Self-adhesive composite waterproof layer for tunnel and paving method of self-adhesive composite waterproof layer

A waterproof layer, self-adhesive technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of waterproof board tearing, holes behind the secondary lining concrete, etc., to avoid being torn, saving procedures, and good self-healing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

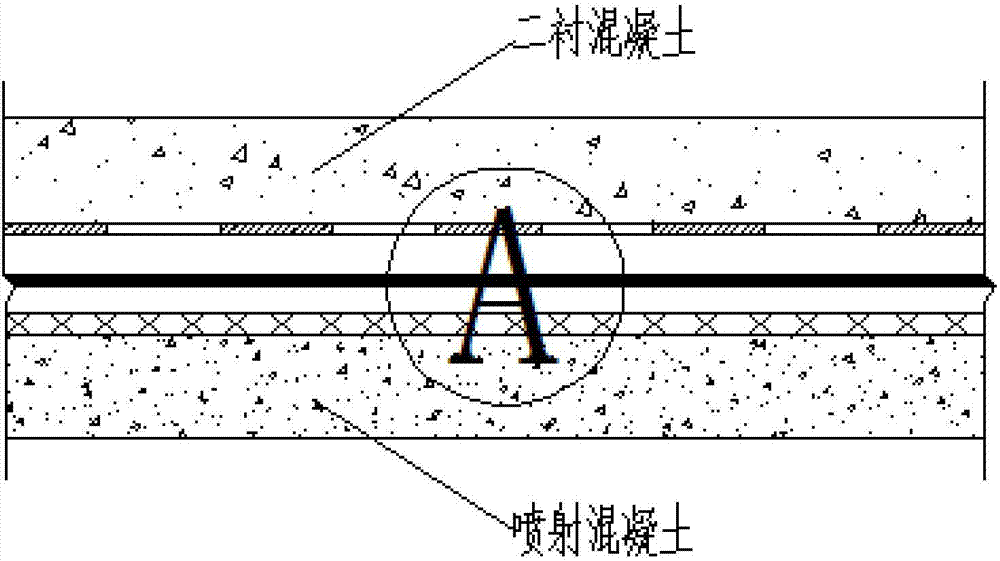

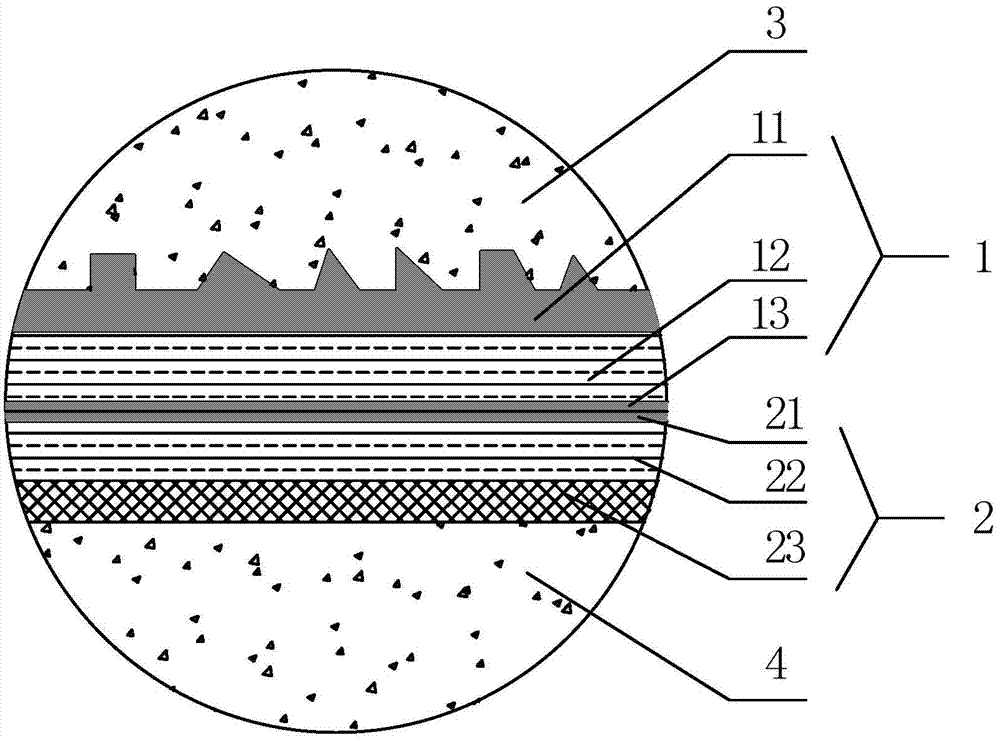

[0028] Such as figure 1 and figure 2 As shown, a self-adhesive composite waterproof layer for tunnels, the waterproof layer is composed of a double-sided self-adhesive film polymer waterproof roll 1 and a single-sided self-adhesive film composite non-woven fabric 2, the double-sided The surface self-adhesive film polymer waterproof roll material 1 includes an asphalt adhesive layer 11, a polymer waterproof material layer 12 and a self-adhesive layer 13 from top to bottom, and the single-sided self-adhesive film composite non-woven fabric 2 is composed of It includes a self-adhesive layer 21, a polymer waterproof material layer 22, and a non-woven fabric layer 23 from top to bottom. The self-adhesive layer 21 of the adhesive film composite non-woven fabric 2 is bonded.

[0029] The polymer waterproof material layer 12 of the double-sided self-adhesive film polymer waterproof coiled material 1 has a thickness of 1.0 mm to 2.0 mm, specifically 1.0 mm, 1.2 mm, 1.5 mm, 1.7 mm, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com