True triaxial experimental device and method capable of obtaining after-peak curve and residual strength of brittle rock

A technology of residual strength and experimental equipment, which is applied in the direction of measuring equipment, strength characteristics, and the use of stable tension/compression to test the strength of materials, etc., can solve problems such as rocks without strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

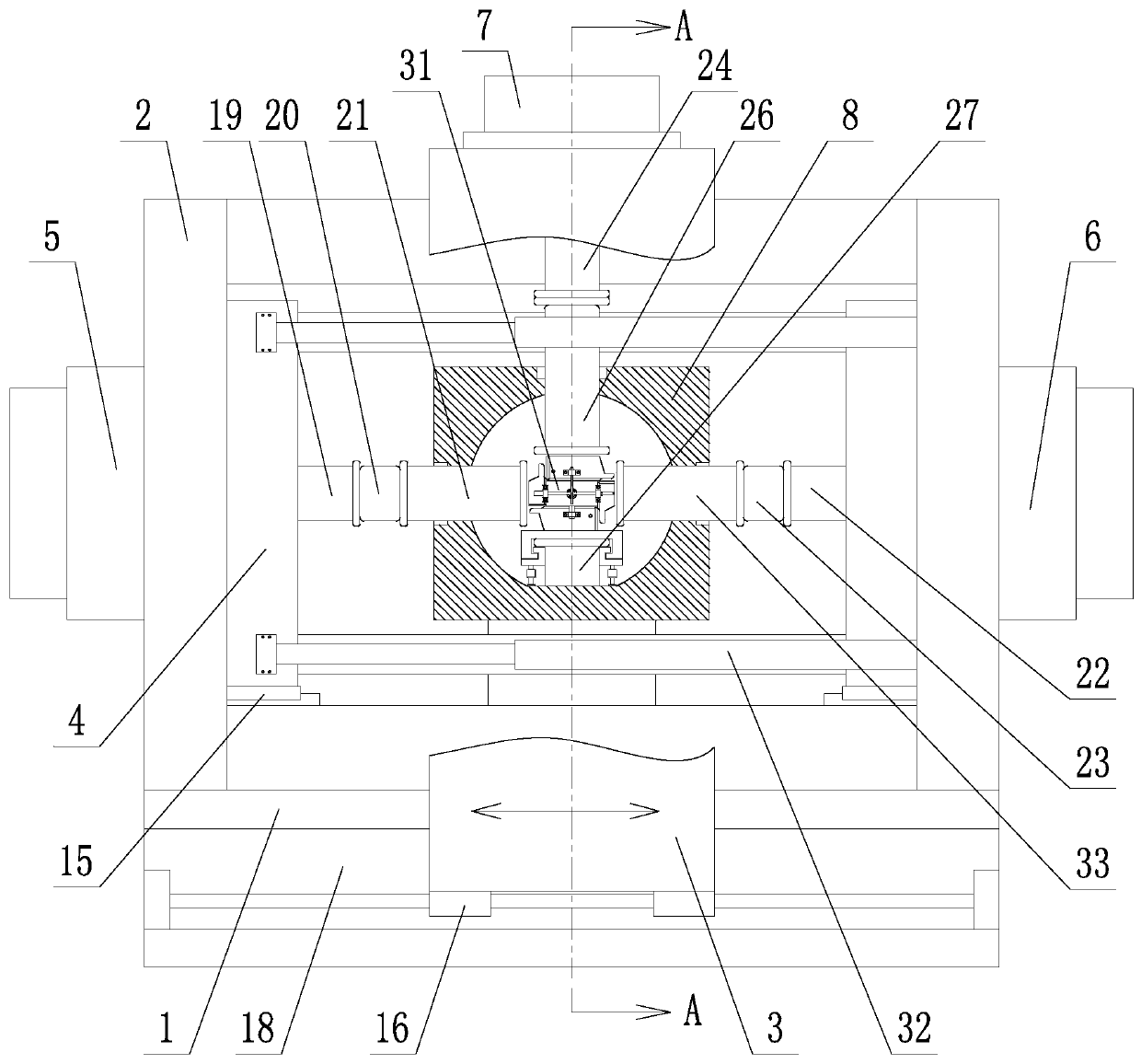

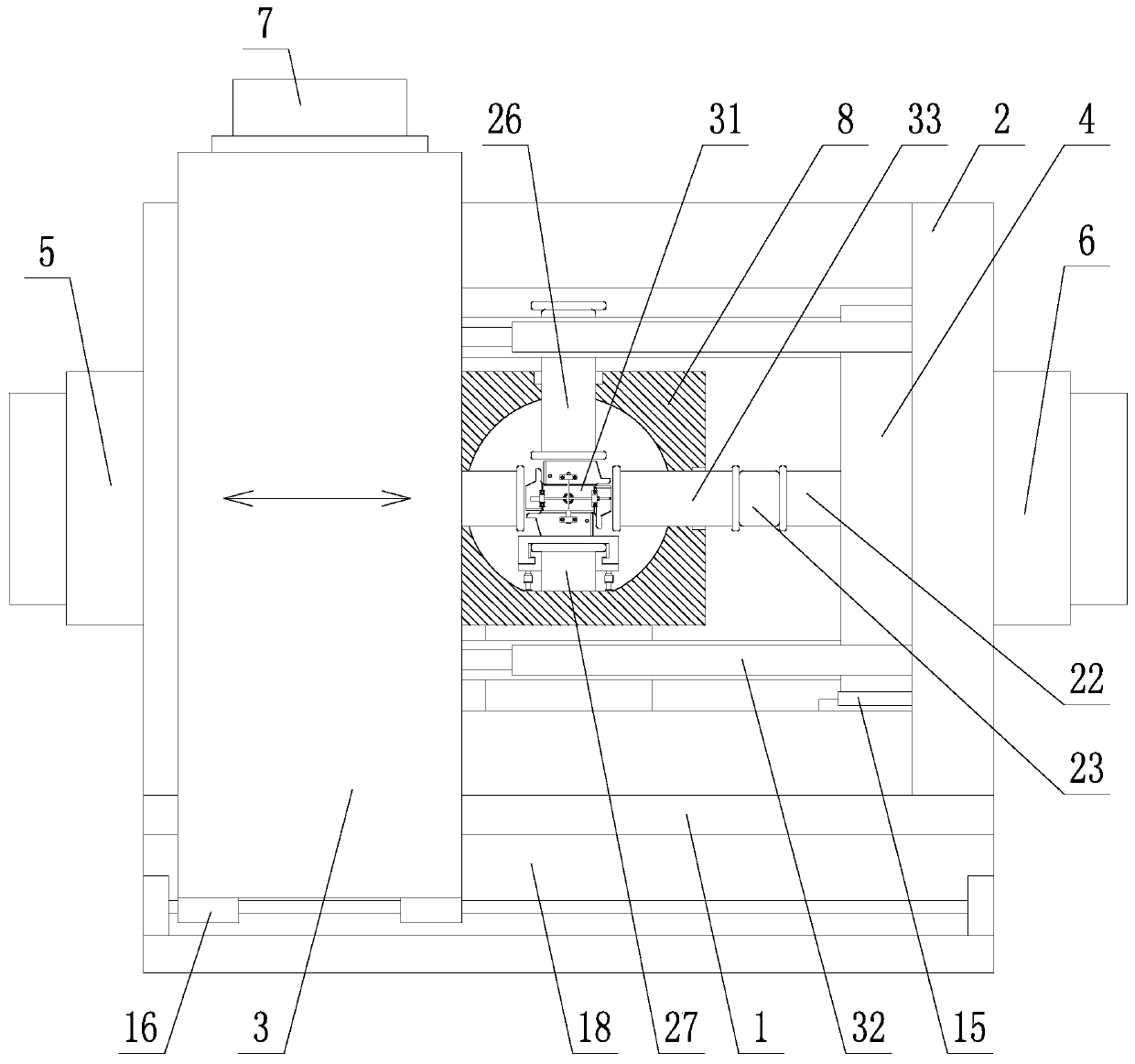

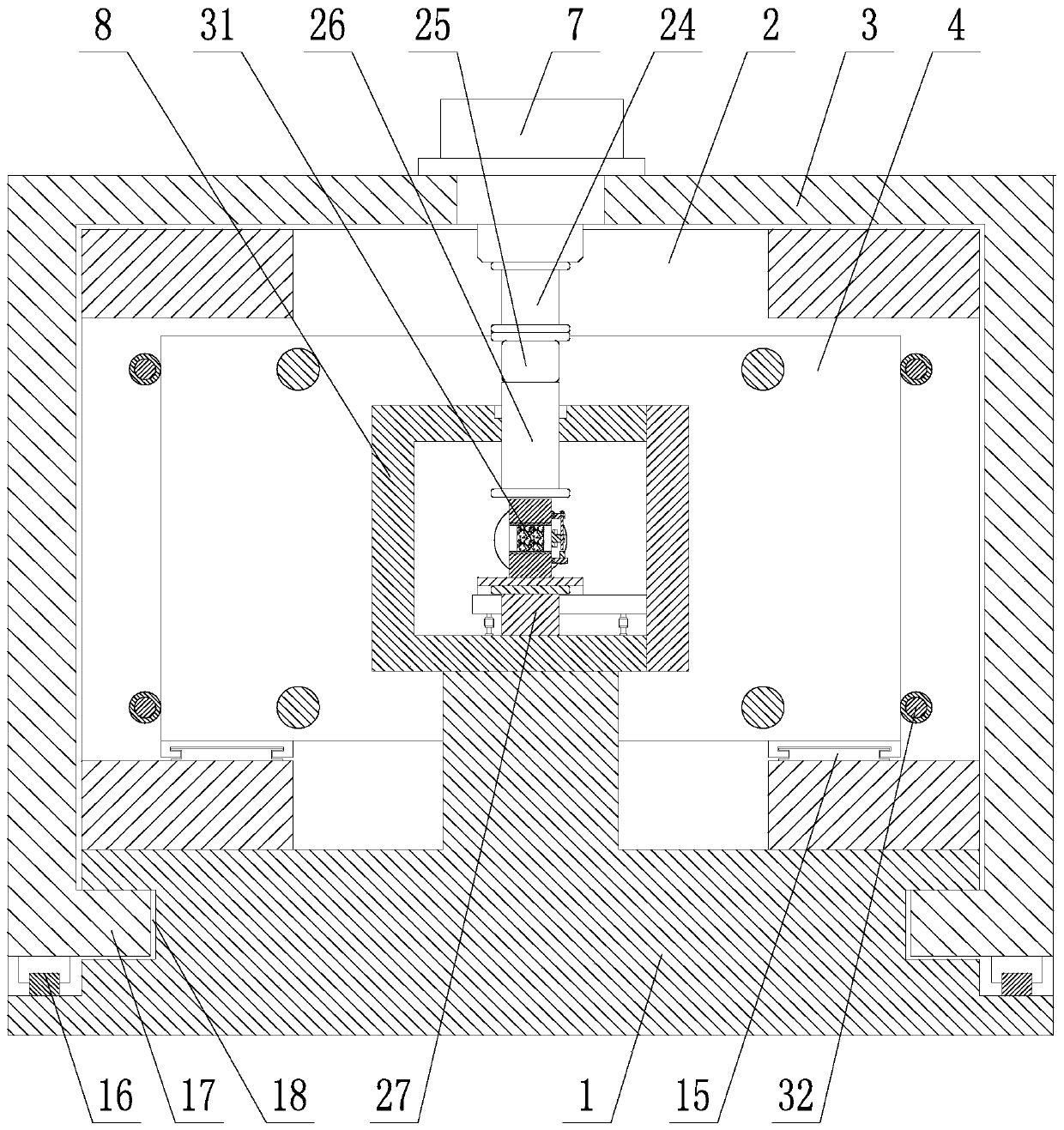

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] like Figure 1~6 As shown, a true triaxial experimental device that can obtain the post-peak curve and residual strength of brittle rock includes a base 1, a fixed high-stiffness reaction frame 2, a mobile high-stiffness reaction frame 3, a rigid loading frame 4, The first maximum principal stress loading actuator 5, the second maximum principal stress loading actuator 6, the intermediate principal stress loading actuator 7 and the pressure chamber 8; the fixed high rigidity reaction force frame 2 is fixedly installed on the base 1; the mobile high-stiffness reaction frame 3 is slidingly installed on the base 1; the rigid loading frame 4 is located inside the fixed high-stiffness reaction frame 2; the first maximum principal stress load actuator 5 and the second maximum principal stress loading actuator 6 are all installed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com