Patents

Literature

2403results about "Insulating layers/substrates working" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

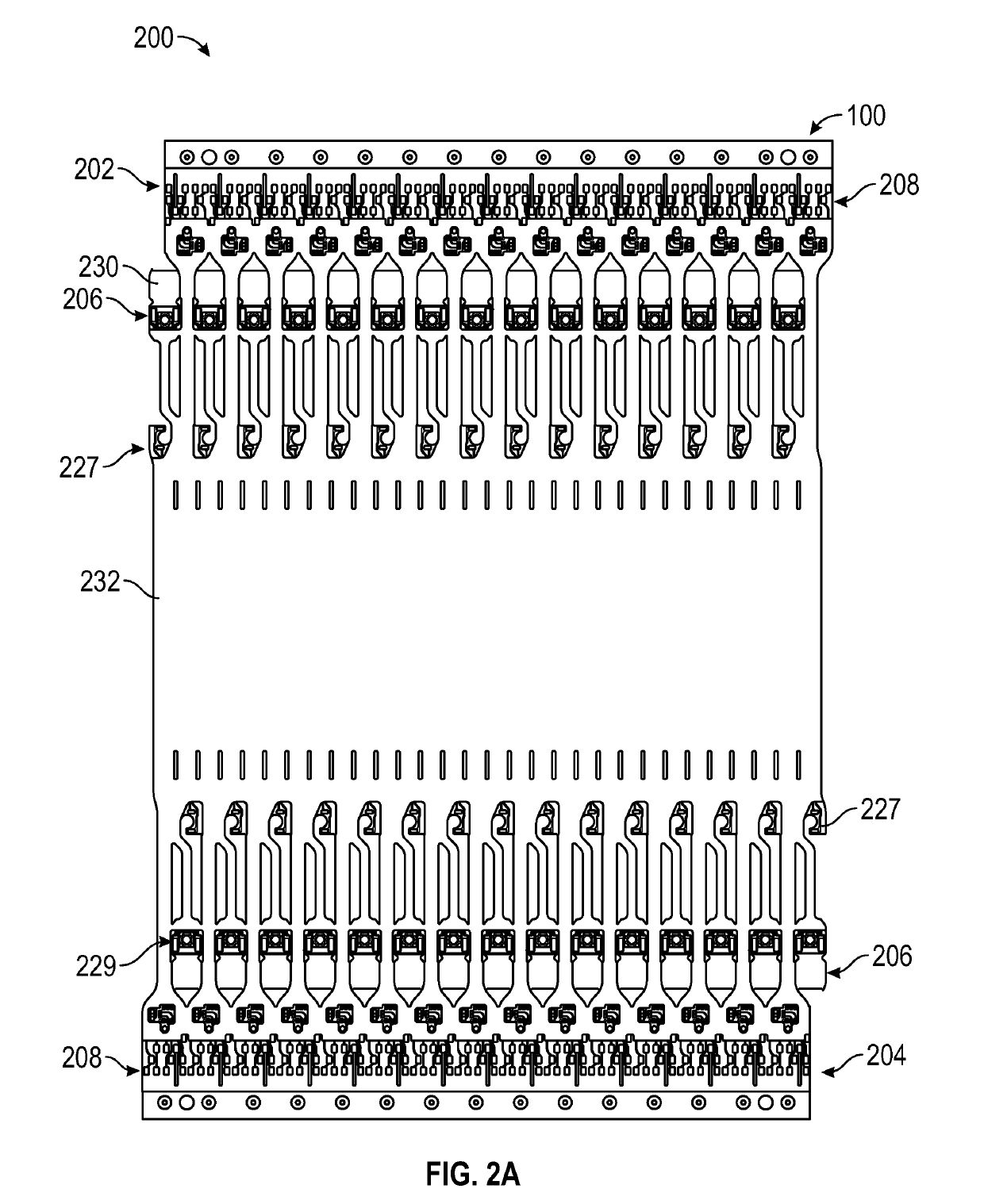

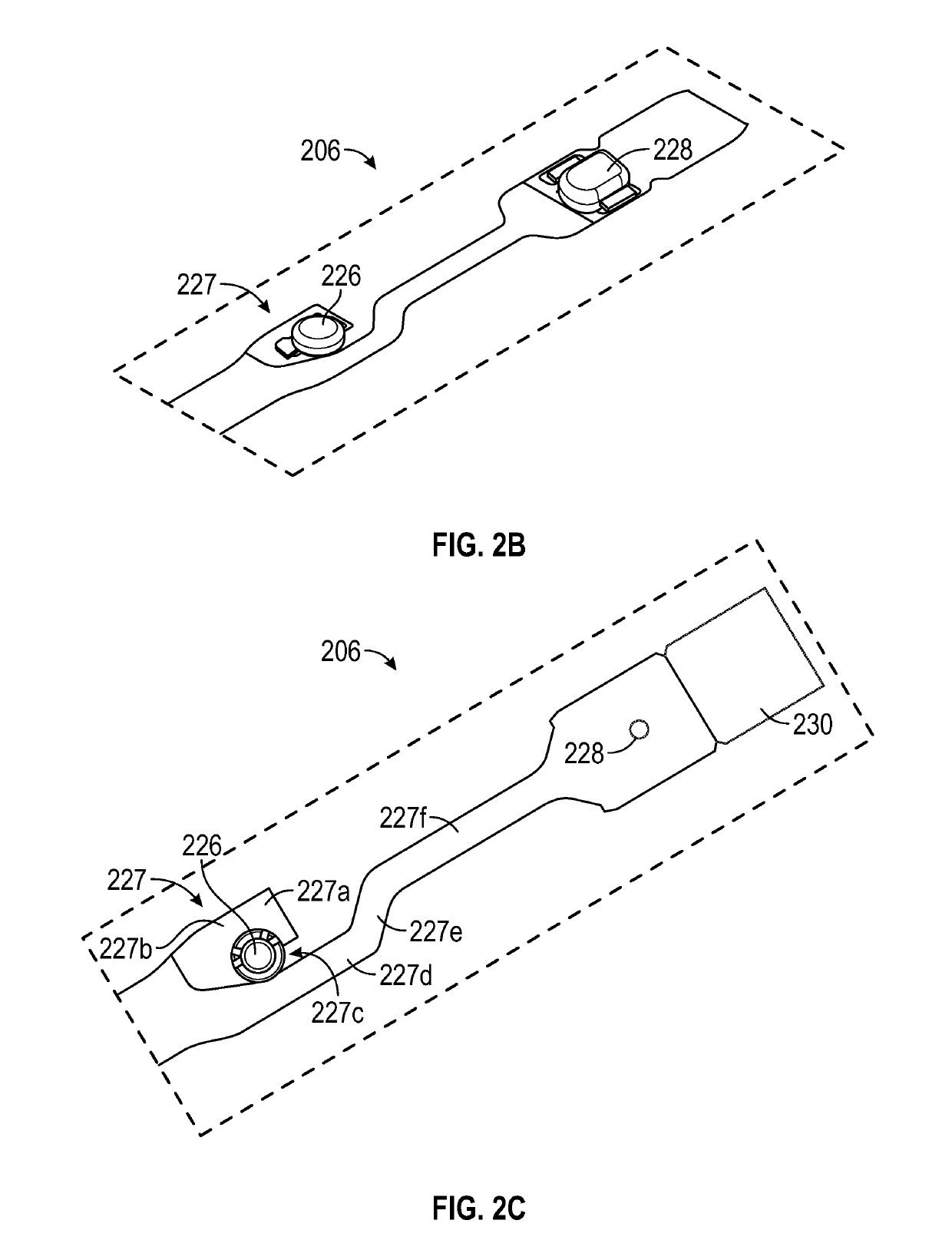

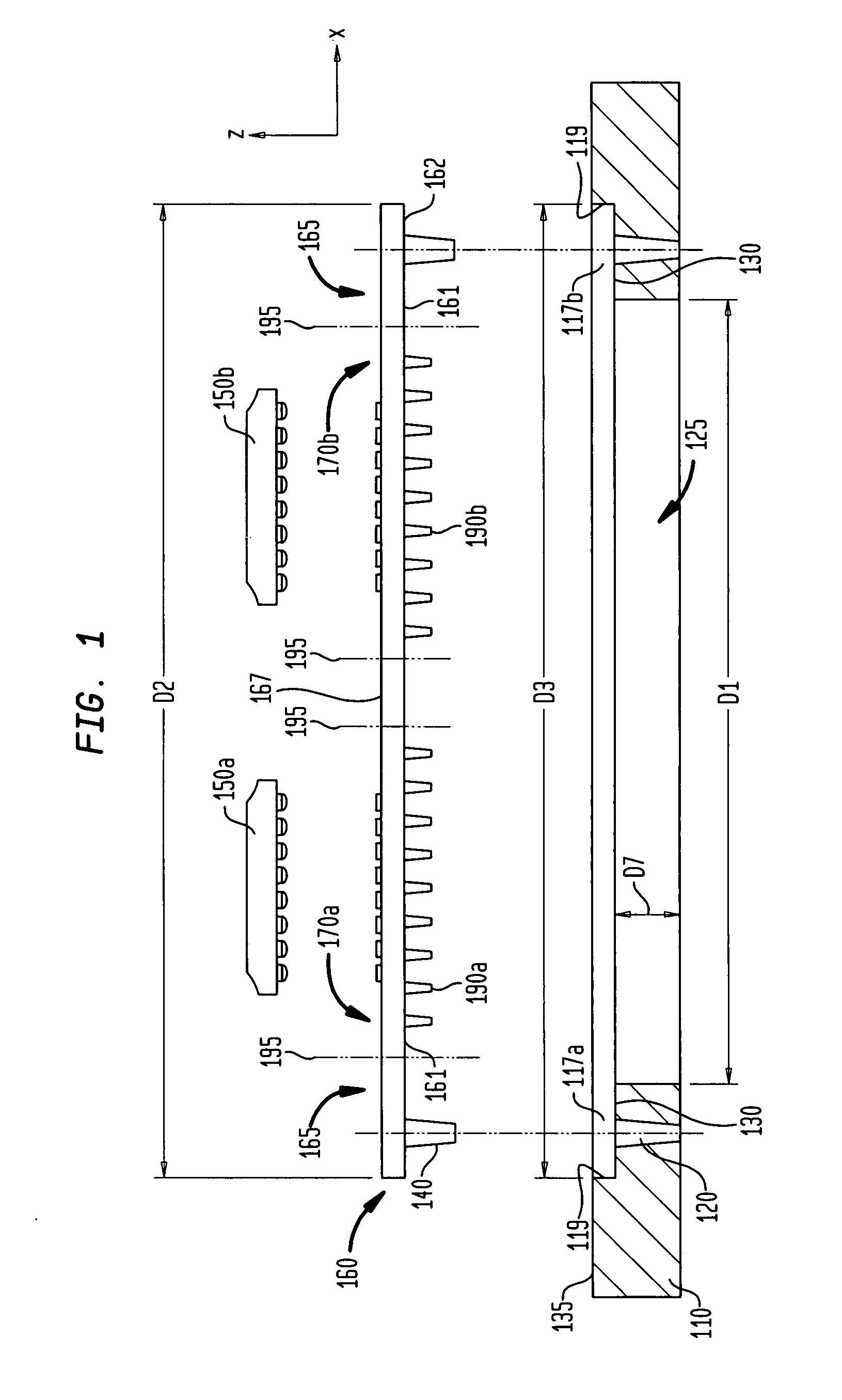

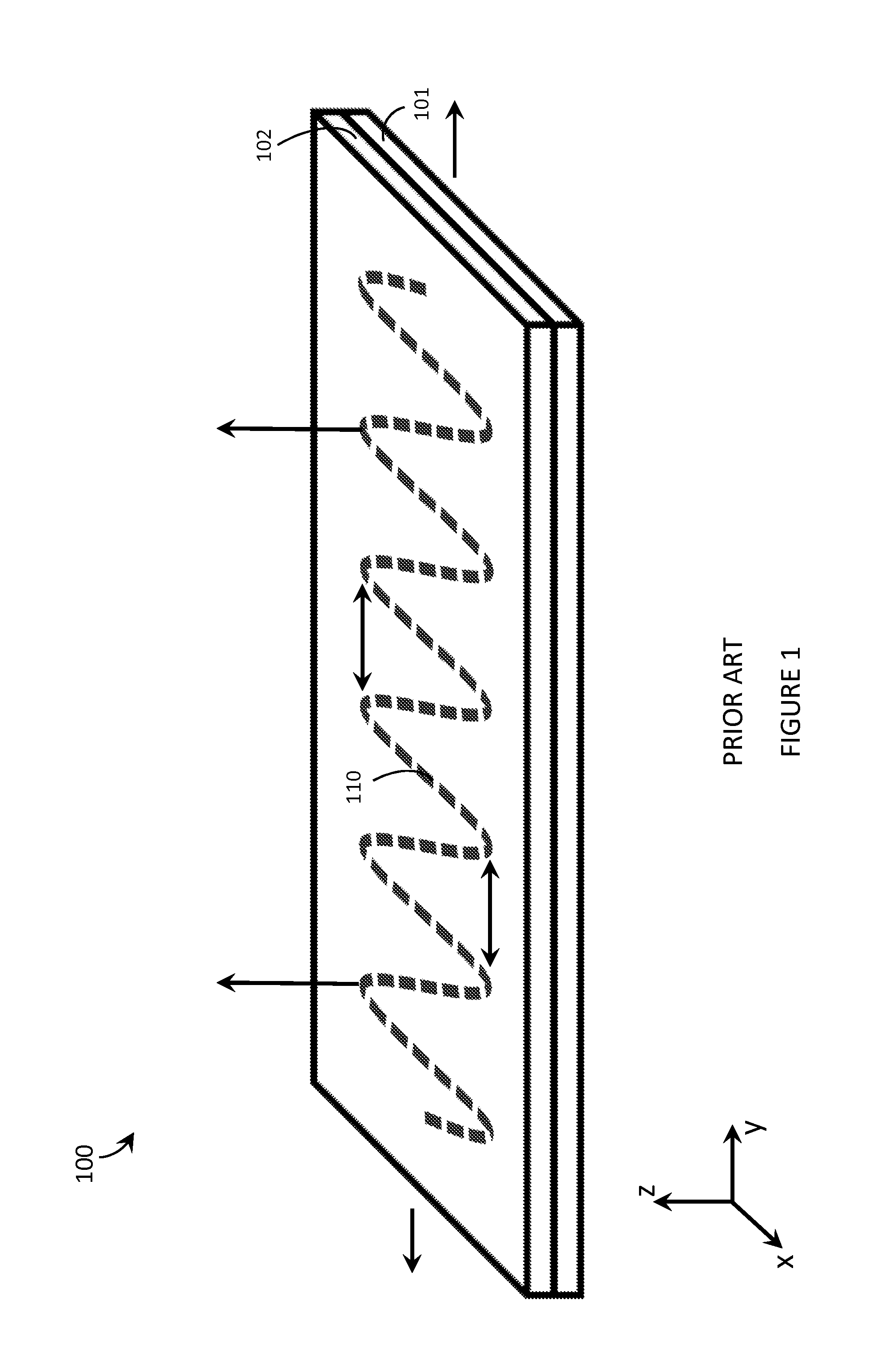

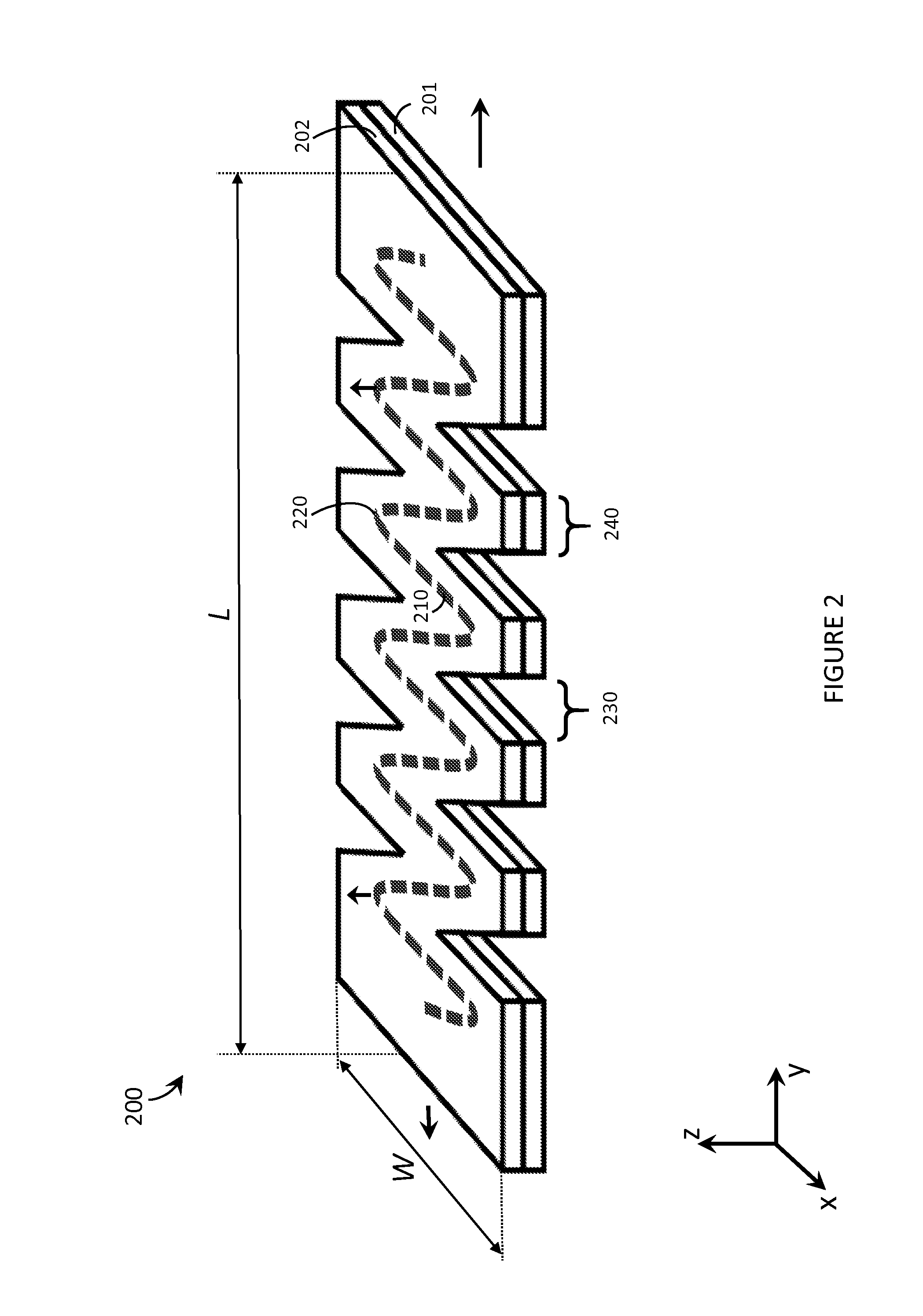

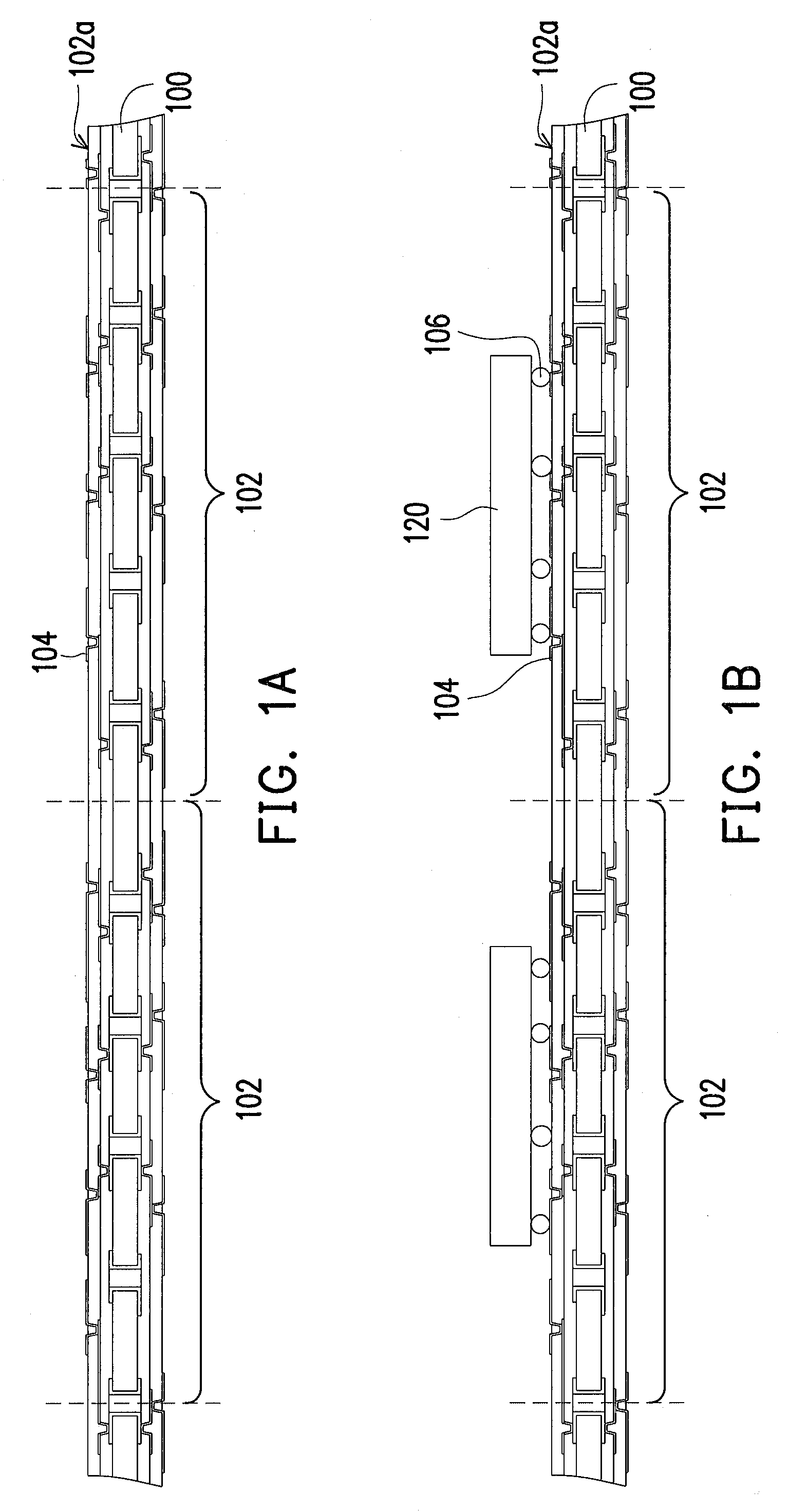

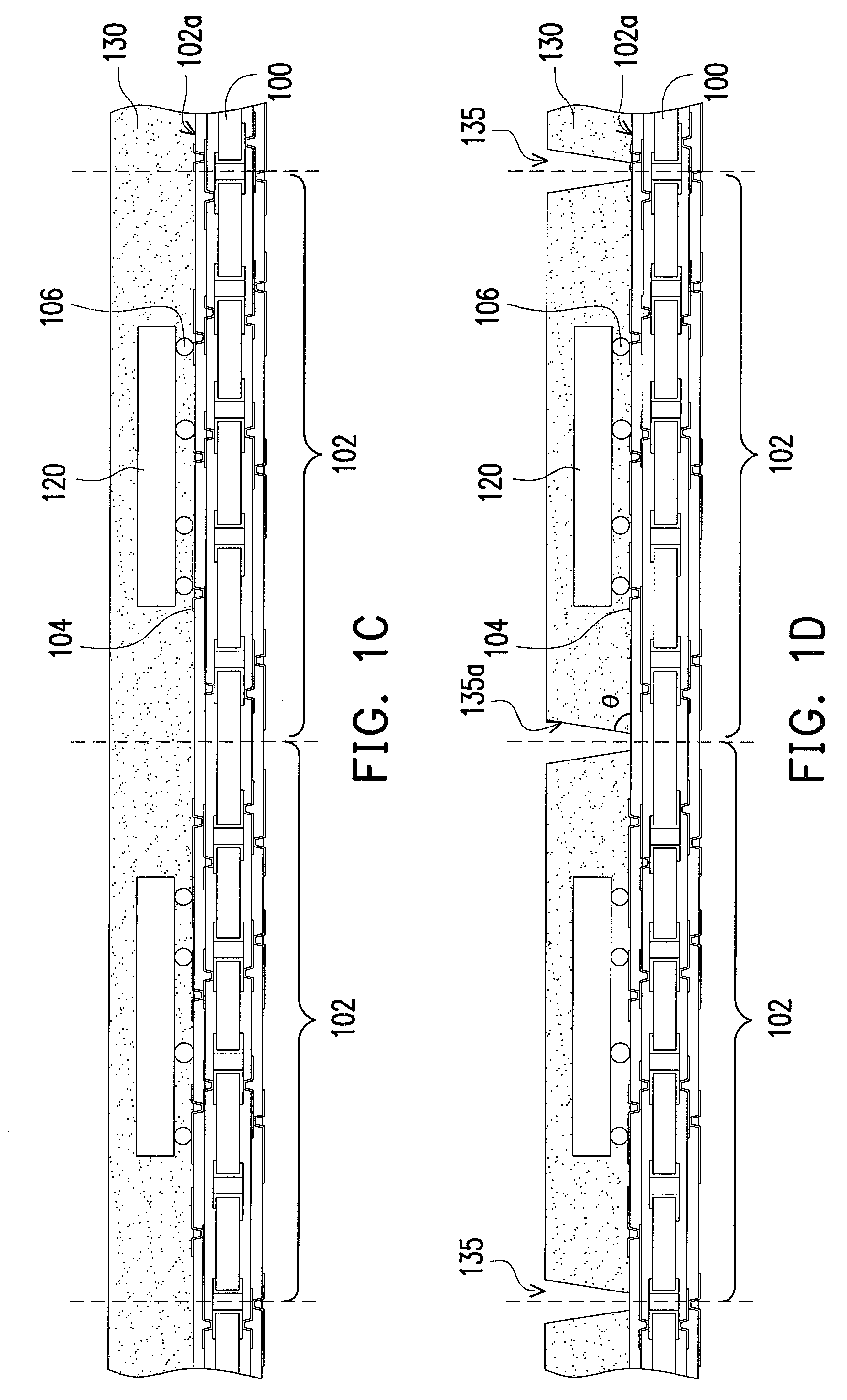

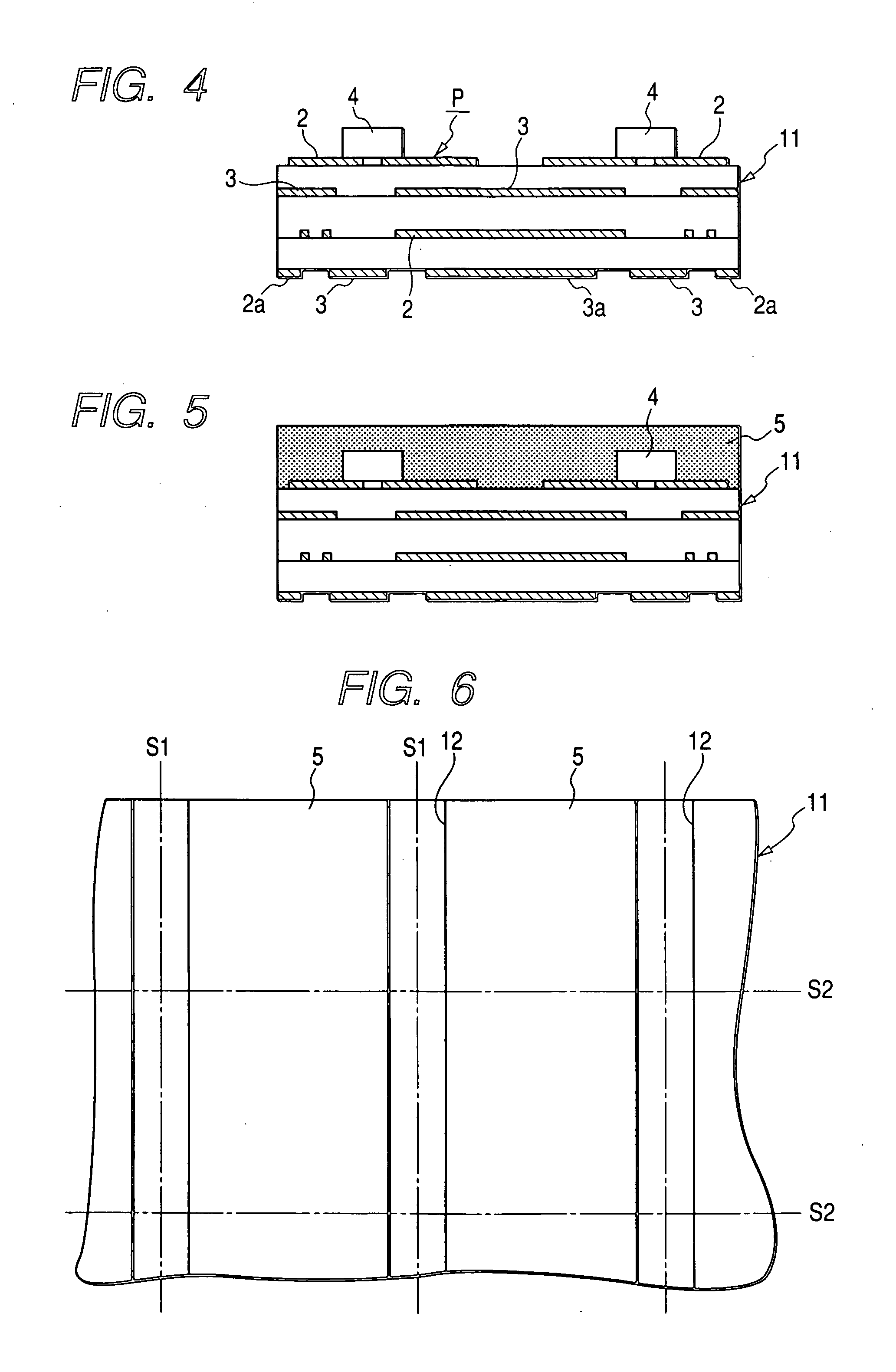

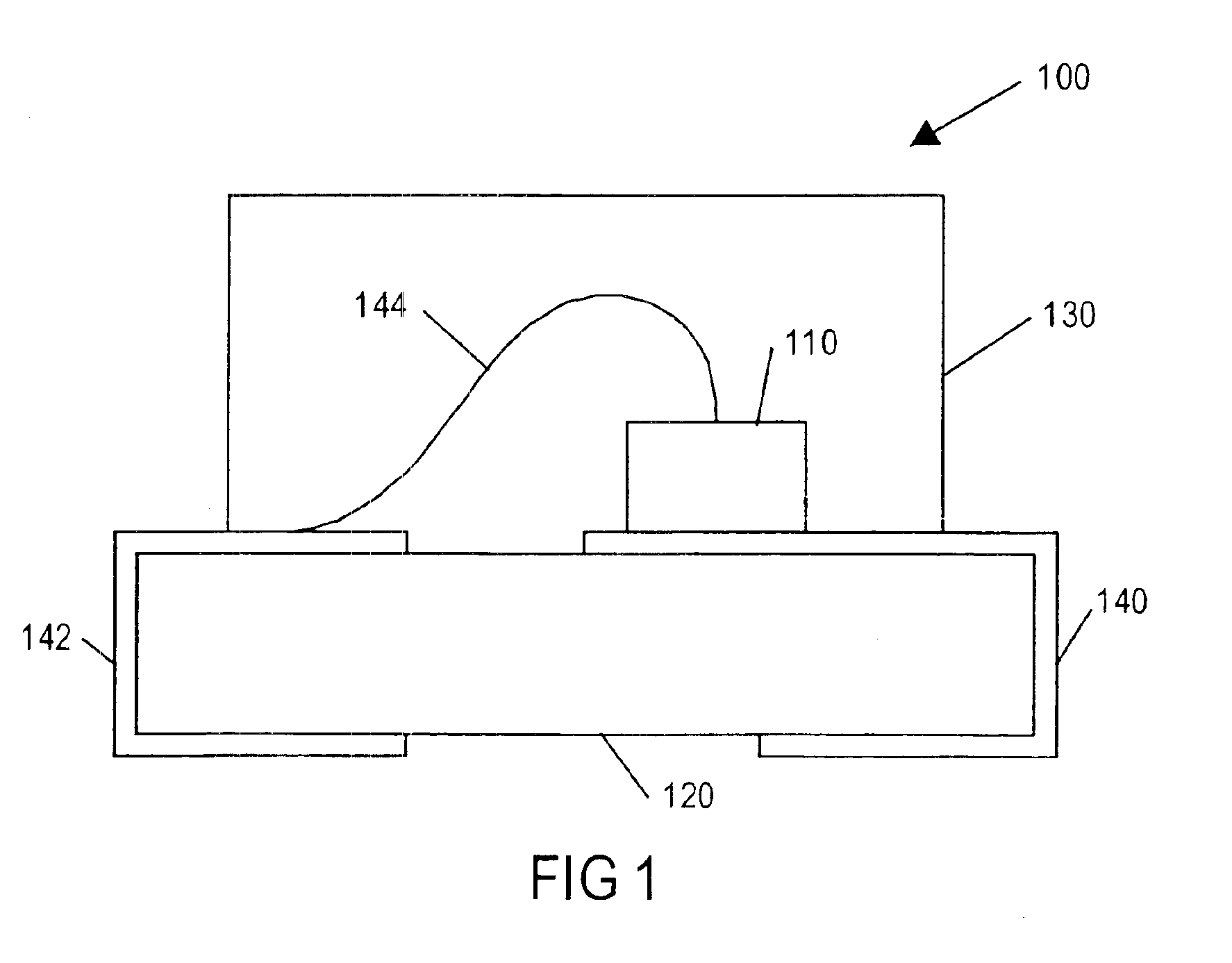

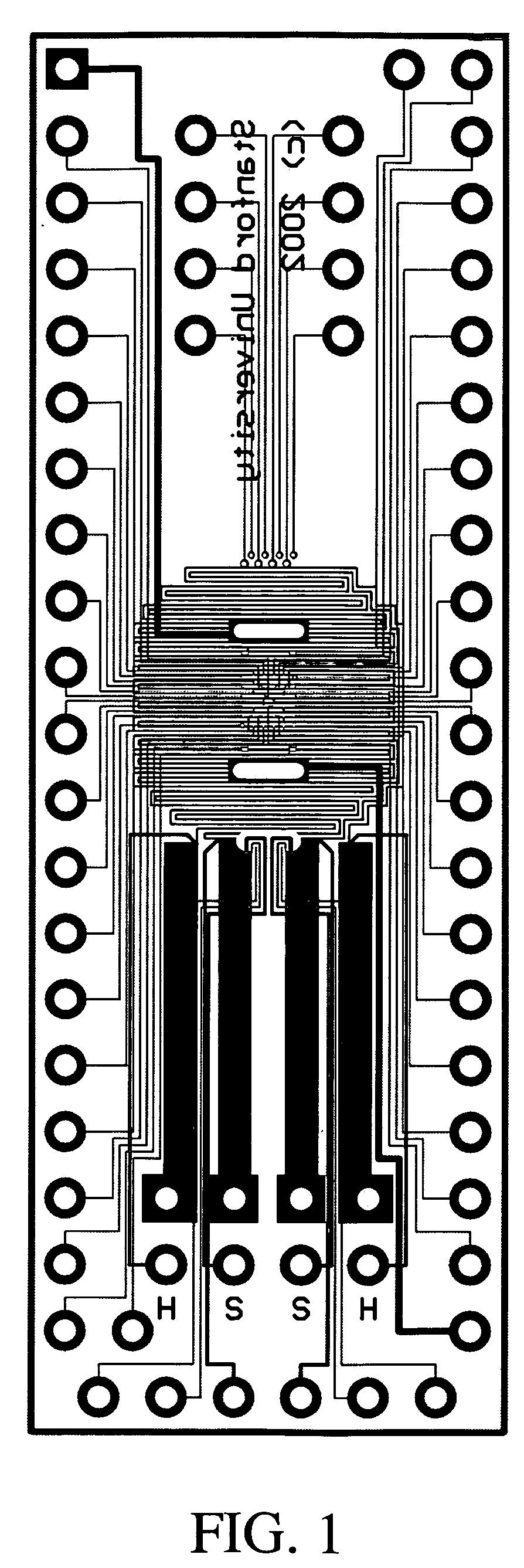

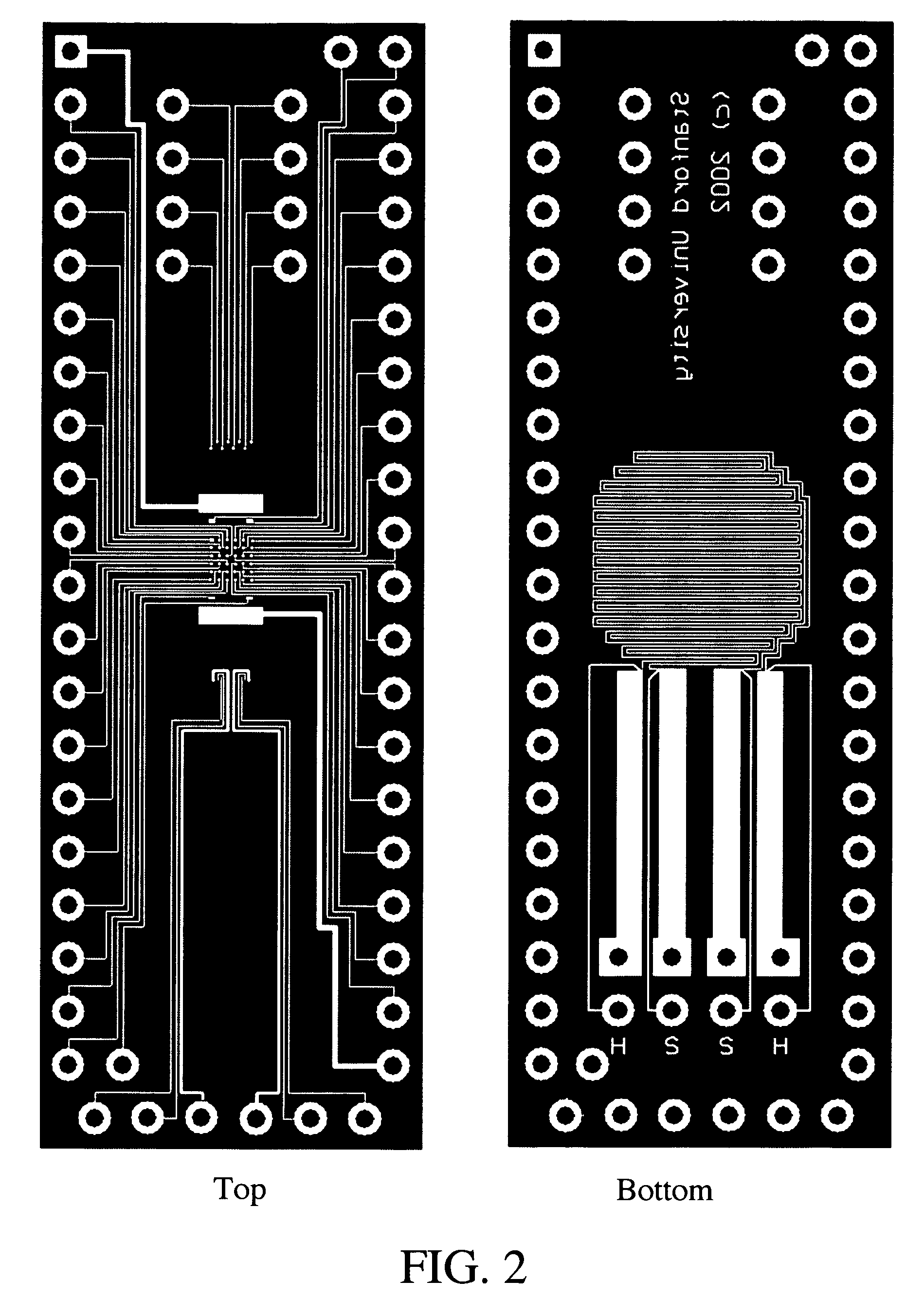

Fold flex circuit for lnop

ActiveUS20160234944A1Low costOptimized material usageDiagnostics using lightPrinted circuit aspectsFolded formFold-forming

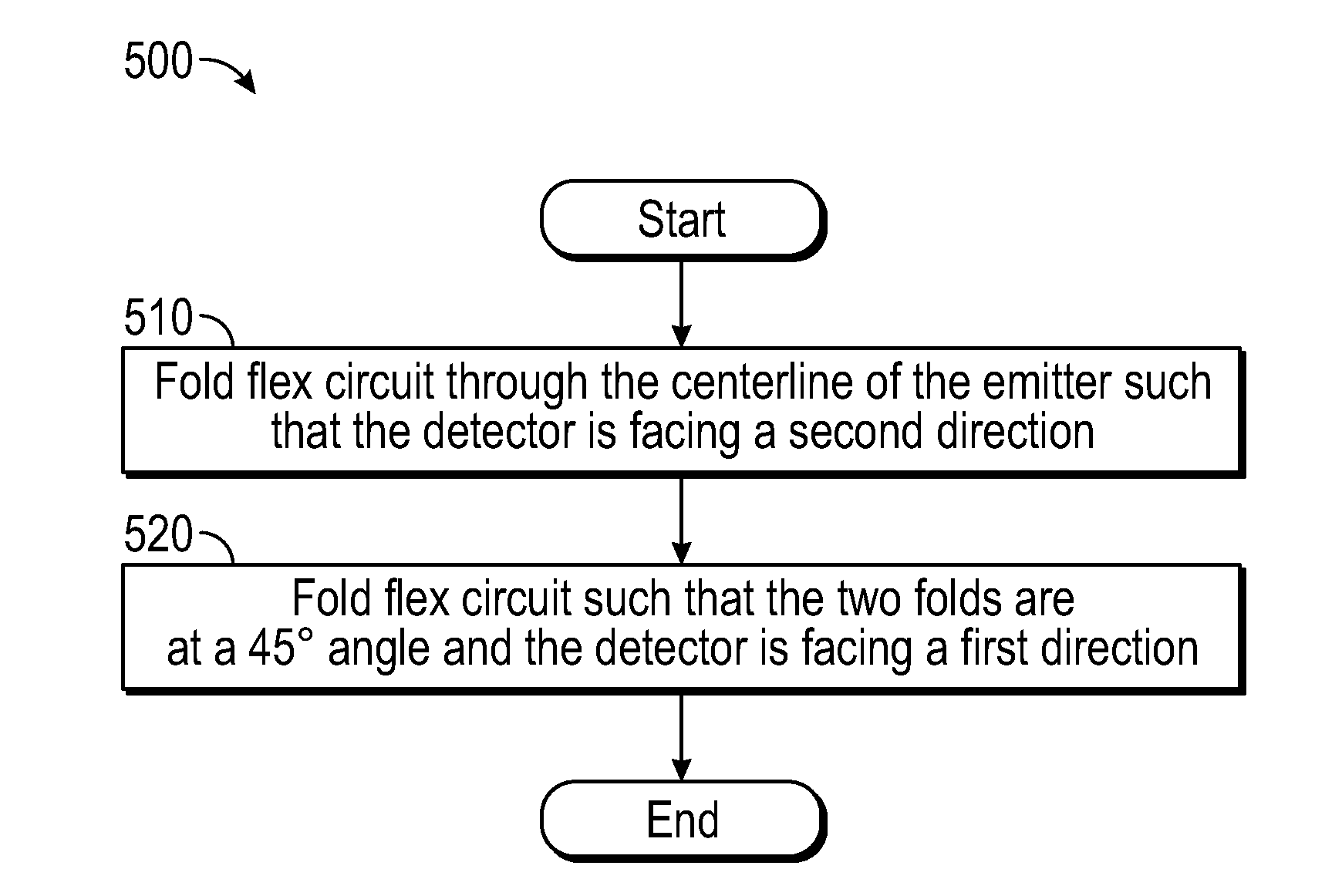

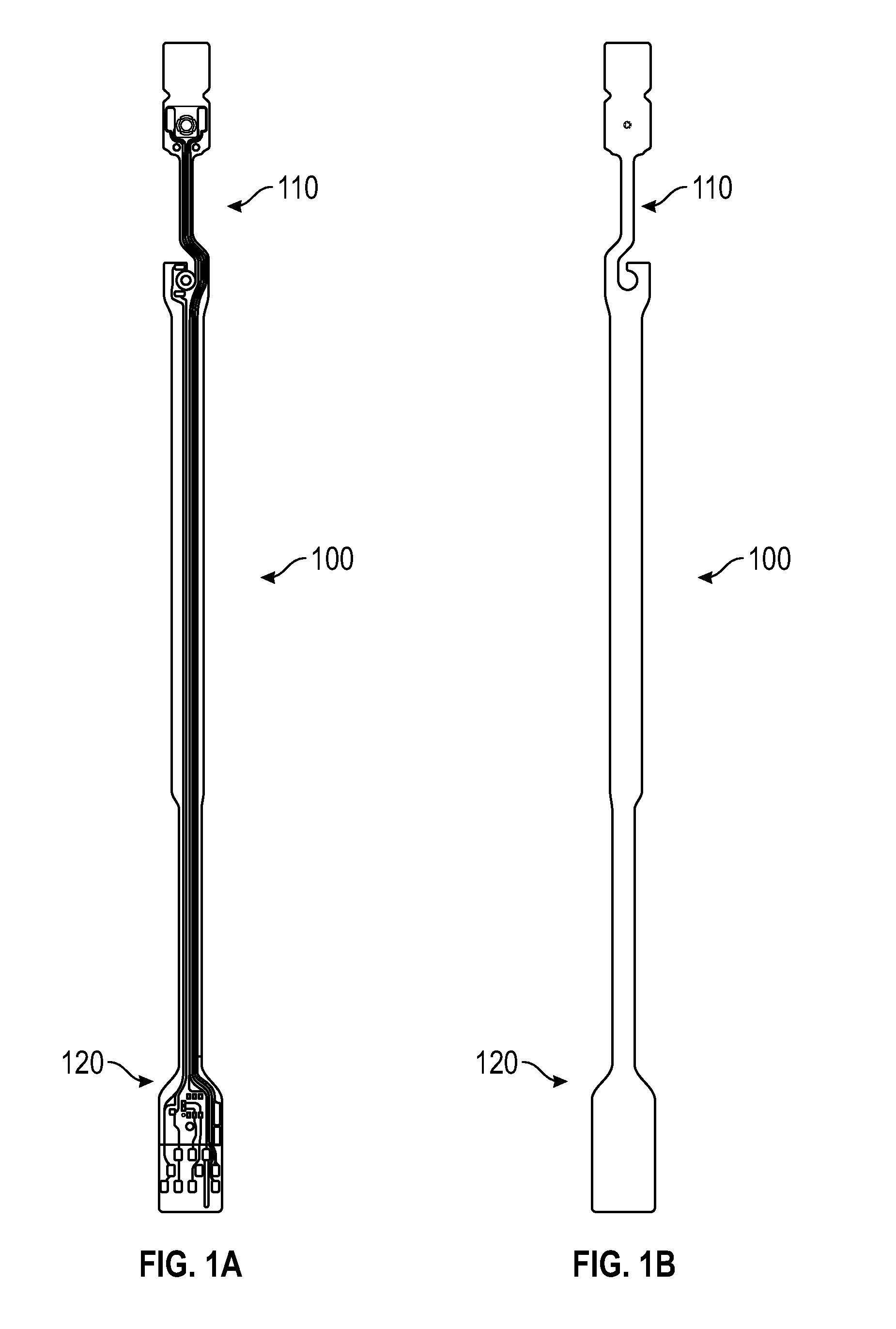

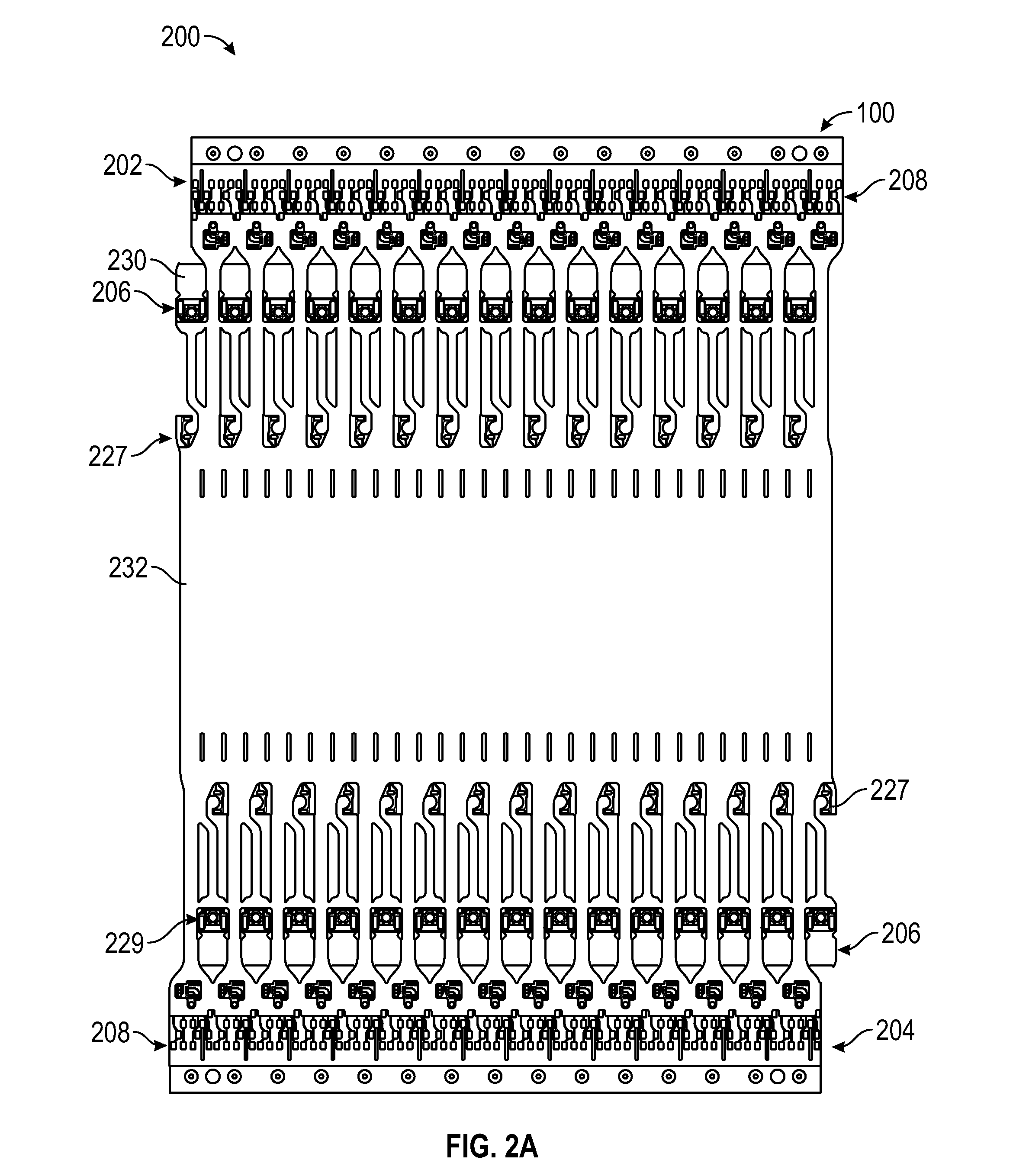

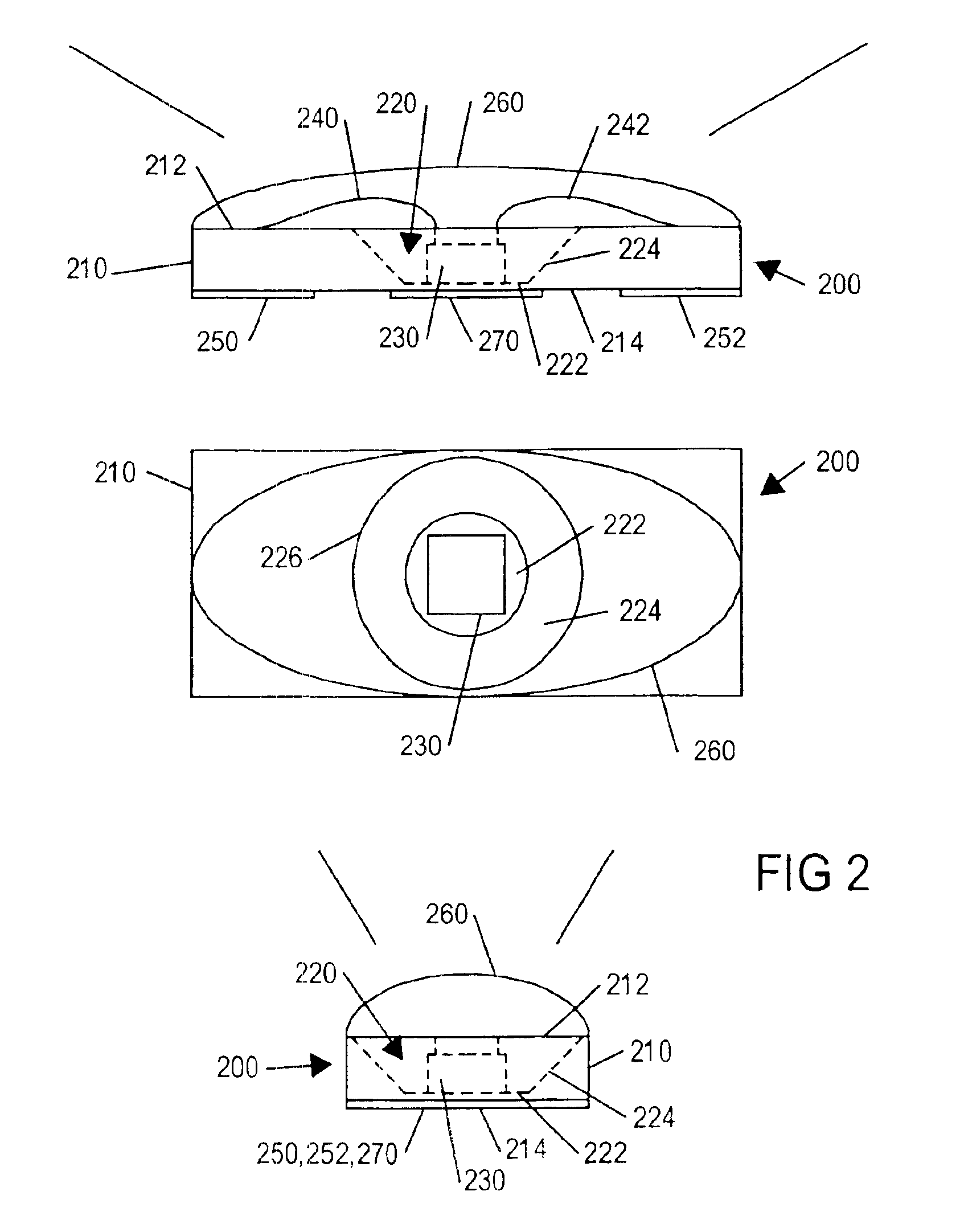

Various sensors and methods of assembling sensors are described. In some embodiments, the sensor assembly includes a first end, a body portion, and a second end. The first end can include a neck portion and a connector portion and the second end can include a flap, a first component, a neck portion, and a second component. A method is also described for sensor folding. The method can include using a circuit with an attached emitter and a detector that is separated by a portion of the circuit. The method can also include folding the portion of the circuit such that a first fold is created through the emitter and folding the portion of the circuit such that a second fold is created such that the first fold and second fold form an angle.

Owner:MASIMO CORP

Fold flex circuit for LNOP

ActiveUS10327337B2Low costMaximize amount of materialDiagnostics using lightPrinted circuit aspectsFolded formEngineering

Various sensors and methods of assembling sensors are described. In some embodiments, the sensor assembly includes a first end, a body portion, and a second end. The first end can include a neck portion and a connector portion and the second end can include a flap, a first component, a neck portion, and a second component. A method is also described for sensor folding. The method can include using a circuit with an attached emitter and a detector that is separated by a portion of the circuit. The method can also include folding the portion of the circuit such that a first fold is created through the emitter and folding the portion of the circuit such that a second fold is created such that the first fold and second fold form an angle.

Owner:MASIMO CORP

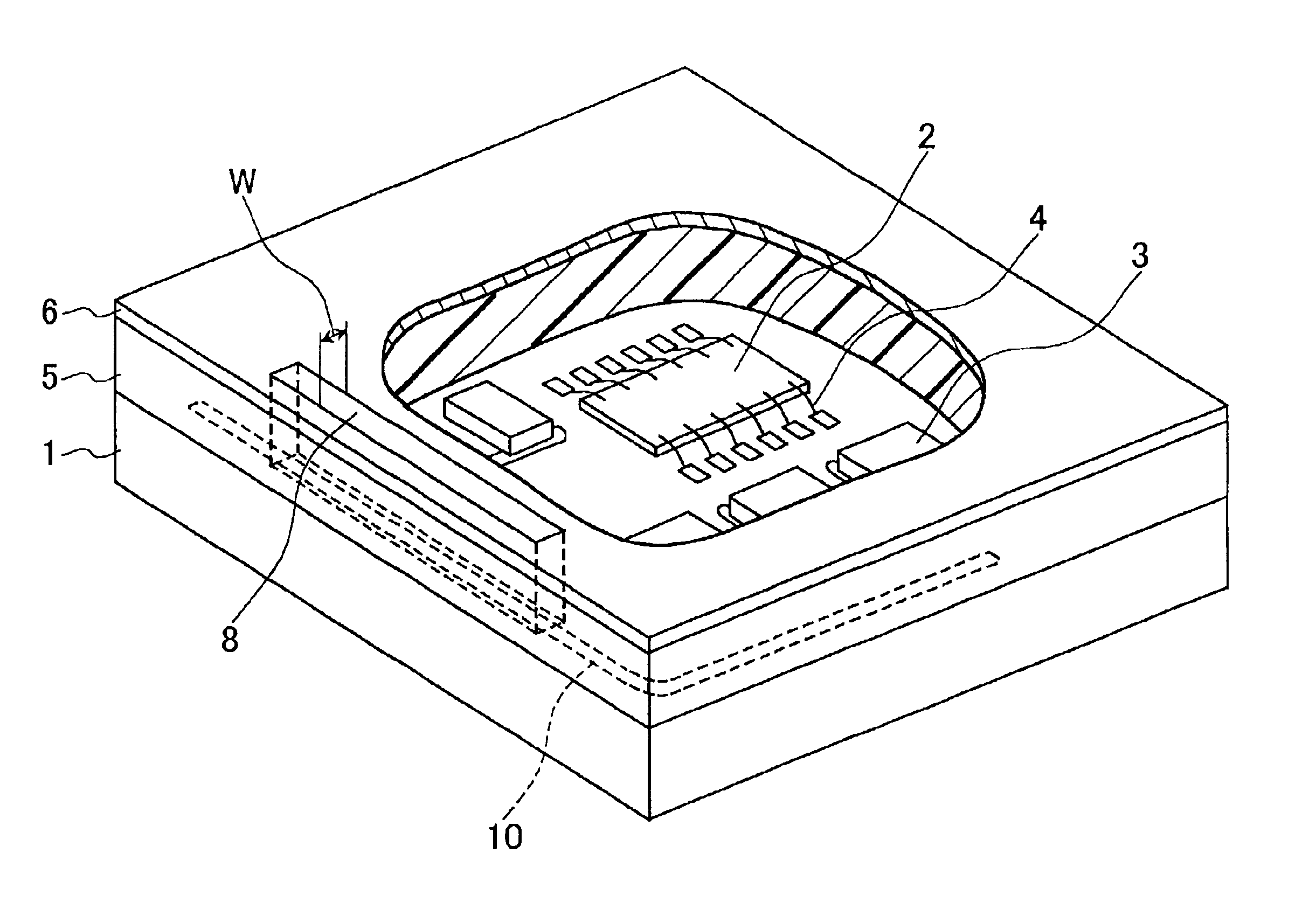

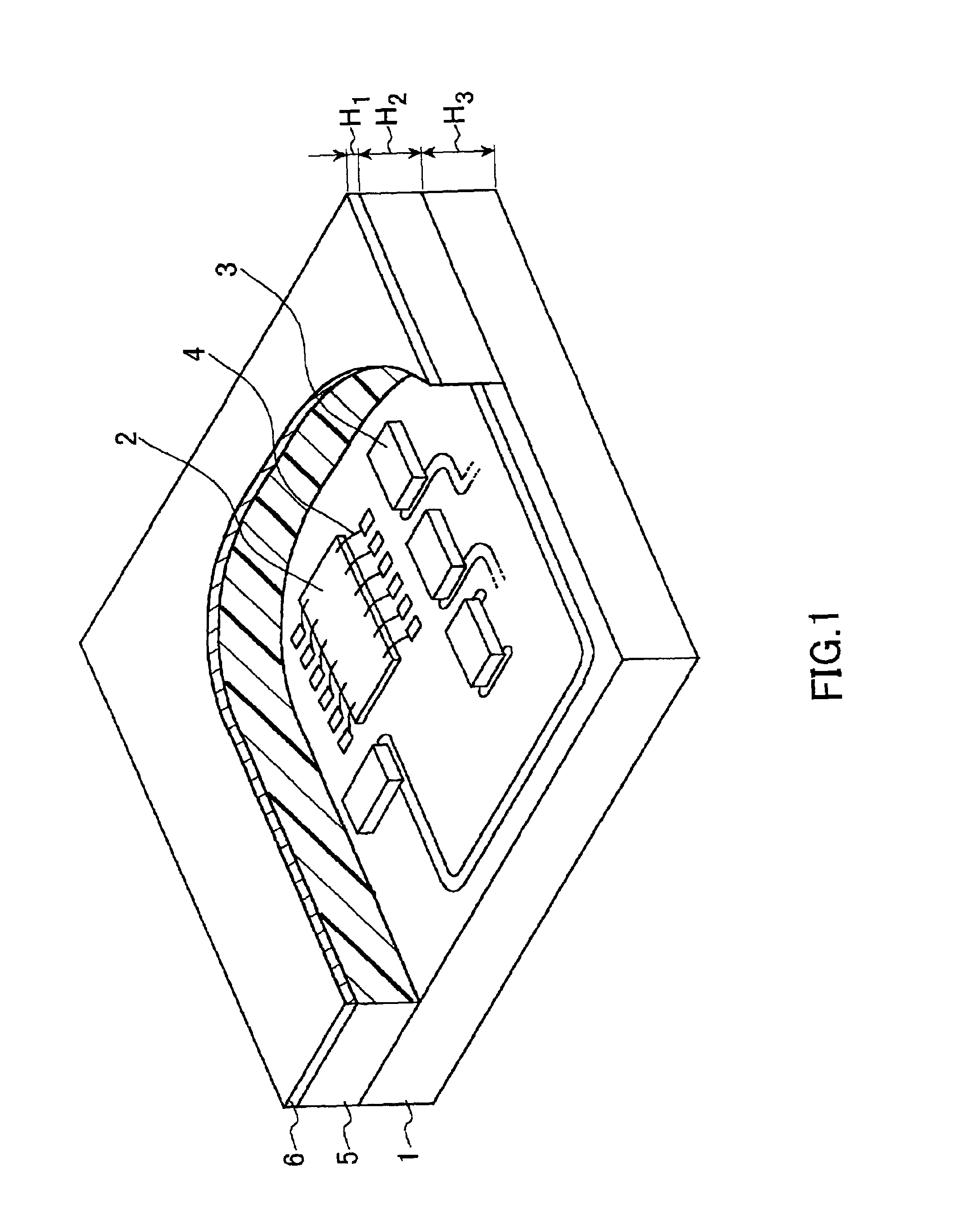

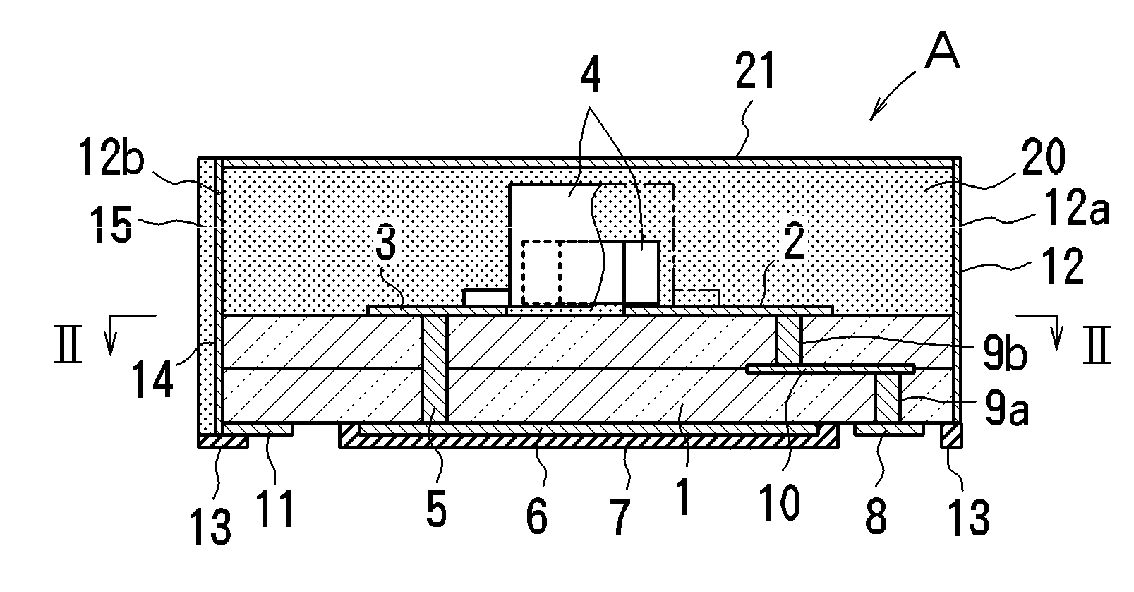

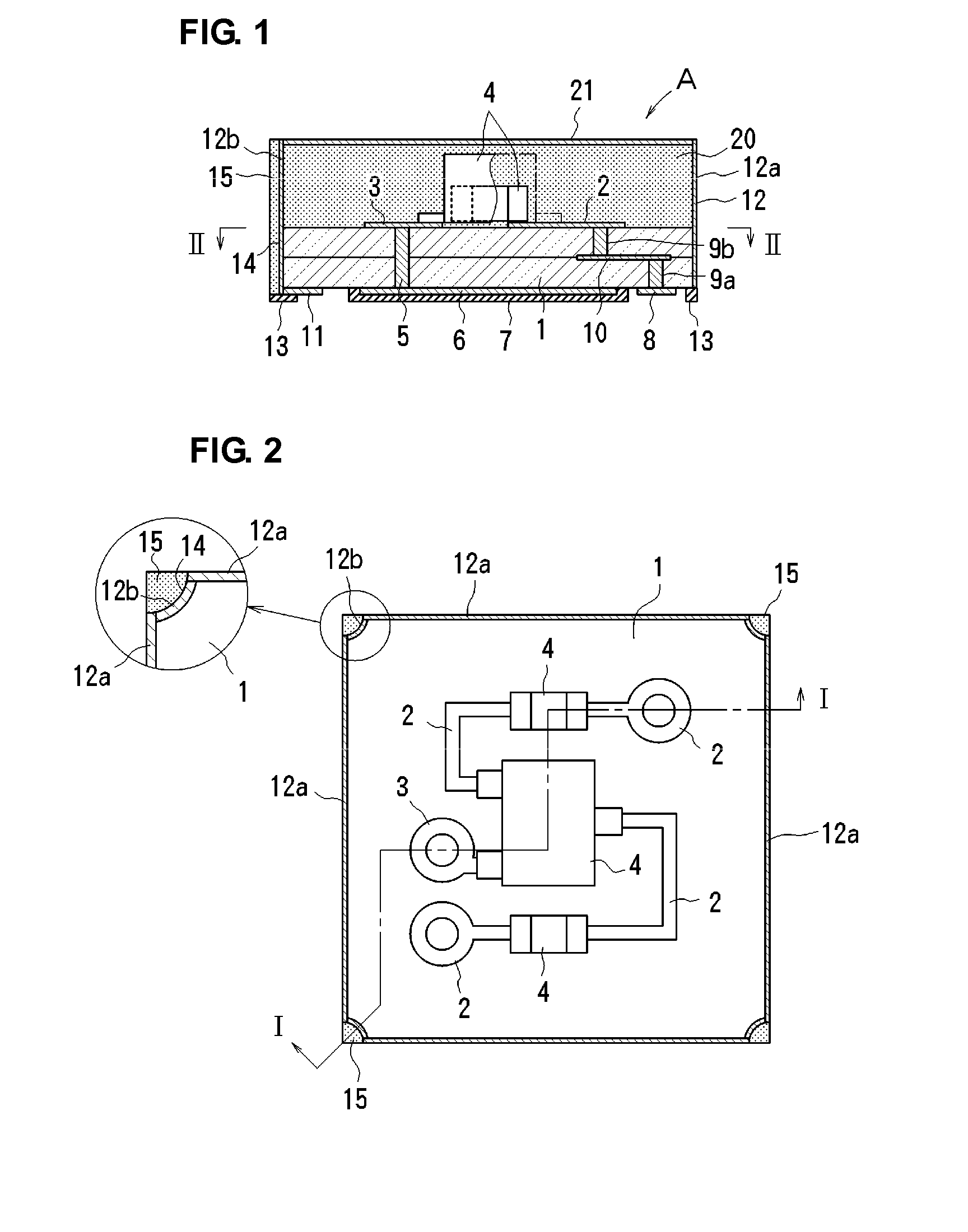

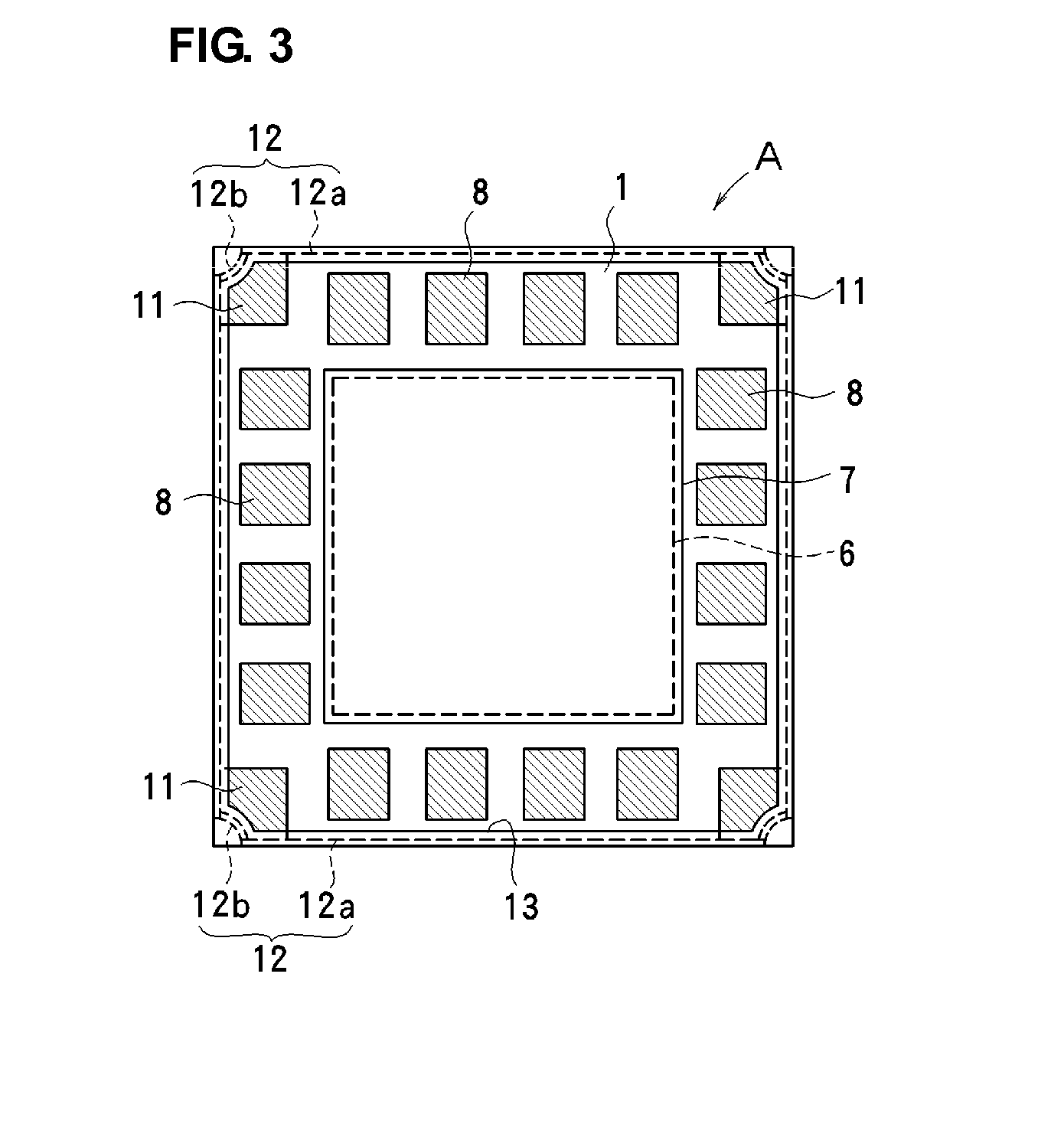

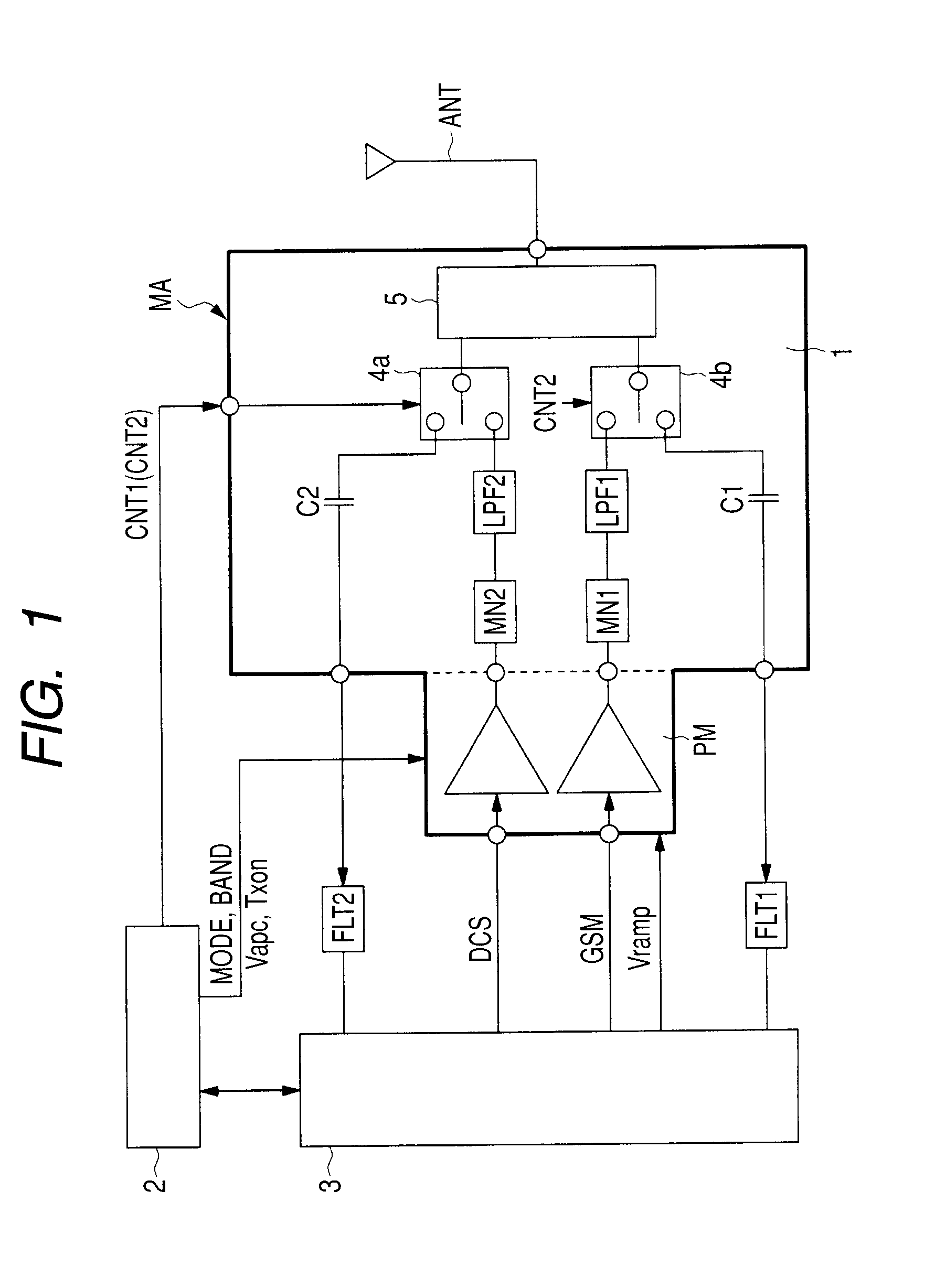

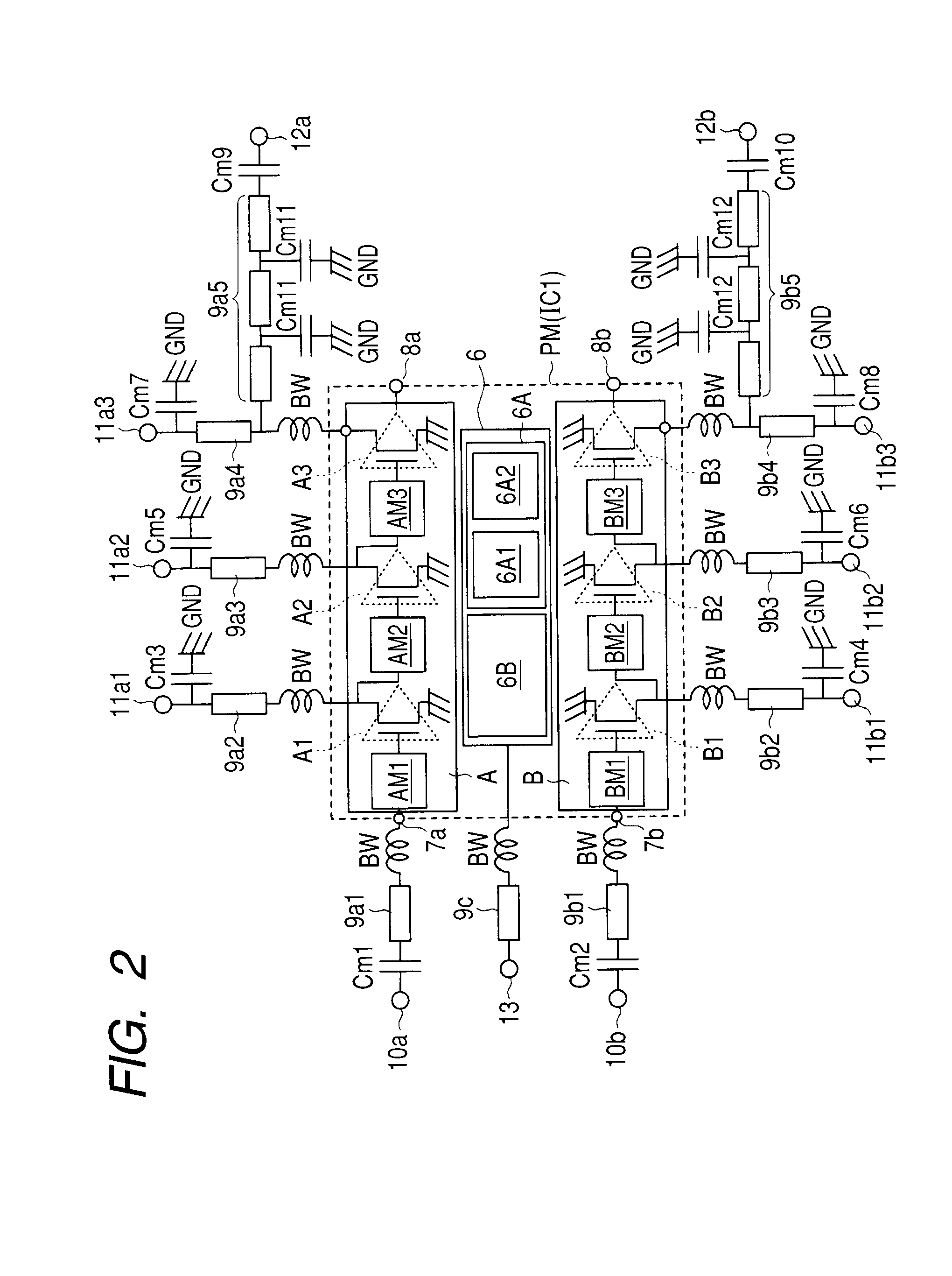

High-frequency module and method for manufacturing the same

InactiveUS7081661B2Reduce electromagnetic influencePliability problemMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectronic component

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

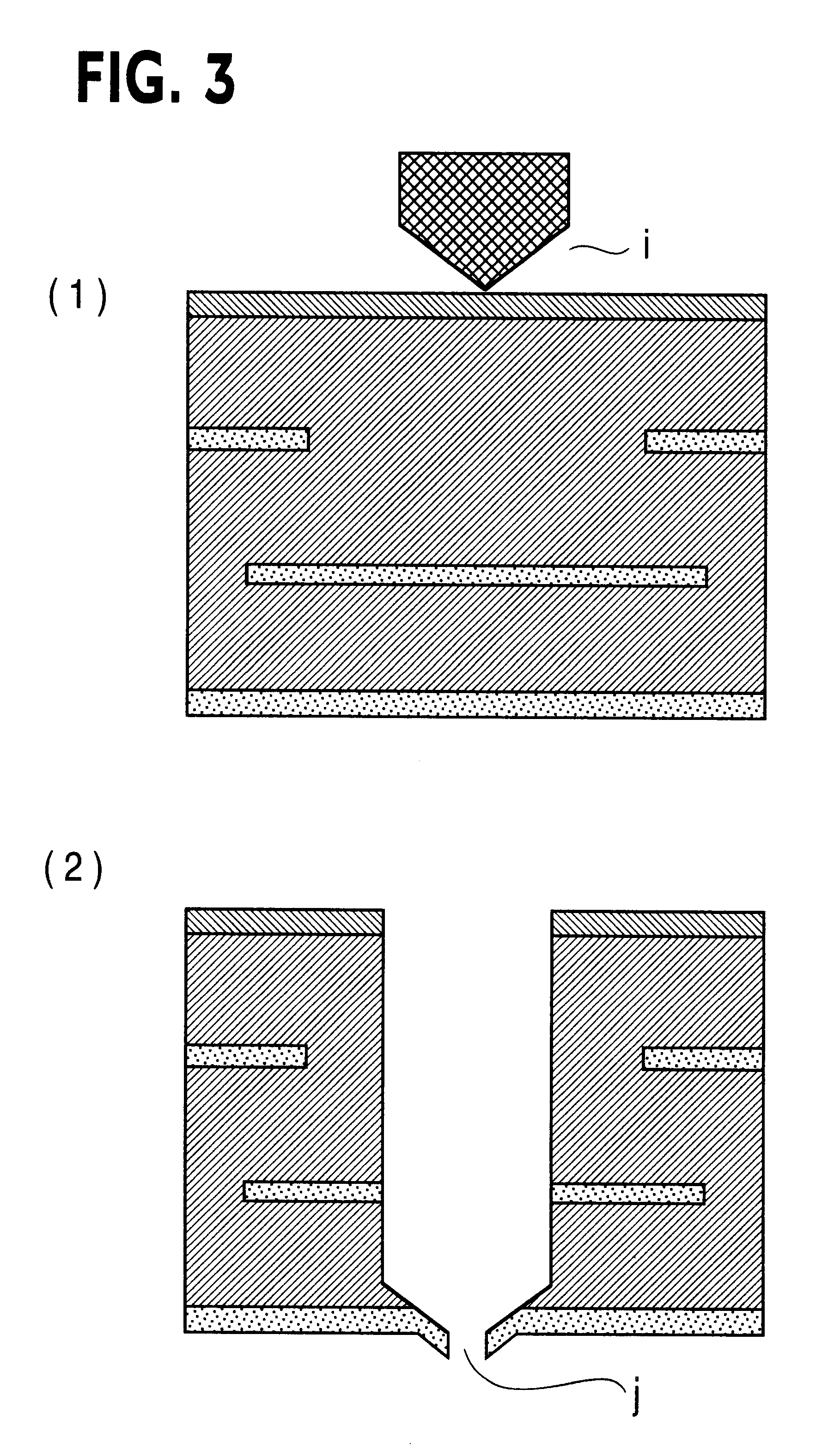

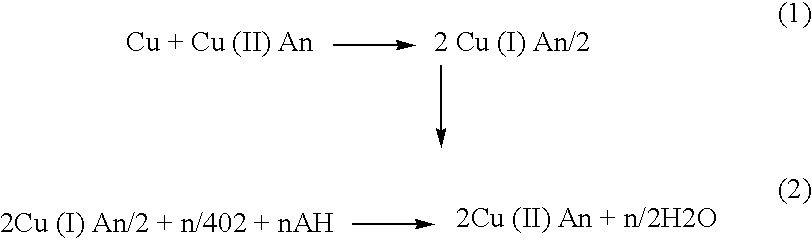

Printed wiring board having highly reliably via hole and process for forming via hole

InactiveUS6280641B1Improve reliabilityImprove productivityLight absorption dielectricsDecorative surface effectsBond energyConductive coating

Disclosed are a printed wiring board having micro-via holes highly reliable for conduction and a method of making the micro-via hole by providing a coating or sheet of an organic substance containing 3 to 97% by volume of at least one selected from a metal compound powder, a carbon powder or a metal powder having a melting point of at least 900° C. and a bond energy of at least 300 kJ / mol on a copper foil as an outermost layer of a copper-clad laminate having at least two copper layers, or providing a coating or sheet of the same after oxidizing a copper foil as an outermost layer, irradiating the coating or sheet with a carbon dioxide gas laser at an output of 20 to 60 mJ / pulse, thereby removing a micro-via-hole-forming portion of at least the copper foil as the outermost layer, then irradiating micro-via-hole-forming portions of the remaining layers with a carbon dioxide gas laser at an output of 5 to 35 mJ / pulse to make a micro-via hole which does not penetrate through the copper foil in a bottom of the micro-via hole, and electrically connecting the copper foil as the outermost layer and the copper foil in the bottom of the micro-via hole with a metal plating or an electrically conductive coating composition.

Owner:MITSUBISHI GAS CHEM CO INC

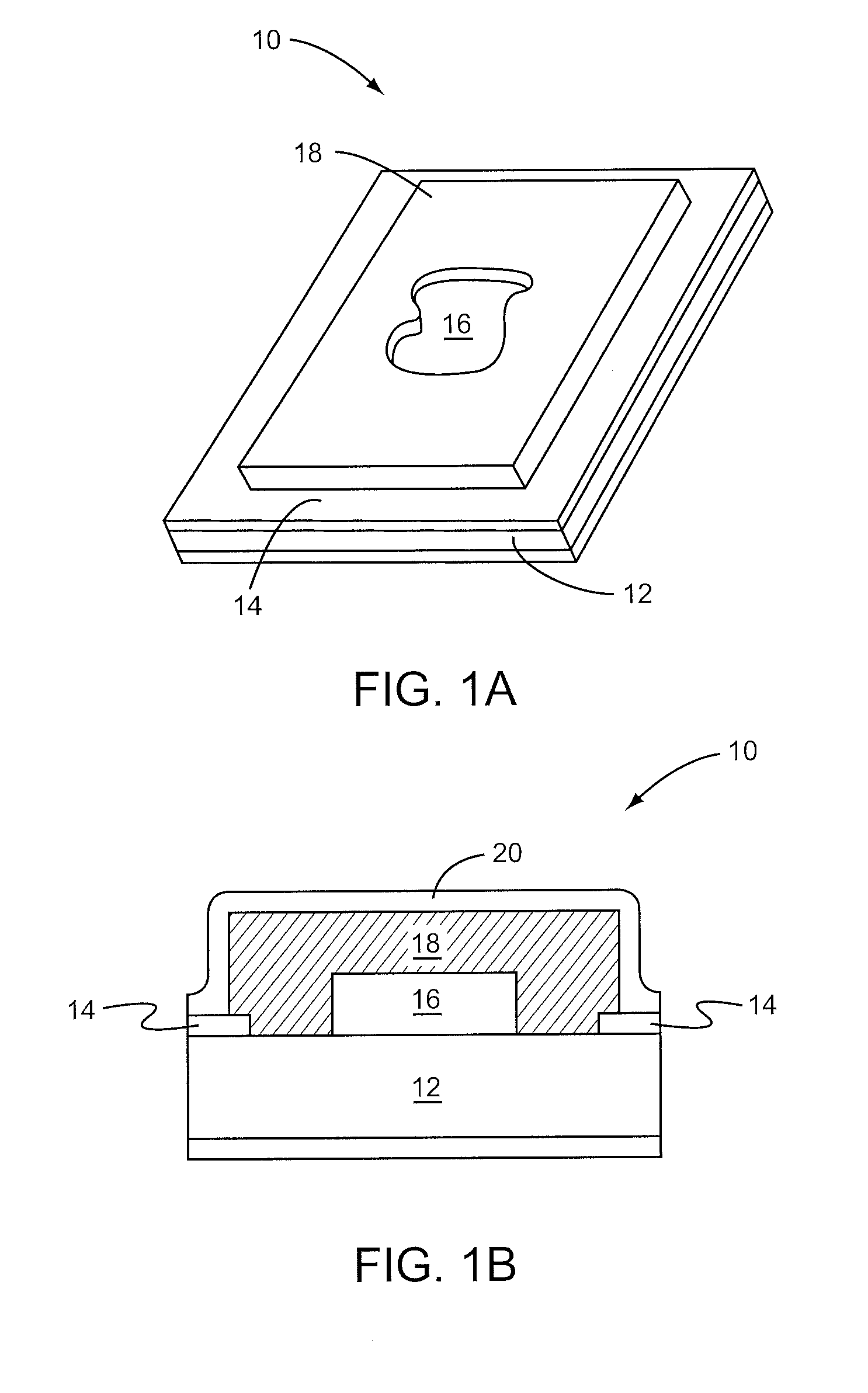

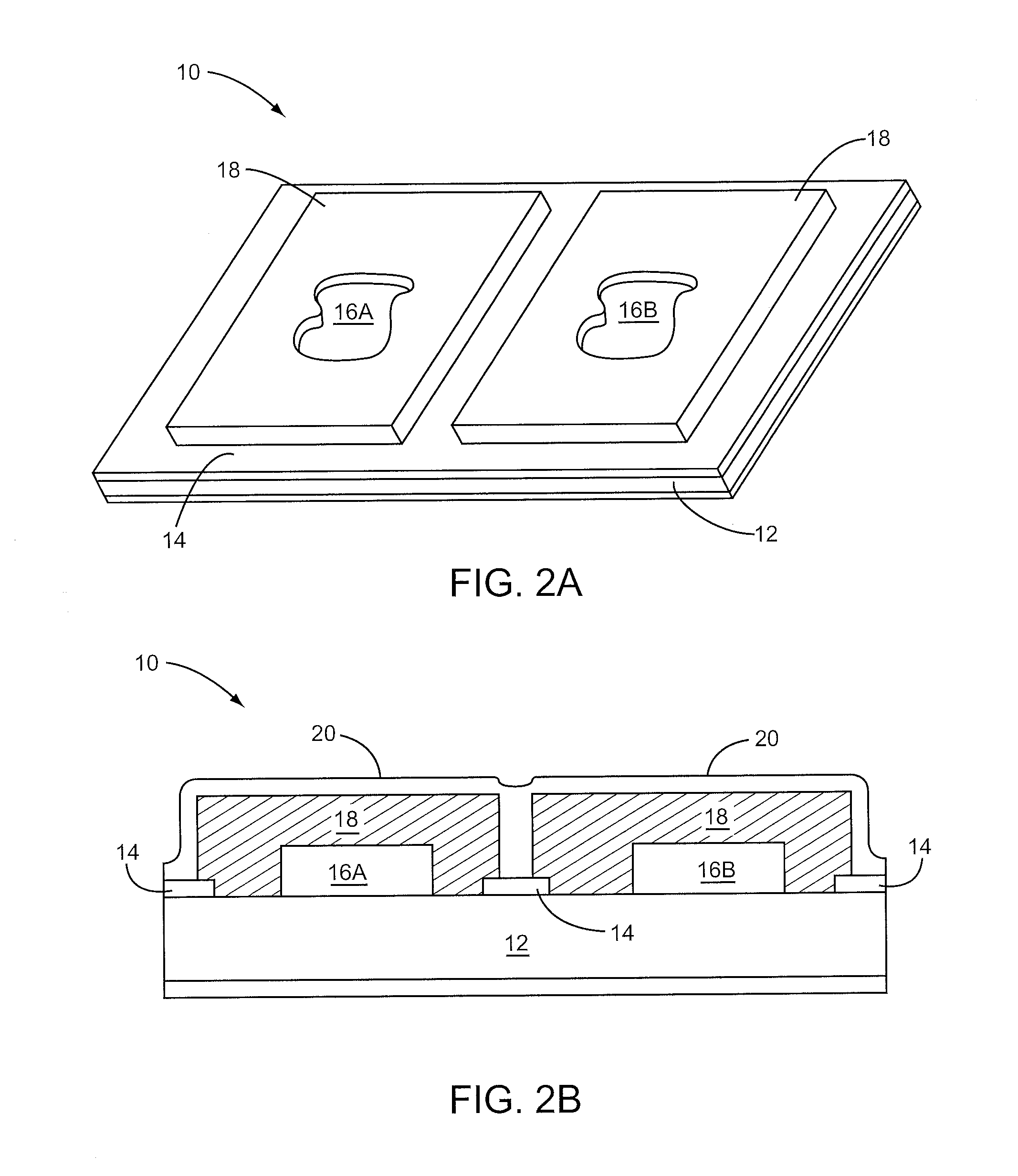

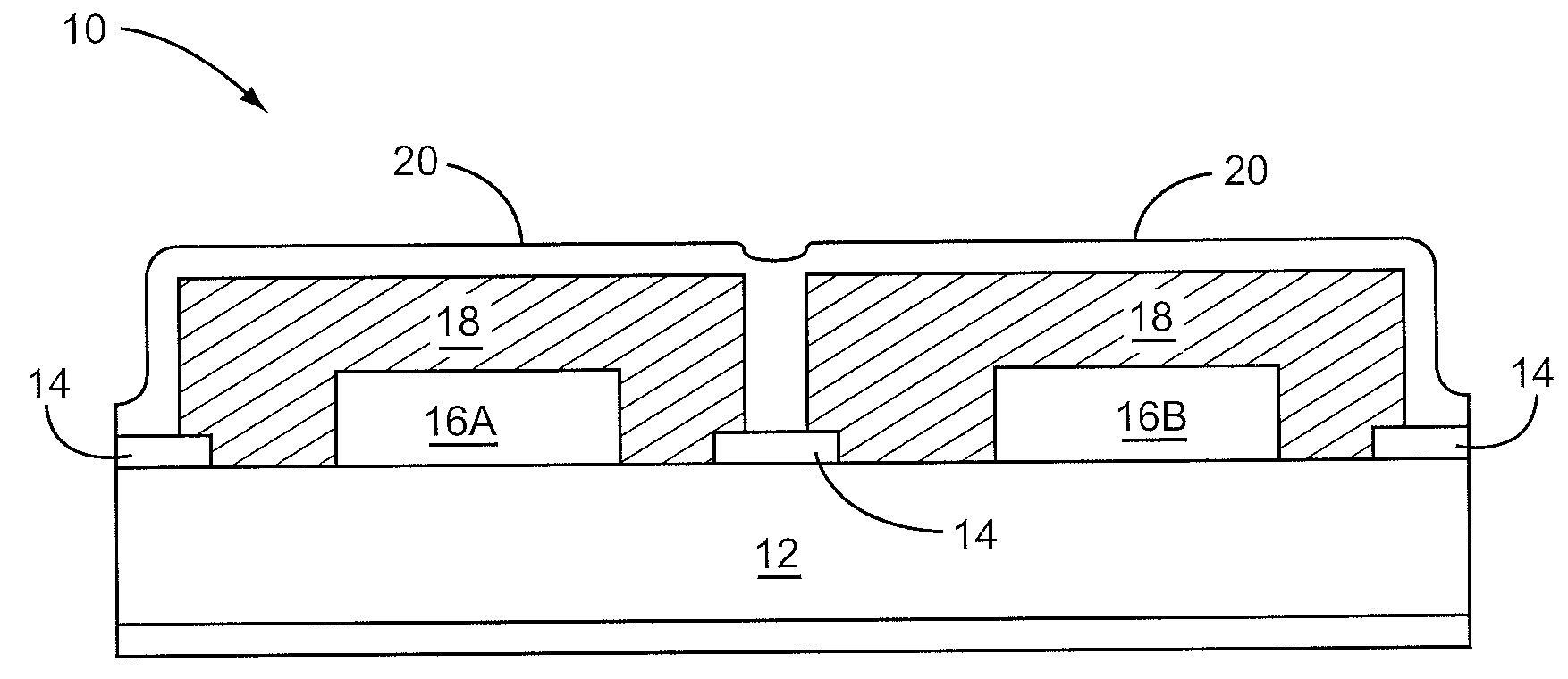

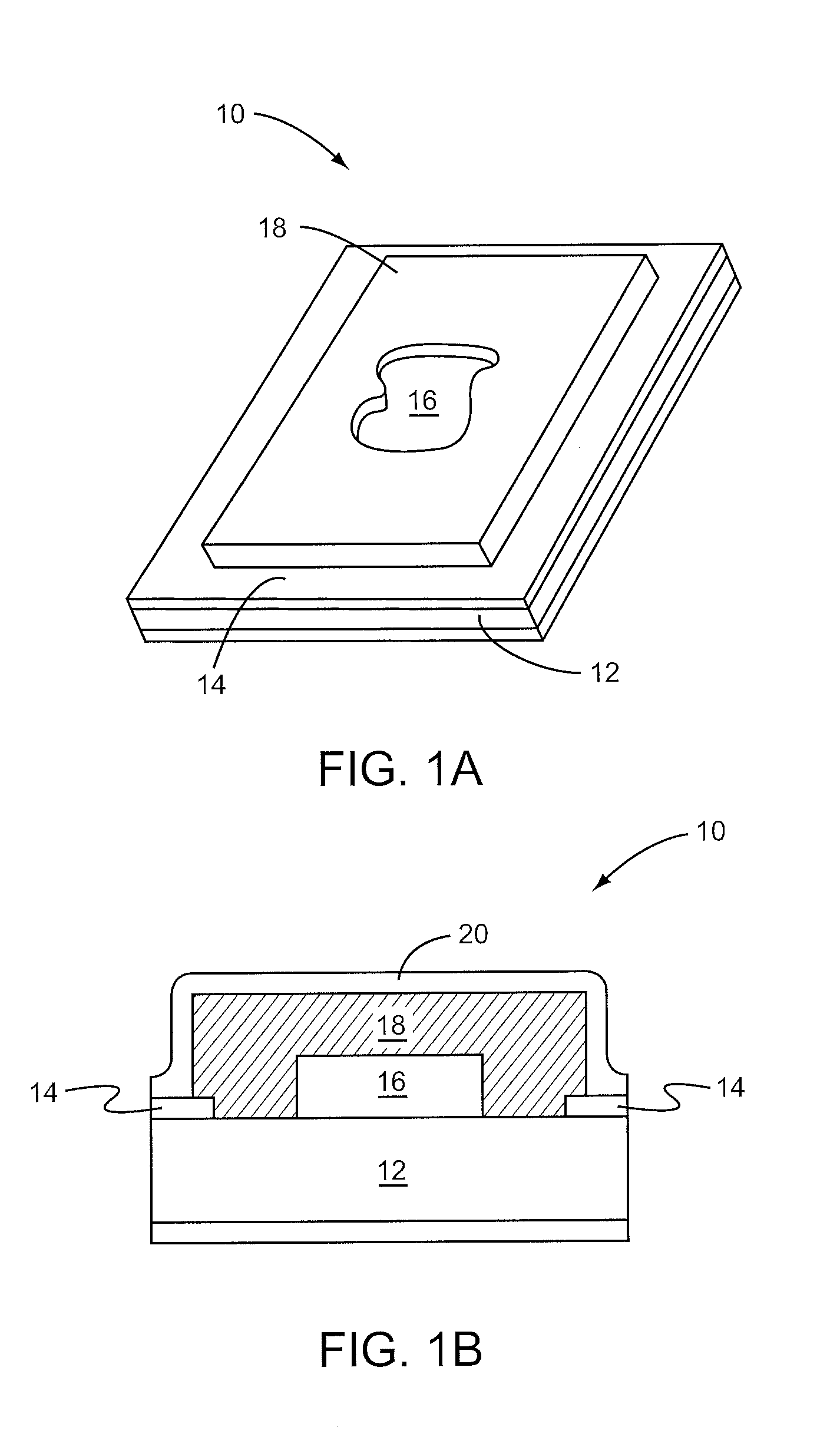

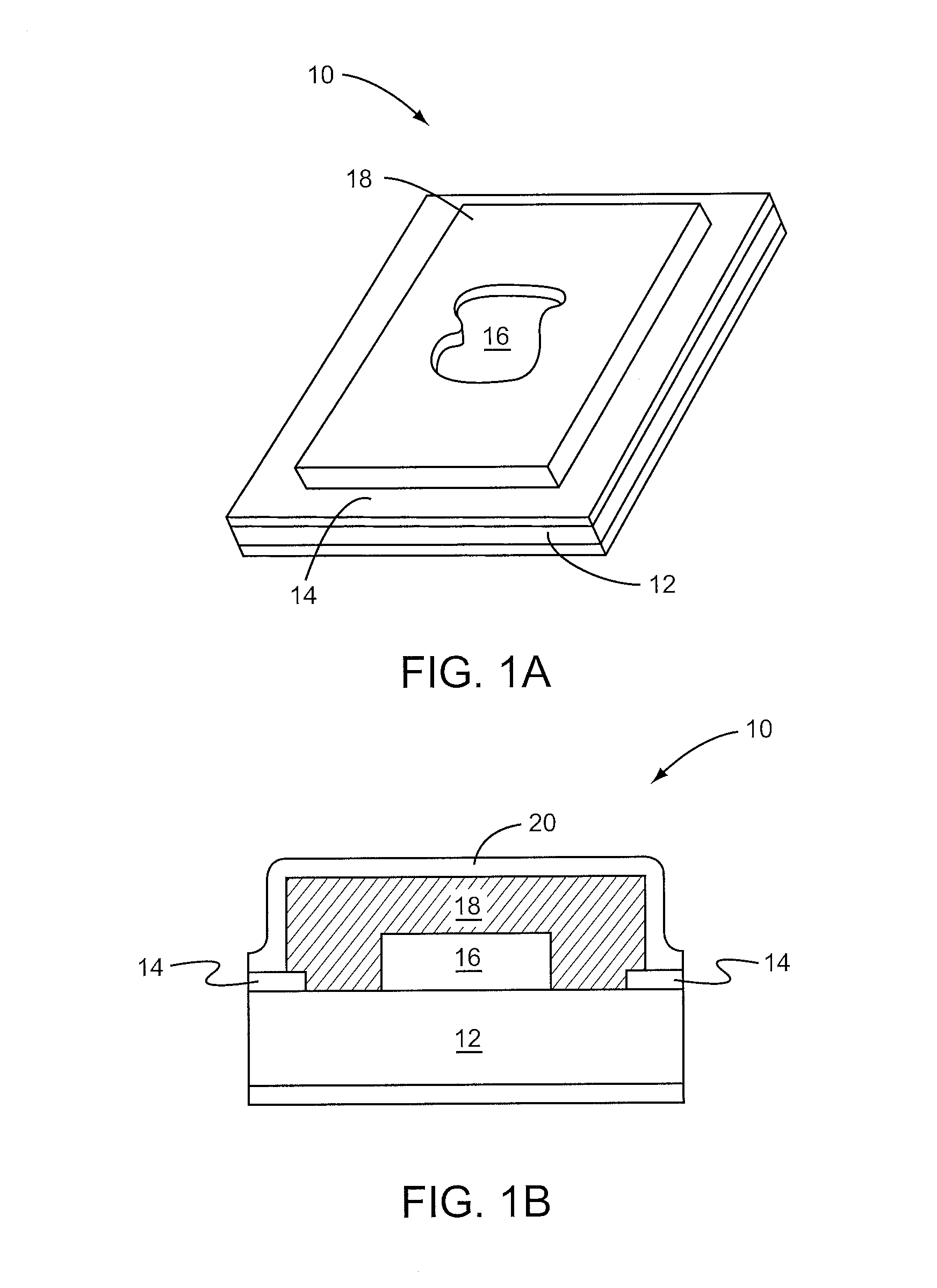

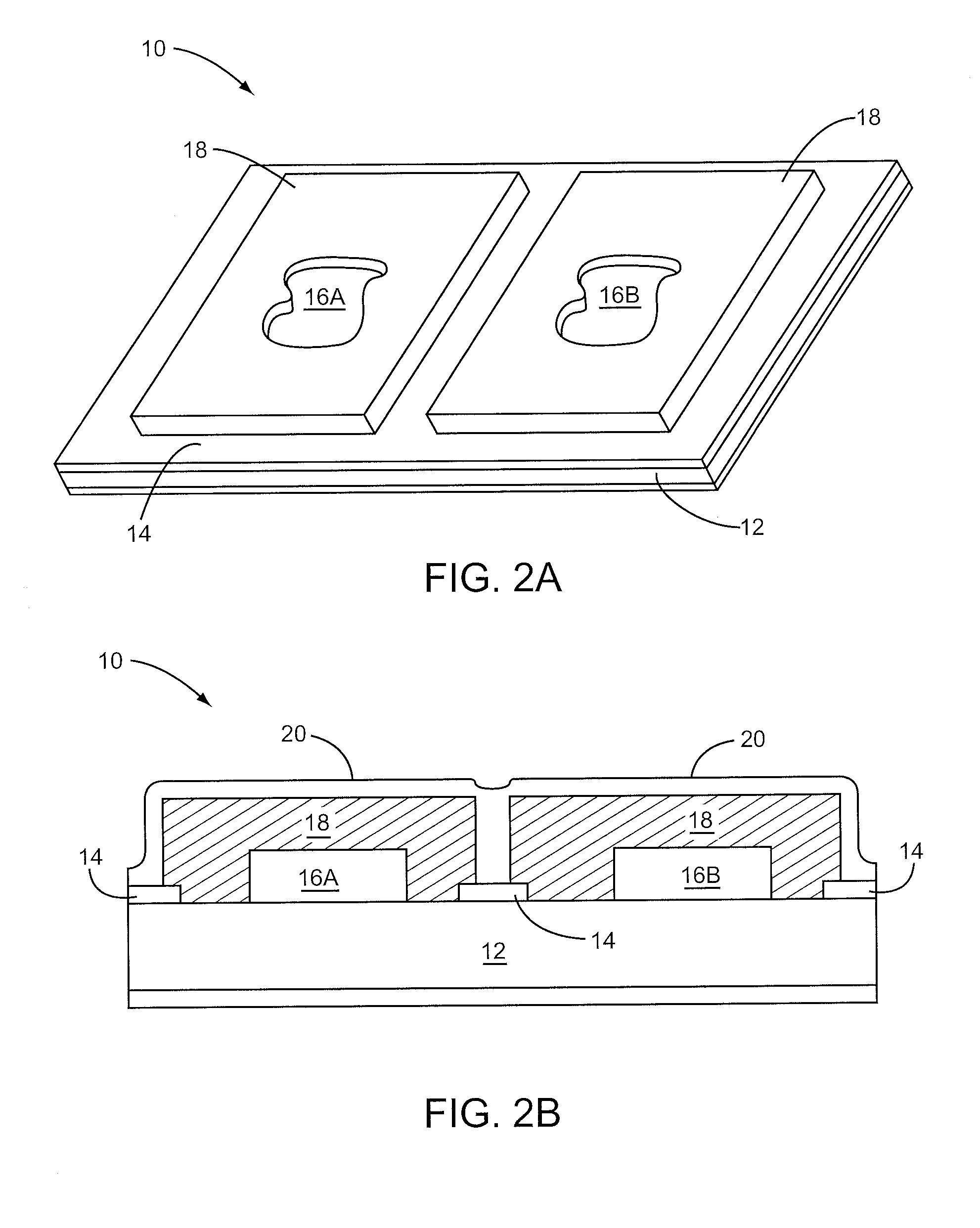

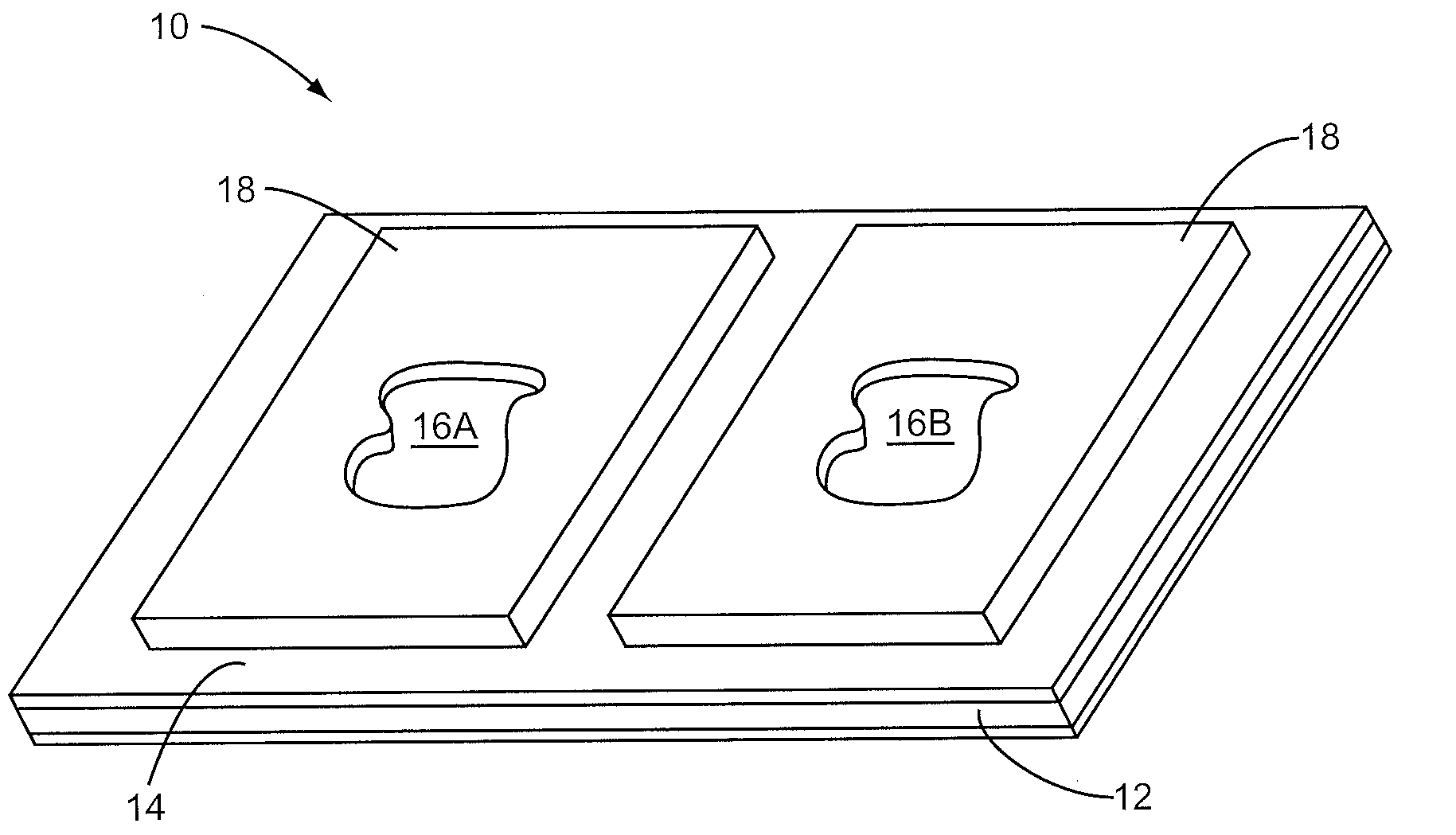

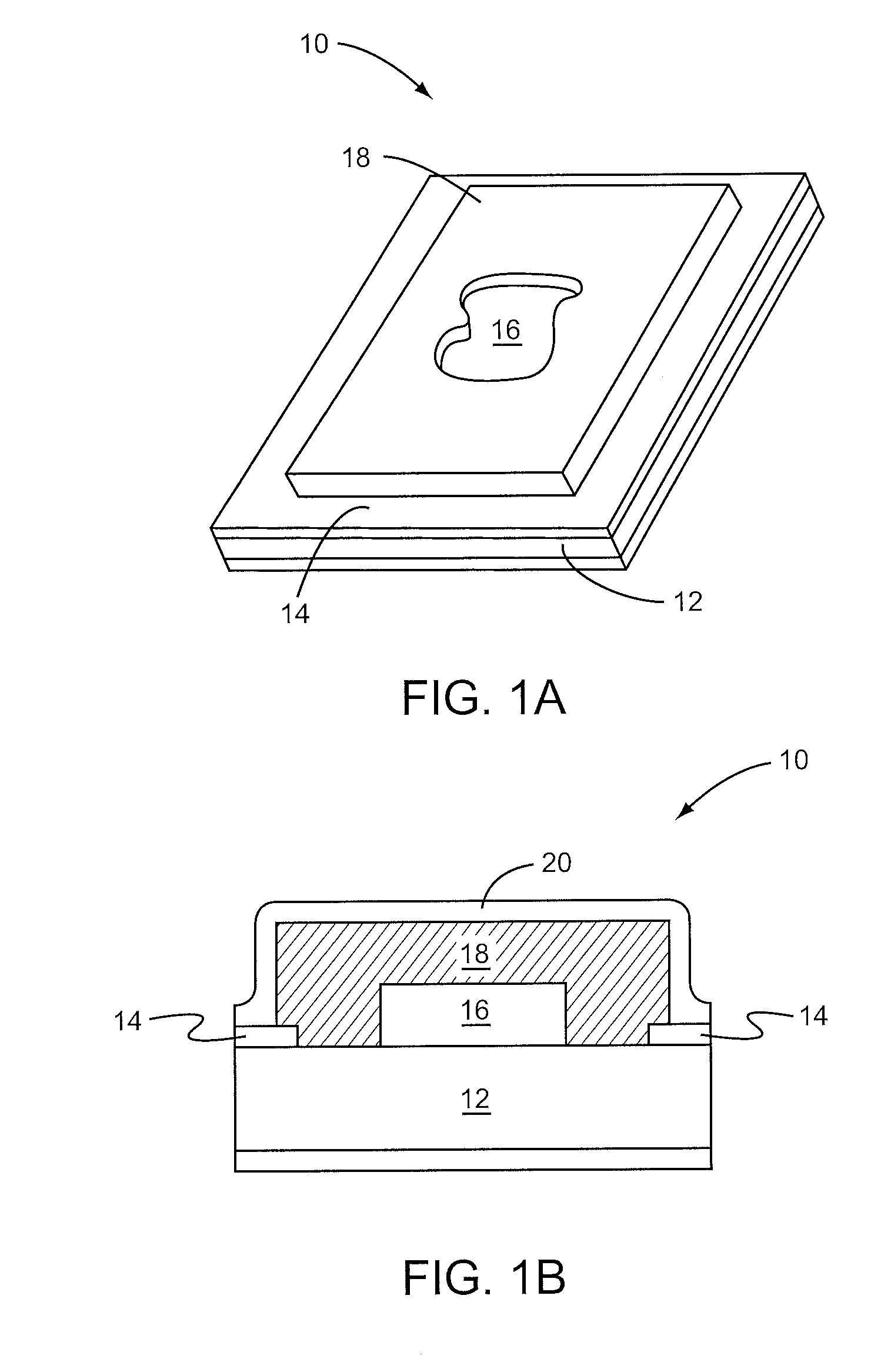

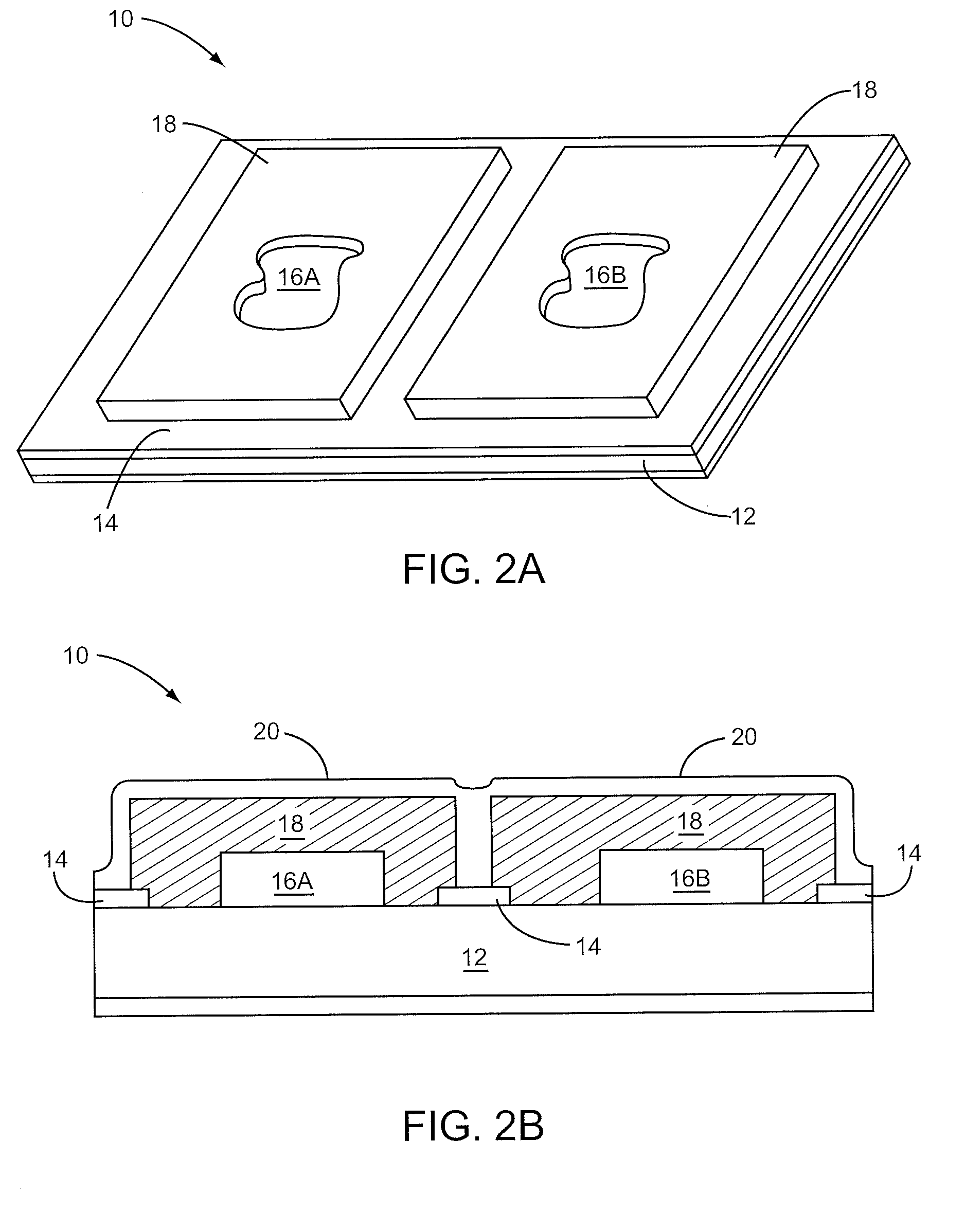

Heat sink formed with conformal shield

ActiveUS20090000114A1Printed circuit assemblingWave amplification devicesEngineeringElectromagnetic shielding

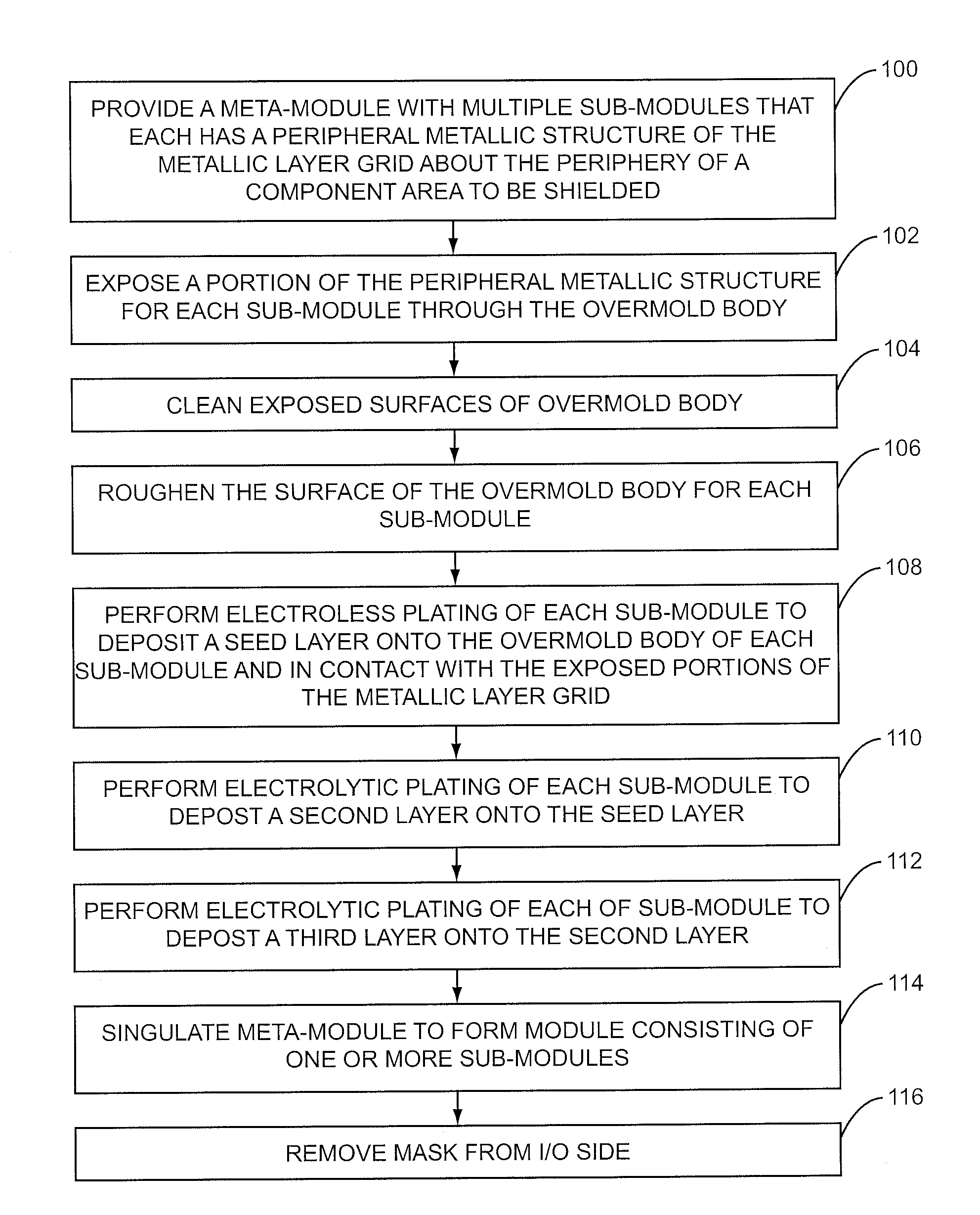

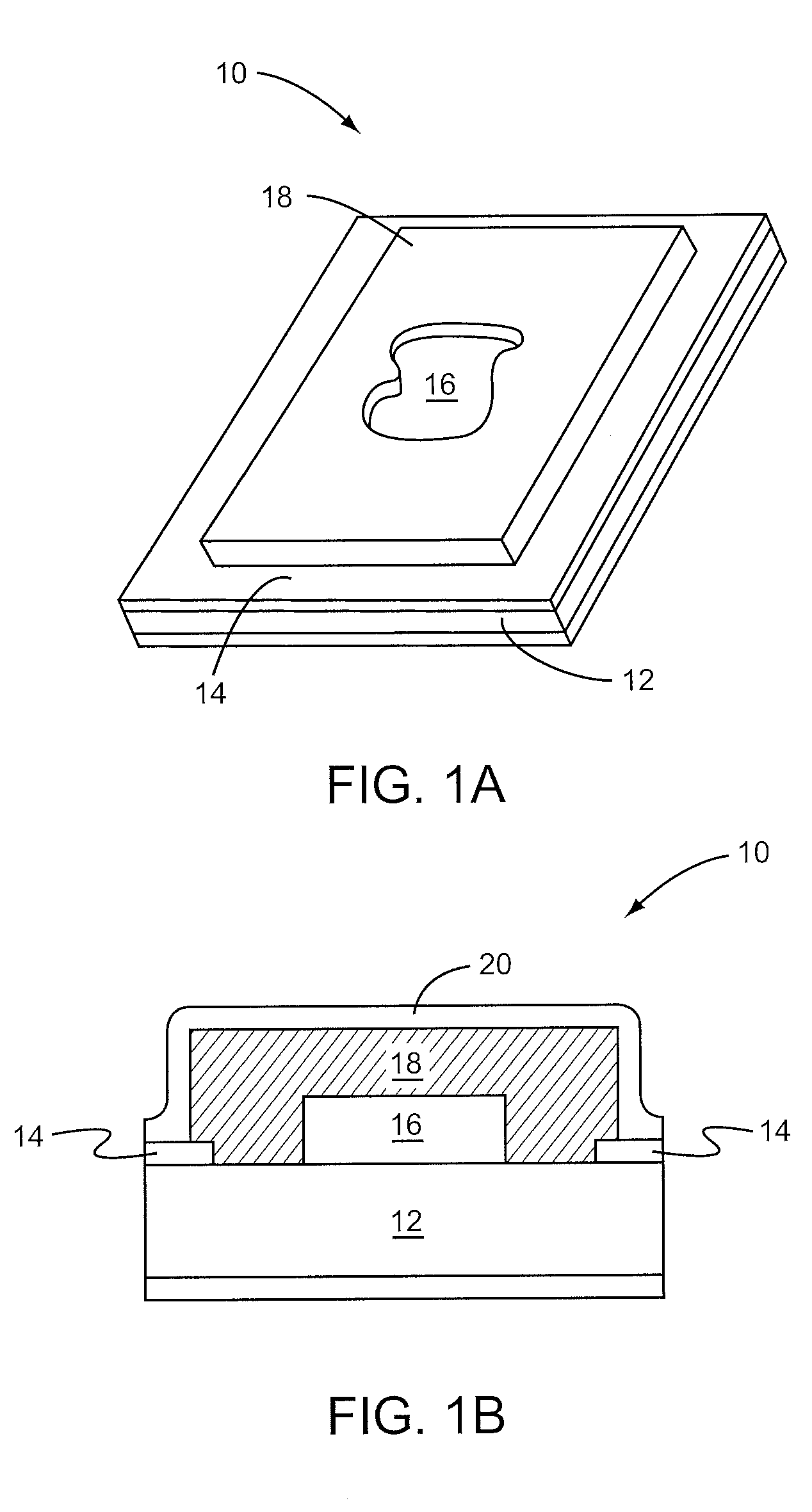

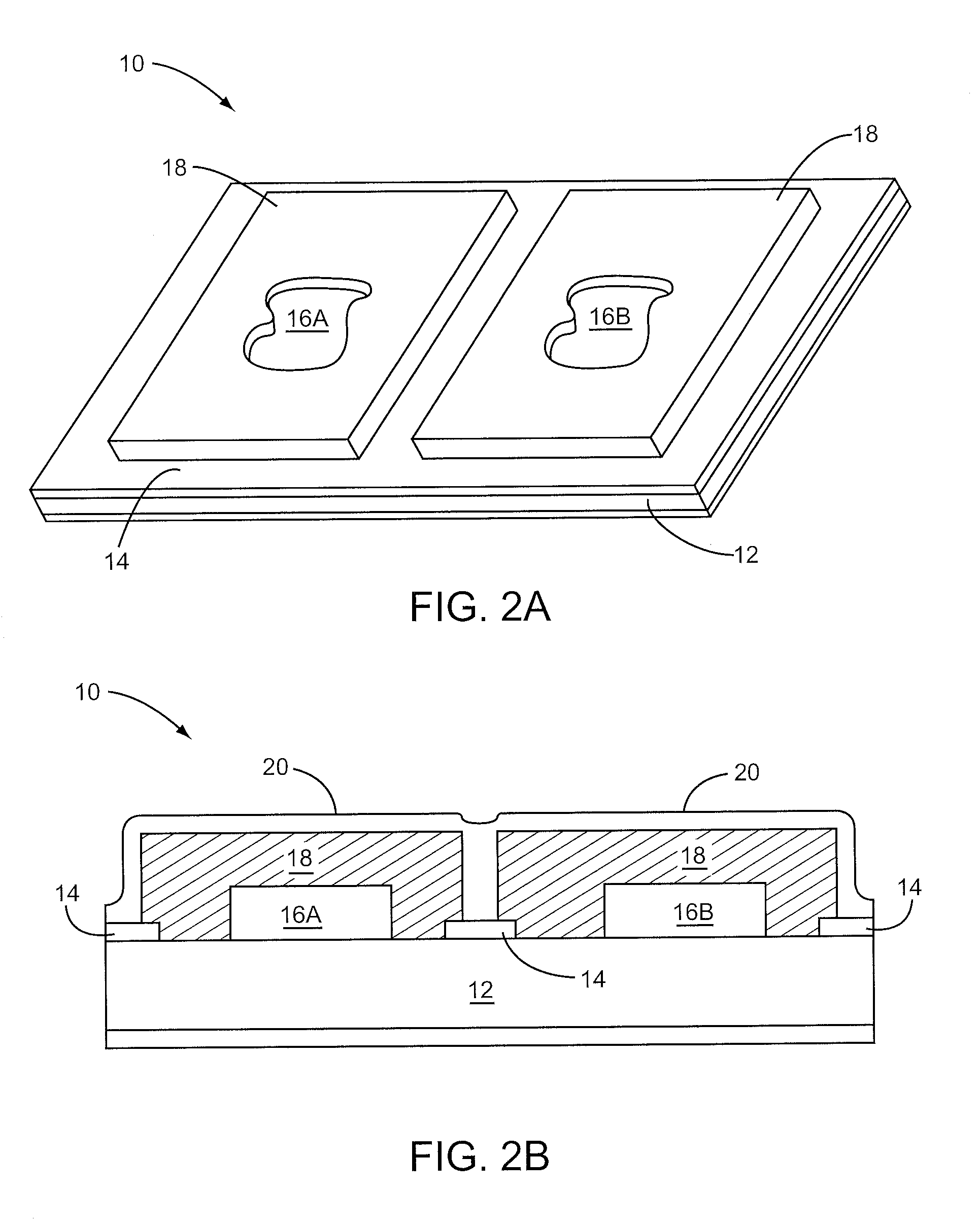

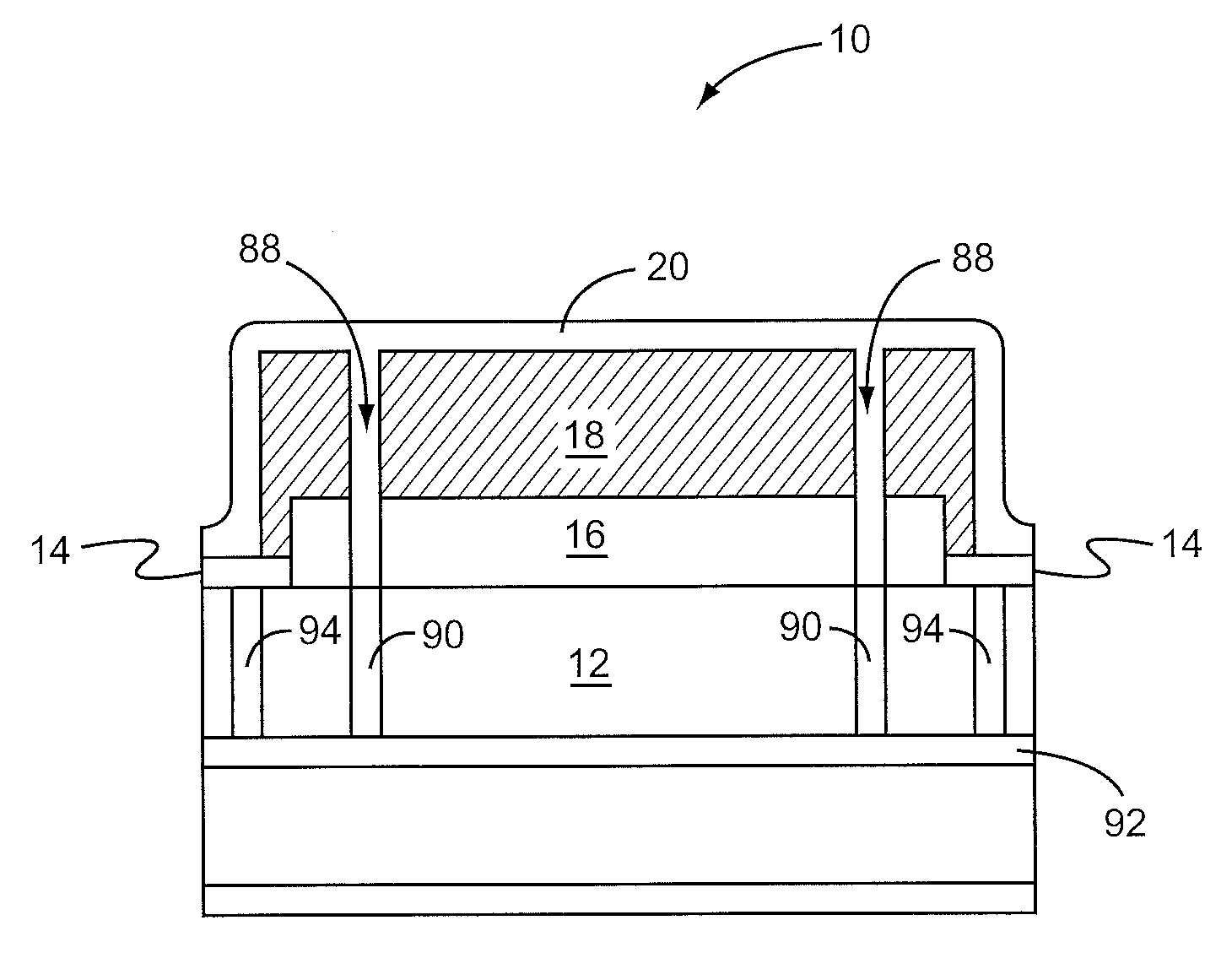

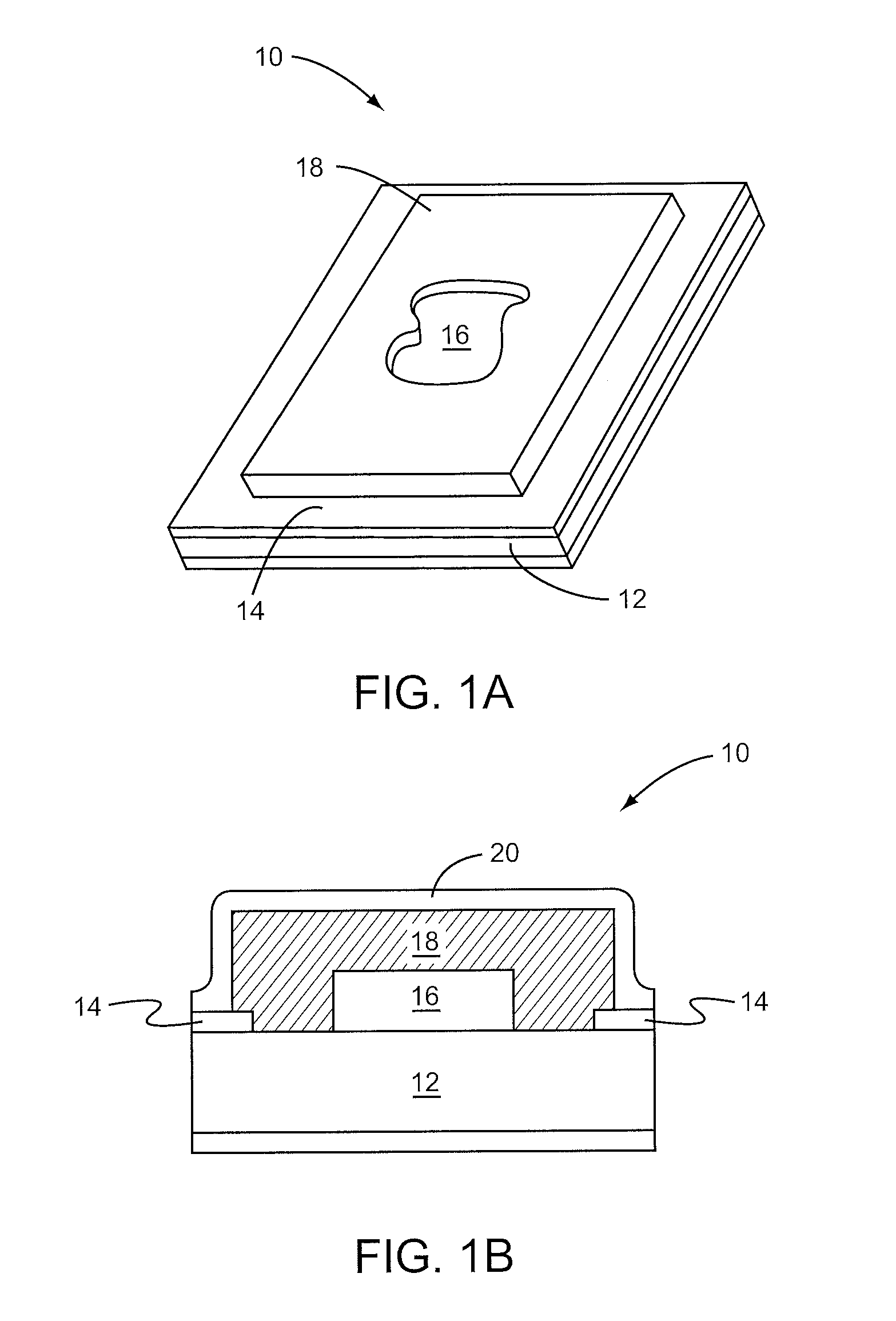

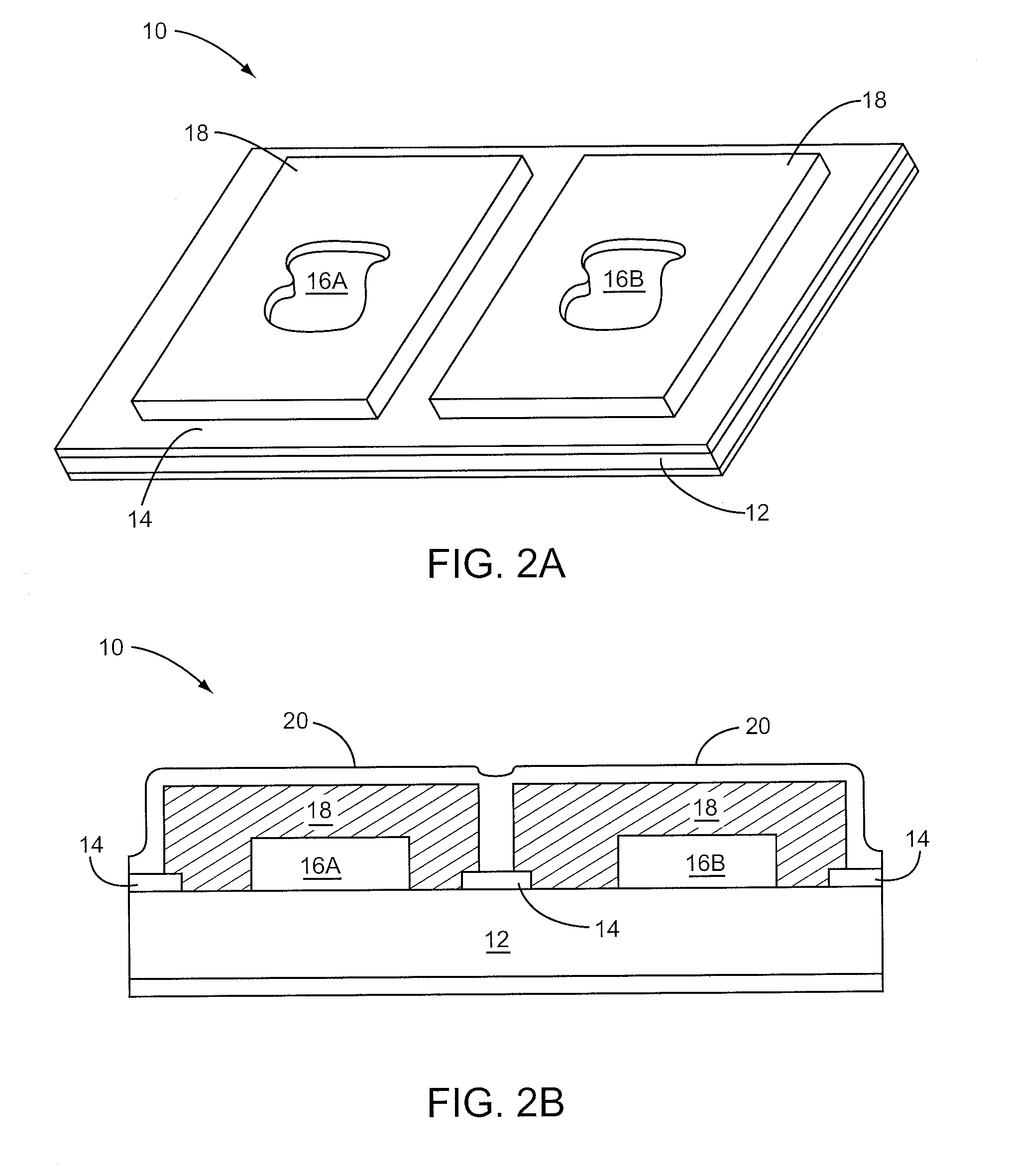

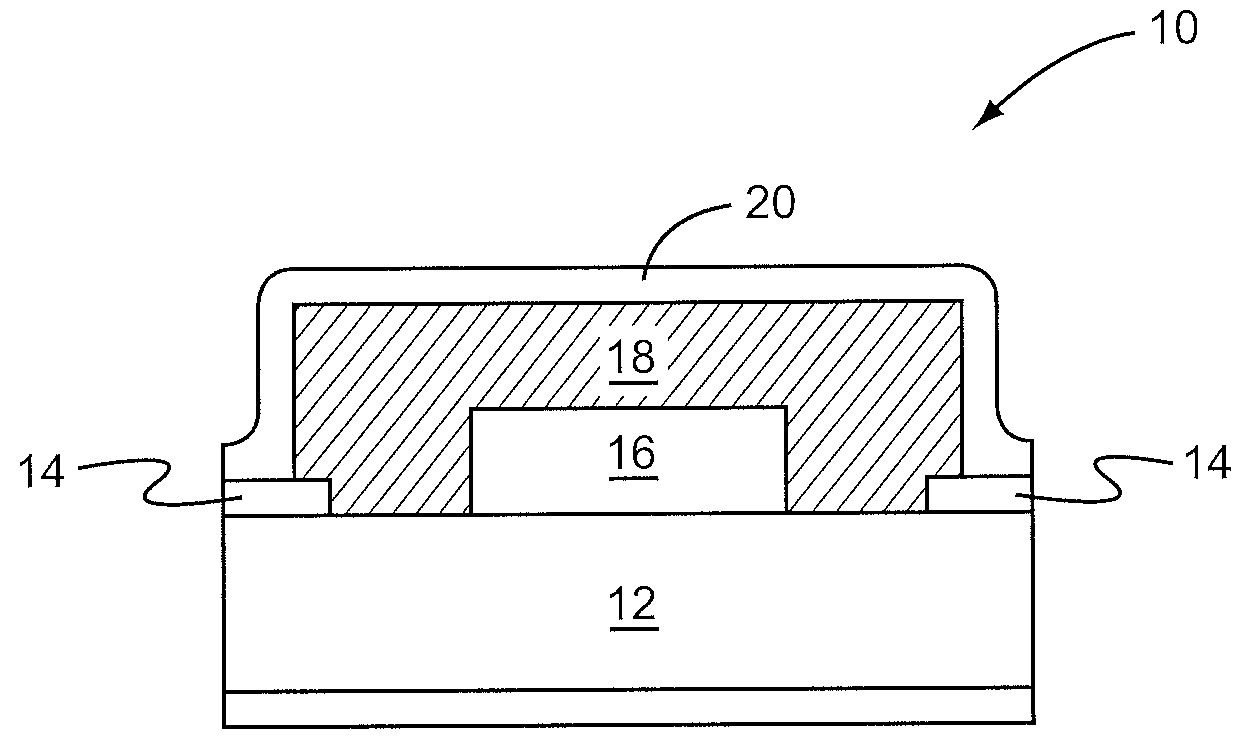

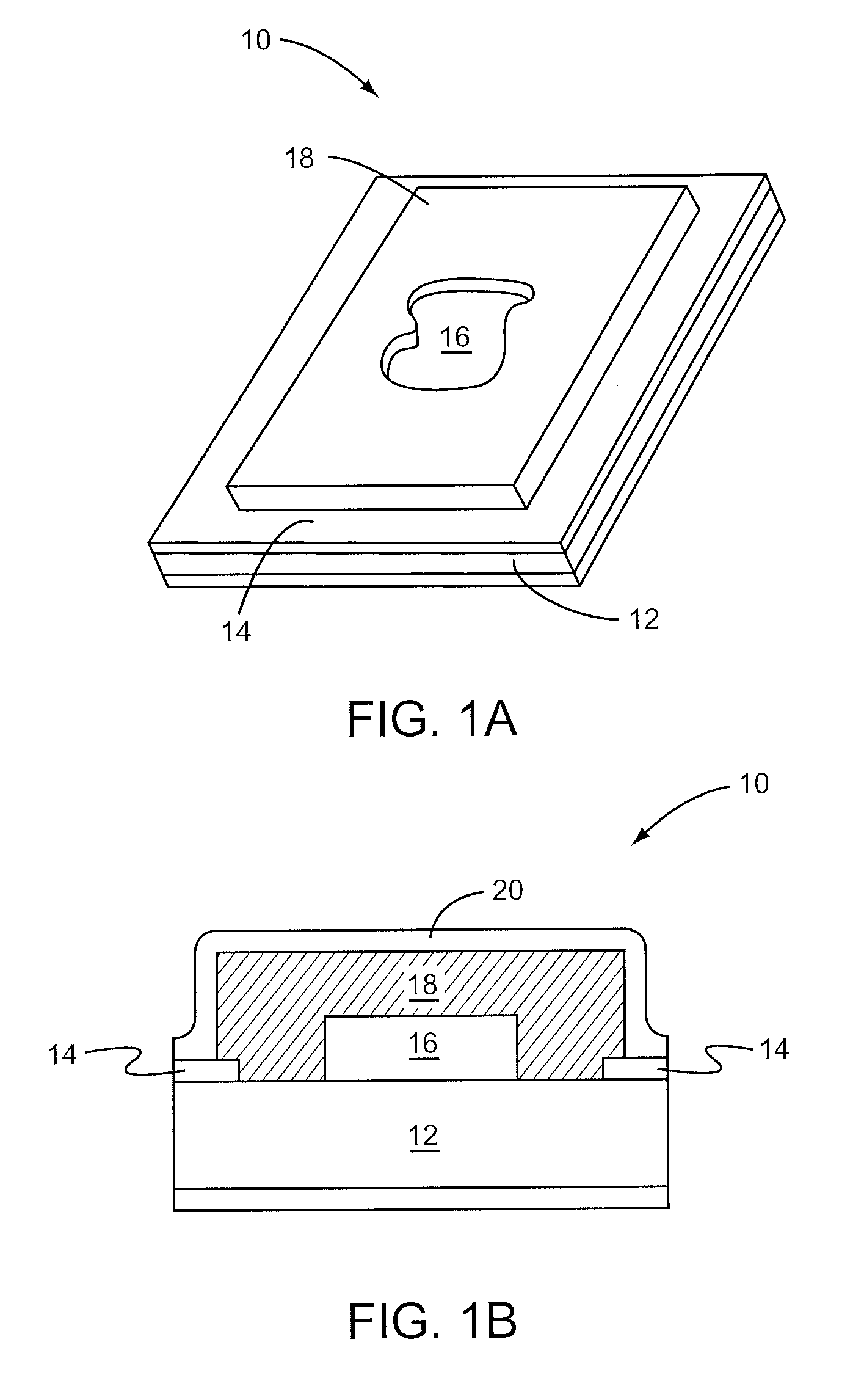

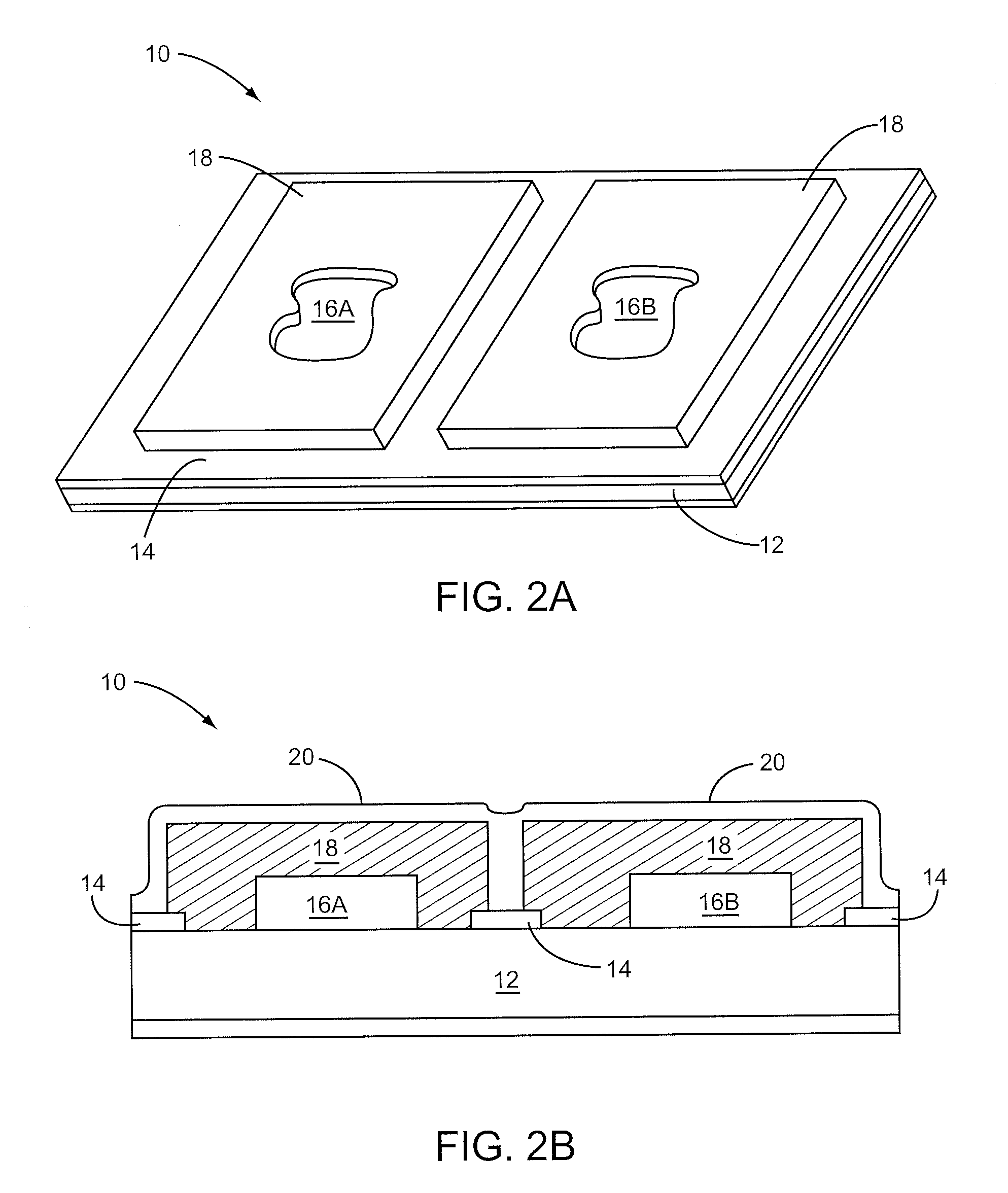

In one embodiment, a meta-module having circuitry for two or more modules is formed on a substrate, which is preferably a laminated substrate. The circuitry for the different modules is initially formed on the single meta-module. Each module will have one or more component areas in which the circuitry is formed. A metallic structure is formed on or in the substrate for each component area to be shielded. A single body, such as an overmold body, is then formed over all of the modules on the meta-module. At least a portion of the metallic structure for each component area to be shielded is then exposed through the body by a cutting, drilling, or like operation. Next, an electromagnetic shield material is applied to the exterior surface of the body of each of the component areas to be shielded and in contact with the exposed portion of the metallic structures.

Owner:QORVO US INC

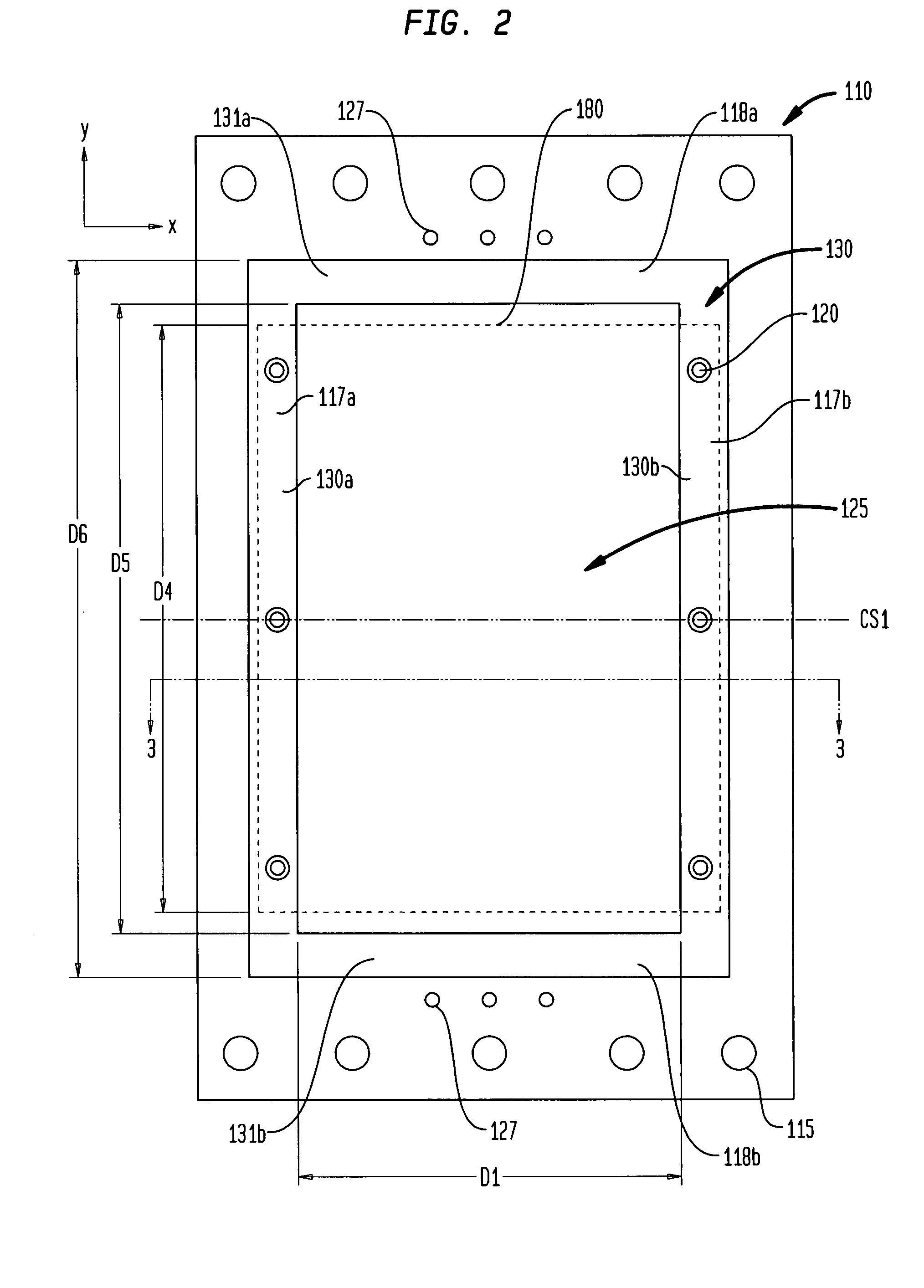

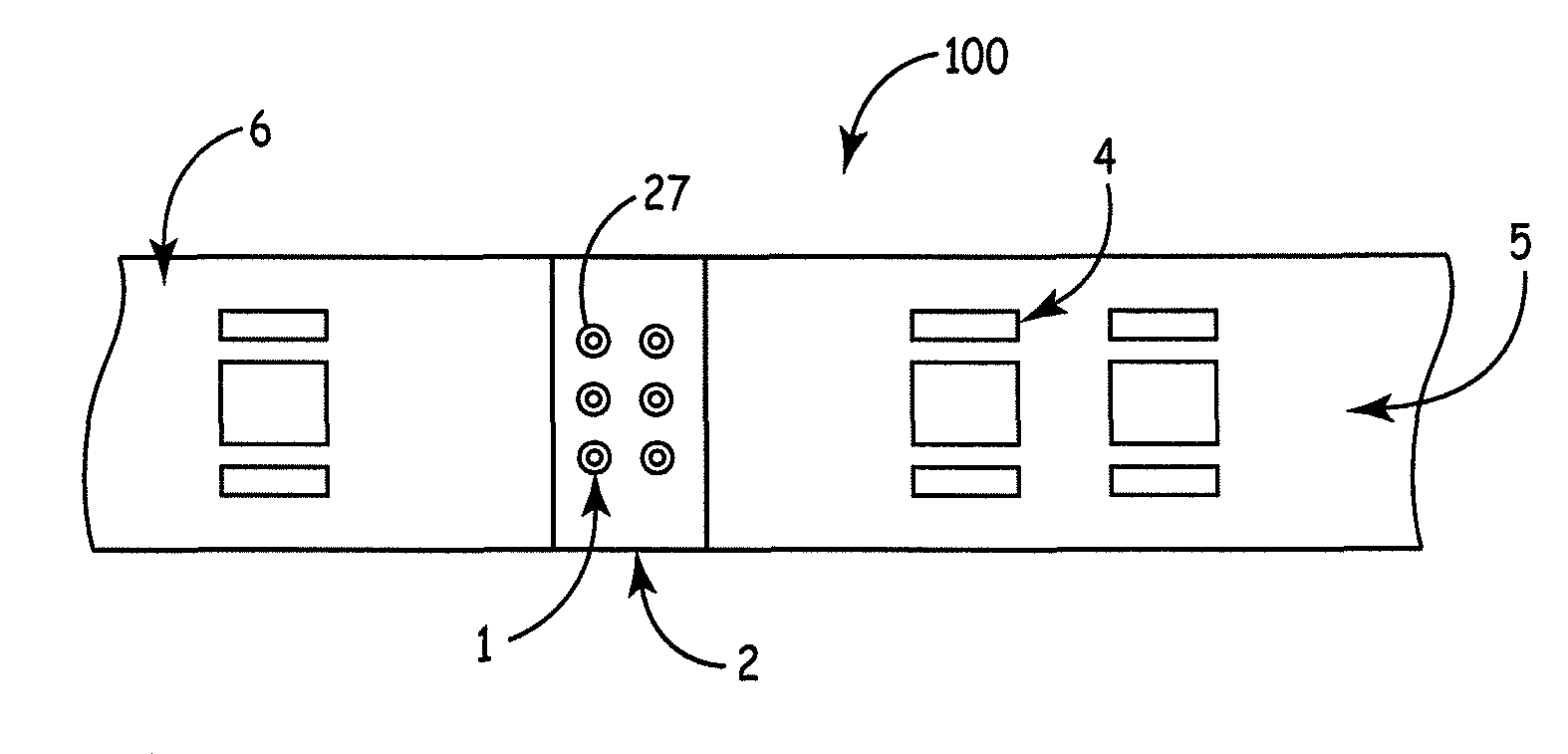

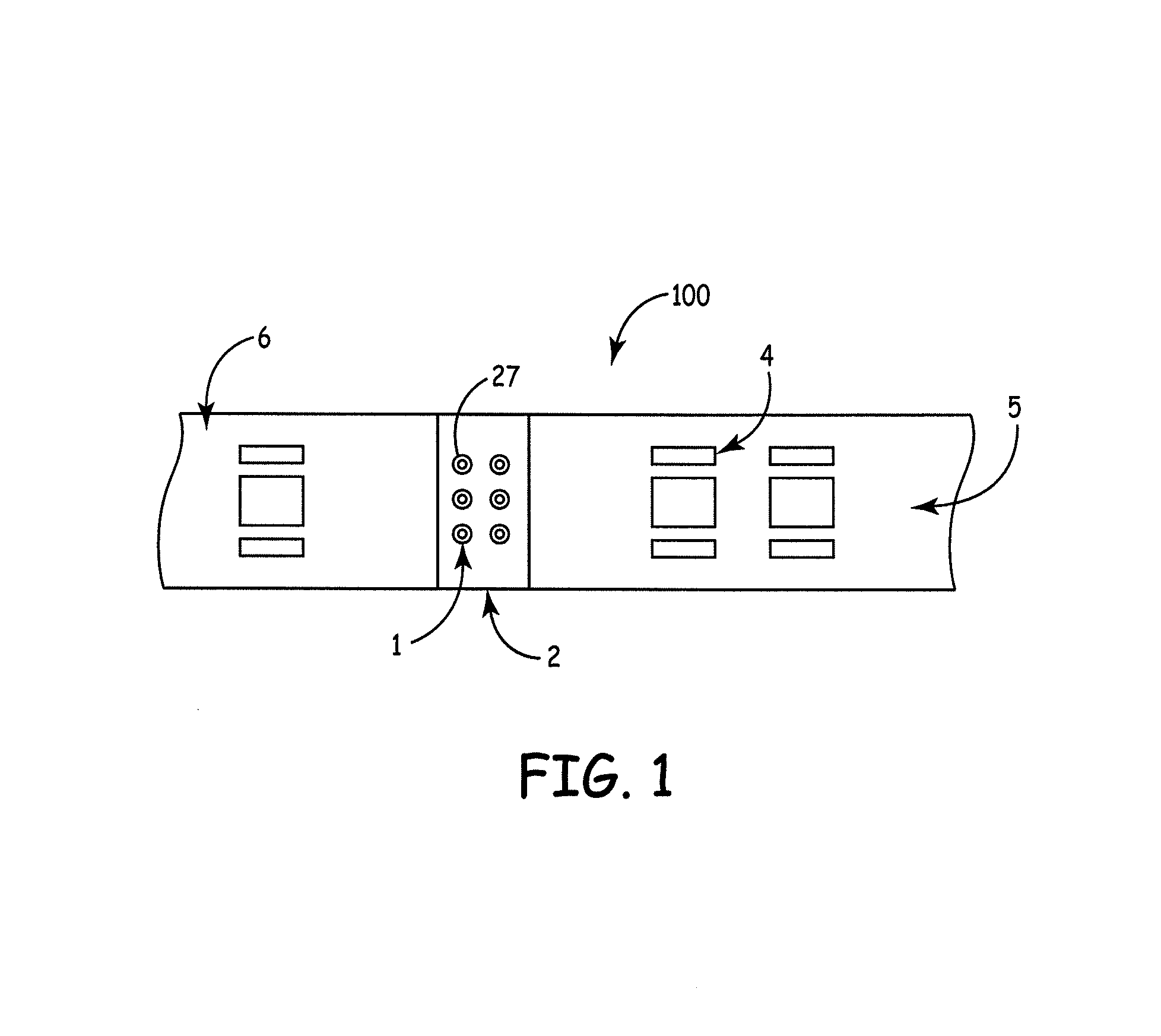

Alignment and cutting of microelectronic substrates

InactiveUS20080156518A1Line/current collector detailsWave amplification devicesEngineeringElectrical and Electronics engineering

A substrate including plural microelectronic device carriers has metallic alignment elements. The alignment elements desirably are disposed in a predetermined positional relationship to terminals on the carriers. The alignment elements are engaged with a carrier frame and a cutting device is aligned with the carrier frame. The cutting device cuts the carriers so that borders of the carriers are in a precise relationship with the terminals.

Owner:TESSERA INC

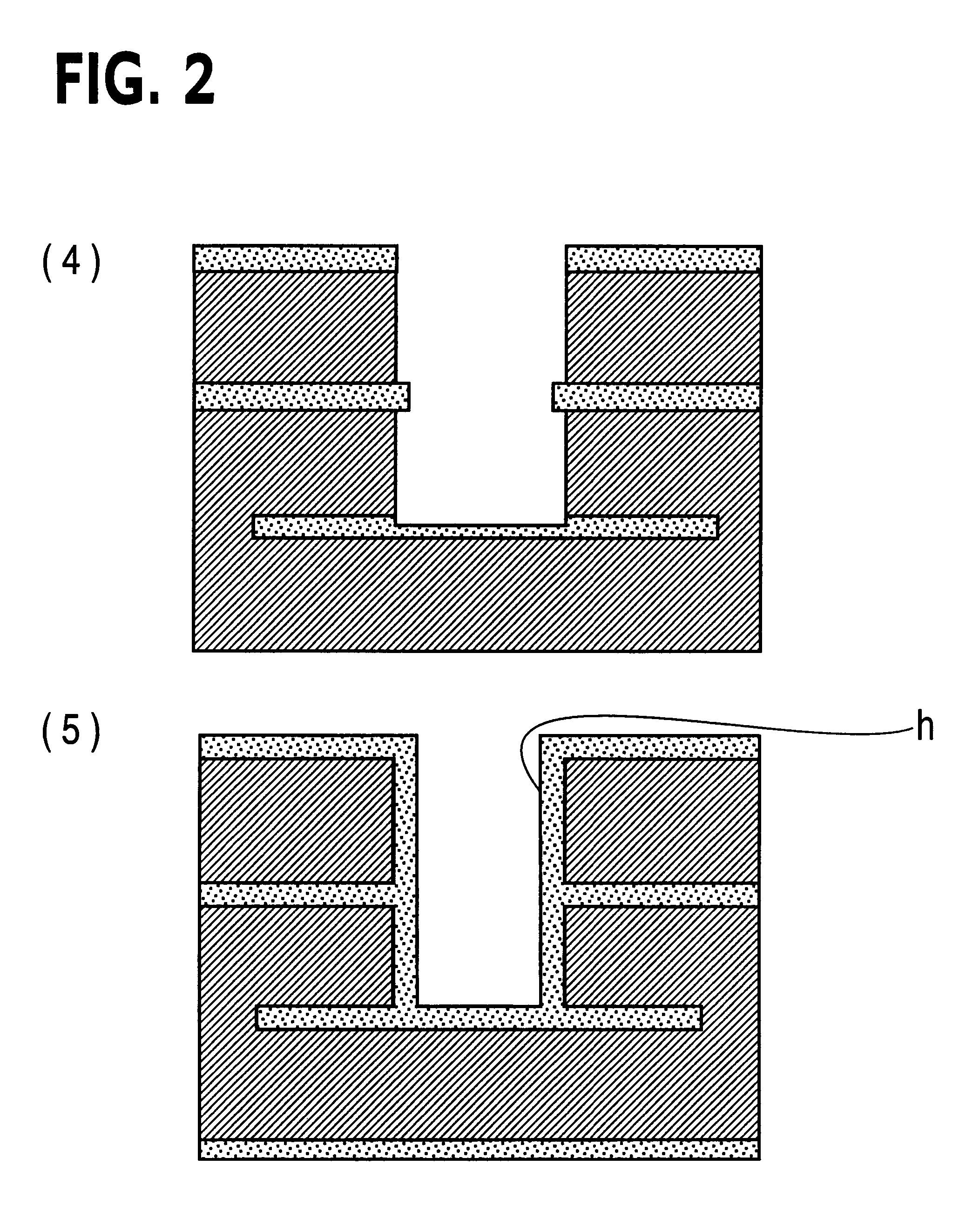

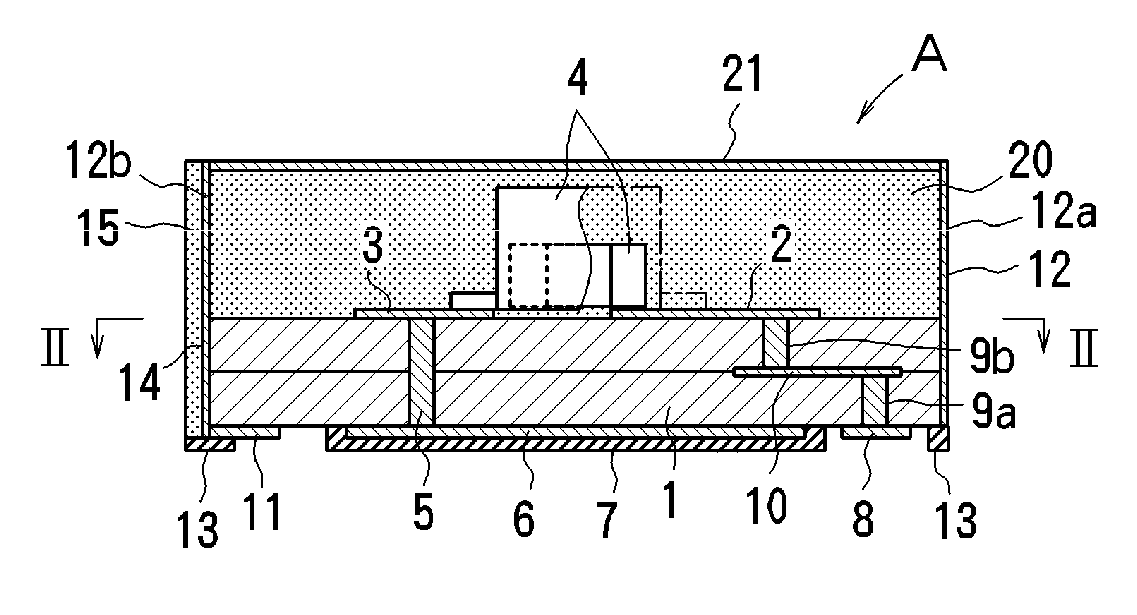

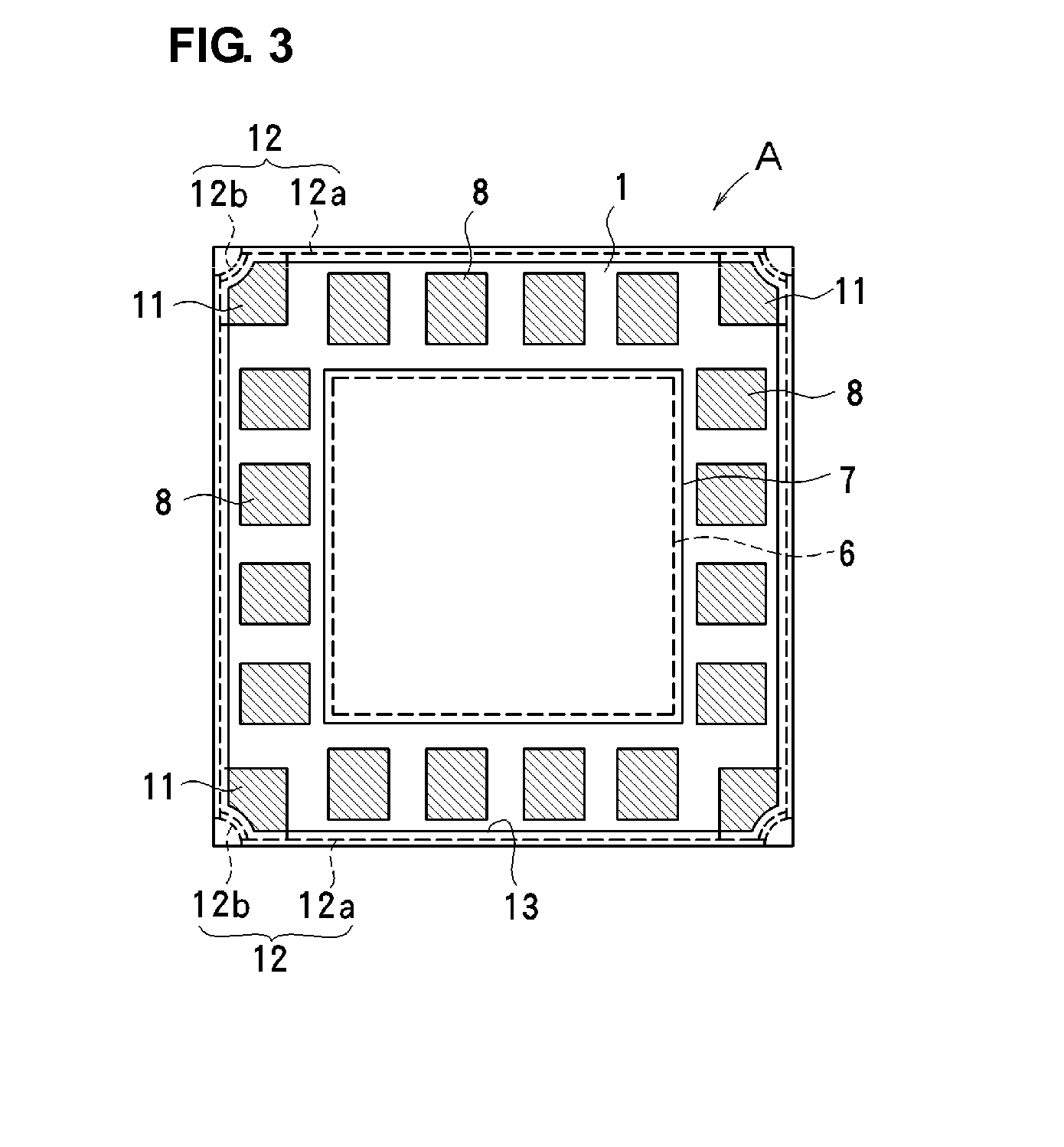

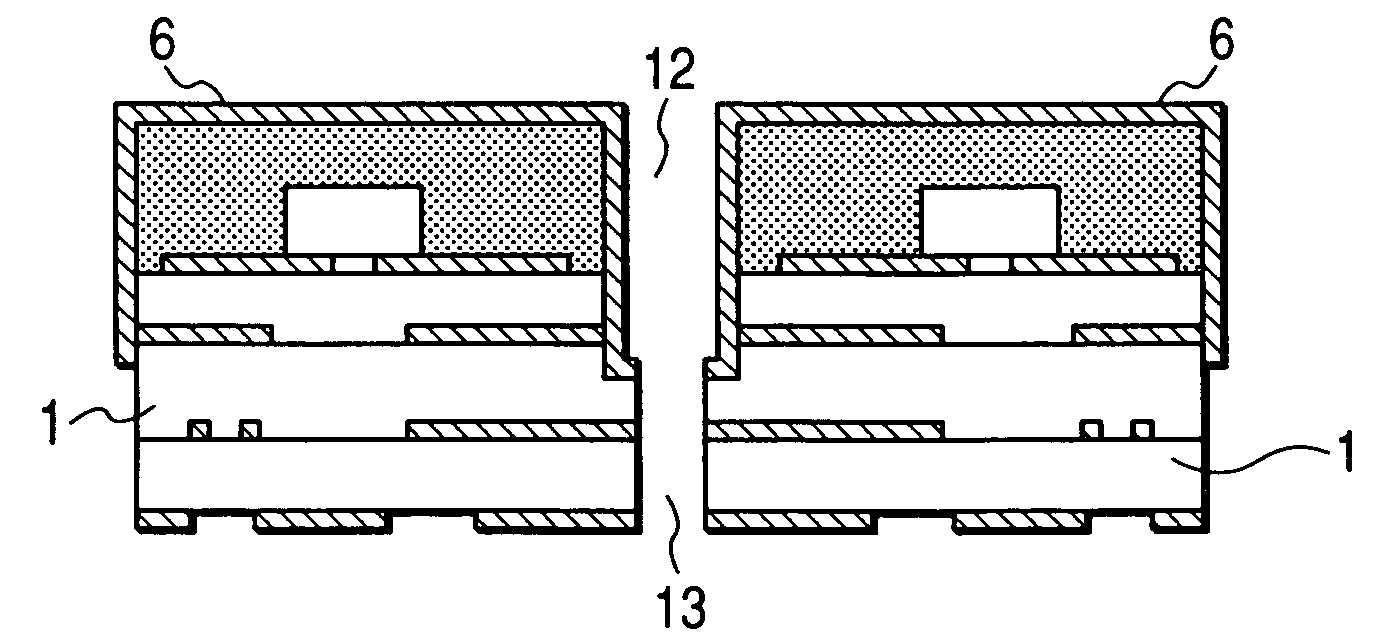

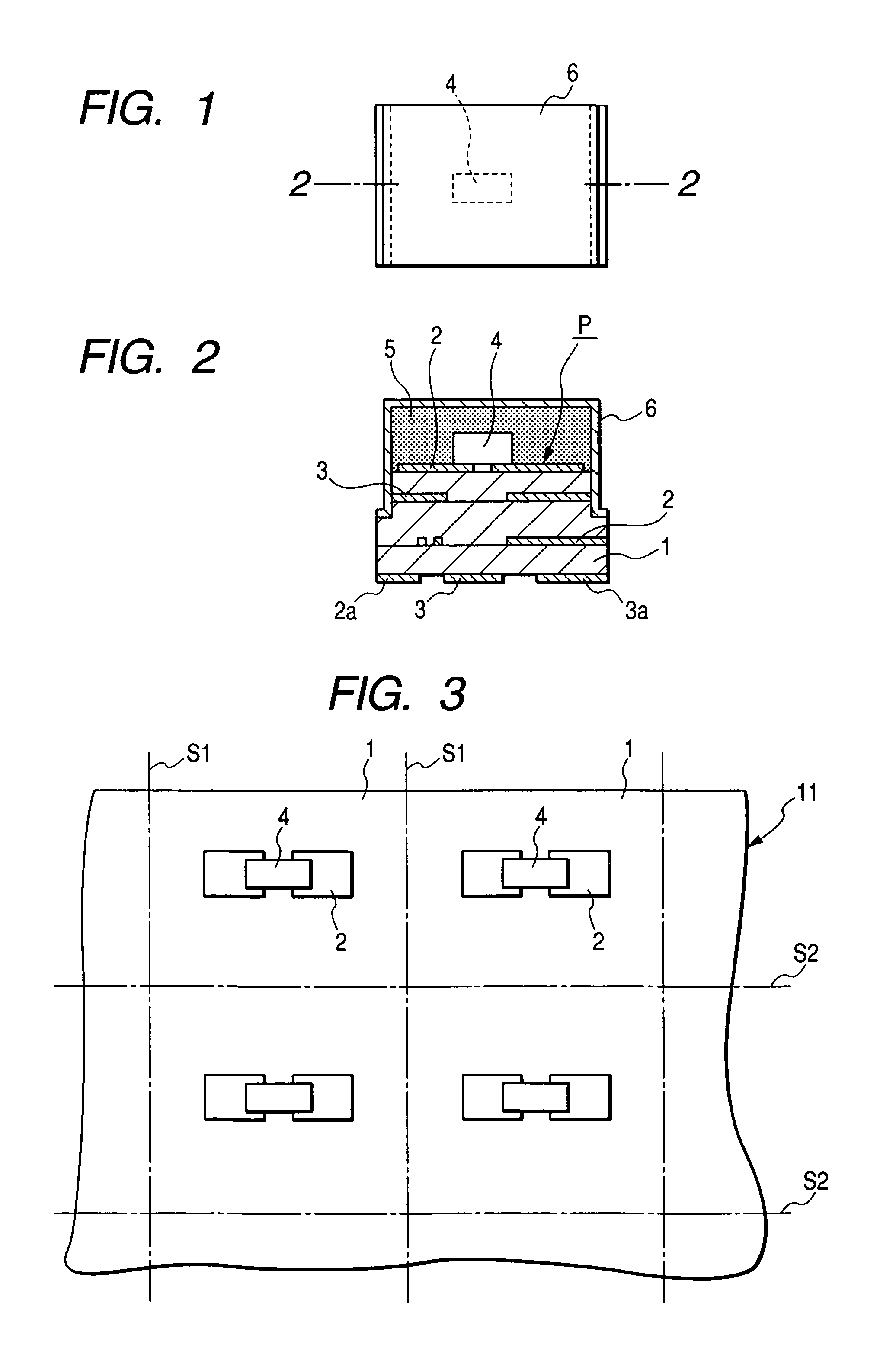

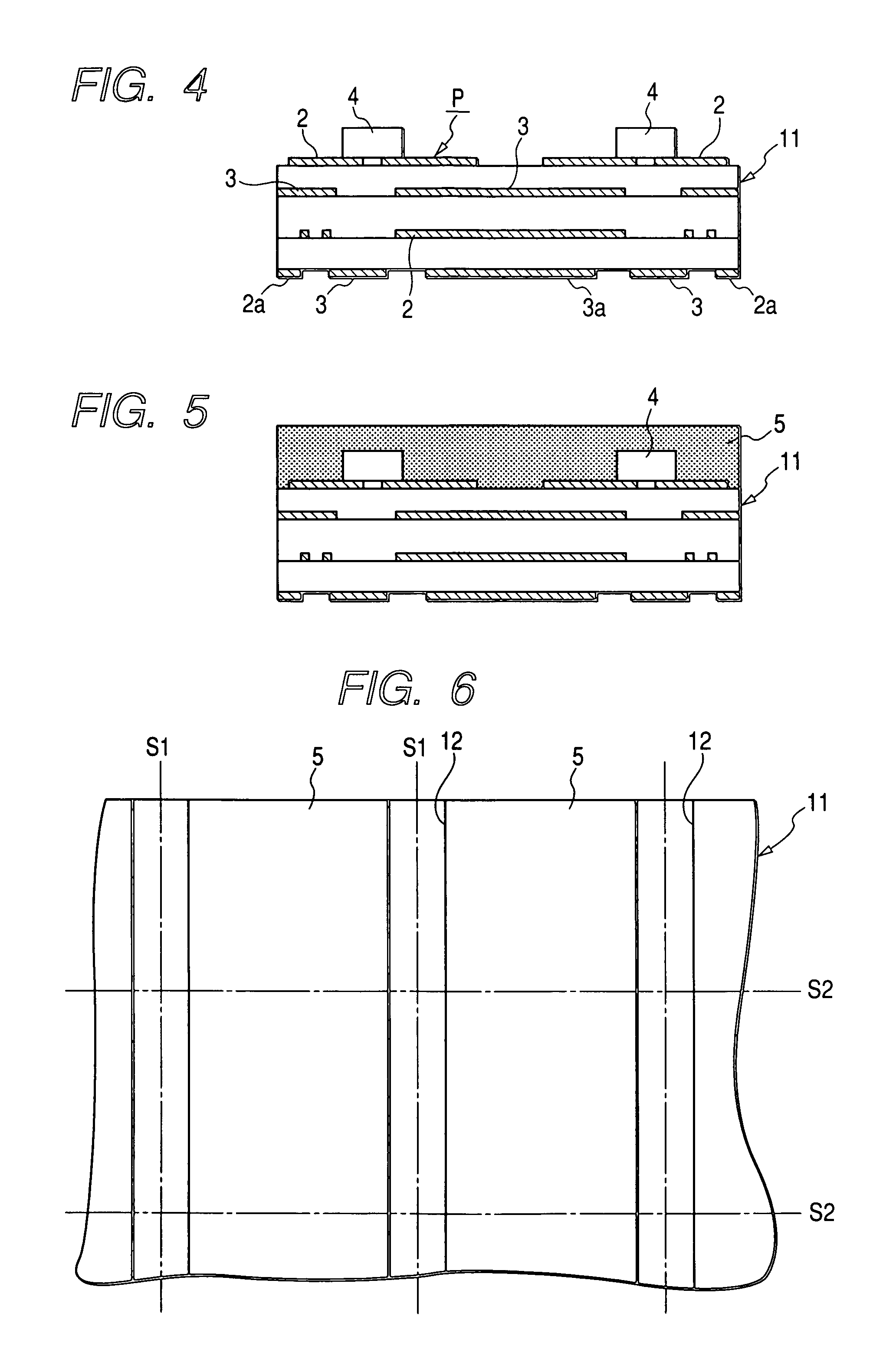

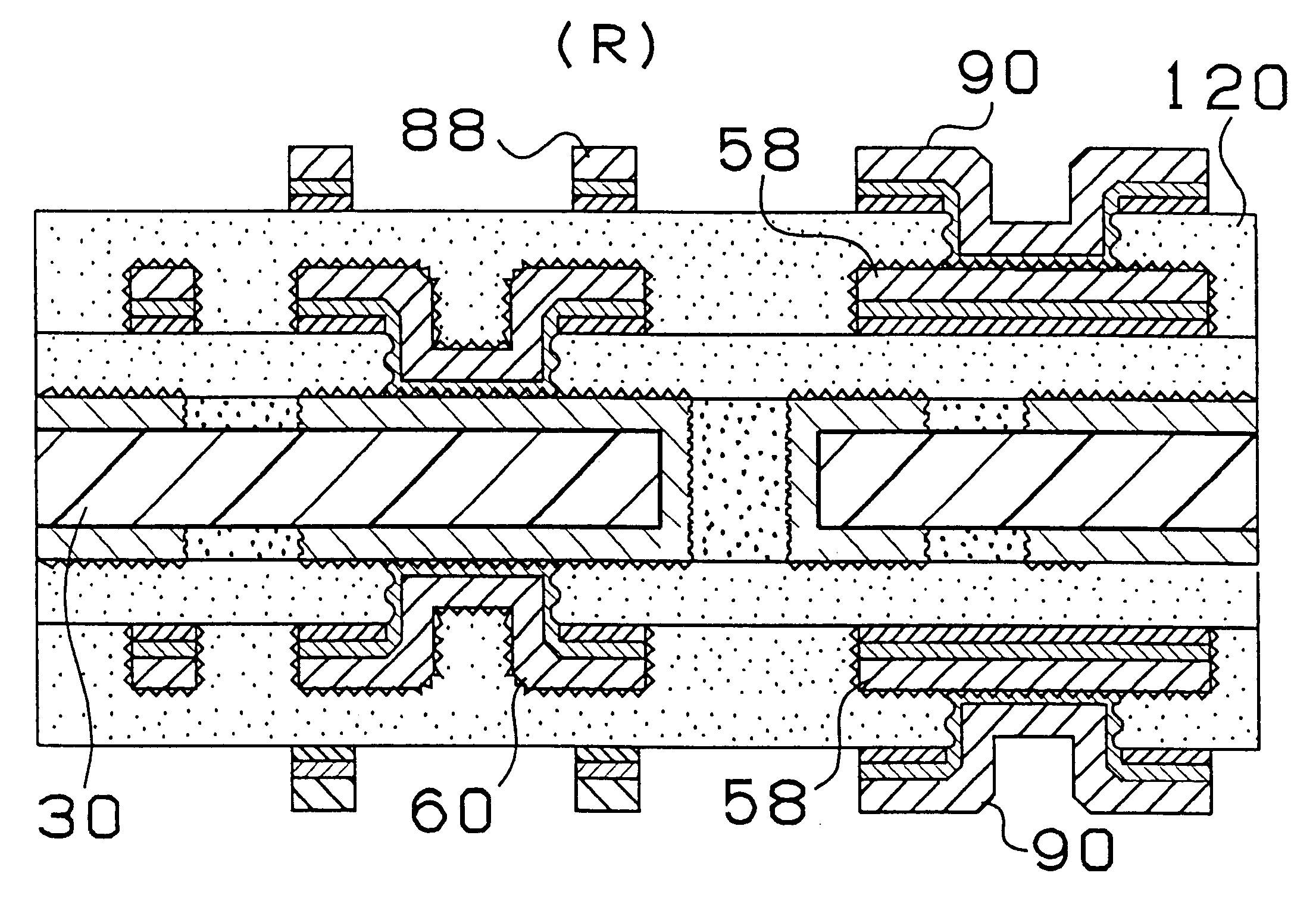

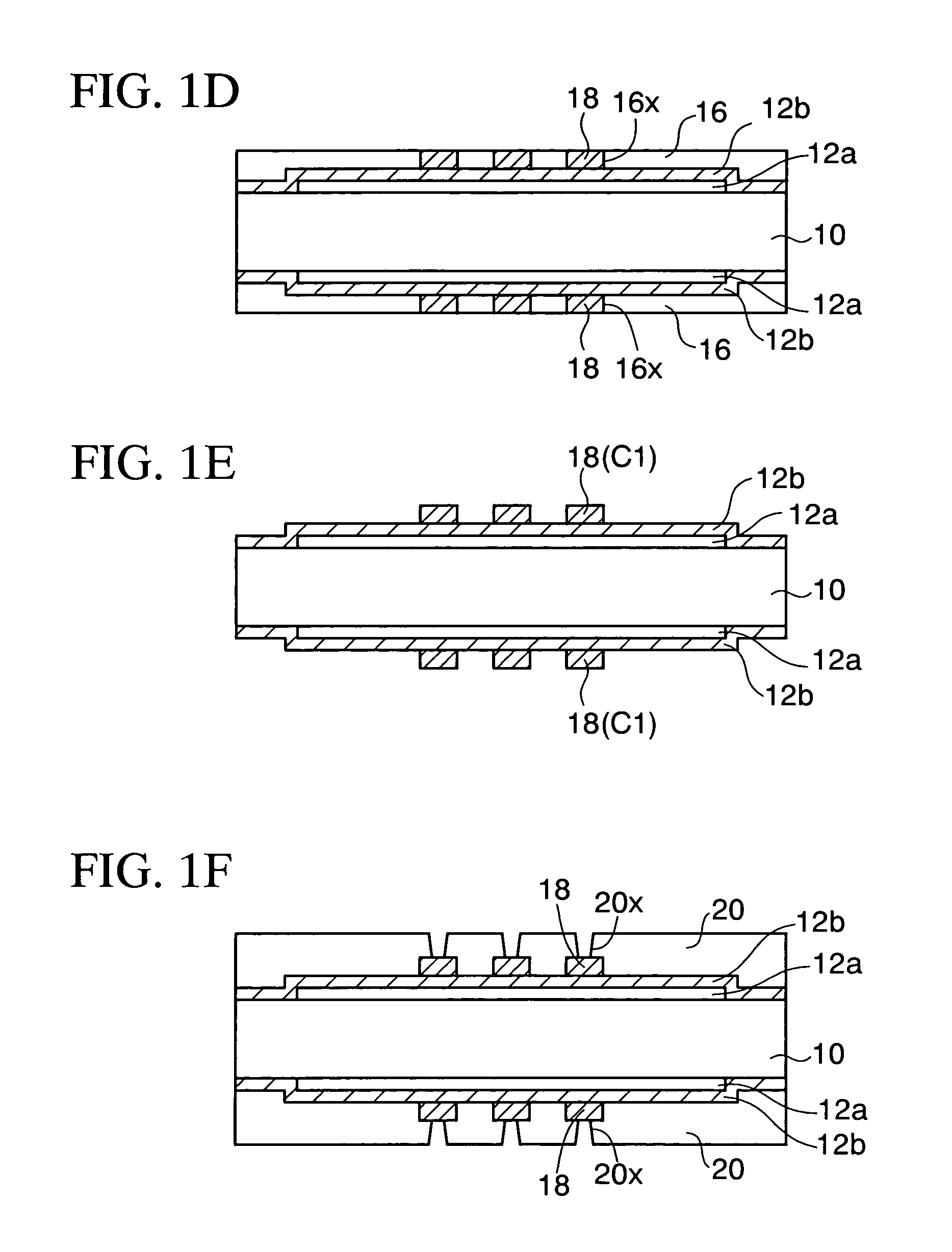

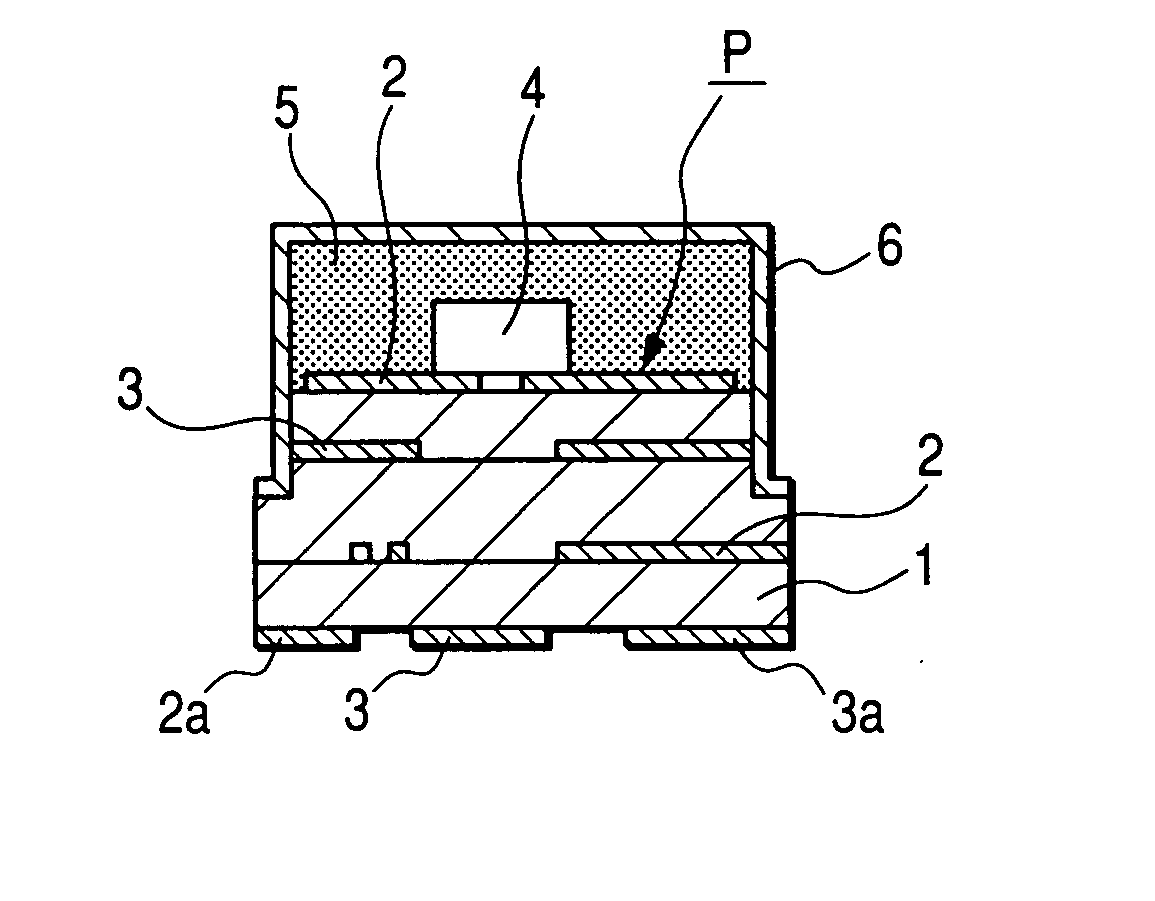

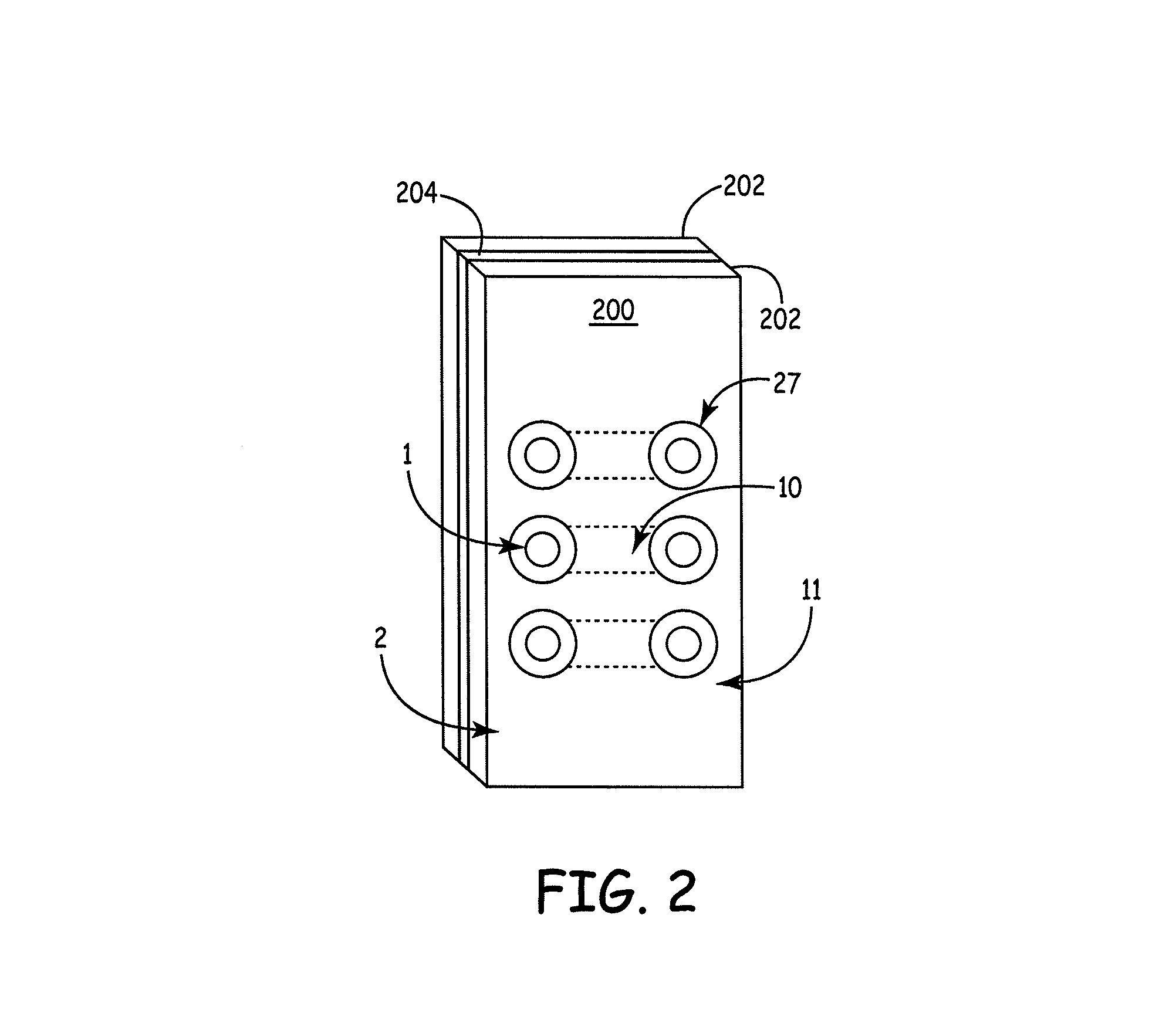

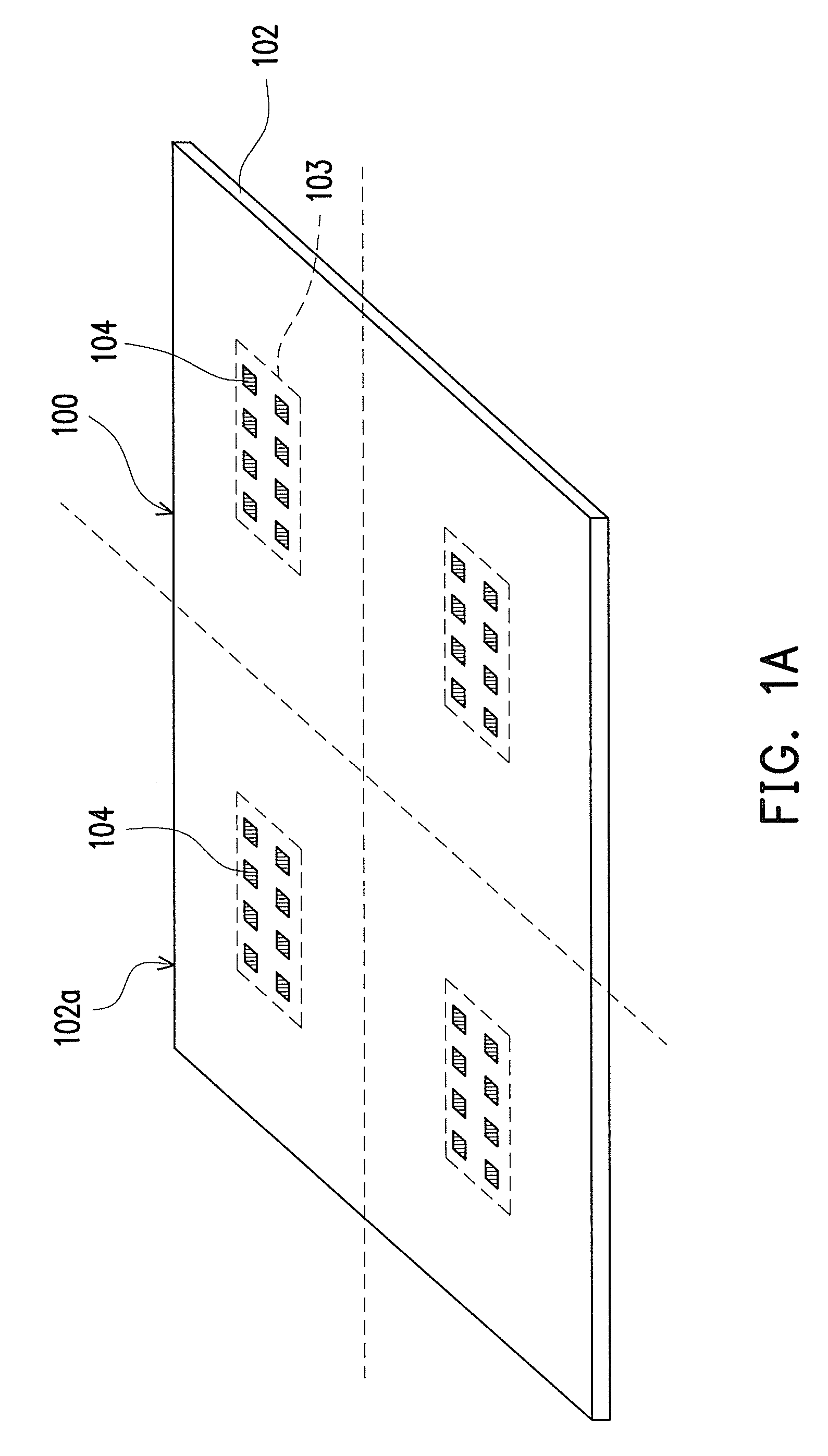

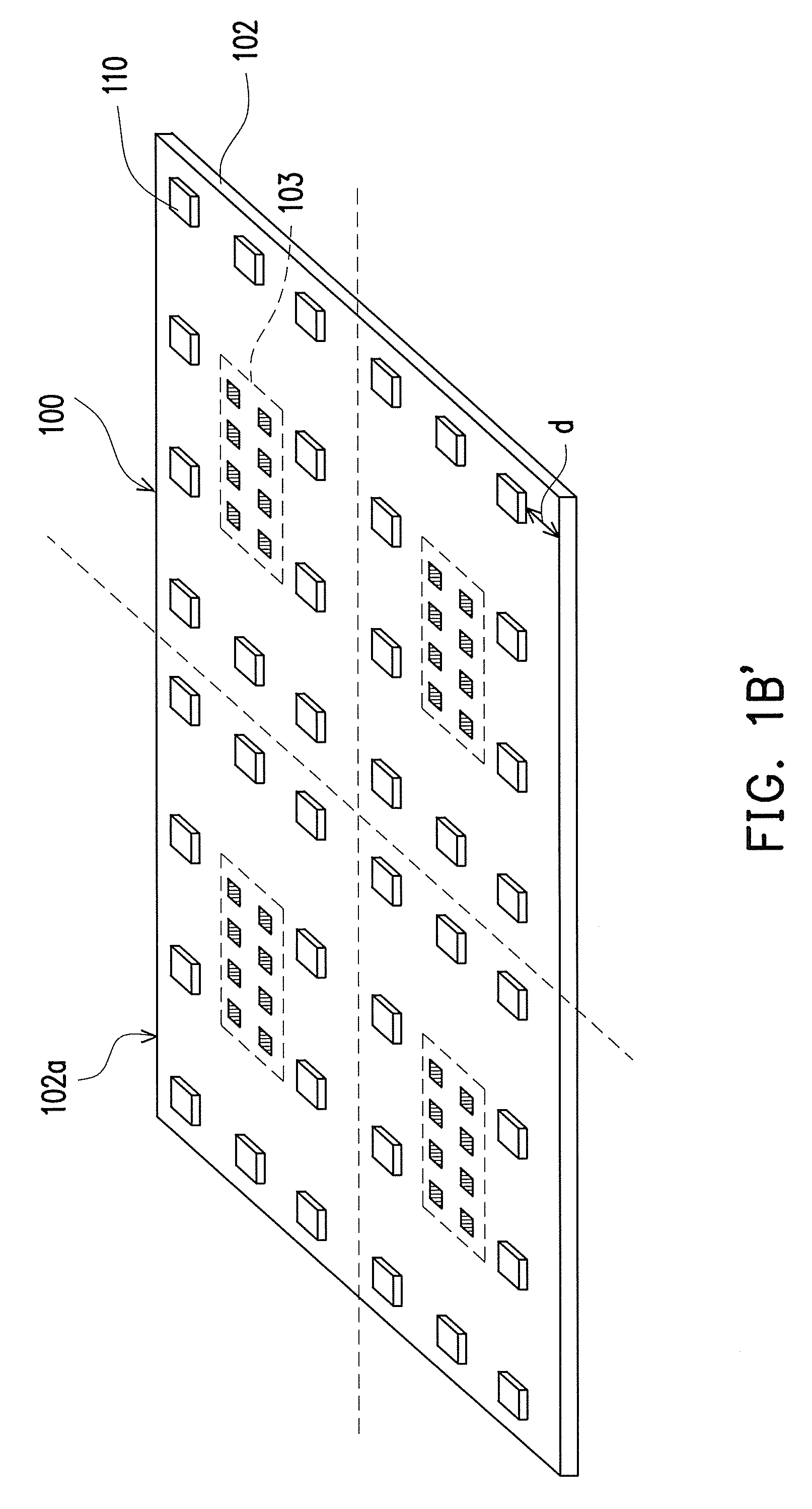

Method for manufacturing circuit modules and circuit module

ActiveUS20080210462A1Easy to manufactureImprove shielding effectPrinted circuit assemblingMagnetic/electric field screeningFilling materialsEngineering

A module substrate defined by an aggregate substrate is prepared, and circuit components are mounted on the module substrate. An insulating resin layer is formed on substantially the entire top surface of the module substrate such that the circuit components are disposed in the insulating resin layer, and a top-surface-shielding layer is formed on the top surface of the insulating resin layer. First through holes are formed in the module substrate and the insulating resin layer at locations corresponding to portions of boundary lines of small substrates so as to extend in a thickness direction of the module substrate and the insulating resin layer. First electrode films are formed on the inner surfaces of the first through holes so as to be connected to the first shielding layer, and the first through holes are filled with a filling material. Next, second through holes are formed at locations corresponding to the remaining portions of the boundary lines of small substrates so as to extend in the thickness direction, and second electrode films are formed on the inner surfaces of the second through holes so as to be connected to the top-surface-shielding layer and the first electrode films. The filling material, with which the first through holes are filled, is cut along the boundary lines of small substrates, resulting in a division of the aggregate substrate into small substrates to obtain circuit modules.

Owner:MURATA MFG CO LTD

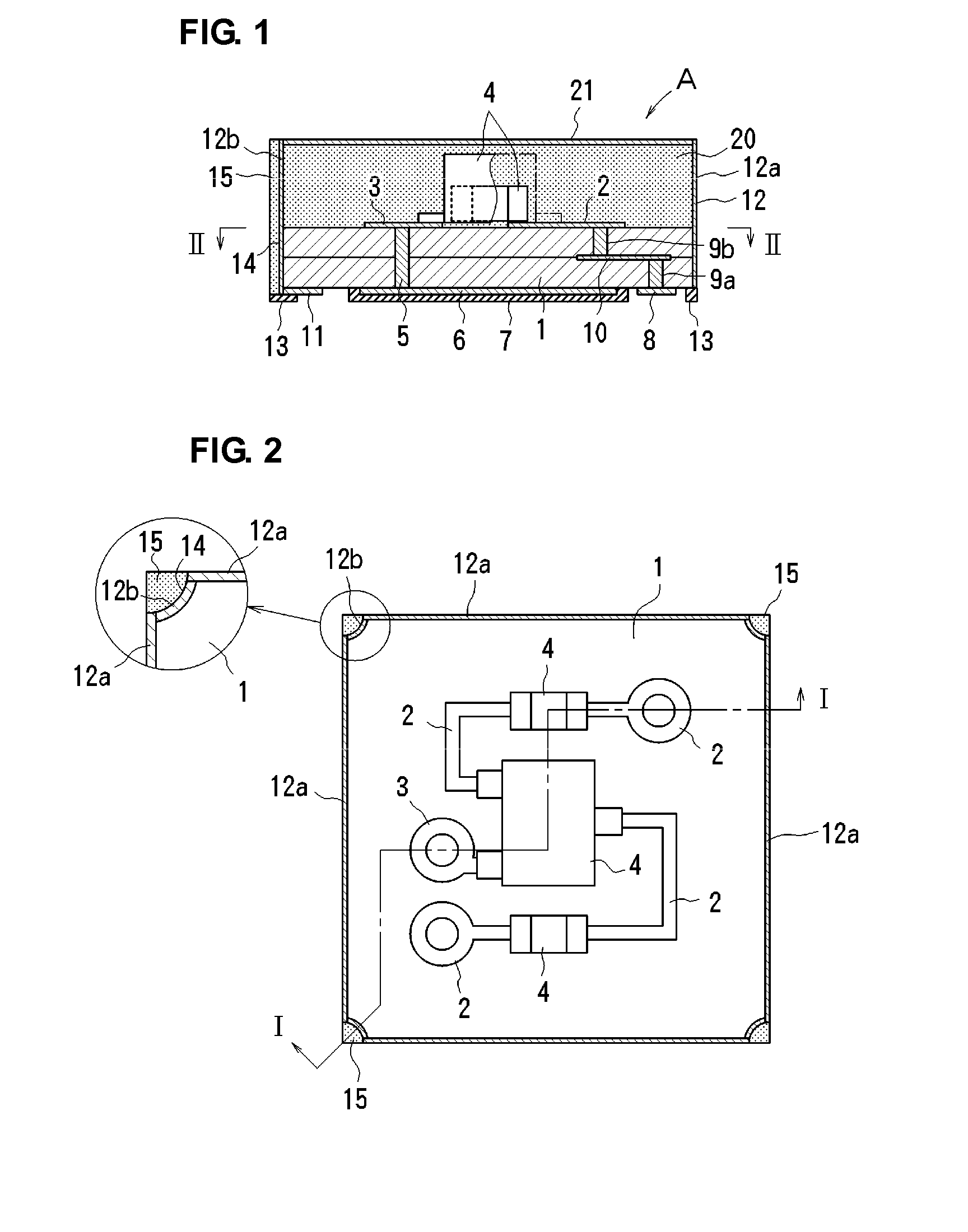

Method of manufacturing shielded electronic circuit units

InactiveUS7478474B2Printed circuit assemblingMagnetic/electric field screeningEngineeringElectronic component

A metallic film and a grounding pattern are surely connected to each other so as to achieve electrical shield of an electronic circuit unit. In an electronic circuit unit, the metallic film is provided on a top surface of a sealing resin portion for burying an electronic component, the side surfaces of the sealing resin portion that are opposite to each other, and the side surfaces of the multi-layered substrate that are opposite to each other. The metallic film is connected to the grounding patterns that are provided on the top surface of the multi-layered substrate or between the laminated layers of the multi-layered substrate. Therefore, it is possible to achieve a superior electrical shielding effect through the metallic film, as compared with the related art. Since the metallic film is formed on the side surfaces of the sealing resin and the side surfaces of the multi-layered substrate, when the metallic film is formed by a plating method, the blind hole may not be provided in the related art. Therefore, it is possible to achieve the superior circulation of the plating liquid, which results in sure connection between the sure connection between the grounding pattern and the metallic film.

Owner:ALPS ALPINE CO LTD

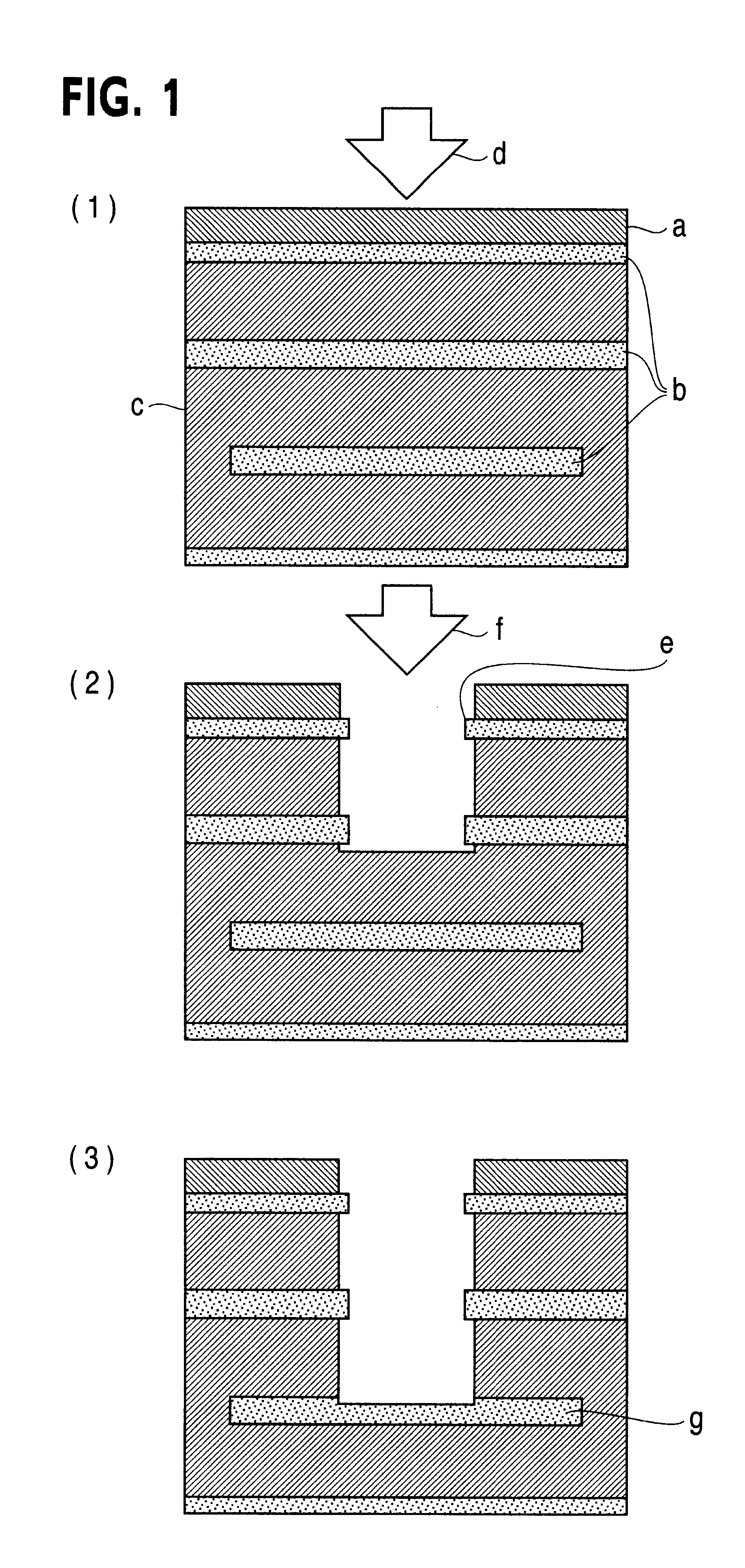

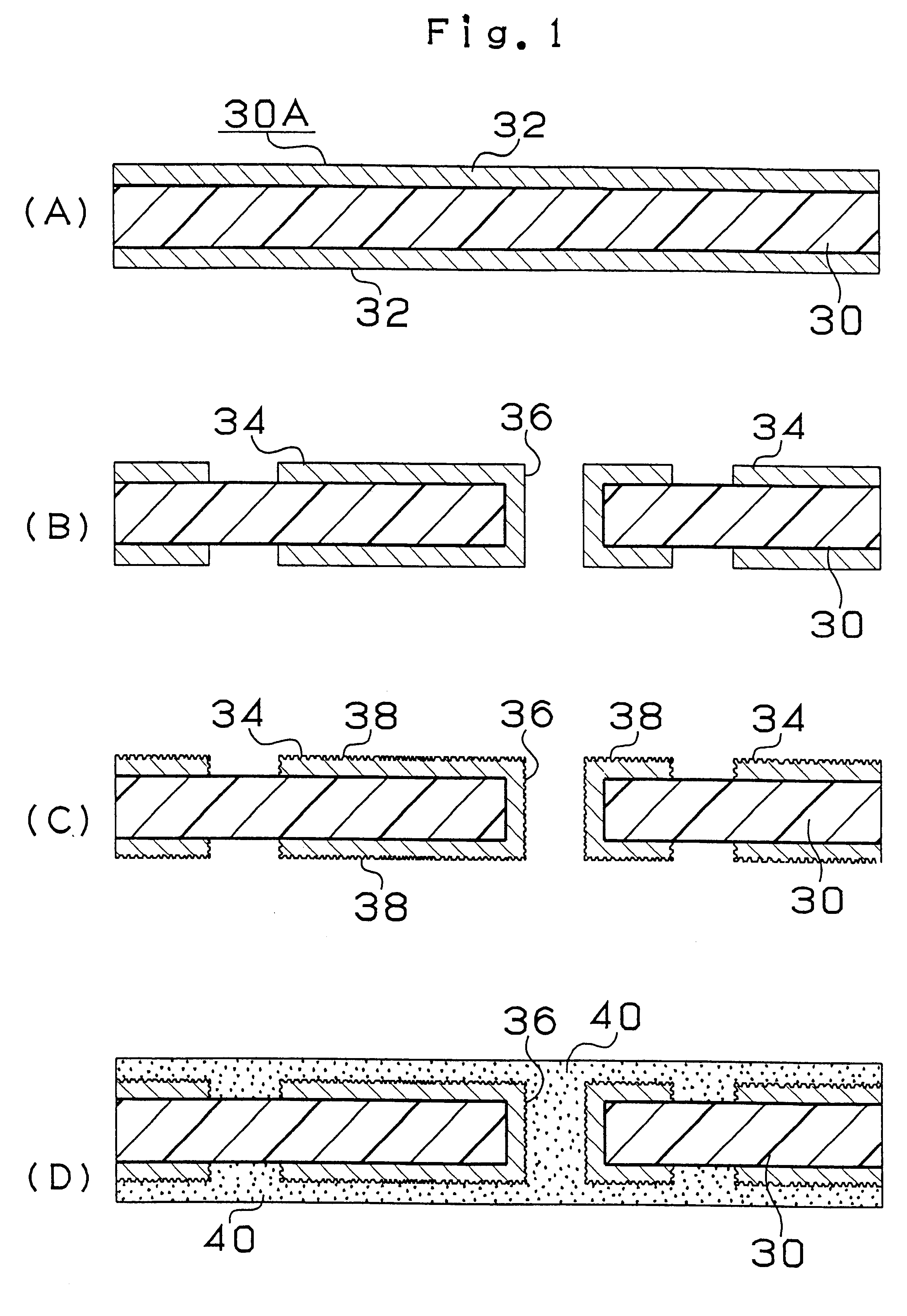

Manufacturing method of a multilayered printed circuit board having an opening made by a laser, and using electroless and electrolytic plating

InactiveUS6591495B2Satisfactory productivityAvoid separationSolid-state devicesInsulating layers/substrates workingCopper foilPulse shaping

An opening is formed in resin by a laser beam so that a via hole is formed. Copper foil, the thickness of which is reduced to 3 mum by etching to lower the thermal conductivity, is used as a conformal mask. Therefore, an opening is formed in the resin and the number of irradiation of pulse-shape laser beam is reduced. Thus, occurence of undercut of the resin, which forms an interlayer insulating resin layer, can be prevented and the reliability of the connection of the via holes can be improved.

Owner:IBIDEN CO LTD

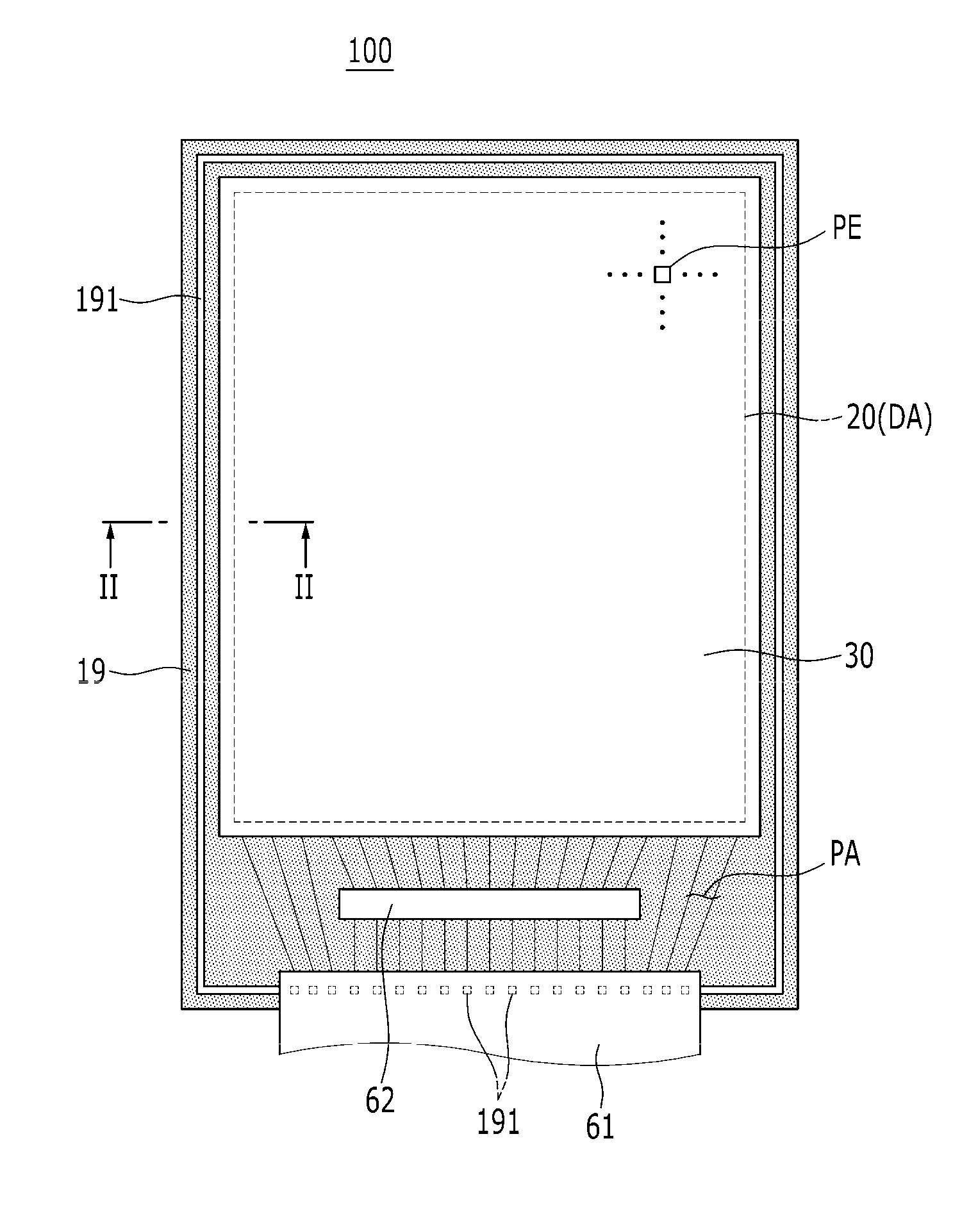

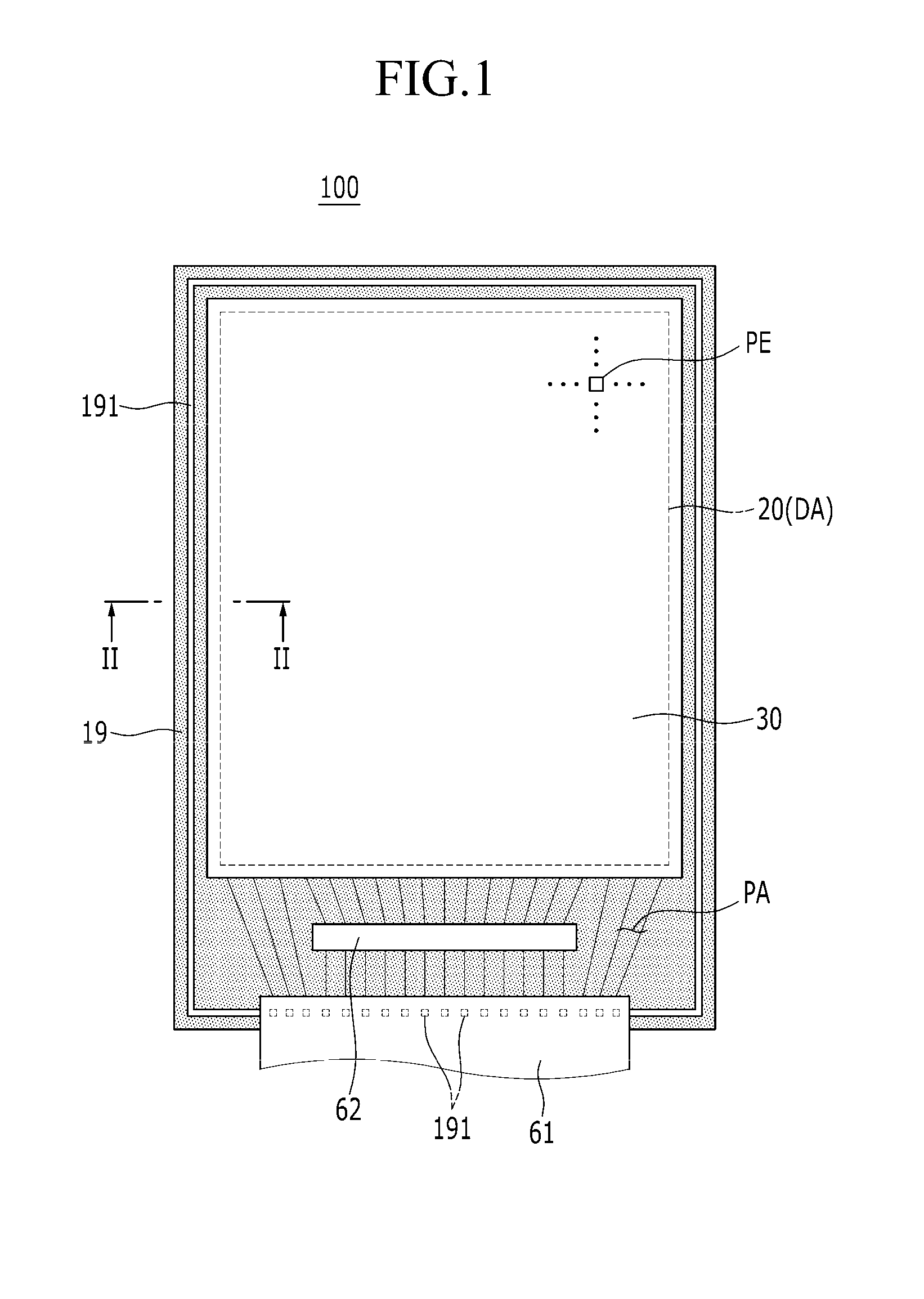

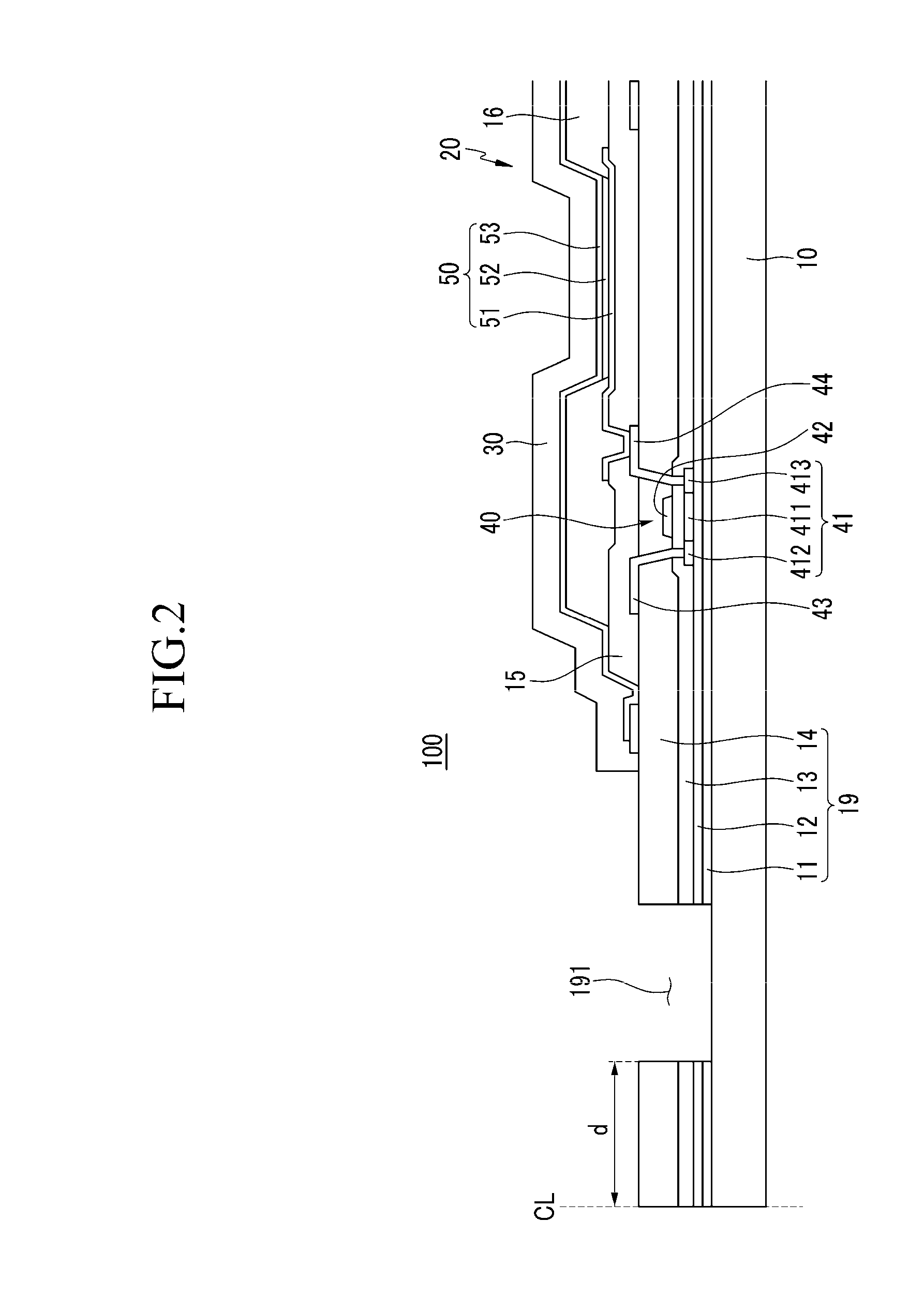

Flexible display device

ActiveUS20150036299A1Improve production yieldSuppressing panel shrinkageFinal product manufactureFlexible printed circuitsFlexible displayComputer science

A flexible display device that can suppress spread of cracks of an inorganic layer is provided. A flexible display device includes a flexible substrate including a display area and a periphery surrounding the display area, an inorganic layer formed on the flexible substrate, a display unit formed on the display area, and a thin film encapsulation layer covering the display unit. The inorganic layer includes an opening disposed on a periphery between edges of the flexible substrate and the thin film encapsulation layer.

Owner:SAMSUNG DISPLAY CO LTD

Systems, articles, and methods for stretchable printed circuit boards

ActiveUS20150065840A1Insulating layers/substrates workingSurface layering apparatusElectrical and Electronics engineering

Improved stretchable printed circuit boards, and fabrication methods thereof, are described. The improved stretchable printed circuit boards include a serpentine conductive trace enclosed by stretchable dielectric material. The stretchable dielectric material has a serpentine shape itself, realized by crenulated edges. The crenulated edges reduce torsional strain on the conductive trace and are formed, for example, by cutting away sections of the stretchable dielectric material proximate segments of the serpentine conductive trace where the serpentine conductive trace changes direction.

Owner:GOOGLE LLC

Method for manufacturing circuit modules and circuit module

ActiveUS7488903B2Easy to manufactureImprove shielding effectPrinted circuit assemblingMagnetic/electric field screeningFilling materialsEngineering

A module substrate defined by an aggregate substrate is prepared, and circuit components are mounted on the module substrate. An insulating resin layer is formed on substantially the entire top surface of the module substrate such that the circuit components are disposed in the insulating resin layer, and a top-surface-shielding layer is formed on the top surface of the insulating resin layer. First through holes are formed in the module substrate and the insulating resin layer at locations corresponding to portions of boundary lines of small substrates so as to extend in a thickness direction of the module substrate and the insulating resin layer. First electrode films are formed on the inner surfaces of the first through holes so as to be connected to the first shielding layer, and the first through holes are filled with a filling material. Next, second through holes are formed at locations corresponding to the remaining portions of the boundary lines of small substrates so as to extend in the thickness direction, and second electrode films are formed on the inner surfaces of the second through holes so as to be connected to the top-surface-shielding layer and the first electrode films. The filling material, with which the first through holes are filled, is cut along the boundary lines of small substrates, resulting in a division of the aggregate substrate into small substrates to obtain circuit modules.

Chip package and manufacturing method thereof

ActiveUS20100109132A1Improve design flexibilityLess effortSemiconductor/solid-state device detailsCross-talk/noise/interference reductionElectromagnetic interferenceElectromagnetic interference shielding

A chip package including a shielding layer having a plurality of conductive connectors for better electromagnetic interferences shielding is provided. The conductive connectors can be flexibly arranged within the molding compound for better shielding performance. The shielding layer having the conductive connectors functions as the EMI shield and the shielding layer is electrically grounded within the package structure.

Owner:ADVANCED SEMICON ENG INC

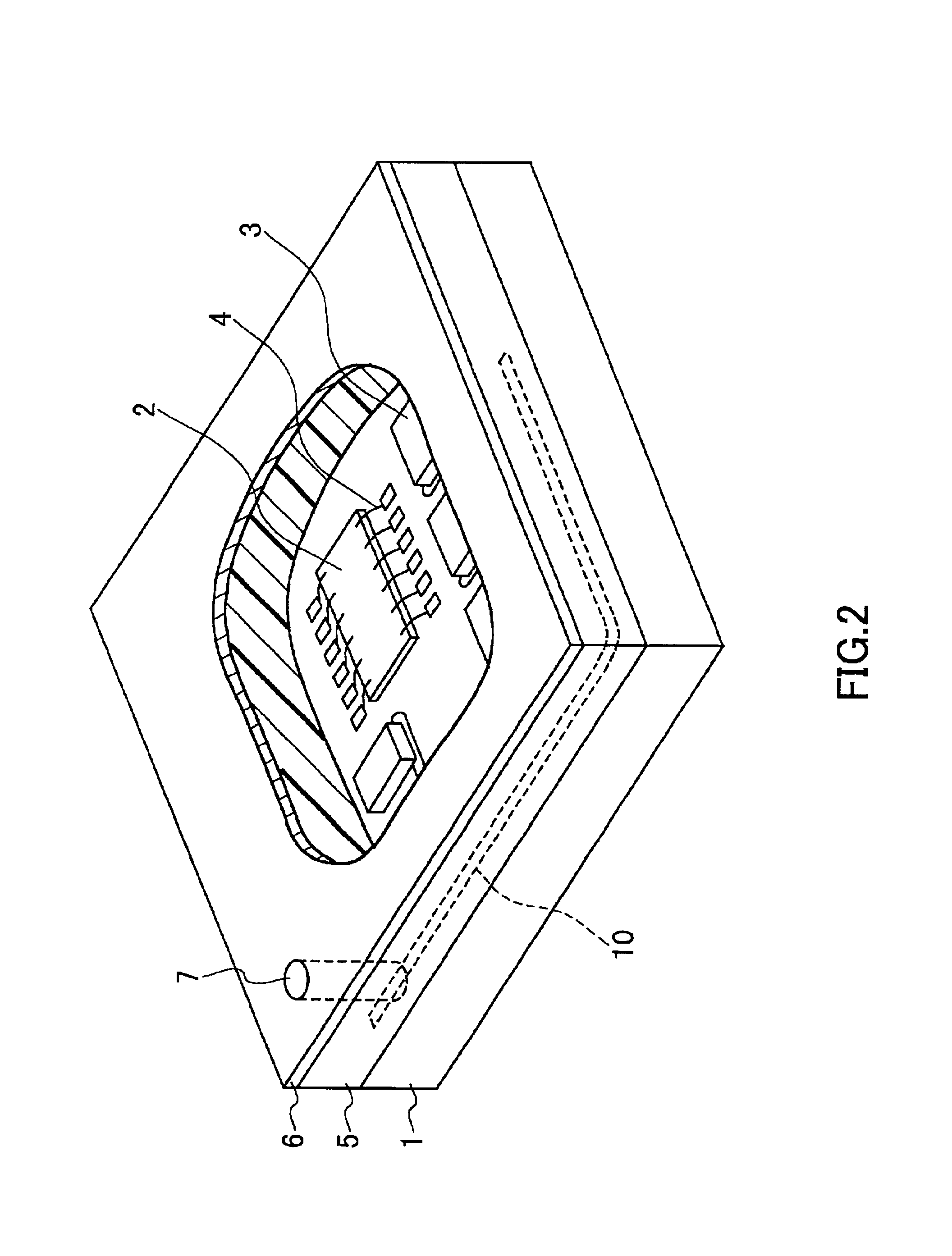

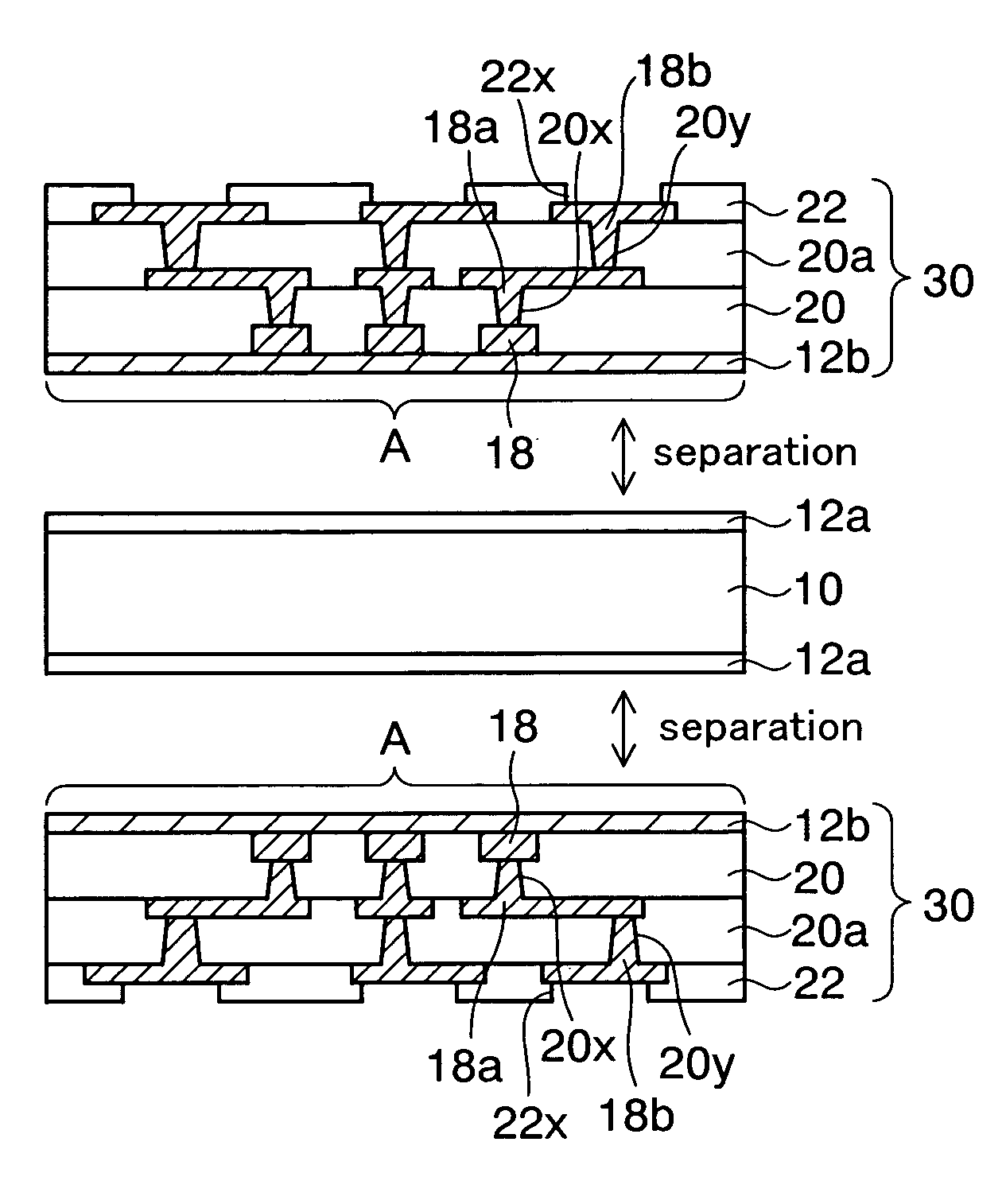

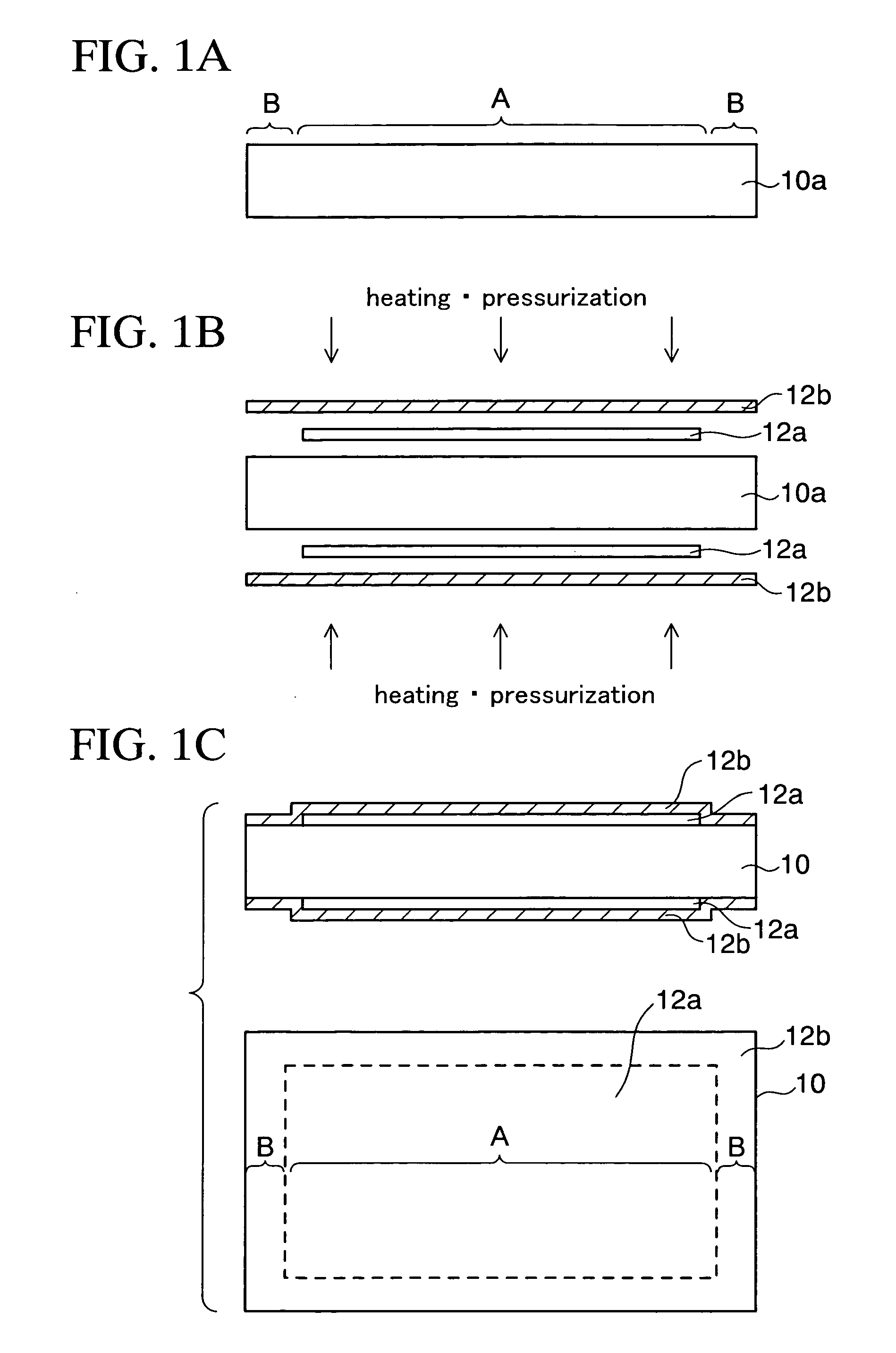

Method of manufacturing wiring substrate and method of manufacturing electronic component mounting structure

ActiveUS20070124924A1Easy to conveyEasy to handlePrinted circuit assemblingLine/current collector detailsMetal foilEngineering

A method of manufacturing a wiring substrate including the steps of, obtaining a temporary substrate from a prepreg, and concurrently attaching a metal foil onto at least one surface of the temporary substrate, by disposing the metal foil on a prepreg through a underlying layer interposed between them, in a way that the underlying layer is disposed in a wiring formation region on the prepreg, and the metal foil having a size larger than that of the underlying layer is caused to contact with an outer peripheral portion of the wiring formation region, and then by hardening the prepreg with heating and pressurization, forming a build-up wiring layer on the metal foil, and obtaining a wiring member in which the build-up wiring layer is formed on the metal foil, by cutting out a portion of structure in which the underlying layer, the metal foil and the build-up wiring layer are formed on the temporary substrate, the portion corresponding to a peripheral portion of the underlying layer, and thus by separating the metal foil from the temporary substrate.

Owner:SHINKO ELECTRIC IND CO LTD

Shielded electronic circuit unit and method of manufacturing the same

InactiveUS20060266547A1Improve shielding effectPrinted circuit assemblingMagnetic/electric field screeningEngineeringElectronic component

A metallic film and a grounding pattern are surely connected to each other so as to achieve electrical shield of an electronic circuit unit. In an electronic circuit unit, the metallic film is provided on a top surface of a sealing resin portion for burying an electronic component, the side surfaces of the sealing resin portion that are opposite to each other, and the side surfaces of the multi-layered substrate that are opposite to each other. The metallic film is connected to the grounding patterns that are provided on the top surface of the multi-layered substrate or between the laminated layers of the multi-layered substrate. Therefore, it is possible to achieve a superior electrical shielding effect through the metallic film, as compared with the related art. Since the metallic film is formed on the side surfaces of the sealing resin and the side surfaces of the multi-layered substrate, when the metallic film is formed by a plating method, the blind hole may not be provided in the related art. Therefore, it is possible to achieve the superior circulation of the plating liquid, which results in sure connection between the sure connection between the grounding pattern and the metallic film.

Owner:ALPS ALPINE CO LTD

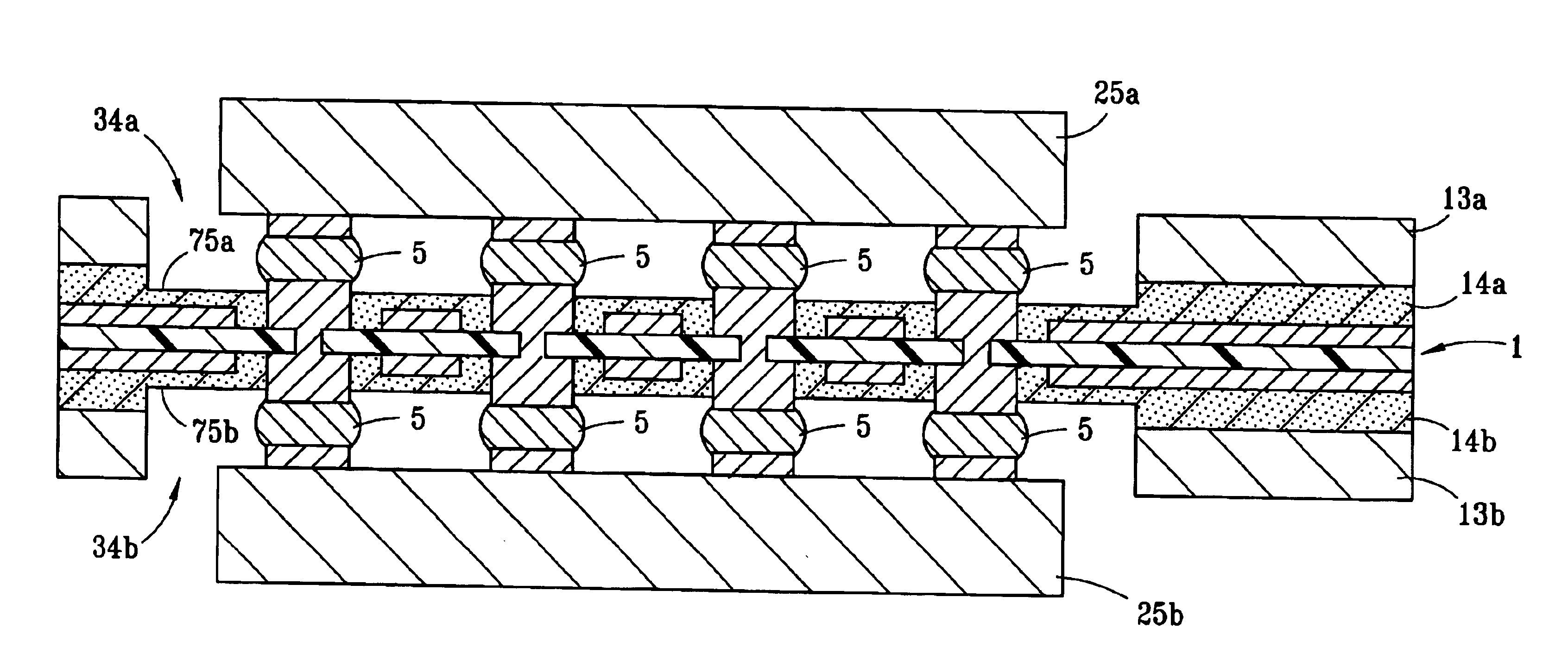

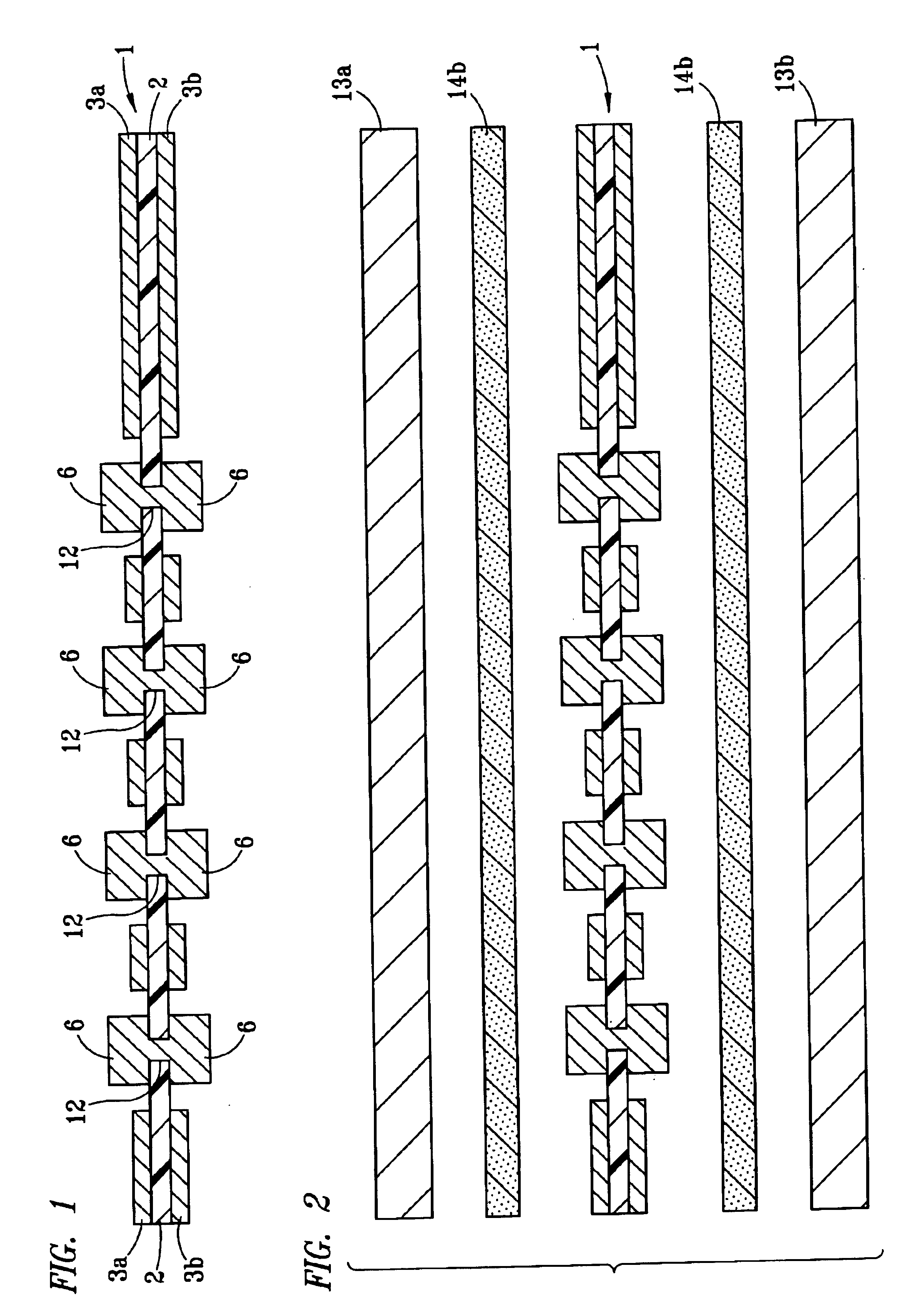

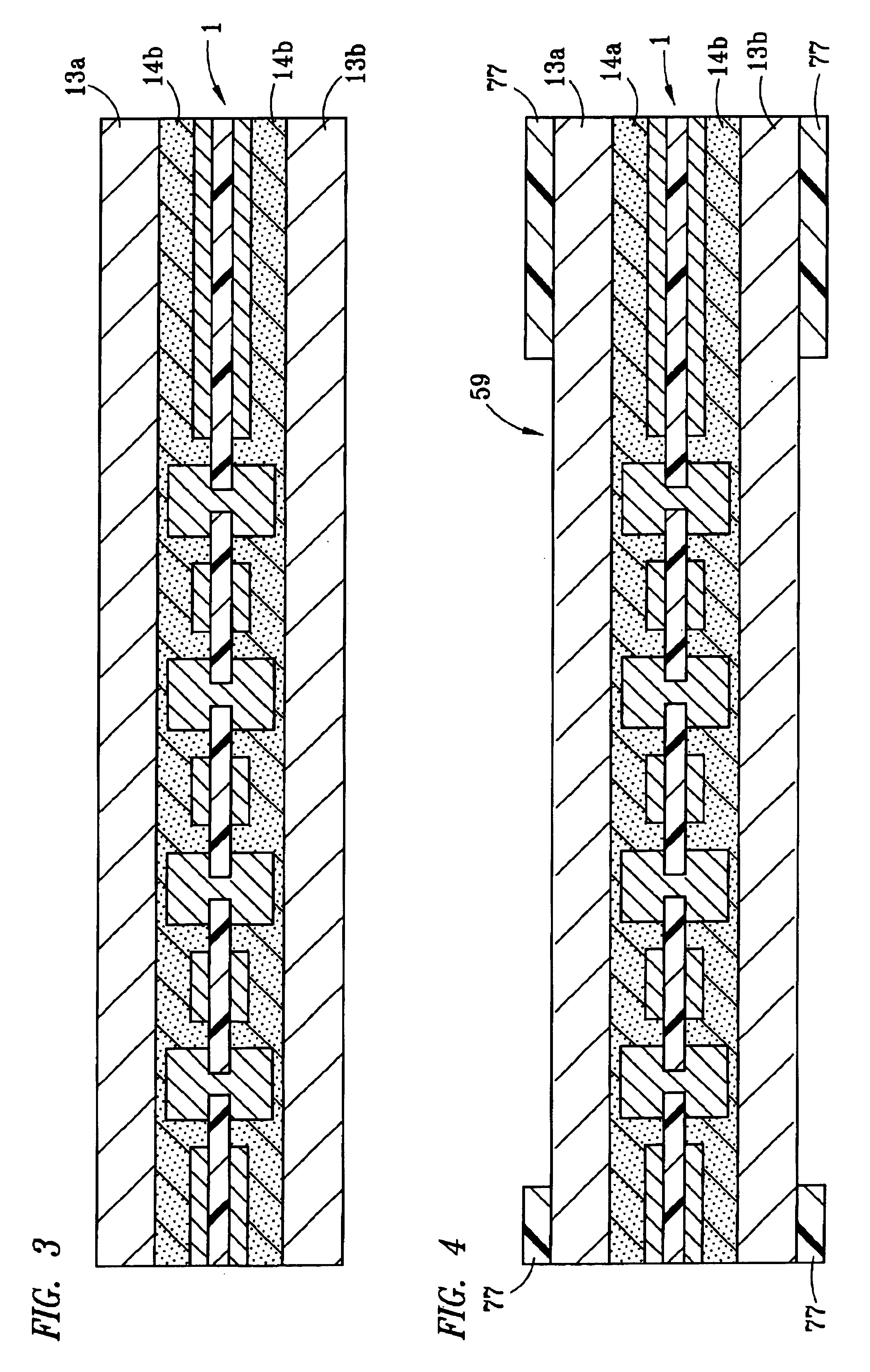

Flex-based IC package construction employing a balanced lamination

InactiveUS6876088B2Short z-dimensionThinner metal stiffenerCross-talk/noise/interference reductionSemiconductor/solid-state device detailsEngineeringIntegrated circuit

The present invention provides for a balanced laminated integrated circuit package. The package includes a two metal layer bumped circuit, a first adhesive layer having a thickness on a first side of the bumped circuit, a first outer conductive layer having a thickness bonded to the first adhesive layer and a second adhesive layer having a thickness substantially equal to the thickness of the first adhesive layer on a second side of the bumped circuit. The invention also includes a second outer conductive layer bonded to the second adhesive layer, the second outer conductive layer having a thickness substantially equal to the thickness of the first outer conductive layer.

Owner:IBM CORP

Backside seal for conformal shielding process

In one embodiment, a meta-module having circuitry for two or more modules is formed on a substrate, which is preferably a laminated substrate. The circuitry for the different modules is initially formed on the single meta-module. Each module will have one or more component areas in which the circuitry is formed. A metallic structure is formed on or in the substrate for each component area to be shielded. A single body, such as an overmold body, is then formed over all of the modules on the meta-module. At least a portion of the metallic structure for each component area to be shielded is then exposed through the body by a cutting, drilling, or like operation. Next, an electromagnetic shield material is applied to the exterior surface of the body of each of the component areas to be shielded and in contact with the exposed portion of the metallic structures.

Owner:QORVO US INC

Isolated conformal shielding

ActiveUS20090025211A1Printed circuit assemblingCross-talk/noise/interference reductionEngineeringElectromagnetic shielding

In one embodiment, a meta-module having circuitry for two or more modules is formed on a substrate, which is preferably a laminated substrate. The circuitry for the different modules is initially formed on the single meta-module. Each module will have one or more component areas in which the circuitry is formed. A metallic structure is formed on or in the substrate for each component area to be shielded. A single body, such as an overmold body, is then formed over all of the modules on the meta-module. At least a portion of the metallic structure for each component area to be shielded is then exposed through the body by a cutting, drilling, or like operation. Next, an electromagnetic shield material is applied to the exterior surface of the body of each of the component areas to be shielded and in contact with the exposed portion of the metallic structures.

Owner:QORVO US INC

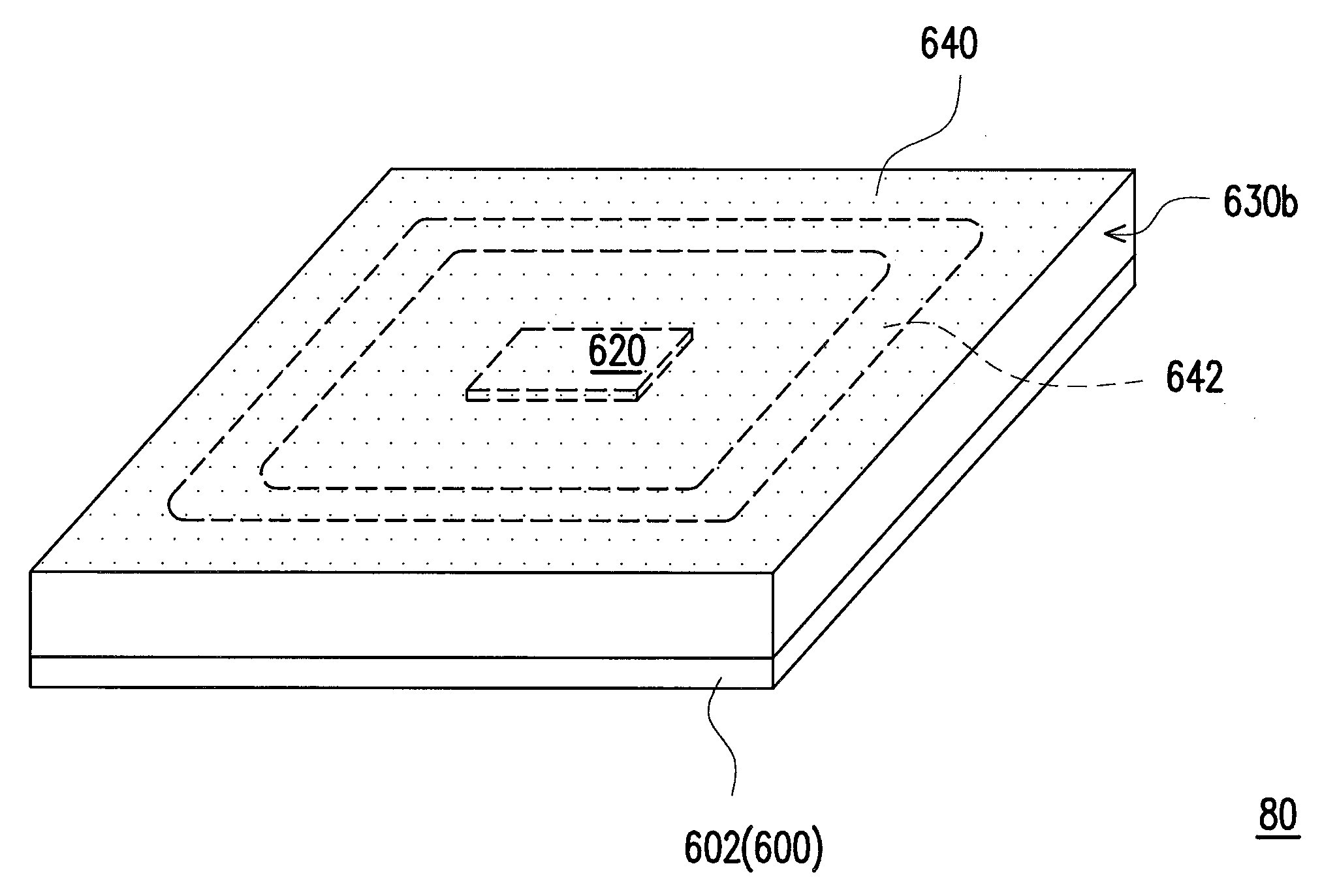

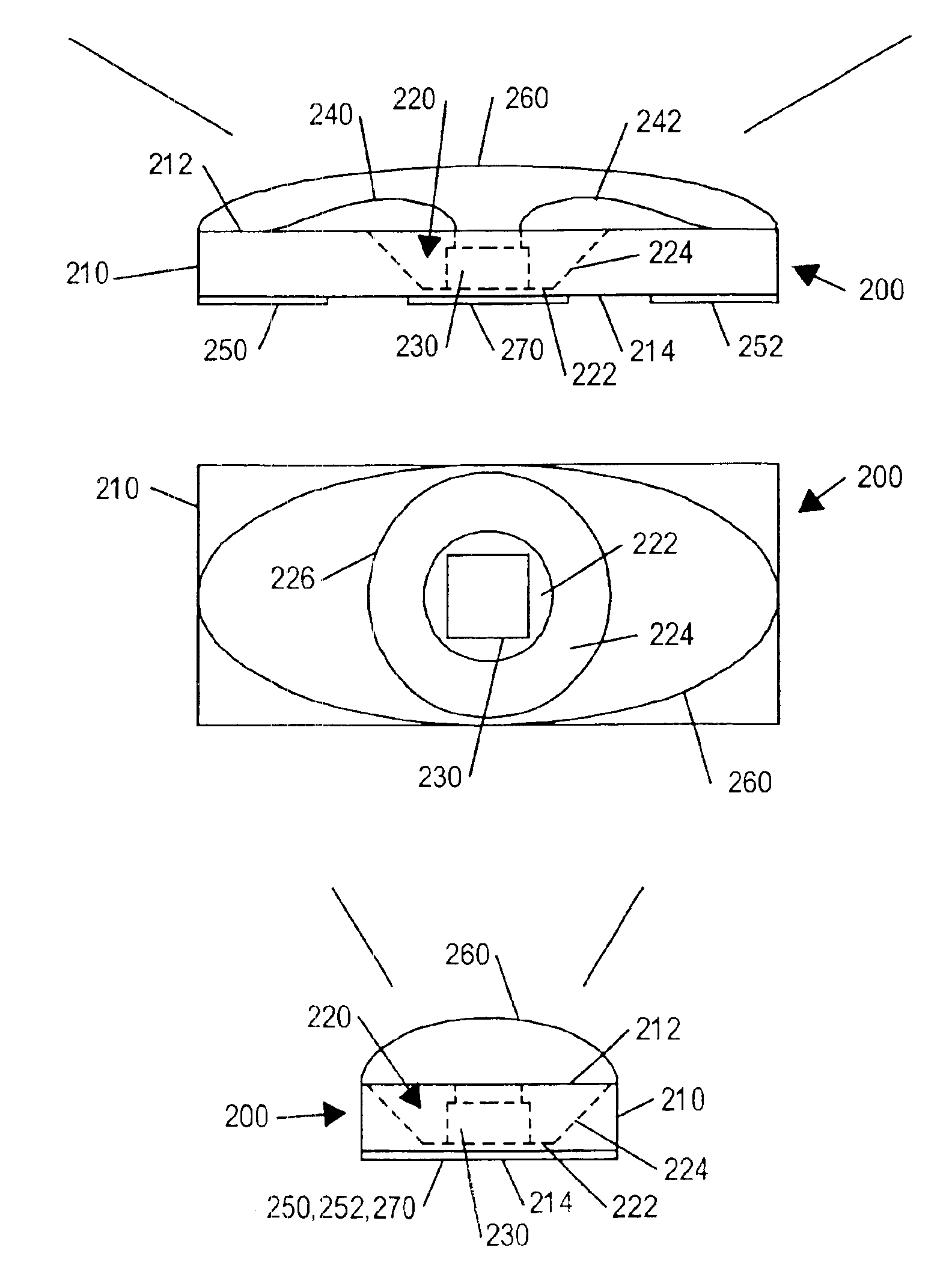

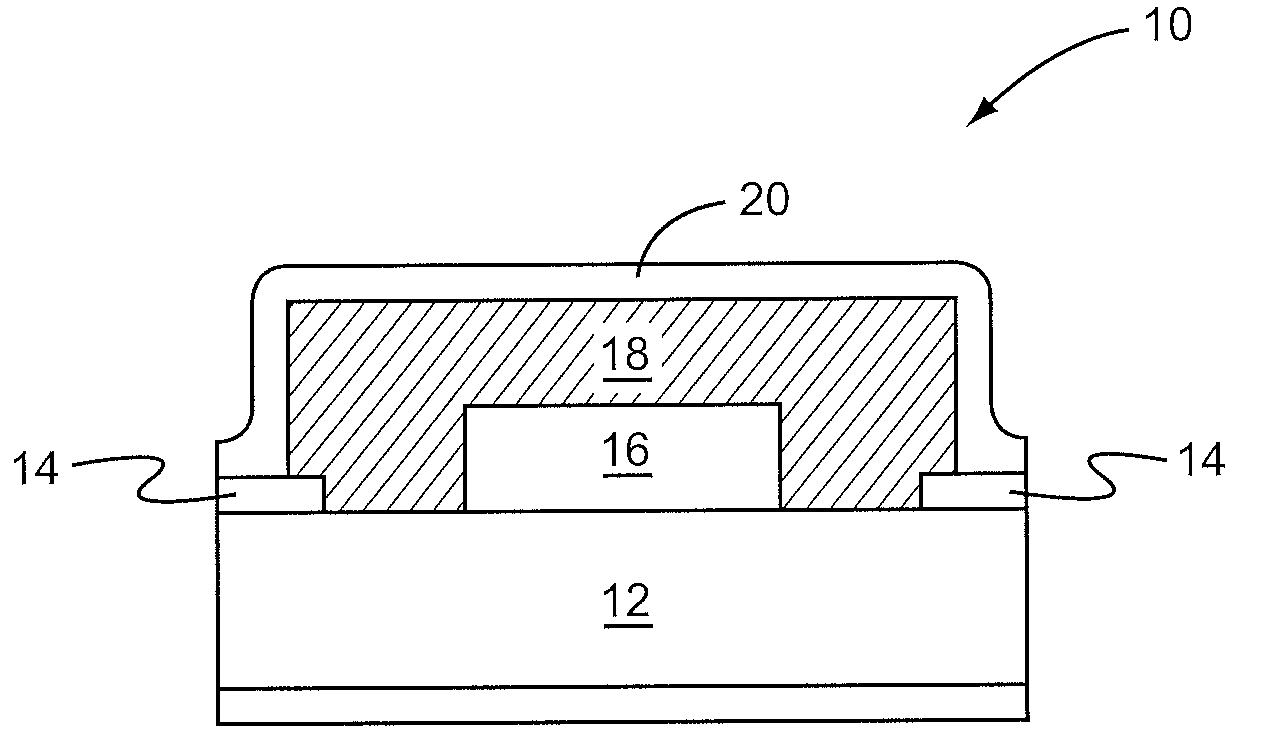

Light source

InactiveUS6949771B2Easy to solveEffective coolingPrinted circuit aspectsSolid-state devicesPlanar substrateSurface mounting

A light source suitable for surface mounting onto a printed circuit board. The light source includes a planar substrate with a centrally positioned aperture. A light emitting diode is mounted on a metallic layer covering the bottom of the aperture, and is encapsulated by a transparent encapsulant material. The metallic layer provides a thermal path for heat generated by the light emitting diode.

Owner:DOCUMENT SECURITY SYST

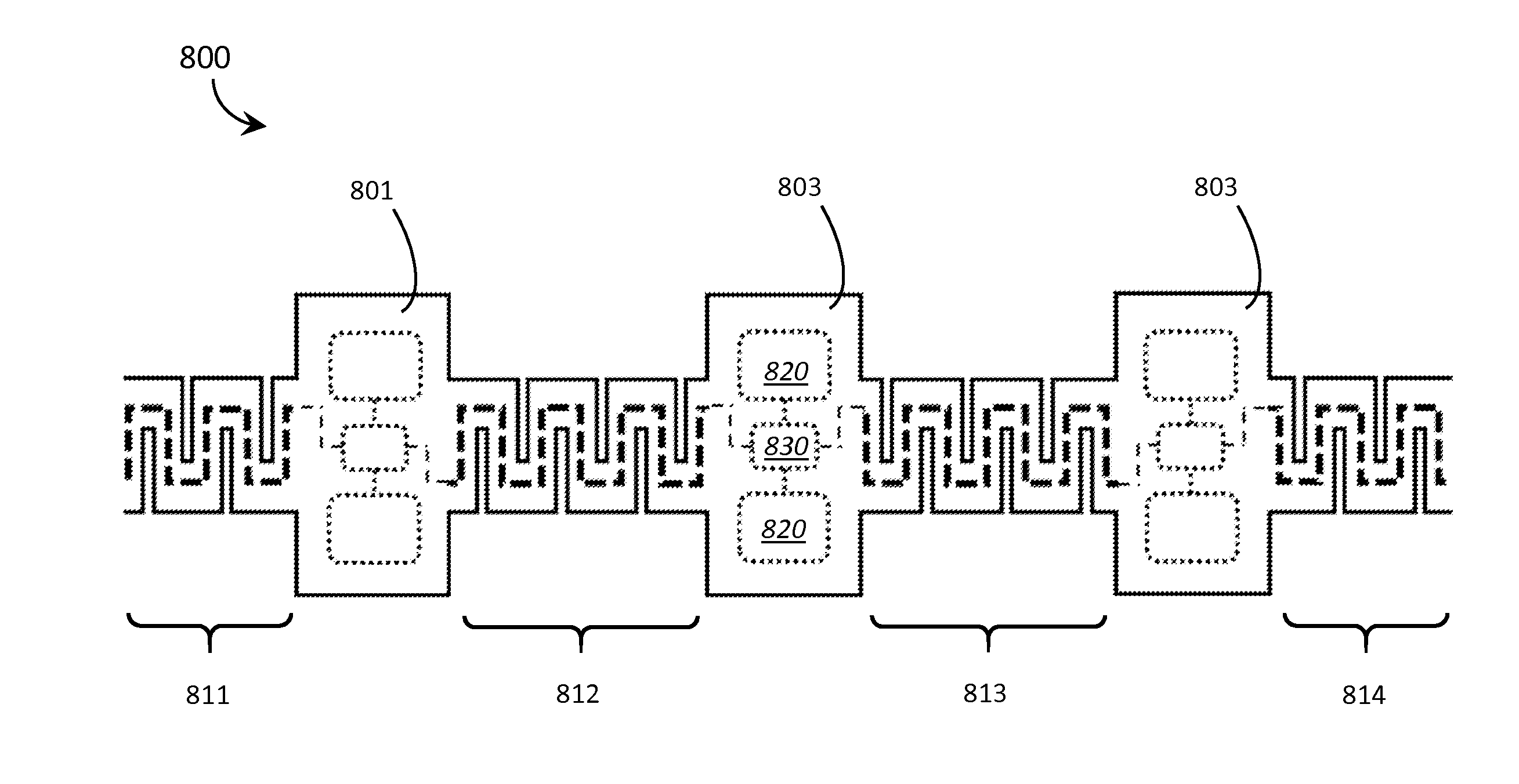

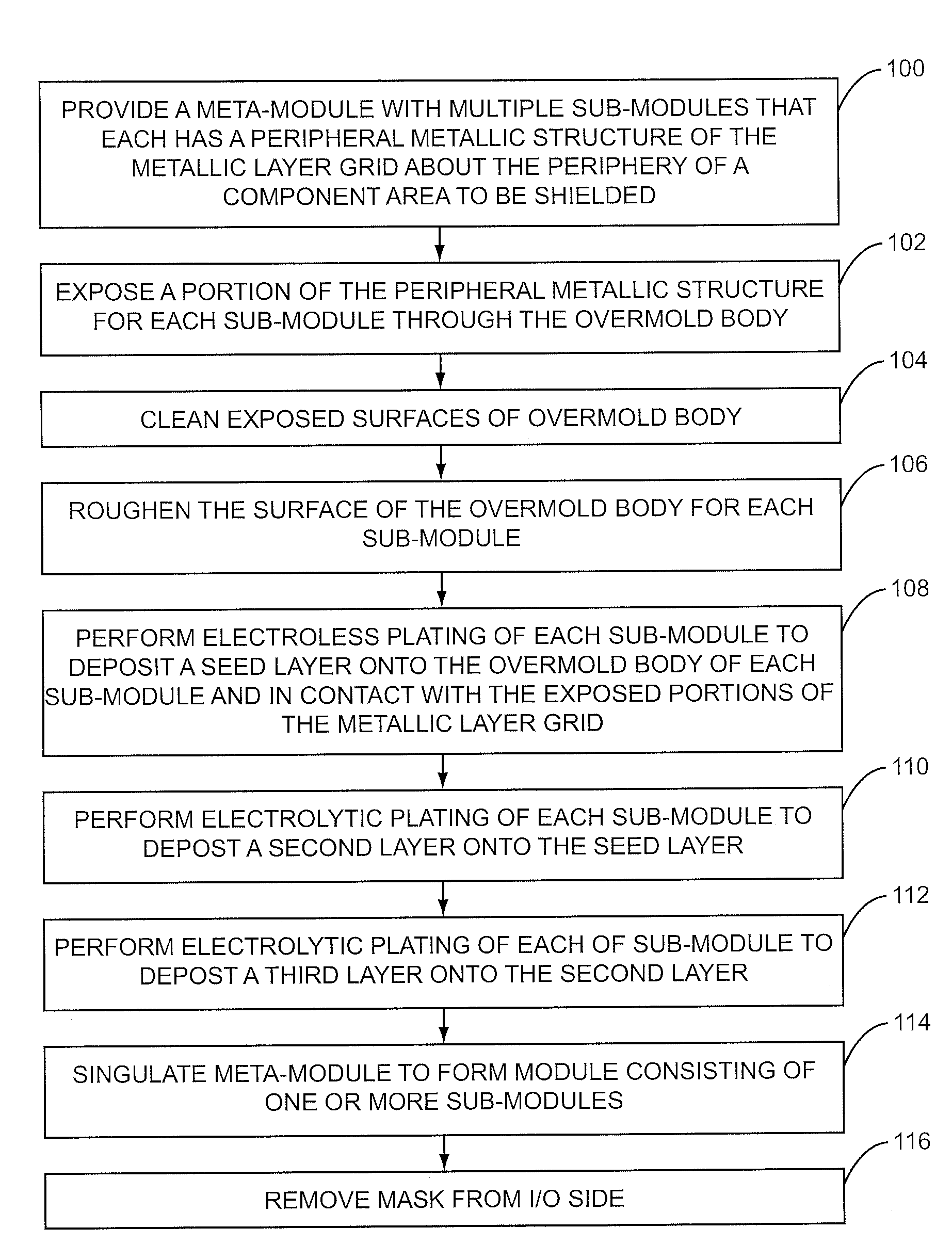

Conformal shielding employing segment buildup

InactiveUS20090000815A1Magnetic/electric field screeningCross-talk/noise/interference reductionElectromagnetic shielding

In one embodiment, a meta-module having circuitry for two or more modules is formed on a substrate, which is preferably a laminated substrate. The circuitry for the different modules is initially formed on the single meta-module. Each module will have one or more component areas in which the circuitry is formed. A metallic structure is formed on or in the substrate for each component area to be shielded. A single body, such as an overmold body, is then formed over all of the modules on the meta-module. At least a portion of the metallic structure for each component area to be shielded is then exposed through the body by a cutting, drilling, or like operation. Next, an electromagnetic shield material is applied to the exterior surface of the body of each of the component areas to be shielded and in contact with the exposed portion of the metallic structures.

Owner:RF MICRO DEVICES

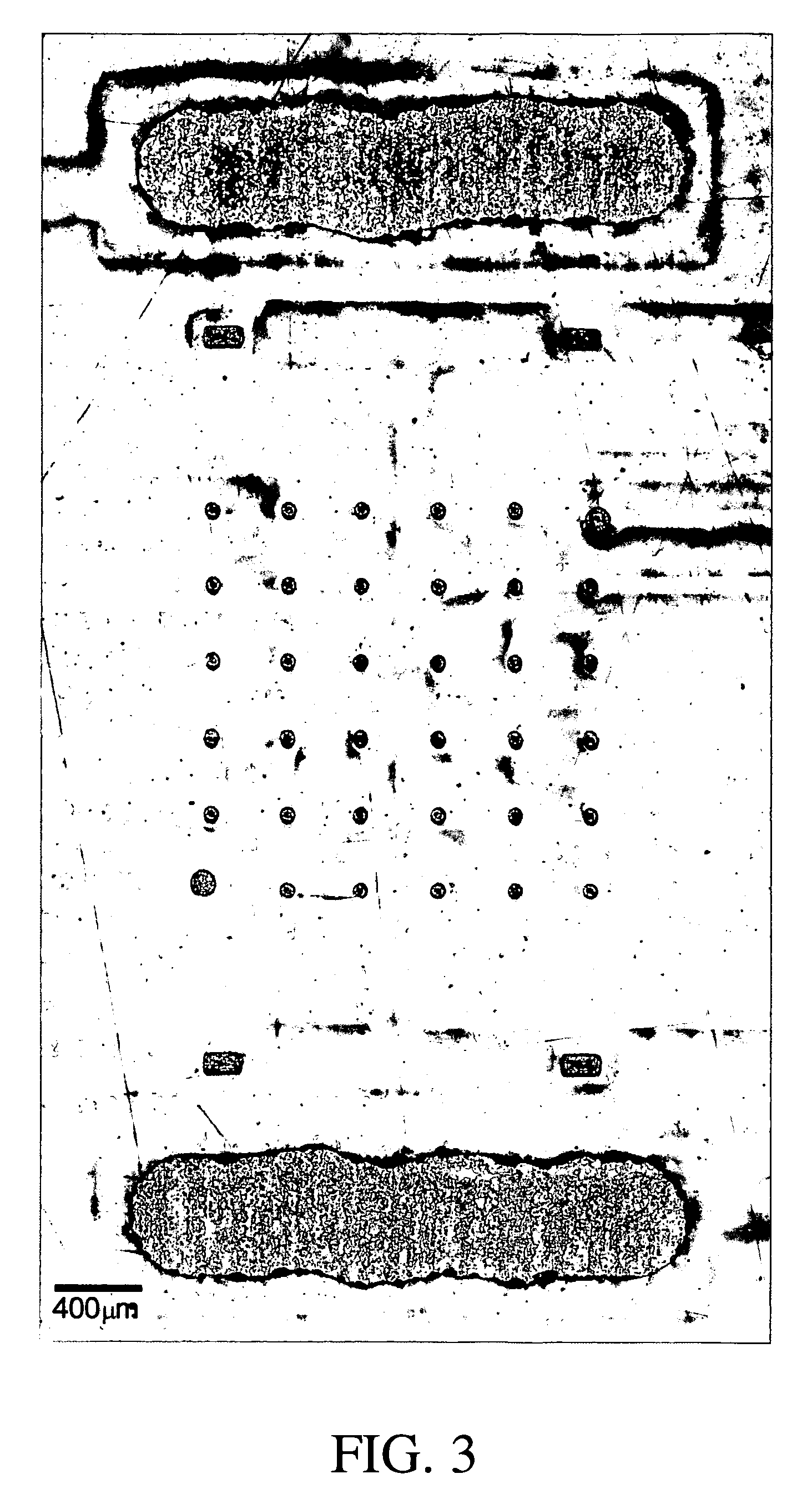

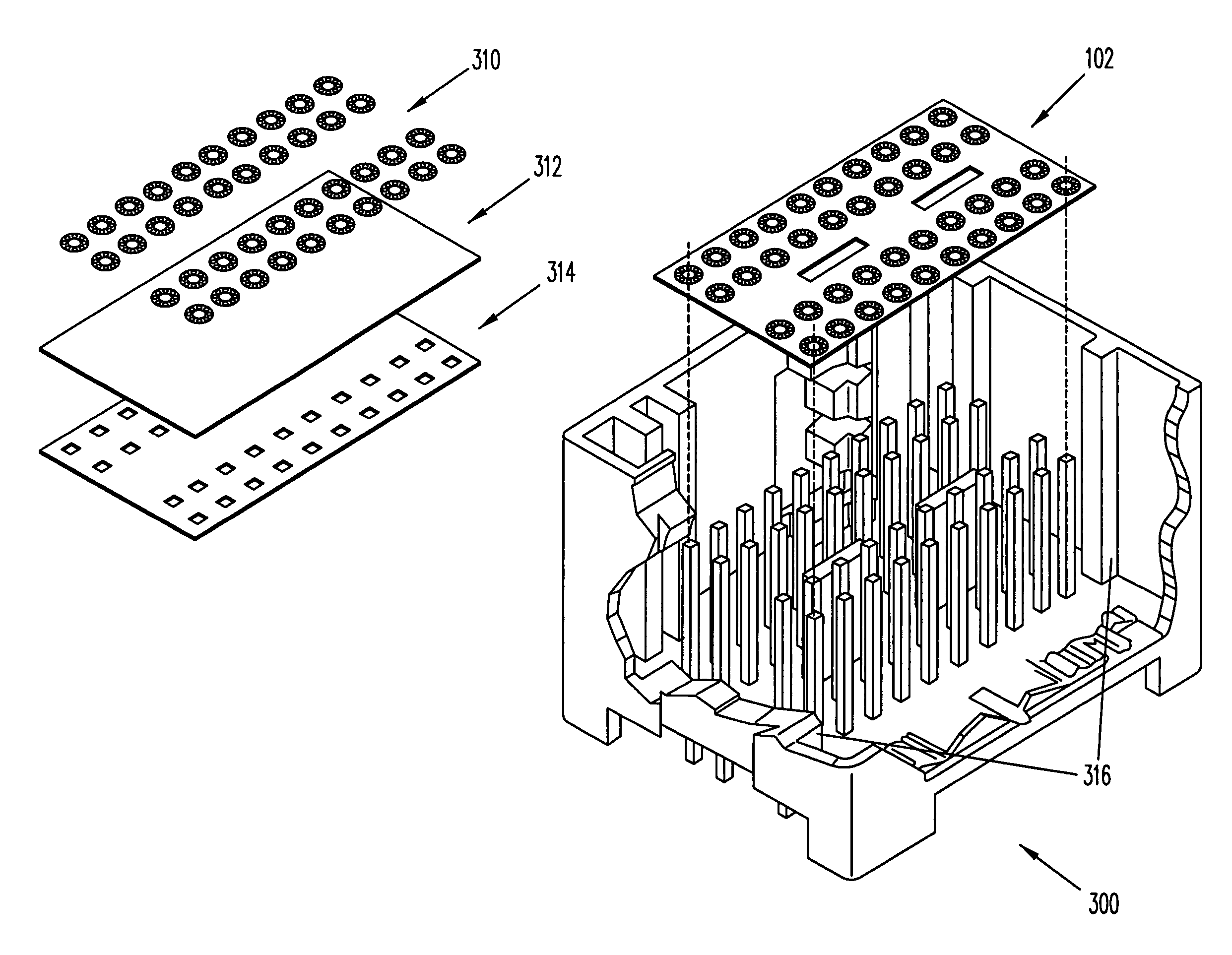

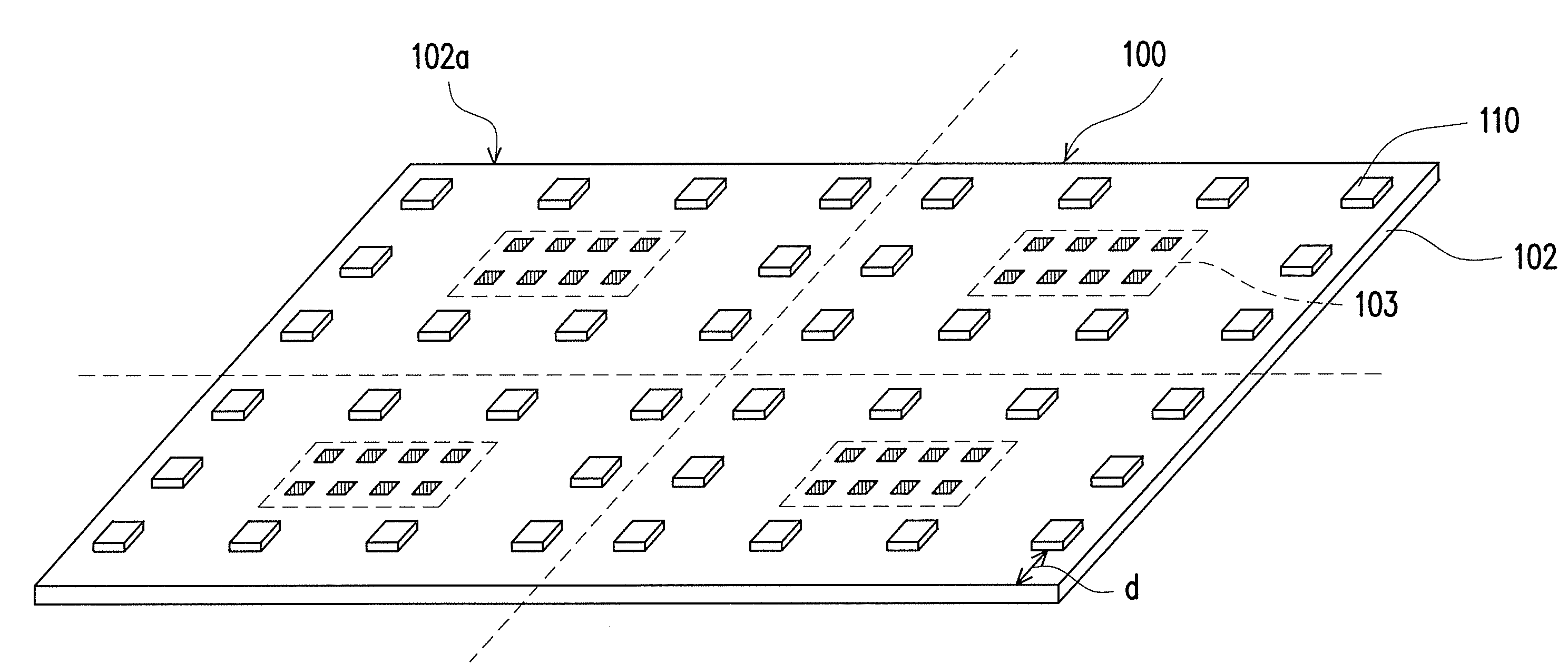

Low cost fabrication of microelectrode arrays for cell-based biosensors and drug discovery methods

InactiveUS20060057771A1Reduce manufacturing costEfficient mass productionImmobilised enzymesBioreactor/fermenter combinationsElectricityManufacturing technology

A method for making a plurality of low-cost microelectrode arrays (MEAs) on one substrate utilizing certain unmodified printed circuit board (PCB) fabrication processes and selected materials. In some embodiments, a MEA device is composed of a thin polymer substrate containing patterned conductive traces. Coverlays on both sides of the substrate insulate the conductive traces and defines the electrodes. Preferably, flexible PCB technology is utilized to simultaneously define the microelectrode arrays. In an embodiment, the sensor is an integrated temperature sensor / heater in which the MEA device operates to record extracellular electrical signals from electrically active cell cultures. The present invention enables economical and efficient mass production of MEA devices, making them particularly suitable for disposable applications such as drug discovery, biosensors, etc.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

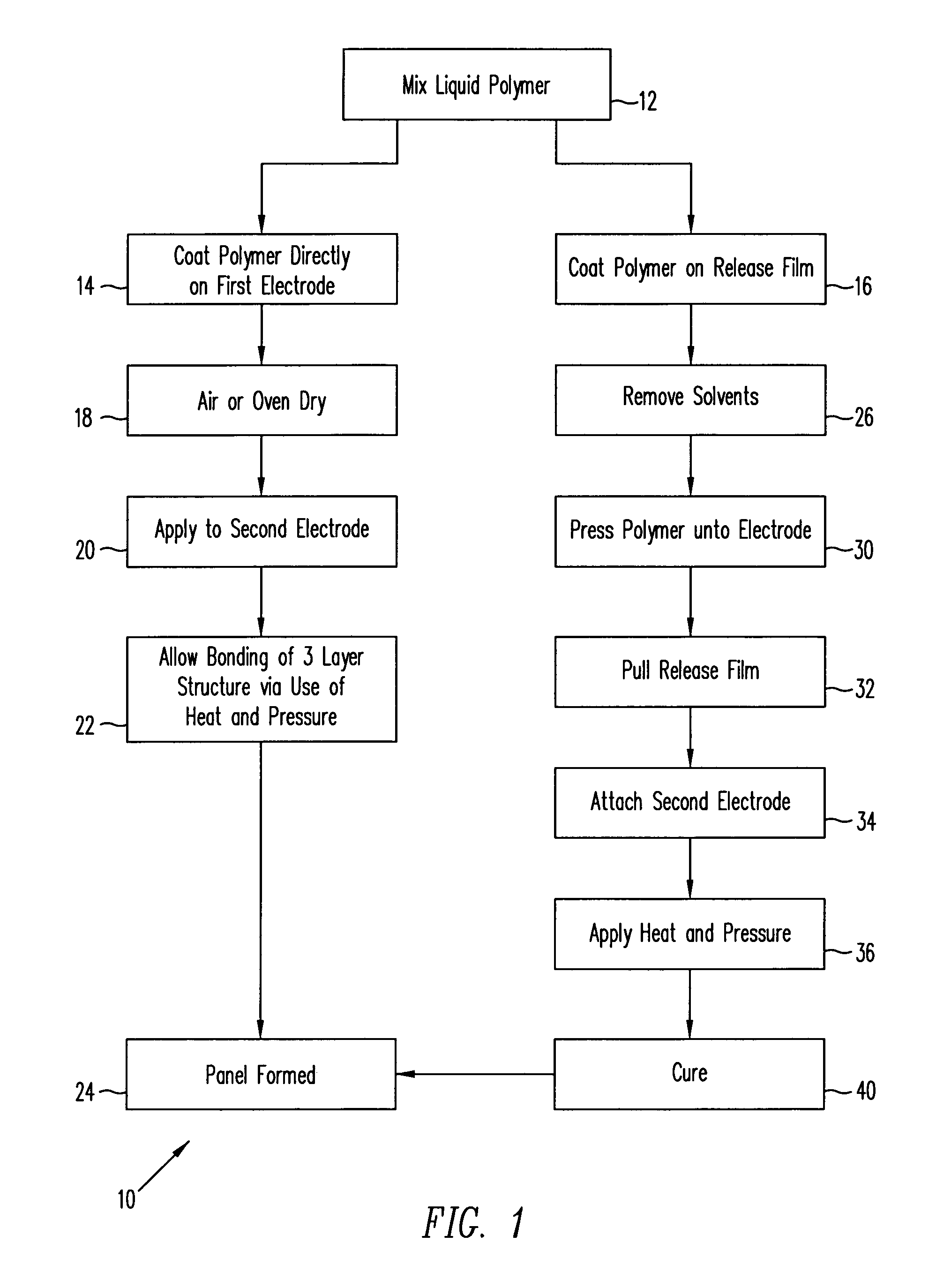

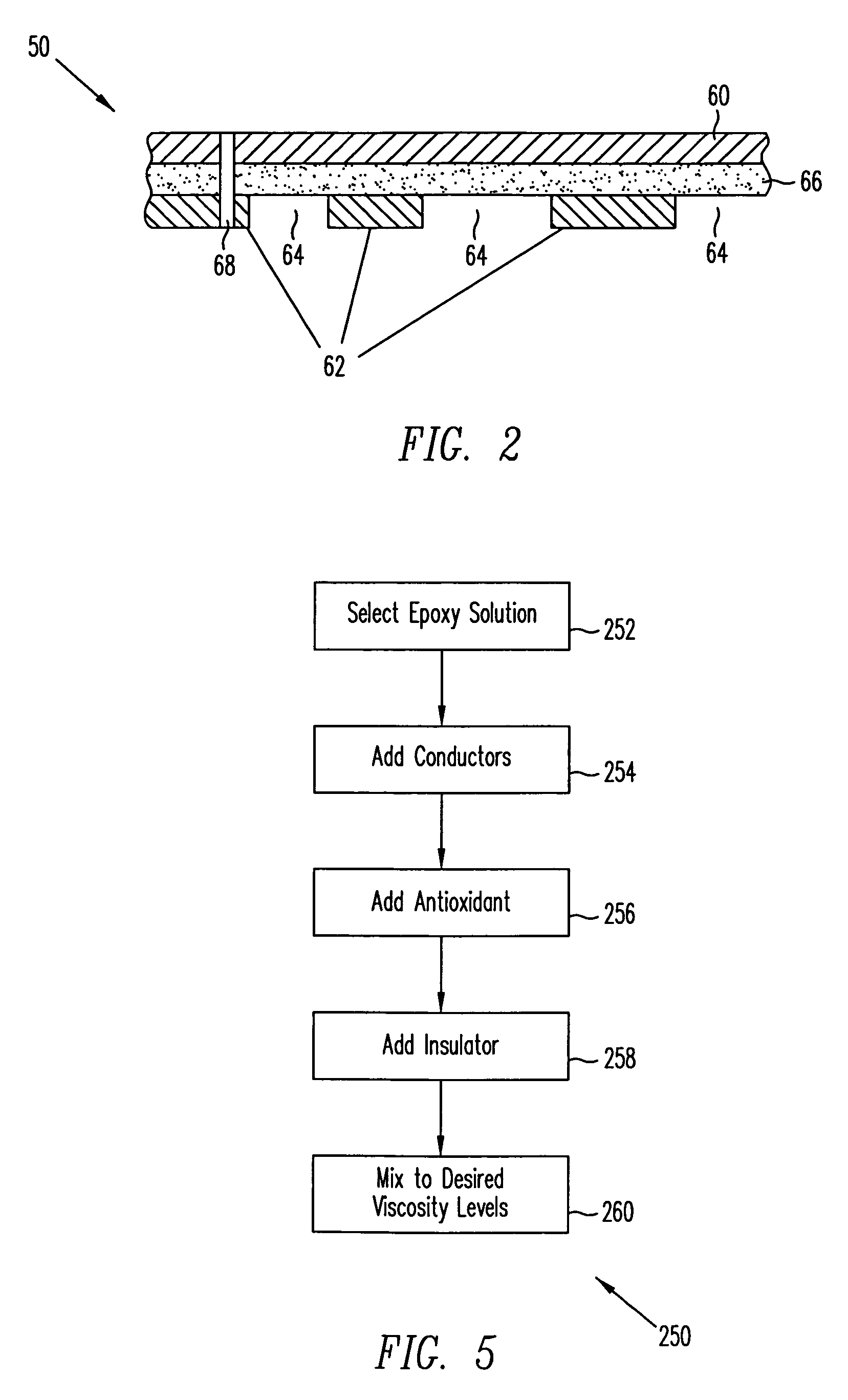

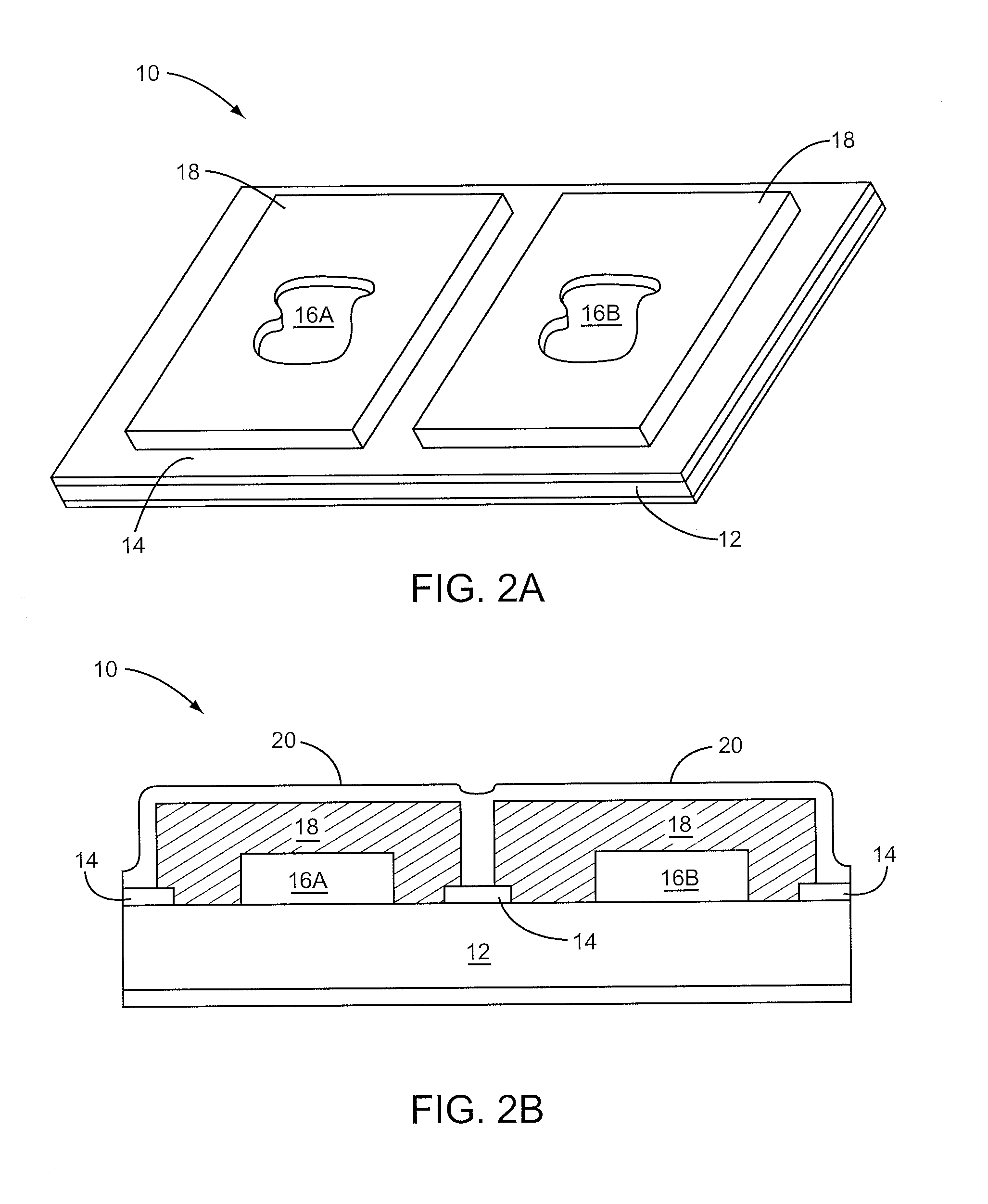

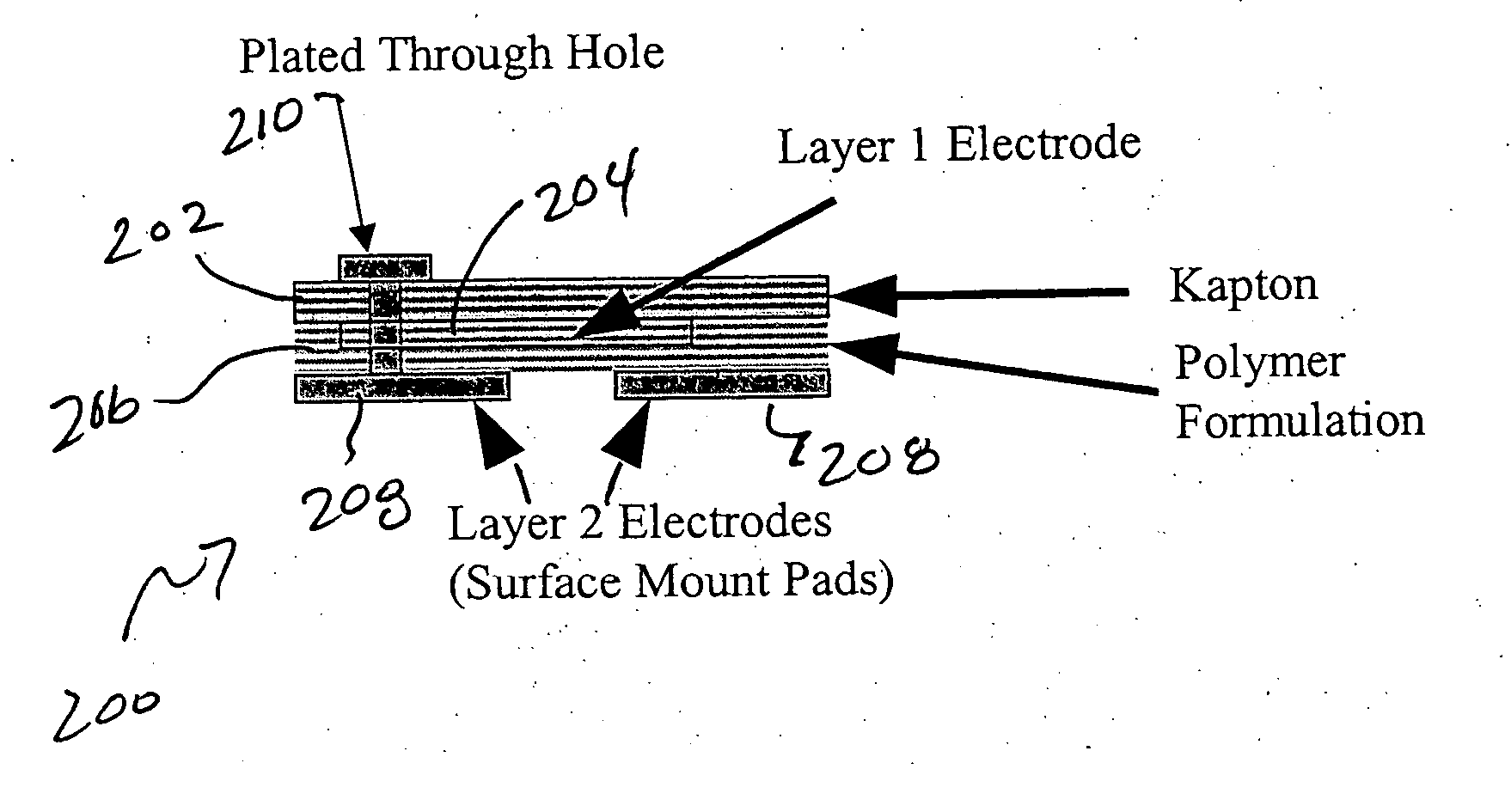

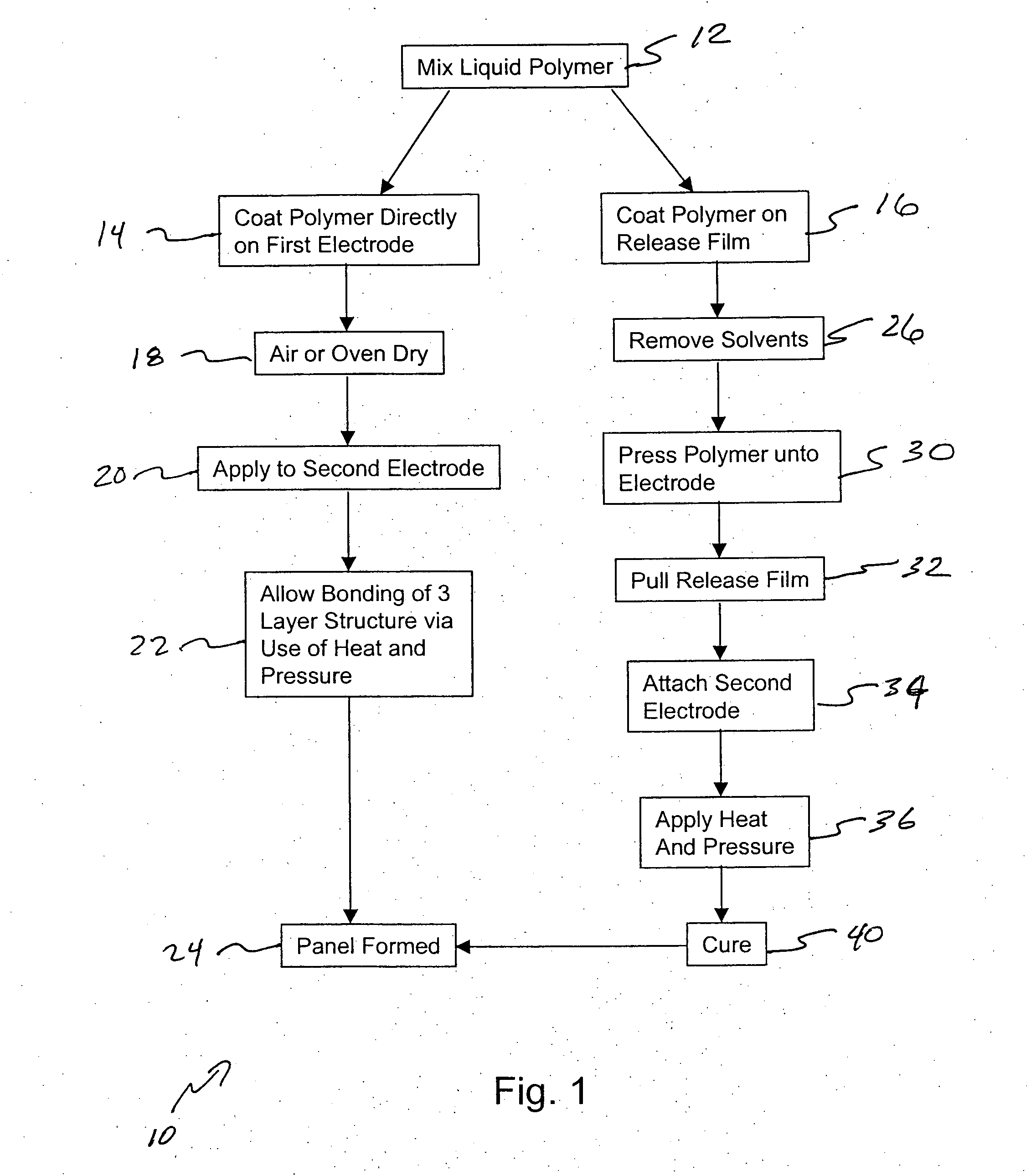

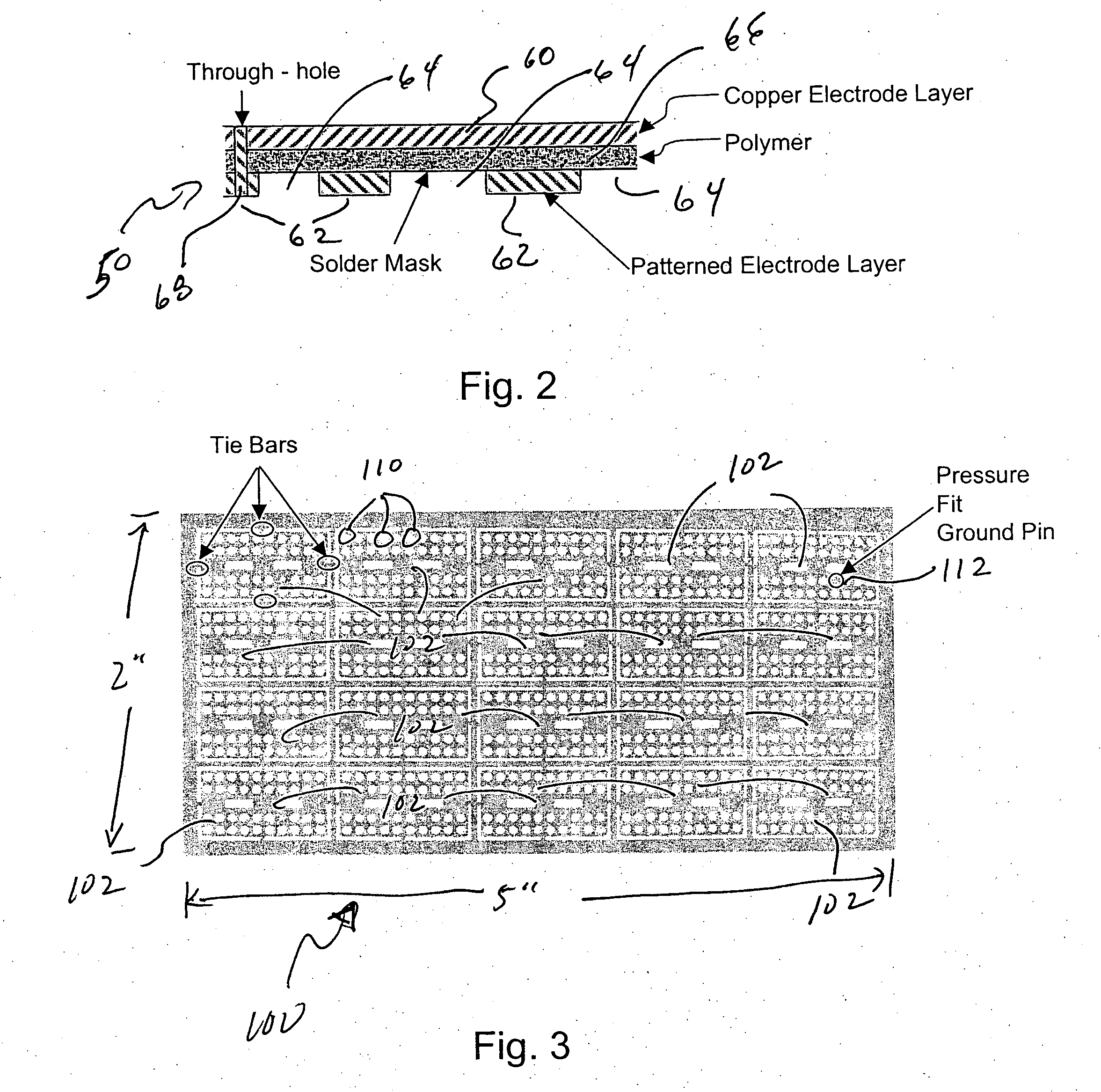

Method of manufacturing devices to protect election components

InactiveUS6981319B2Easy to customizeMake fastFuse device manufactureInsulating layers/substrates workingManufacturing technologyElectronic component

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

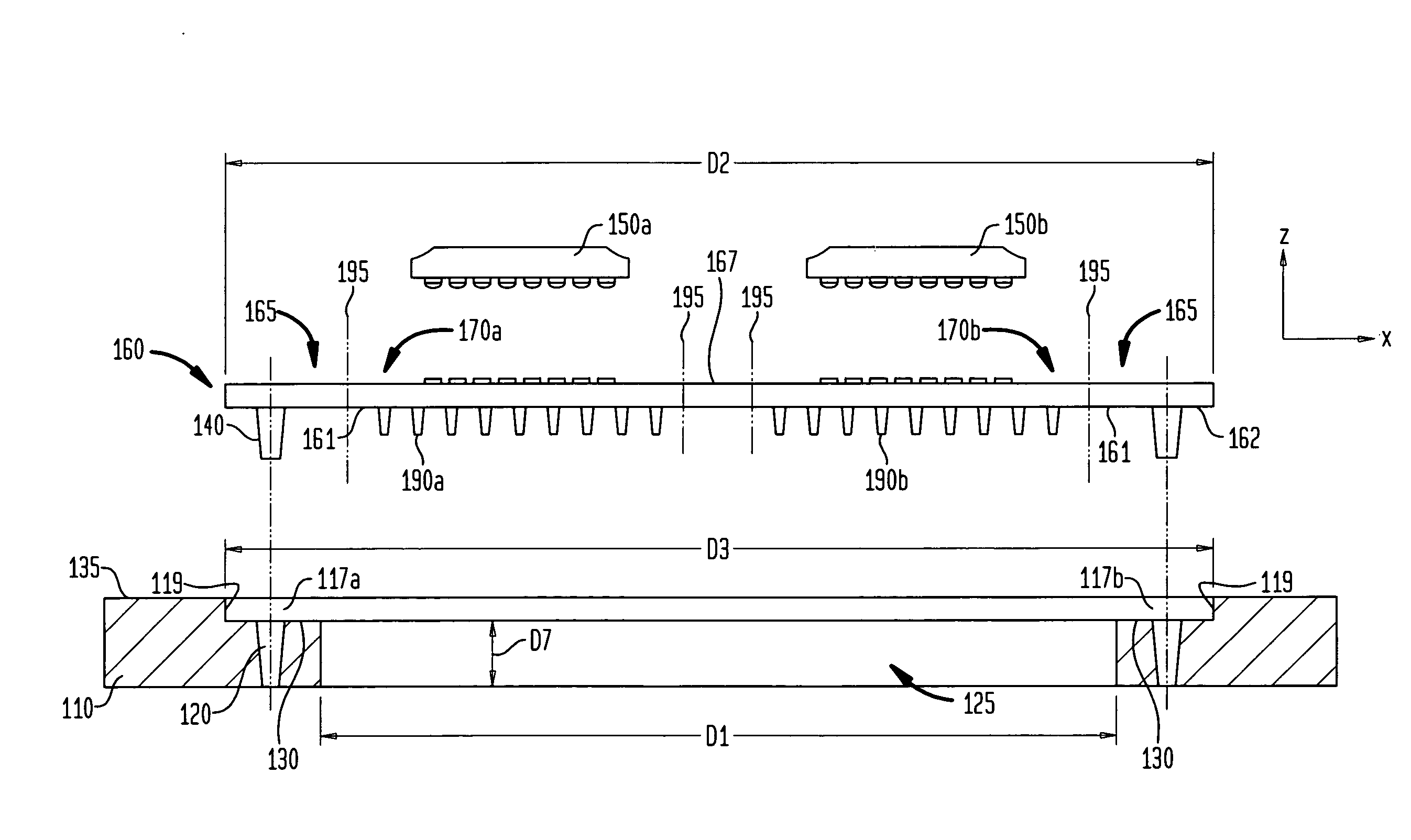

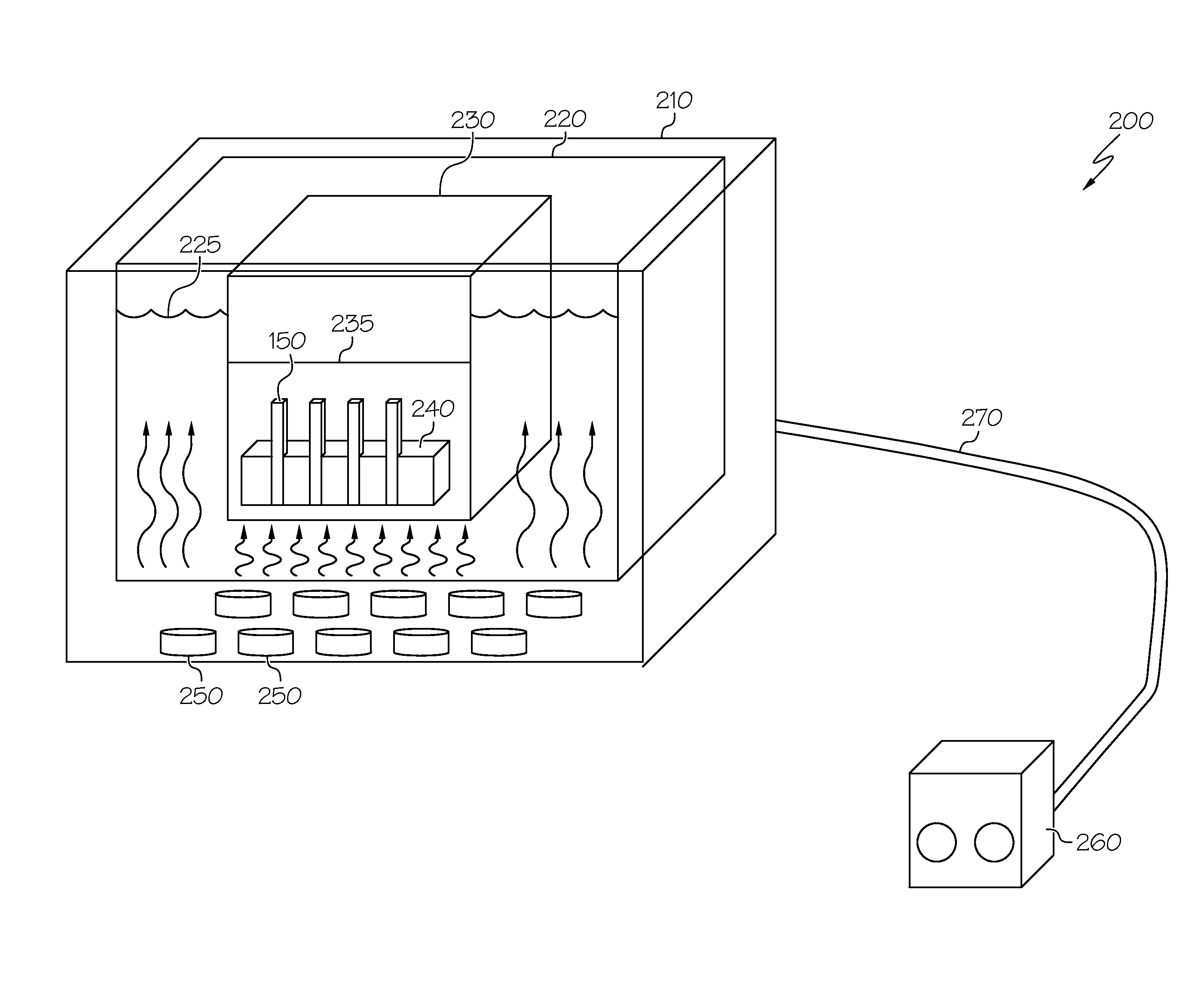

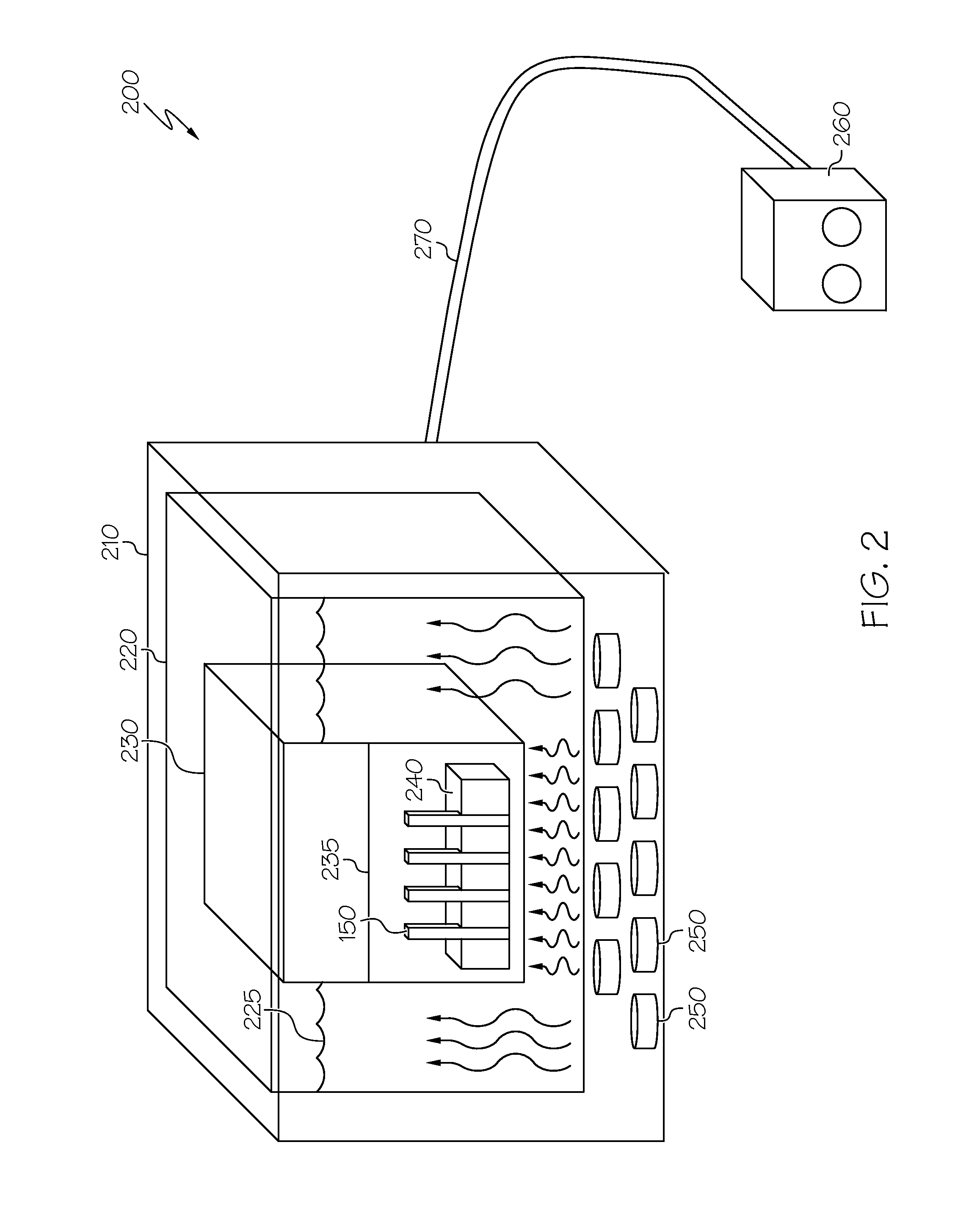

Bottom side support structure for conformal shielding process

ActiveUS20090002971A1Printed circuit assemblingLine/current collector detailsElectromagnetic shieldingEngineering

In one embodiment, a meta-module having circuitry for two or more modules is formed on a substrate, which is preferably a laminated substrate. The circuitry for the different modules is initially formed on the single meta-module. Each module will have one or more component areas in which the circuitry is formed. A metallic structure is formed on or in the substrate for each component area to be shielded. A single body, such as an overmold body, is then formed over all of the modules on the meta-module. At least a portion of the metallic structure for each component area to be shielded is then exposed through the body by a cutting, drilling, or like operation. Next, an electromagnetic shield material is applied to the exterior surface of the body of each of the component areas to be shielded and in contact with the exposed portion of the metallic structures.

Owner:QORVO US INC

ESD protection devices and methods of making same using standard manufacturing processes

ActiveUS20050083163A1Easy to customizeMinimal effortInsulating layers/substrates workingPrinted resistor incorporationManufacturing technologyElectronic component

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

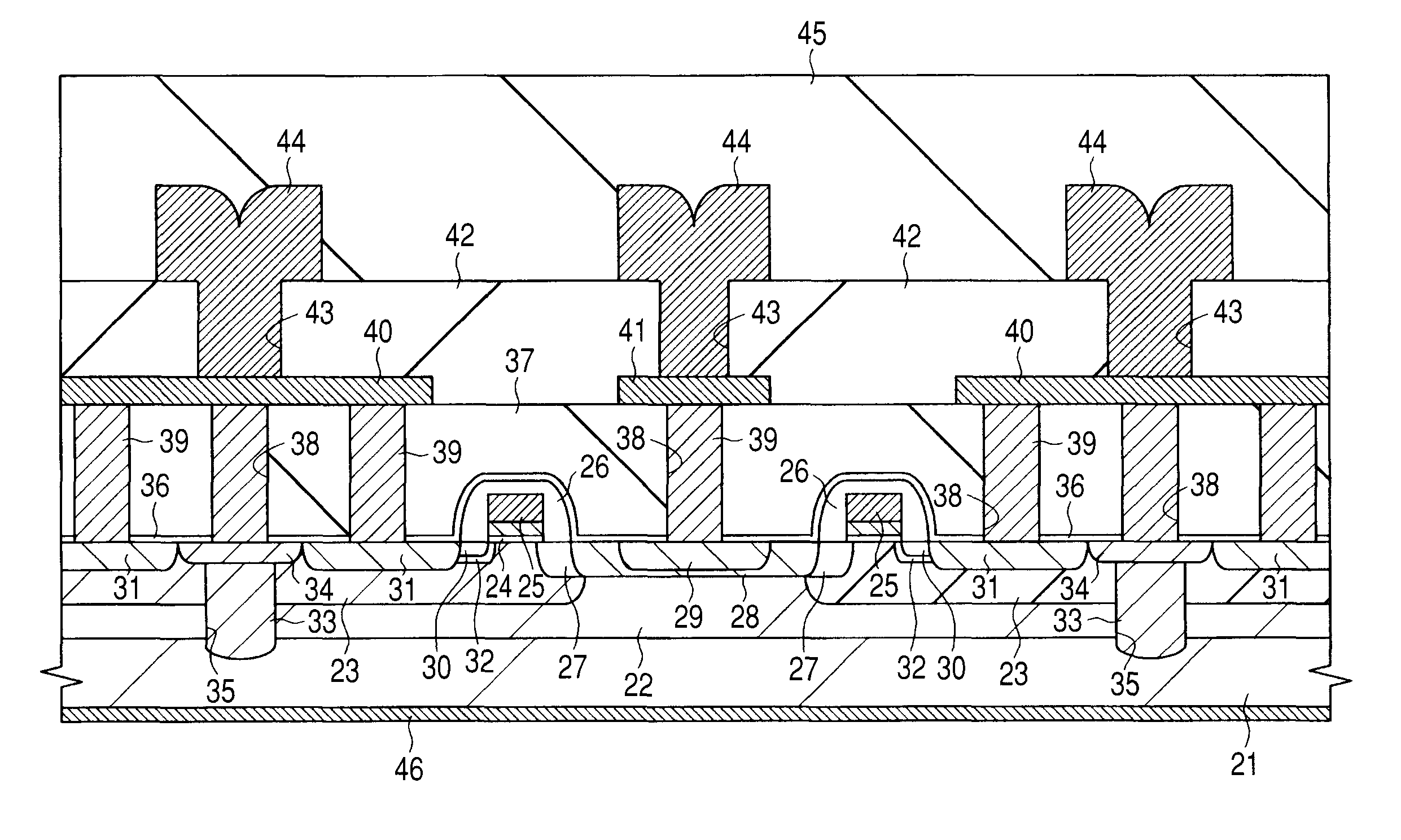

Semiconductor device and manufacturing method thereof

InactiveUS20100230789A1Improve featuresSmall sizeMagnetic/electric field screeningSemiconductor/solid-state device detailsDevice materialElectromagnetic shielding

A technology is provided which allows a reduction in the size of a semiconductor device without degrading an electromagnetic shielding effect and reliability against reflow heating. After a plurality of components are mounted over a component mounting surface of a module substrate, a resin is formed so as to cover the mounted components. Further, over surfaces (upper and side surfaces) of the resin, a shield layer including a laminated film of a Cu plating film and an Ni plating film is formed. In the shield layer, a plurality of microchannel cracks are formed randomly along grain boundaries and in a net-like configuration without being coupled to each other in a straight line, and form a plurality of paths extending from the resin to a surface of the shield layer by the microchannel cracks.

Owner:RENESAS ELECTRONICS CORP

Field barrier structures within a conformal shield

InactiveUS20090002969A1Wave amplification devicesMagnetic/electric field screeningEngineeringElectromagnetic shielding

In one embodiment, a meta-module having circuitry for two or more modules is formed on a substrate, which is preferably a laminated substrate. The circuitry for the different modules is initially formed on the single meta-module. Each module will have one or more component areas in which the circuitry is formed. A metallic structure is formed on or in the substrate for each component area to be shielded. A single body, such as an overmold body, is then formed over all of the modules on the meta-module. At least a portion of the metallic structure for each component area to be shielded is then exposed through the body by a cutting, drilling, or like operation. Next, an electromagnetic shield material is applied to the exterior surface of the body of each of the component areas to be shielded and in contact with the exposed portion of the metallic structures.

Owner:RF MICRO DEVICES

Conformal shielding process using flush structures

ActiveUS20090000816A1Magnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectromagnetic shielding

In one embodiment, a meta-module having circuitry for two or more modules is formed on a substrate, which is preferably a laminated substrate. The circuitry for the different modules is initially formed on the single meta-module. Each module will have one or more component areas in which the circuitry is formed. A metallic structure is formed on or in the substrate for each component area to be shielded. A single body, such as an overmold body, is then formed over all of the modules on the meta-module. At least a portion of the metallic structure for each component area to be shielded is then exposed through the body by a cutting, drilling, or like operation. Next, an electromagnetic shield material is applied to the exterior surface of the body of each of the component areas to be shielded and in contact with the exposed portion of the metallic structures.

Owner:QORVO US INC

Printed circuit board flexible interconnect design

ActiveUS7980863B1Printed circuit aspectsInsulating layers/substrates workingPrinted circuit boardMetal

In some embodiments, a circuit board interconnect may include one or more of the following features: (a) a first circuit board having a plated through hole within a metal pad on the circuit board, the through hole providing a passage for solder to connect the first circuit board to a second circuit board, (b) a second circuit board having a metal pad able to couple to the first circuit board in an overlapping fashion when solder is passed through the plated through hole, and (c) a non-conductive solder repelling material on a surface of one circuit board.

Owner:METROSPEC TECH

Methods for forming vias in glass substrates

ActiveUS20150060402A1Increase the diameterPaper/cardboard articlesDecorative surface effectsAcid etchingOptoelectronics

Methods for forming vias in glass substrates by laser drilling and acid etching are disclosed. In one embodiment, a method forming a via in a glass substrate includes laser drilling the via through at least a portion of a thickness of the glass substrate from an incident surface of the glass substrate. The method further includes etching the glass substrate for an etching duration to increase a diameter of an incident opening of the via and applying ultrasonic energy to the glass substrate during at least a portion of the etching duration. The applied ultrasonic energy has a frequency between 40 kHz and 192 kHz.

Owner:CORNING INC

Chip package and manufacturing method thereof

InactiveUS20100110656A1Improve design flexibilityLess effortMagnetic/electric field screeningCross-talk/noise/interference reductionElectromagnetic interferenceGround plane

A chip package including a plurality of conductive bodies and a shielding layer for better electromagnetic interferences shielding is provided. The shielding layer over the molding compound contacts with the conductive bodies disposed on the substrate, and the shielding layer and the conductive bodies function as EMI shield. The shielding layer is electrically grounded through the conductive bodies connected to the laminate substrate and the ground plane of the substrate.

Owner:ADVANCED SEMICON ENG INC

Popular searches

Optical sensors Printed circuit secondary treatment Printed circuit simultaneous processing Measuring/recording heart/pulse rate Blood flow measurement Printed circuit non-printed electric components association Non-metallic protective coating application Semiconductor devices Cable/conductor manufacture Multilayer circuit manufacture

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com