Flame-retardant waterproof exterior wall paint coating

A technology for exterior wall paints and coatings, applied in the direction of fireproof coatings, wax coatings, polyether coatings, etc., can solve the problems of affecting appearance, aging of exterior wall paints, poor flame retardancy, etc., to prevent the intrusion of water and improve water resistance , The effect of waterproof durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

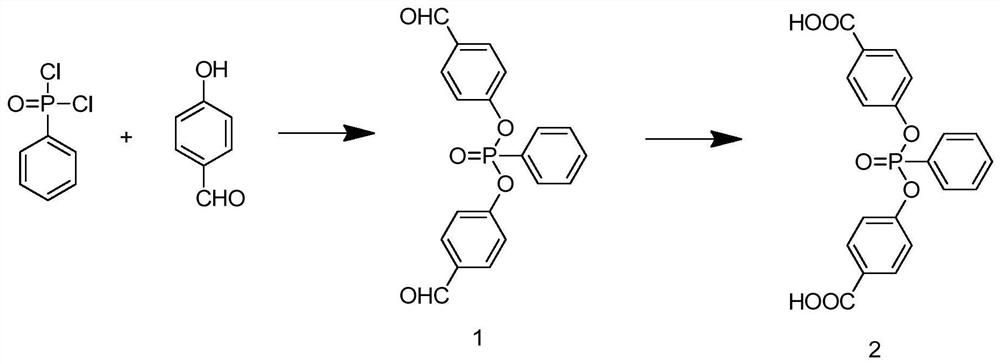

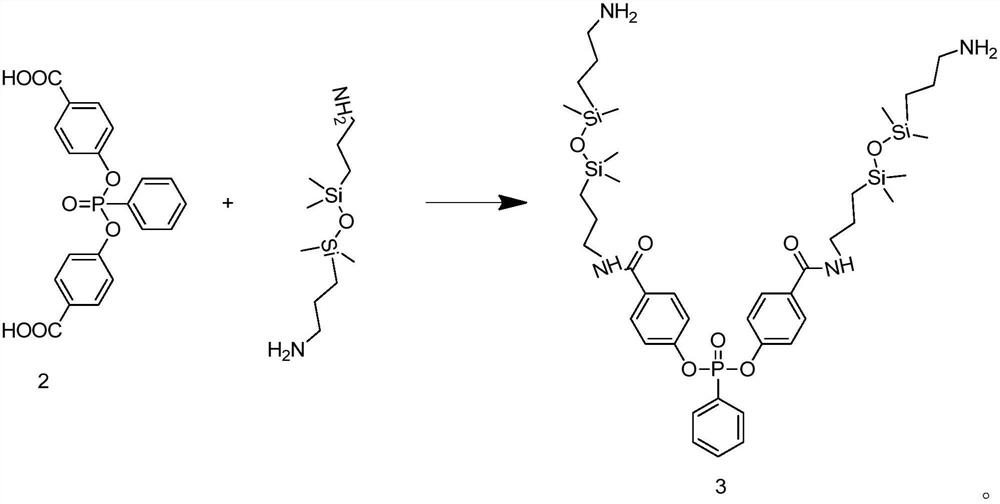

[0033] S1. Preparation of flame retardant components

[0034] Add 38.0g of p-hydroxybenzaldehyde, 150mL of dry acetonitrile and 35.0g of diethanolamine in sequence in the reaction flask, stir at room temperature and dropwise add 29.3g of phenylphosphoryl dichloride into the reaction system within 60min. Raise the temperature to reflux for 24 hours; filter off the diethanolamine hydrochloride, concentrate the filtrate by a rotary evaporator to remove part of the solvent, then pour it into deionized water, and a white solid is precipitated. Washing 3 times, drying in vacuum at 50°C for 48 hours, to obtain intermediate 1 of flame retardant component;

[0035] The reaction formula is as follows:

[0036]

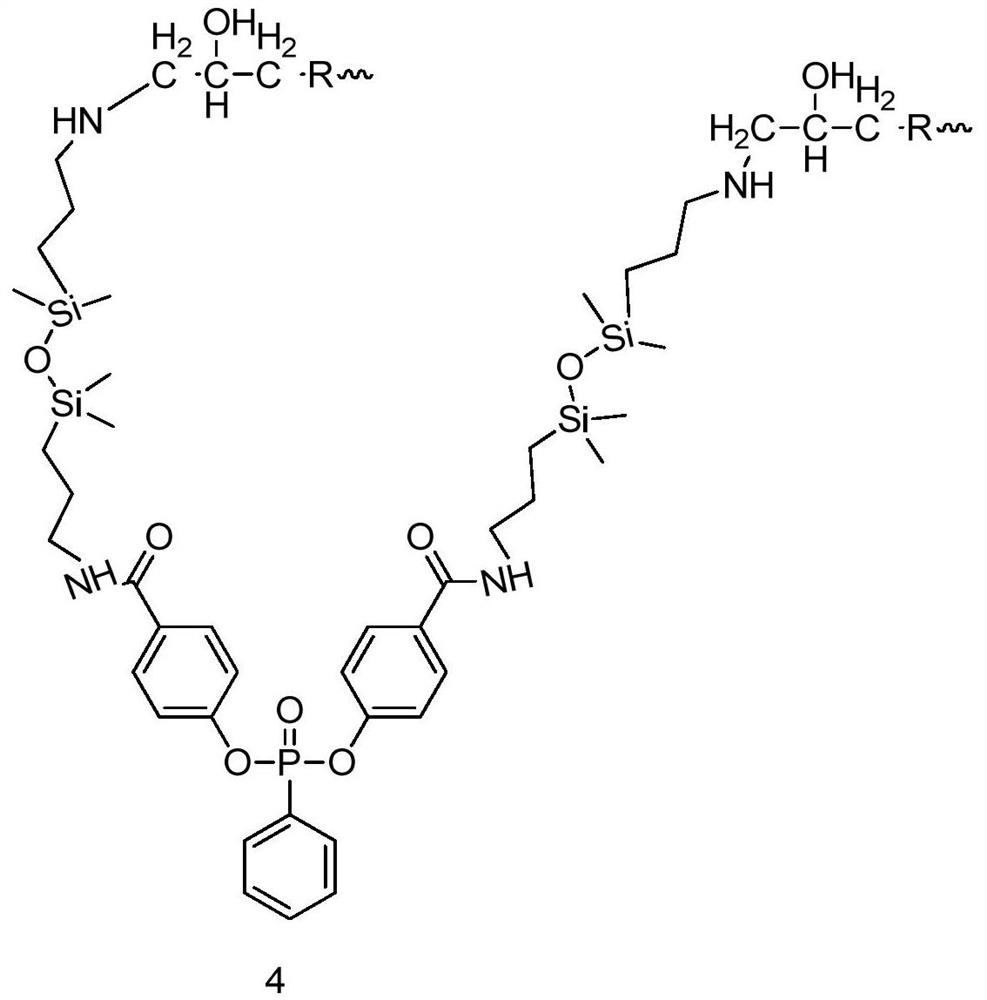

[0037] Then add the flame retardant component intermediate 1 into the reaction flask, add 10% sodium carbonate aqueous solution, start stirring, and when the temperature rises to 66-68°C, slowly add 40% hydrogen peroxide solution dropwise, and the dropwise addition is comple...

Embodiment 1

[0044] A flame-retardant and waterproof exterior wall paint, the weight percentage of each raw material is: 60% epoxy resin, 8% propylene styrene emulsion, 5% phosphorus-containing waterproofing agent, 10% talcum powder, 1% chlorinated paraffin, polyether Polyol 4%, vinyl acetate 6.5%, defoamer 0.5%, ethanol 5%;

[0045] The preparation method of the flame-retardant and waterproof exterior wall paint coating specifically comprises the following steps:

[0046] (1) Curing modification of epoxy resin

[0047] After heating the epoxy resin to 110°C to melt, add phosphorus-containing waterproofing agent in 3 times, add 50% of phosphorus-containing waterproofing agent for the first time, add 30% of phosphorus-containing waterproofing agent for the second time, and add phosphorus-containing waterproofing agent for the third time 10% of the waterproofing agent, after stirring evenly, heat preservation and curing reaction for 2 hours, and a cured modified epoxy resin is obtained, and...

Embodiment 2

[0052] A flame-retardant and waterproof exterior wall paint, the weight percent of each raw material is: epoxy resin 70%, propylene styrene emulsion 5%, phosphorus-containing waterproofing agent 3%, talcum powder 5%, chlorinated paraffin 0.7%, polyether Polyol 2%, vinyl acetate 4%, defoamer 0.3%, ethanol 10%;

[0053] The preparation method of the flame-retardant and waterproof exterior wall paint coating specifically comprises the following steps:

[0054] (1) Curing modification of epoxy resin

[0055] After heating the epoxy resin to 110°C to melt, add phosphorus-containing waterproofing agent in 3 times, add 50% of phosphorus-containing waterproofing agent for the first time, add 30% of phosphorus-containing waterproofing agent for the second time, and add phosphorus-containing waterproofing agent for the third time 10% of the waterproofing agent, after stirring evenly, heat preservation and curing reaction for 2 hours, and obtained a cured modified epoxy resin;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com