Installation method for thermal insulation and decoration integrated facade panels

An installation method and a technology of exterior wall panels, which are applied in covering/lining, construction, building construction, etc., can solve problems affecting construction progress and project quality, shortening the service life of buildings, and cracking of wall finish coatings, etc. Achieve excellent thermal insulation properties, enhanced availability, time-saving and labor-saving handling and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

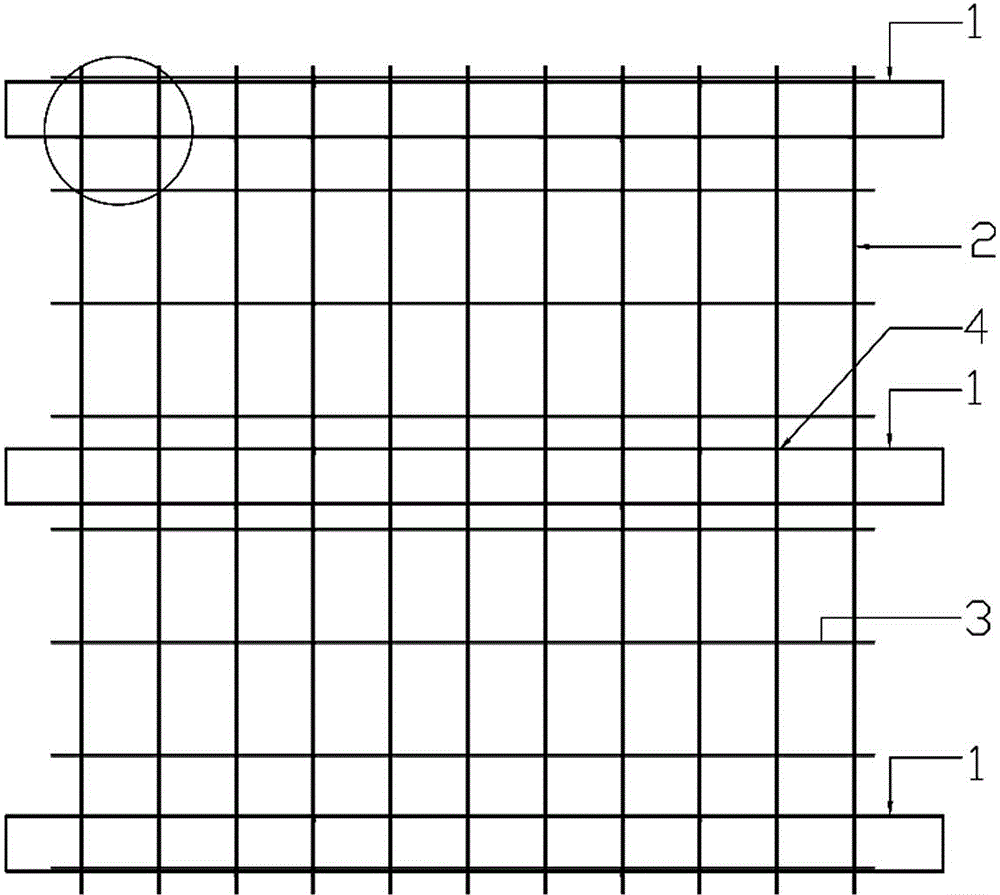

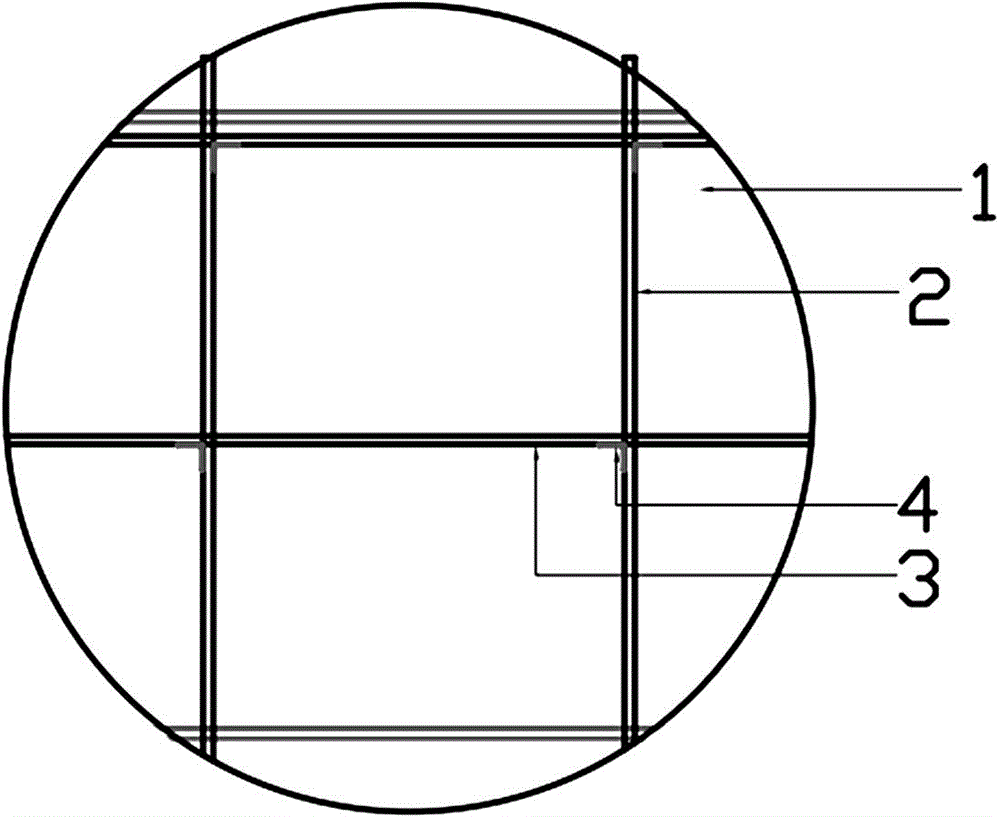

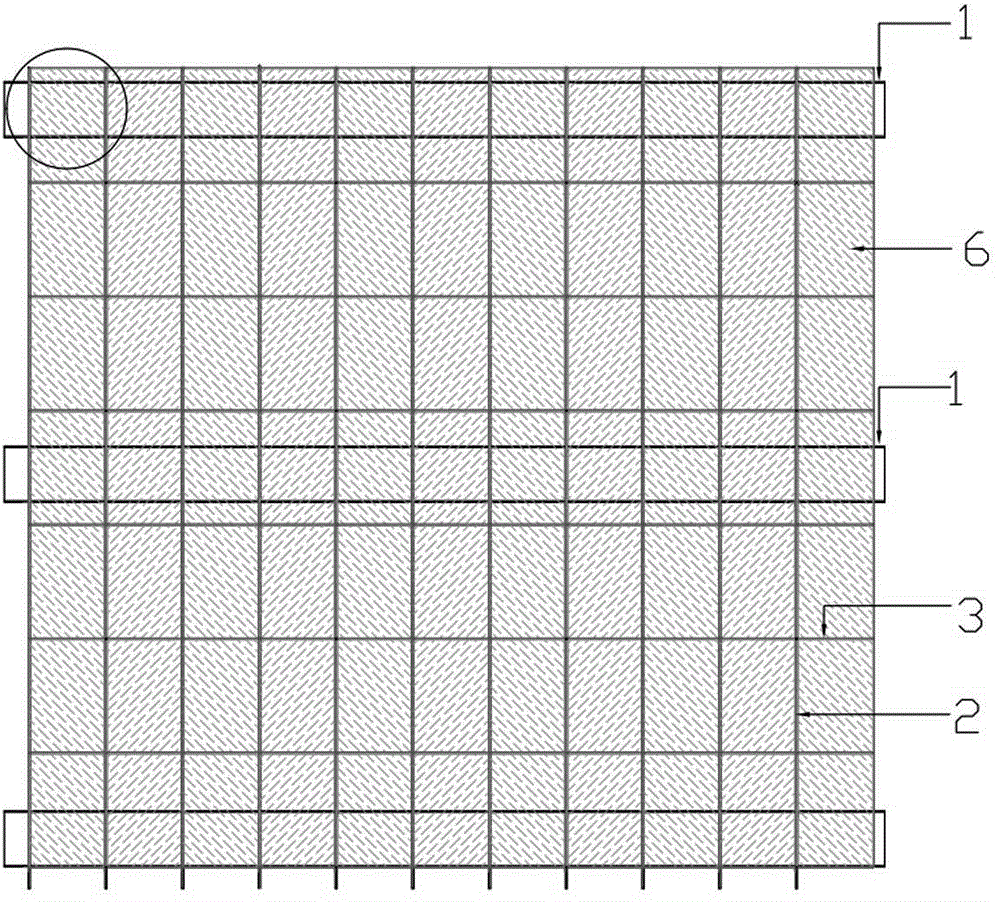

[0052] In this embodiment, refer to Figure 1 to Figure 7 , the specific implementation of the installation method includes the following steps (such as Figure 7 shown):

[0053] The first step is to deal with the main wall surface, check the condition of the original external wall brick, chisel out the hollow part, clean the wall surface with oxalic acid or detergent to ensure that the surface of the brick surface is clean and free of stains, and then use the paste interface Brush the wall surface with the agent to make it completely cover the brick wall surface, and ensure that the flatness reaches the intermediate plastering standard, and finally determine the beam position of the main steel structure of the main wall. In this embodiment, the beam of the main steel structure of the main wall I-beam 1 for transverse setting, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com