Preparation method of cellulose membrane by using ion liquid as solvent

A technology of ionic liquid and cellulose membrane, which is applied in the production of bulk chemicals, etc., can solve the problems of long and complicated production process, large equipment corrosion, high energy consumption and operating costs, so as to reduce production cost, avoid pollution, and be easy to recycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

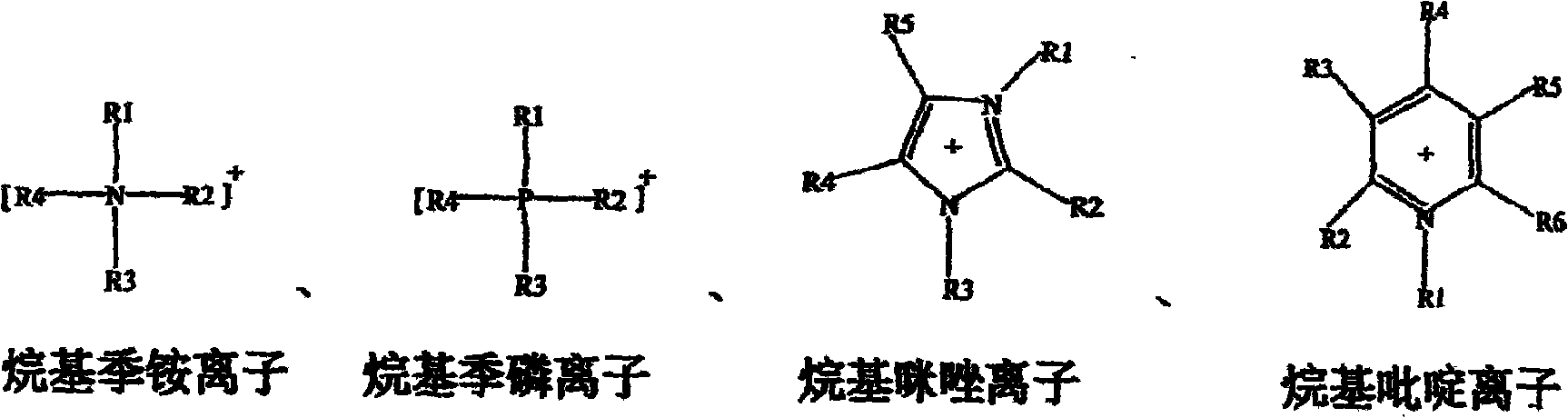

Method used

Image

Examples

Embodiment 1

[0028] Mix the cotton paddle and the ionic liquid evenly, dissolve at 100°C for 4 hours, and obtain the film-making stock solution with a concentration of 8.5%. It is [AMIM]CL (Chinese name 1-propenyl-3-methylimidazolium chloride) ionic liquid aqueous solution, the concentration of ionic liquid in the coagulation bath is 20%, the temperature is 30°C, and the film forming speed is 40M / min , the solidified film is processed by stretching, washing, drying and other procedures to obtain a cellulose film with a tensile strength of 120 MPa.

Embodiment 2

[0030] Mix the refined cotton with the ionic liquid, dissolve at 91°C for 24 hours to obtain the film-making stock solution, the concentration of the film-making stock solution is 5%. The bath is an aqueous solution of [BMIM]CL (the Chinese name is 1-butyl-3-methylimidazolium chloride), the concentration of the ionic liquid in the coagulation bath is 10%, and the temperature is 30°C;

[0031] The film-making speed is 9m / s, and the solidified film is processed by washing, stretching, drying and other procedures to obtain a cellulose film with a strength of 1.4MPa.

Embodiment 3

[0033] Mix the pulverized grass paddle with the ionic liquid, and dissolve it for 100 hours at 55° C. to obtain a film-making stock solution. The concentration of the film-making stock solution is 35%. The film-making stock solution is cast to form a film after filtration and defoaming. The coagulation bath is [AMIM]CL (Chinese name is 1-propenyl-3-methylimidazolium chloride) ionic liquid aqueous solution, in the coagulation bath, the concentration of the ionic liquid is 50%, and the temperature of the coagulation bath is 90°C

[0034] The film-making speed is 10 m / s, and the solidified film is processed by washing, stretching, drying and other procedures to obtain a cellulose film with a strength of 3.8 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com