Method and device for forming plates through gradual approximation bending

A sheet metal forming, step-by-step approximation technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as fast and real-time processing of ship sheets, difficulty in accurate calculation, and lengthy calculation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the embodiment shown in the drawings, the specific content and working process of the step-by-step bending method and device for plate forming of the present invention will be further described.

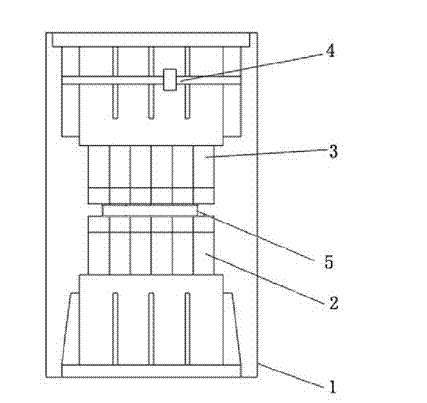

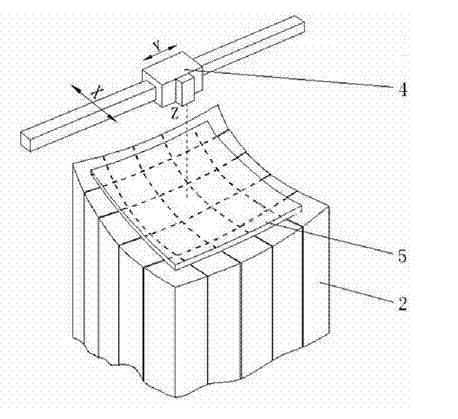

[0031] On one side of the upper mold group 3 of the three-dimensional numerical control plate bending machine 1, an online laser three-dimensional coordinate measuring machine 4 (as attached figure 1 As shown), the online laser three-dimensional coordinate measuring machine 4 can also be set on the upper side of the lower mold group 2 of the three-dimensional numerical control bending machine 1 through the rail, and the rail is fixed on the three-dimensional numerical control bending machine 1, and the online laser three-dimensional coordinate measurement Machine 4 can move on track.

[0032] The specific process is as follows:

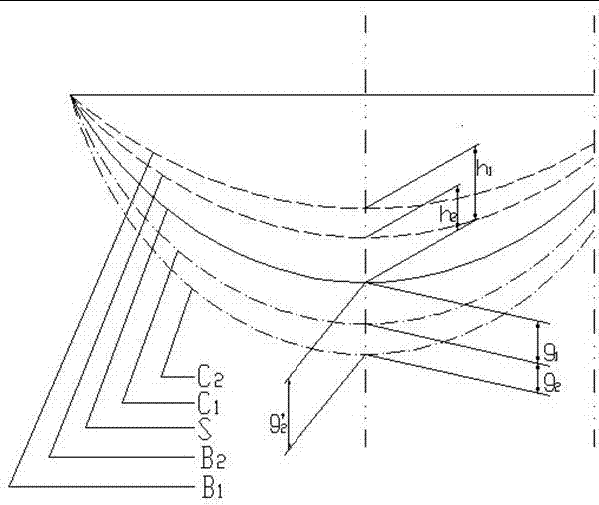

[0033] 1. Adjust the curved surface shape of the lower mold group 2 of the 3D CNC plate bending machine 1 according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com