Catalytic oxidation reaction apparatus of trickle bed

A technology of catalytic oxidation and reaction device, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve unseen problems, prevent surface pollution, expand application fields and scope, and have a good market foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

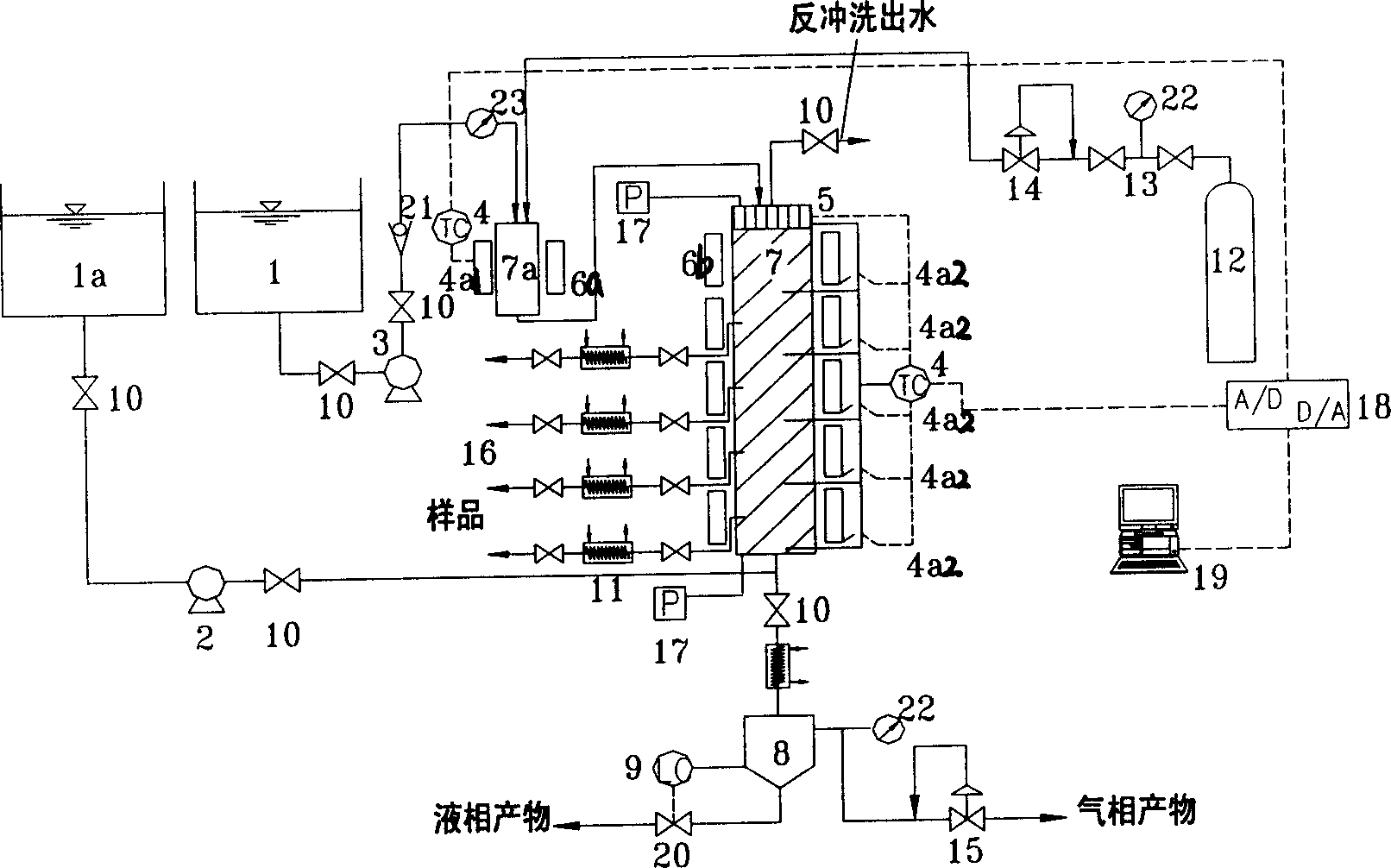

[0013] Example 1, the specification of the wastewater tank is Ф400mm×5mm×500mm, the material is 304 stainless steel, the specification of the clean water tank is Ф400mm×5mm×500mm, the material is 304 stainless steel, the specification of the pre-mixing reactor is Ф45mm×5mm×300mm, and the specification of the reactor is Ф45mm×5mm×850mm, the material is 316L stainless steel, the gas-liquid separator is Ф300mm×5mm×520mm, the material is 304 stainless steel, the sampling condenser is Ф400mm×5mm×500mm, the quantity is 5, and the material is 316L stainless steel , the model of the high-pressure metering pump is J1-5 / 8, the model of the liquid level controller is BLC02X, the model of the valve is J23W-160P, the model of the pressure sensor is RPT-301, the model of the digital / analog converter is AI-708JA, and the PC is 586 type, the gas flowmeter is WFM type, the liquid flowmeter is VFA-1-SSV type, the drain valve is ZCL-2Y electromagnetic flowmeter, the liquid check valve is I-10 typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com