Control method for upward and downward head bending of plate blank

A control method and the technology of warping buckle heads, which are applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as high labor intensity, production stagnation, and different control effects, and achieve flatness improvement, easy maintenance, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

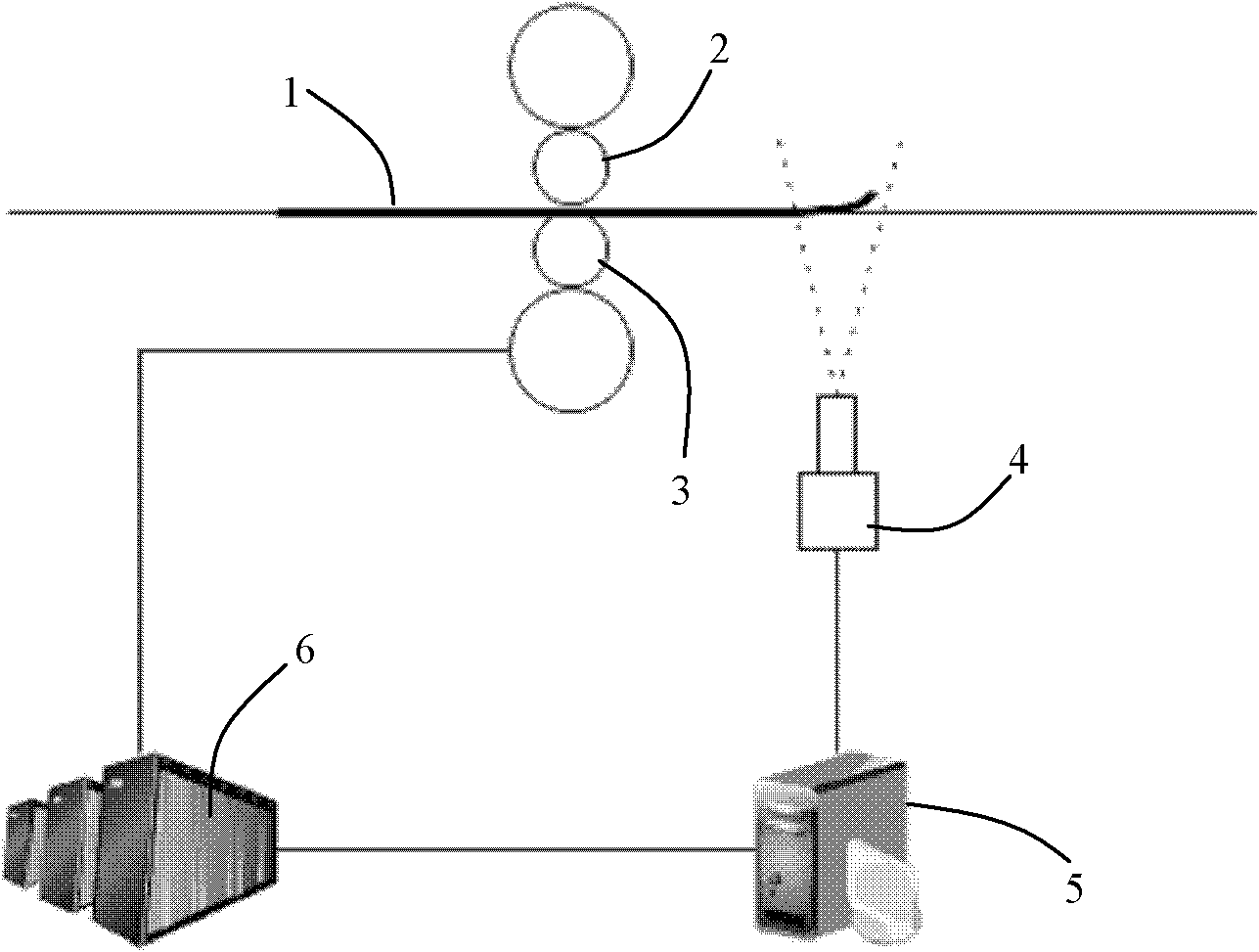

Method used

Image

Examples

Embodiment 1

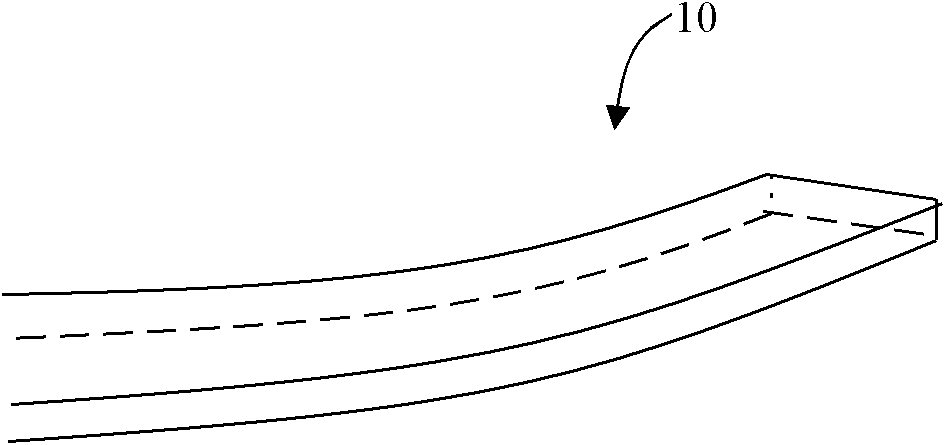

[0154] Embodiment 1 (head warping situation):

[0155] refer to Figure 10 , the current slab thickness Δh = 15cm, the lower roll rolling speed V = 2.3m / s in this pass. According to the steel type and pass before the slab is rolled, the speed difference setting value obtained from the layer file is ΔQ old = 4%, which means that the speed of the lower roll of the slab is 4% faster than that of the upper roll, and the slab warps upward after the current rolling pass, such as figure 1 shown in . The image measurement function separates the edge of the upper surface of the slab from the background, the sampling interval is 1.5m, and the number of sampling points is 20 to represent the warping curve of the slab head. The coordinates of these 20 points are as follows Figure 5 As shown in , the specific values are as follows:

[0156] Form 2

[0157] serial number

1

2

3

4

5

6

7

8

9

10

X=

...

Embodiment 2

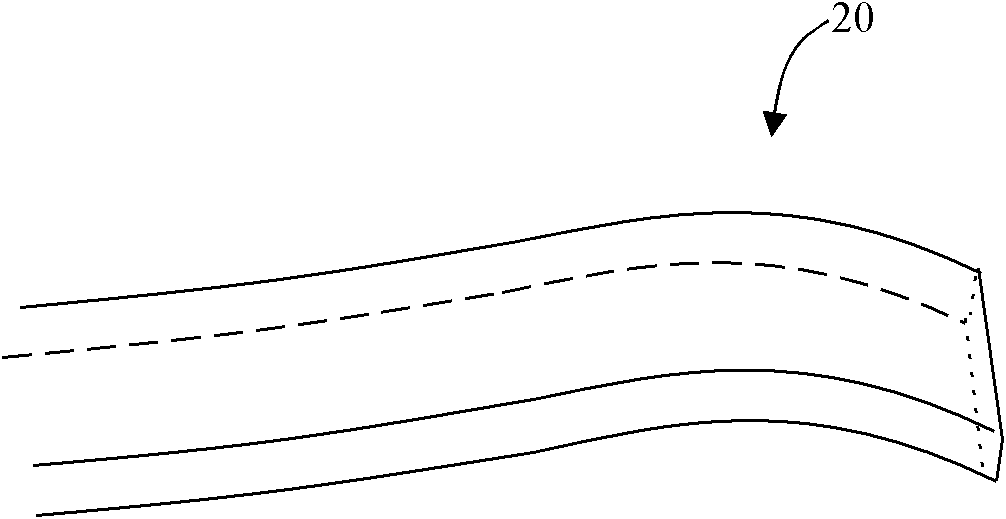

[0204] Embodiment 2 (discount situation):

[0205] like figure 2 As shown, the current slab thickness Δh=19.7cm, the rolling speed of the lower roll V=2.3m / s, and the speed difference setting value obtained from the layer file according to the steel type and pass before rolling is ΔQ old = 0%, it means that there is no speed difference between the upper and lower rolls, and the slab is bent downward after rolling in the current pass, such as figure 2 shown in . The image measurement function separates the edge of the upper surface of the slab from the background, and uses 20 sampling points to represent the warping curve of the slab head, and the sampling interval is 1.5m. The coordinates of these 20 points are as follows Image 6 As shown, the specific values are as follows:

[0206] serial number

1

2

3

4

5

6

7

8

9

10

X=

0

7.8

15.5

23.2

31

38.7

46....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com