Patents

Literature

190 results about "Axial Loadings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An Axial load is a force administered along the lines of an axis. Axial loading occurs when an object is loaded so that the force is normal to the axis that is fixed, as seen in the figure. Taking statics into consideration the force at the wall should be equal to the force that is applied to the part.

Spinal interbody fusion device and method

InactiveUS20050027359A1Resist translationalResist rotational movementInternal osteosythesisBone implantSpinal columnBending of plates

A disc replacement spinal interbody fusion device is provided having a central sleeve with oppositely left and right-hand threaded axial bores with different diameters. Circumferential threaded apertures are located on the sleeve and open into the sleeve bores. The device has two opposing plates which are oval-shaped and centrally, axially bored. Each plate has a perpendicular shaft with an axial bore which communicates with the shaft bore. The first shaft has external left-hand threads and the second shaft has external right-hand threads, each to mate with different bores of the sleeve. The outside diameter of the first shaft is smaller than the inside diameter of the second shaft, allowing the two shafts to axially engage. The spinal interbody fusion device operates like a turnbuckle, vertically expanding when the sleeve is rotated in one direction and retracting when the sleeve is rotated in the opposite direction. The assembled device defines an open channel axially. Once the fusion device is set at its proper height, set screws are threaded into circumferential apertures of the sleeve to compress against the shaft threads of each plate to maintain a fixed height. In situ, axial loading of the spinal column upon the fusion device creates a bending moment manifested by a flexing action of the plates to generate opposing axial directional forces which replicate the physiological function of shock absorption, load bearing and load transmission.

Owner:MASHBURN M LAINE

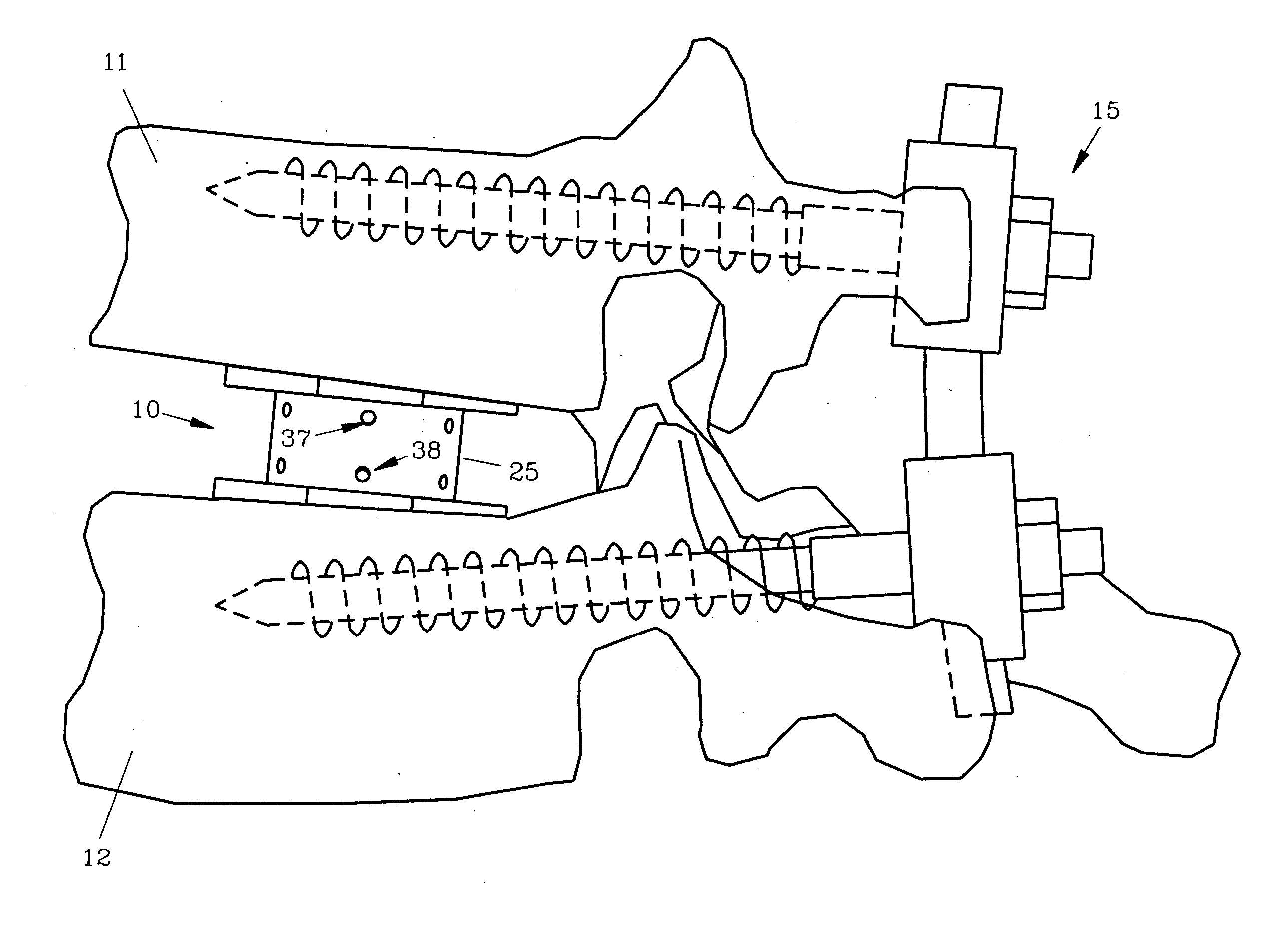

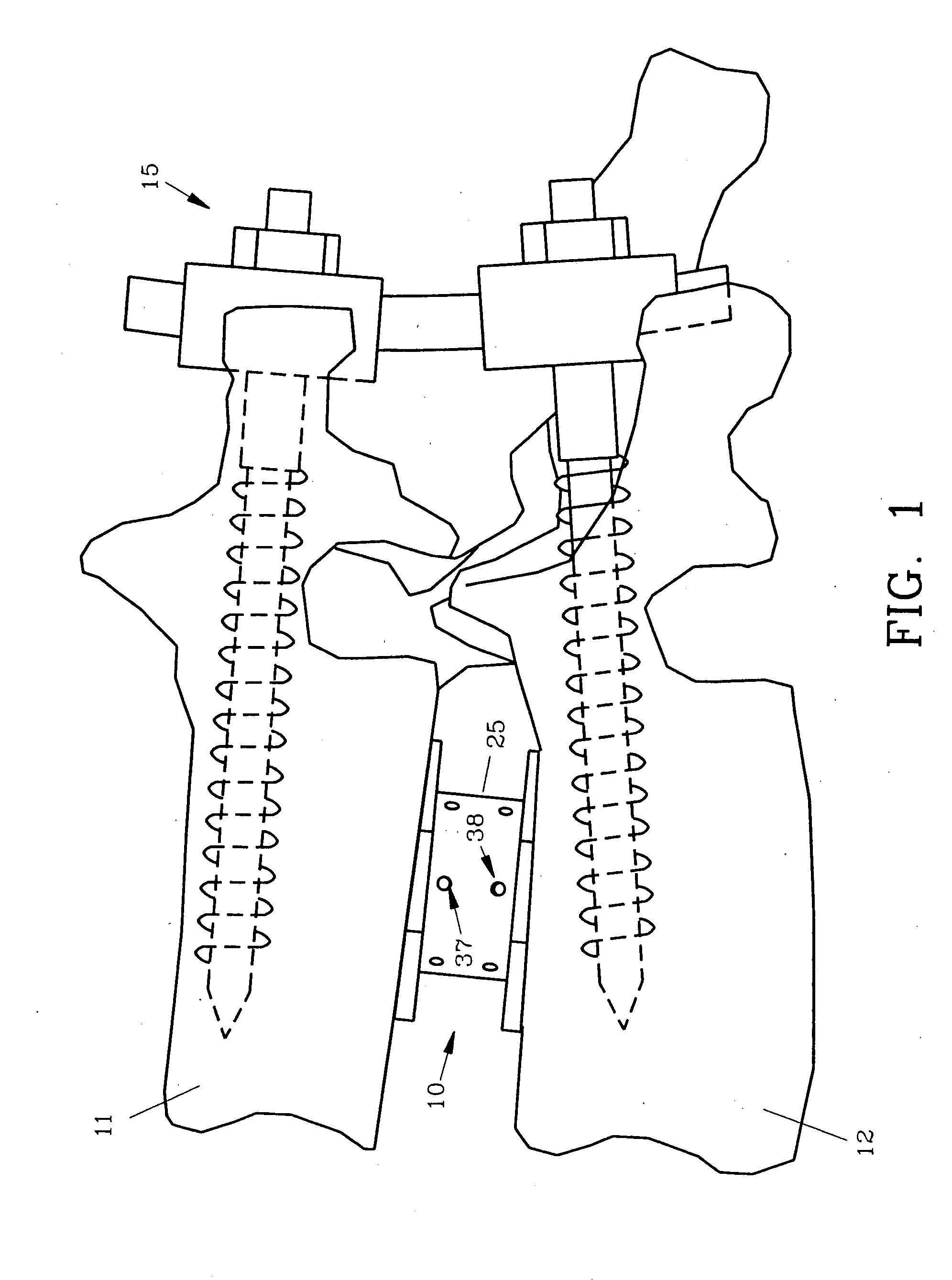

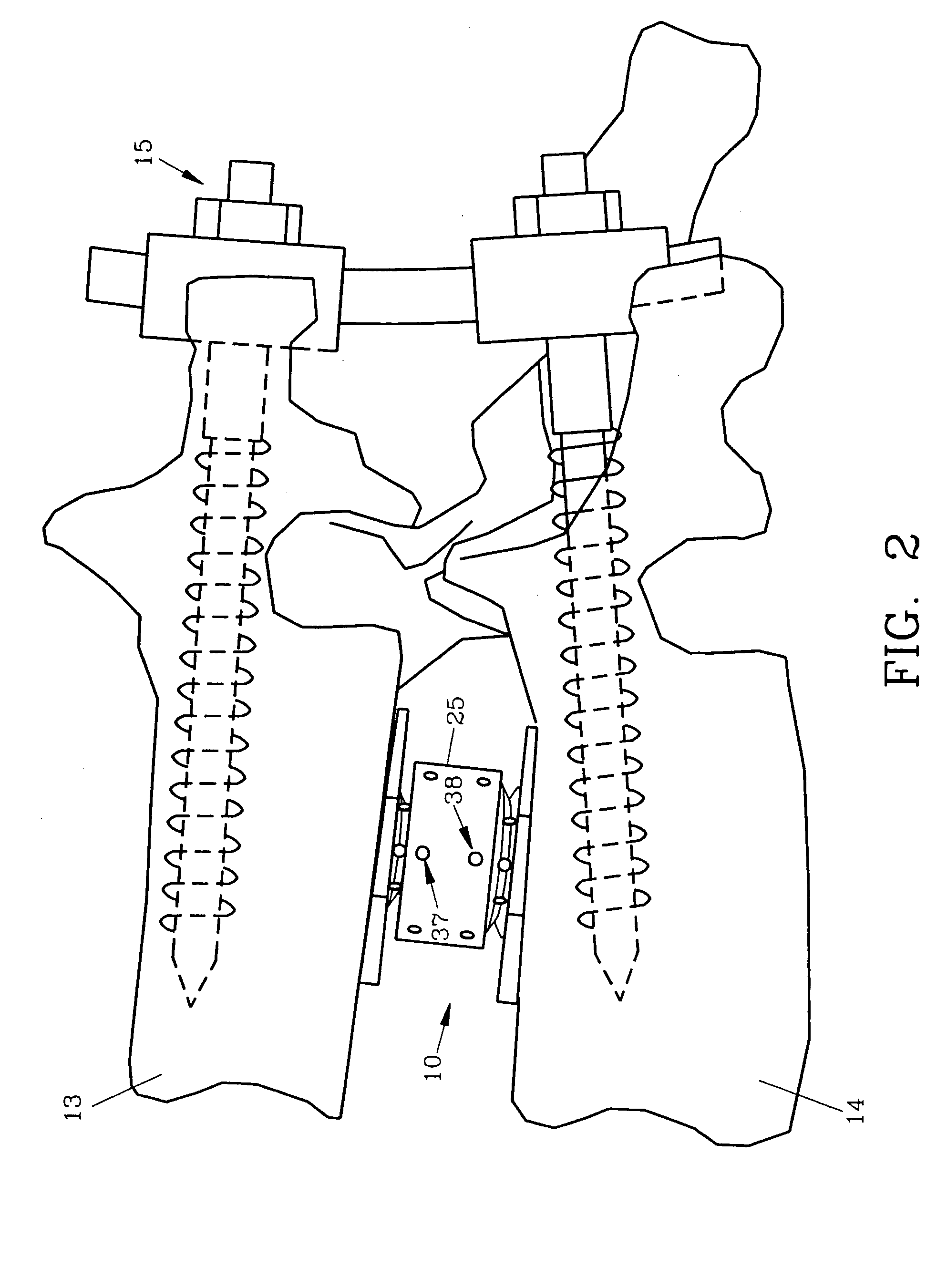

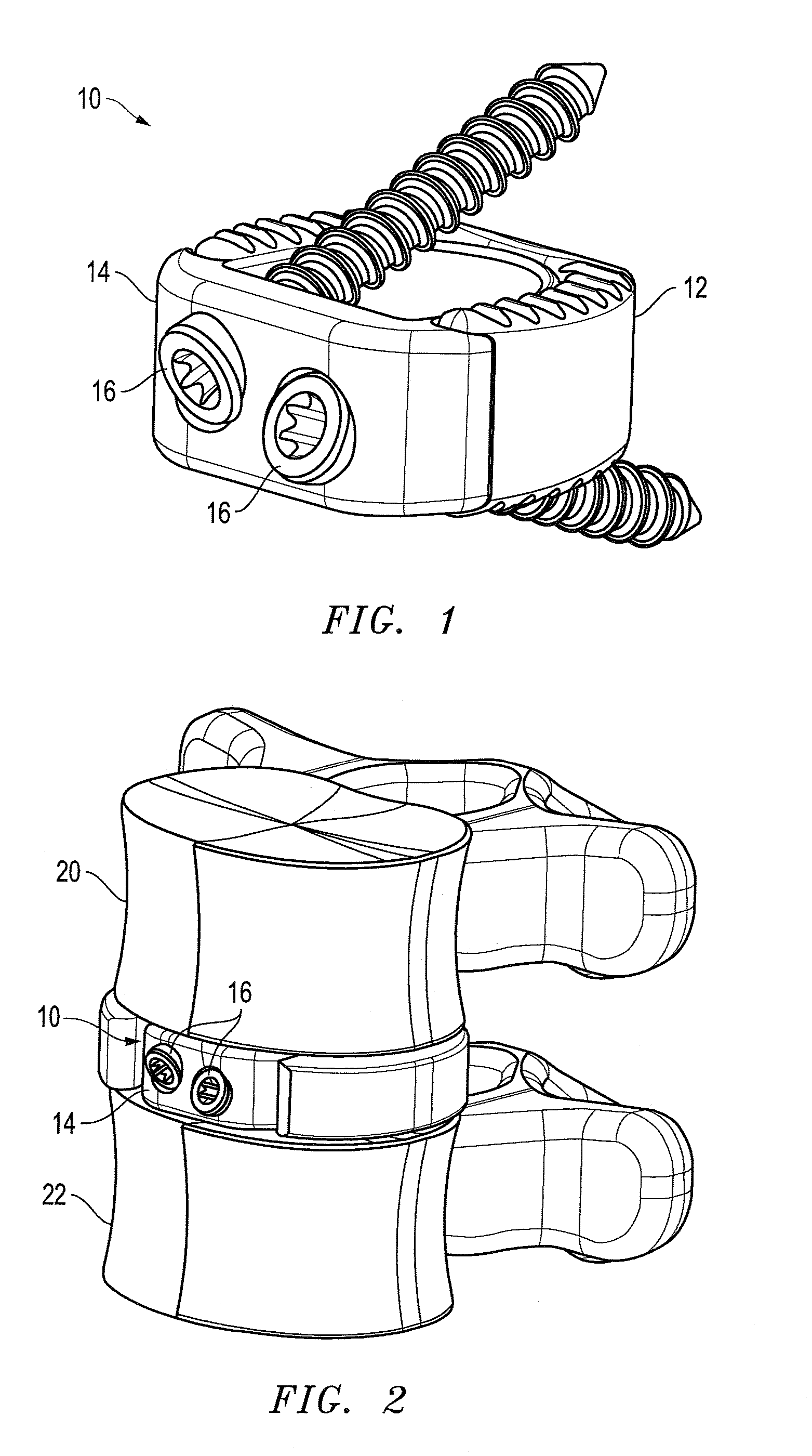

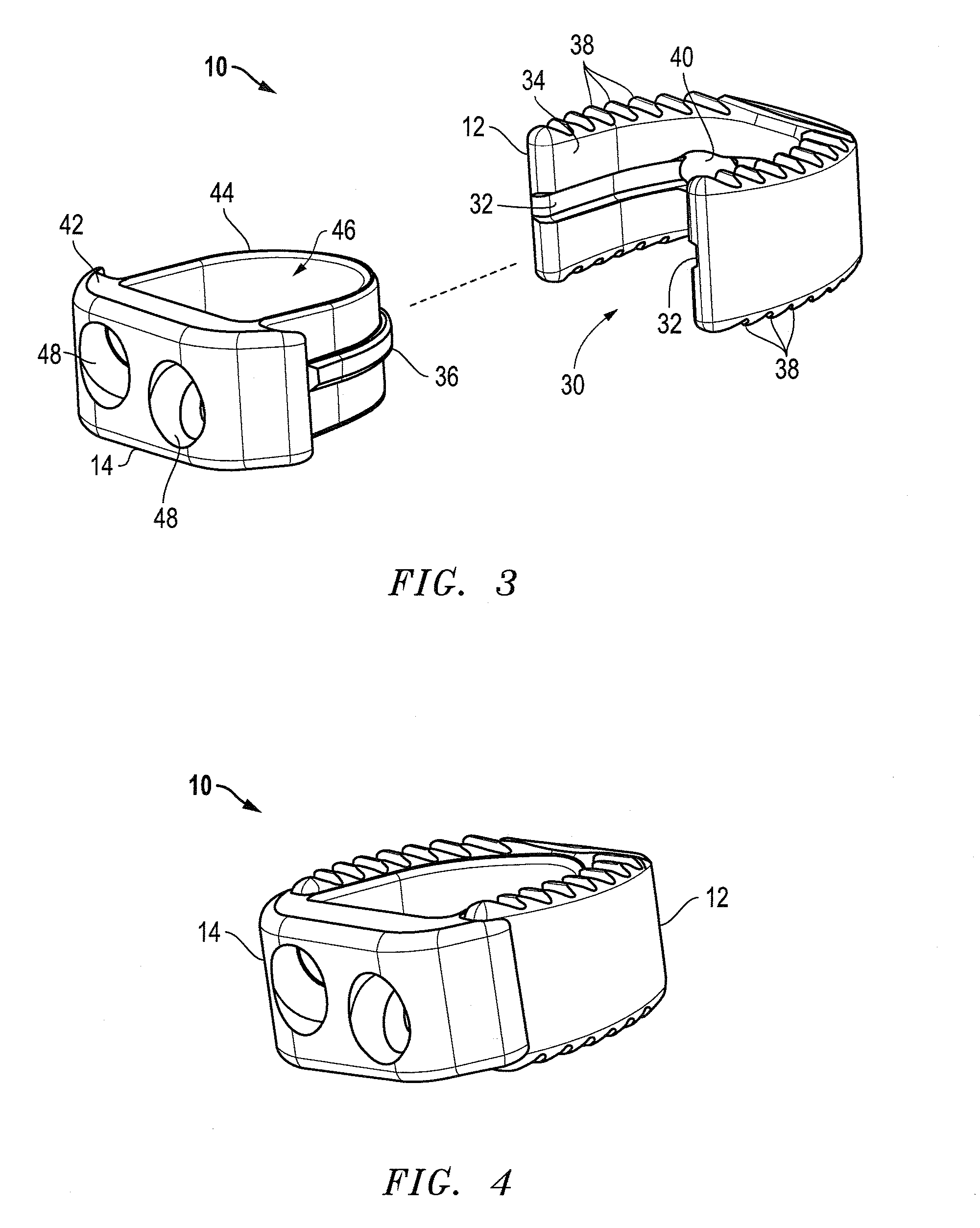

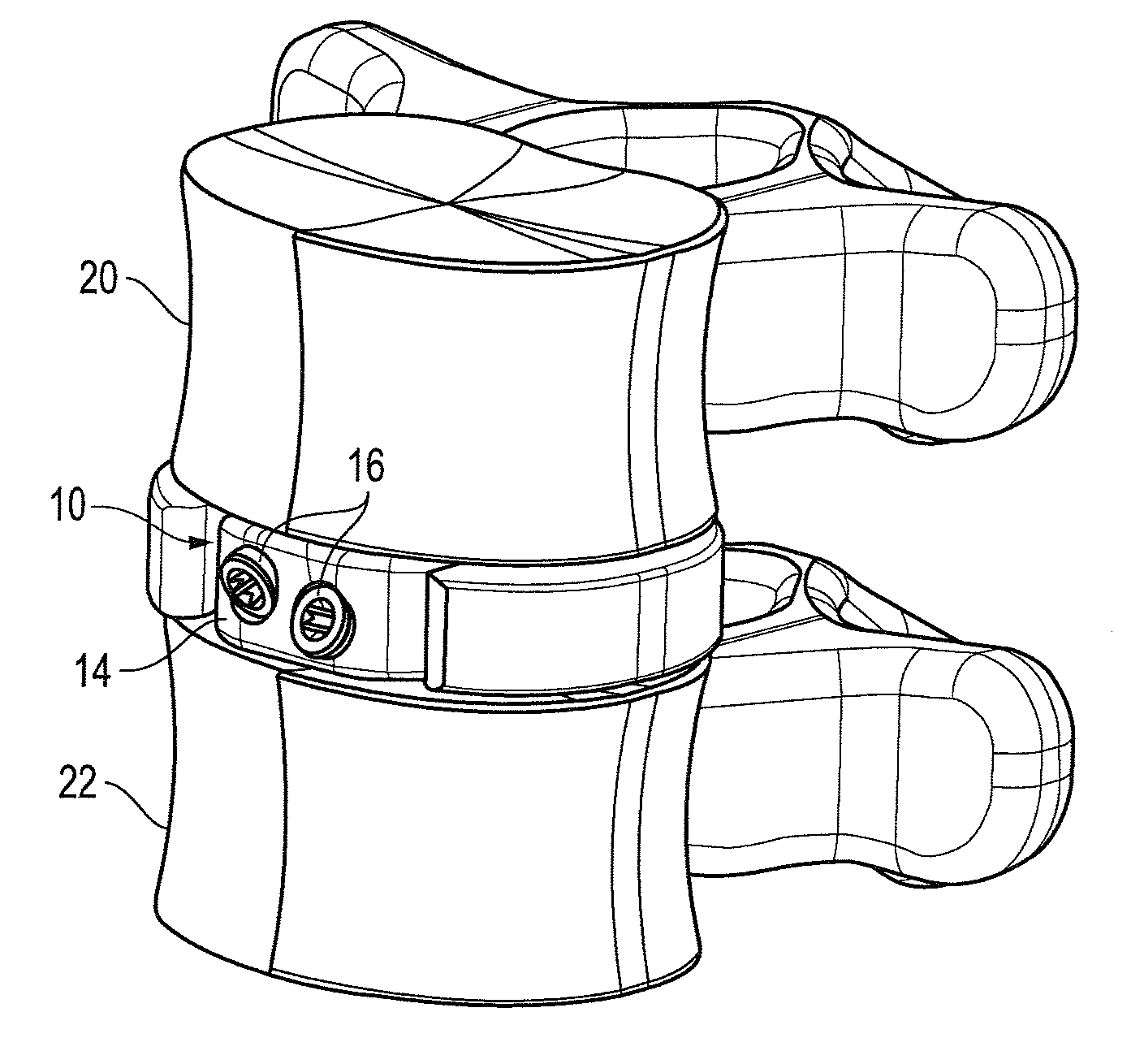

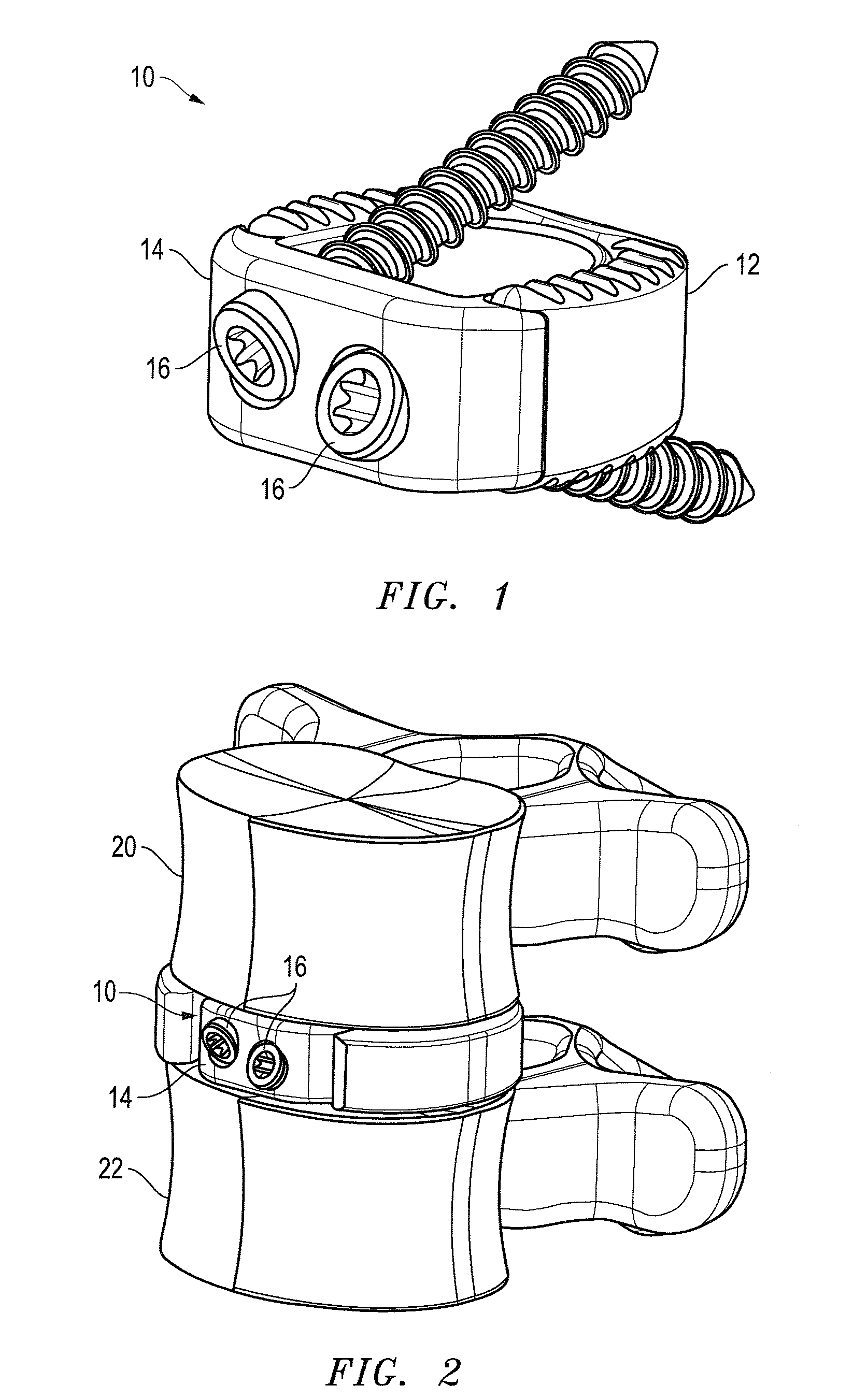

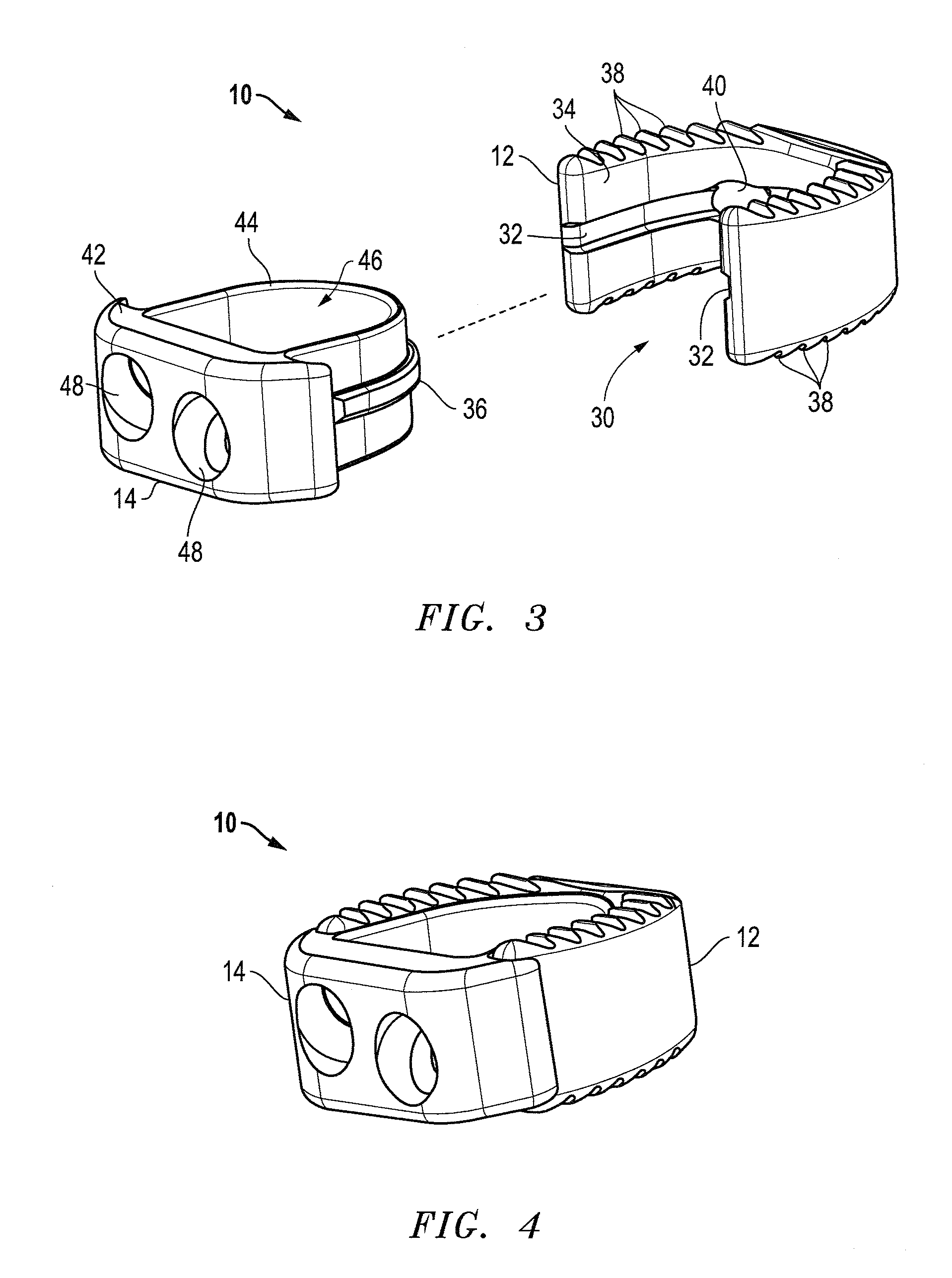

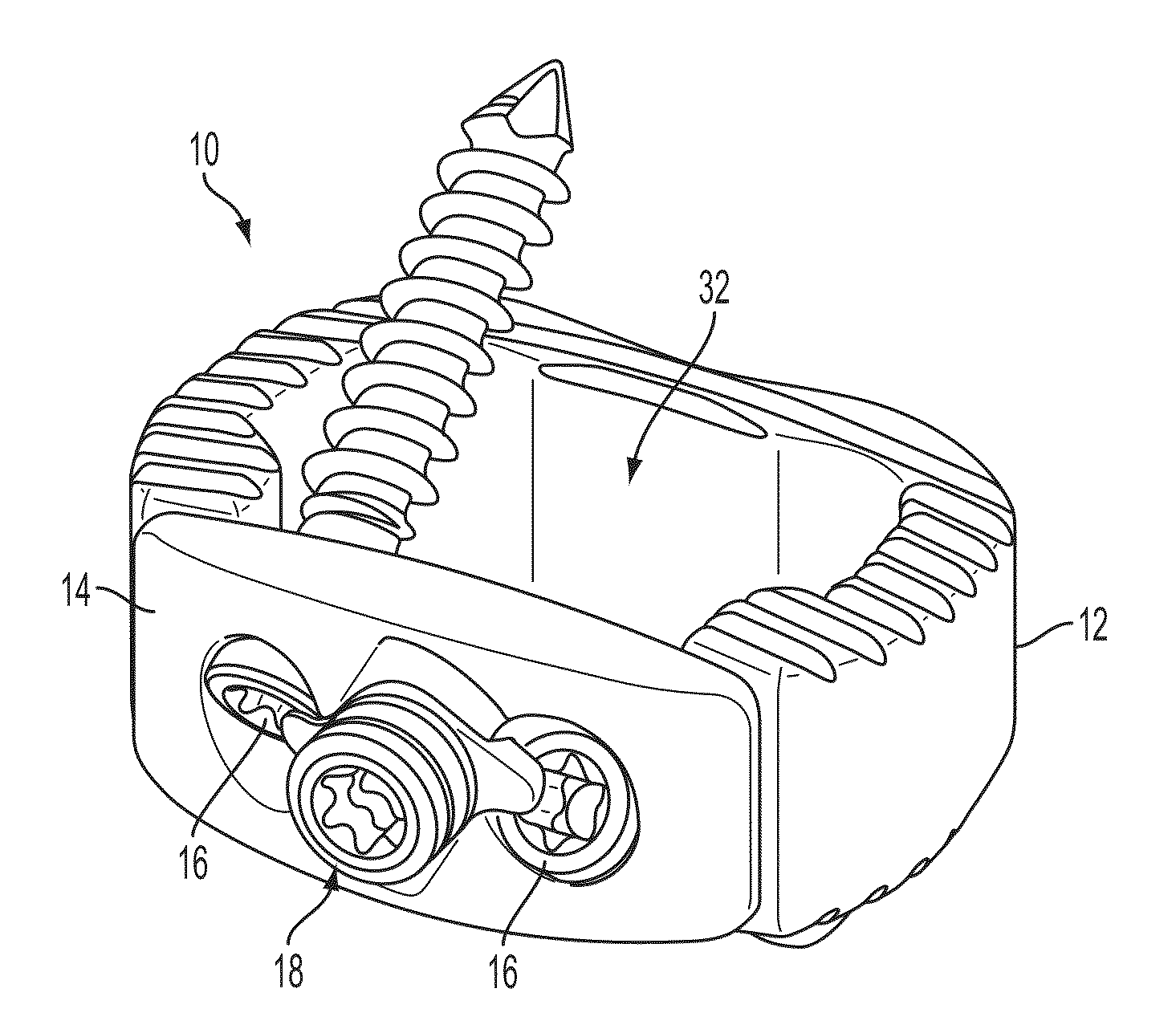

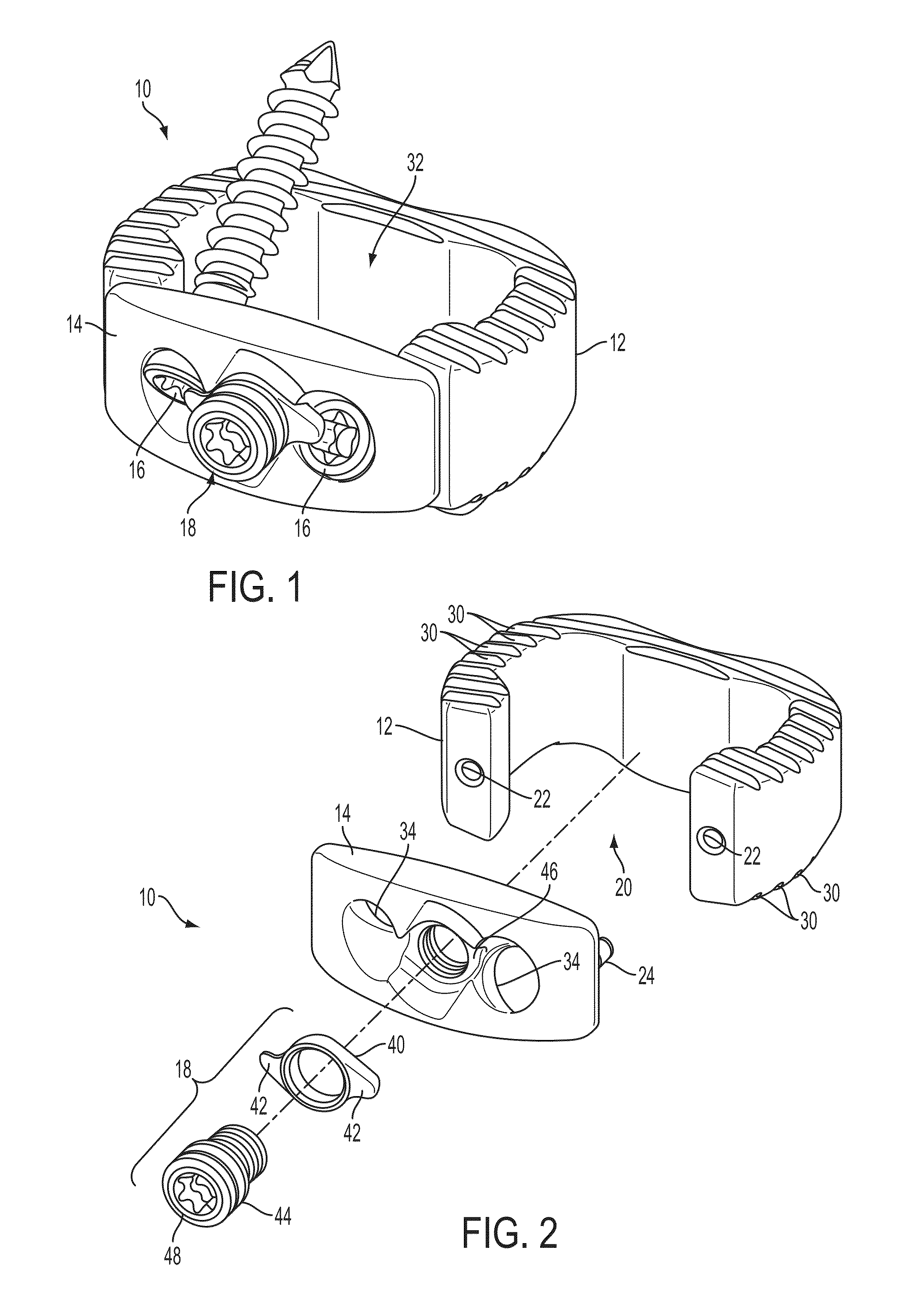

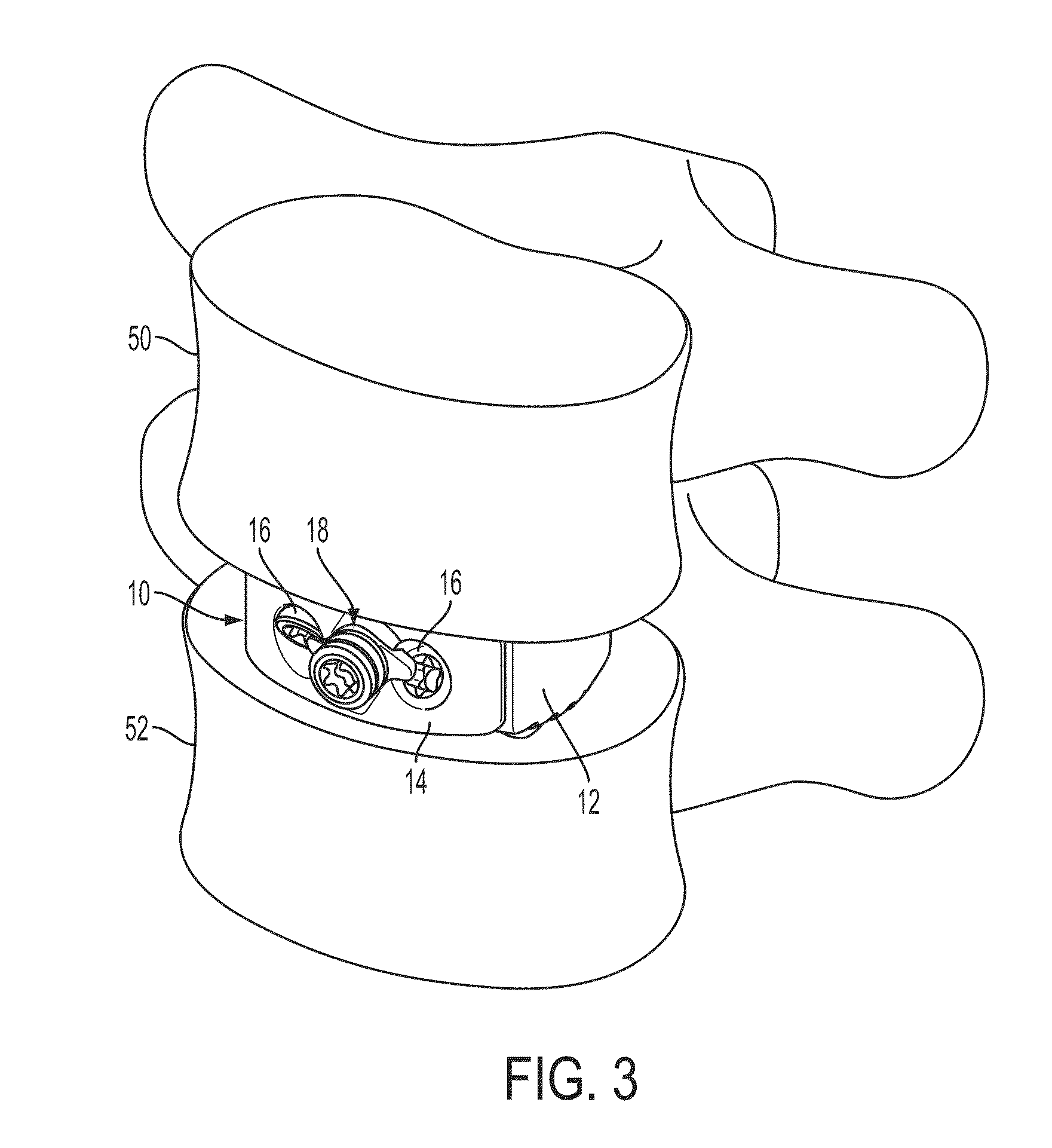

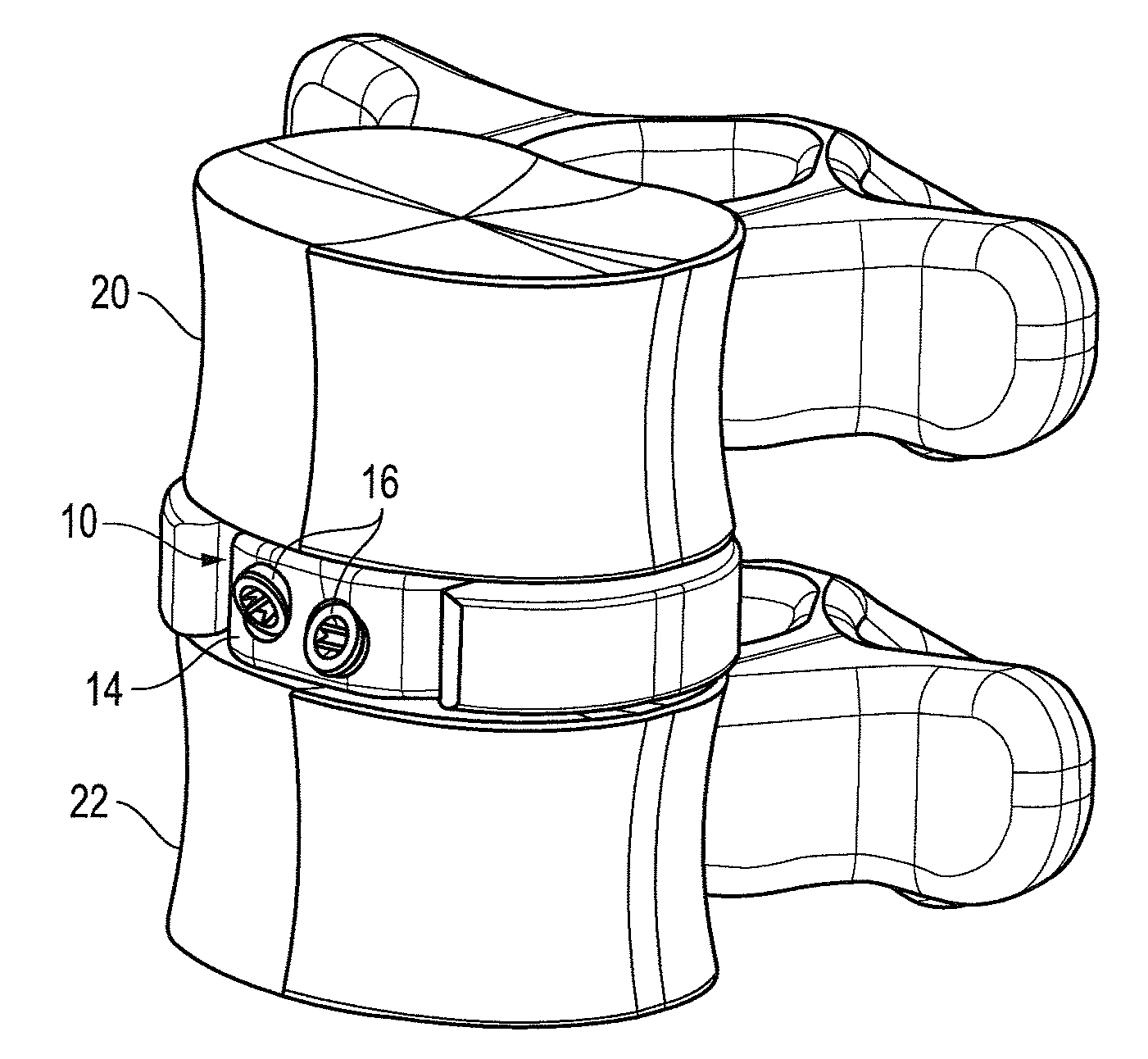

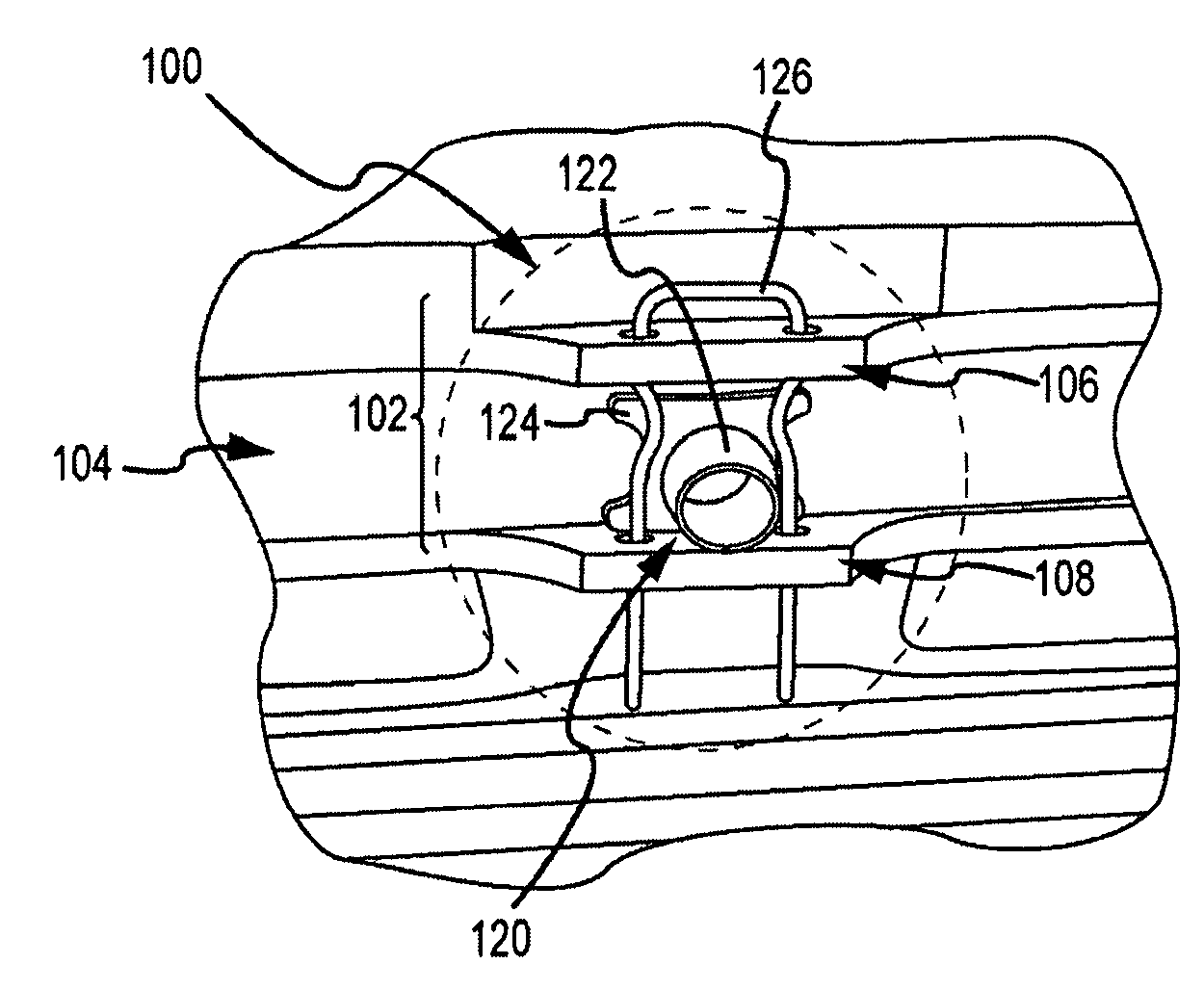

Interbody fusion device with lipped anterior plate and associated methods

ActiveUS20120277873A1Inhibit migrationLow profileBone implantSpinal implantsSpinal cageAxial Loadings

A method and apparatus is provided for use in spinal fusion procedures. An interbody fusion device has a first piece that is a load bearing device designed to bear the axial loading from the end plates of adjacent vertebrae. A second piece of the interbody fusion device is a retention device whose function is to prevent migration of the load bearing device. One or more fasteners secure the retention device to the vertebrae above and below the load bearing device. The fasteners cause the end plates of the vertebrae to compress the end plates to the load bearing device to facilitate proper fusion. The second piece can be configured to include lips that abut the apothyseal rings during, with the plate including bores angled such that fasteners penetrate the apothyseal rings.

Owner:SPINESMITH PARTNERS

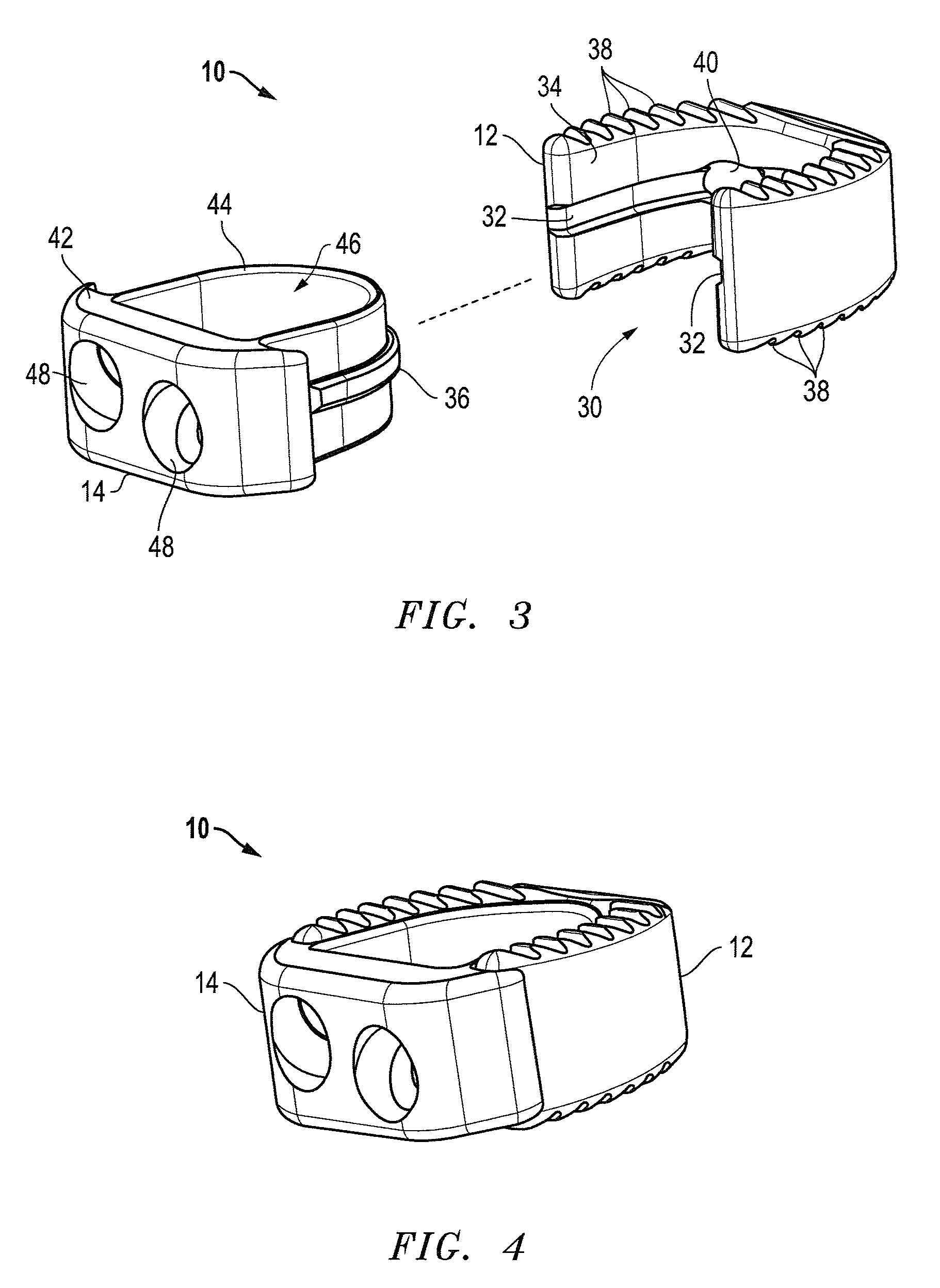

Interbody fusion device with snap on anterior plate and associated methods

A method and apparatus is provided for use in spinal fusion procedures. An interbody fusion device has a first piece that is a load bearing device designed to bear the axial loading from the end plates of adjacent vertebrae. A second piece of the interbody fusion device is a retention device whose function is to prevent migration of the load bearing device. One or more fasteners secure the retention device to the vertebrae above and below the load bearing device. The fasteners cause the end plates of the vertebrae to compress the end plates to the load bearing device to facilitate proper fusion. The device includes a snap in mechanism for coupling the first piece to the second piece.

Owner:SPINESMITH PARTNERS

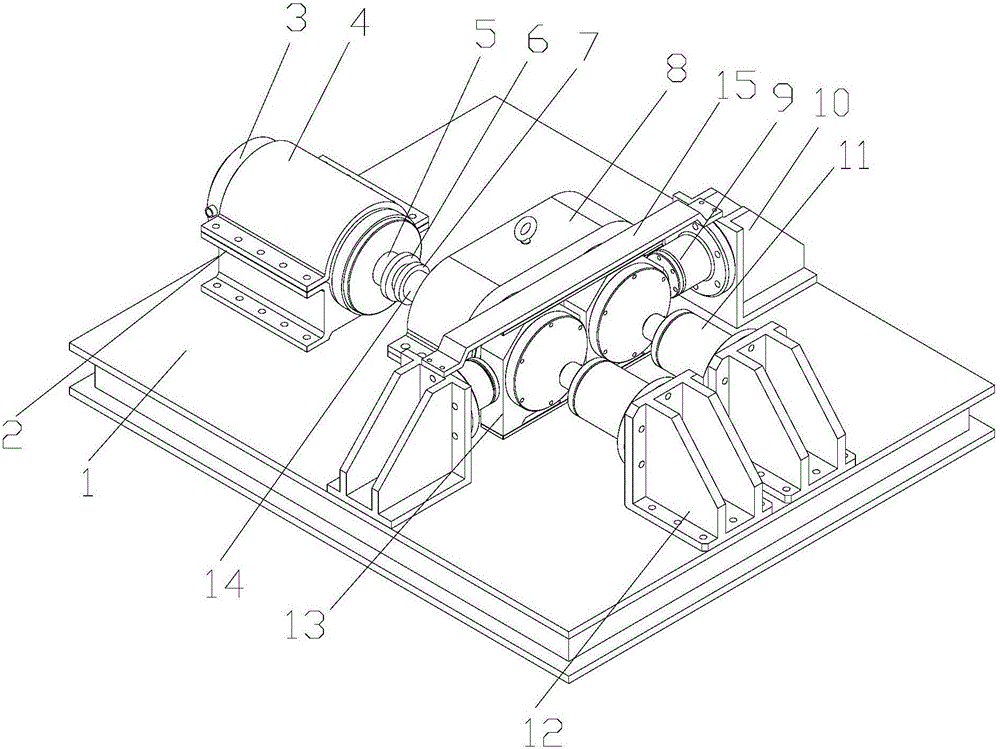

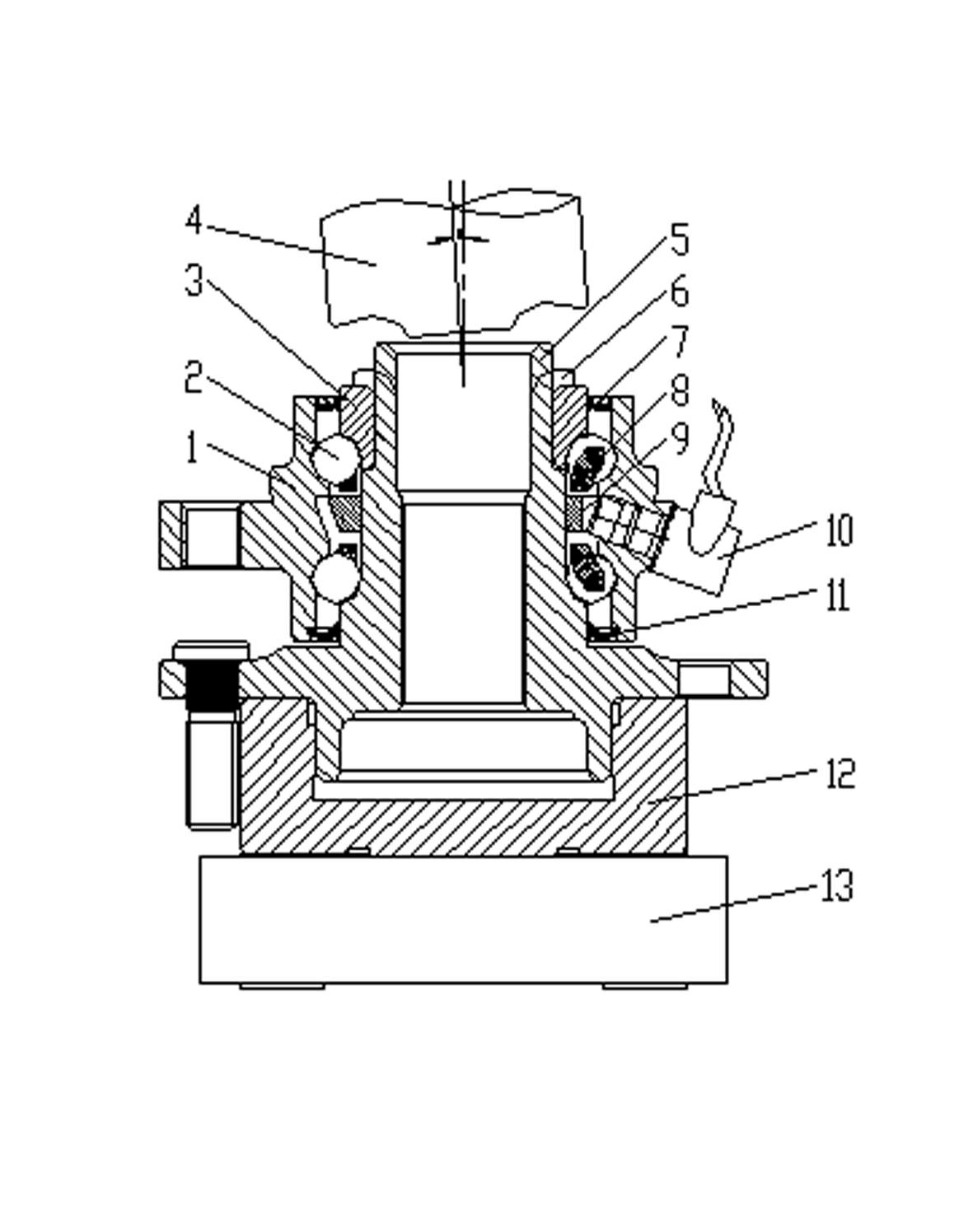

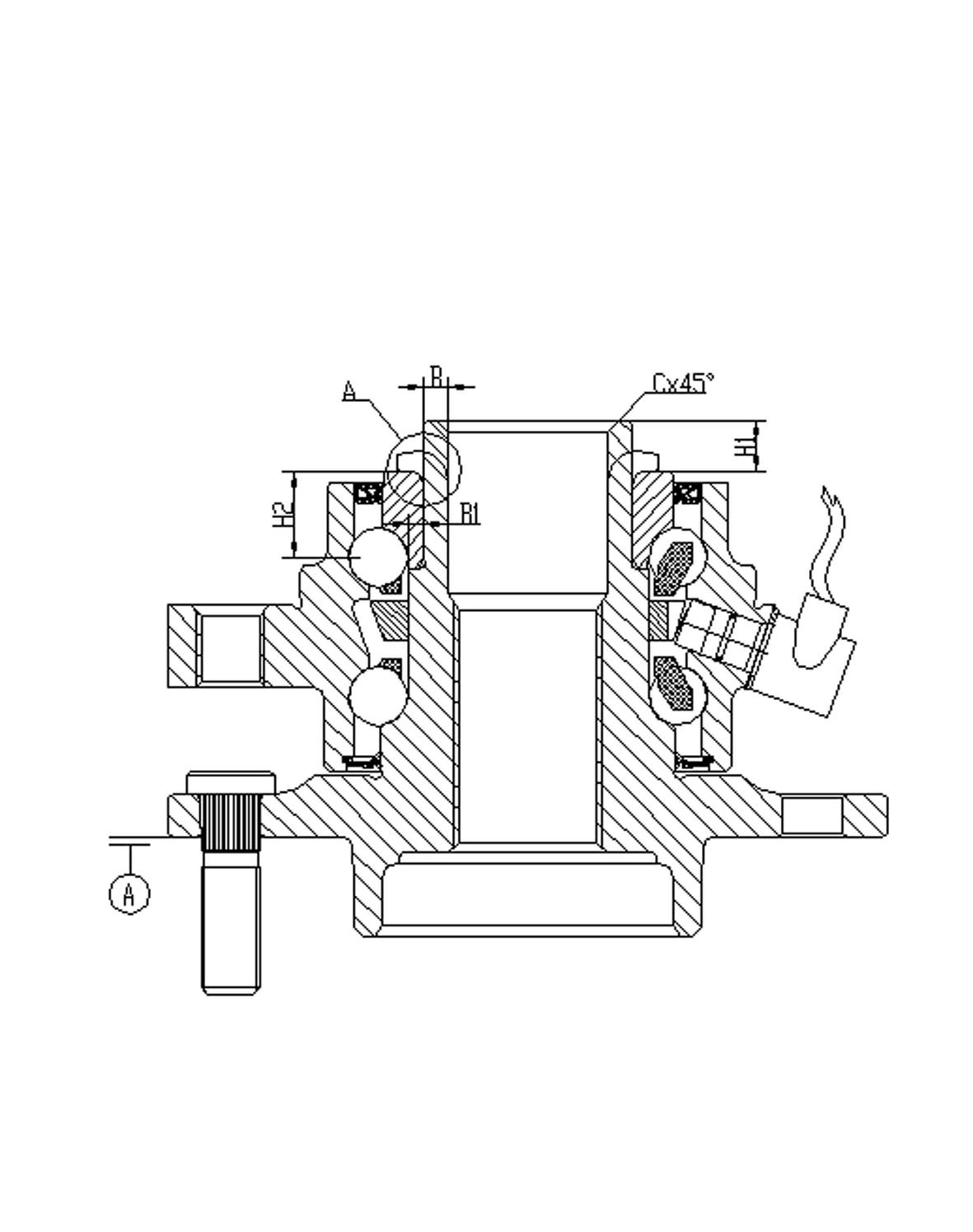

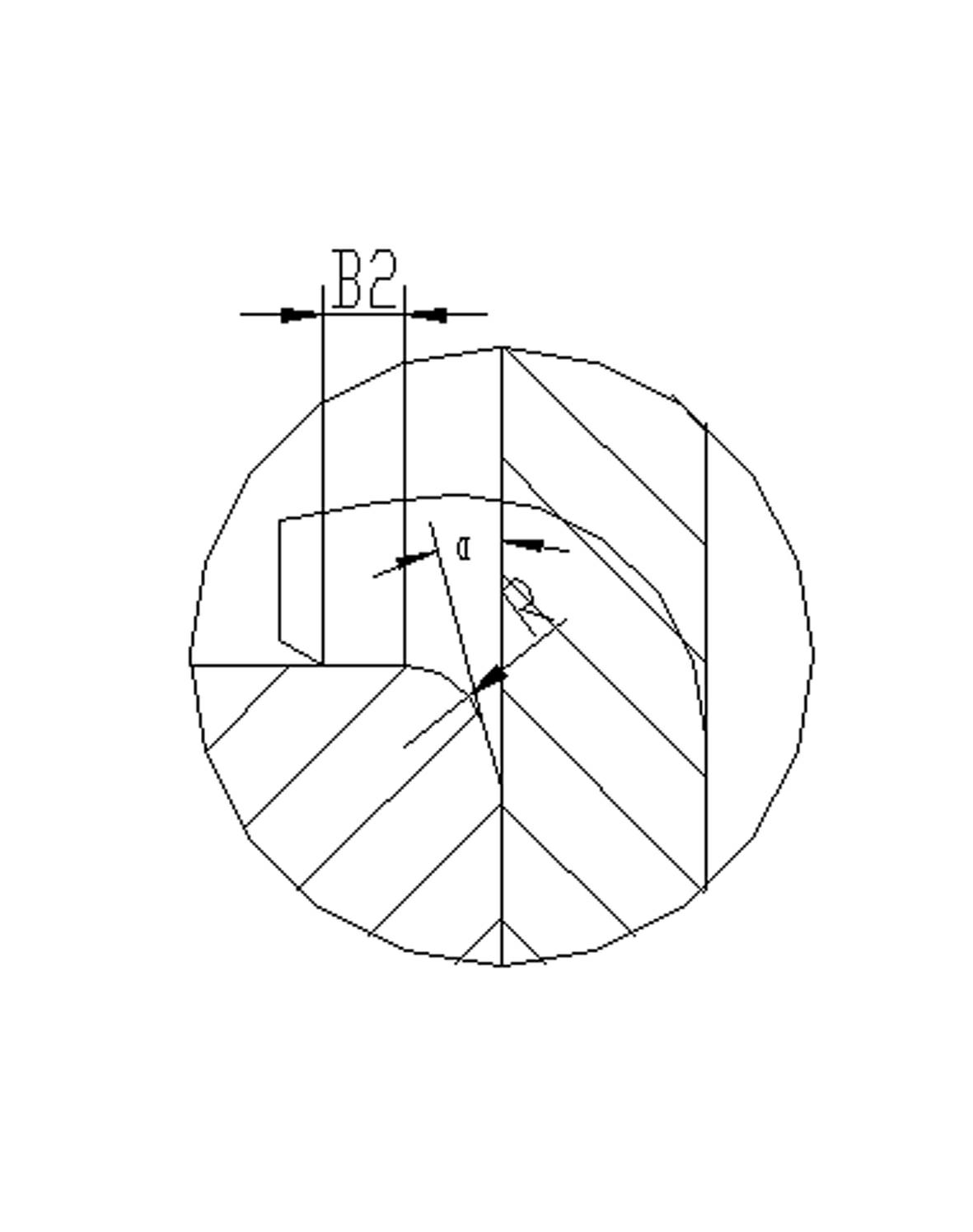

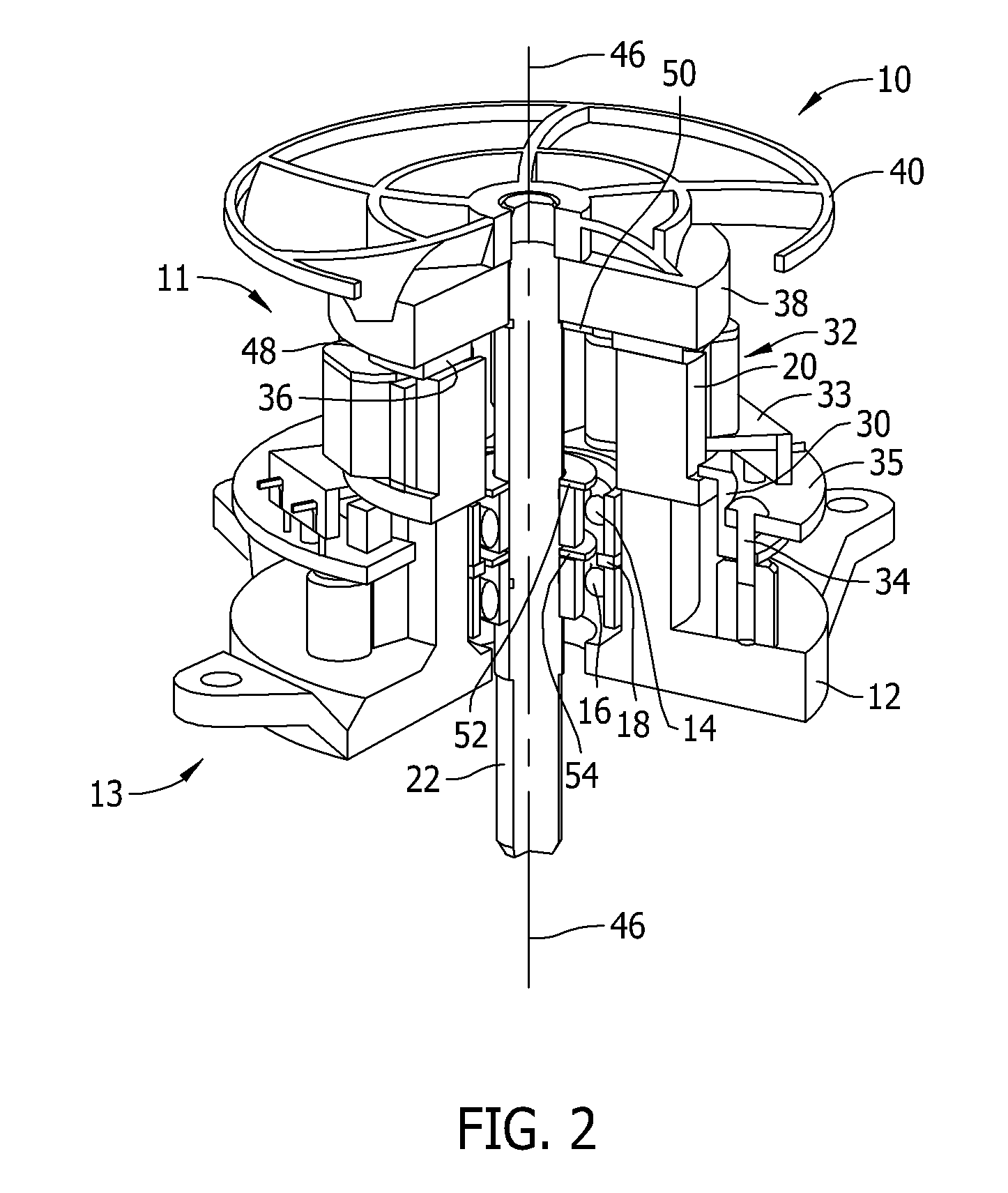

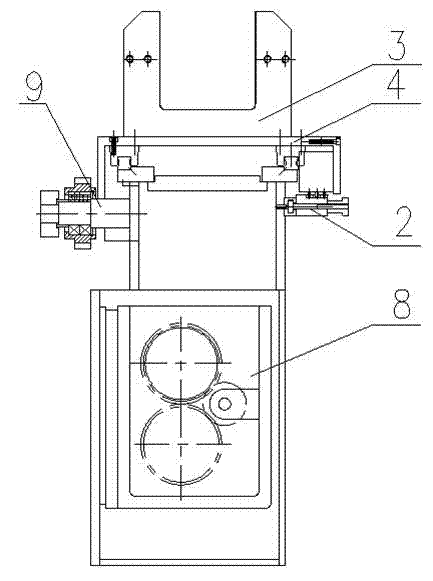

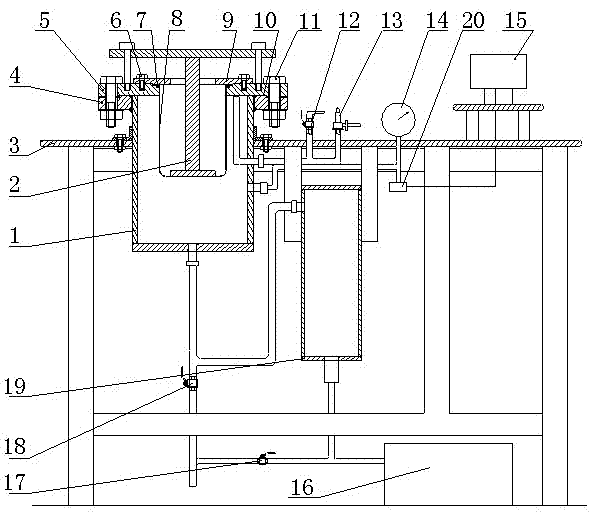

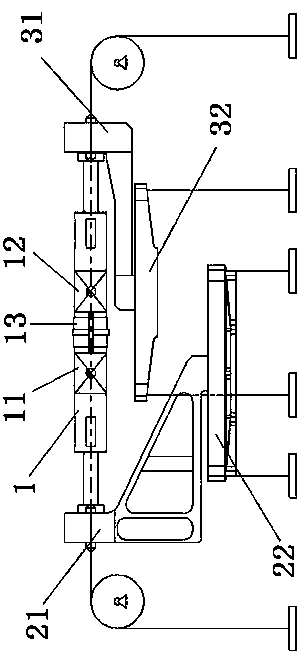

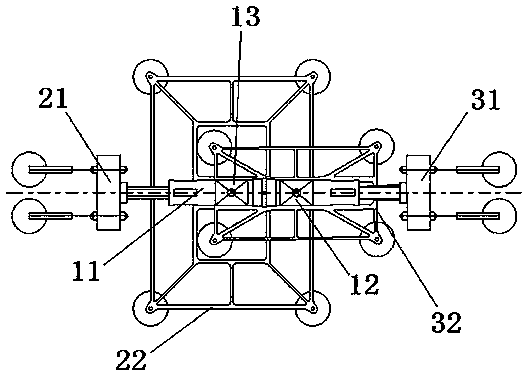

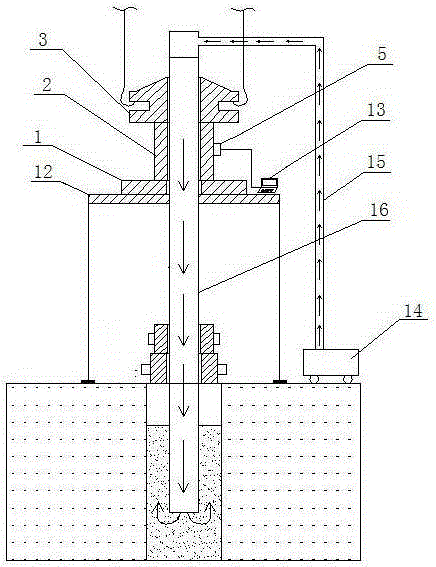

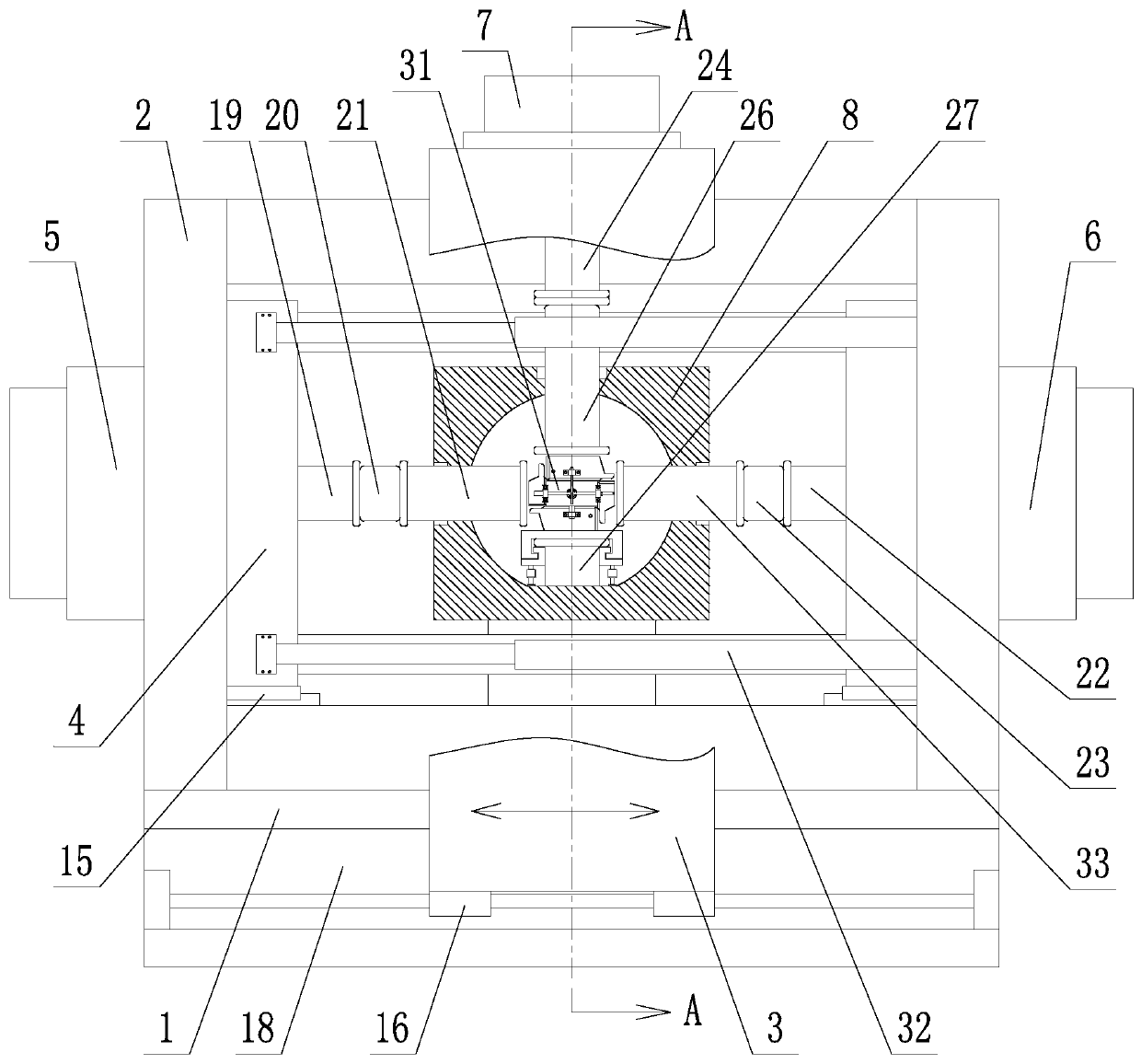

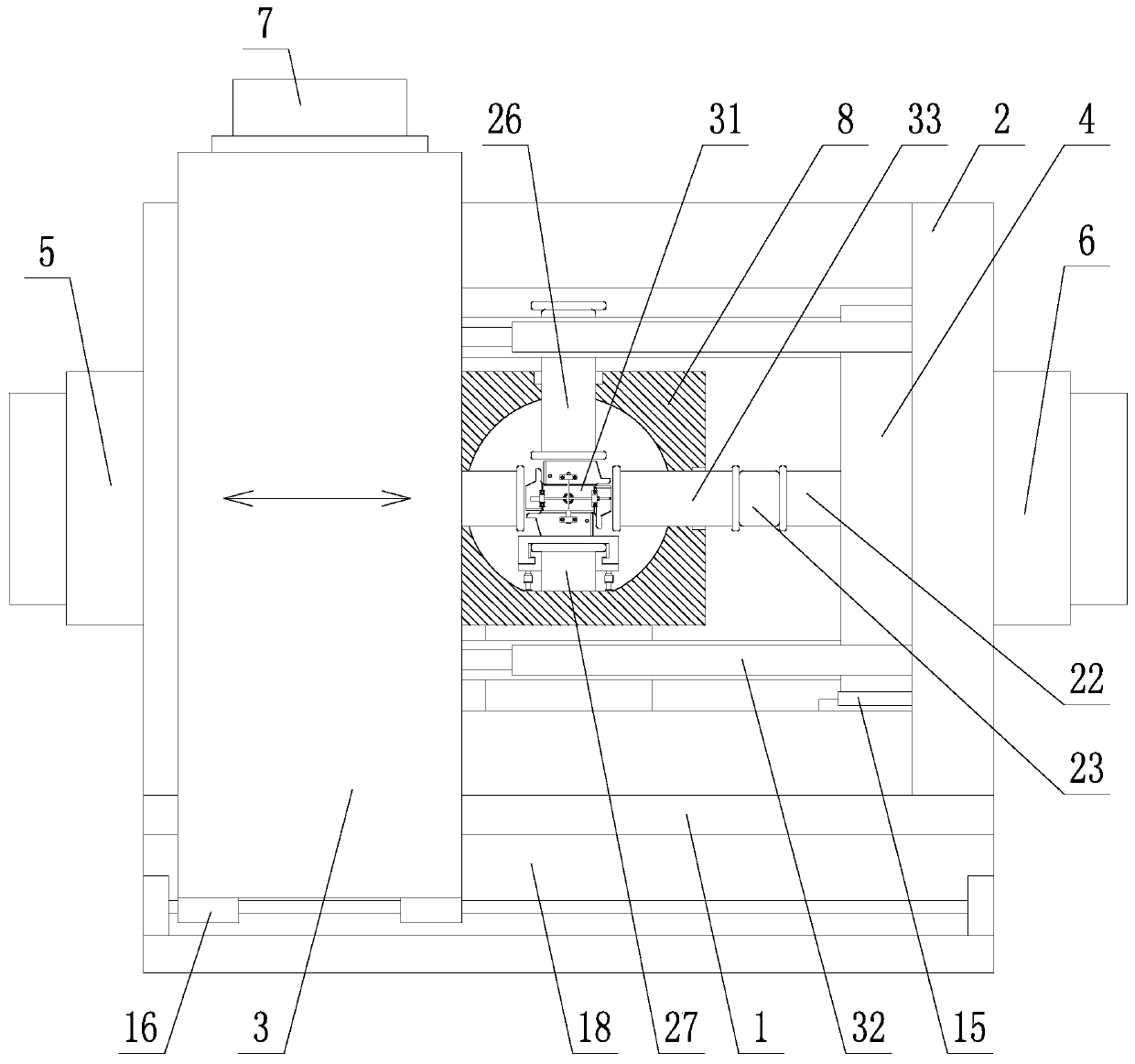

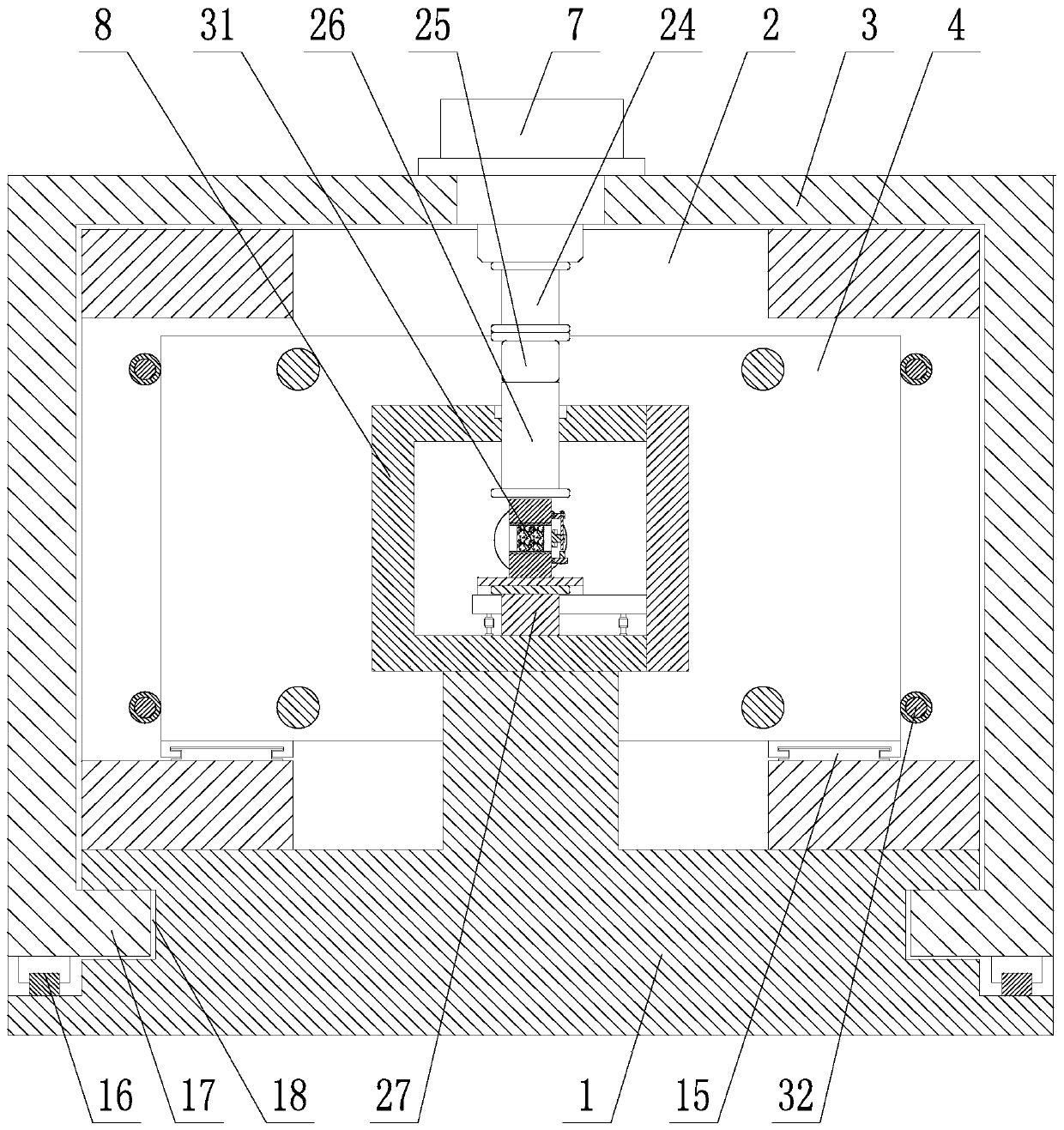

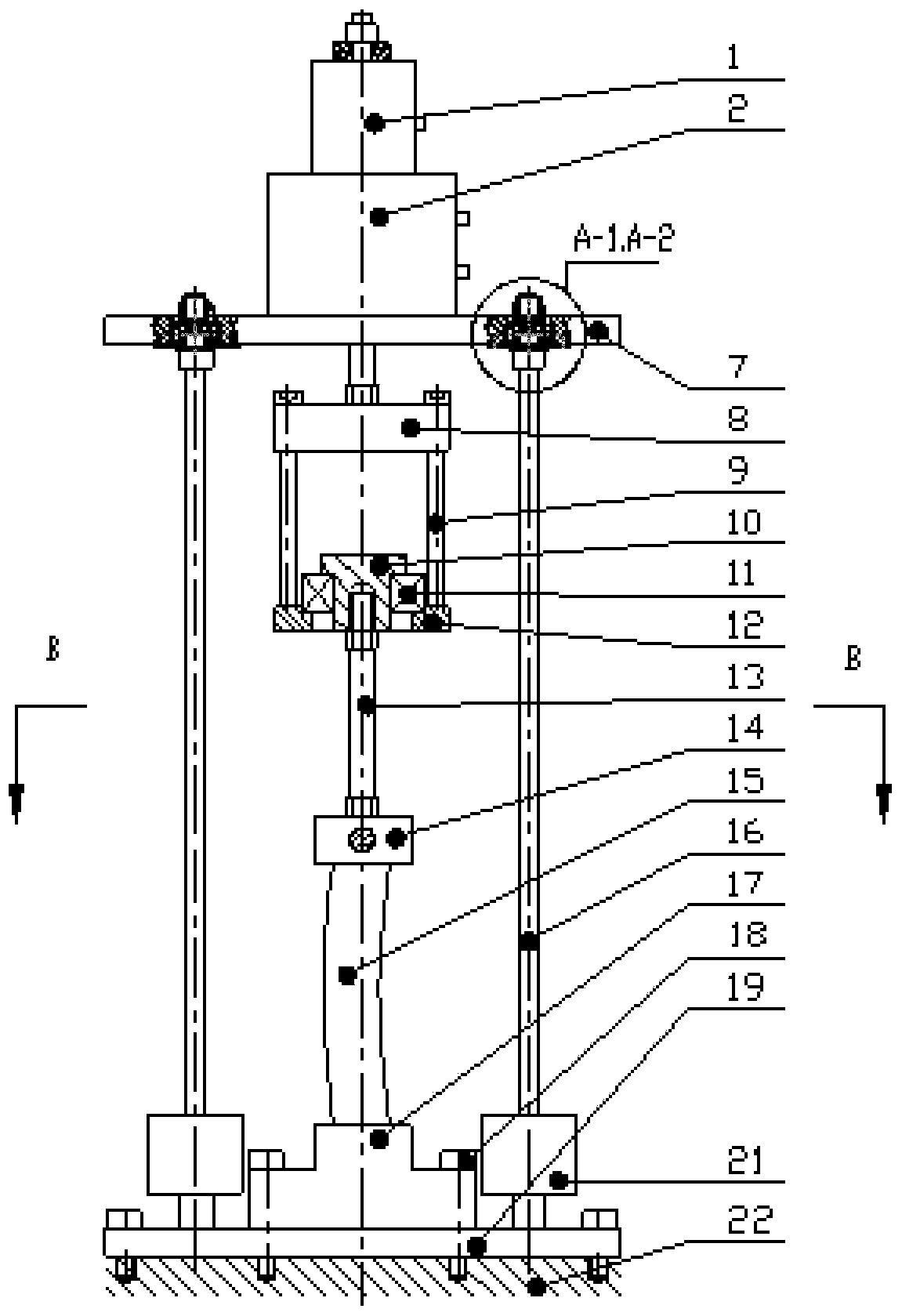

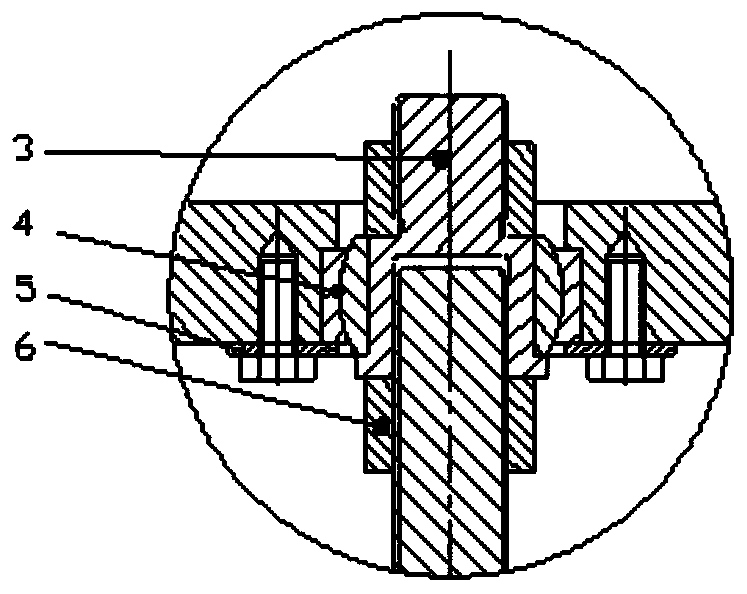

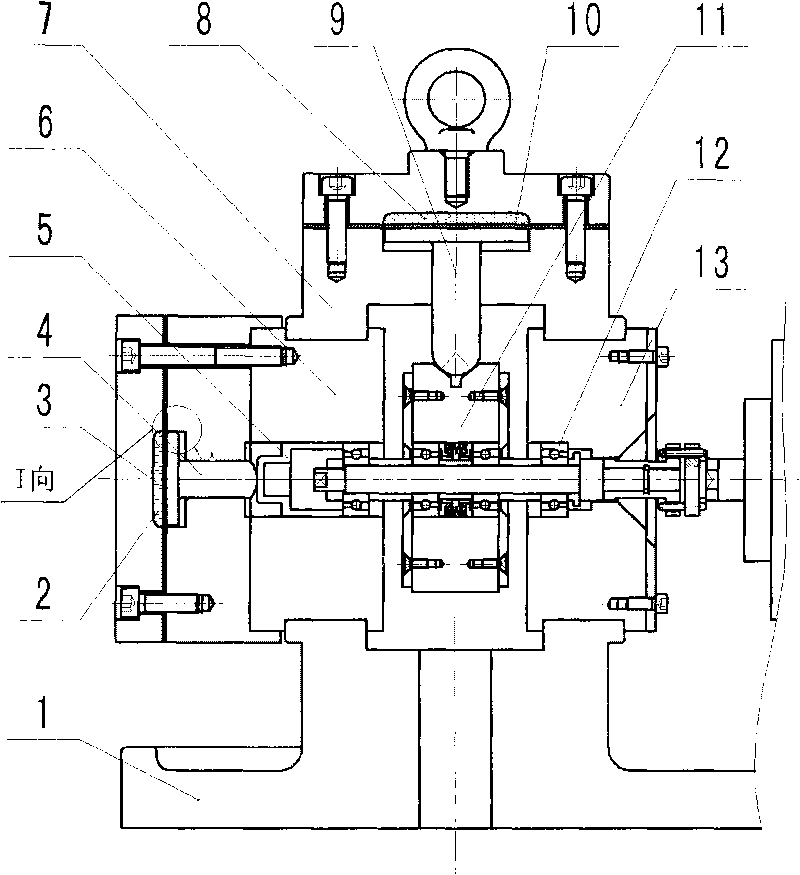

Multifunctional bearing test system

InactiveCN106092576AReal actual service conditionsReliable lifeMachine bearings testingVibration accelerationPilot system

The invention provides a multifunctional bearing test device, which comprises a rotation driving system unit, a loading system unit, a high and low temperature environment box, a lubrication cooling system unit and a measurement control system unit, and is characterized in that the loading system unit can control the loading force and the loading waveform of loading heads on an axial loading unit and a radial loading unit, and the high and low temperature environment box can realistically simulate a real temperature environment of a test. The multifunctional bearing test device can simulate service conditions of a test bearing in a test room, realizes performance testing for the test bearing under conditions of given rotating speed, lubrication, temperature, axial load, radial load and circumferential unbalanced impact load and the like, and analyzes influences imposed on the bearing performance by misalignment, poor lubrication, uneven stress and the like through data such as vibration acceleration, abrasive dust amount and the like acquired in the testing process, thereby being capable of more authentically simulating actual conditions of a rolling bearing when being subjected to the radial load, the axial load and the like, and being more reliable, systematic and scientific in service life and reliability evaluation for the test bearing.

Owner:SUZHOU DONGLING TECH

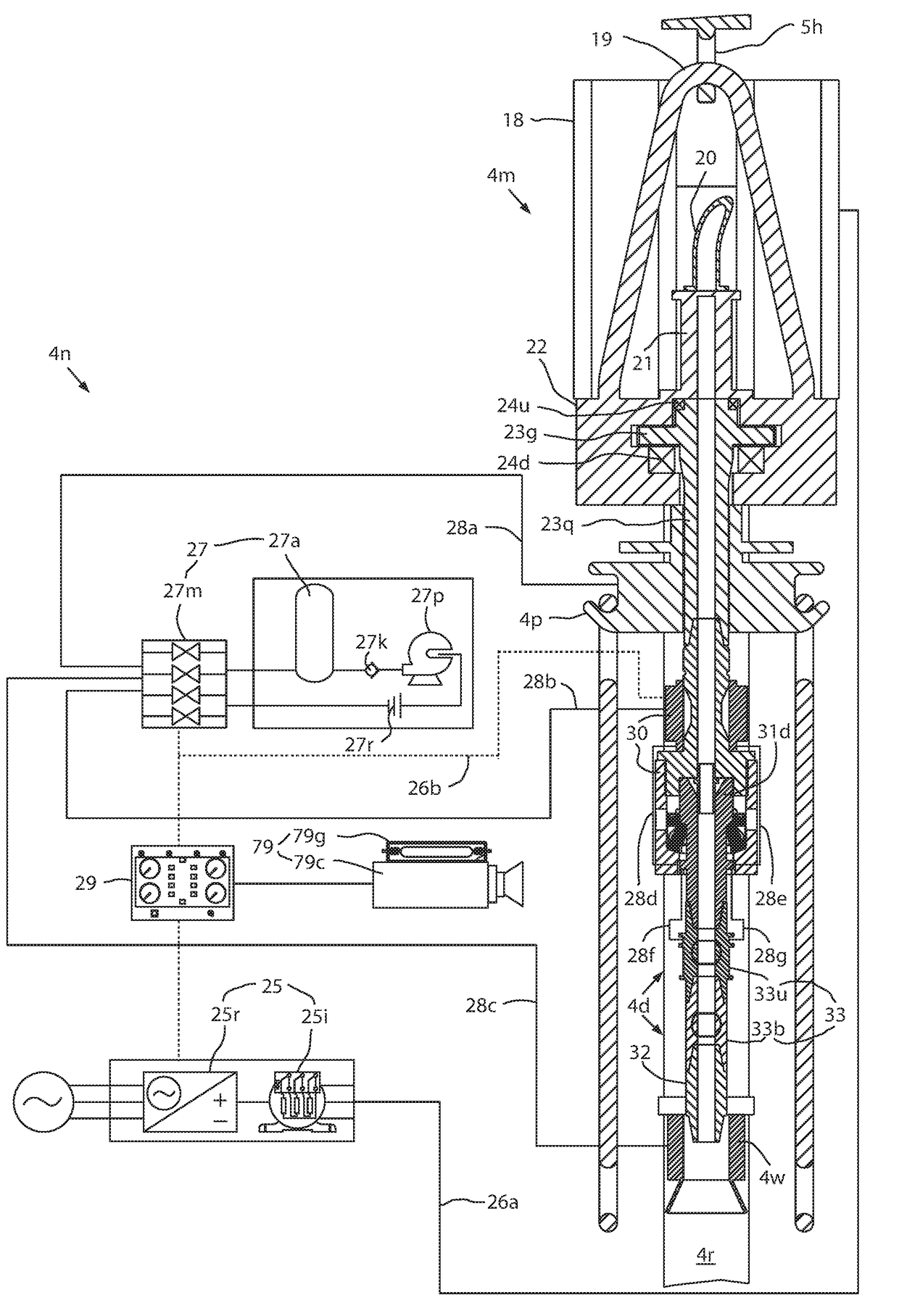

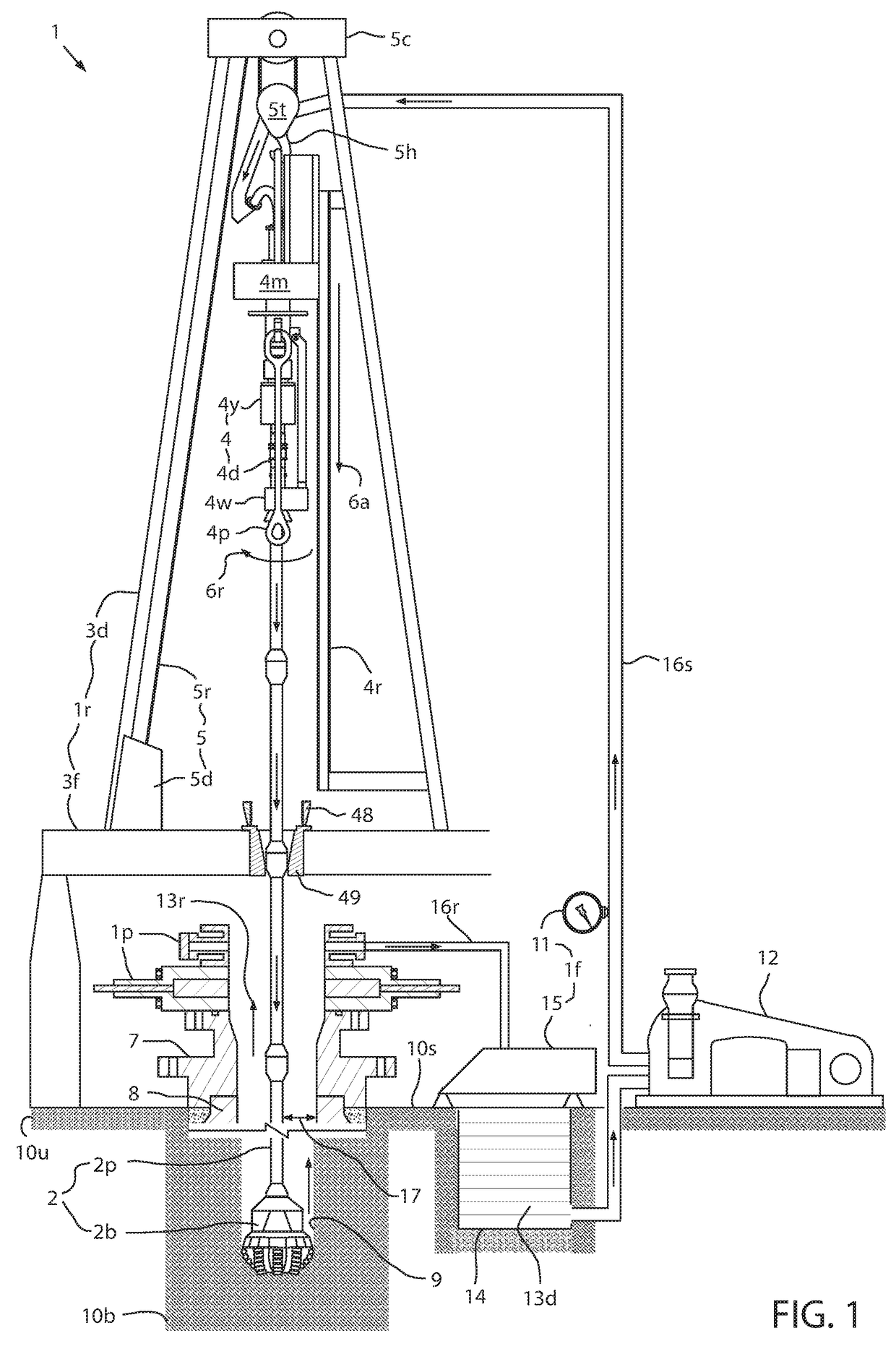

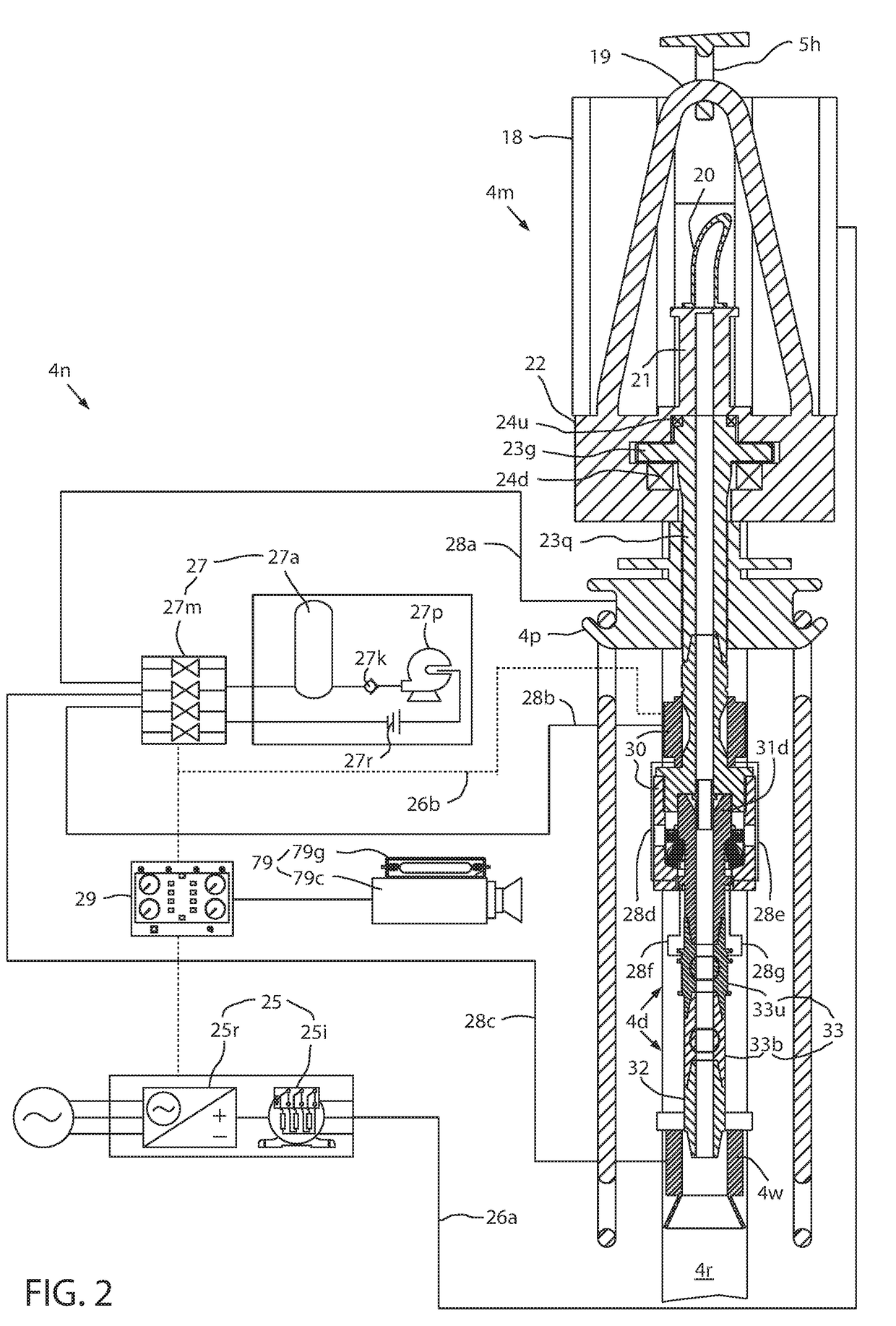

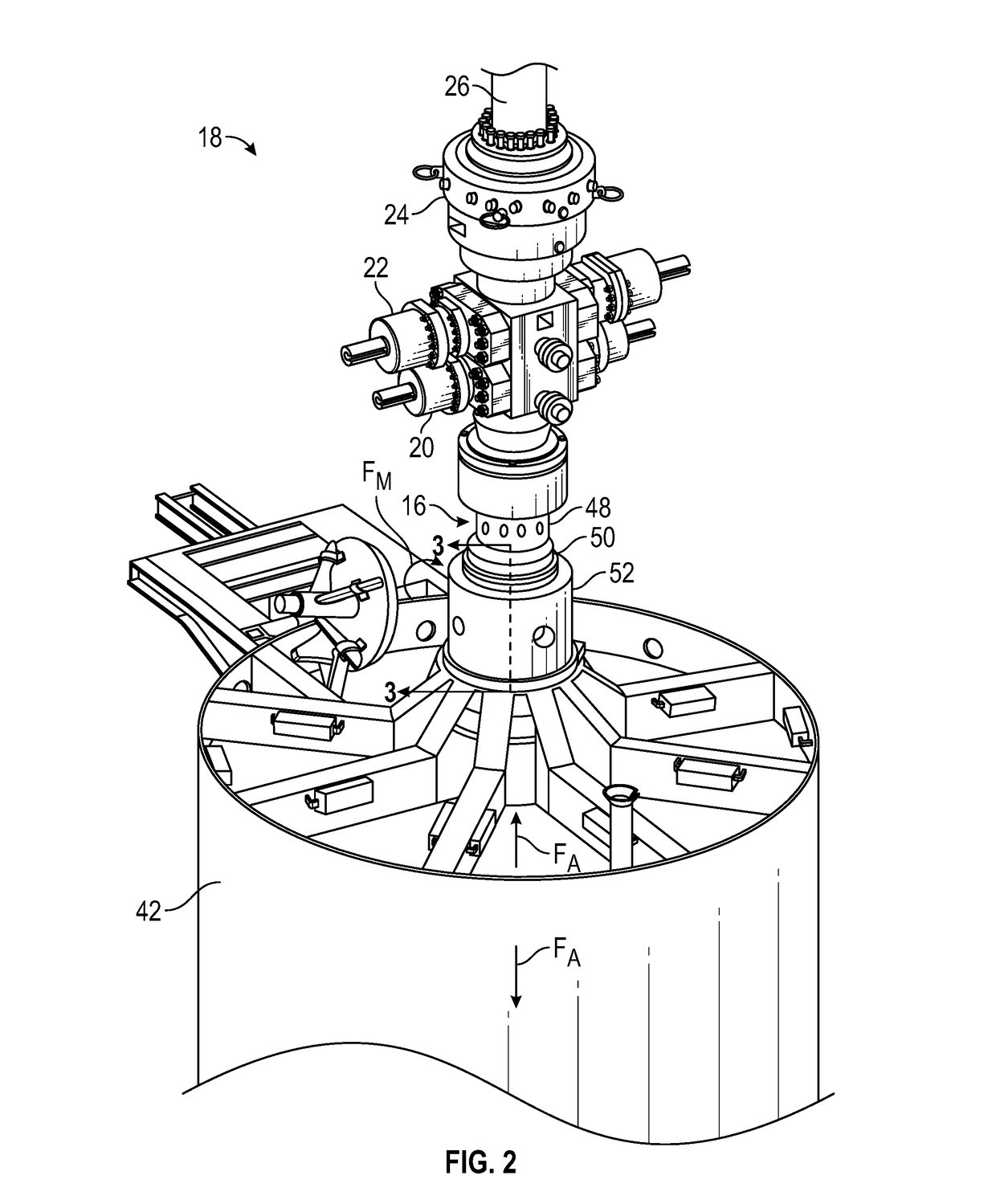

Modular connection system for top drive

The present disclosure generally relates to a modular connection system for a top drive. The modular connection system may include two tubular components, each having a bore, a seal profile, and two or more load transfer features. The first tubular component may be inserted to the second tubular component to make a connection to transfer fluid, axial loads, and torsional loads. Each of the two tubular components may also include a coupler configured to transfer pressured fluid, data, or other signals.

Owner:WEATHERFORD TECH HLDG LLC

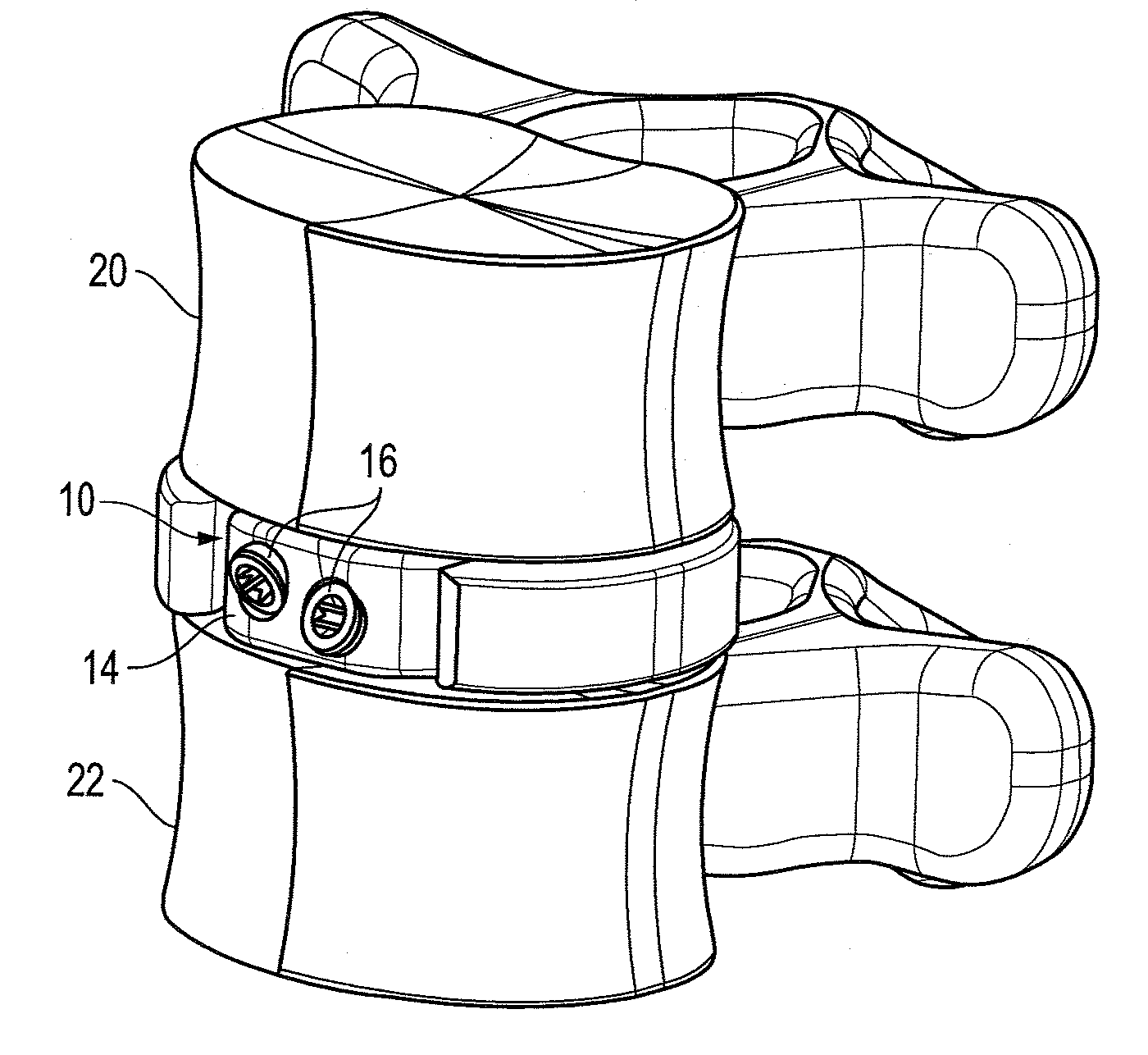

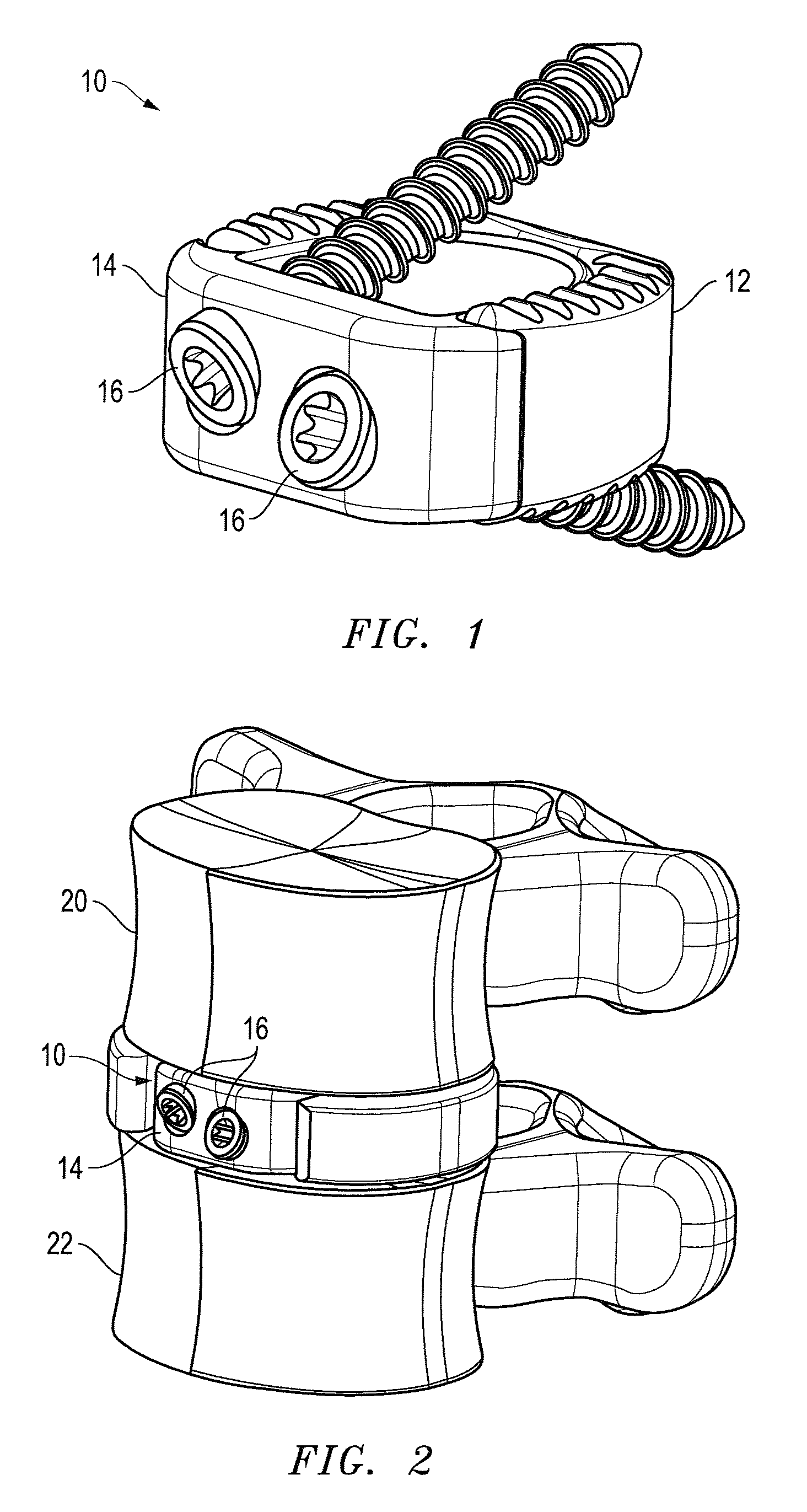

Interbody fusion device and associated methods

ActiveUS9161841B2Reduces potential to cause discomfort and damageBone implantJoint implantsSpinal columnEngineering

A method and apparatus is provided for use in spinal fusion procedures. An interbody fusion device has a first piece that is a load bearing device designed to bear the axial loading from the end plates of adjacent vertebrae. A second piece of the interbody fusion device is a retention component whose primary functions are to prevent migration of the load bearing device and loss or migration of graft material from within the load bearing device. A secondary function of the retention component is to address fixation of fasteners when the surgeon is confronted with a challenging access to adequate boney structures due to excessive curvature / angulation of the vertebrae column, minimal invasive surgery techniques, danger to surrounding vascular or neurological tissues, poor bone quality, or similar surgical complications. A tertiary function of the retention component is to provide better alignment and stabilization of misaligned vertebrae when spondylolisthesis is a significant factor. One or more fasteners secure the retention component to each of the vertebrae above and below the load bearing device. The fasteners cause the end plates of the vertebrae to compress the end plates to the load bearing device to facilitate proper fusion.

Owner:SPINESMITH PARTNERS

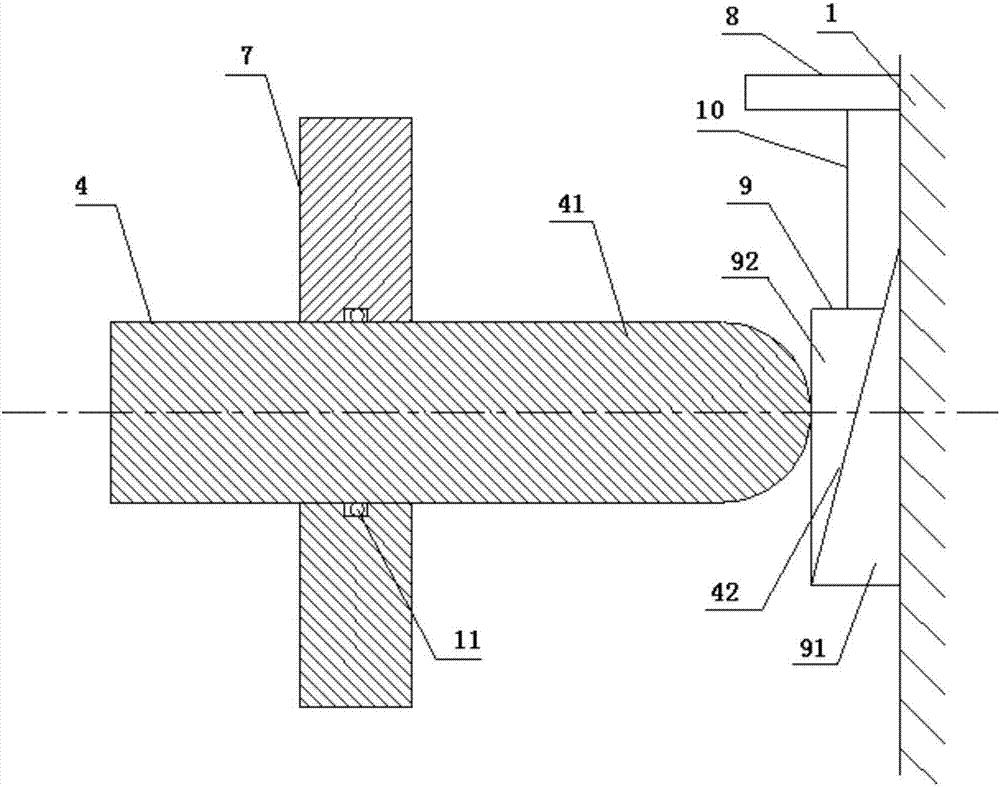

Operational method for measuring creep parameters and infiltration parameters of smashed rocks simultaneously

InactiveCN102620996ALow costEasy to operateMaterial strength using tensile/compressive forcesPermeability/surface area analysisAxial LoadingsAxial pressure

The invention relates to an operational method for measuring creep parameters and infiltration parameters of smashed rocks simultaneously, which realizes loading of axial pressure and infiltration pressure difference by the aid of a smashed rock creep-infiltration full-process coupling testing device. The operational method includes: firstly, determining initial height of rock in a cylinder before loading, starting an axial loading device then, starting an electric test pump to saturate rocks, applying axial load, injecting water to the rocks to infiltrate according to set water pressure, finally changing the axial load to perform the creep-infiltration test of the next-grade stress stage. The infiltration characteristic parameters are obtained by matching of a scatter diagram of hole pressure gradient and average infiltration speed and the Forchheimer formula, and the creep parameters are obtained by matching of Kelvin-Volgt creep model and an axial strain time curve. The operational method has the advantages that creep model during creep and infiltration full-process couple of the smashed rocks can be acquired, mutual affection of creep and infiltration can be indicated through the parameters, operation results can provide theoretical basis for theoretical analysis and numerical value simulation of creep-infiltration of the smashed rocks.

Owner:XUZHOU NORMAL UNIVERSITY

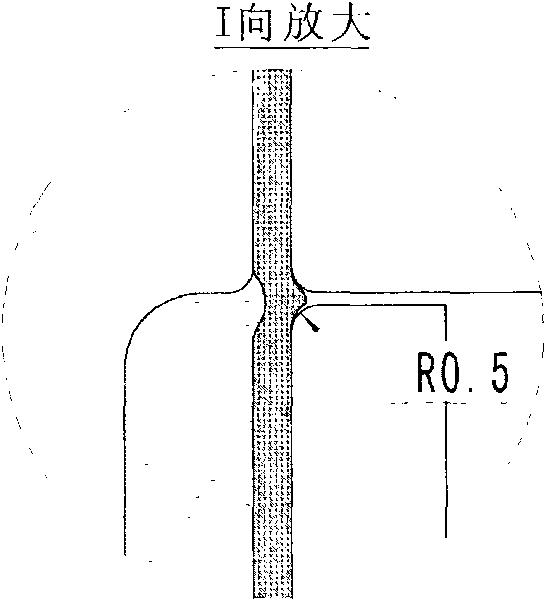

Spinning riveting assembly and manufacturing method of automobile hub bearing unit

The invention relates to a spinning riveting assembly and manufacturing method of an automobile hub bearing unit. The method comprises the following steps: firstly machining a hub bearing; assembling an outer flange, steel balls, a small inner ring and a hub shaft according to the requirements of being approximate to zero end play, and assembling the bearing unit into a state before riveting according to a certain process; placing the assembled bearing unit on a worktable of a riveting machine tool for spinning deformation; and finally inspecting. The spinning riveting assembly and manufacturing method has the beneficial effects that assembly quality and assembly efficiency of the automobile hub bearing unit can be greatly improved, the assembled automobile hub bearing unit becomes a whole body, axial load (clamping force) of the small inner ring can be accurately controlled, reliability, safety and service life of the hub bearing are greatly improved, and production efficiency is very high and up to 20-30sec / unit; and according to product structure design provided by the invention, smooth implementation of spinning riveting assembly can be ensured, loss of raw materials can be effectively reduced, and remarkable effect of saving energy and materials is achieved.

Owner:SHAOGUAN SOUTHEAST BEARING CO LTD

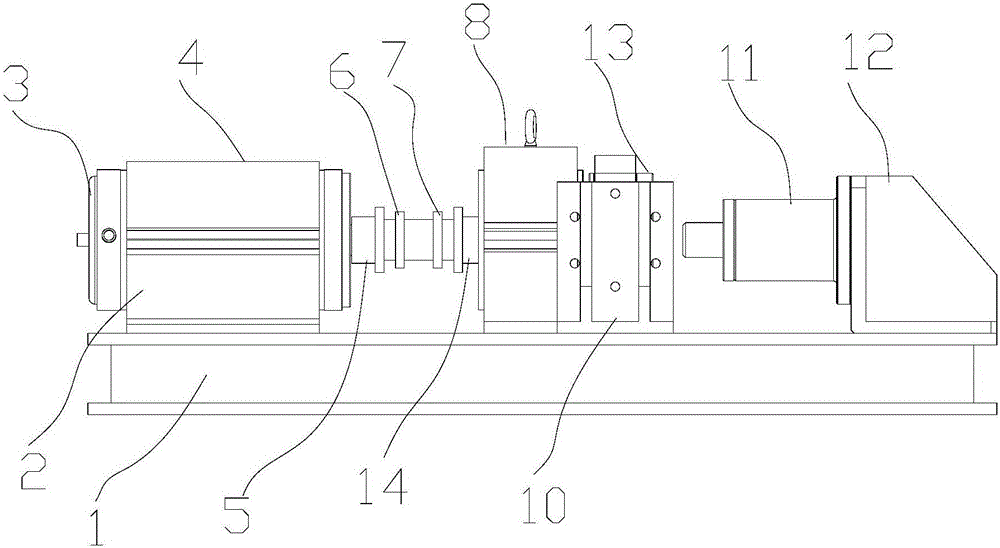

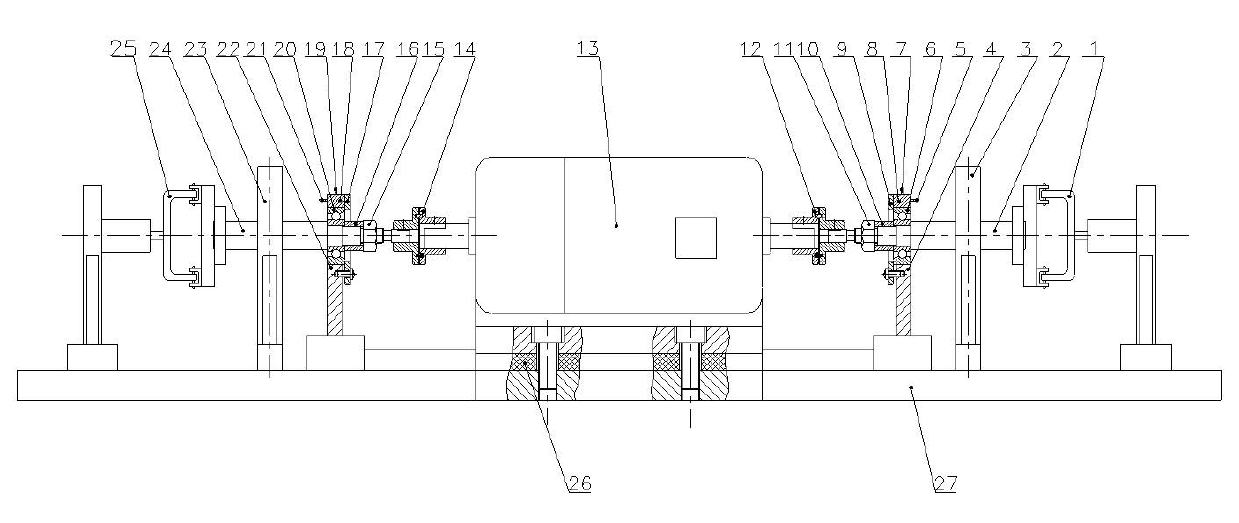

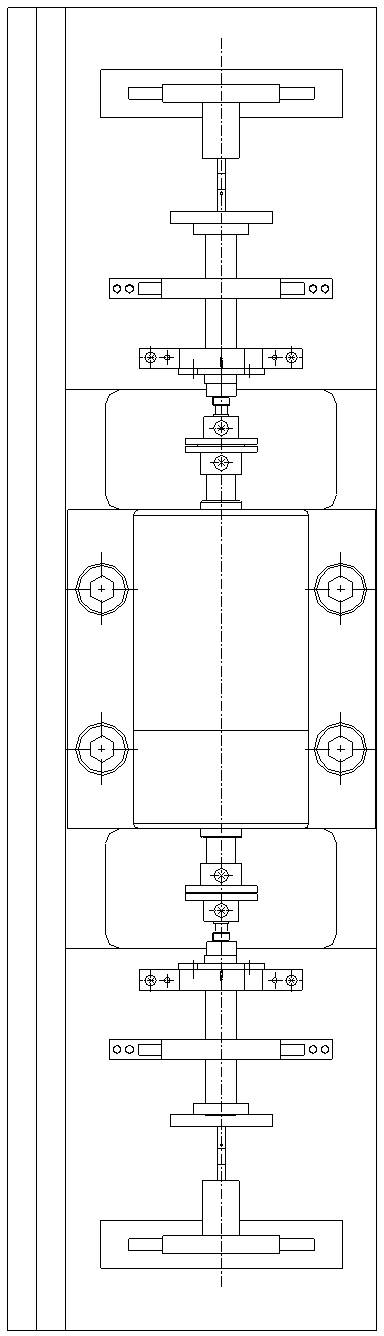

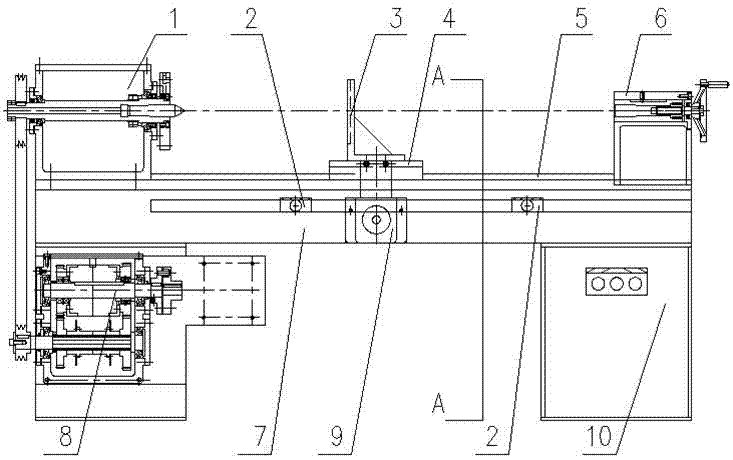

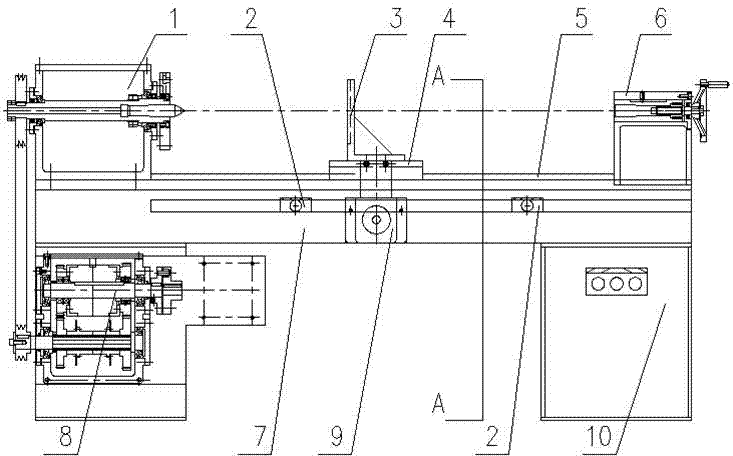

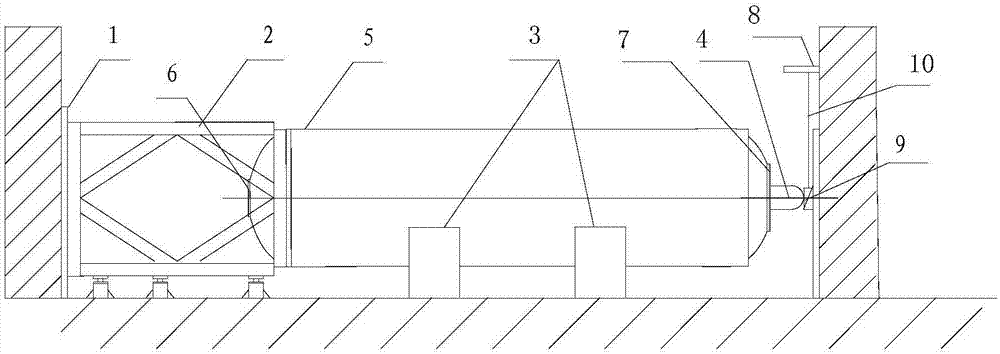

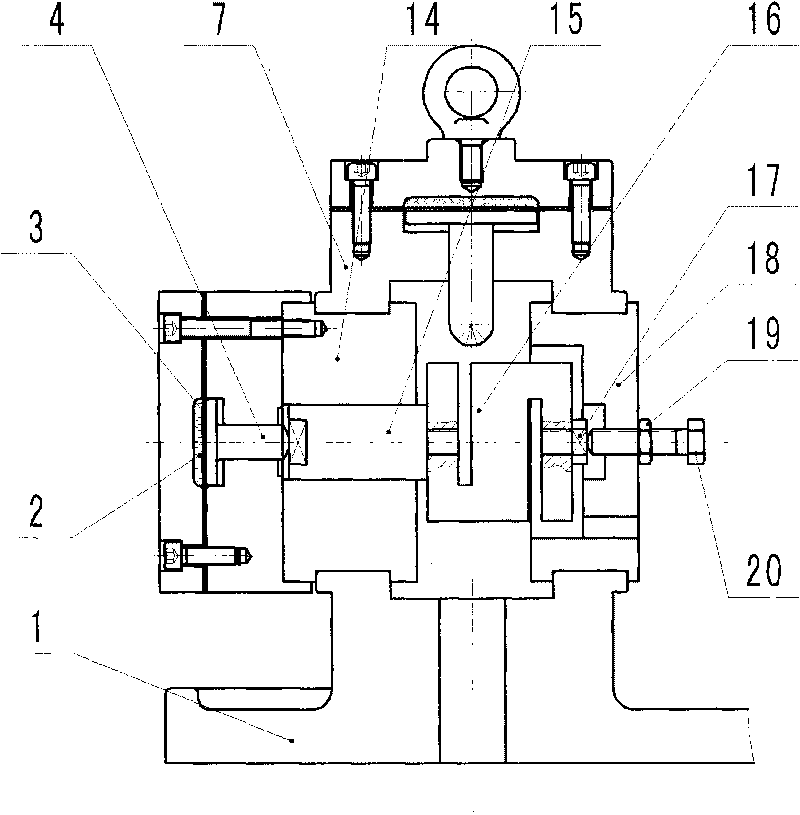

Test-bed for vibration test of rolling bearing

InactiveCN102607849AReduce distractionsVibration measurement in solidsMachine bearings testingVibration measurementRolling-element bearing

The invention discloses a test-bed for a vibration test of a rolling bearing, comprising a test-bed body, a motor, a left test device and a right test device, wherein the motor is a motor with double output shafts, and the left test device and the right test device are connected with the left output shaft and the right output shaft of the motor respectively. The test-bed for the vibration test of the rolling bearing disclosed by the invention can measure the vibrations of two bearings simultaneously, and reduce interference on the vibration measurements of the measured bearings by configuring the motor to be a motor with double output shafts, disposing the left test device and the right test device on the two output shafts of the motor, and omitting a support bearing for supporting the motor; and the test-bed for the vibration test of the rolling bearing disclosed by the invention can perform radial loading on a transmission shaft, and act an axial load by disposing a radial loading device and an axial loading device on the test-bed body, thus being capable of measuring the radial vibrations of the measured bearings in the horizontal direction and the vertical direction.

Owner:CHONGQING UNIV

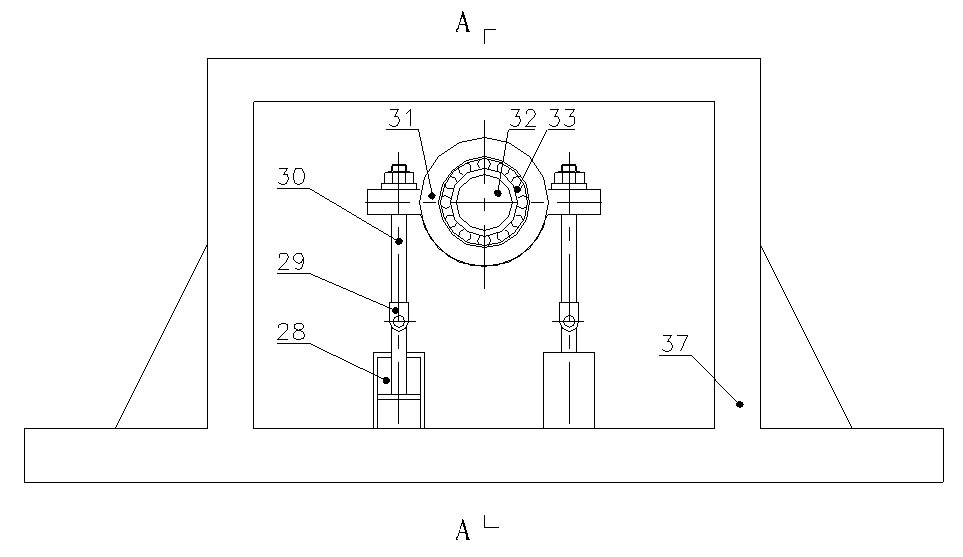

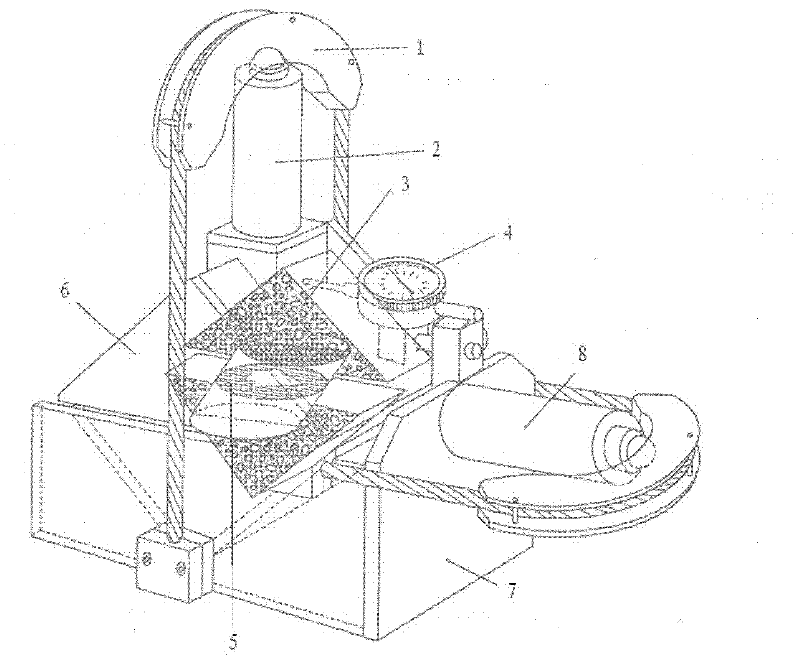

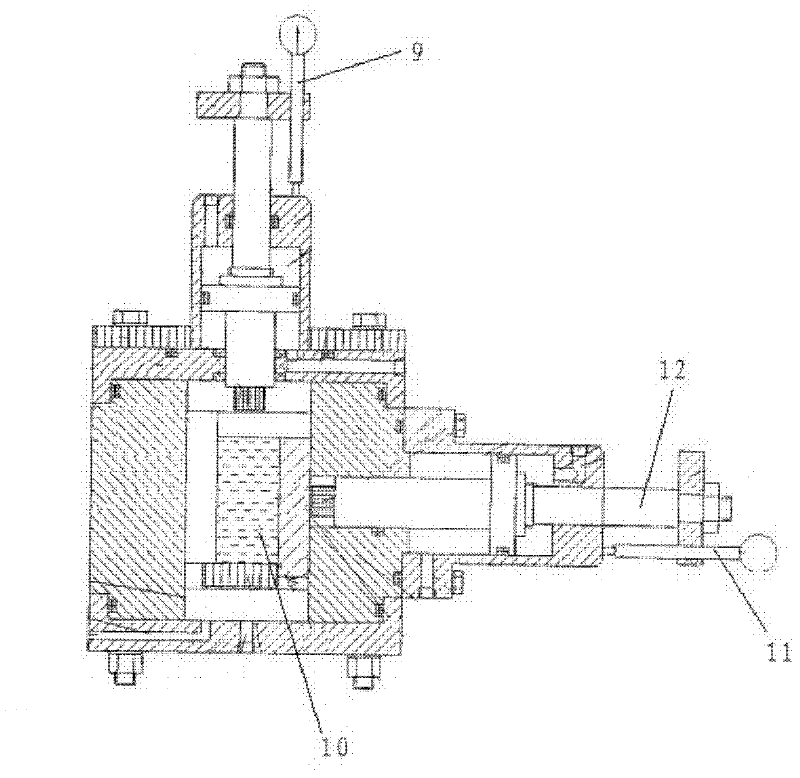

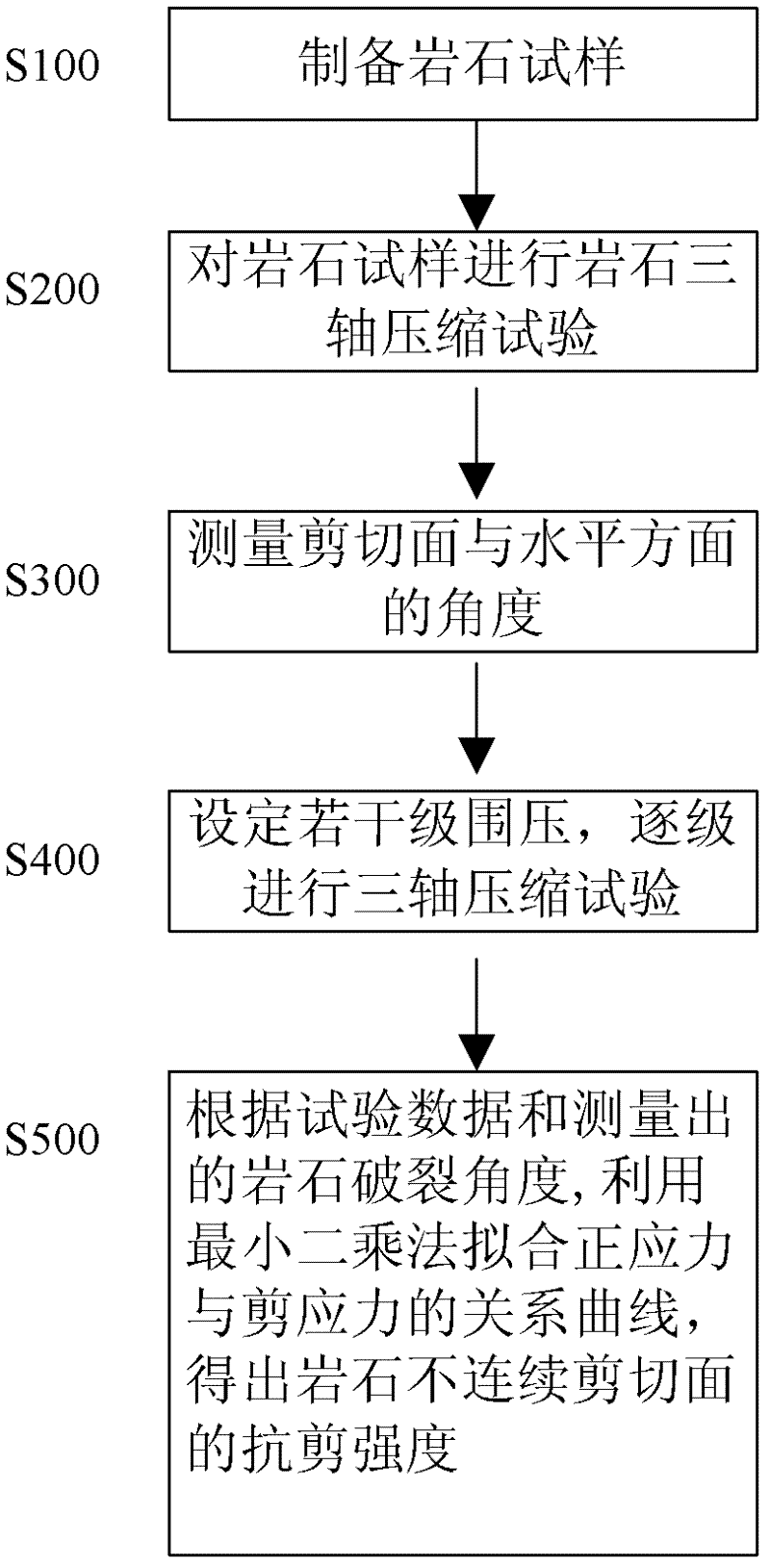

Method for measuring shear strength of discontinuous shear plane of rock by utilizing three-shaft compression

InactiveCN102645383ALong preparation timeReduce precisionMaterial strength using steady shearing forcesShear stressResidual deformation

The invention relates to a shear strength measurement method, in particular to a method for measuring the shear strength of a discontinuous shear plane of a rock by utilizing three-shaft compression. The method comprises the following steps of: S100, preparing a rock sample required by a three-shaft compression test; S200, carrying out the three-shaft compression test on the rock sample, wherein an axial load is applied after confining pressure application till the rock sample is sheared and damaged and generates residual deformation; S300, measuring an angle between the shear plane and the horizontal direction; S400, setting a plurality of grades of confining pressures and carrying out the three-shaft compression test grade by grade; and S500, calculating positive stress and shear stress according to the test data and a rupture angle of the rock sample and fitting relation curves of the positive stress and the shear stress by utilizing a least square method to obtain the shear strength. The method has the beneficial effect that the residual deformation is utilized for replacing a cement pouring process to carry out shear test on the discontinuous shear plane of the rock sample, so that the shear strength of the discontinuous shear plane of the rock sample can be quickly and accurately obtained.

Owner:中冶集团资源开发有限公司 +1

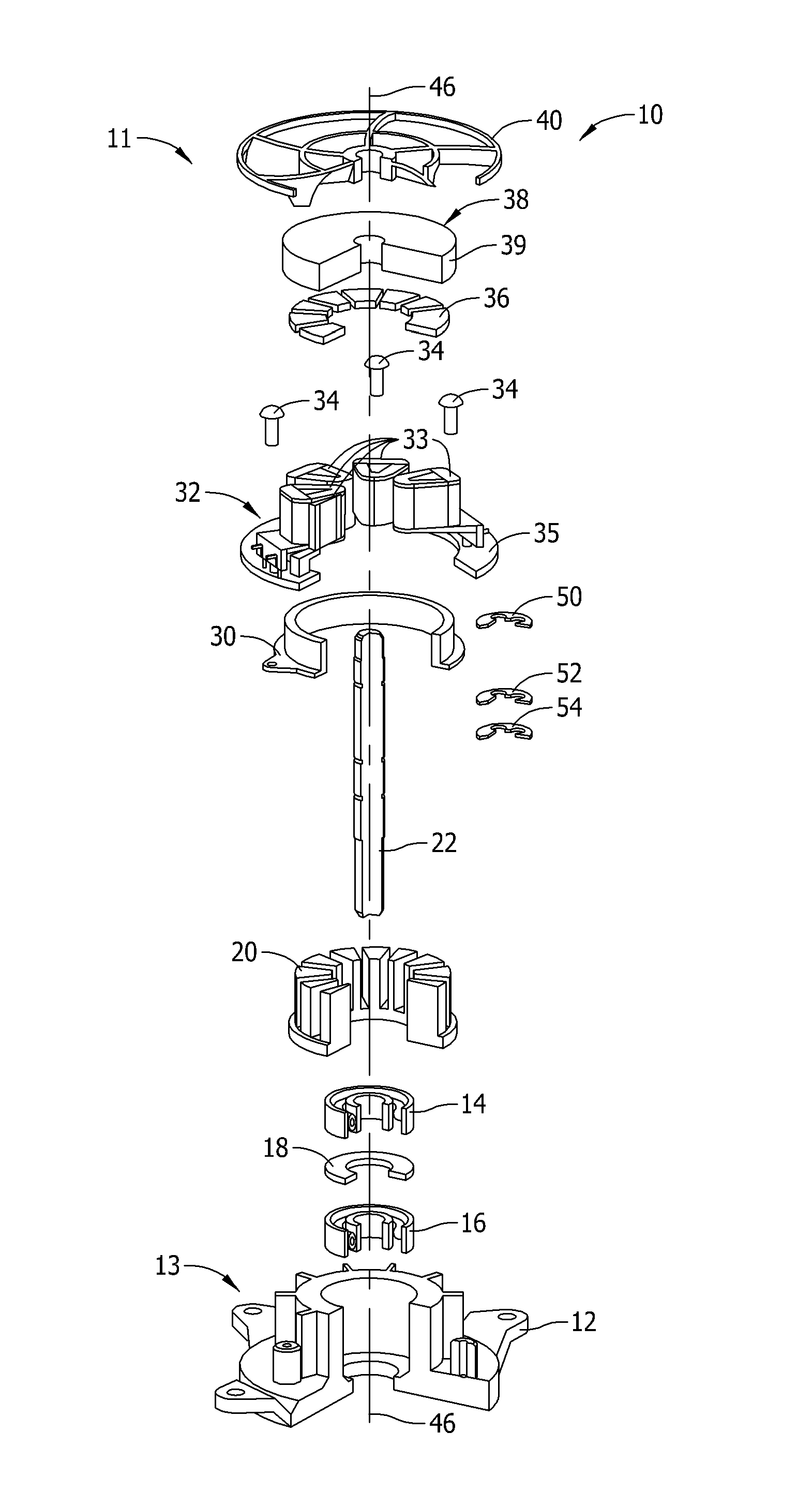

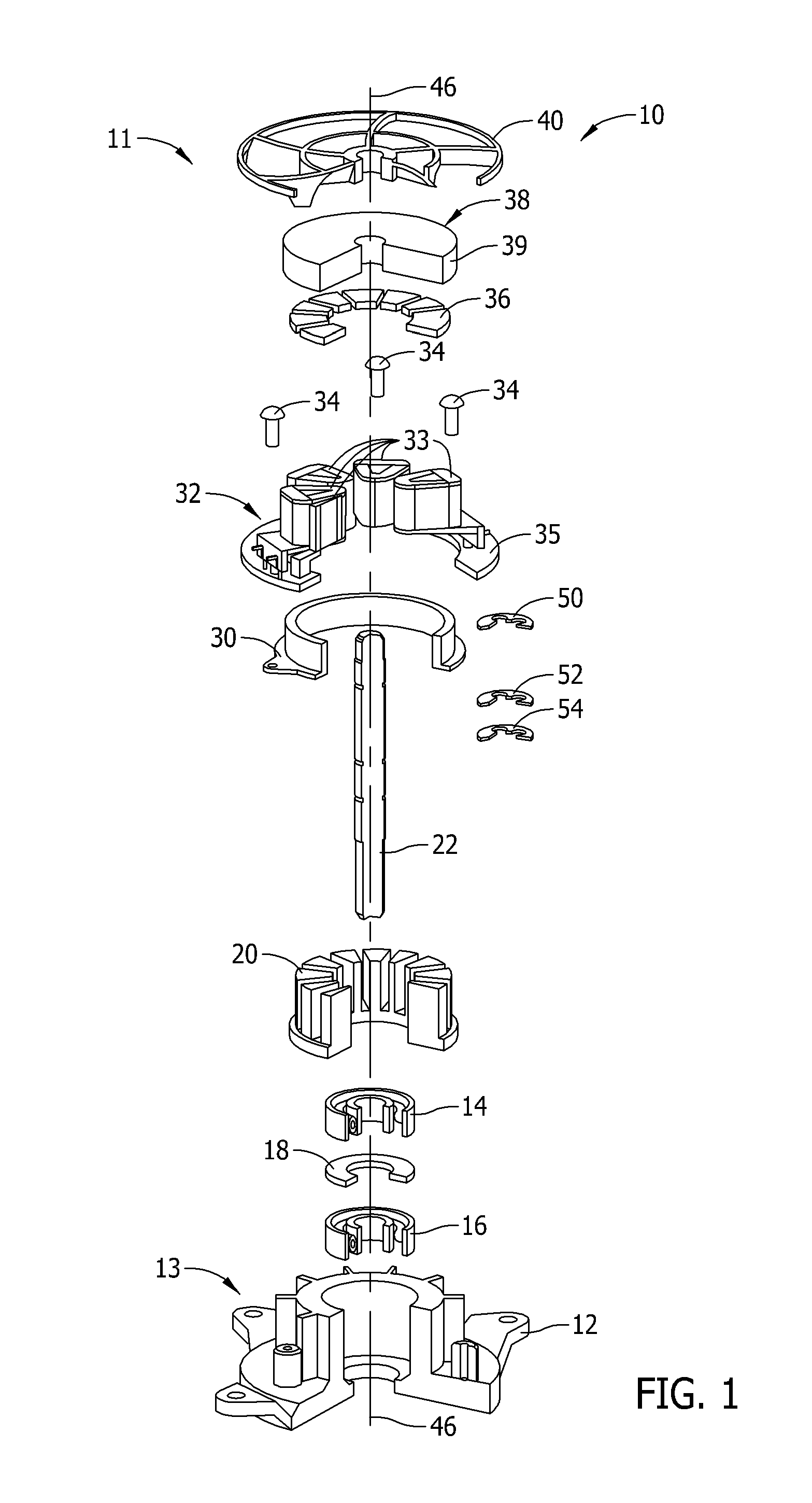

Axial load sharing bearing system and associated method of use

An axial flux electric machine and associated method of use that includes a shaft, a rotor attached to the shaft, a plurality of permanent magnets positioned underneath the rotor, an electrical winding positioned below the plurality of permanent magnets, a stator that encircles the shaft that is located below the rotor, a first bearing assembly located below the stator and encircling the shaft of the rotor, a second bearing assembly located below the first bearing assembly and encircling the shaft, and a spring mechanism, located between the first bearing assembly and the second bearing assembly, to distribute load placed on the shaft between the first bearing assembly and the second bearing assembly.

Owner:REGAL BELOIT AMERICA +1

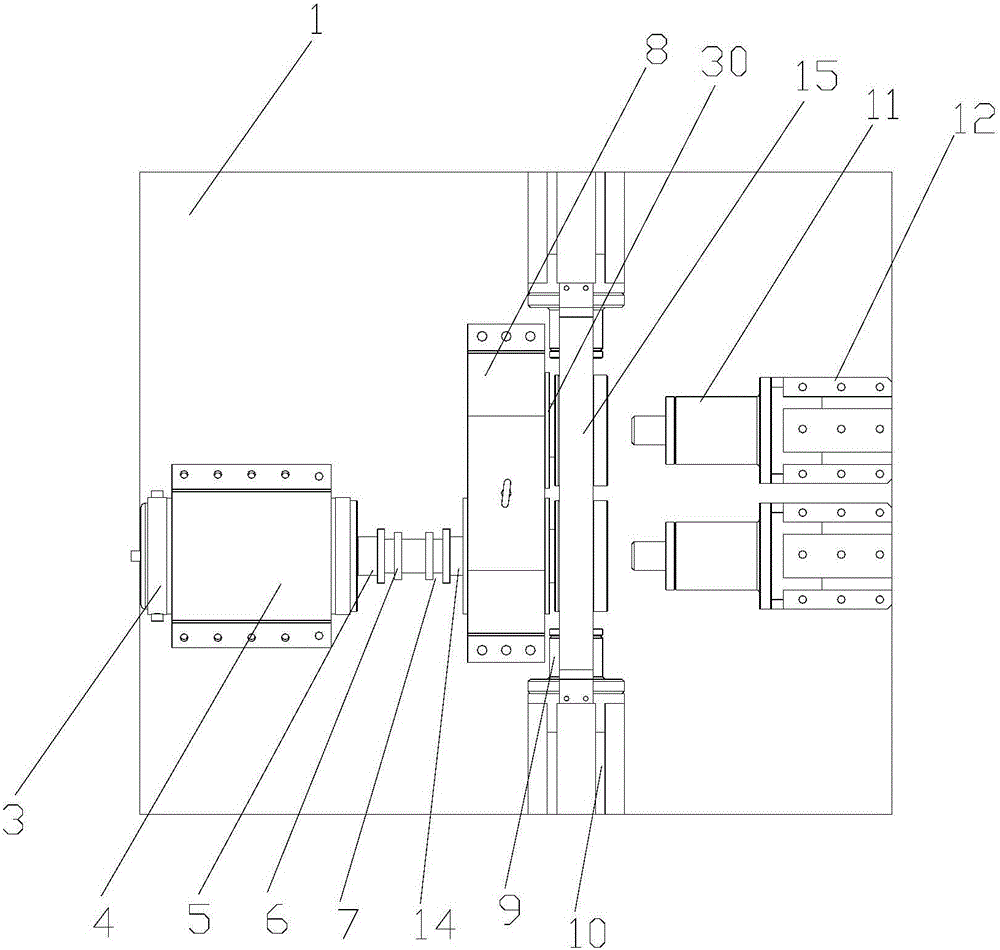

Loading running-in device for ball screw pair and running-in testing method thereof

ActiveCN102445340AImprove factory performanceGood running-in effectMachine gearing/transmission testingTest performanceBrake

The invention discloses a loading running-in device for a ball screw pair and a running-in testing method thereof, which belong to the technical field of running-in test of ball screw pairs. In the running-in device, a main spindle box and a tail seat are used for fixing a ball screw pair; a positioning plate is fixedly connected with a ball nut of the ball screw pair; automatic reversing running-in of the ball screw pair is realized by using a limit switch and a limit switch triggering rod; a magnetic powder brake is used for applying an axial load to the ball screw pair; a reversing mechanism is used for controlling positive and negative rotation of a tip; and a control cabinet is used for controlling other devices to work. The running-in test method comprises the following steps of: loading the ball screw pair; fixing the ball nut; performing a running-in procedure; parking; and testing performance parameters and unloading the ball screw pair. In the invention, the axial load is applied to the ball screw pair by using the magnetic powder brake, so that the delivery performance of the ball screw pair is enhanced; and the magnitude of the loaded load is easy to control, so that temperature rise of the ball screw pair after running-in can be tested accurately and conveniently.

Owner:中润海精密科技有限公司

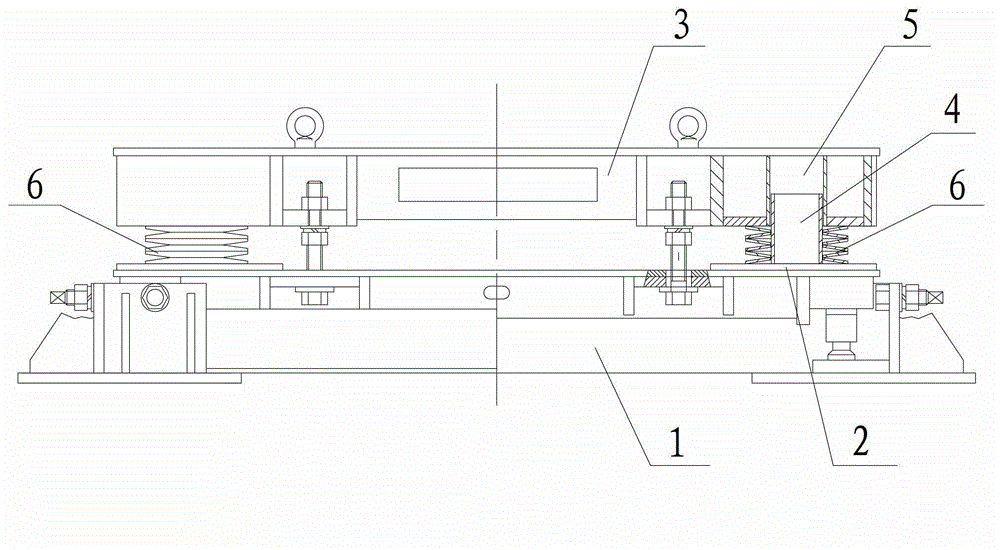

Buffer type weighing machine for iron and steel materials

The invention discloses a buffer type weighing machine for iron and steel materials, wherein a plurality of belleville springs are used as buffer elements of a buffer, can bear a large axial load under the condition of small deformation, has a better buffer vibration absorbing capacity, and is more suitable for an occasion with a small axial space, a large radial space and larger bearing capacity. The buffer can be conveniently arranged between a weighing platform and a weighing sensor, can be used for effectively buffering an impaction force acting on the weighing platform and the weighing sensor, and prevents the weighing platform and the weighing sensor from being damaged by the impact force. In addition, the belleville springs on the buffer are standard members and can be conveniently replaced after losing efficacy, so that parts of the weighing machine for the iron and steel materials are maintained, overhauled and replaced more conveniently in a post-stage use process.

Owner:台衡精密测控(昆山)股份有限公司

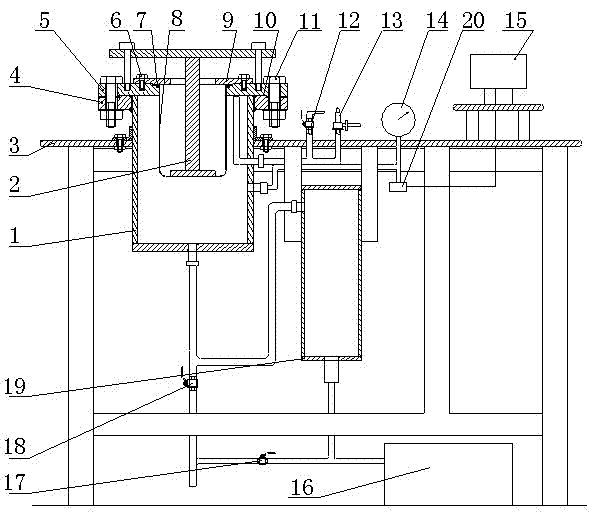

Instability test device of external pressure vessel

InactiveCN102564859AImprove accuracyGuaranteed safe operationMaterial strength using tensile/compressive forcesStructural/machines measurementReactor pressure vesselExhaust valve

The invention discloses an instability test device of an external pressure vessel. The instability test device comprises a cylinder body, a test frame, a flange, a flange cover, a pressing cover, an exhaust valve, a security valve, a digital display pressure meter, a computer, a pressure source, a water discharging valve of a buffering tank, a water discharging valve of the cylinder body, the buffering tank and a pressure sensor. When in use, the instability test device is used for pressurizing to the cylinder body, so that instability test data of a vessel to be measured can be measured under an effect of uniformly distributing external pressure on the circumference or combined circumference external pressure and axial loading effect. The instability test device has the characteristics of simple structure, accurate measurement and real-time data recording.

Owner:ZHEJIANG UNIV

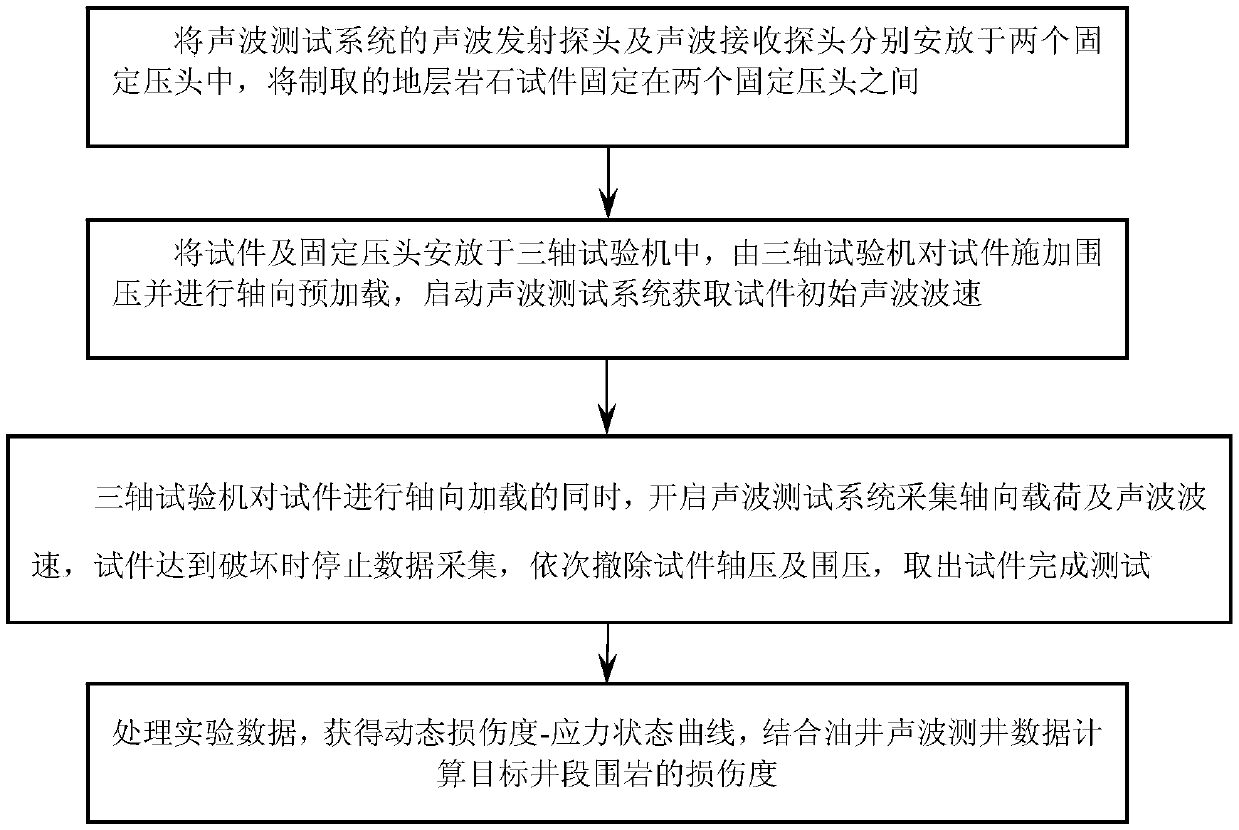

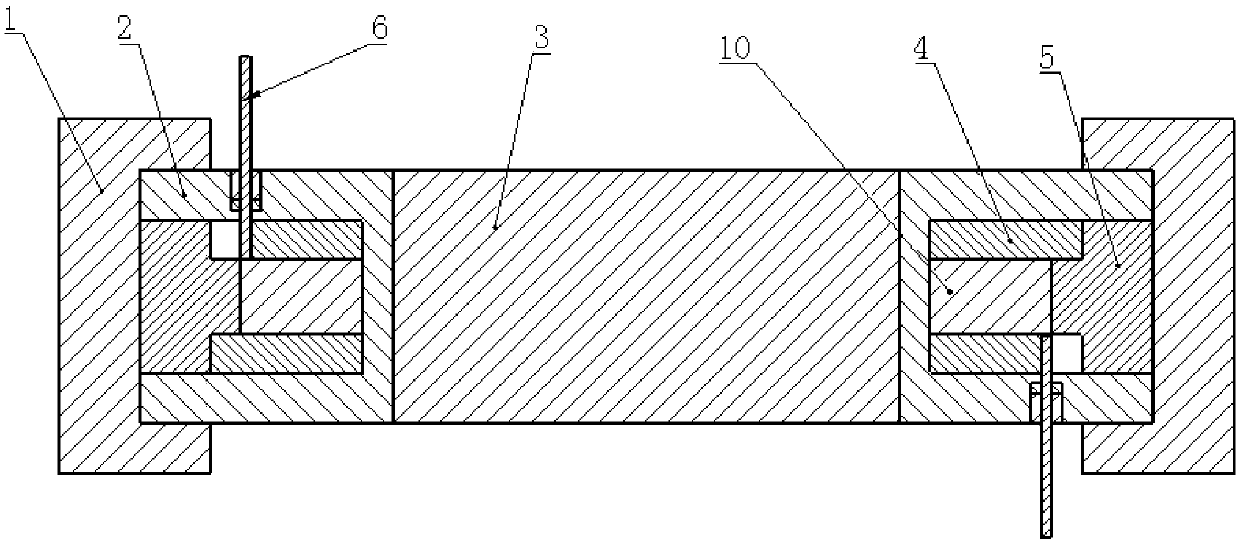

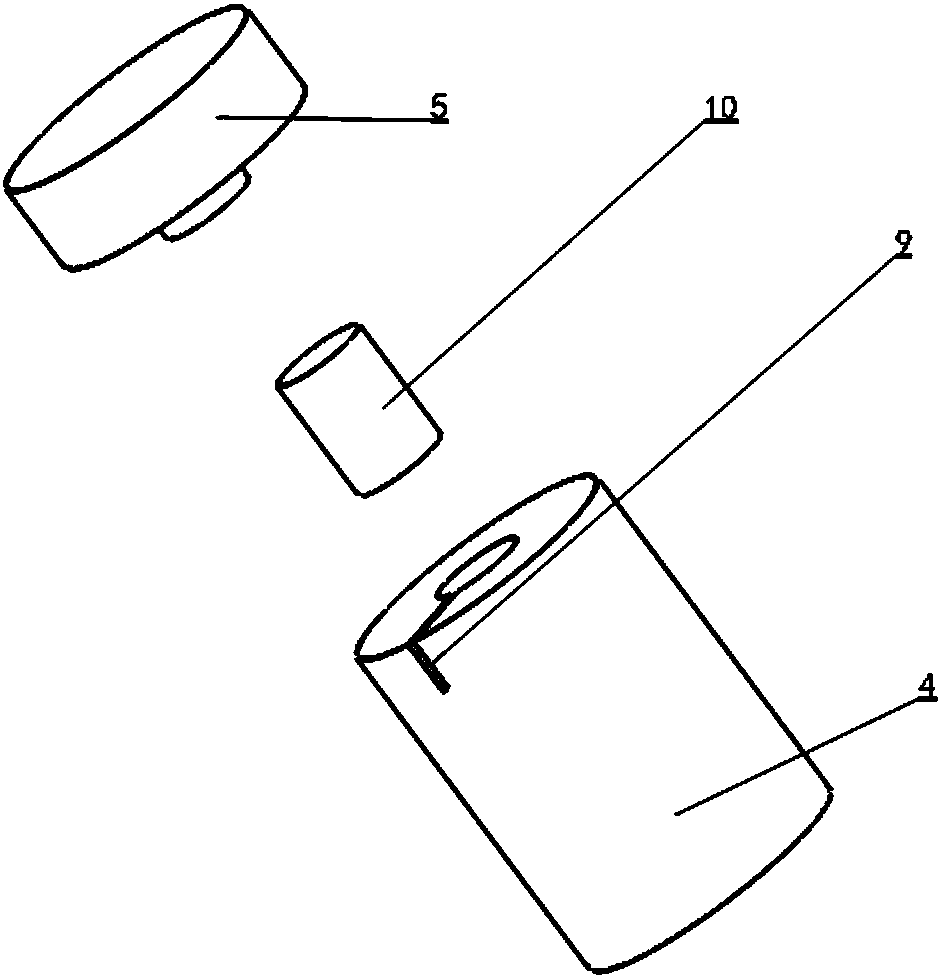

Method for measuring dynamic damage degree of rock in confining pressure condition

InactiveCN107941595ADynamic damage calculationDamage calculationMaterial strength using tensile/compressive forcesTriaxial shear testAxial Loadings

The invention provides a method for measuring the dynamic damage degree of rock in a confining pressure condition. The method comprises: 1) arranging a sound wave emission probe and a sound wave reception probe of a sound wave test system at two fixed pressure heads, and fixing a manufactured stratigraphic rock test piece between the two fixed pressure heads; 2) putting the test piece and fixed pressure heads in a triaxial testing machine, applying the confining pressure to the test piece via the triaxial testing machine and performing axial pre-loading, and starting the sound wave test systemto obtain the initial sound wave speed of the test piece; 3) while performing axial loading on the test piece through the triaxial testing machine, starting the sound wave test system to collect theaxial load and sound wave speed, stopping data collection when the test piece is broken, reducing the axial pressure and confining pressure from the test piece in sequence, and taking the test piece out to finish the test; and 4) treat the experimental data to obtain a dynamic damage degree and stress state curve, and calculating the damage degree of surrounding rock of a target well section according to the sound wave well-logging data of an oil well.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Double-end calibration device and calibration method

ActiveCN104198113ARealize mock loadingSimple structureForce/torque/work measurement apparatus calibration/testingKinematic couplingMeasurement device

The invention relates to a double-end calibration device and a calibration method and belongs to the technical field of aerodynamic force measurement of aerospace force test. The double-end calibration device with the middle fixed and two ends free is used for calibration during force test of wind tunnel aerodynamic / kinematic coupling research. The double-end calibration device mainly comprises two sets of L-shaped sliders and loading heads which are used cooperatively, one end of the front L-shaped slider is connected with the front loading head while the other end of the same is connected with the front end of a double-end force measurement device, and the rear L-shaped slider is connected with the rear loading head while the other end of the same is connected with the rear end of the double-end force measurement device; the loading heads are four-point type frame loading heads, do not interference with each other in space and are used for applying longitudinal load; the L-shaped sliders are connecting pieces between the force measurement device and the loading heads, do not interference with each other in space, are provided with a pair of longitudinally-symmetrical resistance loading points, and are used for applying axial load. The problem about calibration of the double-end force measurement device in special test is solved, six components can be calibrated at most, and the device and the method are simple and feasible special force measurement device calibration schemes indeed.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

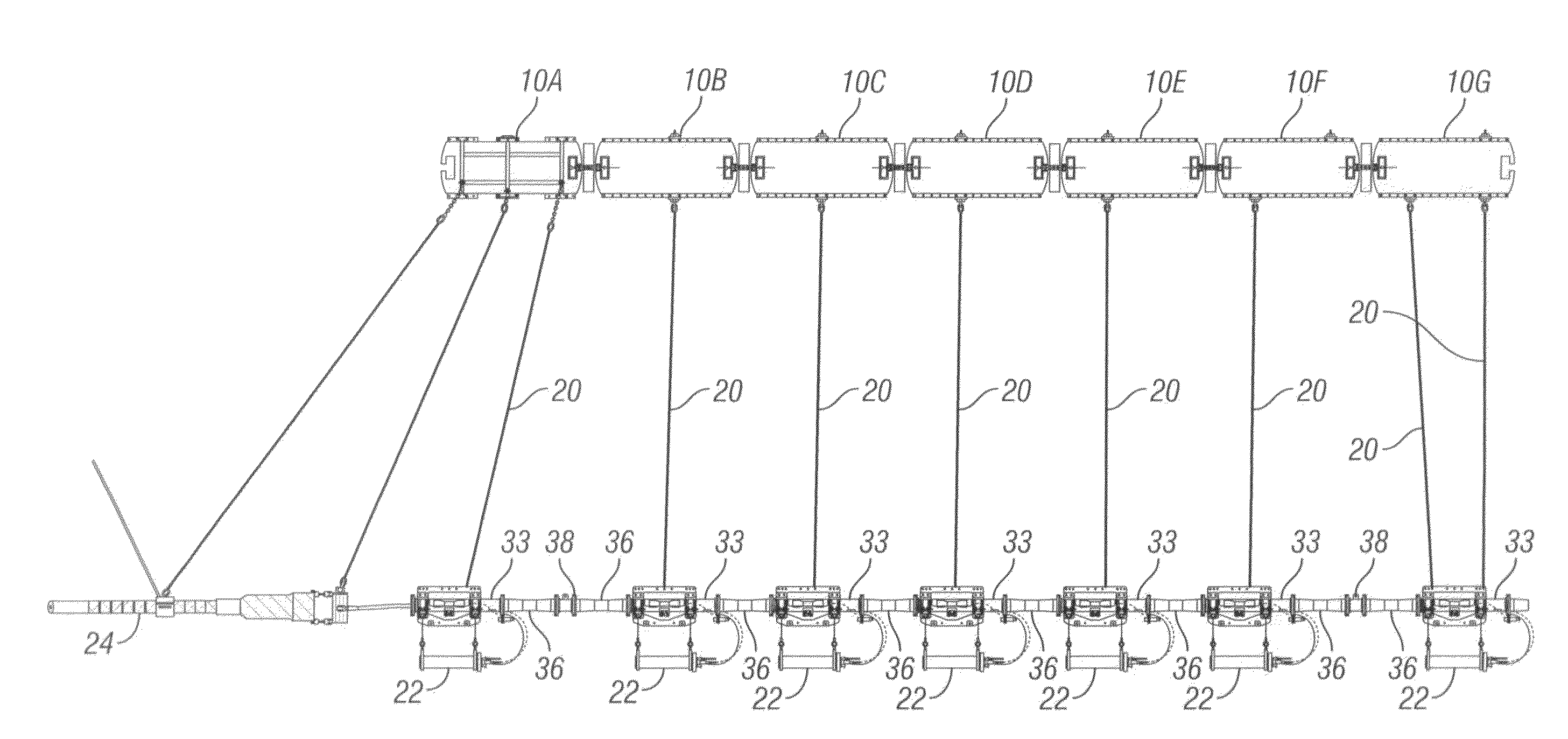

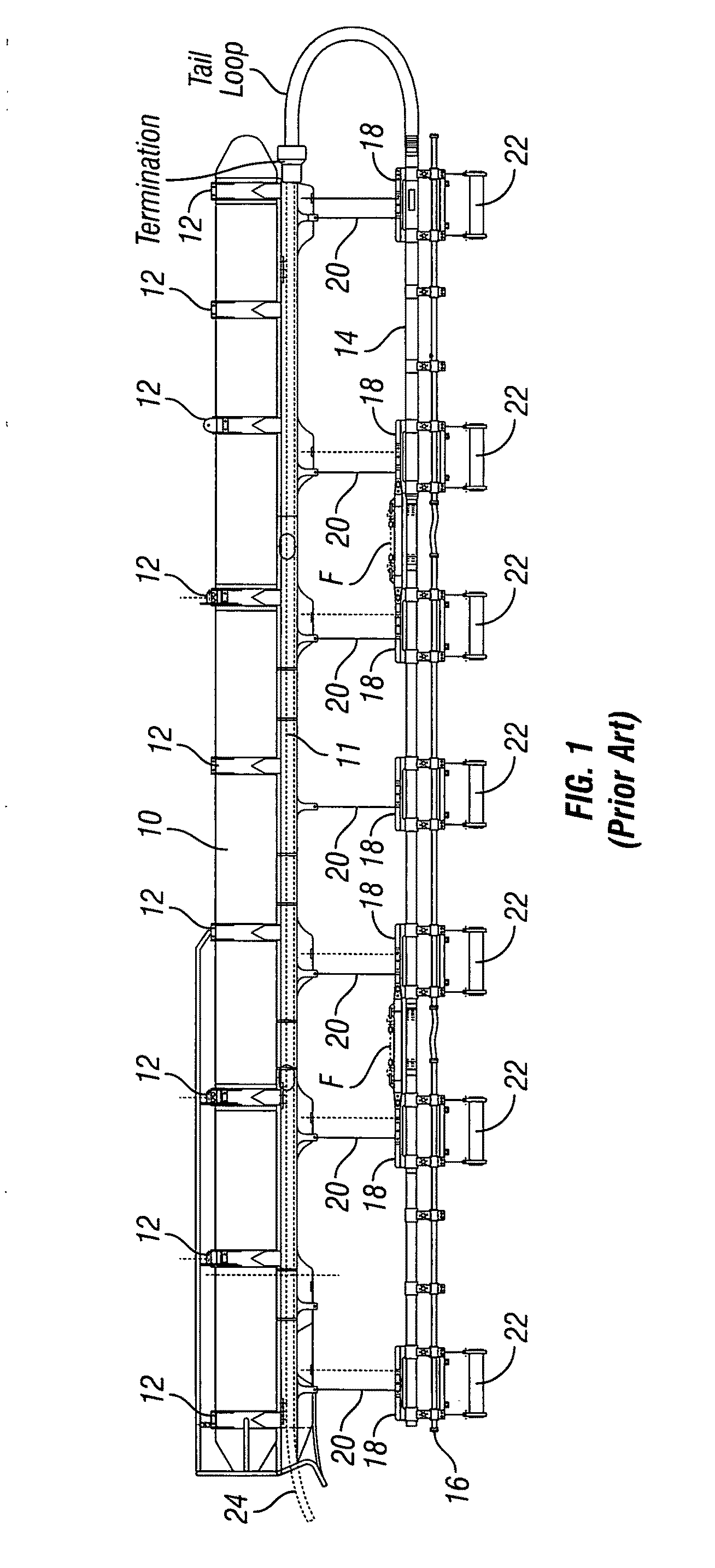

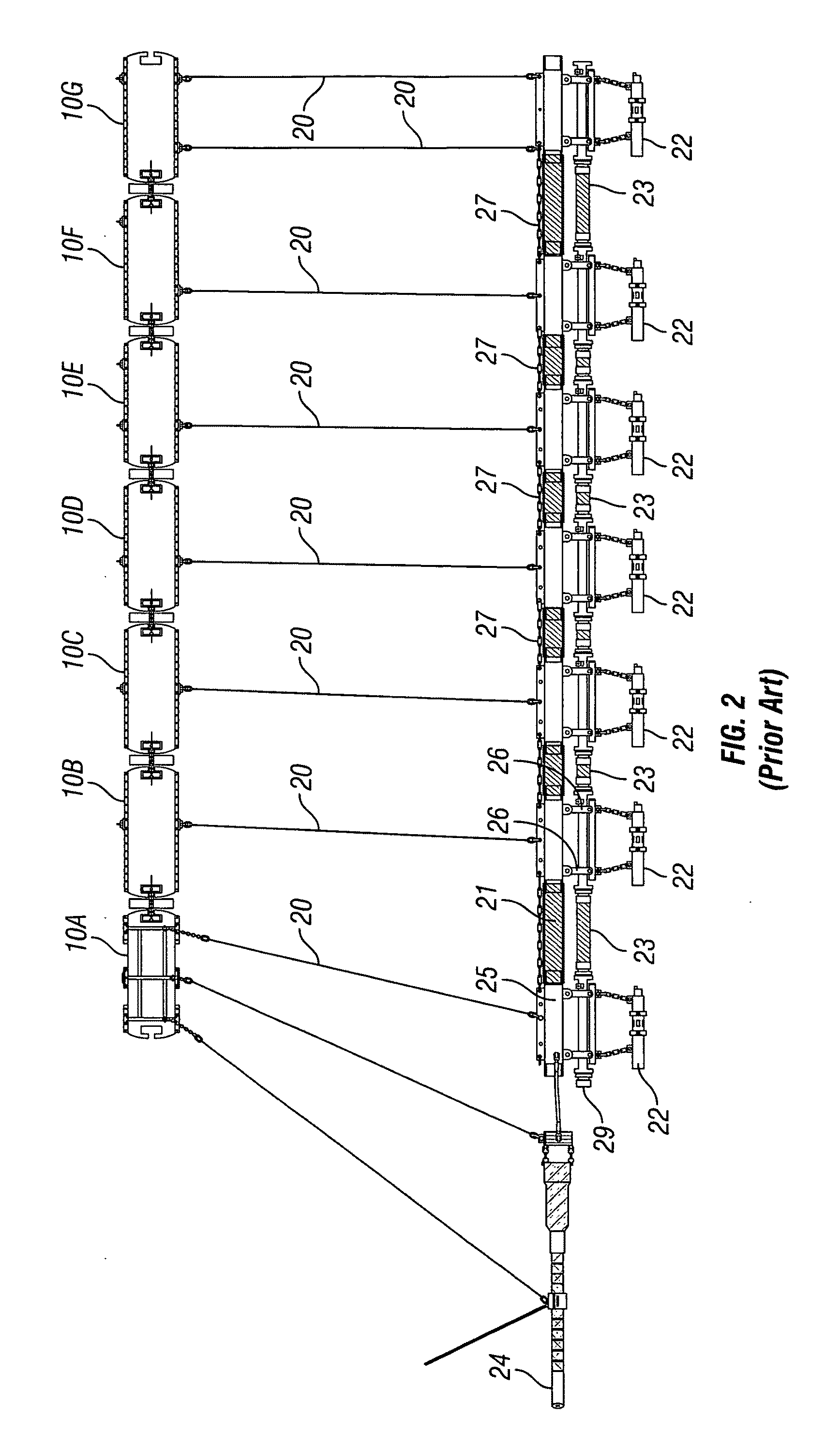

Coaxial support structure for towed marine seismic source arrays

A seismic source array includes at least one float. A plurality of rigid conduit sections each includes a bracket for suspension from the float at a selected depth in a body of water and configured to suspend a seismic energy source therefrom. At least one bend strain relief is coupled between adjacent rigid conduit sections. Each bend strain relief includes a coupling at each longitudinal end. Each bend strain relief includes woven fiber molded into flexible plastic for transmitting axial loading while absorbing bending and torsional stress. A seismic energy source is suspended from each bracket. Lines for operating the seismic energy sources pass through the rigid conduit sections and the at least one bending strain relief.

Owner:PGS GEOPHYSICAL AS

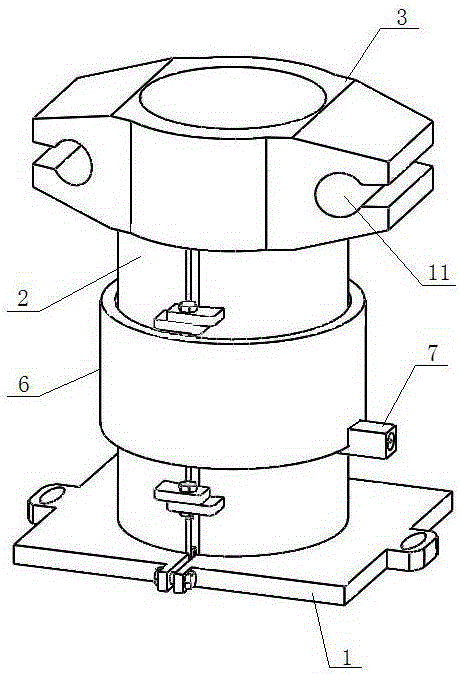

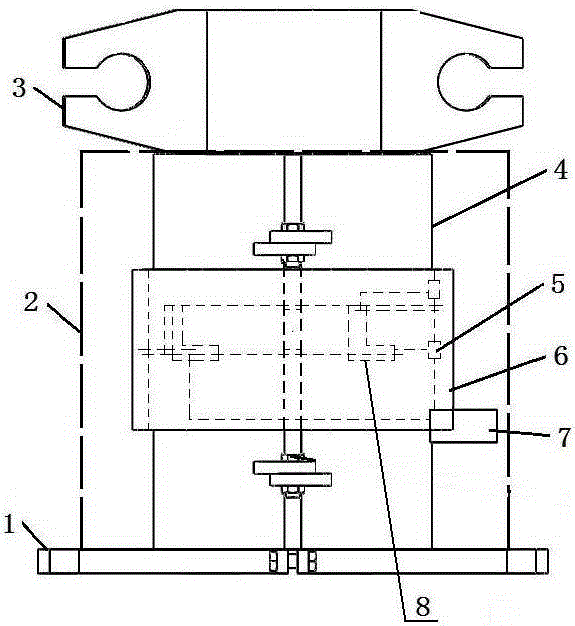

Casing axial load testing device during the period for waiting on cement mortar setting

The present invention relates to a casing axial load testing device during the period for waiting on cement mortar setting. The casing axial load testing device during the period for waiting on cement mortar setting includes a bottom base, a sensor and an upper elevator. The bottom base is fixed on a drilling platform, the sensor is fixed on the bottom base, the upper elevator locates on the sensor, and a casing pipe channel running through the bottom base, the sensor, and the upper elevator is formed. The sensor is composed of a load-carrying elastomer, a testing circuit and an adapter. The load-carrying elastomer is a cylindrical body which is composed of two half cylinders by interlocking. A foil gage is arranged on the load-carrying elastomer, the foil gage bonds the load-carrying elastomer through an adhesive agent, and the testing circuit and the adapter are arranged outside the load-carrying elastomer. The casing axial load testing device during the period for waiting on cement mortar setting performs the on-site dynamic monitoring for casing axial loads during the period for waiting on cement mortar setting by aiming at various well depths and various cement mortar proportions, and the data is true and reliable.

Owner:NORTHEAST GASOLINEEUM UNIV

Interbody fusion device with snap on anterior plate and associated methods

A method and apparatus is provided for use in spinal fusion procedures. An interbody fusion device has a first piece that is a load bearing device designed to bear the axial loading from the end plates of adjacent vertebrae. A second piece of the interbody fusion device is a retention device whose function is to prevent migration of the load bearing device. One or more fasteners secure the retention device to the vertebrae above and below the load bearing device. The fasteners cause the end plates of the vertebrae to compress the end plates to the load bearing device to facilitate proper fusion. The device includes a snap in mechanism for coupling the first piece to the second piece.

Owner:SPINESMITH PARTNERS

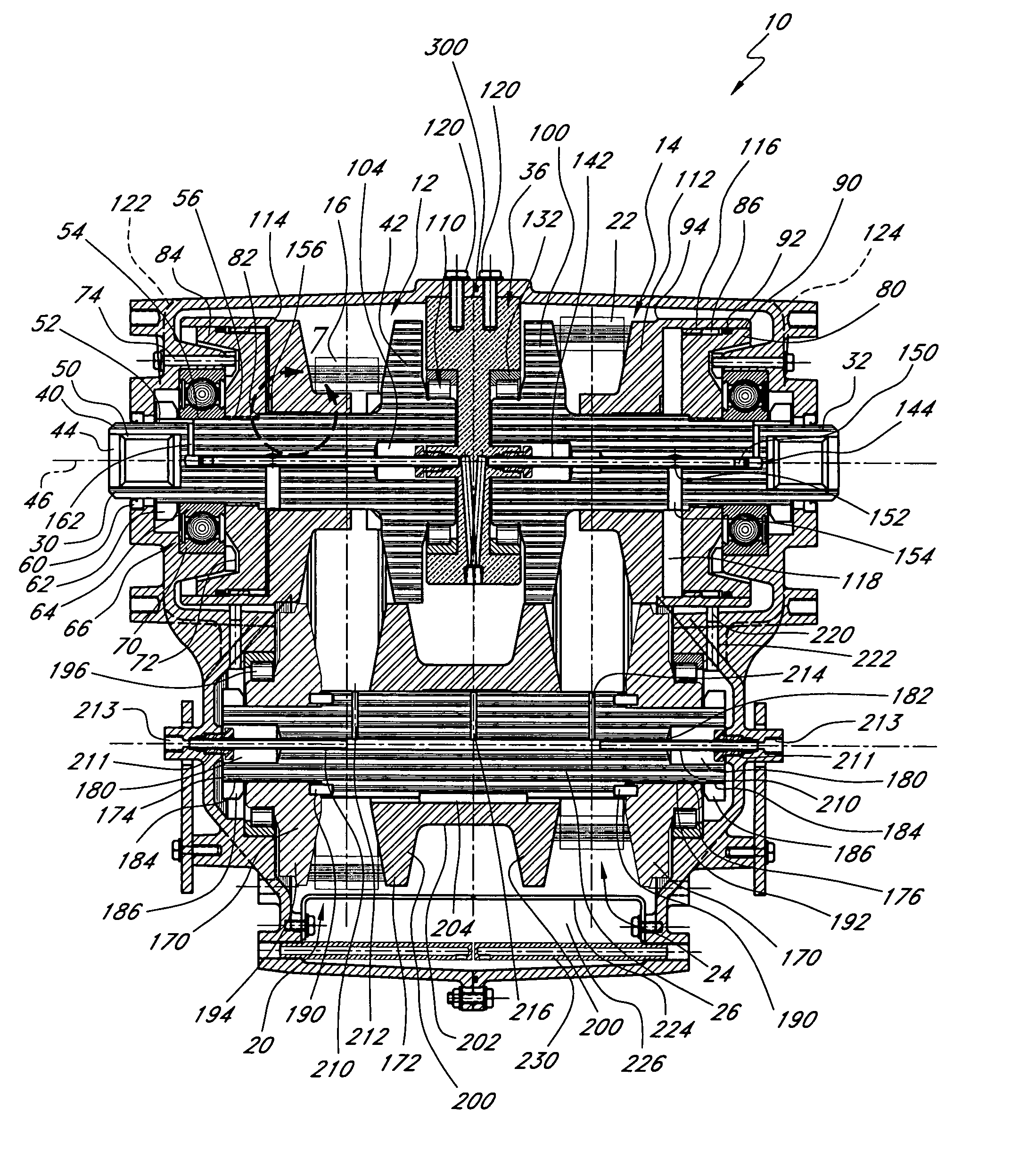

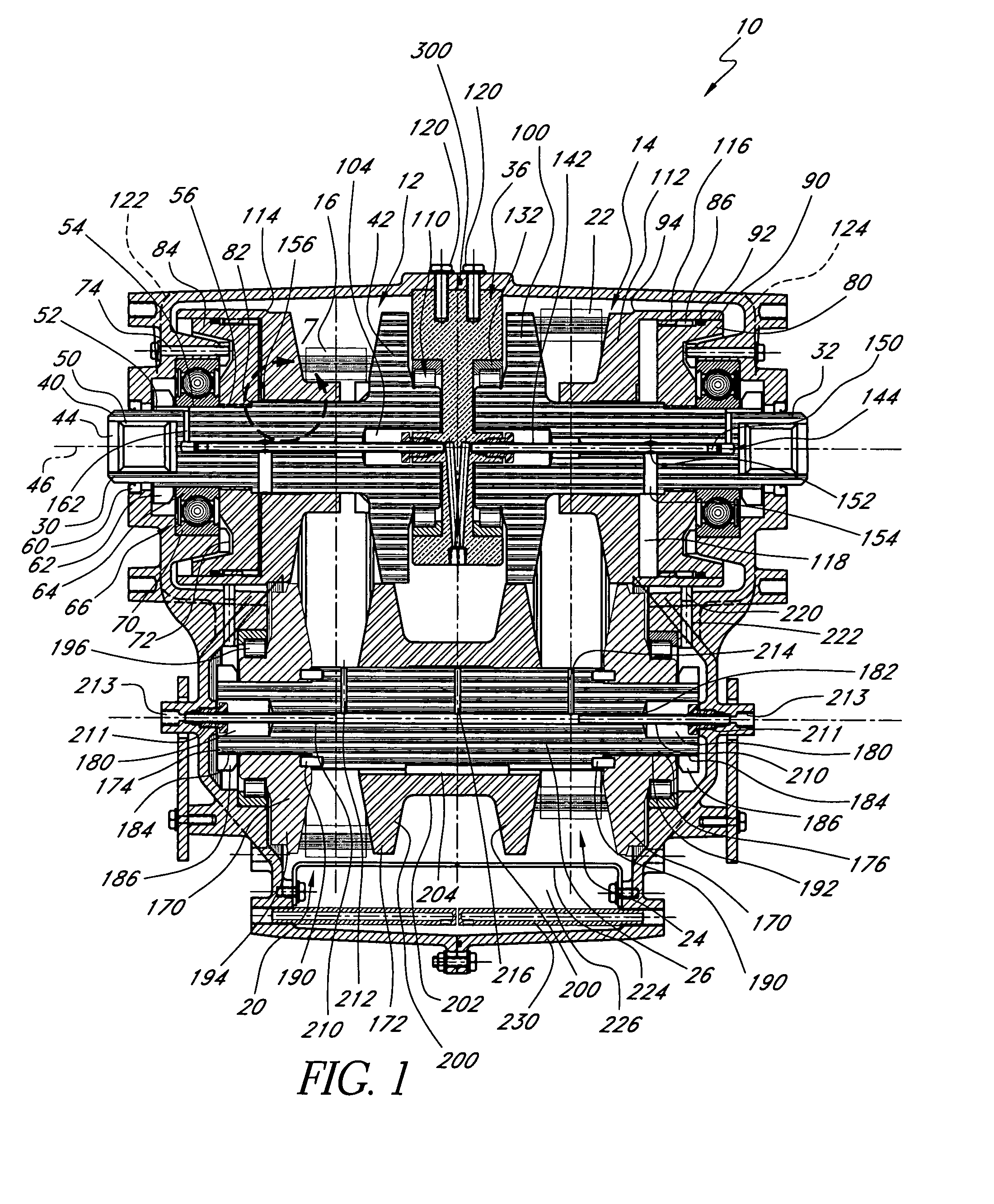

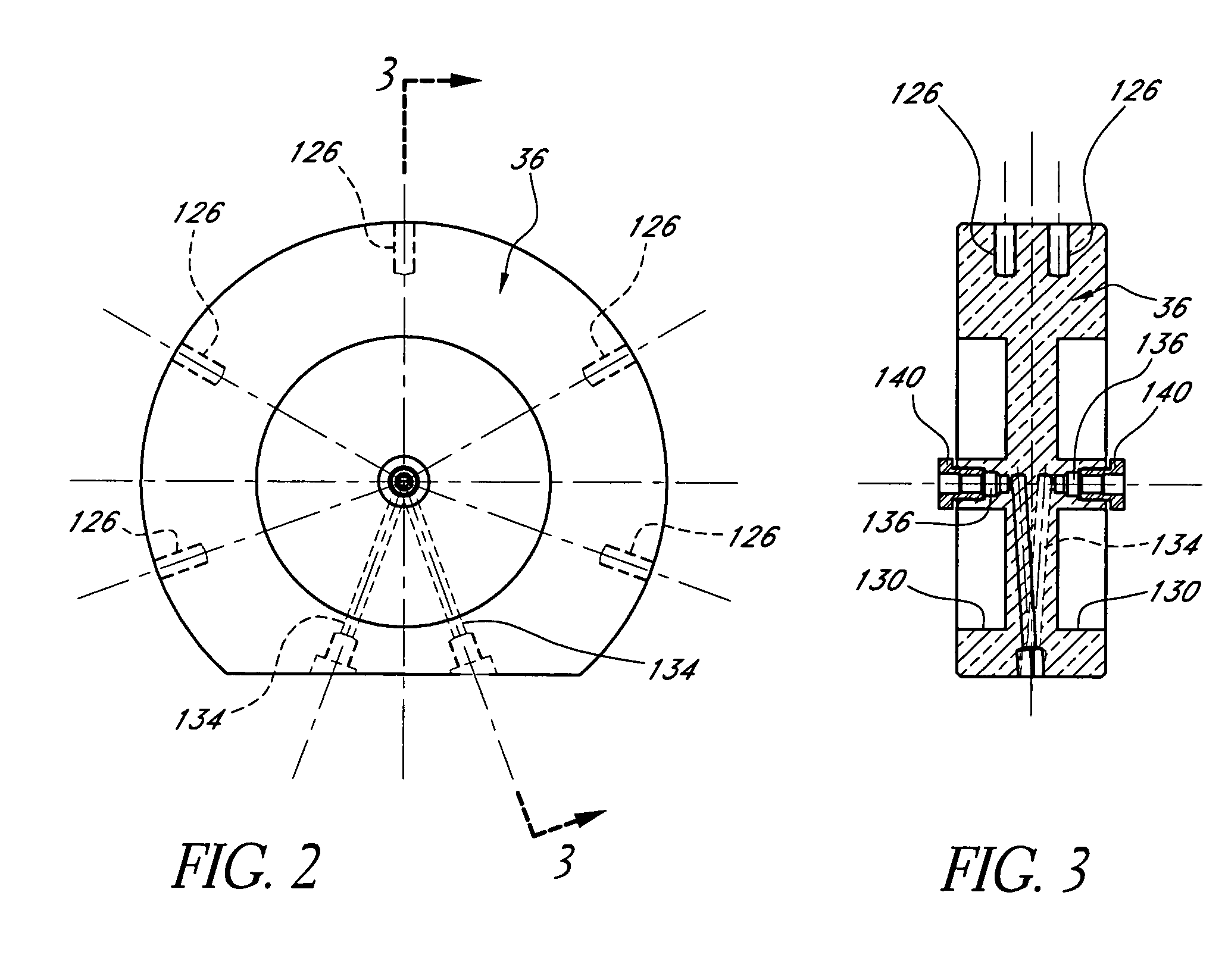

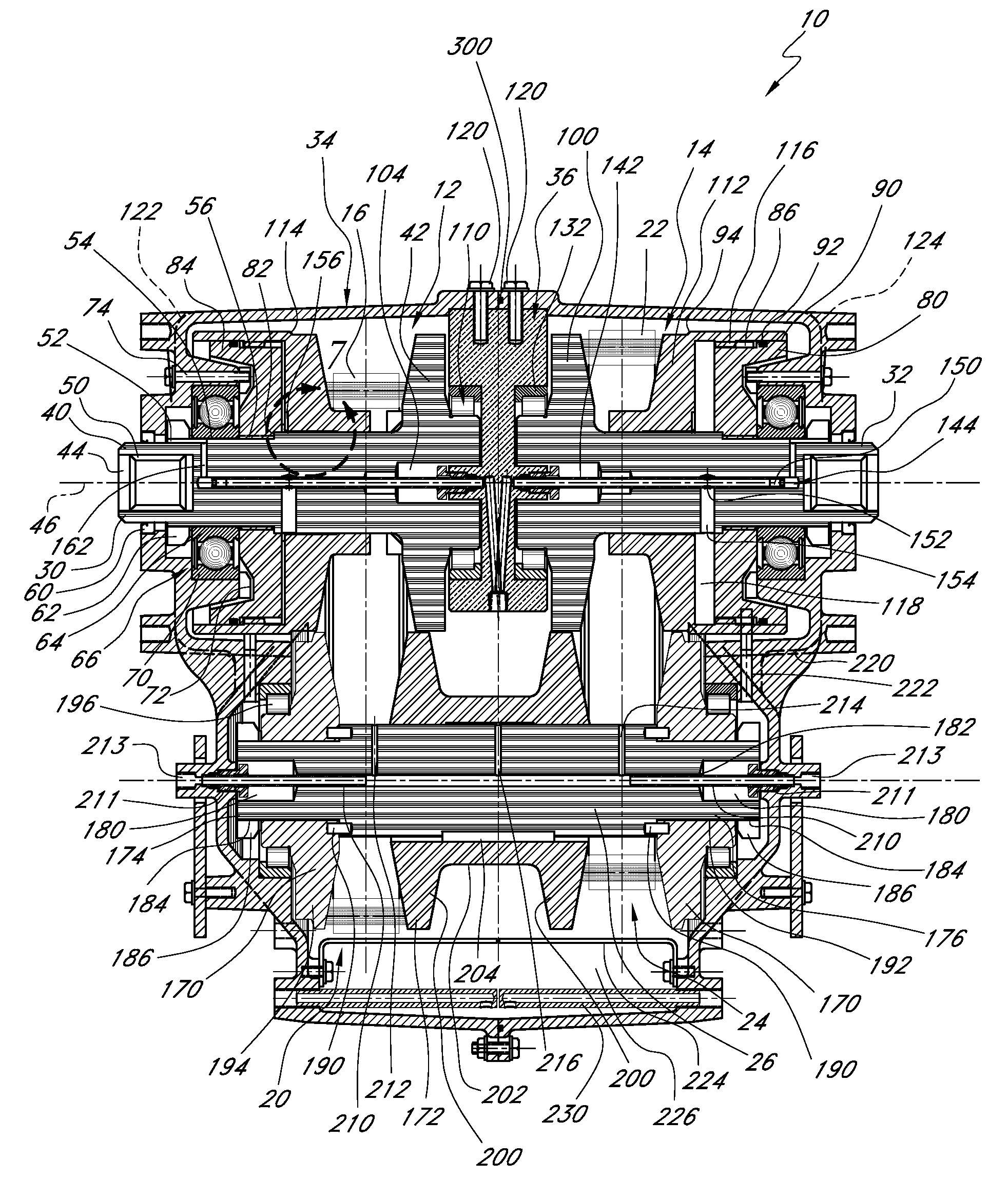

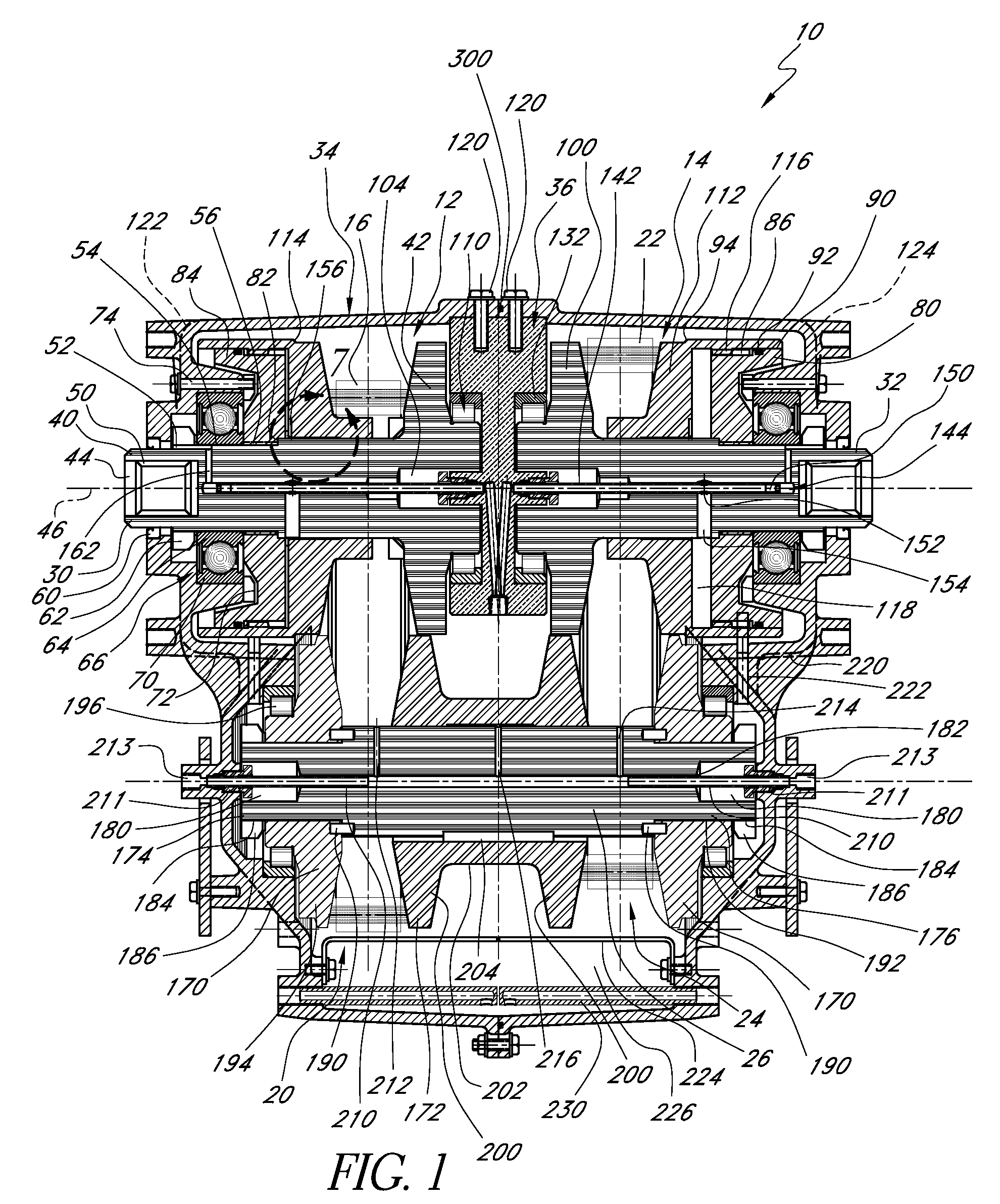

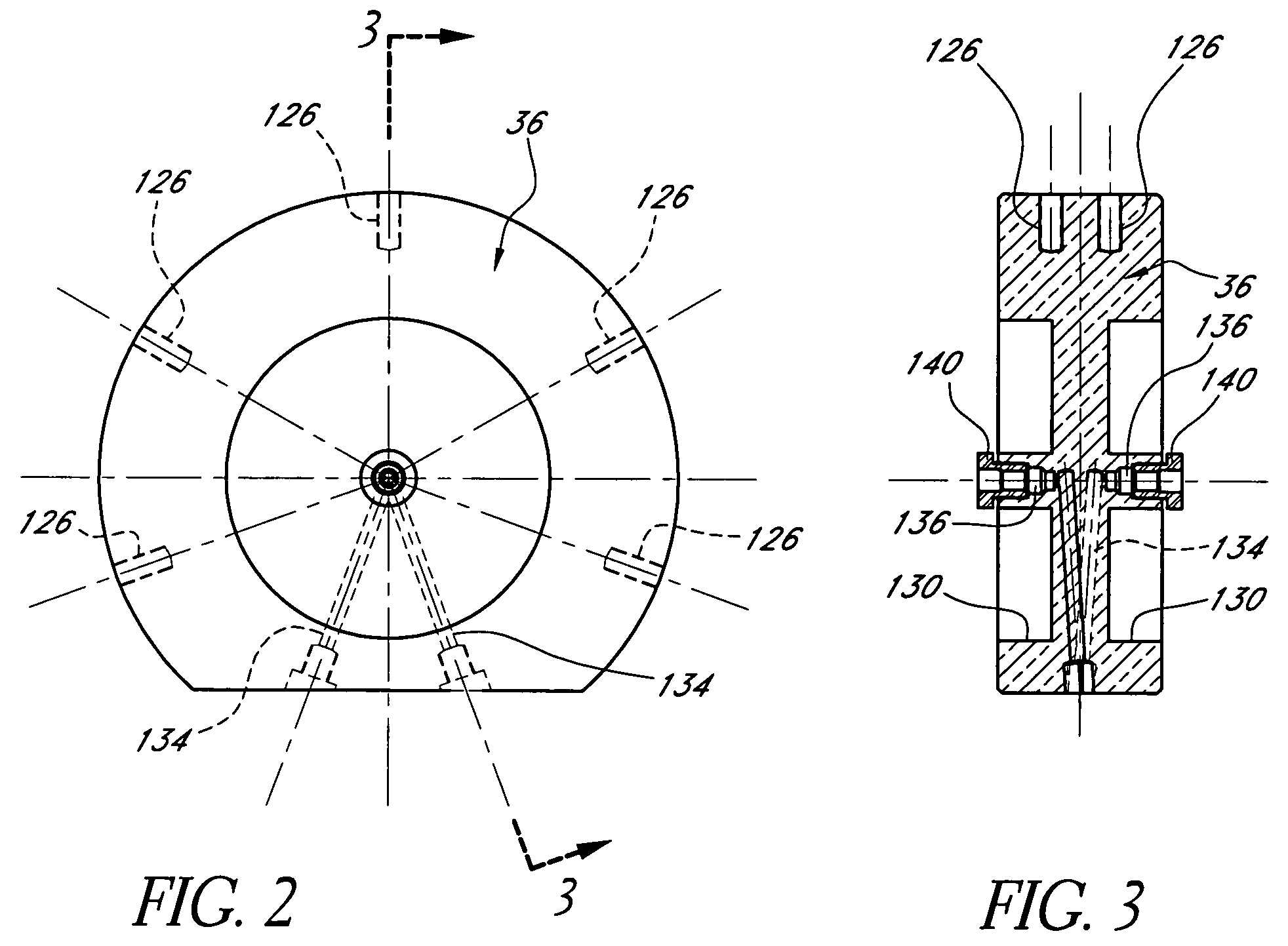

In-series two chain continuously variable transmission

InactiveUS20060154760A1Increased size and weightImprove fuel economyGearboxesGearingAxial LoadingsEngineering

A continuously variable transmission has an input pulley assembly connected to a first transfer pulley assembly with a first chain and a second transfer pulley assembly connected to an output pulley assembly with a second chain. The first transfer pulley assembly and the second transfer pulley assembly shaft a common shuttle disk that moves axially on a countershaft that carries the first and second transfer pulleys. The input pulley assembly and the output pulley assembly are generally axially aligned and a bearing carrier is positioned between the pulleys. A high pressure fluid supply system reduces or eliminates axial loading on the shafts of the transmission.

Owner:BROWN ALBERT W

In-series two chain continuously variable transmission

InactiveUS7540815B2Increased size and weightImprove fuel economyGearboxesGearingAxial LoadingsEngineering

A continuously variable transmission has an input pulley assembly connected to a first transfer pulley assembly with a first chain and a second transfer pulley assembly connected to an output pulley assembly with a second chain. The first transfer pulley assembly and the second transfer pulley assembly shaft a common shuttle disk that moves axially on a countershaft that carries the first and second transfer pulleys. The input pulley assembly and the output pulley assembly are generally axially aligned and a bearing carrier is positioned between the pulleys. A high pressure fluid supply system reduces or eliminates axial loading on the shafts of the transmission.

Owner:BROWN ALBERT W

True triaxial experimental device and method capable of obtaining after-peak curve and residual strength of brittle rock

ActiveCN110411842ARealize full axial displacement control loadingDestabilizingMaterial strength using tensile/compressive forcesResidual strengthPrincipal stress

Disclosed are a true triaxial experimental device and method capable of obtaining the after-peak curve and residual strength of brittle rock. According to the device, a rigid load application framework is arranged in the middle of a fixed high-rigidity counter-force framework, and large principal stress load application actuators indirectly apply loads to a rock sample in a pressure chamber through the rigid load application framework. The method comprises the steps of preparing and sealing the rock sample, and mounting a displacement sensor; mounting the sample, and accurately centering and clamping the sample in a displacement control manner to eliminate gaps; finely adjusting the displacement sensor to a a measuring range; sealing the pressure chamber, and filling the pressure chamber with hydraulic oil; synchronously applying minimum, intermediate and maximum principal stresses, applying axial loads to the rigid load application framework by the first and second maximum principal stress load application actuators, applying the maximum principal stress to the sample through the micro-deformation of the rigid load application framework, and simultaneously measuring the deformation of the sample; applying loads to the sample to make the sample enter an after-peak deformation stage and damaged; continuing applying loads to the sample until the residual strength is obtained; sequentially removing the maximum, intermediate and minimum principal stresses, disassembling the damaged rock sample, and saving experimental data.

Owner:NORTHEASTERN UNIV LIAONING

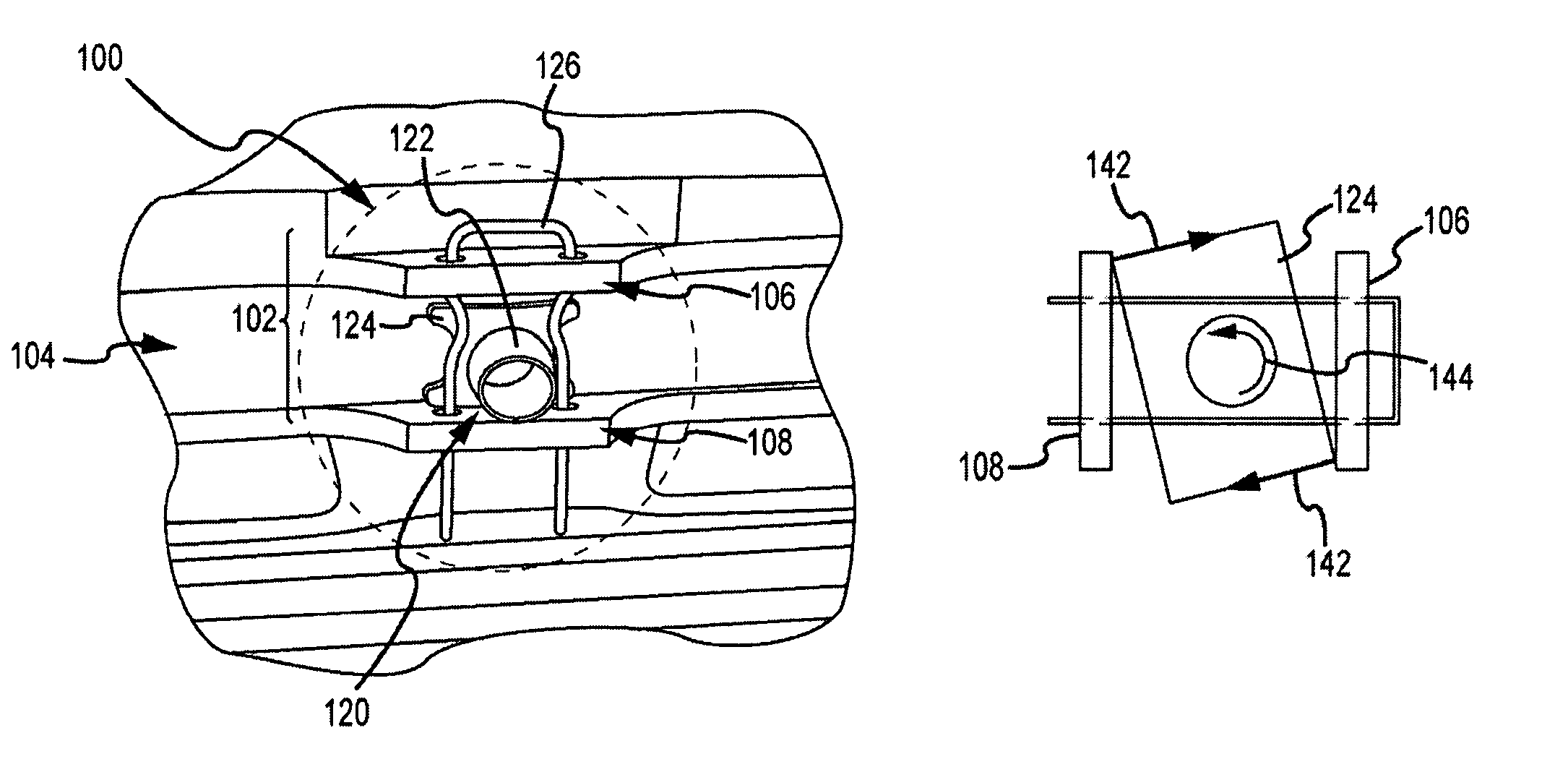

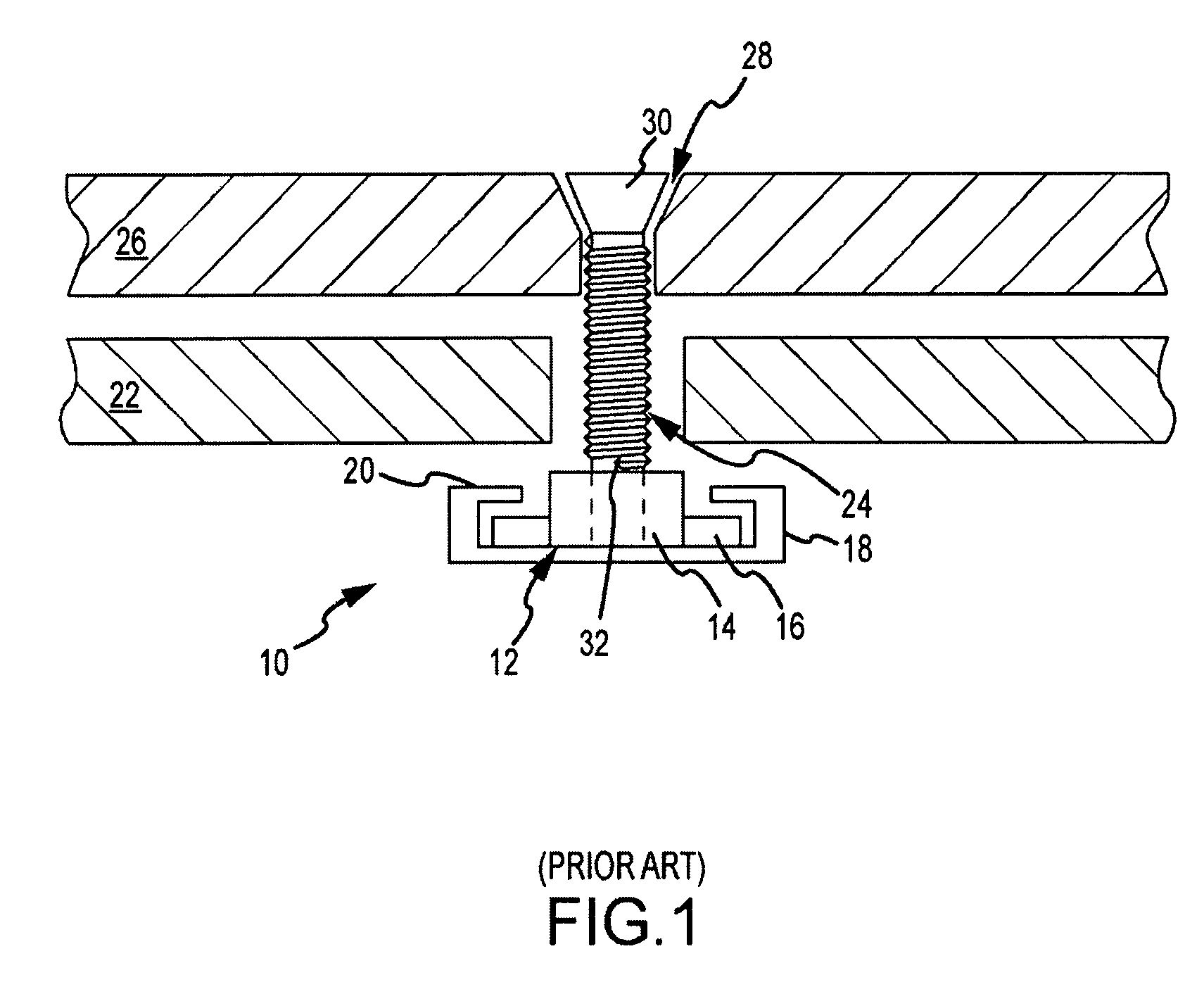

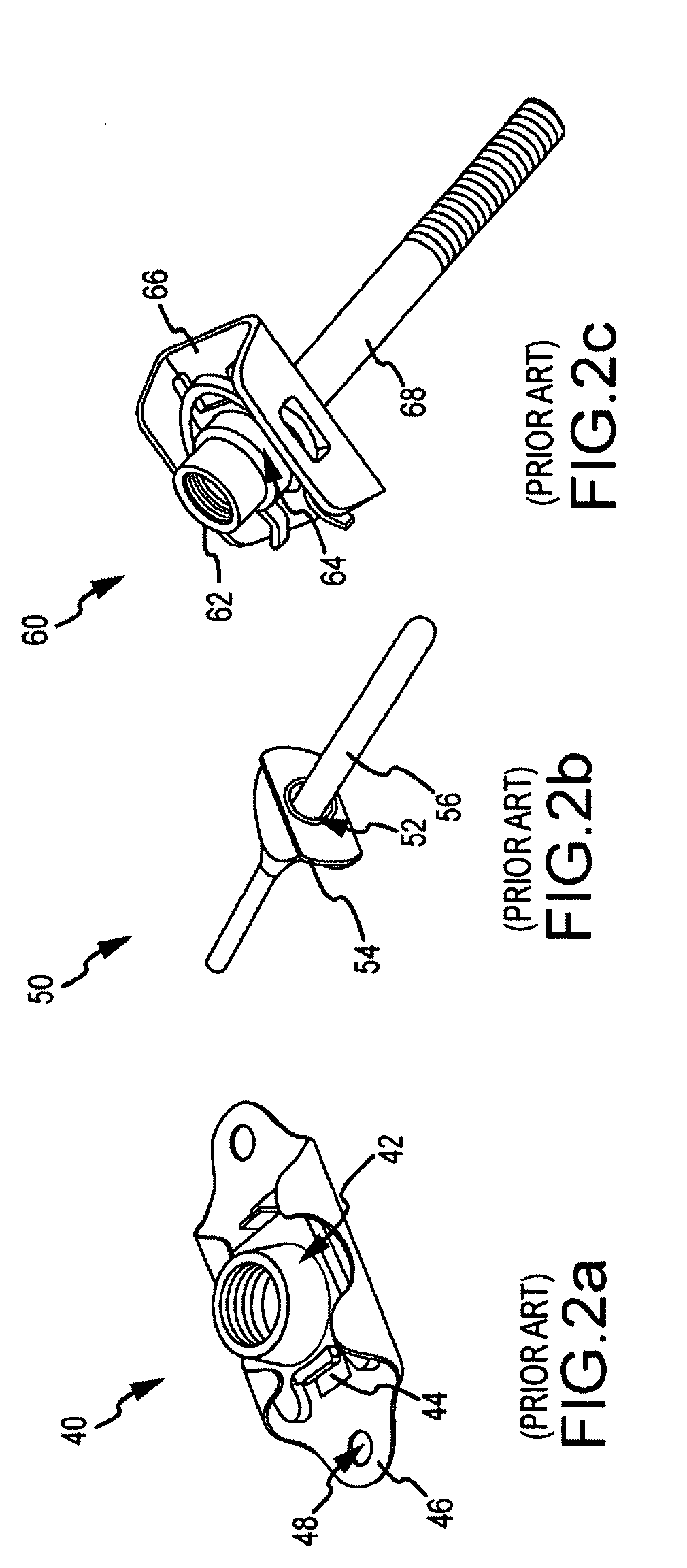

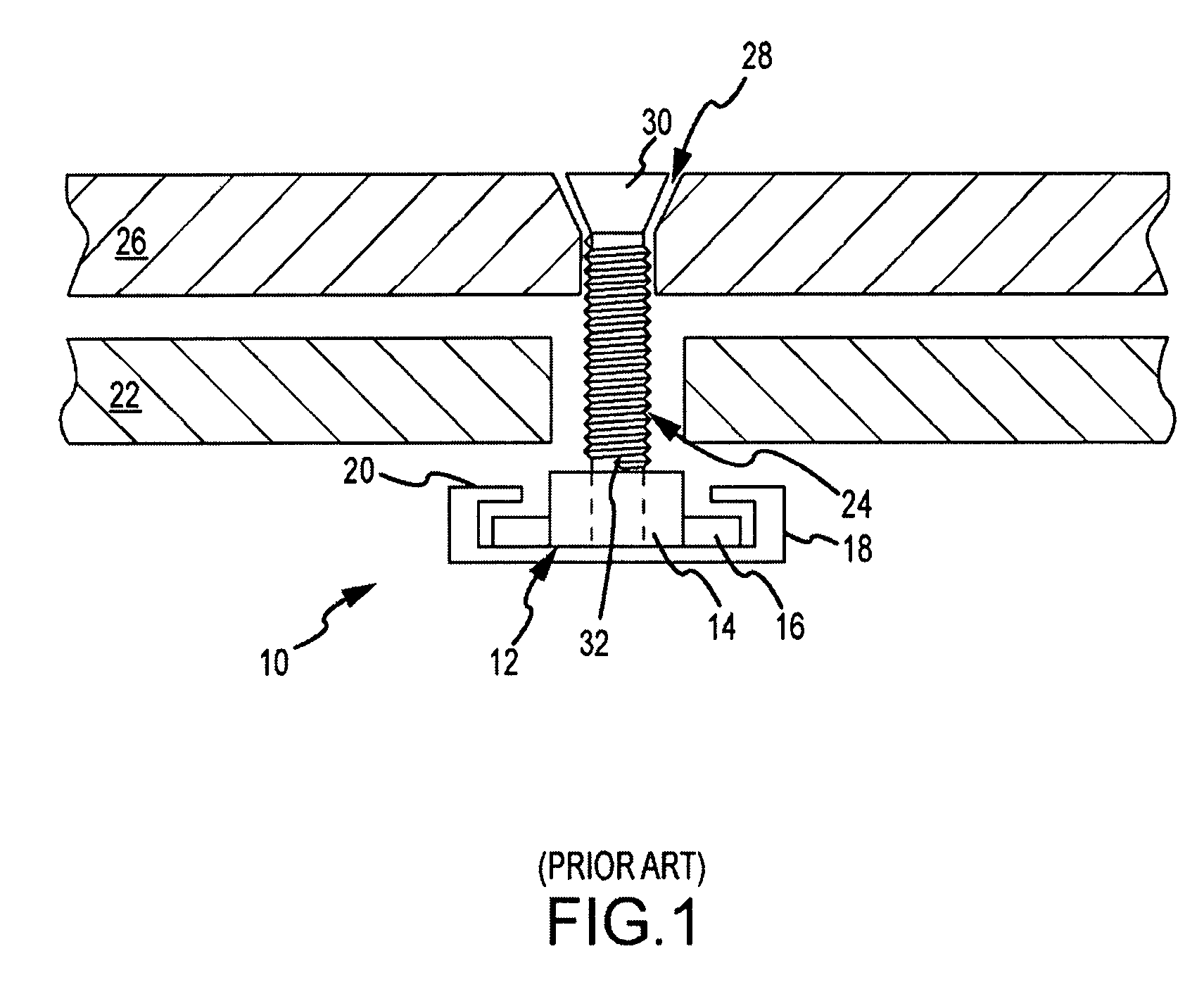

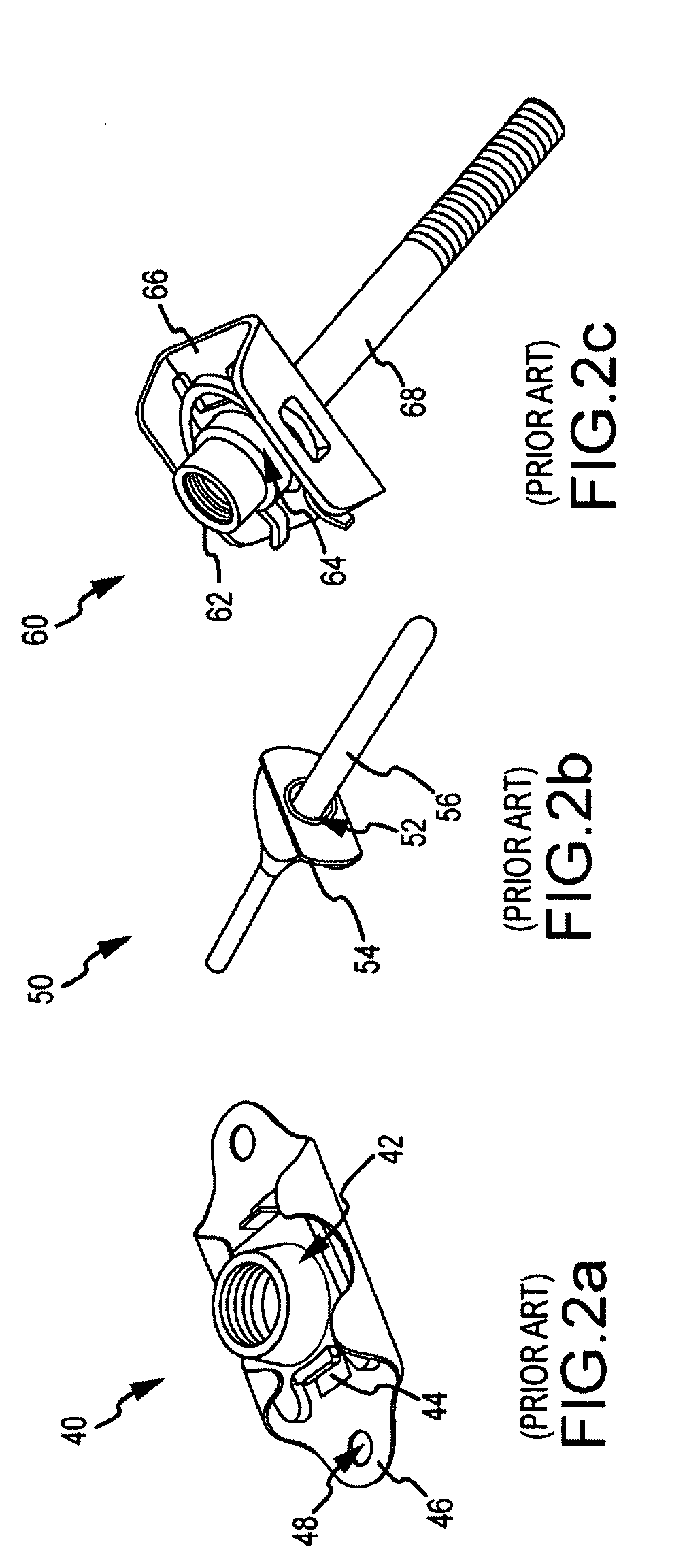

Integrated nutplate and clip for a floating fastener and method of manufacture and assembly

An inexpensive and reliable floating fastener is provided by manufacturing an integrated nutplate into the backside of the interior structural member. A retention clip engages the nutplate to capture the nut while allowing the nut to float. The integrated nutplate roughly aligns the floating nut to the axial through-hole in the structural member and provides the torque resistance required to drive the screw into the nut. The retention clip holds the nut in place and provides the axial resistance required for the lead chamfer of the screw to engage the nut and resist the axial loading on the screw during installation. The nutplate is designed to facilitate cost-effective manufacturing. The per hole cost of the integrated floating-fastener is approximately 30% of the cost of the industry standard riveted floating fastener.

Owner:RAYTHEON CO

Structural static and fatigue test device

The application belongs to the technical field of a static and fatigue test, and particularly relates to a structural static and fatigue test device. The structural static and fatigue test device includes a flexible constraint fixing component for fixing a test piece, an axial load loading component for performing load loading on the test piece in a vertical direction, and a transverse load loading component for performing load loading on the test piece in a horizontal direction. The structural static and fatigue test device adopts an internal force bearing mode. A bearing structure for supporting and constraint is designed as a structure flexible in the horizontal direction and rigid in the axial direction, axial load loading is achieved, and it is ensured that the structure has greater flexibility in the transverse direction. In addition, the direction of centrifugal force can generate self-adaptive deflection with the increase of pneumatic and centrifugal force load, and the accuracy of the centrifugal force in the loading direction is ensured. Furthermore, compared with a traditional method, the test device has the advantages of being high in loading speed, short in test period, small in equipment size and high in loading accuracy.

Owner:AECC SHENYANG ENGINE RES INST

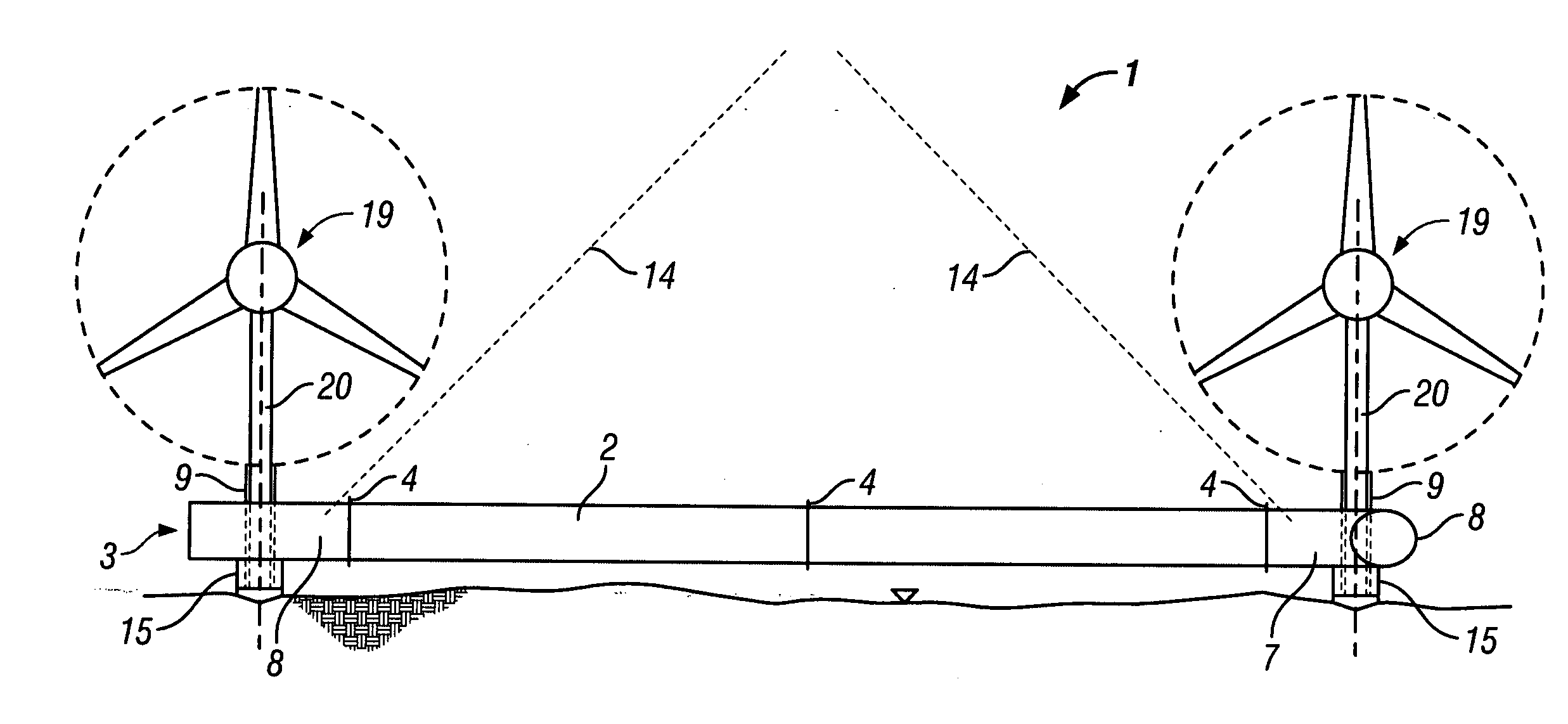

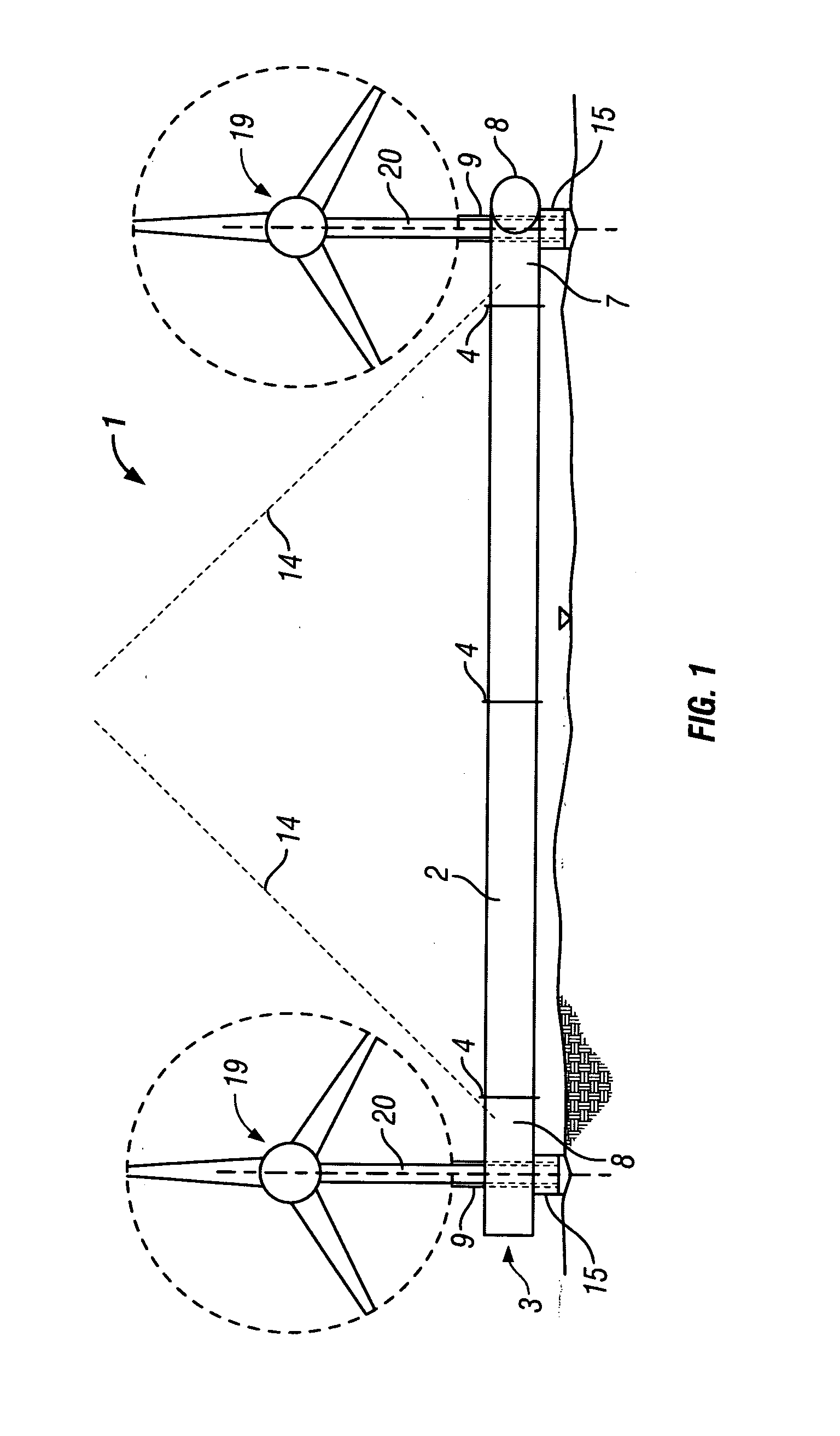

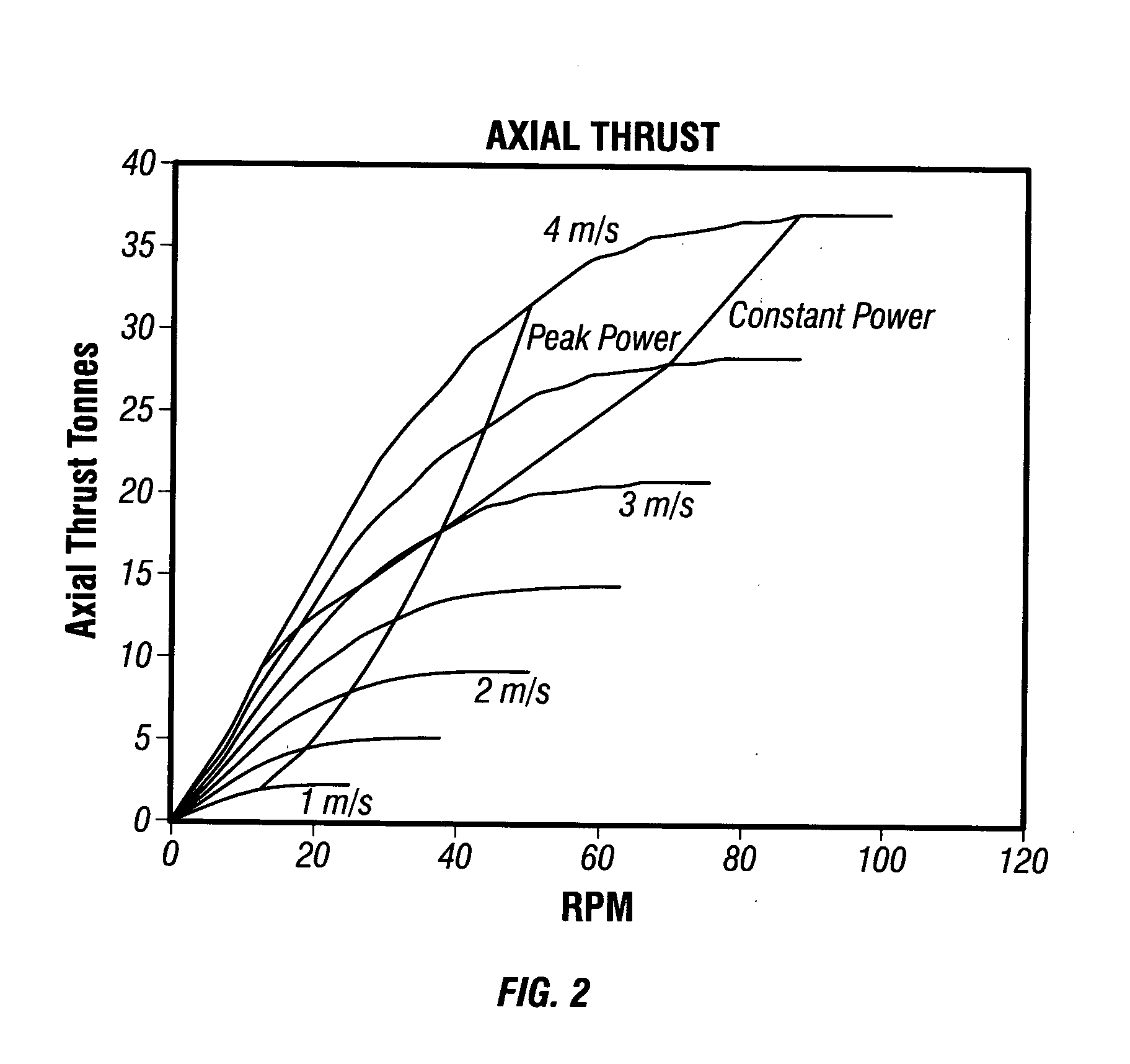

Tidal Turbine System

InactiveUS20110254271A1Increase speedIncrease axial loadReaction enginesSafety/regulatory devicesAxial LoadingsTurbine blade

A tidal flow turbine system has a rotor and turbine blades attached at a fixed attitude with respect to the rotor and extending outwardly from the rotor. The stagger angle of the blades, tip speed ratio, or other blade parameters is such that over the in-service operational speed range of the turbine, over a lower range of rotational or tidal flow speeds, increased speed results in increased axial loading on the turbine, but at higher speed range above a predetermined threshold, axial loading on the turbine does not increase.

Owner:TIDAL ENERGY

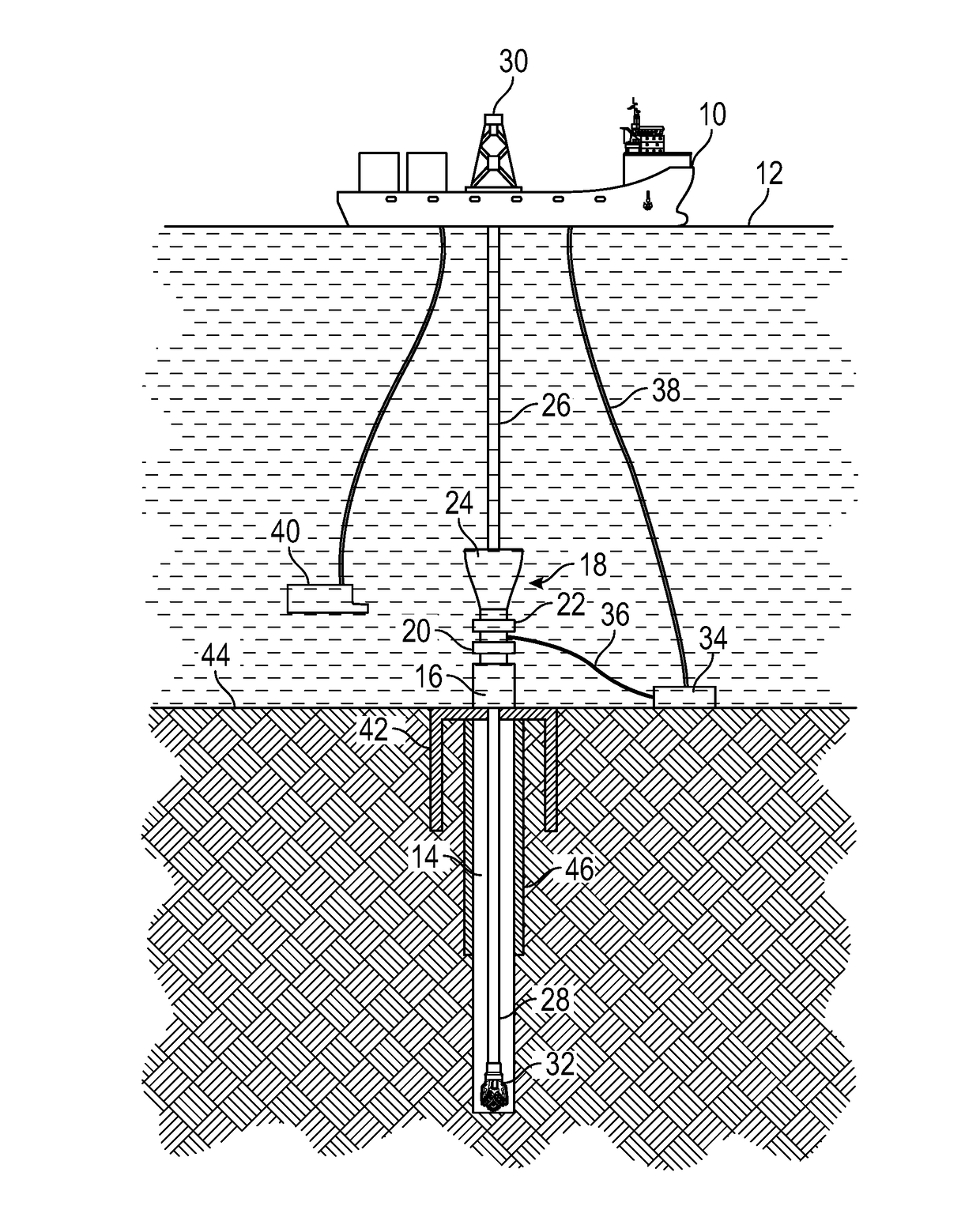

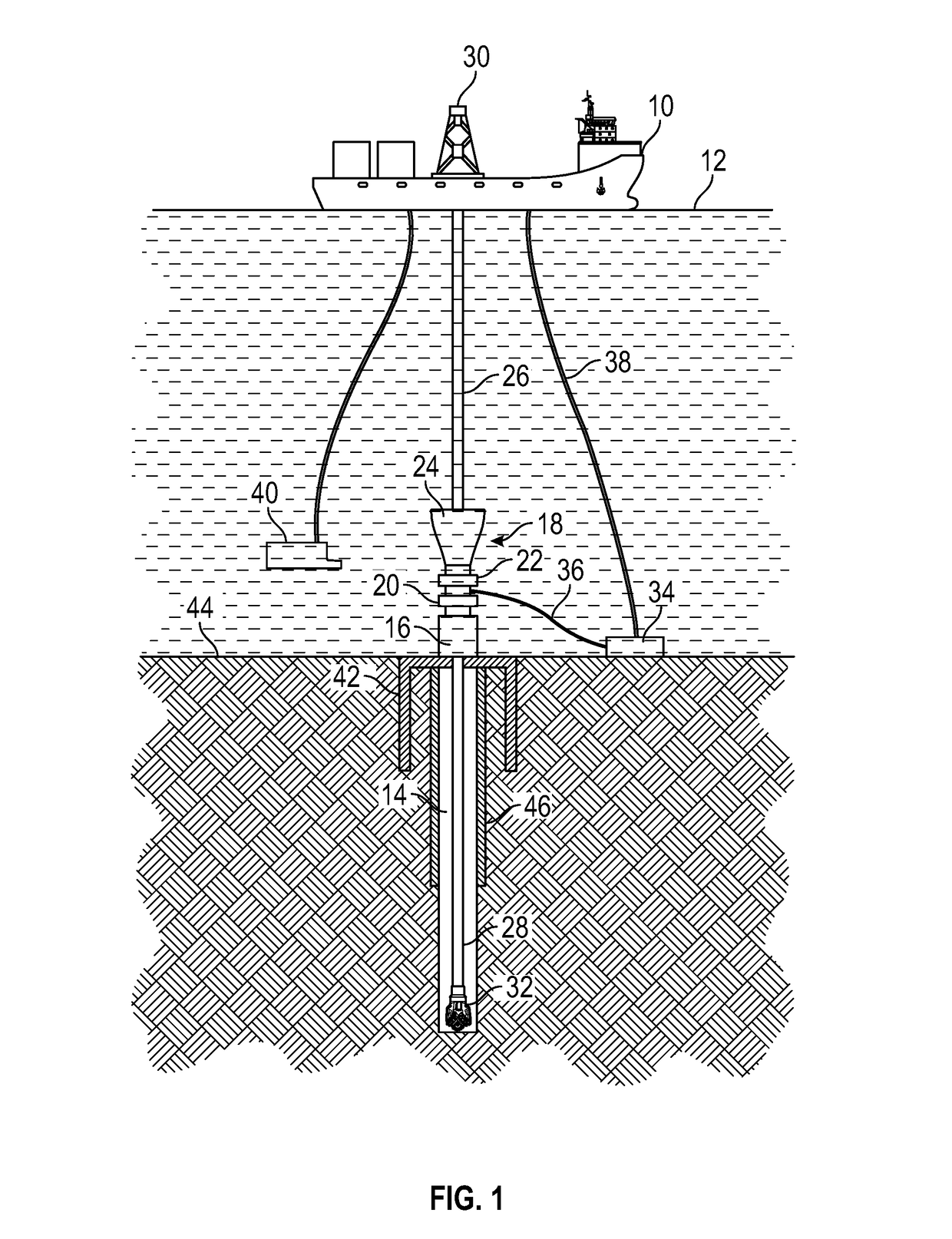

Installation assembly for a subsea wellhead

InactiveUS20170130547A1Maintain positionDrilling rodsUnderwater drillingEngineeringMechanical engineering

A system for load transfer from a wellhead to the sea bed adjacent a subsea well, including a suction pile for securing to the sea bed, and a wellhead housing assembly having a longitudinal axis and attached to the suction pile, the wellhead housing for subjection to an axial load acting in a direction parallel to the longitudinal axis, and a bending load acting in a direction not parallel to the longitudinal axis. The system further includes a suction pile connector that transmits the axial load and the bending load from the wellhead housing through the suction pile toward the sea bed, and that is attached to the suction pile, the suction pile connector engaged with the wellhead housing to substantially maintain the relative positions of the wellhead housing and the suction pile.

Owner:VETCO GRAY

Water-pressure test device for combustor shell of solid-propellant rocket engine

ActiveCN106979097AChange failureIn the case of increased axial pressureRocket engine plantsInternal pressureCombustion chamber

The invention relates to a water-pressure test device for a combustor shell of a solid-propellant rocket engine. The water-pressure test device comprises a force bearing vertical platform, a thrust frame, supporting frames, water-pressure sensors and the combustor shell provided with a front blocking cap and a rear blocking cap. The water-pressure test device is characterized by comprising an unloading mechanism, and the unloading mechanism is used for simulating the condition that the combustor shell is under the axial pressure. Compared with the prior art, the unloading mechanism is additionally arranged and used for simulating the condition that the combustor shell is under the axial pressure so that a water-pressure test can assess the working condition that the combustor shell bears an axial load while assessing the working condition that the combustor shell bears the internal pressure, a special test for assessing the condition that the combustor shell bears the axial load is omitted, and thus the preparation period is shortened; and the conditions that a traditional water-pressure testing mode cannot simulate the relief effect of engine spraying pipes on the shell internal pressure, and the combustor shell loses efficacy due to over-strict assessing are changed.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

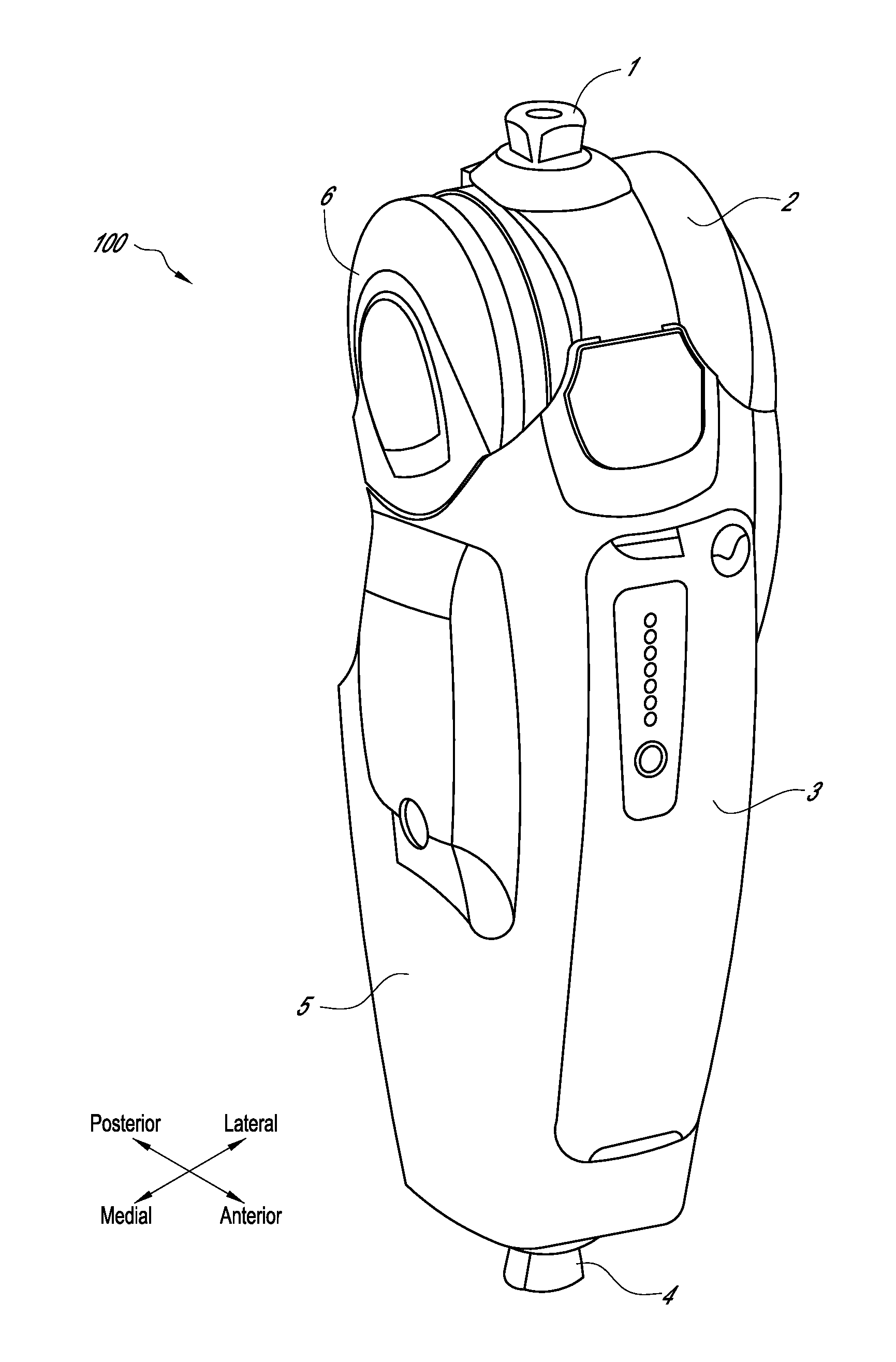

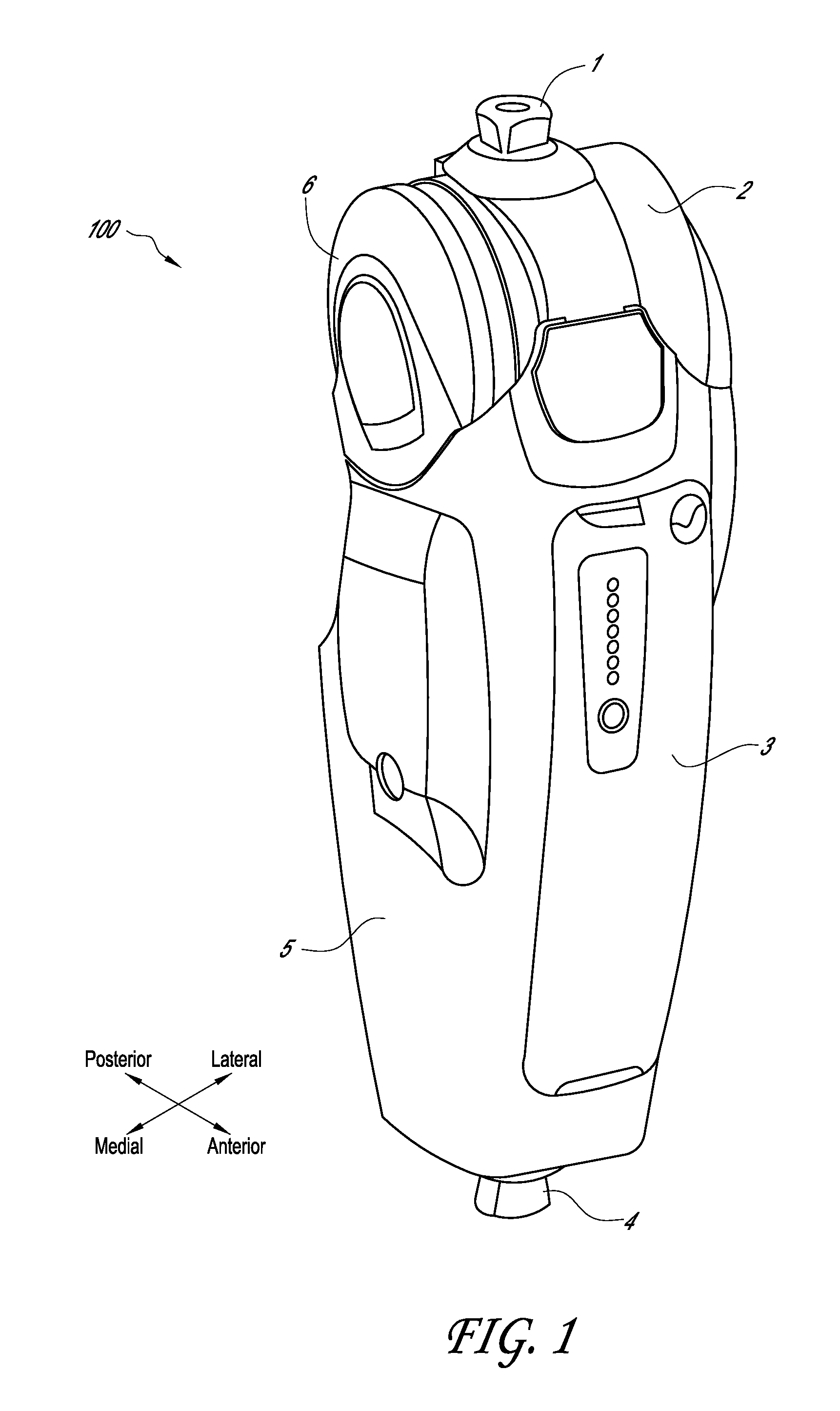

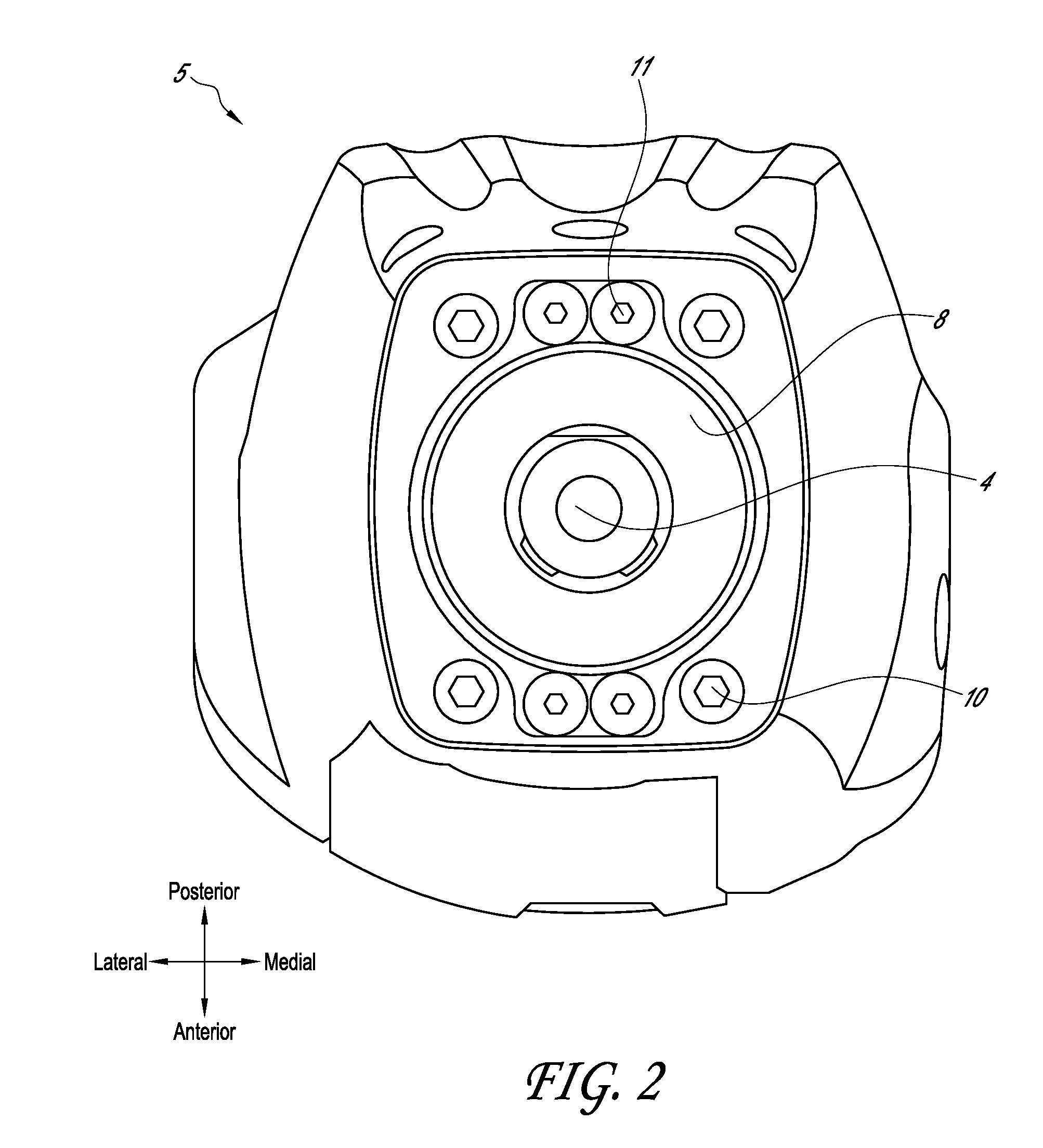

Ground contact sensing systems and methods for lower-limb orthotic and prosthetic devices

ActiveUS20120010729A1Reduce sensitivityReduce loadPerson identificationForce measurementGround contactAxial Loadings

A method of sensing ground contact with a lower limb prosthetic or orthotic device is provided. A first translational displacement between a frame and a connector can be sensed and then processed to identify an axial load caused by heel-ground contact. Additionally, a second translational displacement between the frame and the connector can be sensed and then processed to identify a torsional load caused by toe-ground contact.

Owner:OSSUR HF

Integrated nutplate and clip for a floating fastener and method of manufacture and assembly

ActiveUS20090129889A1Inexpensive and reliableInexpensive and reliable floatingNutsBoltsAxial LoadingsEngineering

An inexpensive and reliable floating fastener is provided by manufacturing an integrated nutplate into the backside of the interior structural member. A retention clip engages the nutplate to capture the nut while allowing the nut to float. The integrated nutplate roughly aligns the floating nut to the axial through-hole in the structural member and provides the torque resistance required to drive the screw into the nut. The retention clip holds the nut in place and provides the axial resistance required for the lead chamfer of the screw to engage the nut and resist the axial loading on the screw during installation. The nutplate is designed to facilitate cost-effective manufacturing. The per hole cost of the integrated floating-fastener is approximately 30% of the cost of the industry standard riveted floating fastener.

Owner:RAYTHEON CO

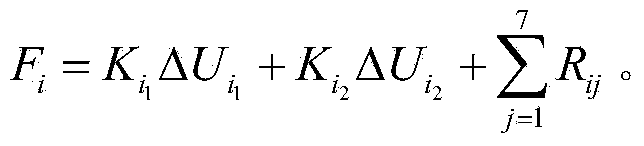

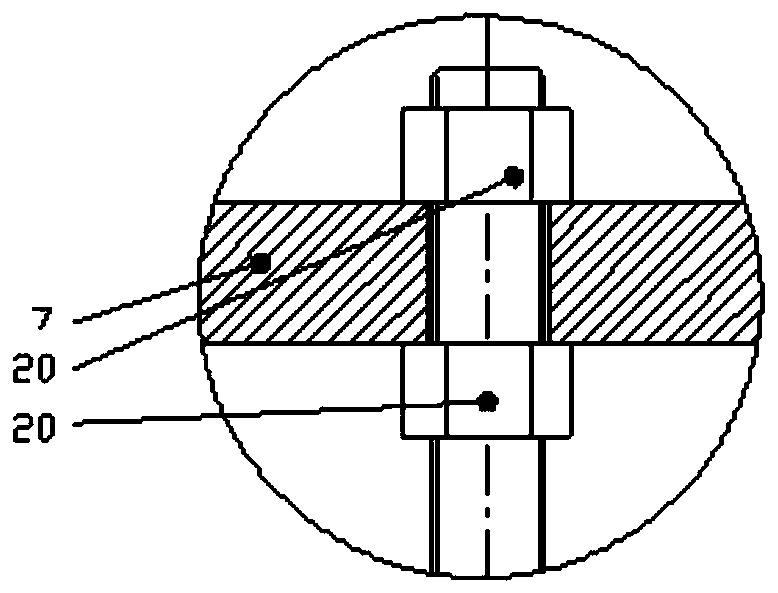

Correction method of equivalent load of axial film oil cylinder of bearing tester

InactiveCN101726411ATest accurateSimple structureMachine bearings testingEngineeringCorrection method

The invention relates to a correction method of the equivalent load of an axial film oil cylinder of a bearing tester, which is characterized in that a set of axial load test device is designed; the axial load test device comprises a left stationary bushing (14), a left positioning mandrel (15), a test pressure sensor (16), a flat head bolt (17), a right stationary bushing (18), a nut (19) and a ball head bolt (20); and after the whole axial load test device is positioned and installed on a base (1) of the bearing tester through the grooves of the left stationary bushing and the right stationary bushing, the correction test of the equivalent load of the axial film oil cylinder of the bearing tester can be carried out. By continuous correction on axial loads and computer correction operation, the correction method of the invention can improve the accuracy of the bearing tester in the axial loading process, enables the steady-state error of full range of the axial film oil cylinder in the loading process to be less than or equal to + / -1%FS, and provides more accurate and stable axial loads for a bearing test.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com