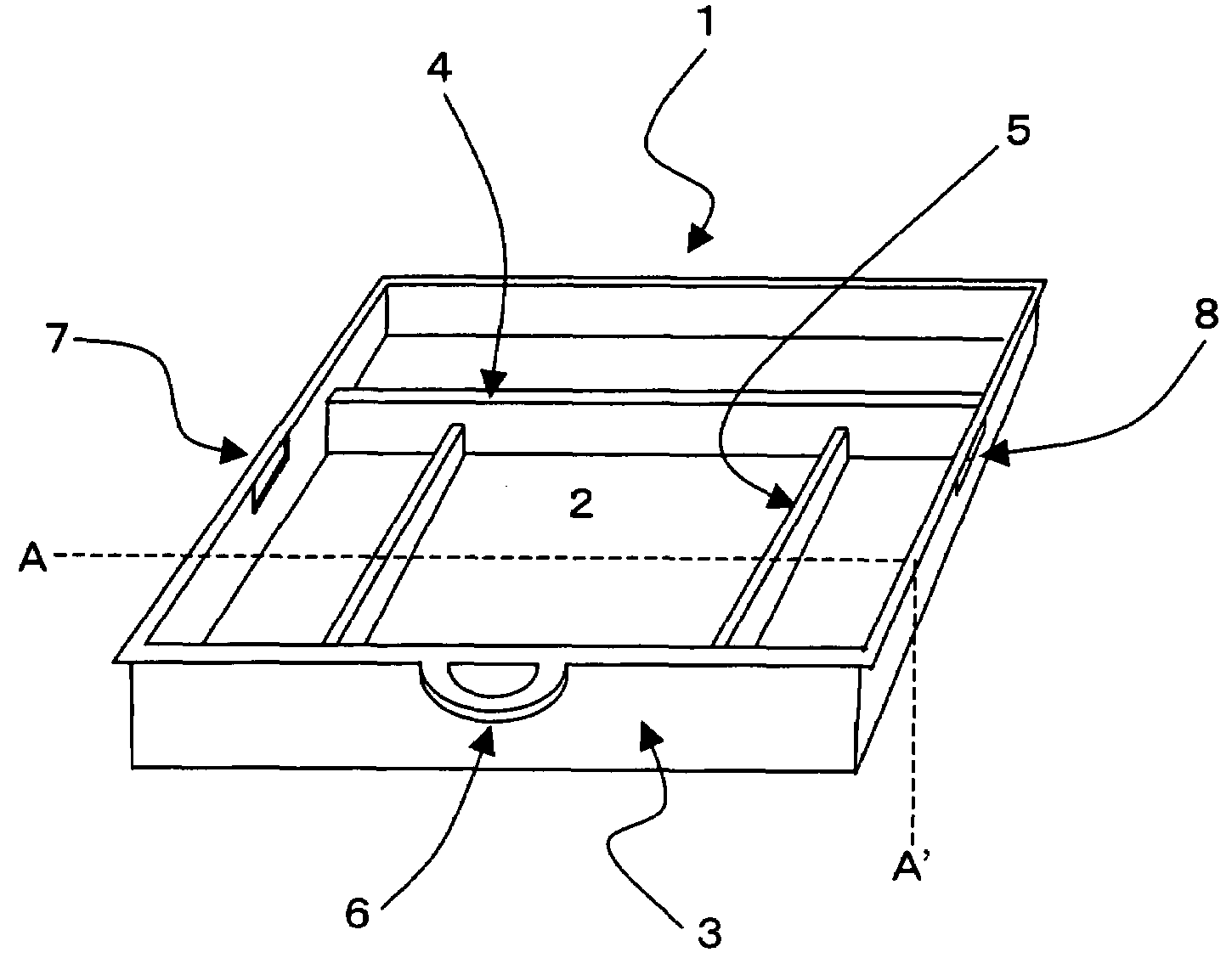

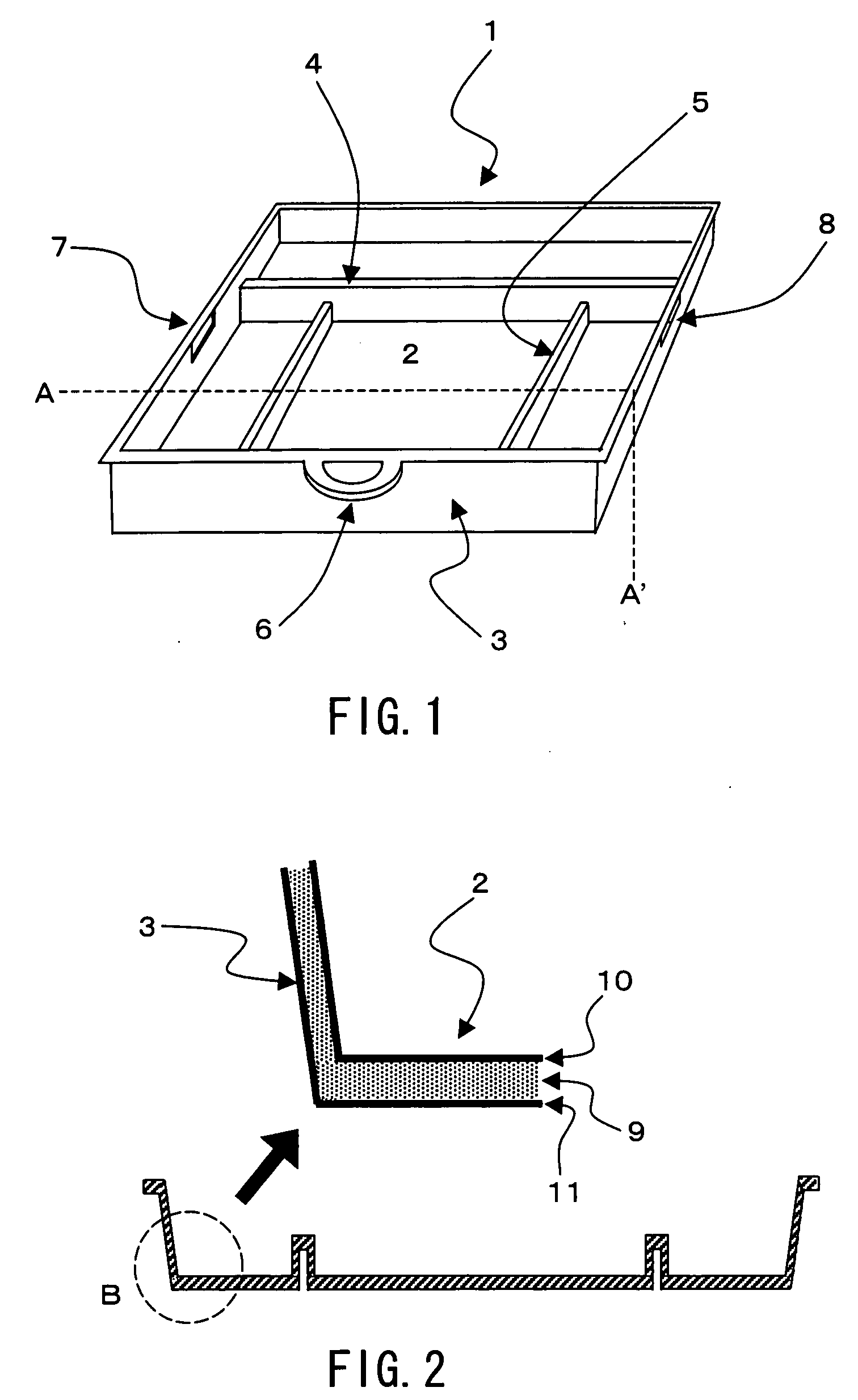

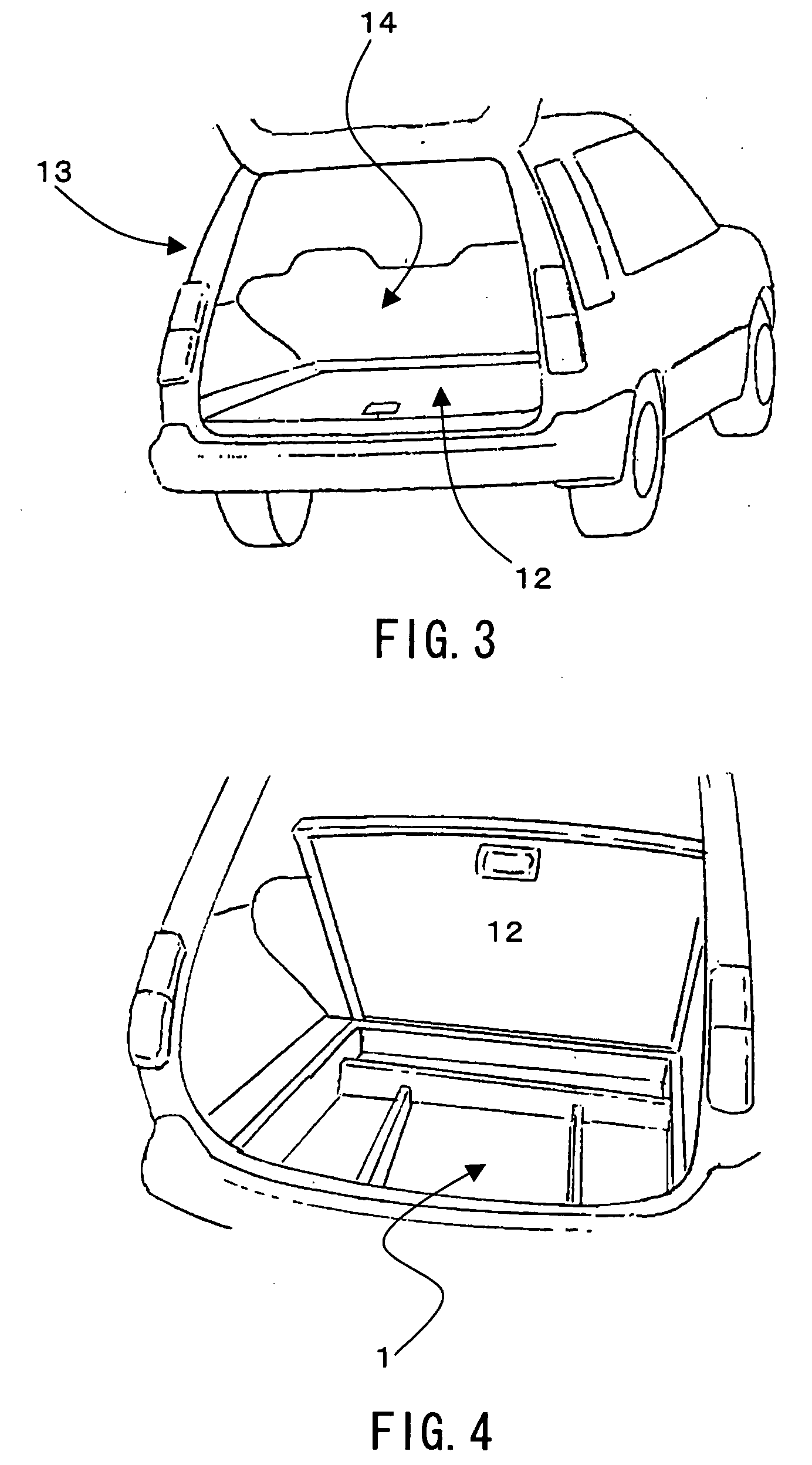

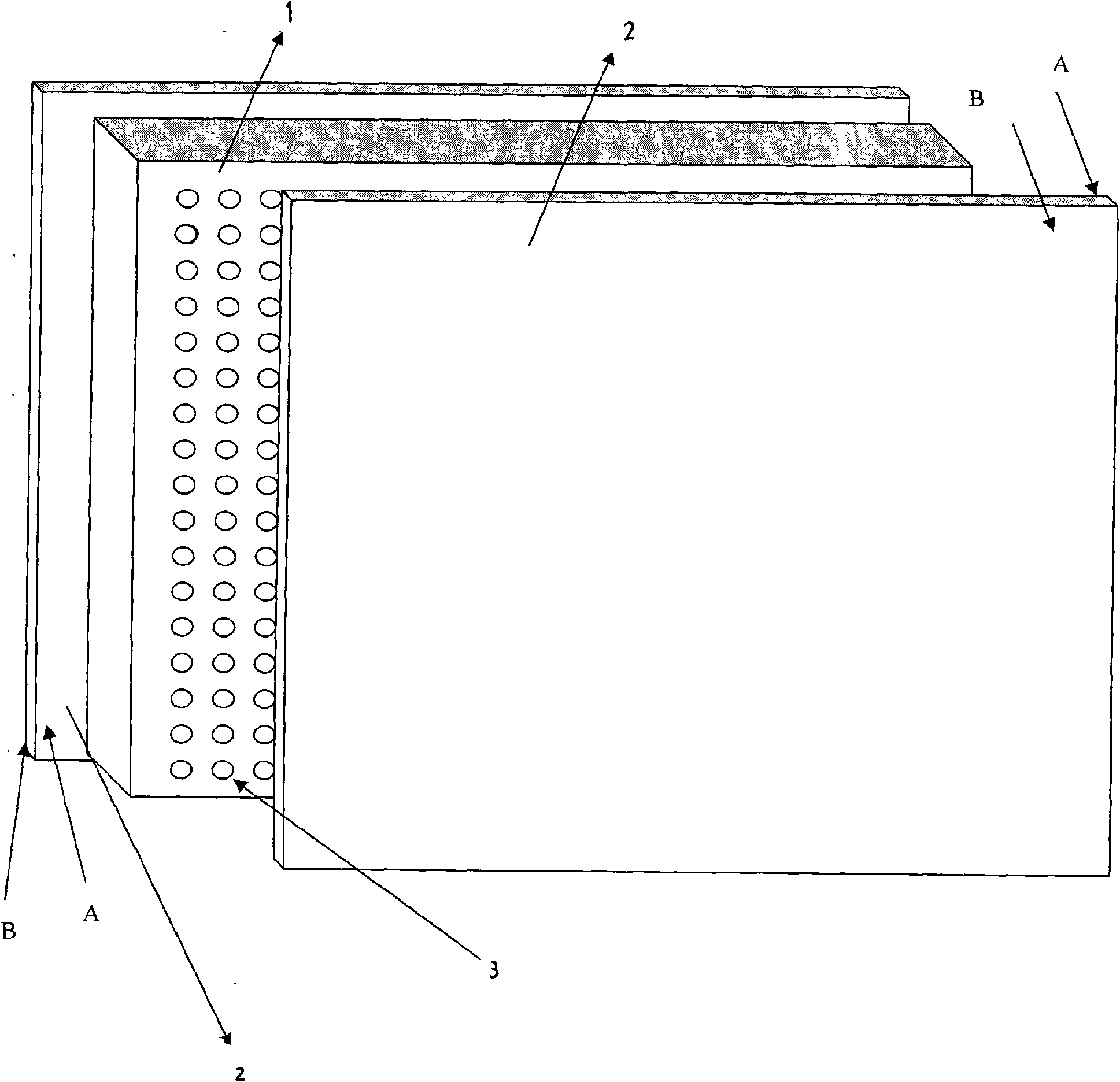

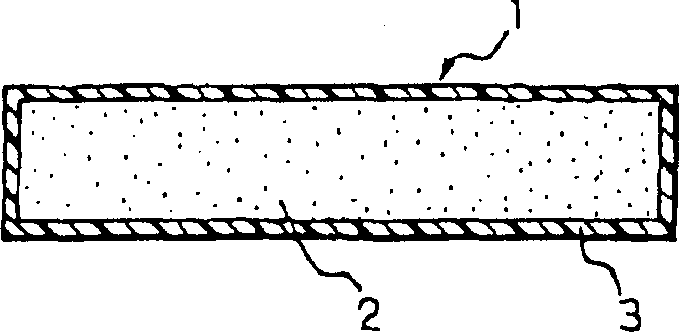

Automotive Luggage Box

InactiveUS20080302843A1Sufficient lightnessSolve the lack of rigidityLuggage compartmentSupplementary fittingsTrunk compartmentEngineering

The present invention provides an automotive luggage box that has sufficient lightness and rigidity and that is excellent in thermal insulating properties and surface appearance / hardness. More specifically, the present invention relates to an automotive luggage box that is a luggage box 1 installed on a luggage compartment floor inside an automobile. The luggage box 1 includes a bottom face portion 2, and an upright wall portion 3 that is integral therewith. Both the bottom face portion 2 and the upright wall portion 3 are made of an injection foam molded article of a thermoplastic resin, having a foam layer 9, and non-foam layers 10 and 11 that are formed on the surface of the foam layer 9.

Owner:KANEKA CORP

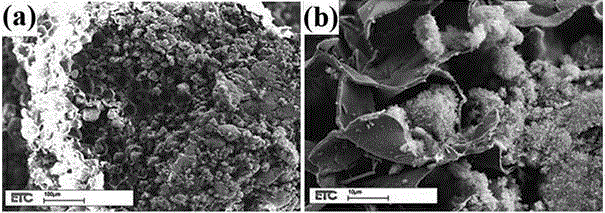

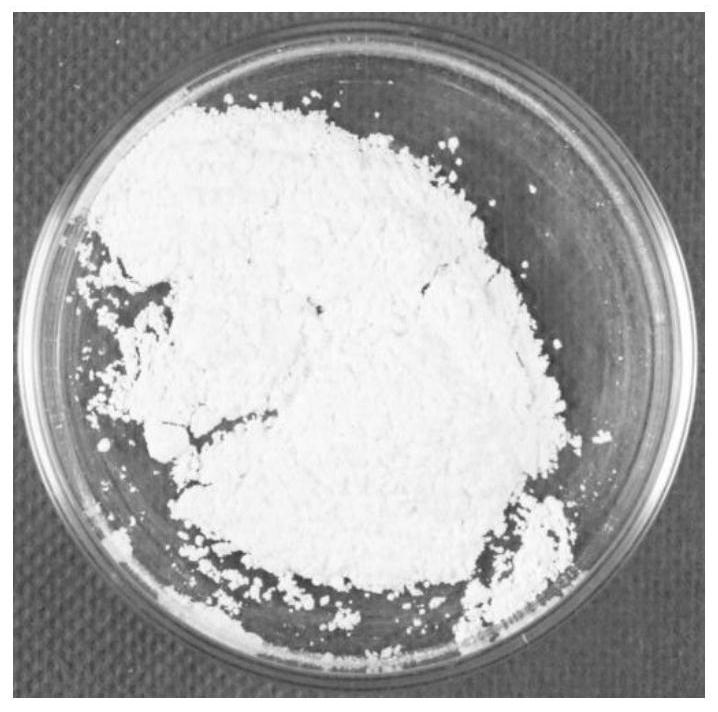

Cork-powder-based porous composite material and preparation method and application thereof

InactiveCN105058541ALow costGreat application potentialDomestic articlesFlat articlesAviationThermal insulation

The invention discloses a cork-powder-based porous composite material and a preparation method and application thereof, and belongs to the field of thermal insulation materials. Cork powder and fumed silica serve as main materials. The preparation method includes the following steps that the cork powder with the particle size of 0.15-1 mm is selected, and structure reforming is conducted on the cork powder through a microwave preprocessing method; and the cork powder is mixed with the fumed silica to obtain composite powder, pressure of 2-20 tons is exerted for 1-20 minutes, and then the cork-powder-based porous composite material can be obtained. According to a vacuum insulation panel compound core prepared according to the method, micro materials of the core material can be regulated and controlled on the aspect of the micrometer and nanometer size, and the core material is uniform in microstructure and low in heat conduction coefficient and has great application prospects in the heat preservation fields of aerospace aviation, construction, traffic transportation, household appliances and the like. In addition, the preparation method has the beneficial effects that the process is simple, cost is low, conditions can be easily controlled, the preparation cycle is short, no special devices are needed, and the preparation method is suitable for large-scale production.

Owner:FUJIAN AGRI & FORESTRY UNIV

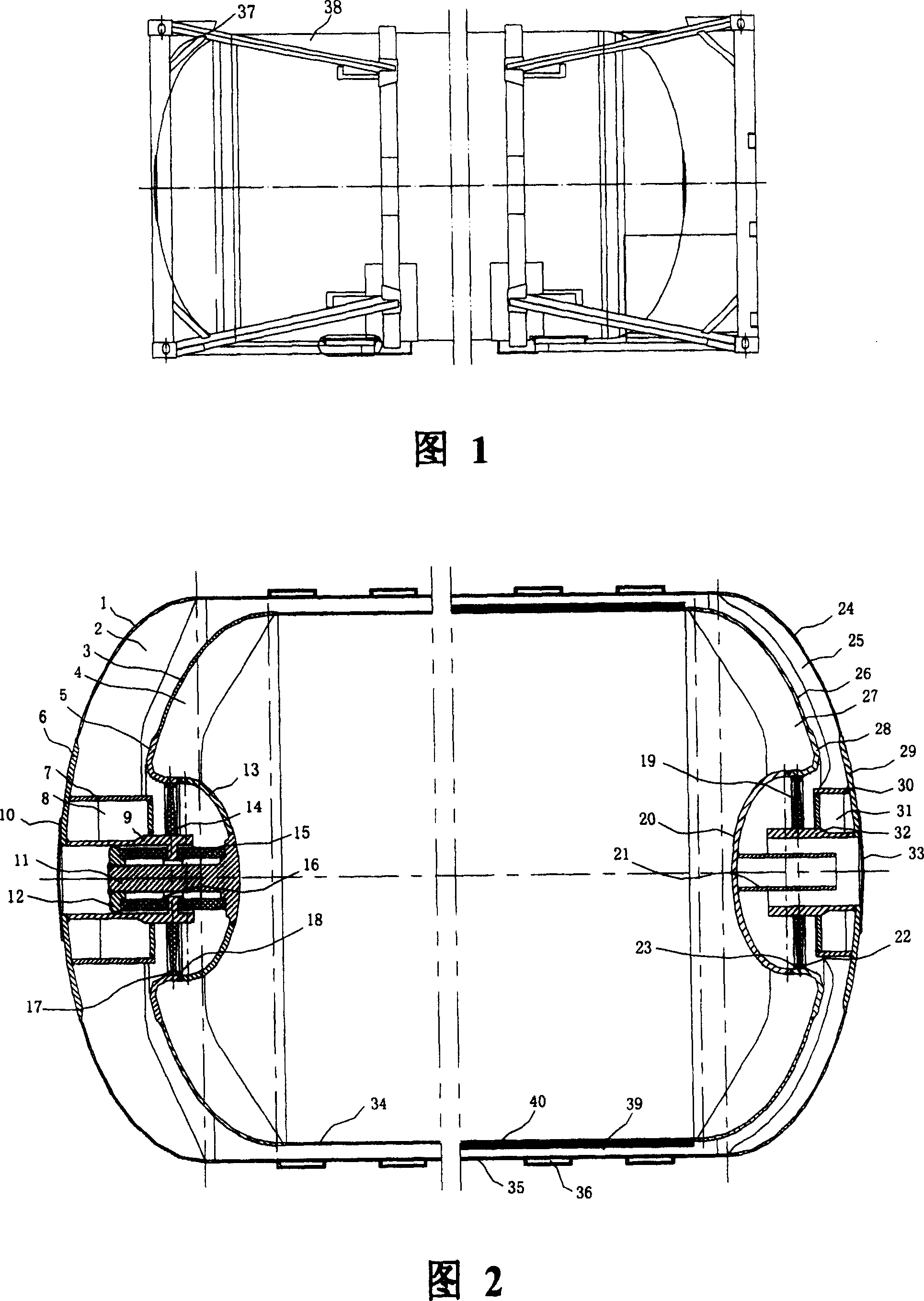

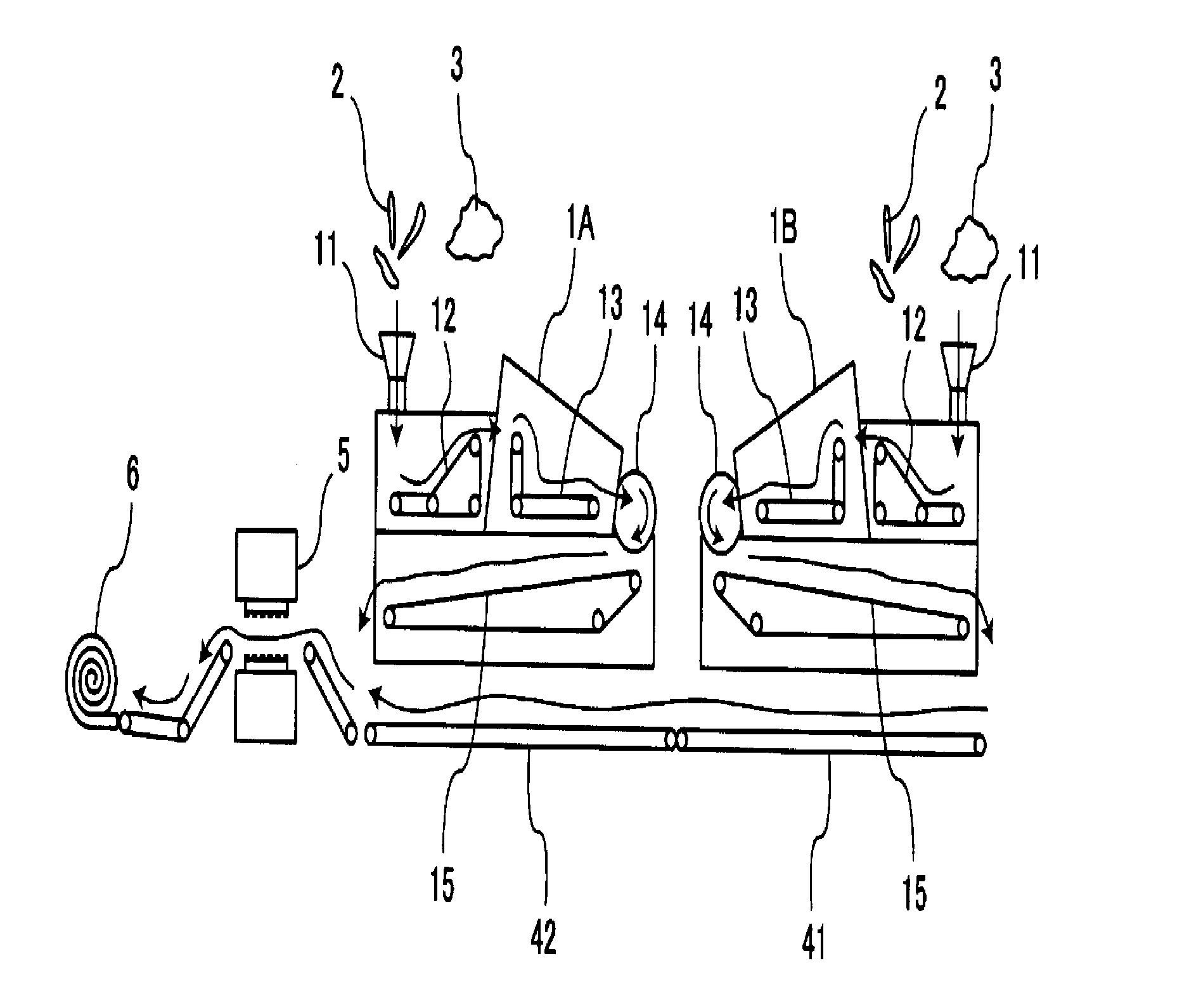

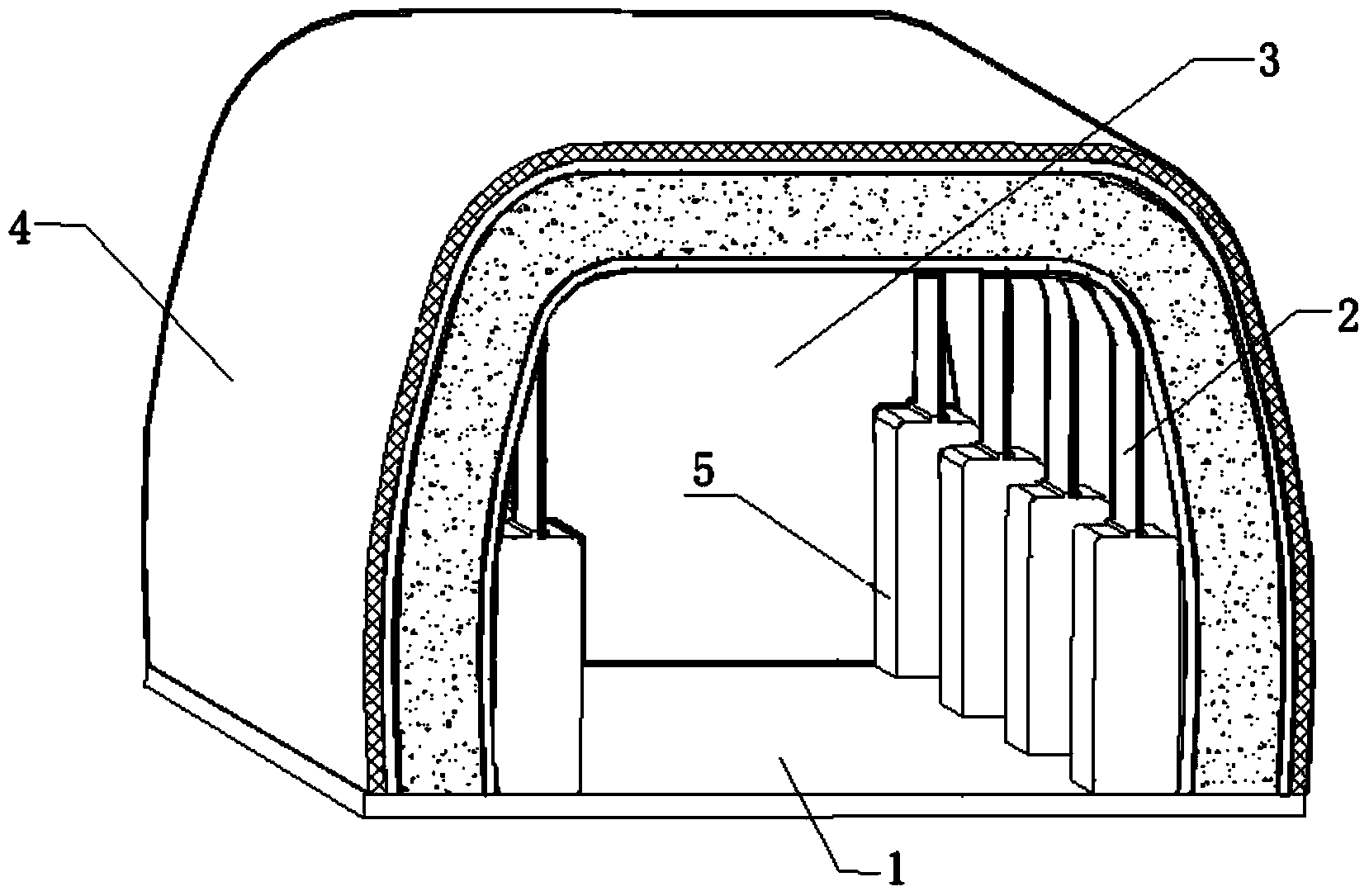

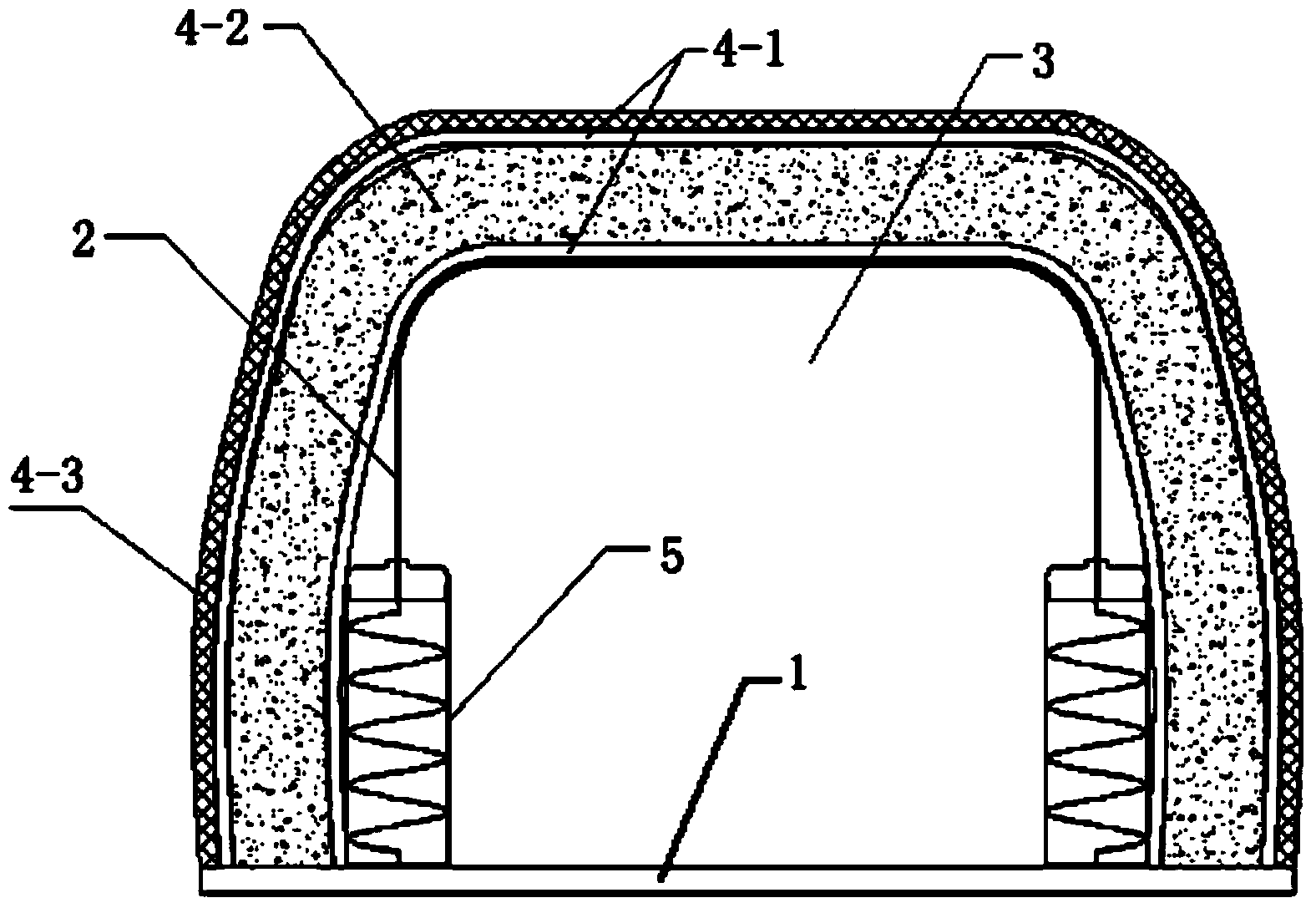

High vacuum heat insulation low temperature liquefied gas storage tank

ActiveCN1333198CIncrease effective volumeReduce heat transfer areaVessel mounting detailsVessel manufacturingAxial LoadingsEngineering

A super-vacuum insulation tank for cryogenic liquefied gas comprises a framework; and a tank body including an outer shell, an inner vessel, and a combined support structure connecting the outer shell and inner vessel. The combined support structure is only provided between the dome ends of the out shell and inner vessel at both ends of the tank, which can bear the force in both radial and longitudinal direction. The conduction heating surface between the inner vessel and the outer shell is small, but the support structure can bear heavy load, and the effective shipment volume of the inner vessel is large.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

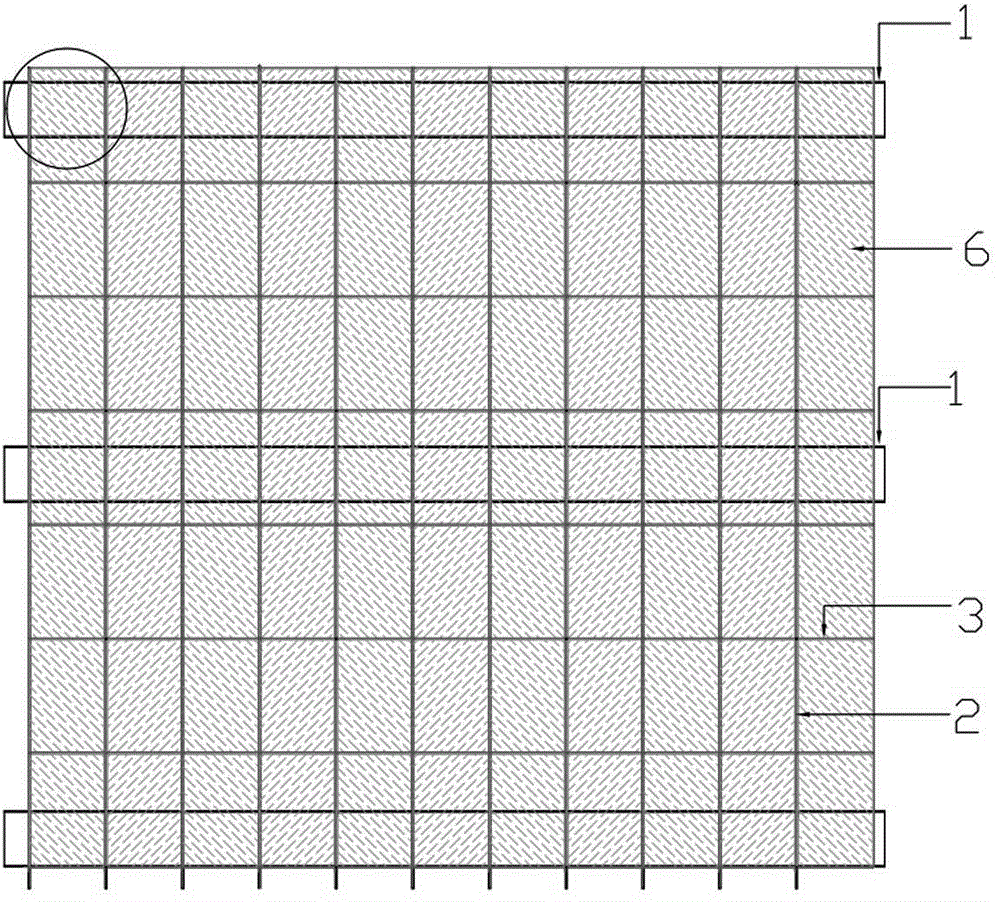

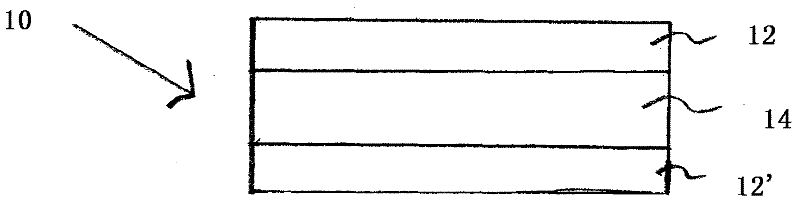

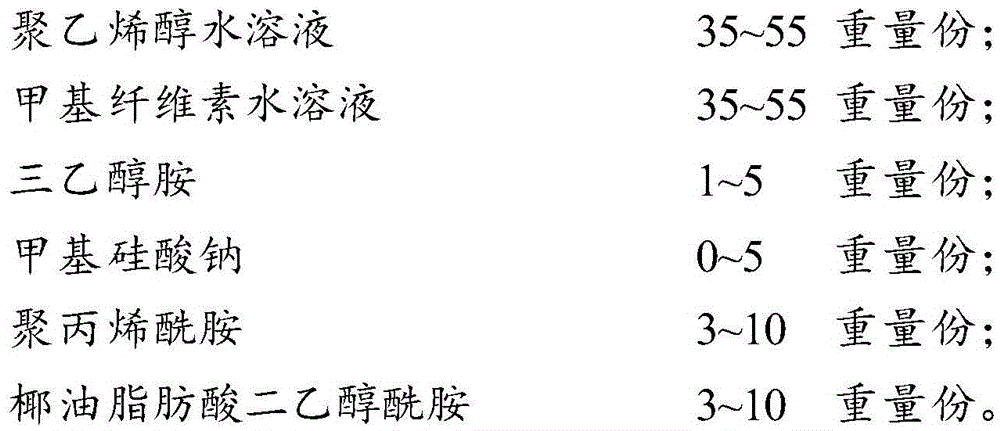

Method for preparing organic-inorganic composite thermal-insulating heat-preservation material

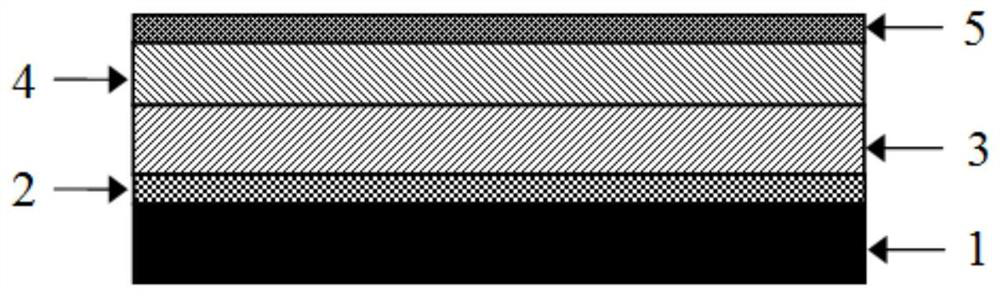

ActiveCN110682619AImprove flame retardant performanceGood heat insulationLiquid surface applicatorsSynthetic resin layered productsGlass fiberMicrosphere

The invention belongs to the field of building heat preservation materials and discloses a method for preparing an organic-inorganic composite thermal-insulating heat-preservation material. The composite thermal-insulating heat-preservation material is prepared by means of laying: a release membrane, inorganic powder packing, a low-density hollow microsphere / glass fiber mesh, an aerogel, a phenolic resin solution / glass fiber mesh, inorganic powder packing and a release membrane, and by using a hot-pressing integral molding method after laying is completed. In addition to light weight and goodthermal insulation, mechanical properties of the composite thermal-insulating heat-preservation material disclosed by the invention are improved to a certain extent, and the composite thermal-insulating heat-preservation material has the potential of large-scale application in fields of heat preservation and thermal insulation of inner walls of buildings, and the like.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Mat material and method for manufacturing the same

InactiveUS20120115387A1Improve flame retardant performanceDecreased specific heat capacityLayered productsNeedling machinesFiberGlass fiber

A lightweight mat material having excellent sound absorption and thermal insulation properties comprises a mixture of glass fibers and sheath-core composite fibers, wherein the melting temperature of the sheath portion is lower than the melting temperature of the core portion. The glass fibers are fused with the sheath portions of the composite fibers by melting on at least one surface of the sheet-shaped mat material.

Owner:NAKAGAWA SANGYO

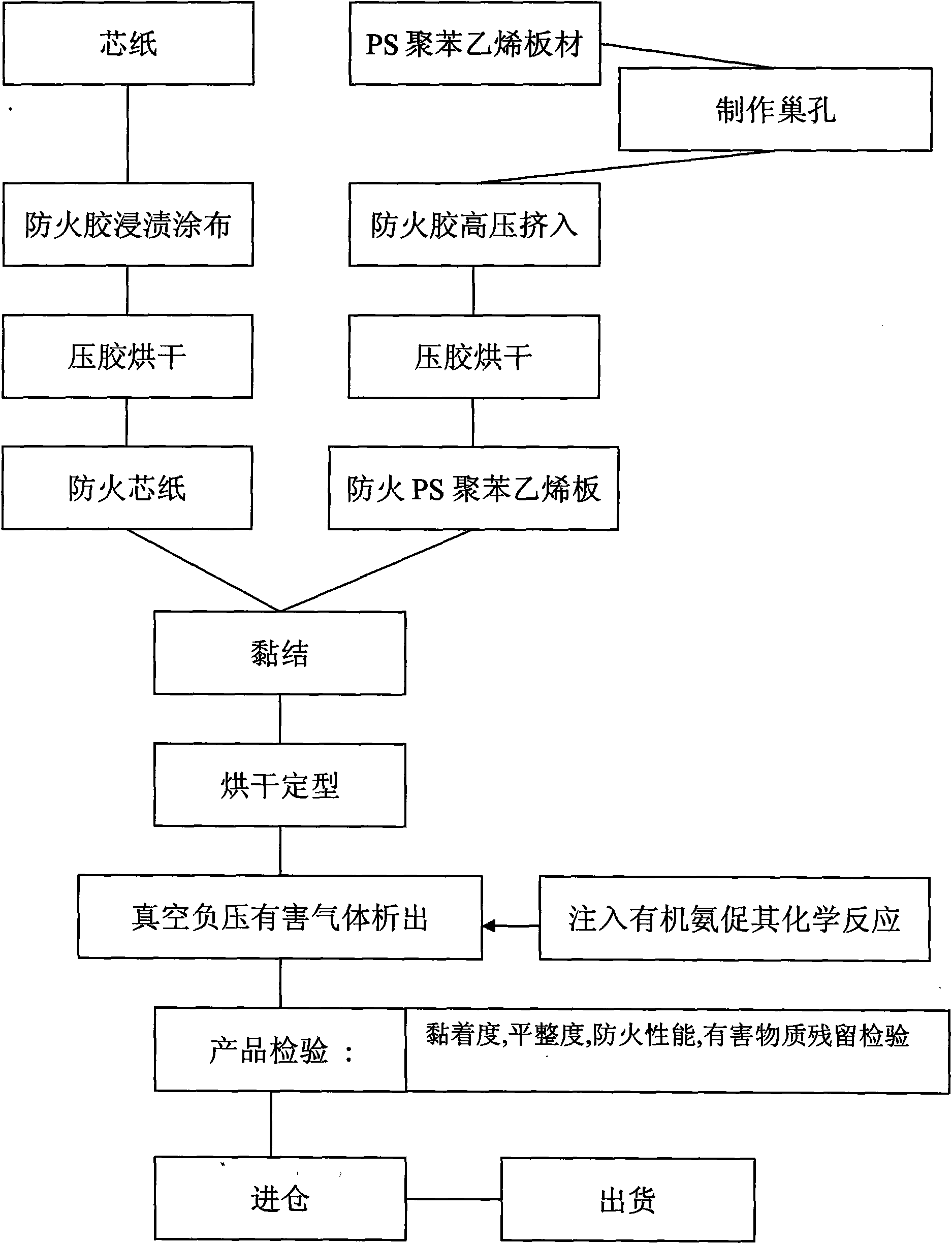

Fireproof plate

InactiveCN101602278AEasy to installLow costLamination ancillary operationsSynthetic resin layered productsChemical reactionHoneycomb

The invention discloses a fireproof plate. A method for preparing the fireproof plate comprises the following steps of: 1, preparing high-efficiency fireproof glue; 2, preparing honeycomb type dense cells on a polystyrene plate; 3, squeezing the high-efficiency fireproof glue in the dense cells on the polystyrene plate in a high-pressure mode; 4, impregnating core paper by the high-efficiency fireproof glue, and drying and shaping the core paper to prepare the fireproof core paper for standby; 5, gluing the fireproof core paper on double sides of the polystyrene plate after fireproof treatment by the high-efficiency fireproof glue; 6, coating waterproof hardening glue on the surface of the fireproof plate; 7, pressing and shaping; 8, performing the negative pressure chemical reaction on the fireproof plate to remove aldehyde; and 9 detecting adhesiveness, smoothness, fireproof performance and residue substances such as formaldehyde of the product.

Owner:FUZHOUSNGHE RESIN MATERIALS

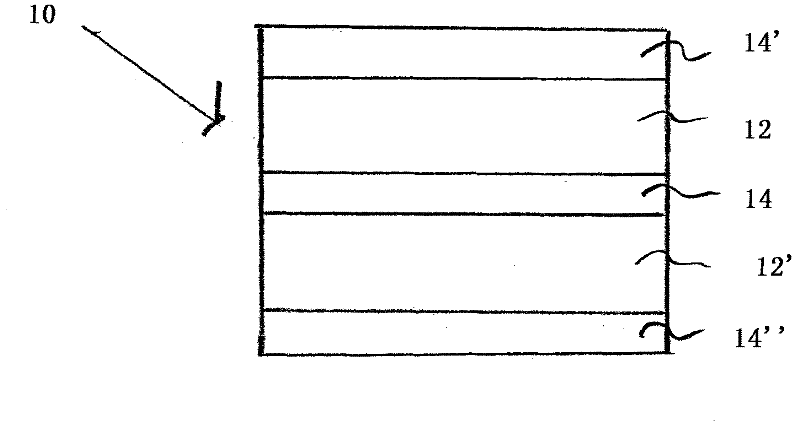

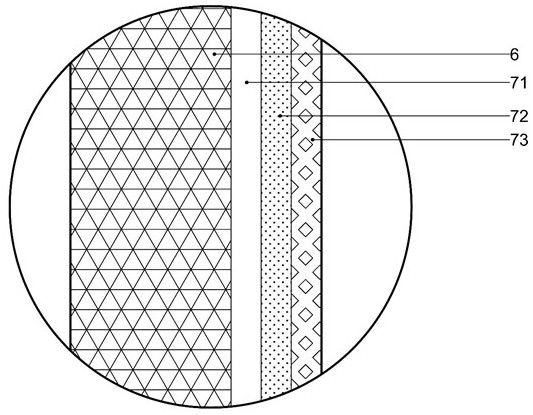

Thermal barrier/infrared low-emissivity integrated coating based on fluorescent sublayer and preparation method thereof

PendingCN113403566ALow thermal conductivityGood thermal stabilityMolten spray coatingMaterial flaws investigationFluorescenceLow emissivity

The invention relates to the technical field of high-temperature infrared stealth coatings, and particularly discloses a thermal barrier / infrared low-emissivity integrated coating based on a fluorescent sublayer, the thermal barrier / infrared low-emissivity integrated coating is of a multi-layer structure, and the thermal barrier / infrared low-emissivity integrated coating sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a rare earth fluorescent sublayer and an infrared low-emissivity layer from inside to outside. According to the thermal barrier / infrared low-emissivity integrated coating disclosed by the invention, aiming at the urgent application requirements of thermal shock resistance life prolonging and external field in-situ detection of a high-temperature infrared stealth coating, the rare earth fluorescent sublayer is added into the ceramic layer by combining a rare earth fluorescent sublayer technology, a thermal barrier ceramic layer technology and a high-temperature infrared low-emissivity coating technology; and damage indication of the infrared low-emissivity layer is achieved, and meanwhile by means of the low infrared emissivity characteristic of the high-temperature low-emissivity coating and the excellent heat insulation characteristic of the ceramic layer, the thermal barrier / infrared low-emissivity integrated coating has the heat insulation performance and the high-temperature infrared stealth performance.

Owner:NAT UNIV OF DEFENSE TECH

A kind of preparation method of composite silica airgel felt

ActiveCN110922095BPrevent powder dropGood thermal insulation propertiesCeramicwareFiberThermal insulation

The invention belongs to the field of thermal insulation materials, and discloses a preparation method of a composite silica airgel felt. Mix water, silica airgel powder, resin, curing agent, and low-density microspheres evenly to obtain airgel slurry; impregnate multiple single-layer fiber mats in the airgel slurry to obtain multiple Single-layer airgel fiber mat; then stack multiple single-layer airgel fiber mats together to obtain multi-layer airgel fiber mat; heat the multi-layer airgel fiber mat at 80~90°C for 1~3 h, and then 100~120°C for 1~4 hours, and finally 140~160°C for 1~3 hours to cure, and then get the composite silica airgel felt. The present invention enhances the mechanical properties of the airgel felt without affecting the heat insulation effect of the airgel felt, overcomes the problem of powder falling off of the traditional silica airgel felt, and reduces the airgel in storage and transportation. Dust pollution problems during installation and use.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

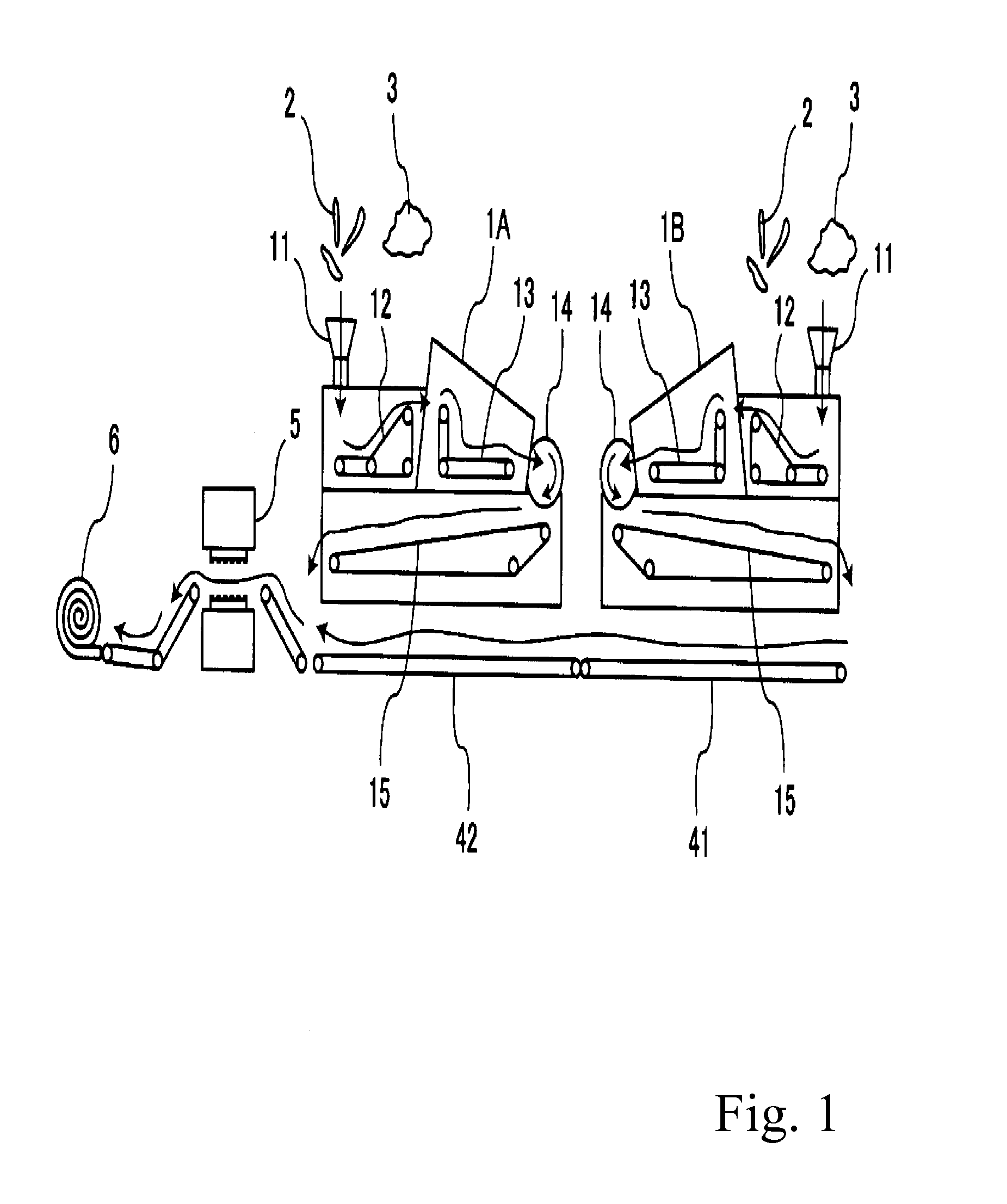

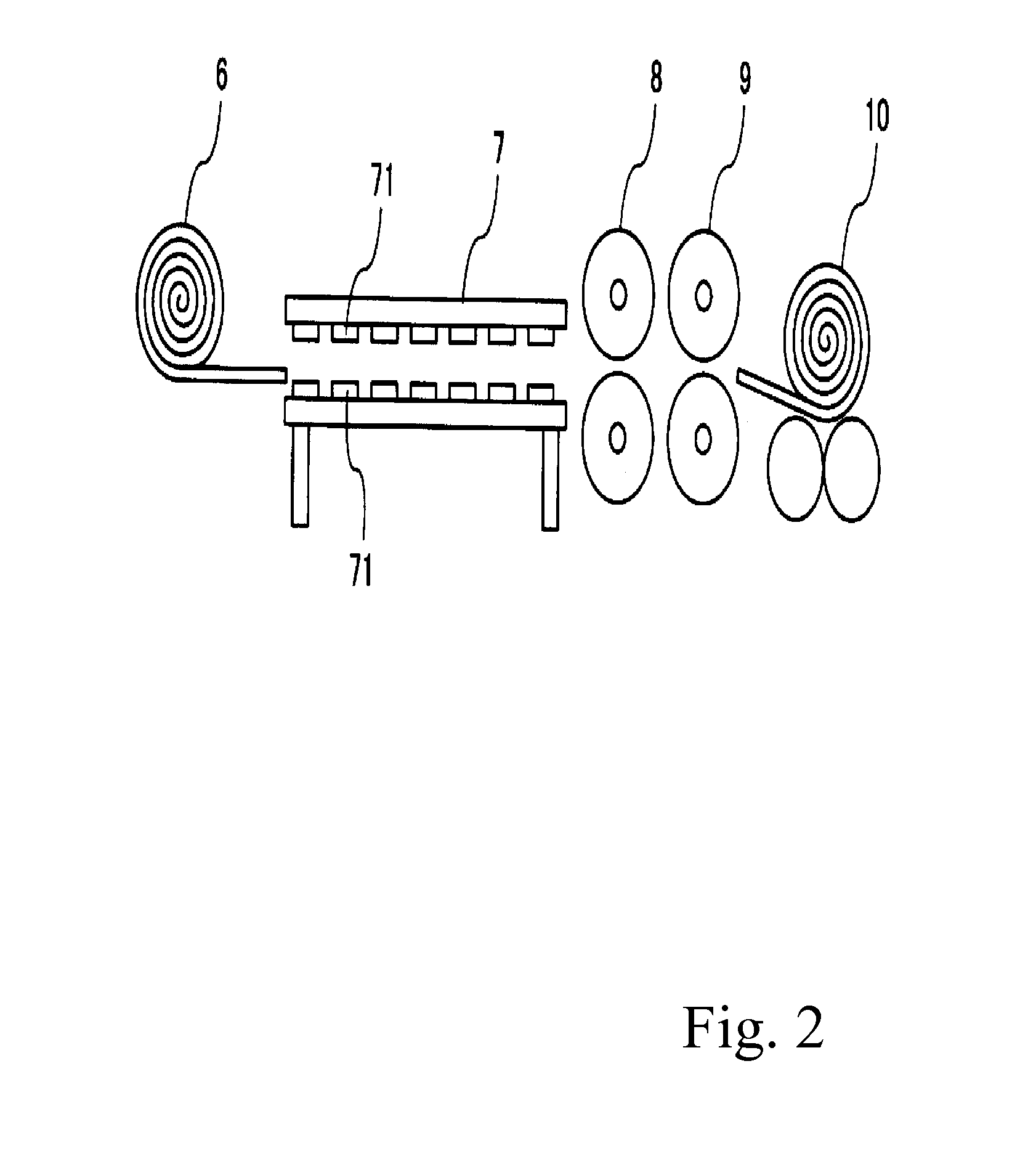

Building board and method for producing building board

InactiveUS20140287220A1Good thermal insulation propertiesImprove design qualitySolid waste managementSynthetic resin layered productsSolid contentCoating

A building board includes an inorganic board having a surface covered by an insulating coating film containing a coating film forming material and organic hollow particles, wherein the organic hollow particles have an average particle size in the range of 5 to 50 μm and an average hollow ratio of 80% or more, and the insulating coating film contains 0 01 to 5.0 parts by mass of the organic hollow particles per 100 parts by mass of solid content thereof, and has an average thickness of 5 to 500 μm. The method for producing a building board includes: applying, onto a surface of an inorganic board, an insulating coating material containing a coating film forming material and organic hollow particles; and drying the insulating coating material to form an insulating coating film.

Owner:NICHIHA CORP

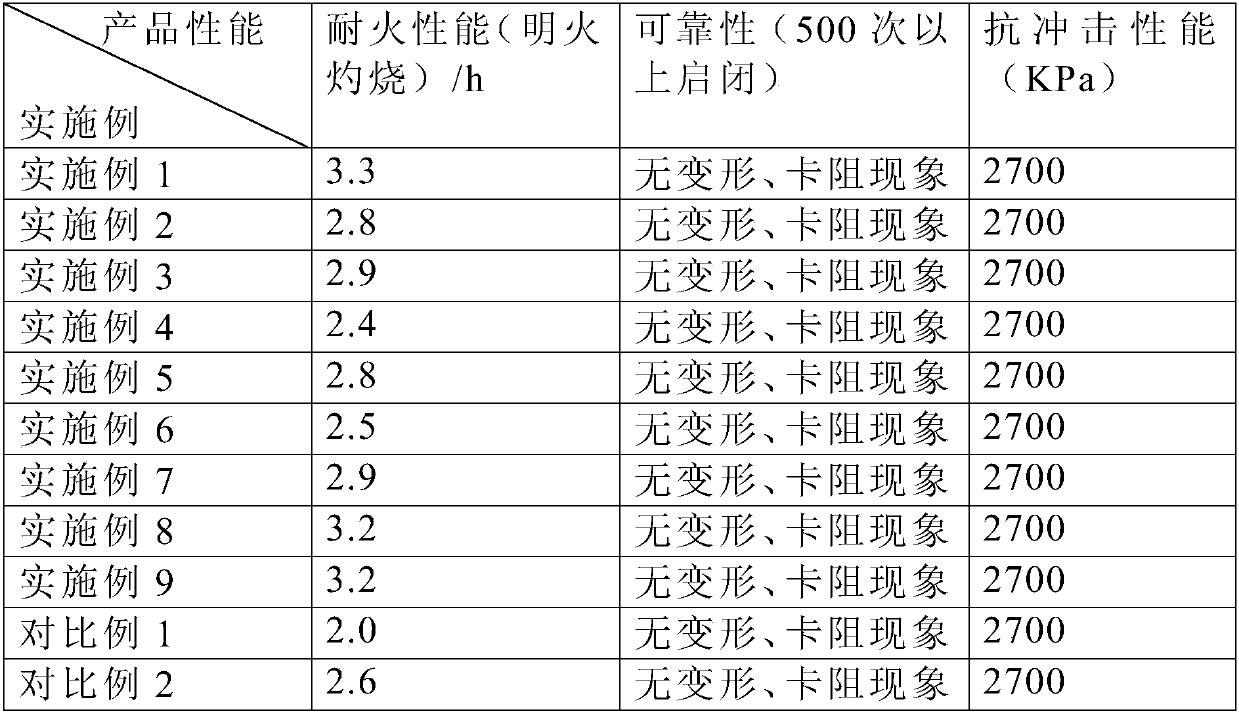

High-performance fireproof plate and preparation method thereof

The invention discloses a high-performance fireproof plate and a preparation method thereof, and belongs to the technical field of fireproof materials. The high-performance fireproof plate sequentially comprises a plate core, fireproof plate bodies and veneers from inside to outside, and the plate core is composed of a skeleton and a filler, wherein the skeleton is filled with the filler. The filler comprises the components of, by weight, 100-500 parts of perlite, 100-200 parts of oil sludge ash, 50-150 parts of tobermorite, 30-50 parts of sodium silicate, 10-20 parts of magnesium oxychlorideand 500-1000 parts of water, wherein the oil sludge ash comprises the components of, by weight, 50-150 parts of shale brick ash, 20-40 parts of kaolin, 30-50 parts of straw ash, 10-20 parts of slakedlime, 10-30 parts of tung oil, 30-50 parts of starch glue and 100-200 parts of water. Meanwhile, preparation of the fireproof plate comprises the three steps of skeleton preparation, plate core filling and finished product pressing and forming. The synthesized attribute of the fireproof plate can be better improved through the synergetic promotion effect of the multiple kinds of fire-resistant materials, the multilayered structure of the fireproof plate is pressed and formed through pressure, the structure is compact, and the airtightness is good.

Owner:宁波宫铁智能科技有限公司

Photocatalyst heat insulation building wall structure

PendingCN112411800AWith air purification effectWith bactericidal functionGas treatmentMechanical apparatusInsulation layerMoisture condensation

The invention discloses a photocatalyst heat insulation building wall structure. The photocatalyst heat insulation building wall structure comprises a building outer wall body and a photocatalyst layer, an inner heat preservation layer and an inner decoration layer are sequentially arranged on the inner side of the building outer wall body from inside to outside, and an outer heat preservation layer, a damp-proof layer and the photocatalyst layer are sequentially arranged on the outer side of the building outer wall body from inside to outside; and the photocatalyst layer is coated on the outer side of an outer hanging plate, and the inner side of the outer hanging plate is fixed on the building outer wall body through a keel framework. The photocatalyst layer on the surface of a buildingwall can adsorb moisture in air, and dirt is prevented from making contact with the surface of the wall; due to the wavy form and the porous characteristic of the outer hanging plate, the surface areaof the wall is increased, the moisture condensation capacity and the moisture absorption capacity of the wall surface are improved, moisture transpiration and heat absorption are achieved when the air temperature rises, thus the wall surface is cooled, and the effects of cooling, heat insulation and self-cleaning are achieved in combination with an air flowing interlayer.

Owner:NANCHANG UNIV

Composite material prepared from cork oak bark softwood and aluminum oxide and preparation method

PendingCN113354440AAdjustable pore size distributionHigh porosityCeramicwareHeat conservationThermal transmittance

The invention relates to the technical field of heat insulation and heat preservation materials, in particular to a cork aluminum oxide porous composite material prepared by utilizing the natural cell structure and flame retardant property of cork, and particularly relates to a composite material prepared from cork oak bark cork and aluminum oxide and a preparation method. The material contains the following components in parts by weight: 70-98 parts of aluminum oxide, 1-25 parts of softwood and 1-5 parts of binder, the softwood is used as a pore-forming agent, the softwood / aluminum oxide porous composite material is prepared by using the natural cellular structure and flame-retardant characteristic of the softwood, and the pore size distribution and porosity are adjustable; the cork / alumina porous composite material prepared by the invention has the advantages of high porosity, small density, high compression strength, low thermal conductivity and favorable heat insulation property, can be used as a furnace lining material of a high-temperature kiln, effectively solves the problem of shortage of high-temperature furnace lining materials in China, and has important significance for realizing energy conservation and emission reduction and improving the additional value of cork products; the material can be widely applied to the heat insulation fields of high-temperature furnaces, buildings, transportation, aerospace and the like.

Owner:山东省栓皮栎产业技术研究院有限公司 +2

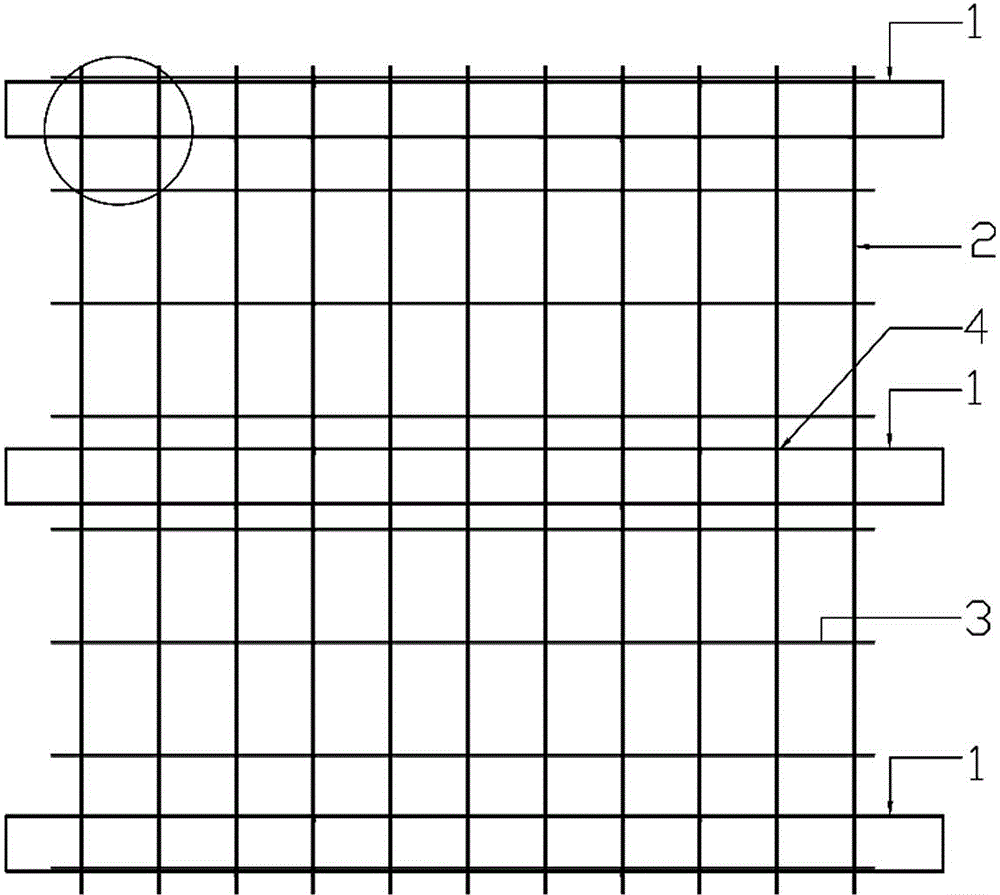

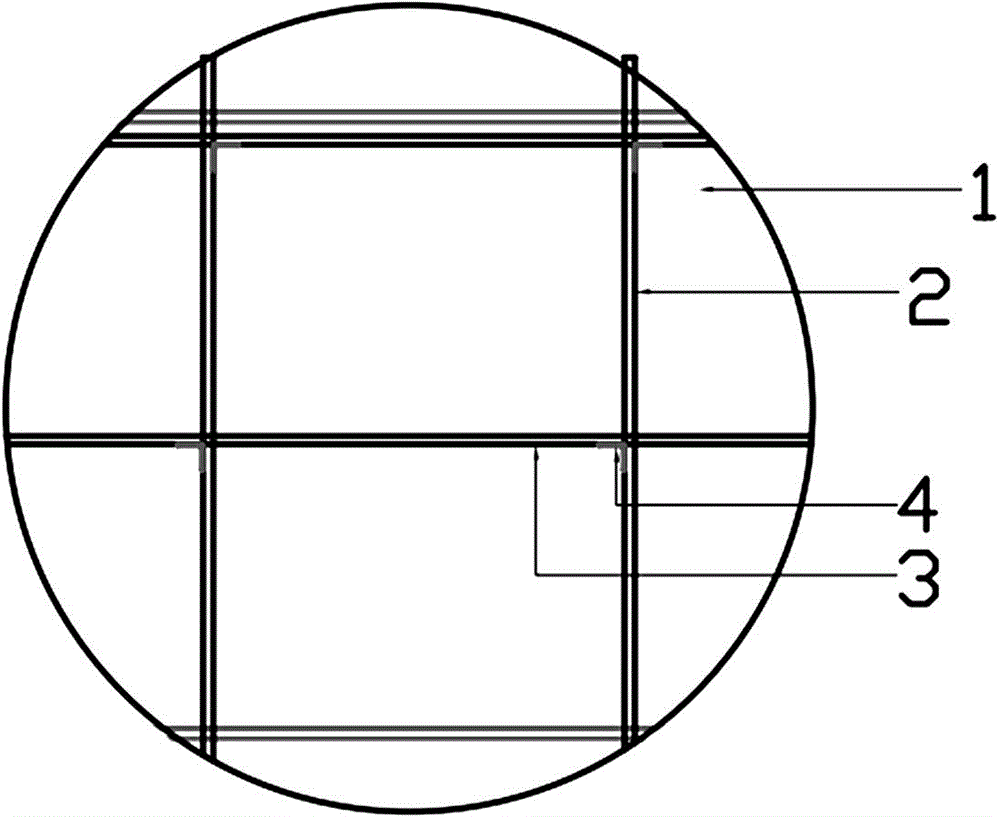

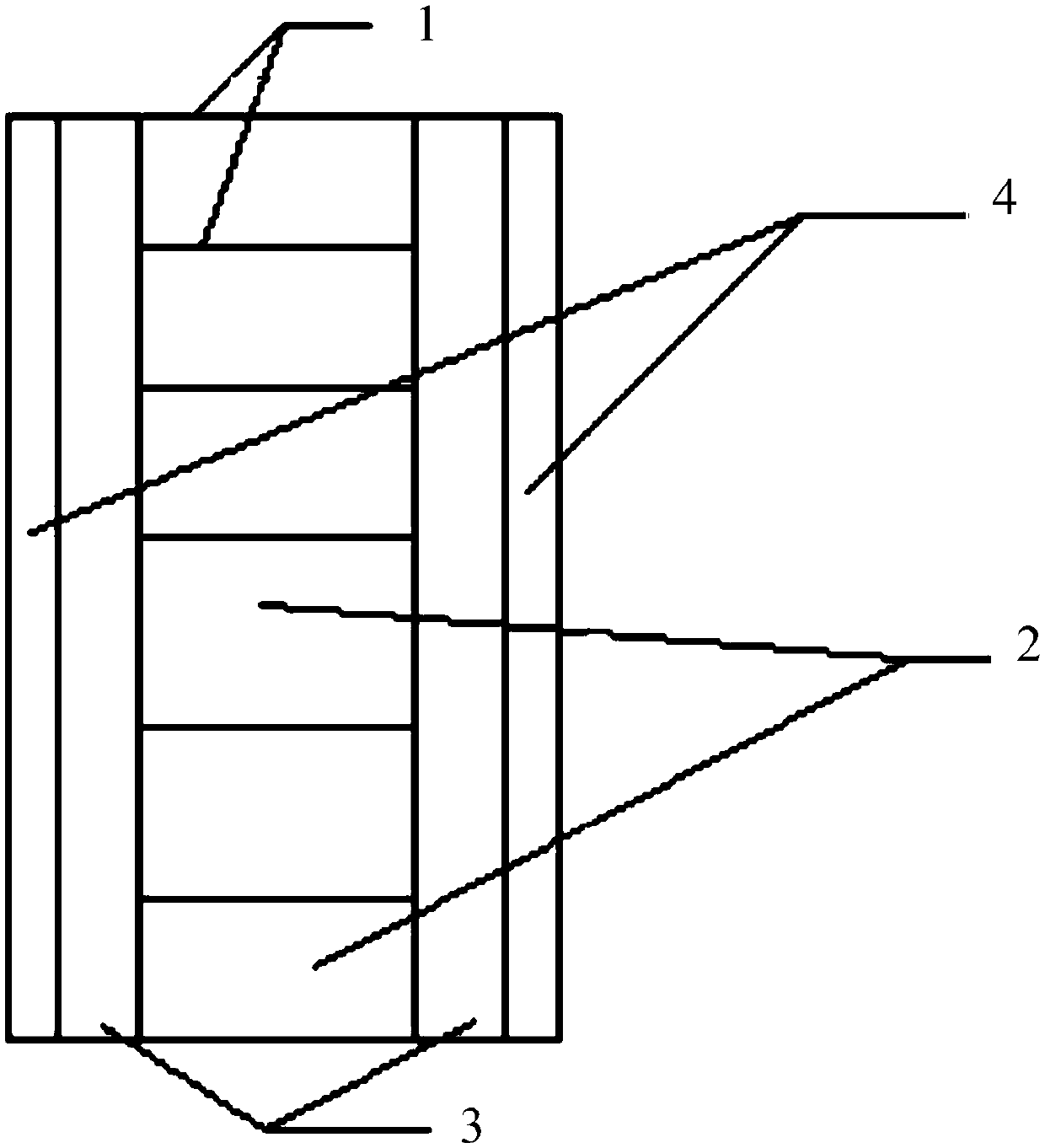

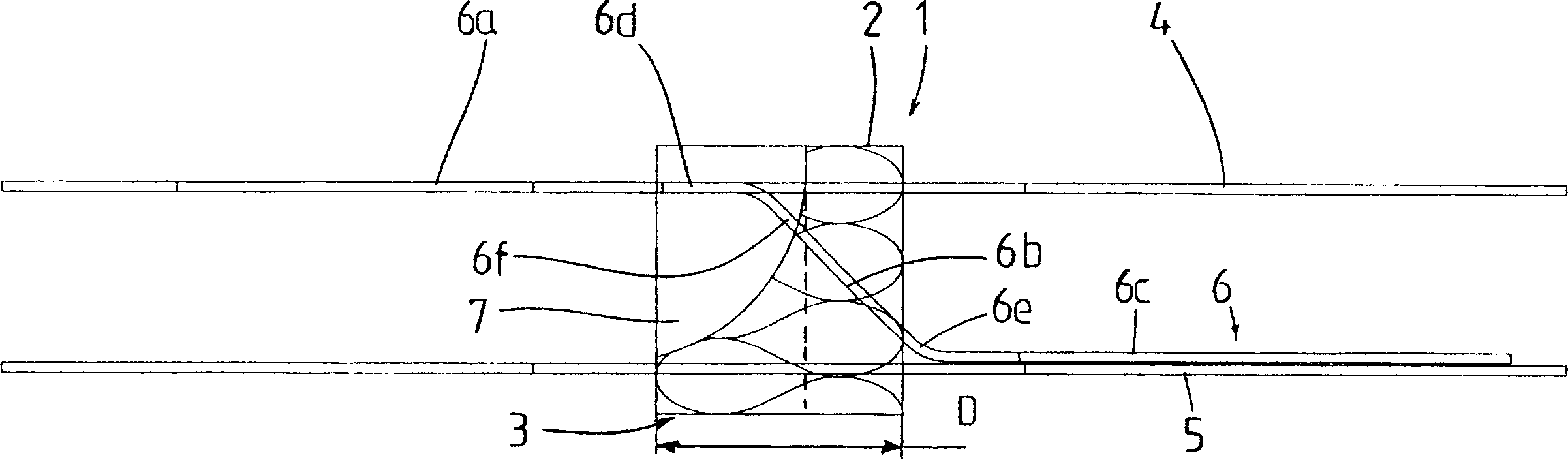

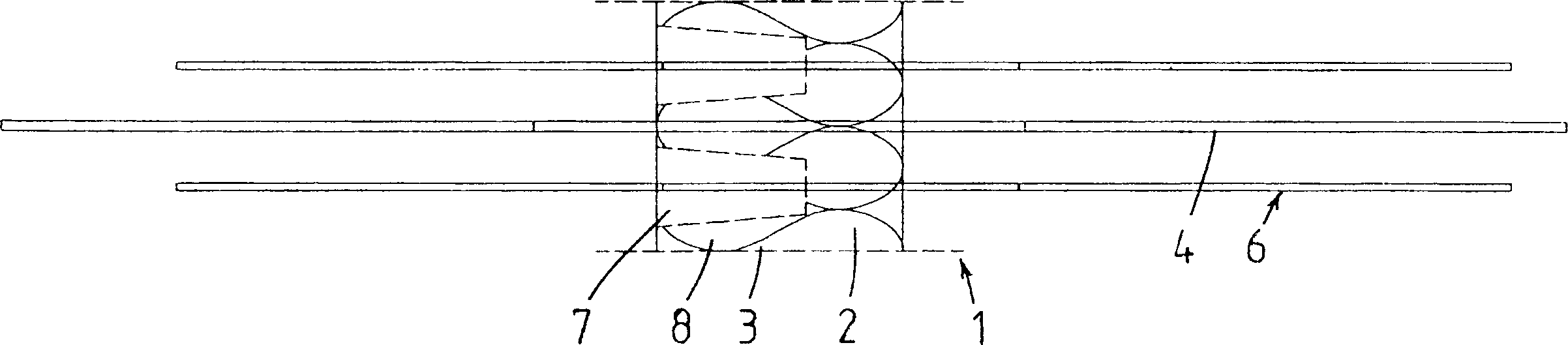

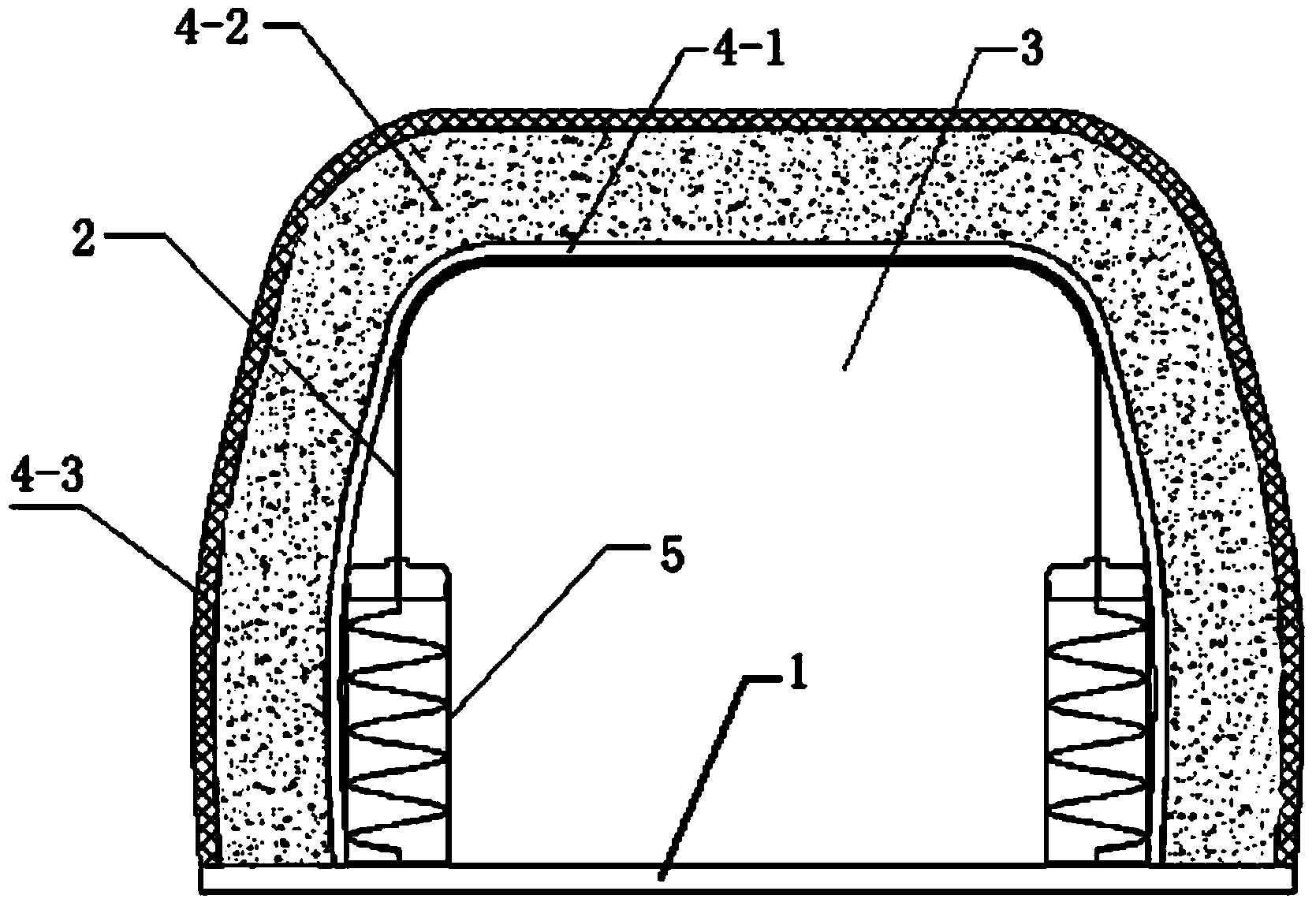

Construction element for heat insulation

InactiveCN1916308AFully supportedReduced thermal insulation performance degradationClimate change adaptationPassive housesThermal insulationArchitectural engineering

A construction element for heat insulation between two construction parts, in particular between a building part and a protruding exterior part, is provided, and includes an insulating body ( 2 ) to be arranged between the two construction parts with reinforcement elements ( 4, 5, 6 ) that can cross it and that can be connected to the two construction parts, with at least shear force rods ( 6 ) being provided as reinforcement elements. The construction element is here adjusted for the installation in passively energy conserving houses such that the insulating body is provided with a protrusion ( 3 ), which includes open recesses ( 7 ) for the upper exit sections ( 6 f) of the shear force rods ( 6 ) that extend out of the insulating body, and extend in the direction of the supporting building part to the area of the horizontally protruding shear force rod sections ( 6a ) so that it laterally overlaps the bent shear force rod sections ( 6d ) in their entirety.

Owner:SCHOCK BAUTEILE GMBH

Ceramsite composite self-heat-insulation wall material and method for preparing same

InactiveCN105645915ASimple waterproof structureGood thermal insulation propertiesFoaming agentExpanded clay aggregate

The invention provides a self-heat-insulation wall material. The self-heat-insulation wall material comprises, by weight, 30-40 parts of base materials, 0-0.5 part of polypropylene fibers, 0-60 parts of fillers, 2-8 parts of waterproofing and reinforcing agents, 1-8 parts of foaming agents, 10-30 parts of ceramsite and 9-20 parts of water. The self-heat-insulation wall material has the advantages that heat-insulation waterproofing and reinforcing for the self-heat-insulation wall material with the waterproofing and reinforcing agents are designed by means of adding special auxiliaries into the base materials, and the base materials, the special auxiliaries, the foaming agents and the ceramsite are jointly blended to obtain the novel light, heat-insulation and waterproof self-heat-insulation wall material; excellent waterproof structures can be particularly formed by the aid of the specific waterproofing and reinforcing agents and the ceramsite, and accordingly the self-heat-insulation wall material is excellent in waterproof performance and heat-insulation characteristic and high in strength.

Owner:HAINAN UNIVERSITY

Composition for ceramics with carbon layer and manufactured method of ceramics using this

InactiveCN101646631AGood thermal insulation propertiesImprove heat resistanceClaywaresCarbon layerCeramic mold casting

Owner:金九汉

Halogen-free flame-retardant polyurethane expanded plastic

The invention belongs to the technical field of expanded plastic, and particularly relates to halogen-free flame-retardant polyurethane expanded plastic. The plastic is prepared from the following raw materials in percentage by weight: 40-80% of water, 10-20% of 1, 4-hexamethylene diisocyanate, 5-35% of polyethylene glycol adipate glycol, 2-5% of a chain extender 1, 4-butanediol, 1-5% of a halogen-free flame retardant, 0.001-0.1% of a catalyst, 0.1-1% of a foam stabilizer and 0.2-0.8% of an antioxidant. Compared with the prior art, the halogen-free flame-retardant polyurethane expanded plastic has the advantages that water is adopted as the foaming agent, so that damage caused by a fluorine-containing foaming agent such as HCFC-141b (1,1-dichloro-1-fluoroethane) to the environment is effectively avoided; the halogen-free flame retardant is added, so that the flame-retardant performance of the TPU (thermoplastic polyurethane) expanded plastic is improved; the flame retardant used does not contain halogens or heavy metal elements such as lead, cadmium, mercury, chromium and the like, so that the plastic satisfies the demand of European Union VDE (Verband Deutscher Elektrotechniker) and is a green and environment-friendly material.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

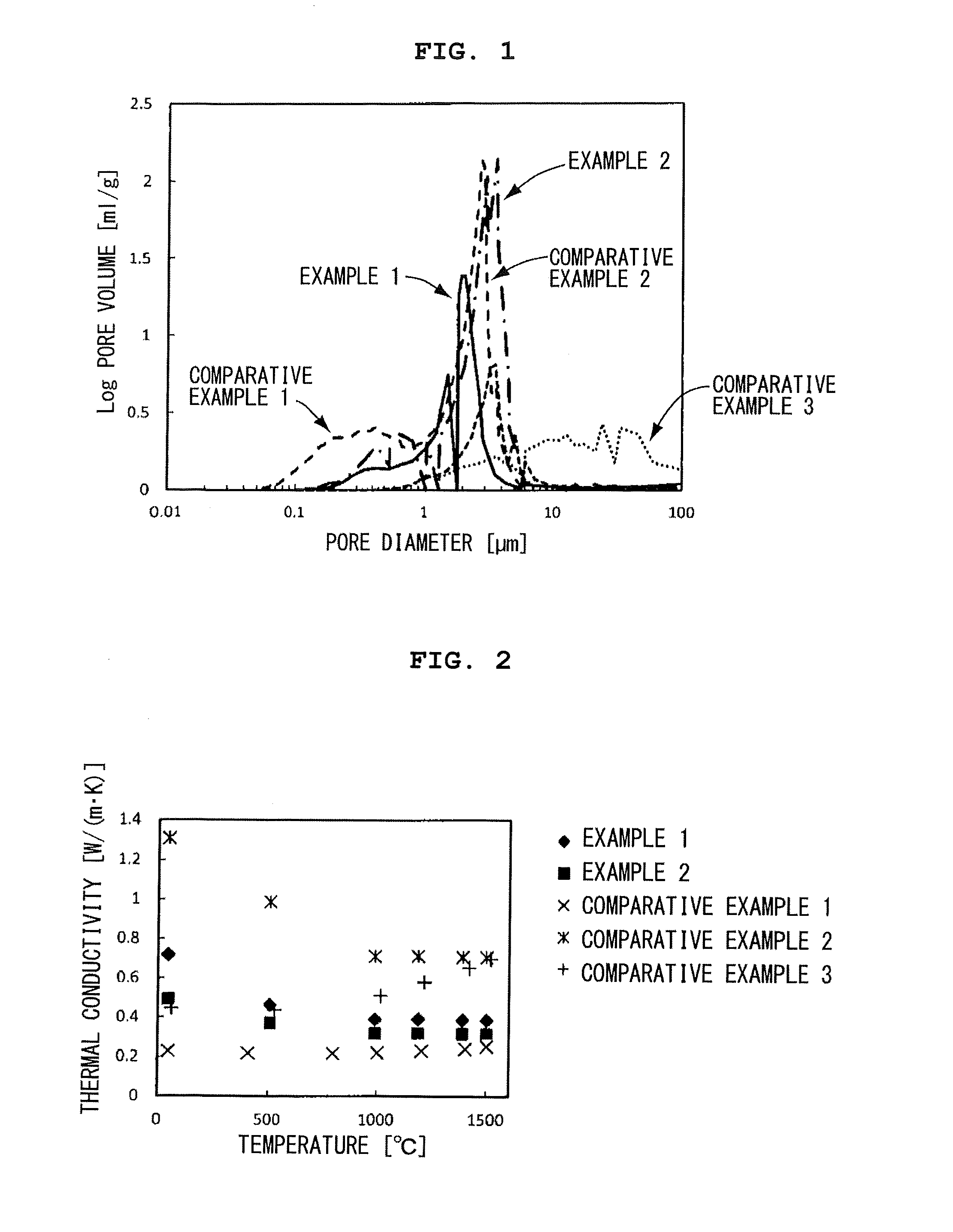

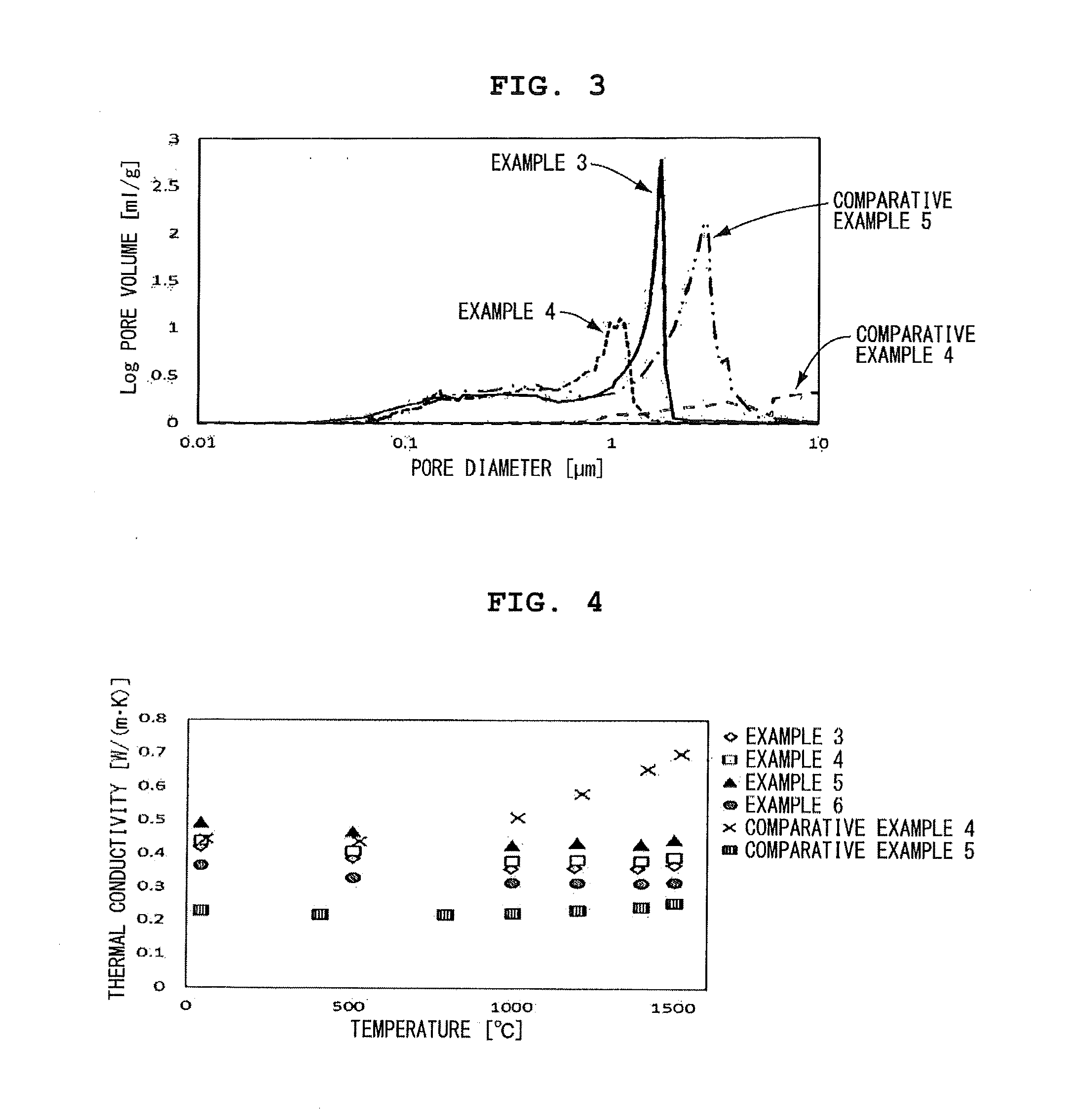

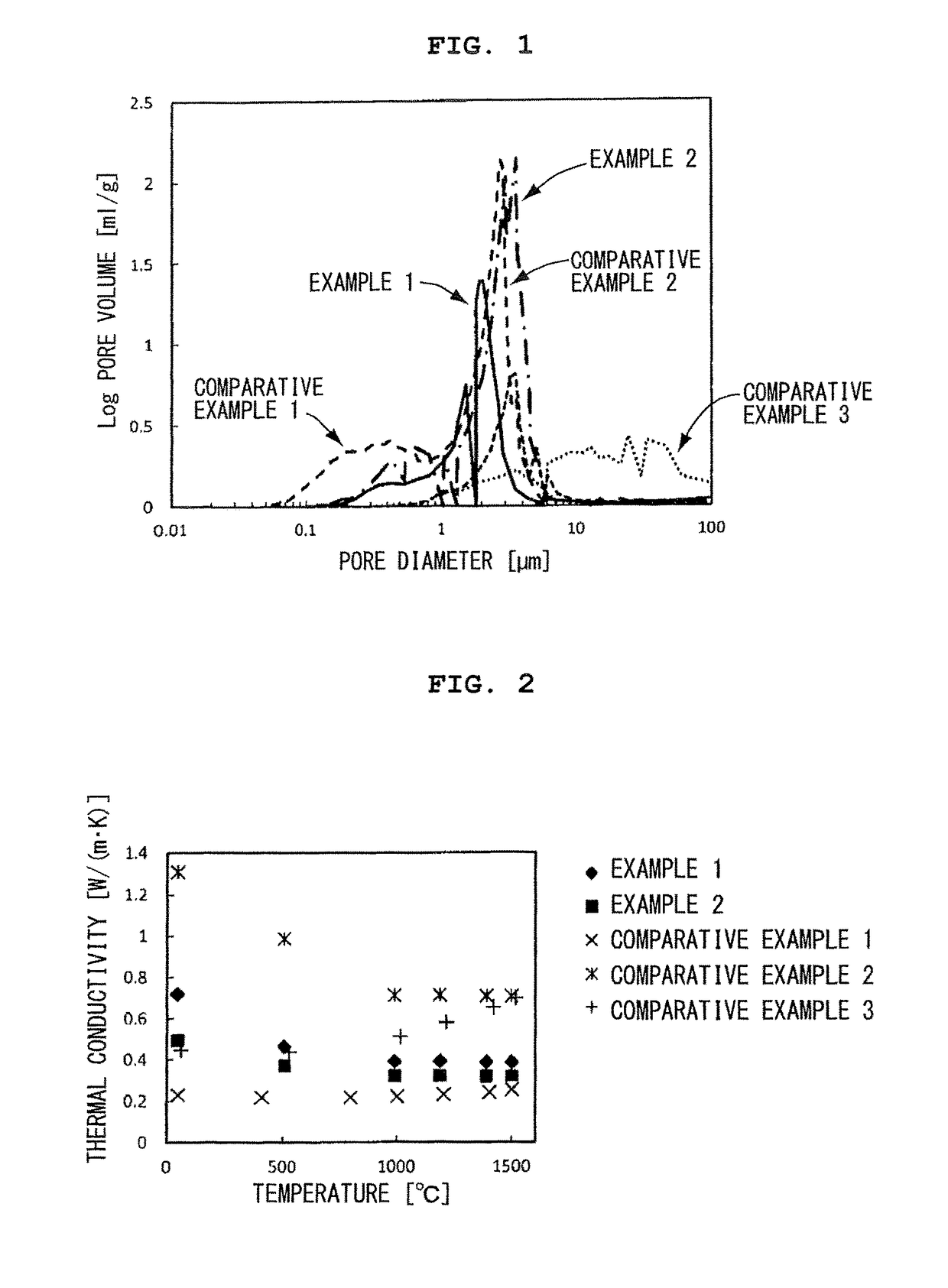

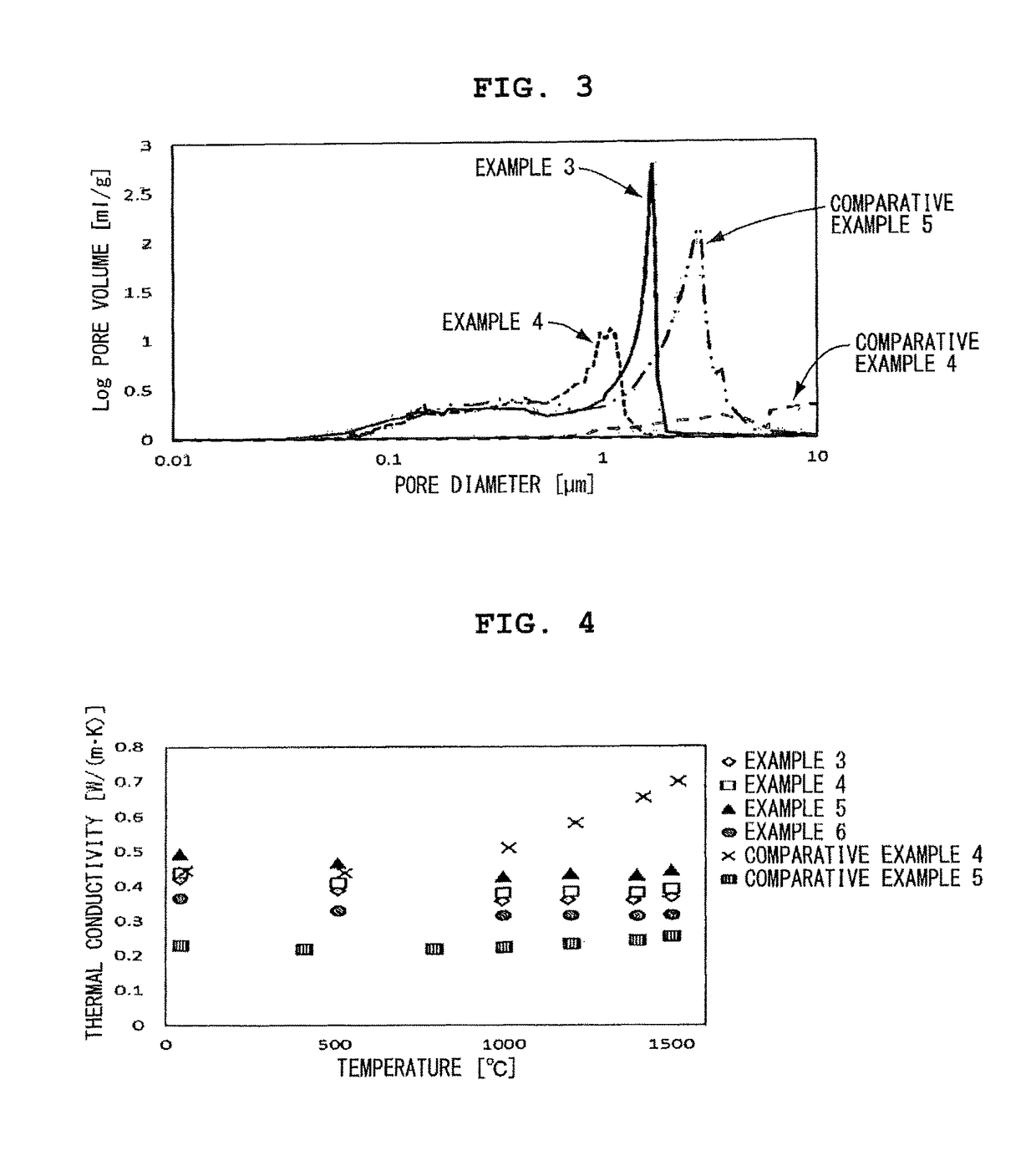

Heat Insulating Material

ActiveUS20150368118A1Improve conductivityGood effectThermal insulationAluminates/aluminium-oxide/aluminium-hydroxide purificationMetallurgyPore diameter

A heat insulating material includes a porous sintered body formed of MgAl2O4 and having a porosity of 60% or more and less than 73%. In the heat insulating material, pores having a pore diameter of 0.8 μm or more and less than 10 μm occupy 30 vol % or more and less than 90 vol % of a total pore volume, pores having a pore diameter of 0.01 μm or more and less than 0.8 μm occupy 10 vol % or more and less than 60 vol % of the total pore volume, the thermal conductivity at 20° C. or higher and 1500° C. or lower is 0.45 W / (m·K) or less, and the compressive strength is 2 MPa or more.

Owner:COORSTEK INC

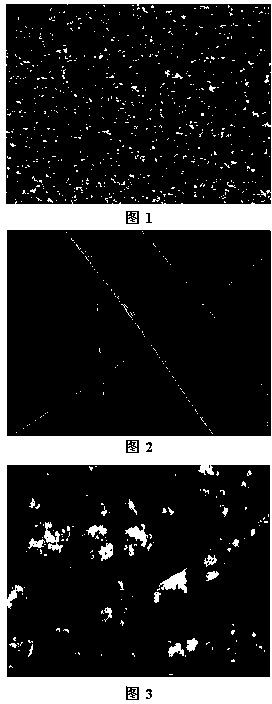

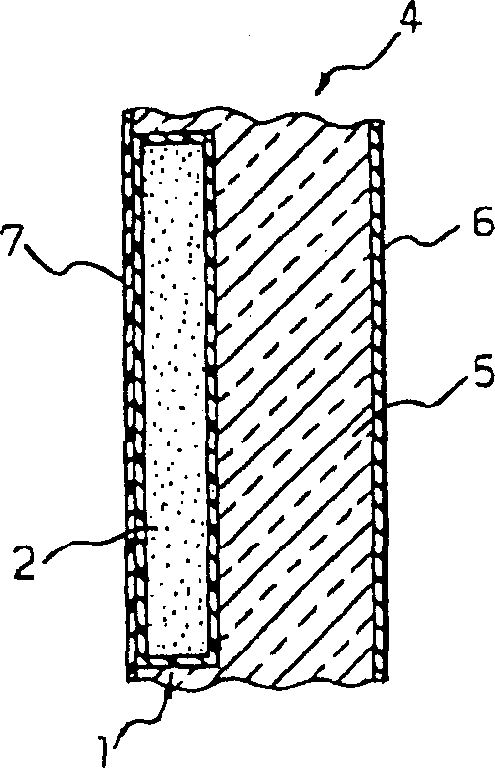

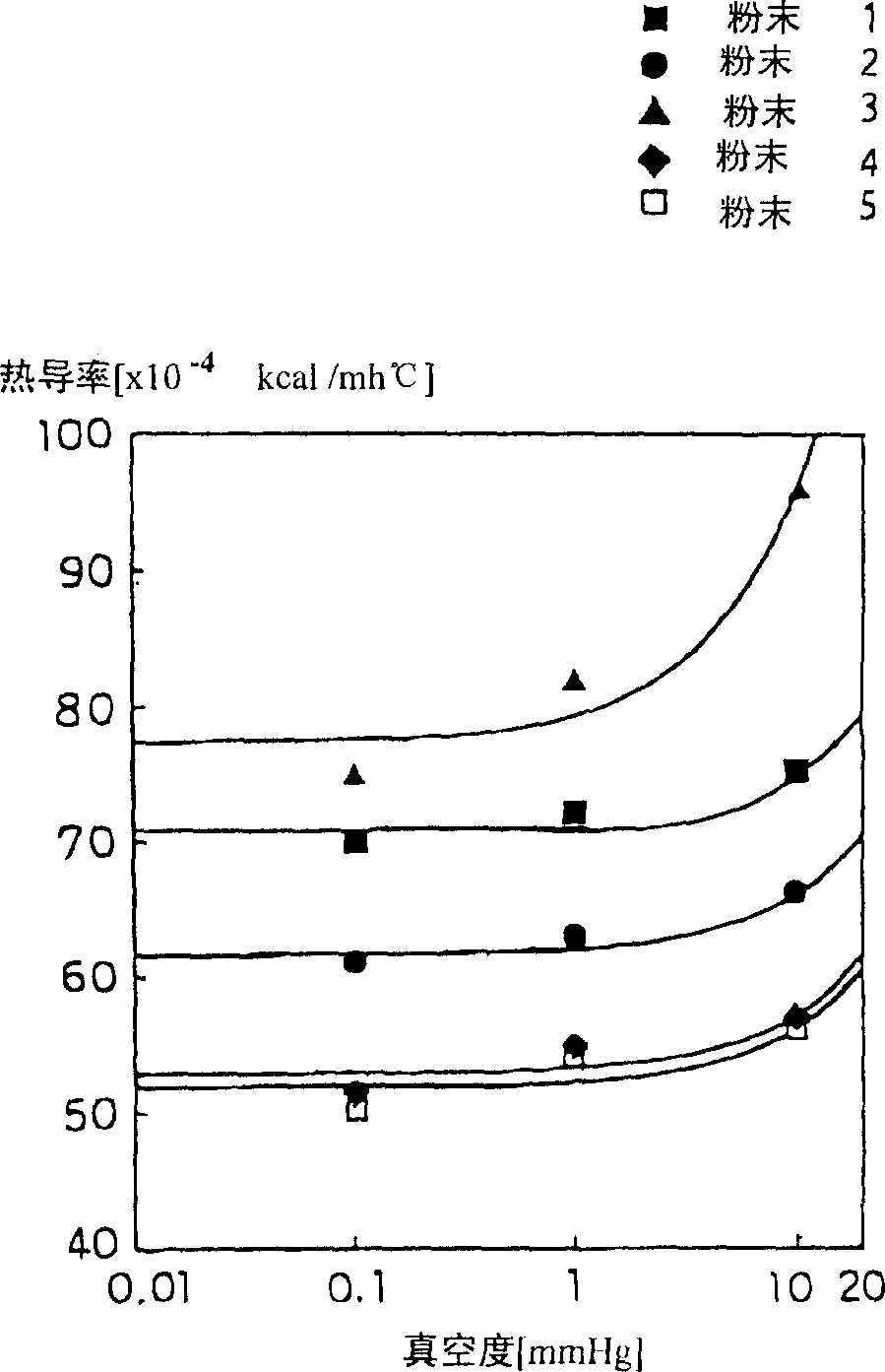

Vacuum heat insulator and heat insulating box using the insulator

InactiveCN1071012CImprove insulation performanceSolve the problem of excessive operating efficiencyThermal insulationPipe protection by thermal insulationThermal insulationRefrigerated temperature

A vacuum thermal insulating material of the present invention and a thermally insulating case using the vacuum thermal insulating material are used as thermal insulation in, for example, refrigerators and freezers. The vacuum thermal insulating material has a core material including two or more different powders and an adsorbent. The vacuum thermal insulating material of the present invention has excellent performance of thermal insulation and is light in weight and manufactured at a low cost. The thermally insulating case of the present invention enables the performance of thermal insulation to be practically maintained over a long time period.

Owner:MATSUSHITA REFRIGERATION

Elastic composite smoke-proof strip

InactiveCN103643869AEfficient use ofGood thermal insulation propertiesFireproof doorsSealing arrangementsEngineeringParallel arrangement

The invention provides an elastic composite smoke-proof strip which comprises a long-strip-shaped fire-proof base plate and a plurality of metal supports fixed to the fire-proof base plate. The metal supports are arch-shaped supports with horizontal top portions, the two ends of each metal support are fixed to the portions, close to the two sides, of the fire-proof base plate through elastic connecting bases respectively, the metal supports are arranged in parallel, and an arch-shaped air channel with a horizontal top is formed between the metal supports and the fire-proof base plate. The outsides of the elastic metal supports are covered with metal and non-metal composite layers, the two side edges of each metal and non-metal composite layer are connected with the fire-proof base plate in a sealed mode to form an arch-shaped surface with a horizontal top surface. The elastic composite smoke-proof strip is simple in structure and high in applicability and has airtight and high-temperature resistant performance; elastic pre-tightening force of the working surface of the elastic composite smoke-proof strip can be adjusted within a certain scope so that a smoke-proof device can be more evenly and tightly attached to a shutter surface; the elastic composite smoke-proof strip can be used as the smoke-proof device and is arranged in a fire-proof and smoke-proof roller shutter to block spreading of smoke and transmitting of heat.

Owner:刘文思

Heat insulating material containing a porous sintered body formed of MgAl2O4

ActiveUS9938195B2Improve conductivityGood effectThermal insulationPipe protection by thermal insulationMetallurgyPore diameter

A heat insulating material includes a porous sintered body formed of MgAl2O4 and having a porosity of 60% or more and less than 73%. In the heat insulating material, pores having a pore diameter of 0.8 μm or more and less than 10 μm occupy 30 vol % or more and less than 90 vol % of a total pore volume, pores having a pore diameter of 0.01 μm or more and less than 0.8 μm occupy 10 vol % or more and less than 60 vol % of the total pore volume, the thermal conductivity at 20° C. or higher and 1500° C. or lower is 0.45 W / (m·K) or less, and the compressive strength is 2 MPa or more.

Owner:COORSTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com