Wet-process high efficient method for purifying flue gas containing simple substance sulfur

A technology of elemental sulfur and flue gas, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as clogging equipment and destroying the stability of colloidal sulfur, so as to facilitate adsorption, avoid nozzle and circulation pump blockage, and improve The effect of capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

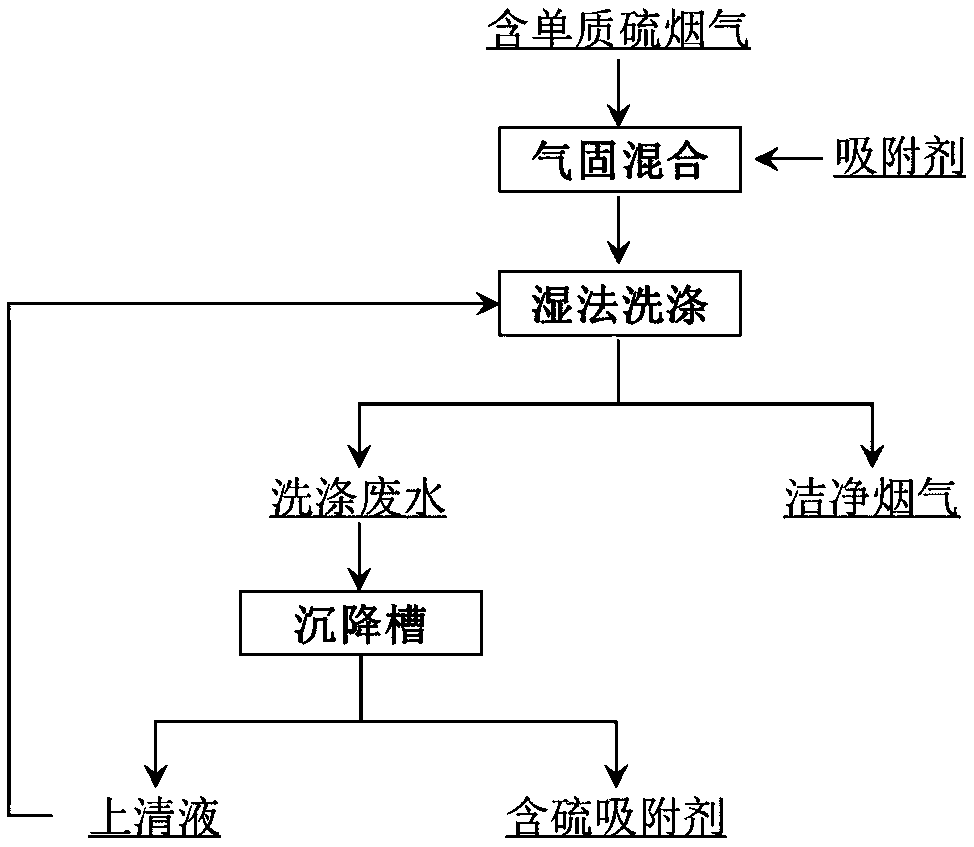

[0071] A method for high-efficiency wet purification of flue gas containing elemental sulfur, the method comprising the following steps:

[0072] 1) Mixing flue gas and adsorbent: adding solid adsorbent to the flue gas containing elemental sulfur;

[0073] 2) Wet washing: pass the flue gas containing solid adsorbent and elemental sulfur into the washing tower, and use the solution to wash the flue gas, and the flue gas is discharged after being washed and purified;

[0074] 3) Solid-liquid separation: Add the waste water produced after washing the flue gas in the washing tower into the settling tank to realize solid-liquid separation, and obtain the supernatant and the settled sulfur-containing solid adsorbent.

[0075] Wherein, the solid adsorbent described in step 1) is activated carbon. The particle size of the solid adsorbent is 20 μm. The amount of solid adsorbent added is 1.3 times the ratio of the amount of elemental sulfur in the flue gas to the adsorption capacity o...

Embodiment 2

[0093] A method for high-efficiency wet purification of flue gas containing elemental sulfur, the method comprising the following steps:

[0094] 1) Mixing flue gas and adsorbent: adding solid adsorbent to the flue gas containing elemental sulfur;

[0095] 2) Wet scrubbing: the flue gas containing solid adsorbent and elemental sulfur is passed into the scrubber, and the flue gas is washed with an acidic solution, and the flue gas is discharged after being washed and purified;

[0096] 3) Solid-liquid separation: Add the waste water produced after washing the flue gas in the washing tower into the settling tank to realize solid-liquid separation, and obtain the supernatant and the settled sulfur-containing solid adsorbent.

[0097] 4) The supernatant obtained in step 3) is transported to the washing tower for recycling.

[0098] Wherein, the solid adsorbent described in step 1) is activated carbon. The particle size of the solid adsorbent is 10 μm. The amount of solid adsorb...

Embodiment 3

[0104] A method for high-efficiency wet purification of flue gas containing elemental sulfur, the method comprising the following steps:

[0105] 1) Mixing flue gas and adsorbent: adding solid adsorbent to the flue gas containing elemental sulfur;

[0106] 2) Wet scrubbing: the flue gas containing solid adsorbent and elemental sulfur is passed into the scrubber, and the flue gas is washed with an acidic solution, and the flue gas is discharged after being washed and purified;

[0107] 3) Solid-liquid separation: Add the waste water produced after washing the flue gas in the washing tower into the settling tank to realize solid-liquid separation, and obtain the supernatant and the settled sulfur-containing solid adsorbent.

[0108] 4) The supernatant obtained in step 3) is transported to the washing tower for recycling.

[0109] Wherein, the solid adsorbent described in step 1) is a molecular sieve. The particle size of the solid adsorbent is 50 μm. The amount of solid adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com