Anti-mite antibacterial polyester staple fiber and preparation method thereof

A polyester staple fiber, anti-mite technology, applied in the direction of botanical equipment and methods, fiber chemical characteristics, acaricide, etc., can solve the problems of poor temperature resistance, endocrine disorder, skin irritation, etc., and achieve high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

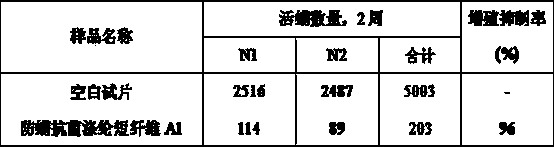

Embodiment 1

[0051] 10kg of Taiji stone, 25kg of boric acid, 40kg of clay, and 15kg of silicic acid were mixed and ground into powders of 1-100 μm, which were pressed into tablets using a powder tableting machine and a mold. The heating rate is increased to 1500°C, calcined for 2~4h, and the anti-mite ceramic powder A1 of 1-60μm is formed after high temperature compounding.

[0052] Using silver nitrate 2kg, sodium chloride 0.63kg, metatitanic acid 7.9kg as raw materials, Ag + and Cl - AgCl is formed by direct reaction and precipitation, and AgCl is used as the seed crystal, and the pH is adjusted to 9-10, so that the metatitanic acid precipitates Ti(OH) on the surface of the seed crystal. 4 , after suction filtration, washing and drying, in a box-type resistance furnace with a heating rate of 10 °C / min to 800 °C, and calcined for 2-3 h to obtain silver-loaded nano-titania composite antibacterial powder A1.

[0053] The preparation method of the anti-mite and antibacterial polyester stap...

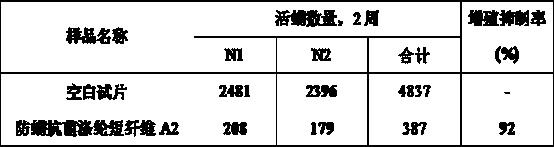

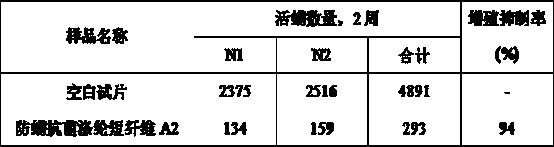

Embodiment 2

[0061] 6kg of Taiji stone, 12kg of boric acid, 30kg of clay, and 8kg of silicic acid were mixed and ground into powders of 1-100 μm, which were pressed into tablets using a powder tableting machine and a mold. The heating rate is increased to 1500°C, calcined for 2~4 hours, and the anti-mite ceramic powder A2 of 1-60 μm is formed after high temperature compounding.

[0062] Using silver nitrate 2kg, sodium chloride 0.63kg, metatitanic acid 8.7kg as raw materials, Ag + and Cl - AgCl is formed by direct reaction and precipitation, and AgCl is used as the seed crystal, and the pH is adjusted to 9-10, so that the metatitanic acid precipitates Ti(OH) on the surface of the seed crystal. 4 , after suction filtration, washing and drying, in a box-type resistance furnace at a heating rate of 10 °C / min, the temperature was raised to 800 °C and calcined for 2-3 h to obtain silver-loaded nano-titania composite antibacterial powder A2.

[0063] The preparation method of the anti-mite and...

Embodiment 3

[0071] Taiji stone 4kg, boric acid 8kg, clay 18kg, silicic acid 6kg were mixed and ground into powders of 1-100 μm, which were pressed into tablets using a powder tableting machine and a mold. The heating rate is increased to 1500°C, calcined for 2 to 4 hours, and the anti-mite ceramic powder B1 of 1-60 μm is formed after high temperature compounding.

[0072] Using silver nitrate 2kg, sodium chloride 0.63kg, metatitanic acid 8.42kg as raw materials, Ag + and Cl - AgCl is formed by direct reaction and precipitation, and AgCl is used as the seed crystal, and the pH is adjusted to 9-10, so that the metatitanic acid precipitates Ti(OH) on the surface of the seed crystal. 4 , after suction filtration, washing and drying, in a box-type resistance furnace with a heating rate of 10 °C / min to 800 °C, and calcined for 2-3 h to obtain silver-loaded nano-titania composite antibacterial powder B1.

[0073] Blend 25kg of micron-scale heat-storage anti-mite ceramic powder B1 and 75kg of P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com