Patents

Literature

93results about How to "Avoid surface contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

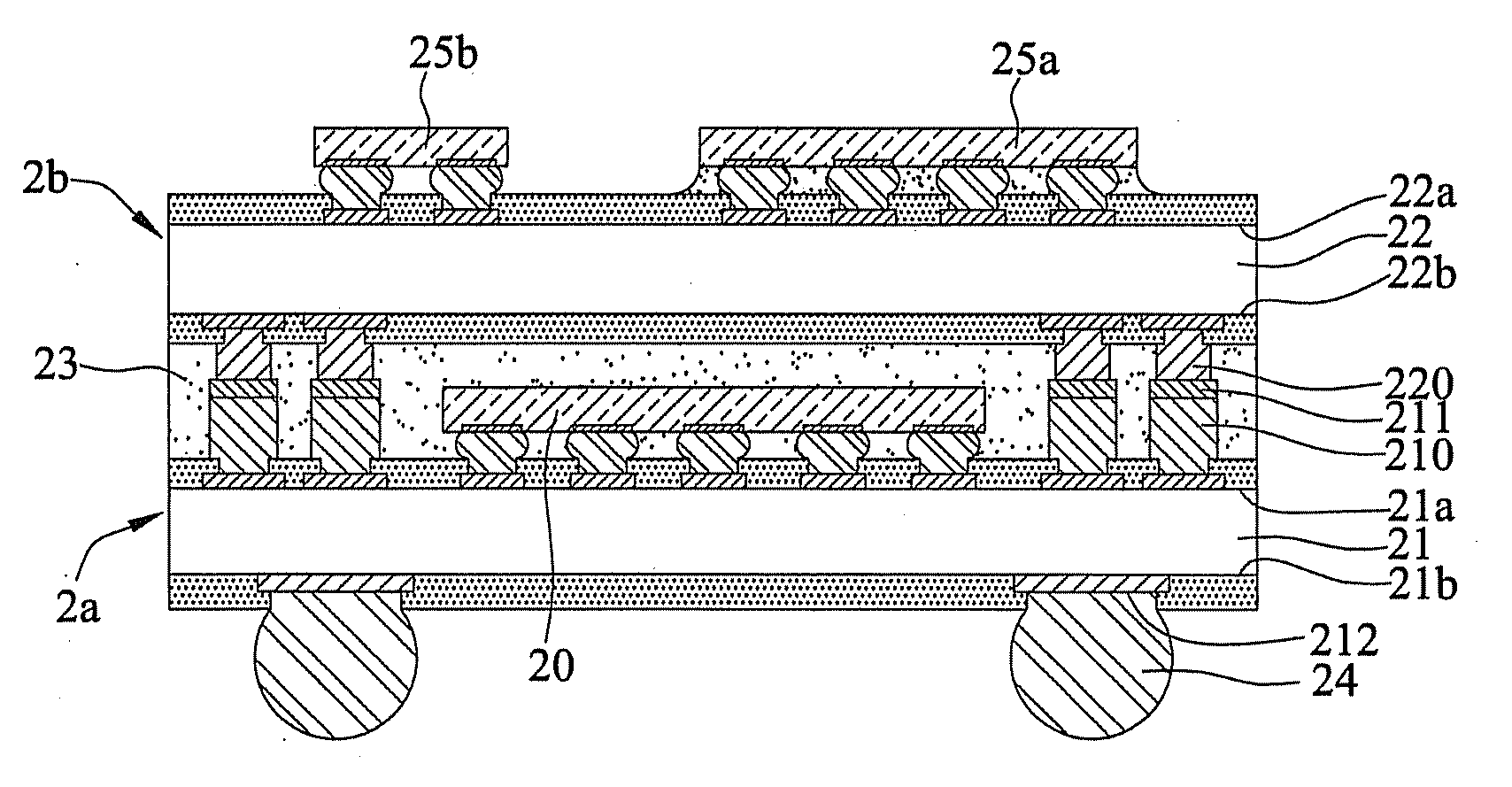

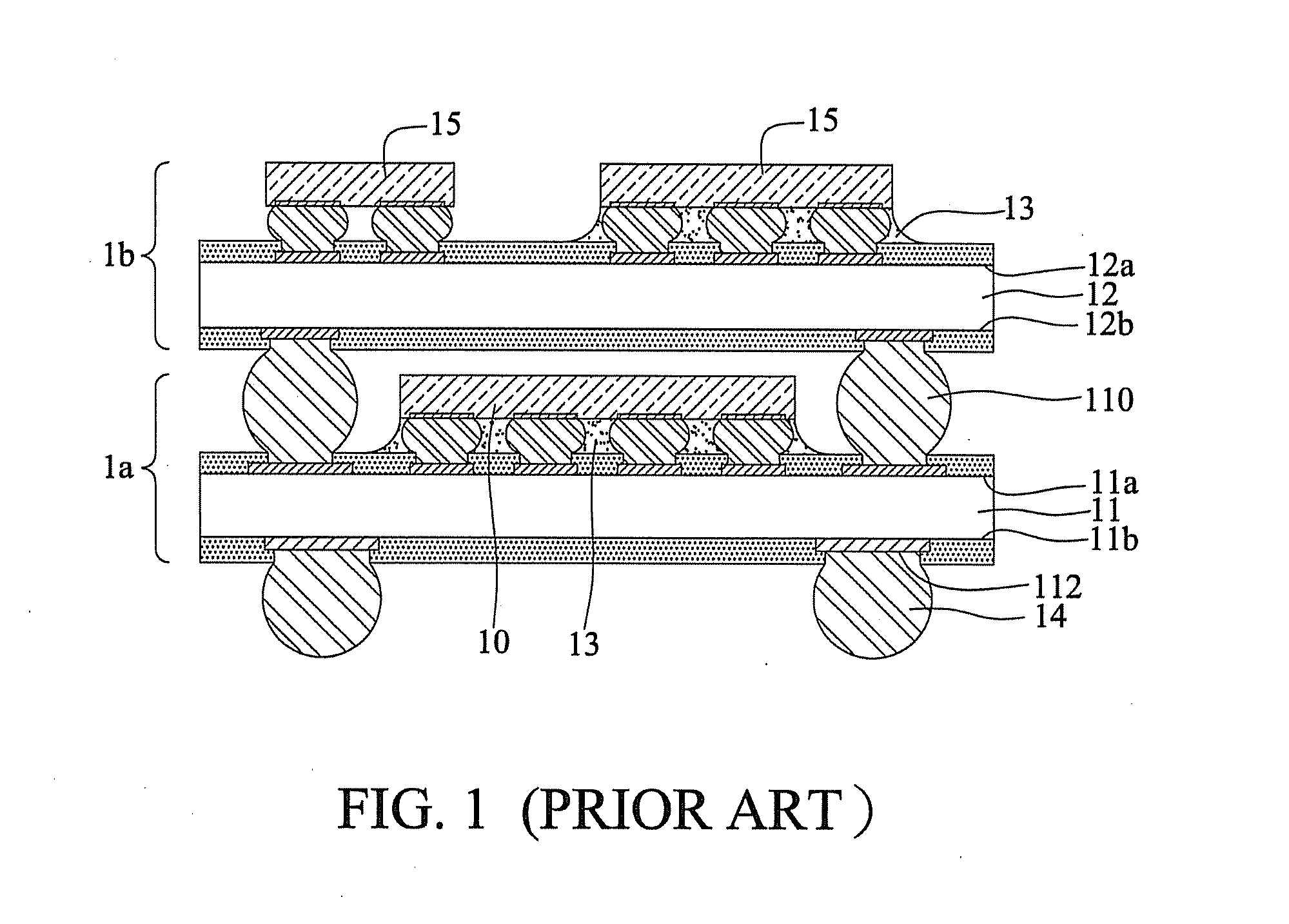

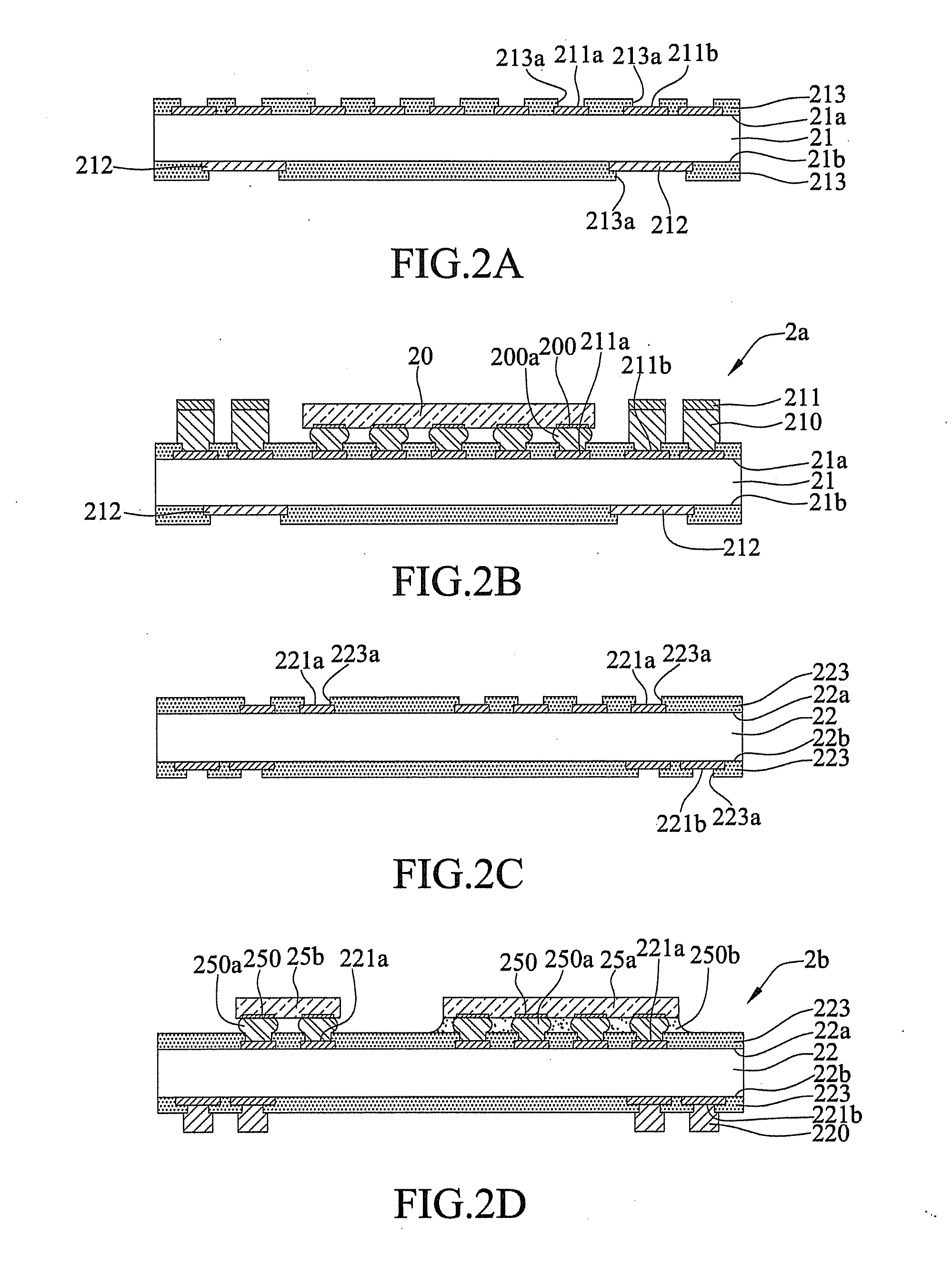

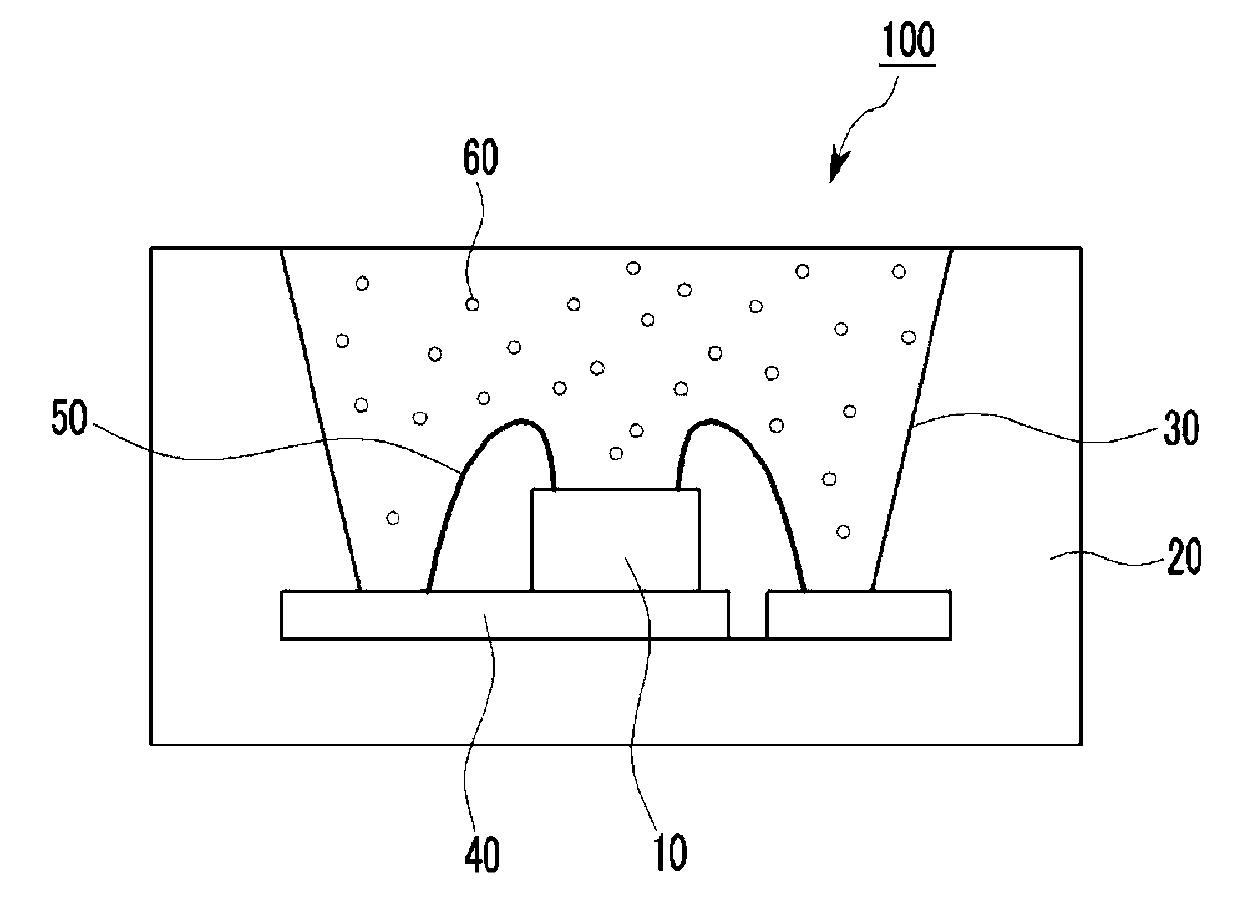

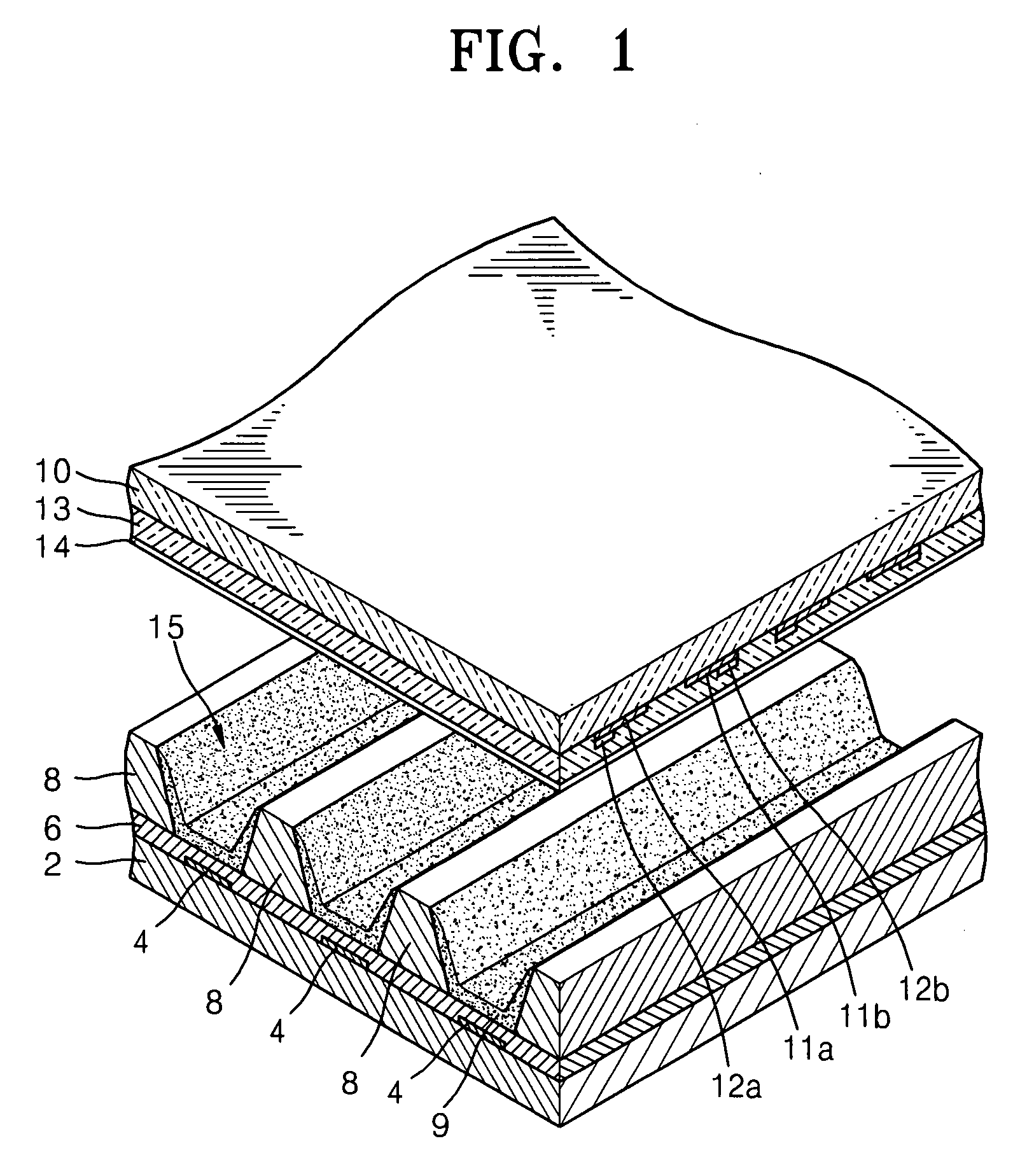

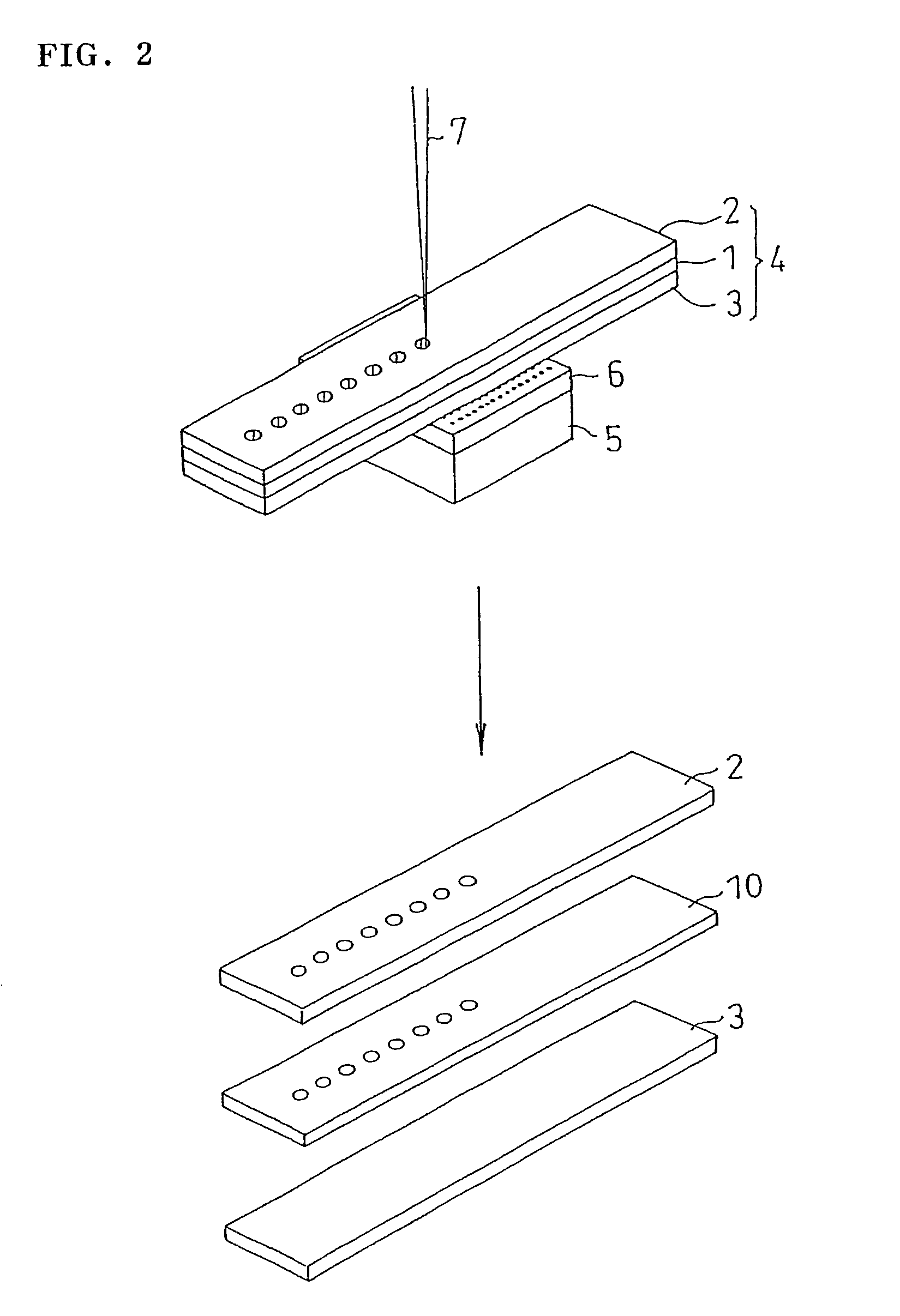

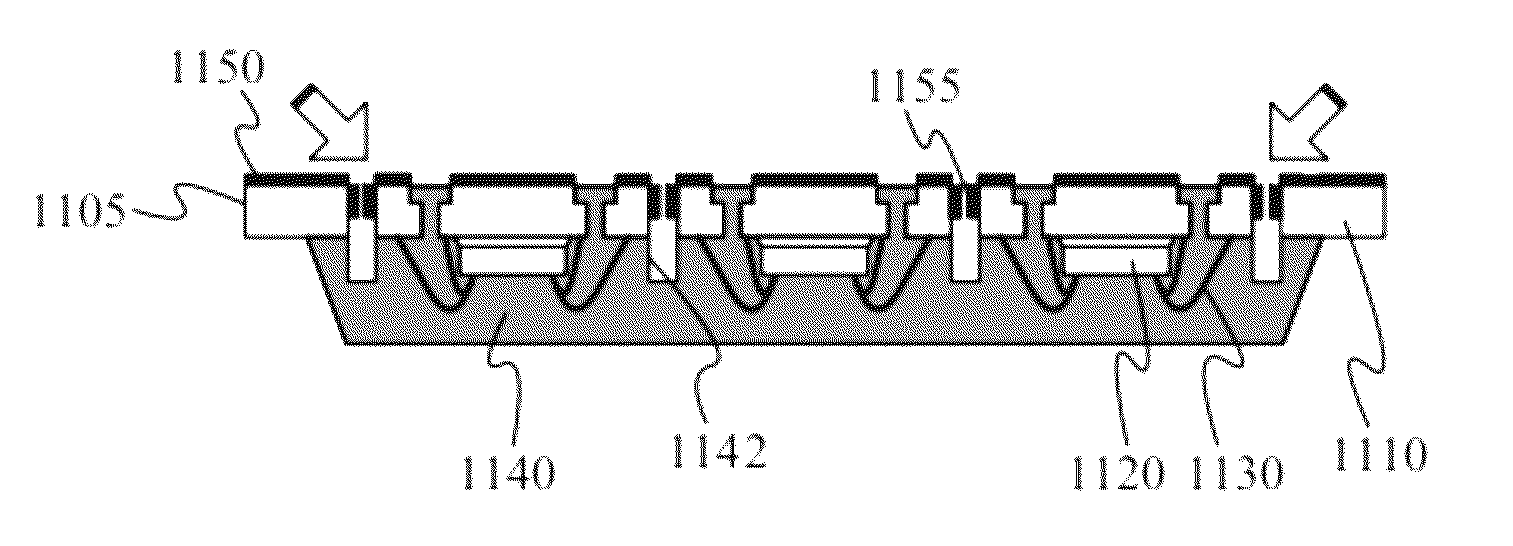

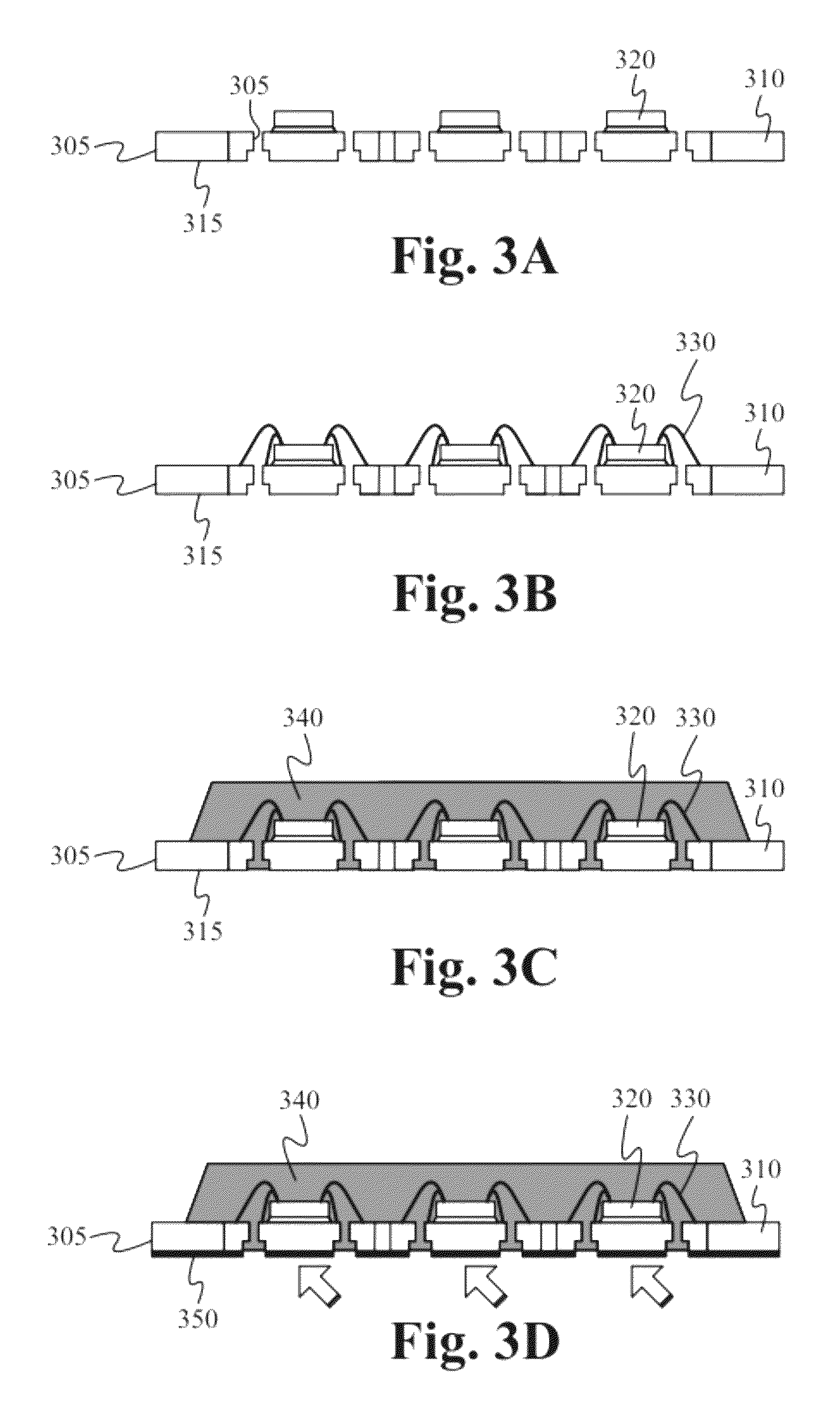

Package stack device and fabrication method thereof

ActiveUS20120193789A1Avoid surface contaminationEasy to controlSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

A package stack device includes a first package structure having a plurality of first metal posts and a first electronic element disposed on a surface thereof, a second package structure having a plurality of second metal posts and a second electronic element disposed on opposite surfaces thereof, and an encapsulant formed between the first and second package structures for encapsulating the first electronic element. By connecting the first and second metal posts, the second package structure is stacked on the first package structure with the support of the metal posts and the encapsulant filling the gap therebetween so as to prevent warpage of the substrate.

Owner:UNIMICRON TECH CORP

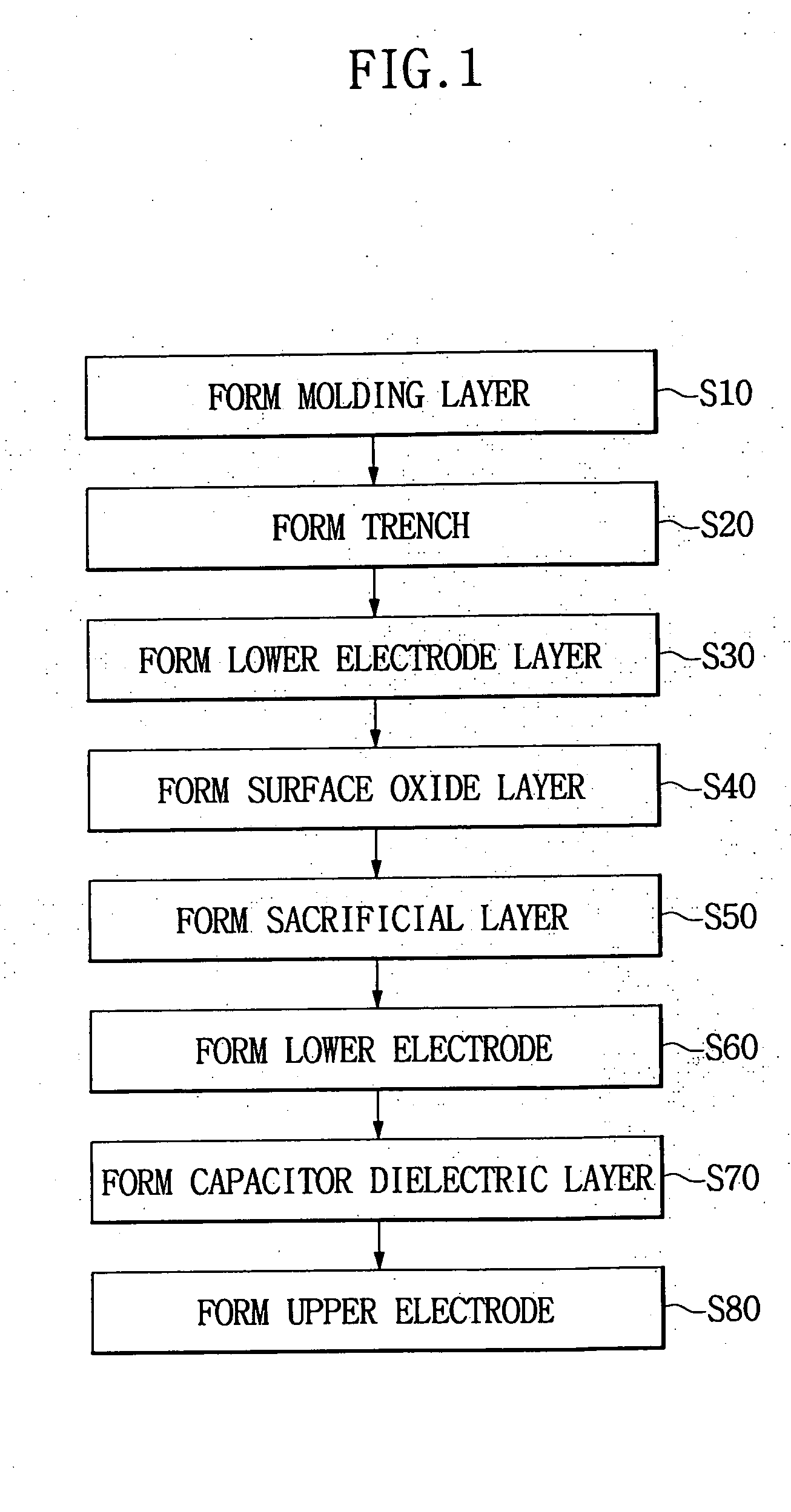

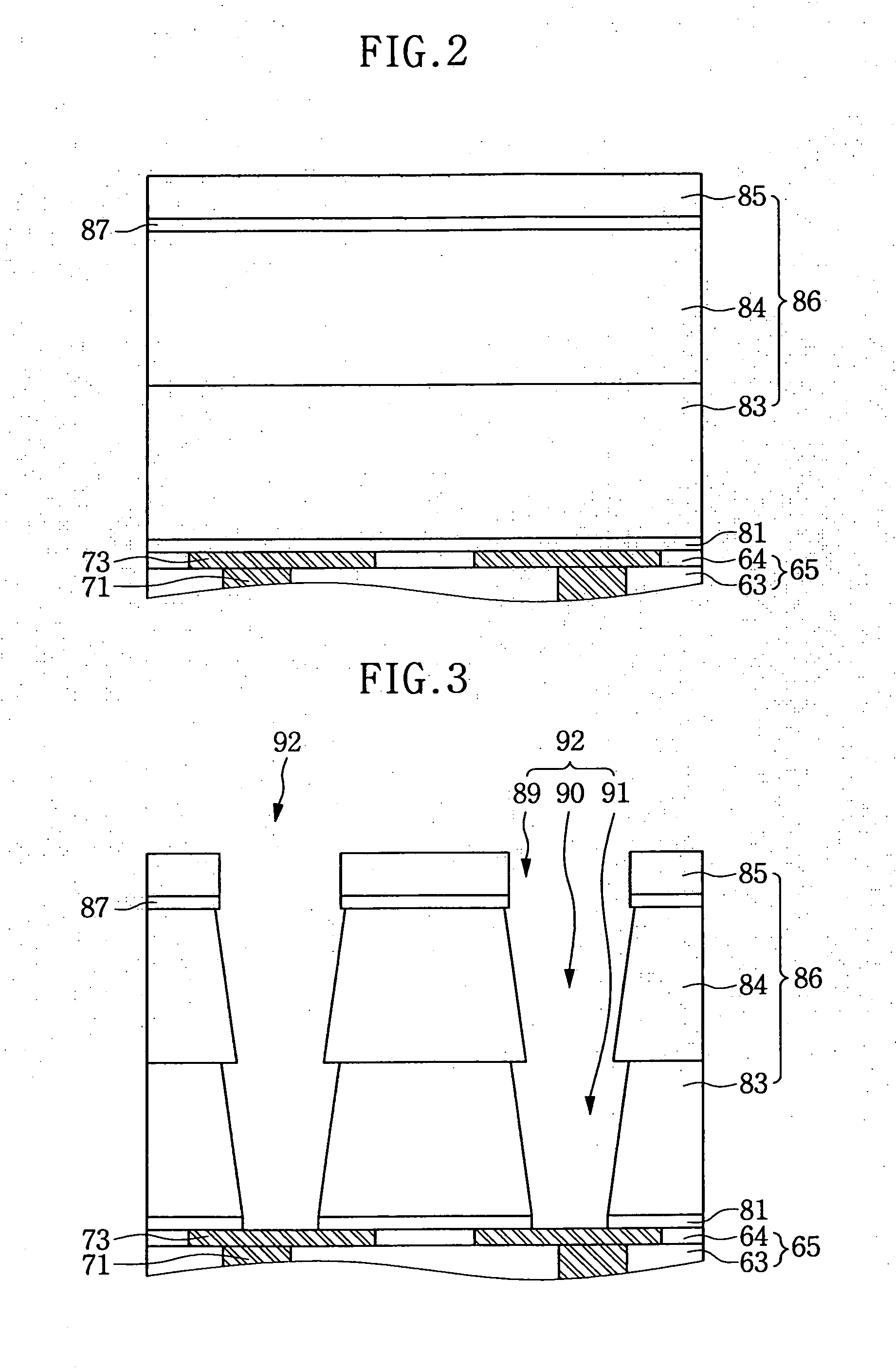

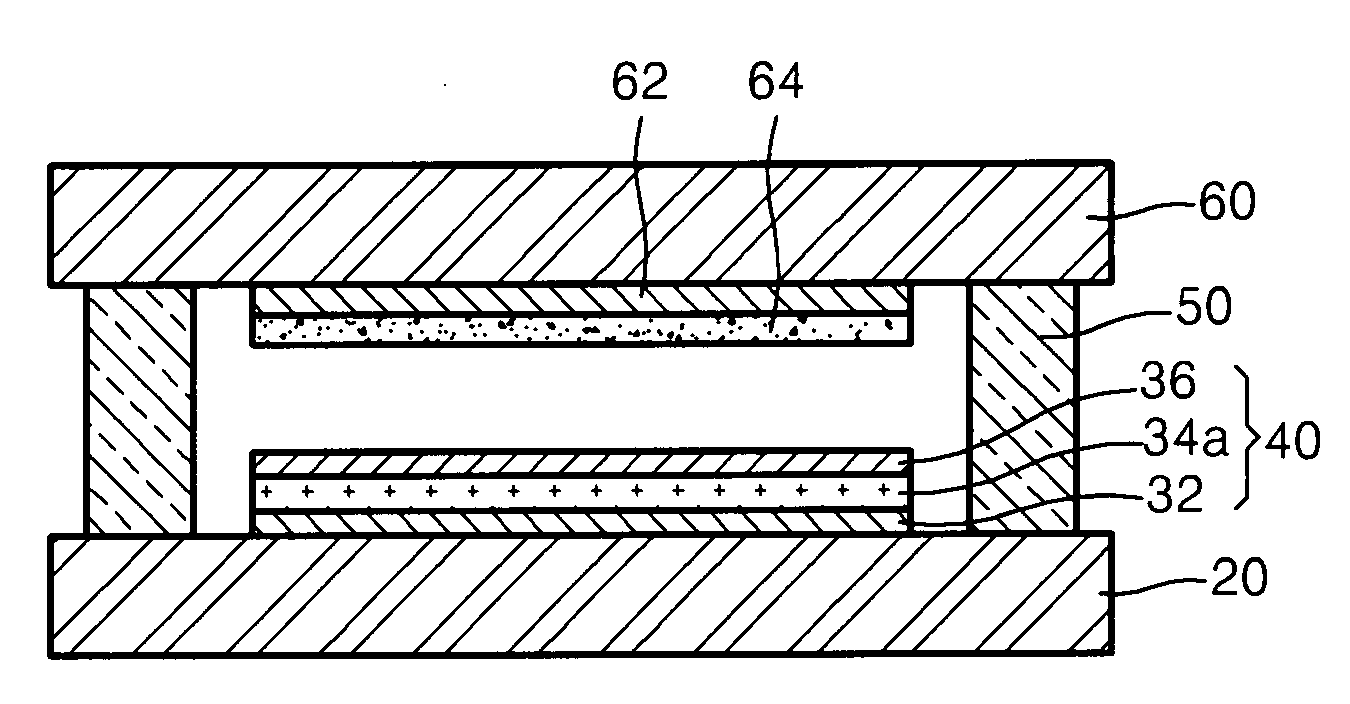

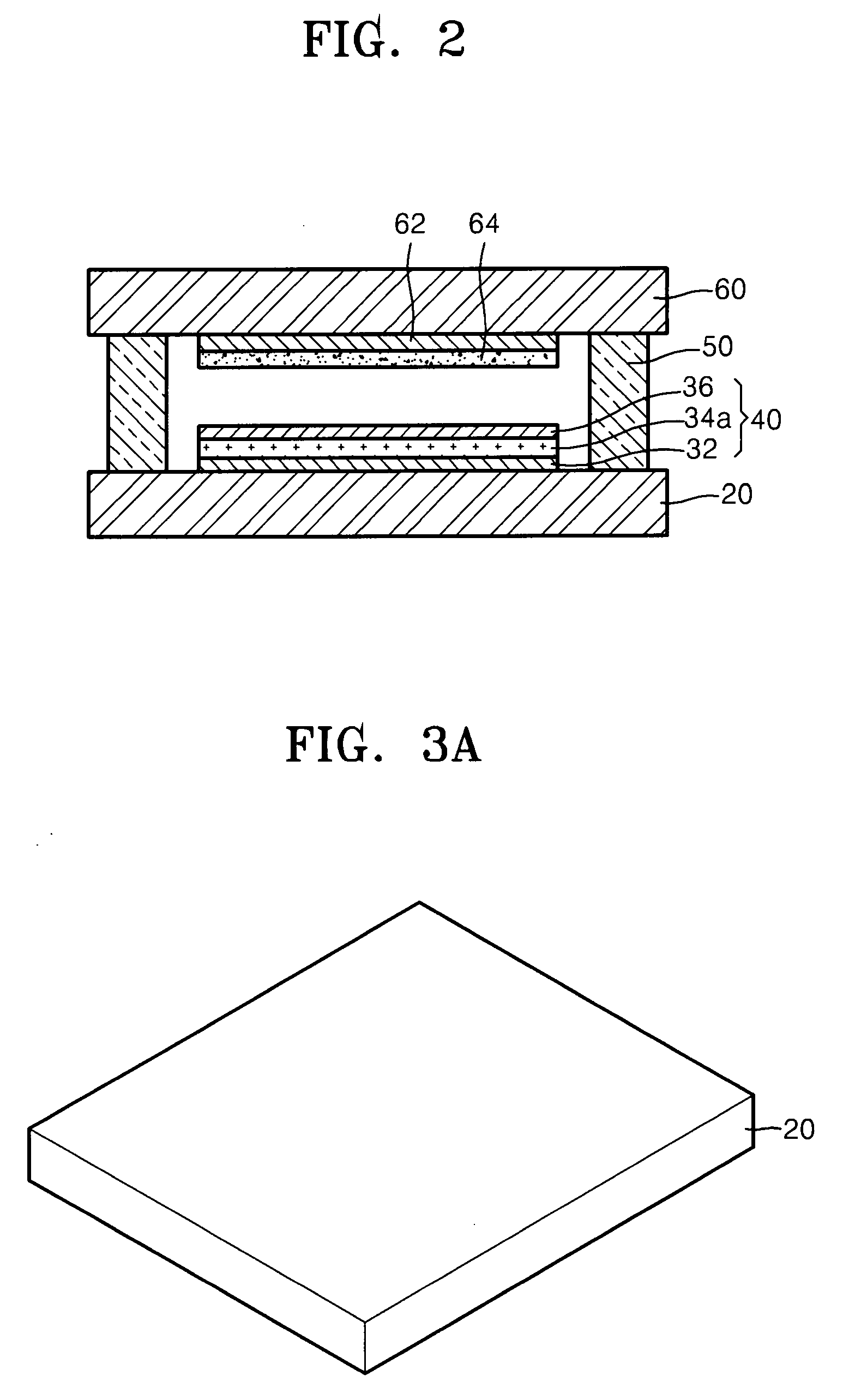

Method of forming semiconductor device having a capacitor

ActiveUS20100240191A1Avoid surface contaminationSolid-state devicesSemiconductor/solid-state device manufacturingSurface oxidationDielectric layer

A method of forming a semiconductor device includes forming a lower electrode layer on a substrate, forming a surface oxide layer on the lower electrode layer, partially removing the lower electrode layer to form a lower electrode, removing the surface oxide layer to expose the lower electrode, forming a capacitor dielectric layer on the lower electrode, and forming an upper electrode on the capacitor dielectric layer.

Owner:SAMSUNG ELECTRONICS CO LTD

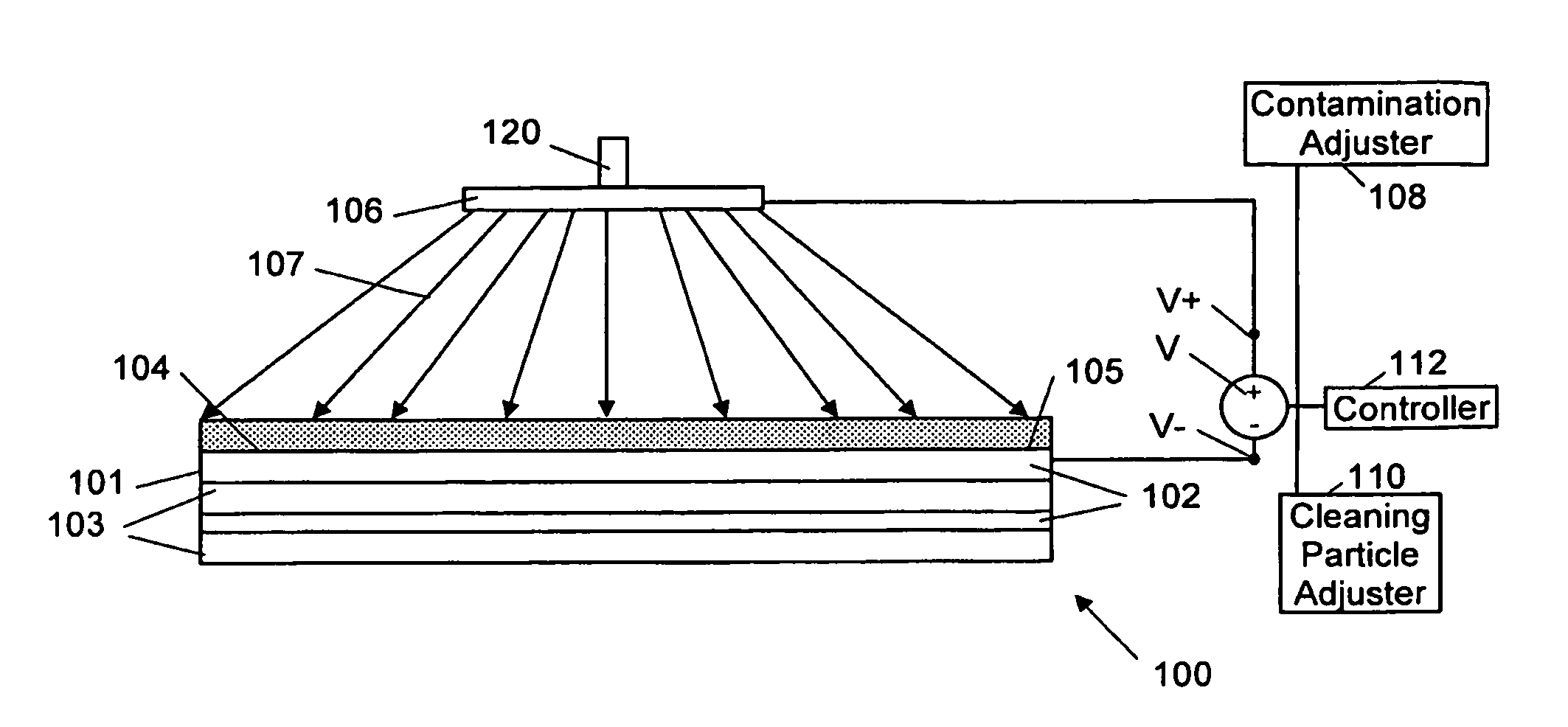

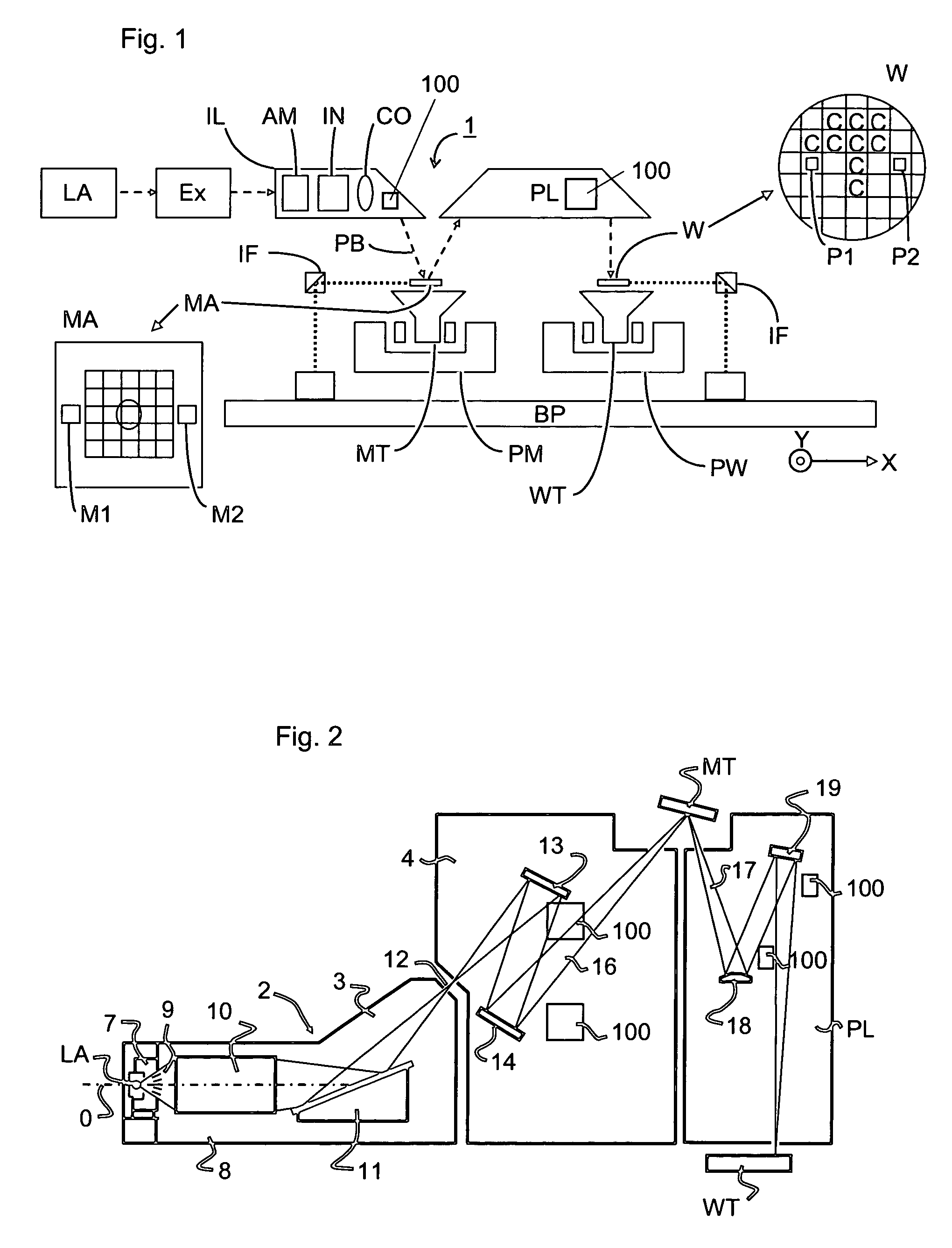

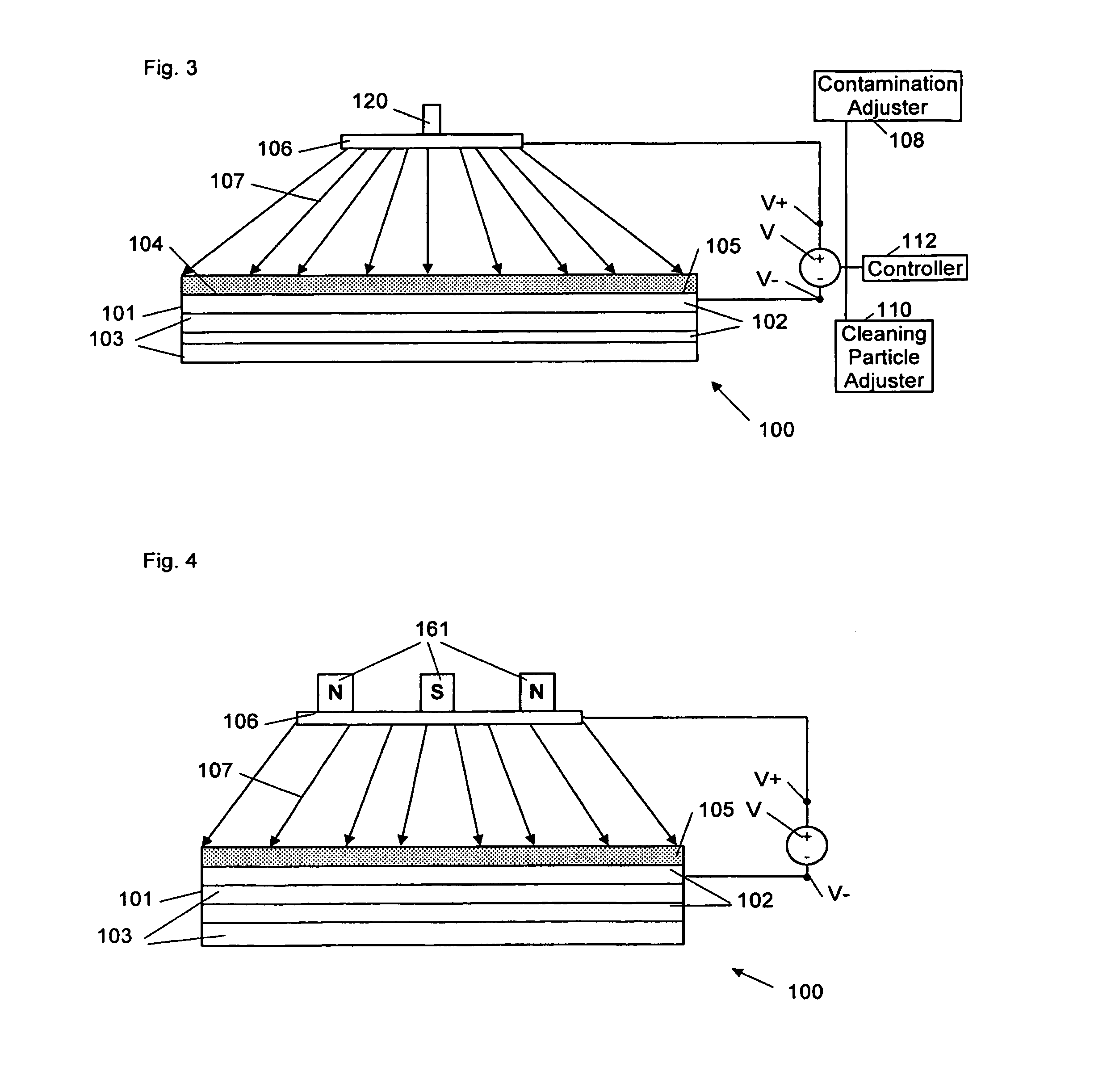

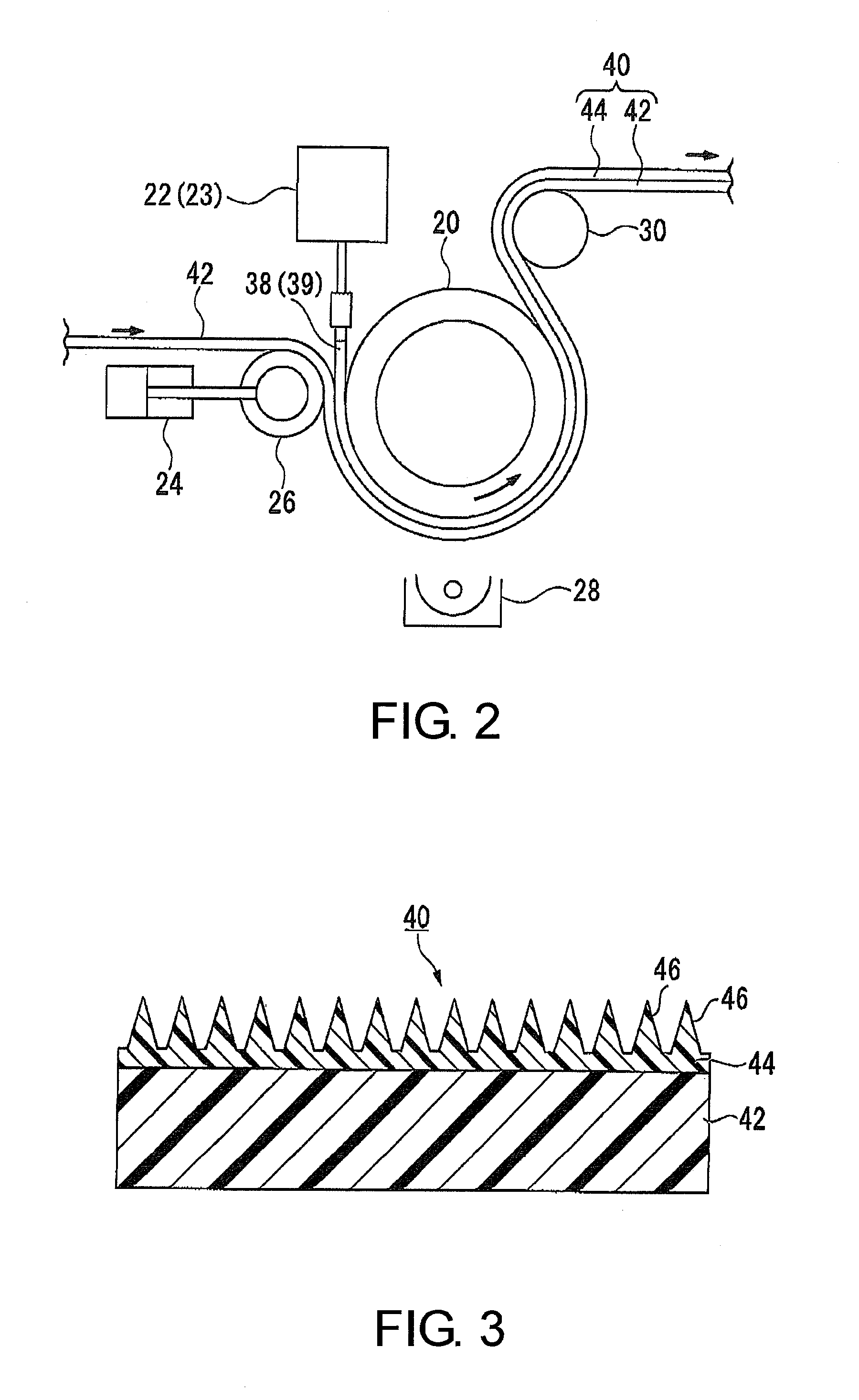

Method for cleaning a surface of a component of a lithographic projection apparatus, lithographic projection apparatus, device manufacturing method and cleaning system

ActiveUS7116394B2Control of removalAvoid surface contaminationInvestigating moving sheetsSemiconductor/solid-state device manufacturingContaminationBiomedical engineering

A cleaning system for removing contamination from at least a part of a surface of a component in a lithographic projection apparatus is disclosed. The cleaning system includes an electric field generator that generates an electric field to provide cleaning particles near the surface of the component.

Owner:ASML NETHERLANDS BV +1

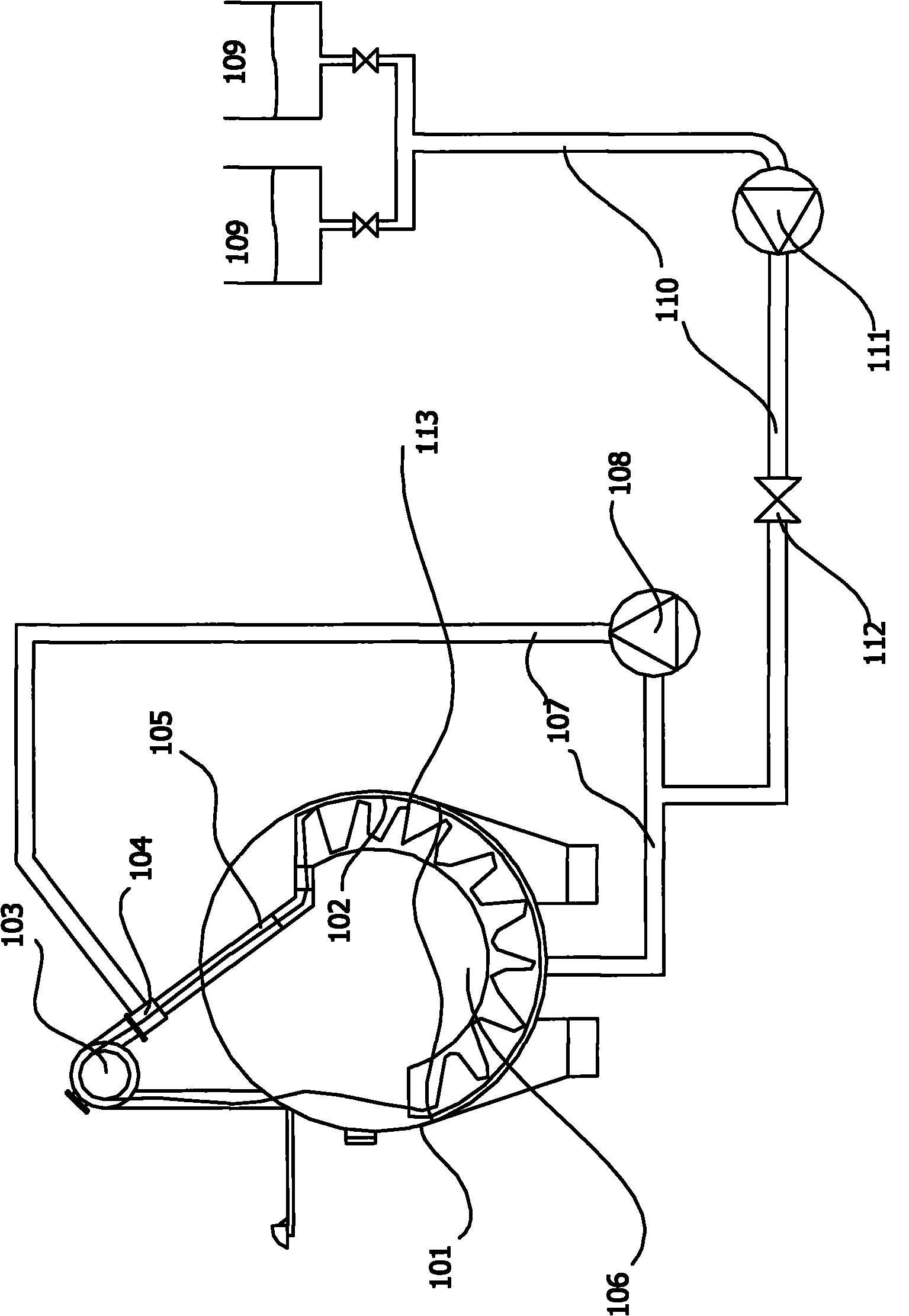

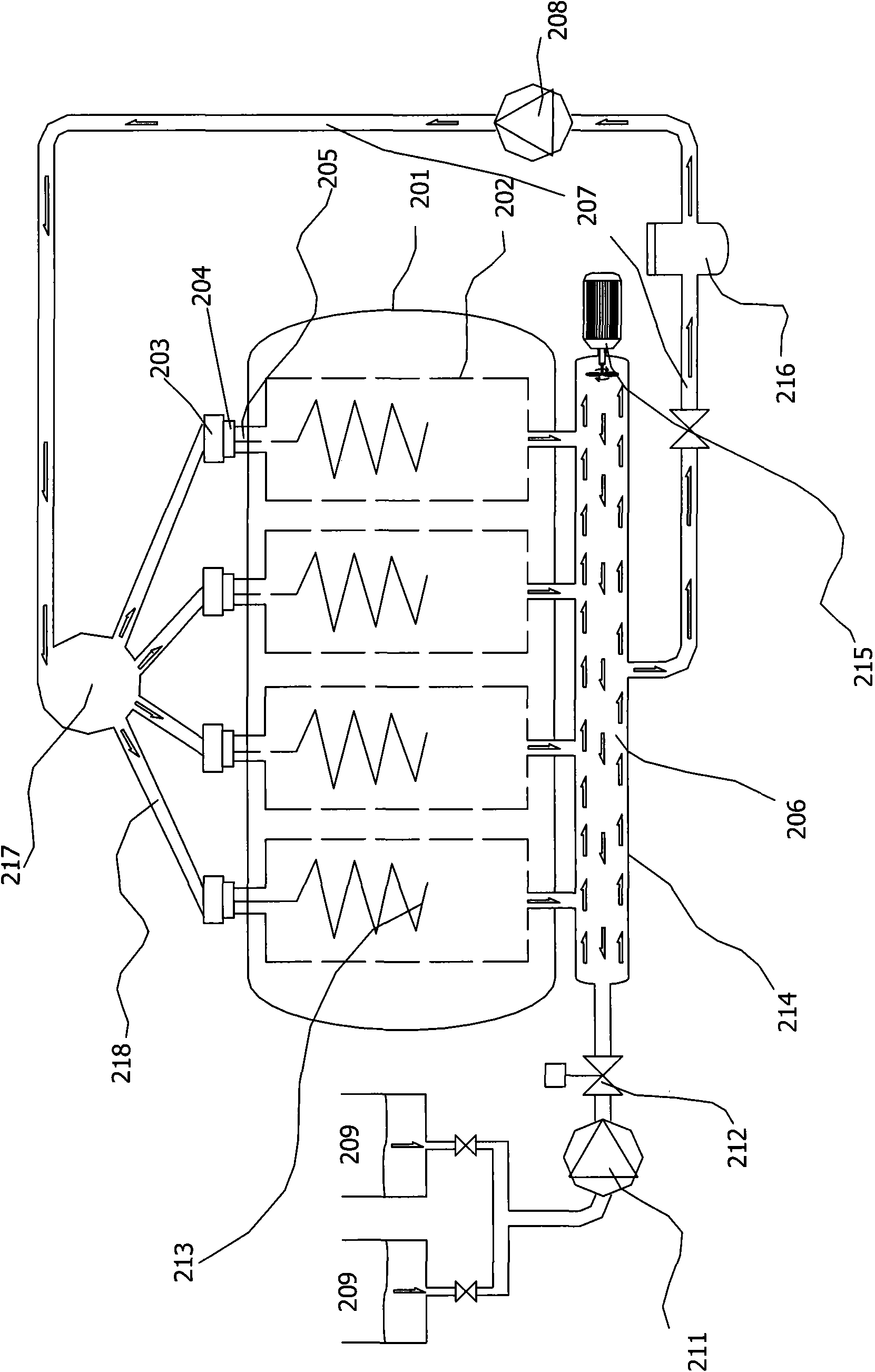

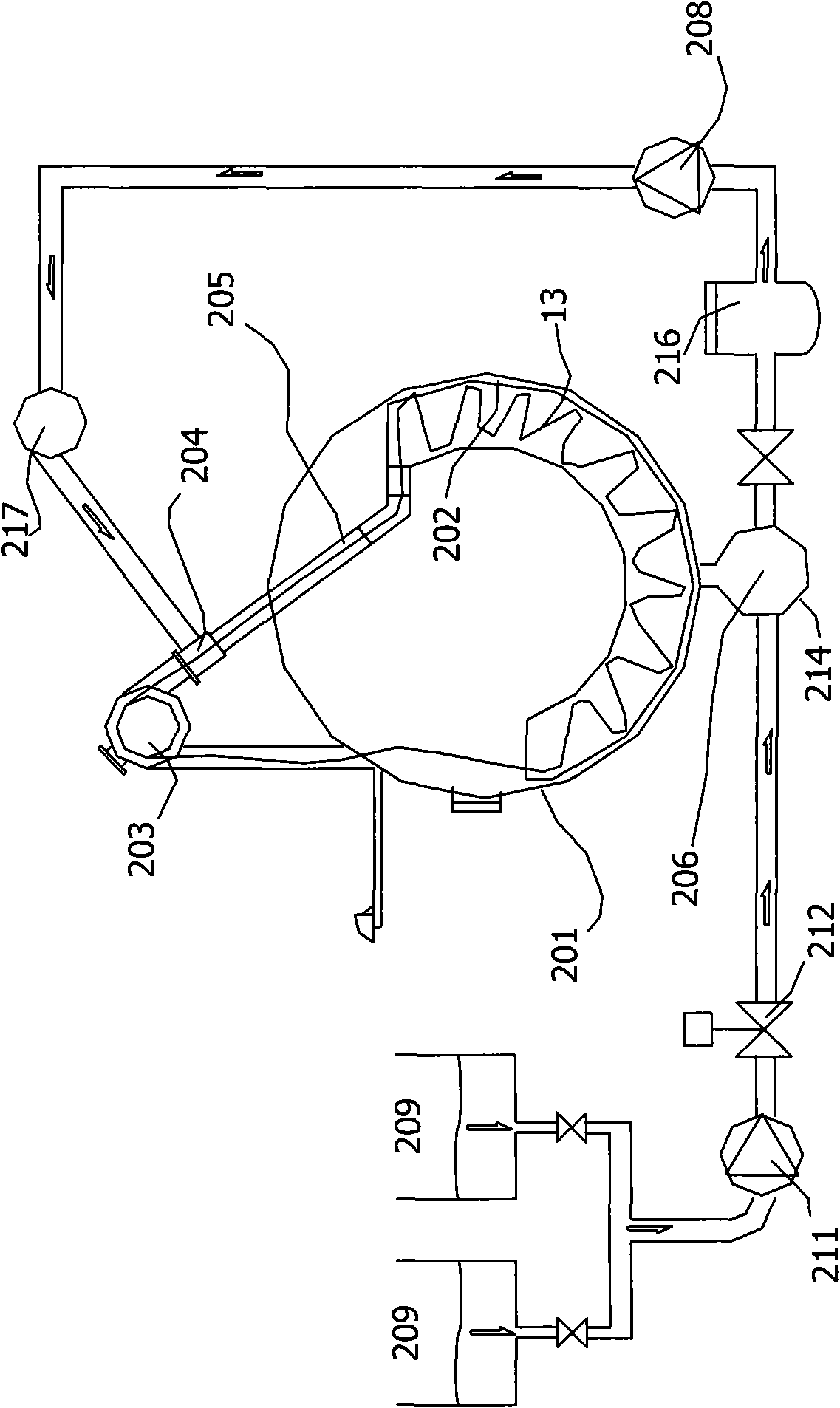

Overflow dyeing machine

InactiveCN101962887ASimple structureWell mixedTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsLiquid storage tankEngineering

The invention discloses an overflow dyeing machine. The overflow dyeing machine comprises a main machine body (201), wherein a dye vat (202) is arranged in the main machine body (201); a cloth lifting pulley (203) is arranged outside the main machine body (201); nozzles (204) are arranged over the main machine body (201); the outlet of the dye vat (202) is communicated with the inlets of the nozzles (204) through a circulation pipeline (207); the outlet of a chemical material vat (209) is communicated with the circulation pipeline (207); a liquid storage tank (214) is also arranged on the circulation pipeline (207); the liquid storage tank (214) is communicated with the outlet of the chemical material vat (209) and the outlet of the dye vat (202) respectively; and a main pump (208) is arranged on the circulation pipeline (207) which connects the outlet of the liquid storage tank (214) and the inlets of the nozzles (204). The overflow dyeing machine provided by the invention has the advantages that: the structure is simple; a dyeing liquid is uniformly mixed; due to the liquid supply balance among the plurality of nozzles, surface contamination of a fabric and blockage of the nozzles is effectively prevented and dyeing is more uniform; the working efficiency is improved; and the technical time is shortened.

Owner:田立法

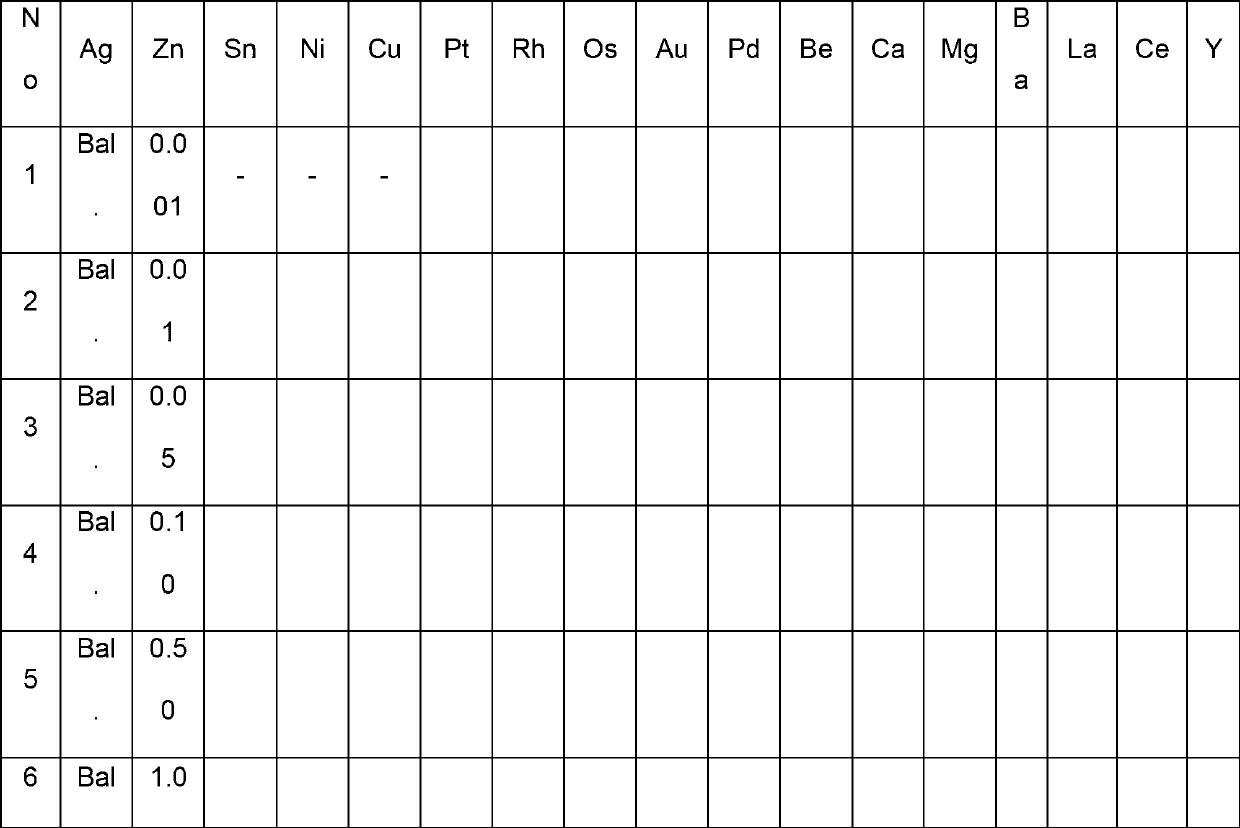

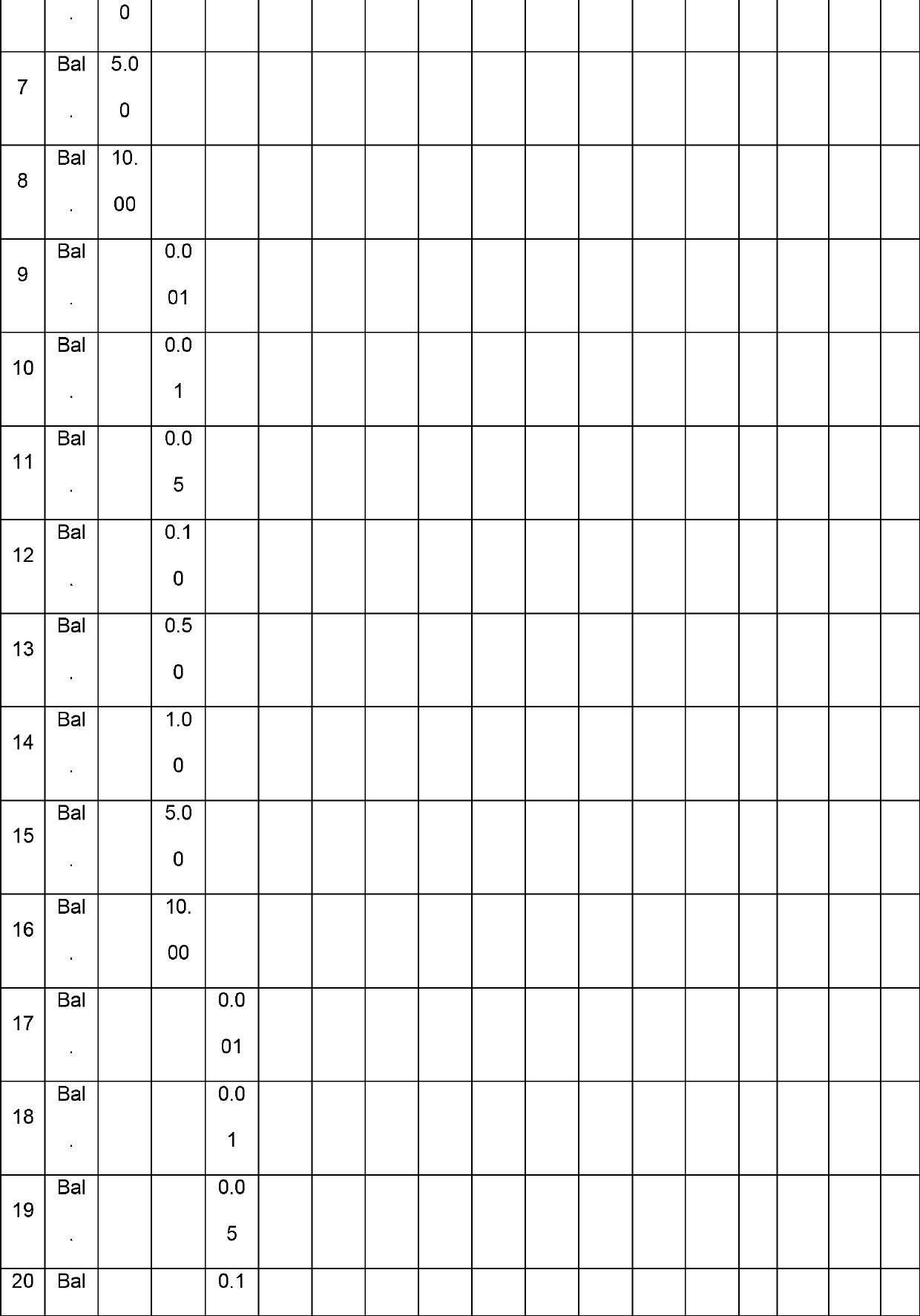

Silver bond wire for semiconductor devices

InactiveCN103131885AImprove productivityAvoid surface contaminationSolid-state devicesDrawing profiling toolsZincSemiconductor

A bonding wire for semiconductor devices and a method of manufacturing the same are disclosed. The bonding wire for semiconductor devices according to the present invention includes at least one selected from the group consisting of zinc (Zn), tin (Sn), and nickel (Ni) at 5 ppm to 10 wt%, and the remainder including silver (Ag) and other inevitable impurities.

Owner:赫劳斯材料工艺有限及两合公司

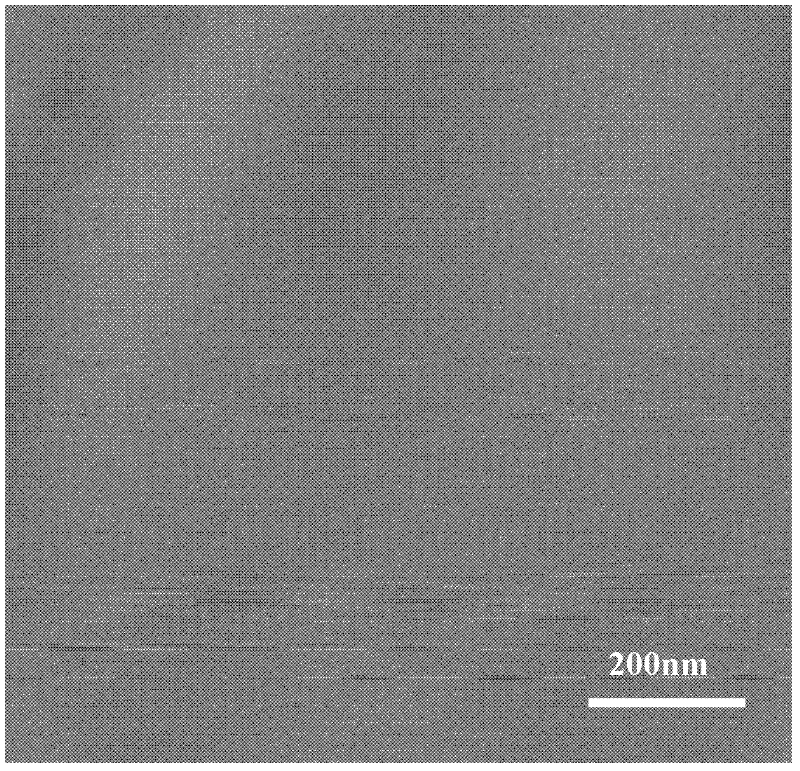

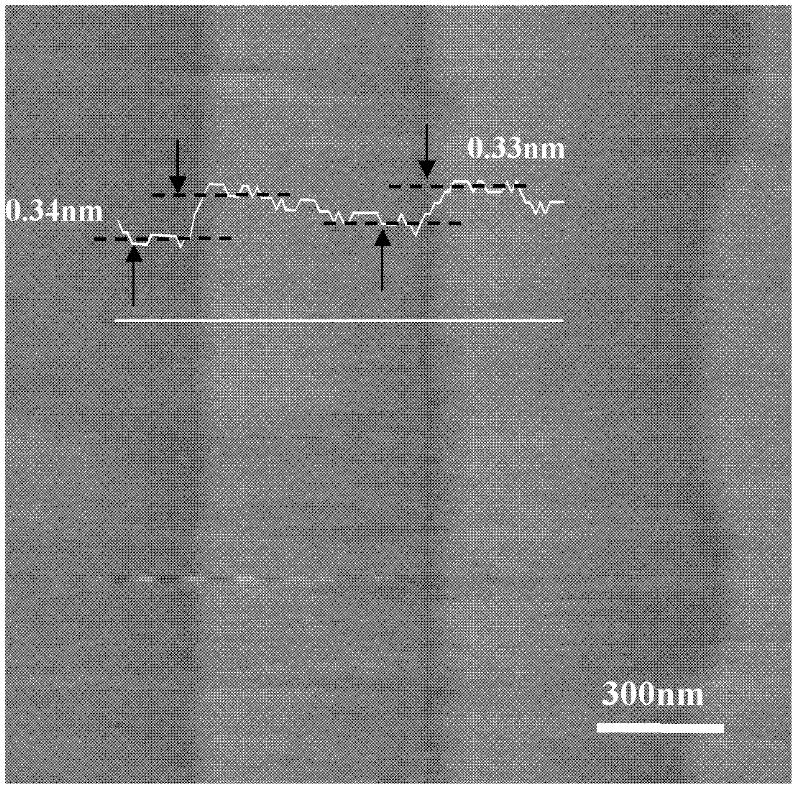

Hexagonal boron nitride substrate provided with single atomic layer step and preparation method and application thereof

ActiveCN102336588AAvoid surface contaminationAvoid pollutionAfter-treatment detailsNanotechnologyHydrogenHexagonal boron nitride

The invention provides a hexagonal boron nitride (hBN) substrate provided with a single atomic layer step and a preparation method thereof, the surface of the hBN substrate undergoes cleavage and a fresh cleavage surface is obtained, then the hexagonal boron nitride is etched via a hydrogen under a high temperature, and a controllable and regular single atomic layer step is obtained. An anisotropy etching effect of the hydrogen upon the hBN is used, etching rate and etching degree are controlled via adjustment of hydrogen rate, annealing temperature, and annealing time, and purpose of etchinga regular single atomic layer step can be reached. The preparation technology is compatible with the preparation technology for grapheme via a chemical vapour deposition method, and can be used for preparation of grapheme nanometers. The hexagonal boron nitride substrate is mainly applied in novel grapheme electronic devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

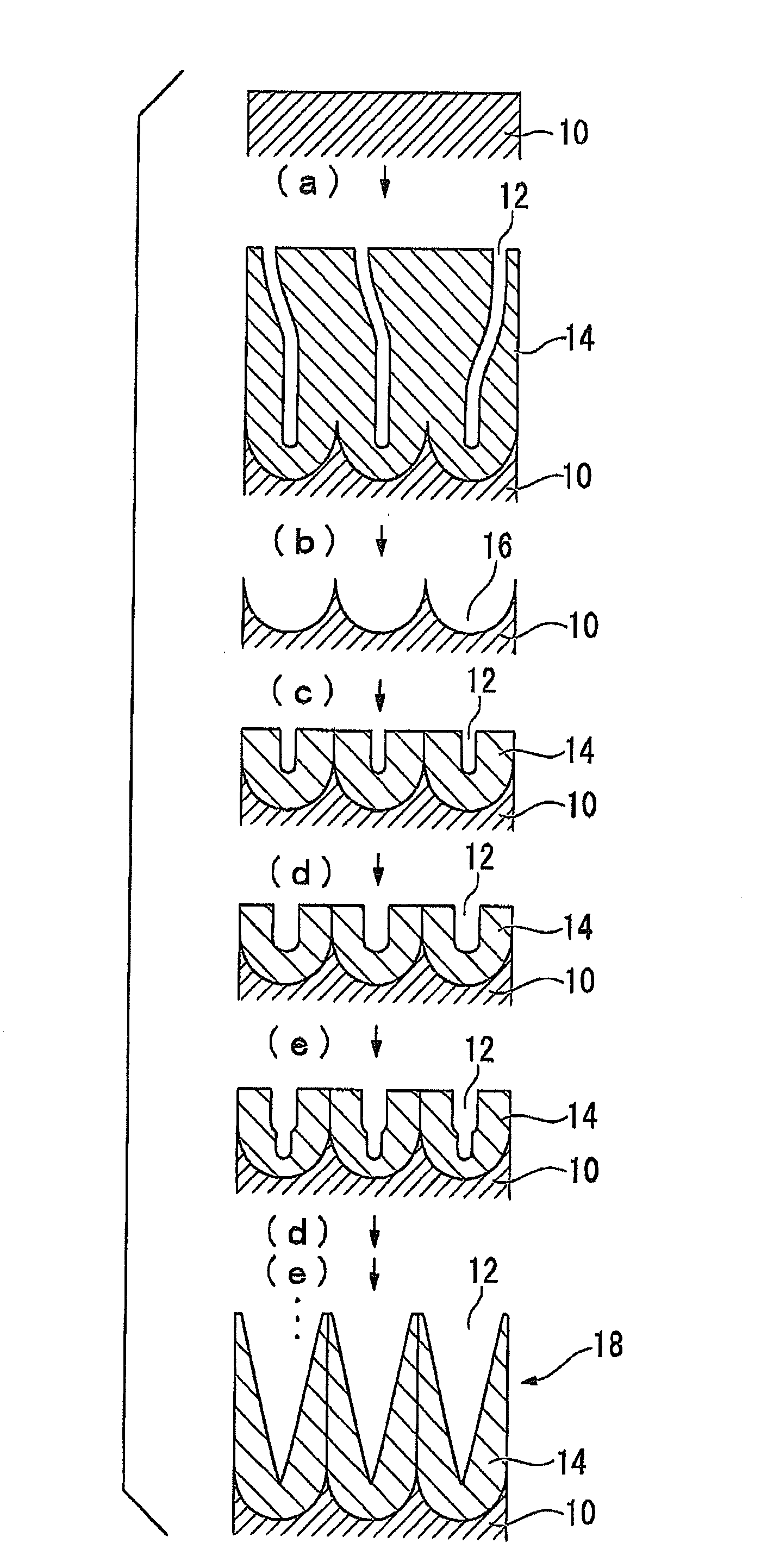

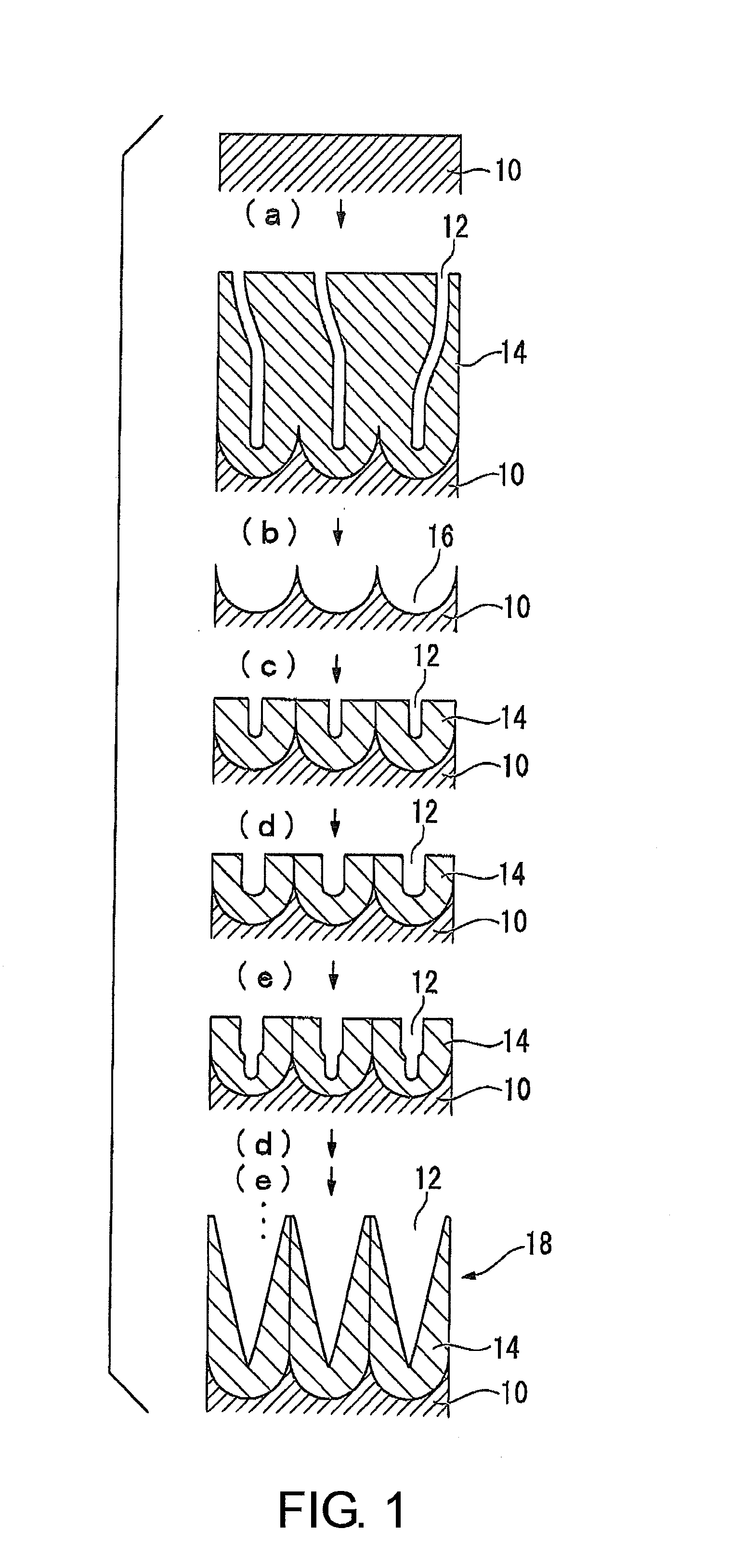

Method for producing product having uneven microstructure on surface thereof, mold release treatment method, and active energy ray curable resin composition for mold surface release treatment

ActiveUS20130075962A1Improve accuracyAvoid surface contaminationLamination ancillary operationsLaminationIrradiationMaterials science

The producing method includes: (I) providing an active energy ray curable resin composition for mold surface release treatment between a mold having uneven microstructure on its surface and a substrate, and after curing the resin composition by irradiation with an active energy ray, peeling off the substrate together with a cured article of the active energy ray curable resin composition from the surface of the mold, thereby performing a release treatment to the surface of the mold; and (II), after step (I), providing an active energy ray curable resin composition for shaping between the substrate and the mold, the surface of which has been treated by the release treatment, and after curing the resin composition by an active energy ray, peeling off the substrate together with a cured article of the active energy ray curable resin composition for shaping from the surface of the mold.

Owner:MITSUBISHI CHEM CORP

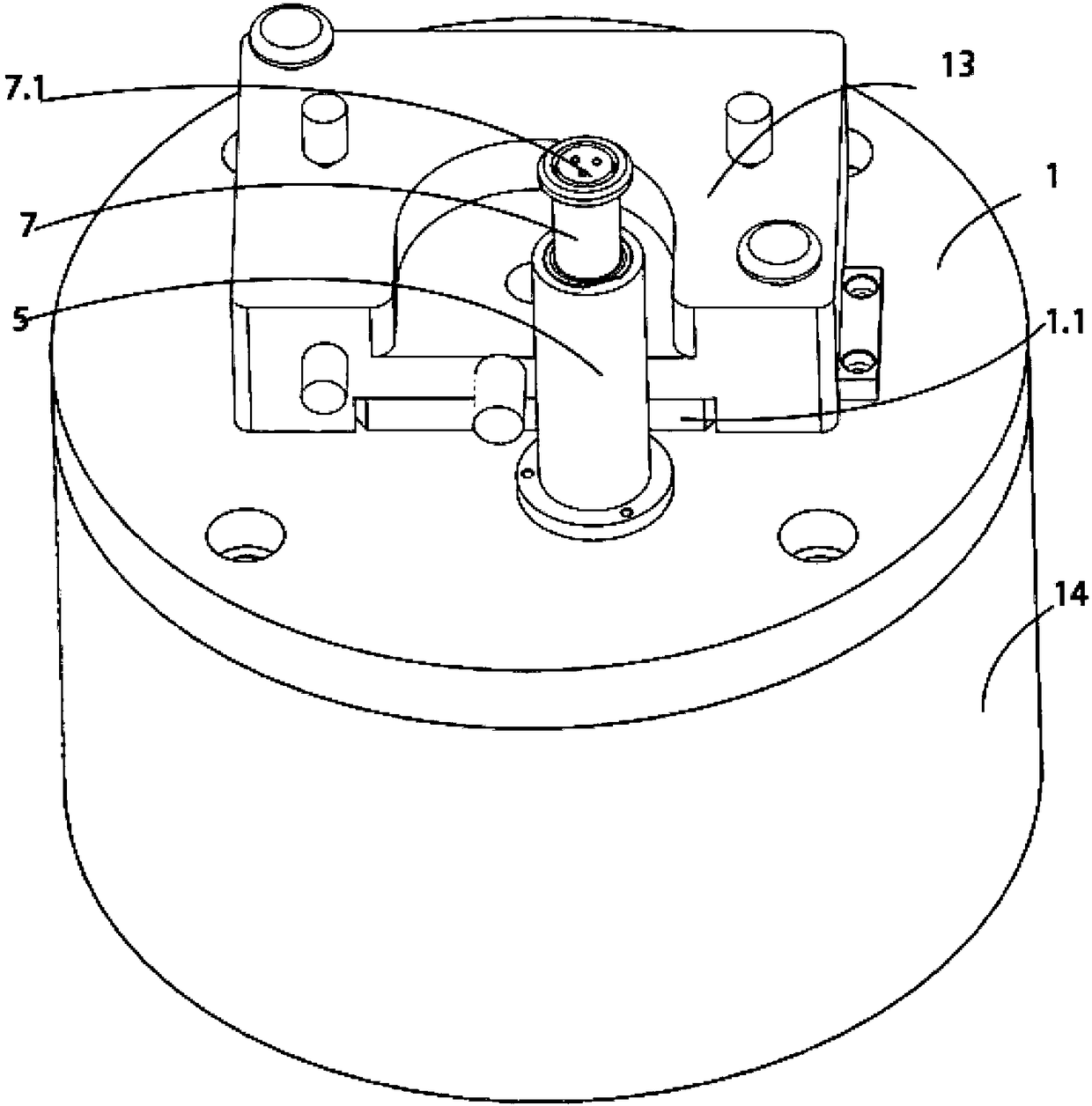

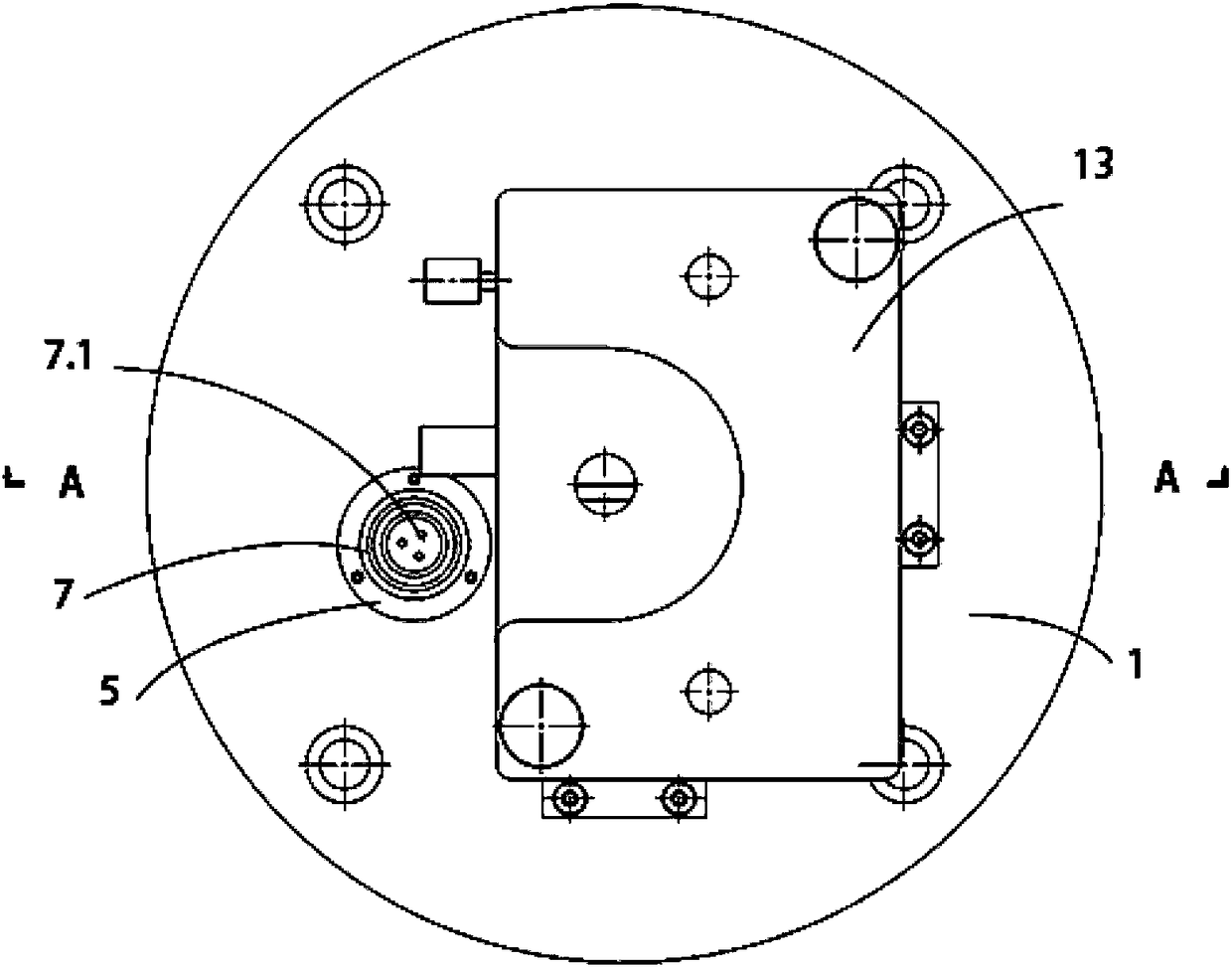

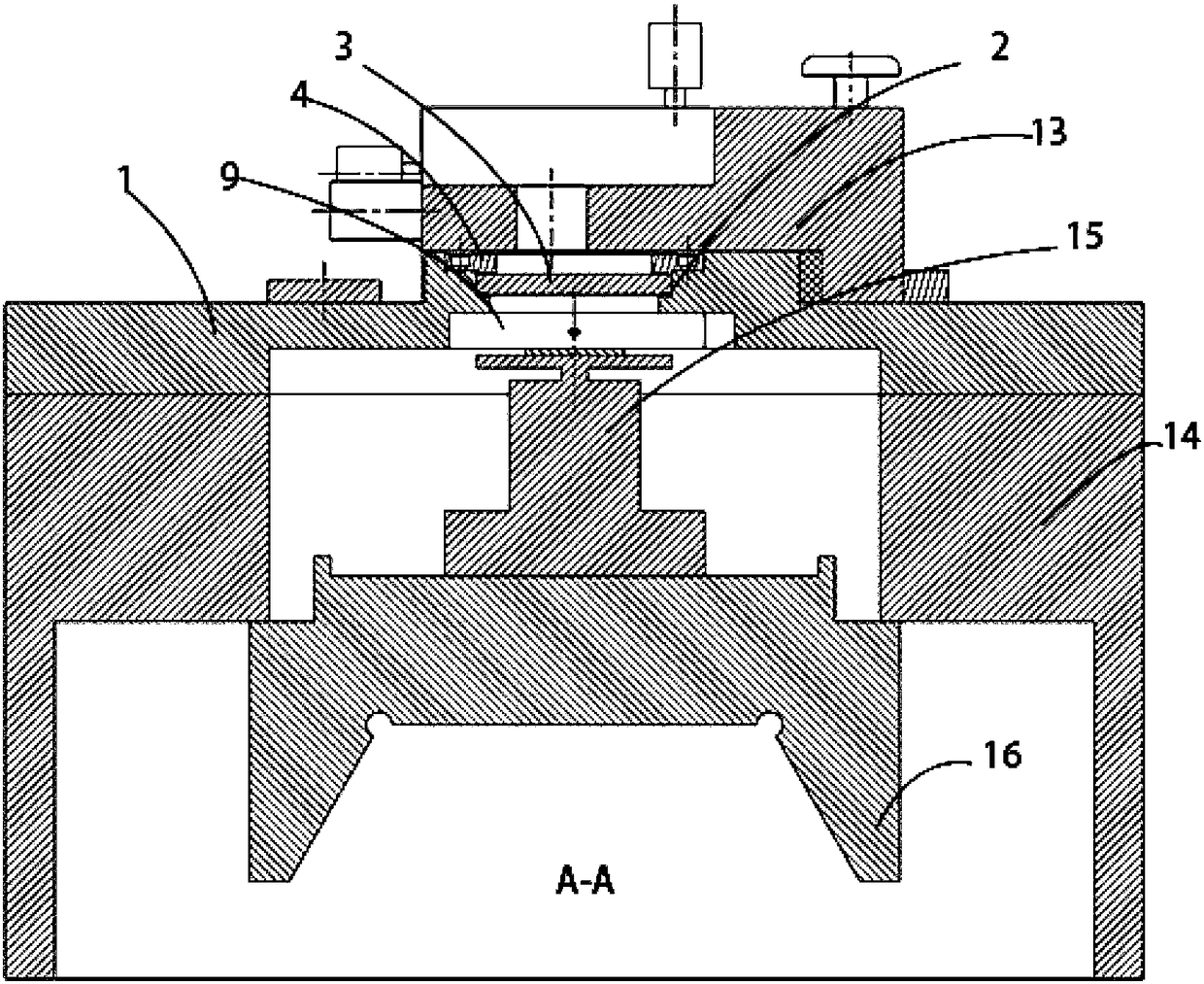

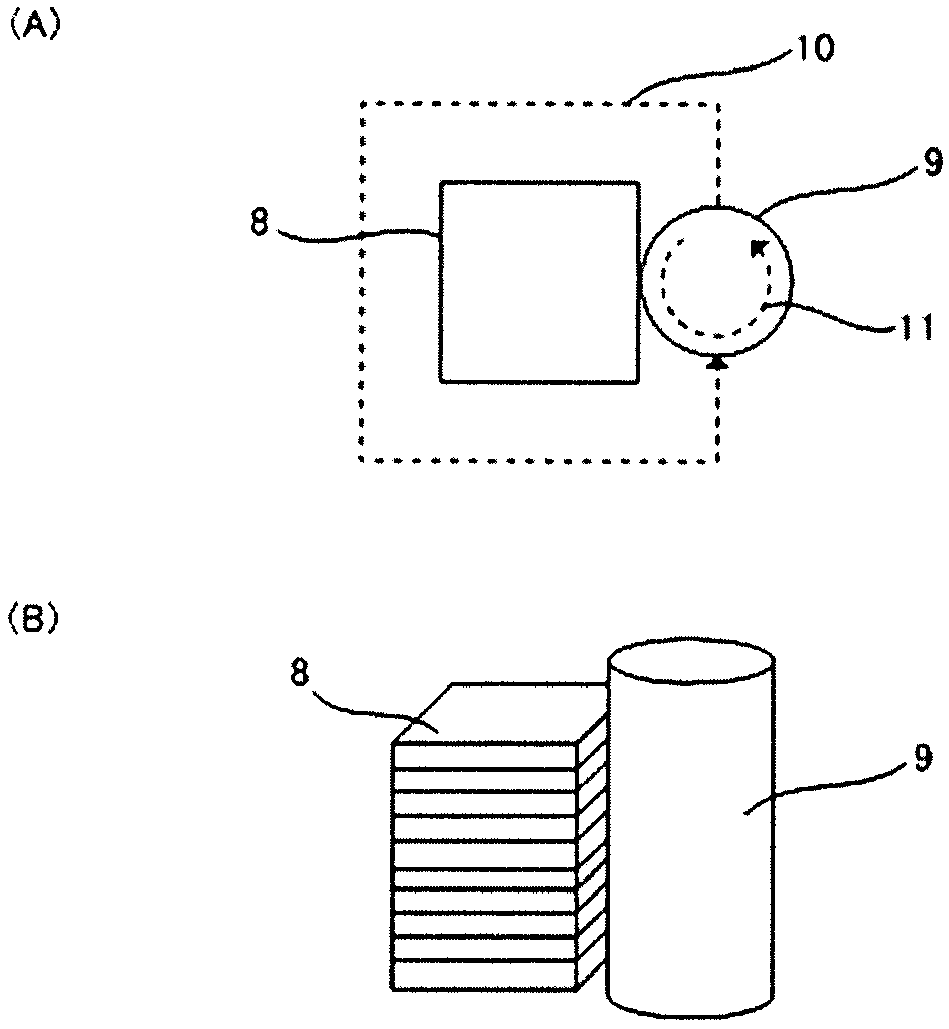

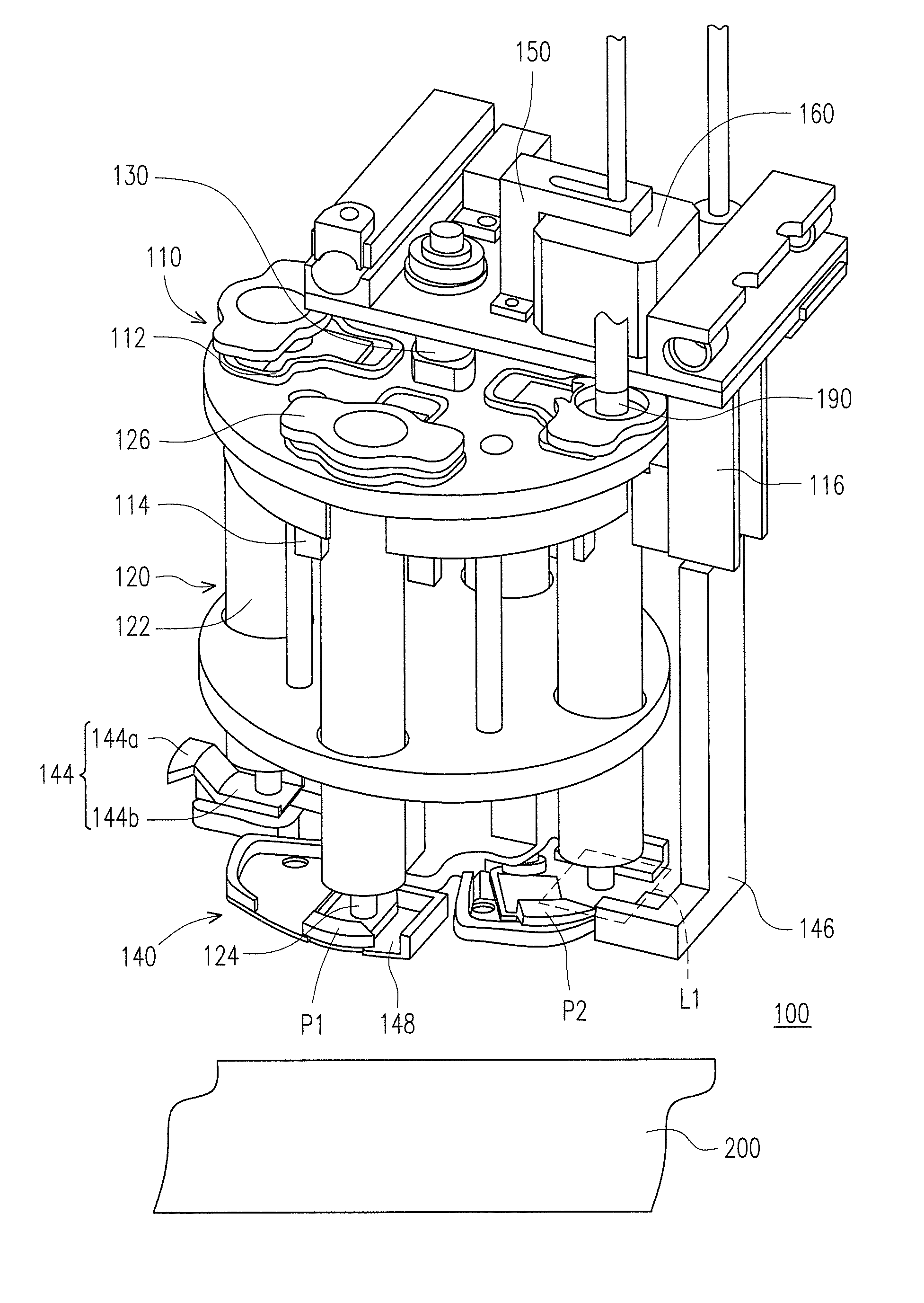

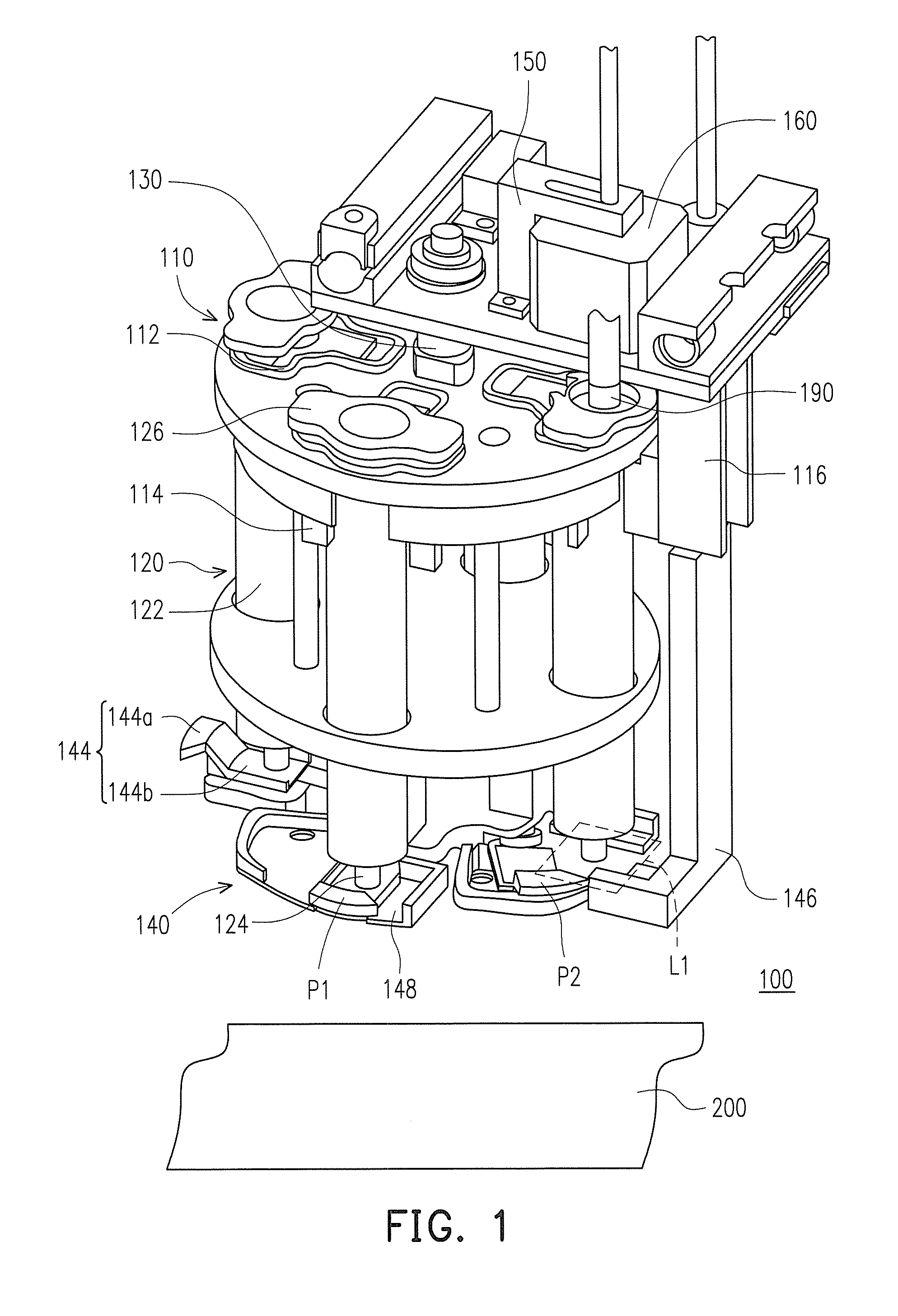

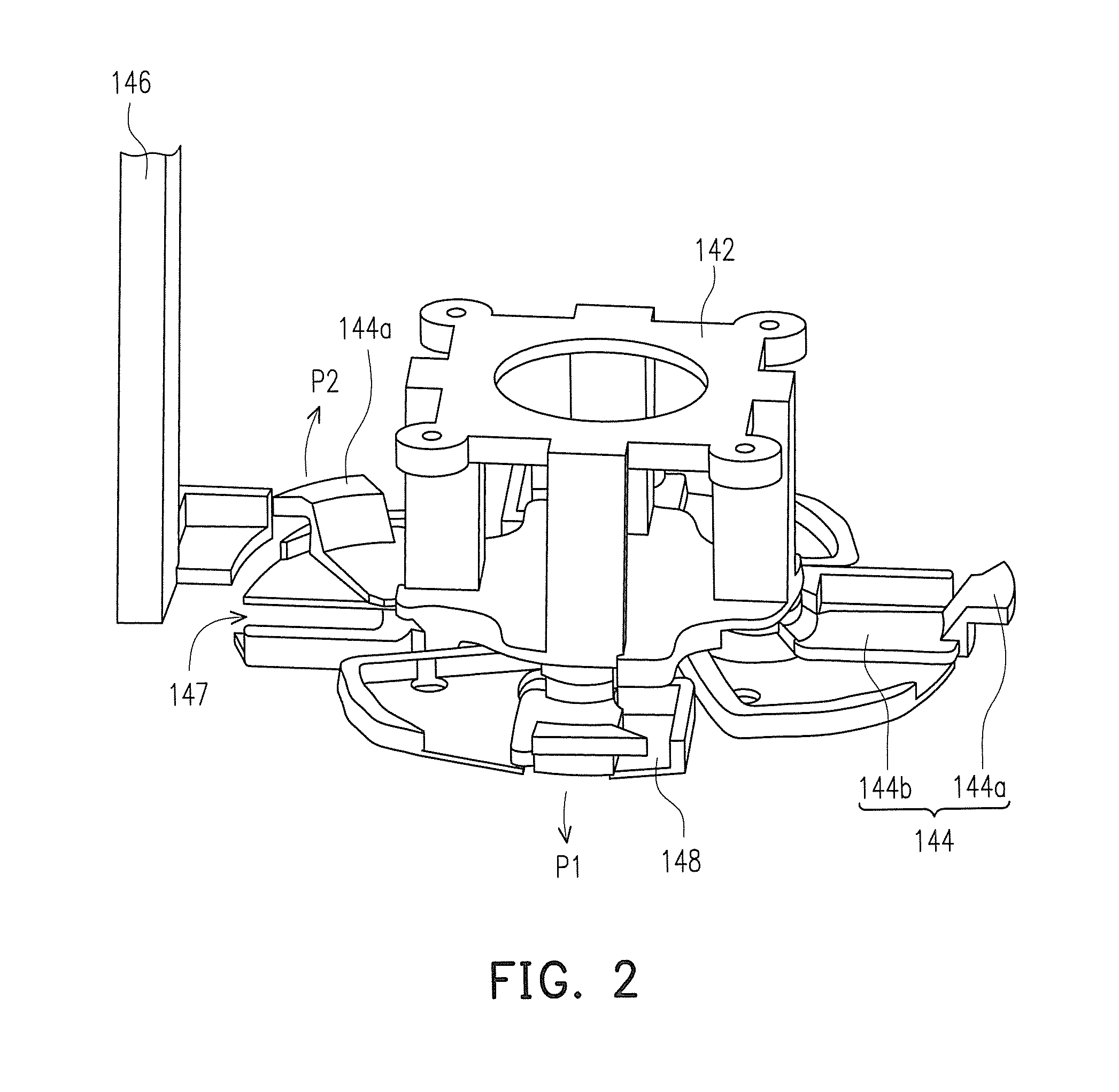

Environment controllable type atomic force microscope-based numerical control rotary type probe switching device

ActiveCN108427016AEffective positioningPrecise positioningScanning probe microscopyNumerical controlEngineering

The invention discloses an environment controllable type atomic force microscope-based numerical control rotary type probe switching device. The environment controllable type atomic force microscope-based numerical control rotary type probe switching device comprises a cavity upper cover and a probe switching structure. An irregular rectangular boss, an inner groove, a rectangular light window structure and a sealing flange structure are arranged on the cavity upper cover. The environment controllable type atomic force microscope-based numerical control rotary type probe switching device has the following prominent advantages: 1) due to the design of the irregular rectangular boss, the inner groove, the rectangular light window structure and the sealing flange structure, the internal working space of the cavity is obviously increased and the space utilization rate is effectively increased; 2) due to asymmetrical cooperative design of the inner groove, an L-shaped transitional plate connecting structure, a probe bracket and a probe carrying block, the laser vertical focusing height and the focusing position are effectively guaranteed; and 3) efficient and accurate switching of 8 probes with different functions is realized through program control and in different working environments of vacuum, atmosphere, liquid and the like, so that the functions of surface shape scanning, Raman spectrum analysis, microscopic friction wear and friction coefficient measurement are realized in situ in the same working environment.

Owner:SOUTHWEST JIAOTONG UNIV

Sexual propagation method of bletilla striata

InactiveCN104429865ARealize artificial large-scale breedingImprove survival rateCultivating equipmentsSoilless cultivationBletilla striataContamination rate

The invention provides a sexual propagation method of bletilla striata. The sexual propagation method of bletilla striata particularly comprises the steps of processing of capsules, preparation of nutrients, inoculation and cultivation, and bottle out domestication, and is characterized in that in the step of processing of capsules, an alcohol lamp drying mode replaces a filter paper sucking dry mode in the prior art; in the step of preparation of nutrients, combination of banana slurry and humus is adopted; in the step of inoculation and cultivation, only inoculation, germination cultivation and strong seedling cultivation steps are included, the conventional enlargement cultivation process in an existing tissue culturing technology is omitted, and the process is simplified and the cost is lowered while the purposes are achieved; in the step of bottle out domestication, cultivation is performed through humus in a greenhouse, domestication is finished under the condition of controlling the relative humidity, temperature and shading rate, and qualified bletilla striata seedlings are obtained. Bletilla striata seeds are used for scale seedling culturing, the survival rate is high, manual scale propagation of bletilla striata is achieved, and the obtained bletilla striata seedlings are low in contamination rate, high in differentiation rate and stable in inheritable character.

Owner:湖北济世药业有限责任公司 +1

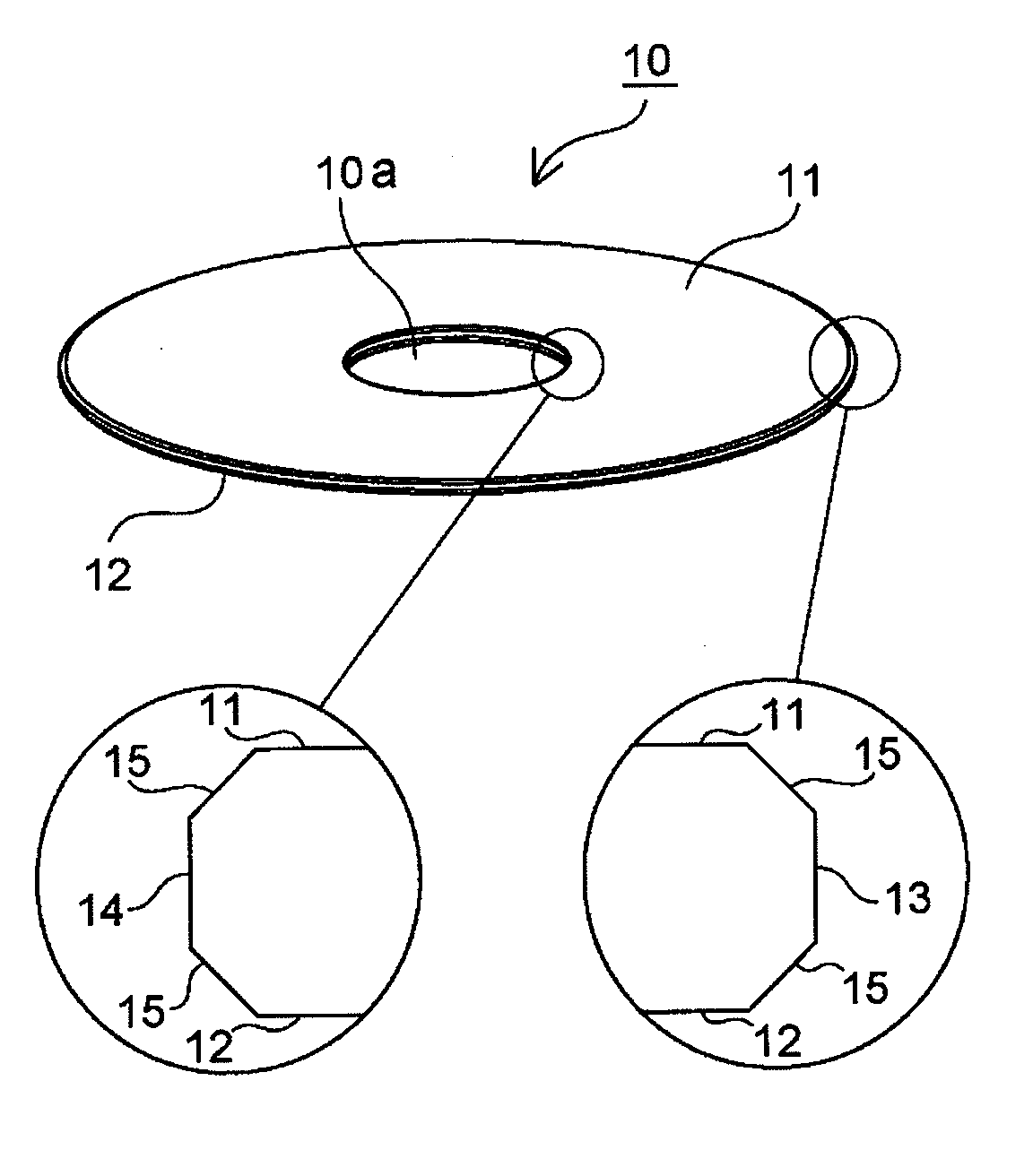

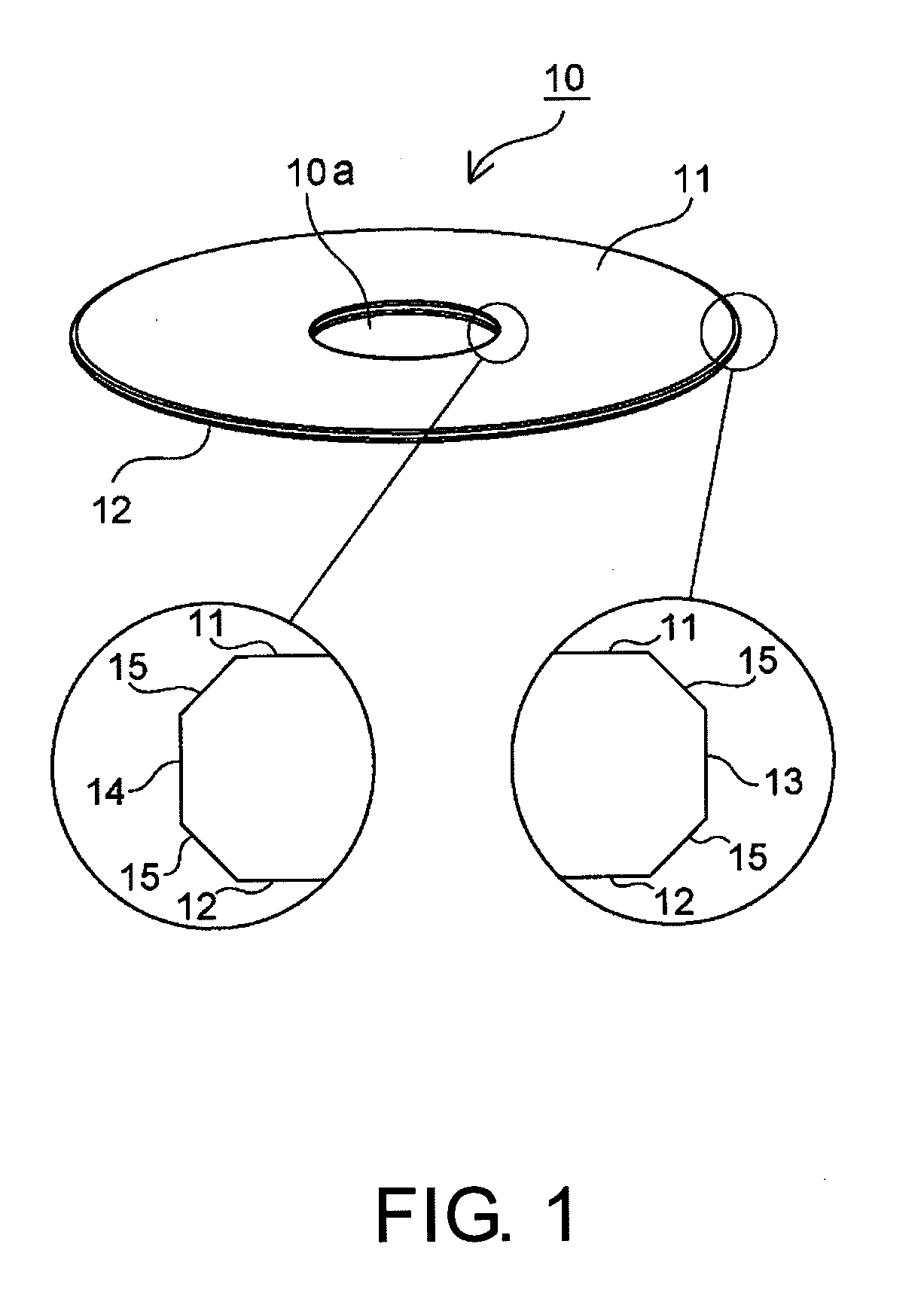

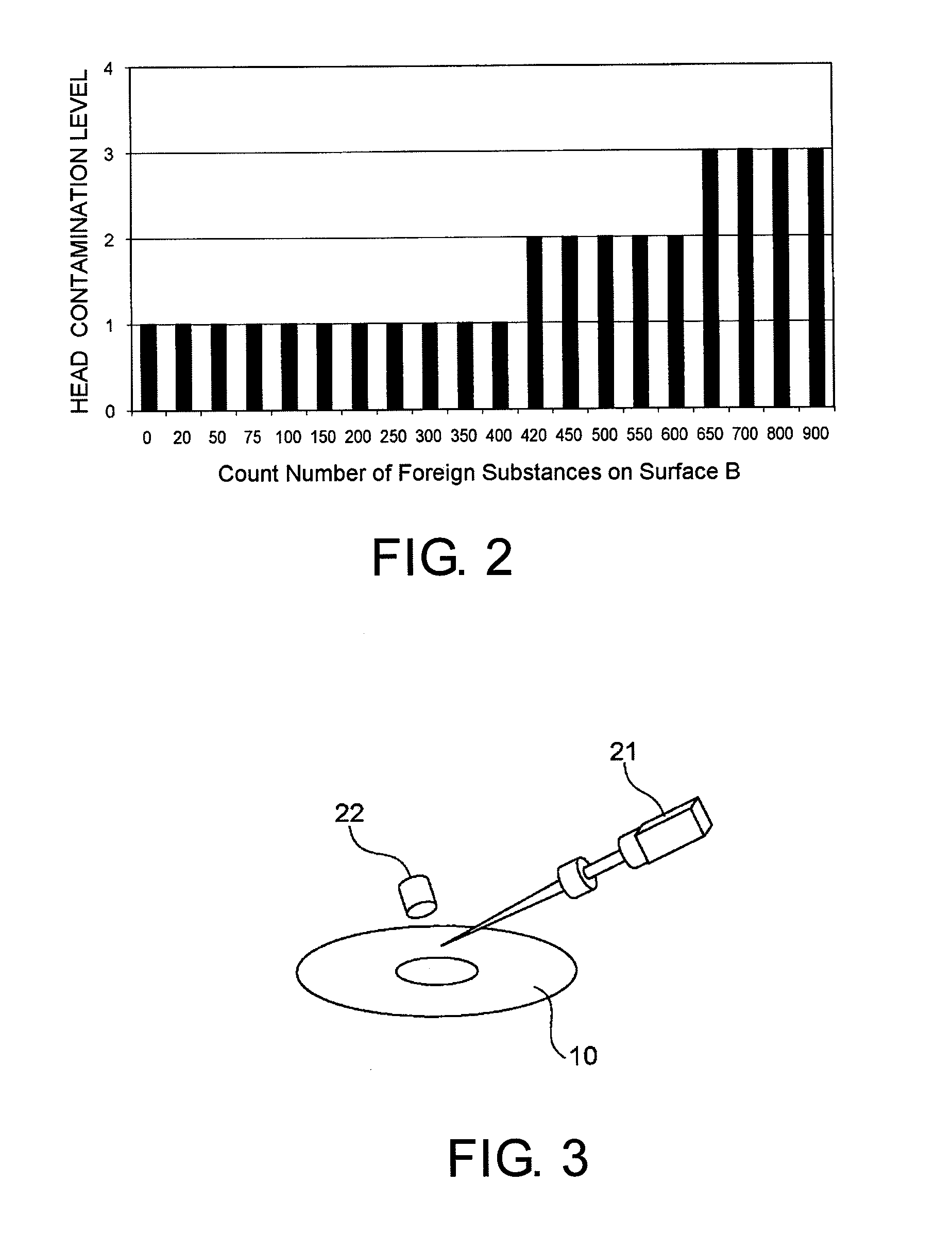

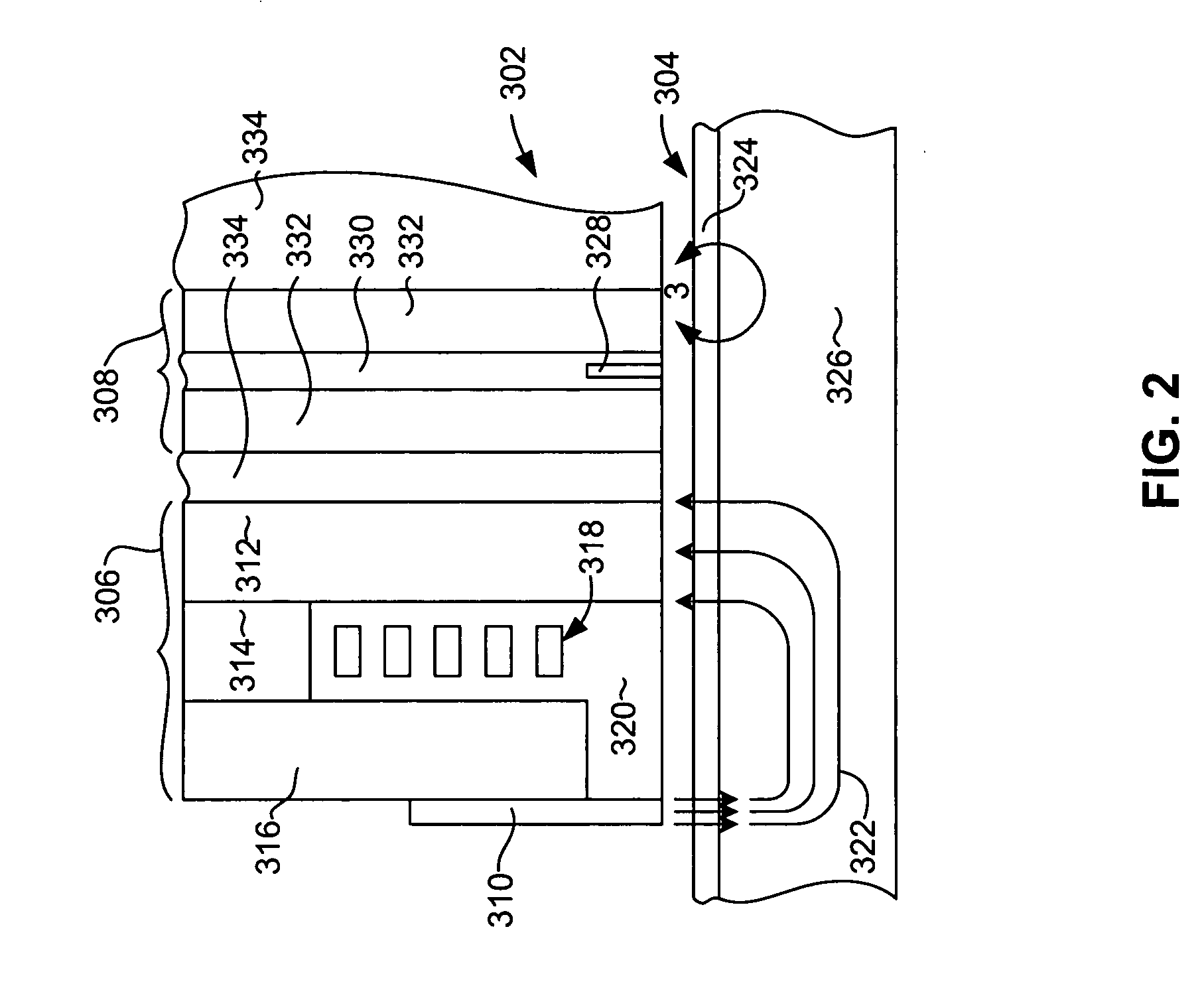

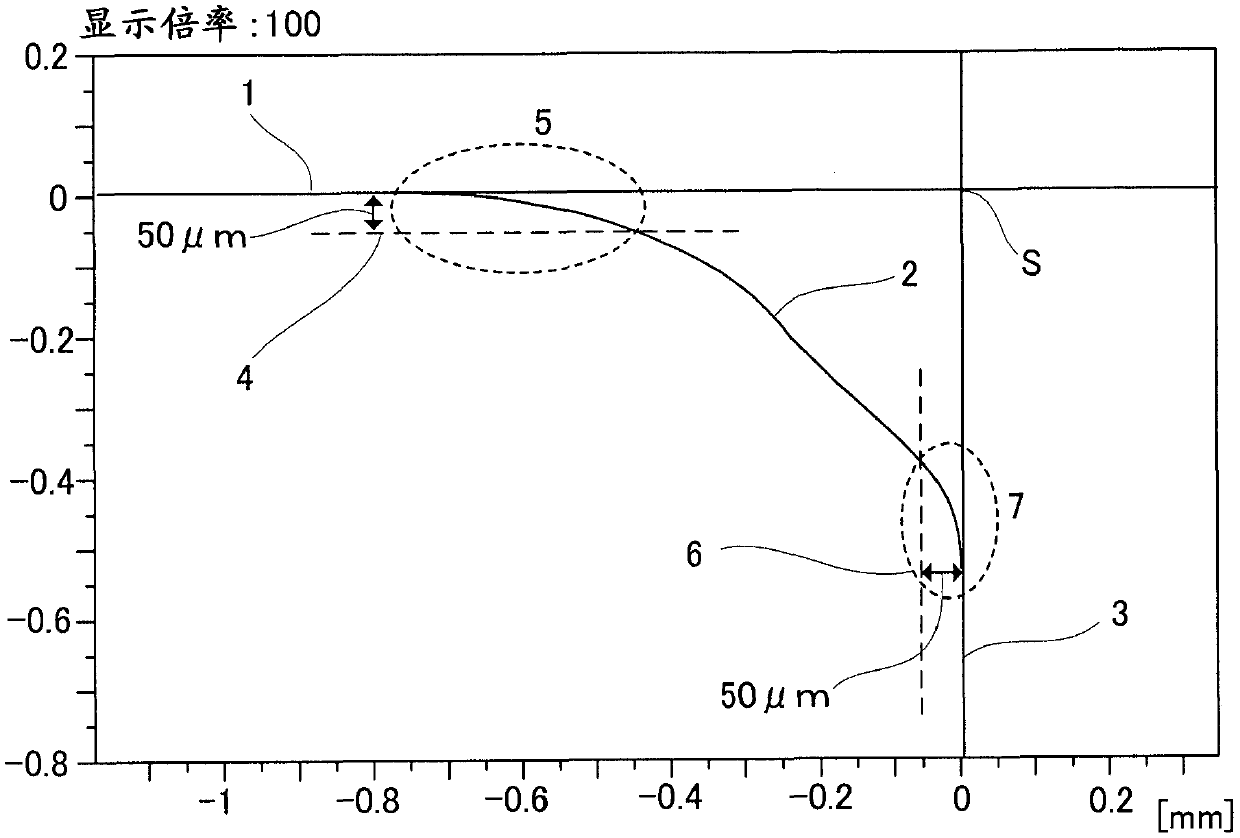

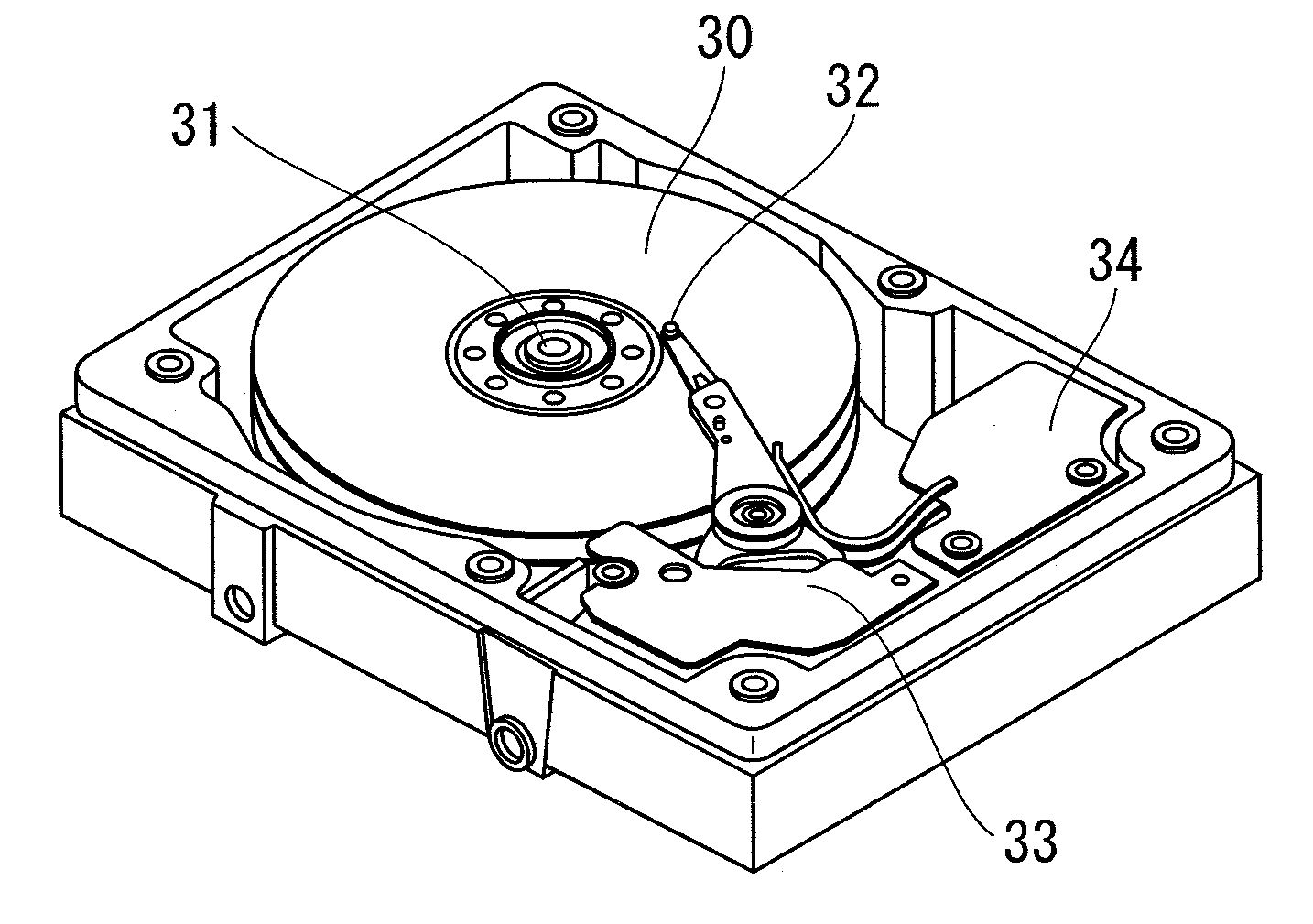

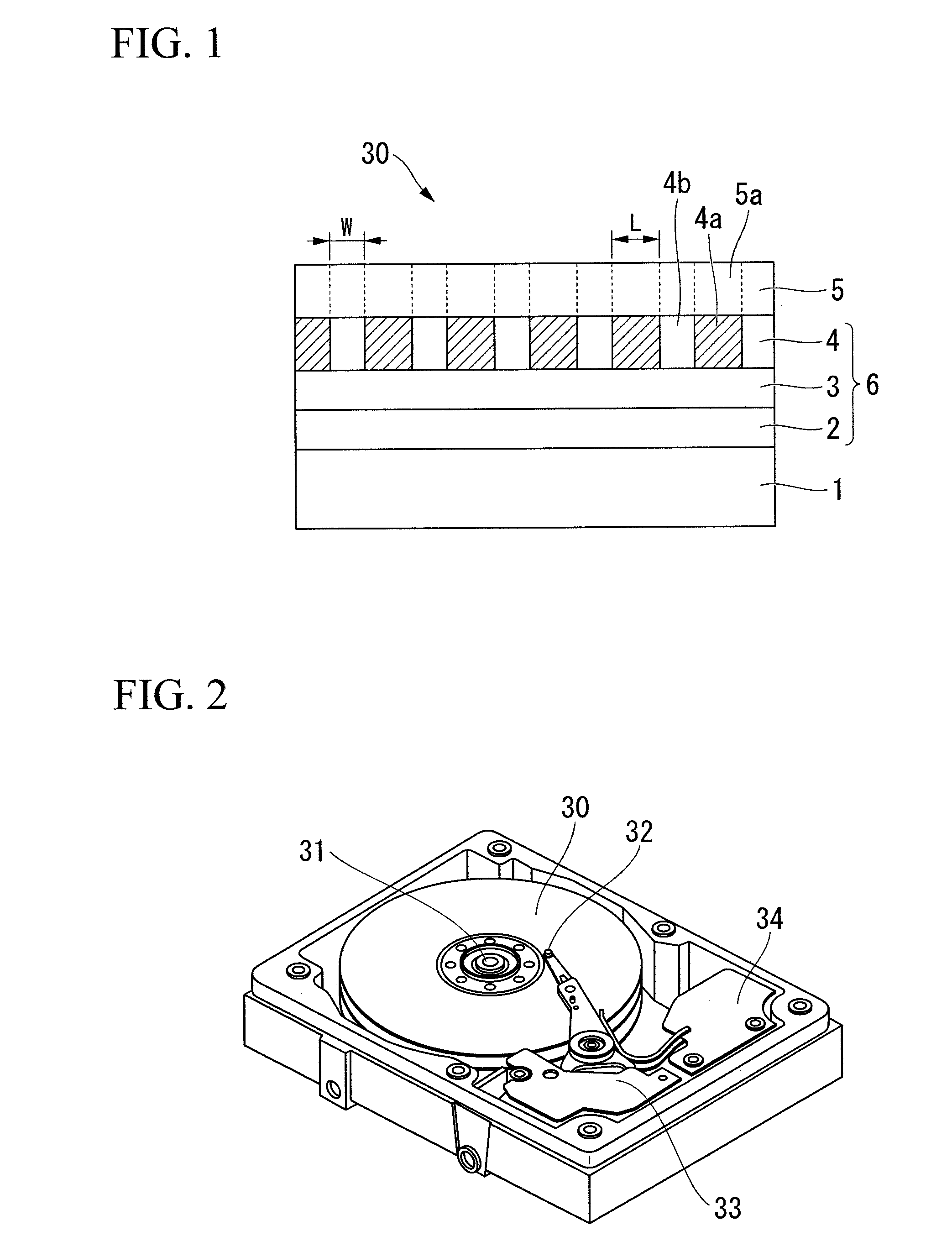

Magnetic disk substrate and magnetic disk

InactiveUS20100081013A1Prevent elutionAvoid surface contaminationMagnetic materials for record carriersRecord information storageForeign matterImage resolution

In a magnetic disk substrate being annular and having a first and a second main surface, (1) surface roughness measured by an atomic force microscope having a resolution of 256×256 pixels per 2 μm square and / or (2) the number of foreign substances detected to have sizes of 0.1 μm or more and 1.0 μm or less upon detection of scattered light from the magnetic disk substrate when laser light with a wavelength of 405 nm is irradiated with a spot size of 5 μm at a laser power of 25 mW differ / differs between the first and the second main surfaces. Only the first main surface has a surface quality usable as a magnetic recording surface. The number of the foreign substances detected to have the sizes of 0.1 μm or more and 1.0 μm or less upon detection of the scattered light from the magnetic disk substrate when the laser light with the wavelength of 405 nm is irradiated with the spot size of 5 μm at the laser power of 25 mW is 400 or less per 30 cm2 on the second main surface.

Owner:HOYA CORP +1

Process for producing packaging laminate

InactiveUS6858106B1Increased durabilityElongation remarkable by breakage can be resistedReady-for-oven doughsAdhesive processesPolyolefinAluminum foil

The invention provides a manufacturing method of a good laminate packaging which does not have the delamination between layers and a method of manufacturing of the laminate for packaging containing a barrier layer such as an aluminum foil and, fibrous carrier layer, etc. The deoxidant of vitamin E, ascorbic acid or its derivative is adhered / attached, to the inside of a barrier layer web, the barrier layer is temporarily rolled round by the reel shape, kept, and laminated by the extrusion lamination by the molten polyolefin.

Owner:TETRA LAVAL HLDG & FINANCE SA

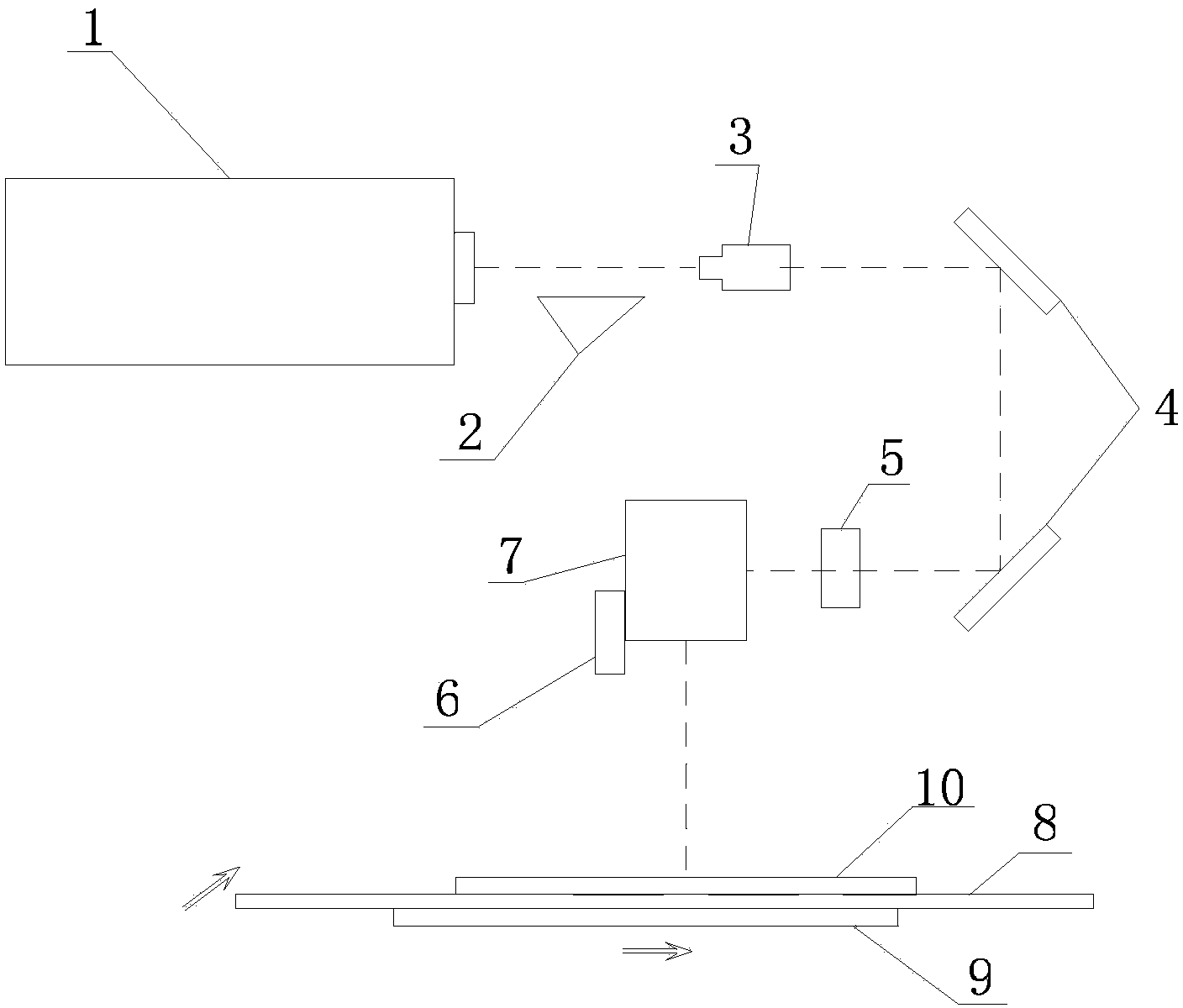

Device and method for carrying out laser machining on light guide board inside glass

InactiveCN104237997AImprove divergence angleSmall spotGlass shaping apparatusOptical light guidesCamera lensThree dimensional microstructure

The invention relates to a device and method for carrying out laser machining on a light guide board inside glass. A beam expander, a 45-degree total reflection mirror set, a beam shaping unit and a scanning galvanometer are arranged on a light path of the output end of a laser in sequence. The beam output end of the scanning galvanometer right faces a carrier platform. A CCD system is installed on the scanning galvanometer. A lens of the CCD system right faces the carrier platform. Laser beams emitted by the laser are coaxially expanded through the beam expander, the beam transmission divergence angle is improved, the light path is made to be aligned, and the light spot is smaller after focusing is carried out by coaxially expanding the laser beams; the expanded beams reach the 45-degree total reflection mirror set and enter the beam shaping unit, the shaped focusing light spot can be of a three-dimensional microstructure inside the glass, the shaped beams reach the scanning galvanometer, laser beams emitted by the scanning galvanometer are focused inside the glass serving as a workpiece to be machined, and marks are etched inside the glass. The device is high in light transmittance, wide in application range, long in service life, not prone to abrasion and accurate in machining position.

Owner:SUZHOU DELPHI LASER

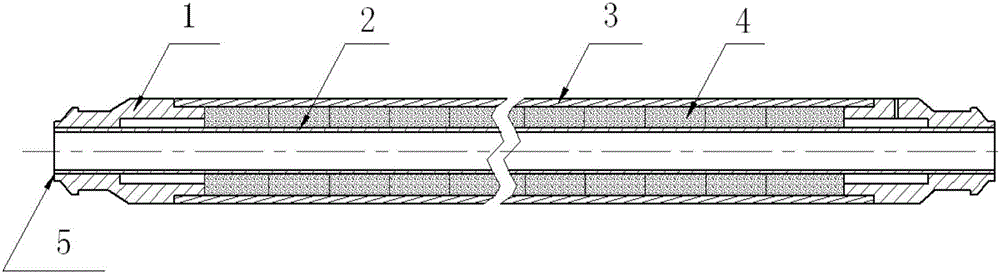

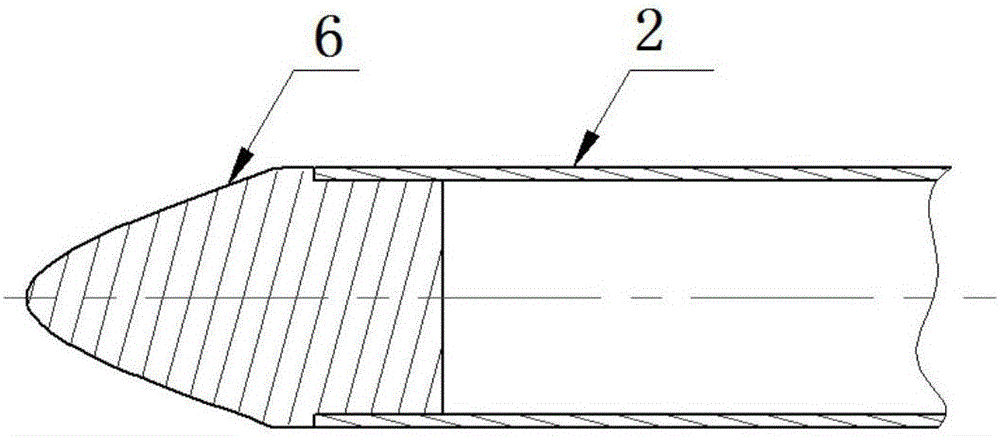

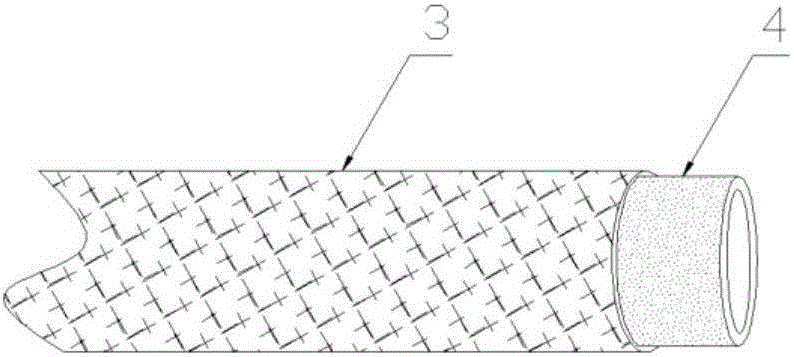

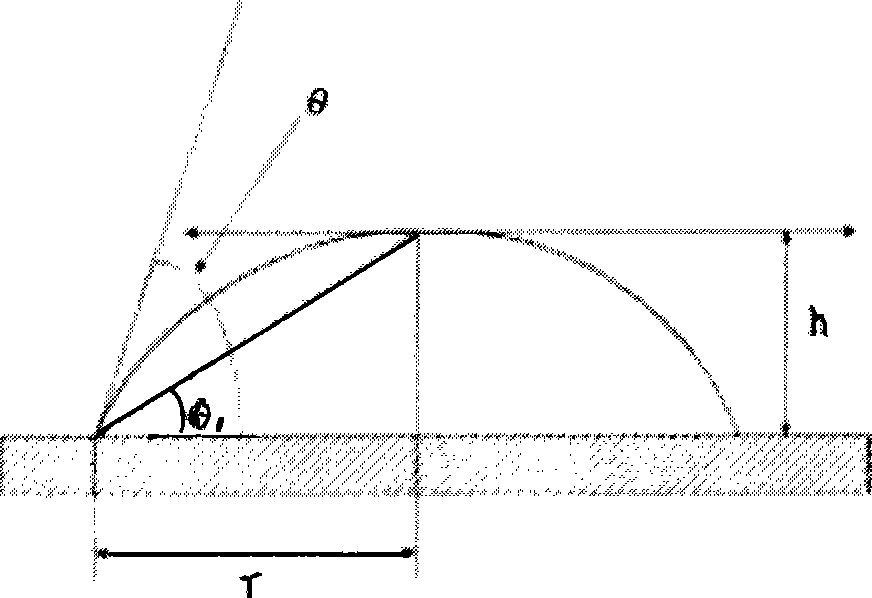

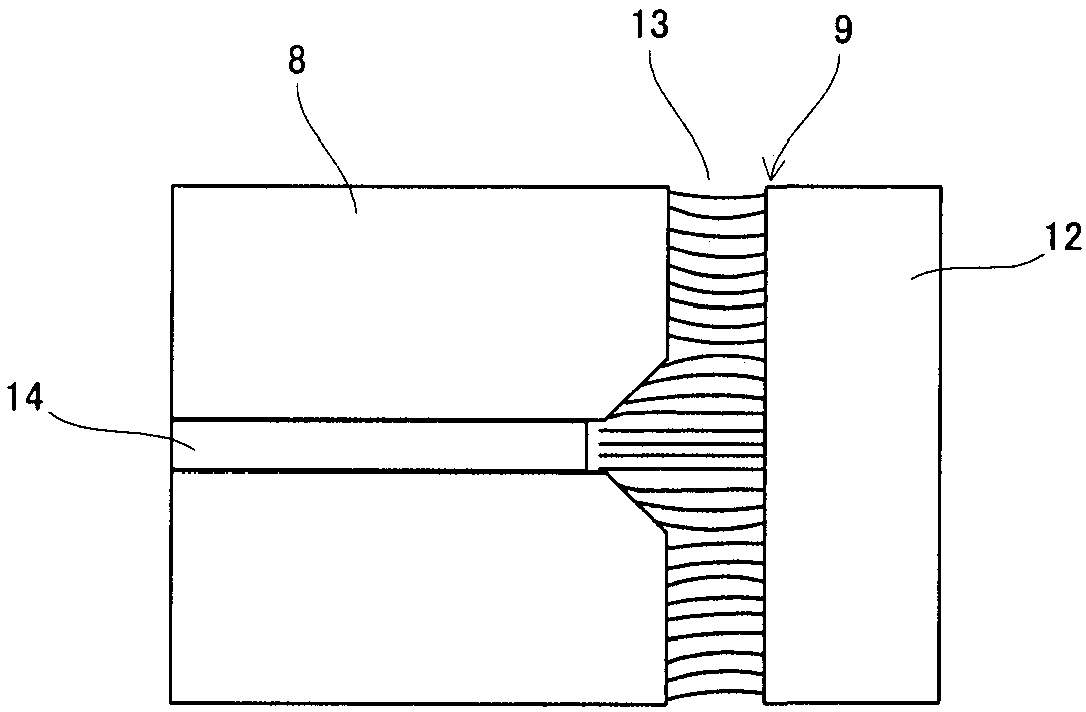

Assembly method of annular fuel element

InactiveCN106531262AAvoid surface contaminationAvoid damageNuclear energy generationReactors manufactureEngineeringDislocation

The invention provides a method for assembling an annular fuel element. The method comprises the following steps: a) taking an inner cladding tube, an outer cladding tube, a guide head and annular cores which are cleaned; b) installing the annular cores into the outer cladding tube one by one; c) installing the guide head into one end of the inner cladding tube; d) installing the end of the inner cladding tube with the guide head into inner holes of the annular cores; e) demounting the guide head; and f) respectively installing an upper end plug and a lower end plug on both ends of the annular fuel element. By using the method, the welding position of the inner cladding tube can not be contaminated or scratched in the assembly process, thereby satisfying the preparation requirements for the inner cladding tube before welding. The added guide head protects the welding position of the inner cladding tube, performs the functions of automatic positioning and guide, prevents the end surface dislocation of the core and the collision with the end surface of the inner cladding tube in the assembly process, effectively relieves the obstruction of the core in the assembly process, prevents the core from damage, reduces the assembly resistance, and implements assembly of the annular fuel element in a simple effective way.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Release process film

ActiveUS7291372B2Avoid surface contaminationDoes not cause shear, lifting or peelingFilm/foil adhesivesSynthetic resin layered productsForeign matterAdhesive

A release process film which comprises a base material film and an adhesive layer disposed on one face of the base material film and is used by attaching to a flexible printed circuit board, wherein the adhesive layer is formed with an adhesive comprising an acrylate-based copolymer at least comprising 40 to 99% by mass of a butyl acrylate unit and 1 to 20% by mass of a monomer unit having a crosslinking functional group and a crosslinking agent and the film has specific properties. The film can effectively suppress contamination of the surface of a printed circuit board with solvents and foreign substances and formation of flaws on the surface in the process using the flexible printed circuit board for producing electronic and electric instruments.

Owner:LINTEC CORP

Acrylic coating composition with enganced oil resistance and water resistance, and preparation thereof

InactiveCN101429400AImprove waterproof performanceGood scrub resistanceAntifouling/underwater paintsPaints with biocidesEtherAcrylic coating

The invention provides an acrylic coating composition with enhanced oil and water resistance and scrub resistance, which comprises the following components in total weight: 20 to 60 weight portions of acrylic latex, and 0.05 to 1.0 weight portion of fluorocarbon surfactant. The invention also provides a method for preparing the acrylic coating composition with the enhanced oil and water resistance and the scrub resistance, which comprises the step of mixing 0.05 to 1.0 weight portion of the fluorocarbon surfactant, 0.05 to 1.0 weight portion of polyethyleneglycol ether dispersant, 0.1 to 5.0 weight portions of polyfluortetraethylene micro powder and 20 to 60 weight portions of the acrylic latex to obtain the acrylic coating composition with the enhanced oil and water resistance and the scrub resistance.

Owner:科慕有限公司

Device for ventilating a patient and process for the operation of the device

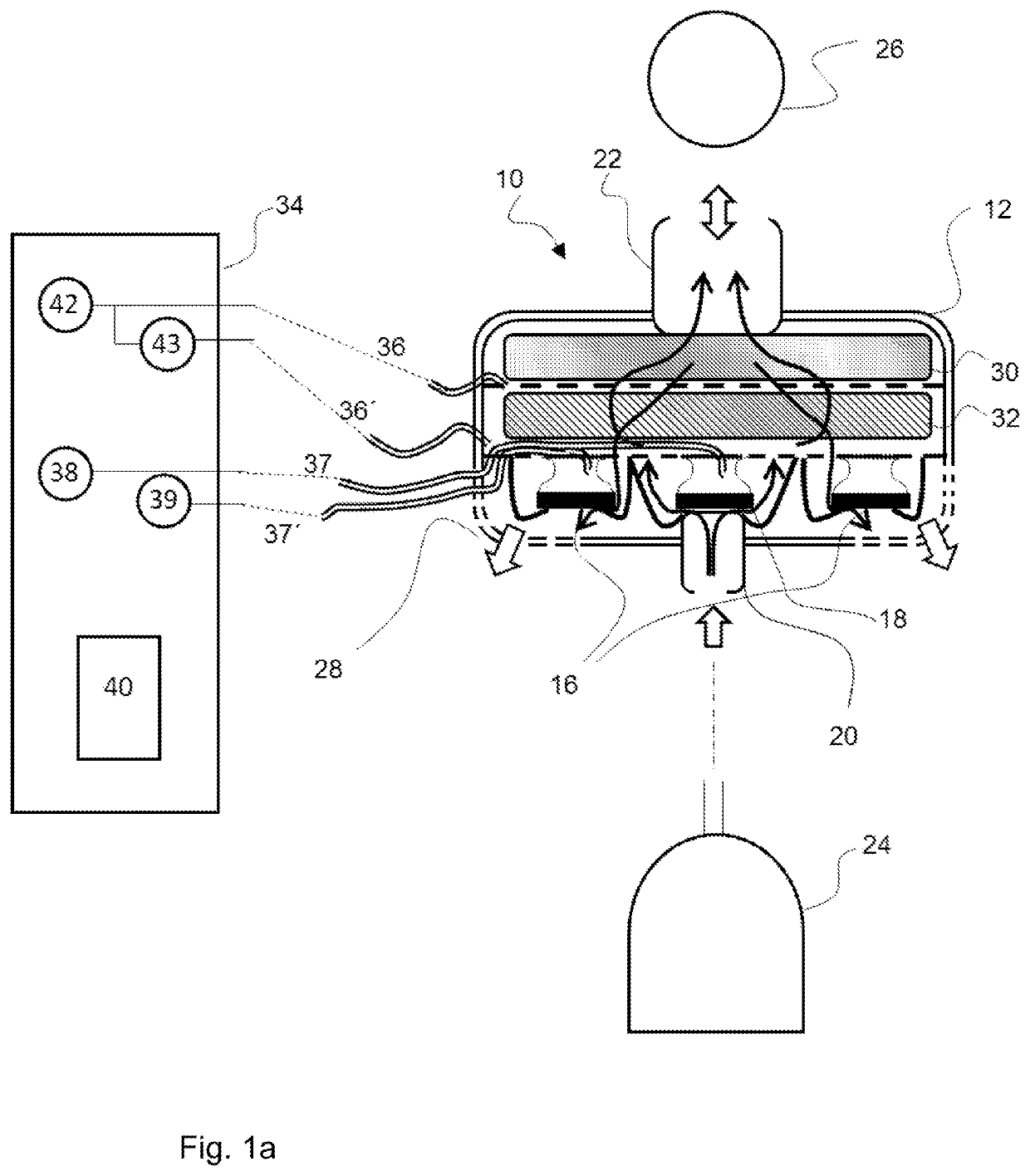

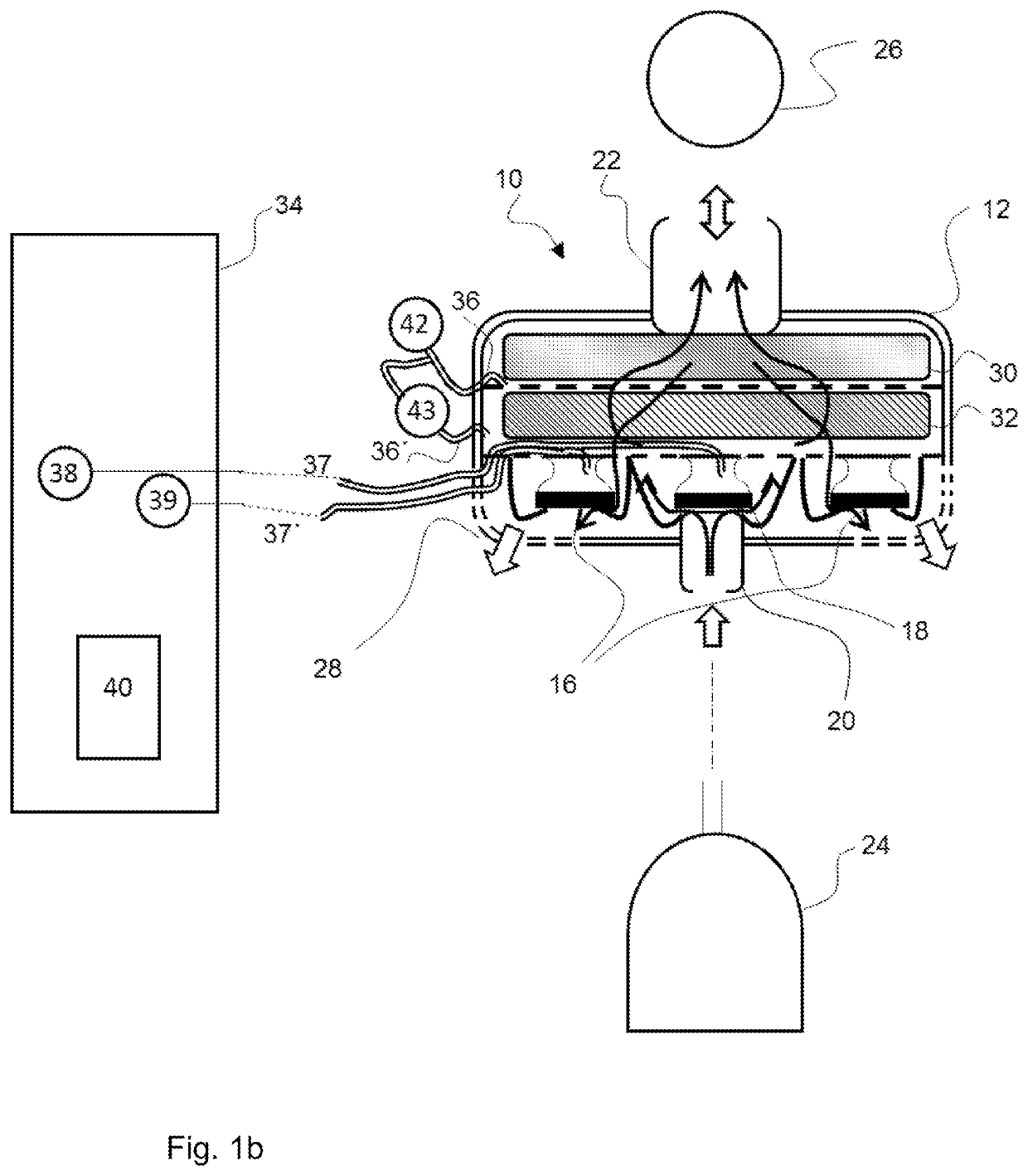

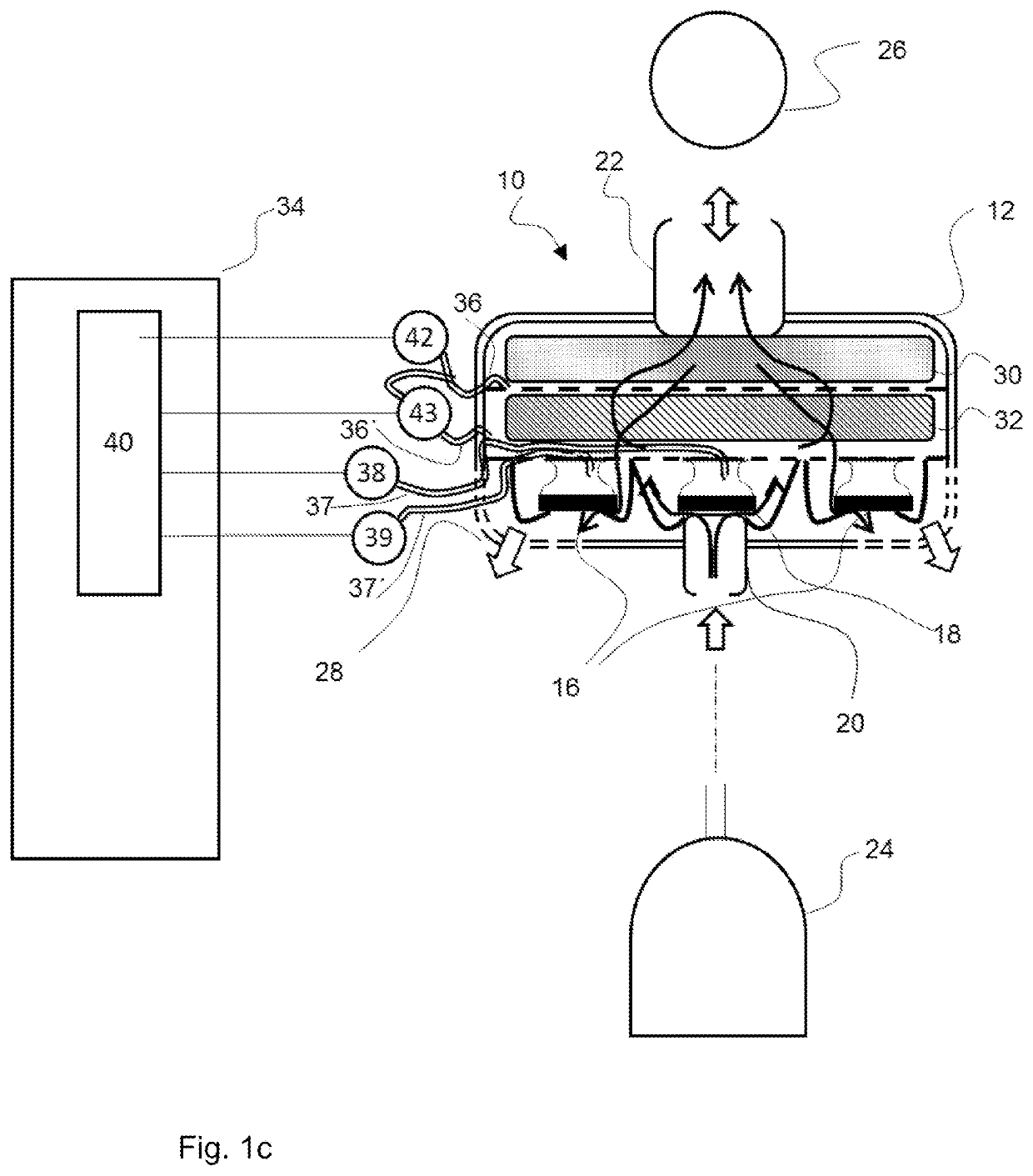

ActiveUS20200061319A1Maintain operabilityNot impair conductivityRespiratorsMedical devicesBreathing gasEngineering

A patient module (10) is intended for use when ventilating a patient with a pressure source (24) that can be fluidically coupled via the patient module (10) to a patient interface (26), which can be connected to the airways of a patient. The patient module (10) includes a housing (12) and a valve section (14) in the housing (12) as well as an HME filter (30) spaced apart from the valve section (14). The HME filter (30) is located upstream of the valve section (14) in relation to an expiratory volume flow, so that the HME filter (30) divides an interior of the housing (12) into a dry area and an area coming into contact with the moisture carried along by the exhaled breathing gas. The valve section (14) is located in the dry area. A process for operating the patient module (10) includes calibration steps.

Owner:DRAGERWERK AG

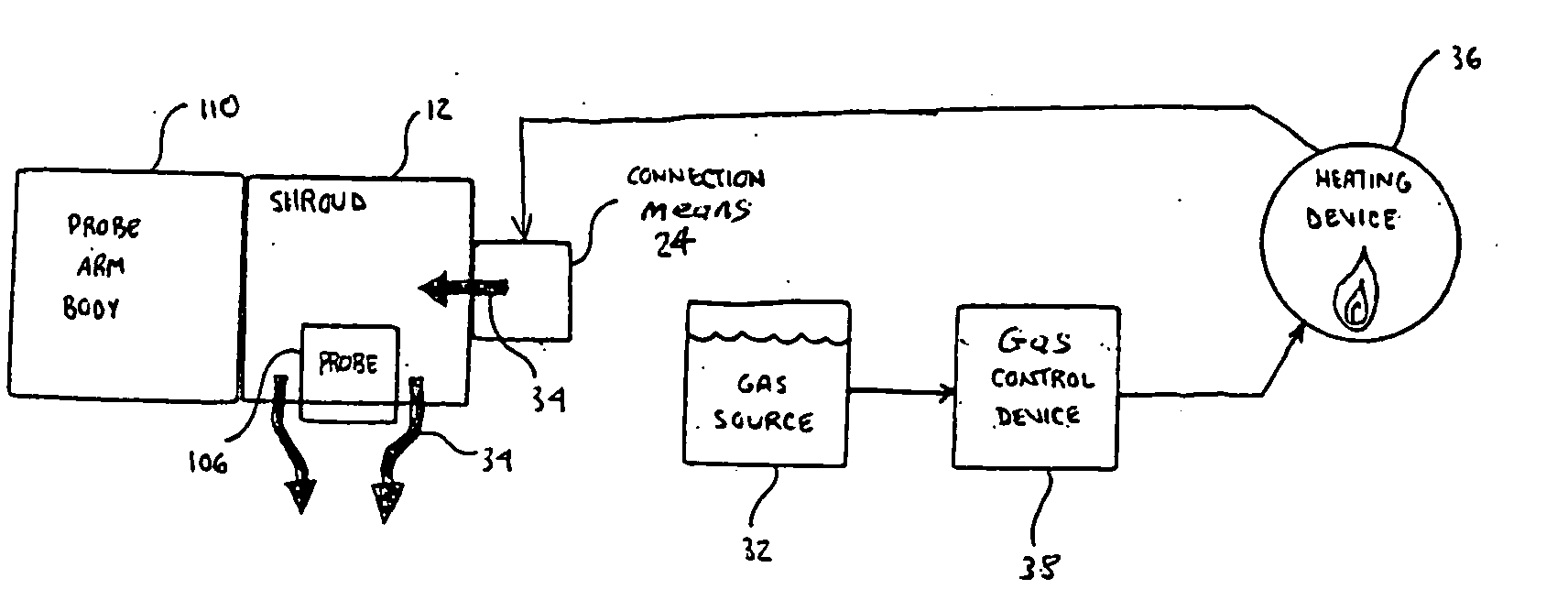

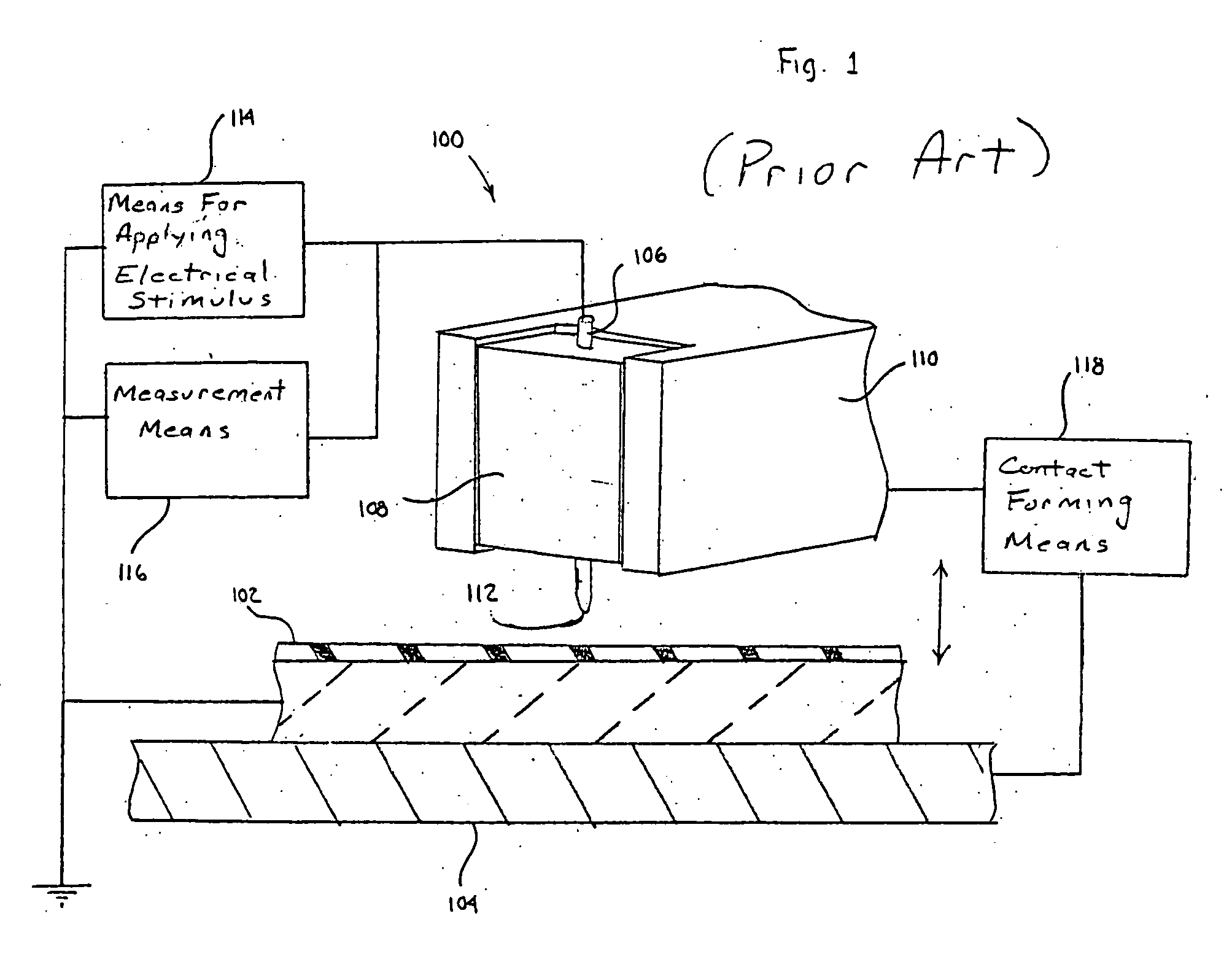

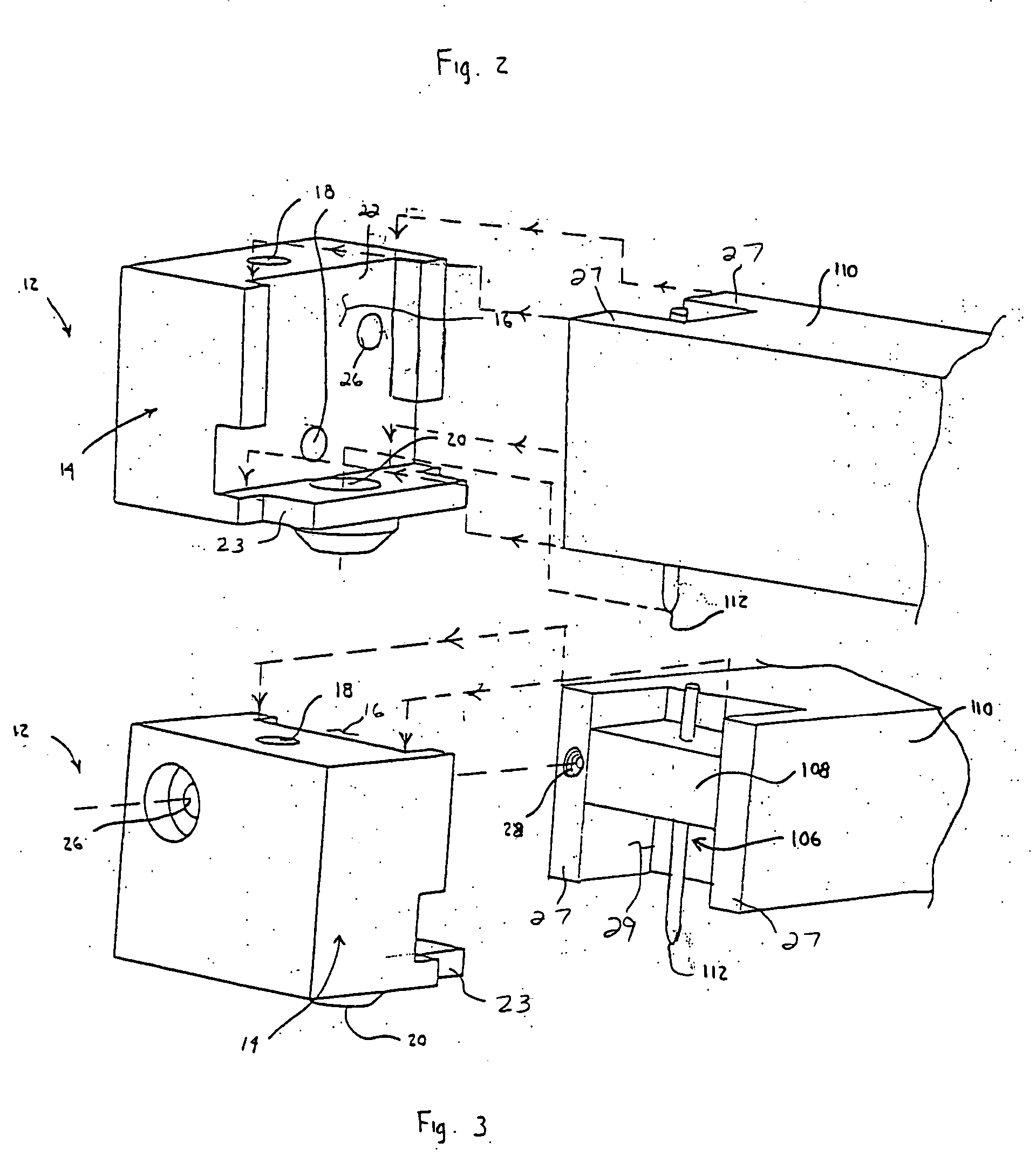

Method and apparatus for removing and/or preventing surface contamination of a probe

InactiveUS20050241175A1Removing and preventing surface contaminationOvercome deficienciesDrying using combination processesSemiconductor/solid-state device testing/measurementBiomedical engineeringContamination

To remove and / or prevent contamination of a probe, at least a portion of the probe is positioned in a chamber having an inlet passage and an outlet passage, with a distal end of the probe extending through the outlet passage and terminating on a side thereof opposite the chamber. A gas is caused to flow through the inlet passage into the chamber and out the outlet passage, thereby modifying an environment surrounding the distal end of the probe. The gas may be heated prior to injection.

Owner:SOLID STATE MEASUREMENTS

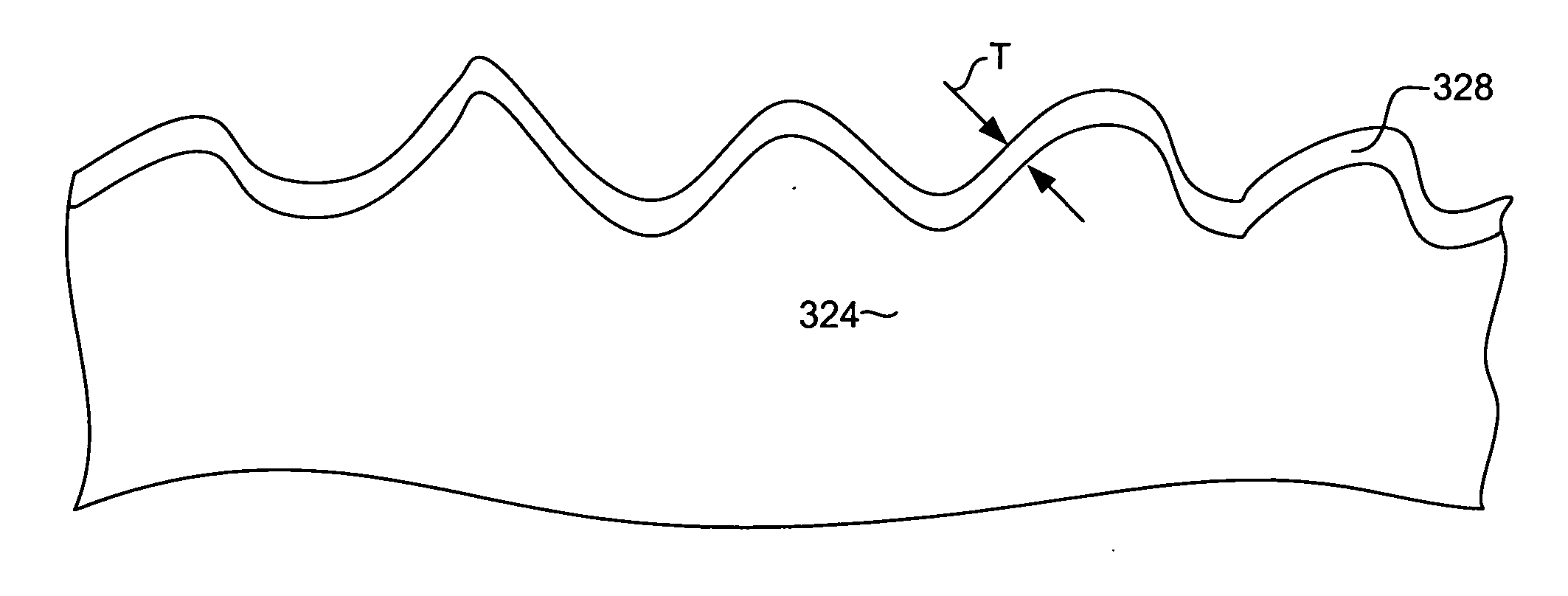

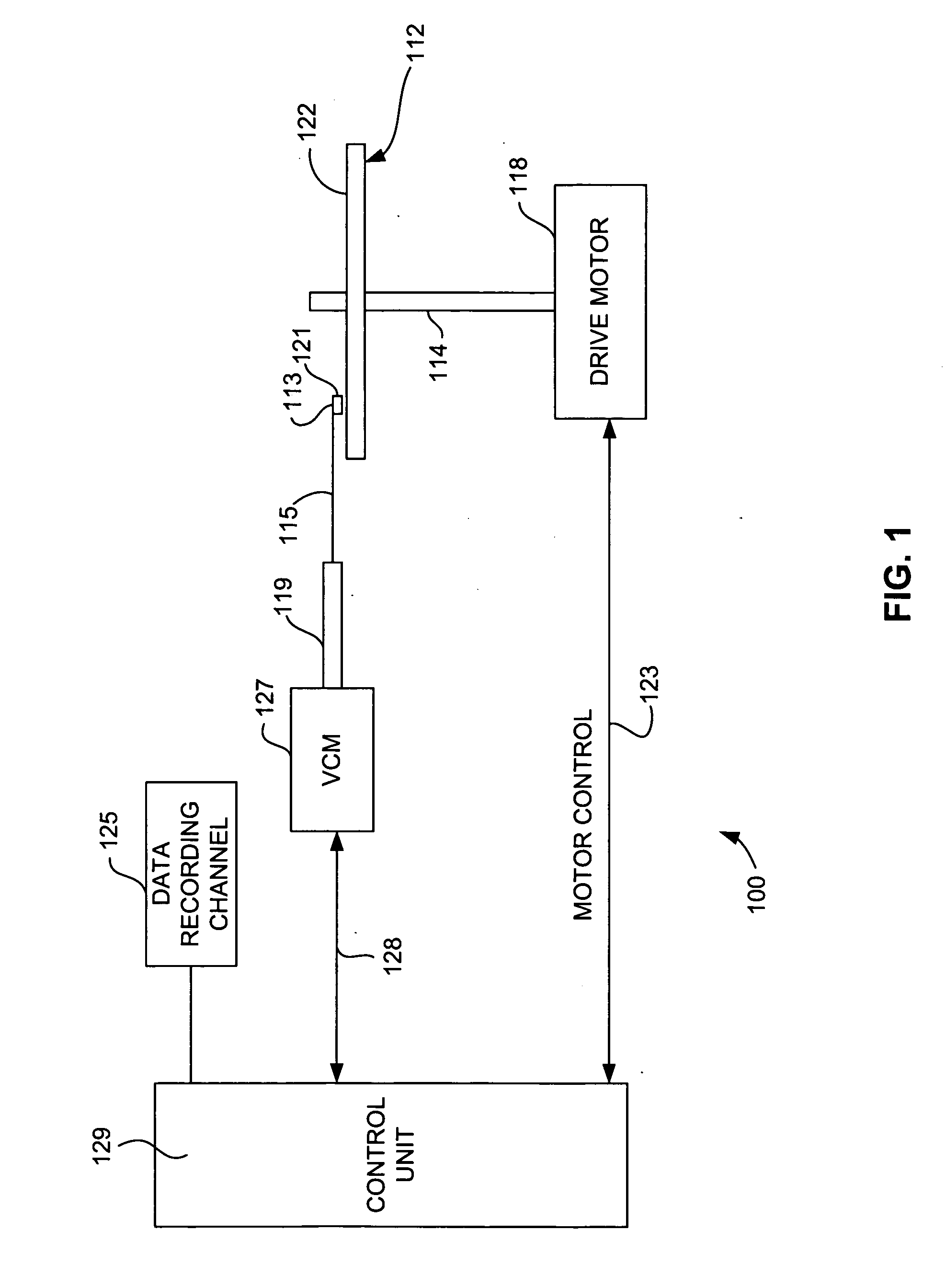

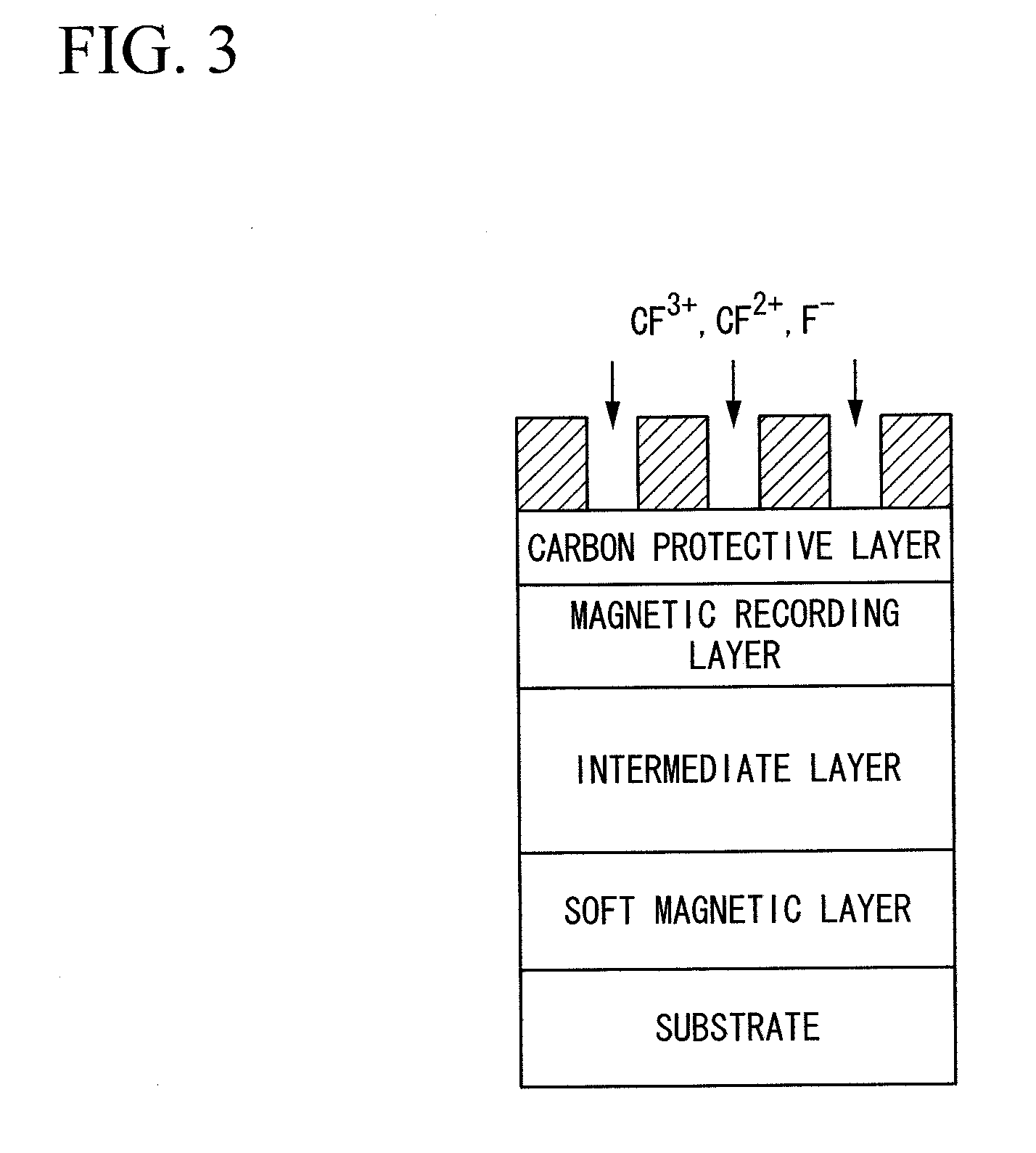

SiN overcoat for perpendicular magnetic recording media

InactiveUS20070054153A1High densityThinner overcoatProtective coatings for layersRecord information storageHigh densityMagnetic media

A SiON overcoat for use on magnetic media for magnetic recording. The SiON overcoat is deposited by pulsed DC sputtering while applying a negative DC bias. The SiON overcoat is especially useful on perpendicular magnetic recording media because of its ability to deposit thinly and evenly on a rough, granular high coercivity recording media while maintaining excellent corrosion protection properties. A SiON overcoat can be applied less than 3 nm thick while still maintaining excellent mechanical and corrosion protection. The overcoat also has a very high density and water contact angle.

Owner:WESTERN DIGITAL TECH INC

Graphite fiber and preparation method thereof

ActiveCN102978747AImprove lyophilicityAvoid surface contaminationFibre chemical featuresResin matrixCeramic materials

The invention discloses a graphite fiber and a preparation method thereof. The preparation method is characterized by comprising the following steps: carrying out preoxidation on a polyacrylonitrile precursor so as to obtain a preoxidated fiber; carrying out low-temperature carbonization on the preoxidated fiber so as to obtain a low-temperature carbonized fiber; carrying out surface coating on the low-temperature carbonized fiber so as to obtain a coated fiber; carrying out high-temperature carbonization on the coated fiber so as to obtain a high-temperature carbonized fiber; carrying out secondary coating on the high-temperature carbonized fiber so as to obtain a secondary coated fiber; and carrying out graphitization on the secondary coated fiber so as to obtain a high-performance graphite fiber. The graphite fiber and the preparation method thereof disclosed by the invention has the advantages that a surface treatment by using an electrolytic bath is not performed, thereby improving the lyophilic property of the graphite fiber, reducing the equipment investments in the electrolytic bath and a rinsing bath, avoiding the surface pollution of the graphite fiber, improving the affinity of the graphite fiber to a resin matrix, and facilitating the preparation of high-performance, high-modulus and high-strength graphite fibers.

Owner:JILIN SHENZHOU CARBON FIBER CO LTD

Method of manufacturing display device including oxidized porous silicon material-based emission source

InactiveUS20070205721A1Improve electron emissionPrevent contamination of surfaceCathode-ray/electron-beam tube vessels/containersGas discharge connecting/feedingPotassium oxideAnodic bonding

Provided are a method of manufacturing a display device including an oxidized porous silicon (OPS) material-based emission source and a display device manufactured using the method. A first and second panels, each of which includes one of sodium oxide (Na2O) and potassium oxide (K2O), are prepared. An OPS material-based emission source is formed on the first panel, and a silicon spacer enclosing the OPS material-based emission source is formed on the first panel. The second panel is anodic bonded to the silicon spacer, so that the first and the second panels are assembled together.

Owner:SAMSUNG SDI CO LTD

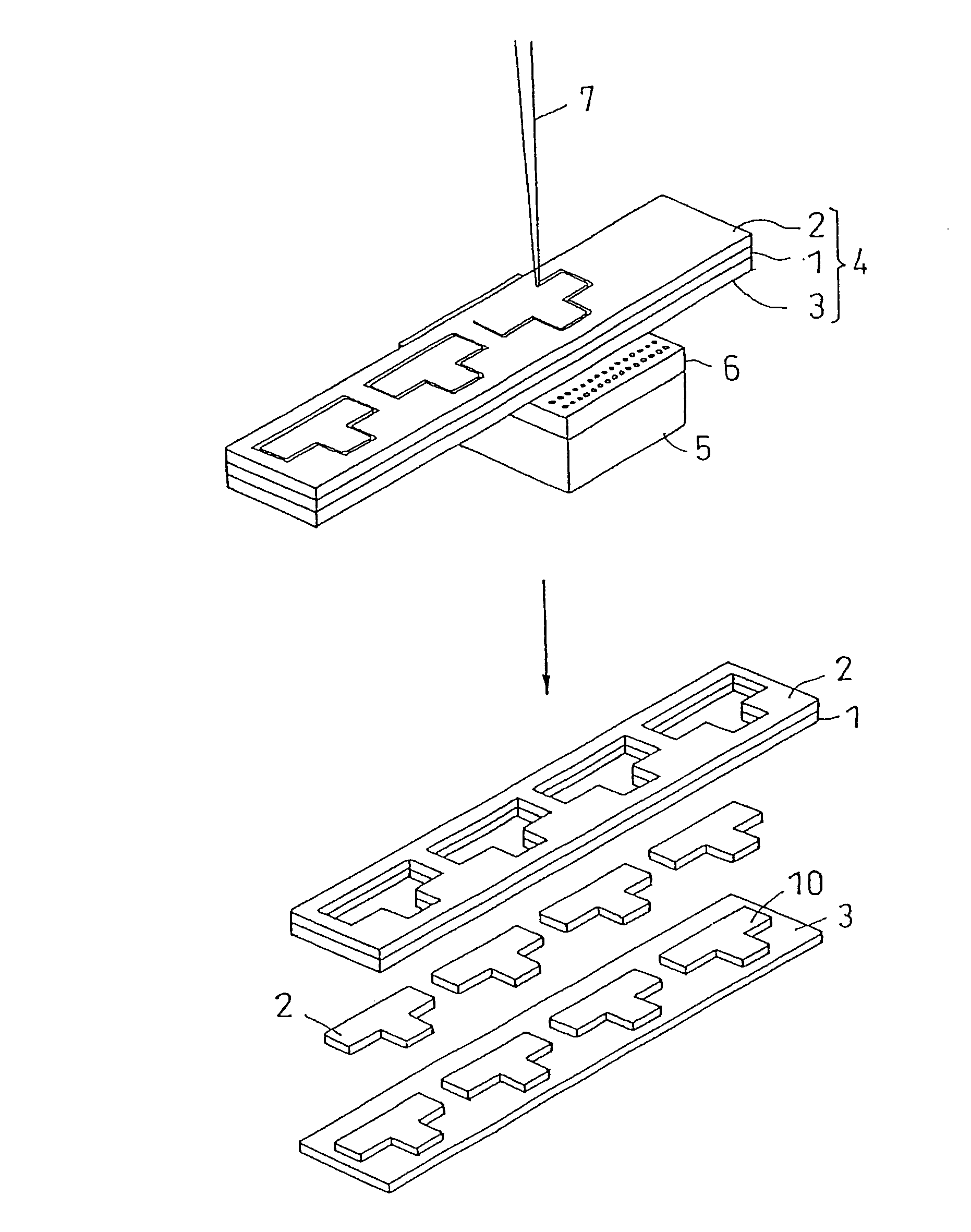

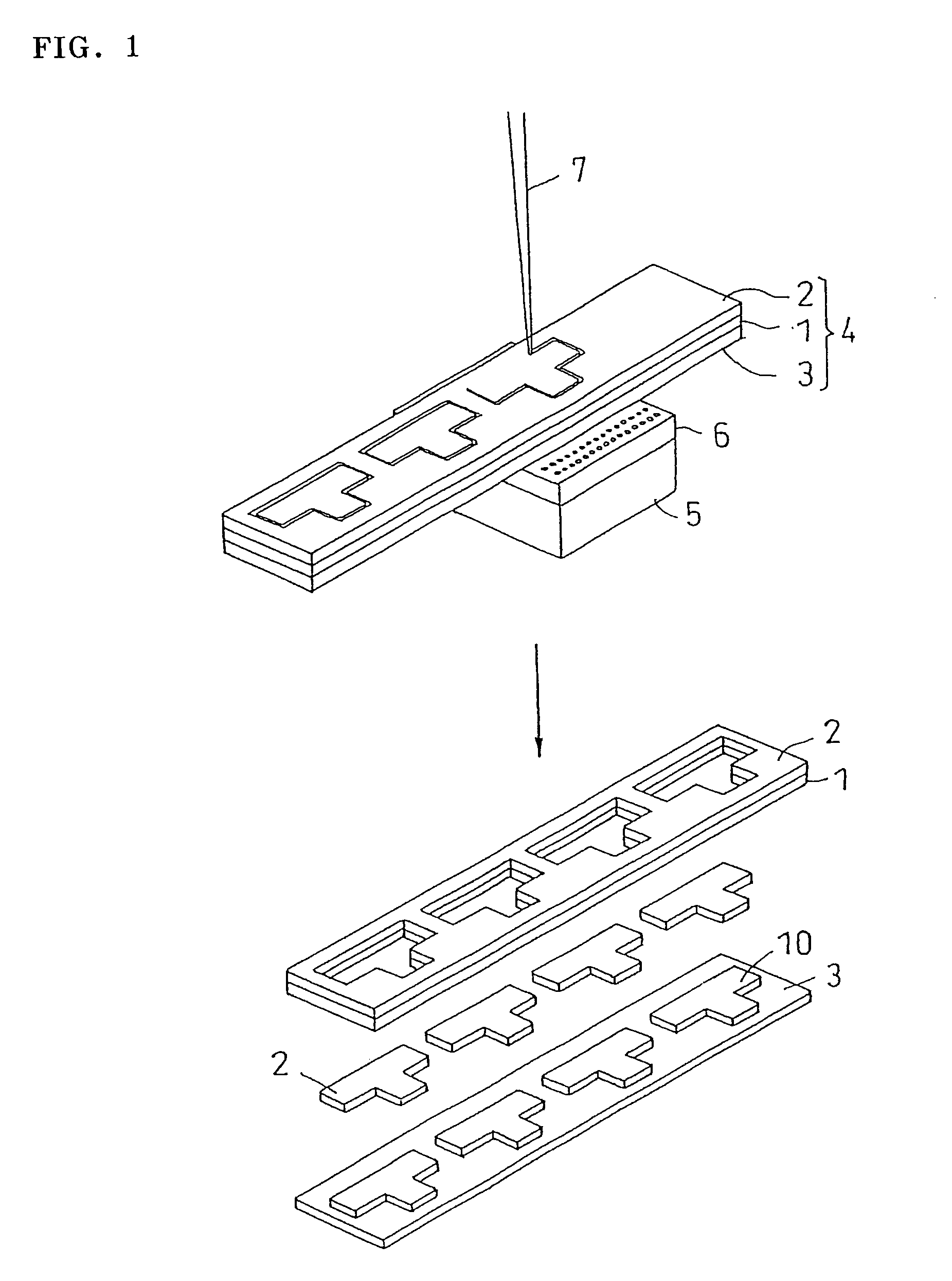

Manufacturing method of laser processed parts and protective sheet for laser processing

InactiveUS8624156B2Avoid surface contaminationImprove accuracyLight absorption dielectricsPhotomechanical apparatusLaser processingDecomposition

Providing a method of manufacturing a laser processed part by using a protective sheet for laser processing capable of effectively suppressing contamination of surface of workpiece by decomposition product, and processing at high precision, when processing the workpiece by optical absorption ablation of laser beam. It is also an object to present a protective sheet for laser processing for use in the manufacturing method of laser processed part.

Owner:NITTO DENKO CORP

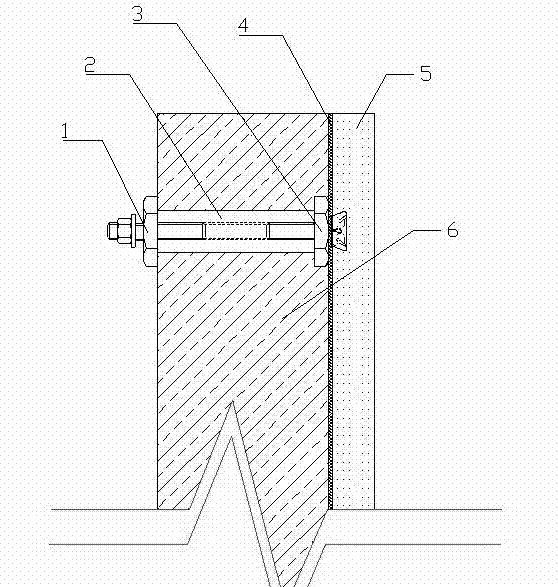

Insulation decoration integrated exterior wall

InactiveCN103195189AReduce energy consumptionAchieve the goal of energy saving and emission reductionCovering/liningsWallsGlass fiberInsulation layer

An insulation decoration integrated exterior wall comprises a plate-shaped insulation layer and a facing layer which are fixedly attached through connecting members, every connecting member is pre-embedded in the facing layer, penetrates through the insulation layer and is fastened and fixed on the side surface of the insulation layer, and heavy-duty glass fiber cloth is arranged between the insulation layer and the facing layer and is attached to the facing layer through adhesive. The insulation decoration integrated exterior wall can effectively solve the problem of energy source loss caused by indoor and outdoor temperature difference in summer and winter, has integrated functions of insulation and decoration, can greatly reduce the structural weight to improve usage safety of buildings, and is applicable to new construction as well as energy saving transformation of old buildings.

Owner:UNIVERSAL MARBLE & GRANITE DONGGUAN

Self-repairing material and preparation method and application thereof

The invention discloses a self-repairing material and a preparation method and application thereof. The self-repairing material comprises lacunose teflon film, holes in the teflon film are filled withperfluocarbon polymer, plasma processing is carried out on the teflon film for modification, and the perfluocarbon polymer accounts for more than 0.1 wt% of mass proportion of the teflon film. The preparation method comprises the steps of washing, drying after washing, the plasma processing for modification and vacuum impregnation, wherein the teflon film is washed with a washing agent for ultrasonic cleaning; the modified teflon film is impregnated in a melting liquid of the perfluocarbon polymer for impregnation; a solvent is used for removing residual perfluocarbon polymer remaining on thesurface of the teflon film, and storage at an indoor temperature is performed to obtain the self-repairing material. The contact angle between the self-repairing material and a liquid is greater than98 degrees, that is, the surface of the material is below 25 Mn / m, and the self-repairing material has antifouling and water-proof functions and has properties of good adhesion, easy coating, corrosion resistance, convenient processing, aging resistance, long-acting slow release, and environment protection.

Owner:李瑞萱

Rectangular glass substrate and method for preparing the same

ActiveCN107775484AAvoid surface contaminationReduced manufacturing yieldEdge grinding machinesPolishing machinesEngineering

Owner:SHIN ETSU CHEM CO LTD

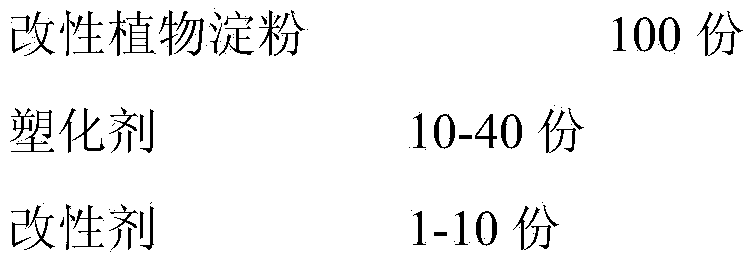

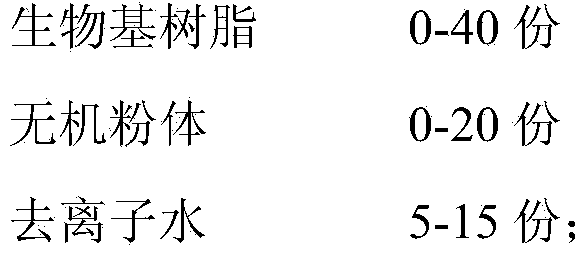

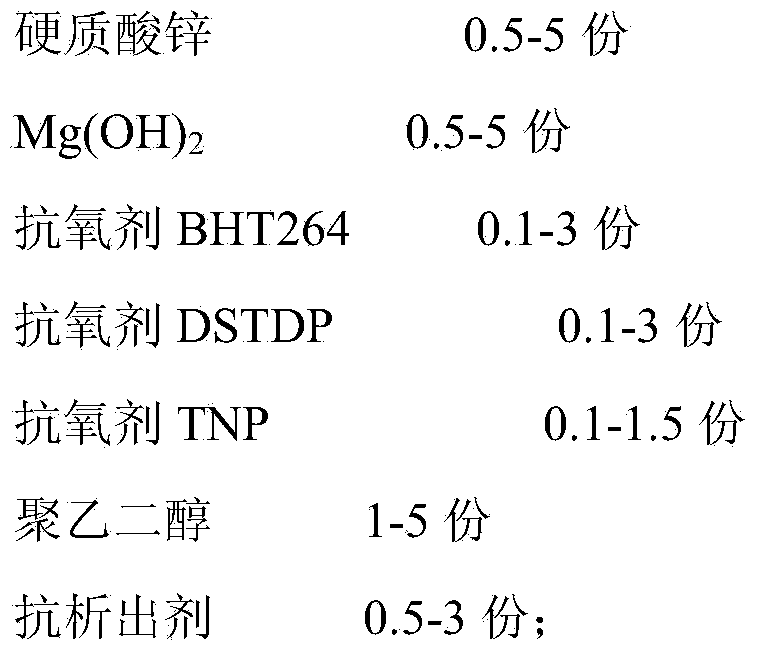

Starch-base tableware and manufacturing method thereof

ActiveCN103923353APlastination Overcome and InhibitionOvercome and inhibit recrystallizationTable equipmentsPotato starchHeat stability

The invention belongs to the field of biodegradation, in particular to starch-base tableware and a manufacturing method thereof. The starch-base tableware comprises modified plant starch, a plasticizer, a modifier, biology-based resin, inorganic powder and deionized water, wherein the modified plant starch is formed by adding a surfactant to one or more of cassava starch, corn starch and sweet potato starch and mixing. By means of the starch-base tableware and the manufacturing method thereof, the problem that a product is hard and fragile due to temperature, humidity or air pressure is solved, pollution of the surface of the product caused due to the fact that environment influences small-molecule material migration is avoided, heat stability of the starch-base tableware is improved, the retrogradation phenomenon is overcome, and the product is more flexible. The invention further provides the manufacturing method of the starch-base tableware, the process is simple, investment is little, and large-scale production is facilitated.

Owner:山东睿安新材料科技有限公司

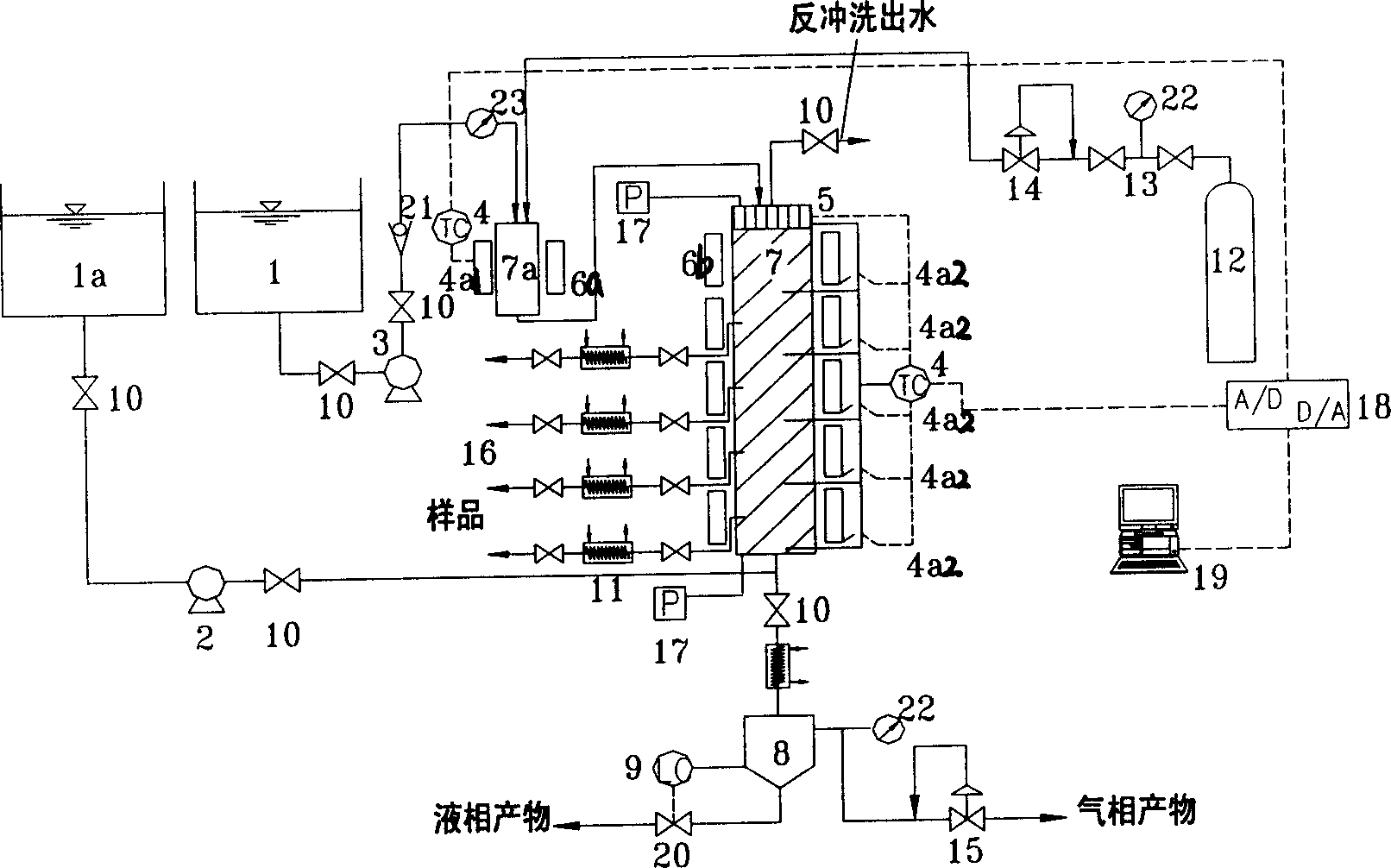

Catalytic oxidation reaction apparatus of trickle bed

InactiveCN1544139ABroaden the field of applicationExpand the scope ofChemical/physical processesWater/sewage treatment by oxidationHigh concentrationChemical industry

The invention relates to a trickle-bed catalytic oxidization reactor, composed of waste water tank, premixing reactor, reactor, gas-liquid separator, condenser, oxygenated part and temperature-control part, which are connected together by pipelines and valves, where the reactor adopts segment heating and temperature control to ensure the reaction at the isothermy. The reactor is set with side sampling mouth able to collect the samples in different positions of the reactor, and has backflushing part able to regularly wash the catalyst in the reactor, effectively the salt stain problem always occurring in the course of wet-oxidizing actual high-concentration organic industrial waste water. It can be used to research the law of effect of technical operating conditions on the catalytic wet-oxidization reaction course of high-concentration, difficult- degradation, poisonous and harmful organic waste water discharged by the industries such as chemical industry, medicine industry and pesticide industry, has a very important significance in further enlarging the application field and range of wet oxidization and has good market prospect.

Owner:TONGJI UNIV

Method for producing magnetic medium, magnetic record reproduction device, and magnetic recording medium

InactiveUS20100007985A1Improve productivityLess pollutionLamination ancillary operationsPatterned record carriersHalogenMagnetic media

One object of the present invention is to provide a method for producing a magnetic recording medium which has excellent magnetic separation properties of the magnetic recording pattern, the present invention providing a method for producing a magnetic recording medium having a magnetic recording pattern which is magnetically separated, comprising the steps of: after laminating at least a magnetic layer and a carbon protective layer on a non-magnetic substrate in this order, partially irradiating with a reactive plasma containing carbon and a halogen or reactive ions which are generated in the reactive plasma on a surface of the carbon protective layer, and thereby forming a halogenated carbon protective layer, which is obtained by partially halogenating the carbon protective layer, and the magnetic recording pattern separated magnetically which is obtained by partially improving the magnetic layer.

Owner:SHOWA DENKO KK

Printing head module

A printing head module includes a bracket, a plurality of printing heads, a pivot shaft, a wiper unit, and a control unit. The bracket includes a plurality of through holes. The printing heads are parallelly aligned with each other, each of the printing heads a nozzle for extruding the modeling material. The pivot shaft connected to the bracket is adapted to rotate the printing heads to a target position. The wiper unit includes a holder, a plurality of wipers, and a wiper opener. The holder is connected to the pivot shaft to be rotated with the bracket and the printing heads. The wipers rotatably connected to the holder and disposed correspondingly to the openings. The wiper opener is disposed at the target position to interfere with the wiper rotated to the target position, so as to drive the corresponding wiper to rotate to the opening position.

Owner:XYZPRINTING +2

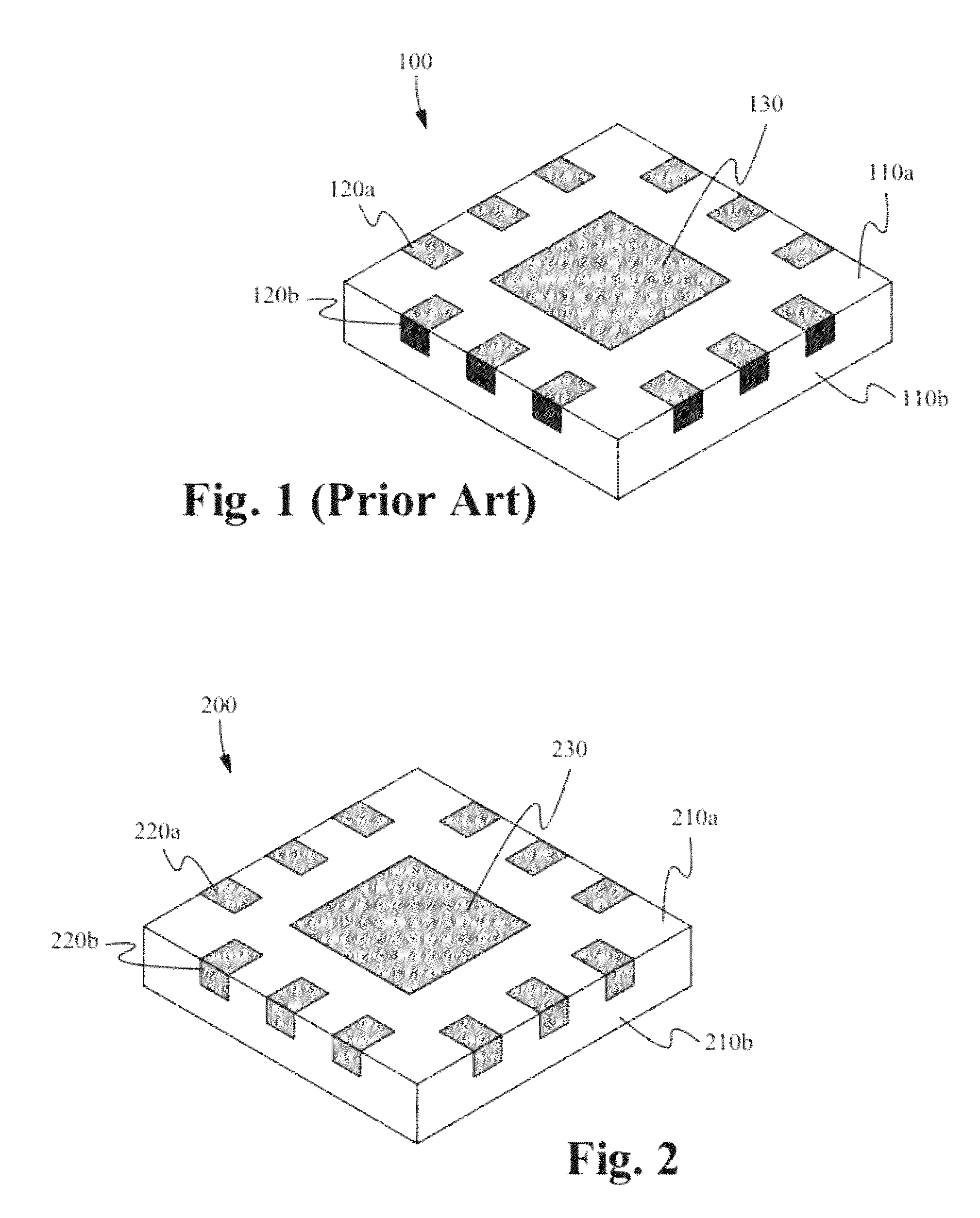

Singulation method for semiconductor package with plating on side of connectors

ActiveUS9349679B2Avoid surface contaminationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A method of singulating semiconductor packages, the method comprising: providing a plurality of semiconductor dies coupled to a single common leadframe, wherein a molding compound at least partially encases the semiconductor dies and the leadframe; singulating the plurality of semiconductor dies, wherein the leadframe is at least partially cut between adjacent semiconductor dies, thereby forming exposed side surfaces on leads of the leadframe; and plating the exposed side surfaces of the leads with a plating material, wherein the plating material is a different material than the leads. In some embodiments, singulating the plurality of semiconductor dies comprises performing a full cut of the leadframe. In some embodiments, singulating the plurality of semiconductor dies comprises performing separate partial cuts of the leadframe.

Owner:UTAC HEADQUARTERS PTE LTD

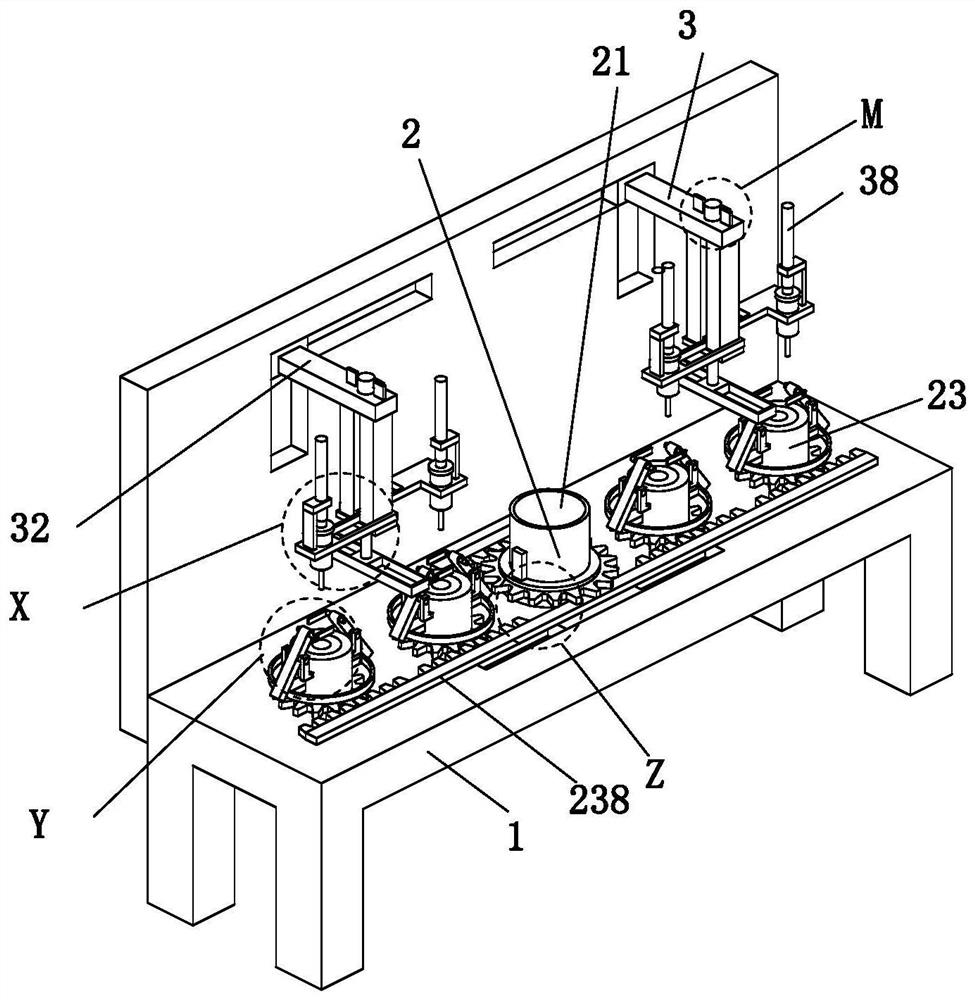

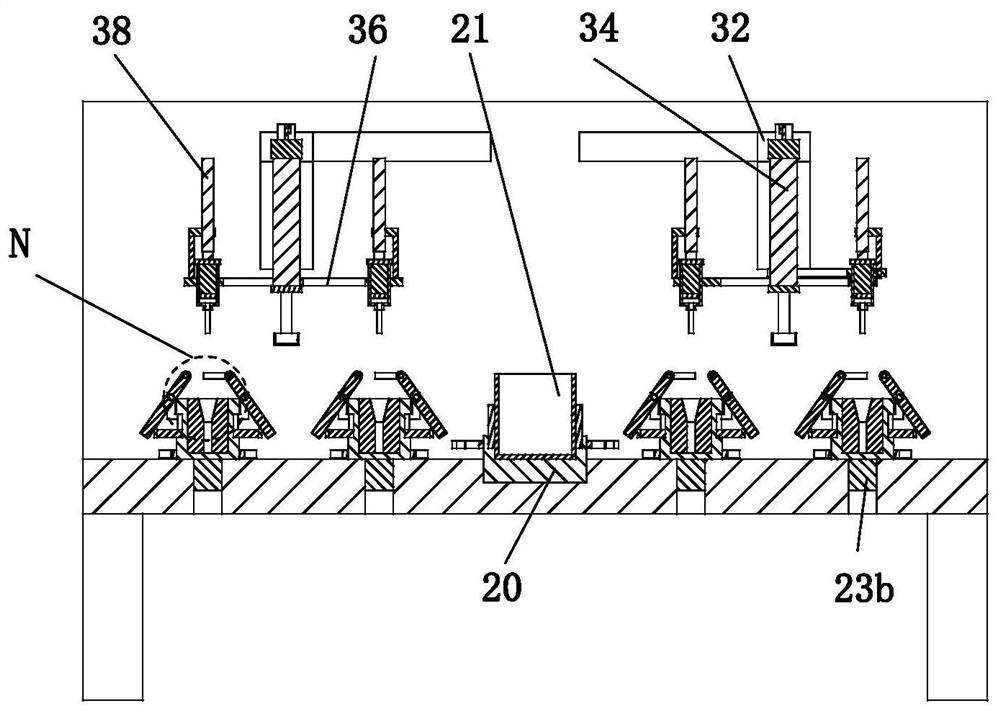

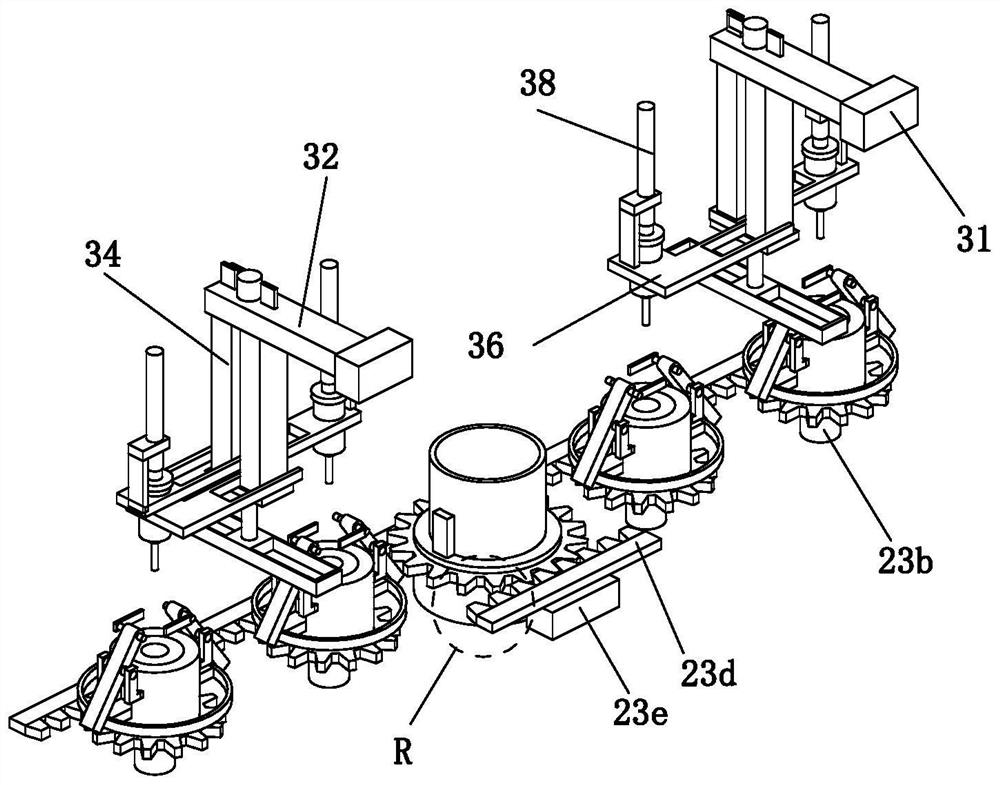

Extraction equipment for detecting high-molecular chemical reagent and extraction process thereof

PendingCN113058468AAvoid phenomena such as chromatographyImprove operational efficiencyRotating receptacle mixersTransportation and packagingMacromoleculeReagent

The invention discloses extraction equipment for detecting a high-molecular chemical reagent and an extraction process thereof.The extraction for detecting the high-molecular chemical reagent is carried out by adopting a multi-station design concept, and an arranged clamping mechanism can be used for clamping glass tubes loaded with reagents and having different sizes; an arranged extraction mechanism can realize synchronous extraction and automatic mixing of various reagents, so that the overall operation efficiency can be greatly improved; and meanwhile, single glass tubes and the mixed reagents can be subjected to centrifugal stirring treatment, so that the phenomena of chromatography and the like of the reagents are avoided, and the mixing speed and uniformity of the mixed reagents are improved.

Owner:深圳市汇知科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com