A bending device for hardware processing

A bending device and hardware technology, applied in the field of hardware processing, can solve the problems of inability to adjust the bending angle, small angle adjustment range, inaccurate bending angle, etc., achieve fast adjustment speed, large adjustment range, and easy replacement or the effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

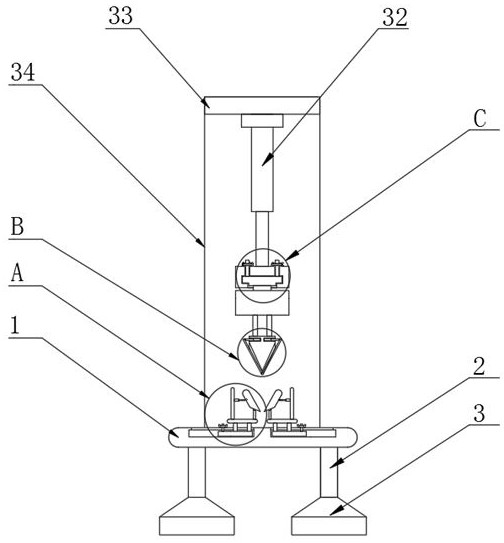

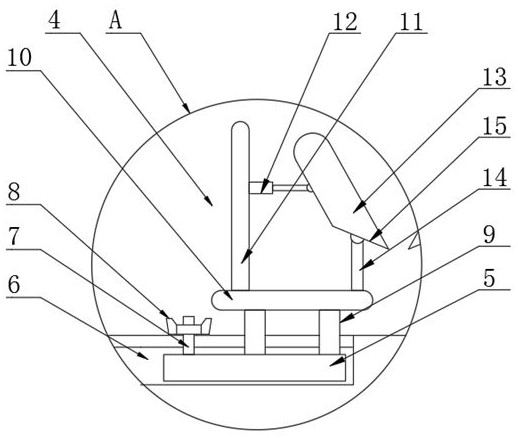

[0025] The present invention provides such as Figure 1-5 The shown bending device for hardware processing includes a bottom plate 1, the bottom of the bottom plate 1 is fixed with a support leg 2, and the bottom of the support leg 2 is fixed with a bottom pad 3, and the bottom pad 3 is formed by Made of rubber material, the surface of the bottom plate 1 is provided with two bottom mold angle adjustment devices 4, the two bottom mold angle adjustment devices 4 are relatively arranged at the center of the bottom plate 1, and the bottom mold angle adjustment device 4 includes a slider 5. The surface of the bottom plate 1 is provided with a chute 6, the slider 5 is slidably connected with the chute 6, the top of the slider 5 is provided with a screw 7, and the outer side of the screw 7 is provided with a wing nut 8, the The wing nut 8 is threadedly connected with the screw rod 7, and the slide block 5 is fixedly provided with a fixed rod 9 on one side of the screw rod 7, and the ...

Embodiment 2

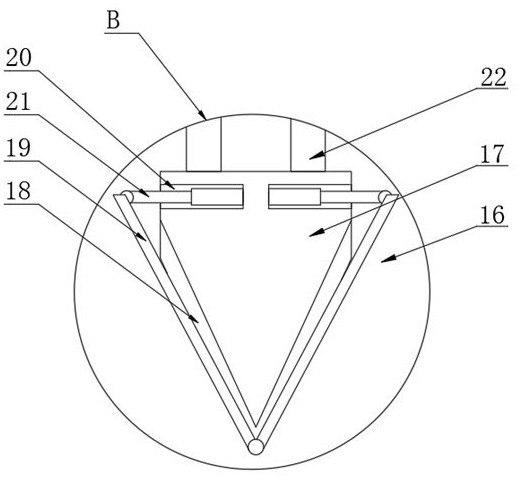

[0028] Further, a stamping device 16 is provided above the adjusting bottom template 13, and the stamping device 16 includes a stamping block 17, grooves 18 are provided on both sides of the bottom of the stamping block 17, and grooves 18 are arranged inside the groove 18. Stamping plate 19, the stamping plate 19 is matched with the groove 18, and the surface of both sides of the stamping block 17 is provided with placement grooves 20.

[0029] Further, the top of the stamping plate 19 is provided with a second hydraulic rod 21, the output shaft of the second hydraulic rod 21 is hinged to the top of the stamping plate 19, the bottom end of the stamping plate 19 is hinged to the inner wall of the groove 18, and the first Two hydraulic rods 21 are arranged inside the placing groove 20 .

[0030] Further, the top of the stamping block 17 is fixed with a connecting rod 22 , and the top of the connecting rod 22 is fixed with a top block 23 .

[0031] Further, the top of the top bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com