Patents

Literature

234 results about "Bending of plates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bending of plates, or plate bending, refers to the deflection of a plate perpendicular to the plane of the plate under the action of external forces and moments. The amount of deflection can be determined by solving the differential equations of an appropriate plate theory. The stresses in the plate can be calculated from these deflections. Once the stresses are known, failure theories can be used to determine whether a plate will fail under a given load.

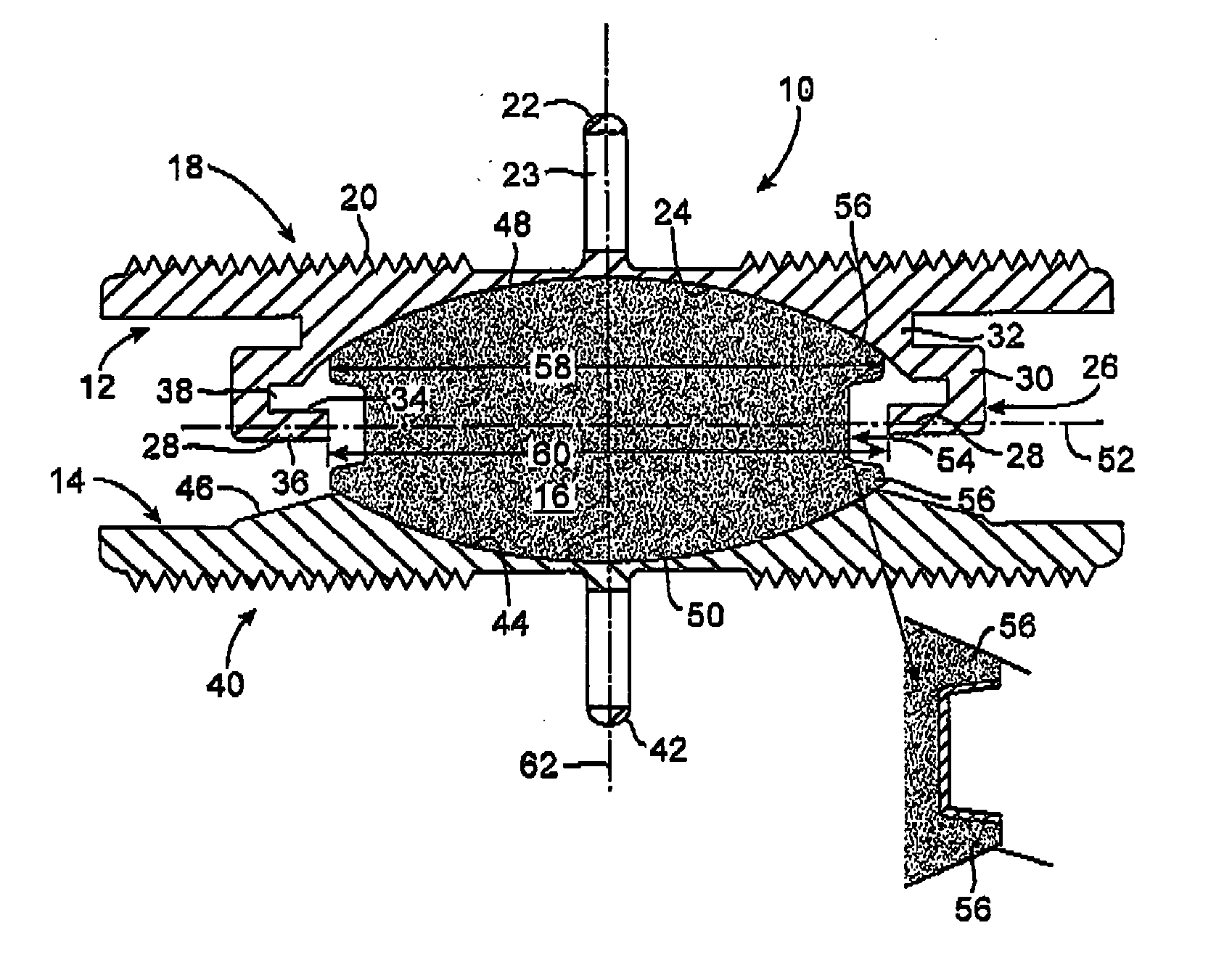

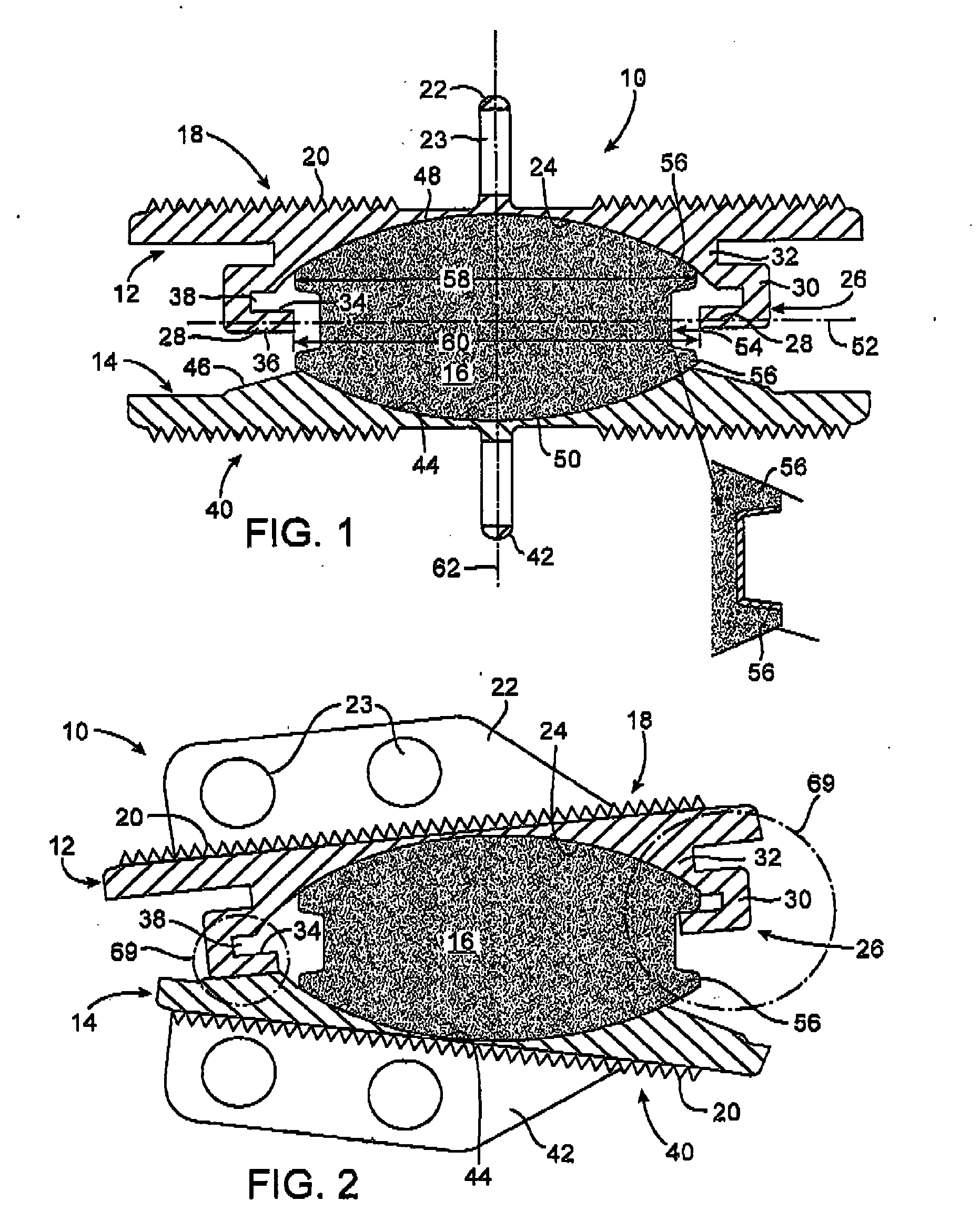

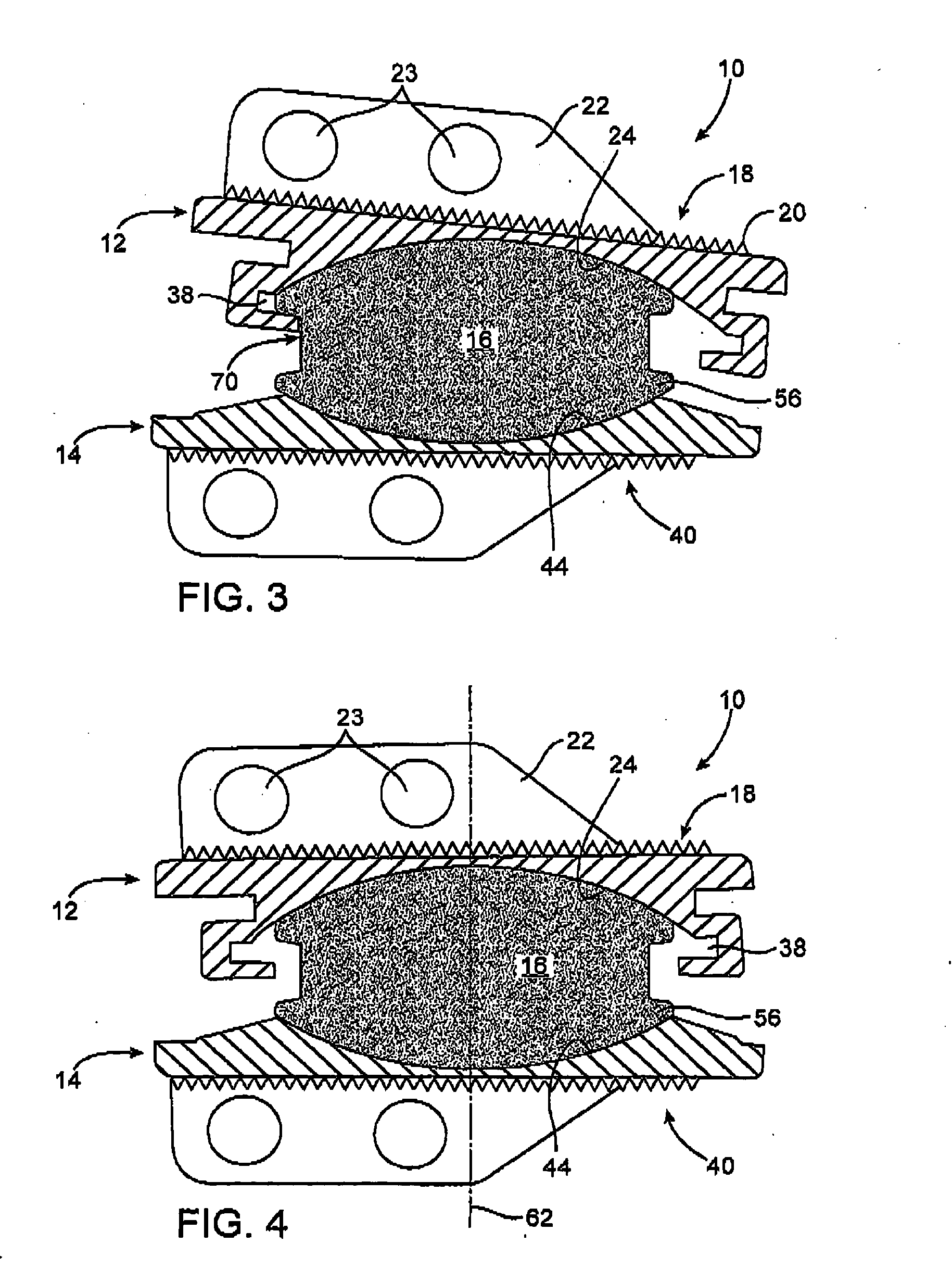

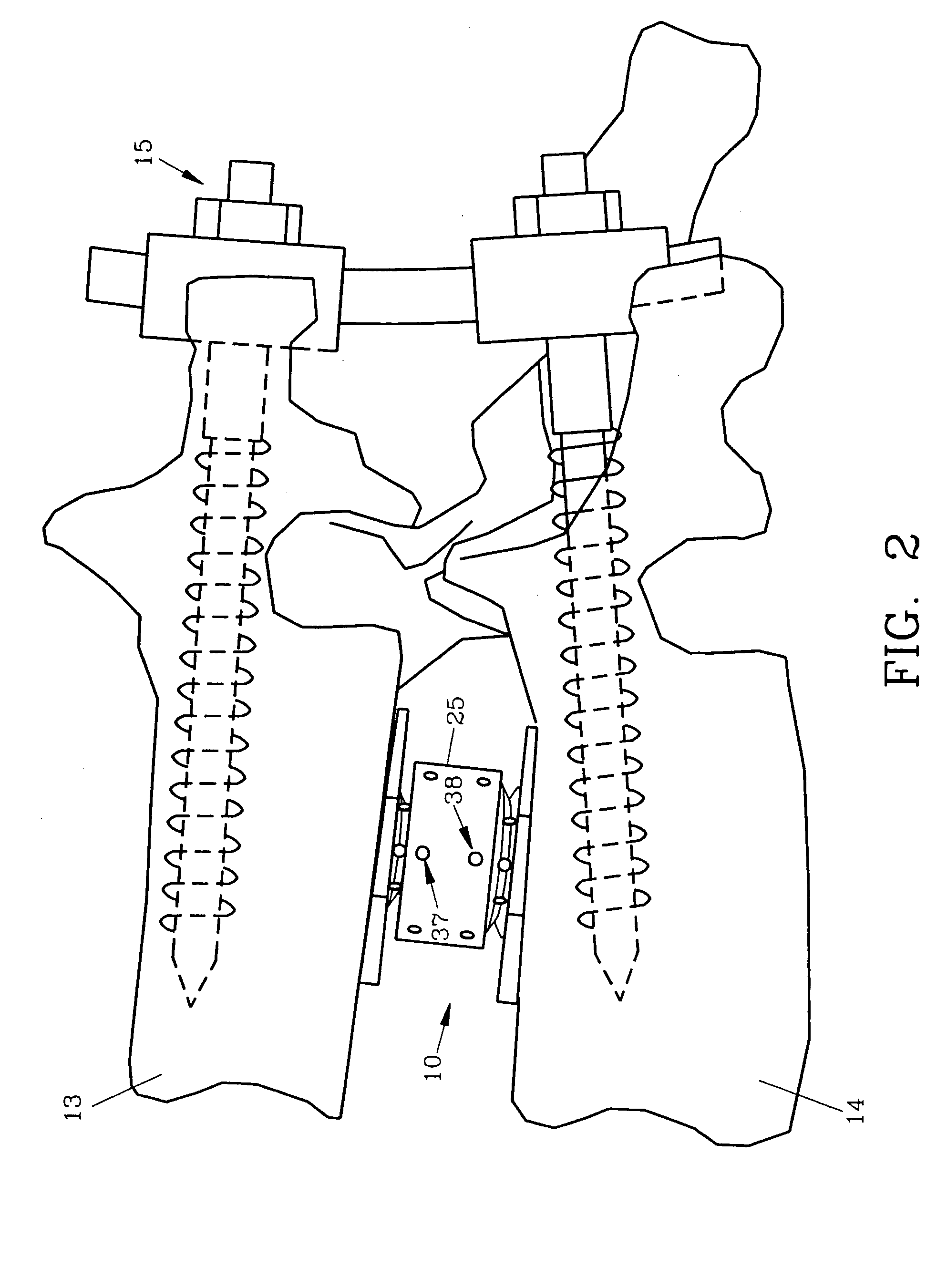

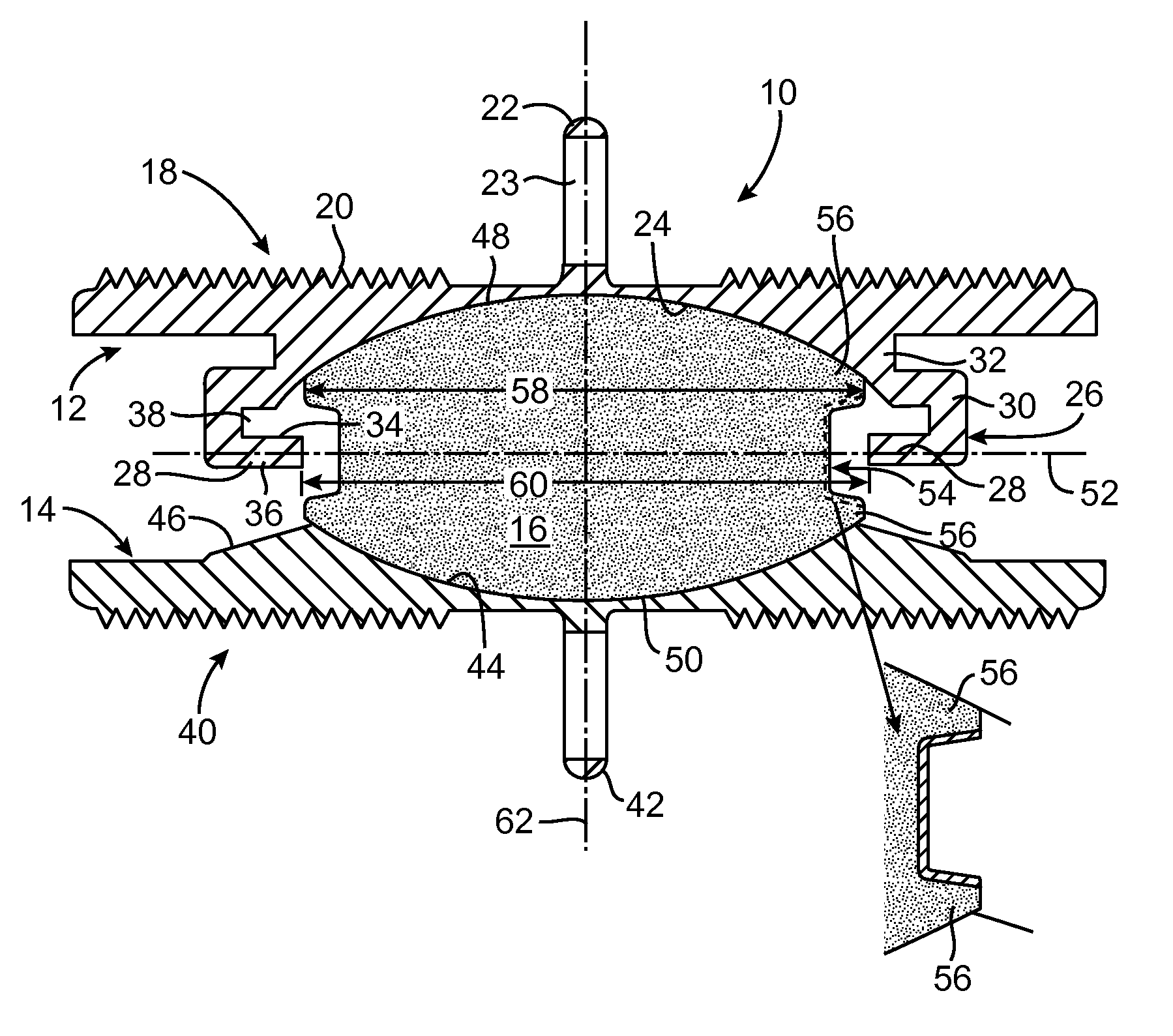

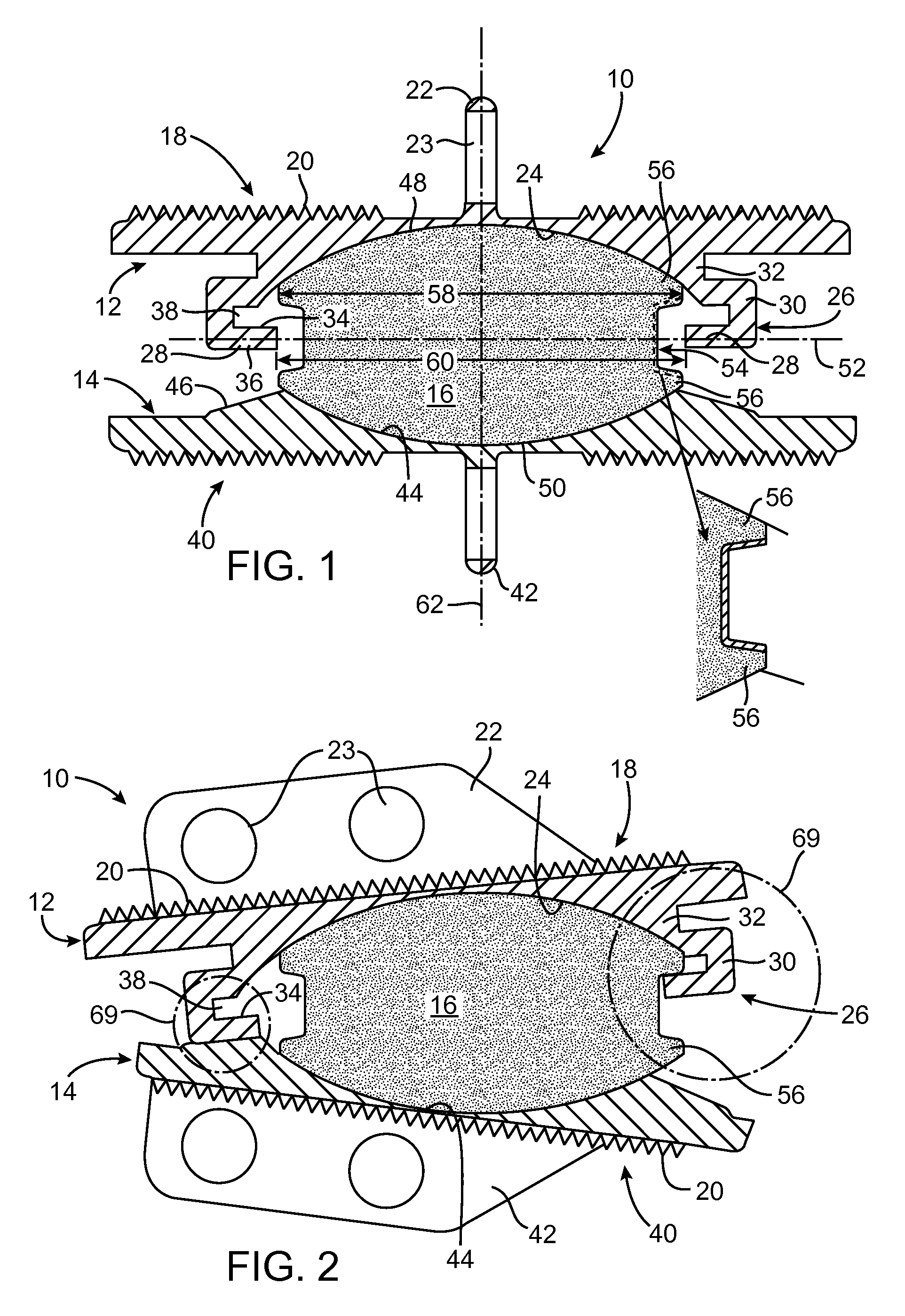

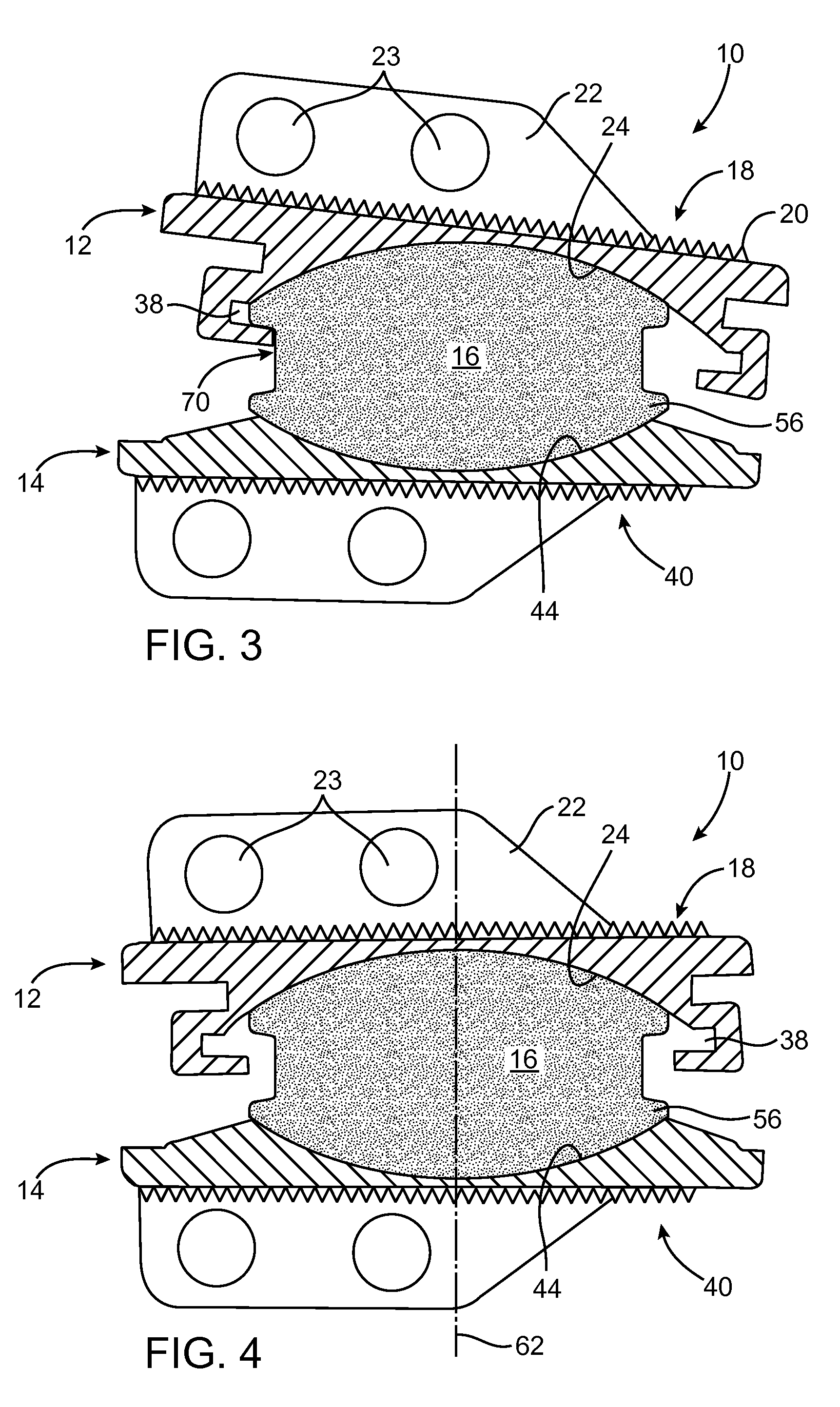

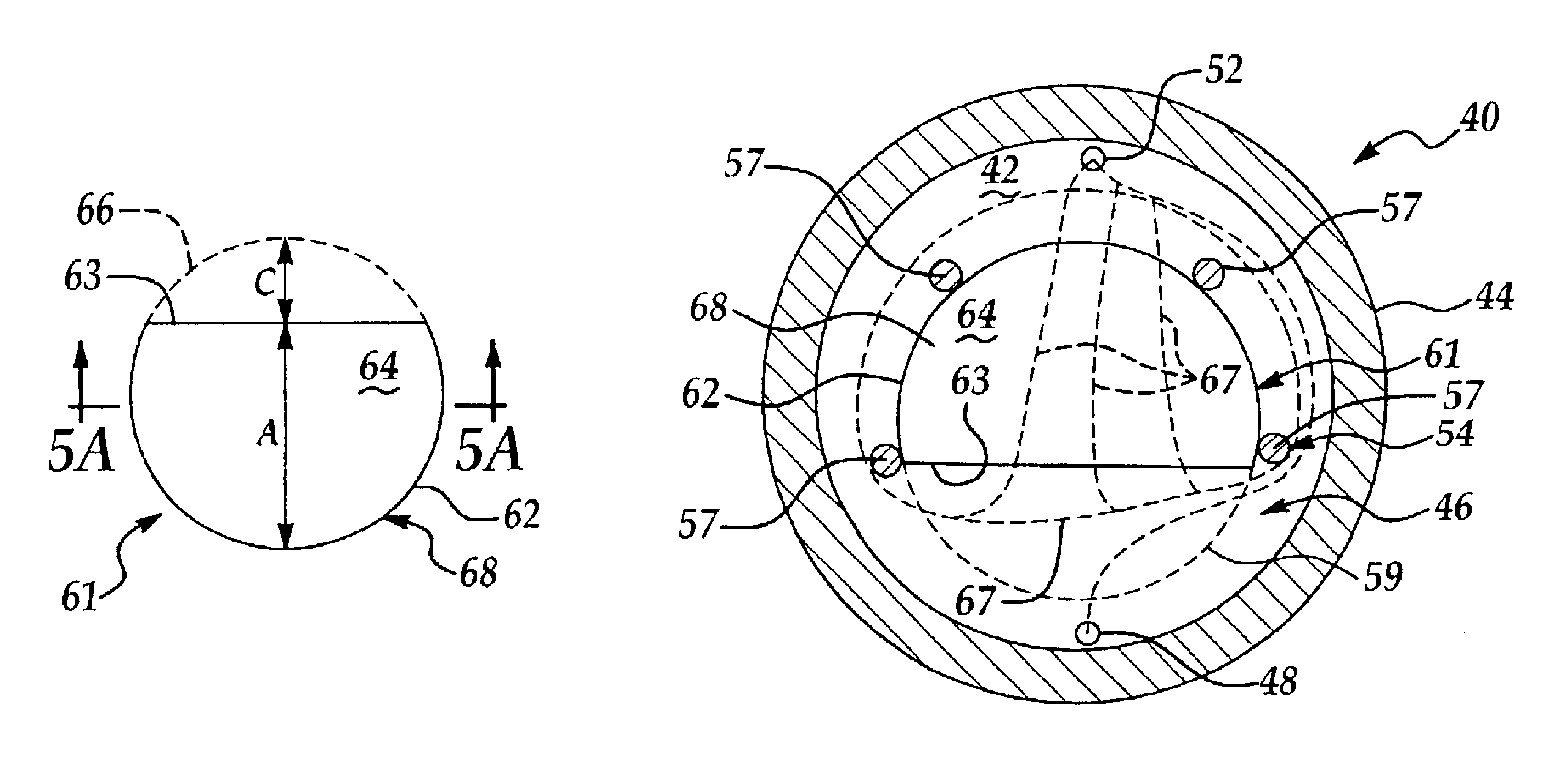

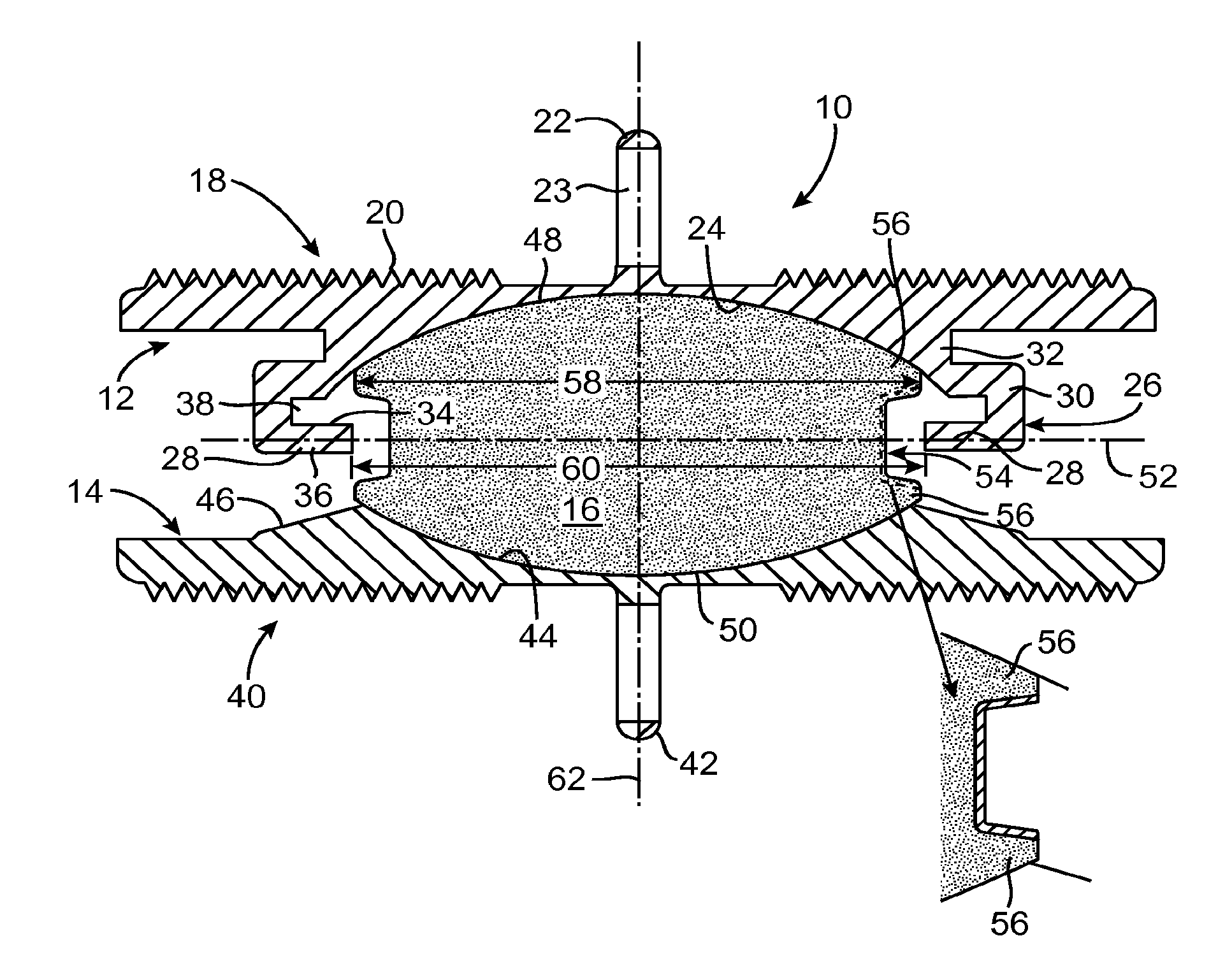

Prosthetic disc for intervertebral insertion

ActiveUS20050021145A1Reduce frictionDiameter can be maximizedJoint implantsSpinal implantsProsthesisIntervertebral disk

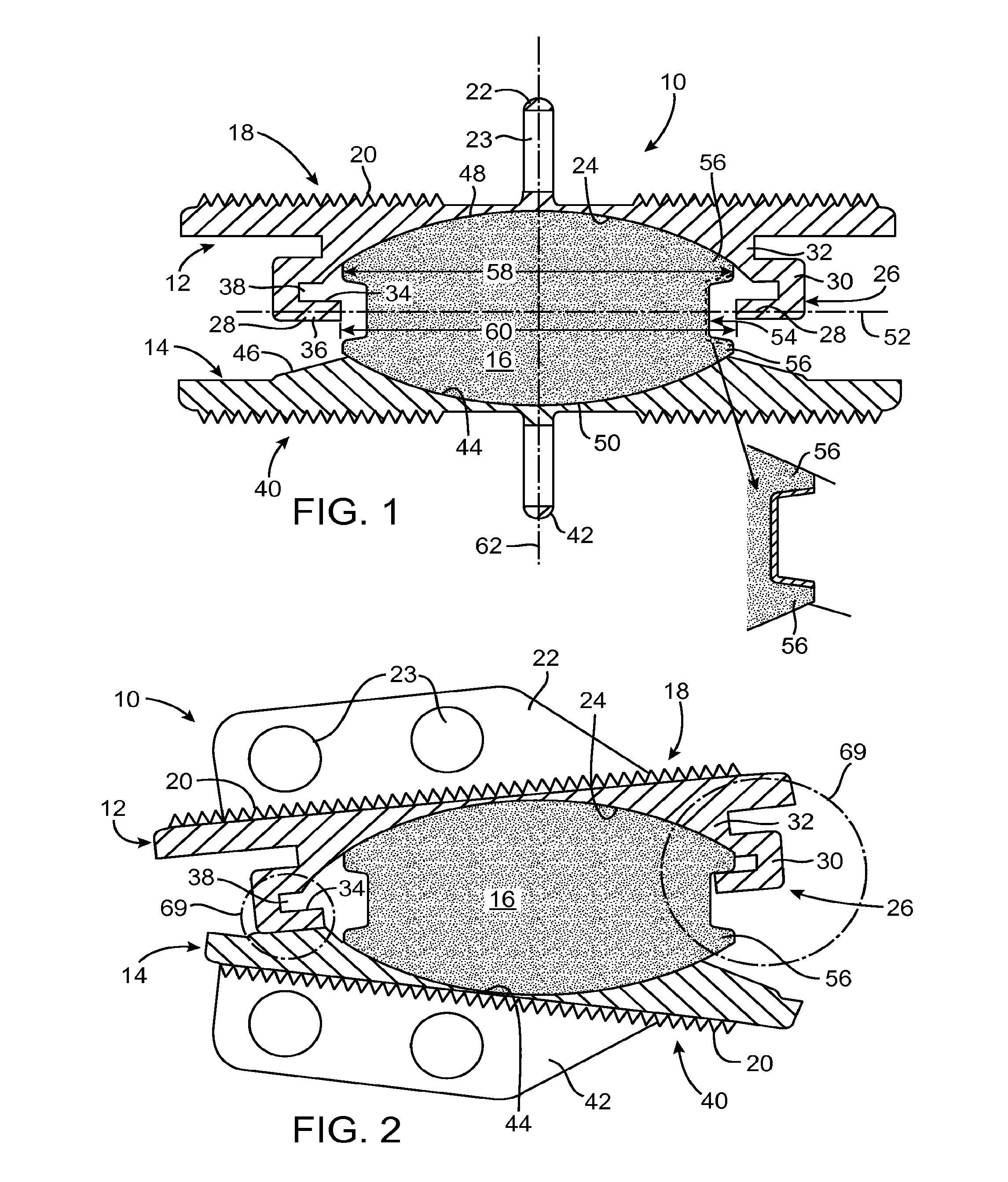

A prosthetic disc for insertion between adjacent vertebrae includes a core having upper and lower curved surfaces, upper and lower plates, and peripheral restraining structure on at least one of the upper plate, the lower plate and the core. Each plate has an outer surface which engages a vertebra and an inner curved surface which slides over the curved surface of the core. The peripheral restraining structure serves to hold the core against a curved surface of at least one of the plates during sliding movement of the plates over the core.

Owner:SIMPLIFY MEDICAL PTY LTD

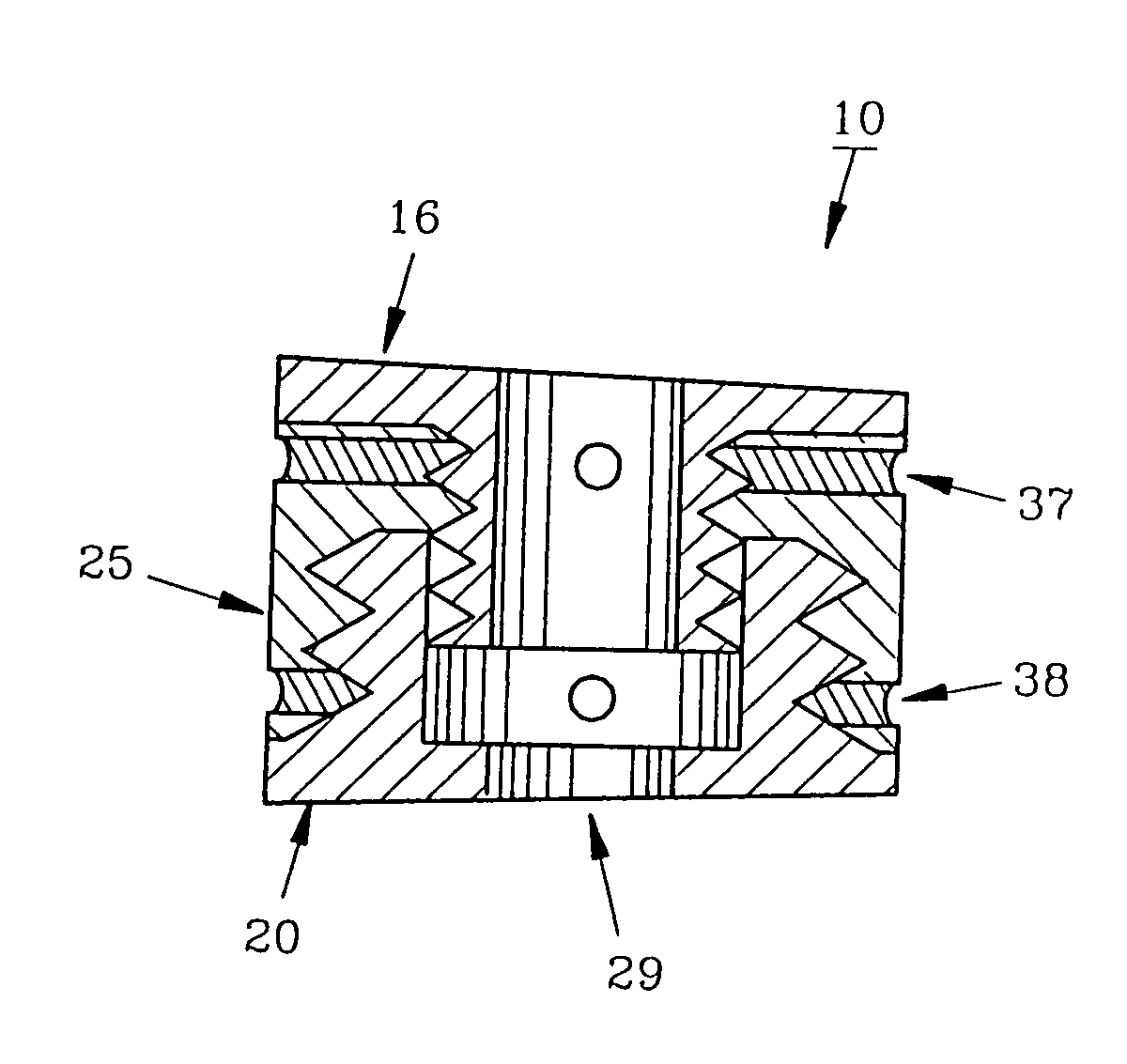

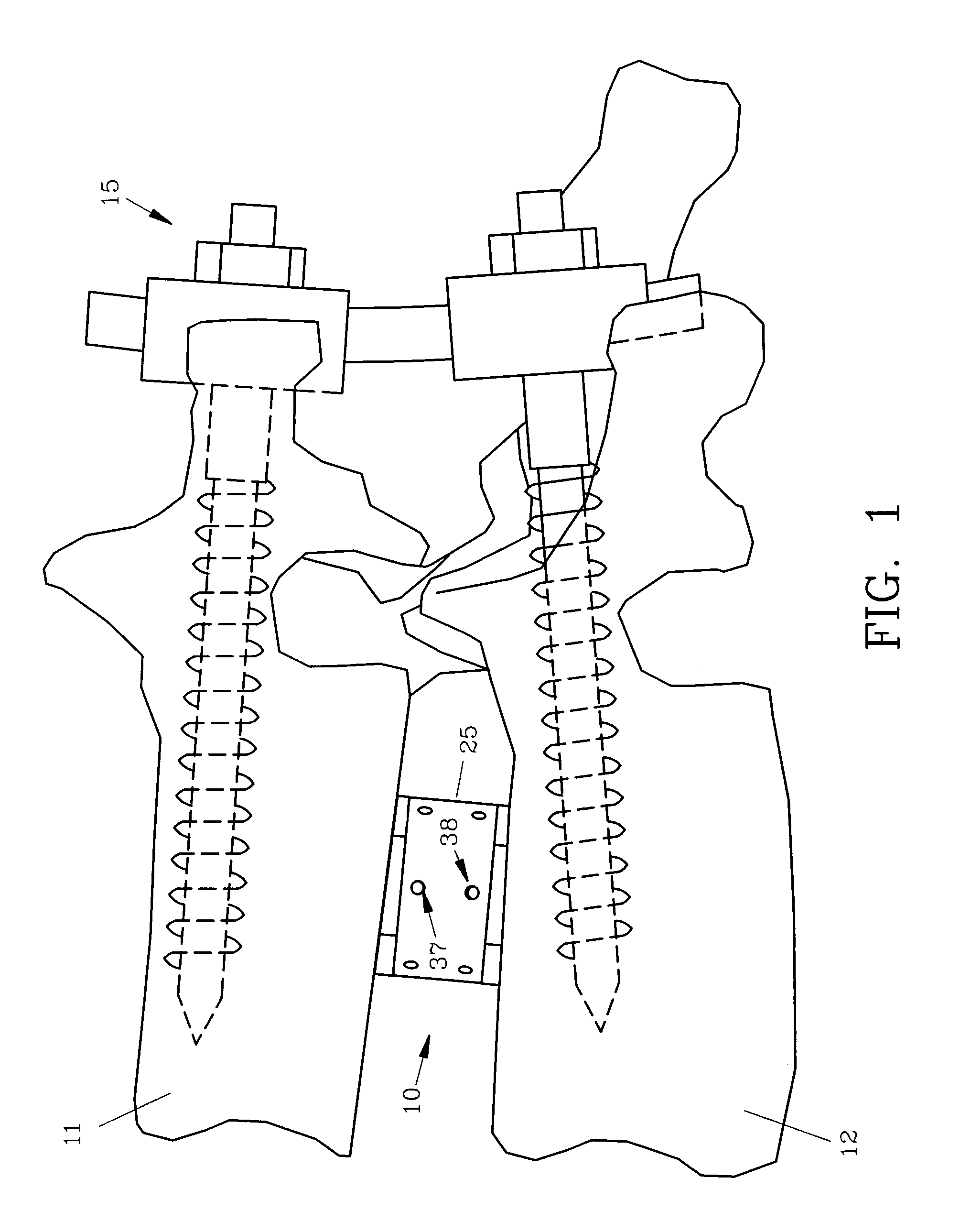

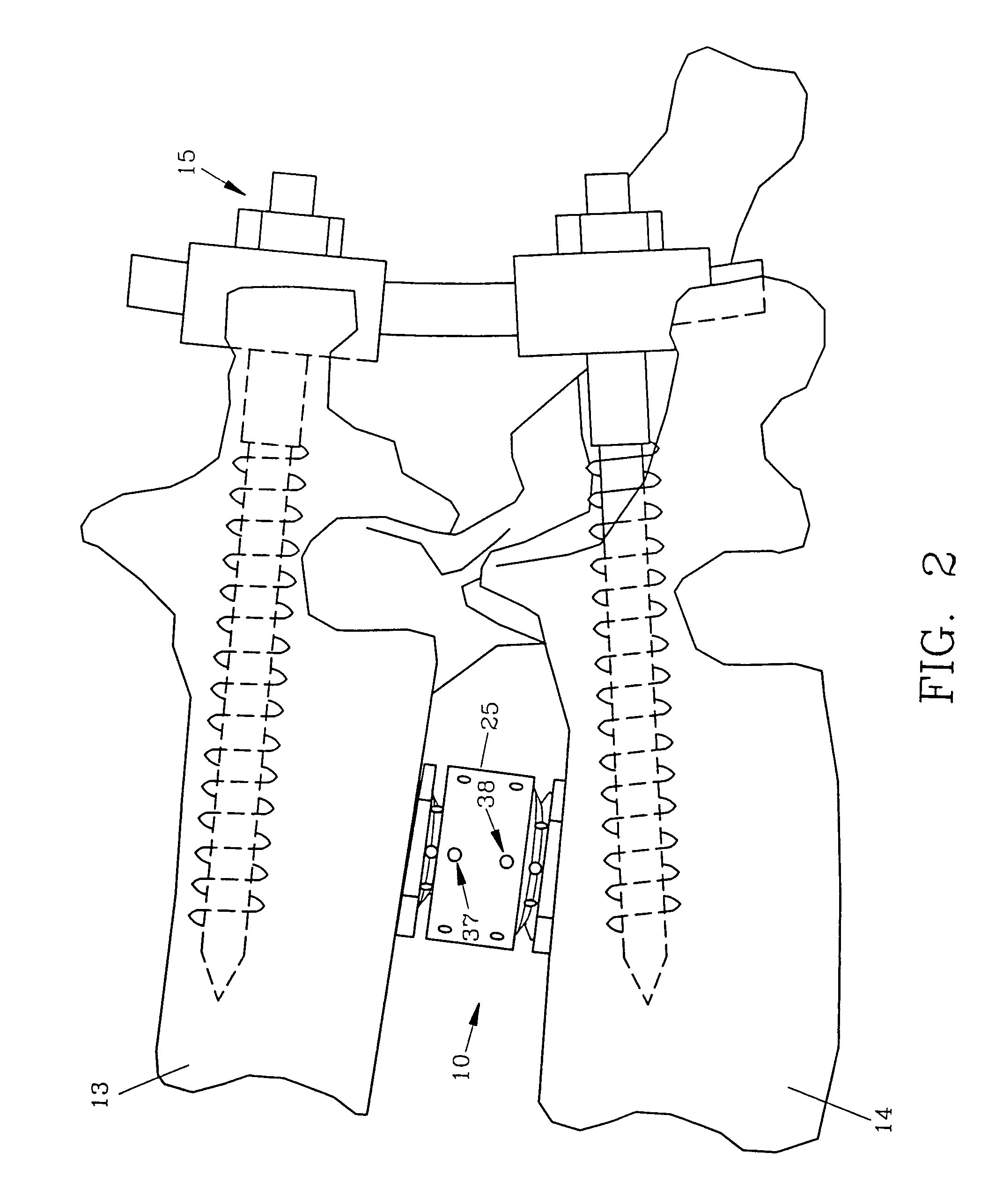

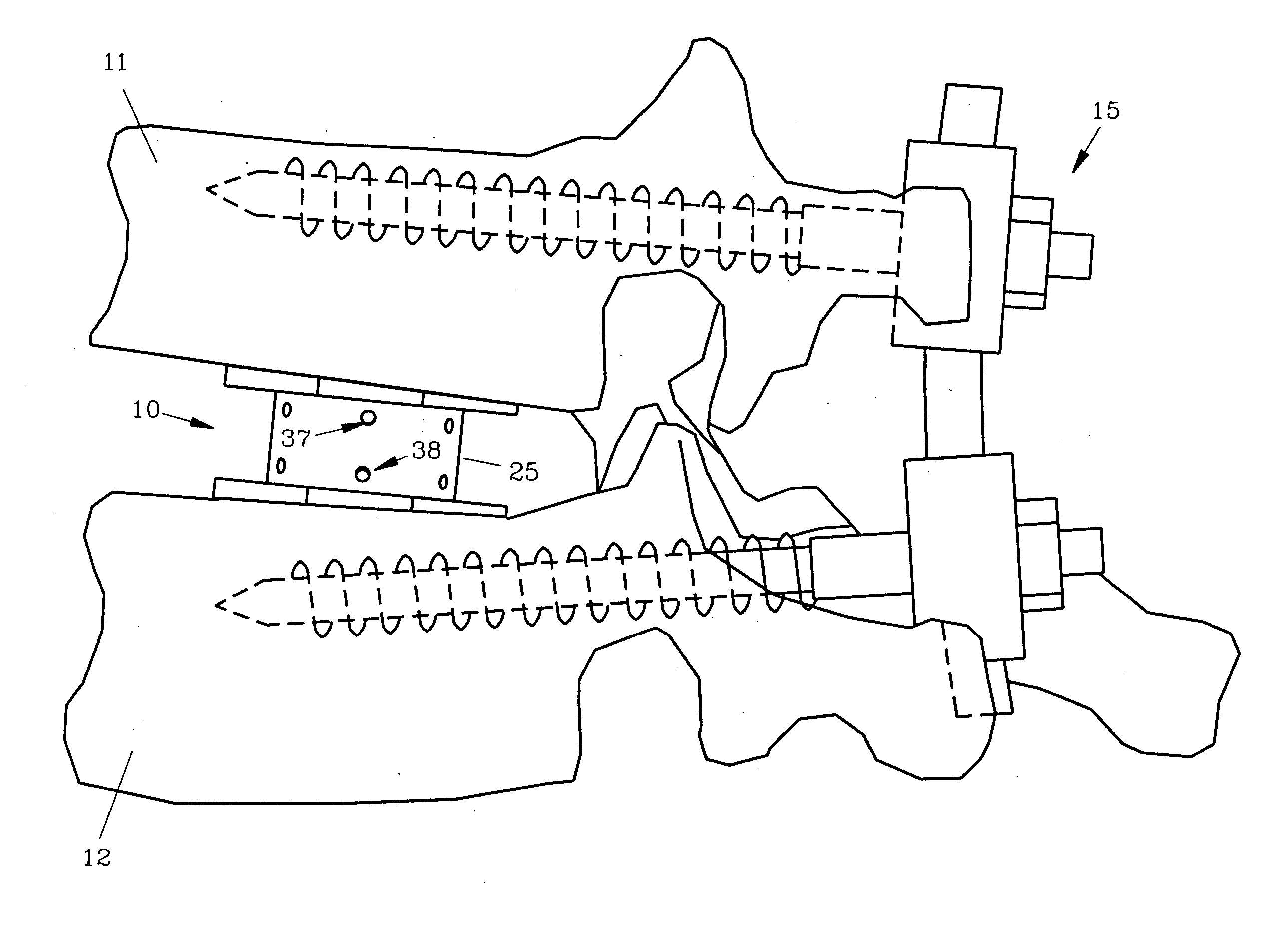

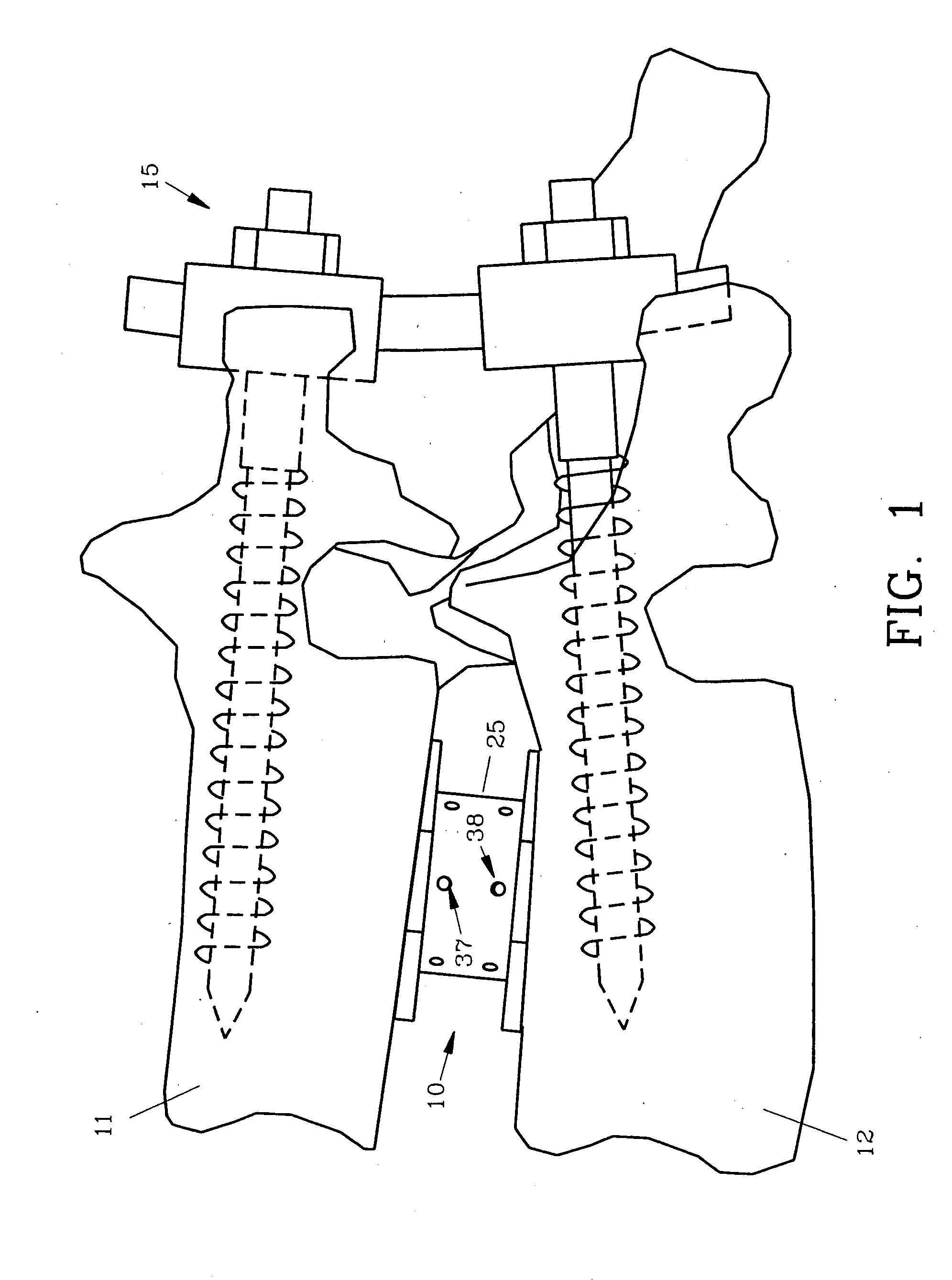

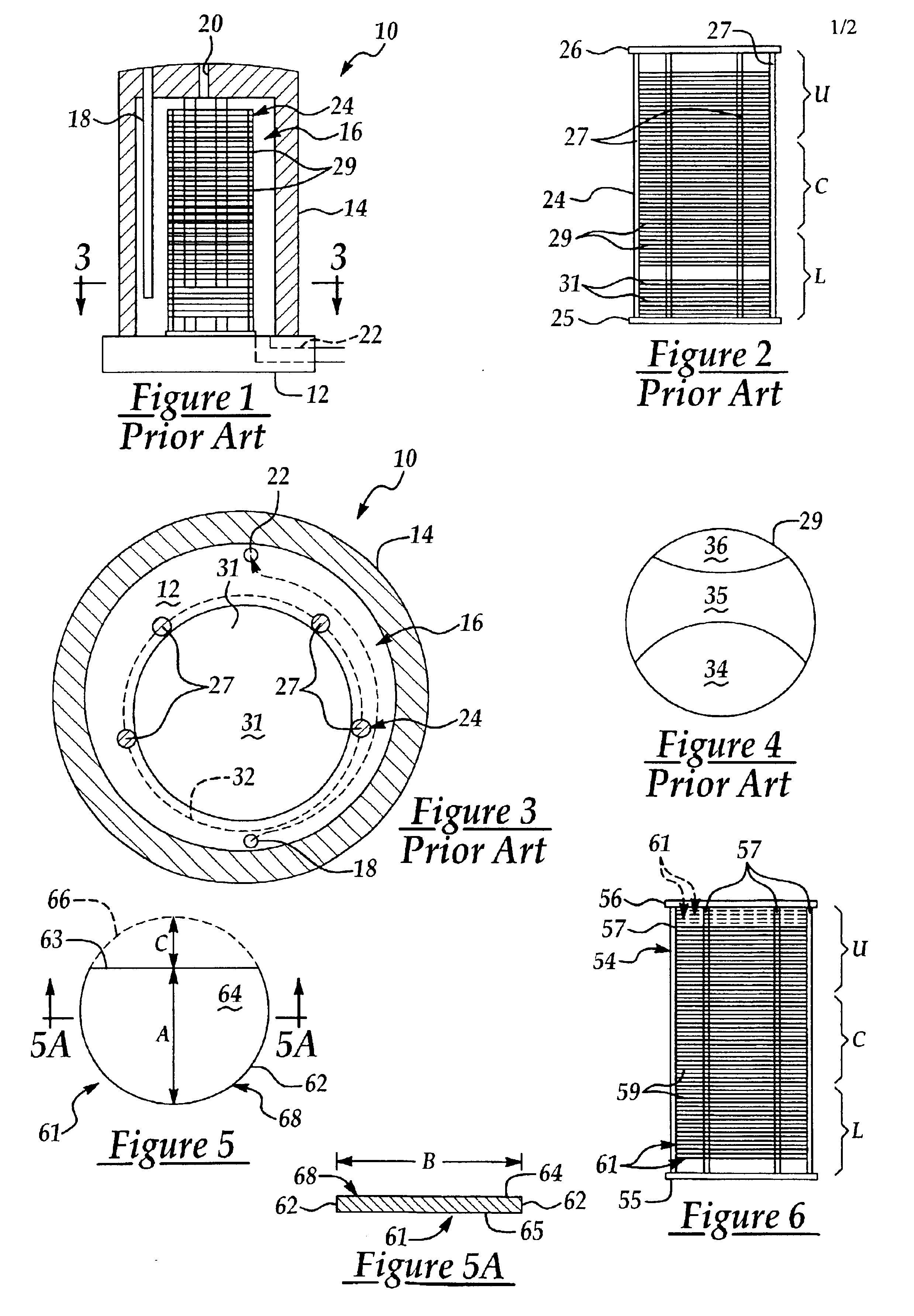

Spinal interbody fusion device and method

InactiveUS7022138B2Easy to copyAvoid injuryInternal osteosythesisBone implantSpinal columnIntervertebral disk

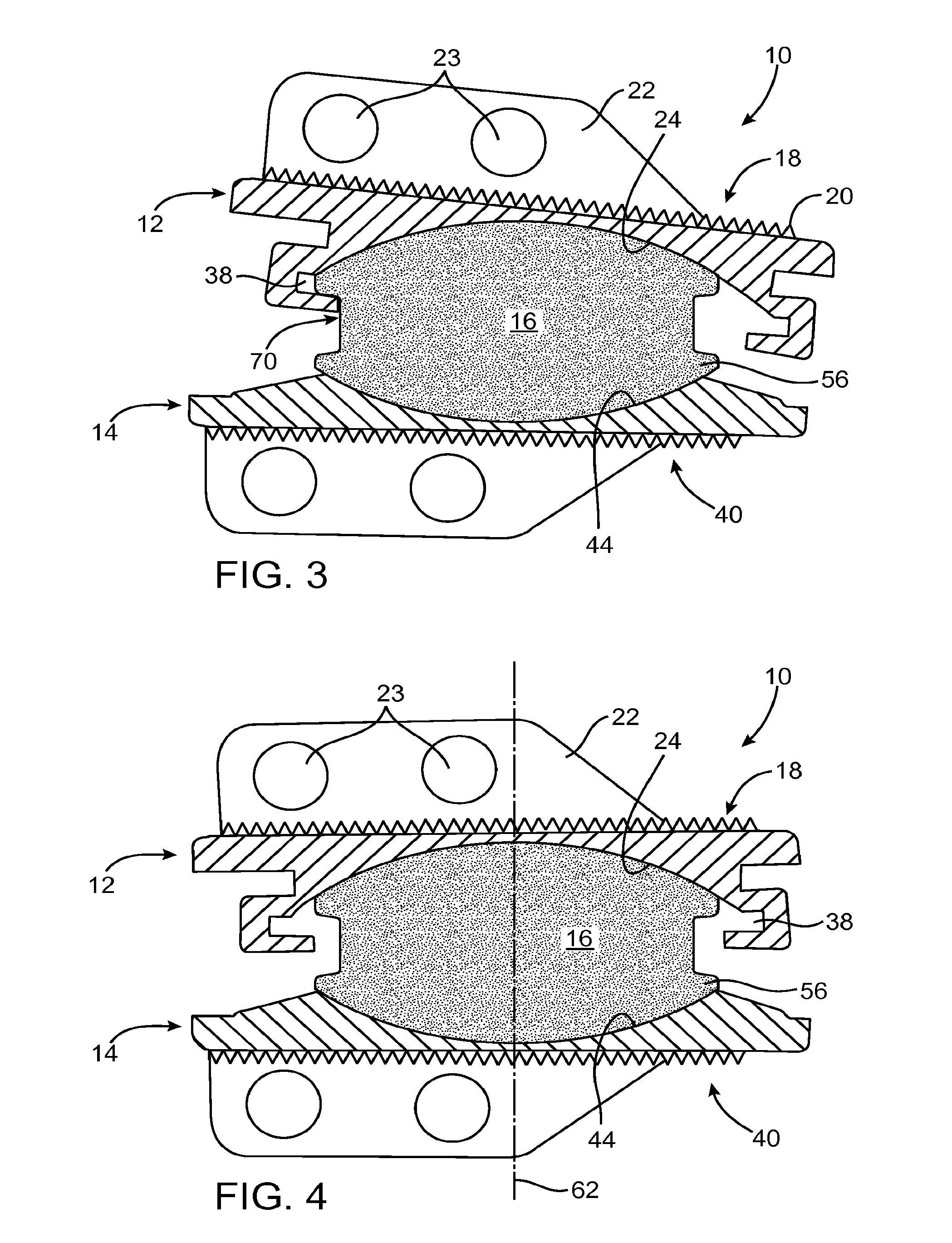

A disc replacement spinal interbody fusion device is provided having a central sleeve with oppositely left and right-hand threaded axial bores with different diameters. Circumferential threaded apertures are located on the sleeve and open into the sleeve bores. The device has two opposing plates which are oval-shaped and centrally, axially bored. Each plate has a perpendicular shaft with an axial bore which communicates with the plate bore. In situ, axial loading of the spinal column upon the fusion device creates a bending moment manifested by a flexing action of the plates to generate opposing axial directional forces which replicate the physiological function of shock absorption, load bearing and load transmission.

Owner:MASHBURN M LAINE

Spinal interbody fusion device and method

InactiveUS20050027359A1Resist translationalResist rotational movementInternal osteosythesisBone implantSpinal columnBending of plates

A disc replacement spinal interbody fusion device is provided having a central sleeve with oppositely left and right-hand threaded axial bores with different diameters. Circumferential threaded apertures are located on the sleeve and open into the sleeve bores. The device has two opposing plates which are oval-shaped and centrally, axially bored. Each plate has a perpendicular shaft with an axial bore which communicates with the shaft bore. The first shaft has external left-hand threads and the second shaft has external right-hand threads, each to mate with different bores of the sleeve. The outside diameter of the first shaft is smaller than the inside diameter of the second shaft, allowing the two shafts to axially engage. The spinal interbody fusion device operates like a turnbuckle, vertically expanding when the sleeve is rotated in one direction and retracting when the sleeve is rotated in the opposite direction. The assembled device defines an open channel axially. Once the fusion device is set at its proper height, set screws are threaded into circumferential apertures of the sleeve to compress against the shaft threads of each plate to maintain a fixed height. In situ, axial loading of the spinal column upon the fusion device creates a bending moment manifested by a flexing action of the plates to generate opposing axial directional forces which replicate the physiological function of shock absorption, load bearing and load transmission.

Owner:MASHBURN M LAINE

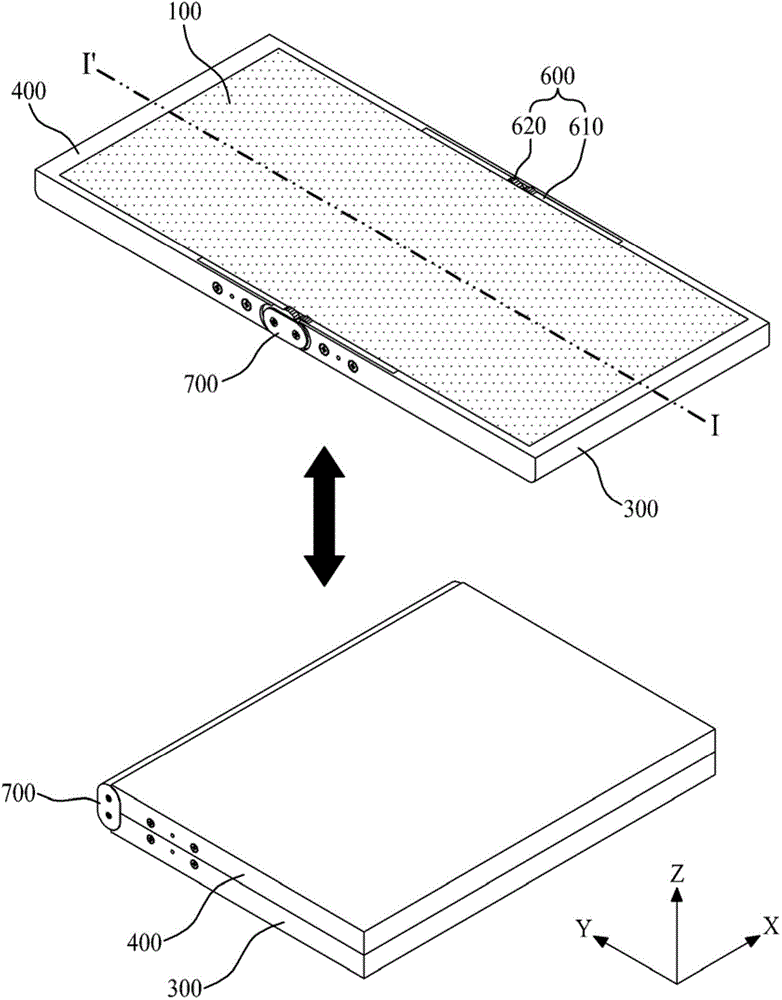

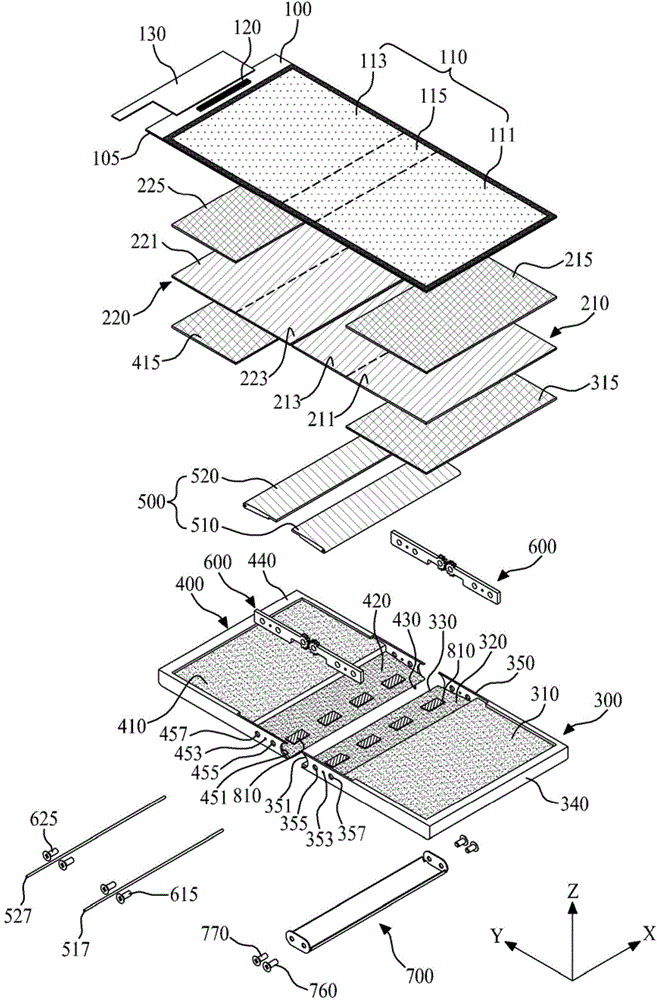

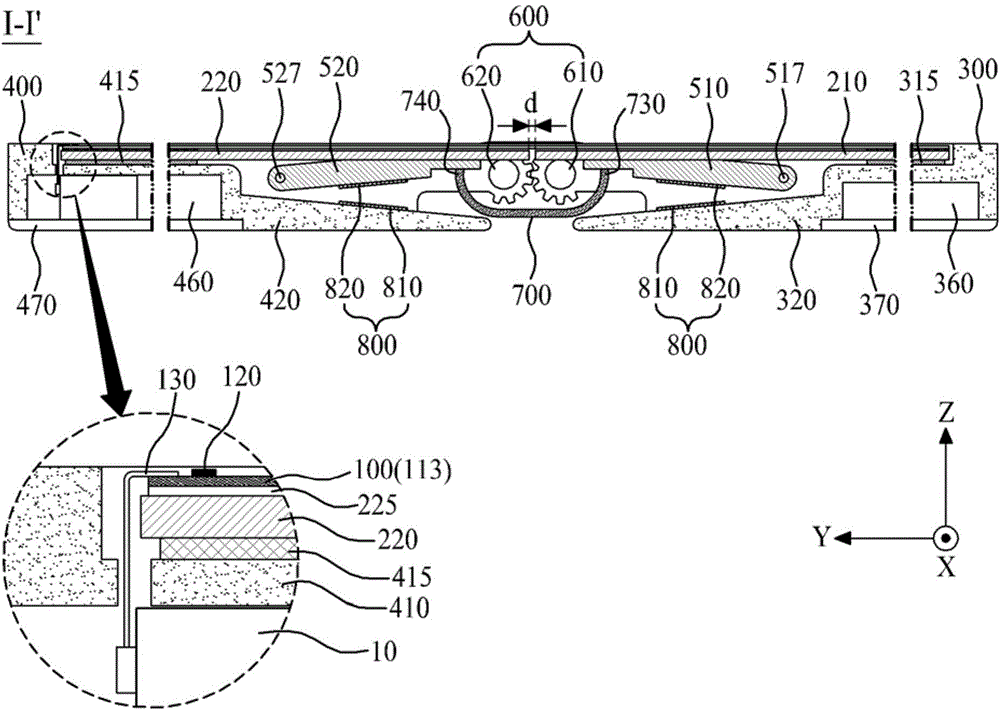

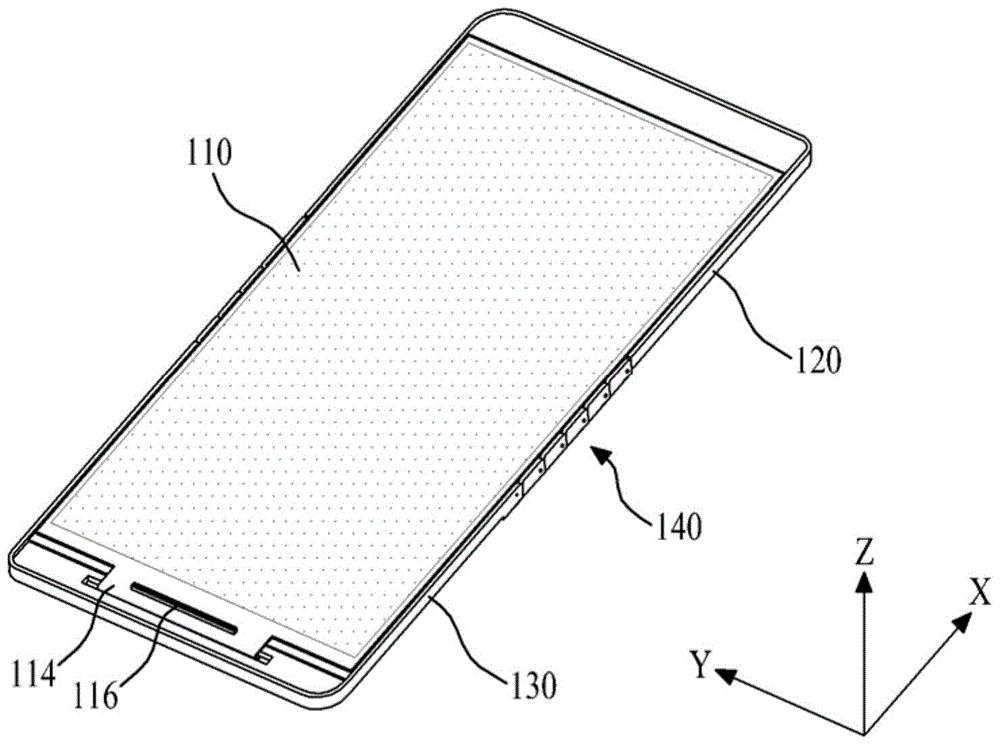

Foldable display apparatus

ActiveCN106205385ADevices with multiple display unitsPrinted circuit aspectsEngineeringFlexible display

Owner:LG DISPLAY CO LTD

Prosthetic Disc for Intervertebral Insertion

ActiveUS20080133011A1Reduce frictionDiameter can be maximizedJoint implantsSpinal implantsProsthesisEngineering

Owner:SIMPLIFY MEDICAL PTY LTD

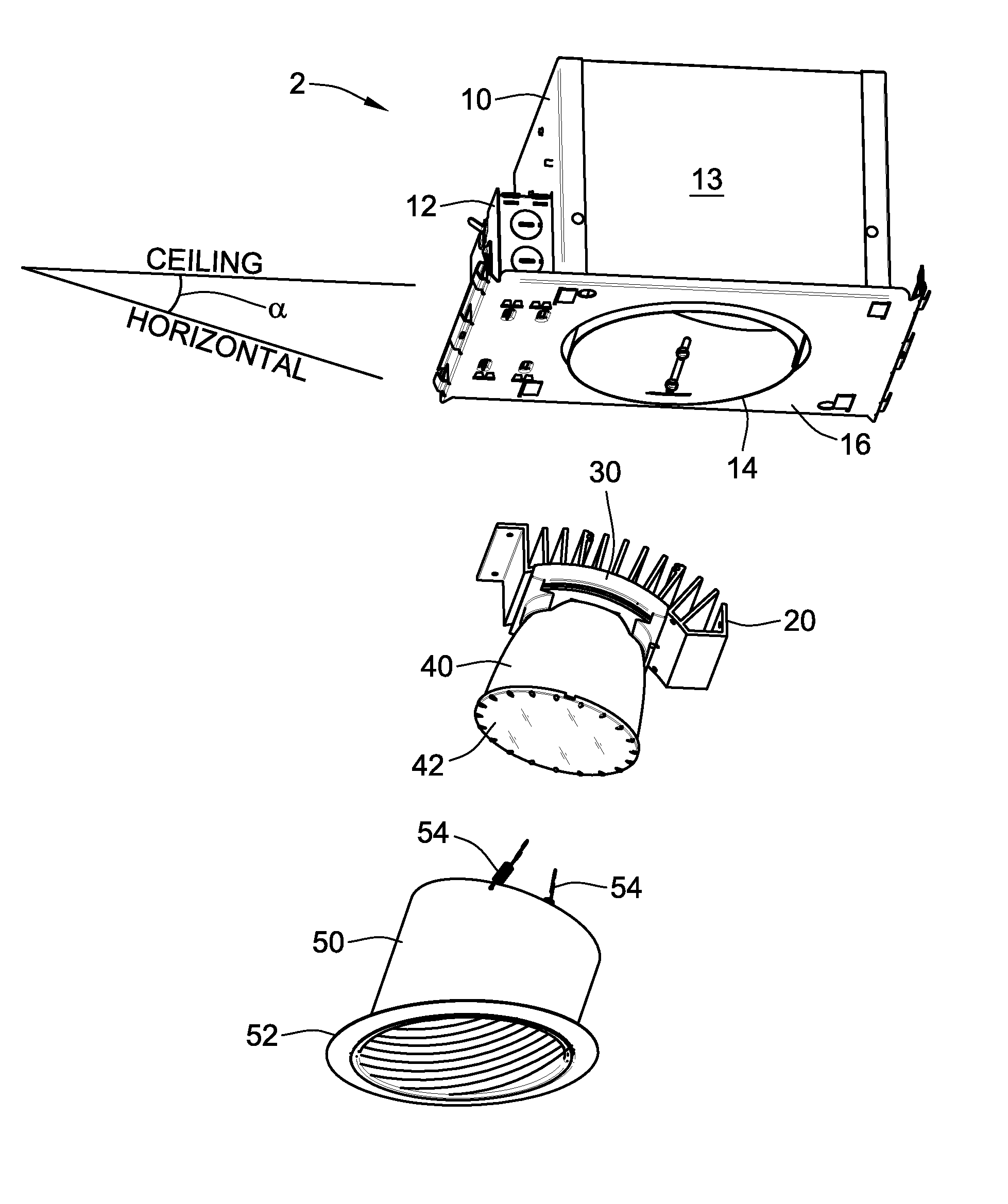

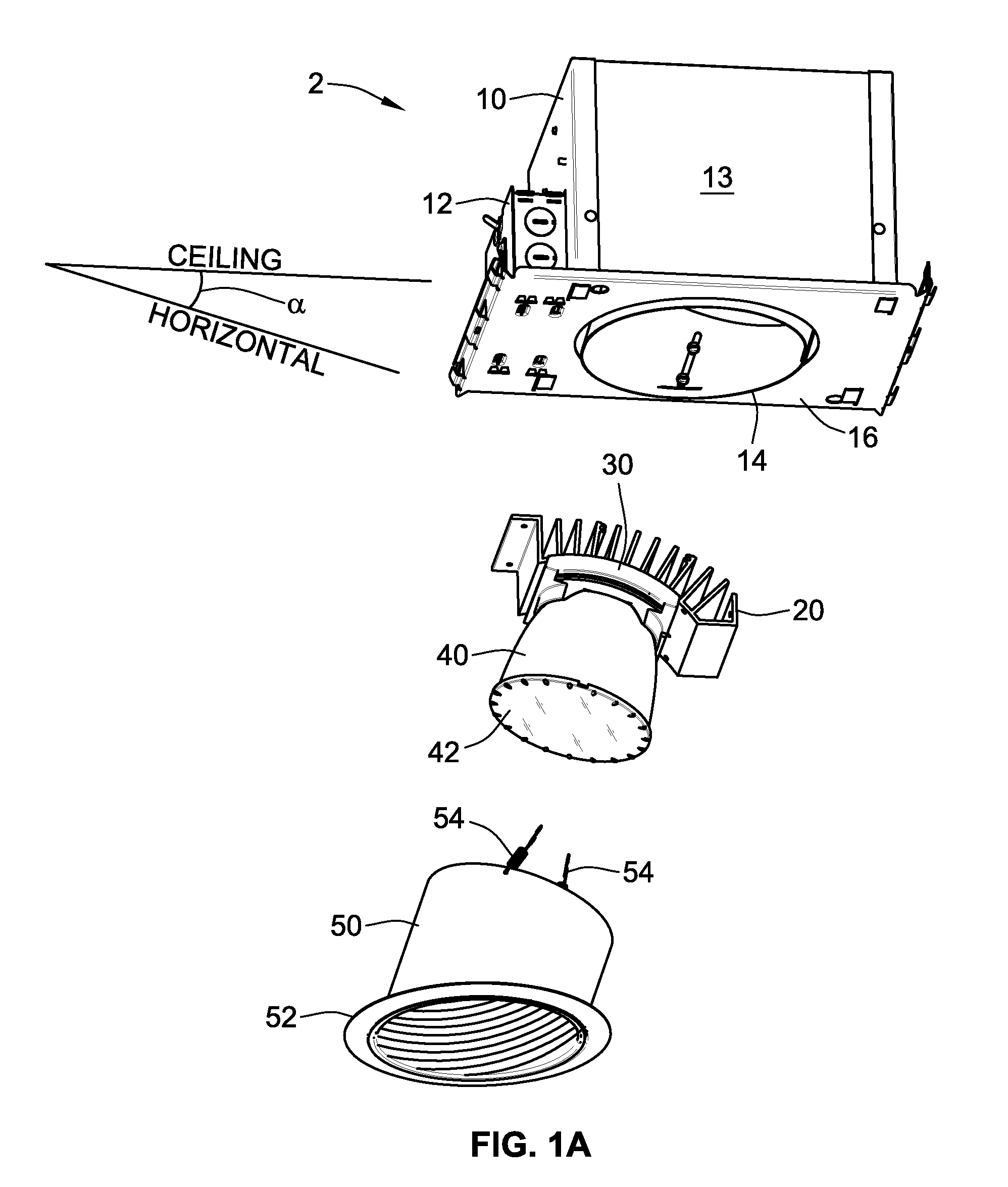

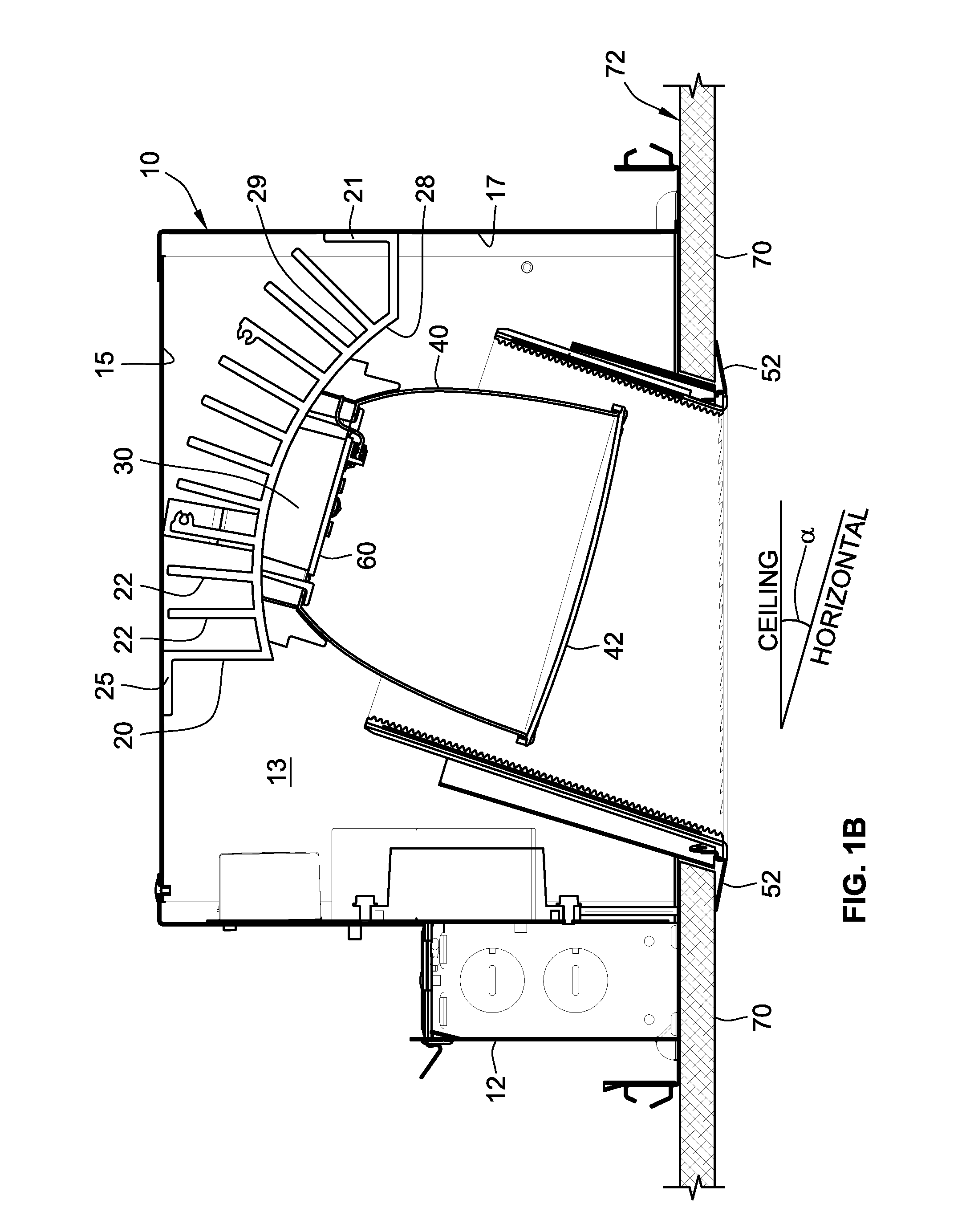

Adjustable slope ceiling recessed light fixture

An adjustable assembly for conveying heat away from a fixture. The adjustable assembly includes a sliding plate having a first side for mounting the fixture thereon and a curved surface opposite the first side. The adjustable assembly also includes a fixed heat sink having a mating surface adapted to allow the curved surface of the sliding plate to slide from a first position to a second position while maintaining a substantially flush contact between the curved surface of the sliding plate and the mating surface of the fixed heat sink. At least one fastener is also provided for securing the sliding plate to the fixed heat sink alternately in the first position or the second position.

Owner:ABL IP HLDG

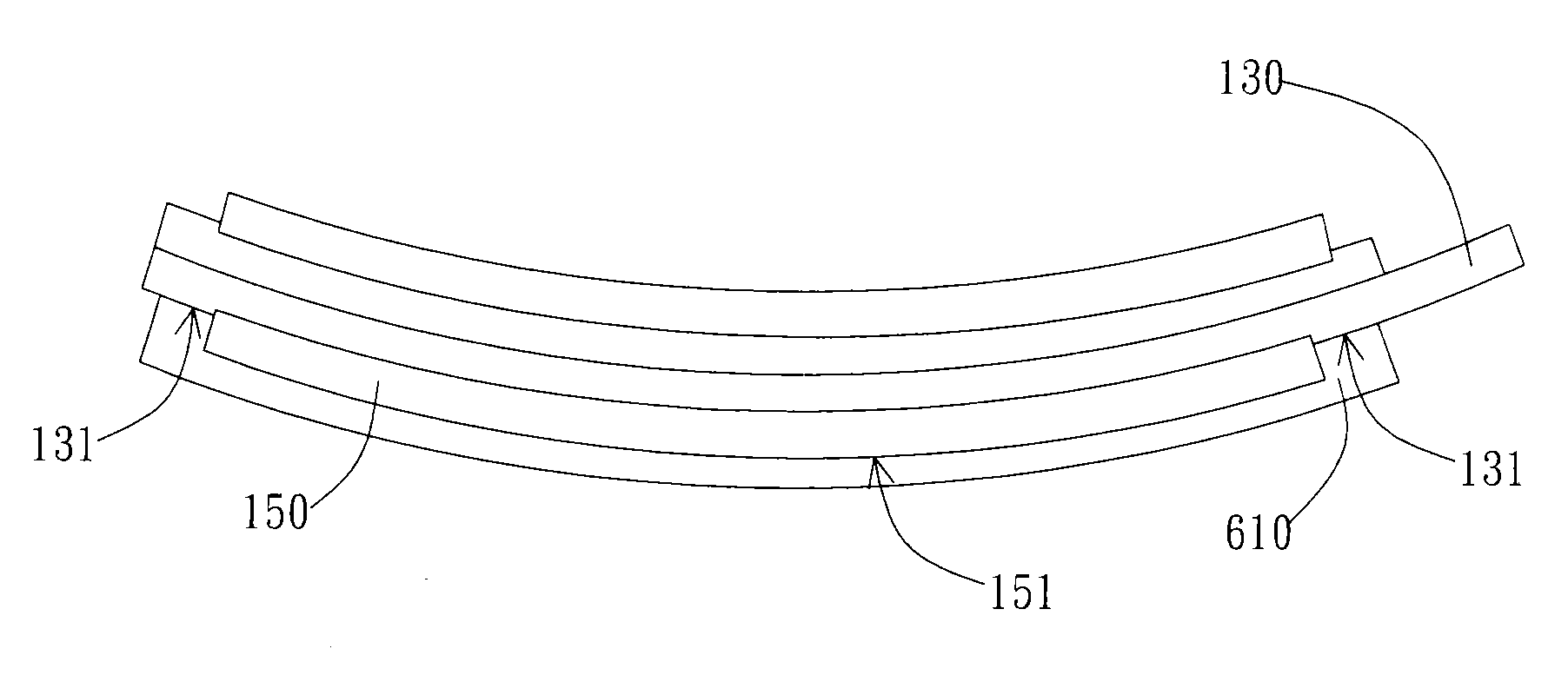

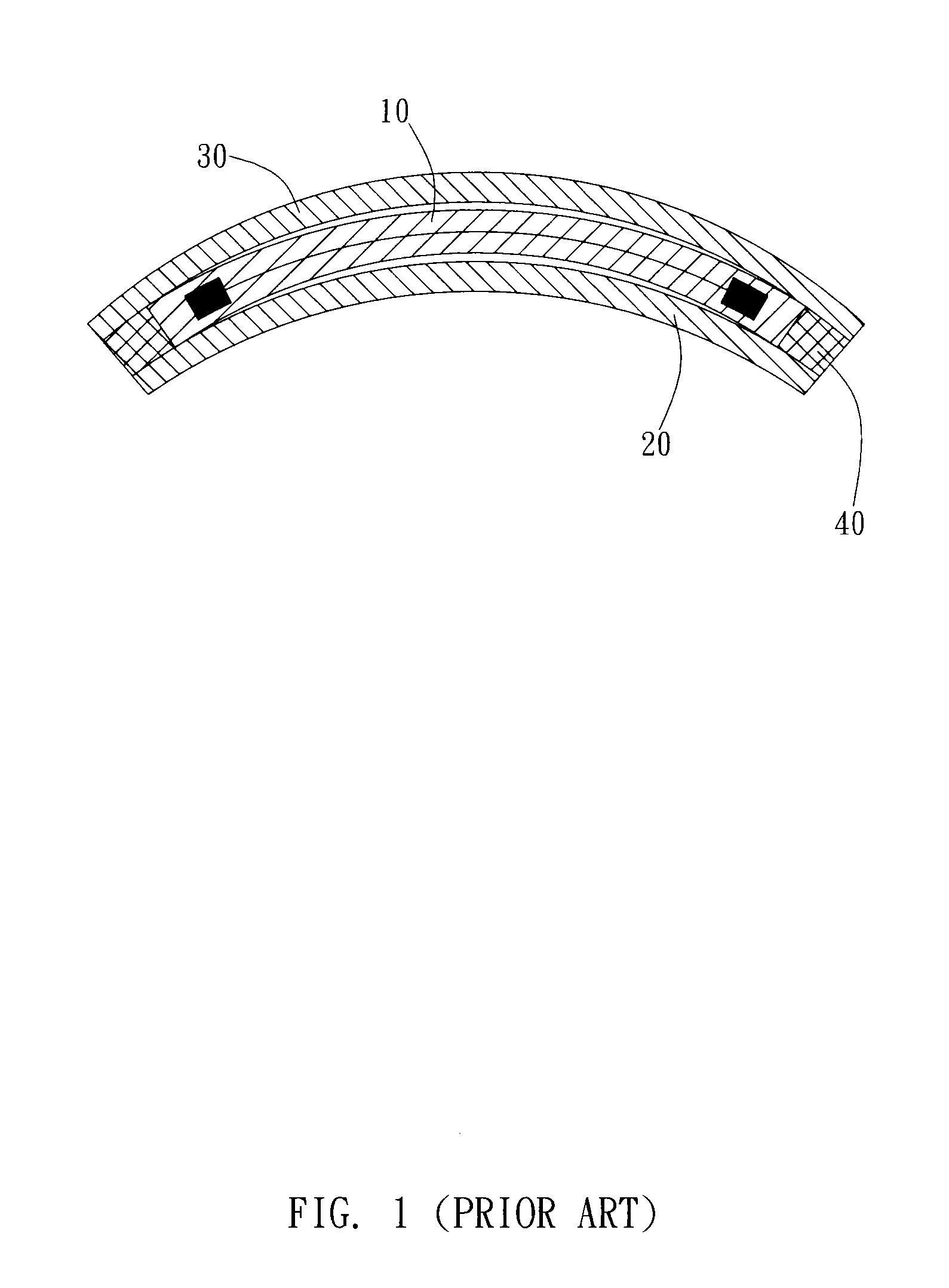

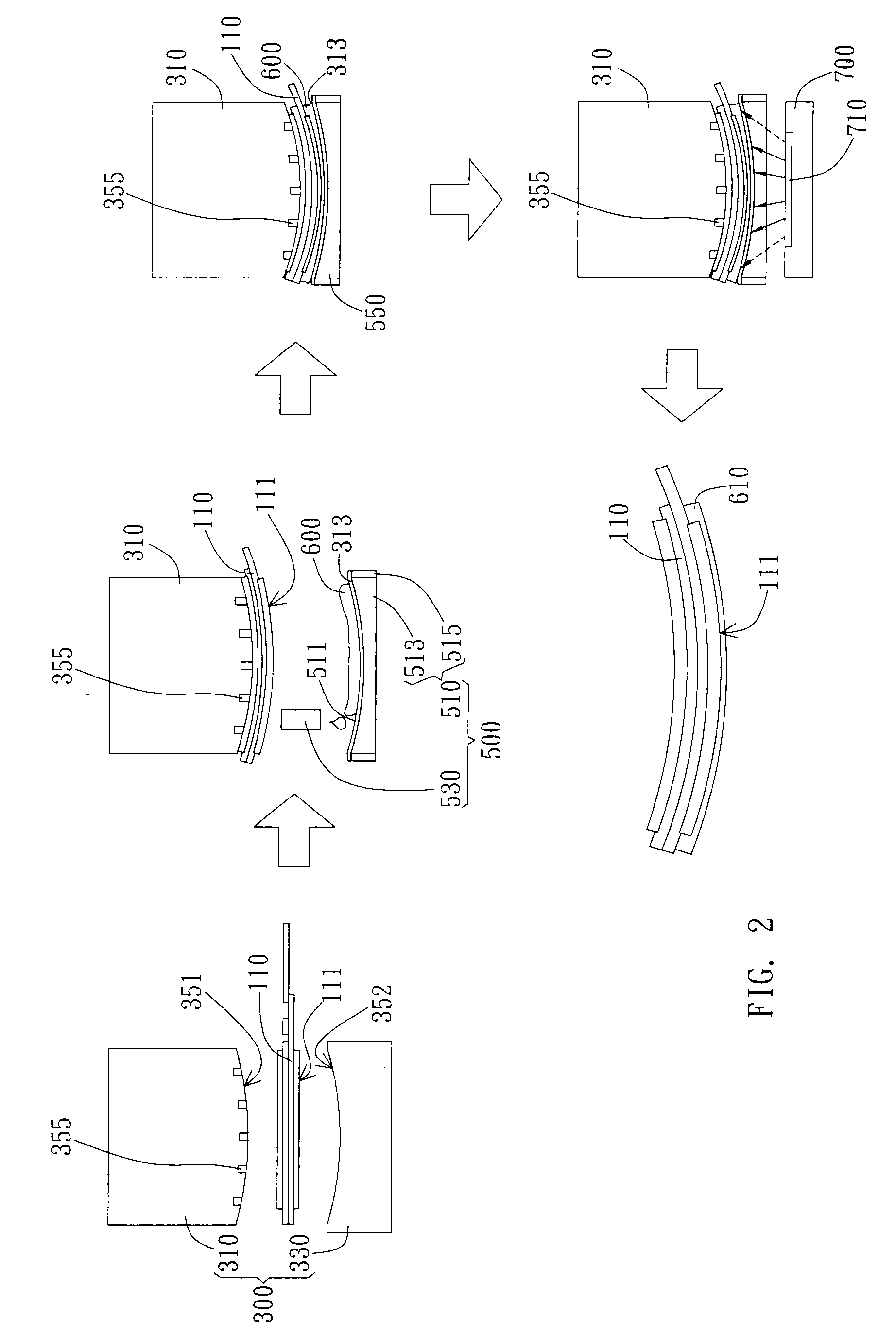

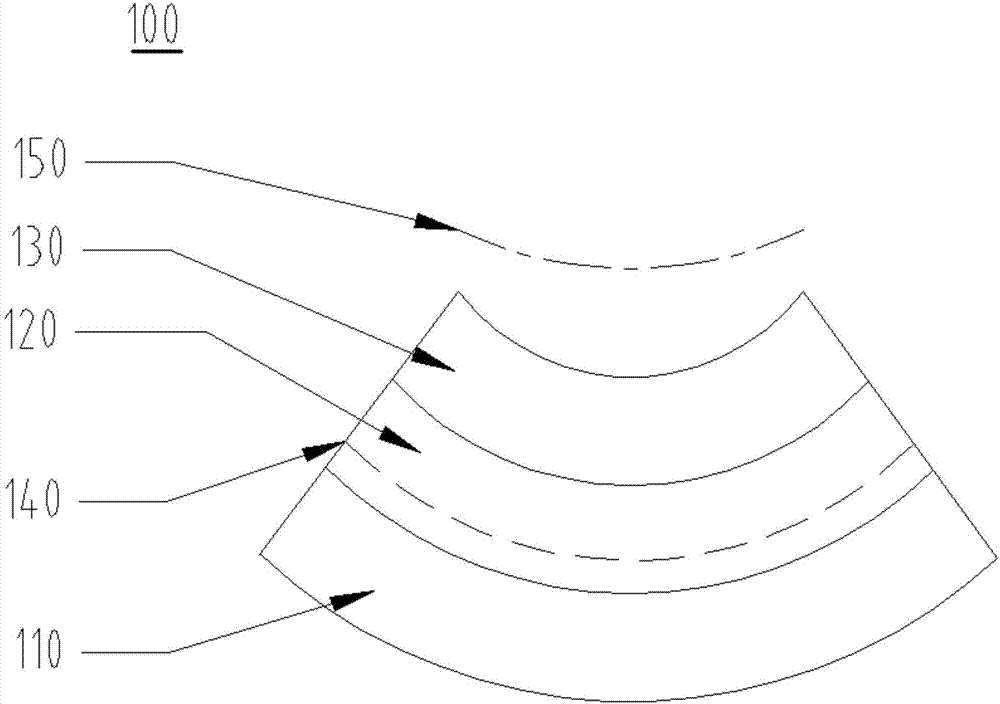

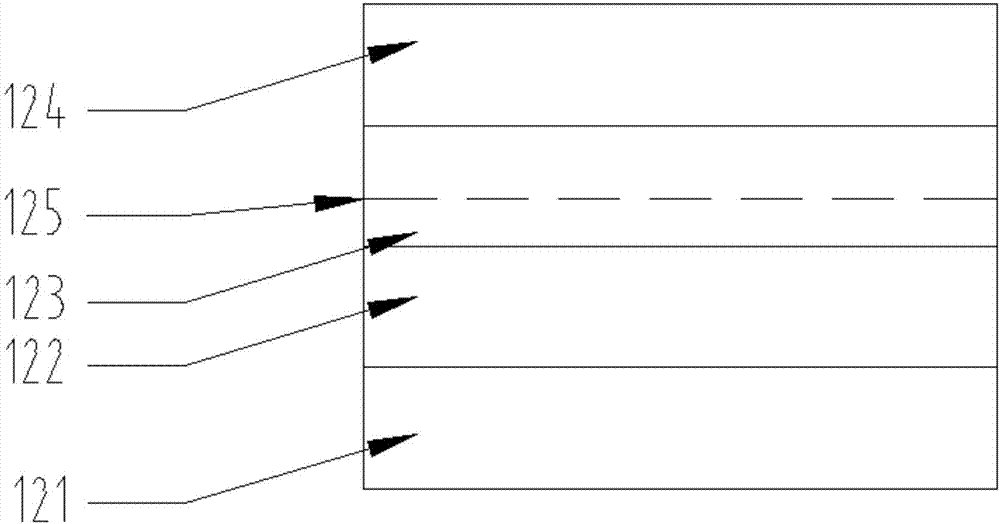

Curve-Shaped Display Module, Manufacture Method Thereof, and Manufacture Apparatus for Manufacturing the Same

ActiveUS20120044618A1Improve structural stabilityDomestic articlesElectrical apparatus contructional detailsAdhesion forceCurve shape

A curve-shaped display module, a manufacture method thereof, and a manufacture apparatus for manufacturing the same are provided. The manufacture apparatus includes a curve-forming mold, a curable material-dispensing device, and a curing device. The manufacture method includes the following steps: pressing the display panel to make the display panel have a curved shape and a first curved surface by using the curve-forming mold; distributing a curable material on the first curved surface by using the dispensing device; and curing the curable material to form a cured casing by using the curing device. The display module has the display panel having the first curved surface and the cured casing formed from the curing of the curable material. The cured casing covers and is closely attached to the first curved surface with an adhesion force therebetween to sustain the curved shape of the display panel.

Owner:AU OPTRONICS CORP

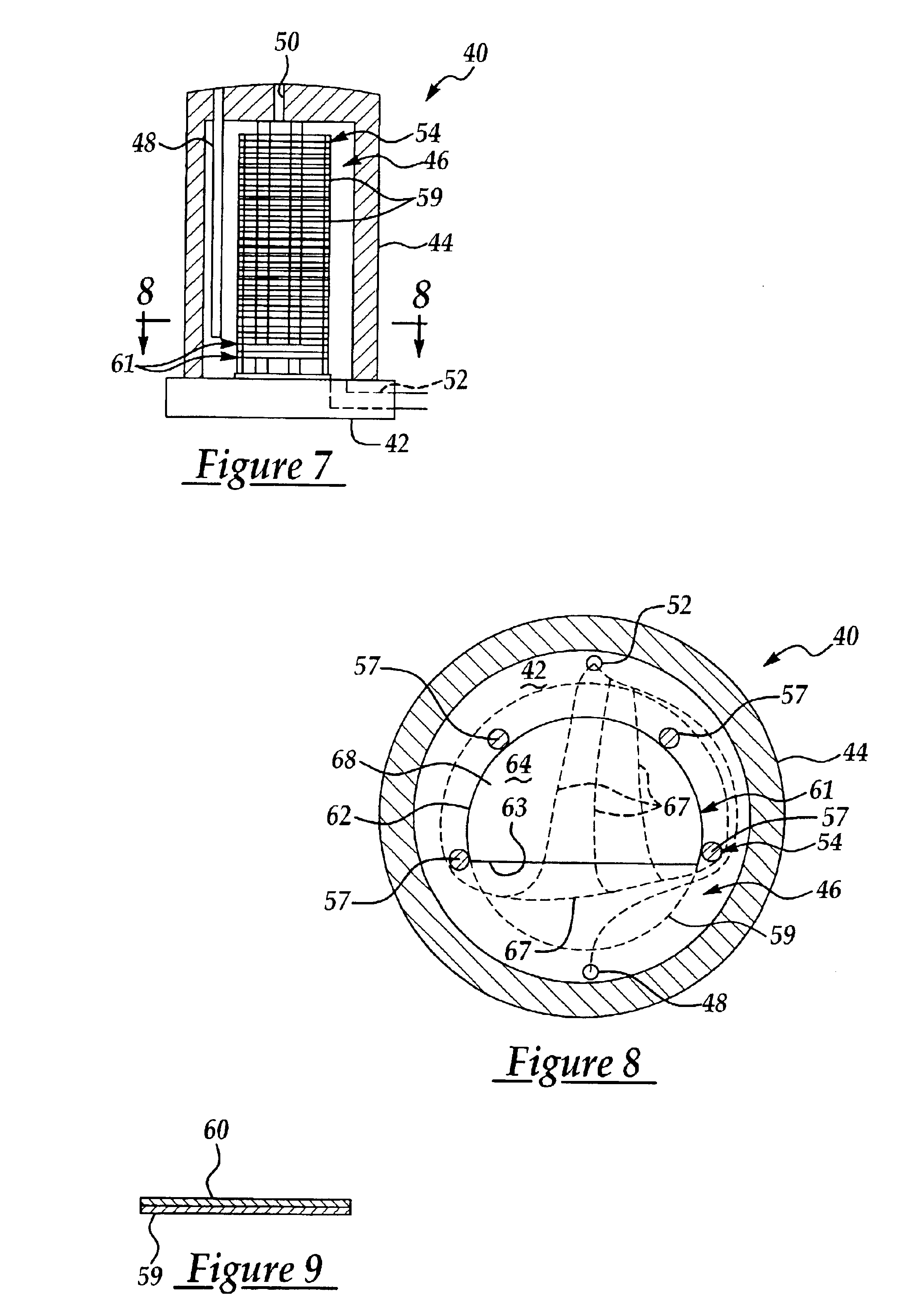

Truncated dummy plate for process furnace

InactiveUS6849131B2Uniform flow of processFacilitate deposition of filmSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringBending of plates

A truncated dummy plate which is suitable for promoting substantially uniform flow of process gases among all regions on the surface of a substrate to facilitate deposition of a film having uniform thickness on the substrate. The truncated dummy plate has a circular shape with a flat edge provided in the curved edge of the dummy plate. At least two, and preferably, about three or four of the dummy plates are positioned in the sites on a wafer boat which are in relatively close proximity to a gas outlet in a process furnace typically during a LPCVD process carried out in the furnace. The flat or truncated edges of the dummy plates are disposed on the gas inlet side of the process chamber, with the round edges of the dummy plates disposed on the gas outlet side of the process chamber.

Owner:TAIWAN SEMICON MFG CO LTD

Backboard and electronic device for curved-display

ActiveCN108831303AFit tightlyAvoid it happening againIdentification meansEngineeringBending of plates

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

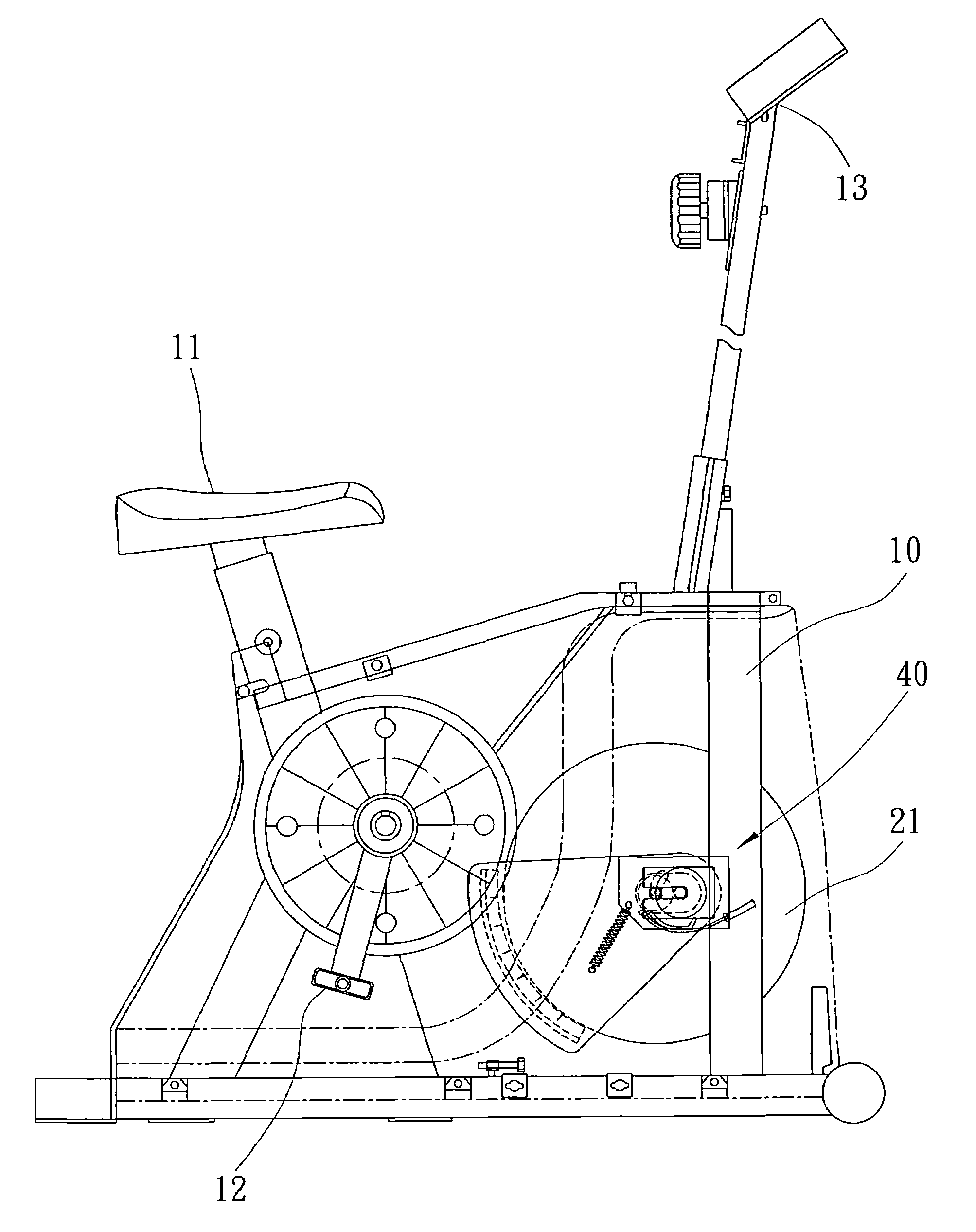

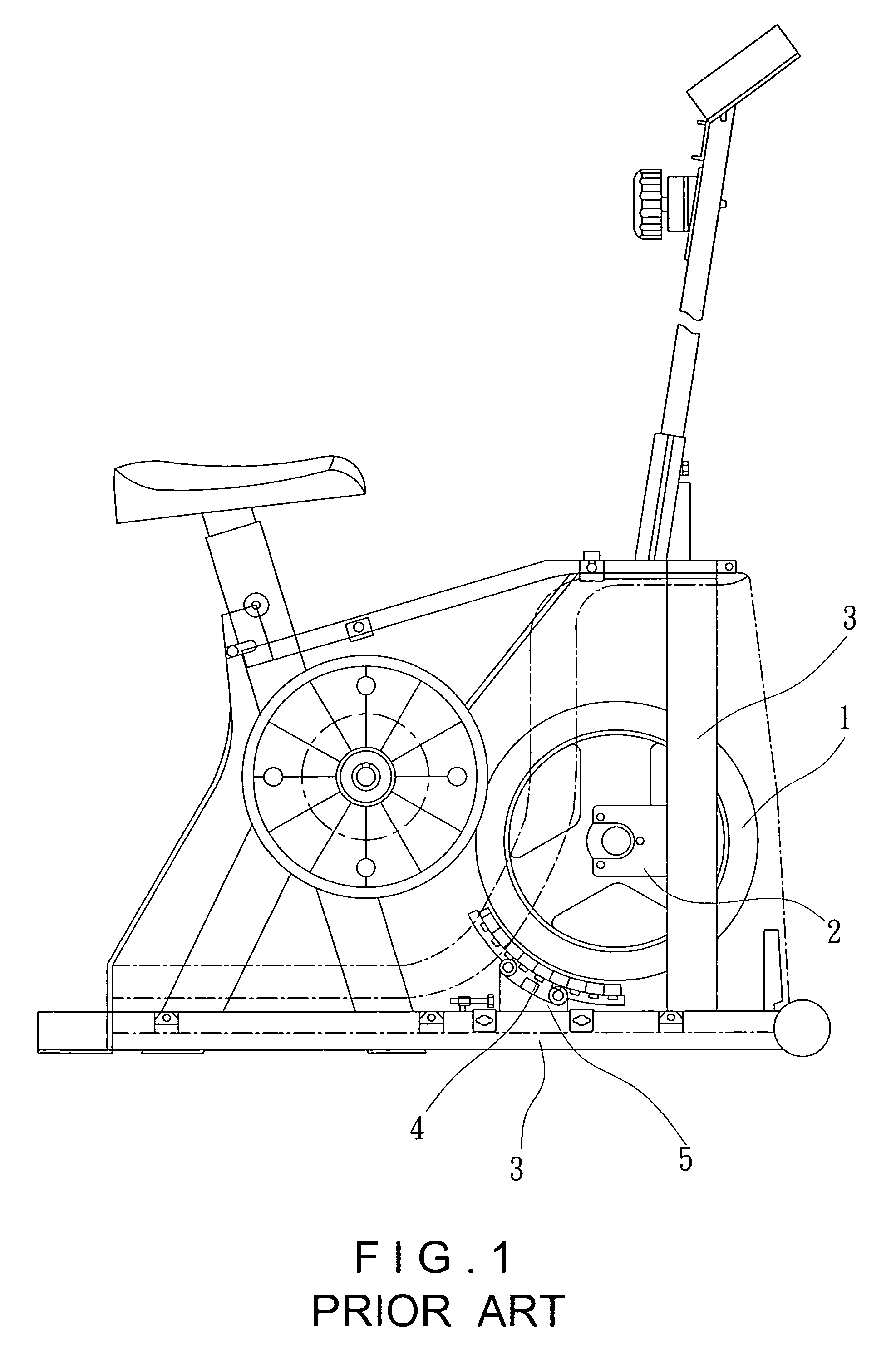

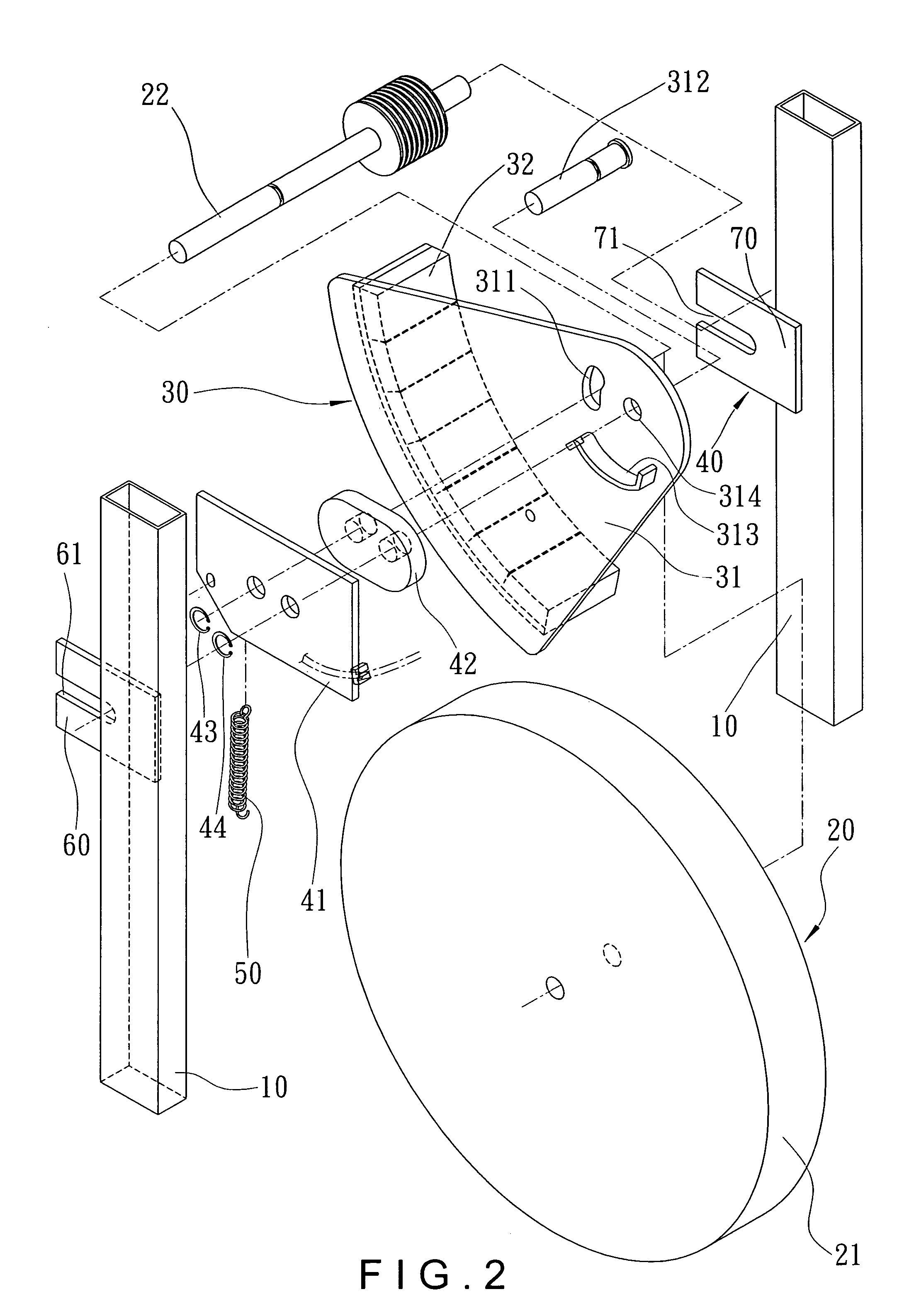

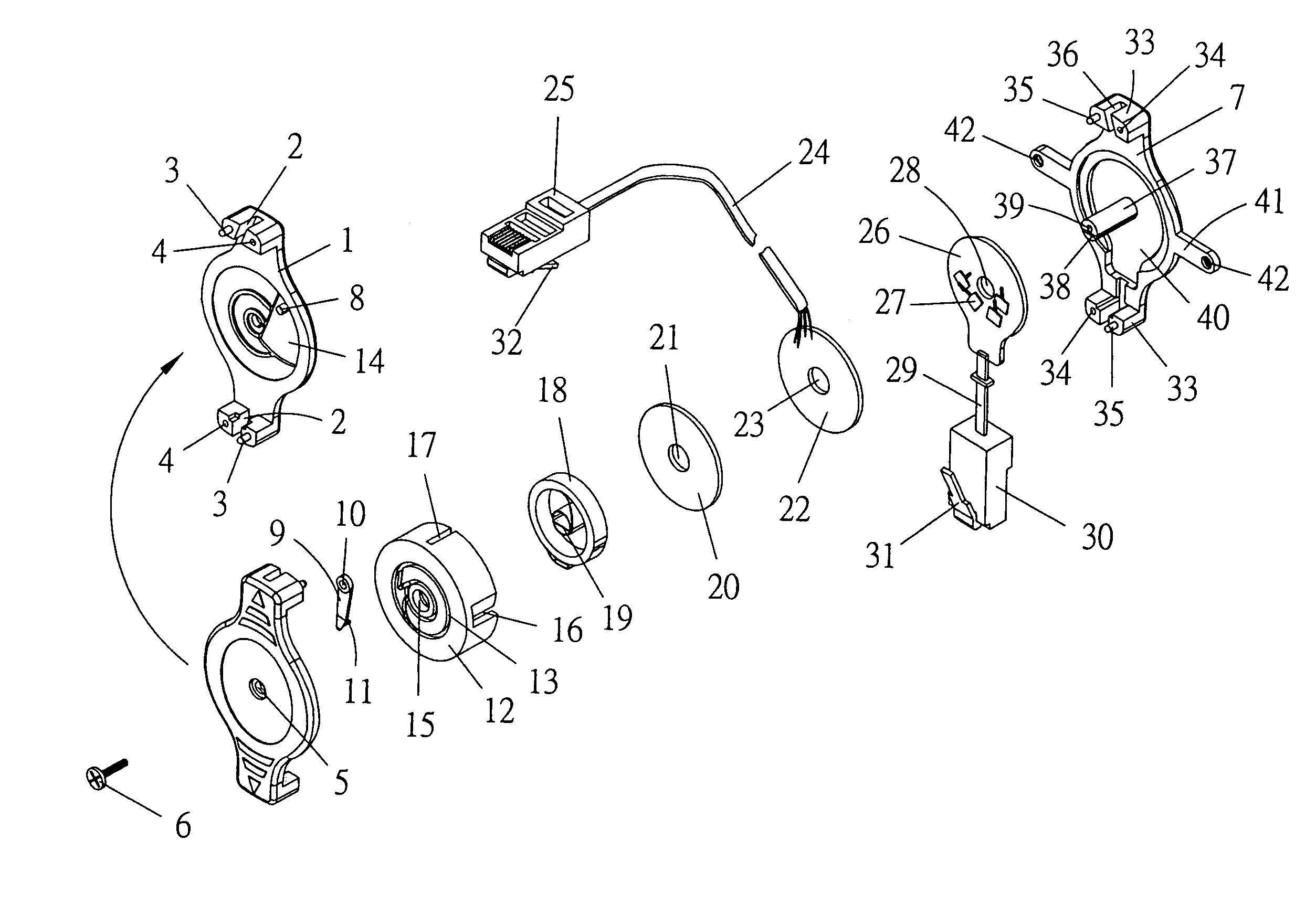

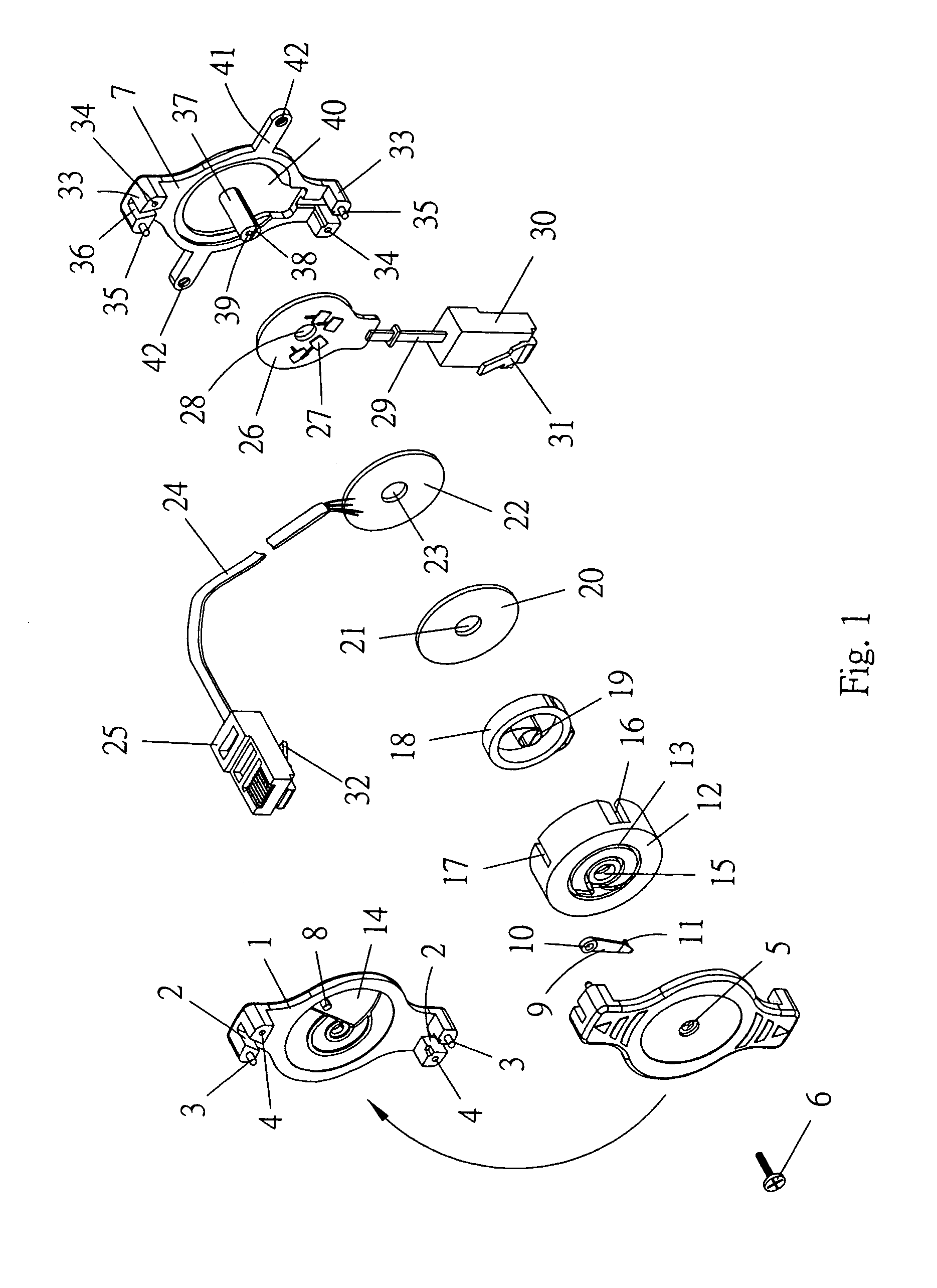

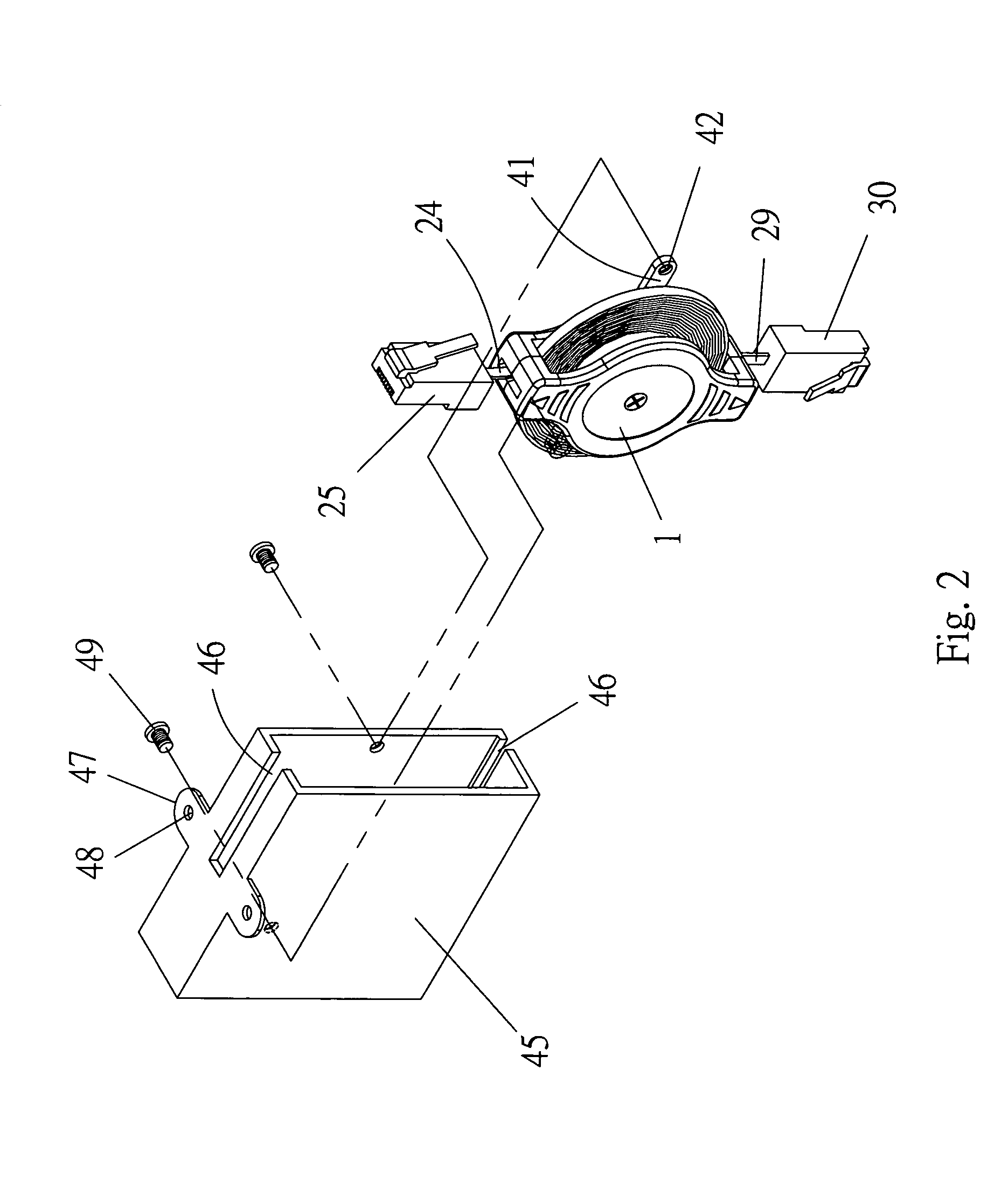

Adjustable magnetic resistance mechanism for upright bikes

InactiveUS7077789B1Easy to adjustMuscle exercising devicesMovement coordination devicesVehicle frameEngineering

An adjustable magnetic resistance mechanism of an upright bike includes a fan-shaped adjustment board which is pivotably connected to the bike's frame and a magnet unit is connected to a distal end of the adjustment board. A connection board is connected to the adjustment board and a shaft of the flywheel extends through a curve slot of the adjustment board. Two ends of the shaft are supported on two support plates on two upright posts of the upright bike. An axle extends through a pivot hole in the adjustment board and the connection board. A resilient member is connected between the connection board and the adjustment board. The adjustment board is pivoted about the axle to adjust the gap between the flywheel and the magnet unit on the adjustment board.

Owner:LIN MICHAEL

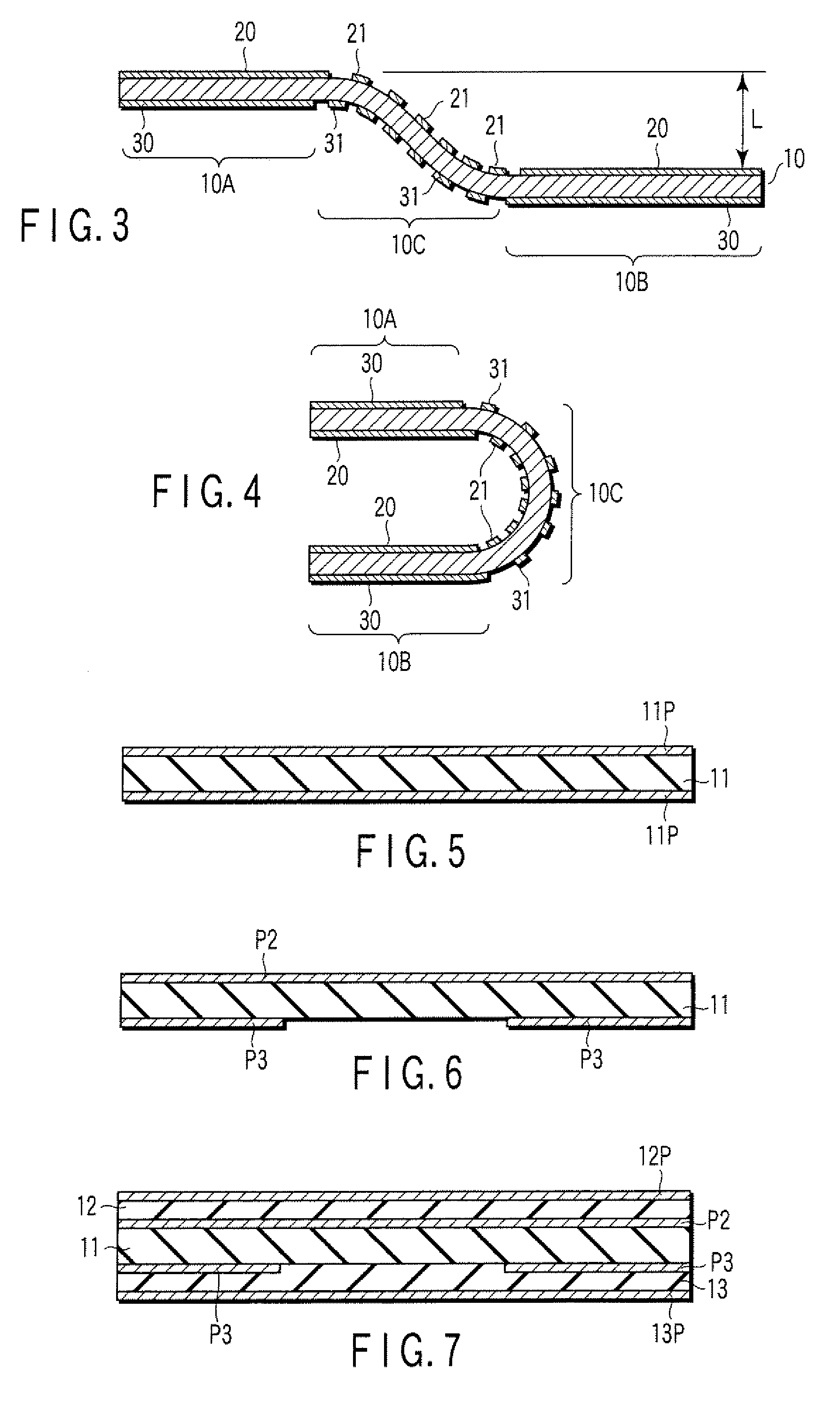

Printed-Wiring Board, Bending Processing Method for Printed-Wiring Board, and Electronic Equipment

According to one embodiment, there is provided a printed-wiring board in which a composite board is formed to have rigid portions and a bending portion, wherein the bending portion includes linear protrusions each formed with solder resist having a bending resistance property.

Owner:KK TOSHIBA

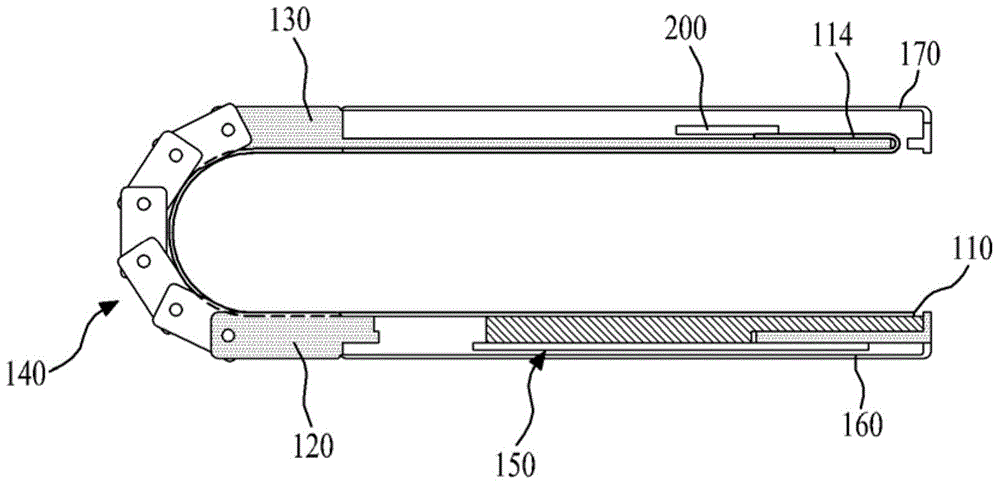

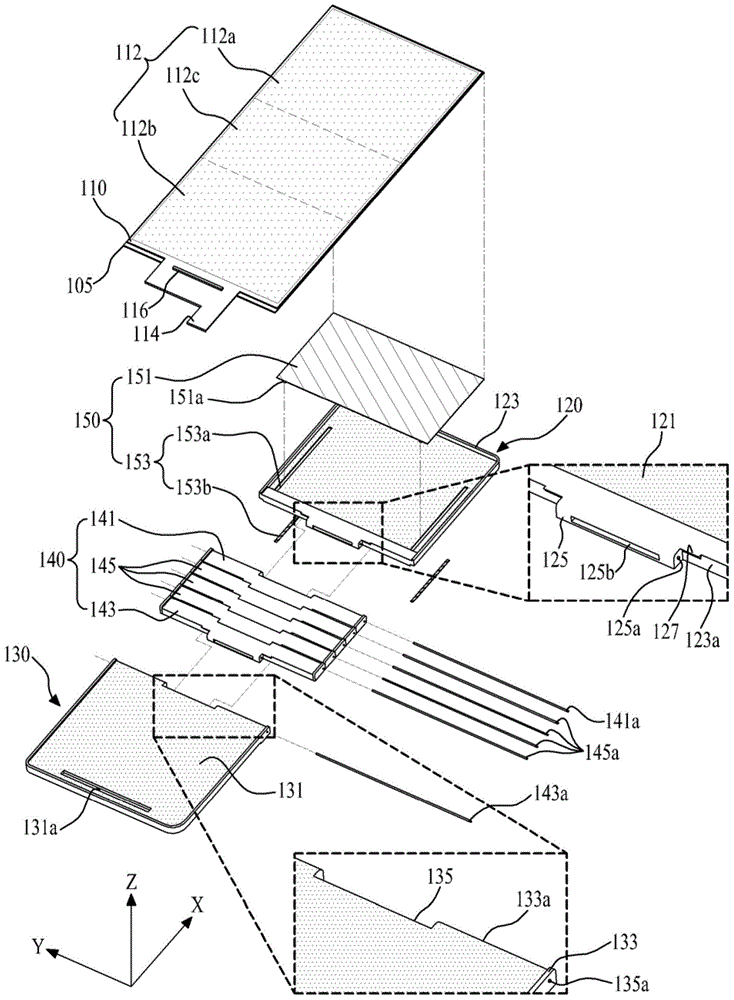

Foldable display apparatus

ActiveCN105321430ADigital data processing detailsCasings/cabinets/drawers detailsDisplay deviceEngineering

Disclosed is a foldable display apparatus which can stably maintain a bending curvature of a folded flexible display, and can maintain a bending display area of an unfolded flexible display in a plane state. The foldable display apparatus includes a display panel folded or unfolded with respect to a bending display area, a first housing configured to support a first area of the display panel, a second housing physically coupled to a second area of the display panel, a link assembly connected between the first and second housings, and configured to support a bending display area of the display panel which is folded or unfolded, and a sliding assembly configured to slide the first area or second area of the display panel according to bending of the link assembly.

Owner:LG DISPLAY CO LTD

Wire winding device for receiving network wires or telephone wires

InactiveUS7001210B1Beautiful outlookEasy to carryRotary current collectorNon-rotary current collectorEngineeringElectric wire

A wire winding device for receiving network wires or telephone wires is disclosed. The round post of the lower cover passes through the via hole of the circuit board, the central hole of the conducting plate, the via hole of the insulating plate; the buckling hole of the spring; the via hole of the spring seat, and the via hole of the upper cover, sequentially. The buckle sheet is engaged to the upper cover. The buckling post of the buckle sheet is movable fixed to the buckling groove. The upper cover and lower cover are combined. The electric wire of the circuit board and the electric wire of the conducting plate are placed in the slot of the upper cover and the slot of the lower cover. A screw serves to lock the upper cover to the lower cover.

Owner:CHIANG WU SUNG

Prosthetic disc for intervertebral insertion

ActiveUS20160250035A1Reduce frictionDiameter can be maximizedSpinal implantsIntervertebral discProsthesis

A prosthetic disc for insertion between adjacent vertebrae includes a core having upper and lower curved surfaces, upper and lower plates, and peripheral restraining structure on at least one of the upper plate, the lower plate and the core. Each plate has an outer surface which engages a vertebra and an inner curved surface which slides over the curved surface of the core. The peripheral restraining structure serves to hold the core against a curved surface of at least one of the plates during sliding movement of the plates over the core.

Owner:SIMPLIFY MEDICAL PTY LTD

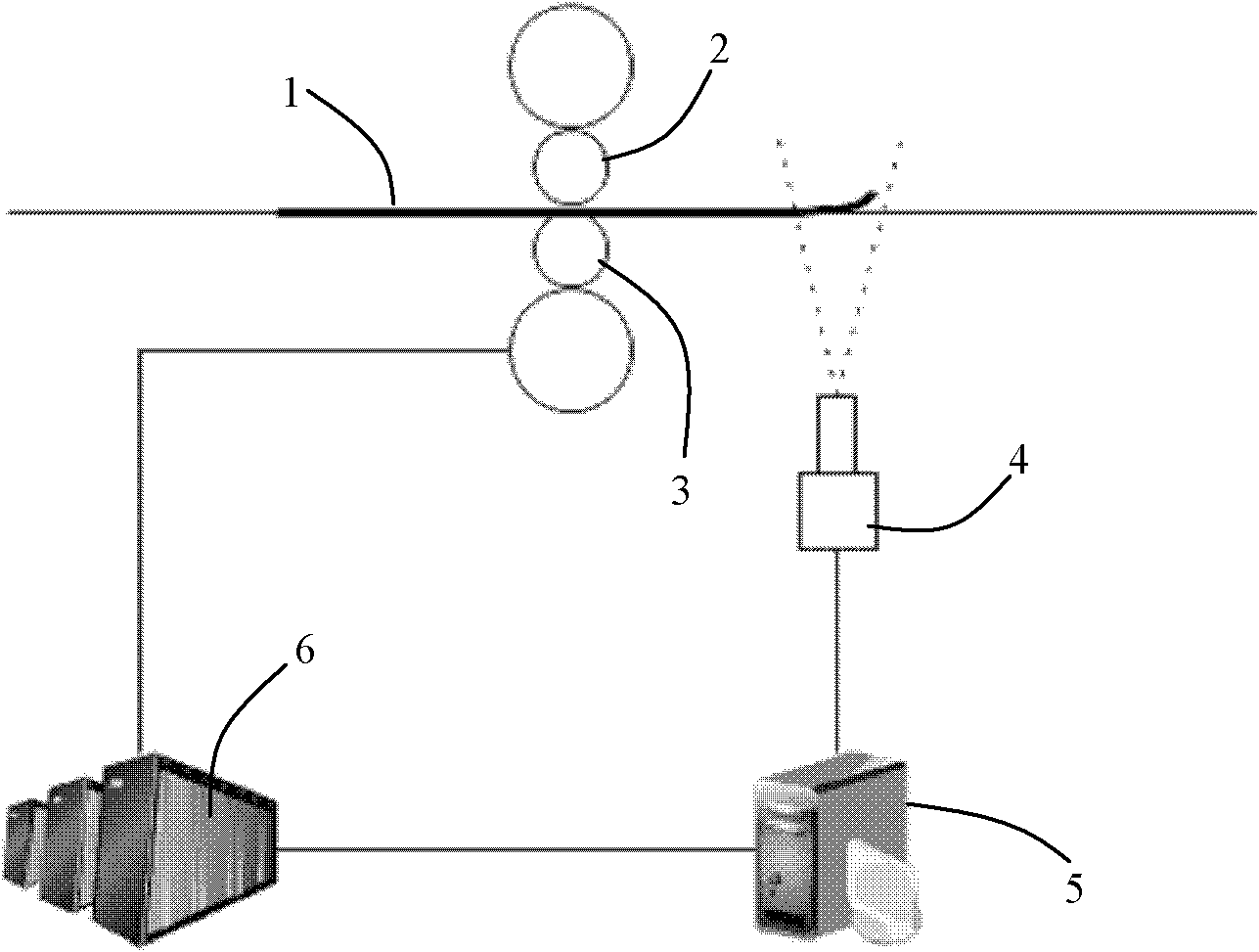

Control method for upward and downward head bending of plate blank

ActiveCN102836883AImprove straightnessHigh measurement accuracyRoll mill control devicesMeasuring devicesEngineeringHead shape

The invention discloses a control method for upward and downward head bending of a plate blank, and the control method comprises the steps that a head shape curve of the plate blank and a plurality of sampling sites are collected by CCD (charge coupled device) camera equipment; a cubic polynomial curve is used for fitting according to the sampling sites; the maximum monotone interval of the curve close to the head of the plate blank is obtained to judge the upward or downward head bending; and quantification is conducted; the arc length deviation value of the upper and lower surfaces between the head end point and the tail end point of the plate blank is calculated; a speed difference adjustment value of upper and lower rolls in the pass is calculated; and a new speed difference is decided according to the speed difference adjustment value. The control method for the upward and downward head bending of the plate blank is high in measurement accuracy and easy to maintain, a set value of the speed difference can be adjusted automatically according to the buckling condition of the rolled plate blank, and the straightness of the rolled plate blank can be improved greatly.

Owner:BAOSHAN IRON & STEEL CO LTD

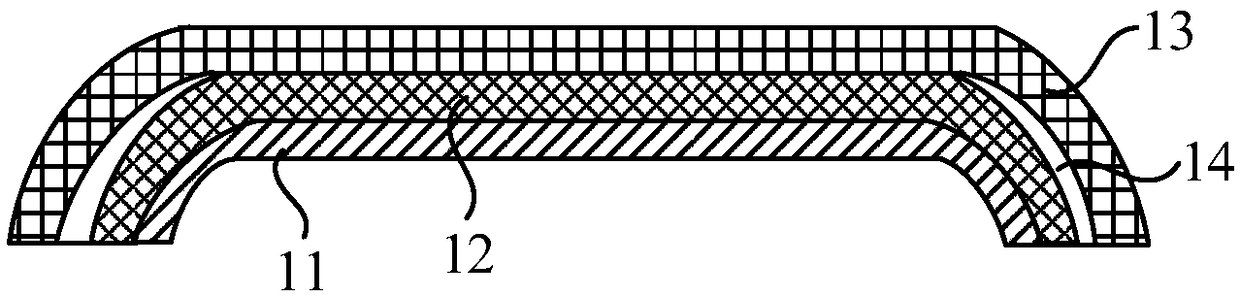

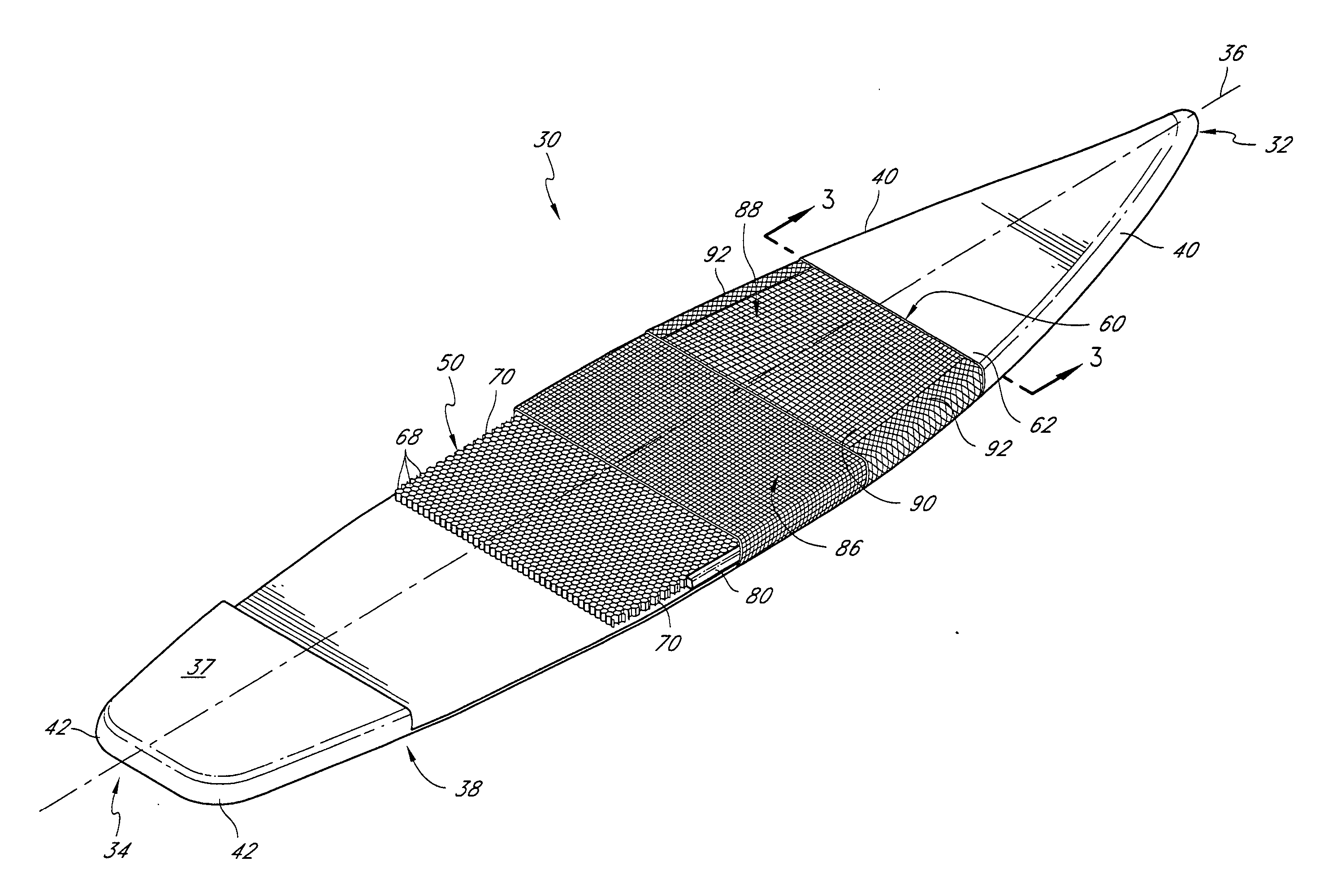

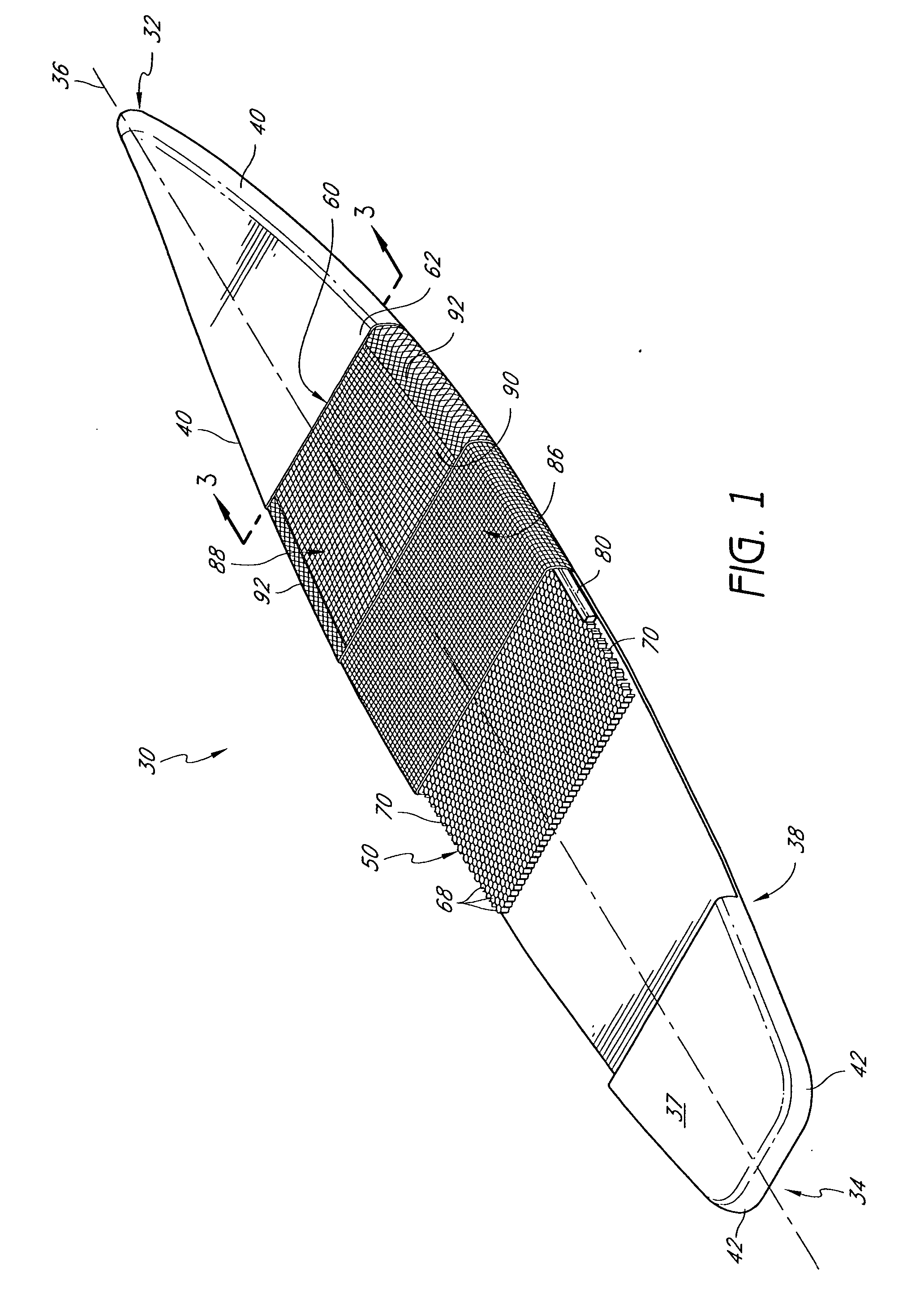

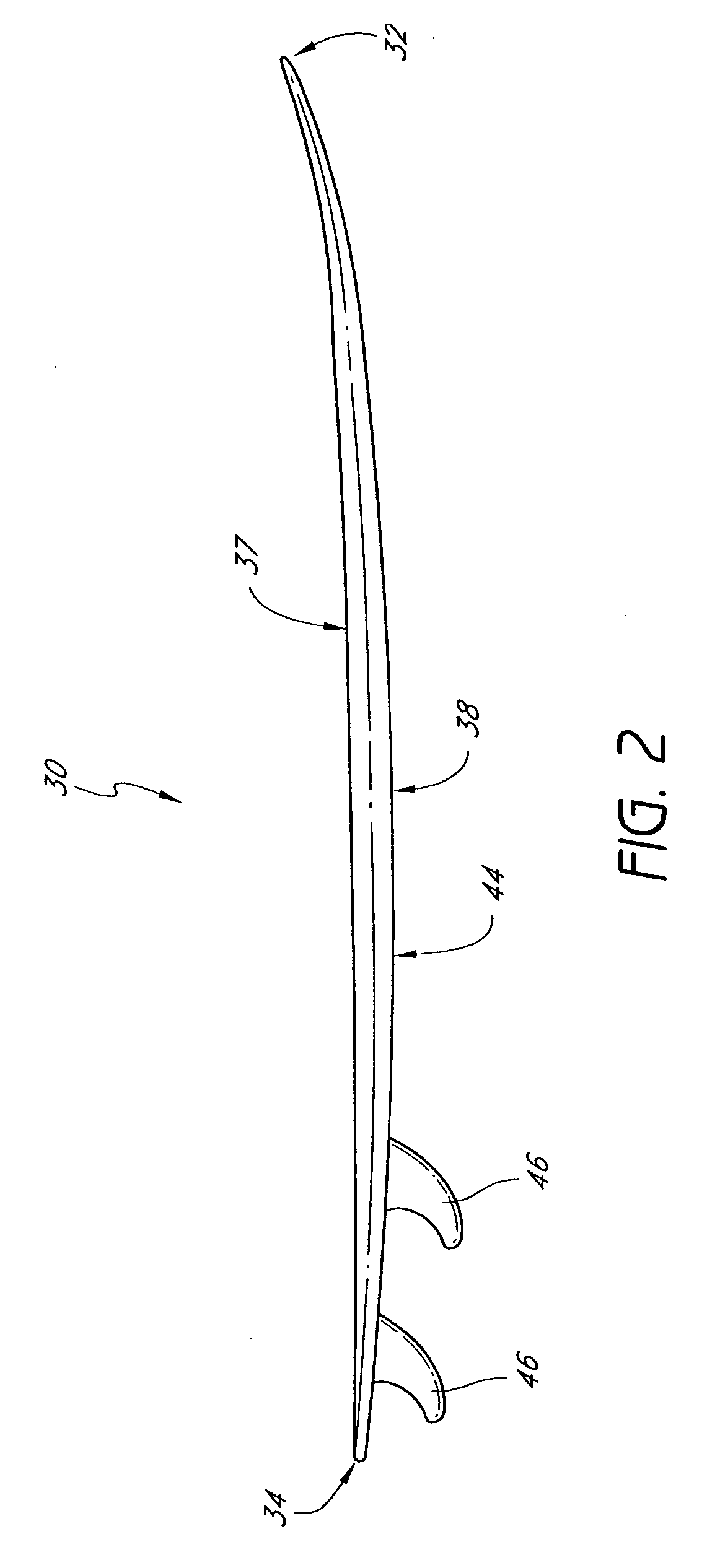

Surfboard having a honeycomb core

InactiveUS20060276087A1Maintaining flexibility characteristicStrong lightWaterborne vesselsWater sport boardsGlass fiberDecrease weight

An aquatic gliding board such as a surfboard is constructed using a honeycomb material for the core. The composite outer skin of the surfboard is constructed of materials having similar flexibility properties as found in a traditional foam / fiberglass surfboard. In a particularly preferred embodiment an aluminum honeycomb core is employed along with a fiberglass skin in order to achieve a surfboard with decreased weight and increased strength to resist failure in bending relative to a traditional foam / fiberglass surfboard, but having similar flexibility characteristics to such a traditional surfboard, or having increased flexibility relative to such a traditional surfboard.

Owner:VARIAL SURFING TECH

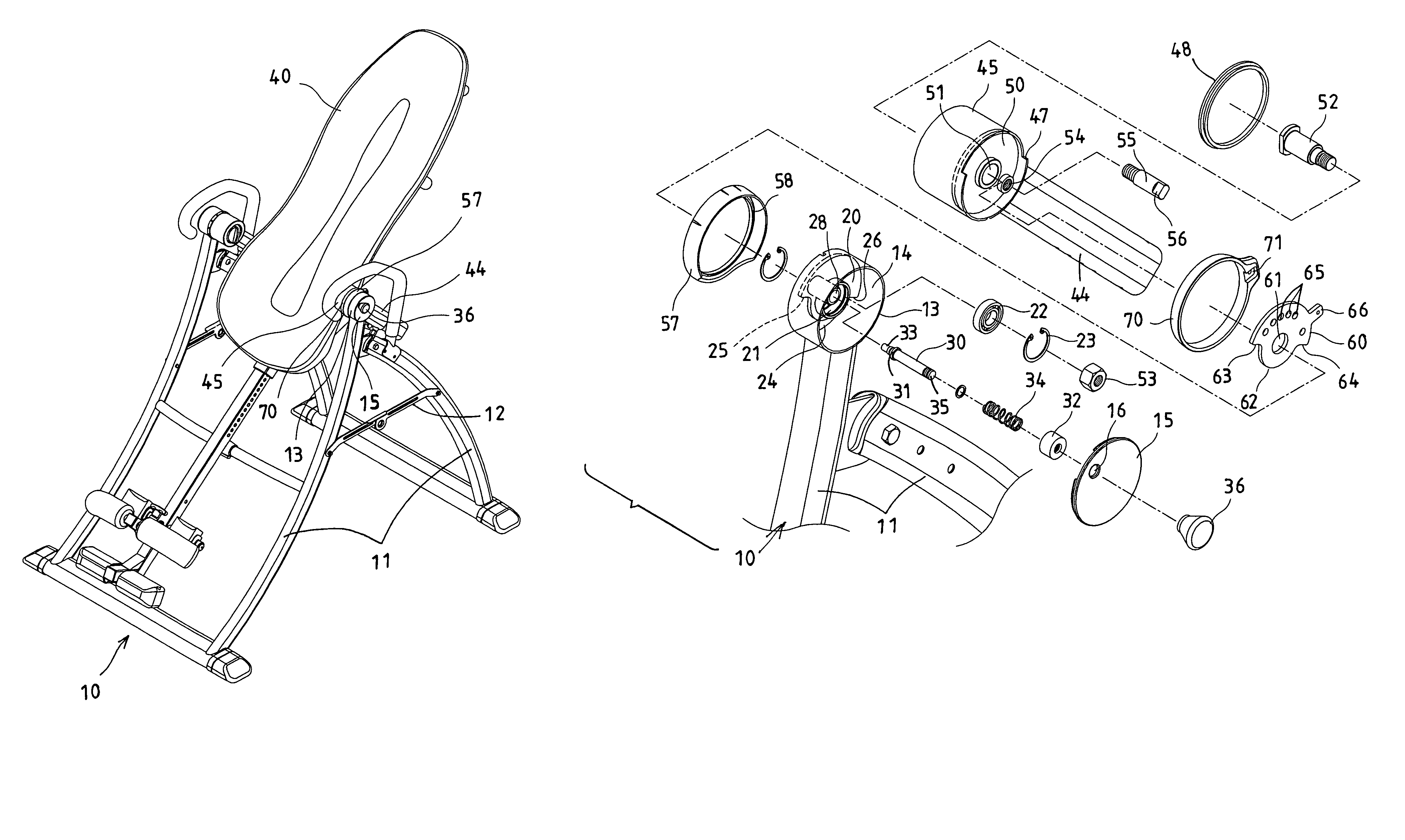

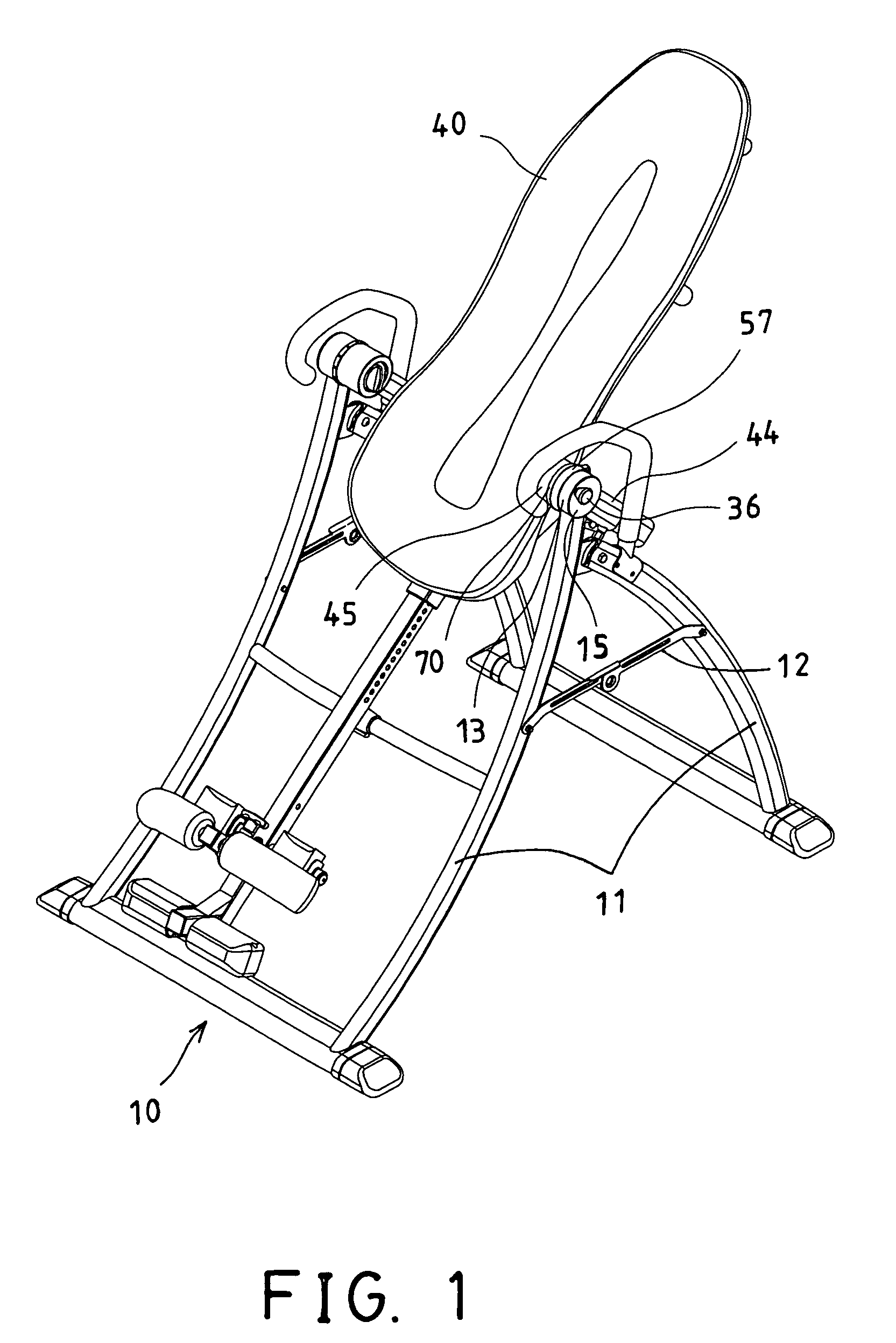

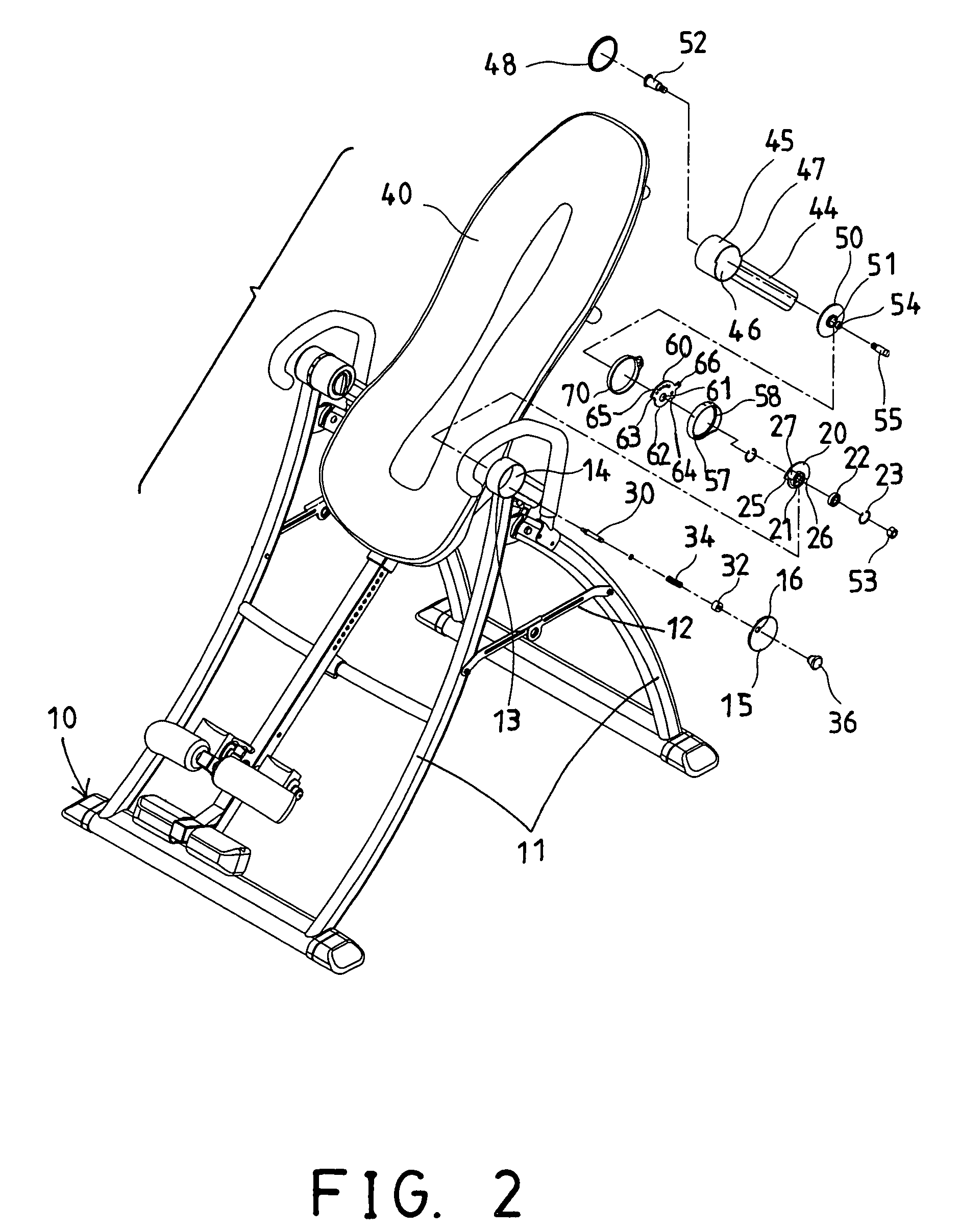

Angle adjusting mechanism for tilting inversion exerciser

ActiveUS7867154B2Prevent rotationChiropractic devicesTherapy exerciseEngineeringMechanical engineering

Owner:TEETER ROGER C +1

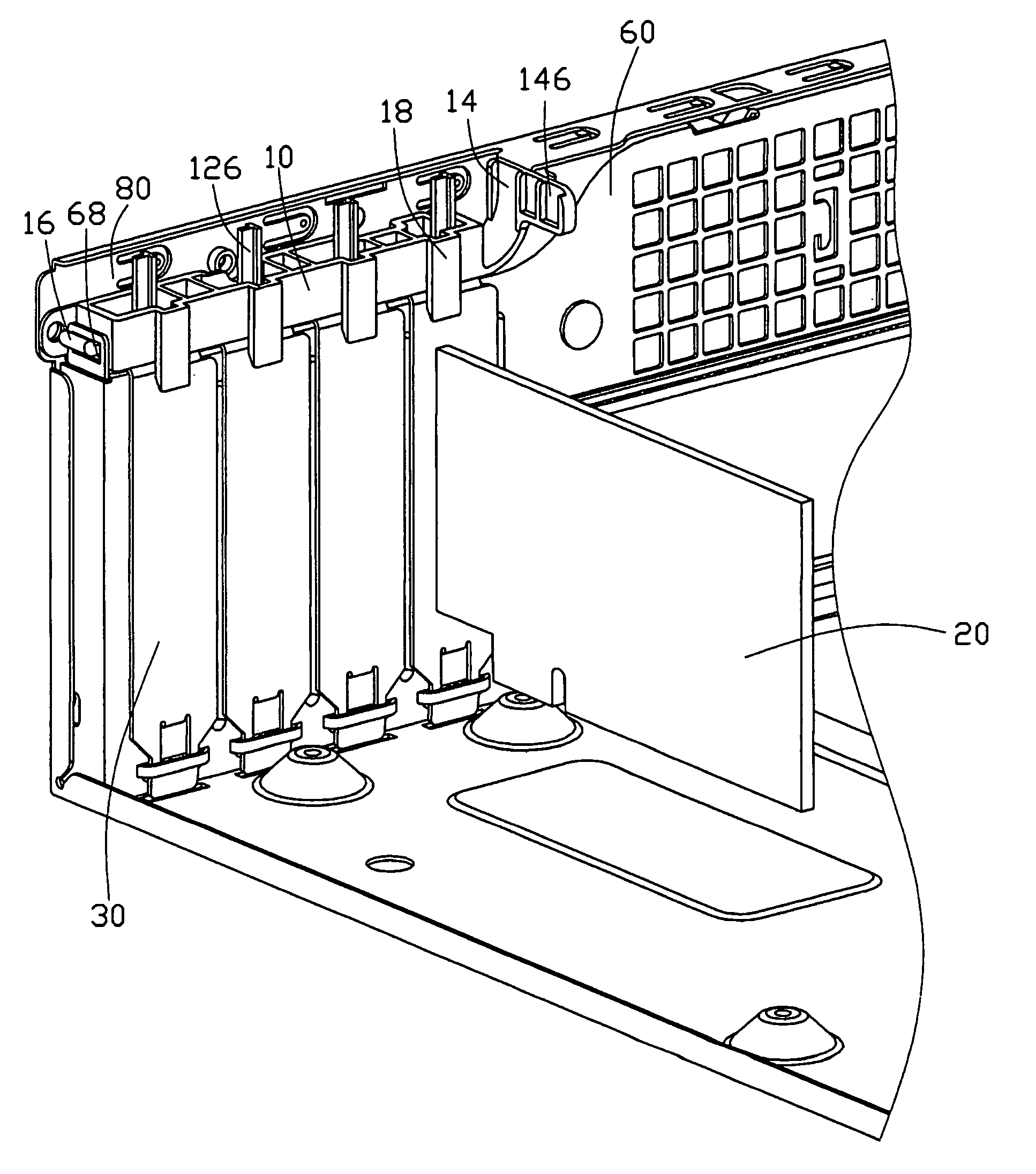

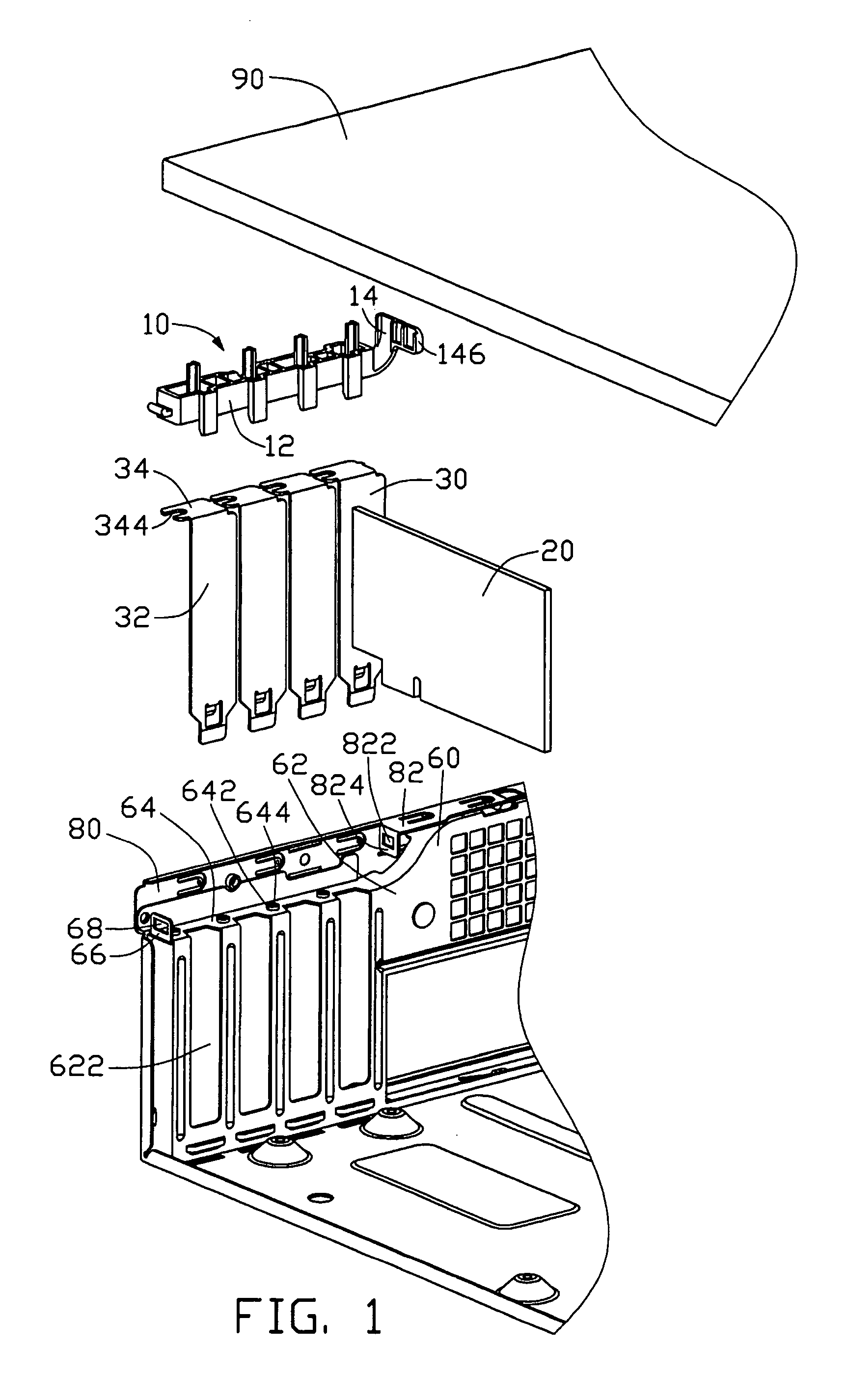

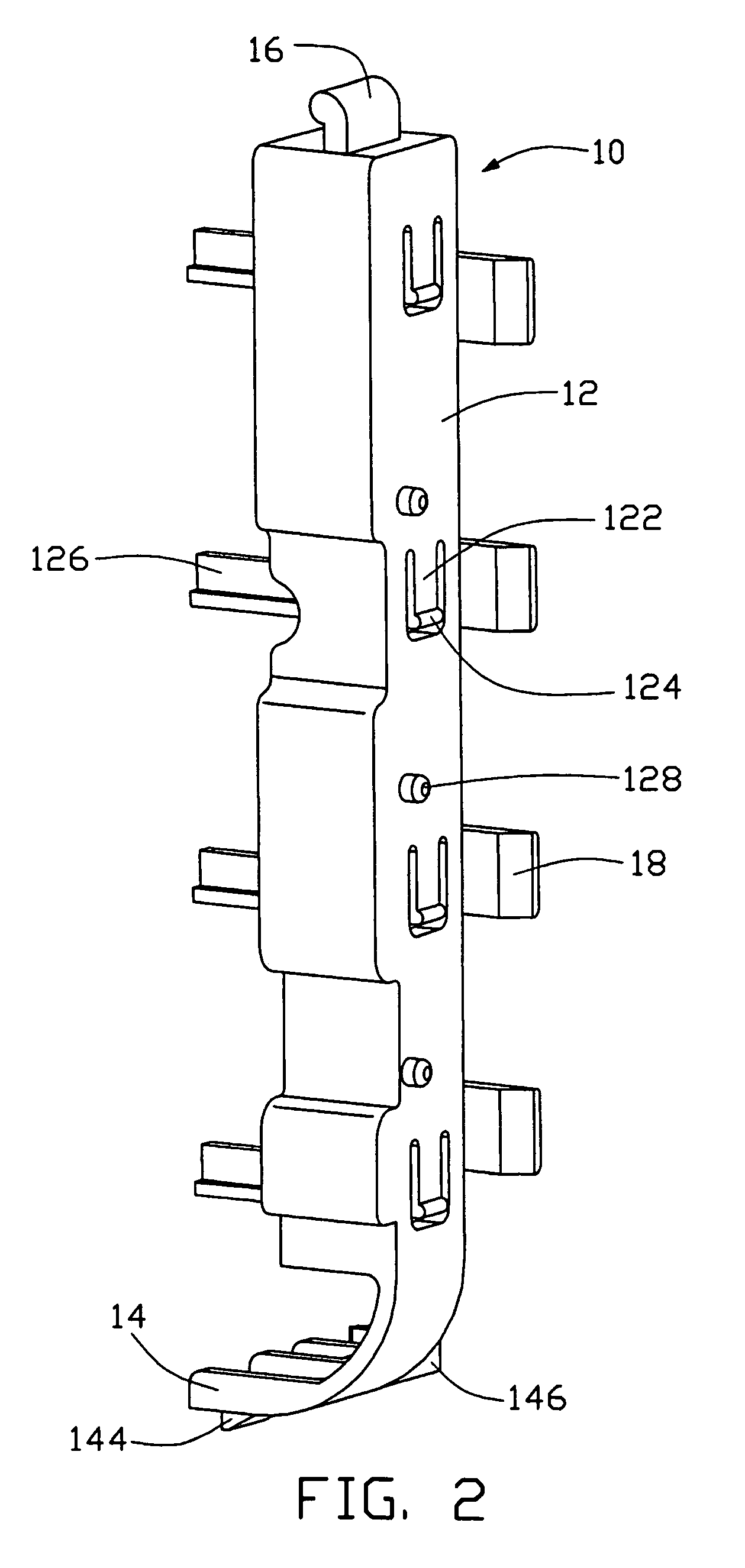

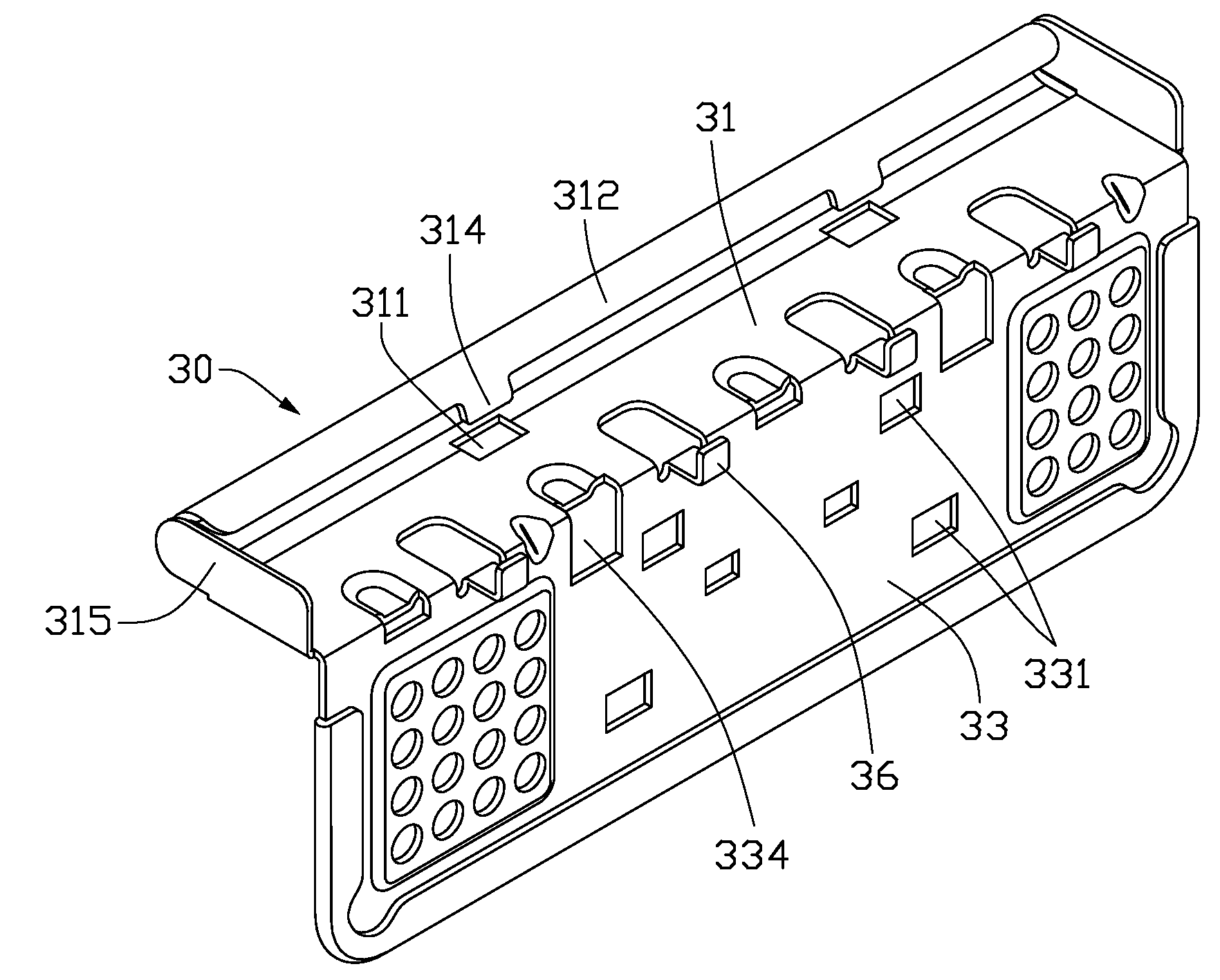

Mounting device for mounting expansion cards in computer enclosure

InactiveUS6972370B2Readily and conveniently attachesEasy to separateCoupling device detailsClamping/extracting meansExpansion cardBending of plates

Owner:HON HAI PRECISION IND CO LTD

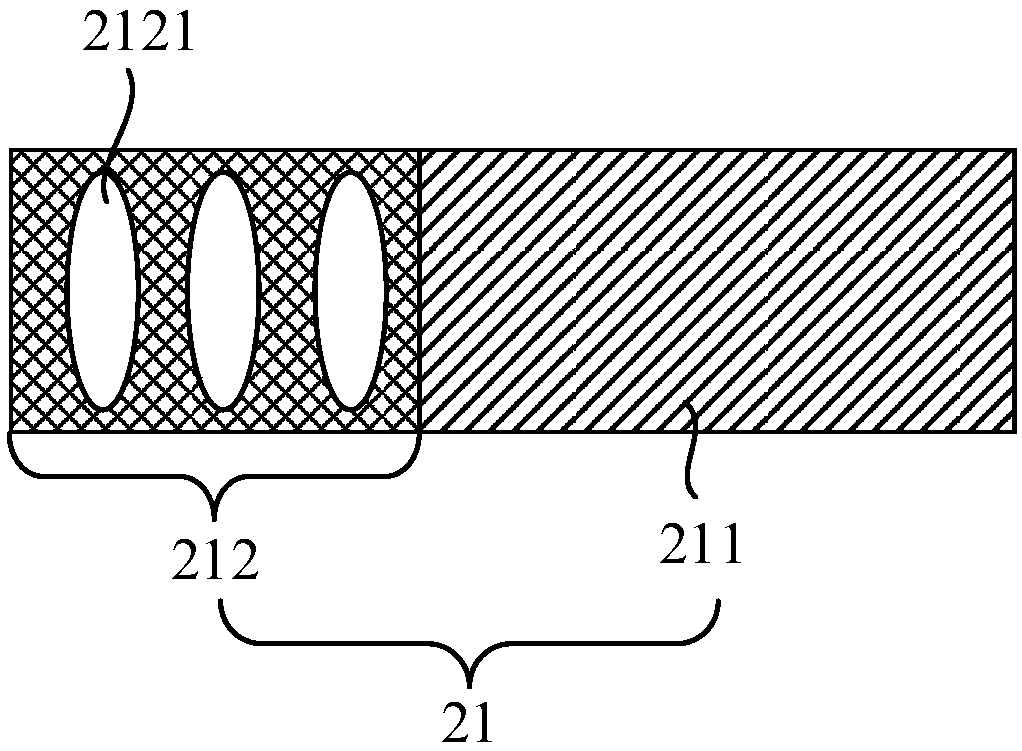

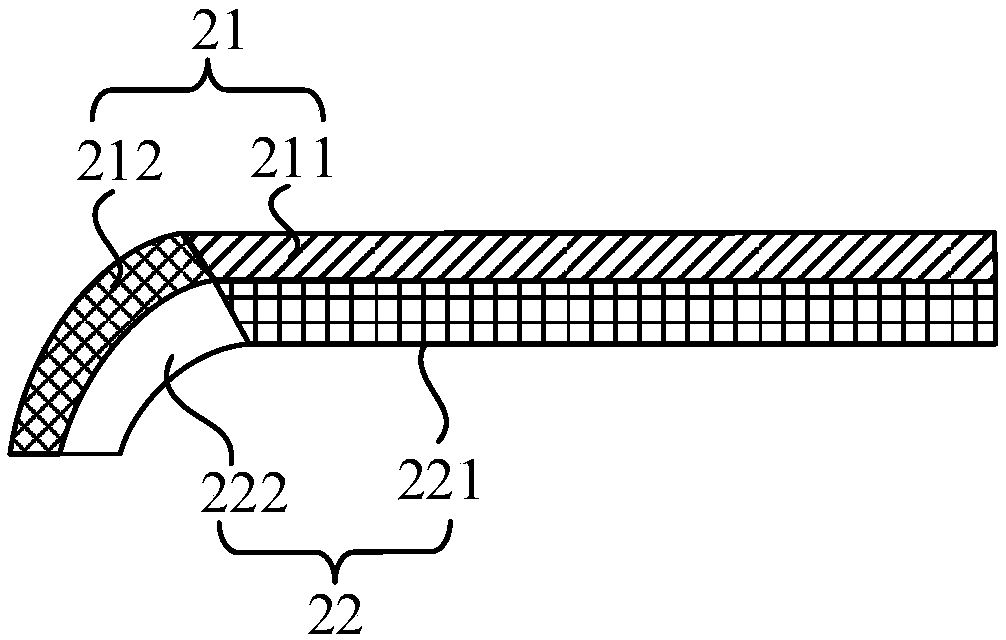

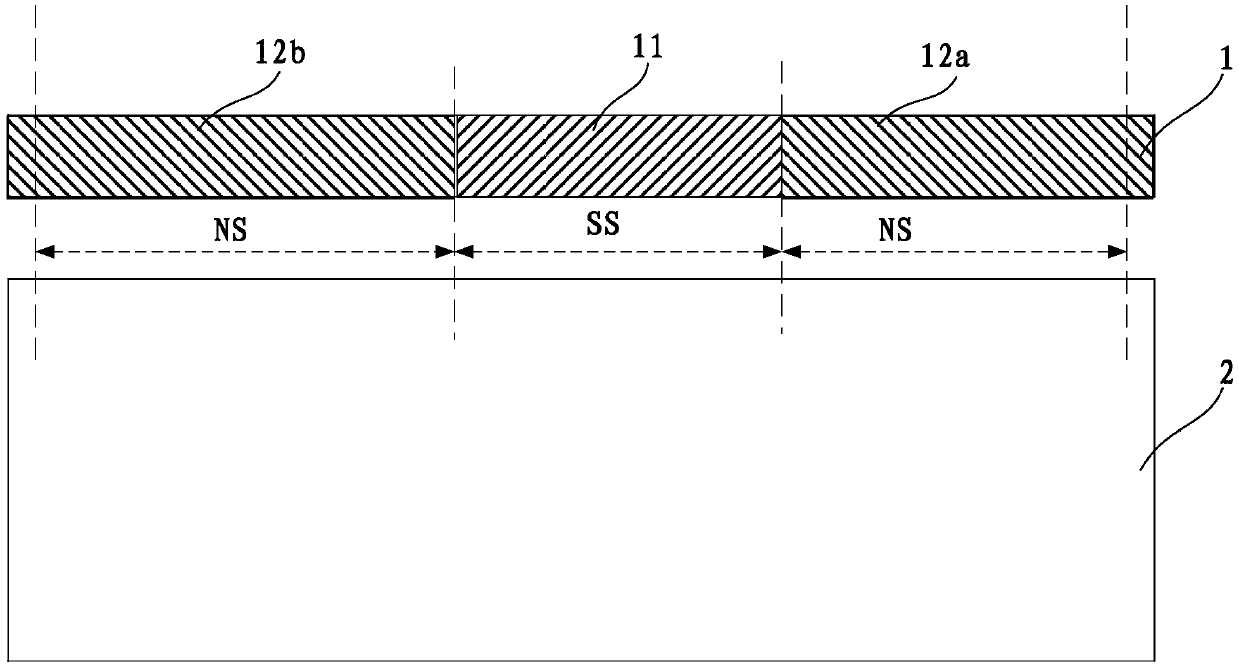

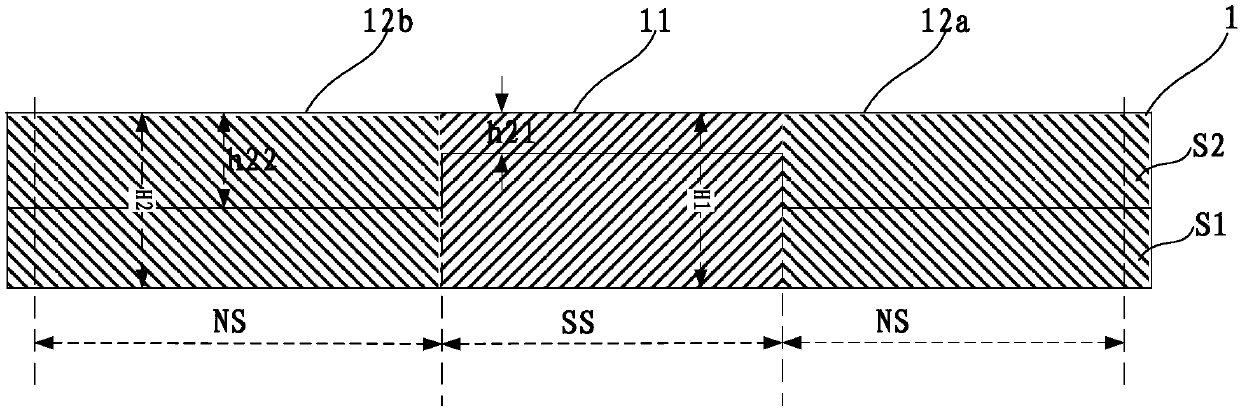

Protective cover plate and flexible display device

ActiveCN109671363ASolve technical problems that are difficult to pass the stress testLow Young's modulusIdentification meansYoung's modulusEngineering

The invention provides a protective cover plate and a flexible display device. The protective cover plate comprises a bending part and a non-bending part, wherein the bending part is located in a bending region, and the non-bending part is located in a non-bending region, and the Young modulus of the bending part is smaller than that of the non-bending part. In this way, since the bending part ofthe protective cover plate has the low Young modulus, the bending part can pass a bending test, meanwhile, the non-bending part has the high Young modulus and therefore can pass a pressure test, and the technical problem is solved that a non-bending part of an existing protective cover plate passes a pressure test with difficulty.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

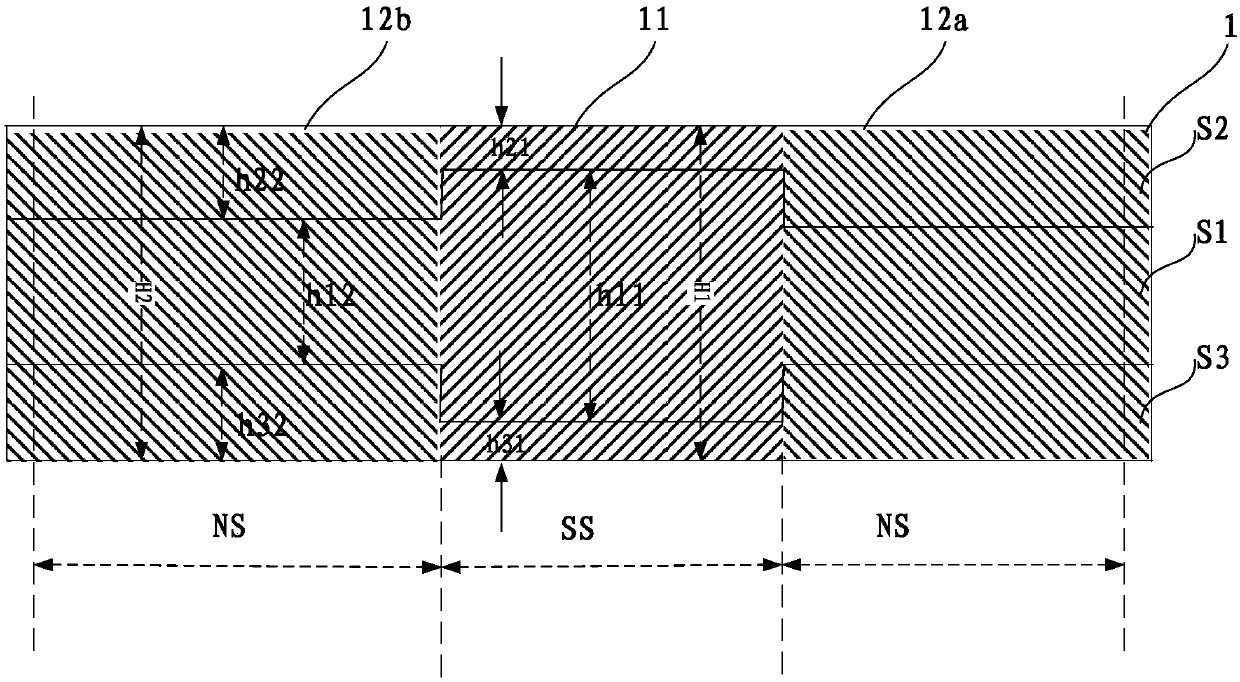

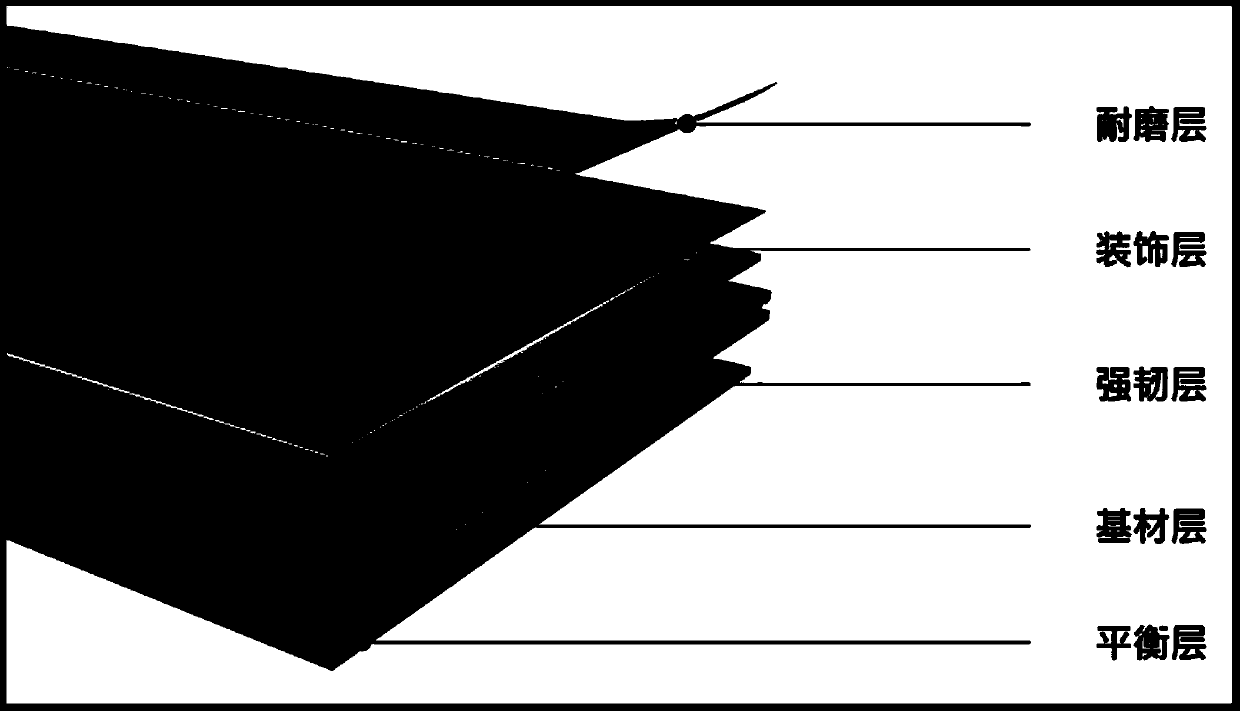

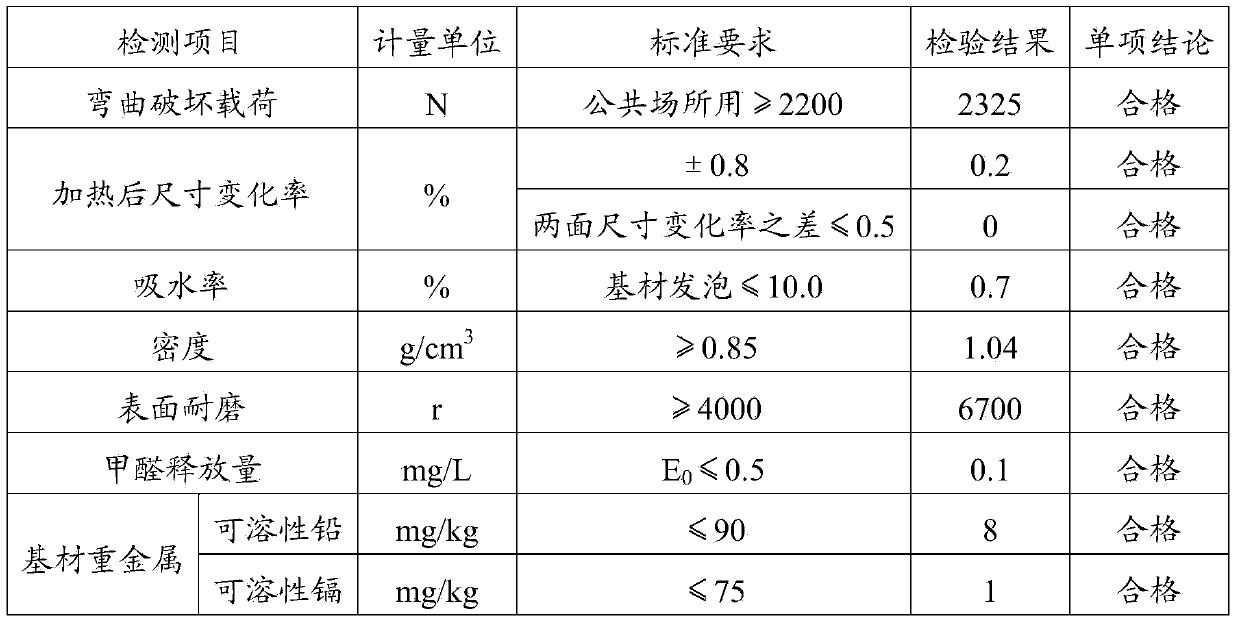

Wood-plastic floor and manufacturing method thereof

The invention provides a wood-plastic floor. The wood-plastic floor comprises a balance layer, a base material arranged on the balance layer, a tough layer arranged on the base material, a decoration layer arranged on the tough layer, and an anti-abrasion layer arranged on the decoration layer. Compared with the prior art, the wood-plastic floor comprises the tough layer arranged between the base material and the decoration layer, and due to the additional arrangement of the tough layer, the mechanical property of the wood-plastic floor is improved. The result shows that the bending failure load of the wood-plastic floor obtained through the first embodiment of the invention is 2325, the size change rate of the wood-plastic floor obtained through the first embodiment of the invention is 0.2 after heating is conducted, and the change rate of the sizes of the two faces of the wood-plastic floor obtained through the first embodiment of the invention is 0 after heating is conducted.

Owner:贾留欣

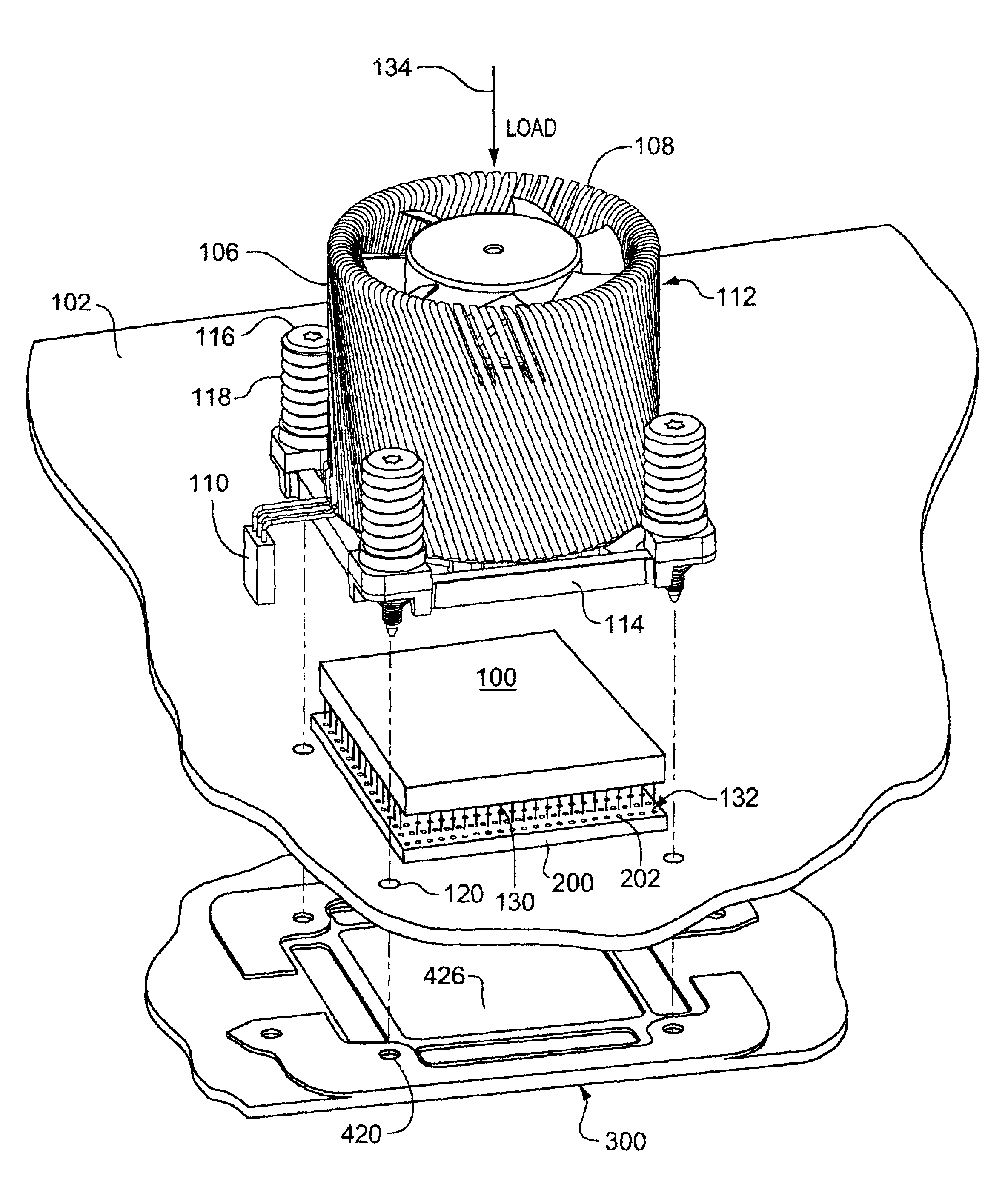

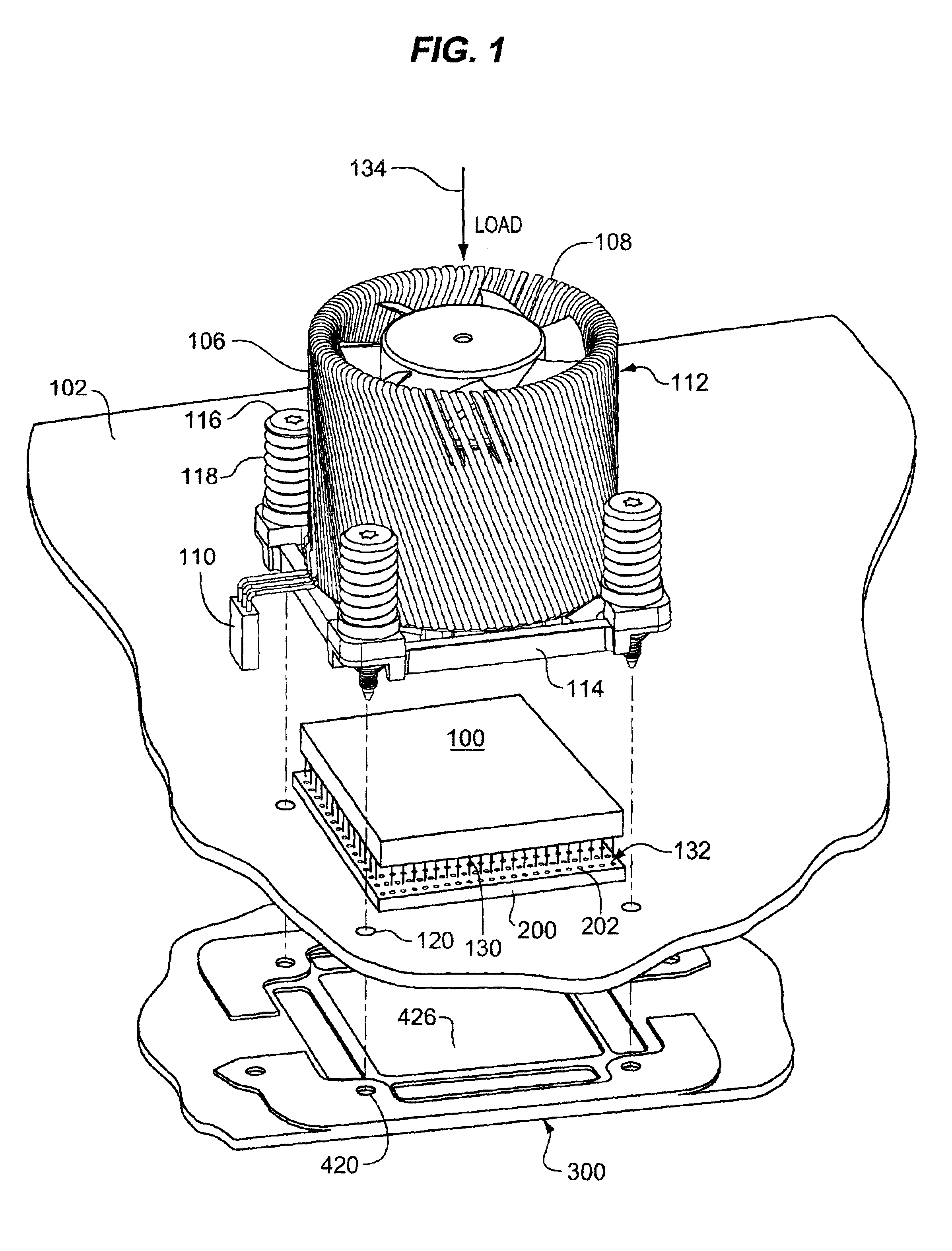

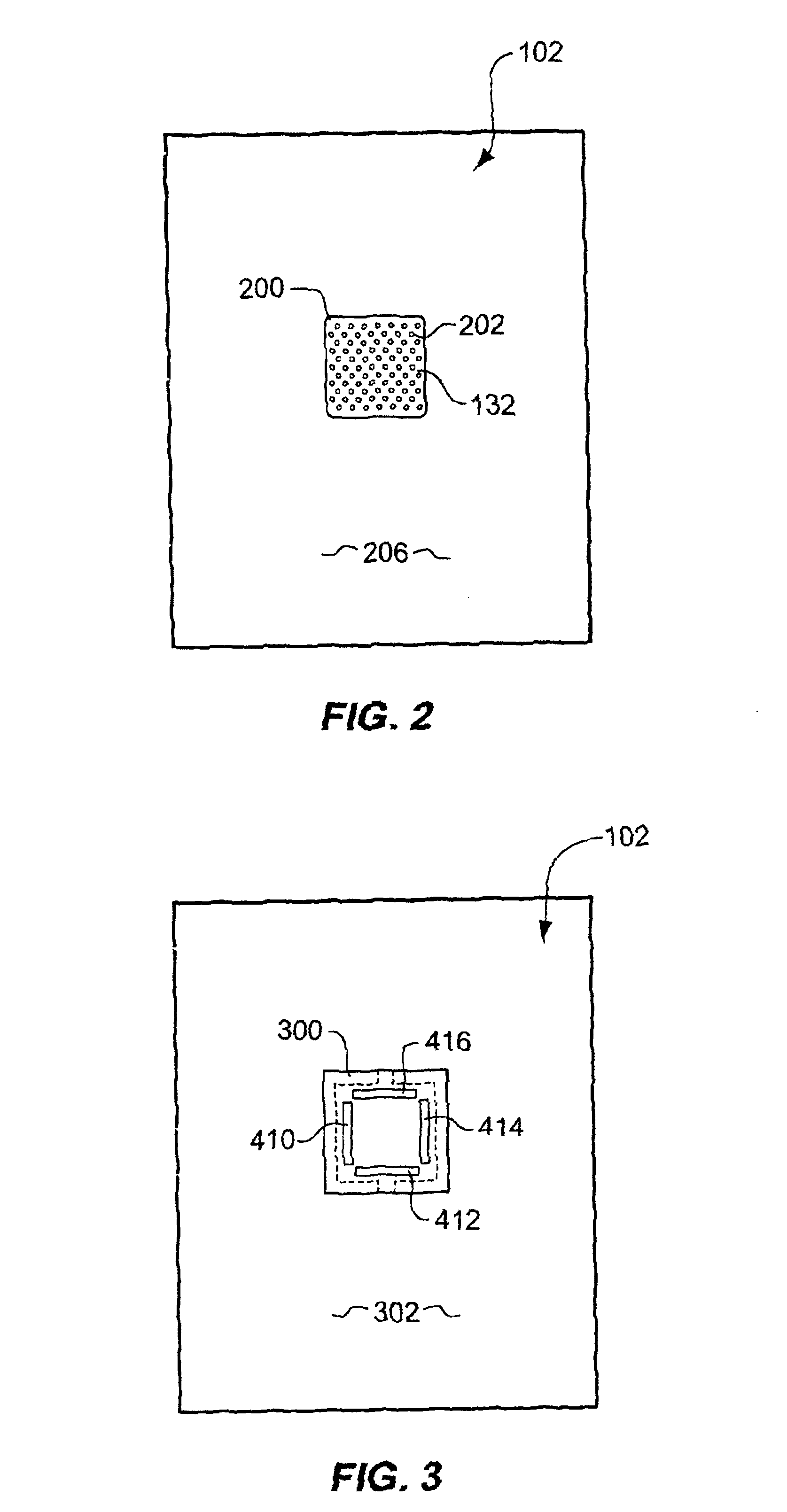

Method of attaching an integrated circuit to a chip mounting receptacle in a PCB with a bolster plate

InactiveUS6789312B2Printed circuit assemblingElectronic circuit testingEngineeringPrinted circuit board

A bolster plate is attached to a printed circuit board and acts as a stiffener that reduces bending in the overall assembly during the attachment of an integrated circuit chip to the printed circuit board under a heavy applied load. The bolster plate is provided with a shim that compensates for bending of the bolster plate under load, thereby preventing damage to the integrated circuit chip. The dimensions of the shim may be selected according to computer model results representing bow deformation in the bolster plate without the shim.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Stackable heat sink

InactiveUS6883591B2Reduce manufacturing costImprove the preparation effectSemiconductor/solid-state device detailsSolid-state devicesComputer engineeringBending of plates

A stackable heat sink comprising a plurality numbers of metal heat dissipation plates, the heat dissipation plate further comprises a bottom plate, two side plates facing each other locates on both sides of the bottom plate, a bending area is bent from the top of the side plate, two standing plates stretches up from the bending area and facing another standing plate, two fastening plates each is formed on the proper location on the standing plate, the fastening plate is bendable and forms a bending line with the standing plate; two fastening crevices each is located on the junction of the bottom plate and the side plate. When two of the heat dissipation plates stack together, the standing plate of the bottom heat dissipation plate inserts into the fastening crevice of the top heat dissipation plate to make the lower portion of the bending line of the fastening plate fastened on the bottom plate of the top heat dissipation plate, the two heat dissipation plates are fastened closely, a distance is formed between two heat dissipation plates is formed by side plates for heat dissipation.

Owner:CHI YUAN

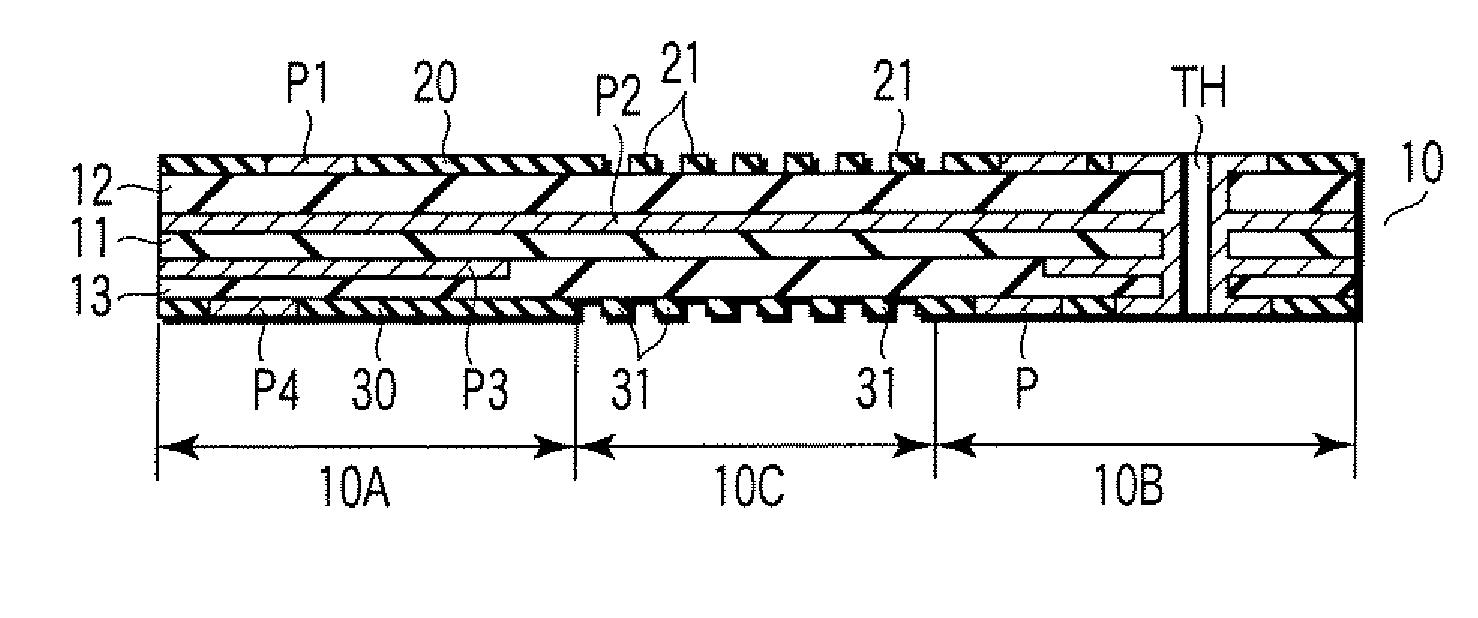

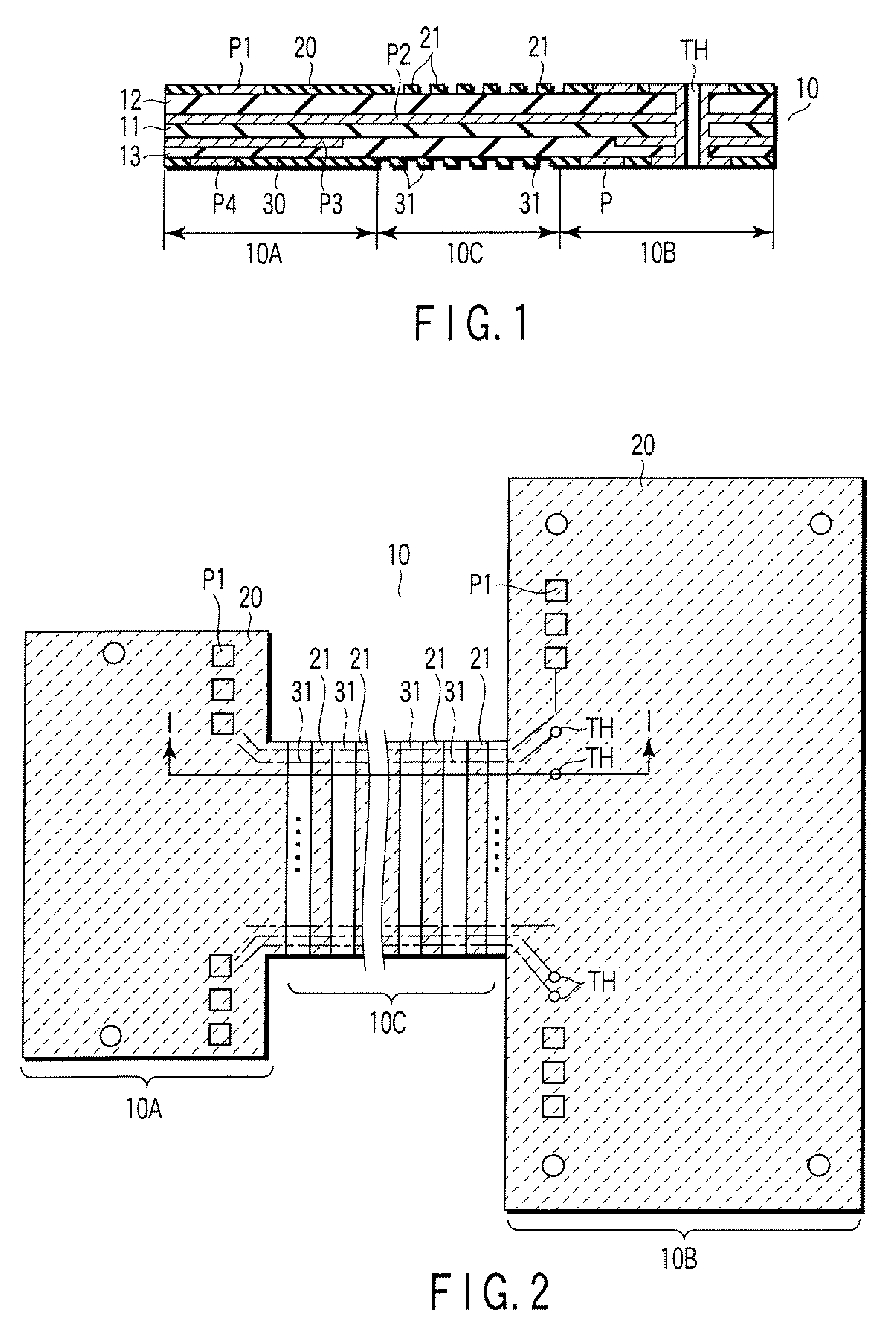

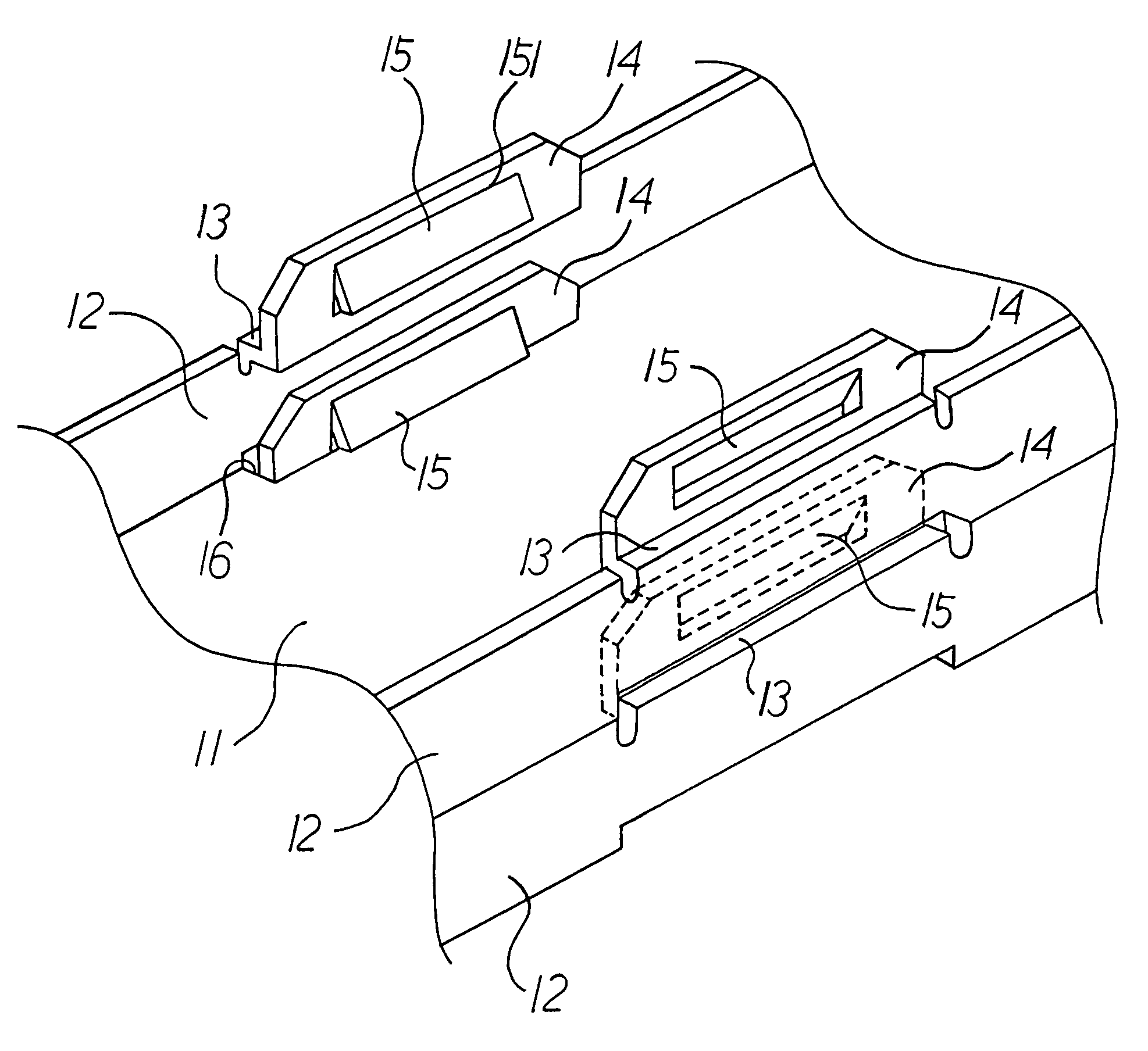

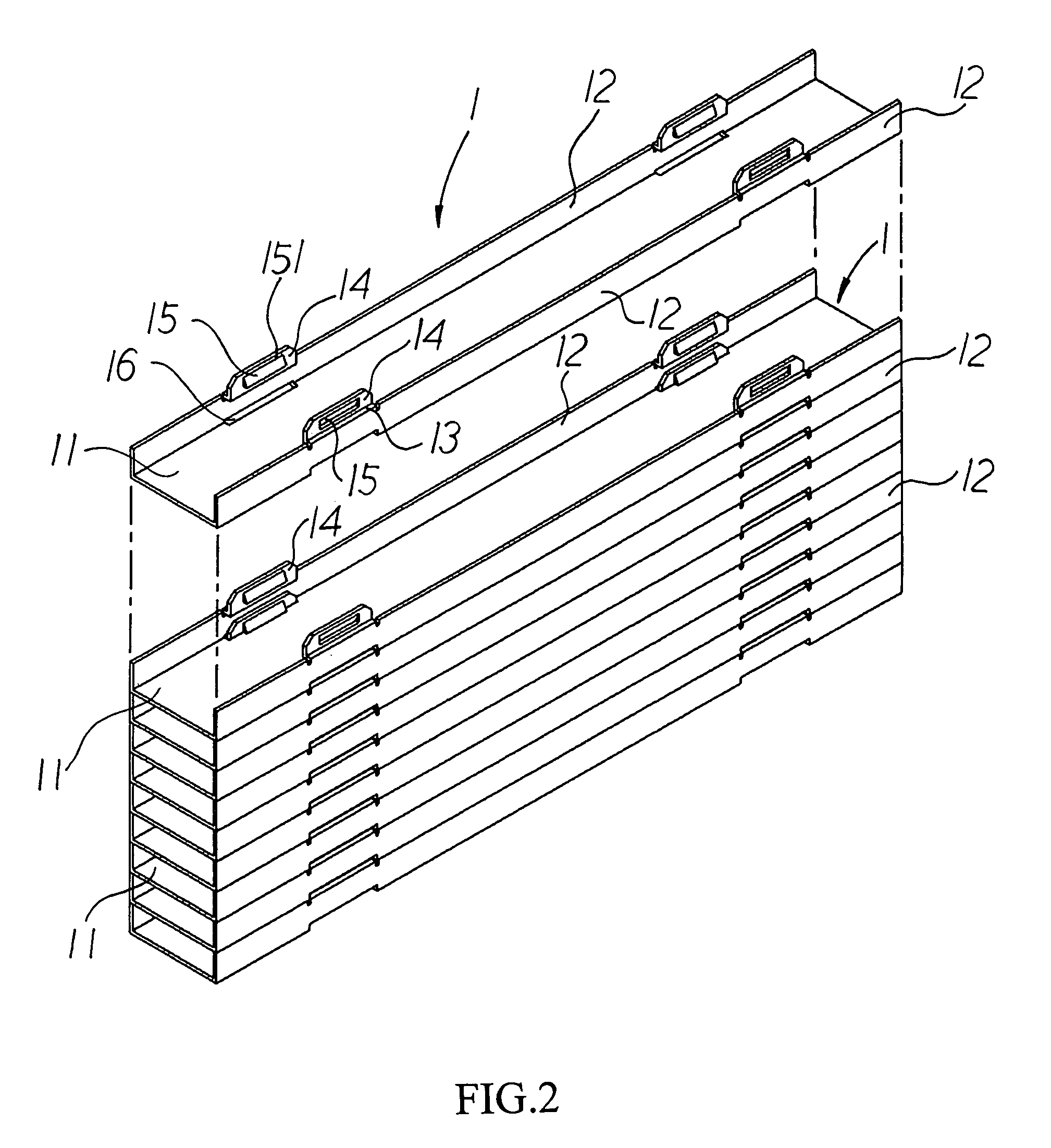

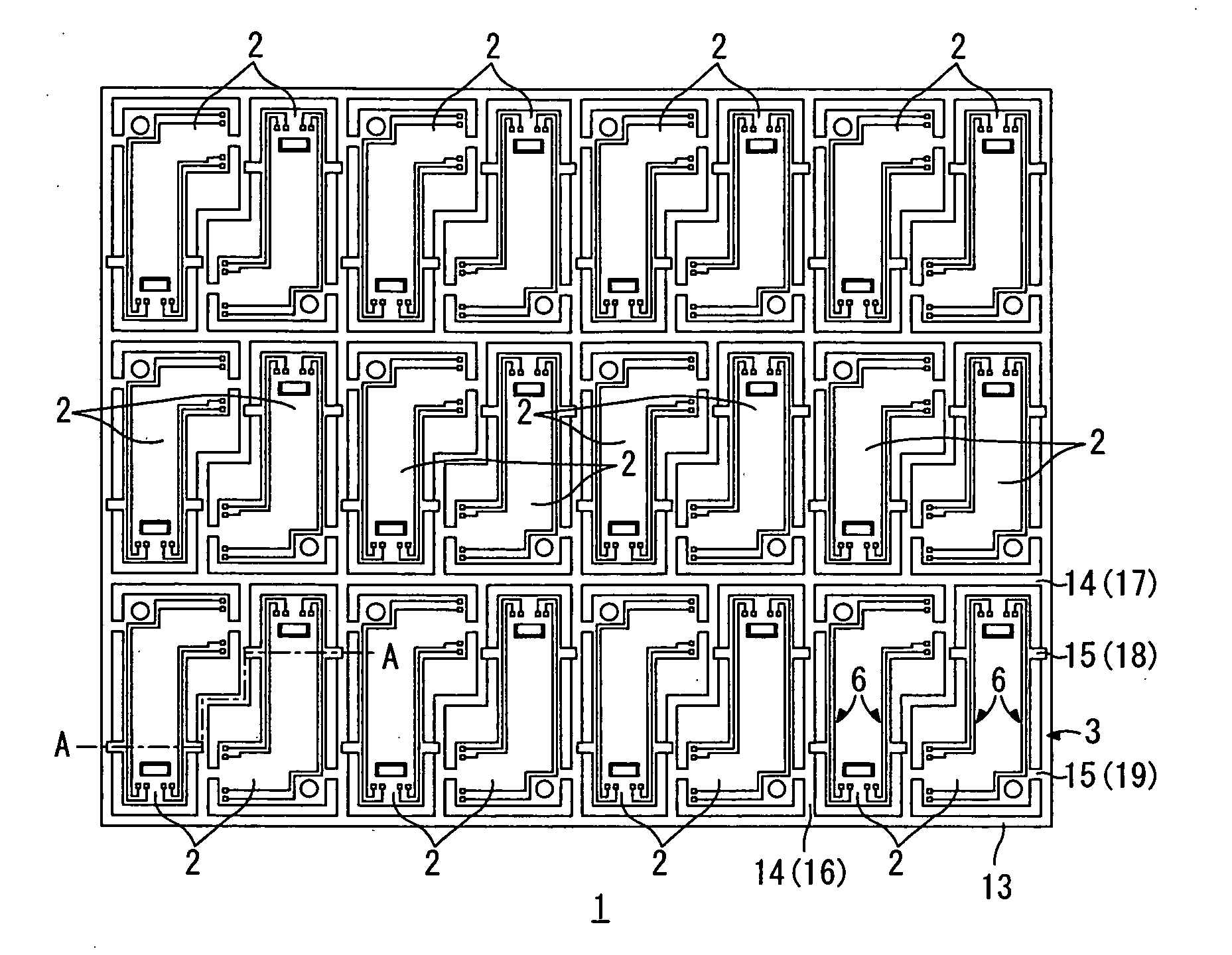

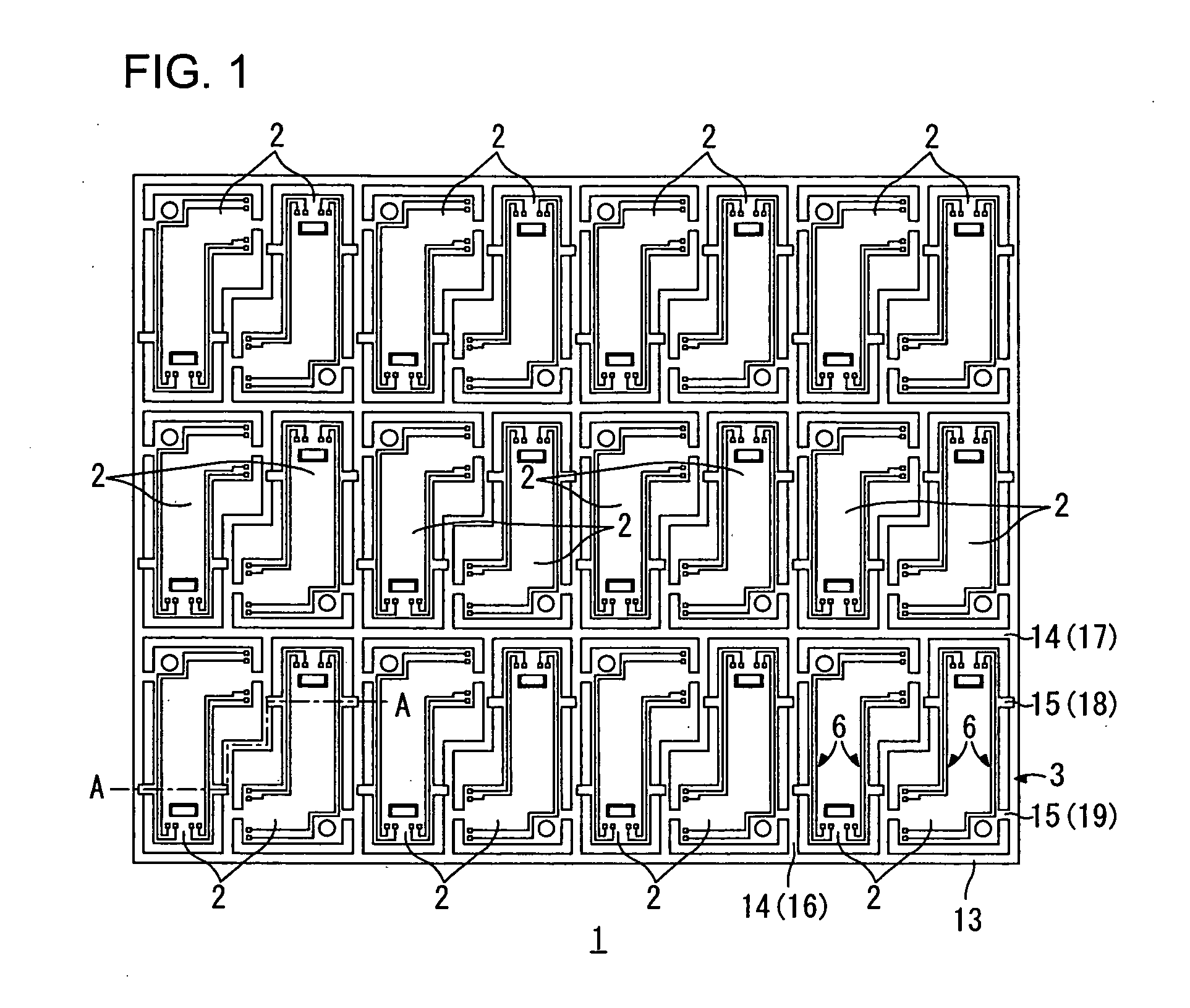

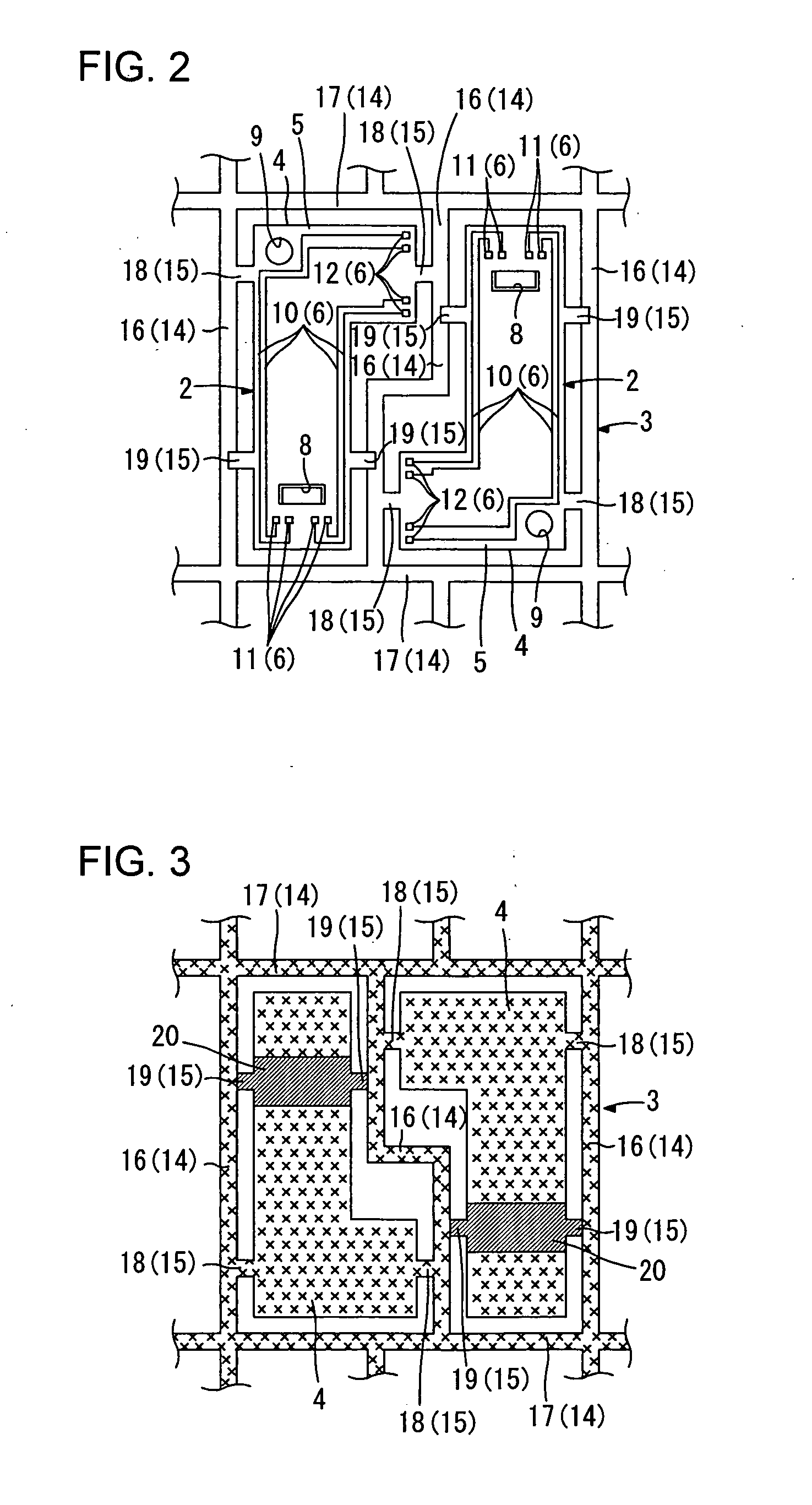

Wired circuit board assembly

ActiveUS20060169486A1Effective prevention of breakageAvoid breakingPrinted circuit aspectsInsulating layers/substrates workingElectrical conductorBending of plates

There is provided a wired circuit board assembly which allows effective prevention of the breakage of the flexing portion of a wired circuit board supported by a support frame. In a wired circuit board support sheet (1), a plurality of wired circuit boards (2) each composed of a base insulating layer (5), a conductor pattern (6), and a cover insulating layer (7) which are formed on a support board (4) are supported by a support frame (3) in such a manner that they are arranged and aligned in mutually spaced relation. Each of the wired circuit board (2) has a flexing portion (20) formed by removing the support board (4) to obtain a flexing property. In addition, second connecting portions (19) are provided in spanning relation between the flexing portion (20) and the vertical frame parts (16) of the support frame (3). The arrangement allows effective prevention of the breakage of the flexing portion (20) of each of the wired circuit boards (2) supported by the support frame (3).

Owner:NITTO DENKO CORP

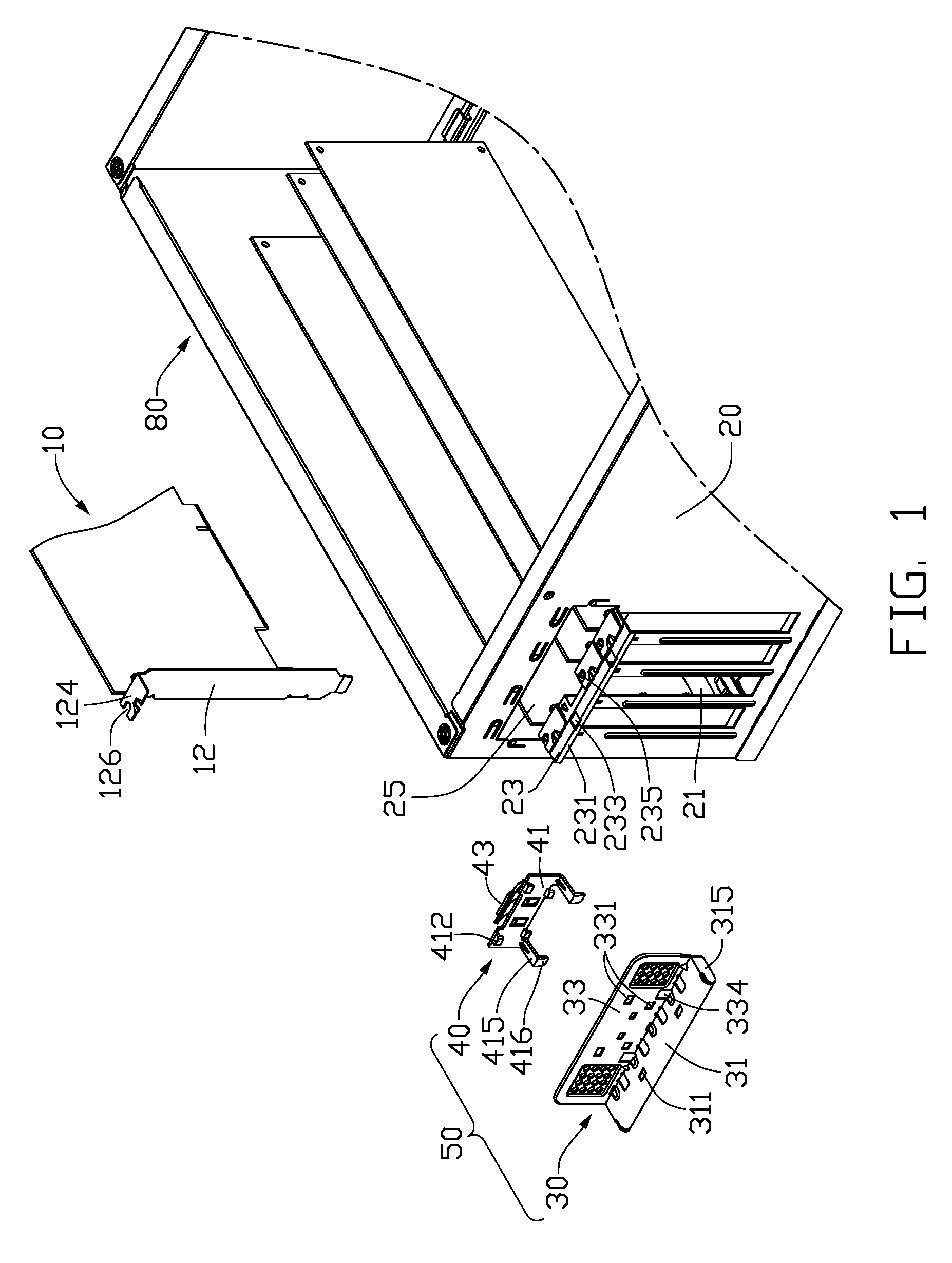

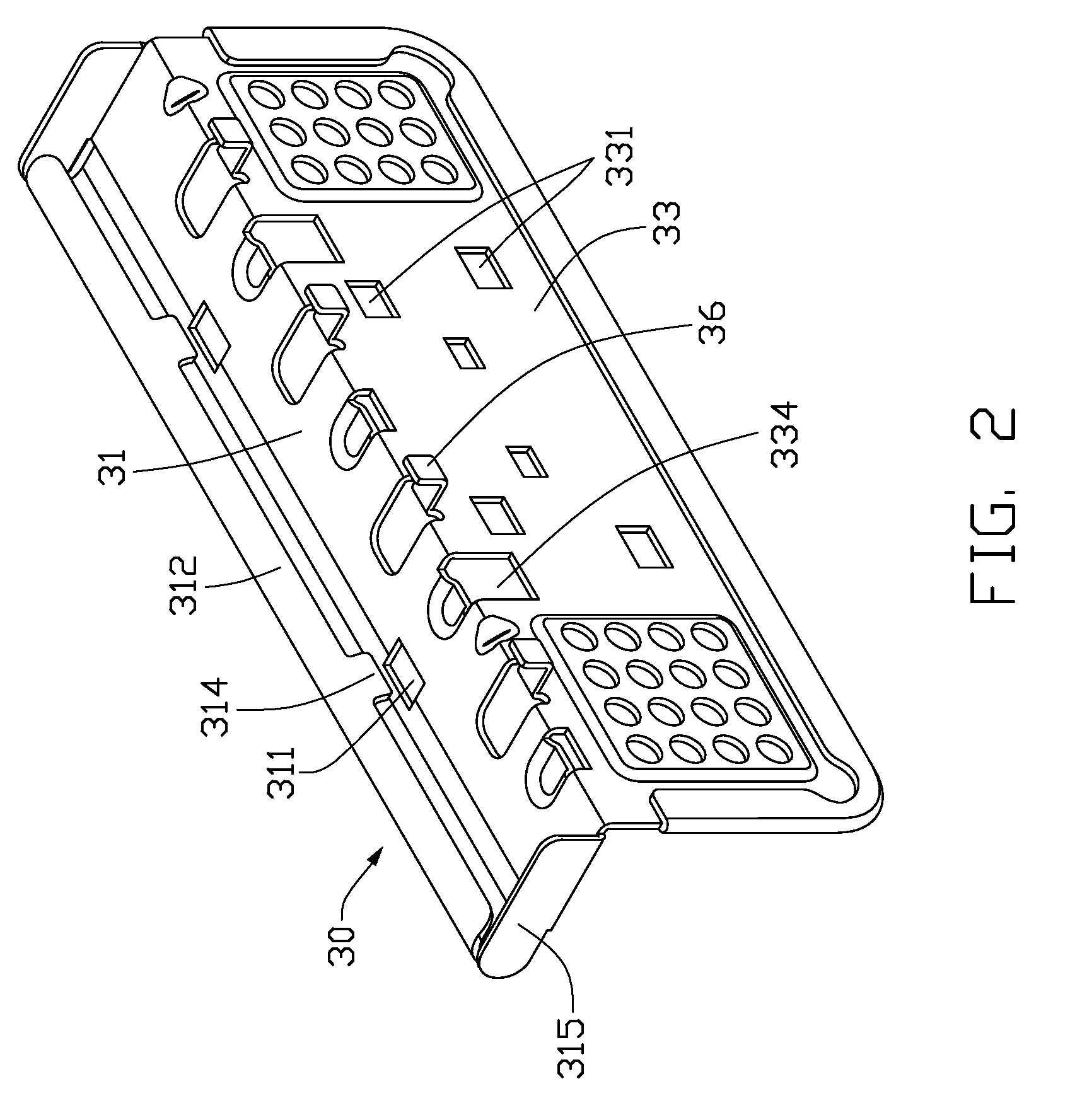

Mounting apparatus for expansion card

InactiveUS20080000850A1Easily dropped into computer enclosureDisassemble screwClamping/extracting meansRack/frame constructionExpansion cardEngineering

A mounting apparatus is provided for mounting expansion cards. The mounting apparatus includes a rear panel, a retainer, and a clip. The rear panel has a support wall for supporting the bent portion of the cover plate, the rear panel defining an opening for facilitating installing or removing the expansion card. The retainer has a pressing plate pivotally coupled to the support wall. The clip has a resilient member for securing the retainer to the rear panel. The retainer has a fixing member for clasping the bent portion of the cover plate when the retainer is rotated to a first position and unclasping the bent portion of the cover plate if the retainer is rotated to a second position.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

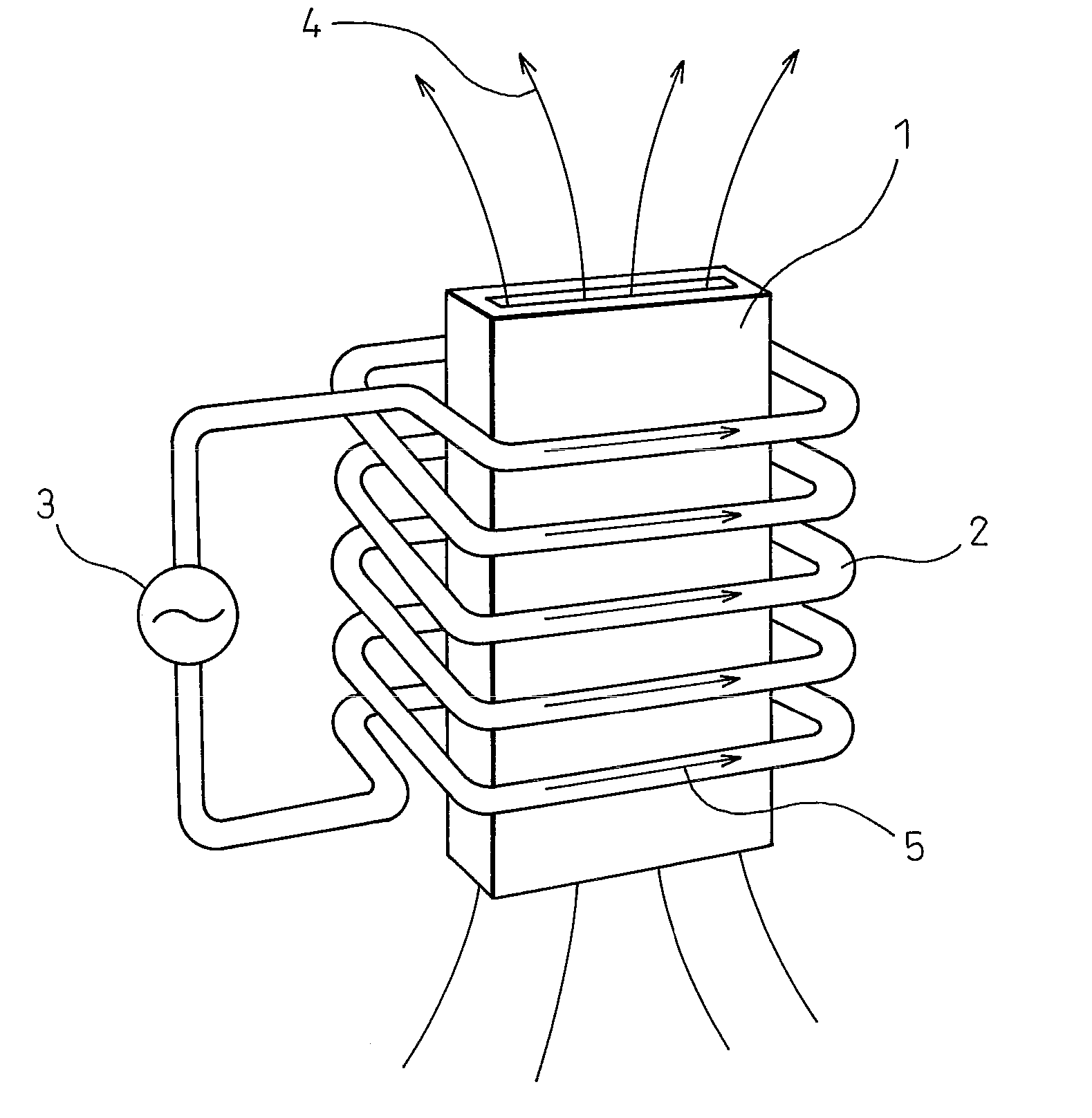

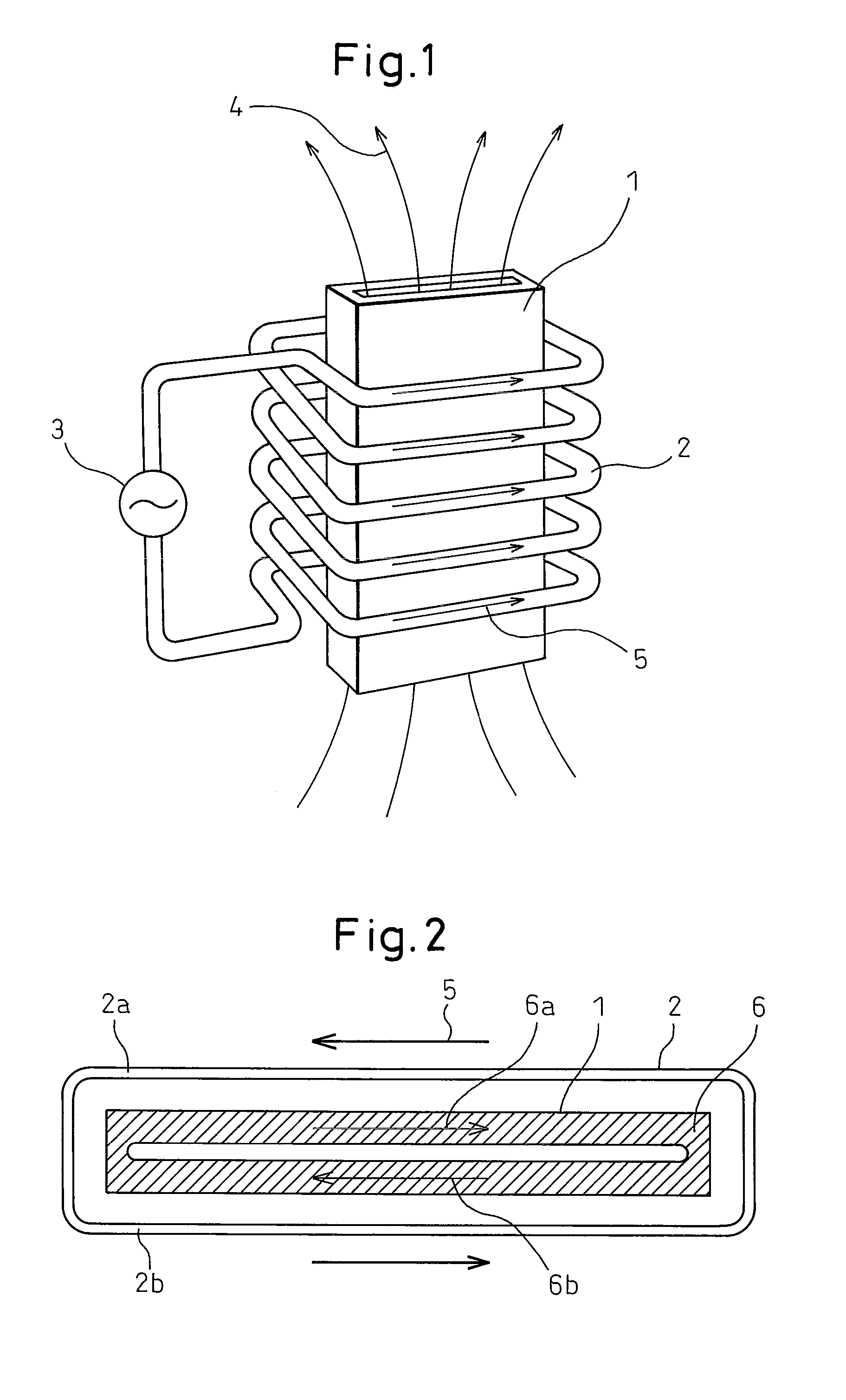

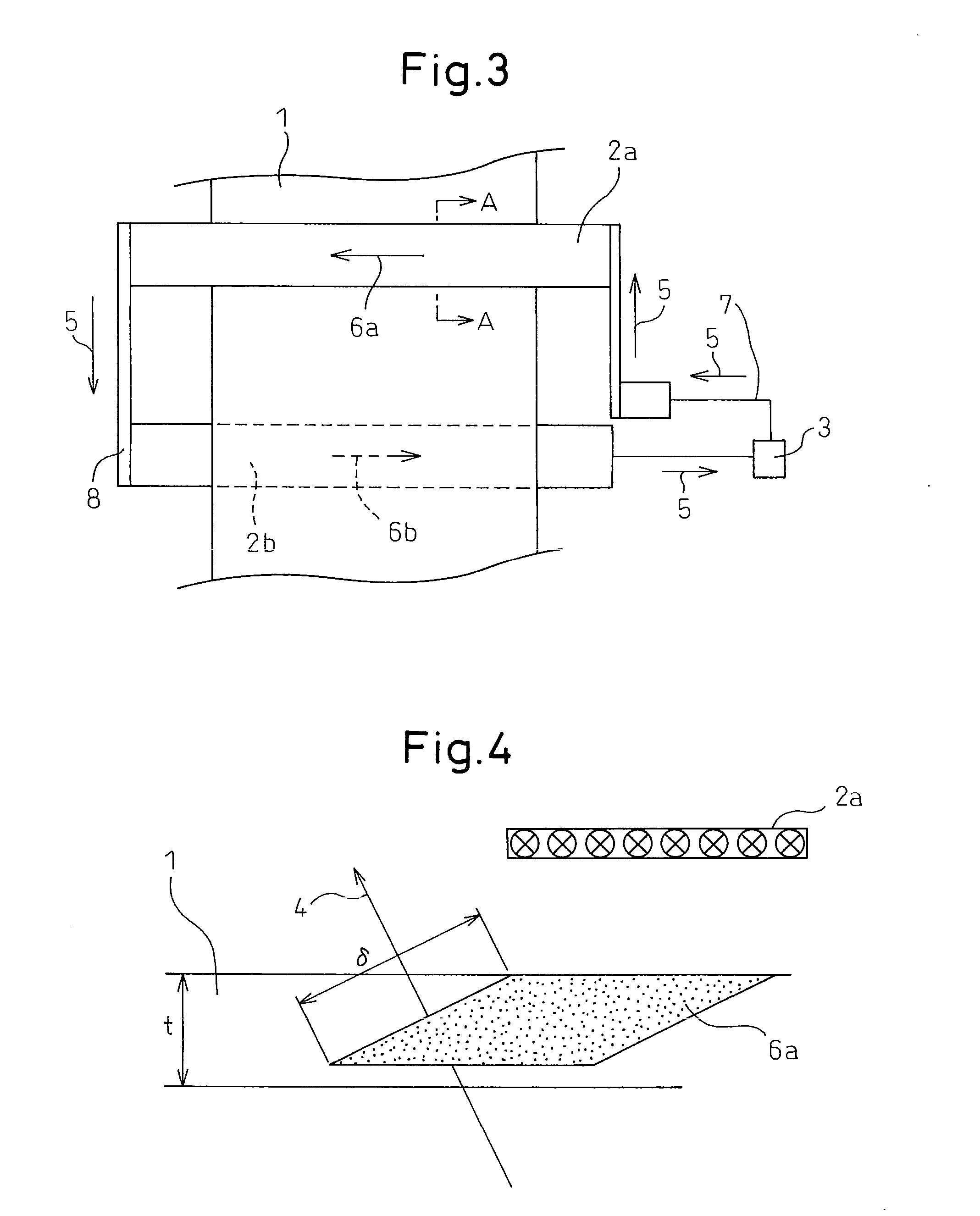

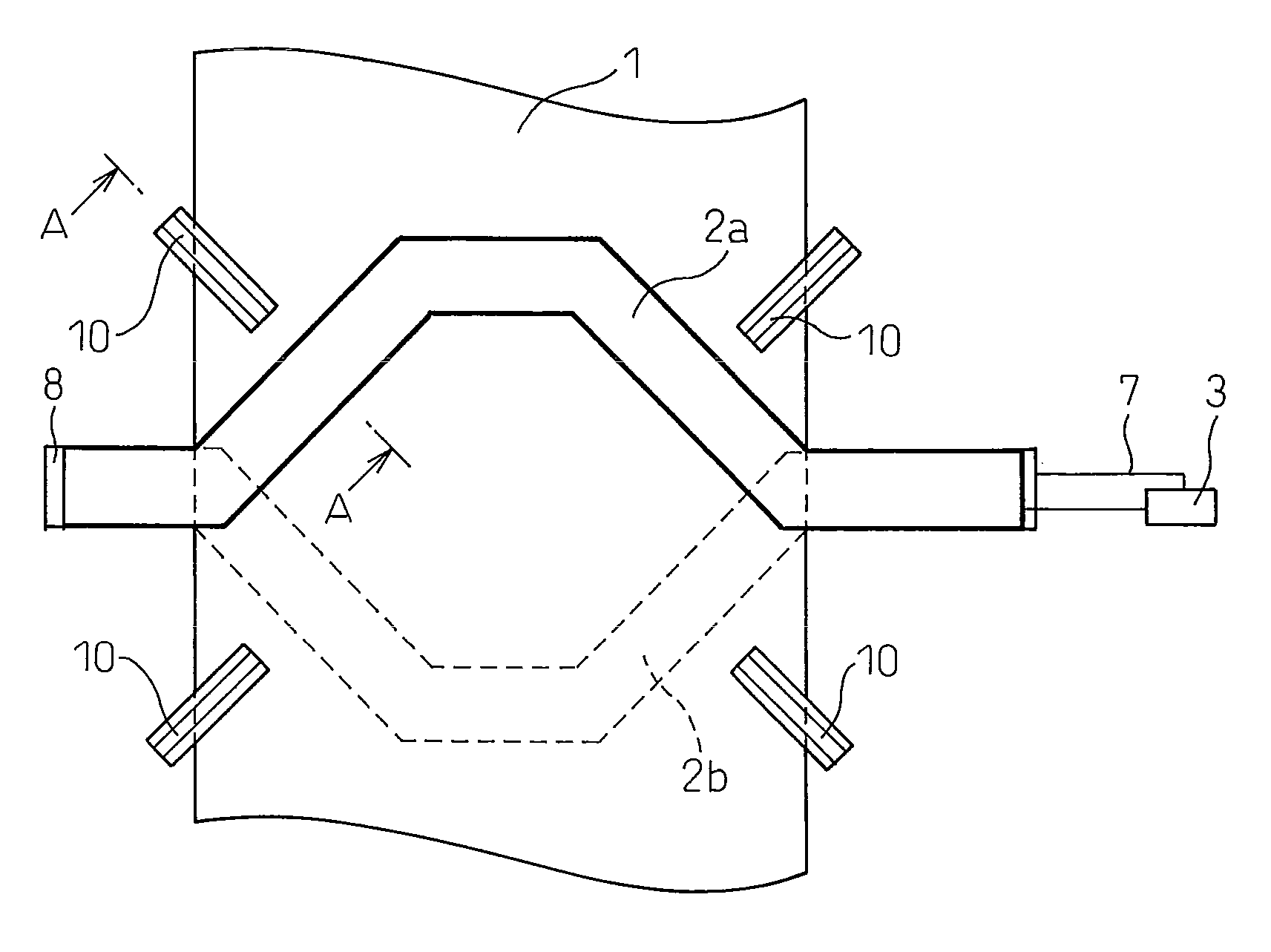

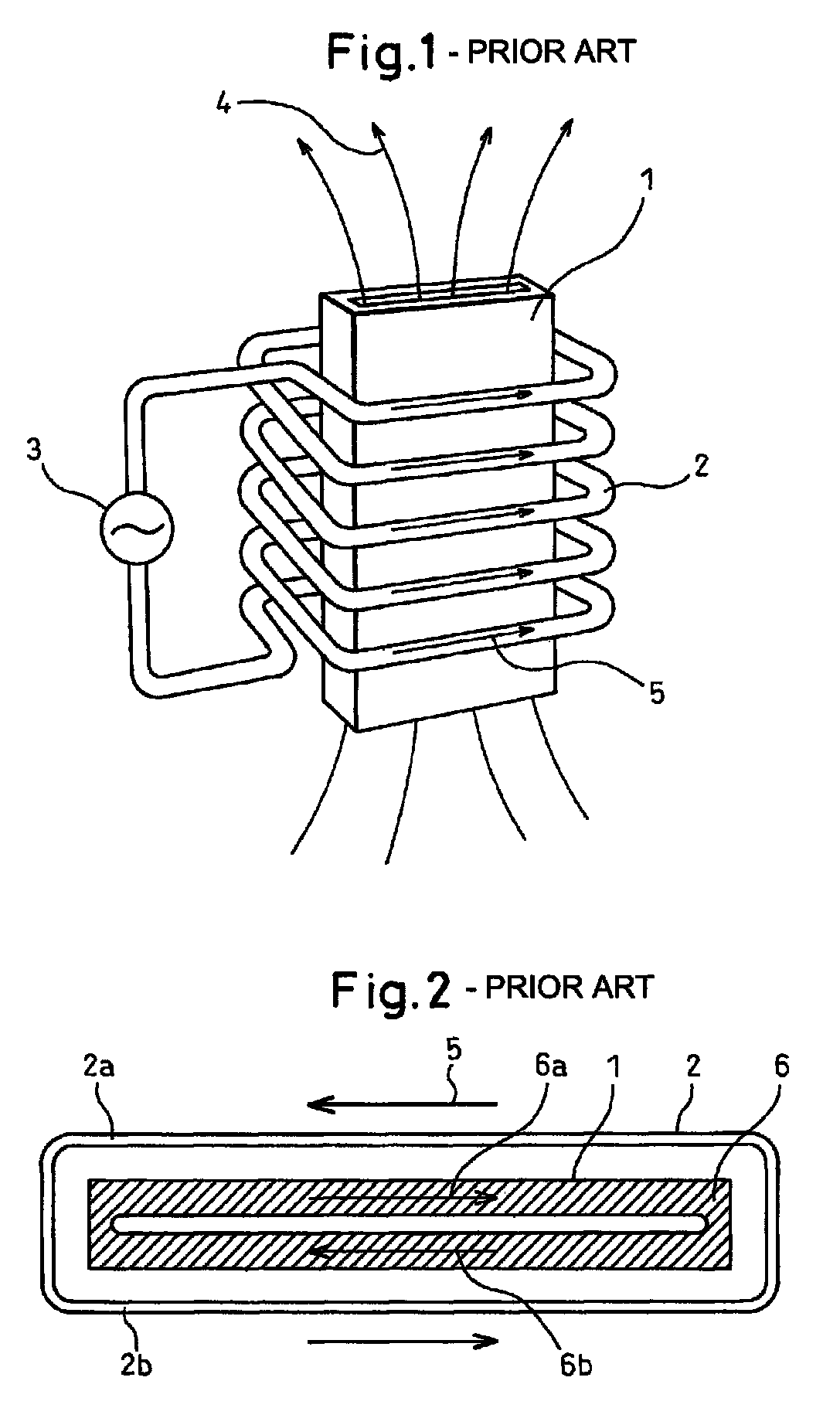

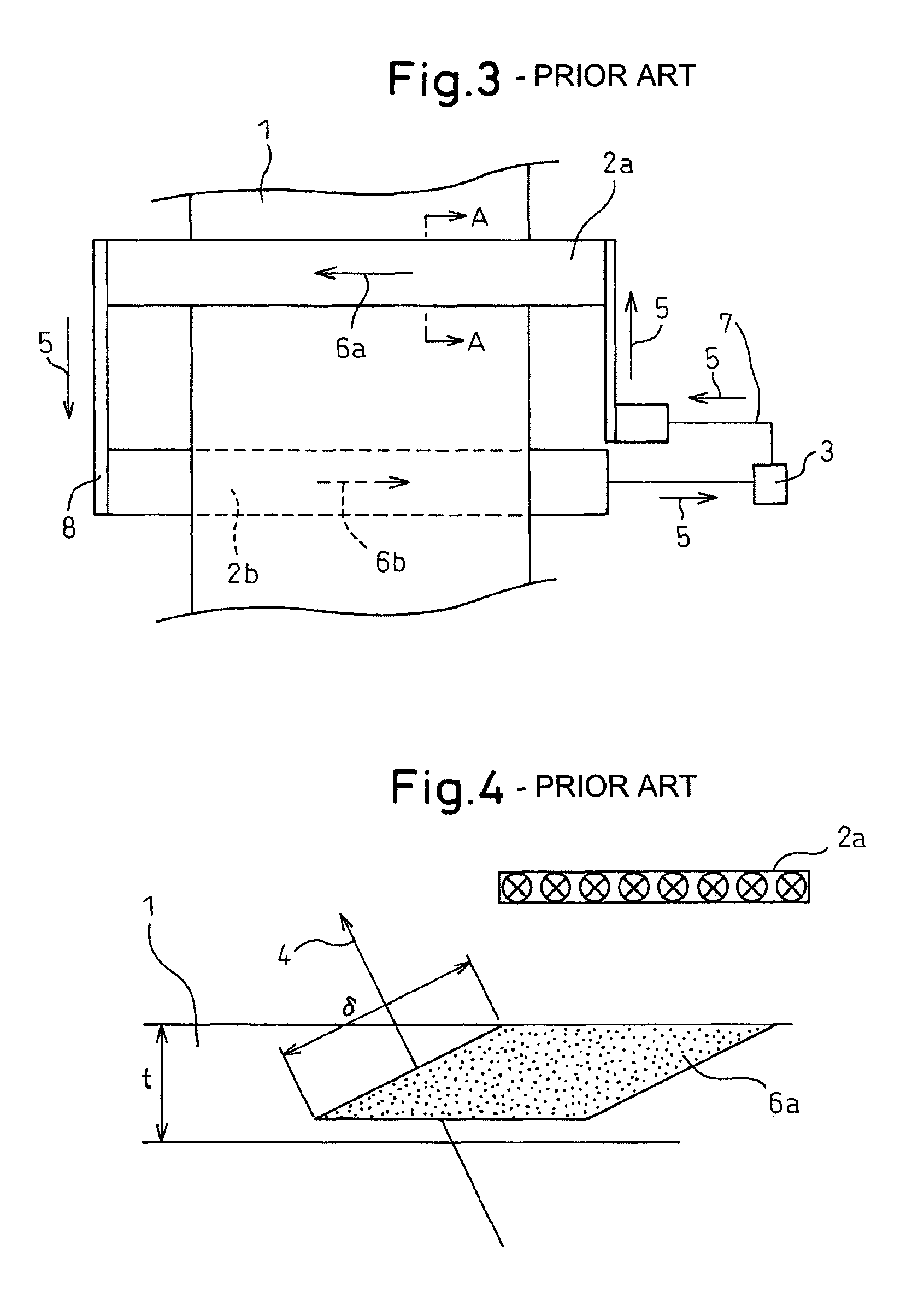

Induction heating apparatus

ActiveUS20100072192A1Increase or decrease capacityFurnaces without endless coreCoil arrangementsElectrical conductorMetal

An induction heating apparatus for controlling the temperature distribution for heating a metal plate irrespective if it has a small thickness, is magnetic or nonmagnetic, and capable of coping with a change in the width of the plate, or meandering of the plate. The apparatus heats a metal plate 1 by induction heating, which passes through the inside of induction coils 2, wherein in a vertical projected image of the conductors on the metal plate 1, the conductors 2a and 2b, parts of the induction coil, placed on the front surface side and the back surface side of the metal plate 1, the conductors 2a and 2b on the front surface side and the back surface side are arranged so as to be deviated from each other in the lengthwise direction of the metal plate 1, the edge portion of at least either the conductor 2a on the front surface side of the metal plate 1 or the conductor 2b on the back surface side thereof is arranged aslant or arcuately, and magnetic cores 10 are arranged at the outer sides of the induction coils 2.

Owner:NIPPON STEEL CORP

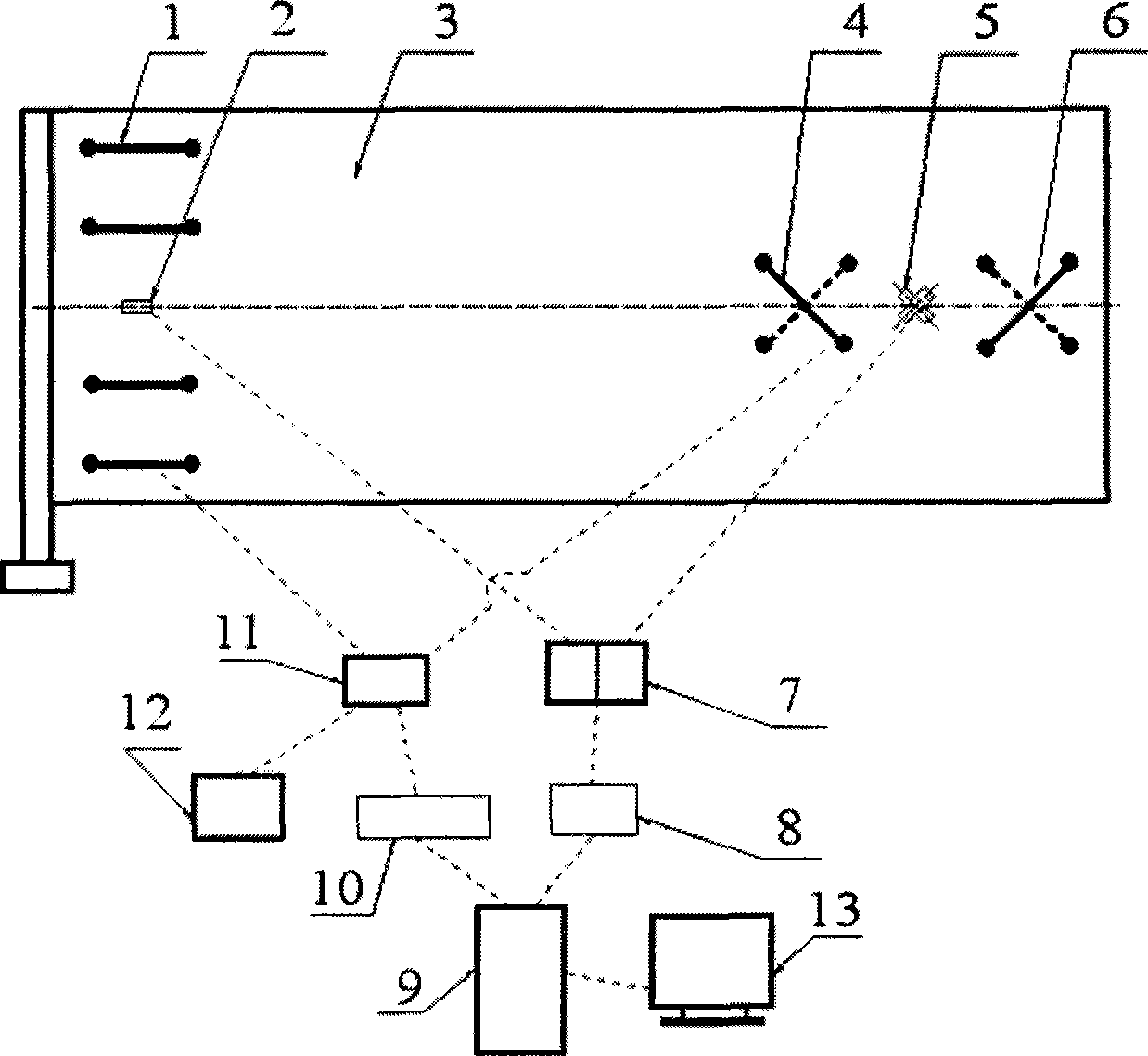

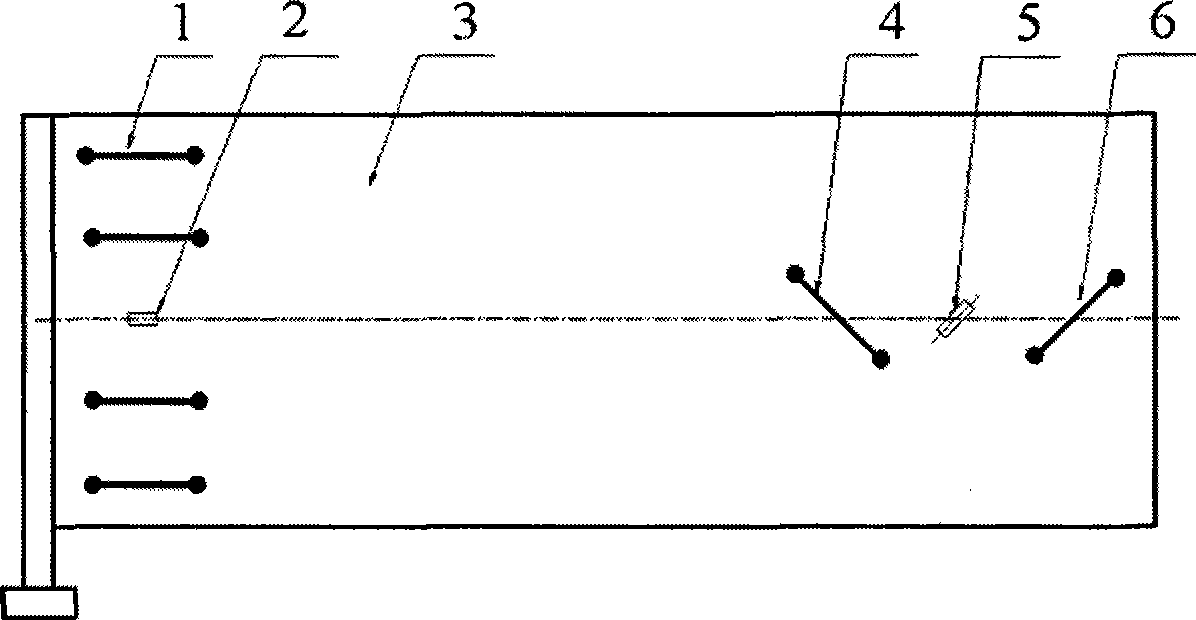

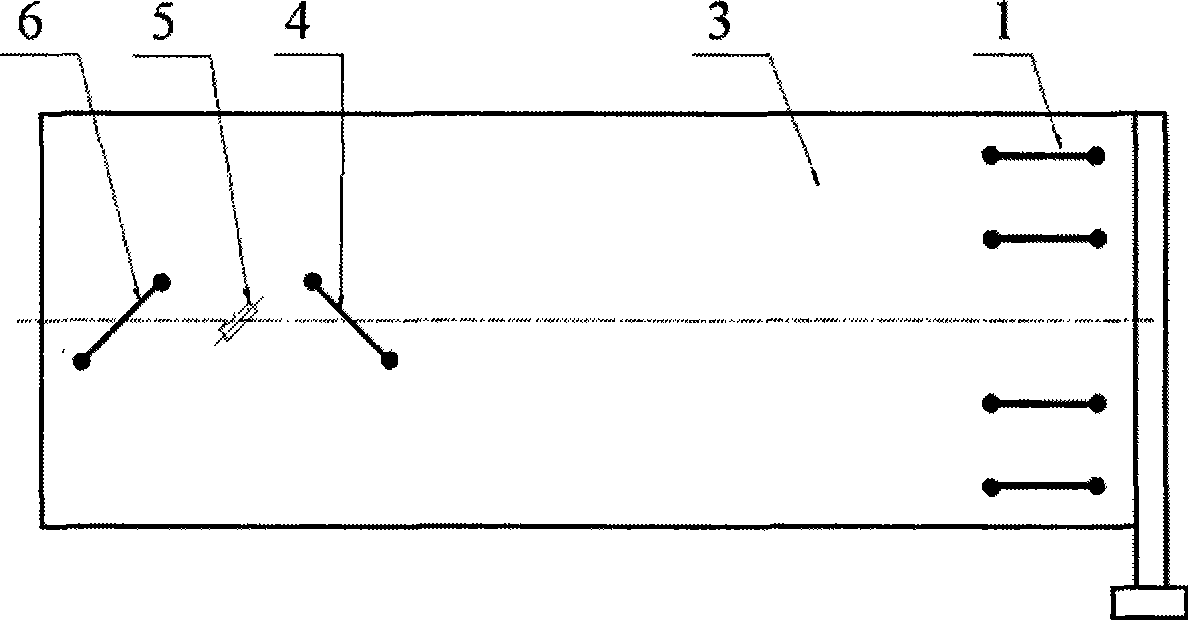

Low frequency modal vibration control apparatus and method for simulating bending and torsion for space sailboard

InactiveCN101382806AEasy to implement decouplingReduce vibrationMechanical oscillations controlComputer controlElectricityElectrical resistance and conductance

The invention discloses a device for controlling vibration when simulating the bending and torsional low-frequency modes of a space sailboard, and a method thereof. The device is stuck with a resistance strain gauge on a flexible cantilever plate close to a longitudinal center line of a fixed end with an attitude angle of 0 degree to serve as a bending mode sensor and multi-way shape memory alloy (SMA) springs are symmetrically arranged on the front surface and the rear surface of the flexible plate, with the attitude angle of 0 degree, to serve as a bending mode piezoelectric actuator. Two resistance strain gauges are anti-symmetrically and bilaterally stuck on the flexible plate close to a free end, with the attitude angle of 45 degrees, to form a torsional mode sensor, and four shape memory alloy springs are anti-symmetrically and bilaterally stuck close to the free end to form two paths of torsional mode drivers with opposite phases. The device and the method utilize the optimized allocation of the SMA springs, realize the decoupling of the bending and torsional low-frequency vibrating modes of a large cantilever plate and the purpose of actively controlling the bending mode and the torsional mode of the flexible cantilever plate.

Owner:SOUTH CHINA UNIV OF TECH

Flexible display device

ActiveCN107369385AImprove performanceIncreased resistance to bendingIdentification meansPolarizerEngineering

The invention provides a flexible display device which comprises a bendable display panel and at least one polarizer. The polarizers comprise polarizing films, absorption axes parallel to stretching directions corresponding to stretching operations are formed after the action of the stretching operations in the preparation process of the polarizing films, the stretching directions corresponding to stretching operations of the polarizing films are consistent with bent directions of the bent display panel, the bending-resistant degree of the polarizing films is enhanced, and performances of the flexible display device are enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Location-Specific Tuning of Stress to Control Bow to Control Overlay In Semiconductor Processing

ActiveUS20180068860A1Reduce overlay errorReduce errorsImage enhancementImage analysisEngineeringInternal stress

Techniques herein include systems and methods for correcting pattern overlay errors by correcting or adjusting bowing of wafers. Location-specific tuning of stress on semiconductor substrates reduces overlay error. Location-specific tuning of stress independently modifies specific regions, areas, or point locations on a substrate to change wafer bow at those specific locations, which reduces overlay error on substrates, which in turn improves overlay of subsequent patterns created on the substrate. Techniques herein include receiving a substrate with some amount of overlay error, measuring bow of the substrate to map z-height deviations across the substrate, generating an overlay correction pattern, and then physically modifying internal stresses on the substrate at specific locations with modifications independent of other coordinate locations. Such modifications can include etching a backside surface of the substrate. One or more processing modules can be used for such processing.

Owner:TOKYO ELECTRON LTD

Induction heating apparatus

ActiveUS8592735B2Increase or decrease capacityCoil arrangementsIncreasing energy efficiencyElectrical conductorEngineering

An induction heating apparatus for controlling the temperature distribution for heating a metal plate irrespective if it has a small thickness, is magnetic or nonmagnetic, and capable of coping with a change in the width of the plate, or meandering of the plate. The apparatus heats a metal plate 1 by induction heating, which passes through the inside of induction coils 2, wherein in a vertical projected image of the conductors on the metal plate 1, the conductors 2a and 2b, parts of the induction coil, placed on the front surface side and the back surface side of the metal plate 1, the conductors 2a and 2b on the front surface side and the back surface side are arranged so as to be deviated from each other in the lengthwise direction of the metal plate 1, the edge portion of at least either the conductor 2a on the front surface side of the metal plate 1 or the conductor 2b on the back surface side thereof is arranged aslant or arcuately, and magnetic cores 10 are arranged at the outer sides of the induction coils 2.

Owner:NIPPON STEEL CORP

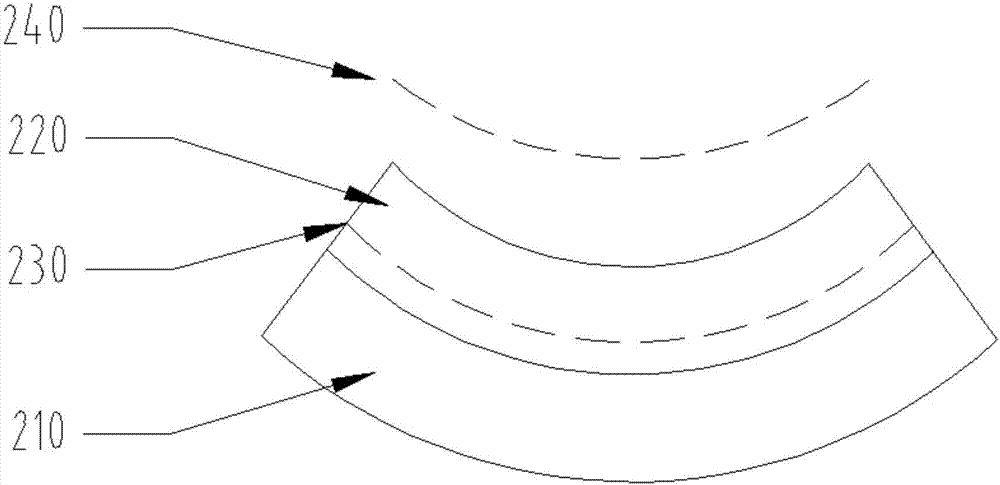

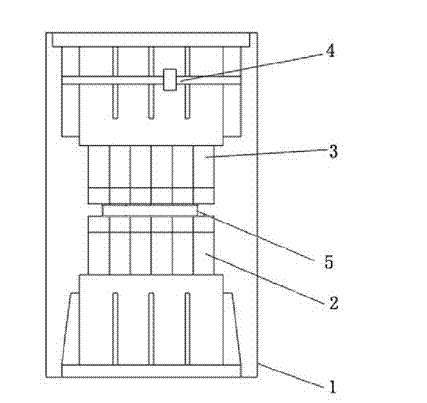

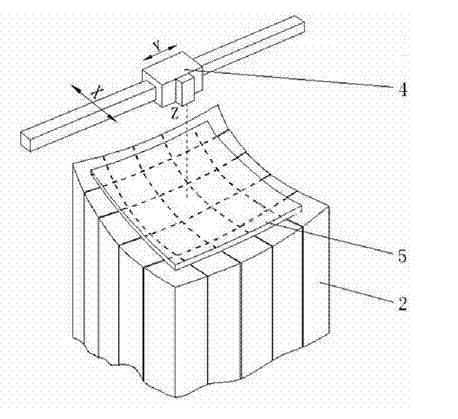

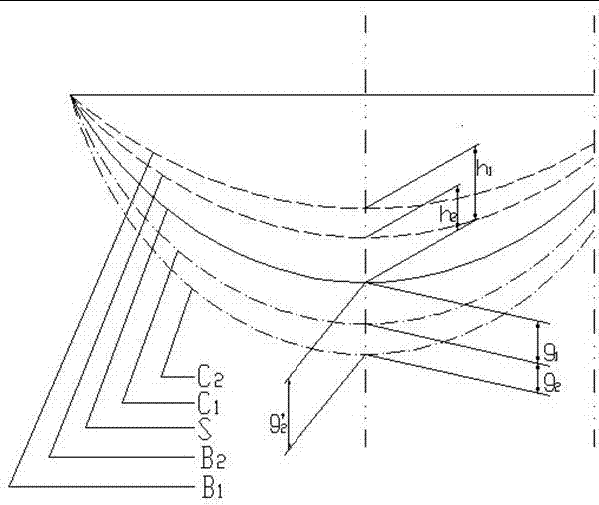

Method and device for forming plates through gradual approximation bending

InactiveCN102500672ASolve the problem of bending springbackResolve reboundMetal working apparatusNumerical controlMeasuring instrument

The invention discloses a method and a device for forming plates through gradual approximation bending on a three-dimensional numerical control plate bending machine (1). The method comprises the following steps of: performing targeted iteration gradual approximation bending by utilizing a resilience rule of a plate (5), comparing a shape of an actually formed curved surface B of the plate (5) subjected to pressing resilience with a shape of a theoretical target curved surface S through online measurement, and setting an approximation bending pressing curved surface C for limited approximation pressing according to an error offset value h after resilience. By the device, an online laser three-dimensional coordinate measuring instrument (4) connected with a computer is arranged on the three-dimensional numerical control plate bending machine (1). Complex mechanical calculation is not needed, the problem of bending resilience of a ship plate can be rapidly solved on line in real time, as long as the approximation bending pressing is performed for 1 to 3 times generally, the requirement on machining accuracy can be met, the problem of resilience of a numerically controlled bent plate is rapidly and effectively solved, the forming accuracy of a three-dimensional curved surface ship plate is guaranteed, and the method and the device have simple and rapid effects.

Owner:SHANDONG SURELY MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com