Patents

Literature

128results about "Light absorption dielectrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

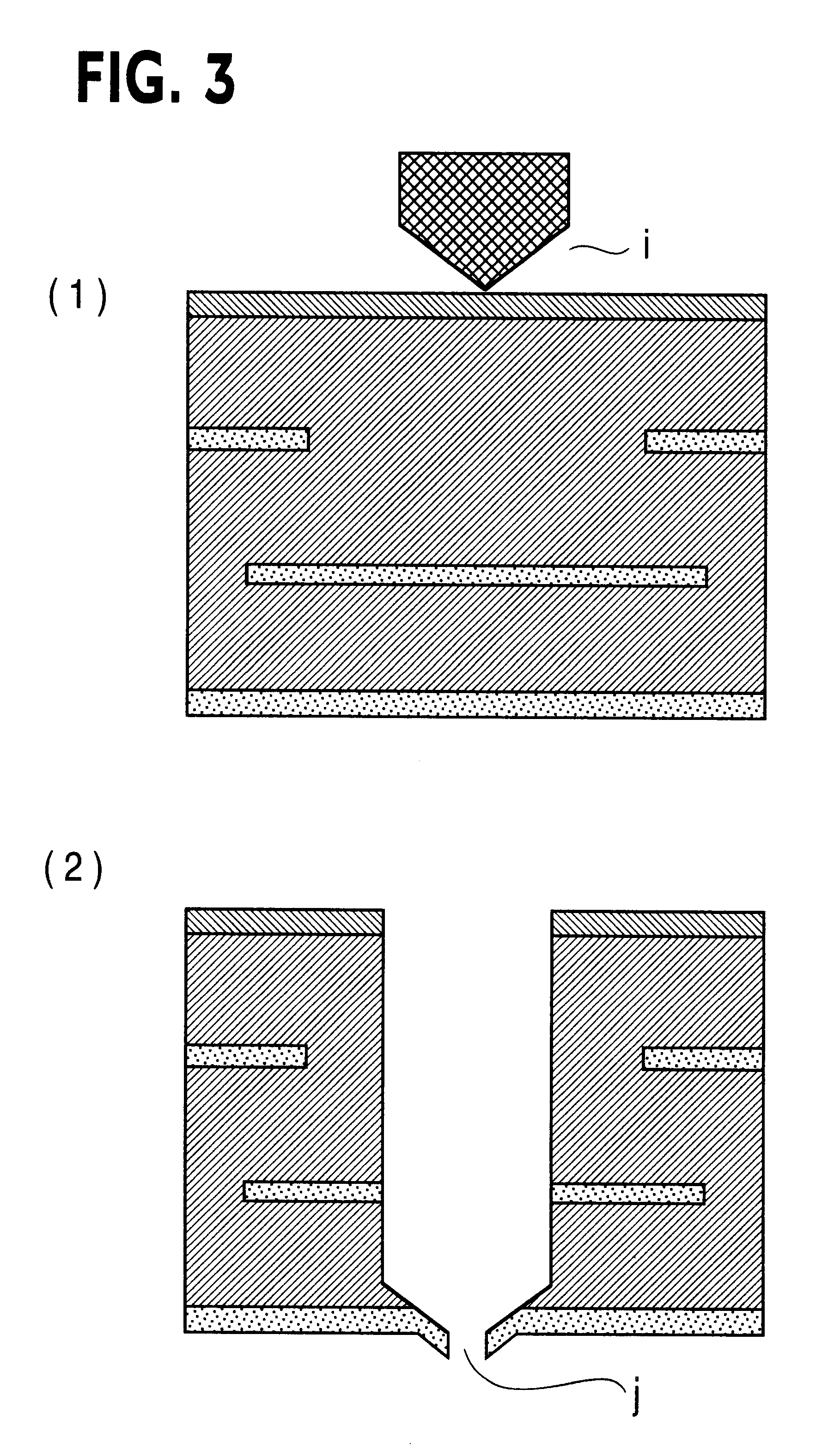

Printed wiring board having highly reliably via hole and process for forming via hole

InactiveUS6280641B1Improve reliabilityImprove productivityLight absorption dielectricsDecorative surface effectsBond energyConductive coating

Disclosed are a printed wiring board having micro-via holes highly reliable for conduction and a method of making the micro-via hole by providing a coating or sheet of an organic substance containing 3 to 97% by volume of at least one selected from a metal compound powder, a carbon powder or a metal powder having a melting point of at least 900° C. and a bond energy of at least 300 kJ / mol on a copper foil as an outermost layer of a copper-clad laminate having at least two copper layers, or providing a coating or sheet of the same after oxidizing a copper foil as an outermost layer, irradiating the coating or sheet with a carbon dioxide gas laser at an output of 20 to 60 mJ / pulse, thereby removing a micro-via-hole-forming portion of at least the copper foil as the outermost layer, then irradiating micro-via-hole-forming portions of the remaining layers with a carbon dioxide gas laser at an output of 5 to 35 mJ / pulse to make a micro-via hole which does not penetrate through the copper foil in a bottom of the micro-via hole, and electrically connecting the copper foil as the outermost layer and the copper foil in the bottom of the micro-via hole with a metal plating or an electrically conductive coating composition.

Owner:MITSUBISHI GAS CHEM CO INC

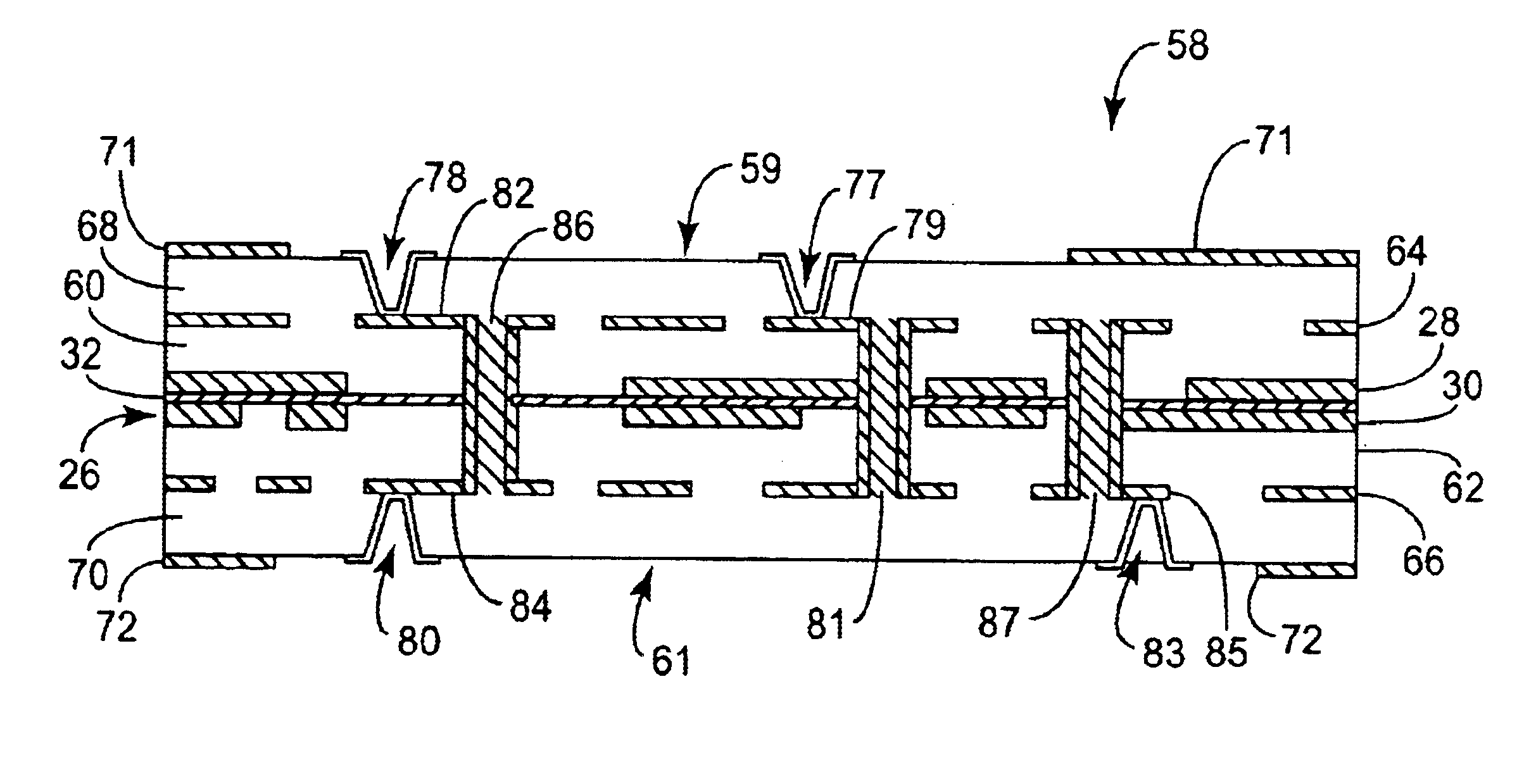

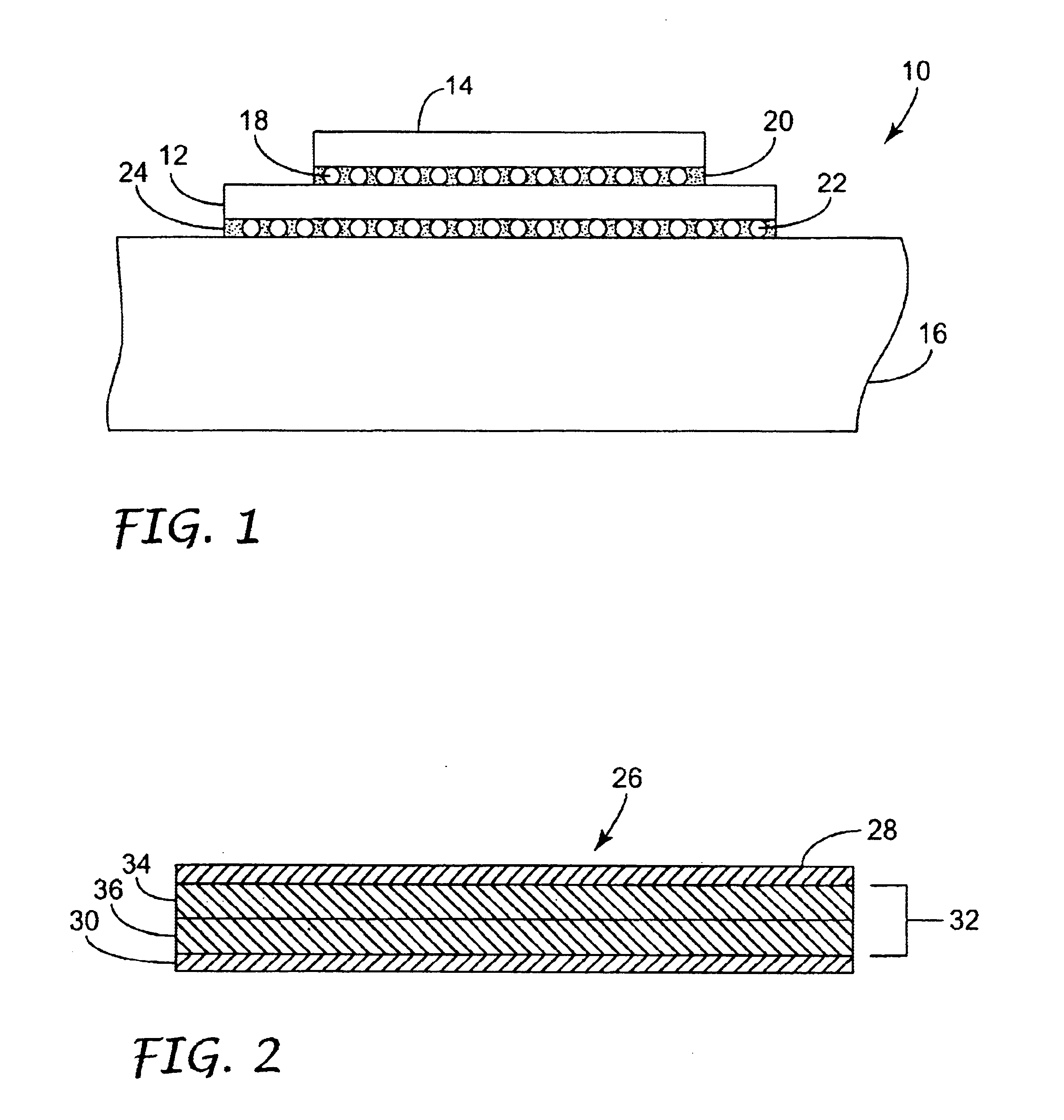

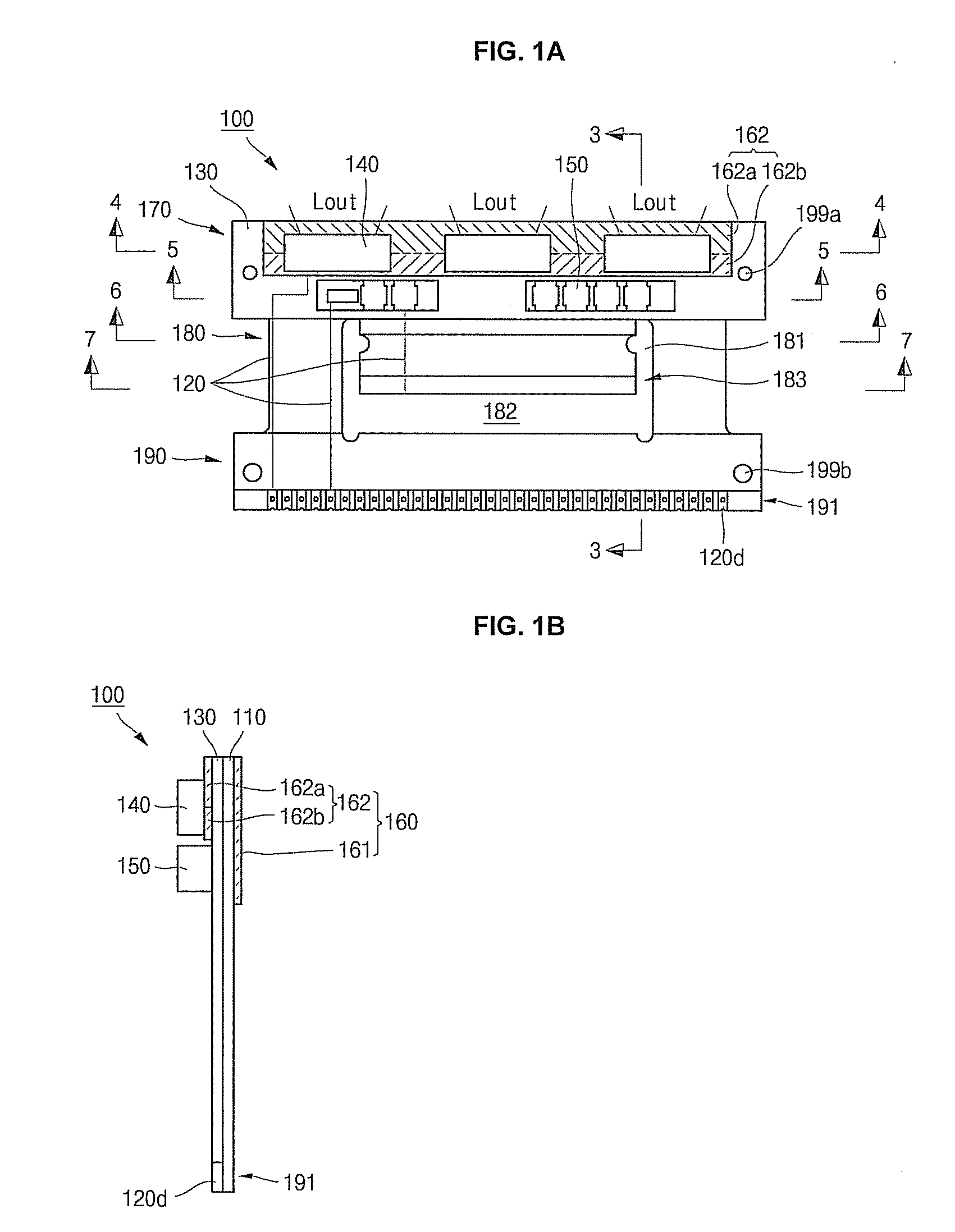

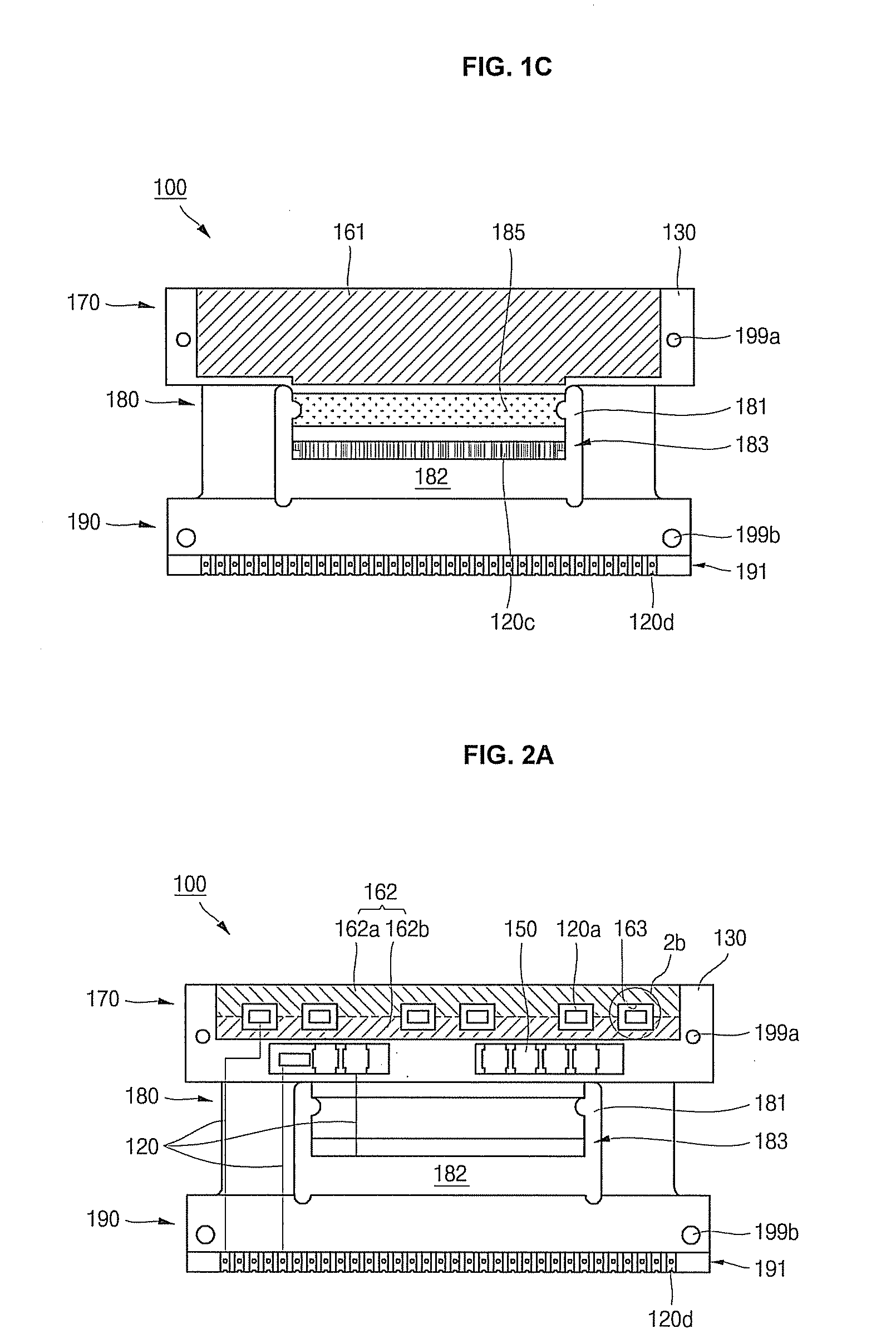

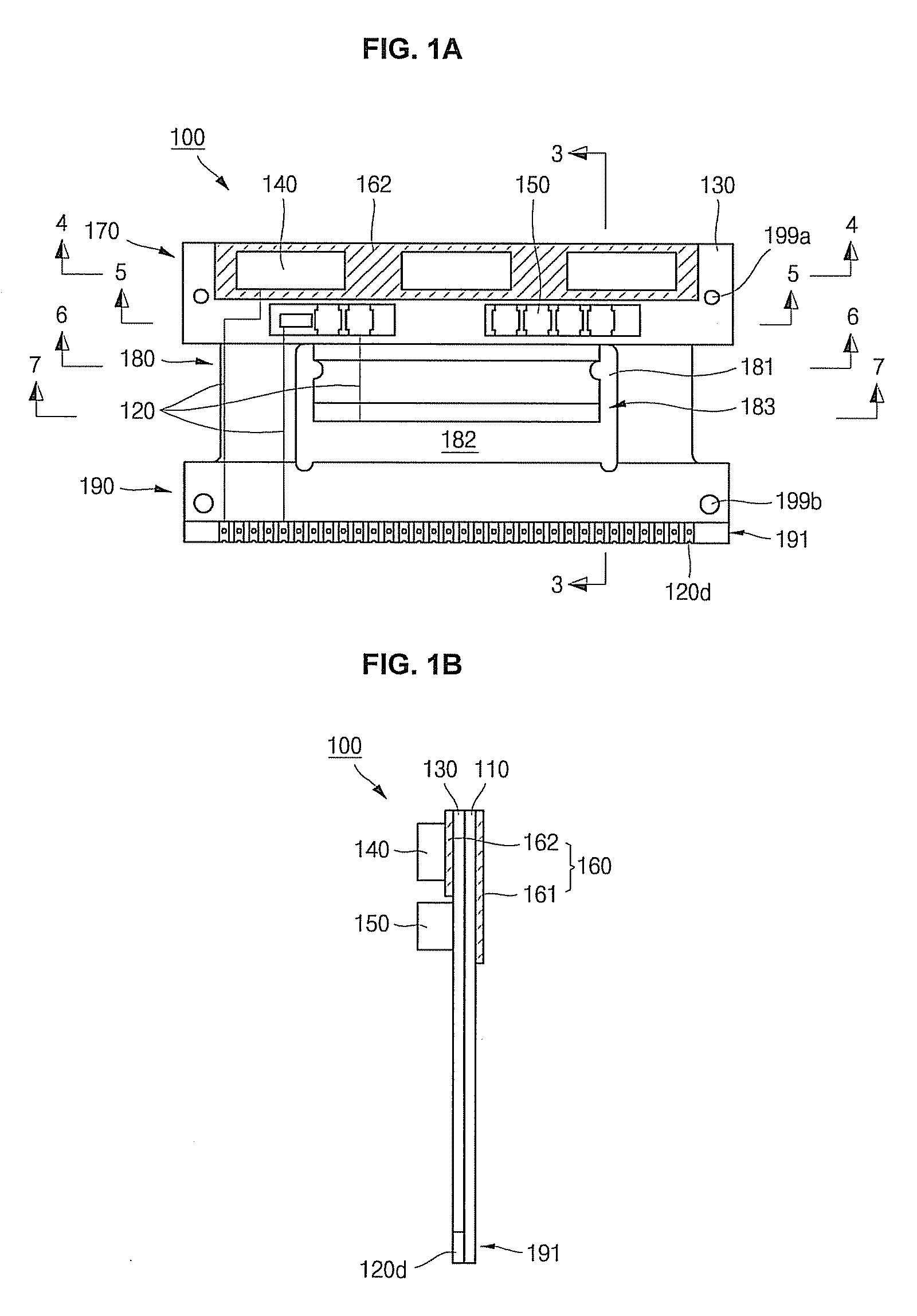

Interconnect module with reduced power distribution impedance

InactiveUS6847527B2Reduced impedance powerReduced ground distributionLight absorption dielectricsSemiconductor/solid-state device detailsSolder ballOperating frequency

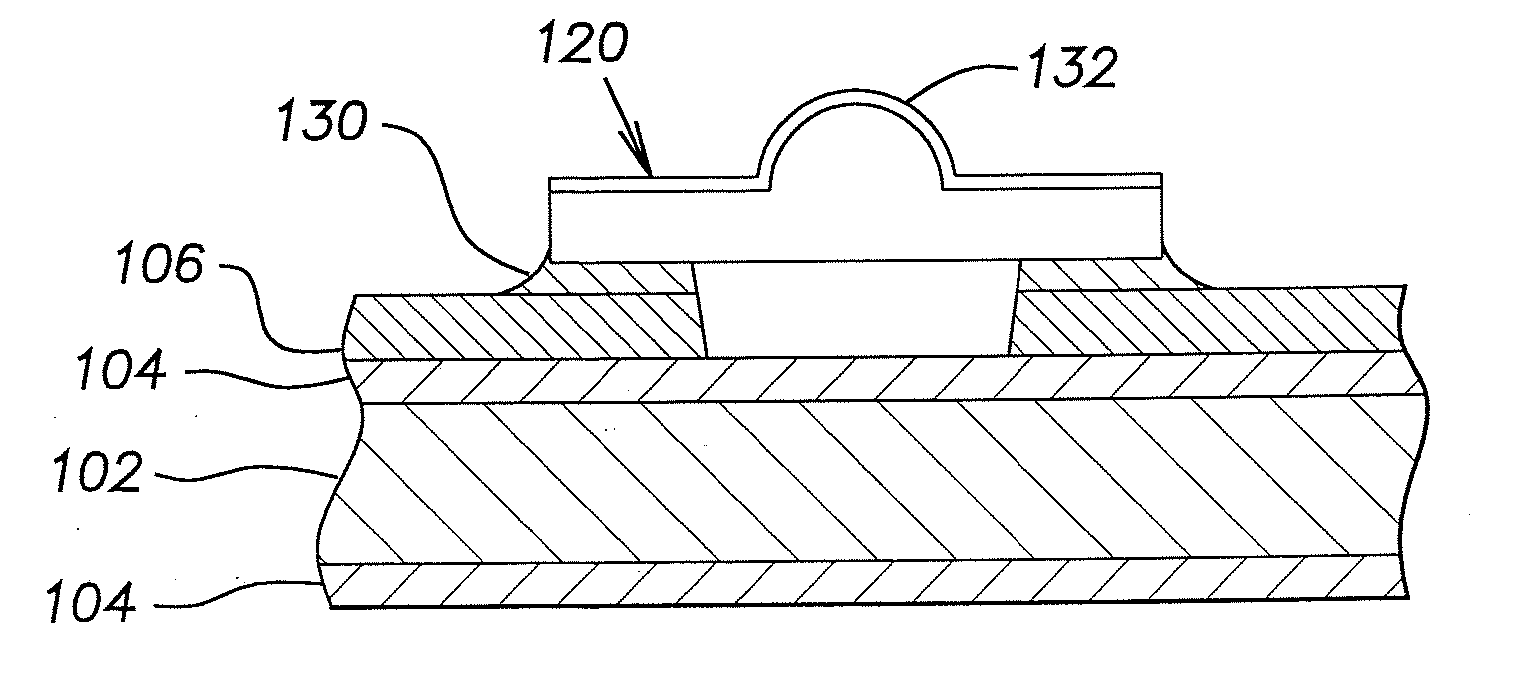

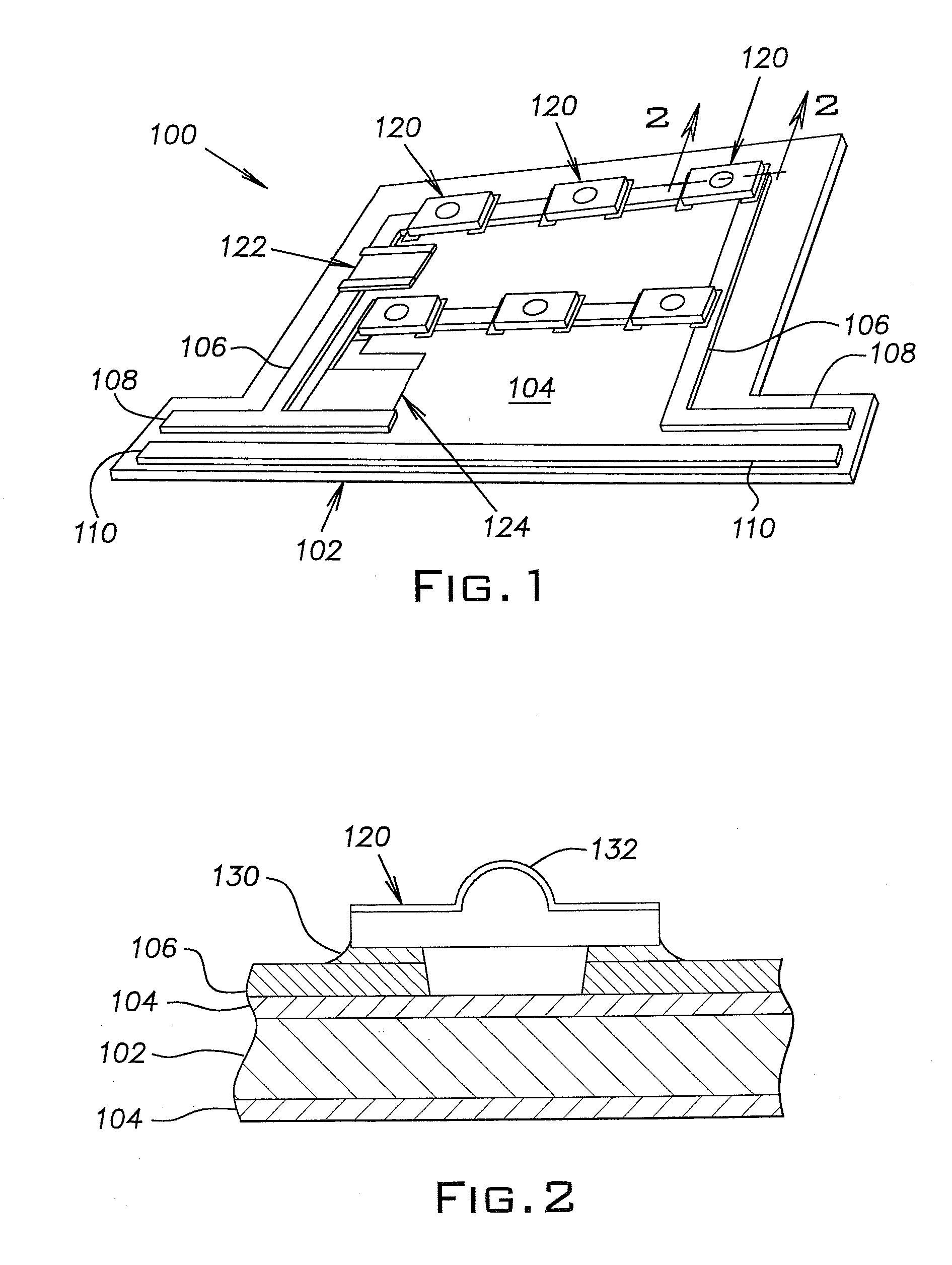

An interconnect module for an integrated circuit chip incorporates a thin, high dielectric constant embedded capacitor structure to provide reduced power distribution impedance, and thereby promote higher frequency operation. The interconnect module is capable of reliably attaching an integrated circuit chip to a printed wiring board via solder ball connections, while providing reduced power distribution impedance of less than or equal to approximately 0.60 ohms at operating frequencies in excess of 1.0 gigahertz.

Owner:3M INNOVATIVE PROPERTIES CO

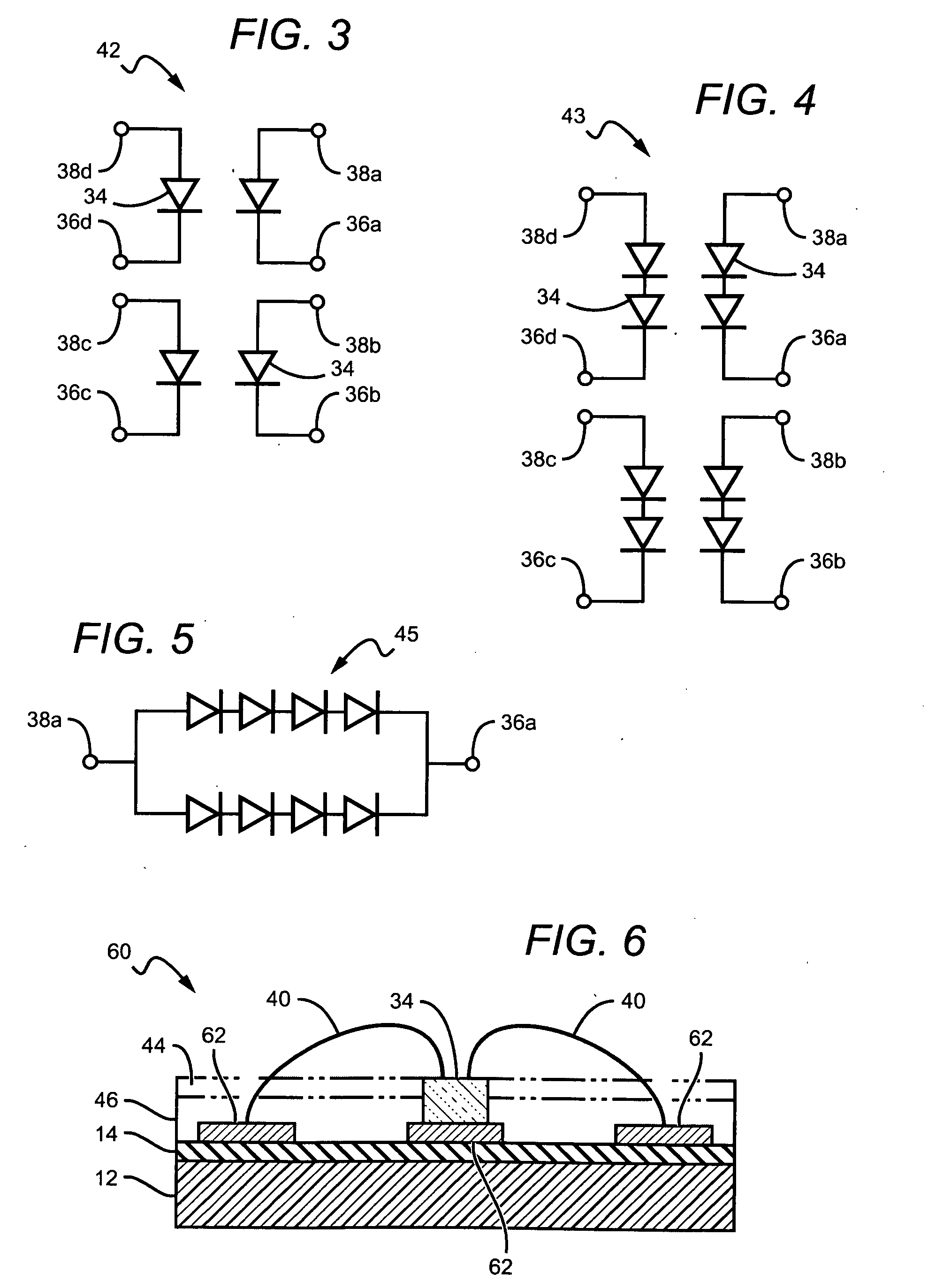

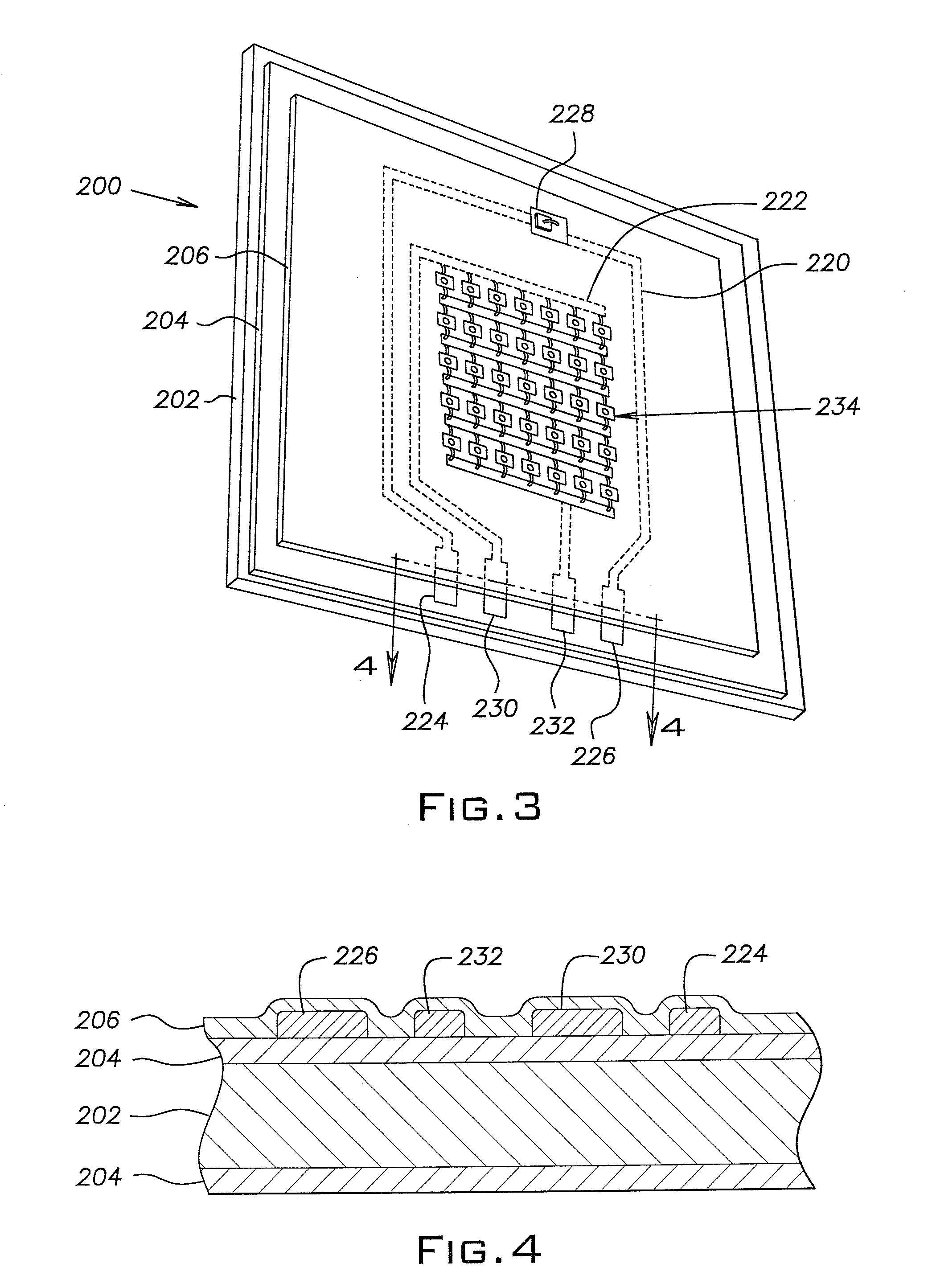

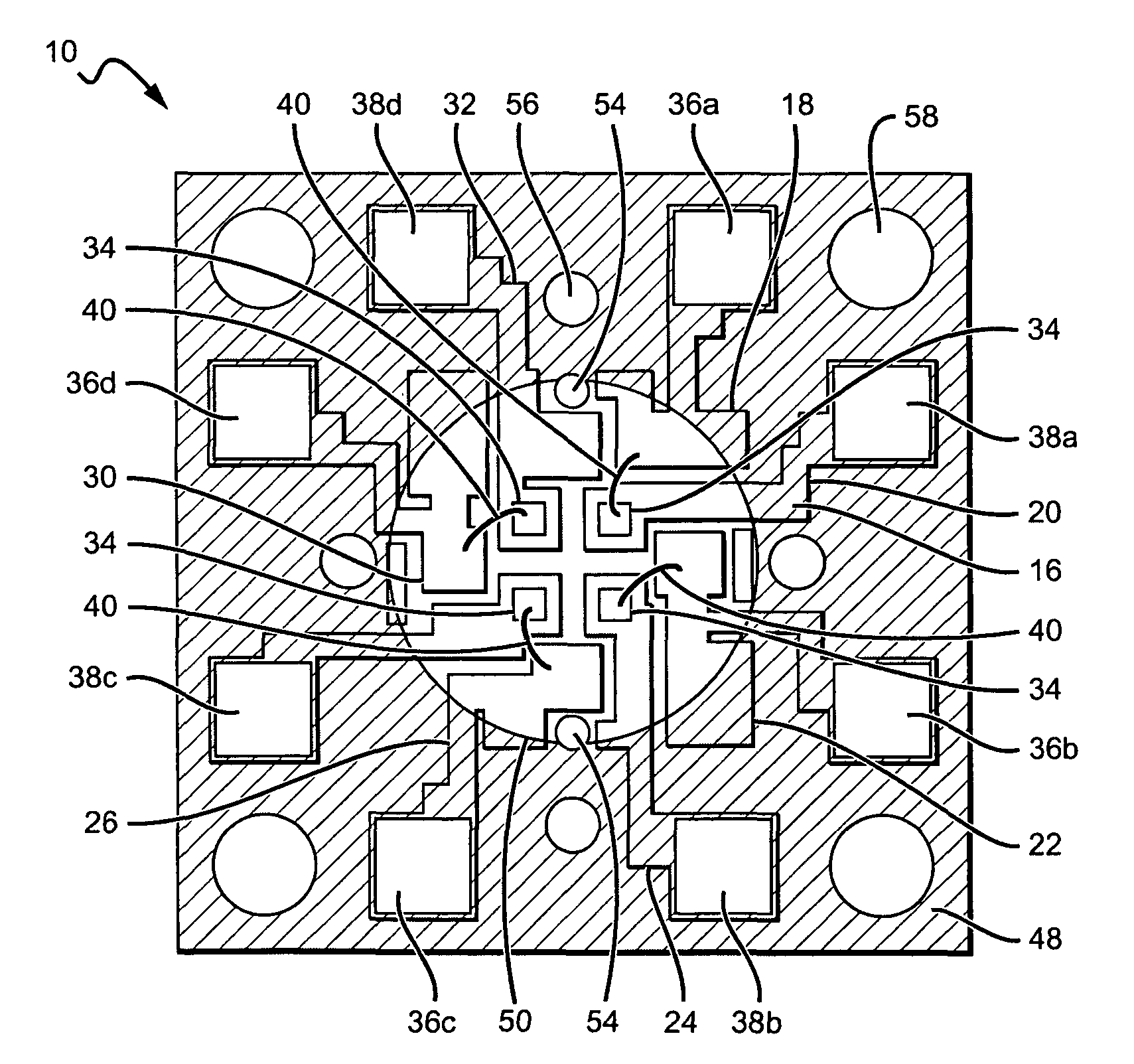

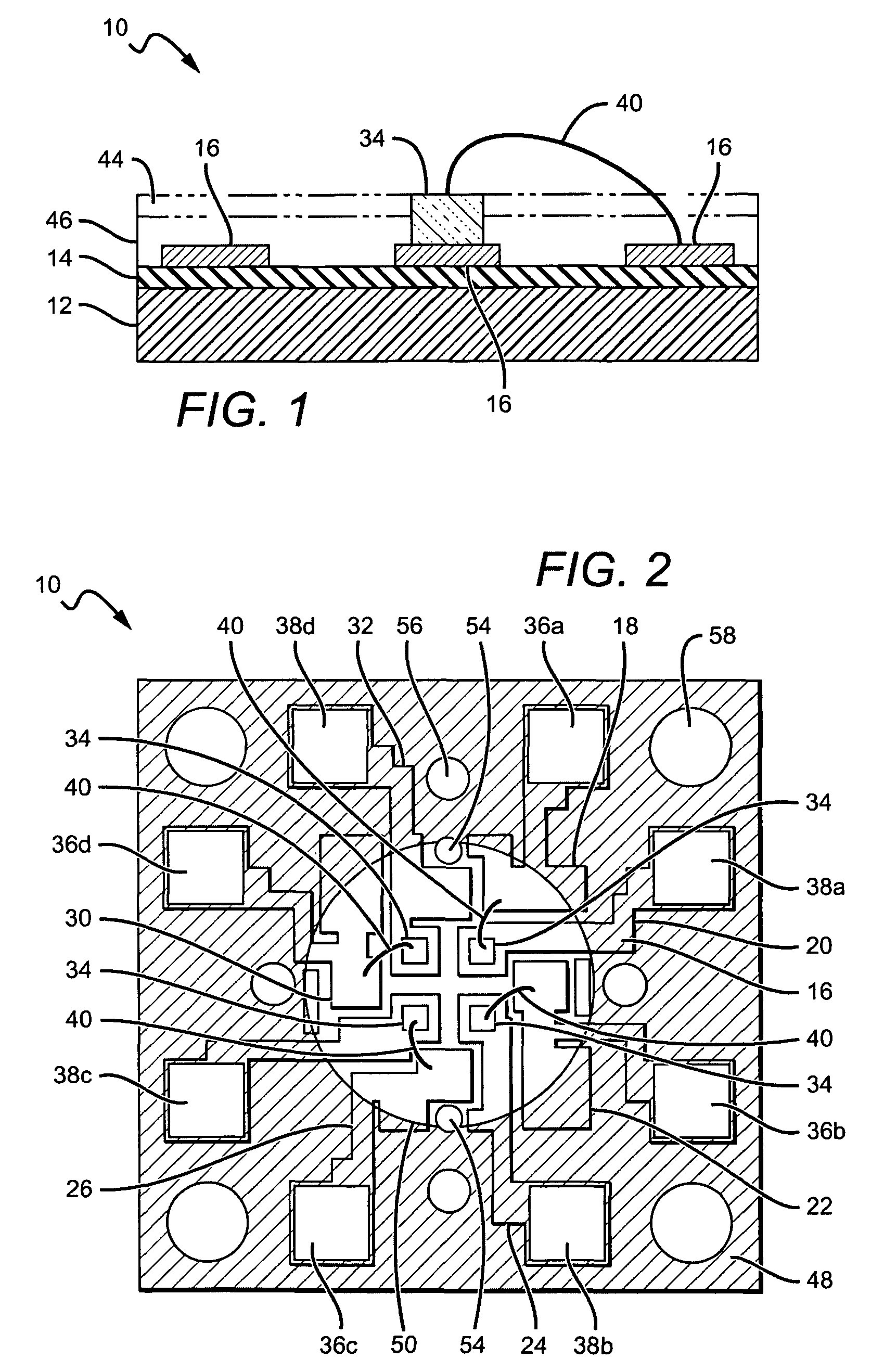

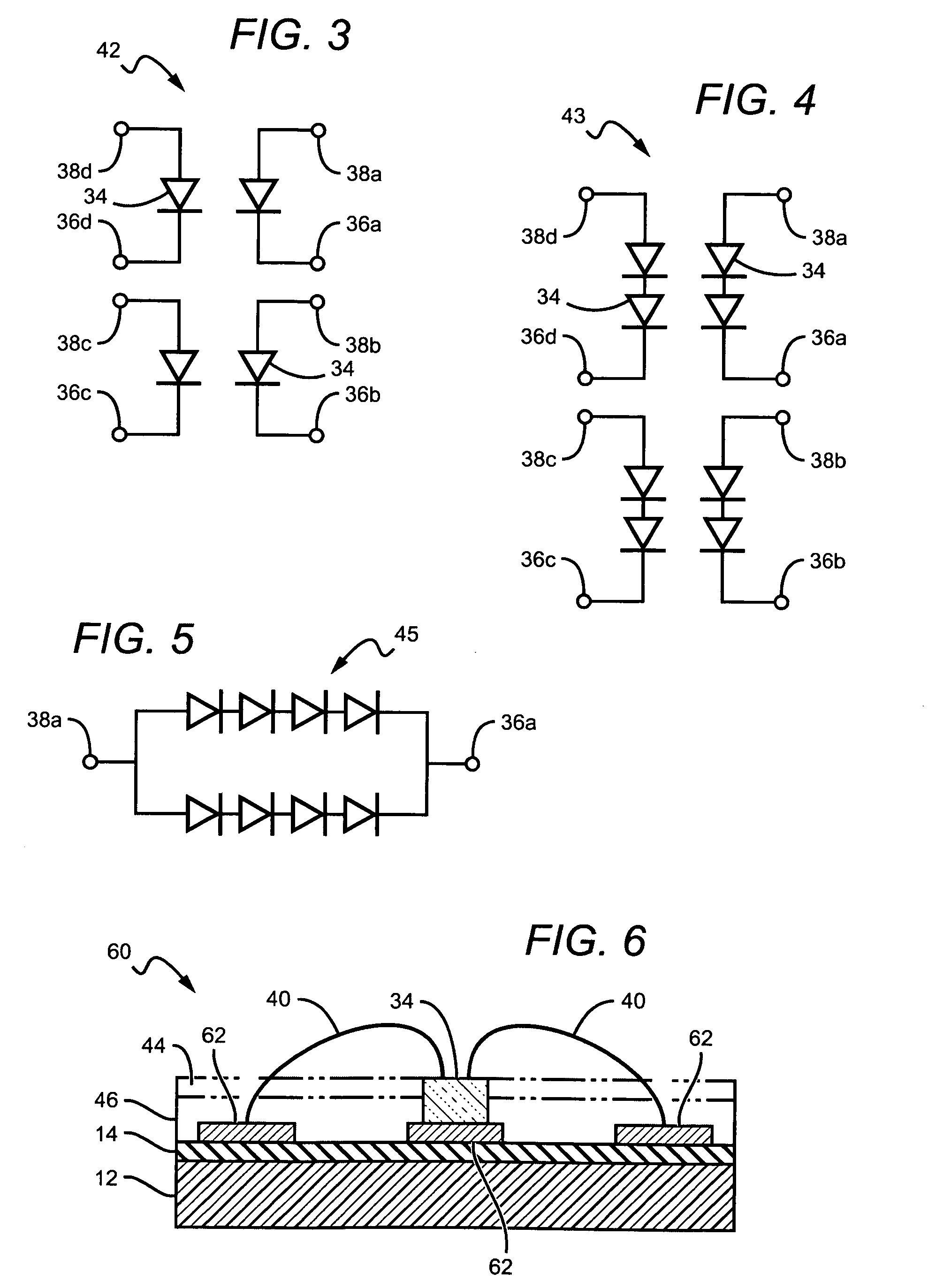

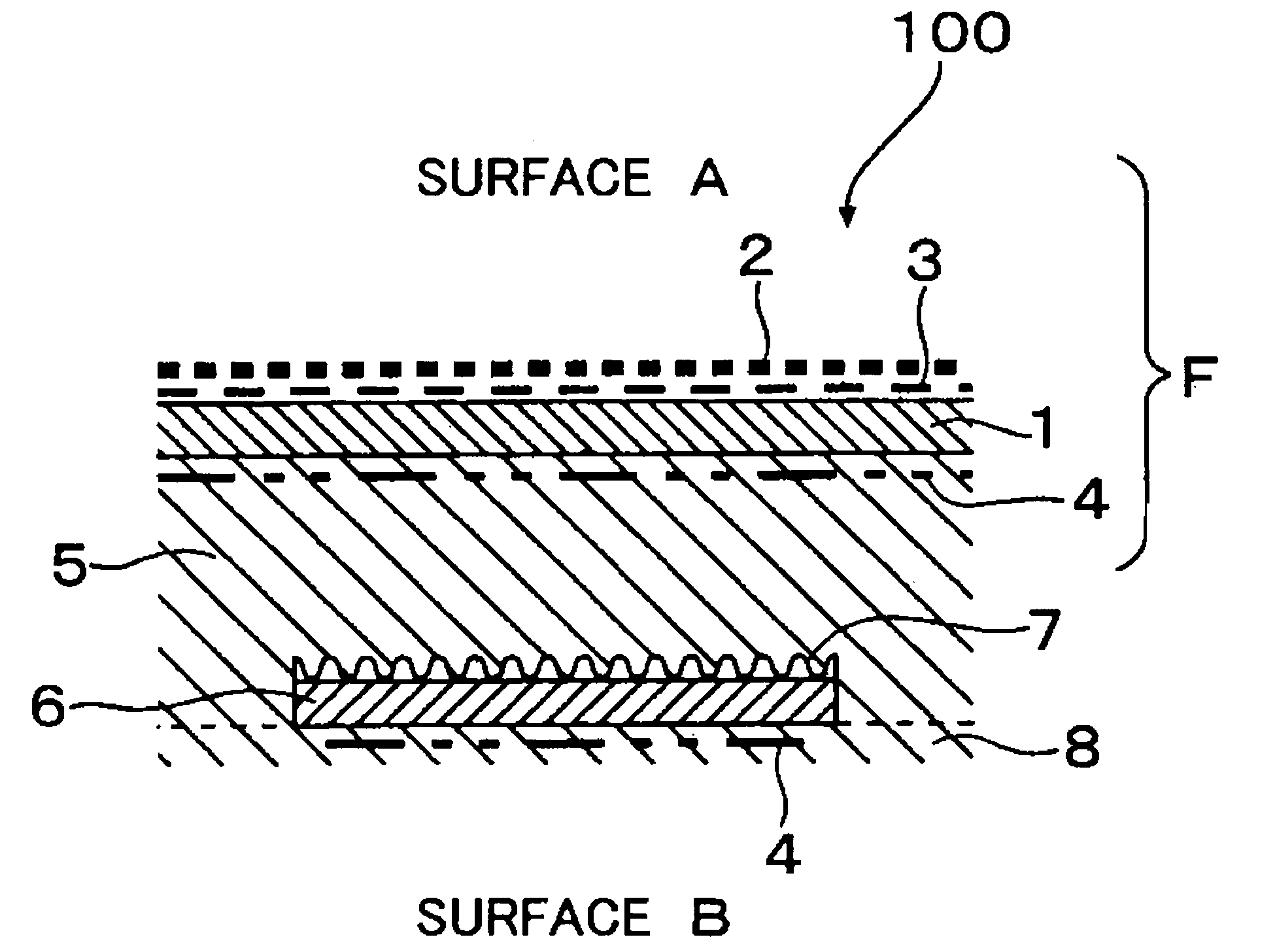

Multi-chip light emitting diode modules

ActiveUS20100117099A1Increased luminous flux outputImprove cooling effectLight absorption dielectricsSemiconductor/solid-state device detailsLuminous fluxReflective layer

A multi-chip lighting module is disclosed for maximizing luminous flux output and thermal management. In one embodiment, a multi-chip module device comprises a substantially thermally dissipative substrate with a dark insulating layer deposited on a surface of the substrate. A plurality of light emitting devices is also provided. An electrically conductive layer is applied to a surface of the substrate, with the conductive layer comprising a plurality of chip carrier parts each having a surface for carrying at least one of the light emitting devices. Each light emitting device has a first and a second electrical terminal. A reflective layer is also provided that at least partially covers the conductive layer.

Owner:CREELED INC

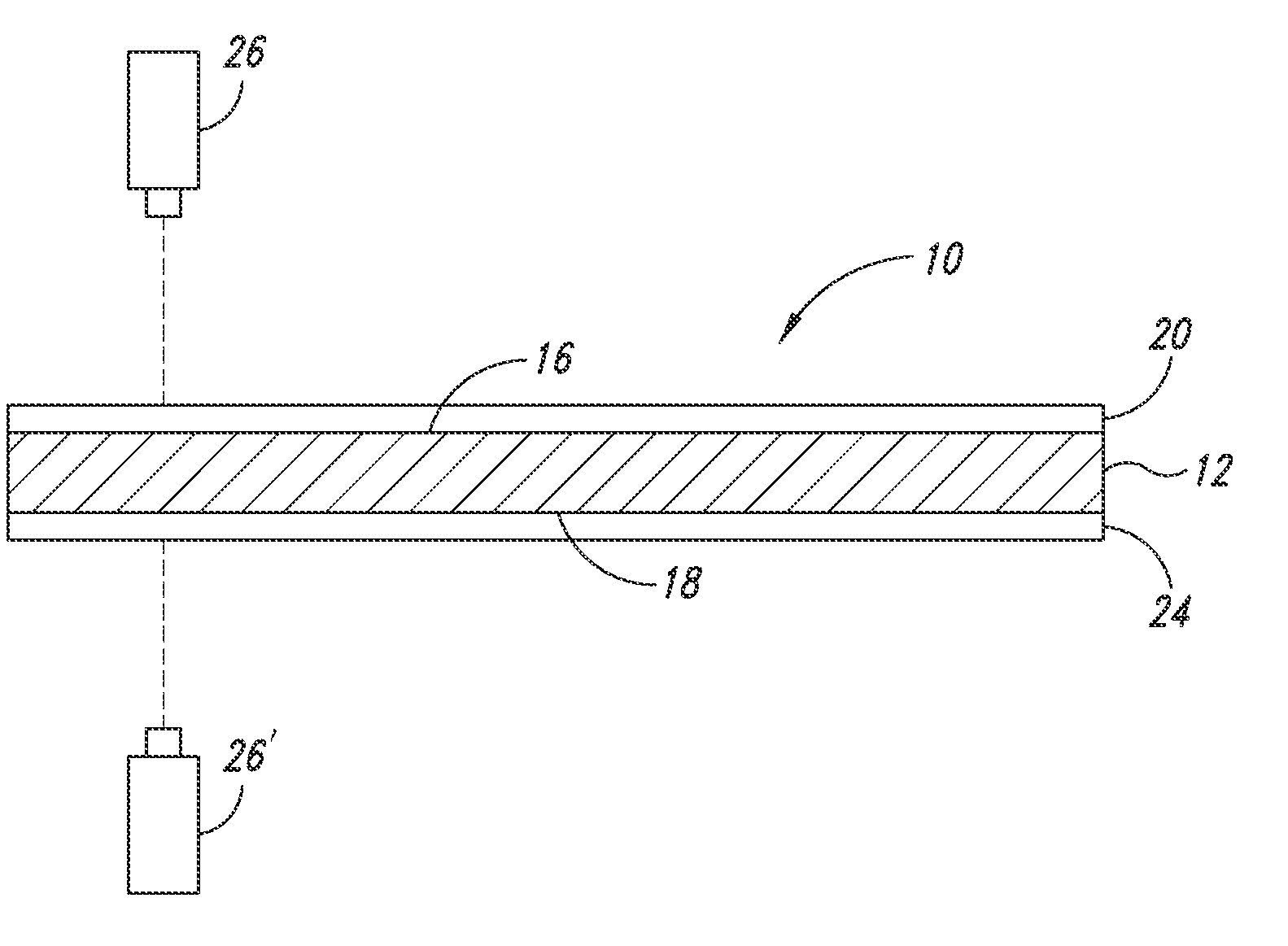

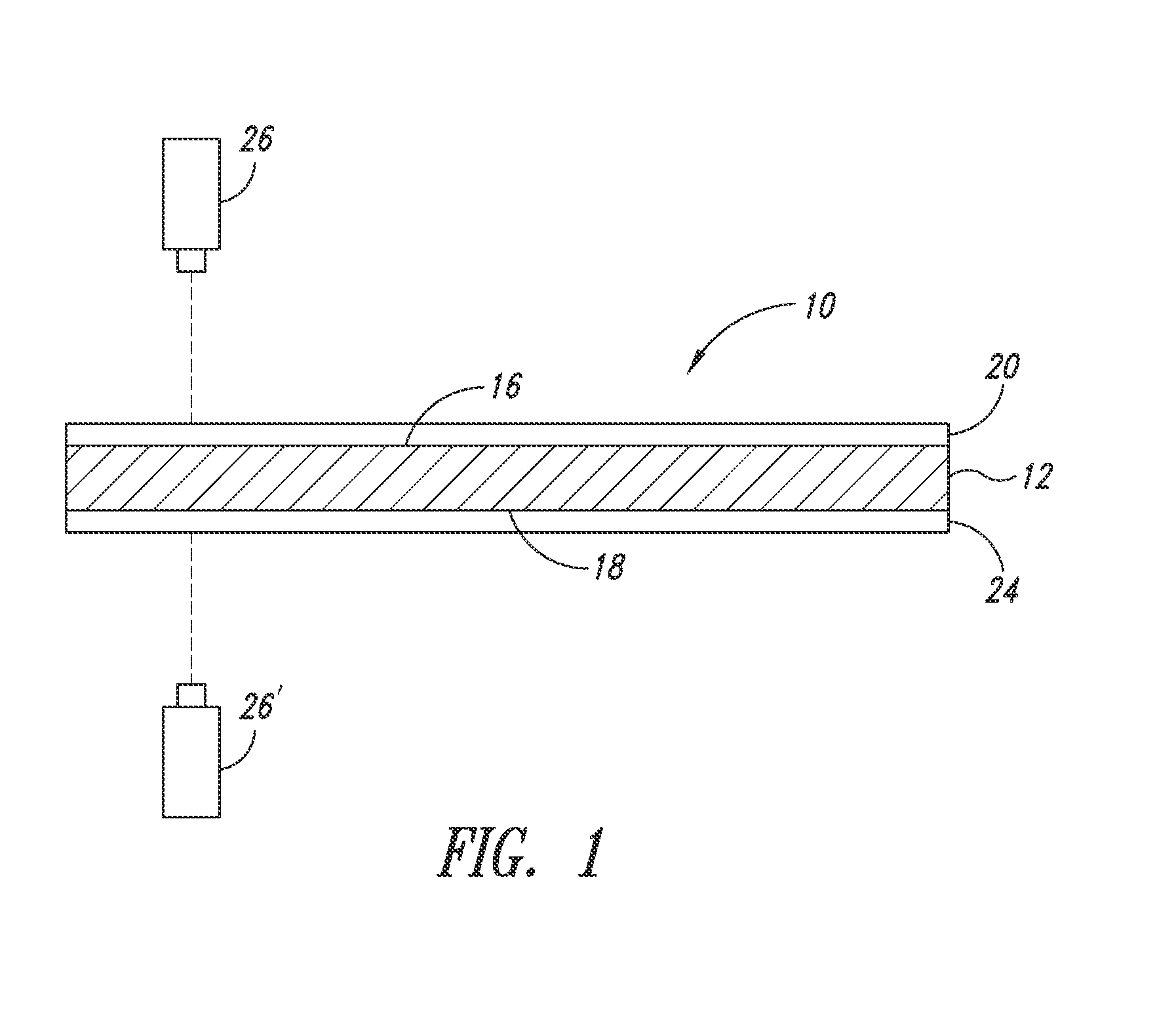

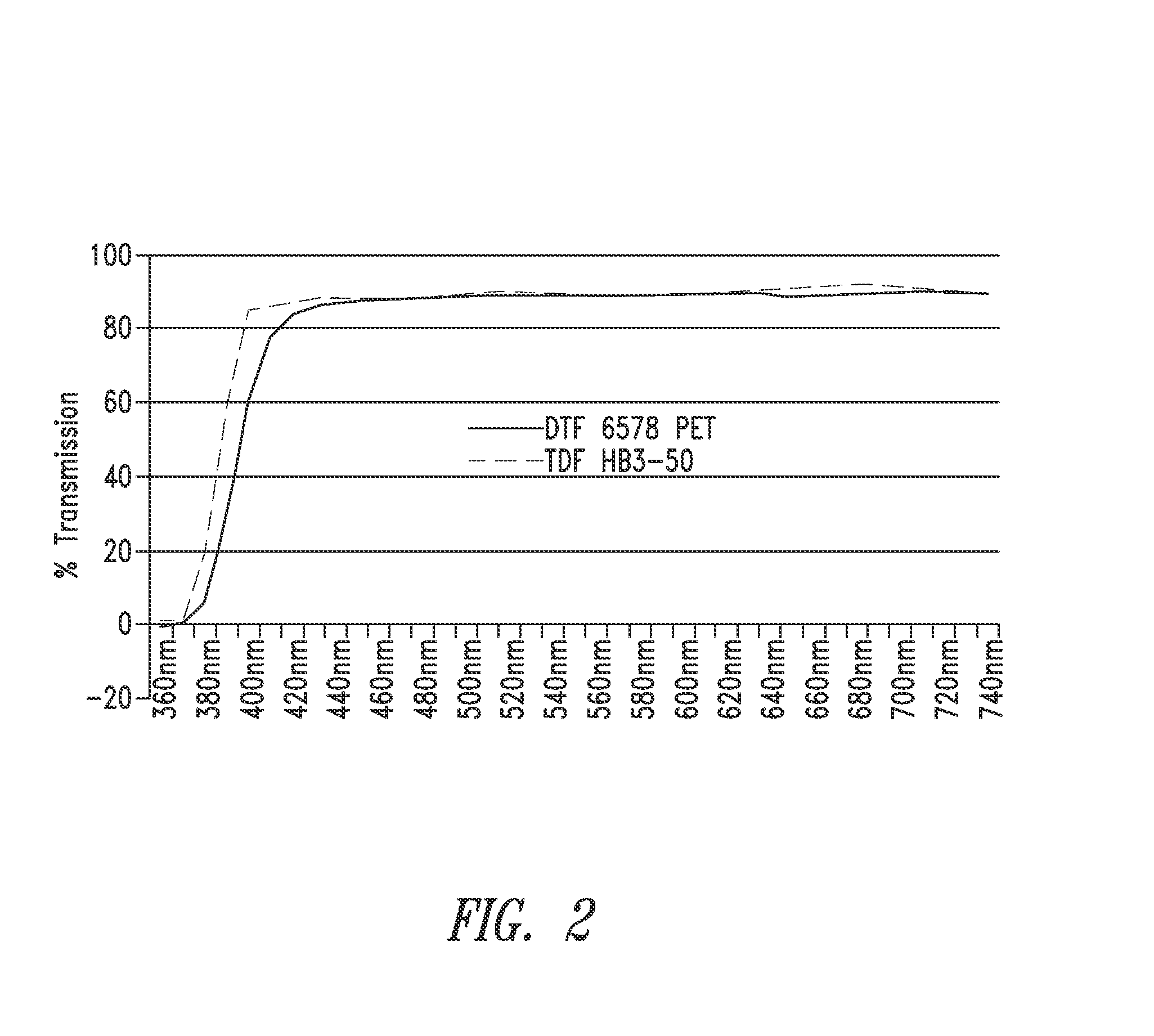

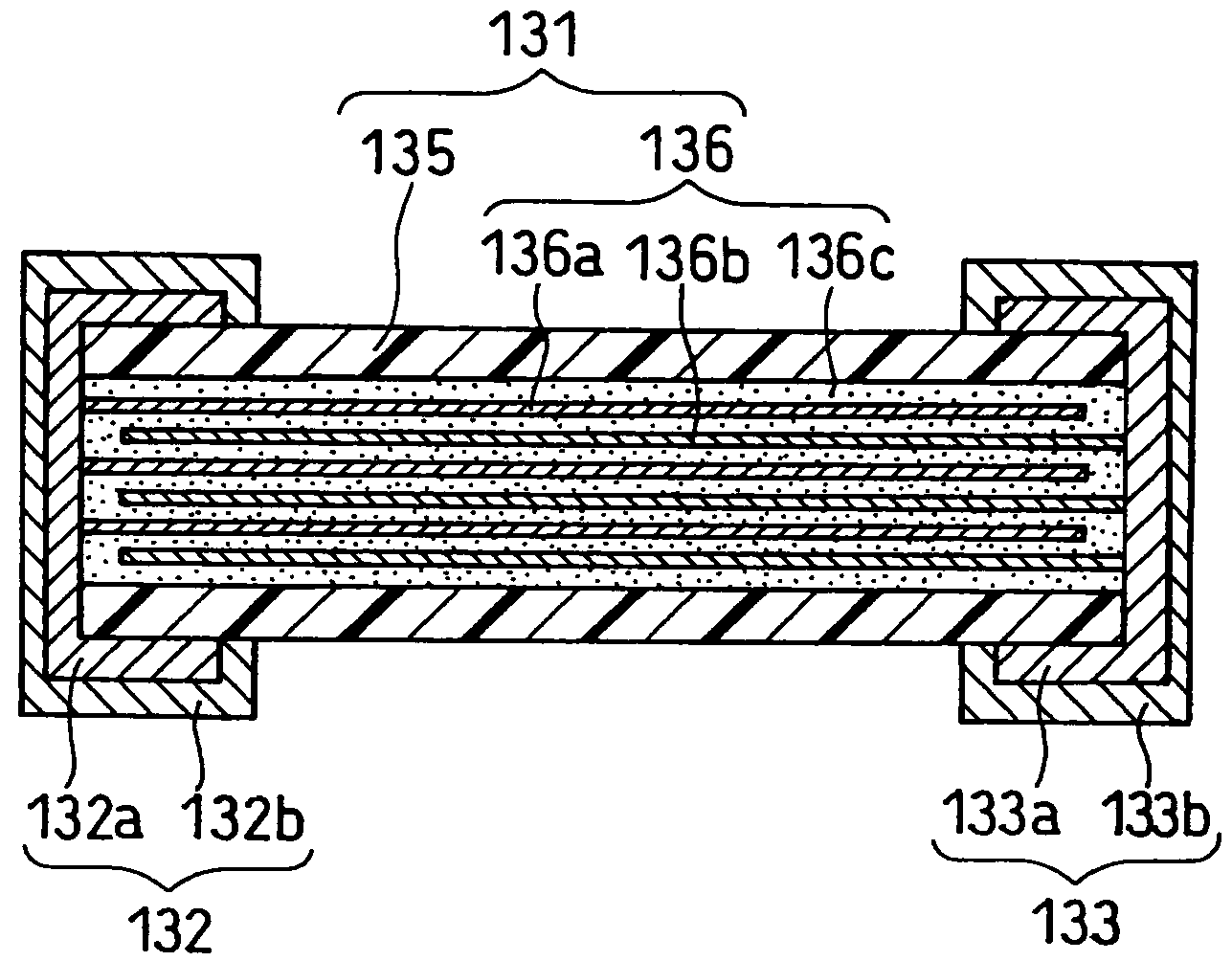

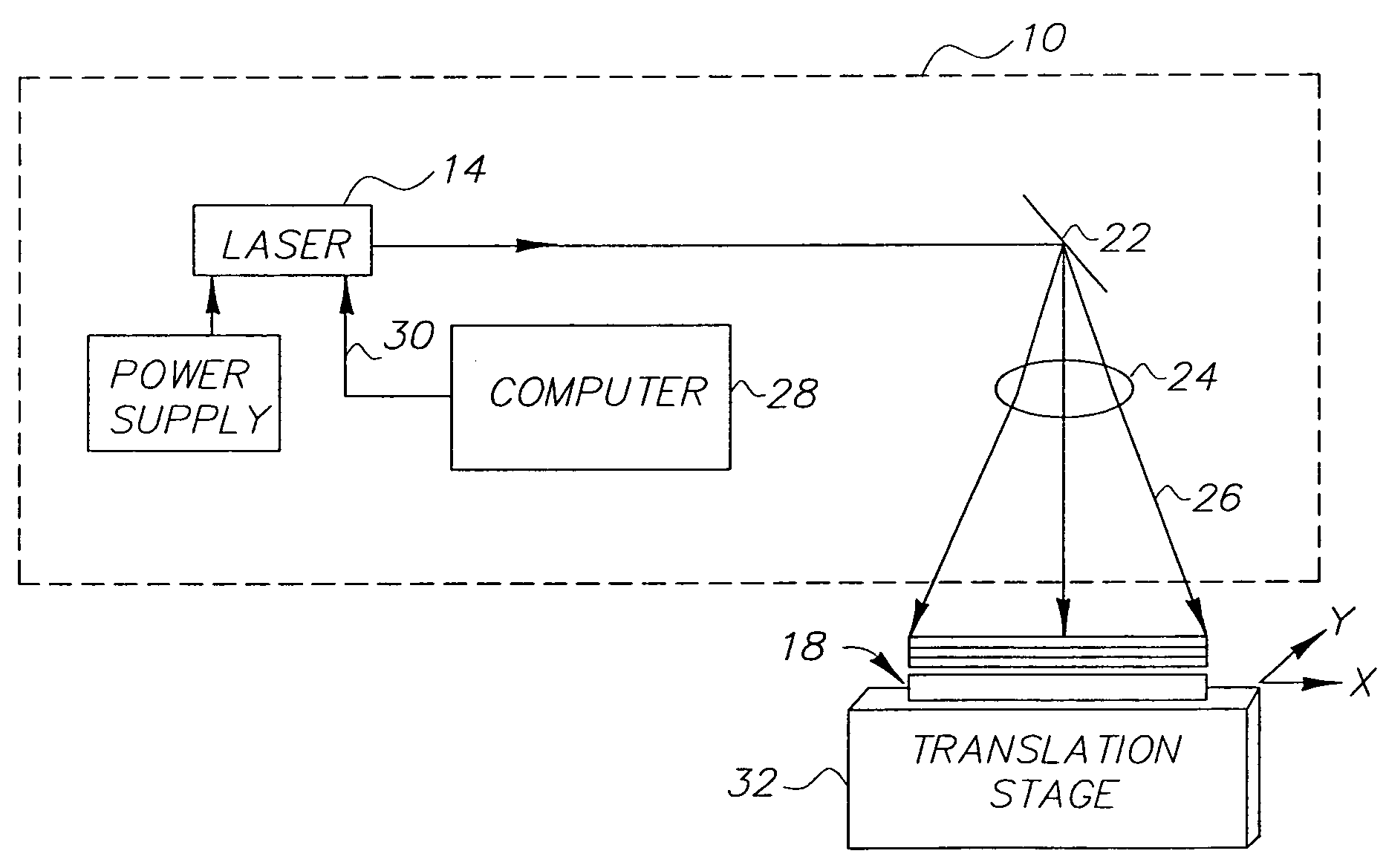

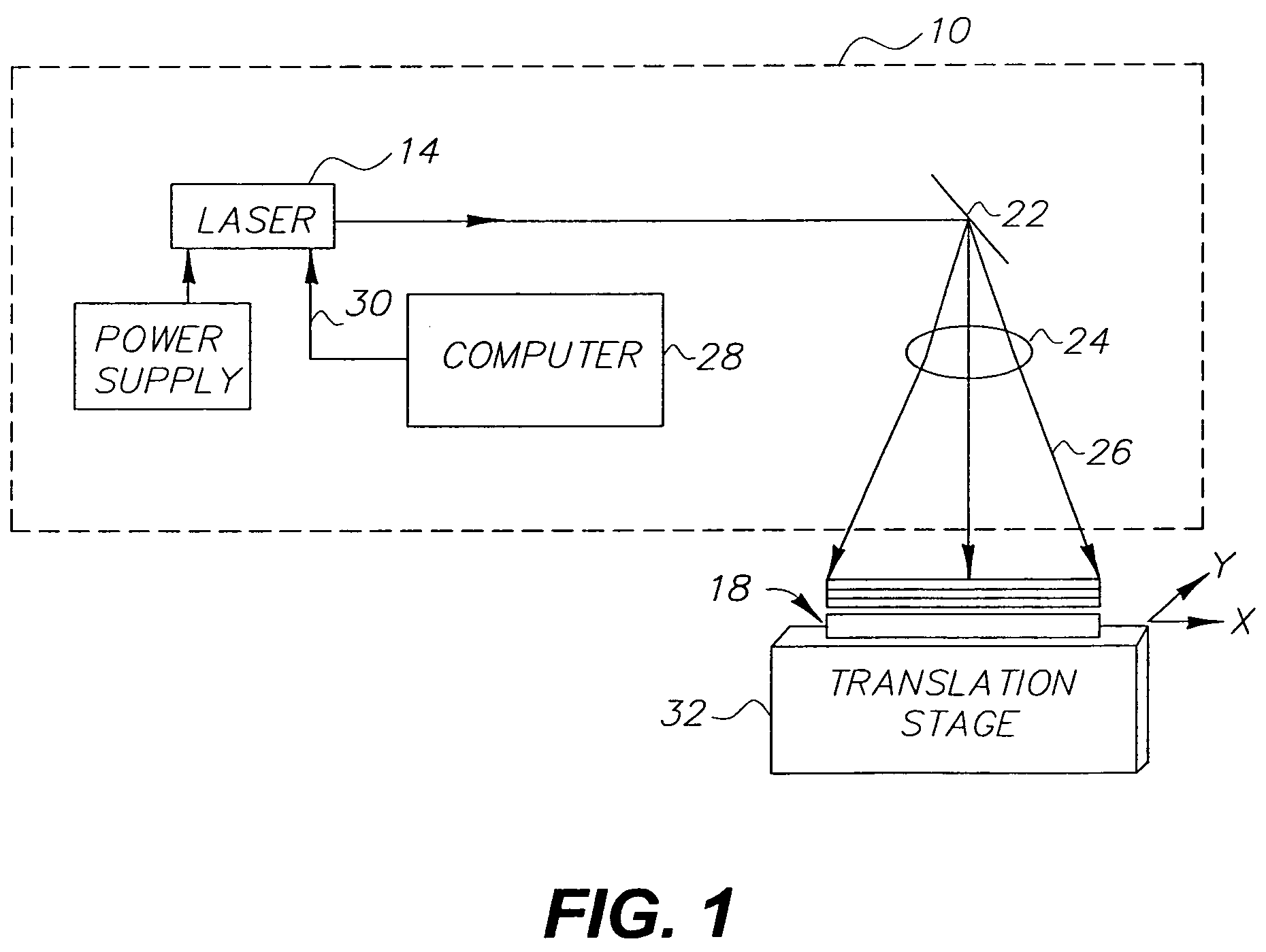

Two-sided laser patterning on thin film substrates

InactiveUS20140202742A1Improve throughputLight absorption dielectricsCircuit optical detailsLaser patterningTransparent conducting film

Owner:CHAMP GREAT INTL

High relative-permittivity B-staged sheet, high relative-permittivity prepreg, its production process, and printed wiring board comprising any one of these

InactiveUS6562179B1High relative permittivityImprove heat resistanceLight absorption dielectricsAdhesive processes with surface pretreatmentPolymer scienceRoom temperature

A high relative-permittivity B-staged sheet obtained by incorporating an insulating inorganic filler having a relative permittivity of at least 500 at room temperature into a solvent-less resin component so as to have an insultaing inorganic filler content of 80 to 99% by weight, a high relative-permittivity prepreg obtained from the above high relative-permittivity B-staged sheet, a process for the production of the high relative-permittivity prepreg, and a printed wiring board obtained from any one of the above high relative-permittivity B-staged sheet and the high relative-permittivity prepreg.

Owner:MITSUBISHI GAS CHEM CO INC

Lighting Device And Method

InactiveUS20070257274A1Improve cooling effectLight absorption dielectricsSolid-state devicesEffect lightLight-emitting diode

A lighting device having a light emitting diode (LED). The device includes a metal substrate having a surface. A dielectric coating layer is superimposed on the surface of the metal substrate. A light emitting diode (LED) is supported on the dielectric coating layer. The metal substrate serves as a heat sink for the heat emitted by LED during operation.

Owner:HEATRON

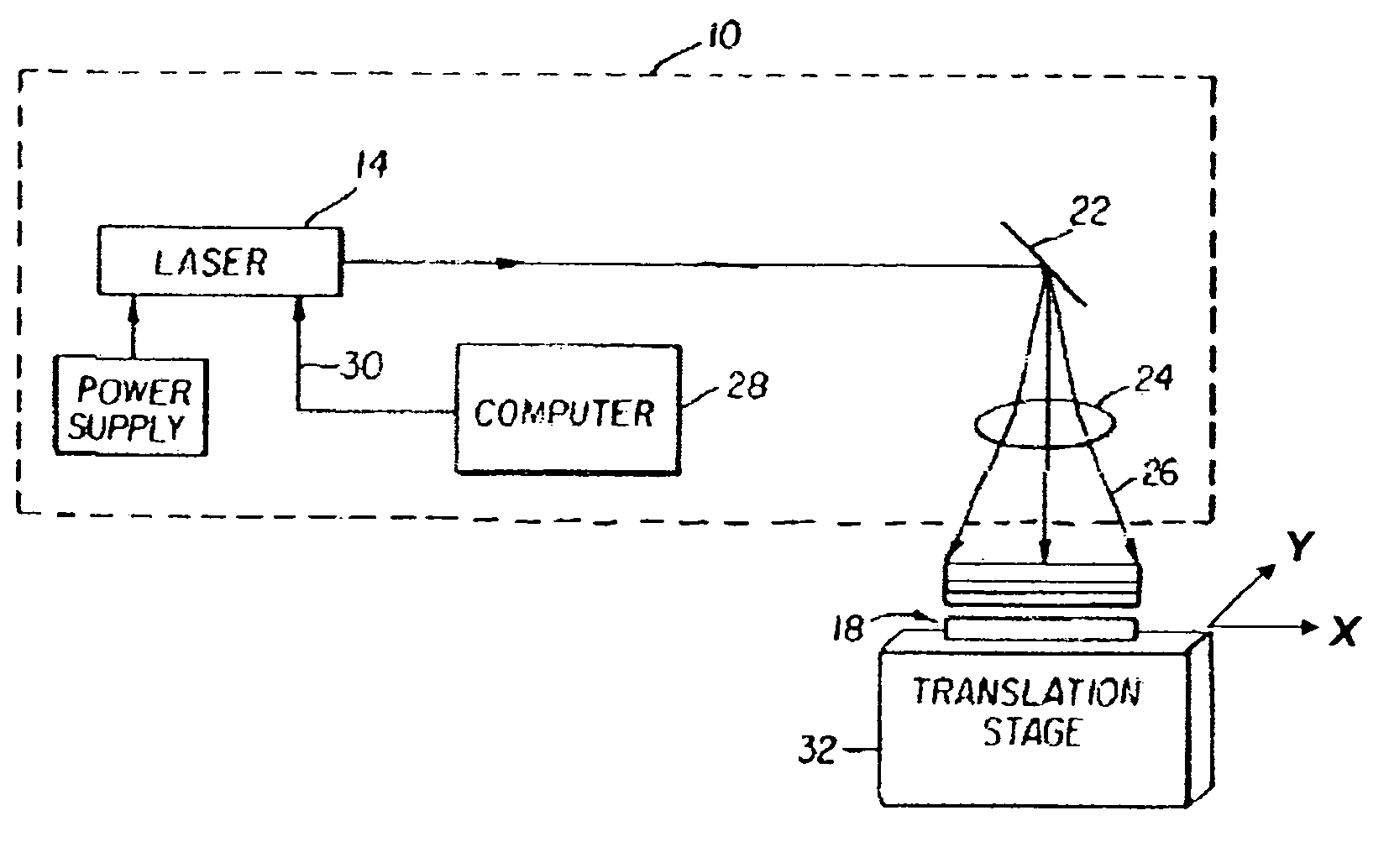

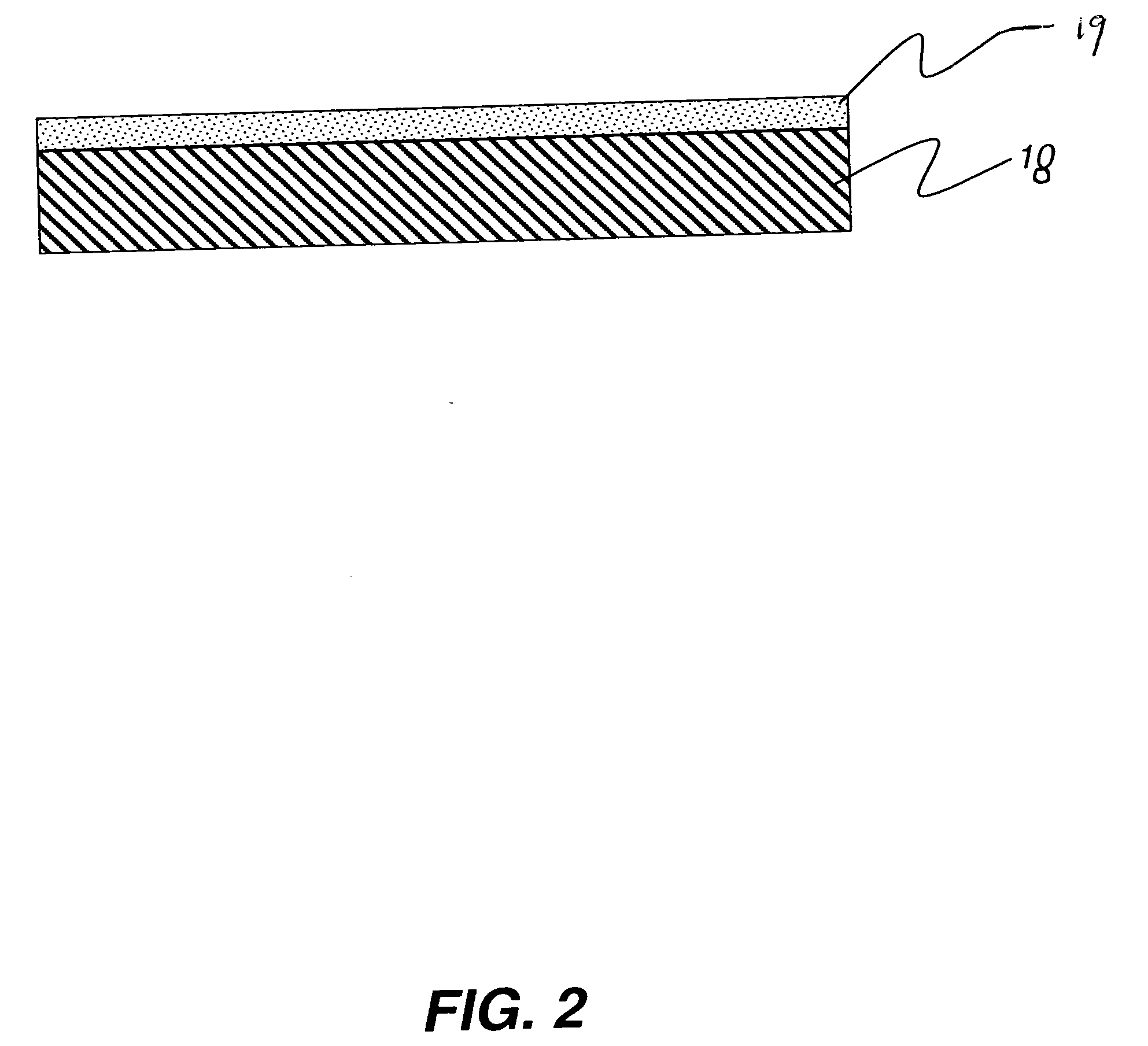

Forming electrical conductors on a substrate

InactiveUS20060003262A1Liquid surface applicatorsLight absorption dielectricsOptoelectronicsConductive materials

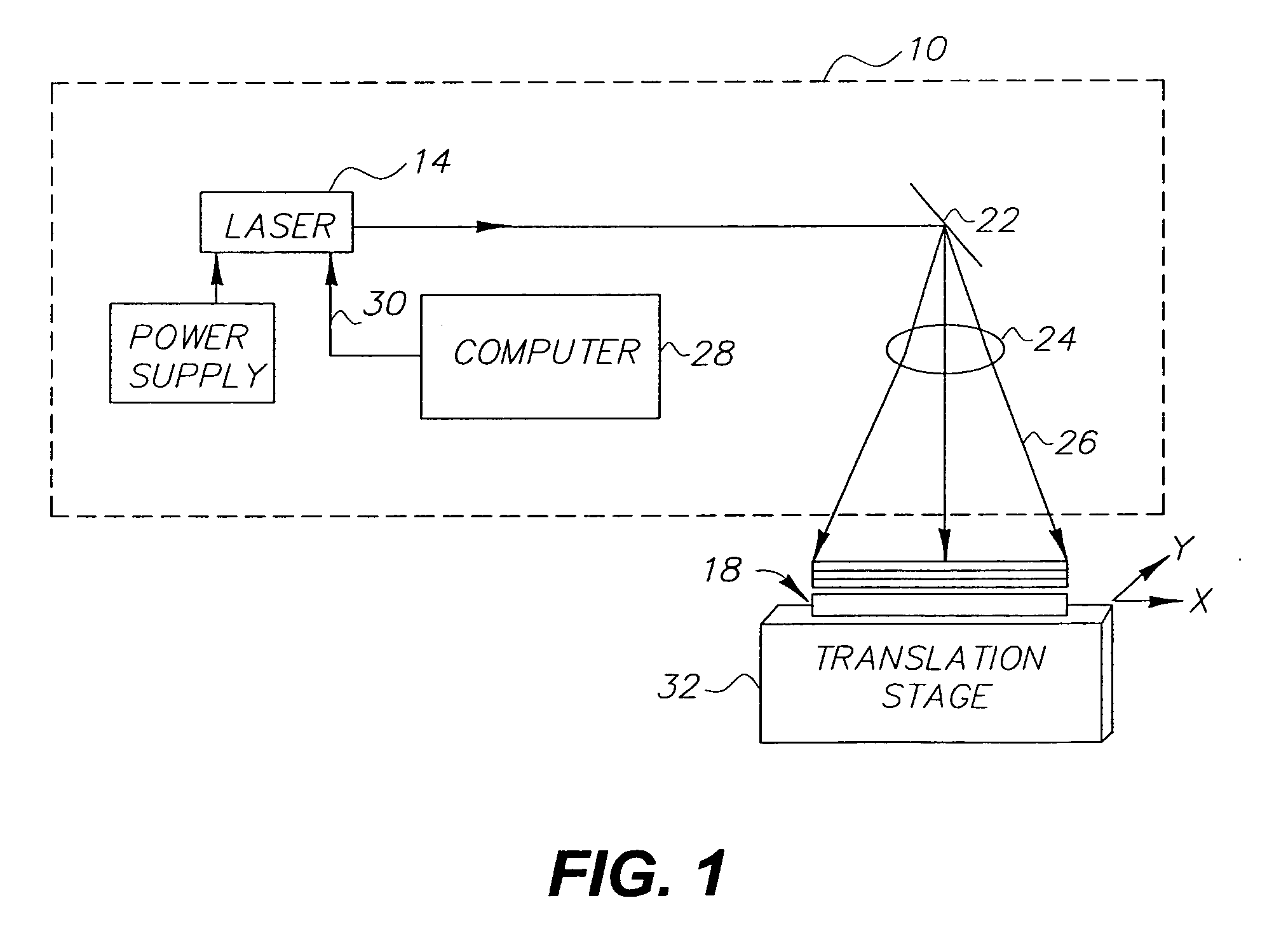

A method of forming a pattern of electrical conductors on a substrate (18) consists of forming metal nanoparticles on a conductive material. A light absorbing dye is mixed with the metal nanoparticles. The mixture is then coated on the substrate. The pattern is formed on the coated substrate with laser light (14). Unannealed material is removed from the substrate.

Owner:EASTMAN KODAK CO

Oriented, thermoplastic polyester film capable of structuring by means of electromagnetic radiation, process for its production, and its use

InactiveUS20050163987A1Cost effective productionGood orientationApparel holdersLight absorption dielectricsPolyesterFilm base

The invention relates to a single- or multilayer, oriented film comprised of a polyester which comprises an additive which when irradiated with electromagnetic radiation forms metal nuclei on which further metal can be accumulated in further steps of the process. The film also comprises another, radiation-absorbing material. The invention further relates to a process for the production of this film and to its use in printed circuit boards, ribbon cables, smart cards, RFID labels, membrane keyboards, and film-based circuits of any type.

Owner:MITSUBISHI POLYESTER FILM

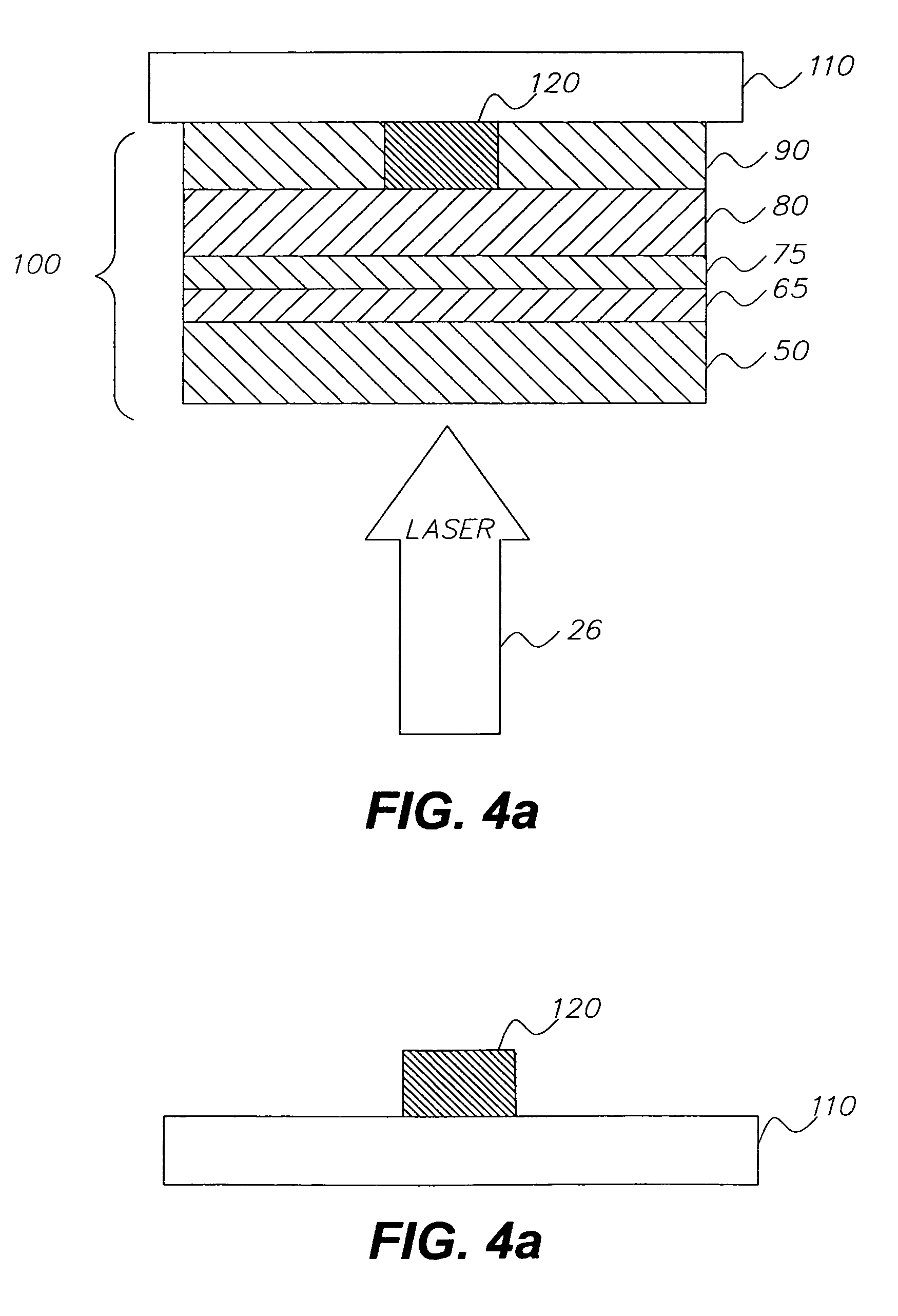

Forming a patterned metal layer using laser induced thermal transfer method

InactiveUS20060263725A1Material nanotechnologyLight absorption dielectricsOptoelectronicsConductive materials

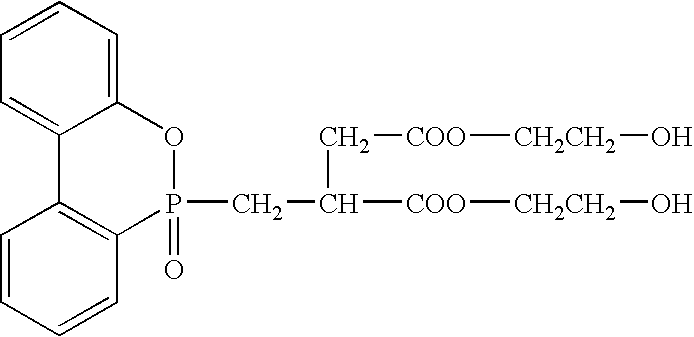

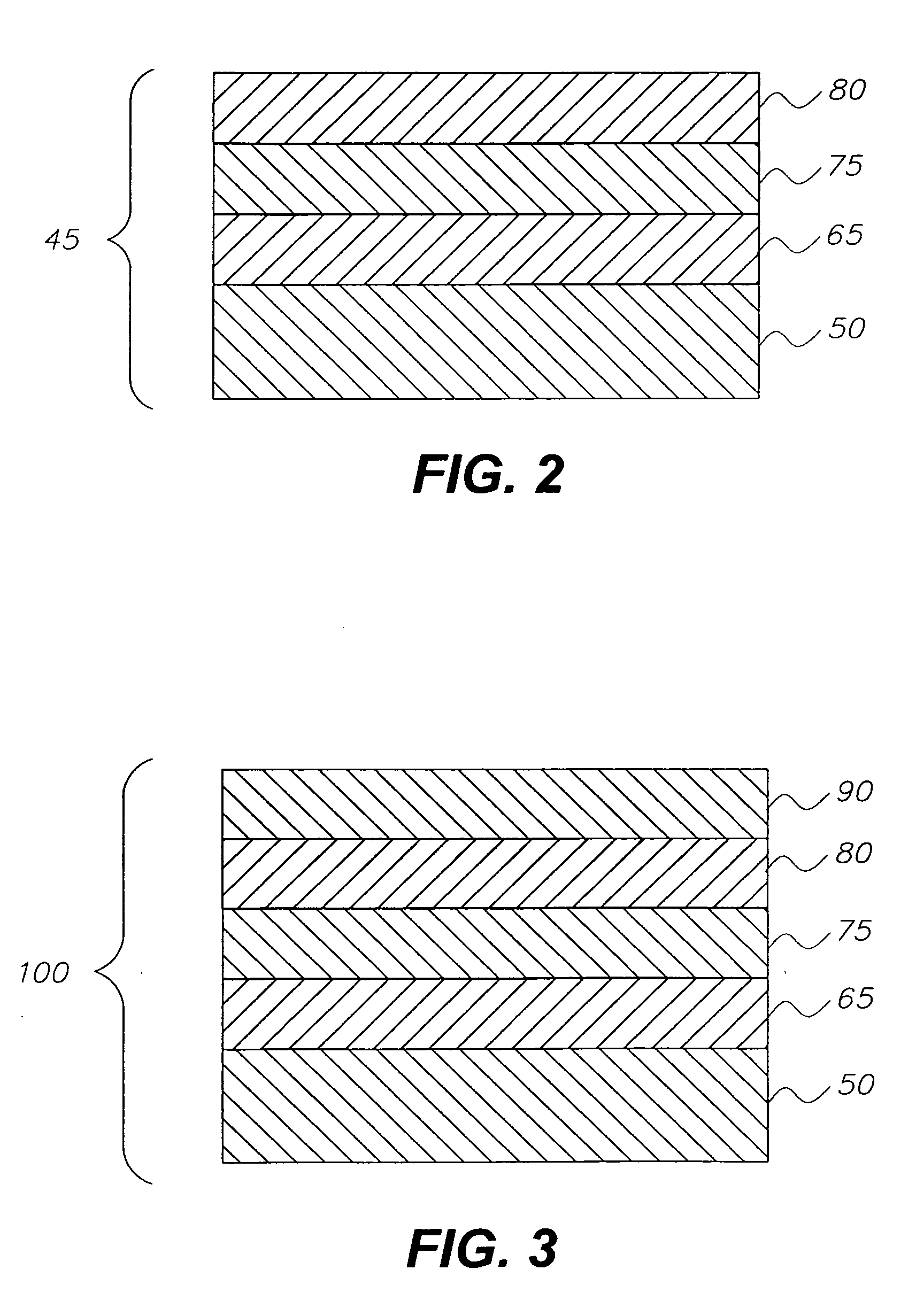

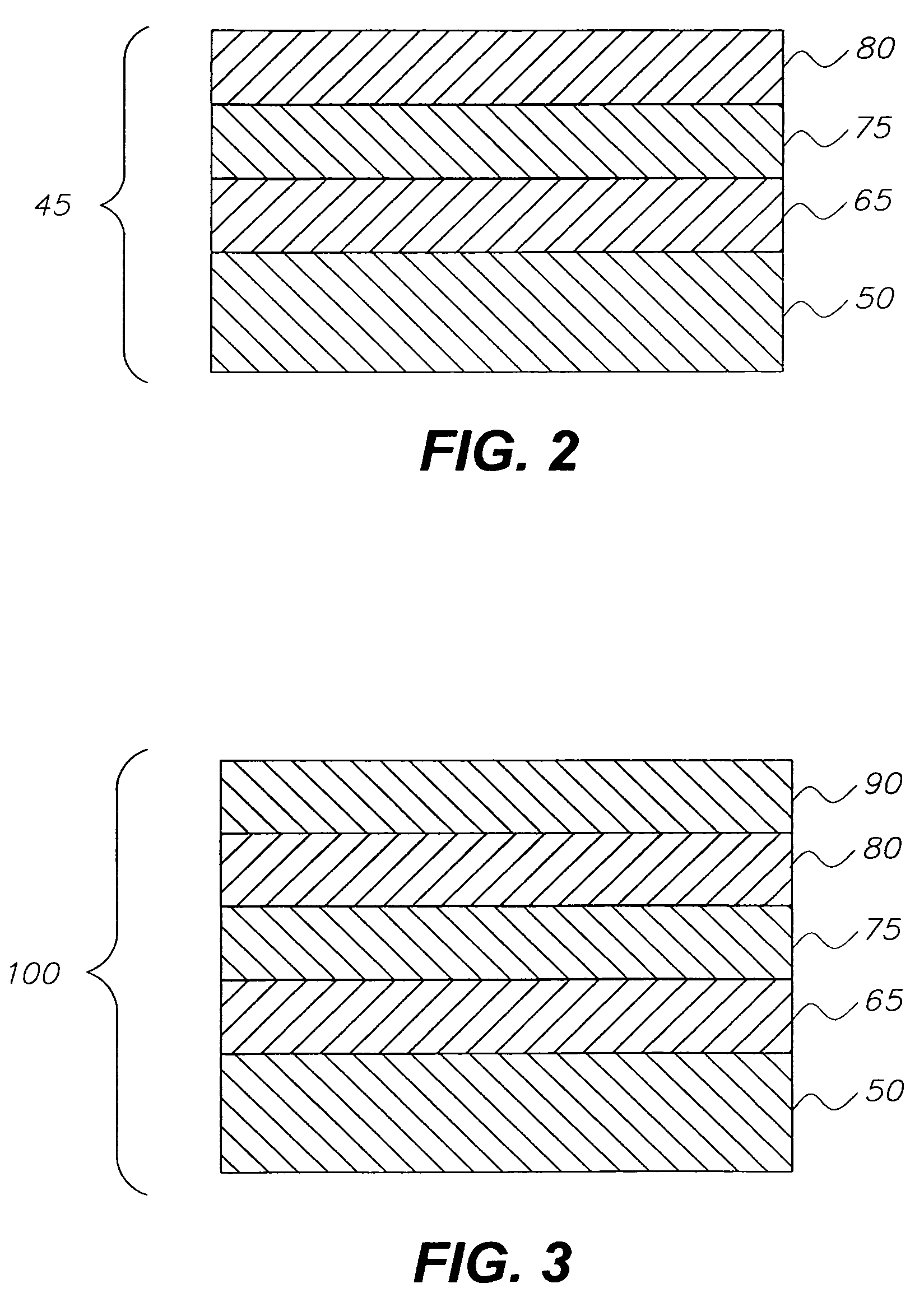

A method of forming a pattern of electrical conductors on a receiving substrate (110) comprises forming metal nanoparticles of a conductive material. A donor substrate (45) is formed. A layer of release material (75) is deposited on a first side of the donor substrate. The metal nanoparticles are deposited on the release material. The metal nanoparticulate layer are placed in contact with the receiving substrate. A pattern is written on a sandwich formed by the donor substrate and the receiving substrate, causing metal nanoparticles from the nanoparticulate layer (90) to anneal and transfer to the receiving substrate to form the pattern of electrical conductors on the receiving substrate.

Owner:EASTMAN KODAK CO

Copper-clad board suitable for making hole with carbon dioxide laser, method of making hole in said copper-clad board and printed wiring board comprising said copper-clad board

InactiveUS6736988B1Not easy to peel offPromote absorptionInsulating substrate metal adhesion improvementLight absorption dielectricsSurface layerHigh absorption

A copper-clad board suitable for making a hole with a carbon dioxide gas laser, which copper-clad board is obtained by disposing a double-side-treated copper foil provided with a metallic-treatment layer having a high absorption rate of a carbon dioxide gas laser energy on at least one surface, at least on an outer layer of a thermosetting resin composition layer such that the metallic-treatment layer is formed on a shiny surface of the copper foil which shiny surface is to be a surface layer, and laminate-forming the double-side-treated copper foil and the thermosetting resin composition layer under heat and pressure, to make an alloy of the metallic-treatment layer and the copper by the above heating, a method of making hole in the above copper-clad board and a printed wiring board comprising the above copper-clad board.

Owner:MITSUBISHI GAS CHEM CO INC

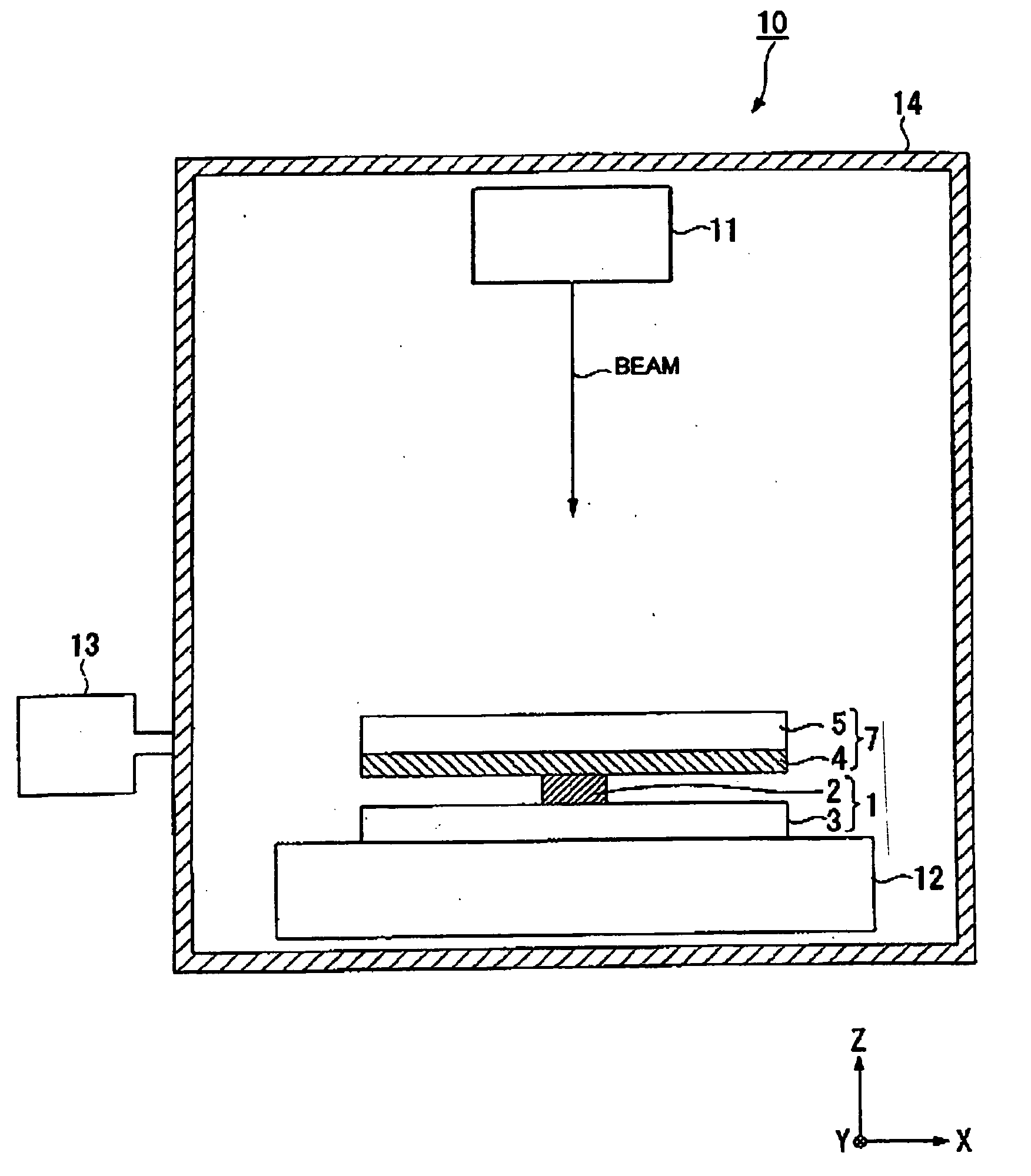

Manufacturing method of laser processed parts and protective sheet for laser processing

InactiveUS20060228650A1Avoid surface contaminationImprove accuracyLight absorption dielectricsPhotomechanical apparatusLaser processingOptoelectronics

Providing a method of manufacturing a laser processed part by using a protective sheet for laser processing capable of effectively suppressing contamination of surface of workpiece by decomposition product, and processing at high precision, when processing the workpiece by optical absorption ablation of laser beam. It is also an object to present a protective sheet for laser processing for use in the manufacturing method of laser processed part.

Owner:NITTO DENKO CORP

Compositions for use in electronics devices

InactiveUS20050247916A1Improve curing speedMaterial nanotechnologyNanostructure manufacturePolymer resinDiluent

A fast curing composition that comprises a polymeric resin, a conductive filler and one or more near-infrared absorbing additives and optionally an oxygen scavenger or corrosion inhibitor or both, and other additives such as reactive or nonreactive diluents, inert fillers, and adhesion promoters. The composition may be conductive, resistive or anisotropically conductive. In another embodiment, this invention is a method for improving the cure speed of a composition by exposing the composition to a near infrared energy source.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Flexible circuit board and liquid crystal display having the same

InactiveUS20080158470A1Accurate connectionLight absorption dielectricsCircuit optical detailsLiquid-crystal displayLight guide

A flexible circuit board and a liquid crystal display having the same prevents emission of light from a light source to peripheral undesired areas, and firmly connects the board to a mold frame. The board includes a first insulating film, conductive patterns formed on the first insulating film, a second insulating film formed on the first insulating film to cover the conductive patterns, a light source coupled to the conductive patterns, and a light absorbing layer formed on the outer circumference of the light source to absorb light from the light source. Also, a mold frame includes an outer frame, an inner frame, and a guide boss. The board is connected to the mold frame, the light guide plate is connected to the mold frame and optically coupled to the board, and the liquid crystal display panel is placed on the light guide plate and coupled to the board.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

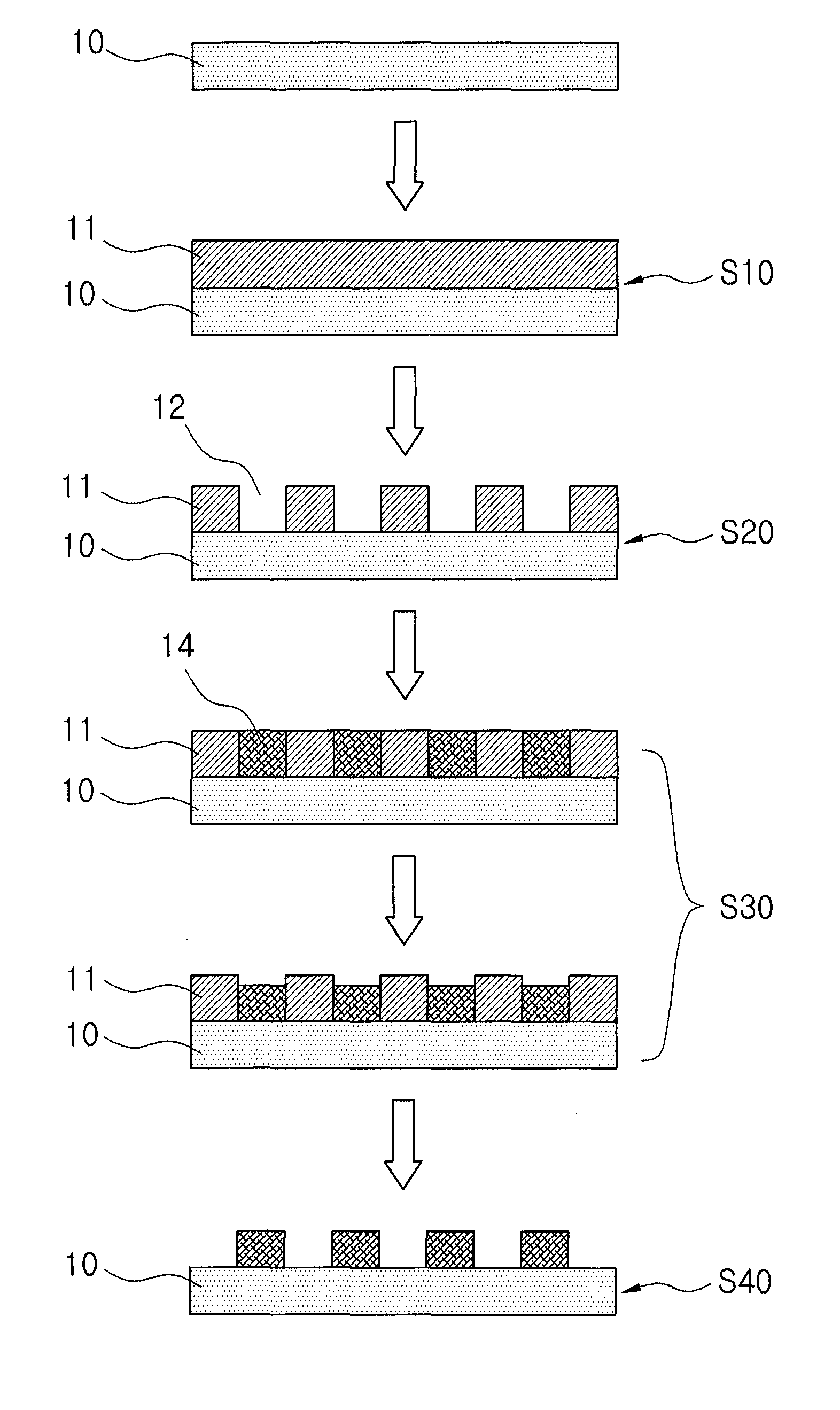

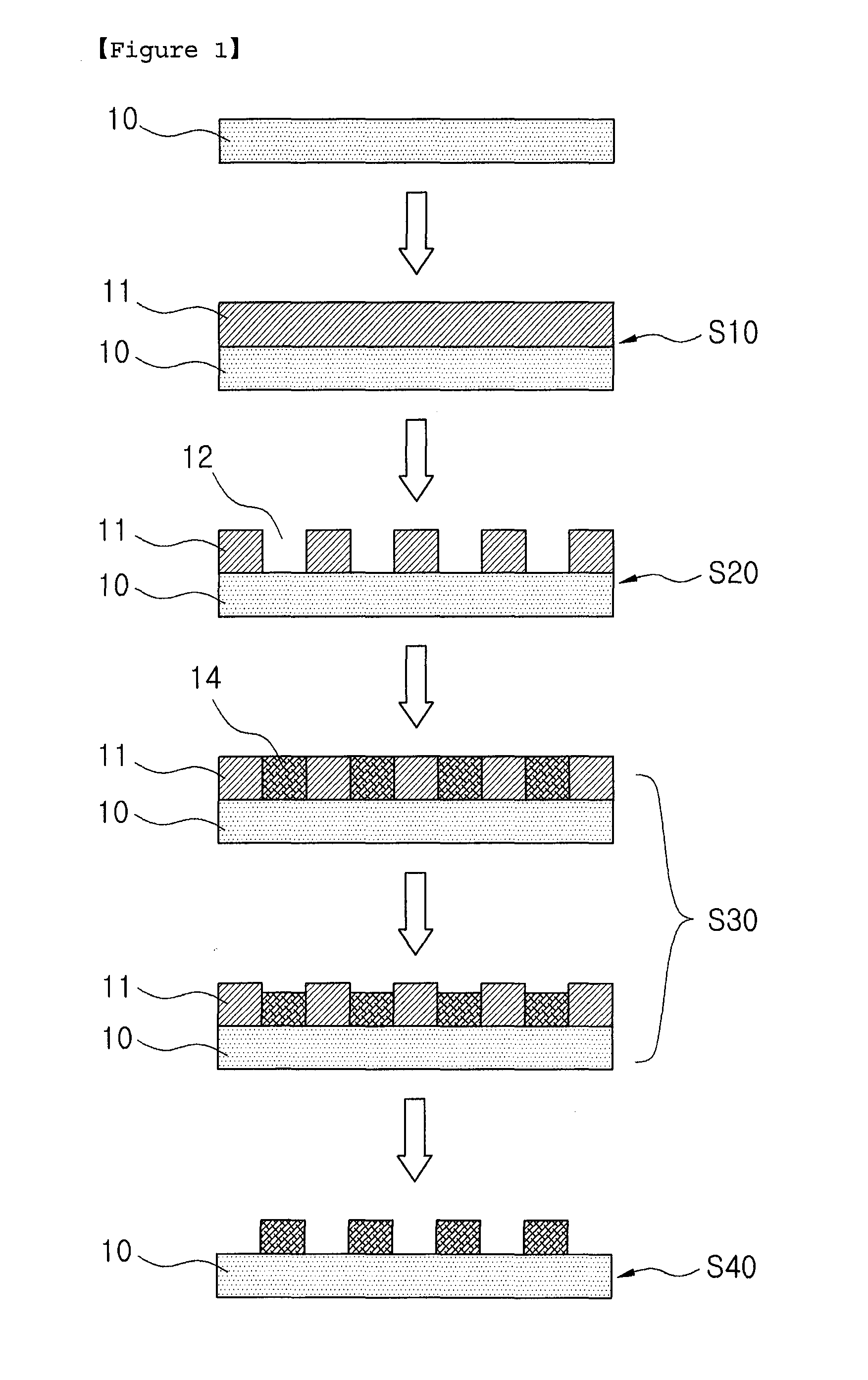

Method for Fabricating Blackened Conductive Patterns

ActiveUS20110003086A1High resolutionImprove conductivityLight absorption dielectricsRadiation applicationsResistConductive materials

The present invention relates to a method for fabricating blackened conductive patterns, which includes (i) forming a resist layer on a non-conductive substrate; (ii) forming fine pattern grooves in the resist layer using a laser beam; (iii) forming a mixture layer containing a conductive material and a blackening material in the fine pattern grooves; and (iv) removing the resist layer remained on the non-conductive substrate.

Owner:INKTEC CO LTD

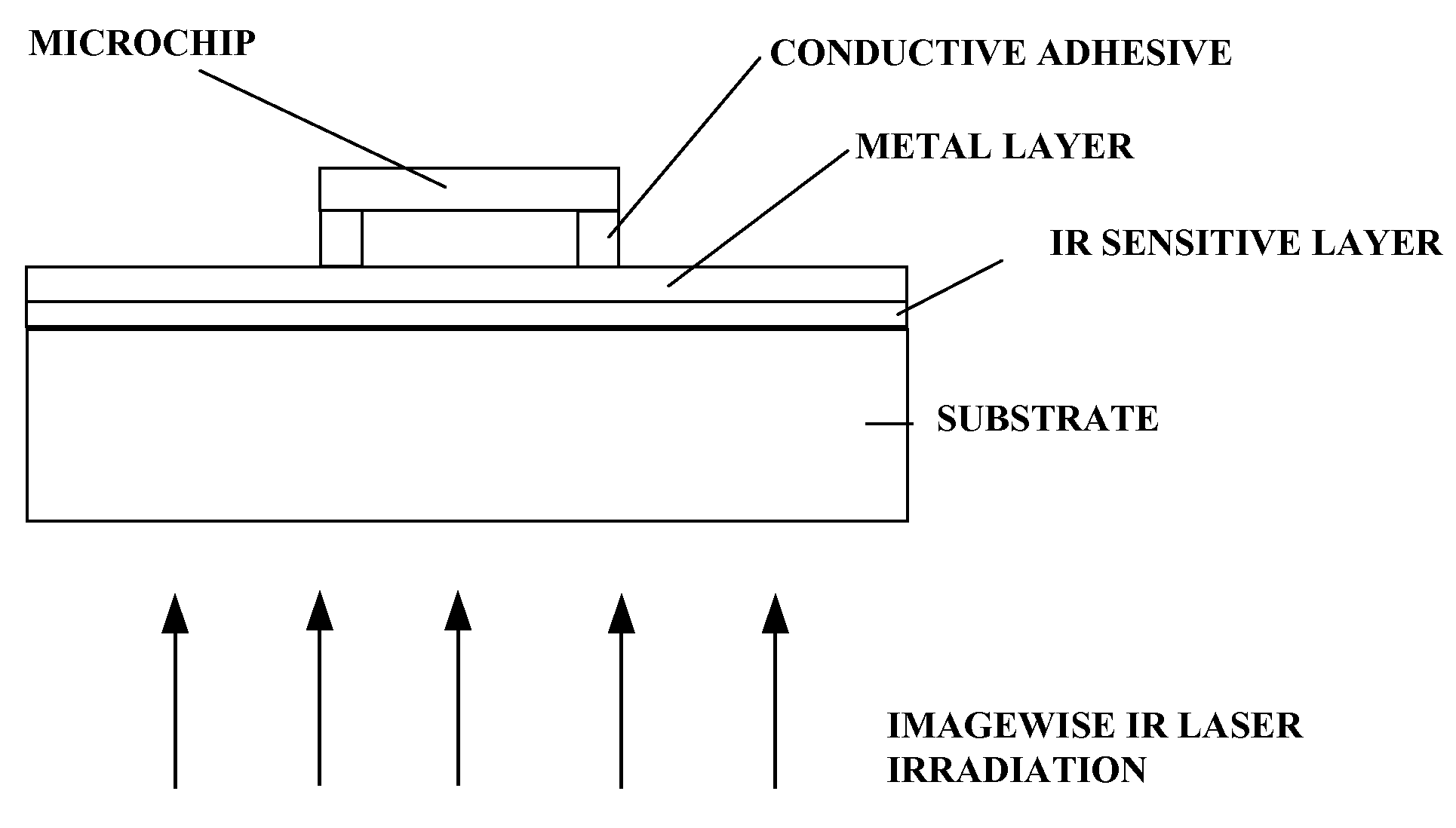

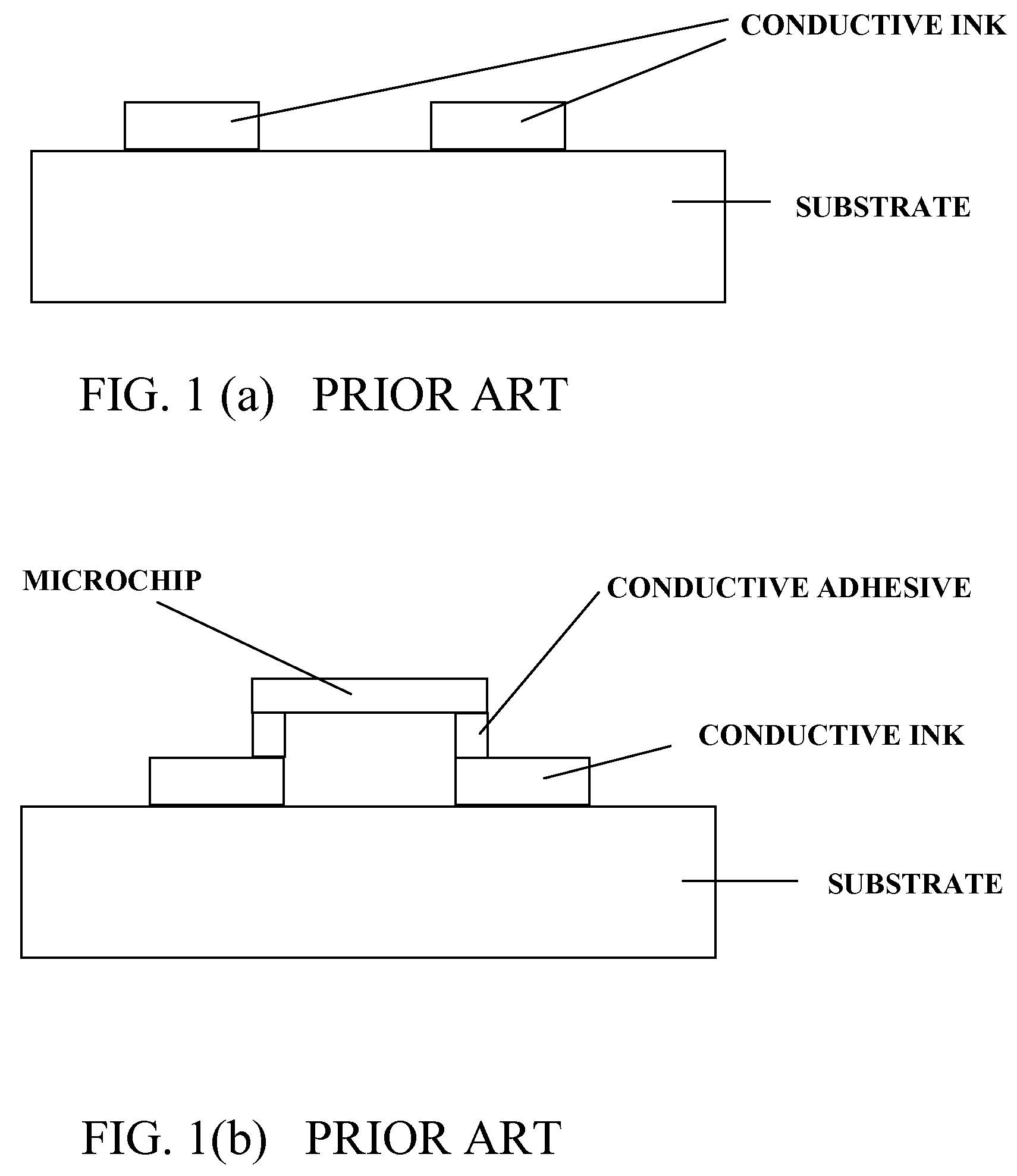

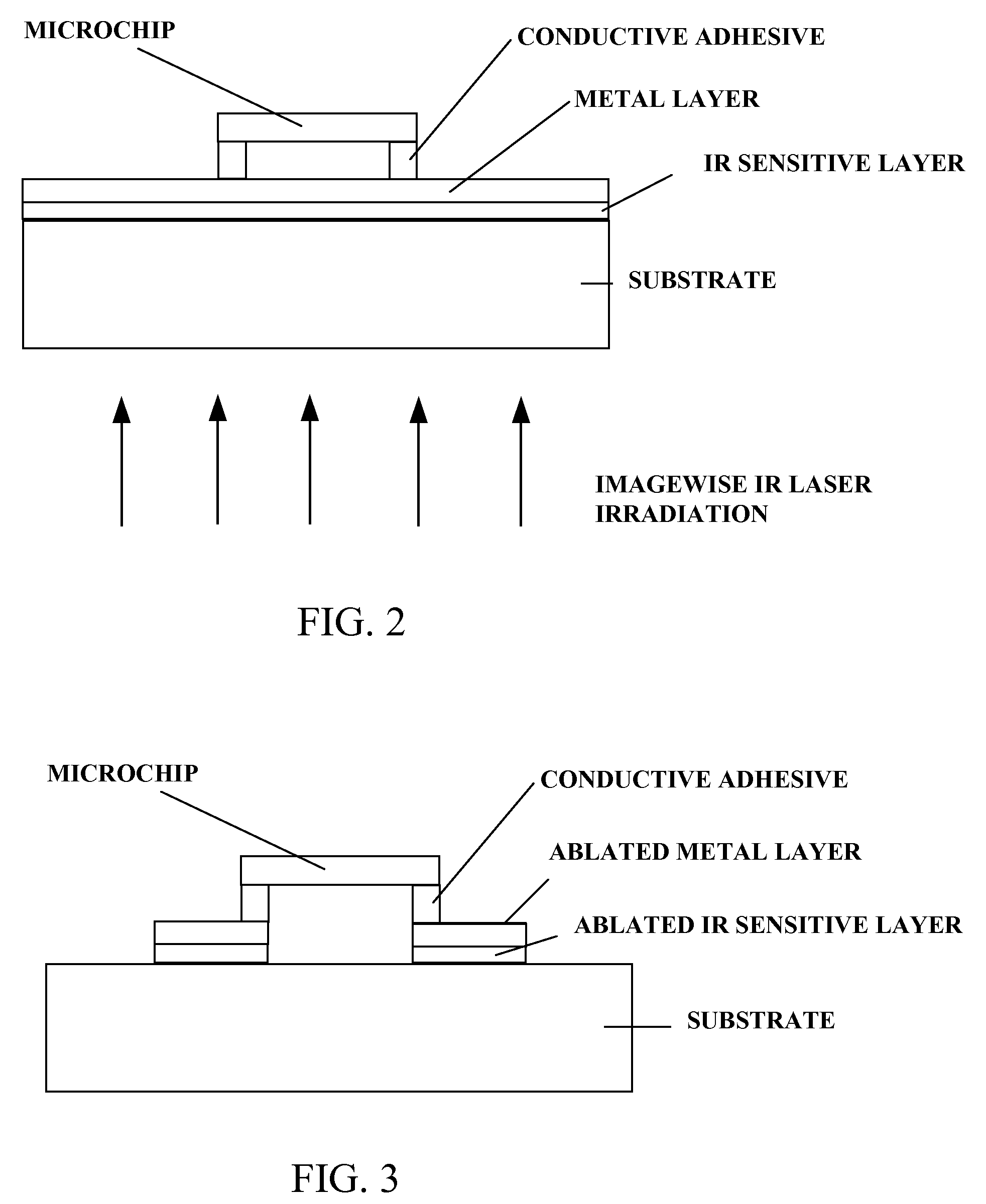

Method for fabricating an electronic device

The invention provides an article and process for producing electronic devices. More particularly the invention relates to an article and process for fabricating patterns of electrically conductive materials on non-electrically conductive substrates by laser ablation. Such an article and process find use in the production of RDIF devices, antennae, electrical circuits, microwave susceptors, contacts, leads, conductors, interactive displays, electrostatic shielding devices and the like. The process involves first providing an electrically conductive metal layer on an electrically non-conductive substrate. Then an electronic circuit is electrically connected to the electrically conductive metal layer. Thereafter a portion of the electrically conductive metal layer is ablated with infrared laser radiation to form a pattern of electrically conductive areas and electrically non-conductive areas on the substrate, wherein at least a portion of the electrically conductive areas are electrically connected to the electronic circuit.

Owner:IDEON LLC

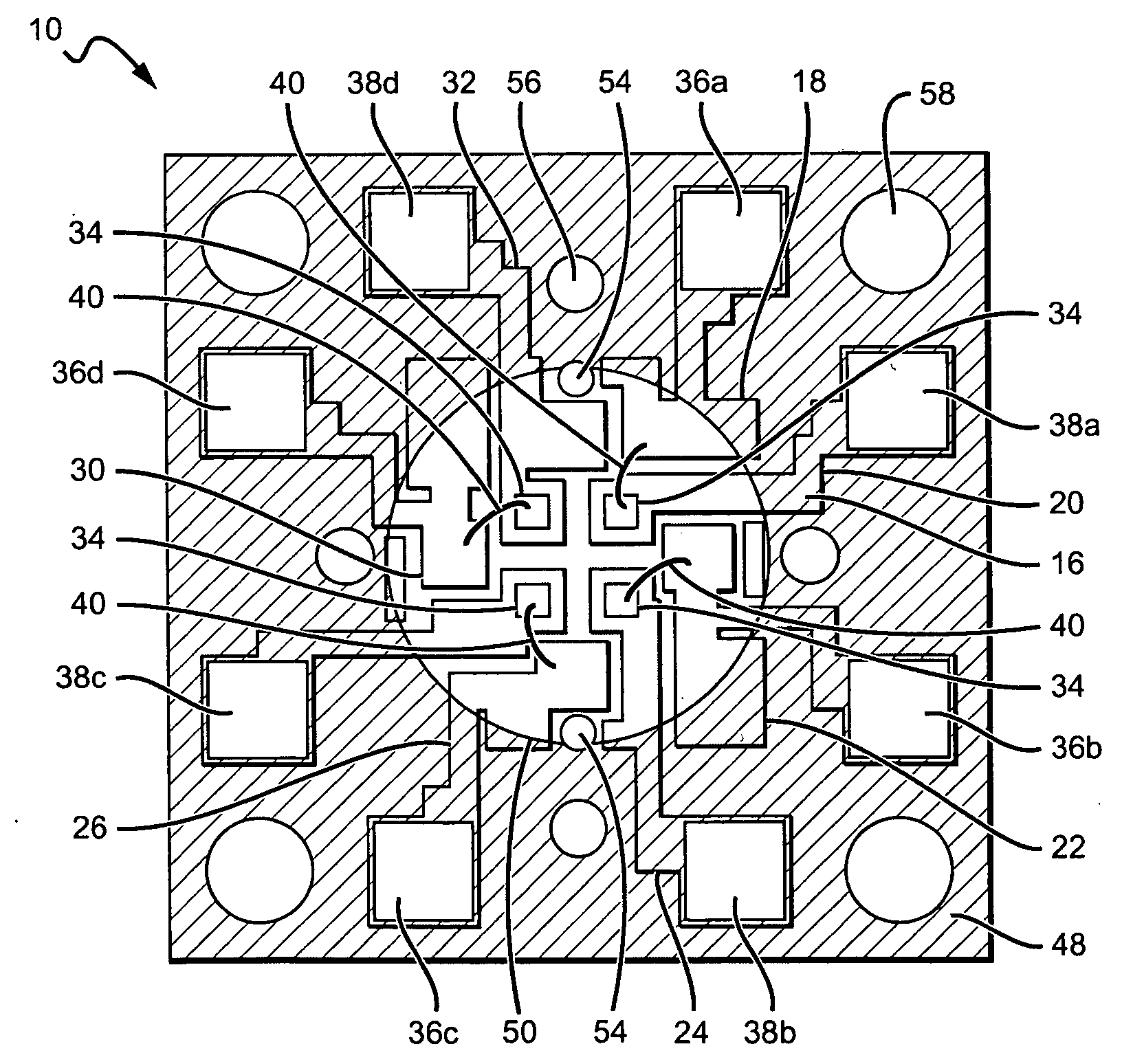

Multi-chip light emitting diode modules

ActiveUS8791471B2Increase heatHigh outputLight absorption dielectricsSemiconductor/solid-state device detailsEffect lightLuminous flux

A multi-chip lighting module is disclosed for maximizing luminous flux output and thermal management. In one embodiment, a multi-chip module device comprises a substantially thermally dissipative substrate with a dark insulating layer deposited on a surface of the substrate. A plurality of light emitting devices is also provided. An electrically conductive layer is applied to a surface of the substrate, with the conductive layer comprising a plurality of chip carrier parts each having a surface for carrying at least one of the light emitting devices. Each light emitting device has a first and a second electrical terminal. A reflective layer is also provided that at least partially covers the conductive layer.

Owner:CREELED INC

Thermosetting adhesive and pressure-sensitive adhesive composition, thermosetting adhesive and pressure-sensitive adhesive tape or sheet, and wiring circuit board

InactiveUS20070036953A1Improve balanceImprove heat resistanceLight absorption dielectricsPrinted circuit detailsPolymer scienceMeth-

A thermosetting adhesive and pressure-sensitive adhesive composition containing 100 parts by weight of an acrylic polymer (X) containing, as monomer components, a (meth)acrylic acid alkyl ester (a) where the alkyl group has 2 to 14 carbon atoms in an amount of 60 to 75% by weight relative to the total amount of monomer components, a cyano group-containing monomer (b) in an amount of 20 to 35% by weight relative to the total amount of monomer components, and a carboxyl group-containing monomer (c) in an amount of 0.5 to 10% by weight relative to the total amount of monomer components and 1 to 20 parts by weight of a carbolic acid-based resorcinol-type phenol resin (Y) represented by the following formula (1), and further containing an ultraviolet absorbent (Z). wherein R1 represents —CH2— or —CH2—O—CH2—, n is a positive integer, and m is an integer of 1 to 4.

Owner:NITTO DENKO CORP

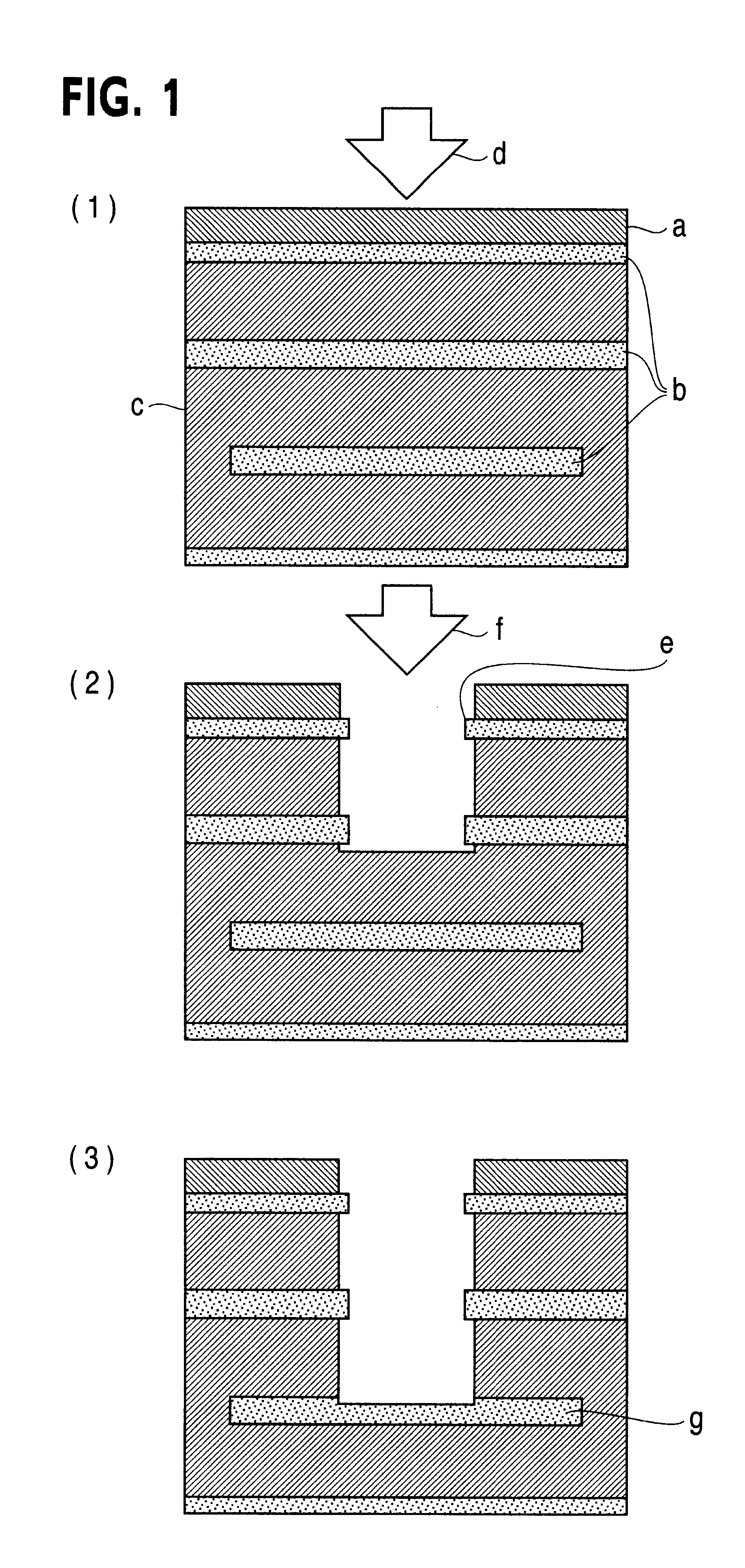

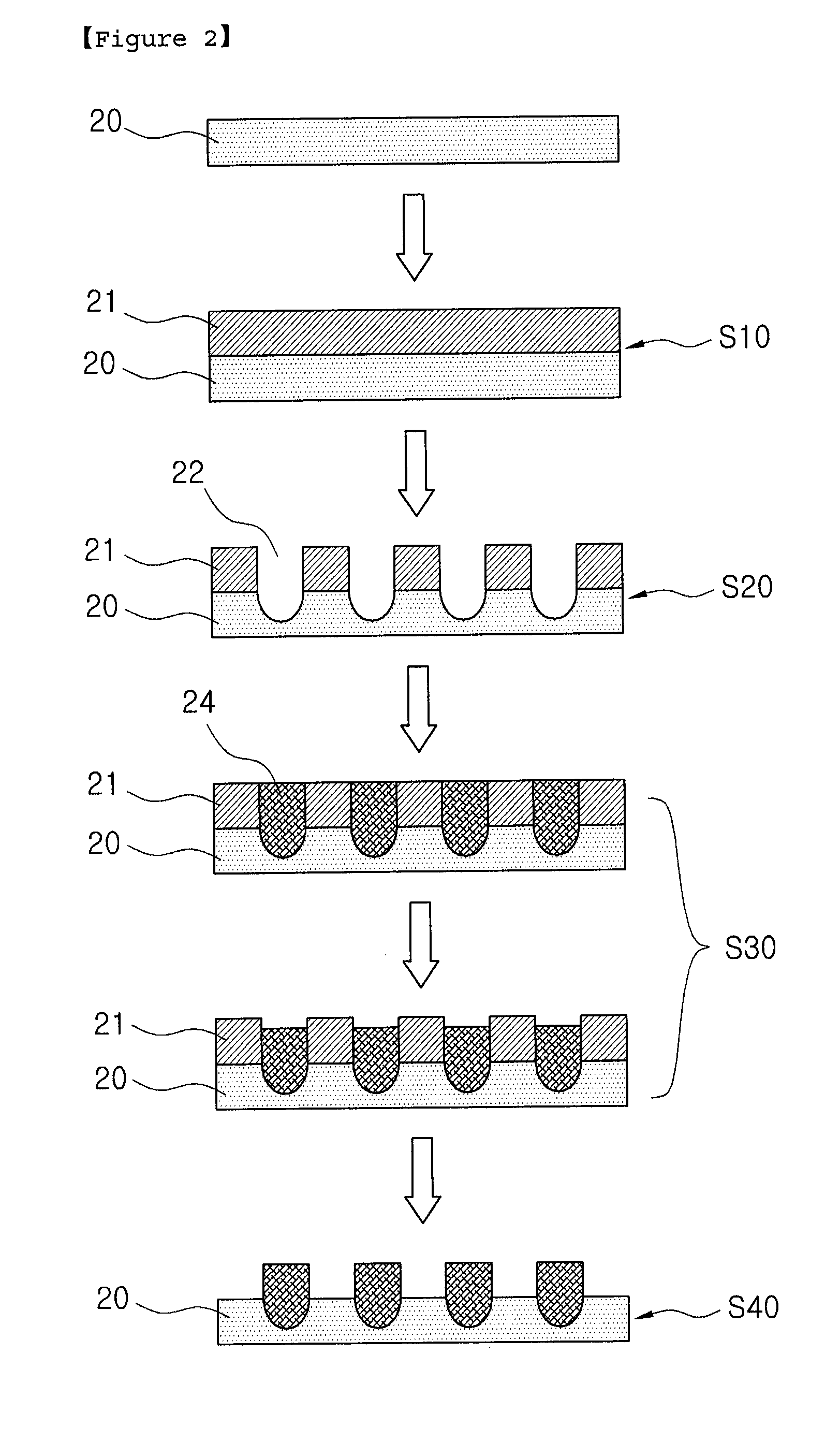

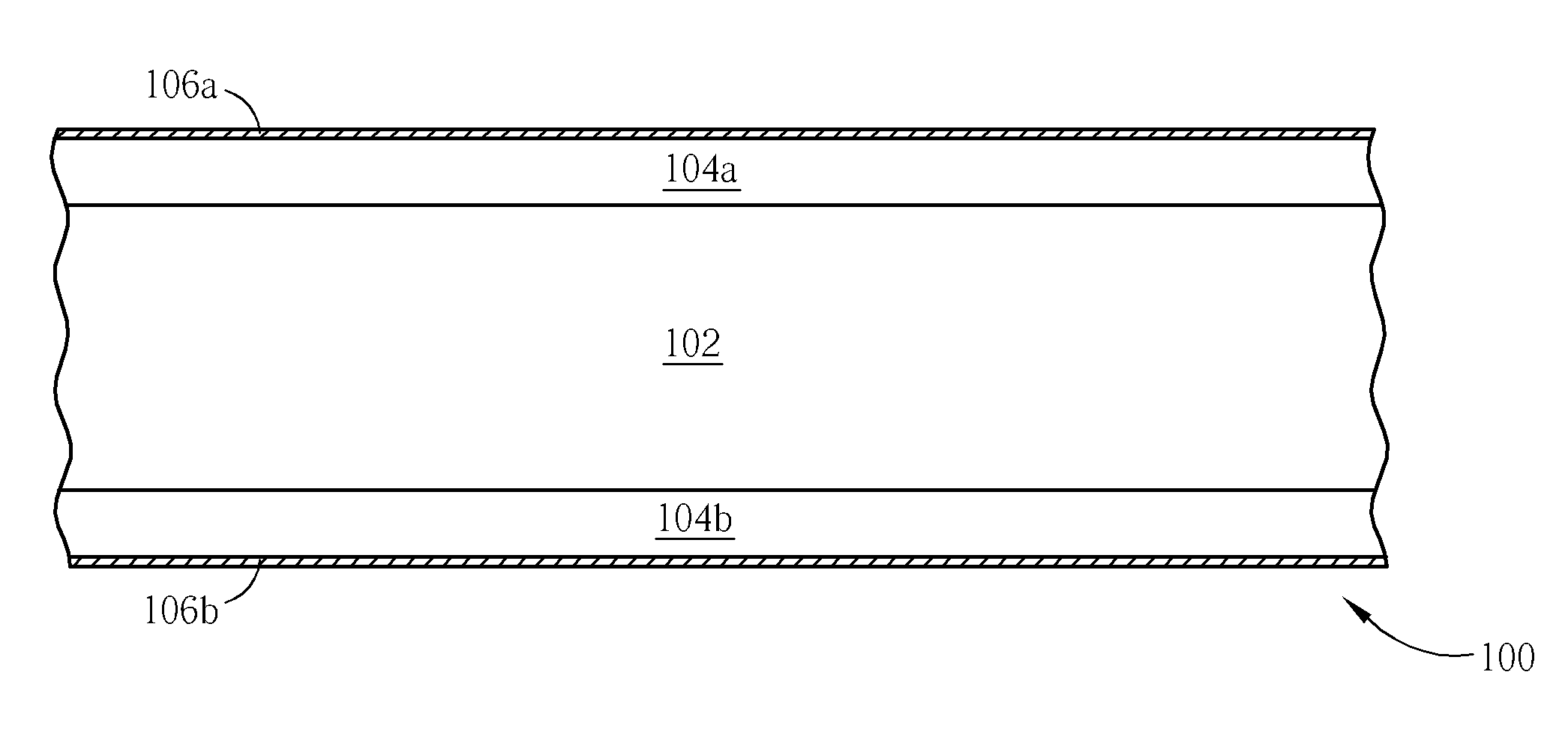

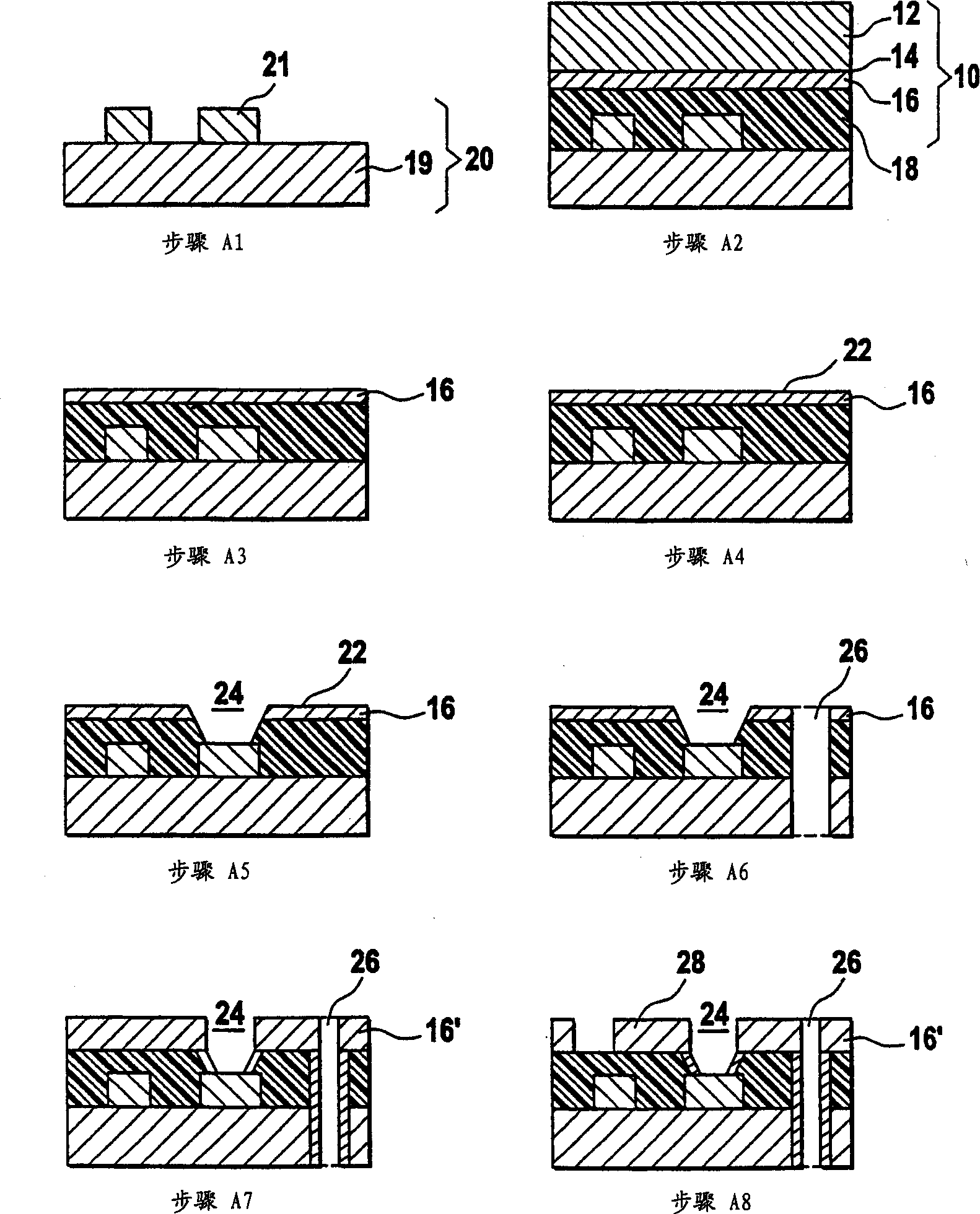

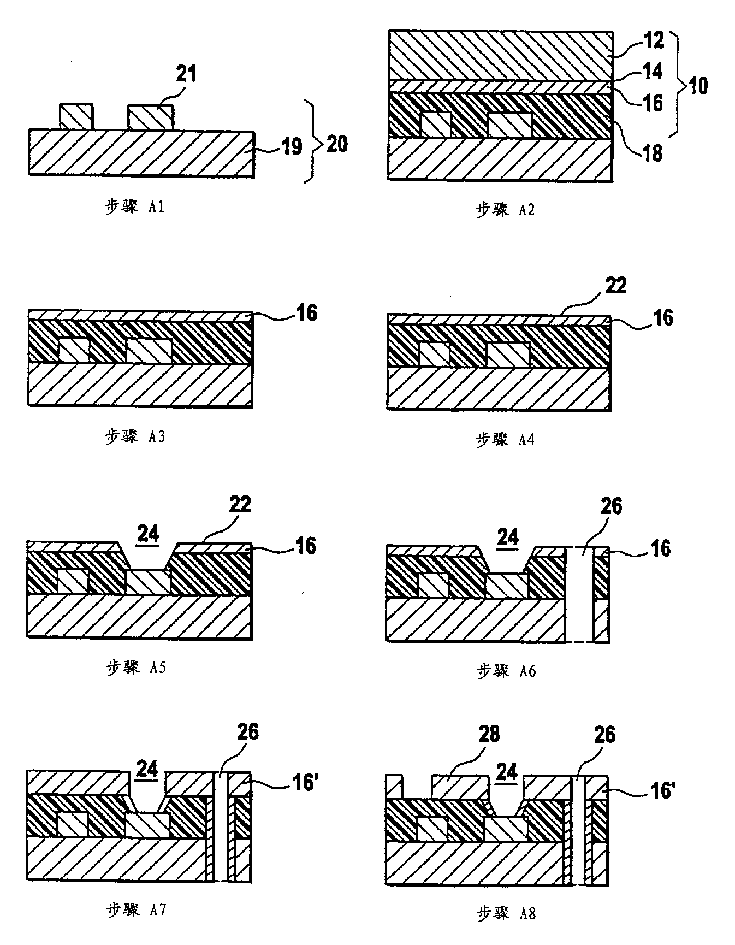

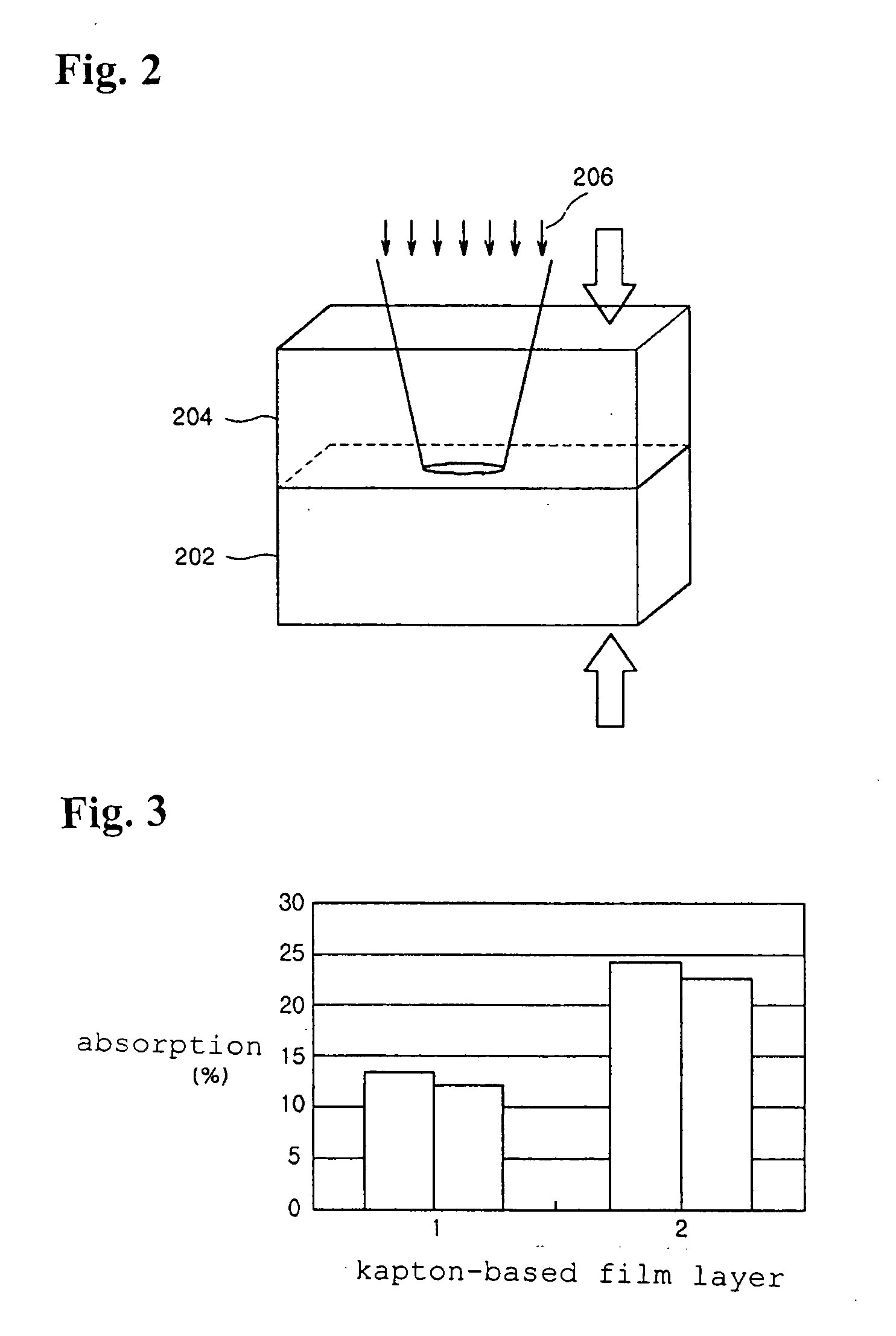

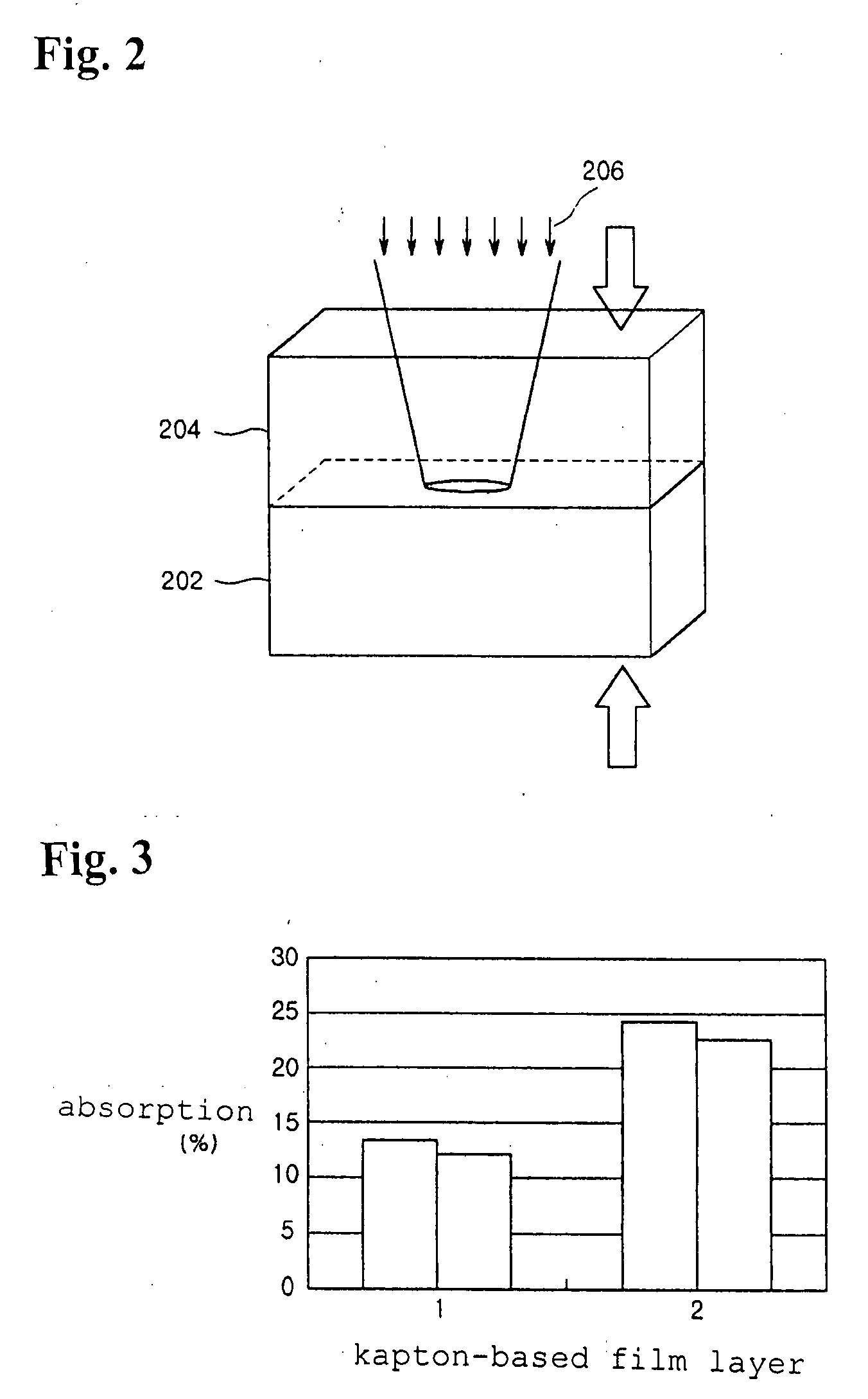

Method for forming micro blind via on a copper clad laminate substrate utilizing laser drilling technique

This invention provides a method for forming a micro blind via on a copper clad laminate (CCL) substrate. A CCL substrate having a dielectric layer sandwiched by a first copper layer and a second copper layer is prepared. A laser absorbing layer is formed on the first copper layer. The laser absorbing layer is subjected to laser drilling. A micro blind via is drilled into the first copper layer and the dielectric layer in one step.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

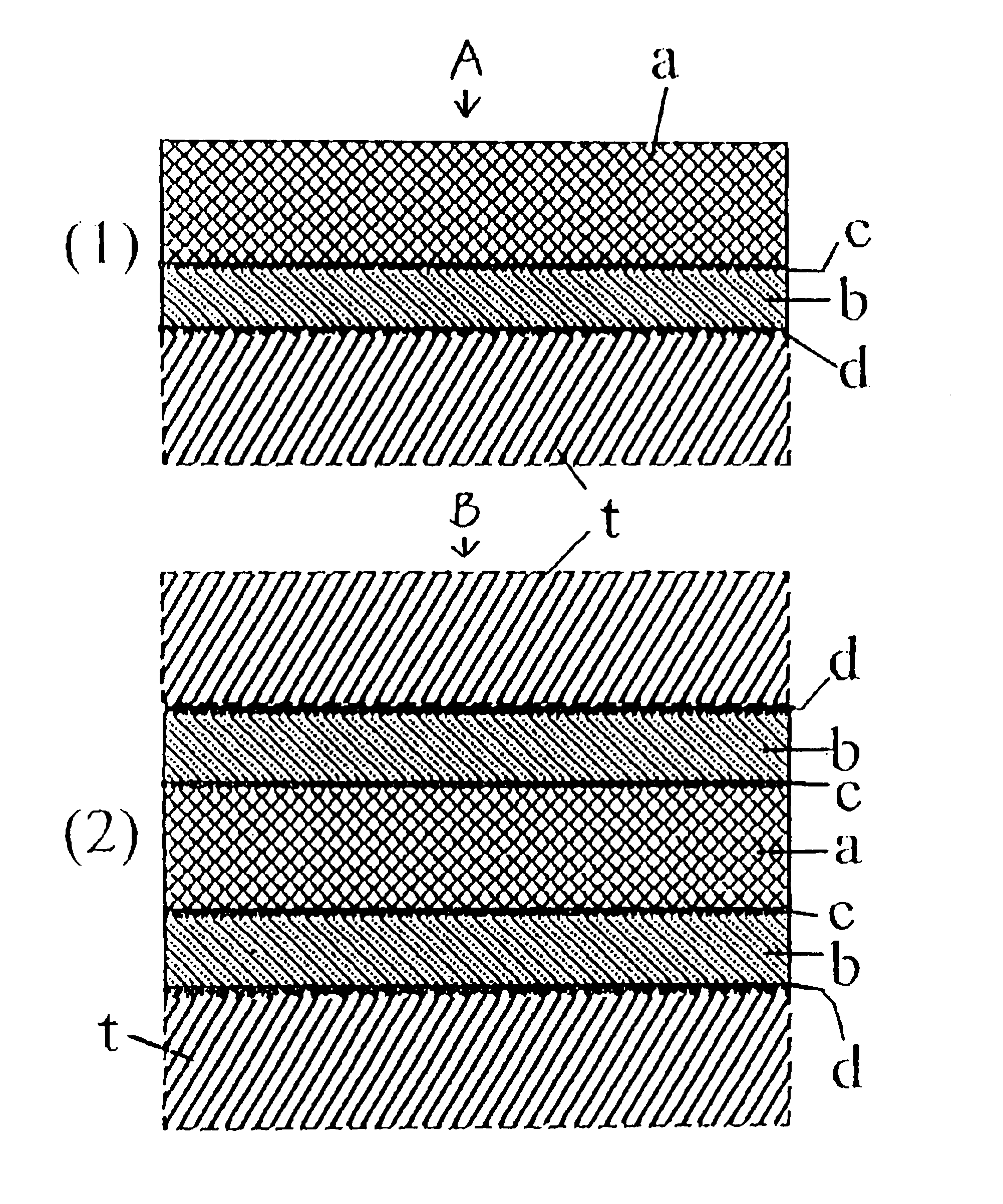

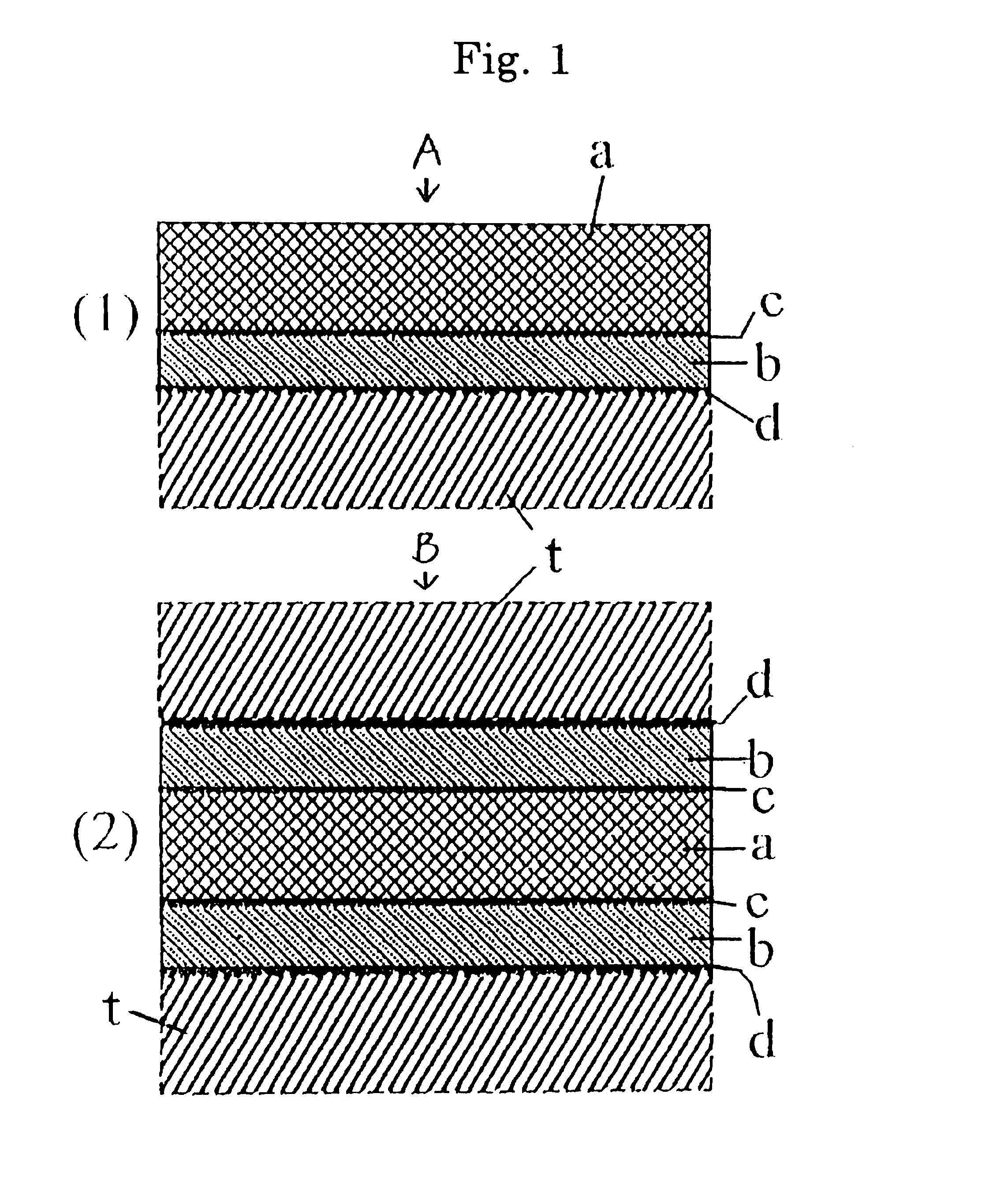

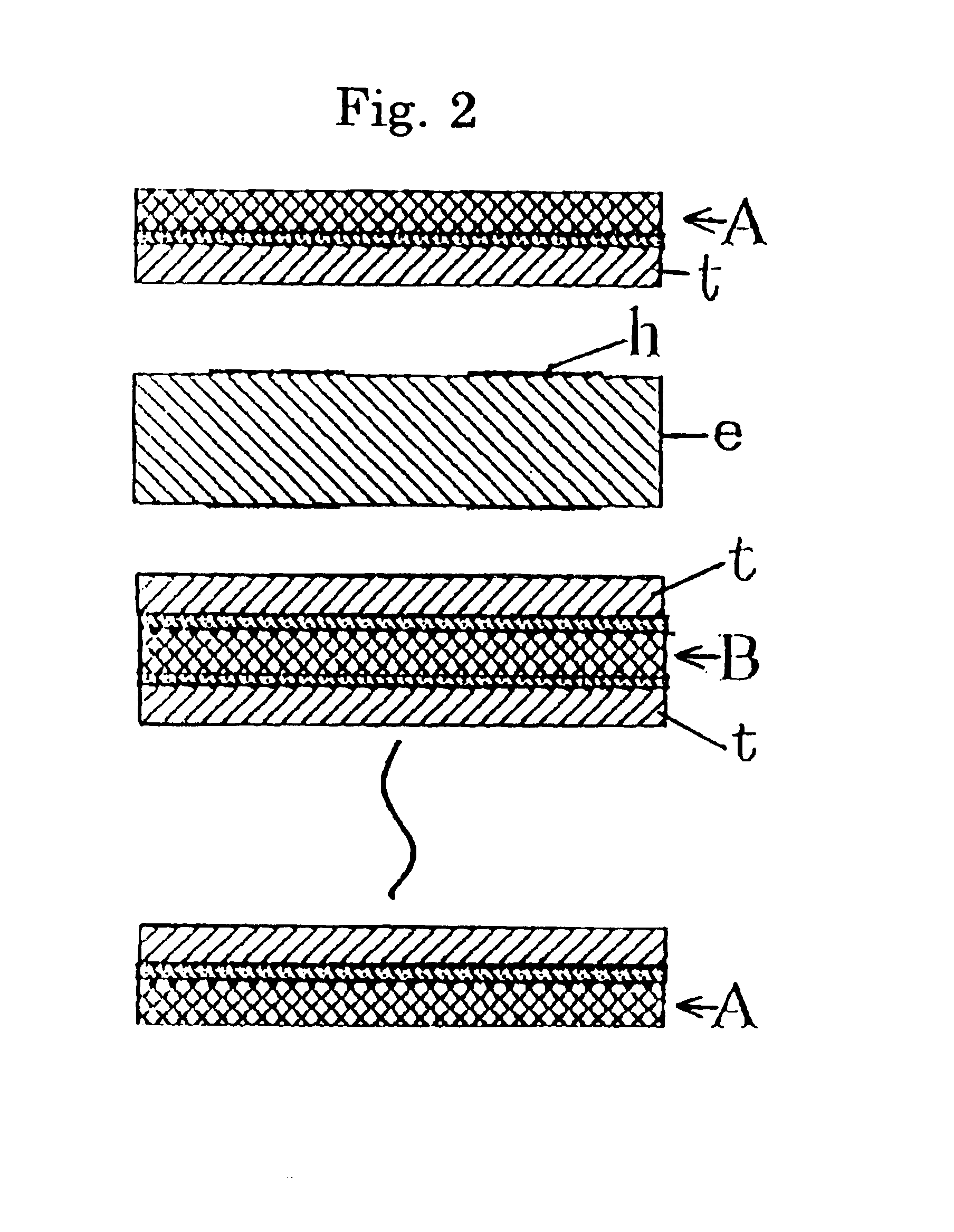

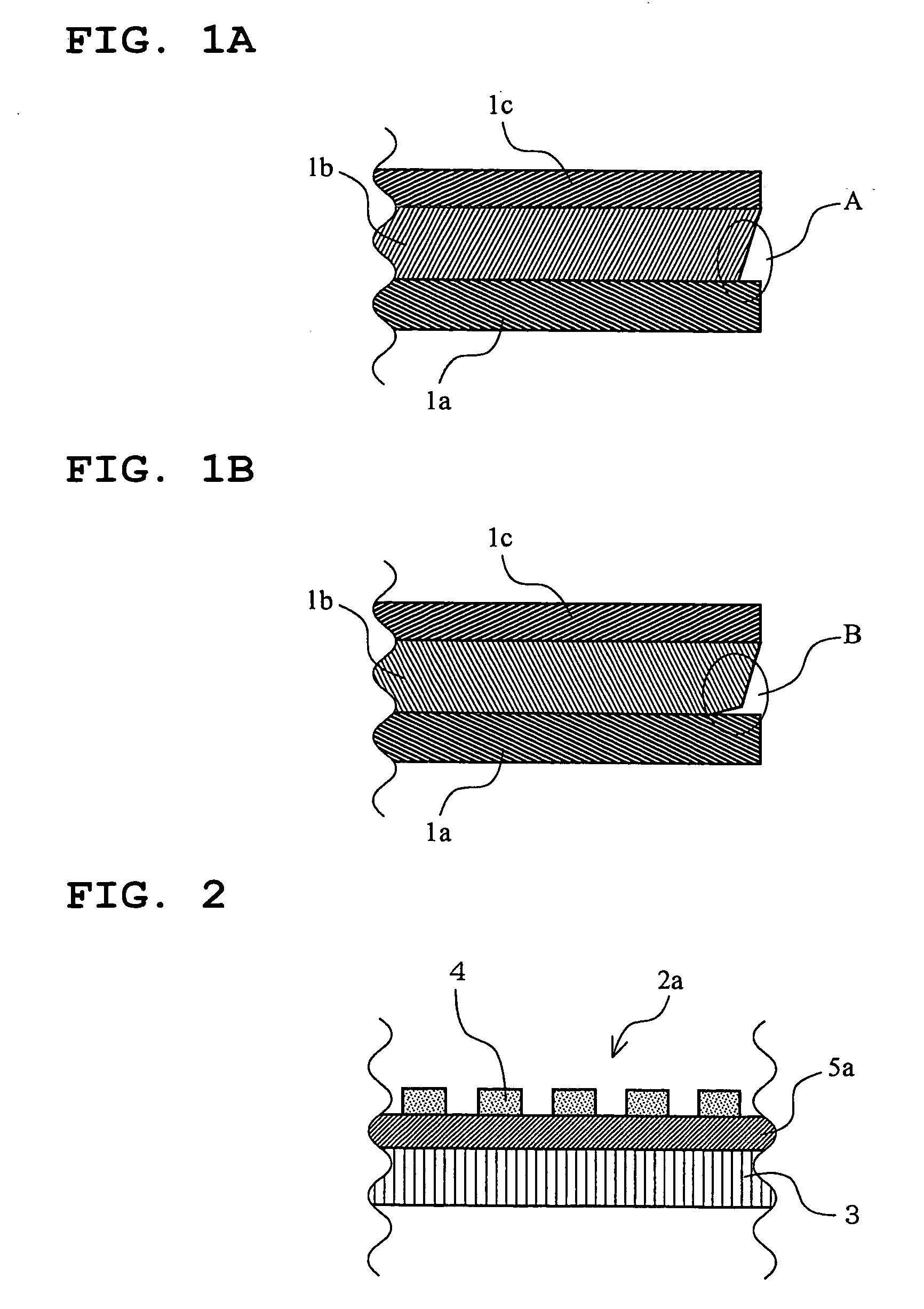

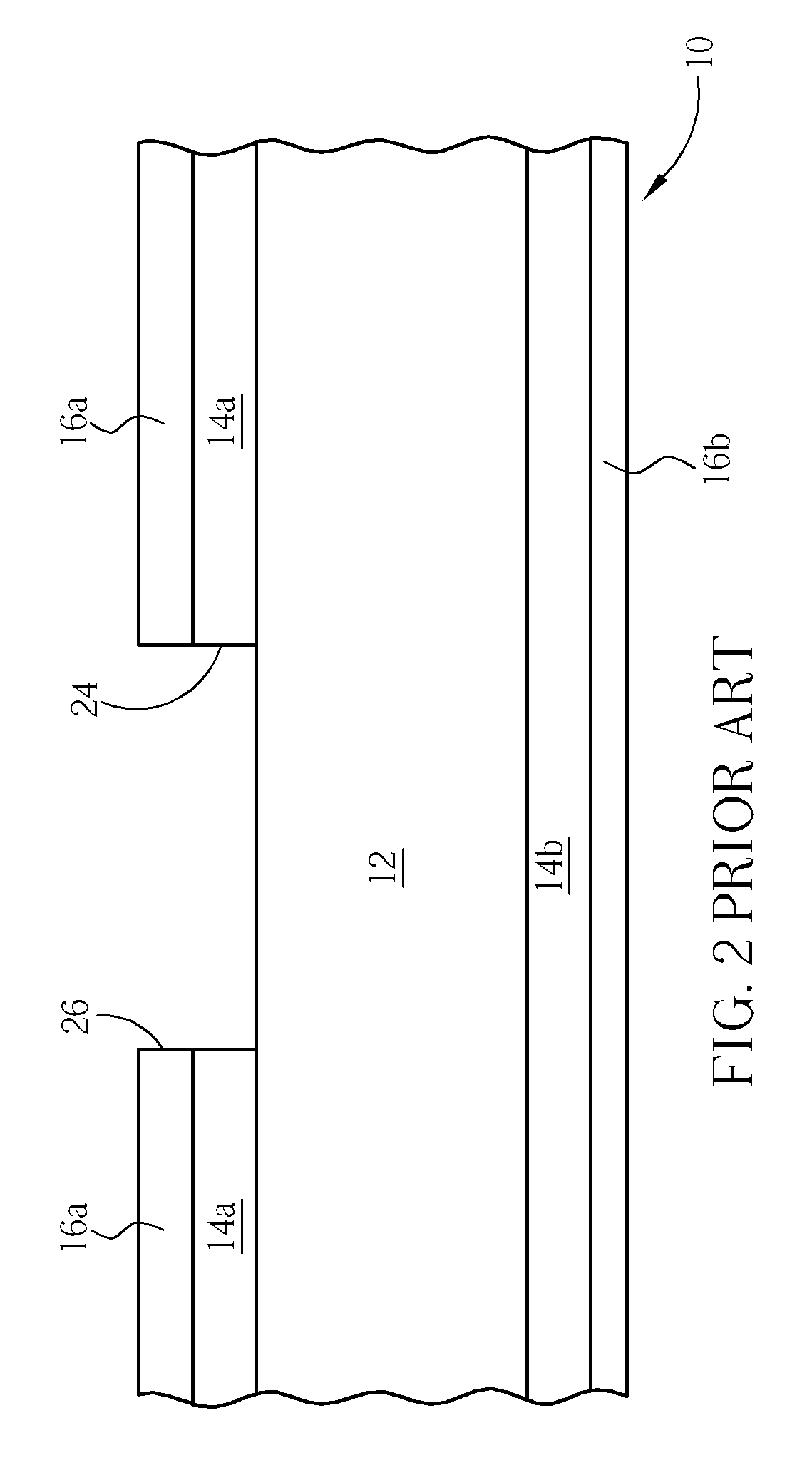

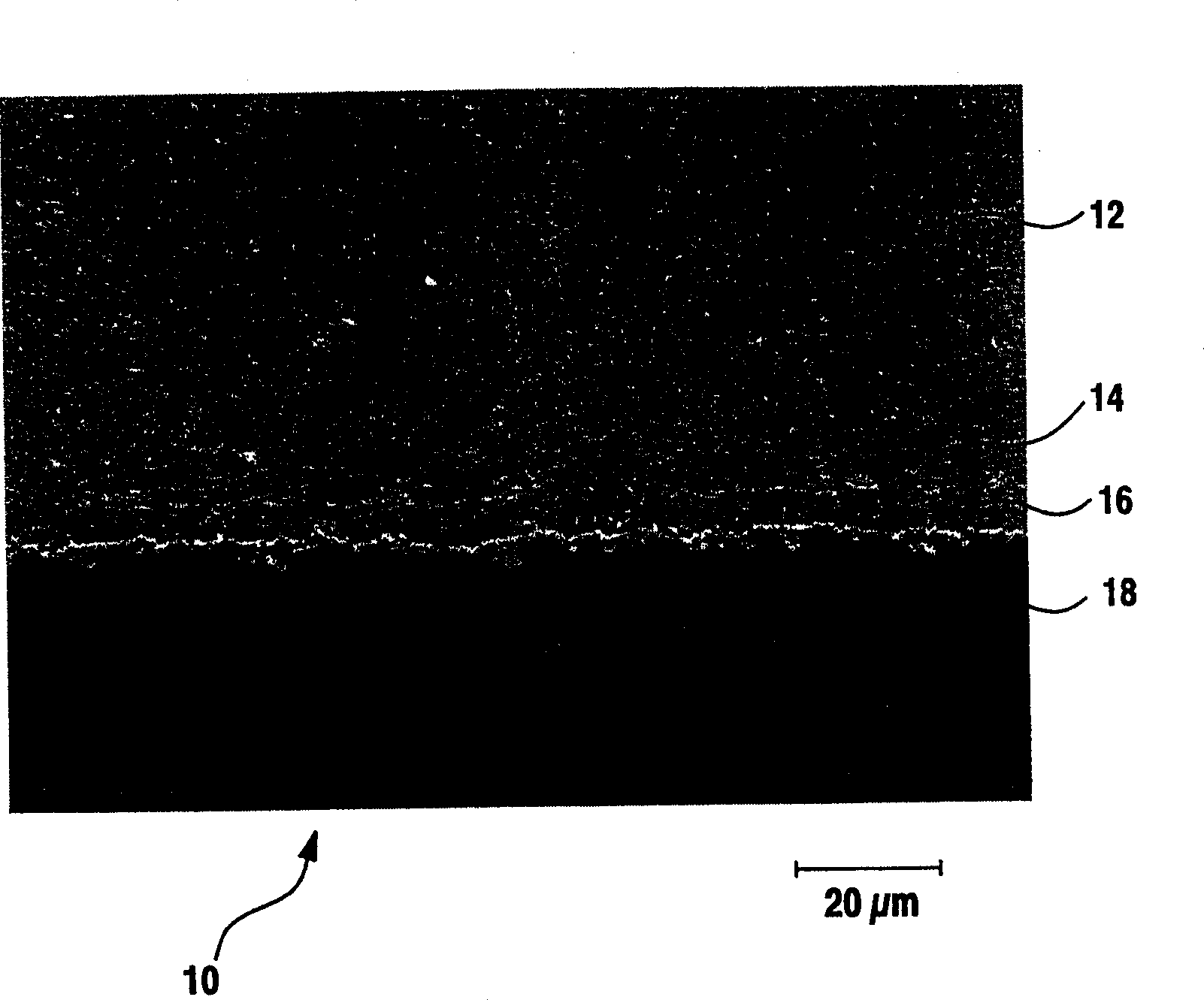

Method for mfg multilayer printed circuit board and composite foil for use therein

InactiveCN1344484AUniform surface shapeUniform roughnessInsulating substrate metal adhesion improvementLight absorption dielectricsEngineeringCopper foil

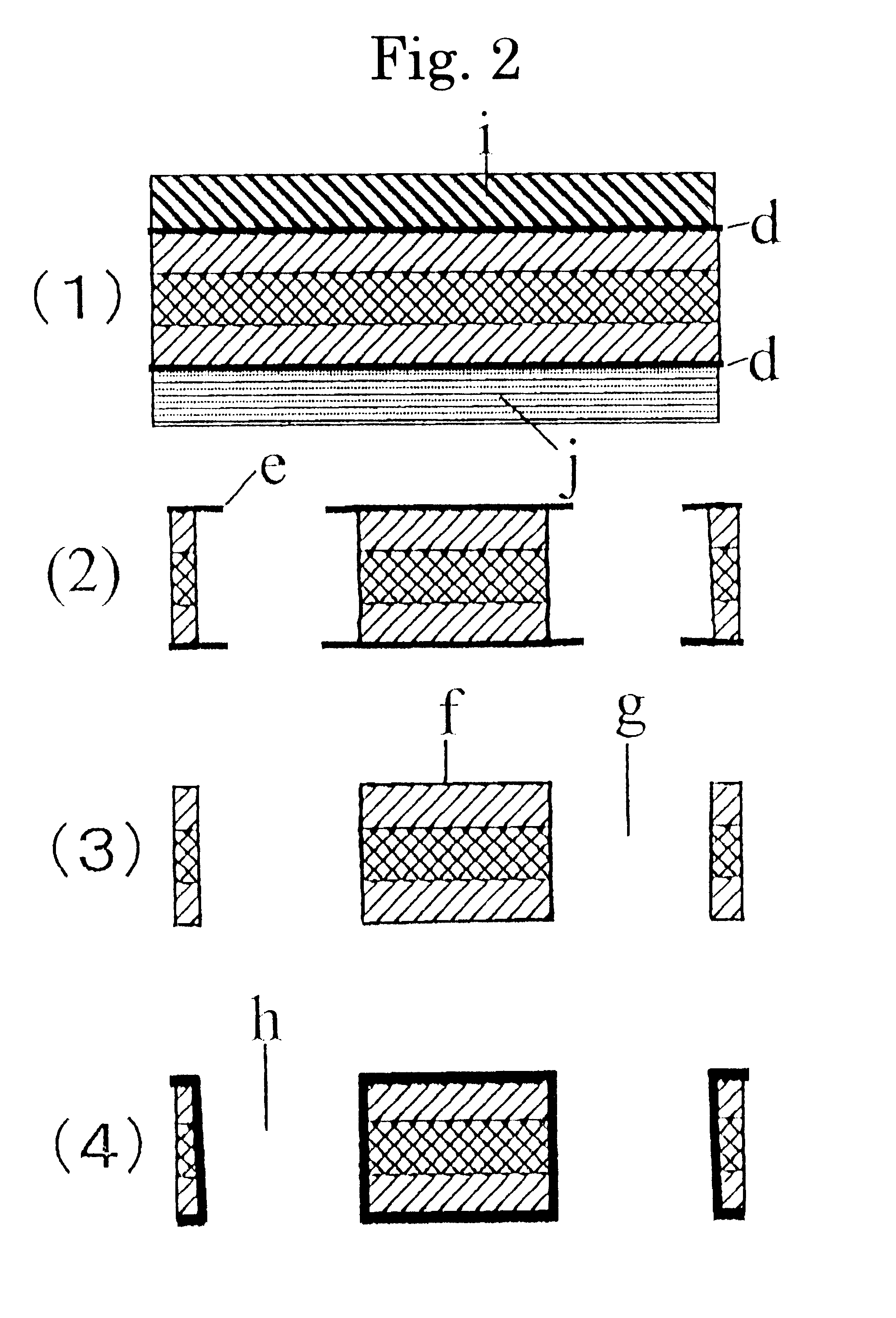

A method for manufacturing a multilayer printed circuit board is disclosed. First a composite foil (10) including a functional copper foil (16) mounted on a carrier foil (12) is laminated on a core board (20). The functional copper foil (16) is less than 10 mu m thick, and has a front side facing the carrier foil (12) and a back side coated with a resin (18). Next, the carrier foil (12) is removed from the functional copper foil (16), in order to uncover the front side of the functional copper foil (16). Then, a CO2 laser source is used to drill holes through the functional copper foil (16) and the resin (18) in order to form micro holes (24). It is also disclosed a composite foil (10) comprising four different layers for use in the manufacture of a multilayer printed circuit board.

Owner:CIRCUIT FOIL LUXEMBOURG R L

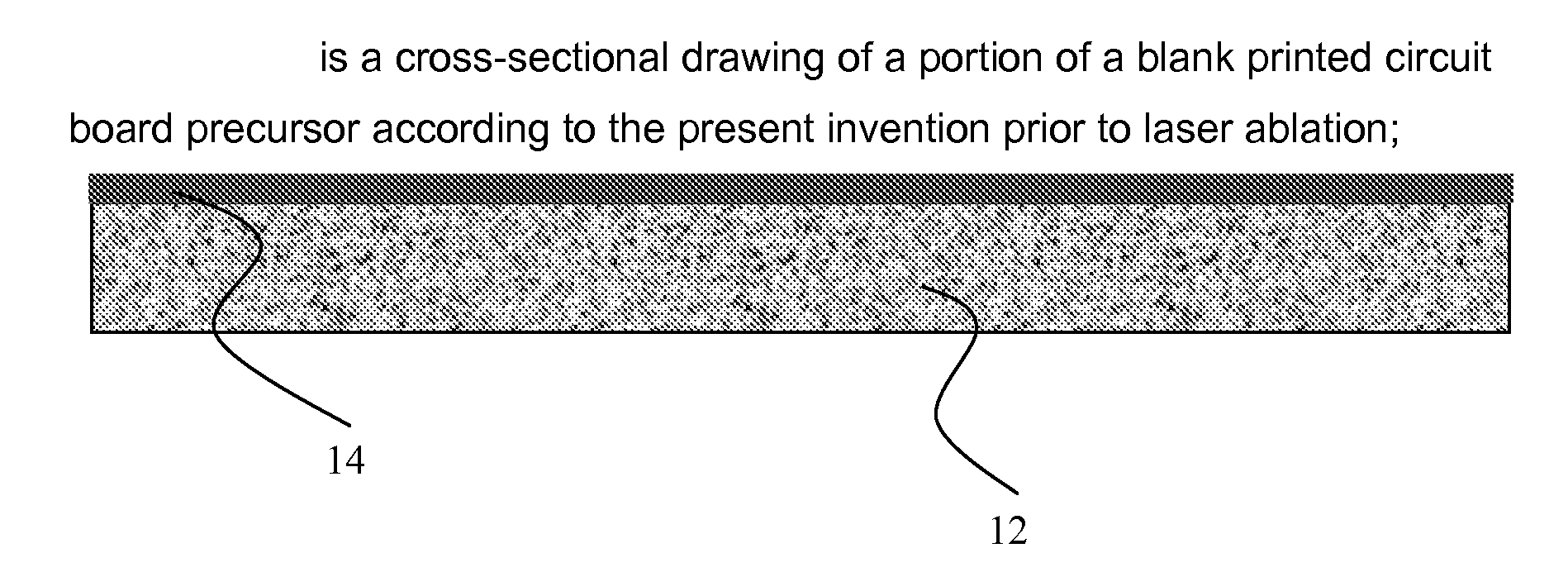

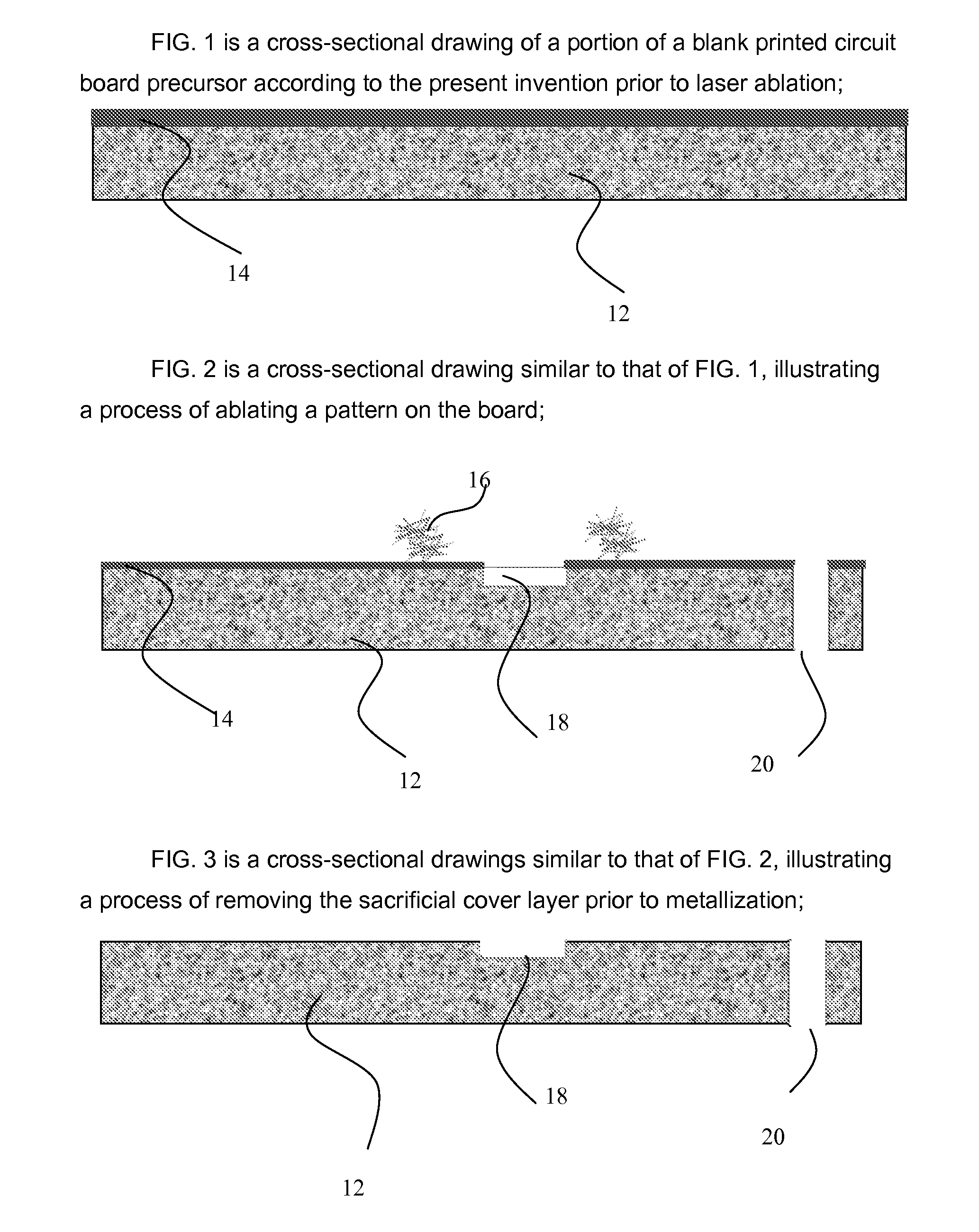

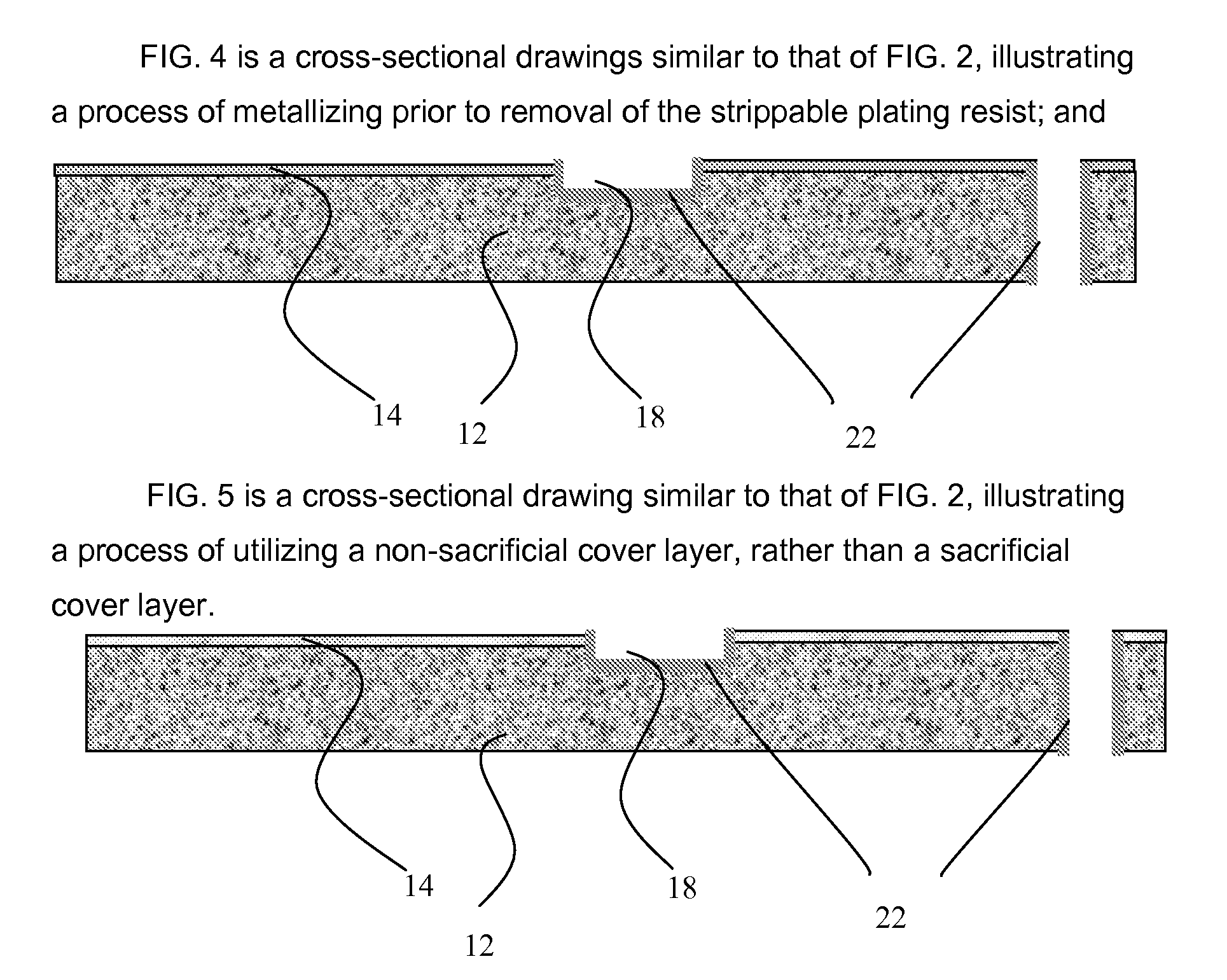

Compositions and methods for creating electronic circuitry

The present invention is directed to non-lithographic patterning by laser (or similar-type energy beam) ablation, where the ablation system ultimately results in circuitry features that are relative free from debris induced over-plating defects (debris relating to the ablation process) and fully additive plating induced over-plating defects. Compositions of the invention include a circuit board precursor having an insulating substrate and a cover layer. The insulating substrate is made from a dielectric material and also a metal oxide activatable filler. The cover layer can be sacrificial or non-sacrificial and is used to remediate unwanted debris arising from the ablation process.

Owner:EI DU PONT DE NEMOURS & CO

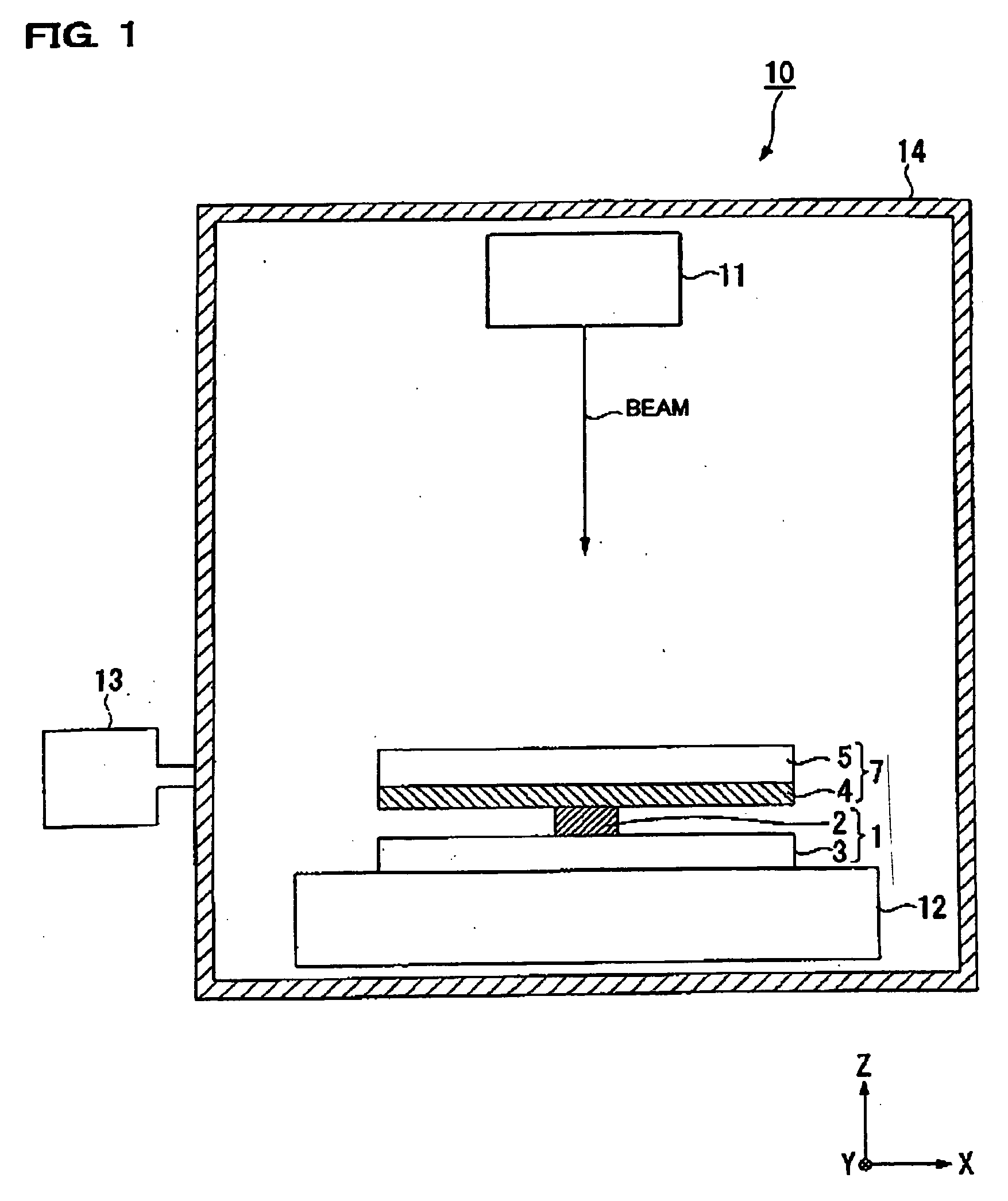

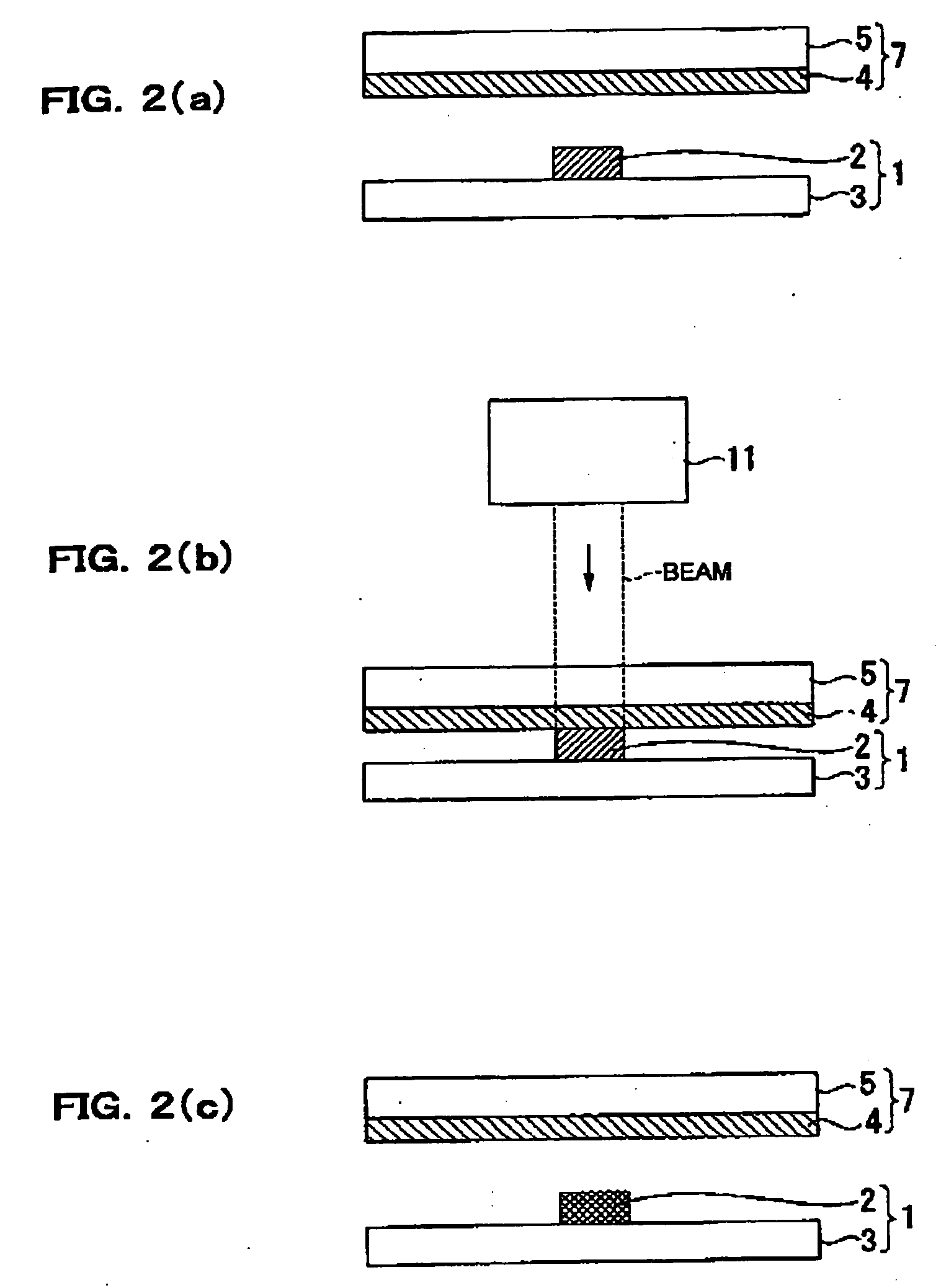

Method of heat treatment, method for forming wiring pattern, method for manufacturing electro-optic device, and electro-optic device and electronic apparatus

InactiveUS20050079338A1Effectively converted into thermal energyIncrease temperatureLight absorption dielectricsLayered productsThermal energyLight energy

To provide a heat treatment method to efficiently heat-treat an object without depending on the material of the object, a heat treatment layer includes a light-to-heat conversion layer to convert light energy into thermal energy and a base material. The heat treatment sheet is opposed to an object and exposed to light. Thus, the object is heat-treated by thermal energy generated from the light-to-heat conversion layer.

Owner:SEIKO EPSON CORP

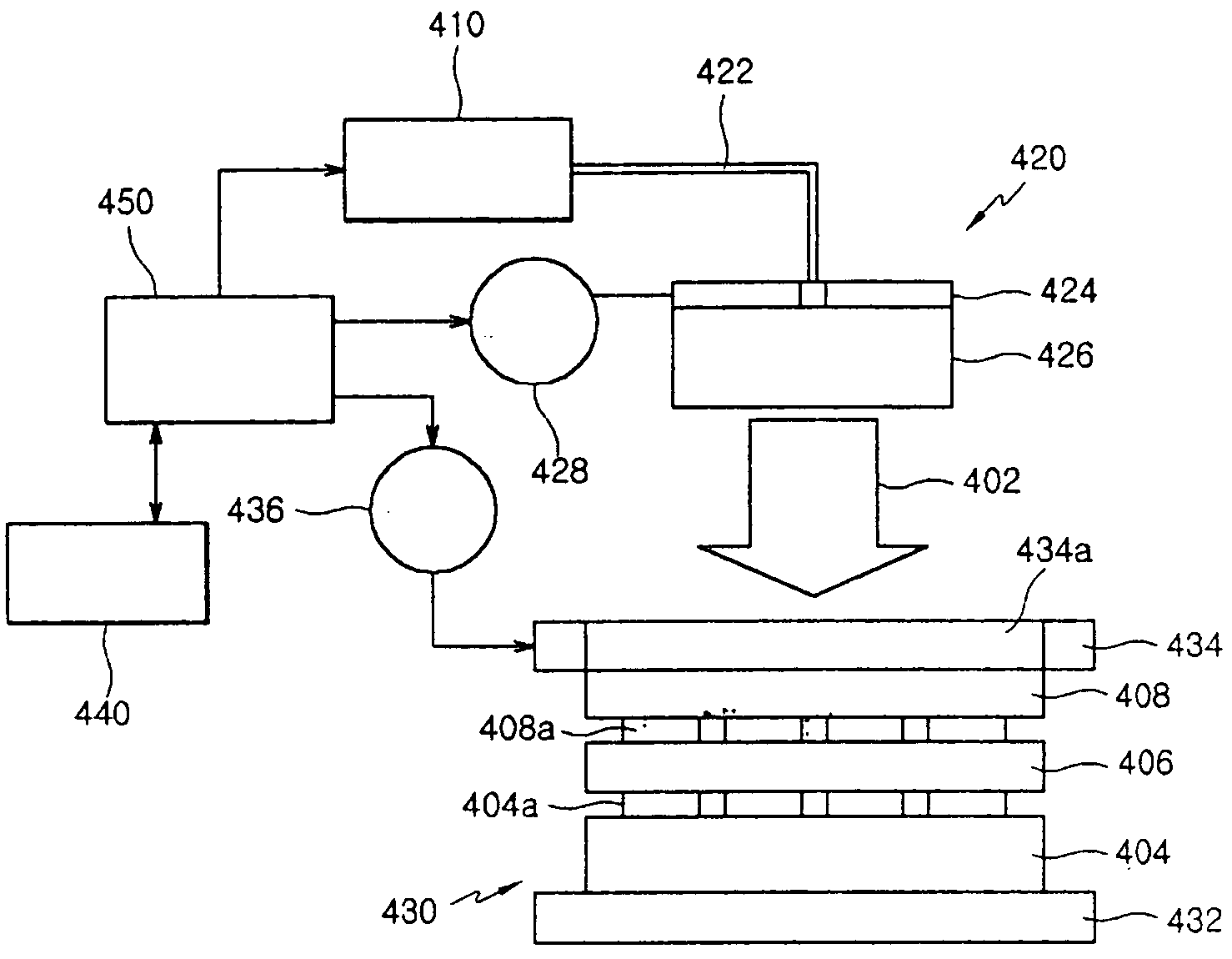

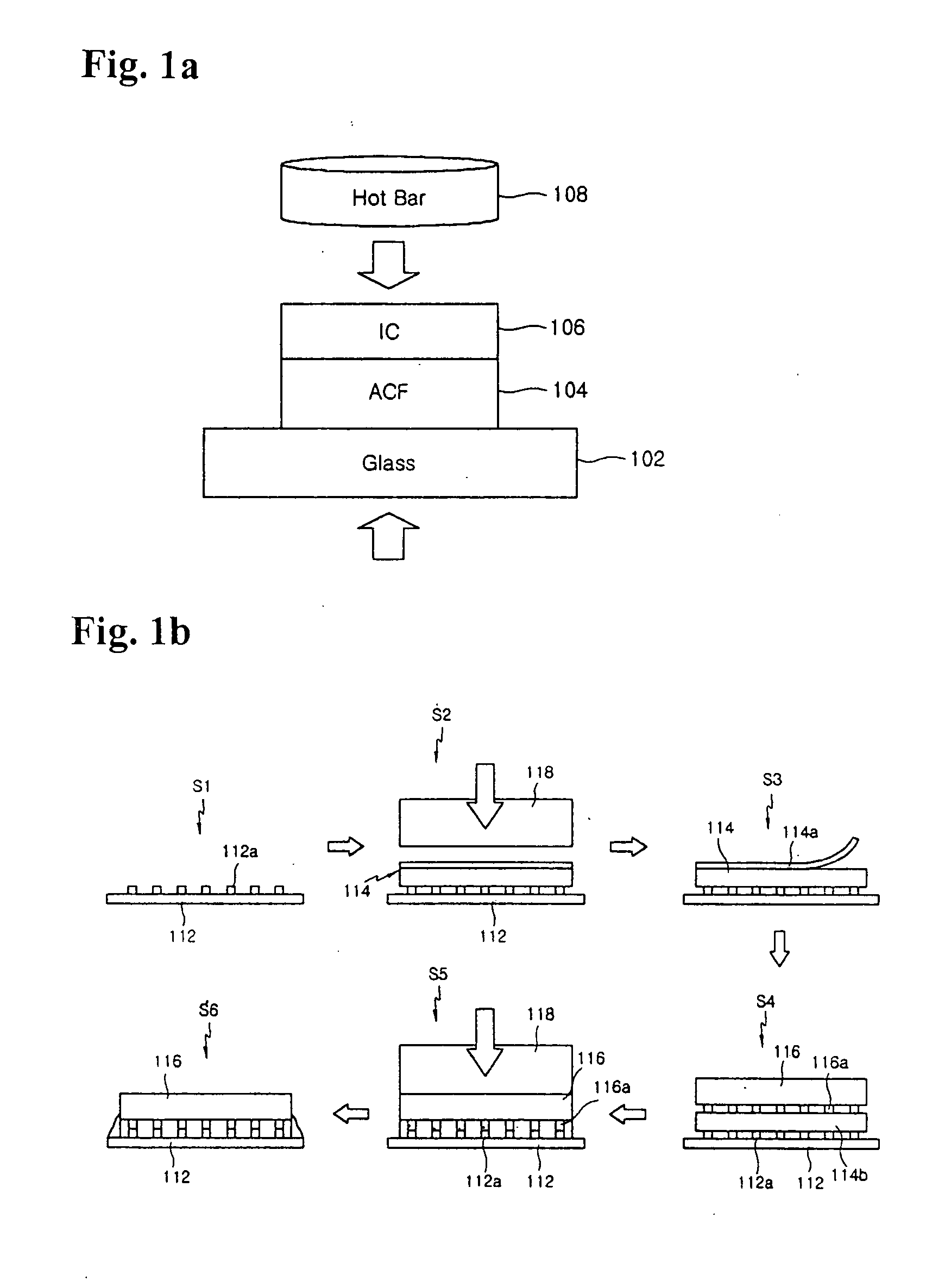

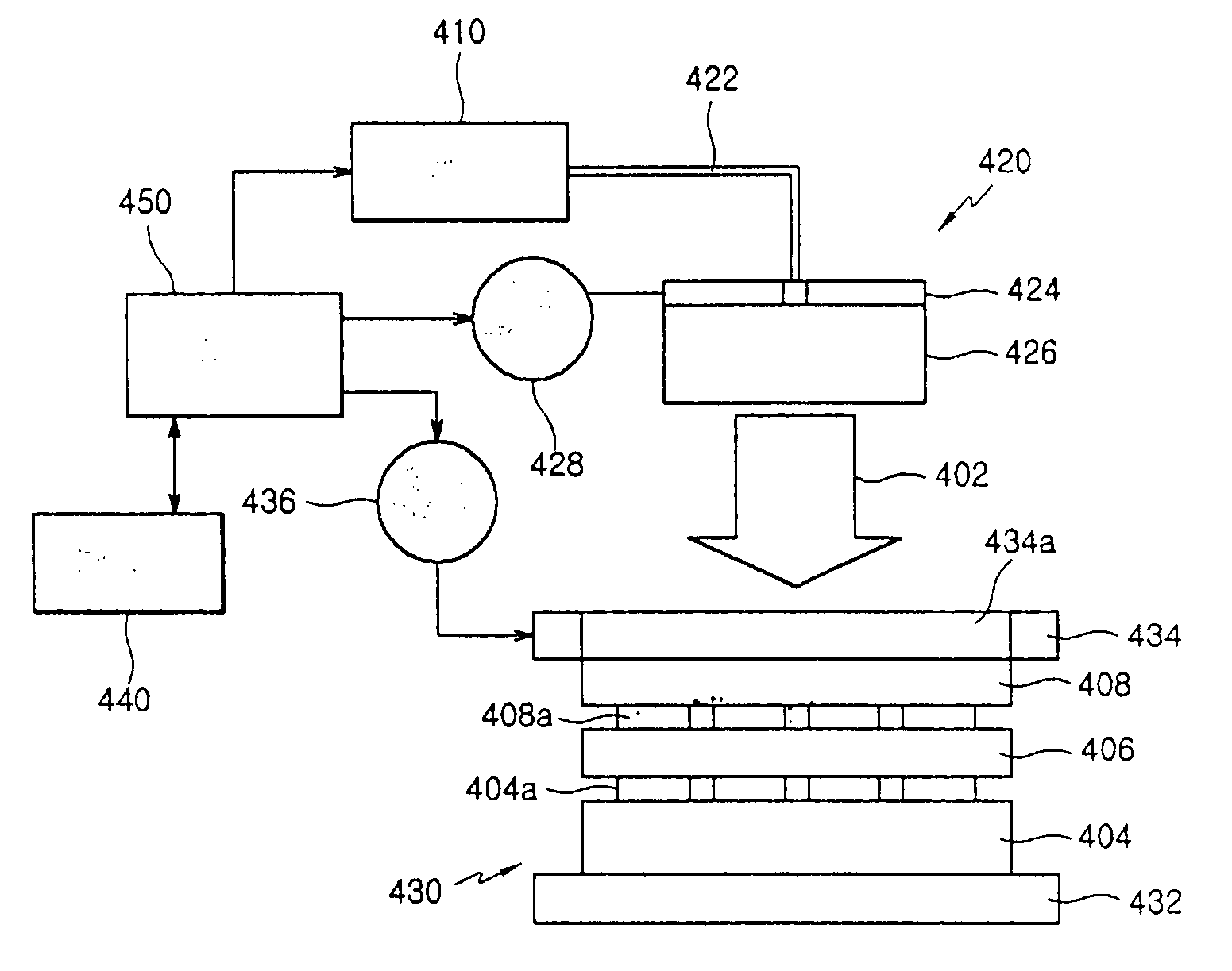

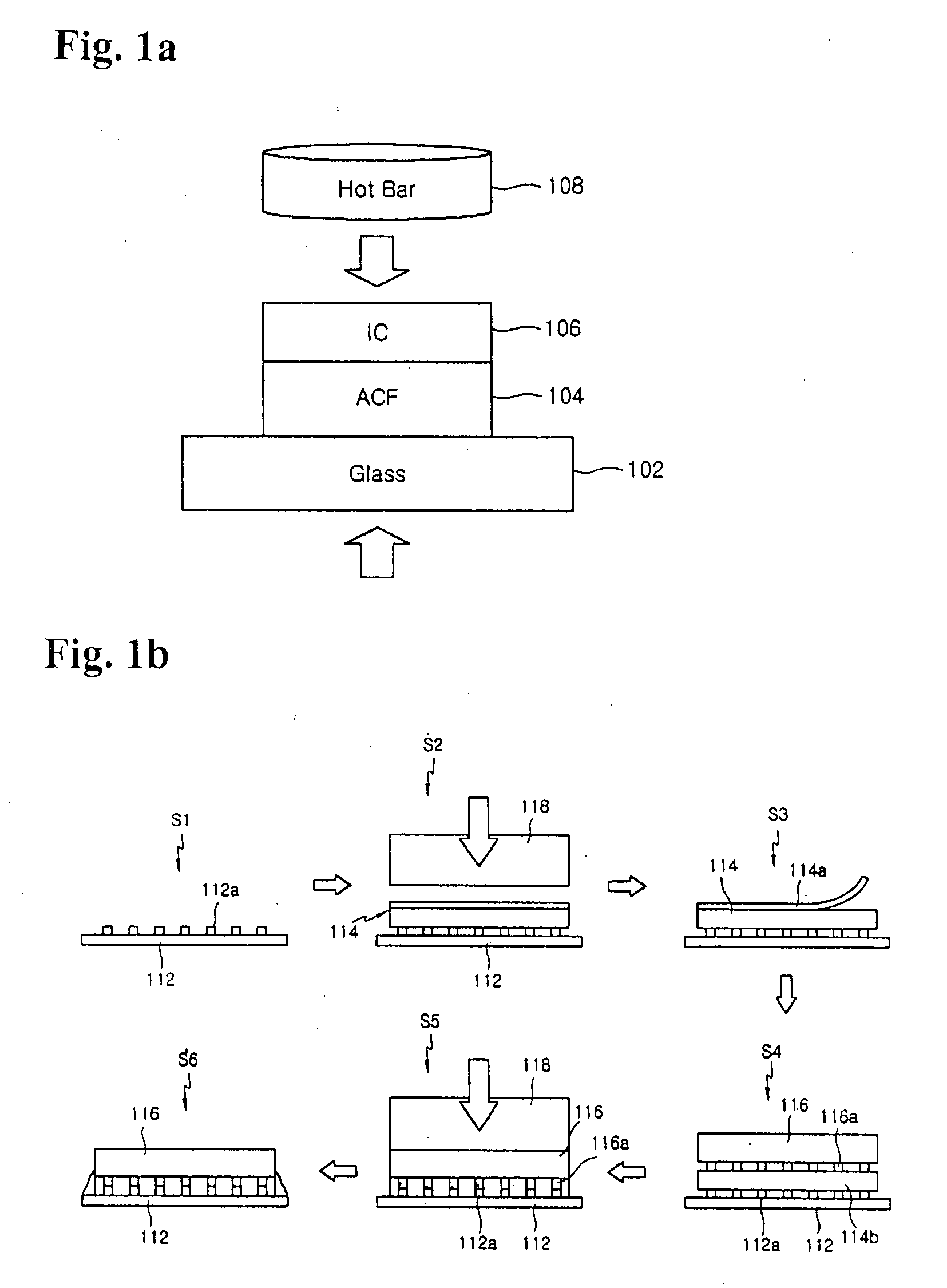

Apparatus and method for bonding anisotropic conductive film using laser beam

InactiveUS20060196600A1Increase light energyImprove the heating effectMechanical working/deformationLight absorption dielectricsAnisotropic conductive filmLaser beams

An anisotropic conductive film bonding apparatus and a method using a laser beam instead of thermal welding using a hot bar are disclosed. The apparatus includes a light source for generating a laser beam, a laser beam transmitter for guiding the laser beam from the light source to project the laser beam onto a connecting portion, a jig, on which the substrate, the ACF, and the material are accumulated, for projecting the laser beam on the accumulated material, a manipulation panel, and a controller for setting intensity and projection manner of the laser beam and pressure and for controlling overall operation of the apparatus. The process using the hot bar as a heat source for the connection of the anisotropic conductive film is replaced with the process using a diode laser, so that reliability and precision of the process can be achieved, the processing time can be also reduced, and full-automated process can enhance productivity

Owner:JET TECH

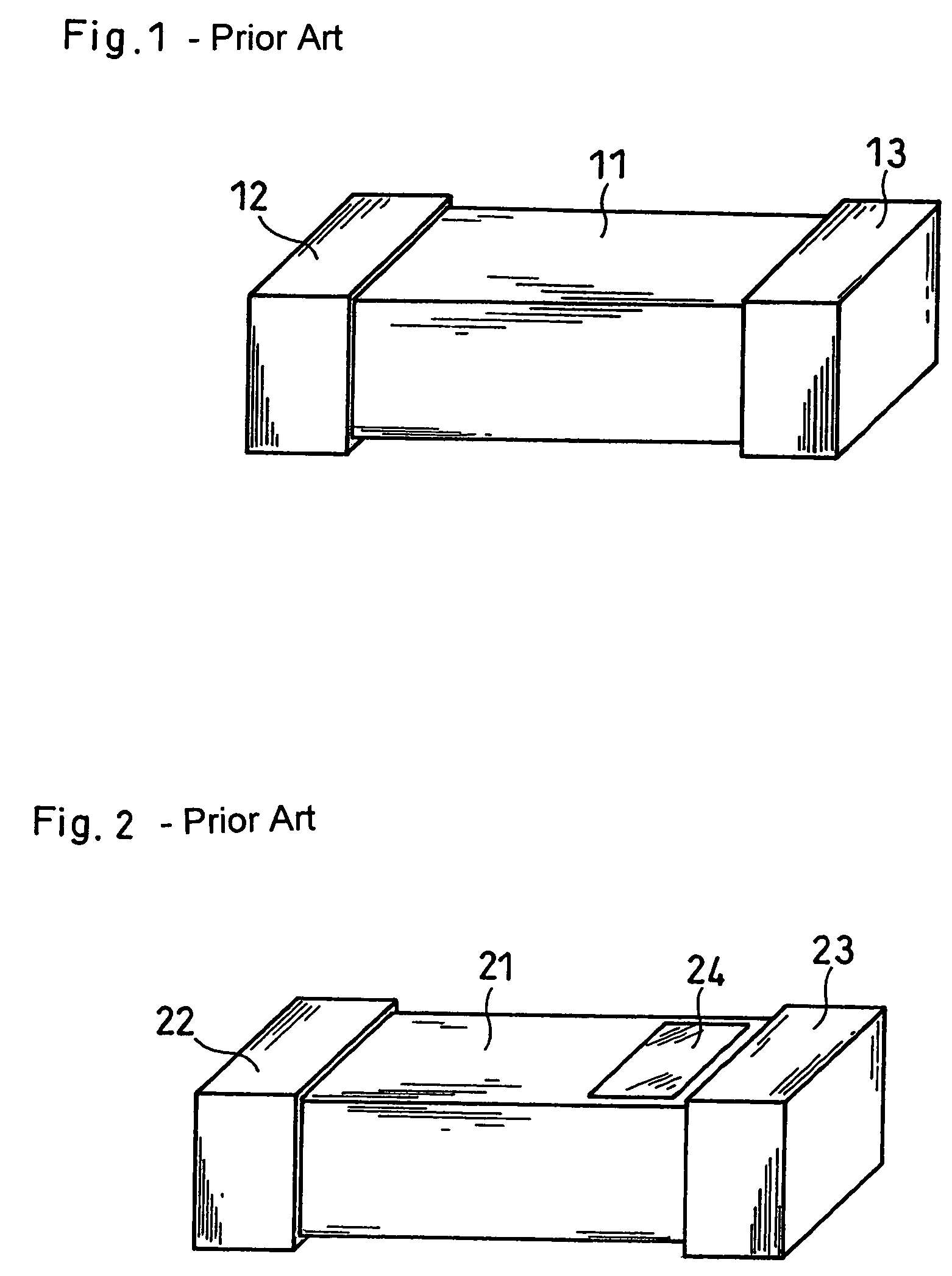

Chip-type battery

InactiveUS7655348B2Low costAvoid connectionPrinted circuit assemblingBatteries circuit arrangementsMetallic materialsElectrical polarity

In order to enhance versatility, a chip-type battery having a means for readily identifying a first terminal and a second terminal is provided. The chip-type battery includes: a body having a substantially rectangular parallelepiped shape and contains a plurality of power generating elements in a stack, each element including a sintered material; a first terminal having a first polarity; and a second terminal having a second polarity. The first terminal is provided at a first side face of the body. The second terminal is provided at a second side face of the body located on other than the first side face. The first terminal and the second terminal include different metal materials.

Owner:PANASONIC CORP

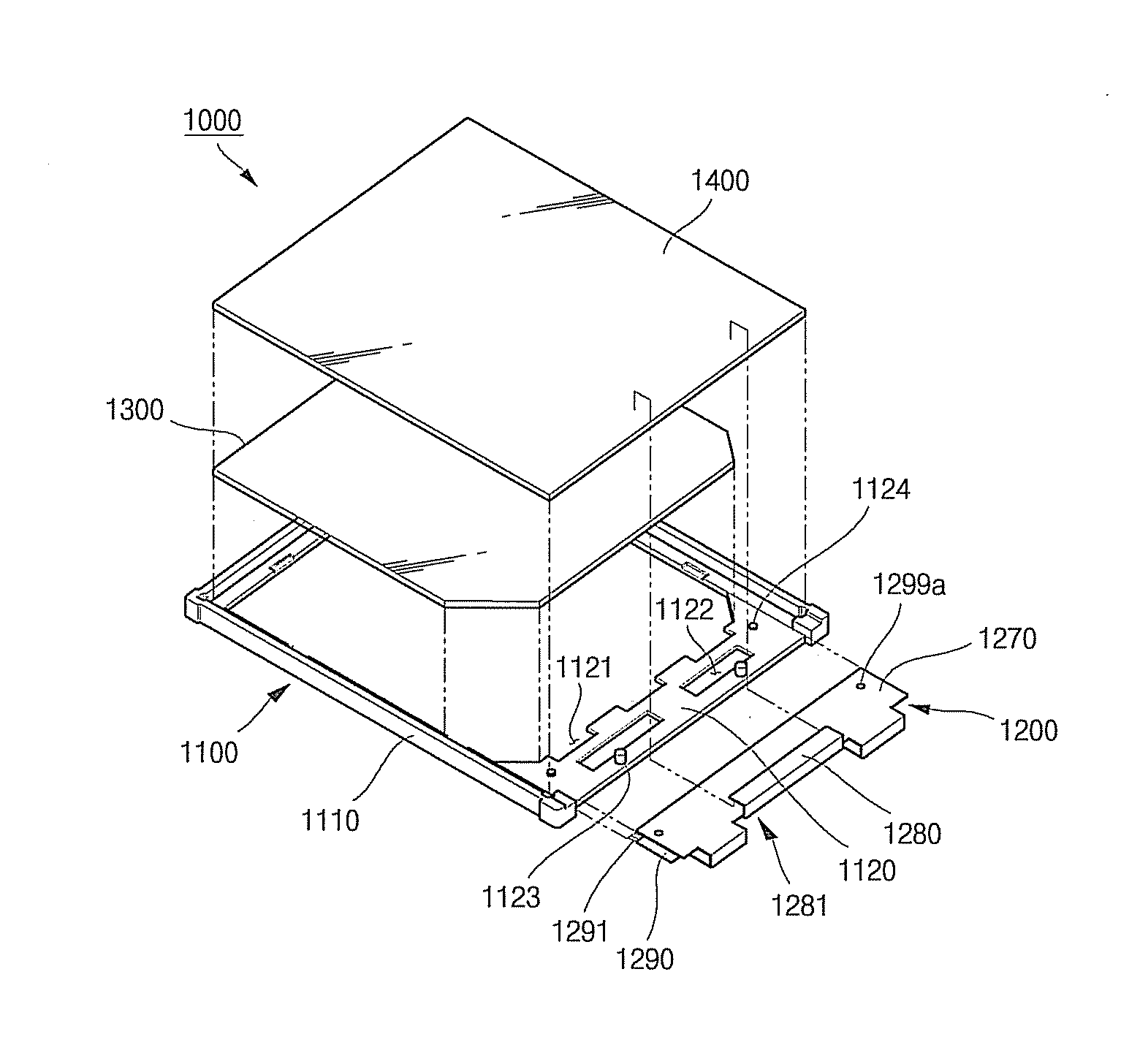

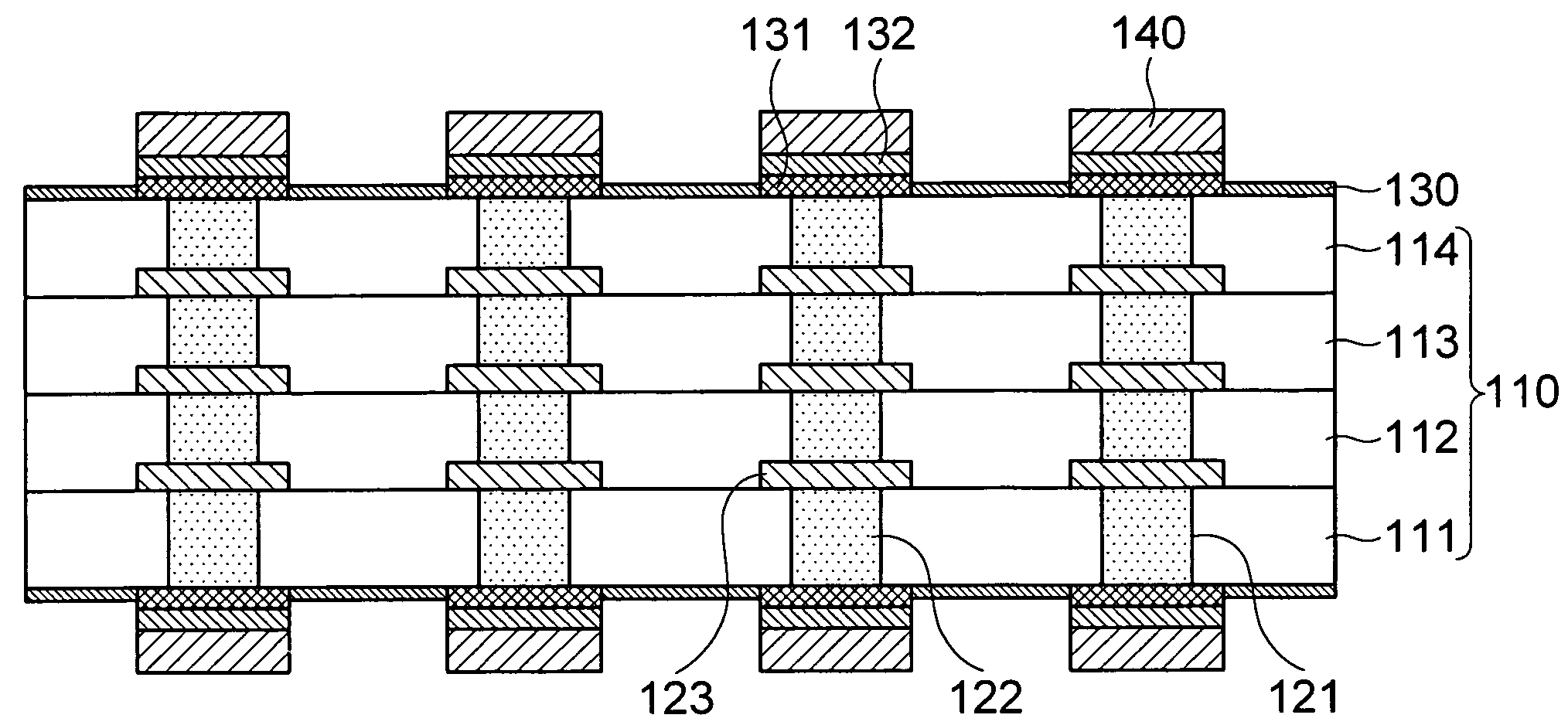

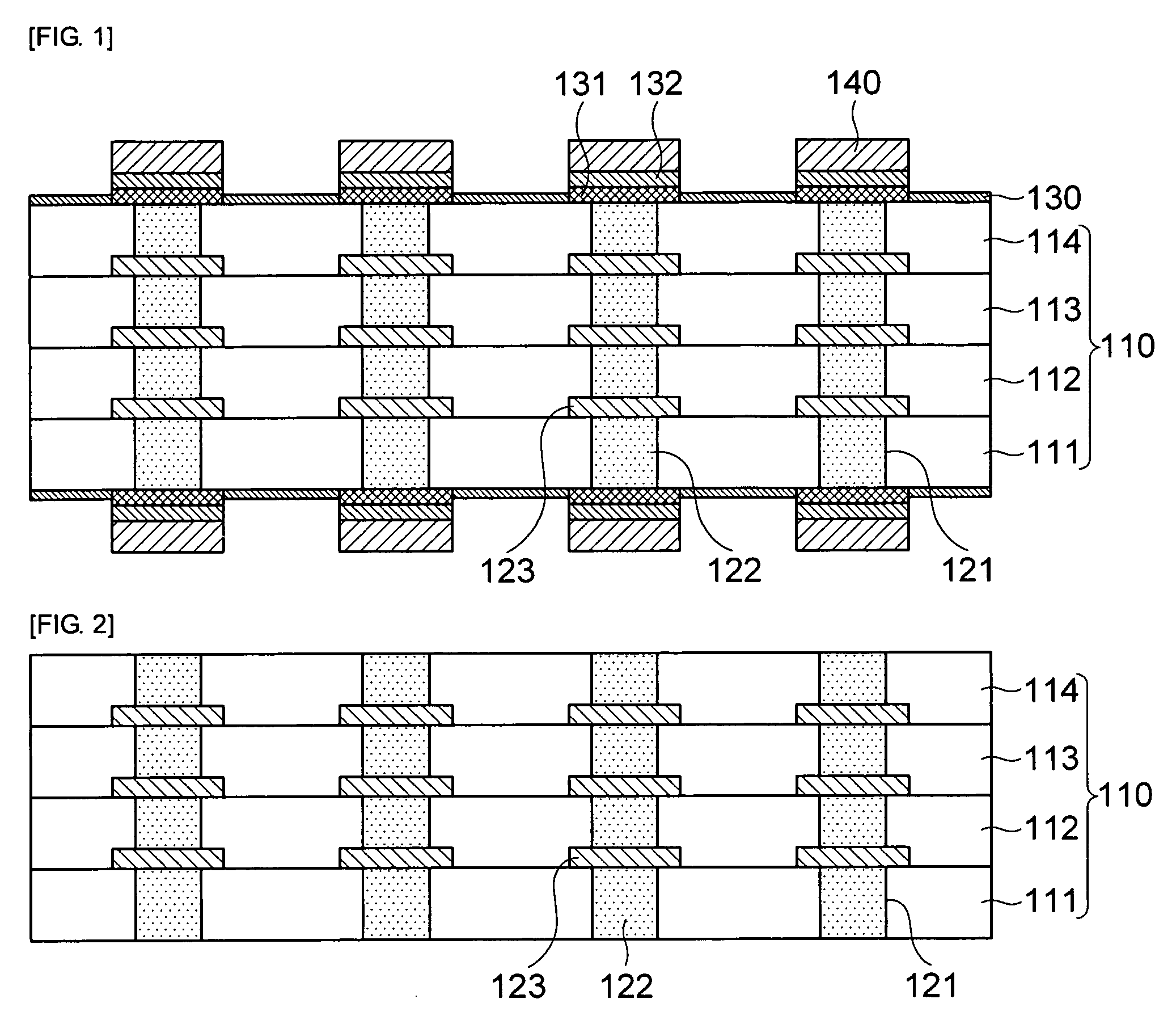

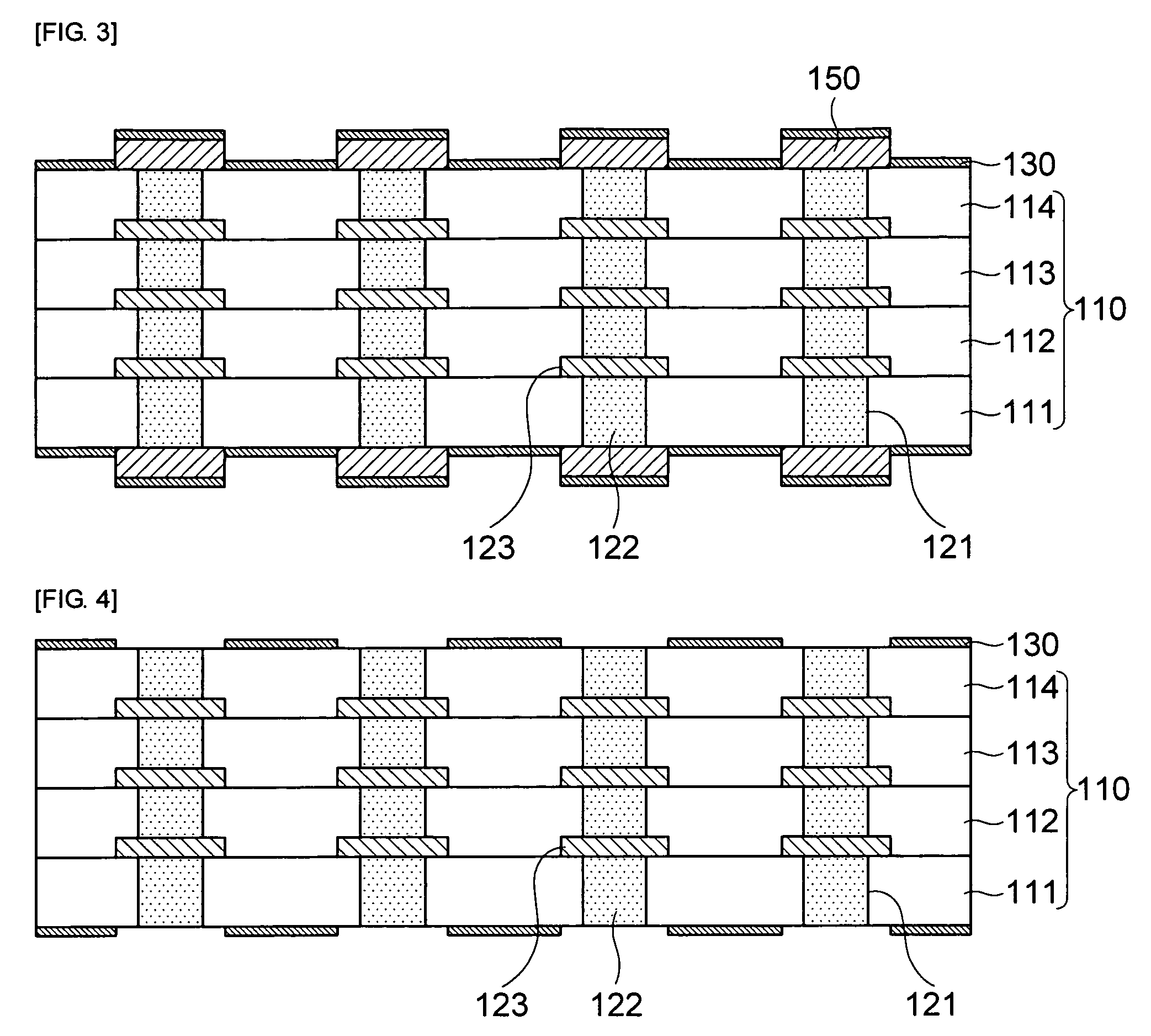

Multilayer ceramic board and manufacturing method thereof

InactiveUS20100300733A1Light absorption dielectricsSurface layering apparatusContact padDiffuse reflection

The present invention relates to a multilayer ceramic board and manufacturing method thereof. The multilayer ceramic board includes: a ceramic stacked structure in which multiple ceramic layers are stacked and interconnected to one another through vias; diffused reflection preventing patterns which expose the vias provided on each of the uppermost ceramic layer and the lowermost ceramic layer, and are disposed on each of a top surface and a bottom surface of the ceramic stacked structure; and contact pads which are electrically connected to the vias exposed by the diffused reflection preventing patterns.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Flexible circuit board of liquid crystal display having a light absorbing layer

InactiveUS20080158472A1Minimizes effect of lightMalfunction can be prevented and reducedLight absorption dielectricsCircuit optical detailsElectricityLiquid-crystal display

A flexible circuit board of a liquid crystal display includes a first insulating film having an ink layer, one or more conductive patterns formed on the first insulating film, a second insulating film formed on the first insulating film and covering the one or more conductive patterns, at least one light source which is electrically coupled to the one or more conductive patterns, and a light absorbing layer formed on the outer circumference of the light source to absorb light from the light source.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

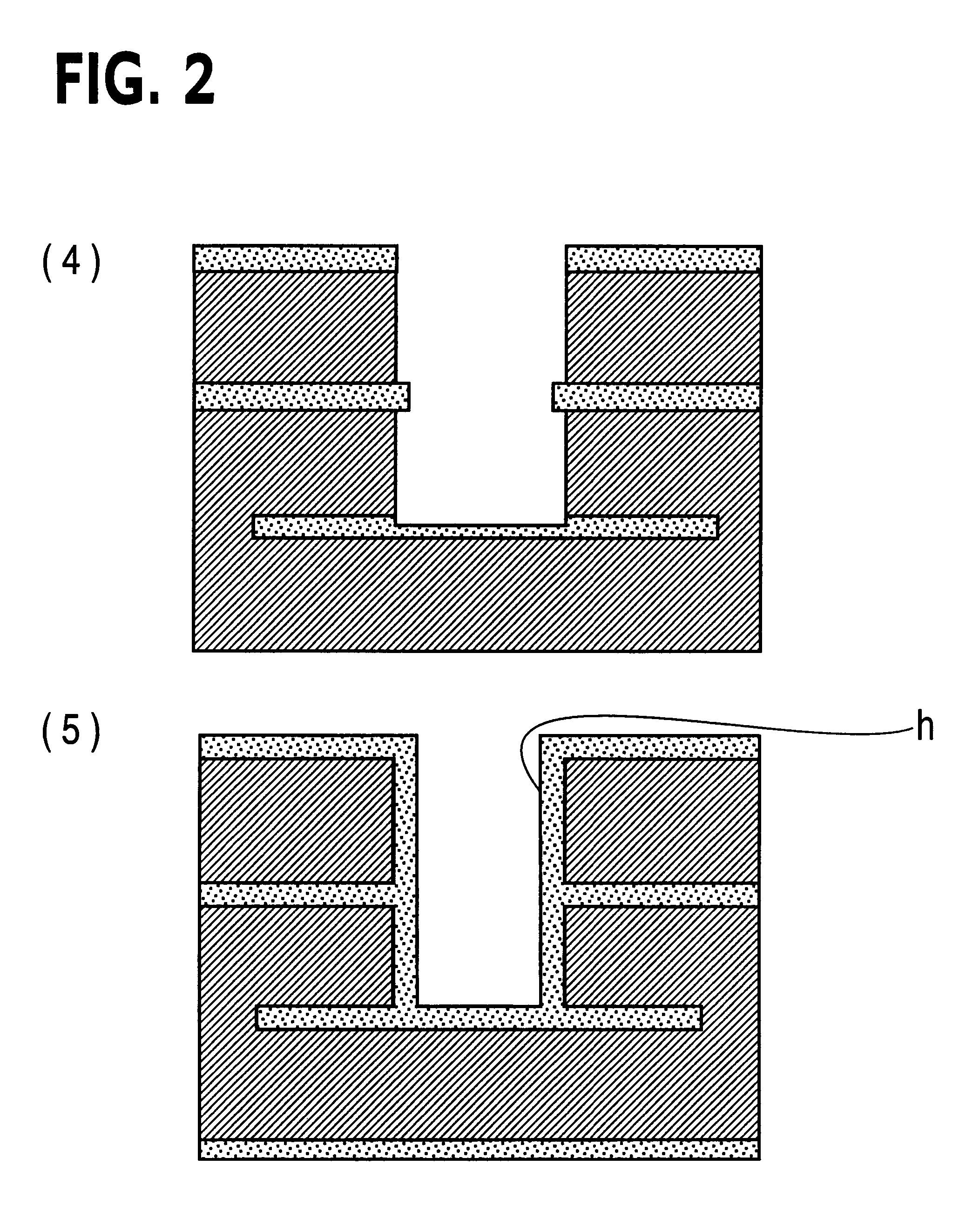

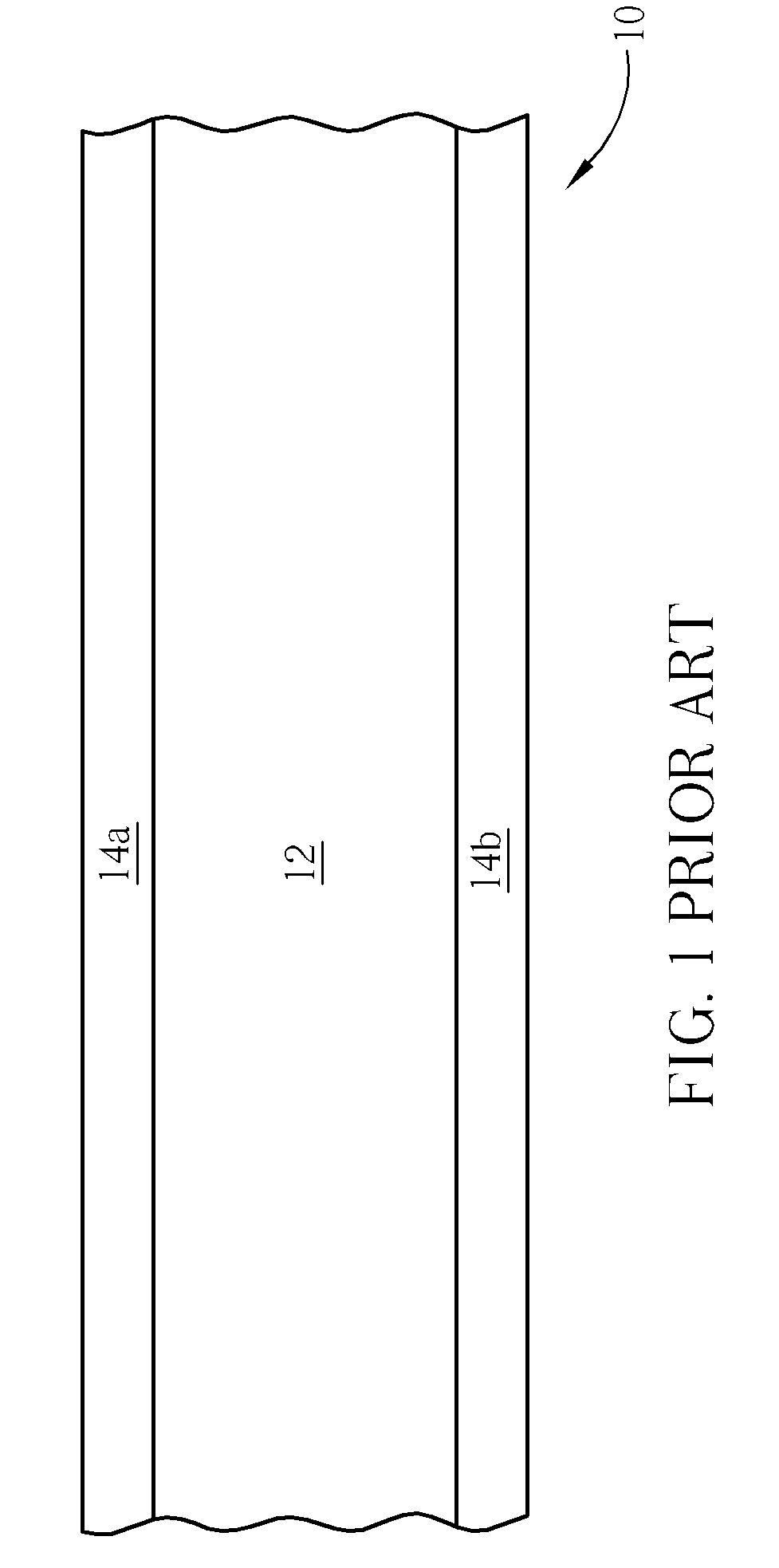

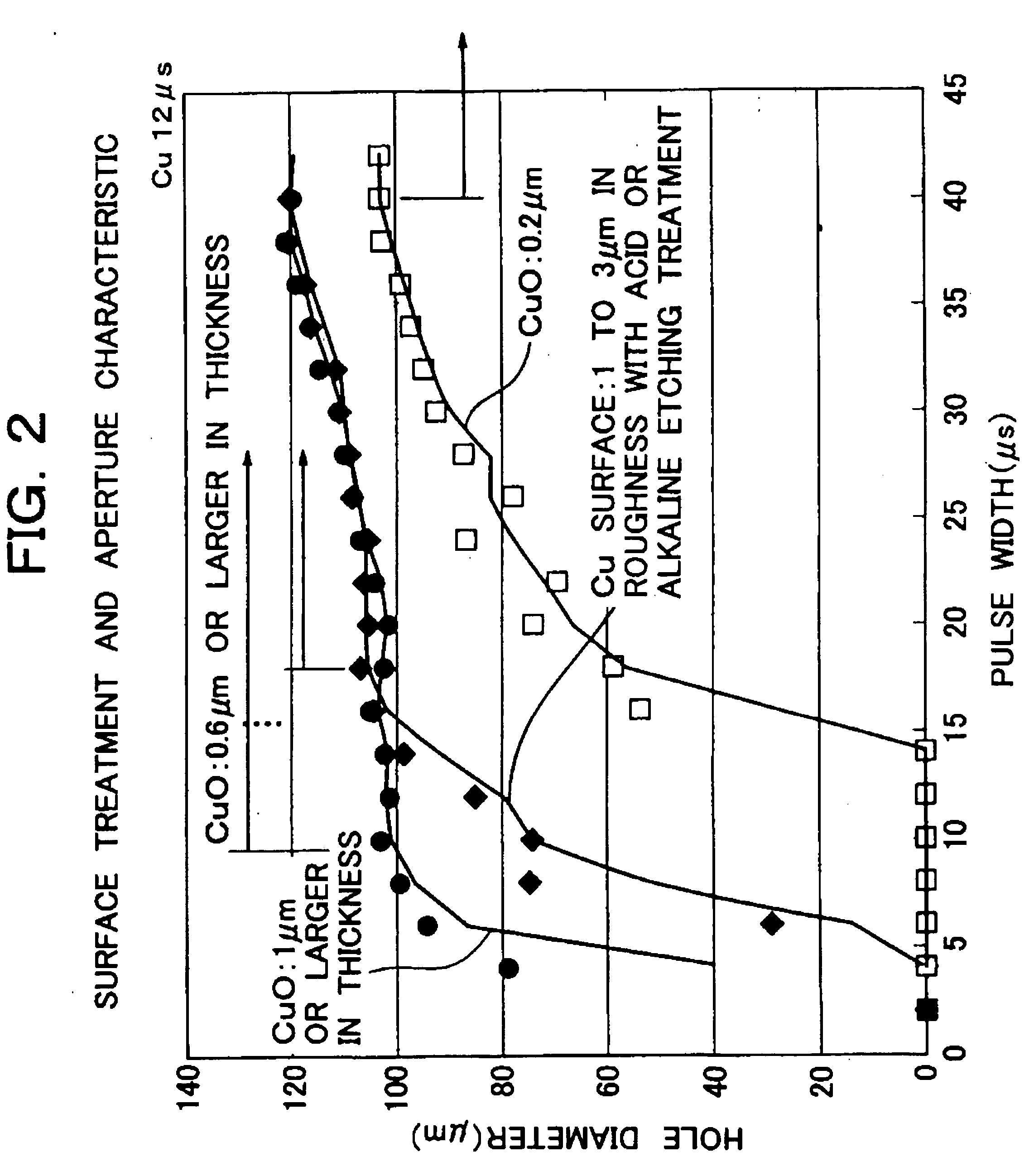

Printed circuit board and method for processing printed circuit board

InactiveUS20050244621A1Low production costUniform processing qualityLight absorption dielectricsCircuit board tools positioningLaser lightPrinted circuit board

The invention is to provide a printed circuit board in which advance of packaging density of the printed circuit board and reduction in production cost can be attained while processing quality can be made uniform, a method for processing the printed circuit board and a method for producing the printed circuit board. There is provided a printed circuit board including an alternate laminate of electric conductor layers and electrically insulating layers, wherein a coating layer capable of absorbing laser light but insoluble in an etching solution dissolving the electric conductor layers is provided on a front surface of a first one of the electric conductor layers. In this case, the coating layer may be provided on a front surface of a rear one of the electric conductor layers. Each of the electric conductor layers may contain Cu as a main component while the coating layer may contain CuO as a main component. The coating layer may have a thickness not thinner than 0.6 μm.

Owner:HITACHI SEIKO LTD

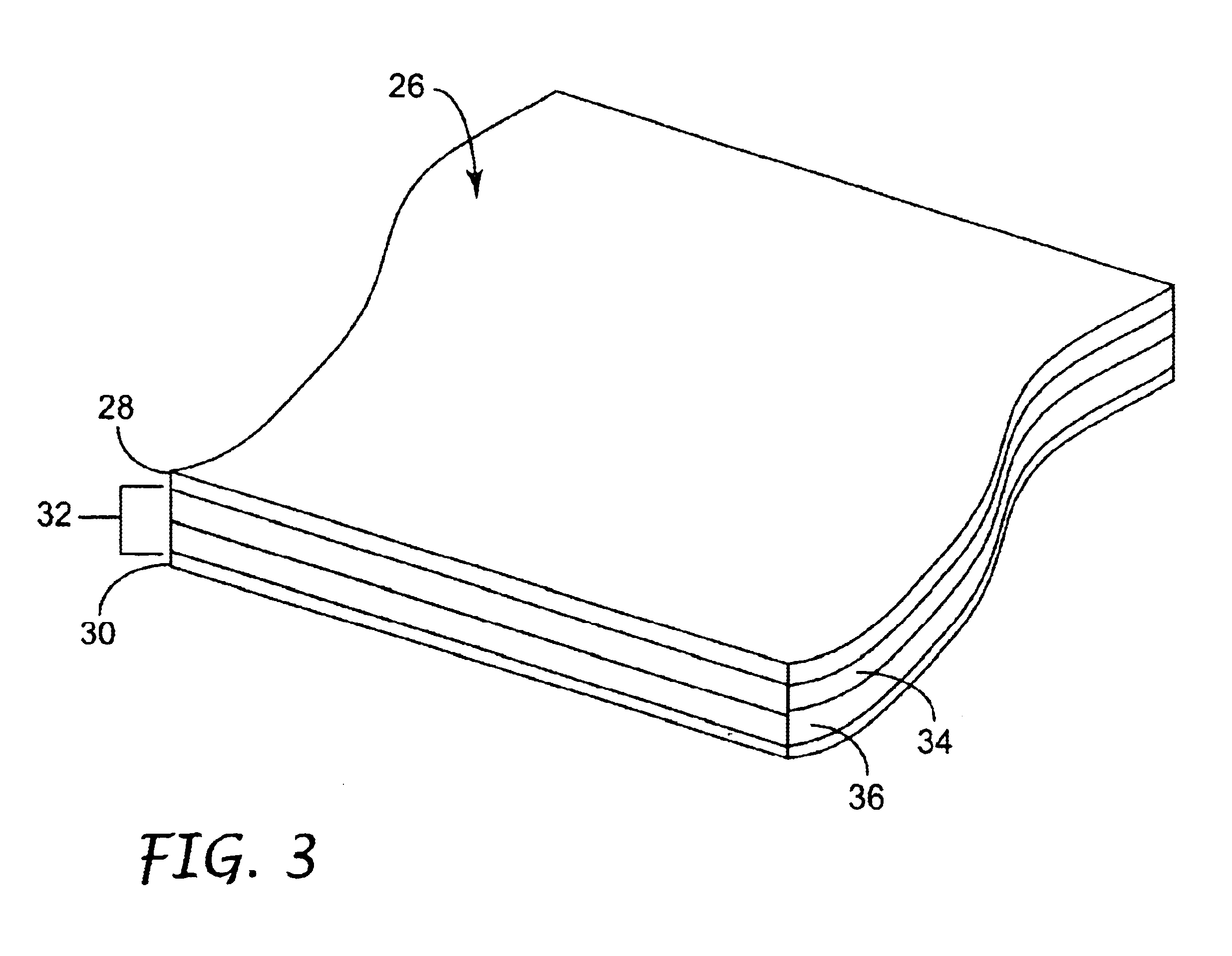

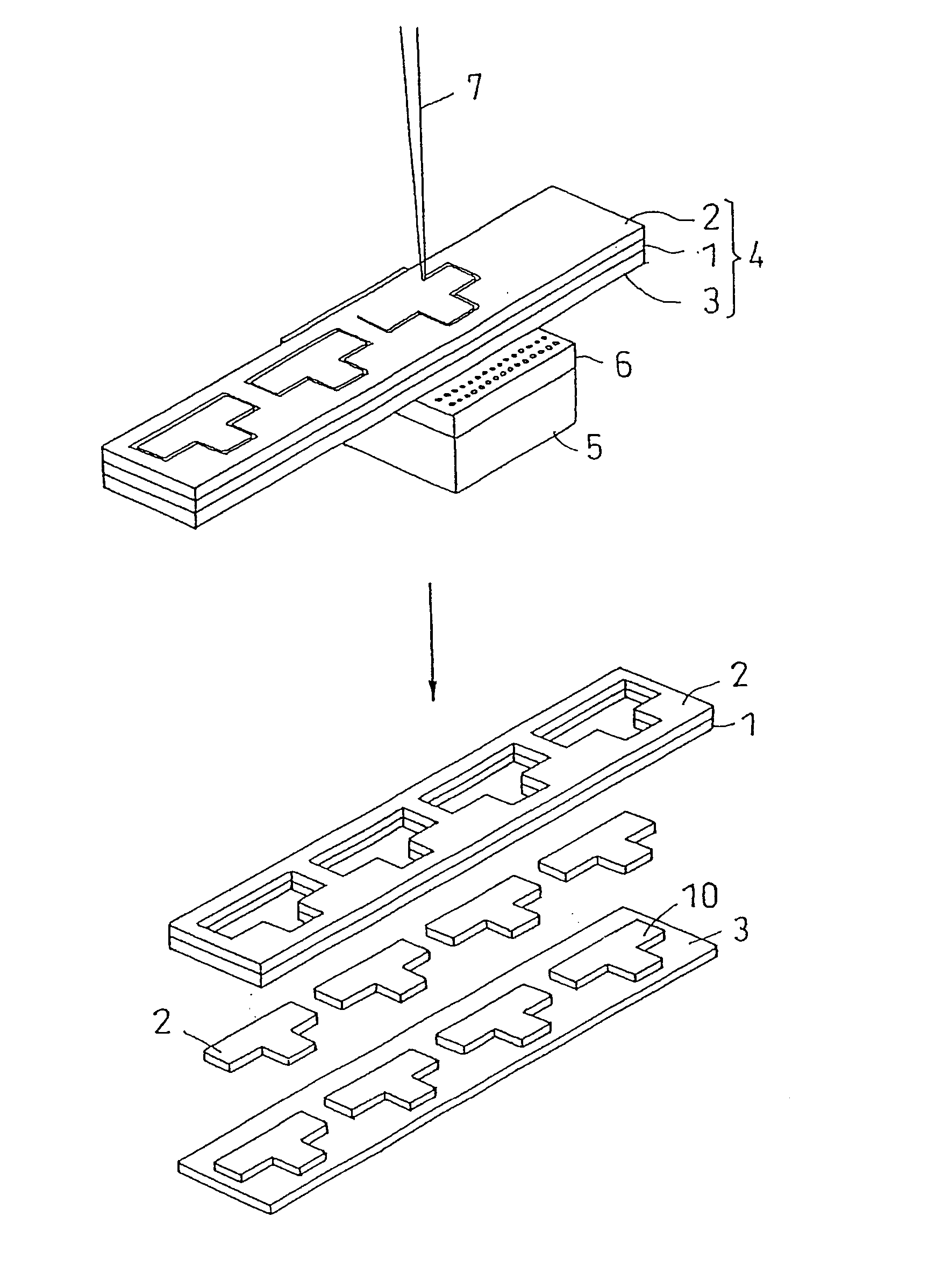

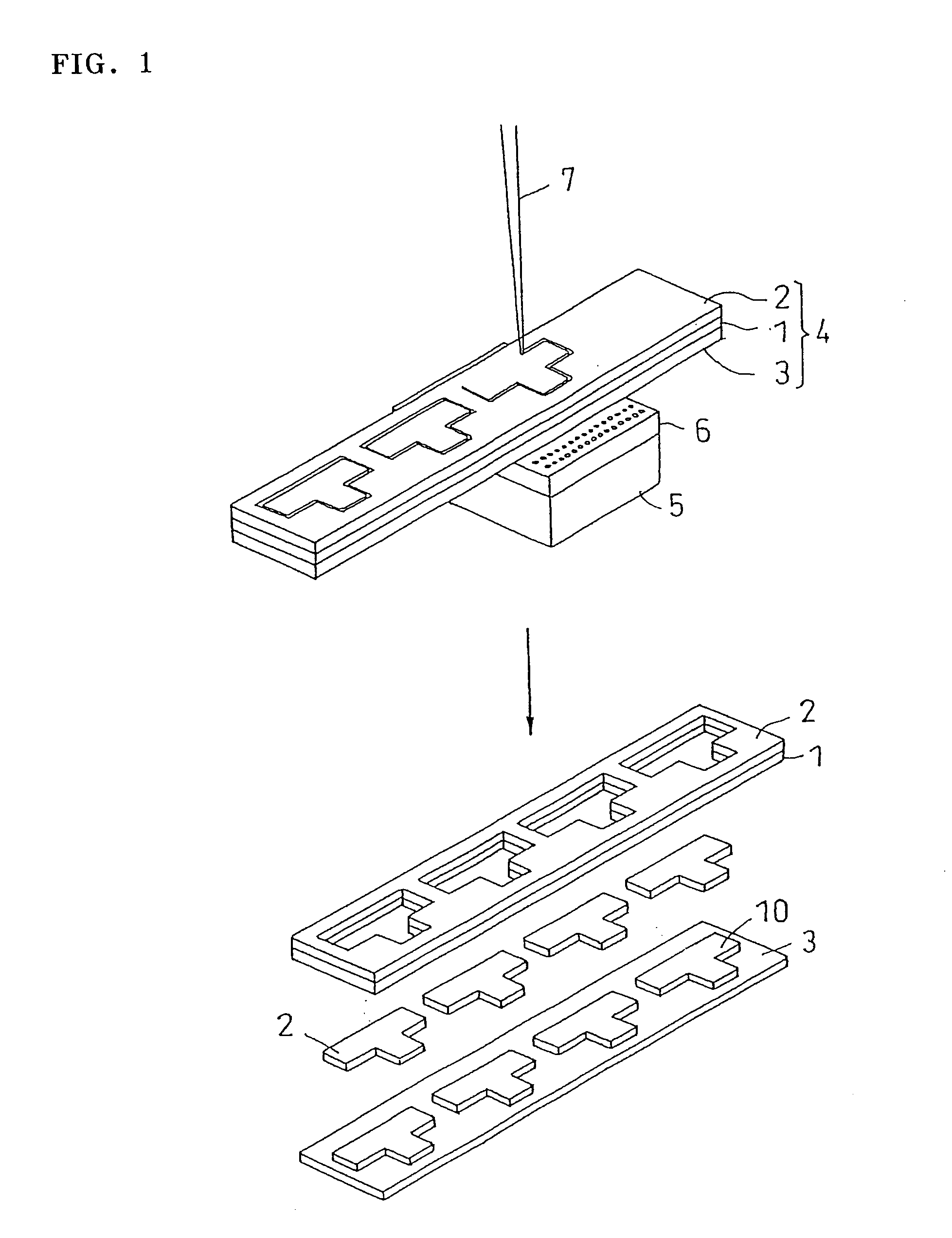

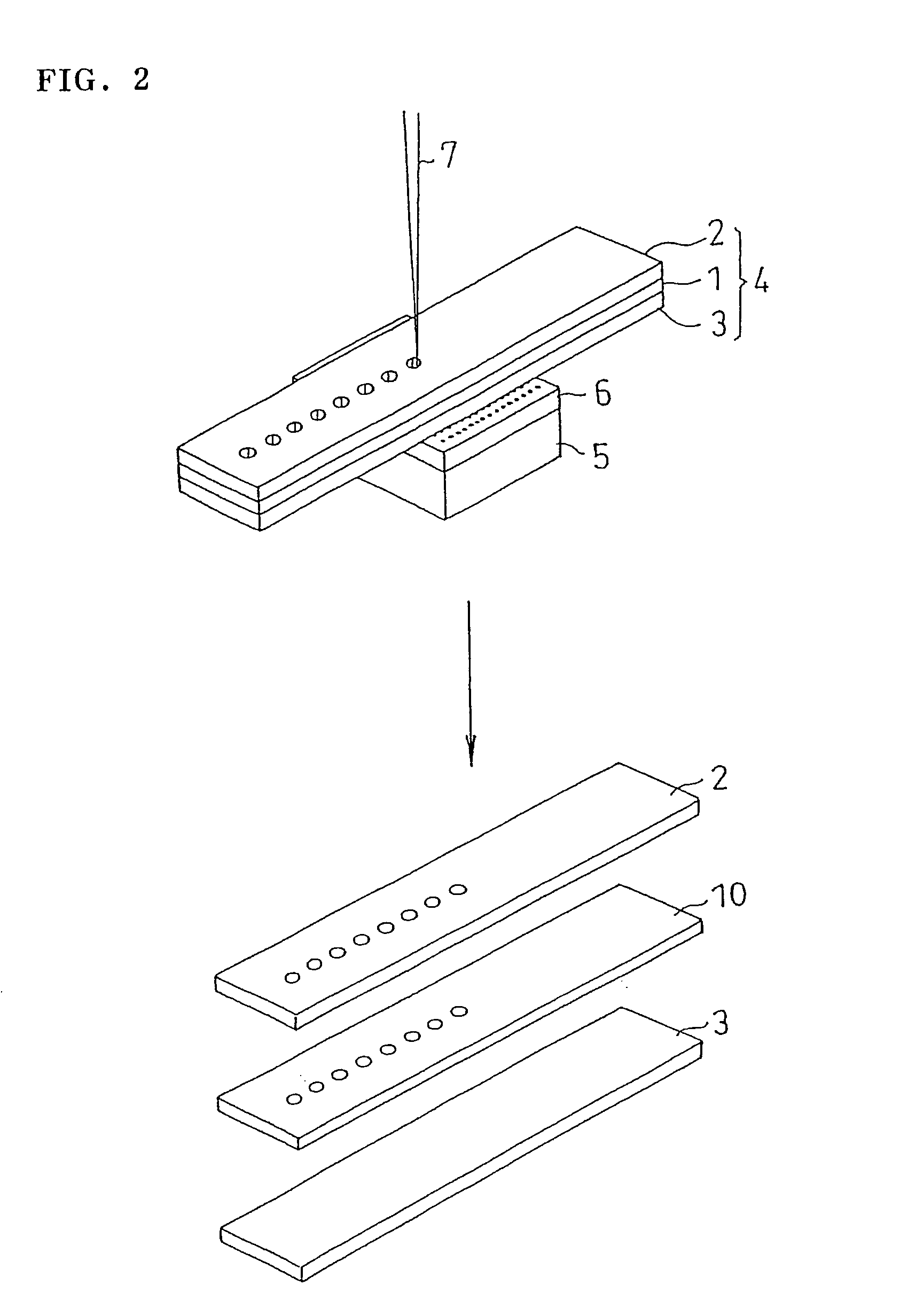

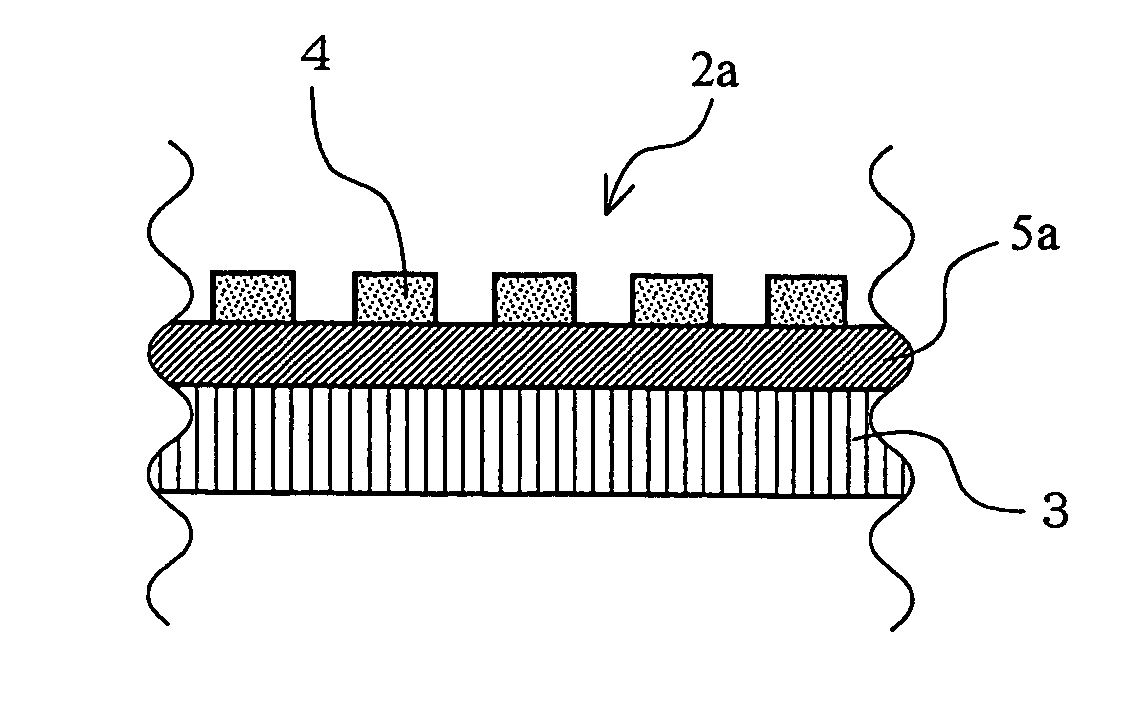

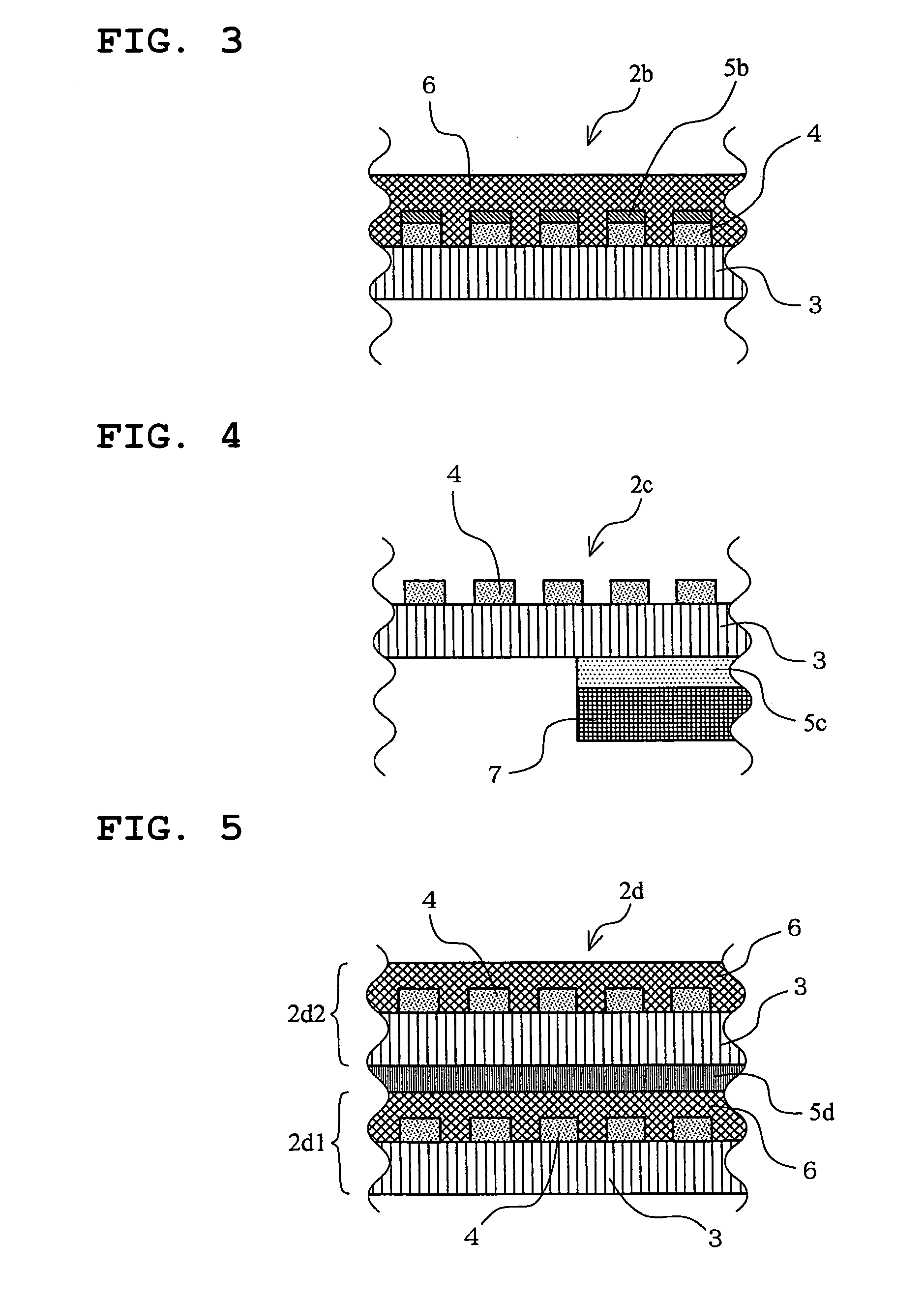

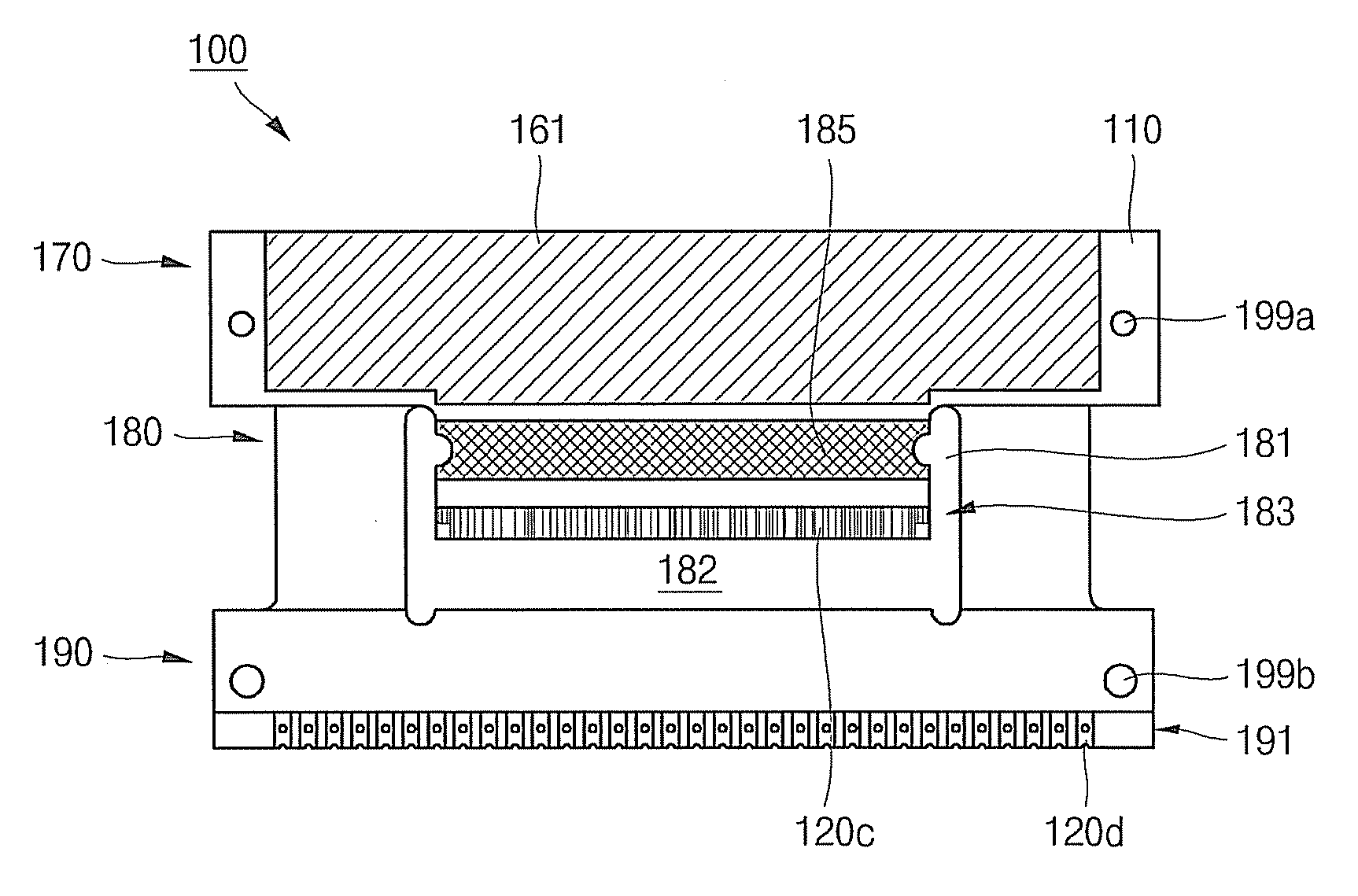

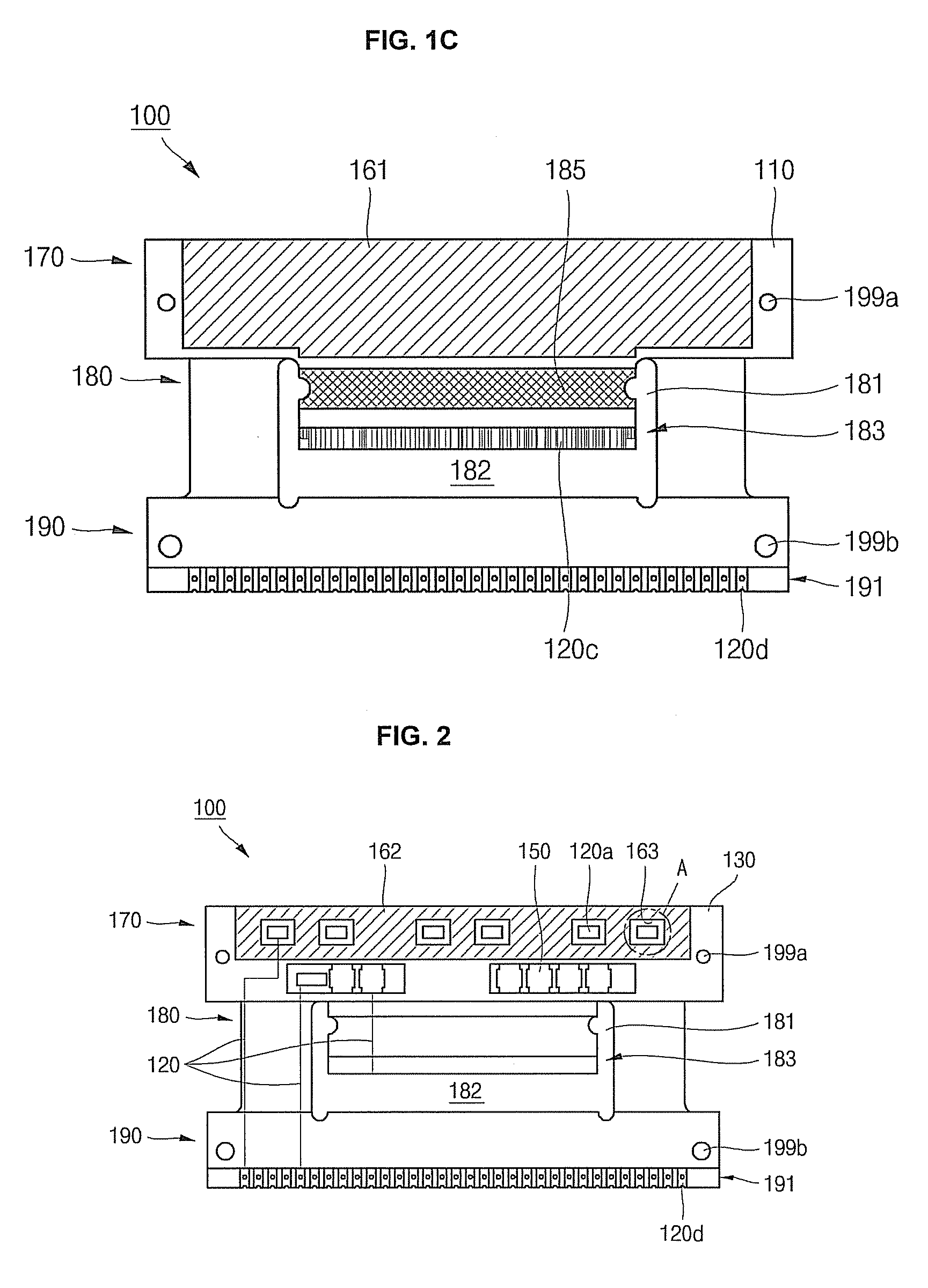

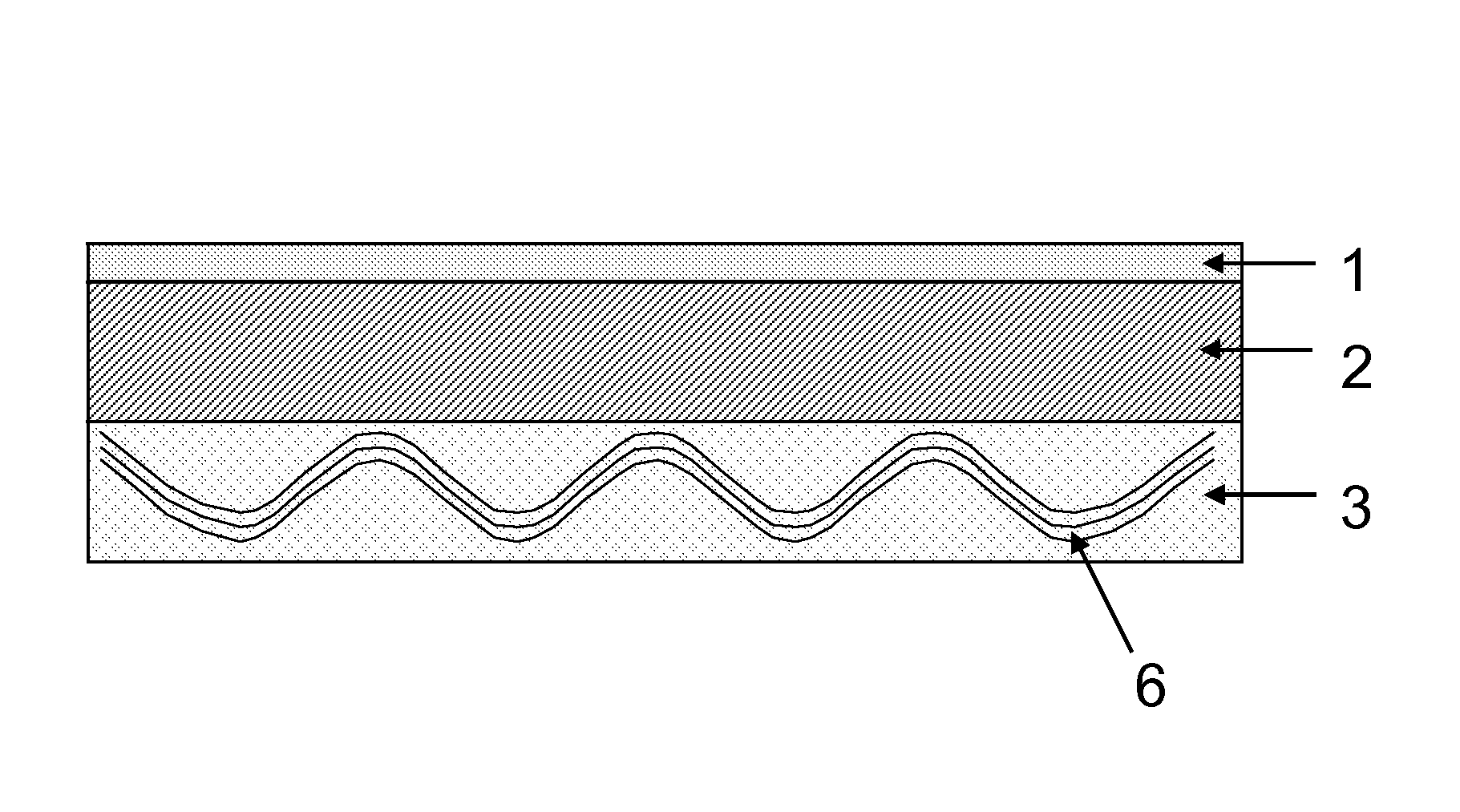

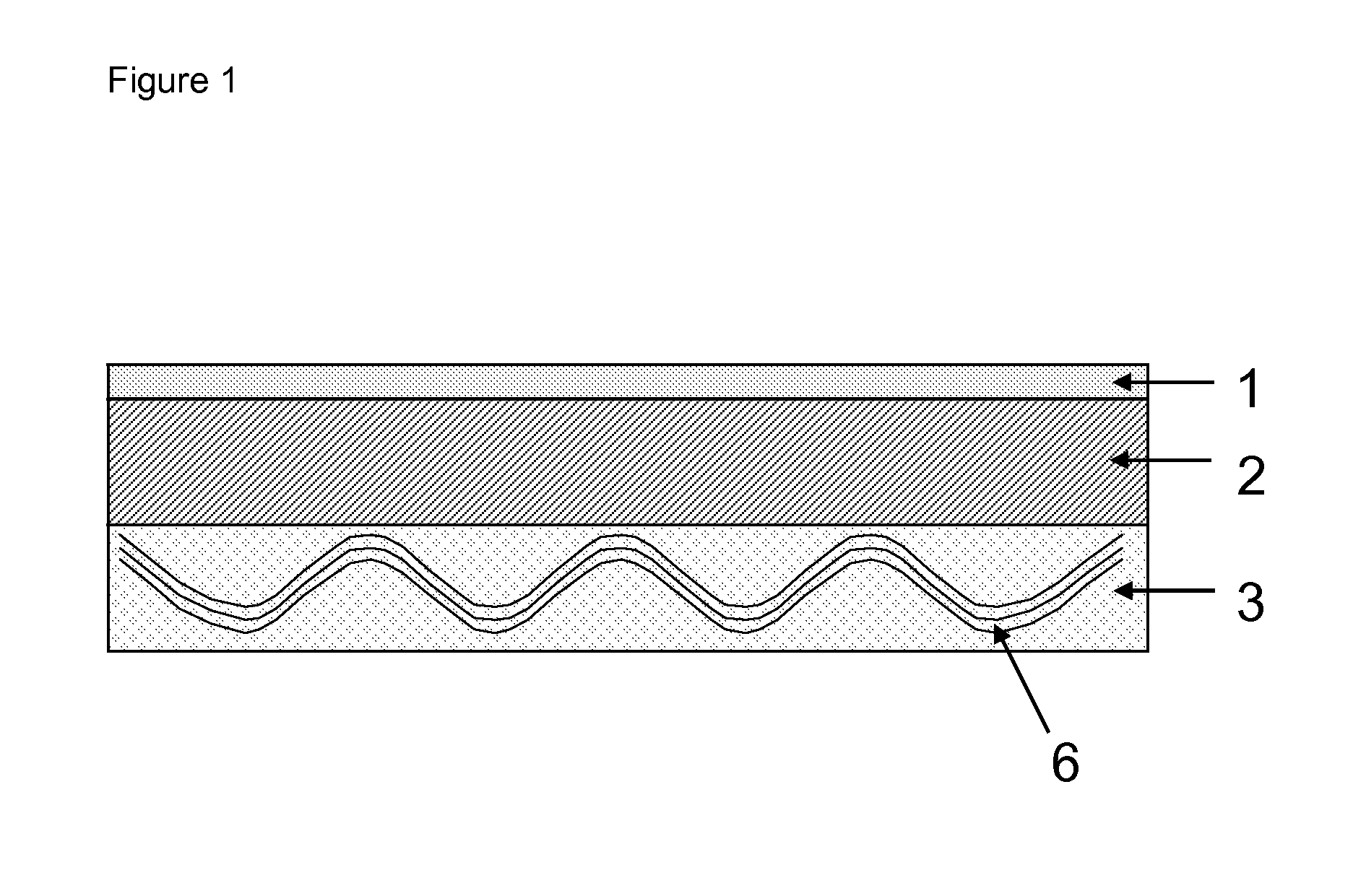

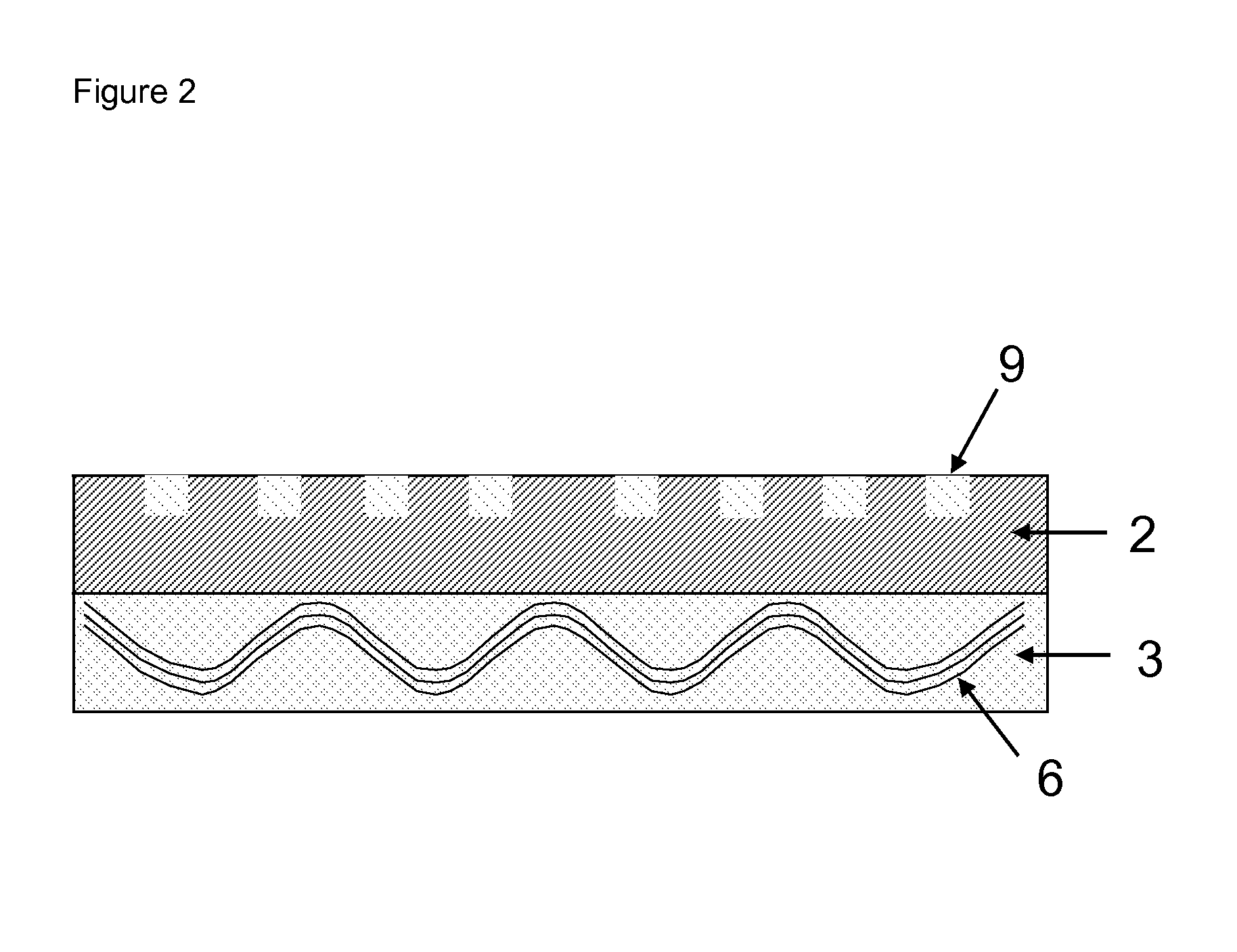

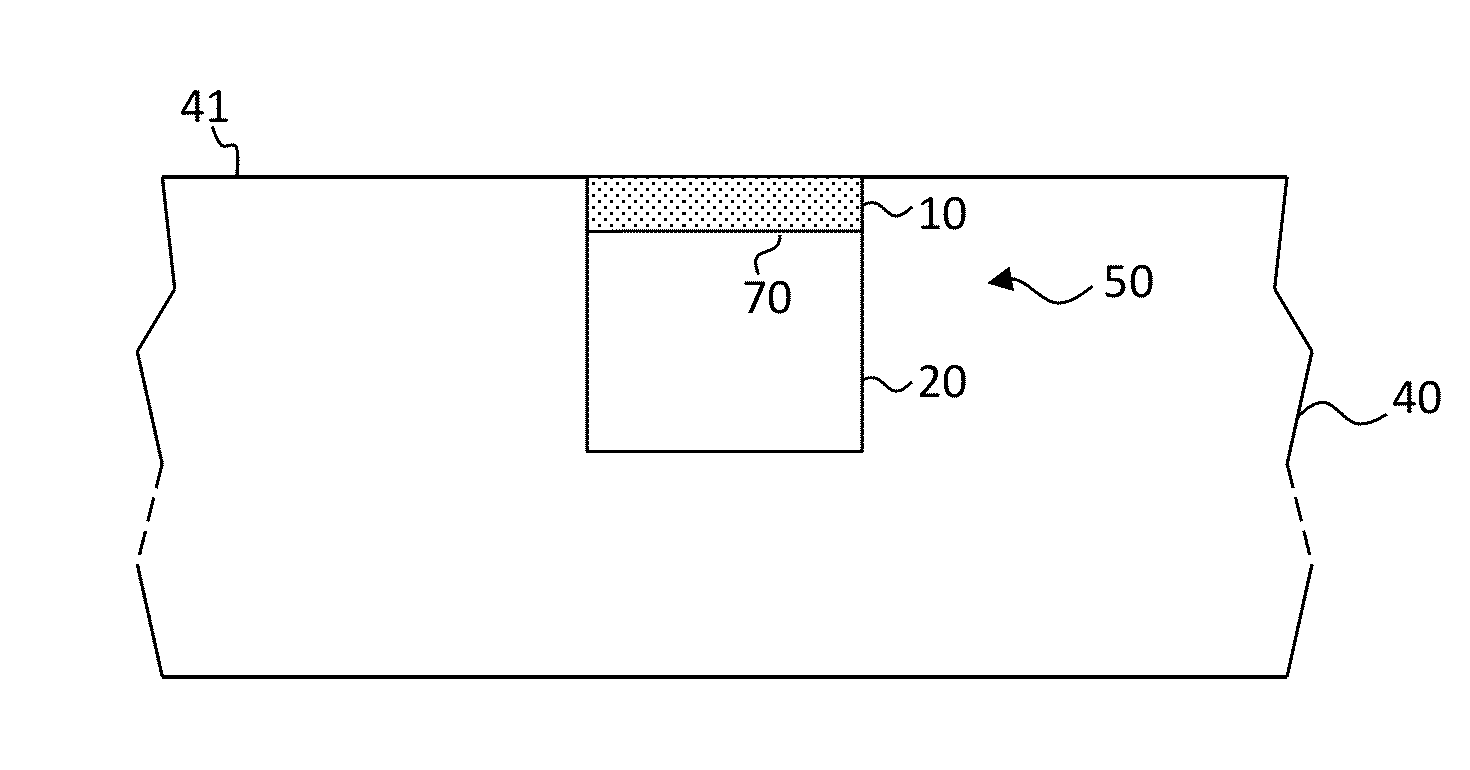

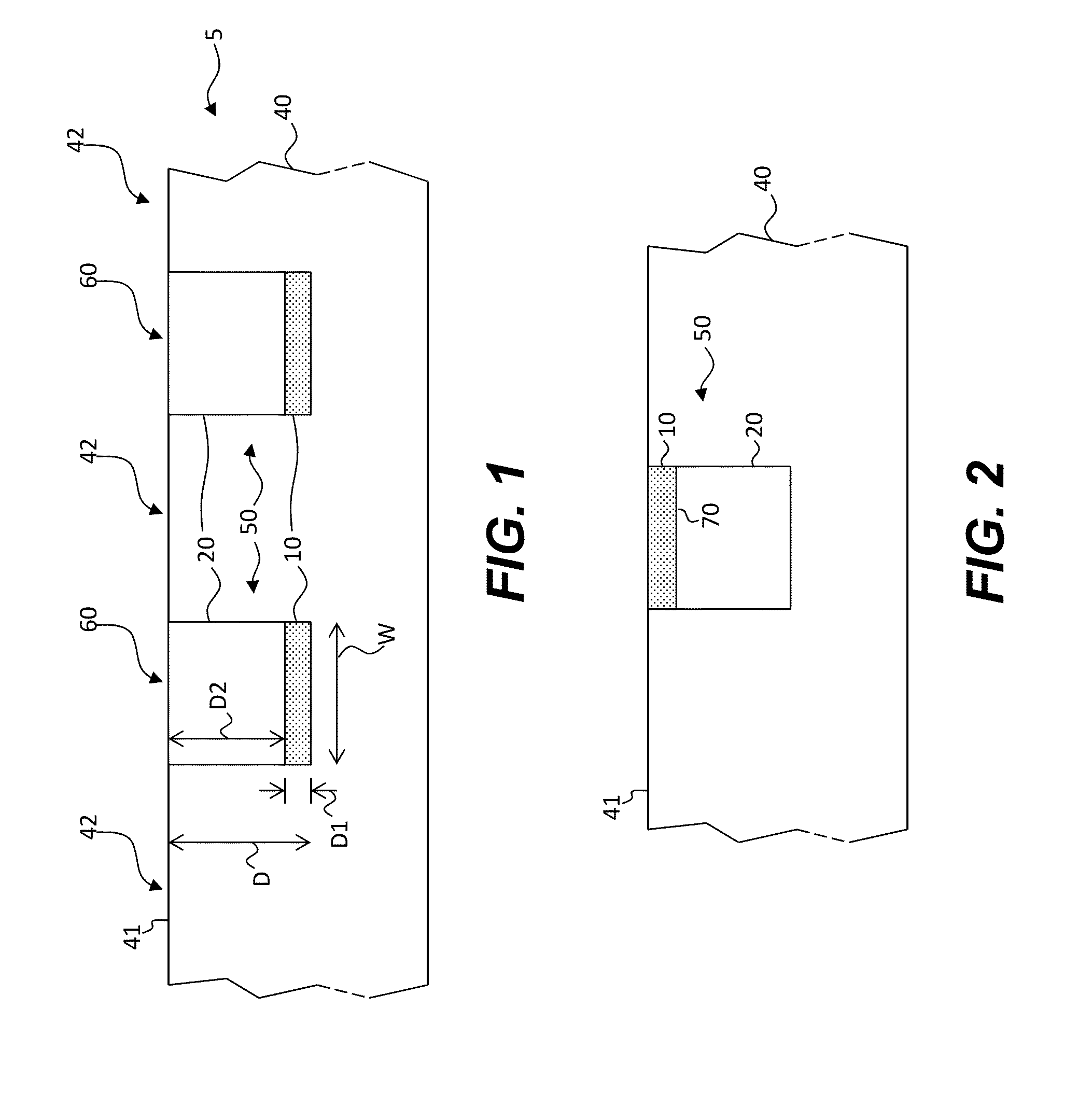

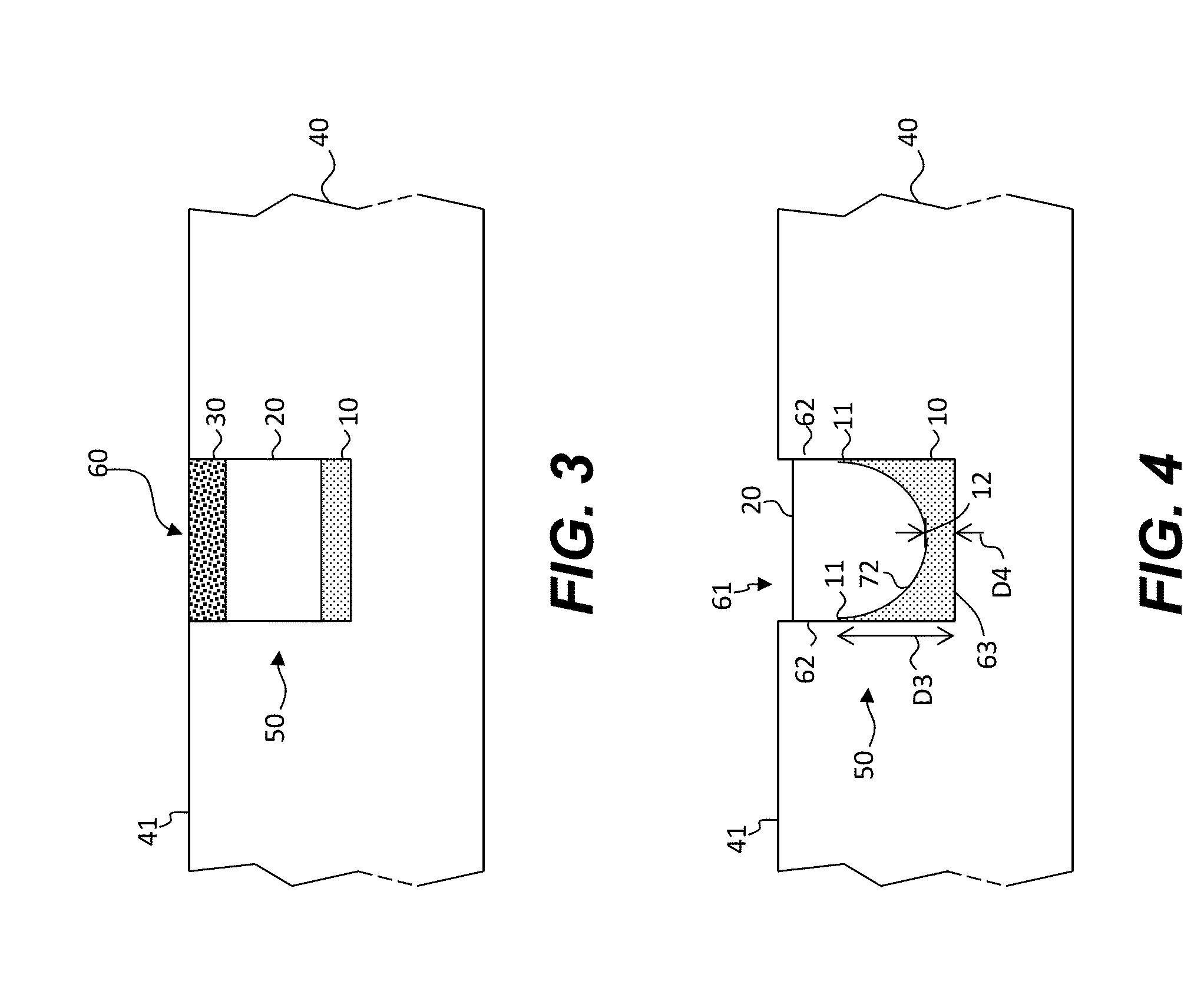

Composite build-up material for embedding of circuitry

InactiveUS20130199825A1Low VOC contentGood dimensional stabilityPrinted circuit liquid treatmentLight absorption dielectricsEngineeringMicrovia

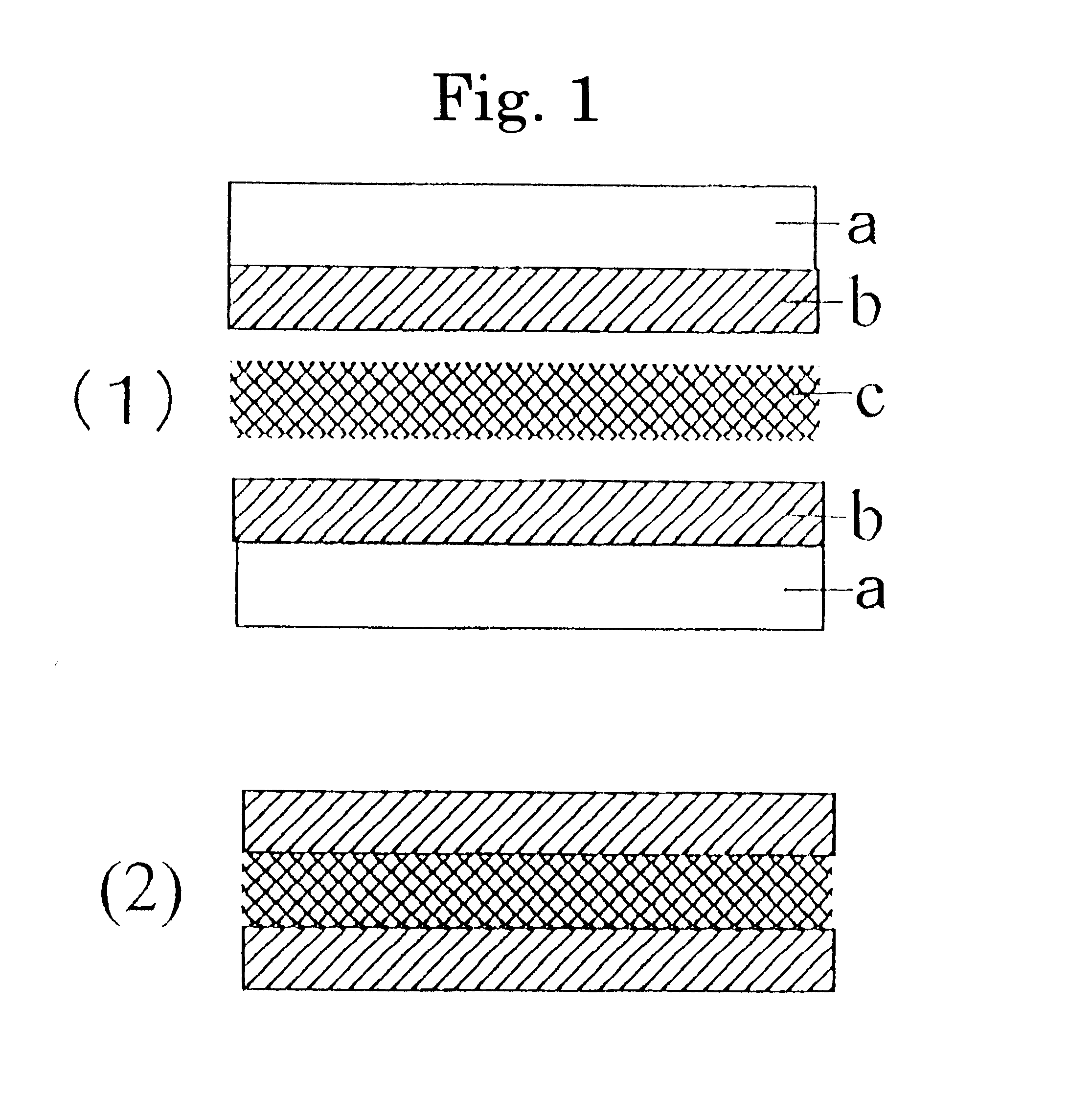

Disclosed are composite build-up materials for the manufacture of printed circuit boards, IC substrates, chip packages and the like. The composite build-up materials are suitable for embedding circuitry such as microvias, trenches and pads. The composite build-up materials comprise a carrier layer (1), a resin layer without reinforcement (2), and a resin layer with reinforcement (3). The circuitry (9) is embedded into the resin layer without reinforcement (2).

Owner:ATOTECH DEUT GMBH

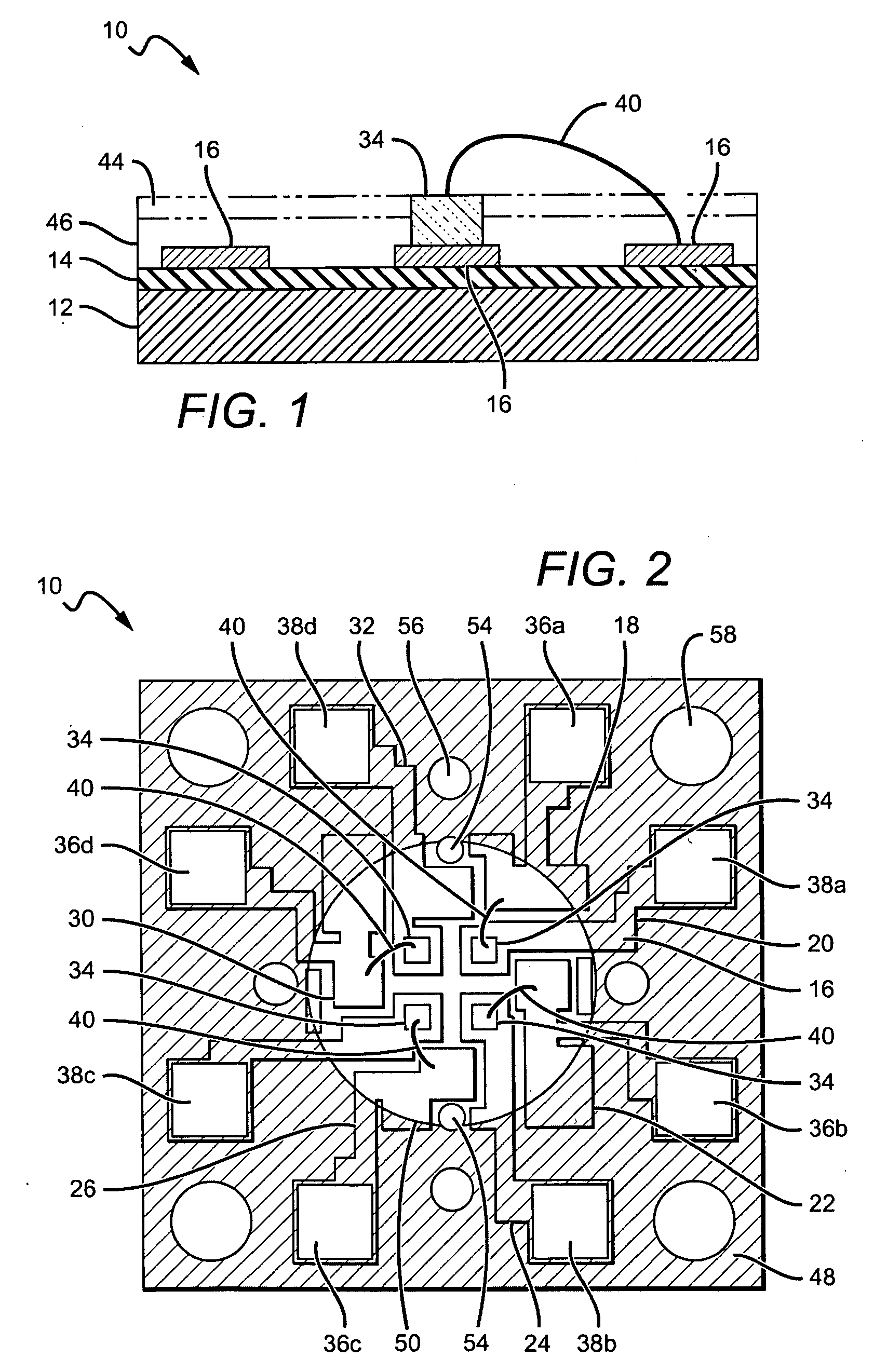

Multi-layer micro-wire structure

InactiveUS20140239504A1Increase contrastImprove reflectivityLight absorption dielectricsSemiconductor/solid-state device detailsSubstrate surfaceElectrically conductive

A multi-layer micro-wire structure includes a substrate having a surface. A plurality of micro-channels is formed in the substrate. A first material composition is located in a first layer only in each micro-channel and not on the substrate surface. A second material composition different from the first material composition is located in a second layer different from the first layer only in each micro-channel and not on the substrate surface. The first material composition in the first layer and the second material composition in the second layer form an electrically conductive multi-layer micro-wire in each micro-channel.

Owner:EASTMAN KODAK CO

Apparatus and method for bonding anisotropic conductive film using laser beam

InactiveUS20080047663A1Increased temperature requirementsImprove reliabilityLight absorption dielectricsLamination ancillary operationsAnisotropic conductive filmLaser beams

An anisotropic conductive film bonding apparatus and a method using a laser beam instead of thermal welding using a hot bar are disclosed. The apparatus includes a light source for generating a laser beam, a laser beam transmitter for guiding the laser beam from the light source to project the laser beam onto a connecting portion, a jig, on which the substrate, the ACF, and the material are accumulated, for projecting the laser beam on the accumulated material, a manipulation panel, and a controller for setting intensity and projection manner of the laser beam and pressure and for controlling overall operation of the apparatus. The process using the hot bar as a heat source for the connection of the anisotropic conductive film is replaced with the process using a diode laser, so that reliability and precision of the process can be achieved, the processing time can be also reduced, and full-automated process can enhance productivity

Owner:JET TECH LTD

Forming a patterned metal layer using laser induced thermal transfer method

InactiveUS7648741B2Material nanotechnologyLight absorption dielectricsOptoelectronicsConductive materials

A method of forming a pattern of electrical conductors on a receiving substrate (110) comprises forming metal nanoparticles of a conductive material. A donor substrate (45) is formed. A layer of release material (75) is deposited on a first side of the donor substrate. The metal nanoparticles are deposited on the release material. The metal nanoparticulate layer are placed in contact with the receiving substrate. A pattern is written on a sandwich formed by the donor substrate and the receiving substrate, causing metal nanoparticles from the nanoparticulate layer (90) to anneal and transfer to the receiving substrate to form the pattern of electrical conductors on the receiving substrate.

Owner:EASTMAN KODAK CO

Popular searches

Insulating layers/substrates working Printed circuit secondary treatment Cable/conductor manufacture Multilayer circuit manufacture Printed element electric connection formation Liquid/solution decomposition chemical coating Conductive pattern formation Solid/suspension decomposition chemical coating Special surfaces Superimposed coating process

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com