Water-based organic silicon waterproof agent

A waterproofing, water-based technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as defects that have not been overcome, and achieve the effect of improving strength, strong impermeability, and strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

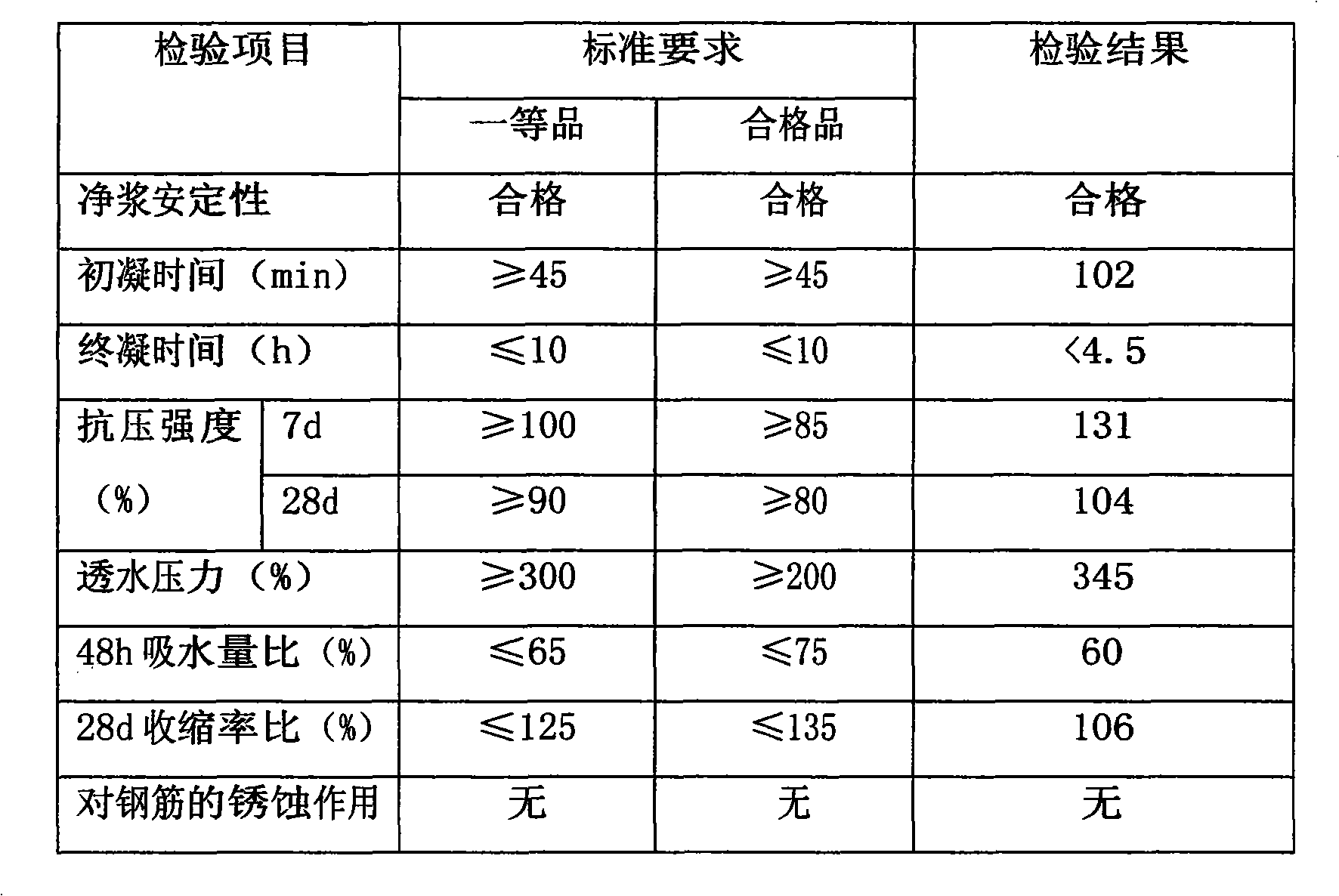

Image

Examples

Embodiment 1

[0060] Under stirring, first dissolve 20g of SSOPA and 20g of polyethylene glycol (PEG 6000) in 100ml of hot water at about 60°C, then add 40g of alum, 25g of silane coupling agent KH-550 and 375g of sodium methyl siliconate, After uniformity, adjust the pH value to 7.5 with phosphoric acid, and finally add water to make up to 1000ml.

Embodiment 2

[0062] Under stirring, first dissolve 20g of SSOPA and 20g of polyethylene glycol (PEG 4000) in 100ml of hot water at about 60°C, then add 40g of alum, 30g of silane coupling agent KH-550 and 470g of sodium methyl siliconate, After uniformity, adjust the pH value to 7.5 with phosphoric acid, and finally add water to make up to 1000ml.

Embodiment 3

[0064] While stirring, first dissolve 20g of SSOPA and 20g of polyethylene glycol (PEG 6000) in 100ml of hot water at about 60°C, then add 40g of alum, 25g of silane coupling agent KH-550 and 475g of sodium methyl siliconate, After uniformity, adjust the pH value to 7.0 with phosphoric acid, and finally add water to make up to 1000ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com