Buffer type weighing machine for iron and steel materials

A steel and buffer technology, applied in measuring devices, instruments, weighing and other directions, can solve the problems of heavy weight, inconvenient installation and layout, high production labor intensity, etc., achieve good buffer vibration absorption capacity, and facilitate replacement, maintenance and replacement of parts. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

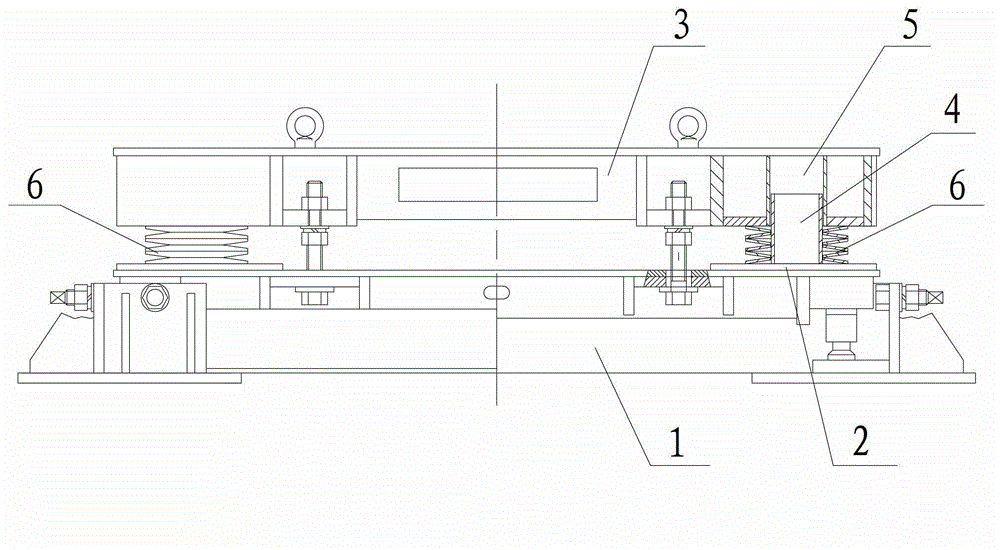

[0015] see figure 1 A buffer type steel scale is shown, the steel scale includes a base 1, a load cell 2 fixedly arranged on the base 1, a weighing platform 3 fixedly arranged on the base 1 for placing objects to be weighed, and the weighing platform 3 is located above the load cell 2 on the base 1. A plurality of buffers are arranged between the load cell 2 and the bottom of the weighing platform 3, and the buffer includes a plurality of guide posts 4 fixedly arranged above the load cell 2, and the axis lines of all the guide posts 4 are along the vertical Extending in the direction, all the guide posts 4 are provided with a plurality of butterfly springs 6, the bottom of the weighing platform 3 is provided with a plurality of blind holes 5 for the guide posts 4 to penetrate in the axial direction, and the guide posts 4 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com